Page 1

I SERIES

Installation and

Operation

Quick Start Guide

Models

Compact 600

IC6-1062/00,

IC6-1082/26, IC6-1082/96,

IC6-2082/26, IC6-2082/96

including T, WR, WT models

communitypro.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Always follow these basic safety precautions when using or installing I SERIES loudspeakers and

accessories:

• Read these instructions prior to assembly.

• Keep these instructions for reference.

• Heed all warnings.

• Follow all instructions, particularly those pertaining to rigging, mounting, hanging and electrical

connections.

• Do not install/use the inside models near water.

• Clean only with dry cloth.

• Do not block any ventilation openings. Install in accordance with the manufacturer’s instruction.

• Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat.

• Only use attachments and accessories that are specified and approved by the manufacturer.

Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been

damaged in any way, such as liquid has been spilled or objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, does not operate normally, or has been dropped.

The terms CAUTION, WARNING, and DANGER may be used in this manual to alert the reader to

important safety considerations. If you have any questions or do not understand the meaning of

these terms, do not proceed with installation. Contact your local dealer, distributor, or call Community

directly for assistance. These terms are defined as:

CAUTION: describes an operating condition or user action that may expose the equipment

or user to potential damage or danger.

WARNING: describes an operating condition or user action that will likely cause damage

to the equipment or injury to the user or to others in the vicinity.

DANGER: describes an operating condition or user action that will immediately damage

the equipment and/or be extremely dangerous or life threatening to the user or to others

in the vicinity.

These installation instructions are for use by qualified personnel only. To reduce the risk of fire or

electric shock do not perform any servicing other than that contained in the operating instructions

unless you are qualified to do so.

RIGGING AND ELECTRICAL SAFETY

IMPORTANT: The loudspeakers described in this manual are designed and intended to be

mounted to diering building surfaces using a variety of rigging hardware, means and

methods. Installation of loudspeakers should only be performed by trained and qualified

personnel. All electrical connections must conform to applicable city, county, state, and

national (NEC) electrical codes.

UNPACKING / INSPECTION

Community I SERIES loudspeakers are engineered

and manufactured to be rugged and they are

carefully packed in sturdy cartons. However, it

is recommended to thoroughly inspect each unit

after it has been removed from the packaging, as

damage could occur during shipping.

Please note that once the shipment has left

your dealer or the Community factory, the

responsibility for damage is always borne by

the freight company. If damage has occurred

during shipping, you must file a claim directly

with the freight company. It’s very important to

contact the freight company as soon as possible

after receiving your shipment, as most freight

companies have a short time limit within which

they will investigate claims. Make sure to save

the carton and the packing material, as most

claims will be denied if these materials are not

retained. Your Community dealer and the factory

will try to help in any way they can, but it is the

responsibility of the party receiving the shipment

to file the damage claim.

It is always a good idea to retain the carton and

packing materials, if possible, in the event that

the unit may need to be returned to your dealer

or distributor for repair in the future.

IN THE CARTON

Each shipping carton contains the following:

• Loudspeaker (fully assembled)

• Information packet

WARNING: I SERIES rigging fittings are

rated at Working Load Limits (WLL)

with a 10:1 safety margin. All mounting

provisions on the IC6 cabinets meet or exceed

the 10:1 safety margin to support the cabinet

when used with the specified mounting brackets,

either from Community or third party vendors.

Failure to heed this warning could result in injury

or death!

DANGER: All rigging fittings must be fully tightened and secured. Any missing fasteners or

parts will compromise the structural integrity of the enclosure and constitute a safety

hazard. Do not suspend this loudspeaker unless all fasteners are securely in place!

. DANGER: It is possible to experience severe electrical shock from a power amplifier.

Always make sure that all power amplifiers are in the “OFF” position and unplugged from

an AC Mains supply before performing electrical work.

IMPORTANT: Refer to the sections on installation and connections later in this manual for

additional information on rigging and electrical safety.

CAUTION: Installation of

I SERIES loudspeakers should

only be performed by trained

and qualified personnel. It is strongly

recommended that a licensed and

IMPORTANT: The flat-head hex-drive rigging screws that come installed in each enclosure

must either be replaced with rigging brackets and threaded fasteners, or they must be

kept in place to seal the enclosure from air leaks. If the rigging fittings do not remain

sealed, air leaks will occur in the enclosure that will compromise the low-frequency

performance with distortion, reduced output, and premature driver failure.

certified professional structural

engineer approve the mounting.

