Manual

Modular fan coil unit

Model PS

Version 2.1

07-2018

17-

Q P

English

B

Copyright

All the information and drawings in this manual are the property of Biddle and may not be

used (other than for the actual operation of

the device), photocopied, duplicated, translated and/or be brought to the attention of

third parties without Biddle’s prior written

permission.

The name Biddle is a registered trademark.

Trademarks

The name Biddle is a registered trademark of

Biddle bv.

Warranty and liability

Please refer to Biddle's Terms of Sales and

Delivery for warranty and liability conditions.

For more information

If you have any comments or questions

about specific topics relating to this product,

please do not hesitate to contact Biddle.

Addresses

United Kingdom

Biddle Air Systems Ltd.

St. Mary’s Road

Nuneaton

Warwickshire CV11 5AU

United Kingdom

telephone: 024 7638 4233

fax: 024 7637 3621

e-mail: sales@biddle-air.co.uk

internet: www.biddle-air.com

Biddle excludes liability for consequential

loss at all times and under all circumstances.

Liability for the contents of

this manual

However much care might have been taken

in ensuring the correctness and, where necessary, completeness of the description of

the relevant parts, Biddle disclaims all liability

for damage resulting from any inaccuracies

and/or deficiencies in this manual.

Should you detect any errors or ambiguities

in this manual then we would be pleased to

hear from you: it helps us to improve our

documentation even further.

Biddle retains the right to change the specifications stated in this manual.

Other countries

Biddle Export

PO Box 15

NL-9288 ZG Kootstertille

The Netherlands

telephone: +31 512 335555

fax: +31 512 335554

e-mail: export@biddle.nl

internet: www.biddle.info

2

Manual model PS

Modular fan coil unit Contents

2.7 Connecting the valve motor............ 12

Contents

2.8 Connecting ducts ............................ 12

2.9 Connecting the unit to the CH

1 Introduction ........................4

1.1 About this manual ............................. 4

1.2 How to use this manual .................... 4

1.2.1 Marginal symbols in the manual ......... 4

1.2.2 Pictograms used on the unit and in

the manual................................................... 4

1.2.3 Related documentation....................... 4

1.3 About the unit.................................... 5

1.3.1 Applications ........................................ 5

1.3.2 Working............................................... 5

1.3.3 Modules .............................................. 5

1.3.4 Type code ........................................... 6

1.3.5 Type plate ........................................... 6

and/or CW system ................................ 12

2.9.1 Water connections............................ 12

2.9.2 Frost protection................................. 13

2.9.3 Connecting water pipes .................... 13

2.10 Connecting the condensate drain. 13

2.10.1 Particulars....................................... 13

2.10.2 Connecting the condensate drain... 13

2.11 Connecting the unit to mains

power supply......................................... 14

2.11.1 General........................................... 14

2.11.2 Connecting to mains....................... 14

2.12 Installing the controller.................. 14

2.13 Switching on and checking

operation............................................... 14

1.4 Components ..................................... 6

1.4.1 Required components......................... 6

1.4.2 Accessories ........................................ 7

1.4.3 Parts not supplied............................... 7

1.5 Safety instructions ............................ 7

1.5.1 Operation............................................ 7

1.5.2 Installation, maintenance and

service ......................................................... 7

2 Installation..........................8

2.1 Safety instructions ............................ 8

3 Maintenance ....................16

3.1 Safety instructions .......................... 16

3.2 Replacing the filter .......................... 16

3.2.1 Introduction....................................... 16

3.2.2 Replacing flat-bed filter in base

module....................................................... 16

3.2.3 Replacing bag-type filter or pleated

filter............................................................ 16

3.3 Cleaning.......................................... 16

3.4 Scheduled maintenance ................. 16

2.2 Delivery check .................................. 8

2.3 General instructions.......................... 8

2.3.1 Order of working ................................. 8

2.3.2 Miscellaneous..................................... 8

2.4 Installing the wall duct ...................... 8

2.5 Installing the roof duct ...................... 9

2.6 Suspending the unit........................ 10

2.6.1 Positioning ........................................ 10

2.6.2 Installing the suspension rail............. 10

2.6.3 Suspending and securing modules....11

4 Service.............................18

4.1 Safety instructions .......................... 18

4.2 Opening the unit ............................. 18

4.2.1 Base module..................................... 18

4.2.2 Electronics compartment .................. 18

4.3 Fuses .............................................. 19

4.4 High-limit thermostat....................... 19

Version 2.1 English (17-07-2018)

3

B

1 Introduction

1.1 About this manual

d

Danger:

This indicates actions which are not permitted. Ignoring this warning may lead to

serious damage or accidents that may

involve physical injury.

This manual describes the installation and

maintenance of the modular fan coil unit,

model PS.

This manual only relates to the unit itself. A

separate manual covers the operation and

control of the unit.

1.2 How to use this manual

For unit

With ... module:

The description applies only to models that

have the feature referred to.

If no specific model is referred to, the description applies to all models.

