Page 1

R SERIES

Installation and

Operation Manual

Models

R.15COAX

R.35COAX

R.35-3896

communitypro.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Always follow these basic safety precautions when using or installing R SERIES loudspeakers and

accessories:

• Read these instructions prior to assembly.

• Keep these instructions for reference.

• Heed all warnings.

• Follow all instructions, particularly those pertaining to rigging, mounting, hanging and electrical

connections.

• Install in accordance with the manufacturer’s instruction.

• Only use attachments and accessories that are specified and approved by the manufacturer.

Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been

damaged in any way, does not operate normally, or has been dropped.

The terms CAUTION, WARNING, and DANGER may be used in this manual to alert the reader to

important safety considerations. If you have any questions or do not understand the meaning of

these terms, do not proceed with installation. Contact your local dealer, distributor, or call Community

directly for assistance. These terms are defined as:

CAUTION: describes an operating condition or user action that may expose the equipment

or user to potential damage or danger.

WARNING: describes an operating condition or user action that will likely cause damage

to the equipment or injury to the user or to others in the vicinity.

DANGER: describes an operating condition or user action that will immediately damage

the equipment and/or be extremely dangerous or life threatening to the user or to others

in the vicinity.

These installation instructions are for use by qualified personnel only. To reduce the risk of fire or

electric shock do not perform any servicing other than that contained in the operating instructions

unless you are qualified to do so.

RIGGING AND ELECTRICAL SAFETY

IMPORTANT: The loudspeakers described in this manual are designed and intended to be

mounted to diering building surfaces using a variety of rigging hardware, means and

methods. Installation of loudspeakers should only be performed by trained and qualified

personnel. All electrical connections must conform to applicable city, county, state, and

national (NEC) electrical codes.

DANGER: R SERIES rigging fittings are rated at a Working Load Limit of 100 lbs (45.4 kg)

with a 10:1 safety margin. No single rigging fitting should ever be subjected to a load that

is greater than 100 lbs. Failure to heed this warning could result in injury or death!

.

mounting. Severe injury and/or loss of life may occur if this product is improperly

installed.

with as little slack as possible so as not to develop undue kinetic force if the mounting

bracket (yoke) were to fail. The safety cable should be attached to the integrated SS

loop on the rear of the cabinet. Refer to the Product Features images.

DANGER: It is possible to experience severe electrical shock from a power amplifier.

Always make sure that all power amplifiers are in the “OFF” position and unplugged from

an AC Mains supply before performing electrical work.

IMPORTANT: Refer to the sections on installation and connections later in this manual for

additional information on rigging and electrical safety.

CAUTION: Installation of R SERIES loudspeakers should only be performed

by trained and qualified personnel. It is strongly recommended that a

licensed and certified professional structural engineer approve the

DANGER: It is essential that a safety cable (not supplied) be utilized whenever

an R SERIES Loudspeaker is installed. The safety cable must be secured to a

suitable load-bearing point separate from the loudspeaker mounting point,

UNPACKING / INSPECTION

R SERIES loudspeakers are engineered and

manufactured to be rugged and they are carefully

packed in sturdy cartons. Ensure that the number

of cartons shown on the freight documents have

actually been delivered. It is recommended to

thoroughly inspect each unit after it has been

removed from the packaging, as damage could

occur during shipping.

Please note that once the shipment has

left your dealer or the Community factory,

the responsibility for damage is always

borne by the freight company. If damage

has occurred during shipping, you must file

a claim directly with the freight company.

It’s very important to contact the freight

company as soon as possible after receiving

your shipment, as most freight companies

have a short time limit within which they

will investigate claims. Be sure to save the

carton and the packing material, as most

claims will be denied if these materials are

not retained. Your Community dealer and

the factory will try to help in any way they

can, but it is the responsibility of the party

receiving the shipment to file the damage

claim.

It is always a good idea to retain the carton and

packing materials, if possible, in the event that

the unit may need to be returned to your dealer

or distributor for repair in the future.

IN THE CARTON

Each shipping carton contains the following:

• One (1) R SERIES Loudspeaker

• One (1) Steel Mounting Yoke

• One (1) Weather Cover and Gasket

• Weather Cover Mounting Hardware:

Pan Head Screws [R.15: 3.5 x 13mm (x4);

R.35: 3.5 x 19mm (x6)]

• One (1) 13.5mm (.5") ID Gland Nut

• One (1) Operation and Installation

Manual

• One (1) Warranty Card

• Yoke Mounting Hardware: 8x32 mm

threaded studs (x2), 8mm lock washers

(x2), 8mm flat washers (x2), 8mm hex

nuts (x2),and 2" OD rubber gaskets (x2),

All 8 mm hardware is stainless steel.