Severe injury and/or loss of life may

occur if this product is improperly

installed.

Page 2 Quick Start Guide I SERIES Compact 600

Page 3

PRODUCT NAMING CONVENTION

I SERIES presents a logical way of easily

deciphering each model's characteristics

(family, type, level, number and size of woofer,

crossover bands, and horn pattern). The

Product Family

I = I SERIE S

diagram at right demonstrates the product

naming convention behind each model.

IC6-1062/00B translates as:

I SERIES Compact 600

Single 6-inch Two-way, 100° x 100°, Black

The standard configuration is indoor construction with low impedance

operation. All models also have T, WR and WT versions

T = 70V/100V autoformer operation

WR = weather-resistant low impedance

WT = weather-resistant + autoformer

I C 6 1 0 6 2 00 B

Product Type

P = Point S ource

C = Compact

S = Subwoo fer

Trim Level

PRODUCT REPRESENTATION

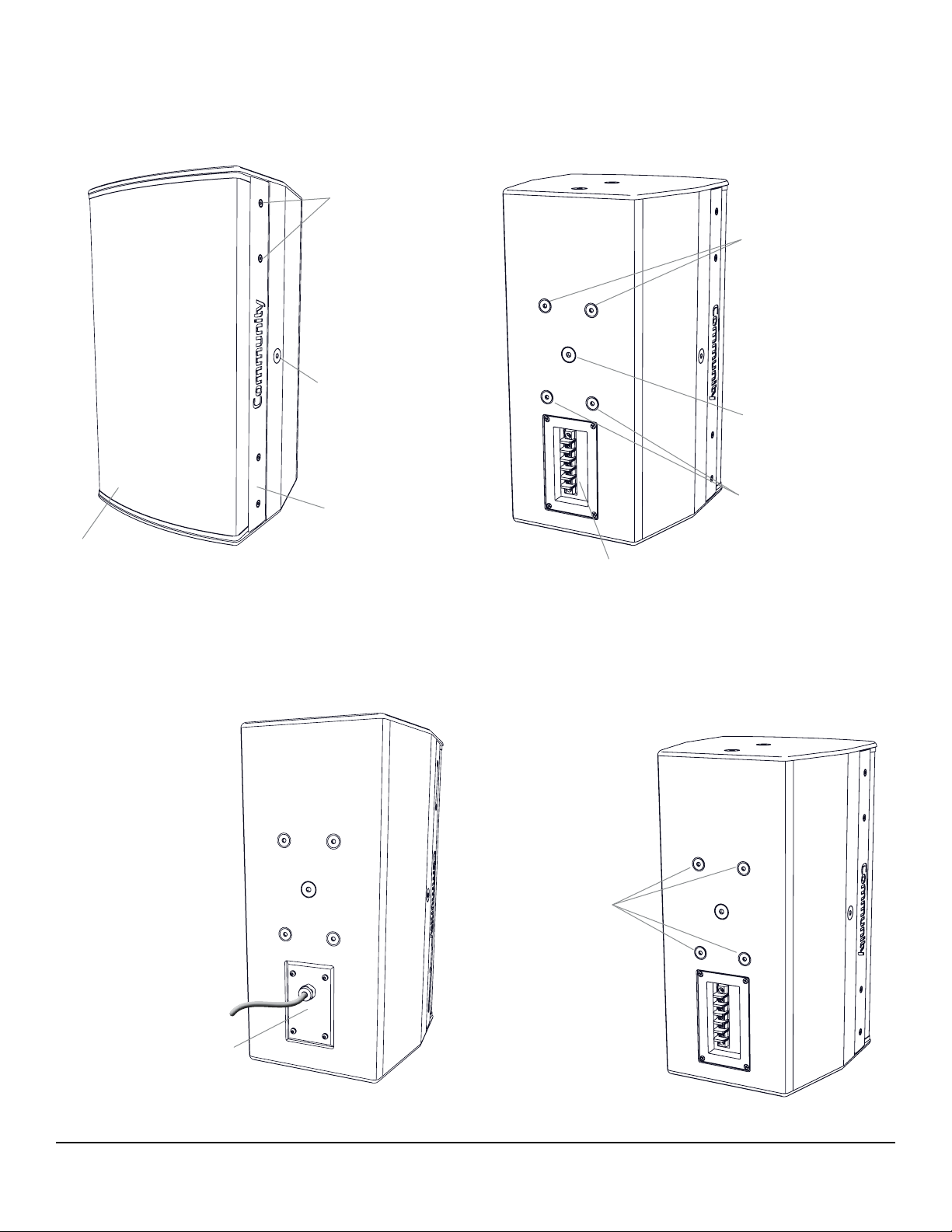

I SERIES LOUDSPEAKER (IC6-1062)

