Page 1

NUOVA BIANCHI S.p.A. Viale Parigi, 5-7-9

24040 ZINGONIA DI VERDELLINO (BG) - ITALIA

Tel. 035 88 22 25 (ra) - Fax 035 88 33 04

E-mail: postvendita@bianchivending.it

Cod. ...................

1415

1415

Page 2

Mariella Trapletti

Zingonia (BG) - Italy

03/2001

DICHIARAZIONE DI CONFORMITÀ CE

La Nuova Bianchi S.p.A., con sede in via Parigi n°5 Zingonia - Bergamo - Italia, nella persona del suo Consigliere Delegato, -

Mariella Trapletti -, dichiara che il distributore modello

IRIS

è conforme alle misure di sicurezza previste dalla direttiva cons. 98/37/CEE del 22-06-1998 nei suoi capitoli 1-2-3-4 e relativi

allegati 1-2-3-5 Requisiti di sicurezza e salute e successivi.

Sono applicate le disposizioni per la prevenzione e leliminazione dei radiodisturbi in ottemperanza delle direttive CEE 89/336,

CEE 93/68 e successivi e del D.L. nr. 476 e successivi, che prescrivono la conformità alle norme EN 55014 3a ed., EN 55104,

ENV 50141 e EN 61000.

Le norme seguite per le prove didoneità al contatto con le sostanze alimentari rispondono alle disposizioni del D.M. 21-03-1973

e successivi.

In generale sono applicate le direttive 90/128/CEE, 73/23/CEE, 89/336/CEE e successive. Le norme seguite per le prove

di sicurezza delle parti elettriche sono secondo documento IEC 335-1 e successive.

DECLARATION OF EEC CONFORMITY

Nuova Bianchi Spa - situated in via Parigi n°5, Zingonia (Bergamo) Italy, represented by Mariella Trapletti - states that the

vending machines model:

IRIS

are in conformity with the safety measures provided for by the Law nr. 98/37/EEC dated 22-06-1998 in its items n.1-2-3-4 and

relative enclosures 1-2-3-5 Safety and Health and subsequent, and 73/23/CEE and subsequent.

Nuova Bianchi has applied the Standards for the prevention and the elimination of the radio disturbances in respect of the EEC

Standards 89/336, 93/ 68 and subsequent annexes and of the D.L. nr. 476 and subsequent annexes , that are in conformity

with the norms EN 55014 3a ed., EN 55104, ENV 50141 and EN 61000.

The Standards used for testing of the suitability for contact with food substances are in accordance with DM 21-03-1973

Standards and subsequent annexes.

In general the rules of the Standards 90/128/EEC ,73/23/CEE and 89/336/CEE and subsequent annexes have been

applied. The Standards used for the safety tests on electrical parts are in accordance, ref. IEC 335-1 and subsequent .

DÉCLARATION DE CONFORMITÉ CE

La Nuova Bianchi Spa, dont le siège social se trouve en Viale Parigi 5/5/9 Zingonia (Bg) - Italie - en la personne de son

Conseiller Délégué - Mariella Trapletti - déclare que le distributeur modèle:

IRIS

est conforme aux mesures de sécurité prévues dans la directive 98/37/CEE du 22-06-1998 dans ses chapitres 1-2-3-4 et

relatives annexes 1-2-3-5 Les critères de sécurité et de santé, ainsi que 73/23/CEE et relatives annexes.

Les normes suivies pour la prévention et élimination des parasites électriques répondent aux dispositions CEE 89/336, CEE 93/

68 et successifs et du D.L. nr. 476 et successifs, qui prescrivent la conformité au normes EN 55014 3a ed., EN 55104, ENV

50141 et EN 61000.

Les normes suivies pour les essais de conformité au contact des substances alimentaires répondent aux dispositions de DM

21.03.1973 et successifs.

En générale sont appliqués les directives 90/128/CEE, 73/23/CEE , 89/336 CEE et successives. Les normes suivies pour les

essais de sécurité des parties électriques sont selon le document IEC 335-1 et successives.

Mariella Trapletti

Il Consigliere Delegato

Legal Representative

Le Conseiller Délégué

Page 3

DECLARACIÓN DE CONFORMIDAD CE

La firma Nuova Bianchi S.p.A., son sede en la calle Parigi nº 5 Zingonia Bérgamo Italia, en la persona de su Administrador

Delegado, - Mariella Trapletti - declara que el distribuidor modelo

IRIS

está conforme con las medidas de seguridad previstas por la directiva cons. 98/37/CEE del 22-06-1998 en sus capítulos 1-23-4- y relativos anexos 1-2-3-5 Requisitos de seguridad y salud y sucesivos.

Están aplicadas las disposiciones para la prevención y la eliminación de las radioperturbaciones en cumplimiento con las directivas

CEE 89/336, CEE 93/68 y sucesivas y con el D.L. nº 476 y sucesivos, que prescriben la conformidad con las normas EN

55014 3ª ed., EN 55104, ENV 50141 y EN 61000.

Las normas seguidas para las pruebas de idoneidad del contacto con las substancias alimenticias responden a las disposiciones

del D.M. 21-03-1973 y sucesivas.

En general son aplicadas las directivas 90/128/CEE, 73/23/CEE, 89/336/CEE y sucesivas. Las normas seguidas para las

pruebas de seguridad de las partes eléctricas responden a las disposiciones del documento IEC 335-1 y sucesivas.

Mariella Trapletti

Zingonia (BG) - Italy

03/2001

Das geschäftsführende Verwaltungsratmitglied

El administrador Delegado

Administrador Delegado

EU-KONFORMITÄTSERKLÄRUNG

Das Unternehmen Nuova Bianchi S.p.A. mit Geschäftssitz in via Parigi Nr. 5 - Zingonia - Bergamo - Italien, erklärt in Eigenschaft

seines geschäftsführenden Verwaltungsratmitgliedes, - Mariella Trapletti -, dass der Verkaufsautomat Modell

IRIS

den Sicherheitsmassnahmen, aus Kapitel 1-2-3-4 der EU-Bestimmung Kons. EU 98/37 vom 22-06-1998 und den entsprechenden

Anlagen 1-2-3-5 - Anforderungen in bezug auf Sicherheit und Gesundheit und darauffolgenden, entspricht.

Es werden, unter Beachtung der EU 89/336, EU 93/68 Bestimmungen und darauffolgenden sowie des Gesetzeserlasses Nr.

476 sowie darauffolgenden, die Konformität mit den Normen EN 55014 3ª Ed., EN 55104, ENV 50141, EN 61000 vorschreiben,

die Bestimmungen zur Vorbeugung und Eliminierung von Funkstörungen angewandt.

Die bei den Eignungsprüfungen für Lebensmittelkontakte befolgten Normen entsprechen den in Ministerialerlass 21-03-1973

enthaltenen Bestimmungen und darauffolgenden.

Im allgemeinen werden die EU-Bestimmungen EU 90/128, EU 73/23, EU 89/336 und darauffolgende angewandt. Die bei den

für die Sicherheit der elektrischen Teile durchgeführten Tests befolgten Normen entsprechen dem Dokument IEC 335-1 und

darauffolgende.

DECLARAÇÃO DE CONFORMIDADE CE

A Nuova Bianchi S.p.A., domiciliada em via Parigi n°5 Zingonia - Bergamo - Itália, na pessoa de seu Conselheiro Delegado, Mariella Trapietti -, declara que o distribuidor modelo

IRIS

é conforme às normas de segurança contempladas pela norma cons. 98/37/CEE do 22-06-1998 nos seus capítulos 1-2-3-4 e

anexos 1-2-3-5 Requisitos de segurança e saúde e sucessivos.

Vem aplicadas as normas para a prevenção e a eliminação dos radiointerferências em respeito às normas CEE 89/336, CEE

93/68 e sucessivos e do D.L. nr. 476 e sucessivos, que contemplam a conformidade às normas EN 55014 3a ed., EN 55104,

ENV 50141 e EN 61000.

As normas para a idoneidade ao contato com substancias alimentares sao as relativas ao D.M. 21-03-1973 e sucessivos.

Geralmente vem aplicadas as normas 90/128/CEE, 73/23/CEE, 89/336/CEE e sucessivos. As normas para as provas de

segurança das partes elétricas sao as indicadas no segundo documento IEC 335-1 e sucessivas.

Page 4

4

IRIS

SAFETY SYMBOLS

PICTOGRAMS

IMPORTANT NOTICES

MAINTENANCE TECHNICIAN

The maintenance technician is defined as being the person responsible for filling up the containers with

soluble products, sugar, coffee, stirrers and cups.

The maintenance technician is also responsible for cleaning the distributor (see operations indicated in

chapter 9.0). In the event of a fault the maintenance technician must call the installation technician.

INSTALLATION TECHNICIAN

The installation technician is defined as the person responsible for the installation of the automatic distributor,

the starting up operations and the function settings.

Each regulation operation is the exclusive responsibility of the installation technician who also holds the

programming access password.

BEFORE USING THE MACHINE, READ THIS MANUAL CAREFULLY FOR ITS CORRECT USE IN

ACCORDANCE WITH THE CURRENT SAFETY STANDARDS.

ATTENTION: Important safety indications

READ the instruction manual machine carefully before using the machine

For any service or maintenance switch off the machine

ATTENTION: machine switched on

ATTENTION: hot parts in contact!

Page 5

5

IRIS

Tools necessary for undertaking

interventions on the automatic dispenser.

SOCKET SPANNERS

n° 5,5

n° 7

n° 8

n° 10

n° 20

n° 22

SPANNERS (fork type)

n° 7

n° 8

n° 10

n° 12

n° 14

SCREWDRIVERS

Small size

Medium size

Large size

Normal cross

Small cross

Medium cross

Large cross

Of Teflon, small size for Trimmer regulation.