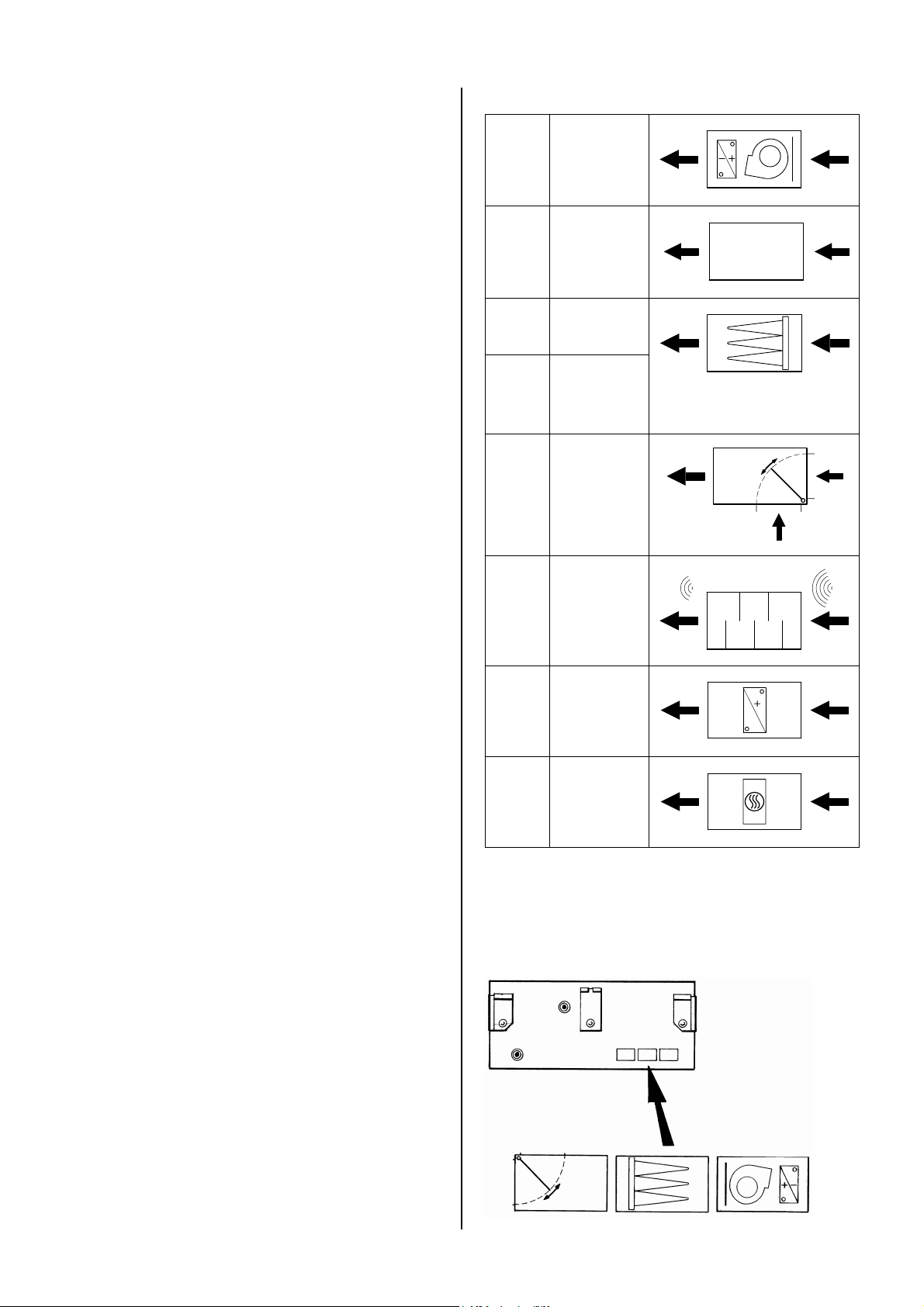

1.2.2 Pictograms used on the unit and

in the manual

The below pictograms refer to possible risks

or dangers. These pictograms can also be

found on the unit.

ê

s with … :

w

Warning:

You are entering an area which

contains live components.

1.2.1 Marginal symbols in the manual

n

Note:

Draws your attention to an important part of

the text.

c

Caution:

If you do not carry out this procedure or

action correctly, you may damage the unit.

So, follow the instructions carefully.

w

Warning:

If you do not carry out this procedure or

action correctly, you may cause material

damage and/or physical injury.

So, follow the instructions carefully.

Accessible to qualified maintenance staff only. Caution is

urged.

ç

1.2.3 Related documentation

Besides this manual, the following documents come with the unit:

- documentation for control and operation

(if applicable);

- wiring diagram for installation and service purposes.

w

Warning:

This surface or part can be hot.

There is a risk of burns on contact.