Page 2 Installation and Operation Manual R.15COAX, R.35COAX, R.35-3896

Page 3

PRODUCT REPRESENTATION

R.15 FULL RANGE

Model: R.15COAX

Bracket /

Yoke

8mm Rigging Points

(2 sides)

FRONT REAR

R.35 FULL RANGE MODEL

Models: R.35COAX, R.35-3896

3-Layer

WeatherStop™

Grille

3-Layer

WeatherStop™

Grille

8mm Rigging Points

(2 sides)

3.5 x 13mm Pan

Head Screws

(x4)

Weather Cover

Gland Nut

13.5mm (.5") ID

Safety Attachment

Point (user must supply

appropriate fastener and

safety cable)

Bracket / Yoke

8mm Rigging Points

(2 sides)

Weather Cover

Gland Nut

13.5mm (.5") ID

Safety Attachment Point

(user must supply appropriate

fastener and safety cable)

8mm Rigging Points

(2 sides)

FRONT

Internal Transformer Mounting

Bolts (D o not adjust)

3.5 x 19mm Pan

Head Screws (x6)

REAR

R.15COAX, R.35COAX, R.35-3896 Installation and Operation Manual Page 3

Page 4

RIGGING / SUSPENSION AND SAFETY

TERMINOLOGY: The terms “rigging", “flying" and “suspension" are often used

interchangeably to describe the installation of loudspeaker systems above ground level.

None of these terms pertain to, or attempt to describe, the actual method that is used

(cables, yokes, chains, etc.).

DANGER: The loudspeakers described in this manual are designed and intended

to be suspended using a variety of rigging hardware, means, and methods. It is

essential that all installation work involving the suspension of these loudspeaker

products be performed by competent, knowledgeable persons who understand safe

rigging practices. Severe injury and/or loss of life may occur if these products are

improperly suspended.

DANGER: All rigging fittings and inserts must remain sealed with the included

hardware or they must be fitted with properly rated optional mounting hardware.

Any missing fasteners will compromise the weather resistance of the enclosure.

COMMUNITY RIGGING HARDWARE WARRANTY:

Community warrants that its loudspeaker systems and its optional mounting and

rigging hardware have been carefully designed and tested. Community loudspeakers

may be safely suspended when each loudspeaker model is suspended with Communitymanufactured mounting and rigging brackets or yokes specifically designed for use

with that particular model of loudspeaker. This warranty applies only for use under

normal environmental conditions, and when all loudspeakers, component parts, yokes

and hardware are assembled and installed in strict accordance with Community’s

installation guidelines contained herein. Beyond this, Community assumes no further

or extended responsibility or liability, in any way or by any means whatsoever. It is the

responsibility of the installer to insure that safe installation practices are followed, and

that such practices are in accordance with any and all local, state, federal, or other, codes,

conditions, and regulations that may apply to, or govern the practice of, rigging, mounting,

and construction work in the relevant geographic territory. Any modifications made to

any parts or materials manufactured or supplied by Community shall immediately void

all pledges of warranty or surety, related in any way to the safe use of those parts and

materials.

WARNING

NON-COMMUNITY RIGGING HARDWARE:

Non-Community hardware used for rigging an R SERIES loudspeaker must be

certified by the supplier for such use and must be properly rated for safety.

Correct

Yoke tight against rubber

washer and enclosure

Yoke

Custom

Bracket

NOT Correct

Bracket spaced away

from enclosure

IMPORTANT NOTES ON

RIGGING LOUDSPEAKERS

There are three areas of responsibility

for rigging loudspeakers. The first is the

building structure. Always consult with the

building architect or structural engineer to

assure the ability of the structure to support

the loudspeaker system. The second

area of responsibility is the loudspeaker

itself. Community certifies its loudspeaker

systems and rigging accessories for

suspension when they are properly

installed according to our published

guidelines. The third area of responsibility

is everything between the loudspeaker

and the building structure and the actual

process of installation. The installing

contractor assumes this responsibility.

Loudspeaker rigging should be performed

only by certified rigging professionals using

certified rigging hardware chosen for the

specific application. Prior to installation,

the contractor should present a rigging

plan, with drawing and detailed parts list,

to a licensed structural engineer (P.E.) or

architect for written approval.