RATCHET SPANNER no.14

TESTER

ELECTRICIANS SCISSORS

PROGRAMMING KIT

Keys at the disposal of the

MAINTENANCE and INSTALLATION

technicians

This key can also be given to the

maintenance technician exclusively

authorized to undertake the

operations as described in chapter 8.0

Keys at the disposal of the

MAINTENANCE and INSTALLATION

technicians

Page 6

6

IRIS

1.0 PREMISE

1.1 Important notices

This automatic distributor has been designed and constructed in

full accordance with current safety regulations and is therefore

safe for those who follow the ordinary filling and cleaning

instructions as indicated in this manual.

The user must not under any circumstances remove the

guards that require a tool for removal.

Some maintenance operations (to be done solely by specialized

technicians and indicated in this manual with a special symbol)

require that specific safety protections of the machine must be

switched off .

In accordance with the current safety regulations, certain

operations are the exclusive responsibility of the installation

technician, and the ordinary maintenance technician may have

access to specific operations on with specific authorization.

The acquaintance and absolute respect, from a technical point of

view, of the safety instructions and of the danger notices contained

in this manual, are fundamental for the execution, in conditions

of minimum risk, for the installation, use and maintenance of

this machine.

1.2 General Instructions

Knowledge of the information and instructions contained in the

present manual is essential for a correct use of the automatic

vending machine on the part of the user .

Interventions by the user on the automatic vending machine

are allowed only if they are of his competence and if he has

been duly trained.

The installation technician must be fully acquainted with all

the mechanisms necessary for the correct operation of the

machine.

It is the buyers responsibility to ascertain that the users have

been trained and are informed and regulations indicated in

the technical documentation supplied.

Despite the full observance of the safety regulations by the

constructor, those who operate on the automatic dispensers

must be fully aware of the potential risks involved in operations

on the machine.

This manual is an integral part of the equipment and as such

must always remain inside of the same, so as to allow further

consultations on the part of the various operators, until the

dismantlement and/or scrapping of the machine.

In case of loss or damage of the present manual it is possible

receive a new copy making application to the manufacturer,

with prior indication of the data registered on machines serial

number.

The functional reliability and optimization of machines services

are guaranteed only if original parts are used.

Modifications to the machine not previously agreed on with the

construction company and undertaken by the installation

technician and/or manager, are considered to be under his

entire responsibility.

INDEX

1.0PREMISE

1.1 Important notices

1.2 General Instructions

2.0TECHNICAL CHARACTERISTICS

3.0DESCRIPTION OF THE MACHINES TECHNICAL

CHARACTERISTICS

3.1 Description of the machine

3.2 Scheduled Use

3.3 Models

3.4 Basic instructions for the machine operation

4.0 TRANSPORTING THE AUTOMATIC VENDING MACHINE

4.1 Moving and Transport

4.2 Stocking

4.3 Packing

4.4 Reception

4.5 Unpacking

5.0SAFETY RULES

6.0INSTALLATION

6.1 Positioning

6.2 Water supply connection

6.3 Power supply connection

6.4 Machine starting up

6.5 Installation

6.5.1 Filling of water circuit

6.5.2 Cleaning of parts in contact with food

substances

6.5.3 Payment system installation

6.6 Product loading

6.6.1 Product container loading

6.6.2 Label application

6.6.3 Cup loading

6.6.4 Spoon loading

7.0 PROGRAMMING

7.1 Function description

7.2 General description and preliminary operations

8.0 MAINTENANCE

9.0 MAINTENANCE AND INACTIVITY

9.1 Cleaning and loading procedures

9.1.1 Recommended maintenance

9.1.2 Periodic cleaning by the maintenance

technician

9.1.3 Daily cleaning recommended

9.1.4 Weekly cleaning

9.1.5 Product loading

9.1.6 Ordinary and Extraordinary Maintenance

9.2 Maintenance procedures

9.2.1 Sanitization

9.2.2 Temperature control

9.3 Regulations

9.3.1 Dosage and grinding regulation

9.3.2 Instant electrovalve water flow regulation

9.4 When the unit is not working

10.0 ACCESSORIES

10.1 Basic furniture kit

10.1.1 Installation of coffee ground discharge

chute

10.1.2 Liquid ground collection

10.1.3 Installation of chutes and coin/token

box

10.1.4 Pump kit

11.0 TROUBLESHOOTING GUIDE FOR THE

FAILURES OR MOST COMMON ERRORS

12.0 DISMANTLEMENT

Page 7

7

IRIS

ZINGONIA (BERGAMO)- ITALIA

MATRICOLA N.

V 230 kW

Hz. 50

CE 01

SISTEMA FRIGORIFERO CLASSE

ABCDEFGHILMN 890123

MAX PRESS. ACQUA RETE 0.65 MPa ( 6.5 bar)

ZINGONIA (BERGAMO)- ITALIA

FIG.1.2

FIG.1.1

( ++39 35 419 67 20

fax ++39 2 700 486 69

All the operations necessary to maintain the machines

efficiency, before and during its use are at the users charge.

Any manipulations or modifications made to the machine that

are not previously authorized by the manufacturer, relieve the

latter from any responsibility for damages deriving from, and

will automatically result in the cancellation of the machine

guarantee terms.

This manual reflects the status at the moment of the emission

of the automatic vending machine on the market; possible

modifications, upgrading, adaptments that are done the

machine and that are subsequently commercialized do not

oblige NUOVA BIANCHI neither to intervene on the machine

previously supplied, nor, neither to update the relative technical

documentation supplied together with the machine.

It is however NUOVA BIANCHIs faculty, when deemed op-

portune and for valid motives, to adjourn the manuals already

present on the market, sending to their customers adjournment

sheets that must be kept in the original manual.

Possible technical problems that could occur are easily resolvable

consulting this manual ; For further information, contact the

distributor from whom the machine has been purchased, or contact

Nuova Bianchis Technical Service at the following numbers:

IWhen calling it is advisable to be able to give the following

information:

l The data registered on the serial number label (Fig.1.1)

l version of program contained in the microprocessor (adhesive

label applied to the component the assembled on the Master

board ) (Fig.1.2).

Nuova Bianchi S.p.A. declines any responsibility for damages

caused to people or belongings in consequence to:

l Incorrect installation

l Inappropriate electrical and/or water connection.

l Inadequate cleaning and maintenance

l Not authorized modifications

l Improper use of the distributor

l Not original spare parts

Under no circumstances is Nuova Bianchi spa obliged to com-

pensate for eventual damage resulting from the forced

suspension of drink deliveries as the result of faults.

Installation and maintenance operations , must be done

exclusively by qualified technical personnel with prior training

for carrying out these duties.

For refilling use only food products that are specific for

automatic vending machines.

The automatic distributor is not suitable for external installation.

The machine must be installed in dry places, with temperatures

that never go below 1°C it must not be installed in places

where cleaning is done with water hoses (ex. big kitchens.).

Do not use water jets to clean the machine.

If at the moment of the installation, if conditions differing from

those indicated in the present manual, or should the same

undergo changes in time, the manufacturer must be

immediately contacted before use of the machine.

Also check that any other eventual norms or regulations as

laid down by national or local legislation are taken into account

and applied.

Page 8

8

IRIS

Fig. 2.1

670

465

540

Height mm 670

Widt h mm 465

De

p

th mm 540

Wei

g

ht kg 49

Power Su

pply

V 230

Power fre

q

uenc

y

Hz. 50

Installed

p

ower

(1)

from 1,8 kW t o 2,1 kW

Nominal current 7,42 A

AVERAGE CONSUMPTIONS:

In standb

y

100 Wh

For 50 d rinks 300 W h

Water connection 3/4"

g

as

Electric connection SCHUKO

plug

WAT ER SUP PLY

from main su

pply

wi t h pressure between 0.5 and 6.5 bar

CUP DI SP ENSER

Suitable for cu

p

s with diameter mm 70-74

BOI LER RESISTANCES

of armoured t

yp

e:

of 1500 W for the coffee boiler

of 2000 W for the instant boiler

PRODUCT CONTAINER CAPA CI TY

Coffee in beans k

g

1,20

Instant coffee k

g

0,45

Milk kg 0,55

Milk

(

Double unit

)

kg 1,40

Creamer k

g

1,20

Creamer

(

Double unit

)

kg 2,90

Chocolate k

g

1,30

Chocolate

(

Double unit

)

kg 3,00

Lemon tea kg 2,00

Natural tea k

g

1,00

Broth k

g

1,25

Su

g

ar kg 1,70

Cu

ps (

166 cc

)

N° 180

S

p

oons N° 180

Neon li

g

ht (optional

)

of 6 Watt

(1)

Check the rated output indicated on the data plate applied by

the distributor.

2.0 TECHNICAL CHARACTERISTICS

Page 9

9

IRIS

INSTANT

VERSION

1

2

3

4

5

6

7

8

9

10

11

13

12

Fig. 3.1

3.0 GENERAL TECHNICAL DESCRIPTIONS

3.1 Machine description (Fig.3.1)

1 Push button panel group

2 Push button panel board

3 Blade distributor group

4 Sugar dispenser group

5 Coffee grinder group

6 Cup dispenser

7 Coin-acceptor group

8 Coffee group

9 Liquid ground collecting tank

10 Coffee ground collecting tank

11 Electronics board (Master)

12 Solenoid valve group

13 Instant product boiler group

3.3 Models

The following terminology is used so as to distinguish the various

models of automatic distributors:

IRIS E (version with espresso coffee and instant beverages)

IRIS I (version with instant beverages)

The manual is compiled for the most complete model:

it is therefore possible, to find descriptions or explanations

not related to your machine.

3.2 Foreseen use

The distributor is exclusively for the dispensing of drinks, prepared

mixing food substances with water (by infusion as far as concerns

coffee).

For this purpose use products declared as suitable by the

manufacturer for automatic distribution in open containers.

The drinks are made in specific plastic cups automatically dispensed

by the machine.

Where foreseen, also the spoon for mixing the sugar is dispensed.

The drinks must be consumed immediately and in no case are to

be kept for subsequent consumption.

Page 10

10

IRIS

Fig. 3.2

Fig. 3.3

Fig. 3.4

3.4 Basic operation concepts

During the normal functioning the distributor remains in standby

status.