4

Manual model PS

Modular fan coil unit 1 Introduction

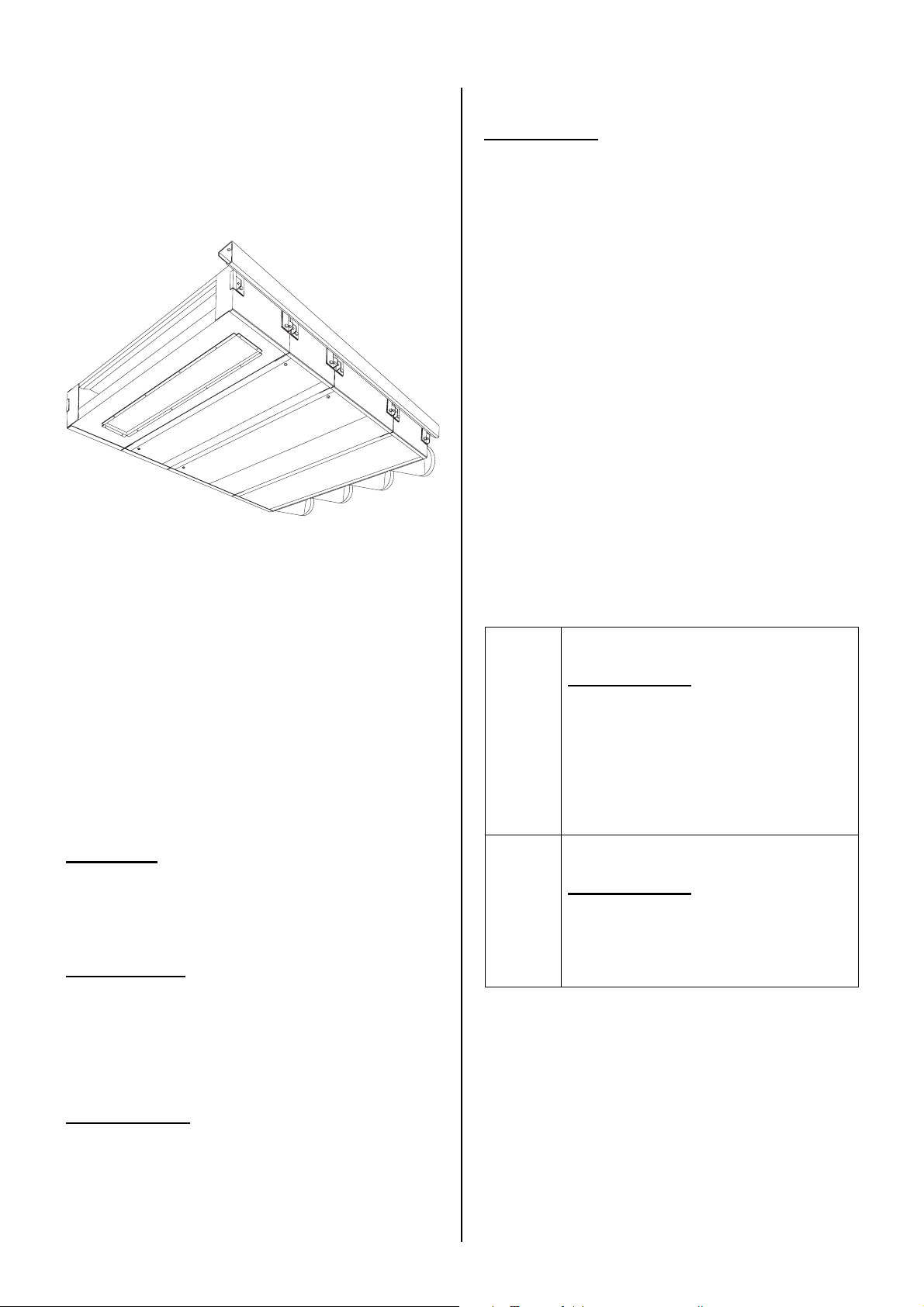

1.3 About the unit

1.3.1 Applications

The modular fan coil unit is designed for

heating, cooling and/or ventilating rooms.

The inlets and outlets of the unit are positioned in such a way that the discharged air

flow is distributed evenly across the room

without causing discomfort to the people in it.

The unit’s dimensions are geared to integrating the unit in suspended ceilings.

1.3.2 Working

The fan coil unit blows a flow of air into the

room. The air may be taken in, at the user’s

option, either from outside (ventilation) or

from the room itself (recirculation). Thus, the

unit offers two benefits:

- The room is kept at the desired temperature.

Type references and symbols of modules

PS B

PS P

PS F

PS FP

PS L

PS G

base

module

plenum

module

filter

module

pleated

filter

module

air valve

module

attenuation

module

- Gradual deterioration of air quality in the

room is counteracted.

1.3.3 Modules

A modular fan coil unit is made up of modules. Each module has its specific function.

By combining different modules, modular fan

coil units with different features can be composed.

PS V

PS VE

heating

module

(water)

heating

module

(electric)

The symbols can be found on the underside

of each module. On the base module, these

symbols indicate the order of the modules of

the delivered modular fan coil unit.

Version 2.1 English (17-07-2018)

5

B

1.3.4 Type code

The type references, when combined, constitute the type code of the unit's modules, for

instance:

PS B-20-H1-M

PS P-21

PS G-40

PS V-61-H1C3-I

Various combinations can be made.