WARNING: R SERIES rigging fittings

are rated at a Working Load Limit of

100 lbs (45.4kg) with a 10:1 safety

margin. No single rigging fitting should

ever be subjected to a load that is greater

than 100 lbs. Failure to heed this warning

could result in injury or death!

ACCEPTABLE MOUNTING POINT

LOADING

The mounting points should always be

used so that either shear force is applied

perpendicular to the direction of and in

tight proximity to the mounting hole, or

tension force is applied perpendicular to

the enclosure surface. See Figure 1 at left.

DANGER: Use the mounting points

only as described above. Do not use

them in such a way as to apply

sideways leverage to them. Failure to

follow this instruction could result in

immediate failure of the mounting points

resulting in damage to the loudspeaker and

serious injury or death to personnel.

Enclosure

Figure 1. Mounting point load

R.15COAX, R.35COAX, R.35-3896 Installation and Operation Manual Page 4

Page 5

INSTALLATION

BEFORE YOU START

__Read all instructions and gather tools necessary before starting the installation.

Please read all safety instructions and warnings regarding rigging and installation of

the loudspeaker. The "_" preceding each step can be used to check o each step as it is

completed (or applicable).

Every eort has been made to ensure that the information contained in this manual was

complete and accurate at the time of printing. However, due to ongoing technical advances,

changes or modifications may have occurred that are not covered in this publication.

The latest version of this manual is always available at www.communitypro.com. The

revision date can be found on the rear cover.

MOUNT THE LOUDSPEAKER YOKE

Attach the yoke to the support structure

prior to mounting the loudspeaker

enclosure. Community oers several

pole mount kits to facilitate mounting

loudspeakers to poles. Follow instructions

included with those items for proper

installation of the loudspeaker.

__Determine the appropriate location and

mount the yoke to the support structure

using properly rated, corrosion-resistant

fasteners. For mounting to a round pole,

use a properly rated mounting system.

Mounting hardware is not included and

should be specified by a structural engineer.

For the R.35 models, ensure that the

wider angled portion of the yoke will be

at the rear of the loudspeaker when in the

vertical position, or toward the bottom of

the enclosure in the horizontal position.

Always use the holes in line with the larger

center hole as the primary mounting points.

See Figures 2a (R.15) and 2b (R.35) for yoke

orientations.

Additional yokes for pan/tilt and downfiring mounting options are available (see

Accessories section). Custom brackets

may be used, but must be approved by

a structural engineer and rated for the

expected load.

R.15 Yoke

Figure 2a. Orient the R.15 yoke

Use holes aligned with large

center hole as primary mounting

points - these are aligned with the

center of gravity. Use other holes

as secondary reinforcement.

R.35 Yoke

Mount using holes in the

yoke. Large hole in center

notes center of gravity

when loudspeaker is

suspended from above.

Orient angled

side to the

rear of the

loudspeaker

Figure 2b. Orient the R.35 yoke correctly

Page 5 Installation and Operation Manual R.15COAX, R.35COAX, R.35-3896

Page 6

MOUNT THE LOUDSPEAKER

The factory yoke uses threaded studs

and a nut / lock washer / flat washer

combination rather than bolts. This makes

it easier to attach the loudspeaker to the

yoke after the yoke is mounted to the

support structure.

__Attach the loudspeaker to the yoke.

See Figure 3. Screw an 8mm stud into

each side of the loudspeaker so that it

protrudes about 3/4" (19mm). Place the

rubber washers on the studs and then lift

the loudspeaker into place between the

yoke arms. Attach as shown. Support the

enclosure until both sides are secured.

Tighten bolts to finger tight (enough to hold

the loudspeaker in position).

__Determine the approximate angle of

downward tilt. It must be angled at least

5° down from horizontal to maintain the

stated enclosure IP55 rating. Tighten the

hex nuts until suciently tight enough to

hold the angle.

IMPORTANT: The loudspeaker is not

designed to be rotated 90° or mounted

upside-down. Doing so may cause

water pooling in the safety cable recess,

compromising rigging safety and

performance, and may void the product

warranty. Pan-tilt and full rotation yokes

are available for multi-angled and downfire applications.