Can be ordered with or without 70V/100V autoformer operation.

8 = 800

6 = 600

–

LF Qty

LF Size

Use 2 digi ts:

08 = 8-inc h

Crossover Bands

1-way

2-way

3-way

(Omit for S-type)

/

Form/Mode

/ = Indoor s tandard

T = Transfor mer

WR = Weath er-resistan t

WT = WR +Tran sfo rme r

C = CTO (Con figured)

Horn Pattern

H x V

(Omit for S-type)

Cabinet Color

B = Black

W = White

(WR and W T are Grey

by defa ult - no color

code is sh own)

Front (grille o)

Rear

Models

IC6-1062/00 (B/W) Indoor Low Impedance

IC6-1062T00 (B/W) Indoor 70V/100V

IC6-1062WR00 Outdoor Low Impedance

IC6-1062WT00 Outdoor 70V/100V

IC6-1062C00 Configured-to-Order

I SERIES Compact 600 Quick Start Guide Page 3

Page 4

PRODUCT REPRESENTATION

I SERIES LOUDSPEAKER (IC6-1082)

Models are available in two horn patterns with or without a 70V/100V autoformer (IC6-1082/26 front shown with grille

o). Primary orientation is vertical (portrait) for indoor models and horizontal (landscape) for outdoor (WR/WT) models.

Horns in the WR/WT models are rotated at the factory to maintain orientation of the wider coverage angle (90* or 120*) to

the horizontal plane. All horns may be rotated in the field by the installer to accommodate dierent cabinet orientations

for both the indoor and outdoor models.

Models

120° x 60° coverage

IC6-1082/26 (B/W) Indoor Low Impedance

IC6-1082T26 (B/W) Indoor 70V/100V

IC6-1082WR26 Outdoor Low Impedance

IC6-1082WT26 Outdoor 70V/100V

IC6-1082C26 Configured-to-Order

90° x 60° coverage

IC6-1082/96 (B/W) Indoor Low Impedance

IC6-1082T96 (B/W) Indoor 70V/100V

IC6-1082WR96 Outdoor Low Impedance

IC6-1082WT96 Outdoor 70V/100V

IC6-1082C96 Configured-to-Order

(B/W) - black or white finish

WR/WT - grey finish is standard, but black

or white finishes can be ordered

Custom colors available as CTO

Front

Rear

I SERIES LOUDSPEAKER (IC6-2082)

Models are available in two horn patterns with or without a 70V/100V autoformer (IC6-2082/96 shown with grille o).

Primary orientation is horizontal (landscape). All horns may be rotated in the field by the installer to accommodate

vertical (portrait) cabinet orientation.