Explanation of type code

series

module

capacity

with base

module and/or

heating module:

heating and/or

cooling

with base

module:

electronic

control

PS

B, P, F, FP,

L, G, V, VE

20, 21, 40,

41, 60, 61

H1, H2,

H3, H4

C3, C4

H1C3,

H2C2

HE

M

S

modular fan

coil unit

see Section

1.3.3

water heating

water cooling

water heating

and cooling

electric heating

modulating

control

speed control

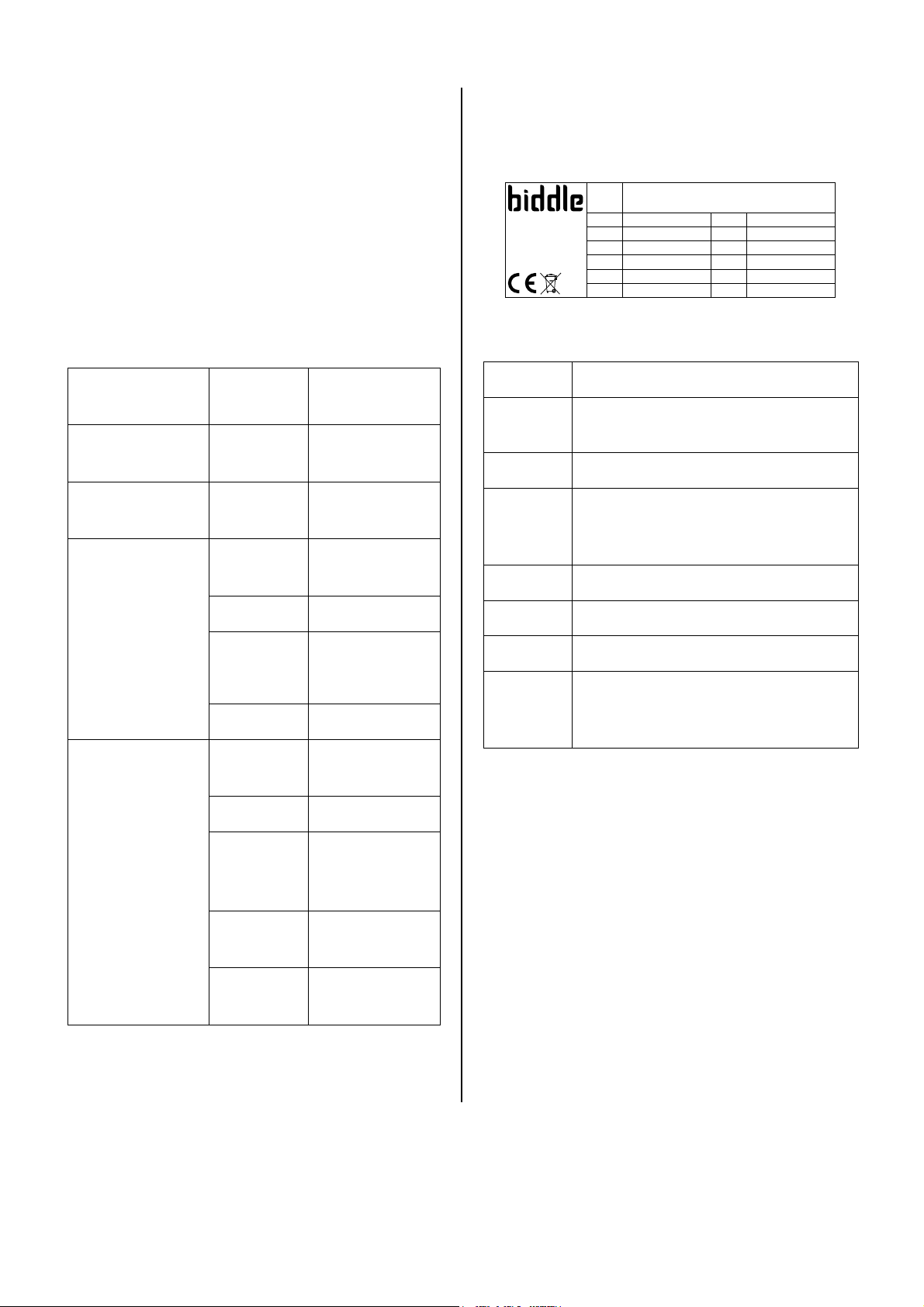

1.3.5 Type plate

The type plate is located on the base module.

