Page 1

Community

R Series R.35-3896-EN

Installation and Operation Guide

Connecting people through extraordinary audiovisual experiences™

R.35-3896-EN

PRODUCT DESCRIPTION

The R.35-3896-EN is a fully horn-loaded triaxial threeway, full-range loudspeaker system designed to provide

high quality voice and music reproduction in applications

requiring extreme weather resistance. The R.35-3896-EN

features our innovative MultiSource Waveguide™ horn

design; the output from the dual midrange compression

drivers and 1-inch exit HF driver are combined seamlessly

into a single time-coherent source, resulting in excellent

musicality, intelligibility and dispersion consistency.

CONTENTS

• One (1) R.35-3896-EN Loudspeaker

• One (1) Steel Mounting Yoke

• One (1) Weather Cover and Gasket

• Weather Cover Mounting Hardware:

Pan Head Screws: 3.5 x 19mm (x6)

• One (1) 13.5mm (.5") ID Gland Nut

FEATURES

• EN54-24 Certied loudspeaker

• Excellent musicality and intelligibility, low distortion, and

high sensitivity and output

• Weather-resistant, compact, high impact ABS plastic

modied-trapezoidal enclosure

• Hydrophobically-treated grille and LF driver cones,

polymer HF and MR diaphragms, and moisture-sealed

crossover

• Documentation: Safety Guide and Installation Guide

• Yoke Mounting Hardware: 8x32 mm threaded studs

(x2), 8mm lock washers (x2), 8mm at washers (x2),

8mm hex nuts (x2),and 2" OD rubber gaskets (x2),

All 8 mm hardware is stainless steel.

A: 9300 S.W. Gemini Drive Beaverton, OR 97008 USA W: www.biamp.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Always follow these basic safety precautions when using or installing R SERIES loudspeakers and accessories:

• Read these instructions prior to assembly.

• Keep these instructions for reference.

• Heed all warnings.

• Follow all instructions, particularly those pertaining to rigging, mounting, hanging and electrical connections.

• Install in accordance with the manufacturer’s instruction.

• Only use attachments and accessories that are specied and approved by the manufacturer.

Refer all servicing to qualied service personnel. Servicing is required when the apparatus has been damaged in any way,

does not operate normally, or has been dropped.

The terms CAUTION, WARNING, and DANGER may be used in this manual to alert the reader to important safety

considerations. If you have any questions or do not understand the meaning of these terms, do not proceed with

installation. Contact your local dealer, distributor, or call Biamp directly for assistance. These terms are dened as:

CAUTION: describes an operating condition or user action that may expose the equipment or user to

potential damage or danger.

WARNING: describes an operating condition or user action that will likely cause damage to the equipment

or injury to the user or to others in the vicinity.

DANGER: describes an operating condition or user action that will immediately damage the equipment

and/or be extremely dangerous or life threatening to the user or to others in the vicinity.

These installation instructions are for use by qualied personnel only. To reduce the risk of re or electric

shock do not perform any servicing other than that contained in the operating instructions unless you are qualied to do so.

UNPACKING / INSPECTION

R SERIES loudspeakers are engineered and

manufactured to be rugged and they are carefully packed

in sturdy cartons. Ensure that the number of cartons shown

on the freight documents have actually been delivered. It is

recommended to thoroughly inspect each unit after it has

been removed from the packaging, as damage could occur

during shipping.

Please note that once the shipment has left your dealer or

the Biamp factory, the responsibility for damage is always

borne by the freight company. If damage has occurred

during shipping, you must le a claim directly with the

freight company. It’s very important to contact the freight

company as soon as possible after receiving your shipment,

as most freight companies have a short time limit within

which they will investigate claims. Be sure to save the

carton and the packing material, as most claims will be

denied if these materials are not retained. Your Biamp

dealer and the factory will try to help in any way they can,

but it is the responsibility of the party receiving the shipment

to le the damage claim.