Introducing the necessary amount, according to the set price,

and after pressing the key relative to the desired drink, the drink

dispensing cycle is activated and can be divided different processes:

CUP DISTRIBUTION

It is the first operation started up by the distributor (except

selections with no cup preselection).

- the motor inside the cup dispenser moves the volutes which

separates the cup making it fall into the special holder fork

(Fig. 3.2)

SUGAR DISPENSER

Where set and requested , an amount of sugar in the preset

maximum dose is dispensed with the possibility of stopping (in

the espresso version only) the latter at the desired dose.

The sugar is dispensed directly in the cup in the E versions whereas

for the I versions it is pre-mixed with the instant drinks.

The dispensing procedure occurs according to the following

phases:

1. the geared motor activates the helicoidal screw conveyor of

the sugar product container, dispensing the desired quantity

into the product chutes (Fig.3.3).

2. the reduction gear is activated which, via the cam, carries out

the chute handling to convey the sugar into the cup (Fig.3.4).

Page 11

11

IRIS

Fig. 3.8

Fig. 3.7

Fig. 3.6

Fig. 3.5

INSTANT VERSION

SPOON DISPENSER

This process is activated only in the versions where the spoon

dispenser is foreseen; In these versions it is possible to select

the spoon in the selections without sugar and/ or in the instant

selections .

- the geared motor that operates the spoon release device is

activated making the spoon fall into the cup (Fig.3.5).

INSTANT DRINKS

This process is activated when the cup and spoon dispensing

processes (when requested) have been completed.

According to the type drink requested and to the distributor model,

several of the various processes described here below can be activated.

If present, the whipper motor is activated (Fig.3.6).

The solenoid valve fixed to the coffee boiler is engaged in order

to deliver the required quantity of water into the mixer (fig.3.7);

In the IRIS I model, the activated solenoid valve is placed on

the tank (Fig.3.7).

The pump that delivers the required amount of water is activated;

and controlled by a special electronic device (volumetric counter),

which withdraws from the coffee boiler (Fig. 3.11).

The instant product geared motor activates the helicoidal screw

conveyor so as to dispense the quantity of product programmed

into the mixer (in some versions more than one product can

be conveyed into the same mixer) (Fig.3.8).

Once the preset quantity of water and powder is dispensed,

the whipper motor is switched off.

Page 12

12

IRIS

Fig. 3.9

Fig. 3.11

Fig. 3.10

Fig. 3.12

ESPRESSO COFFEE

This process functions only the models equipped with the coffee

espresso group, after the cup and sugar dispensing processes

have been effected.

the grinder is activated until it reaches the dose of ground

coffee set by the doser (Fig.3.9)

the doser electromagnet is activated , causing the opening of

the door and consequent fall of the coffee into the brew chamber

the rotation group geared motor brings it into the dispensing

position and simultaneously compresses the ground coffee

(Fig.3.10).

the pump that dispenses the quantity of programmed water

and that is controlled by a specific electronic device, (volume

meter), withdrawing the water from the coffee boiler (Fig.3.11).

the coffee group geared motor is activated again so as to bring

again into standby position; during this movement the used

coffee grounds are expelled (Fig.3.12).

Page 13

13

IRIS

Fig. 4.1

Fig. 4.2

Fig. 4.3

Fig. 4.4

4.0 MOVING AN AUTOMATIC VENDING

MACHINE

4.1 Moving and transport (Fig.4.1)

The transport of the distributor must be effected by competent

personnel.

The distributor is delivered on a pallet; for the shifting use a

trolley and move it slowly in order to avoid capsizing or dangerous

movements.

Avoid :

lifting the distributor with ropes or presses

dragging the distributor

upset or lay down the distributor during transport

give jolts to the distributor

Avoid as the distributor:

bumping it

overloading it with other packages

exposing it to rain, to cold or sources of heat

keeping it in damp places

The construction company is not liable for any damage which

may be caused for the partial or complete non-observance of the

warning notices indicated above.

4.2 stocking

For eventual stocking, avoid laying several machines over each

other, maintain it in vertical position, in dry places with

temperatures not inferior to 1°C (Fig.4.2).

4.3 Packing

The distributor is protected with polystyrene angles and by a

transparent film in polypropylene (Fig.4.2).

The automatic distributor will be delivered packed, assuring both

a mechanical protection and protection against damages from

the external environment.

On the package labels are applied indicating:

l maneouver with care

l dont turn upside-down

l protect from the rain

l dont superimpose

l protect from sources of heat

l not resistant against bumps

l type of distributor and serial number.

4.4 Reception

Upon reception of the automatic distributor you need to check

that the same has not suffered damages during the transport.

If damages of any nature are noticed place a claim with the

forwarder immediately.

At the end of the transport the packing must result

without damages which means it must not :

present dents, signs of bumps, deformations or damages of

the external packaging

present wet zones or signs that could lead to suppose that the

packing has been exposed to rain, cold or heat.

present signs of tampering

4.5 Unpacking

Free the distributor from the packaging , cutting the protective

film in which it is wrapped, along one of the protection angles

(Fig.4.3).

Remove the distributor from transport pallet, unscrewing the

screws (A) that block the fixing cross staff heads to the pallet

(Fig.4.4).

Page 14

14

IRIS

Fig. 4.6

Fig. 4.5

remove the key from the drink dispensing chamber (Fig.4.5)

open the door of the distributor and remove the adhesive tape

from the components listed here below:

l cup turret (example in Fig.4.6)

l coin box

l sugar container

l weight on the spoon dispenser column

l coin mechanism cover / Master board

l product containers

The packing material must not be left accessible to

others, as it is a potential environmental pollution

sources. For the disposal contact qualified companies

authorized.

Page 15

15

IRIS

Fig. 6.2

5 cm

60 cm

60 cm

60 cm

Fig. 6.1

5.0 SAFETY NORMS

ATTENTION!

before using the automatic distributor, read this manual

carefully.

The installation and maintenance operations must be performed

exclusively by qualified technical personnel.

The user must not in any circumstance be able accede to those

parts of the automatic distributor that are protected and require

a tool in order to be accessible.

The knowledge and the absolute respect, from a technical point

of view of the safety instructions and of the danger notices

contained in this manual, constitute the basis for the operation,

in conditions of minimum risk, of the installation, starting and

maintenance of the machine.

Always disconnect the POWER CABLE before

maintenance or cleaning interventions.

ABSOLUTELY DO NOT INTERVENE ON THE MACHINE AND

DO NOT REMOVE ANY PROTECTION BEFORE THE

COOLING OF THE HOT PARTS!

The functional reliability and optimization of machines services

are guaranteed only if original parts are used.

The distributor is not suitable for external installation. The

machine must be connect in dry places, with temperatures

that never go below 1°C it must not be installed in places

where cleaning is done with water hoses (ex. big kitchens).

Do not use water jets to clean the machine.

In order to guarantee normal operation, the machine must be

installed in areas that the environmental temperature is between

a minimum of -1°C and a maximum of +32°C end humidity of

not over 70%.

In order to guarantee a regular operation, always maintain

the automatic distributor in perfect cleaning conditions

Nuova Bianchi S.p.A. declines all responsibility for damages

product to people or belongings in consequence to:

l Incorrect installation

l Inappropriate electrical and/or water connection.

l Inadequate cleaning and maintenance (See section 9.0

MAINTENANCE).

l Not authorized modifications

l Improper use of the distributor

l Not original spare parts

Futhermore verify observance of any other eventual local and

national standards.

6.0 INSTALLATION

6.1 Positioning

As already specified in paragraph 5.0, Safety regulations, the

distributor is not suitable for external installation. The machine

must be connect in dry places, with temperatures that never go

below 1°C it must not be installed in places where cleaning is

done with water hoses(ex. big kitchens.) . It must be installed in

places without danger of explosions or fires.

If positioned near to a wall, there must be a minimum distance

from the wall of at least 5 cm. (Fig.6.1) so as to allow a regular

ventilation. In no case cover the distributor with cloths or similar.

Position the distributor, checking the leveling by means of the

adjustable feet already assembled on the machines (Fig.6.2).

make sure that the distributor doesnt have an inclination of

more than 2 degrees.

WARNING! Do not position the device near inflammable

objects, keep a minimum safety distance of 30 cm.

Nuova Bianchi declines all responsibility for inconveniences due

to the non observance of the above mentioned installation norms.

If the installation is made in safety evacuation corridors make

sure that with the distributor door open there is anyhow sufficient

space to pass by (Fig.6.1).

So as to avoid that the floor gets dirty, due to accidental spilling

of the products, use, if necessary, under the distributor, a protection

sufficiently wide to cover the distributors operating space.

6.2 Connection to the main water supply

Before proceeding with the connection of the distributor to the

water main supply verify the following water characteristics:

that it is drinkable (eventually through an laboratorys analysis

certification)

it has a pressure comprised between 0.5 and 6.5 bar ( if this

should not be the case, use a pump or a water pressure, reducer

according to the case).

Page 16

16

IRIS

Fig. 6.7

Fig. 6.3

Fig. 6.4

Fig. 6.5

Fig. 6.6

OK

NO

NO

Fig. 6.8

install, if not present, a tap in an accessible position to isolate

the machine from the water mains should it be found to be

necessary (Fig.6.3).

before making water connections, make some water flow out

of the tap so as to eliminate possible traces of impurities and

dirt (Fig.6.4)

connect the cock to the distributor, using a pipe in nylon material

suitable for food products and suitable for the mains pressure.

In the event of the use of a flexible pipe it is necessary to fit

the reinforcement bush supplied inside (Fig. 6.5).

the foreseen connection is a 3/4 gas (Fig.6.6).

6.3 Main Power supply connection

The distributor is suitable for operation at single-phase voltage of

230 volt and is protected by 2 12.5 A fuses and by a 10A fuse on

the MASTER card.

We suggest to check that:

the tension of net of 230 V doesnt have a difference of more

than ± 10%

The power supply output is able to bear the power load of the

machine.

use a system of diversified protection

position the machine in such a way as to ensure that the plug

remains accessible

The machine must be connected to earth in observance with the

current safety norms.