Front

Rear

Models

120° x 60° coverage

IC6-2082/26 (B/W) Indoor Low Impedance

IC6-2082T26 (B/W) Indoor 70V/100V

IC6-2082WR26 Outdoor Low Impedance

IC6-2082WT26 Outdoor 70V/100V

IC6-2082C26 Configured-to-Order

90° x 60° coverage

IC6-2082/96 (B/W) Indoor Low Impedance

IC6-2082T96 (B/W) Indoor 70V/100V

IC6-2082WR96 Outdoor Low Impedance

IC6-2082WT96 Outdoor 70V/100V

IC6-2082C96 Configured-to-Order

(B/W) - black or white finish

WR/WT - grey finish is standard, but

black or white finishes can be ordered

Custom colors available as CTO

Page 4 Quick Start Guide I SERIES Compact 600

Page 5

PRODUCT REPRESENTATION

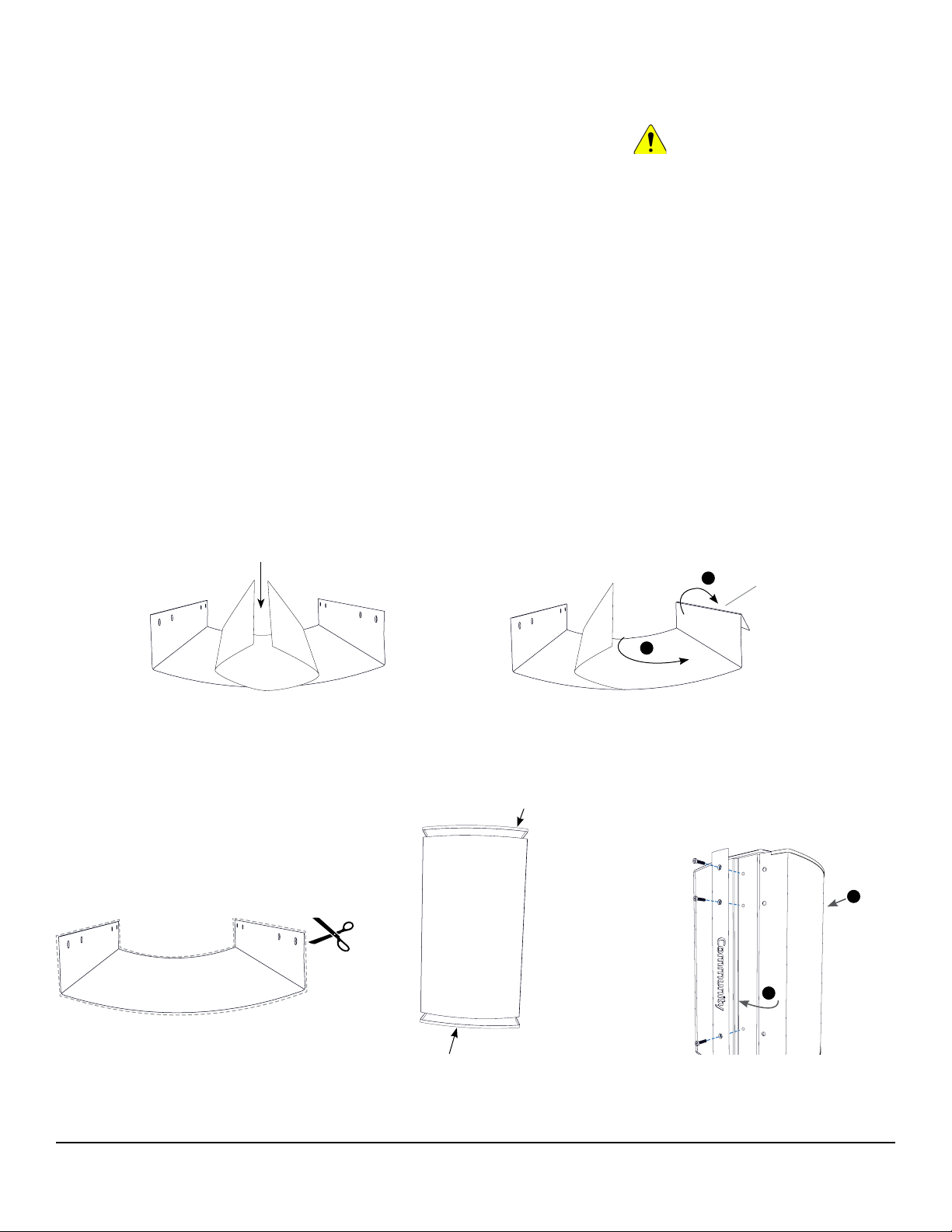

EQUIPMENT BASICS

Mounting Points

IC6-1082/2082-M10 Screws

(Top, Bottom, Side points)

IC6-1062-M6 Screws

(Top, Bottom - no Side points)

Aluminum Grille

Retainer Screws

Rear (4) Mounting Point s

IC6-1062 (M6 Screws)

IC6-1082/2082 (M8 Screws)

Rear Center Mounting Point

IC6-1062 (M6 Screws)

IC6-1082/2082 (M10 Screws)

Grille

Front

WEATHER-RESISTANT MODELS

All IC6 WR/WT models have the input

panel covered with a factory installed

sealed gland nut and cable

(IC6-1082WR shown)

Aluminum Grille

Retainer

Rear (4) Mounting Point s

IC6-1062 (M6 Screws)

IC6-1082/2082 (M8 Screws)

Input panel

Rear

ALL MODELS

All IC6 models have four (4) rear

mounting points compatible with

a variety of third party mounting

systems. Refer to table on page 15

of this manual.