Type PS B-40-H2-M

Biddle bv

Markowei 4

NL-9288 HA Kootstertille

Example of a type plate

References on the type plate

Type

Code

M

P

max

U

I

max

P

motor

P

heating

Code U 230 V ~ 50 Hz

4023

Nº 123456/1-1 07-12 I

M 51 kg I

Medium LPHW P

p

600 kPa P

max

max

I

max

max

motor

heating

L1 0.88 A

L2 -

L3 -

0.20 kW

-

full type code of unit

if applicable:

unit code of electronic control

weight of unit

with water heating:

maximum allowable operating

pressure

supply voltage

maximum amperage

maximum power absorbed by fans

with electric heating:

maximum power absorbed by heating

1.4 Components

6

I

B

without

reference

Interface, either

with or without

touch control

Basic, without

control

not described

in this manual

1.4.1 Required components

The following components are delivered

separately but are always required:

- mounting kit, consisting of a suspension

rail and fasteners for linking modules

- electronic control system components,

such as a controller, control cables, etc.

(see the documentation of the control

system)

Manual model PS

Modular fan coil unit 1 Introduction

1.4.2 Accessories

The following optional accessories are available:

- water control unit

- servomotor for air valve module

- ventilation module for the control of an

extractor fan

- wall sleeve

- external air intake grille

- roof cap

- duct connection (PS TH and PS TV)

- flexible connection sleeves, with or with-

out connecting flange

- wall and ceiling grilles, fixed or adjustable

- condensate drain tray

- condensate discharge pump

1.5.2 Installation, maintenance and

service

w

Warning:

The unit may be opened by qualified

technical staff only.

ê ç

Before opening the unit:

- Switch the unit off using the controller.

- Wait until the fans have stopped rotating.

- Allow the unit to cool down as the heat

exchanger or heating element can get

very hot.

- Disconnect the mains supply.

- Shut off the CH and/or CW supply (if

possible).

1.4.3 Parts not supplied

The following parts are not supplied by

Biddle and should be procured from other

suppliers:

- threaded suspension rods (M8)

- mounting rail

1.5 Safety instructions

1.5.1 Operation

w

Warning:

Do not put any objects in the inlets and

outlets.

Do not block the inlets and outlets.

w

Warning:

The fins of the heat exchanger are sharp.

ç

The upper surface of the unit can become

hot during operation.

Version 2.1 English (17-07-2018)

7

B

2 Installation

2.1 Safety instructions

2.3.2 Miscellaneous

c

Caution:

The infiltration of coarse dust, cement, etc.

may damage the unit. So long as such contaminants are in the room,

w

Warning:

Installation works may be performed by

qualified technical staff only.

Before opening the unit, follow the safety

instructions in Section 1.5.

2.2 Delivery check

- Check the unit and its packaging for

correct delivery. Report any transport

damage to the driver and supplier immediately.

- Make sure that all parts and components

have been supplied (see Section 1.4).

Report any defects to the supplier immediately.

- do not put the unit into operation;

- cover the inlets and outlets.

2.4 Installing the wall duct

Accessory, only in combination with air valve

module (PS L)

The wall duct is made up of a wall sleeve

and an external air intake grille. The wall duct

is made up of two parts which are slid into

one another.

B

A

2.3 General instructions

2.3.1 Order of working

Biddle recommends following the order of

working described in this section for performing the installation works.

n

Note:

Make sure you perform all operations that

are required for the installation of your unit.

Check the type plate and refer to Section

1.3.5 if you are not sure about the model or

type of your unit.

Opening dimensions for wall duct

type opening, A x B wall thickness

PS 20, 21

PS 40, 41

PS 60, 61

1 Apply the included expanding foam gas-

ket around the ventilation opening of the

air valve module.

2 Make an opening in the wall.

628 x 142 mm

1003 x 142 mm

1503 x 142 mm

200 – 350 mm

or

350 - 650 mm

(dep. on type)

8

Manual model PS

Modular fan coil unit 2 Installation

3 Fix the duct sections as you please, e.g.,

by bricking them in or by fixing them with

screws. If using screws, mind their positions: the screws must not hinder the installation of the external grille.

n

Note:

Seal any gaps between sleeve and wall in a

draught- and leakage-free manner.

4 Drill the (∅ 5mm) grille fixing holes into

the flanges of the sleeve section that is

fixed to the outer wall.

5 Apply paste onto the inner side of the

grille flanges. The paste is to seal off the

gap between grille and sleeve in a

draught- and leakage-free manner.

6 Fix the grille to the flanges using sheet

metal screws.

1

B

A

Opening dimensions for roof duct

type opening, A x B

PS 20, 21

PS 40, 41

PS 60, 61

1 Apply the included expanding foam gas-

ket around the ventilation opening of the

air valve module.

628 x 145 mm

1003 x 145 mm

1503 x 145 mm

Tar mastic

Timber 70x70

c

Caution:

Place the grille with the blades correctly

positioned: oriented outward to allow for runoff.

2.5 Installing the roof duct

Accessory, only in combination with air valve

module (PS L)

The roof duct is made up of two parts: a roof

curb and a roof cap. The roof cap consists of

a cover and a sleeve. On delivery, these are

attached to one another.

2 Make an opening in the roof.

3 Make a water-tight curb 1 around the

opening.

4 Detach the cap from the sleeve. To do

so, loosen the screws in the upper side

of the sleeve.

2

5 Insert the sleeve into the opening. Con-

nect sleeve and curb by fixing screws 2

through the sleeve’s inner side.