It is always a good idea to retain the carton and packing

materials, if possible, in the event that the unit may need

to be returned to your dealer or distributor for repair in the

future.

RIGGING AND ELECTRICAL SAFETY

IMPORTANT: The loudspeakers described in this manual are designed and intended to be mounted to

differing building surfaces using a variety of rigging hardware, means and methods. Installation of

loudspeakers should only be performed by trained and qualied personnel. All electrical connections must

conform to applicable city, county, state, and national (NEC) electrical codes.

DANGER: R SERIES rigging ttings are rated at a Working Load Limit of 100 lbs (45.4 kg) with a 10:1

safety margin. No single rigging tting should ever be subjected to a load that is greater than 100 lbs. Failure

to heed this warning could result in injury or death!

. DANGER: It is possible to experience severe electrical shock from a power amplier. Always make sure

injury and/or loss of life may occur if this product is improperly installed.

mounting point, with as little slack as possible so as not to develop undue kinetic force

if the mounting bracket (yoke) were to fail. The safety cable should be attached to the

integrated SS loop on the rear of the cabinet. Refer to the Product Features images.

that all power ampliers are in the “OFF” position and unplugged from an AC Mains supply before performing

electrical work.

IMPORTANT: Refer to the sections on installation and connections later in this manual for additional

information on rigging and electrical safety.

CAUTION: Installation of R SERIES loudspeakers should only be performed

by trained and qualied personnel. It is strongly recommended that a licensed

and certied professional structural engineer approve the mounting. Severe

DANGER: It is essential that a safety cable (not supplied) be utilized

whenever an R SERIES Loudspeaker is installed. The safety cable must be

secured to a suitable load-bearing point separate from the loudspeaker

Page 2 Installation and Operation Manual R.35-3896-EN

Page 3

PRODUCT REPRESENTATION

R.35-3896-EN FULL RANGE MODEL

3-Layer

WeatherStop™

Grille

8mm Rigging Points

(2 sides)

Safety Attachment Point (user

must supply appropriate fastener

FRONT

Weather Cover

Gland Nut

13.5mm (.5") ID

and safety cable)

Bracket / Yoke

8mm Rigging Points

(2 sides)

Internal Transformer Mounting Bolts

(Do not adjust)

3.5 x 19mm Pan

Head Screws (x6)

REAR

R.35-3896-EN Installation and Operation Manual Page 3

Page 4

RIGGING / SUSPENSION AND SAFETY

TERMINOLOGY: The terms “rigging", “ying" and “suspension" are often used

interchangeably to describe the installation of loudspeaker systems above ground level.

None of these terms pertain to, or attempt to describe, the actual method that is used

(cables, yokes, chains, etc.).

DANGER: The loudspeakers described in this manual are designed and intended

to be suspended using a variety of rigging hardware, means, and methods. It is

essential that all installation work involving the suspension of these loudspeaker

products be performed by competent, knowledgeable persons who understand safe

rigging practices. Severe injury and/or loss of life may occur if these products are

improperly suspended.

DANGER: All rigging ttings and inserts must remain sealed with the included

hardware or they must be tted with properly rated optional mounting hardware.

Any missing fasteners will compromise the weather resistance of the enclosure.

BIAMP RIGGING HARDWARE WARRANTY:

Biamp warrants that its loudspeaker systems and its optional mounting and rigging

hardware have been carefully designed and tested. Biamp loudspeakers may be safely

suspended when each loudspeaker model is suspended with Biamp-manufactured

mounting and rigging brackets or yokes specically designed for use with that particular

model of loudspeaker. This warranty applies only for use under normal environmental

conditions, and when all loudspeakers, component parts, yokes and hardware are

assembled and installed in strict accordance with Biamp’s installation guidelines

contained herein. Beyond this, Biamp assumes no further or extended responsibility

or liability, in any way or by any means whatsoever. It is the responsibility of the

installer to insure that safe installation practices are followed, and that such practices

are in accordance with any and all local, state, federal, or other, codes, conditions,

and regulations that may apply to, or govern the practice of, rigging, mounting, and

construction work in the relevant geographic territory. Any modications made to any

parts or materials manufactured or supplied by Biamp shall immediately void all pledges

of warranty or surety, related in any way to the safe use of those parts and materials.