These 4 mounting points

(on all IC6 models) are

compatible with third

party pan-tilt, wall and

ceiling brackets

Input panel cover with

sealed gland nut and cable

Rear

Rear

I SERIES Compact 600 Quick Start Guide Page 5

Page 6

CONNECTIONS AND INSTALLATION

4.11”

Label# 113799

I SERIES Compact 600

Autoformer 200W

Label# 114047

I SERIES Compact 600

Autoformer 100W

Revised 6/1/2016

Label# 113799

I SERIES Compact 600

Autoformer 200W

Revised 6/1/2016

USE THE CORRECT WIRE OR CABLE

All I SERIES loudspeakers are fitted with captive-clamp terminal blocks on the

input panel to connect to the amplifier. Terminating the wires with a spade or

ring connector (Figure 1) is recommended for secure connections. The maximum

Ring

terminal

width of the ring or spade lug should be 0.375" (9.5mm), or less. The terminal

screws are #8 (M4). The maximum wire size that can be accommodated for bare

wire connections is 10 AWG (5.26 mm2).

Note: Wire insulation colors may vary depending upon region or manufacturer. Be consistent with

conductor color use throughout the system.

Spade

terminal

Figure 1. Wire Connectors

IMPOR TANT: All electrical installation connections for loudspeaker lines are subject to all applicable

governmental building and fire codes. The selection of appropriate electrical hardware to interface with the

I SERIES loudspeaker lies solely with the installation professional. Community recommends that an

appropriately licensed engineer, electrician, or other qualified professional identify and select the appropriate

conduit, fittings, wire, etc. for the installation.

CONNECTION: LOUDSPEAKER INPUT PANEL (INDOOR MODELS)

The compact models can be ordered as Low Impedance or Autoformer "T"

versions. See below for input panels for each model type.

LOW IMPEDANCE

OPERATION

MODELS

70V/100V

OPERATION

'T' MODELS

NC

IC6-1062T

+ – + –

PASSIVE

INPUT

PASSIVE

THRU

I SERIES

IC6-1062 / 1082 / 2082

Community Light & Sound, Inc.

333 East Fifth Street, Chester, PA 19013 USA

Made in the USA

IC6-1082T / 2082T

Figure 1. Input panel wiring for I SERIES compact indoor models

Page 6 Quick Start Guide I SERIES Compact 600

Page 7

INPUT CABLE CONNECTION: WEATHER-RESISTANT MODELS

All I SERIES weather-resistant loudspeakers are fitted with input panel covers

and gland nuts sealing the prewired SJOW cable. Internal conductor color

terminations are shown below.

Standard for WR Models

WHITE

BLACK

Standard for WT Models

RED

YELLOW

ORANGE

BROWN

BLACK

IC6-1062WT00

Figure 2. Wiring diagrams for WR/WT (outdoor) models

POS (+)

COM (–)

70V

12.5W

25W

50W

100W

COM

100V

25W

50W

100W

N/C

COM

70V

RED

YELLOW

ORANGE

BROWN

BLACK

IC6-1082WT96, IC6-1082WT96

IC6-2082W T26, IC6 -2082W T26

25W

50W

100W

200W

COM

100V

50W

100W

200W

N/C

COM

LOUDSPEAKER WEIGHTS

COMPACT Indoor [lbs (kg)]

Low impedance

IC6-1062 16.0 (7.3) 20.0 (9.1) 12.6 (5.7) 16.6 (7.5)

IC6-1082 25.0 (11.3) 29.0 (13.2) 19.2 (8.7) 23.2 (10.5)

IC6-2082 31.0 (14.1) 35.0 (15.9) 23.9 (10.8) 27.9 (12.7)

I SERIES Compact 600 Quick Start Guide Page 7

Indoor [lbs (kg)]

Autoformer "T"

WR [lbs (kg)]

Weather-Resistant

WT [lbs (kg)]