For this reason, verify the plants earth wire connection to ascertain

that it is efficient and it answers national and European safety

electric standards. If necessary require the intervention qualified

personnel for the verification of the plant.

The distributor is equipped with a power supply cable of H05VV-

F 3x1,5mm², with SCHUKO plug (Fig.6.7).

The sockets that are not compatible with that of the machine

must be replaced. (Fig.6.8).

The use of extension, adapters and/ or multiple plugs is

forbidden.

Nuova Bianchi S.p.A. declines all responsibility for damages

deriving for the complete or partial failure to observe these

warnings.

Should the power cable be found to be damaged, immediately

disconnect from the power socket.

The power supply cables are to be replaced by

skilled personnel.

Page 17

17

IRIS

ON

OFF

Fig. 6.9

Fig. 6.10

Fig. 6.11

6.4 Starting up of the unit

The distributor is provided with a connection cable for connection

to the mains water supply (fig.6.9) and a switch which cuts off

the power from all users each time that it is operated (fig.6.10).

Should it be necessary to operate inside the distributor for any

ordinary or special maintenance operates, it is necessary to isolate the user appliances by activating the switch (fig.6.11), bearing

in mind that with the electrical connection engaged, the power

terminals are live.

Each time the distributor is switched on a diagnosis cycle is

performed in order to verify the position of the mobile parts and

the presence of water and of some products.

Page 18

18

IRIS

Fig. 6.12

Fig. 6.13

Fig. 6.15 Fig. 6.14

6.5 Installation

6.5.1 Filling the water circuit

The appliance undertakes automatic filling of the water supply

circuit.

The operational sequence will be as follows:

- Remove the back cover to access the boiler (Fig. 6.12).

- floating tank filling.

It is advisable to press the pipe that connects the heater to the

water tank a few times, in order to eliminate any air bubbles that

might form (Fig. 6.13)

- when the presence of water inside the tank can be seen from

the inspection hole (Fig. 6.14) the cup column will start for

filling and the coffee unit will undertake a trial cycle.

- filling will stop when the maximum level is reached.

- at the end of the water filling (Fig.6.15), effect a cleaning cycle

of the mixer group so as to fill all the circuits and remove

eventual residues from the boiler.

Page 19

19

IRIS

Fig. 6.16

Fig. 6.19

Fig. 6.17

Fig. 6.18

Fig. 6.20

6.5.2 Cleaning of the parts in contact with

food substances

With distributor switched on effect a cleaning of the mixers

pressing the buttons according to what is described in the service

functions so as to eliminate any dirt from the coffee boiler and the

instant boiler.

wash your hands carefully

Move the cup column forward to access the tanks (Fig.6.16).

prepare an anti-bacterial cleaning solution with a chlorine base

(products that can be purchased in pharmacies) following the

concentrations given on the product instruction labels.

remove all the product containers from the distributor (Fig.6.17)

remove the lids from the product containers covers and product

chutes (Fig.6.18). Dip all in the solution previously prepared

remove all the powder chutes, water funnels, mixing bowls

and whippers and silicone tubes and dip these parts also in

the prepared solution (Fig.6.19)

with a cloth soaked with the solution clean the whipper assembly

base (Fig.6.20)

the parts must soak in the solution for the time indicated on

the solutions instruction label.

Recover all the parts, rinse them abundantly, dry them perfectly

and proceed with the re-assembly in the distributor.

For further safety after the assembly of the parts, effect

some automatic cleaning cycles so as to eliminate any

eventual residues.

6.5.3 Payment system installation

The distributor does not have a payment system; any possible

damages to the distributor itself and/or objects and/or people

deriving from its incorrect installation are responsibility of who

installs the payment system,

To install the payment system partially unscrew the three screws

mount the token slot without selector.

Tighten the three screws and mount the selector

connect the coin mechanism to the Master board.

The selectors must be directly connected to the Master board the

and the serial executive system through the interface cable

supplied with the machine.

Then go into programming for the correct settings.

Consult chapter 7.0 PROGRAMMING so as to verify setting of

the parameters, that must be coherent with the system used.

Page 20

20

IRIS

Fig. 6.21

Fig. 6.22

Fig. 6.23

LATTE

MILK

LAIT

MILCH

Fig. 6.24

6.6 Product container loading

(with machine off)

6.6.1 Loading containers

Filling is possible keeping the containers inserted, and by raising

the upper flap of the distributor (Fig. 6.21) or by extracting each

container.

For granulated coffee in particular it is necessary to close the

closure plat before extracting the container.(Fig.6.22).

remove the covers of each container and load the product

according to the product indicated on the label (Fig.6.23-

Fig.6.24).

pay attention that they there are no clots, avoid pressing the

product and using an excessive quantity, so as to avoid its

aging in relation to the consumption forseen in the time period

between two loadings.

Check the container product capacity in the section TECHNICAL

CHARACTERISTICS.

Page 21

21

IRIS

Fig. 6.25

Fig. 6.26

IRIS 6 INSTANTS DEKA IRIS 6 INSTANTS STANDARD

6.6.2 Product selection label application

The labels showing the selections shall be inserted under the transparent cover of every single key.

To carry out this operation proceed as follows:

Open the front door (Fig. 6.25) and by means of a screwdriver act on the tabs holding the cover on every key (Fig. 6.26).

Insert the labels according to the selections in the different versions (see following diagrams) and install back the cover.

Milk

Tea

Chocolate

Instant coffee

Sugar

Instant coffee

second

Milk

Tea

Chocolate

Instant coffee

Sugar

Instant

product

Page 22

22

IRIS

IRIS 6 ESPRESSO DEKA IRIS 6 ESPRESSO STANDARD

Milk

Tea

Chocolate

Instant coffee

Sugar

Coffee in

beans

Milk

Chocolate

Sugar

Coffee in

beans

Page 23

23

IRIS

Fig. 6.27

Fig. 6.28

Fig. 6.29

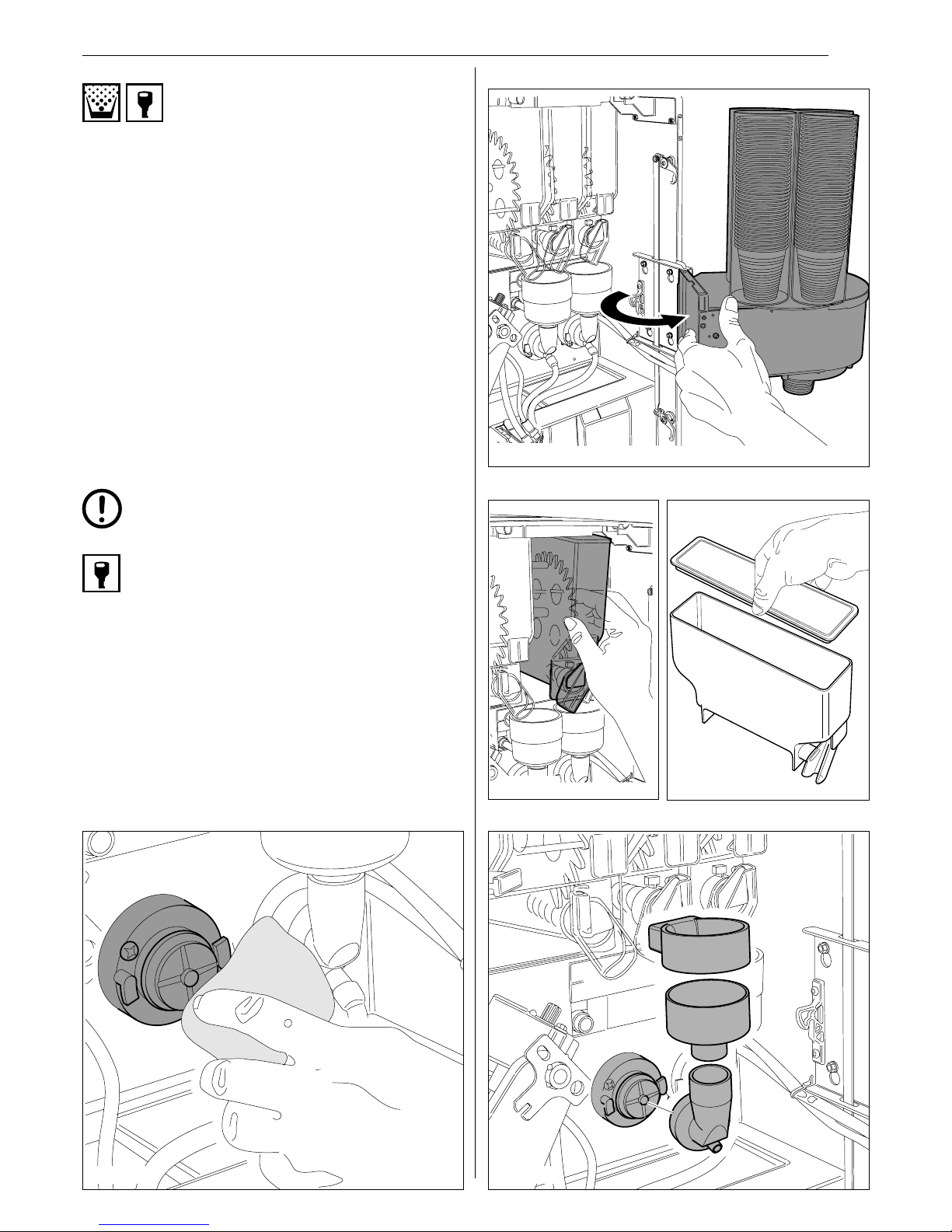

6.6.3 Cup loading

Use only cups designed for automatic vending machines, with a

diameter of more than 70-74 mm, avoid compressing the cups

between themselves during the loading.

First filling

In installation phase with the cup dispenser completely empty,

operate as follows:

- take the cup dispenser with its cup column and push them

forward to make them rotate to the outside of the machine

(Fig. 6.27)

CAUTION!

Do not carry out this operation taking the cup

column only as some breakages may occur.

- Now load the cup column from above without manually rotate

it (Fig. 6.28).

- Once the loading has been completed, place the cup dispenser

back to its work position by rotating inside the machine.