WARNING

NON-Biamp RIGGING HARDWARE:

Non-Biamp hardware used for rigging an R SERIES loudspeaker must be

certied by the supplier for such use and must be properly rated for safety.

Correct

Yoke tight against rubber

washer and enclosure

Yok e

Custom

Bracket

NOT Correct

Bracket spaced away

from enclosure

IMPORTANT NOTES ON

RIGGING LOUDSPEAKERS

There are three areas of responsibility

for rigging loudspeakers. The rst is the

building structure. Always consult with the

building architect or structural engineer to

assure the ability of the structure to support

the loudspeaker system. The second

area of responsibility is the loudspeaker

itself. Biamp certies its loudspeaker

systems and rigging accessories for

suspension when they are properly

installed according to our published

guidelines. The third area of responsibility

is everything between the loudspeaker

and the building structure and the actual

process of installation. The installing

contractor assumes this responsibility.

Loudspeaker rigging should be performed

only by certied rigging professionals using

certied rigging hardware chosen for the

specic application. Prior to installation,

the contractor should present a rigging

plan, with drawing and detailed parts list,

to a licensed structural engineer (P.E.) or

architect for written approval.

WARNING: R SERIES rigging

ttings are rated at a Working Load

Limit of 100 lbs (45.4kg) with a 10:1

safety margin. No single rigging tting

should ever be subjected to a load that is

greater than 100 lbs. Failure to heed this

warning could result in injury or death!

ACCEPTABLE MOUNTING POINT LOADING

The mounting points should always be

used so that either shear force is applied

perpendicular to the direction of and in tight

proximity to the mounting hole, or tension

force is applied perpendicular to the

enclosure surface. See Figure 1 at left.

DANGER: Use the mounting points

only as described above. Do not

use them in such a way as to apply

sideways leverage to them. Failure to

follow this instruction could result in

immediate failure of the mounting points

resulting in damage to the loudspeaker and

serious injury or death to personnel.

Enclosure

Figure 1. Mounting point load

Page 4 Installation and Operation Manual R.35-3896-EN

Page 5

INSTALLATION

BEFORE YOU START

Read all instructions before starting the installation including all safety instructions and

warnings regarding rigging and installation of the loudspeaker. The latest version of this

manual is available by contacting your sales dealer or representative. The revision date

is on the rear cover.

MOUNT THE LOUDSPEAKER YOKE

1. Attach the yoke to the support

structure before mounting the

loudspeaker enclosure with properly

rated, corrosion-resistant fasteners.

Mounting hardware is not included

and should be specied by a structural

engineer.

NOTES: The wider angled portion of the yoke

must be at the rear of the loudspeaker when

mounted vertically, and toward the bottom of the

enclosure in the horizontal position. See Figure 2

for yoke orientation. Always use the holes in line

with the larger center hole as the primary

mounting points.

Optional pan/tilt and down-ring mounting

brackets are available (see Accessories section).

Custom brackets may be used, but must be

approved by a structural engineer and rated for

the expected load.

2. Attach the loudspeaker to the yoke.

See Figure 3. Screw an 8mm stud

into each side of the loudspeaker until

it protrudes 3/4" (19mm). Place the

rubber washers on the studs and then

lift the loudspeaker into place between

the yoke arms. Attach remianing

hardware. Support the enclosure until

both sides are secured. Tighten bolts

enough to hold the loudspeaker in

position.

3. Determine the approximate angle

of downward tilt. It must be angled

at least 5° down from horizontal to

maintain the stated enclosure IP55

rating. Tighten the hex nuts until

suciently tight enough to hold the

angle.