WR Autoformer

Page 8

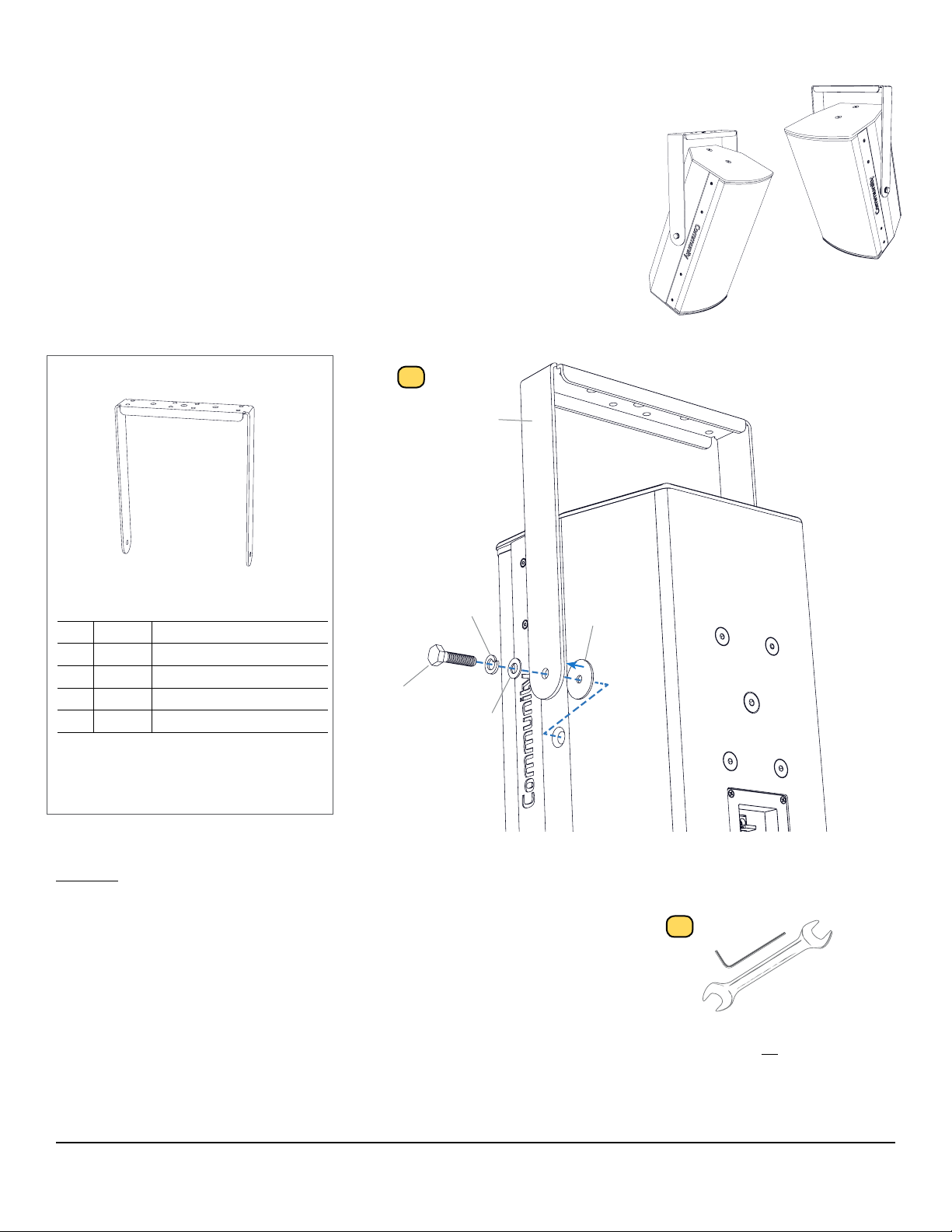

GRILLE REMOVAL / HORN ROTATION

The horns on the IC6-1082 or IC6-2082

models can be rotated 90° by removing

the grille, rotating the horn and then

reinstalling the horn and grille. This

is suggested to maintain the stated

coverage pattern if you are mounting

the IC6-1082 horizontally (landscape)

or the IC6-2082 vertically (portrait).

Illustrations (at right) show the

IC6-1082/26.

Remove the screws holding one

Community grille retention bar to the

cabinet. Remove the bar and loosen the

grille. Then remove the other retention

bar and pull the grille o and set aside.