- The cup dispenser is in the correct position only when it is

locked (Fig. 6.29).

Page 24

24

IRIS

Fig. 6.30

Fig. 6.31

Fig. 6.32

6.6.4 Spoon loading

Remove the metal weight from the spoon dispensing column

(Fig. 6.30)

insert the spoons with their pack wrapping in the column and

when they are positioned on the bottom cut and remove the

wrapping (Fig. 6.31)

once the loading is completed put the weight back in the spoon

dispensing column.

Check that the spoon are cut burr-free, that they are not bent

and that they are all placed horizontally (Fig. 6.32).

The IRIS I models do not have the spoon dispensing column as

the sugar is mixed directly with the products.

Page 25

25

IRIS

Fig. 7.1

7.0 PROGRAMMING

With the programming procedures described in this section it is

possible to set all the parameters relative to the configuration of

the machine, to the setting of the single doses, the prices of the

drinks and extract all the vending statistical data.

The dialogue between the operator and the machine occurs by

means of the 32 digit liquid crystal display and the use of the

selection key touc pad.

The distributor is regulated with standard values from the testing

stage with Coffee temperature, soluble drink temperature,

selections combined with price number 1.

Product regulation = quantity of water and powder, for improved

results it is possible to regulate the degree of grinding and dosing.

7.1 General description and preliminary operations

PROGRAMMING KEY

You access the programming function by pressing P11 key placed

on the component side of the keyboard card (Fig.7.1). The display

will request the access code to be entered via the keyboard.

The display messages are in four different languages that can

be selected at choice by the operator during the installation

phase (Fig.7.2) (suitable for hardware with potential for

expansion to eight languages).

The programming data can be of two kinds:

l NUMERICAL DATA

This is all the data that refers to the water , powder, prices, time

and date settings.

l LOGICAL DATA

This is all the data that refers to the logical status of the OPTION

menus that describe the status (enabled or disabled ) of a specific

function.

On entering the correct code one enters the true programming

mode.

Default code is 00001.

If the slave is missing to which the menu heading refers, the

corresponding parameter is nit displayed and line 2 appears empty.

In general keys 1 and 2 modify the parameters or scroll menu

entries displayed in line 2.

For programming part of the keys of the selection keyboard are

used which are namely:

n key 1 +

Increments the flashing digit or sets YES or sets ON.

n key 2 -

Decrements the flashing digit or sets NO or sets OFF.

n key 3 CUR

Cursor: when flashing, it shows the digit to be modified.

n key 4 ENTER

Is used to confirm the changes done.

n key 5 ESC

Comes from the current programming submenu, and returns to

the sub-menu of origin.

n push button P11 on the board ESC

Comes from the current programming submenu, and returns to

the sub-menu of origin.

The functions of the above keys will be valid throughout this

manual unless otherwise specified.

In this status the LCD contrast can be digitally adjusted. The

keys to be used are:

7 to increment contrast

8 to decrement contrast

4 to confirm value

The other keys have no effect in this status.

PROGRAMMING

1=+ (increase)

2=- (decrease)

3 = CUR (cursor)

4 = ENTER (confirm)

5 = ESC

push button P11 = ESC

Programming panel

Page 26

26

IRIS

MAINTENANCE

(Espresso version)

1 COFFEE GROUP ROTATION OR ALARM SCROLL (if present)

2 MILK CHOCOLATE MIXER WASHING.

3 TEA OR DECAF MIXER WASHING

4 CUP CONVEYOR MOVEMENT

5 CUP RELEASE

6 SPOON RELEASE

7 TESTING OF WATER ONLY OF A SELECTION

8 COMPLETE TESTING OF A SELECTION

9 TOTAL ENTRY DISPLAY

10 ALARM RESET

P12 RETURN TO NORMAL STATUS OR EXIT FROM TEST OR

WATER TEST.

Maintenance panel (Espresso version)

Maintenance panel (Instant version)

MAINTENANCE

(Instant version)

1 MIXER WASHING 1 OR ALARM SCROLL (if present)

2 MIXER 3 WASHING

3 CUP RELEASE

4 TOTAL ENTRY DISPLAY

5 MIXER 2 WASHING

6 WASHING

7 CUP CONVEYOR MOVEMENT

8 TESTING OF WATER ONLY OF A SELECTION

9 COMPLETE TESTING OF A SELECTION

10 ALARM RESET

P12 RETURN TO NORMAL STATUS OR EXIT FROM TEST OR

WATER TEST

P13 TRANSLATOR MOVEMENT ONLY IF CONVEYOR OPTION IS

YES

Page 27

27

IRIS

Fig. 7.2

7.1.1 Language selection

Espresso version

Instant version

So as to go into programming again it is necessary to know the

access code or password.

cod. 00000

The code to be entered is composed of five digits.

The cursor appears under the first; with the keys + and -

(1st and 2nd of the keyboard) increase or decrease the number;

with the 3rd key (CUR) move the cursor.

Repeat the operations until the access code is composed.

Once the code is composed, press the key Enter (4th) so as to

accede to programming.

the default code is 00001

On the display, after entering the code, the first function is

displayed:

pressing ENTER you accede to the latter.

pressing + the next function will be displayed.

pressing ESC you exit from the sub menu of operation.

N.B.: If you are in selection mode you can pass to programming

mode.

Page 28

28

IRIS

And are in SERVICE mode, after which go first into SELECTION

mode and then accede to the PROGRAMMING.

The main menu bears the wording Menu choice on the first line,

the second line bears the wording of the program menu relating

to the following list:

SALES

OPTIONS

BEVERAGES

TIME SNACK

TEMPERATURE

PRICE-KEYS

COINS

PRICES

MDB DATA (only if MDB is selected in the option menu)

MDB PIPE FILLING (only if MDB is selected in the option menu)

MDB PIPE EMPTYING (only if MDB is selected in the option menu)

CODE

DEFAULT DATA

DISCOUNTS (only of clock chip is inserted)

INCLUDE-JUG

MILK FIRST (only Espresso version)

CLOCK (only of clock chip is inserted)

PREVENTIVE ACTION

For those menu items referred to Vega slave,if this is not present,

line 2 is blank.

The escape from the programming mode press ESC until return

to the selected mode.

The display visualization is on two lines.

It is possible to make selection by using a programme on the

WinBianchi PC .

For each drink, the possible programmable does are indicated

under the heading Sxx.

7.2 Function description

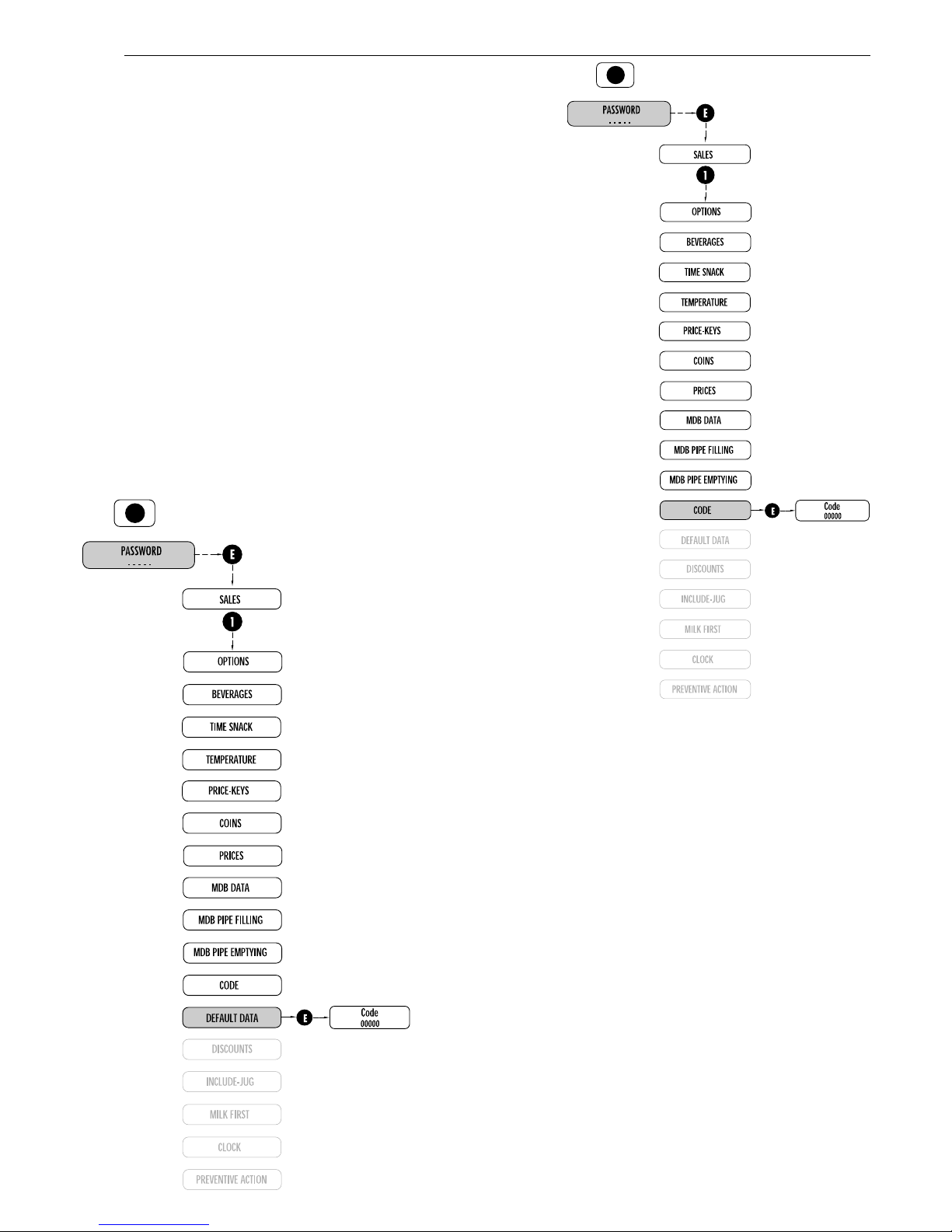

7.2.1 SALES (Fig.7.2)

Espresso version

Instant version

Gives access to all the selling statistics audited by the machine

Confirming with the ENTER key, gives you access in sequence to

the following menus for statistical data and the processing of the

same:

TOTAL CASH= total of the non cancellable sales prices

CASH = total for the cancellable sales prices

DISCOUNT = discounted value total

OVERPAY = total cash without sales

(N.B. active only for coins and G13)

TOTAL COUN = total sum of the selections made (sales *

tests) which cannot be cancelled

COUN = total count of selections made (sale +

tests) that can be set to zero.