IMPORTANT: The loudspeaker is not designed

to be rotated 90° or mounted upside-down.

Doing so may cause water pooling in the safety

cable recess, compromising rigging safety and

performance, and may void the product warranty.

Pan-tilt and full rotation yokes are available for

multi-angled and down-re applications.

Enclosure

Figure 2. Orient the R.35 yoke correctly

Figure 3. Mount the loudspeaker to the yoke

Use holes aligned with large center

hole as primary mounting points these are aligned with the center

of gravity. Use other holes as

secondary reinforcement.

R.35 Yoke

Yok e

2" OD

Rubber Gasket

8mm SS

Hex Nut

8mm SS

Lock Washer

8mm SS Flat Washer

8 x 32 mm SS Stud

(leave 3/4" sticking out)

Orient angled

side to the rear of

the loudspeaker

R.35-3896-EN Installation and Operation Manual Page 5

Page 6

INSTALLATION (CONTINUED)

ATTACH SAFETY CABLE

4. Attach a safety cable to the

integrated eyebolt on the rear of each

loudspeaker (see Figure 4).

The safety cable and hardware are not

included. Consult a structural engineer

for the appropriate cable for the load

and application. The safety cable must

be secured to a suitable load-bearing

point separate from the loudspeaker

mounting point, with as little slack as

possible, so as not to develop undue

kinetic force if the primary mounting

were to fail.

Attach safety cable here

Figure 4. Attach the safety cable

WIRING AND ELECTRICAL SAFETY

All standard R.35 loudspeakers are provided with two methods of connecting

the amplier to the loudspeaker: a standard NL4-type locking connector, and

a pressure-screw terminal strip. The loudspeaker is intended to be connected

directly to the amplier.

If installed outdoors, the insulation of the installer-provided cabling should

be resistant to water, the eects of temperature, and the eects of ultraviolet

radiation from the sun. We recommend the use of a SJOW or SJOOW rated

cable for most applications. Using the recommended cable with the included

gland nut and the weather cover will form a good weather-tight seal.

5. Wire the loudspeaker. Spade or

ring terminals with barrel-type crimp

connectors that are crimped with a

forged crimp tool are recommended.

This method results in a gas-tight

Standard Wiring

(–) ( Black)

(+) ( White)

connection that is quick and easy

to accomplish. The maximum width

of the ring or spade lug should be

Ring

terminal

0.375" (9.5mm), or less. The terminal

screws are #8 (M4). The maximum

wire size that can be accommodated

for bare wire connections is 10 AWG

(5.26 mm2).

IMPORTANT: If the NL4 connection is used then

the weatherproof cover cannot be attached.

Direct connection to the terminal strips is the

preferred connection method for all permanent

or outdoor applications.

Page 6 Installation and Operation Manual R.35-3896-EN

Spade terminal

Wire Connectors

Page 7

INSTALLATION (CONTINUED)

INPUT PANEL CONNECTIONS

6. Insert the cable through the gland nut and weather cover and wire the unit

for your system voltage. Refer to the label - see Figure 5. There is a preinstalled

jumper that should be left in the marked position for 70/100V use, or moved to

the bottom terminals for 8Ω operation. Failure to do so can result in damage

to the loudspeaker and/or amplier. Set the Music/Voice switch to the desired

position. The NL4 connection can only be used for low impedance 8Ω operation.

NL4

Music /

Voice

Switch

Must remove jumper, or move it to the bottom

terminals, for 8Ω operation (see arrow below)

Amplier

Terminal Strip

Follow label to

determine

correct (+)

terminal

connection

+

from

–

NL4-Type Connector

1+

1–

2–

2+

IMPORTANT: The gland nut,

weather cover and all of the

attachment screws must be used in

outdoor and indoor harsh environment

applications. Without these, the loudspeaker

will not have the stated weather-resistant

rating and may negate the warranty.