6 Mount the cap to the sleeve.

n

Note:

Seal any gaps between sleeve and roof in a

draught- and leakage-free manner.

Version 2.1 English (17-07-2018)

9

B

2.6 Suspending the unit

2.6.1 Positioning

- Make sure that the structure from which

the modules are to be suspended can

carry the weight of the whole modular fan

coil unit.

Module weights

PS 20, 21 PS 40, 41 PS 60, 61

PS B

PS P

PS F, FP

PS L

PS G

PS V, VE

- Suspend the unit at a minimum height of

1.8 m.

- Suspend the modules level. This results

in proper venting of the heat exchanger

and (for units with cooling) in proper discharge of condensate.

32 kg 51 kg 62 kg

8 kg 10 kg 12 kg

10 kg 13 kg 16 kg

13 kg 16 kg 20 kg

18 kg 24 kg 31 kg

15 kg 19 kg 22 kg

2.6.2 Installing the suspension rail

The modules are hooked into the included

suspension rail n one side. On the opposite

side (connection side), the modules are

suspended from a thread rod. The suspension rail may either be suspended from a

thread rod 1 (as illustrated above) or be

mounted directly onto the ceiling (as illustrated below).

1 Make a suspension structure using

thread rods, mounting rails and the supplied suspension rail. On each thread

rod, apply two nuts at an intermediate

distance of about 4 cm 2.

- Provide for proper sealing if wall or roof

sleeves and the like are installed. Improper installation can cause draught

and condensate problems.

- Ensure the air can flow freely through the

unit’s inlets and outlets.

- Position the unit such that the modules

will be easy to access both during and

after installation.

190

Centre distance between mounting rails and

suspension rails

PS 20, 21 PS 40, 41 PS 60, 61

A

n

Note:

- Keep a minimum distance of 190 mm

between the centre of the suspension rail

and a wall or obstacle, such as a pillar.

This is to allow the modules to be

hooked in.

- Mount the rails in line with a possible

opening for a roof or wall sleeve.

782 mm 1157 mm 1657 mm

A

10

Manual model PS

Modular fan coil unit 2 Installation

2.6.3 Suspending and securing

modules

5 Interlink the modules 7.

c

1 The base module (PS B) and the at-

tenuation module (PS G) are provided

with a securing bracket 3. Remove it.

Caution:

When linking the modules, do not fully press

the rubber seal 8 together.

Ensure that the air valve module, if any, is

attached to the roof or wall duct in a draughtfree manner.

2 Hook the modules into the suspension

structure one by one. Hook the suspension brackets 4 into the suspension rail

on the one side, and the suspension

hook 5 in the thread rod on the other

side.

In suspending the modules, follow the

order that is indicated in the schedule on

the base module (see Section 1.3.3).

3 Using the thread rods, adjust the mod-

ules vertically so that they are level.

6 Re-attach the securing bracket 9, which

was removed in step 1, to the relevant

module(s).

w

Warning:

Make sure that the module(s) is (are) secured. Unsecured suspension may lead to

a module falling out of the suspension

structure.

4 Secure the suspension hook 6 between

the two nuts on the thread rod.

Version 2.1 English (17-07-2018)

11

B

2.7 Connecting the valve

motor

Accessory with air valve module (PS L)

The air valve module is available with a premounted valve motor. If the module does not

yet have a valve motor, you must mount it

first.

1 Both the valve motor and the base mod-

ule have a cable with a connector. Connect these.

Connection through rectan-gular ducts is

possible with the duct connections

and PS TV, using flexible connection sleeves

(not illustrated).

Mounting the ducts depends on the local

situation, and is to be carried out according

to your own judgment. However, follow the

below instructions in order not to affect the

unit’s performance:

- Avoid any abrupt duct transitions.

- Keep ducts as short as possible.

- Mount flexible connection sleeves to the

intake opening under slight tension (this

is to prevent the connection sleeve from

being sucked to a close at high fan

speeds).

PS TH

2 You may want to set a stop to the valve

motor.

This allows you to open the air valve partially, so the unit will ventilate and recirculate at the same time.

2.8 Connecting ducts

Only with plenum PS P or duct

connections PS TH and PS TV

The plenum module PS

the modular fan coil unit to be connected, via

circular ∅ 200 mm ducts, to a discharge or

intake opening.

P (illustrated) allows

- Provide for proper sealing at transitions

in the duct system.

2.9 Connecting the unit to the

CH and/or CW system

Only for units with water heating and/or cooling

2.9.1 Water connections

Depending on the type, the connections have

female-thread fittings or compression fittings.

The heat exchanger may come with premounted control valves. If so, the CH and/or

CW pipes are to be connected to them.

The connections are marked with arrows that

indicate either supply or return: with heating,

the arrows are red; with cooling, blue.

12

Manual model PS

Modular fan coil unit 2 Installation

2.9.3 Connecting water pipes

1 Lay the water pipes, and connect them to

the screwed or compression fittings.

c

Caution:

Tighten the compression fittings well.