Bev. coun x with x = 1..13 indicates the beverage

referred to for the value displayed on line 2 [0..65535]

Sect. Coun xy with x=1..6 y=1..8 indicates the sector for

Vega [0..65535]

FREE = total count and count per each singl selection of

the free SELECTIONS (with the option free vend

key)

JUG = total count and count per each single

selection of the JUG SELECTIONS (with

the option JUG key).

TEST = total count and count for single selection of test

selections, that can be set to zero.

COINS = Coin line x with x = 1..8 indicates the coin

referred to for the value displayed on line 2

DELETE Code entry [0..9999]

Repl.code? Replace code? [Yes/No]

Code Code setting [0..9999]

Set to zero? Sets sale data to zero [Yes/No]

The item to set a new code will be displayed only by answering

Yes to the Repl.code? item.

Pressing the key + will take you through the menu up to the

desired function; pressing the enter key gives access to the first

data of the function selected; by pressing ENTER again gives you

access to the other data, if present.

Pressing the ESC key takes you back to the original menu.

To reset the data operate as follows:

go to CANCEL

press ENTER key

COD 0000 will appear on the display

input the resetting code using the same criteria.

press ENTER

request if you wish to change the resetting code will appear.

press the key + if you do not wish to change the code.

RESET ? will appear on the display

confirm with the CURSOR key

at the end of the resetting, pressing the ESC key takes you back

to the original menu.

The data resetting code (4 digits) can be different from the

programming access code (5 digits).

The default code is 0001

N.B. If you want to change the default code proceed as follows:

when the request if you want to change the code appears,

press ENTER

the old code will be displayed

use the keys +, - to compose the new code.

confirm with ENTER at the end.

Page 29

29

IRIS

Fig. 7.2

Espresso version

Instant version

Page 30

30

IRIS

7.2.2 OPTIONS (Fig. 7.3)

Espresso version

This functions provides a sequence access to a series of options

listed below, on pressing ENTER access is provided to a sub-menu

in which the first option is displayed. For each OPTION the logicl

ON or OFF must be entered with engages the function or not.

Language Language selection for message display. The

available languages are 4 and 4 on message

eeprom; if this is present, and can be

updated with the message program.

Payment system Sets the payment system used

[G13/Executive/MDB]

ECS diff. Only if the executive payment system has

been set. Set the differentiated ESC option

(ON/OFF)

Price holding Only if the executive payment system has

been entered. Sets the price holding option

[On/Off]

Vega type = type of Vega machine [Snack, Pan]

Decaffeinated Decaffeinated preselection option, if set on

YES the preselection key is enabled [YES/NO]

Spoons for inst. Enables spoon delivery for all drinks

[YES/NO]

Always spoons Enables spoons [YES/NO]

Sweet presel. Sets the preselection key as sweet if YES

or unsweetened if NO [YES/NO]

Sugar mixer Enables sugar mixer option; when this

option is enabled the instant product order

is reversed [YES/NO]

Single sugar Enables the single sugar option [YES/NO]

Single sugar time Enables time for sugar if the single sugar

option is enabled [00.0 s 25.5 s]

Instant Grinding Sets grinding type: instant grinding with YES,

traditional grinding with NO [YES/NO]

Grinder threshold Sets the power threshold for the grinder

[05.0 18.0]

Grinder timeout Sets the grinder timeout [00.0 s 25.5 s]

Unit timeout Sets the unit timeout [00.0 s 25.5 s]

Pump timeout Sets the pump timeout [00.0 s 25

Cup sens. Cup sensor activation (ON/OFF)

Permanent credit Engages the credit timeout function for 3

minutes. Yes to engage the option and NO

to disengage it [YES/NO]

Credit recovery This option engages credit recovery in the

event of unsuccessful drink dispensing

operation. The credit is not recovered if there

is a capacity signal or in the presence of other

signals hot water delivery is requested. YES

to engage. NO to deactivate [YES/NO]

Autonomous pump Enables the autonomous pump running

[On/Off]

Aut.pump timeout Sets the time for the autonomous pump

[0..60 s]

Reintegration Enables reintegration. YES to engage and NO

to disengage [YES/NO]

Multisale Enables multisale. YES enables option,

NO disables option [YES/NO]

Machine number Machine number [0..999999]

Rental number Rental number [0..65535]

Decimal point To define the display of the decimal point,

P1 and P2 for selection and P4 for

confirmation.

[0000 / 0000.0 / 000.00 / 00.000]

Washing Engages washing cycle with clock. [On/Off]

Washing cycle Engaged the washing cycle. [On/Off]

Jug 1 Number of deliveries of drinks associated to

key 1. [2..99]

Jug 2 Number of deliveries of drinks associated to

keys 2..8 . [2..99]

Credit timeout Recovers credit if delivery fails (Vega)

[YES/NO]

Vega falling sensor Enables Vega product falling sensor

[YES/NO]

Use keys + and - to vary the logical values like change of

state from yes (ON=engaged) to no (OFF=deactivated) or use

keys +,- and CUR to alter the numeric values.

On pressing ENTER the set value is confirmed and the following

option appears: on pressing ESC again we return to the OPTIONS

menu.

Page 31

31

IRIS

Fig. 7.3

Espresso version

Page 32

32

IRIS

7.2.2 OPTIONS (Fig. 7.4)

Instant version

This functions provides a sequence access to a series of options

listed below, on pressing ENTER access is provided to a sub-menu

in which the first option is displayed. For each OPTION the logicl

ON or OFF must be entered with engages the function or not.

Language Language selection for message display. The

available languages are 4 and 4 on message

eeprom; if this is present, and can be

updated with the message program.

Payment system Sets the payment system used

[G13/Executive/MDB]

ECS diff. Only if the executive payment system has

been set. Set the differentiated ESC option

(ON/OFF)

Price holding Only if the executive payment system has

been entered. Sets the price holding option

[On/Off]

Vega type = type of Vega machine [Snack, Pan]

Decaffeinated Decaffeinated preselection option, if set on

YES the preselection key is enabled [YES/NO]

Sweet presel. Sets the preselection key as sweet if YES

or unsweetened if NO [YES/NO]

Conveyor Sets DA for running sugar conveyor and

spoons [YES/NO]

Spoons for inst. Enables spoon delivery for all drinks

[YES/NO]

Single sugar Enables the single sugar option [YES/NO]

Single sugar time Enables time for sugar if the single sugar

option is enabled [00.0 s 25.5 s]

Water integration T Sets the amount of water integration,

[0.0 s 6.0 s]

Cup sens. Cup sensor activation (ON/OFF)

Permanent credit Engages the credit timeout function for 3

minutes. Yes to engage the option and NO

to disengage it [YES/NO]

Credit recovery This option engages credit recovery in the

event of unsuccessful drink dispensing

operation. The credit is not recovered if there

is a capacity signal or in the presence of other

signals hot water delivery is requested. YES

to engage. NO to deactivate [YES/NO]

Autonomous pump Enables the autonomous pump running

[On/Off]

Aut.pump timeout Sets the time for the autonomous pump

[0..60 s]

Multisale Enables multisale. YES enables option,

NO disables option [YES/NO]

Machine number Machine number [0..999999]

Rental number Rental number [0..65535]

Decimal point To define the display of the decimal point,

P1 and P2 for selection and P4 for

confirmation.

[0000 / 0000.0 / 000.00 / 00.000]

Washing Engages washing cycle with clock. [On/Off]

Washing cycle Engaged the washing cycle. [On/Off]

Jug 1 Number of deliveries of drinks associated to

key 1. [2..99]

Jug 2 Number of deliveries of drinks associated to

keys 2..8 . [2..99]

Min probe sens. Sets the sensitivity of the minimum level

probe (20..200). A sensitivity value is

associated to the level probes used on the

machine.

Probe sensitivity is to be reduced in the

presence of low-conductivity water.

Max prove sens. Sets the sensitivity of the maximum level

probe (20200). A sensitivity value is

associated to the level probe used on the

machine.

Probe sensitivity is to be reduced in the

presence of low-conductivity water.

Credit timeout Recovers credit if delivery fails (Vega)

[YES/NO]

Vega falling sensor Enables Vega product falling sensor

[YES/NO]

Use keys + and - to vary the logical values like change of

state from yes (ON=engaged) to no (OFF=deactivated) or use

keys +,- and CUR to alter the numeric values.

On pressing ENTER the set value is confirmed and the following

option appears: on pressing ESC again we return to the OPTIONS

menu.

Page 33

33

IRIS

Fig. 7.4

Instant version

Page 34

34

IRIS

Fig. 7.5

7.2.3 BEVERAGES

Espresso version (Fig. 7.5)

The beverage menu structure is repeated according to the number

of drinks, so that the same structure will be repeated for a single

drink indicating an x instead of the number of drinks, so that it is

sufficient to replace x with the corresponding drink number.

The following combinations have been made for the soluble drinks:

1 = milk

2 = chocolate

3 = tea or decaffeinated

For keys 1-13 line 1 shows the keys referred to for enabling, the

doses and times shown on line 2, listed below:

On enables drink

Coffee sol.v. 000 cc quantity of water for coffee,

[000 cc 999 cc]

Add.wat. 000 cc additional quantity of water for coffee,

[000 cc 999 cc]

Sol.v.2 000 cc quantity of water for instant drinks 1 and 2,

[000 cc 999 cc]

The Ton indicates the amount of time

for which the gear motor remains on,

while the toff indicates the amount

of time which it remains off. The time

sequence is Ton-Toff-Ton-Toff etc for

the entire duration of the relative

soluble product.