IMPORTANT: All electrical

installation connections for

loudspeaker lines are subject to all

applicable governmental building and re

codes. The selection of appropriate

electrical hardware to interface with the R

SERIES loudspeaker lies solely with the

installation professional. Biamp

recommends that an appropriately licensed

engineer, electrician, or other qualied

professional identify and select the

appropriate conduit, ttings, wire, etc. for the

installation.

DANGER: The output power

capabilities of audio ampliers

present a danger to installers

especially in 70-volt and 100-volt distributed

systems. To minimize the risk of electric

shock from loudspeaker connecting cables,

conrm that the power ampliers are turned

“o" before connecting loudspeaker cable(s)

to the loudspeaker or amplier. Always

follow local electrical codes and proper

electrical safety procedures.

Figure 5. R.35 input panel

FINAL ASSEMBLY AND TESTING

7. Secure the gland nut to the weather

Weather Cover

cover. Align the weather cover with the

holes and attach using the provided

pan head screws. See Figure 6.

Gland Nut

(Barrel)

8. All provided hardware (or other

approved replacement) must be

installed in order to maintain weatherresistance and preserve the product

warranty.

9. Power and test the system.

Wire

Figure 6. Weather cover attachment

R.35-3896-EN Installation and Operation Manual Page 7

Gasket

Pan Head

Screws

Gland Nut

(Nut)

Input panel

Page 8

MAINTENANCE

FIELD SERVICE

Remove the loudspeaker from service to ease repair and avoid any exposure of internal

components to the elements. Any driver or crossover service required is accessed from the

front of the enclosure by rst removing the front grille and then unscrewing and removing

the horn assembly. Take note of wiring positions prior to removing any drivers from the

loudspeaker. In order to maintain the weather resistance, components and assemblies

must not remain removed from the loudspeaker any longer than needed for replacement.

Extended exposure could cause failures and void the warranty on the loudspeaker.

1. Remove the grille. Refer to illustrations in Figure 7. Remove the screws

securing the grille to the enclosure. The grille frame locks into the enclosure

frame. Carefully insert a thin at bladed screwdriver between the grille frame and

the enclosure frame while gently pressing down on the grille. Starting at the top

and moving down, twist the blade to release the grille from the frame. Repeat as

necessary to release the other side and remove the grille.

2. Remove the screws holding the horn assembly to the enclosure and replace or

service the components as necessary.

3. Replace the driver assembly securing it with all of

the original hardware. Push the grille frame into place

- one side and then the other, ensuring that the frames

are fully seated. The grille should easily snap into

place. Secure the grille with screws (in the same corner

locations).

Remove any screws

securing the grille

Insert thin blade of screwdriver

between frame and enclosure

and move down seam while

twisting to loosen grille

Remove grille

Figure 7. Remove grille

Page 8 Installation and Operation Manual R.35-3896-EN

Page 9

ACCESSORIES

EN54-24:2008

R-VTY35 VARY-TILT YOKE FOR R.35

Provides pan-tilt operation.

Zinc-rich epoxy dual-layer

powder-coated steel with

hardware, color-matched to

loudspeaker.

R-FRY35 FULL ROTATION YOKE FOR R.35

Provides full rotation mounting

capability for down-ring

application (i.e. top of press

box). Zinc-rich epoxy dual-layer

powder-coated steel with

hardware, color-matched to

loudspeaker.

MAINTAINING WEATHER RESISTANCE

GUIDELINES FOR OUTDOOR USE

The R.35-3896-EN is suitable for outdoor installation when used

as recommended.

• Always orient the loudspeaker so the mouth of the horn is, at a

minimum, pointing at least 5 degrees downward. Failure to do

this could result in water collecting inside the enclosure under

extreme weather conditions.

• Be careful not to scratch or scrape the nish on the grille,

yoke, or enclosure.

• All mounting holes must be sealed o with the stainless

steel bolts, washers, and rubber washers supplied. If, for any

reason, these bolts must be removed, seal o the hole with

silicone caulking or some other suitable weather-tight sealant.