Enclosure

Rubber Gasket

2" OD

Enclosure

R.35

Yoke

R.15

8mm SS Lock Washer

8mm SS Hex Nut

8mm SS Flat Washer

8 x 32 mm SS Stud

(leave 3/4" sticking out)

Rubber Gasket

2" OD

8 x 32 mm SS Stud

(leave 3/4" sticking out)

Yoke

8mm SS

Hex Nut

8mm SS

Lock Washer

8mm SS Flat Washer

Figure 3. Mount the loudspeaker to the yoke

ATTACH SAFETY CABLE

__Attach a safety cable to the integrated

eyebolt on the rear of each loudspeaker (see

Figure 4). The safety cable and hardware

are not included. Please consult a structural

engineer for the appropriate cable for the

load and application. The safety cable must

be secured to a suitable load-bearing point

separate from the loudspeaker mounting

point, with as little slack as possible, so

as not to develop undue kinetic force if the

R SERIES mounting were to fail.

Page 6 Installation and Operation Manual R.15COAX, R.35COAX, R.35-3896

R.15

Attach safety cable here

R.35

Figure 4. Attach the safety cable

Page 7

WIRING AND ELECTRICAL SAFETY

All standard R.15 and R.35 loudspeakers are provided with two methods of connecting

the amplifier to the loudspeaker: a standard NL4-type locking connector, and a pressurescrew terminal strip. The loudspeaker is intended to be connected directly to the amplifier.

If installed outdoors, the insulation of the installer-provided cabling should be resistant

to water, the eects of temperature, and the eects of ultraviolet radiation from the sun.

We recommend the use of a SJOW or SJOOW rated cable for most applications. To make

the connection from the loudspeaker to the wiring junction box when less than 3m (10')

in length. These are recommended insulations: UV-stabilized polyethylene, neoprene,

Teflon™, Silicon™, and Hypalon™. The following insulations are not recommended

because of potentially shorter life expectancy in outdoor environments: rubber, PVC

(polyvinyl chloride), polypropylene, polyurethane, and nylon. UV-stabilized polypropylene

may be acceptable.

Using the recommended cable with the included gland nut and the weather cover will

form a good weather-tight seal.

Examples of recommended cable include:

Grainger #1W312 (www.grainger.com)

McMaster-Carr #7422K61

(www.mcmaster.com)

__Wire the loudspeaker. We recommend

using spade or ring terminals with barreltype crimp connectors that are crimped

with a forged crimp tool (such as Klein

1005) or a ratcheting tool (such as Klein

T1720), as this method, when properly

executed, results in a gas-tight connection

that is quick and easy to accomplish. The

maximum width of the ring or spade lug

should be 0.375" (9.5mm), or less. The

terminal screws are #8 (M4). The maximum

wire size that can be accommodated for

bare wire connections is 10 AWG (5.26 mm2).

Important Note: If the NL4 connection is

used then the weatherproof cover cannot

be attached. Direct connection to the

terminal strips is the preferred connection

method for all permanent or outdoor

applications.

Spade terminal

Note: Wire insulation colors may vary depending upon region or manufacturer. Be

consistent with conductor color use throughout the system.

Standard Wiring

Wire Connectors

(–) ( Black)

(+) ( White)

Ring

terminal

IMPORTANT: The gland nut, weather cover and all of the attachment screws must

be used in outdoor and indoor harsh environment applications. Without these, the

loudspeaker will not have the stated weather-resistant rating and may negate the

warranty.

IMPORTANT: All electrical installation connections for loudspeaker lines are

subject to all applicable governmental building and fire codes. The selection of

appropriate electrical hardware to interface with the R SERIES loudspeaker lies

solely with the installation professional. Community recommends that an appropriately

licensed engineer, electrician, or other qualified professional identify and select the

appropriate conduit, fittings, wire, etc. for the installation.

DANGER: The output power capabilities of audio amplifiers present a danger to

installers especially in 70-volt and 100-volt distributed systems. To minimize the

risk of electric shock from loudspeaker connecting cables, confirm that the power

amplifiers are turned “o" before connecting loudspeaker cable(s) to the loudspeaker or

amplifier. Always follow local electrical codes and proper electrical safety procedures.

R.15COAX, R.35COAX, R.35-3896 Installation and Operation Manual Page 7

Page 8

INPUT PANEL CONNECTIONS

R.15: The connectors are wired in parallel.

If utilizing the NL4-type connector, refer

to the detail inset. If utilizing the weather

cover, insert the cable end through the

gland nut and weather cover, and wire the

terminal strip. Set the Music/Voice and

Voltage selector switches according to your

application (see Figure 5a).