NOTE: If decaffeinated option is NO,

keys 9-13 are not displayed.

Sol.v.del.2 00.0 s water dose delay for instant drinks 1 and 2,

[00.0 s 25.5 s]

Extra m 1 00.0 s mixer extra time 1, [00.0 s 25.5 s]

Inst.1 00.0 s dose for instant drink 1, [00.0 s 25.5 s]

Del.Inst.1 00.0 s dose delay for instant drink 1,

[00.0 s 25.5 s]

Ton inst.1 00.0 s time on reduction gear for instant drink 1,

[00.0 s 25.0 s]

Toff inst.1 00.0 s time off- reduction gear for instant drink 1,

[00.0 s 25.0 s]

Inst.2 00.0 s dose for instant drink 2, [00.0 s 25.5 s]

Del.Inst.2 00.0 s dose delay for instant drink 2,

[00.0 s 25.5 s]

Ton Inst.2 00.0 s time on reduction gear for instant drink 2

[00.0 s 25.0 s]

Toff Inst.2 00.0 s time off- reduction gear for instant drink 2,

[00.0 s 25.0 s]

Sol.V..3 000 cc quantity of water for instant drink 3,

[000 cc 999 cc]

Del.Sol.v.3 00.0 s water dose delay for instant drink 3,

[00.0 s 25.5 s]

Extra m 2 00.0 s mixer extra time 2, [00.0 s 25.5 s]

Inst.3 00.0 s dose for instant drink 3, [00.0 s 25.5 s]

Del.Inst.3 00.0 s dose delay for instant drink 3,

[00.0 s 25.5 s]

Ton Inst.3 00.0 s time on reduction gear for instant drink 3,

[00.0 s 25.0 s]

Toff Inst.3 00.0 s time off- reduction gear for instant drink 3,

[00.0 s 25.0 s]

Sol.v.4 000 cc quantity of water relevant to solenoid valve 4,

[000 cc 999 cc]

Del.Sol.v.4 00.0 s water dose delay relevant to solenoid valve 4,

[00.0 s 25.5 s]

Sugar 00.0 s sugar dose, [00.0 s 25.5 s]

Page 35

35

IRIS

Fig. 7.6

7.2.3 BEVERAGES

Instant version (Fig. 7.6)

The beverage menu structure is repeated according to the number

of drinks, so that the same structure will be repeated for a single

drink indicating an x instead of the number of drinks, so that it is

sufficient to replace x with the corresponding drink number.

Yes/No enables drink

Yes/No enables spoon (only with conveyor option YES)

Sol.v.1 00.0 s quantity of water for instant drink 1,

[00.0 s 25.5 s]

Del.Sol.v.1 00.0 s water dose delay for instant drink 1,

[00.0 s 25.5 s]

Extra m 1 00.0 s mixer extra time 1, [00.0 s 25.5 s] (only

with conveyor option NO)

Inst.1 00.0 s dose for instant drink 1, [00.0 s 25.5 s]

(only with conveyor option NO)

Del.Inst.1 00.0 s dose delay for instant drink 1,

[00.0 s 25.5 s]

(only with conveyor option NO)

The Ton indicates the amount of time for which the gear motor

remains on, while the toff indicates the amount of time which it

remains off. The time sequence is Ton-Toff-Ton-Toff etc for the

entire duration of the relative soluble product.

NOTE: If decaffeinated option is NO, keys 9-13 are not displayed.

Ton Inst.1 00.0 s time on reduction gear

for instant drink 1,[00.0 s 25.0 s]

(only with conveyor option NO)

Toff Inst.1 00.0 s time off- reduction gear

for instant drink 1, [00.0 s 25.0 s]

(only with conveyor option NO)

Sol.v.2 00.0 s quantity of water for instant drinks 2 and 3,

[00.0 s 25.5 s]

Del.sol.v.2 00.0 s water dose delay for instant drinks 2 and 3,

[00.0 s 25.5 s]

Extra m 2 00.0 s mixer extra time 2, [00.0 s 25.5 s]

Inst.2 00.0 s dose for instant drink 2, [00.0 s 25.5 s]

(only with conveyor option NO)

Del.Inst.2 00.0 s dose delay for instant drink 2,

[00.0 s 25.5 s]

(only with conveyor option NO)

Ton Inst.2 00.0 s time on reduction gear for instant drink 2,

[00.0 s 25.0 s]

(only with conveyor option NO)

Toff Inst.2 00.0 s time off- reduction gear for instant drink 2,

[00.0 s 25.0 s]

(only with conveyor option NO)

Inst.3 00.0 s dose for instant drink 3, [00.0 s 25.5 s]

Del.Inst.3 00.0 s dose delay for instant drink 3,

[00.0 s 25.5 s]

Ton Inst.3 00.0 s time on reduction gear for instant drink 3,

[00.0 s 25.0 s]

Toff Inst.3 00.0 s time off- reduction gear for instant drink 3,

[00.0 s 25.0 s]

Sol.v.3 00.0 s quantity of water for instant drinks 4 and 5,

[00.0 s 25.5 s]

Del.Inst.3 00.0 s water dose delay for instant drinks 4 and 5,

[00.0 s 25.5 s]

Extra m 3 00.0 s mixer extra time 3, [00.0 s 25.5 s]

Inst.4 00.0 s dose for instant drink 4, [00.0 s 25.5 s]

Del.Inst.4 00.0 s dose delay for instant drink 4,

[00.0 s 25.5 s]

Ton Inst.4 00.0 s time on reduction gear for instant drink 4,

[00.0 s 25.0 s]

Toff Inst.4 00.0 s time off- reduction gear for instant drink 4,

[00.0 s 25.0 s]

Inst.5 00.0 s dose for instant drink 5, [00.0 s 25.5 s]

Del.Inst.5 00.0 s dose delay for instant drink 5,

[00.0 s 25.5 s]

Ton Inst.5 00.0 s time on reduction gear for instant drink 5,

[00.0 s 25.0 s]

Toff Inst.5 00.0 s time off- reduction gear for instant drink 5,

[00.0 s 25.0 s]

Sol.v.4 00.0 s water dose for instant drink 6, [00.0 s 25.5 s]

Del.Sol.V.4 00.0 s water dose delay for instant drink 6,

[00.0 s 25.5 s]

Extra m 4 00.0 s mixer extra time 4, [00.0 s 25.5 s]

(only with conveyor option YES)

Inst.6 00.0 s dose for instant drink 6, [00.0 s 25.5 s]

Del.Inst.6 00.0 s dose delay for instant drink 6, [00.0 s 25.5 s]

Ton Inst.6 00.0 s time on reduction gear for instant drink 6,

[00.0 s 25.0 s]

Toff Inst.6 00.0 s time off- reduction gear for instant drink 6,

[00.0 s 25.0 s]

Sugar 00.0 s sugar time, [00.0 s 25.5 s]

(only with conveyor option Yes)

Page 36

36

IRIS

Fig. 7.7

7.2.4 TIMES SNACK (with Master/Slave) (Fig.7.7)

Espresso version

Instant version

This function makes it possible to check certain parameters of the

configuration of the Vega series distributor to which it is connected.

Motor Timeout Vega spiral motor timeout

[00.0 s 25.0 s]

Testing Password for protected menu

[88000]

Motor zero setting Vega motor setting to zero [On/Off]

Temperature Offset Vega temperature offset [-5 5°C]

Note:

For access to the headings after Trial, password 88000 must be

entered.

Page 37

37

IRIS

Fig. 7.8

7.2.5 TEMPERATURE (Fig.7.8)

Espresso version

Instant version

Heater temp Heater temp [70÷110 °C]

Tank temp Vega temperature [8÷15 °C, >15 °C = Off]

Temp. delta Vega temperature hysteresis [1.0÷5.0 °C]

Safety delta Vega safety delta [5÷50 °C]

Safety time Vega safety time [1÷9 hours]

Defrost after Vega defrost frequency [1÷12 hours]

Defrost for Vega defrost duration [1÷30 minutes]

- The Safety delta and Safety time parameters are displayed

only for the Vega machine Pan type.

- The Defrost for parameter is displayed only for the Vega

machine Snack type.

Page 38

38

IRIS

Fig. 7.9

7.2.6 PRICE- KEYS (Fig. 7.9)

Espresso version

Instant version

This menu shows the coupling of a price to the key or of a Vega

sector.

Line 1 shows the key or sector referred to while the desired price

no. has to be set on line 2.

To change number press keys P1 and P2 for incrementing or

decrementing respectively, P3 for cursor and P4 (Enter) to save

the selection.

Page 39

39

IRIS

Fig. 7.10

7.2.7 COINS (Fig.7.10)

Espresso version

Instant version

Coin x shows the coin coupled with the value set below

(x=1..6), [00000 65535]

Page 40

40

IRIS

Fig. 7.11

7.2.8 PRICES (Fig.7.11)

Espresso version

Instant version

All at price 1 shows whether every drink is coupled to

price 1, [Yes No]

Price x shows the price coupled to index x,

with x = 1..24, [00000 65535]

Page 41

41

IRIS

Fig. 7.12

7.2.9 MDB DATA (Fig. 7.12)

Espresso version

Instant version

Maximum change Maximum change delivered from the coin box

[0÷9999]

Coin change Engages the change lever [On/Off]

Coin x engage Activates coin x, with x=1 ... 16 [On/Off]

Note: the programming of the coin engagement function will only

come into effect after switching the coin box off and then on

again and/or the cards.

Page 42

42

IRIS

Fig. 7.13

7.2.10 MDB PIPE FILLING (Fig. 7.13)

Espresso version

Instant version

MDB pipe filling (Esc to escape)

From this menu it is possible to enter coins into the coin box

without any updating of the credit on the card.

Page 43

43

IRIS

Fig. 7.14

7.2.11 MDB PIPE EMPTYING (Fig. 7.14)

Coin 1 (key 3 empty)

...

Coin 16 (key 3 empty)

On pressing key 3 the selected coin will be delivered.