• The rubber washers supplied with the mounting bolts must

always seat against the enclosure.

• The grille assembly is designed to prevent normal and winddriven rain from directly entering the mouth of the loudspeaker.

The grille is not designed to withstand such things as being

directly sprayed from a hose; therefore this should be avoided.

• If you use any hardware in place of hardware provided with

your R SERIES loudspeaker, it should also be made of

stainless steel.

EC STATEMENT OF CONFORMITY

This document conrms that Biamp's range of products bearing the CE label meet all the requirements laid down by

the Member States Council for adjustment of legal requirements, furthermore the products comply with the rules and

regulations referring to the electromagnetic compatibility of devices from 16 April 2016.

The Biamp products bearing the CE label comply with the following directives: Low Voltage Directive 2014/35/EU and the

Waste from Electrical Equipment Directive 2002/96/EC RoHS.

The authorized declaration and compatibility certication resides with the manufacturer and can be viewed upon request.

The responsible manufacturer is the company:

Biamp Systems, LLC

9300 SW Gemini Drive • Beaverton, OR 97008, USA

biamp.com

18

0905

R.35-3896-EN Installation and Operation Manual Page 9

Page 10

SPECIFICATIONS

Additional technical information and full specications are available by contacting Biamp's

Loudspeaker Support Group (within Customer Support) or your sales representative.