The (1/8") vent cocks 1 are mounted to the

collectors of the heat exchanger, protruding

from the side of the module.

c

Caution:

Biddle recommends the inclusion of a valve

in each pipe.

Operating pressure for CH and CW systems

temperature maximum

operating

pressure

screwed fittings

compression fittings all 3 bar

< 20° C 16 bar

< 93° C 10 bar

< 110° C 6 bar

2 Fill the CH and/or CW system.

3 Vent the heat exchanger.

4 Check the connections for leaks.

2.10 Connecting the

condensate drain

Only for units with cooling

2.10.1 Particulars

2.9.2 Frost protection

Only for units with ventilation

Depending on the control system, the unit

has a frost protection thermostat or a controller-integrated protection.

c

Caution:

This reduces the risk of the heat exchanger

freezing but does not warrant 100% protection.

Prevent the heat exchanger from freezing:

- Provide for constant circulation of the

water at the right temperature.

- Add glycol to the water when the unit is

not in operation during the wintertime.

The unit has two (∅ 15mm) condensate wa-

ter drains 2. One of the drains must be fitted

with a stink trap and connected to the sewer.

The second drain is closed with a compression cap but can be used if necessary.

The unit can be provided with a condensate

drain tray and/or a condensate pump (accessories). If so, their drains must be connected.

2.10.2 Connecting the condensate

drain

1 Install a sewer connection incl. stink trap.

2 Connect the condensate drain tray to a

flexible hose.

3 Connect the hose, with a stink trap, to

the sewer.

Version 2.1 English (17-07-2018)

4 Insulate the pipes that are not hanging

over the condensate drain tray.

13

B

2.11 Connecting the unit to

mains power supply

2.11.1 General

w

Warning:

The unit must be earthed.

The unit must be connected in accordance with all applicable local laws and

regulations.

c

Caution:

Do not switch the unit on and off with the

mains switch but rather with the controller.

2.11.2 Connecting to mains

For units with water heating and/or cooling:

2.12 Installing the controller

Depending on the type, the unit can be fitted

with an electronic controller. Install it according to the respective manual.

The connections are located on the electronics compartment or on the control unit's PCB

in the compartment (see Section 4.2.2).

1 Install an earthed wall socket at no more

than 1.5m from the connection side of

the base module.

c

Caution:

Do not yet insert the plug into the wall

socket.

For electrically heated units:

1 Install an all-pole switch with a minimum

contact distance of 3 mm.

2 Connect the switch to the mains.

w

Warning:

Make sure that the mains supply

group is switched off.

3 Connect the unit to the switch according

to the wiring diagram.

2.13 Switching on and

checking operation

For all units:

1 Check if all modules are correctly sus-

pended and secured.

2 Check the order of installation of the

modules (see Section 1.3.3).

3 Check the connection to the mains.

4 Check the controller connections (see

the corresponding documentation).

5 Switch on the mains supply.

6 Make the controller ready for use accord-

ing to the appropriate manual.

7 Switch on the unit using the controller.

Check whether the unit blows out air.

For units with water heating and/or cooling:

c

Caution:

Do not yet switch the mains supply group on!

14

Check if the heat exchanger is properly connected:

8 Make sure the CH and/or CW system is

(are) switched on.

Manual model PS

Modular fan coil unit 2 Installation

9 Let the unit heat and/or cool using the

controller. Feel whether the discharged

air is getting hot (if heating) or cold (if

cooling).

10 Vent the heat exchangers if necessary.

For units with cooling and condensate discharge pump (accessory):

Check the working of the condensate discharge pump:

11 Pour water into the external drip tray.

The condensate pump should start working shortly.

For units with air valve module:

12 Check the seal of the fresh air duct: it

should be draught-free.

13 Check whether the air valve closes off

the ventilation opening properly in both

modes.

14 Let the unit ventilate and recirculate

using the controller. Check whether the

air valve moves to the right position.

For units with an air valve module featuring a

valve motor with spring return:

15 Switch off the mains power supply and

check whether the valve automatically

closes the duct.

16 Switch on the mains supply and check

whether the valve works normally again.

Version 2.1 English (17-07-2018)

15

B

3.2.3 Replacing bag-type filter or

3 Maintenance

3.1 Safety instructions

w

Warning:

Maintenance works may be performed by

qualified technical staff only.

Before opening the unit, follow the safety

instructions in Section 1.5.

3.2 Replacing the filter

3.2.1 Introduction

The filter must be replaced regularly. A dirty

filter may cause inadequate heating, cooling

or ventilation as well as a high noise level.

The interval at which the filter is to be replaced depends on the use of the room.

New filters are available from Biddle. You

may also clean the filter material with, for

instance, a vacuum cleaner. After some

cleanings, however, the filter must be replaced.

pleated filter

Only for filter module PS F or PS FE

1 Remove the inspection panel from the

filter module (Section 4.2.1).

2 Gently pull 1 the cassettes and the filter

material out of the unit. If you handle the

cassettes too roughly, dust may fall out.

3 Replace the cassettes with cassettes of

the same filter class.