Page 44

44

IRIS

Fig. 7.15

Fig. 7.16

7.2.13 DEFAULT DATA (Fig.7.16)

Espresso version

Instant version

This functions permits the entering of the all default data.

Which as well as the times and measures also include the password,

coins, prices, key-price association, general programming,

engagement function, decounters, sales data or other.

Default data?

To re-enter the default data press YES and press ENTER, [Yes/No]

7.2.12 CODE (Fig.7.15)

Espresso version

Instant version

Code

for the entering of a new code, [00000 99999]

Page 45

45

IRIS

Fig. 7.18

Fig. 7.17

7.2.15 INCLUDE JUG (Fig.7.18)

Espresso version

Instant version

X key Jug

Engages the jug option for selection x (x=1..13), [On/Off]

7.2.14 DISCOUNTS (Fig.7.17)

Espresso version

Instant version

Discount x

Indicates the discount associated with drink x (x=1..8),

[00000 65535]

Page 46

46

IRIS

Fig. 7.19

7.2.16 MILK FIRST (Fig. 7.19)

Espresso version

Milk before tas. x enables milk before option for

selection x (x=1..13), [On/Off]

Page 47

47

IRIS

Fig. 7.20

7.2.17 CLOCK (Fig.7.20)

Espresso version

Instant version

The following menus are available:

Hour/time set

Switch on

Washing

Discount

Hour/minute set:

Hour/minute set sets the current hour and minutes

[00:00..23:59]

Switch on:

Start 1 sets the time for switch on 1

[00:00..23:59]

End 1 sets the time for switch off 1

[00:00..23:59]

Start 2 sets the time for switch on 2

[00:00..23:59]

End 2 sets the time for switch off 2

[00:00..23:59]

Note: if start is great or equal to end the switch on band is not

engaged.

Washing

Wash 1 sets the time for wash 1 [00:00..23:59]

Wash 2 sets the time for wash 2 [00:00..23:59]

Discount

Start 1 sets the start time for discounted prices 1

[00:00..23:59]

End 1 sets the end time for discounted prices 1

[00:00..23:59]

Start 2 sets the start time for discounted prices 2

[00:00..23:59]

End 2 sets the end time for discounted prices 2

[00:00..23:59]

Note: if the start is greater or equal to end the discount band

is not engaged.

Page 48

48

IRIS

Fig. 7.21

4.2.18 PREVENTIVE ACTION

Espresso version (Fig.4.21)

Softener sets the softener value [0 50000]

Coffee grinders sets the coffee grinder value [0 50000]

Coffee filters sets the coffee filter value [0 50000]

Solenoid valves sets the solenoid valve value [0 50000]

Gaskets sets the gasket value [0 50000]

Boiler sets the boiler value [0 50000]

HACCP Sanitiz. sets the HACCP sanitization value

[0 50000]

Page 49

49

IRIS

Fig. 7.22

4.2.18 PREVENTIVE ACTION

Instant version (Fig.7.22)

Softener sets the softener value [0 50000]

Solenoid valves sets the solenoid valve value [0 50000]

Boiler sets the boiler value [0 50000]

HACCP Sanitiz. sets the HACCP sanitization value

[0 50000]

Page 50

50

IRIS

Fig.8.1

8.0 MAINTENANCE

IMPORTANT ! This operation is to be undertaken with

the machine on, and therefore is only permitted to the

technical staff authorized to carry out such operations.

Press key P12 for access to this maintenance menu which is

positioned on the components side of the keyboard card (Fig.8.1).

On entering this maenu the coin box function is deactivated, the

wording maintenance xxx will appear on line 1, in which xxx stands

for the heater temperature, while line 2 is blank.

In this state the keyboard keys assume the following significance:

Espresso version:

● Key 1: Carries out a coffee group rotation or alarm

scrolling (if any).

● Key 2 : Milk/chocolate mixer washing. On pressing this

key the milk/chocolate solenoid valve is operated and the pump

and after 1" the milk/chocolate mixer with the equivalent of

100 cc of water, after which there is a 6" wait period. During

which time the washing message is displayed and on line 2 the

wording Message wait. At the end of which we escape from the

washing condition and return to maintenance state.

● Key 3 : Tea mixer washing. On pressing this key the tea

solenoid valve is operated and the pump and after 1" the tea

mixer with the equivalent of 100 cc of water, after which there

is a 6" wait period. During which time the washing message is

displayed and on line 2 the wording Message wait. At the end

of which we escape from the washing condition and return to

maintenance state.

● Key 4 : Translator movement, at every key pressing, the

translator is activated and moves one position forward (pos.

1→pos.2→pos.3→pos.1).

l Key 5 : Cup release

l Key 6 : Spoon release

● Key 7: Testing of the water of a selection. On line 2

the wording Water test appears and the machine awaits

selection. Selection will be made by placing all the solubles at

zero, and at the end of the delivery operation the machine

escapes from its testing state and return to its maintenance

state. To return to maintenance state without making any

selection, simply press key P9.

● Key 8: Complete testing of a selection. After pressing

this key on line 2 the word TEST appears and the machine

awaits a selection, at the end of the delivery function the

machine escapes from its testing condition and returns to a

maintenance condition. To return to the maintenance state,

without any selection, simply press key P9.

● Key 9: The total number of non-cancellable entries are

displayed for a period of 2 seconds after which we return to

maintenance state.

● Key 10 Alarm reset. All alarms are set to zero and the

diagnosis of the group and translator is carried out. Line 2

shows the Reset message for 2 seconds.

● Push button 11: not used.

● Push button 12: Return to normal status or exit from test or

water test.

● Push button 13: not used.

Washing

Key 13 installed on the component side of the keyboard card

(Fig.8.1) carries out the consecutive washing of the coffee group

(group rotation), of the milk/chocolate solenoid valve and relevant

blender, and of the tea solenoid valve and relevant blender.

This key is active only when the machine is in normal status and

not during maintenance or programming.

Maintenance panel (espresso version)

Page 51

51

IRIS

Instant version:

● Key 1 : Mixer 1 washing. On pressing this key the solenoid

valve 1 is operated and the pump and after 1" the mixer 1 with

the equivalent of 100 cc of water, after which there is a 6" wait

period. During which time the washing message is displayed

and on line 2 the wording Message wait. At the end, exit from

the washing condition and return to the maintenance or alarm

scrolling (if any) status.

● Key 2 : Mixer 3 washing. On pressing this key the solenoid

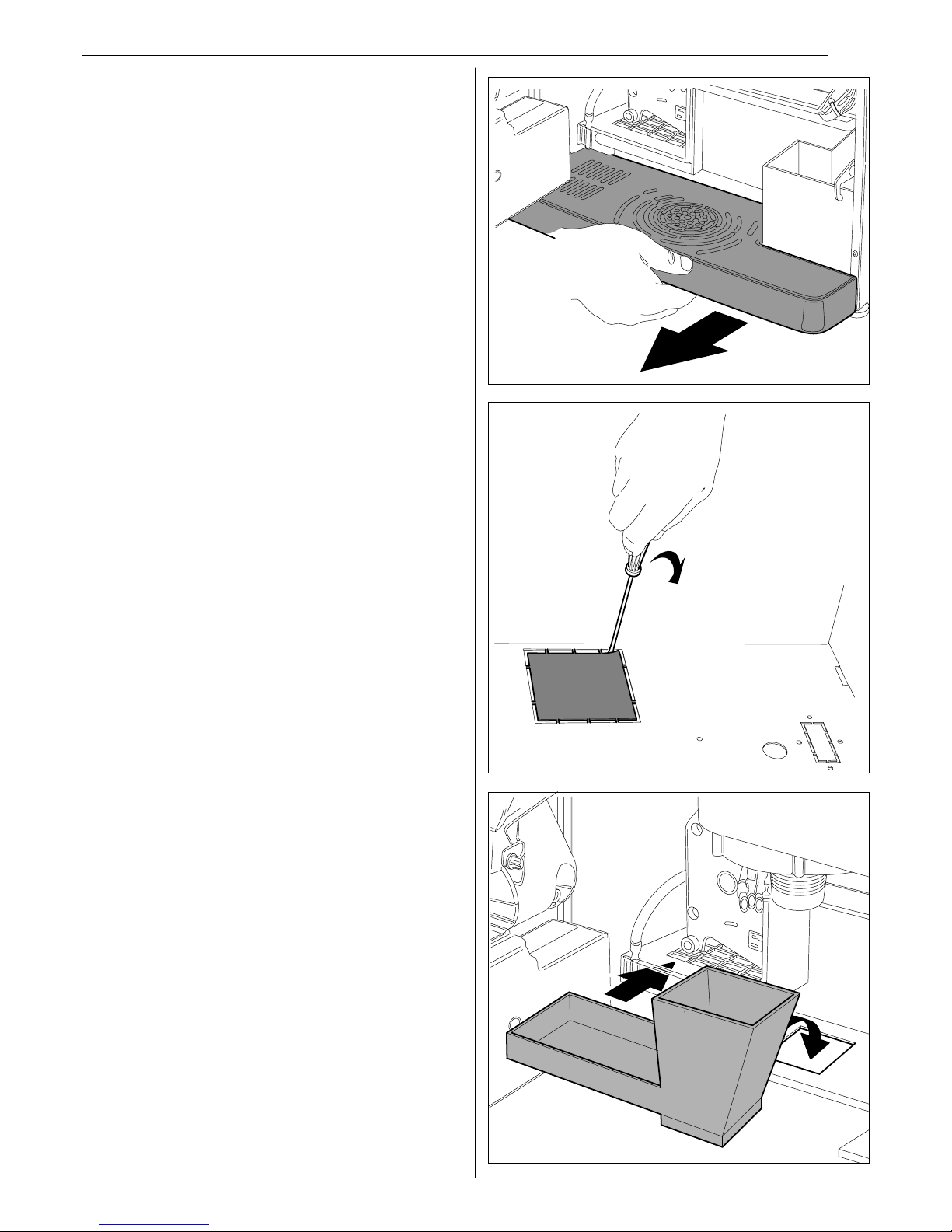

valve 3 is operated and the pump and after 1" the mixer 3 with