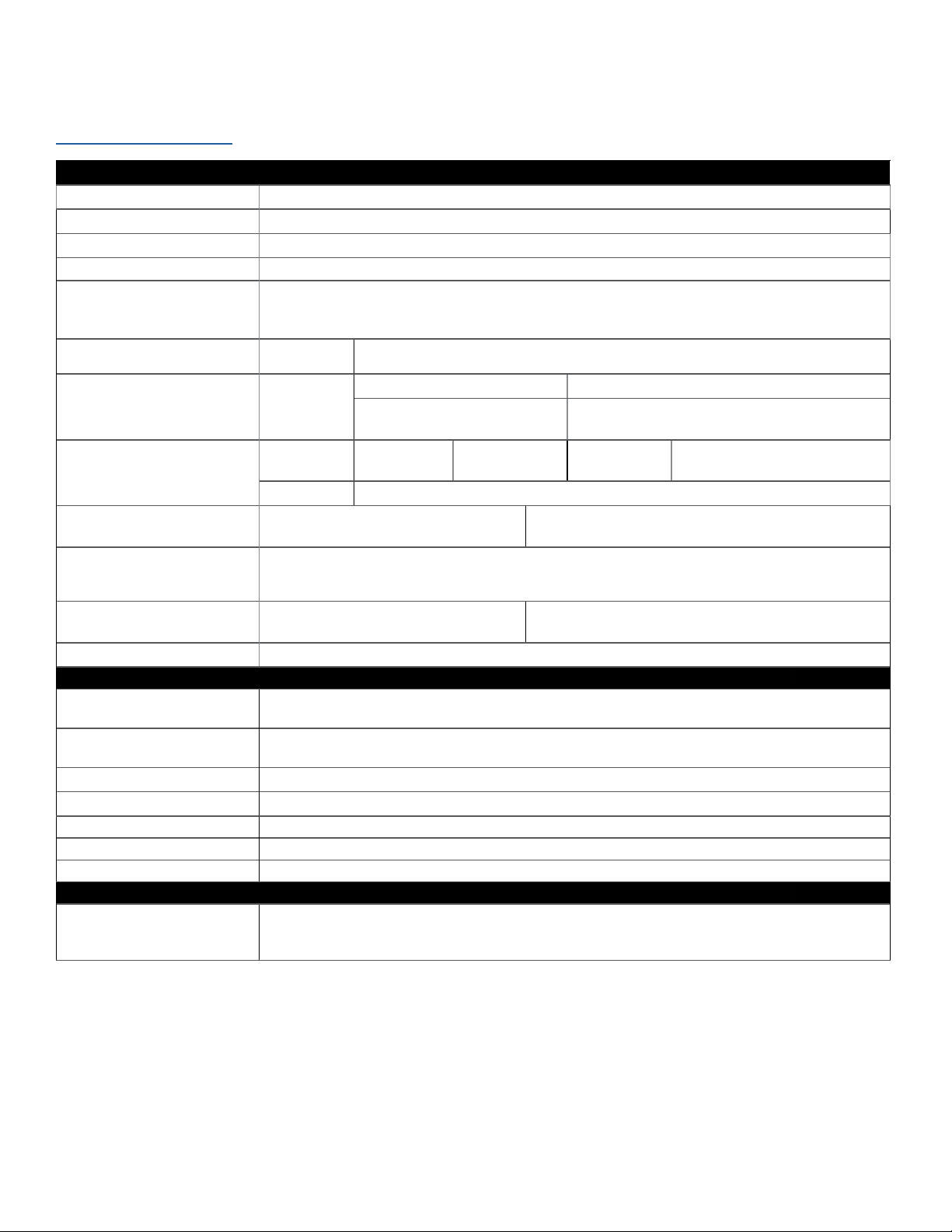

TECHNICAL SPECIFICATIONS

Operating Mode

Operating Environment

Operating Range

1,2

Nominal Beamwidth

Triaxial Transducers

Continuous Power Handling @

Nominal Impedance

Sensitivity

4

3

Nominal Maximum SPL4

(Whole Space)

Autoformer Taps/Impedance

Declared values of SPL

1/3 Oct band CPB,

1W/4m, per EN54-24 (Hz:dB)

Coverage (-6dB)

Horiz/Vert per EN54-24

Required Accessories

PHYSICAL

Input Connection

Mounting/Suspension Points

Input Panel Weather Cover

Environmental

Dimensions H x W xD

Weight

Finish

OPTIONS

Accessories

Footnotes

1. Operating Range: 10dB from rated sensitivity

2. Axes and Planes: See Diagram (page 11)

3. Continuous Power Handling: IEC, 2 hours

4. Measurement Environment: All measurements are made in outdoor free-eld conditions

5. Sensitivity/Max SPL @ 4m (per EN54-24): "Music" mode must be used for applications necessitating EN54-24 compliance

6. Nominal Max SPL @ 1m: Calculated from continuous power handling and sensitivity @ 1m

7. Rated Noise Power (per EN54-24): The 100W/ 100V and 50W/100V taps are certied for EN54-24 use. Low impedance, all 70V inputs, and 200W/100V tap are not rated

for EN54-24 use.

Passive, Low impedance or 70V/100V

All Conditions, suitable for continuous outdoor direct exposure

95 Hz to 19 kHz

90° x 60°

LF 1 x 8" Carbon ring hydrophobically-treated cone, 3" VC

MF 2 x 2.35" MultiSource Waveguide™ compression

HF 1 x 1" exit compression

56V

400W @ 8 ohms (1600W peak)

Music Speech

1W/1m

5

1W/4m

Continuous

@1m6

5,7

@4m

124 dB

103.4 dB at 100W/100V tap

25W (70V), 50W (100V) Tap: 143 Ω

50W (70V), 100W (100V) Tap: 75 Ω

98 dB

82.4 dB

Peak

130 dB

Continuous

126 d B

100W (70V), 200W (100V) Tap: 41 Ω

200W (70V), N/A (100V) Tap: 23 Ω

100 dB

Peak

132 d B

500: 69.3, 630: 69.7, 800: 69.2, 1000: 69.2,

1250: 70.5, 1600: 69.1, 2000: 67.5, 2500: 70.8,

3150: 69.4, 4000: 71.7

500Hz: 146 / 180

1 kHz: 110 / 110

2 kHz: 88 / 103

4 kHz: 81 / 46

Digital Signal Processor; 80 Hz 24 dB / Octave High Pass Filter

NL4 Speakon-type connector for low impedance operation only;

and 7-position terminal strip for low impedance or constant voltage operation

Two M8 rigging points, zinc-rich epoxy dual-layer powder-coated yoke,

included integral safety cable mounting point

Color-matched ABS plastic with 13.5mm ID gland nut installed in 21mm knockout

IP55W per IEC 60529 (with a recommended 5° down-tilt); designed to meet MIL-STD-810G standard