Keep the rubber extrusions protecting

the top and bottom edges of the grille

in place (Figures 3a, 3b).

Remove the screws holding the horn in

place (Figure 3c).

Carefully pull the horn forward, rotate

it 90° and push back into place, aligning

the screw holes (Figure 3d).

Reattach the horn (Figure 3e).

Flex the g rille slightly to fi t it back on the

cabinet (one side at a time). Reattach

one grille retention bar, then flex the

grille, align and attach the other side.

Fully tighten the screws only after both

sides have been secured (Figure 3f).

Note: The grille retention bars will only align with

the threaded inserts in one direction - refer to the

product view for orientation. All fasteners should

be in place and fully tightened to prevent any

undesirable noise from vibration.

5mm x 20mm

Socket Head

Screw

Figure 3a. Remove one retention bar,

loosen that side of the grille and then

remove the other retention bar

Figure 3c. Remove the screws holding

the horn in place and set aside

Grille

Retention Bar

Grille

4mm x 20mm

Socket Cap

Screws

Figure 3b. Remove the grille and set

aside for reattachment

1

2

Figure 3d. Pull the horn forward and

rotate it 90° and realign holes

1

3

2

Figure 3e. Reattach the horn

Figure 3f. Reinstall the grille one side at a

time with correct orientation of the grille

retention bars.

Page 8 Quick Start Guide I SERIES Compact 600

Page 9

RIGGING SAFETY

IMPOR TANT: The loudspeakers described in this manual are designed

and intended to be mounted to diering building surfaces using a

variety of rigging hardware, means and methods. Installation of loudspeakers

should only be performed by trained and qualified personnel. It is strongly

recommended that a licensed and certified professional structural engineer

approve the mounting plan. Severe injury and/or loss of life, and property

damage may occur if these products are improperly installed.

DANGER: All rigging fittings must be fully tightened and secured. Any

missing fasteners will compromise the structural integrity of the

enclosure and constitute a safety hazard. Do not suspend any loudspeakers

unless all fasteners are securely in place!

ACCEPTABLE MOUNTING POINT LOADING

The mounting points should always be used so that either shear force is applied

perpendicular to the direction of and in tight proximity to the mounting hole, or

tension force is applied perpendicular to the enclosure surface.

DANGER: Use the mounting points only as described above. Do not use

them in such a way as to apply sideways leverage to them. Failure to

follow this instruction could result in failure of the mounting points resulting in

damage to the loudspeaker and serious injury or death to personnel.

Figure 4. Possible safety cable mounting

point with an eyebolt (not included)

ATTACH SAFETY CABLE

Attach a safety cable to one of

the unused mounting points.

The safety cable and hardware

are not included. Please consult

a structural engineer for the

appropriate cable and hardware

for the load and application. The

safety cable must be secured

to a suitable load-bearing point

separate from the loudspeaker

mounting point, with as little

slack as possible, so as not to

develop undue kinetic force if the

loudspeaker mount were to fail

(see Figure 4 above).

IC6-1062

The U-Brackets and Vertical Yokes

have hole patterns compatible with

BalancePoint™ Flyware rails and

frames, and are also compatible with

many third party manufacturers'

speaker stand adapter plates, ceiling

or pole mount brackets and wall mount

arms. Refer to our reference table or

manufacturer's website for details.

Figure 5. Shown with optional U-Brackets

IC6-2082

IMPORTANT: I SERIES Compact

IMPORTANT: The flat-head hex-drive rigging screws that come installed in

each enclosure must either be replaced with rigging brackets and threaded

fasteners, or they must be kept in place to seal the enclosure from air leaks. If

the rigging fittings do not remain sealed, air leaks will occur in the enclosure that will

compromise the low-frequency performance with distortion, reduced output, and

premature driver failure.

using Community supplied or third party

manufactured mounting brackets.

Additional cabinets should NOT be

suspended from any mounting point.

rigging fittings are designed to

support the load of the cabinet

I SERIES Compact 600 Quick Start Guide Page 9

Page 10

LOUDSPEAKER CABINET PAINTING PROCEDURE

I SERIES cabinets are available in standard colors of Black and White, and the

weather-resistant cabinet is Grey; custom colors may be ordered as Configuredto-Order (CTO) items for both types of models, alleviating the need to paint your

own.