R.35: Insert the cable through the gland nut and weather cover and wire the unit referencing

the label for connections for your system voltage. See Figure 5b. There is a preinstalled

jumper that should be left in the marked position for 70/100V use, or moved to the bottom

terminals for 8Ω operation. Failure to do so can result in damage to the loudspeaker and/

or amplifier. Set the Music/Voice switch to the desired position based upon your type of

application. The NL4 connection can only be used for low impedance 8Ω operation.

Terminal

Strip

Music/

Voice

Switch

+

from

Amplifier

–

NL4-Type Connector

NL4

Wattage

Selector

Switch

1+

1–

2+

Music /

Switch

Must remove jumper, or move it to the bottom

terminals, for 8Ω operation (see arrow below)

2–

NL4

Voice

Figure 5a. R.15 input panel Figure 5b. R.35 input panel

Terminal Strip

Follow label to

determine

correct (+)

terminal

connection

FINAL ASSEMBLY AND TESTING

__Secure the gland nut to the weather cover.

Align the weather cover with the holes and

attach using the provided pan head screws.

See Figure 6.

Weather Cover,

Gasket (internal)

Gland Nut

(Barrel)

__All provided hardware (or other approved

replacement) must be installed in order to

maintain weather-resistance and preserve

the product warranty.

__Power and test the system.

Pan Head

Screws

Wire

Input panel

Figure 6. Weather cover attachment (R.15 shown)