279 x 330 x 343 mm (11" x 13" x 13.5")

15.4 kg (34 lbs) with included yoke

Refer to the Technical Drawing

R-VTY35: Provides pan-tilt aiming; color-matched zinc-rich epoxy DLPC steel with SS hardware

R-FRY35: Provides full rotation mounting capability for down-ring application; color-matched zinc-rich epoxy

DLPC steel with SS hardware

Page 10 Installation and Operation Manual R.35-3896-EN

Page 11

TECHNICAL DRAWING / DIMENSIONS / FINISH

H x W x D

279 x 330 x 343 mm

(11" x 13" x 13.5")

Unit Weight

15.4 kg (34 lbs) with included yoke

Shipping Weight

18.1 kg (40 lbs)

0.8 4" (21mm)

13.5" (343mm)

Center of

Gravity

1" (25 mm)

13" (330mm)

Top

Center of

Load

Grille

3-layer Weather-Stop™ featuring hydrophobically-treated

polyester mesh, foam, zinc-rich powder-coated perforated

aluminum color-matched to enclosure

Enclosure / Finish

ABS plastic, matte nish, Light Grey (RAL # 7038)

12.12" (3 08 mm)

6.0 6" (154 mm)

Ø 0.35" (Ø 9m m)

8 places

8. 22 " (2 09 mm)

8. 54 " (217m m)

2.6" (66mm)

4.65" (118mm)

Yoke Hole Dimensions

Ø 0.51" (Ø 13mm)

2.6" (66mm)

4.65" (118mm)

3.1 7" (81m m)

M8 Hang Po int /

Center of G ravit y

1.58" (40mm)

0.98" (25mm)

11" (2 79 mm)

Front

AXES AND PLANES

3

4

Center of

Gravity

1

5.5" (140mm)

Sides

1. Reference Plane (red) is coincident with the center of the

2

loudspeaker grille

2. Reference Axis (black) perpendicular to the reference plane,

passing through the center of the grille

3. Vertical Plane (blue) intersects the reference plane at a right

angle including the reference axis and the center point of the

cabinet's front radius

4. Horizontal Plane (green) intersects the reference plane at a

right angle and includes the reference axis

R.35-3896-EN Installation and Operation Manual Page 11

Page 12

PERFORMANCE

USE A DIGITAL SIGNAL PROCESSOR

For best performance, loudspeaker protection and system longevity, a digital signal

processor (DSP ) should be used with all R SERIES loudspeakers. Biamp recommends

using Biamp's Amplied Loudspeaker Controllers (ALC) and ArmoníaPlus software*

containing all of the information (high pass lters, limiters, factory tunings) and DSP

settings to fully optimize your system. For more information on installing and operating

your R SERIES loudspeaker, please contact our Loudspeaker Support Group at

support@biamp.com.

Note: Every eort has been made to insure

that the information contained in this manual

was complete and accurate at the time of

printing. However, due to ongoing technical

advances, changes or modications may

have occurred that are not covered in this

manual. The latest version is available at

biamp.com.

*ArmoiníaPlus® is a registered trademark of Powersoft S.p. A.

CONTACT US

Email: support@biamp.com

Web: support.biamp.com

Warranty: biamp.com/legal/warranty-information

Safety & Compliance: biamp.com/compliance

A: 9300 S.W. Gemini Drive Beaverton, OR 97008 USA W: www.biamp.com

# 114678 v: 4.1 19OCT2022

Loading...

Loading...