3.3 Cleaning

You can clean the unit's exterior as well as

the air intake and discharge grilles with water

and a domestic cleaning agent. Do not use

any solvents.

3.2.2 Replacing flat-bed filter in base

module

1 Remove the inspection panel from the

base module (Section 4.2.1).

2 Gently pull 1 the frame and the filter

material out of the unit. If you handle the

filter too roughly, dust may fall out.

3 Replace the filter with a filter of the same

class.

w

Warning:

Make sure no water enters the unit.

Carefully remove dust from the heating element with a vacuum cleaner.

3.4 Scheduled maintenance

Biddle recommends to have the following

inspections performed by an installer or other

technical expert every year.

For all units:

- Check if the filter is clean enough, and

undamaged. Replace the filter if necessary.

16

Manual model PS

Modular fan coil unit 3 Maintenance

- Check the air intake and discharge grilles

for contamination and clean them if necessary.

- Check the heating elements and the fans

for dust and other contaminants. Clean

them if necessary.

- Check the working of the fan.

For units with water heating and/or cooling:

- Check for water leaks. If there is a leak,

disconnect the unit from the mains, and

repair the leak.

- Check if the water circuit contains any

entrapped air. If yes, vent the circuit.

For units with cooling:

- Check if the condensate drain and con-

densate tray (accessories) are clean.

Contamination may lead to poor drainage and to growth of bacteria and fungi.

- Clean the filter of any condensate pump

(accessory) in the float module.

For units with air valve module:

- Check if the ventilation valve closes

properly in both modes.

- Check if the valve closes automatically if

the power supply is interrupted.

Version 2.1 English (17-07-2018)

17

B

4 Service

4.1 Safety instructions

w

Warning:

Service work on the unit may be performed by qualified technical staff only.

Before opening the unit, follow the safety

instructions in Section 1.5.

4.2 Opening the unit

4.2.1 Base module

The base module houses:

- the fan;

4.2.2 Electronics compartment

The electronics compartment is located on

the side of the base module. It contains:

- the PCB and the electronic control connections;

- the transformer with fuse (in some

types).

- the heat exchanger;

- the transformer with fuse (in some

types).

Remove the inspection panel from the base

module to access these components:

1 Turn the two quarter-turn fasteners 1.

2 Pull 2 the inspection panel about 3 cm

down.

3 Slide 3 the panel towards the discharge

opening.

Remove the cover from the electronics compartment to access the PCB.

You may want to remove the inspection

panel in its entirety:

4 Position the panel diagonally in the open-

ing, and remove it from the module.

18

Manual model PS

Modular fan coil unit 4 Service

4.3 Fuses

The fuse rating is indicated near the fuse

holder.

Location of fuses

unit type

control M or S

with capacity

20, 21, 40 or

60

control M or S

with capacity

41 or 61

control I on electronics

fuse holder

transformer control

on electronics

compartment

on electronics

compartment

and in base

module (near

transformer)

compartment

no individual

fuse

no individual

fuse

on PCB

2 Press the knob on the side of the base

module or heating module.

control B in base mod-

ule (near

transformer)

not applicable

4.4 High-limit thermostat

For base module or electric heating module

The unit is protected with a high-limit thermostat. When the heating elements reach a

too high temperature, the high-limit thermostat will switch off the electric heating for

safety reasons. You can switch the heating

on again by resetting the high-limit thermostat.

w

Warning:

If the high-limit thermostat is activated

frequently, there may be a dangerous

defect. In that case, disconnect the unit

from the mains and consult Biddle.

The high-limit thermostat may also be activated when power is supplied to the unit after

a power failure.

To reset the high-limit thermostat:

1 Allow the unit to cool down.

Version 2.1 English (17-07-2018)

19

m

anufacturer:

Biddle BV

address:

Markowei 4

9288 HA Kootstertille

p

roduct description:

Modular

Fan Coil Unit

brand:

Biddle

model: PS t

ype: PS-20/21/40/41/60/61

2006/95/EC

the Low Voltage Directive

2004/108/EC

the Electromagnetic Compatibility Directive

EN 61000

-6-2

Electromagnetic

Compatibility (EMC)

-- Part 6

-

1: Generic

EN 61000

-6-3

Electromagnetic Compatibility (EMC)

-- Part 6

-

3: Generic

EN 60335

-1

Safety of household and similar electrical appliances

EN 60335

-2-30 Safety of household and similar electrical appliances

hat the equipment named above has been designed to comply with the relevant sections

s

igned by:

W. de Vries

, Managing Director

,

2012

Declaration of Conformity

The Netherlands

We declare that the following product:

In accordance with the following Directives:

2006/42/EC

Has been designed and manufactured to the following specifications:

(including A14)

I hereby declare t

of the above referenced specifications. The unit complies with all essentials requirements of the directives.

the Machinery Directive

standards – Immunity for industrial environments

standards – Emission standard for residential, commercial and

light-industrial environments

Part 1: General requirements

Part 2-30: Particular requirements for room heaters

Loading...

Loading...