Page 8 Installation and Operation Manual R.15COAX, R.35COAX, R.35-3896

Page 9

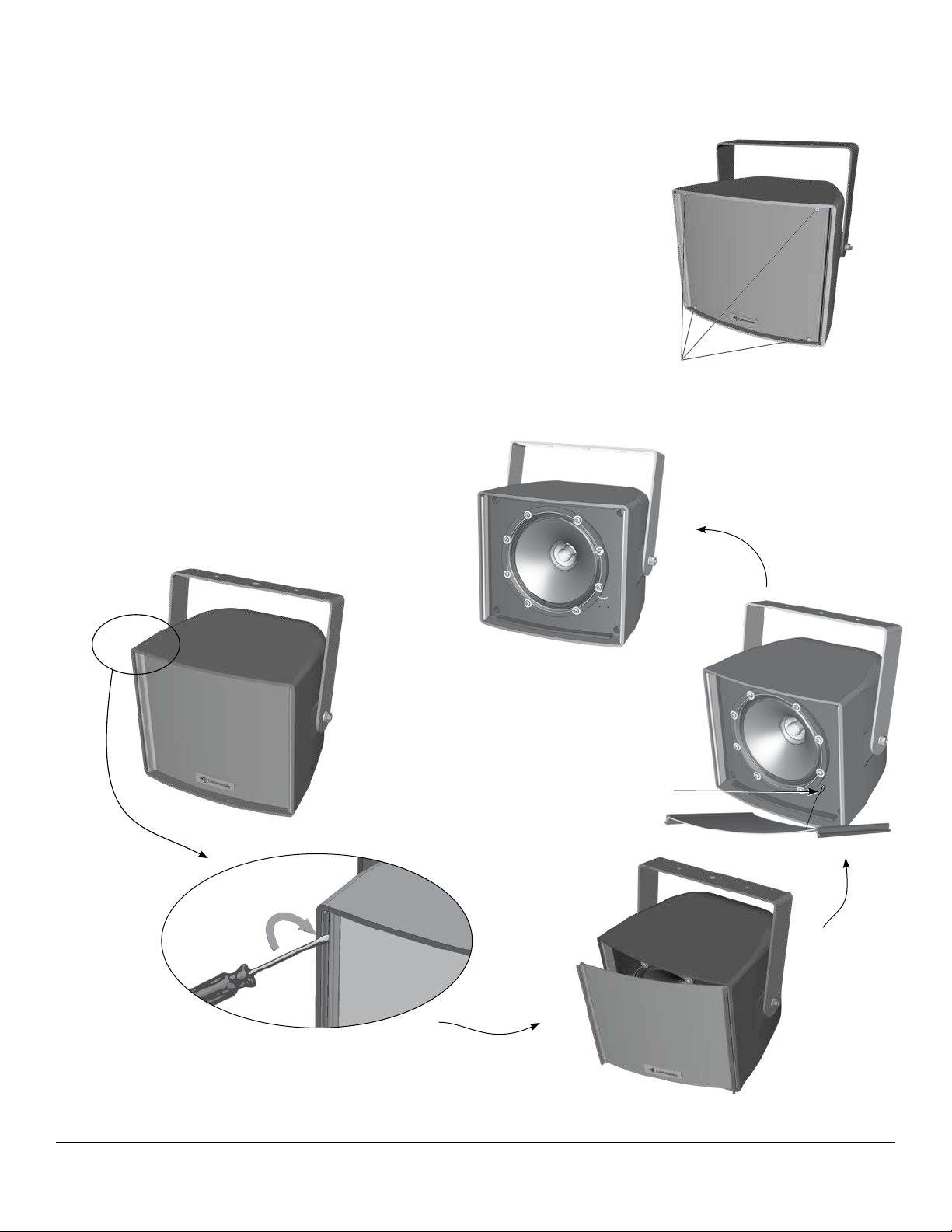

FIELD SERVICE

Any driver or crossover service required is accessed from the front of the enclosure by

first removing the front grille and then unscrewing and removing the LF driver or the

horn assembly. Take note of wiring positions prior to removing any drivers from the

loudspeaker. In order to maintain the weather resistance, components and assemblies

must not remain removed from the loudspeaker any longer than needed for replacement.

Exposure of internal components to the elements for extended periods could cause

failures and void the warranty on the loudspeaker.

__Remove the grille. Refer to illustrations in Figure 7. Remove screws securing the grille

on the R.35 models. The grille frame locks into the enclosure frame. Carefully insert a thin

flat bladed screwdriver between the grille frame and the enclosure frame while gently

pressing down on the grille. Starting at the top and moving down, twist the blade to pop

the grille frame free of the enclosure. There is a safety tether at the bottom of the grille

that can be unhooked to fully remove the grille.

__Remove the screws holding the drivers and replace or service the components as

necessary.

__Replace the components, securing with all of the original

hardware. Reattach the grille safety tether to the face (R.15) and

push the grille frame into place - one side and then the other,

ensuring that the frames are fully seated. The grille should easily

snap into place. Secure the grille with screws in the same corner

locations (R.35 models only).

Remove any screws securing

the grille (R.35 only)

Unhook grille tether

(if present) to fully

remove grille

Insert thin blade of

screwdriver between frame

and enclosure and move

down seam while t wisting to

pop grille loose

Figure 7. Remove grille (R.15 shown)

R.15COAX, R.35COAX, R.35-3896 Installation and Operation Manual Page 9

Page 10

ACCESSORIES

MAINTAINING WEATHER RESISTANCE

R-VTY15 VARY-TILT YOKE FOR R.15

Provides pan-tilt operation.

Zinc-rich epoxy dual-layer

powder-coated steel with

hardware, color-matched to

loudspeaker.

R-VTY35 VARY-TILT YOKE FOR R.35

Provides pan-tilt operation.

Zinc-rich epoxy dual-layer

powder-coated steel with

hardware, color-matched to

loudspeaker.

R-FRY35 FULL ROTATION YOKE FOR R.35

GUIDELINES FOR R SERIES OUTDOOR USE

R SERIES is suitable for outdoor installation when used as

recommended. For best results in outdoor applications, follow

these guidelines:

• Always orient the loudspeaker so the mouth of the horn

is, at a minimum, pointing at least 5 degrees downward.

Failure to do this could result in water collecting inside the

enclosure under extreme weather conditions.

• When handling an R SERIES loudspeaker, be careful not to

scratch or scrape the finish on the grille, yoke, or enclosure.

• All mounting holes must be sealed o with the stainless

steel bolts, washers, and rubber washers supplied. If, for

any reason, these bolts must be removed, seal o the hole

with silicone caulking or some other suitable weather-tight

sealant.

• The rubber washers supplied with the mounting bolts must

always seat against the enclosure.

• The grille assembly is designed to prevent normal and

wind-driven rain from directly entering the mouth of the

loudspeaker. The grille is not designed to withstand such

things as being directly sprayed from a hose; therefore this

should be avoided.

• If you use any hardware in place of hardware provided

with your R SERIES loudspeaker, it should also be made of

stainless steel.

Provides full rotation

mounting capability for

down-firing application

(i.e. top of press box).

Zinc-rich epoxy dual-layer

powder-coated steel with

hardware, color-matched to

loudspeaker.

PAINT

The ABS plastic cabinets accept almost any type of latex or enamel (oil based) paint.

We recommend application of two coats. The grille must be spray painted.

PAINTING PROCESS

• Remove the grille.

• Clean the grille assembly and the loudspeaker cabinet by rubbing them with a lightly

dampened cloth. Do not use abrasives such as sandpaper or steel wool.

• Mask the loudspeakers so that the surrounds, horns, cones and internal components

will not receive any paint. We advise against using conventional masking tape and

NEVER use duct tape in this application; these kinds of tape generally leave adhesive residue that can be dicult to remove and

that may actually cause damage. Painters tape is best.

• After cleaning, apply two or more thin coats of either latex or oil-based paints. Latex paint will adhere better if an oil-based primer

is used first. Apply the paint with a roller or brush, or spray it on, except as noted below.

• To paint the grille, tape o the Community logo, and spray paint with 2 light coats – enough to cover grille and exterior extrusion

surface. Let dry and reattach.

paint thinner, harsh detergents or other

chemicals on the loudspeaker. These

chemicals and agents may permanently

damage the finish. Some are also toxic

and highly flammable.

CAUTION: NEVER use abrasives,

gasoline, kerosene, acetone,

methyl ethyl ketone (MEK),

Page 10 Installation and Operation Manual R.15COAX, R.35COAX, R.35-3896

Page 11

PERFORMANCE AND SPECIFICATIONS

USE A DIGITAL SIGNAL PROCESSOR

For best performance, loudspeaker protection and system longevity, a digital

signal processor (DSP ) should be used with all R SERIES loudspeakers. Community's

dSPEC226 processor(s) and Resyn® software contain all of the information (high pass

filters, limiters, factory tunings) and DSP settings to fully optimize your system. For

more information on installing and operating your R SERIES loudspeaker, please refer to

Community’s website at communitypro.com, or contact our Technical Applications Group

(TAG) at tagteam@communitypro.com, or by phone at 610-876-3400 or toll-free (within

the US and Canada) at 800-523-4934.

SPECIFICATIONS AND INFORMATION

Full product specifications, technical drawings and current documentation (manuals,

sales literature) is available at communitypro.com. Additional technical information

to assist you in operating and optimizing your system or understanding more about

loudspeaker operation is also available on the website or by contacting the Technical

Applications Group (TAG).

WARRANTY INFORMATION

TRANSFERABLE WARRANTY “(LIMITED)" VALID IN THE USA ONLY

The R SERIES loudspeakers are designed and backed by Community Professional

Loudspeakers. For complete warranty information within the USA please refer to www.

communitypro.com/warranty. Please call 610-876-3400 or visit the website to locate

your nearest Authorized Field Service Station. For Factory Service call 610-876-3400. You

must obtain a Return Authorization (R/A) number prior to the return of your product for

factory service.

Note: Every eort has been made

to insure that the information

contained in this manual was

complete and accurate at the

time of printing. However, due

to ongoing technical advances,

changes or modifications may

have occurred that are not covered

in this manual. The latest version

is available at communitypro.com.

WARRANTY INFORMATION AND SERVICE FOR COUNTRIES OTHER

THAN THE USA

To obtain specific warranty information and available service locations for

countries other than the United States of America, contact the authorized

Community Distributor for your specific country or region.

EC STATEMENT OF CONFORMITY

This document confirms that the range of products of Community Professional Loudspeakers bearing the CE label meet all

the requirements laid down by the Member States Council for adjustment of legal requirements, furthermore the products

comply with the rules and regulations referring to the electromagnetic compatibility of devices from 16 April 2016.

The Community Professional Loudspeaker products bearing the CE label comply with the following directives: Low Voltage

Directive 2014/35/EU and the Waste from Electrical Equipment Directive 2002/96/EC RoHS.

The authorized declaration and compatibility certification resides with the manufacturer and can be viewed upon request.

The responsible manufacturer is the company:

Community Light & Sound

333 East Fifth Street, Chester, PA 19013 USA

Phone: (610) 876-3400 • www.communitypro.com

R.15COAX, R.35COAX, R.35-3896 Installation and Operation Manual Page 11

Page 12

©2018 Community Professional Loudspeakers v: 25SEP2018

Community Professional Loudspeakers

333 East Fifth Street, Chester, PA 19013-4511 USA

Phone (610) 876-3400 • Fax (610) 874-0190

www.communitypro.com

Loading...

Loading...