Indoor: The cabinet finish is a resilient water-based paint that makes an excellent

substrate to accept most types of paints, allowing custom colors to be applied

in the field. If you are considering painting the cabinet, we recommend ordering

the White version of the cabinet for the most predictable results when colormatching existing colors. A Black or White replacement grille cloth kit should

also be ordered. For most custom colors, black grille cloth is recommended. The

kit also includes replacement soft plastic trim strip (to fit upper/lower edges of

grille).

Follow grille removal instructions (Figure 6a) and reserve hardware for

reattachment.

Warning: The grille edges are sharp! Use care when handling the unprotected

edges of the grille to prevent injury.

CABINET

Mask o the input panel and front face, including all drivers and por ts (Figure 6b).

Paint the cabinet and allow the paint to fully cure.

Grille Retention Bar

Outdoor WR/WT models:

The weather-resistant models are

finished with an exterior-grade UVresistant finish, and can be repainted

with a similar spray paint. The grille

paint must be compatible with a

powder-coated surface.

Note: Please specify weather-resistant material

when ordering the grille cloth replacement kit.

Grille

5mm x 20mm

Socket Head

Screw

Figure 6a. Remove one retention bar, loosen that side of

the grille and then remove the other retention bar

GRILLE AND ALUMINUM RETENTION STRIPS

The grille and aluminum retention strips must be removed and

painted separately. To paint the grille, carefully remove the grille

cloth backing and the soft plastic strips protecting the top and

bottom edges (Figure 6c).

Use paint that is compatible with powder coating, and paint the

outside (front and sides) of the grille and allow the paint to fully

cure. Do not paint the cloth or rubber trim. Paint the front and

edges of the grille retainers with the same paint used on the grille.

Allow paint to fully cure before reassembling.

Front

Rear

Figure 6b. Mask o the internal

components and rear input panel

Figure 6c. Remove trim strips and

grille cloth

Page 10 Quick Start Guide I SERIES Compact 600

Page 11

GRILLE CLOTH REPLACEMENT

Apply a fine mist of spray adhesive to the inside surface of the grille including

the inside corners. Do not clog the perforations.

Position the grille cloth so that the side with the tighter, smoother weave faces

the rear side of the grille. Hold the corners of the cloth and place it onto the

center, inside of the grille (Figure 7a). The cloth will be oversized.

Align the edges, and spread the cloth toward the sides one side at a time, while

smoothing out any ripples (Figure 7b-1).

Bring the excess cloth edge up and over the sides of the grille making sure that the

cloth is fully adhered to the inside corners and edges of the grille (Figure 7b-2).

Trim the side edges of the cloth to leave 0.5" (13mm) to wrap over the edge. Apply

a bead of adhesive to the outside edge of the grille sides (about 1/4" [7mm] from

the top), and fold the grille cloth over to adhere the edge.

Trim the top and bottom of the cloth to be even with those edges (Figure 7c) and

make sure that the cloth is fully adhered to the grille without any wrinkles.

One end at a time, fit the soft plastic trim strips on the top and bottom edges of

the grille (Figure 7d) and secure the ends and corner bends with small amounts

of cyanoacrylate adhesive (commonly known as "Super Glue"). Trim excess after

it is fitted onto the grille edges.

Follow the manufacturer's instructions and allow the adhesives to fully cure

before reattaching the grille to the loudspeaker cabinet (Figure 7e).

Warning: The grille edges are

sharp! Use care when handling

the unprotected edges of the

grille to prevent injury.

Important (for weather-resistant models):

You must order (and use) the weatherresistant grille cloth to maintain the

moisture resistance of the loudspeaker.

Figure 7a. Spray inside of grille with adhesive,

center the grille cloth fabric (with tighter

weave side down) and align short edges

2

1

Figure 7b. Press fabric against grille

and into the bends, smoothing out any

wrinkles

Trim excess fabric 0.5"

(13mm) and fold over the

bent sides

1

2

Figure 7c. Trim top and bottom of grille

cloth, open screw holes, and secure

folded sides with glue

Figure 7d. Reinstall the soft plastic trim

and secure ends and corners with glue

Figure 7e. Reinstall the grille one side

at a time with correct orientation of the

grille retention bars

I SERIES Compact 600 Quick Start Guide Page 11

Page 12

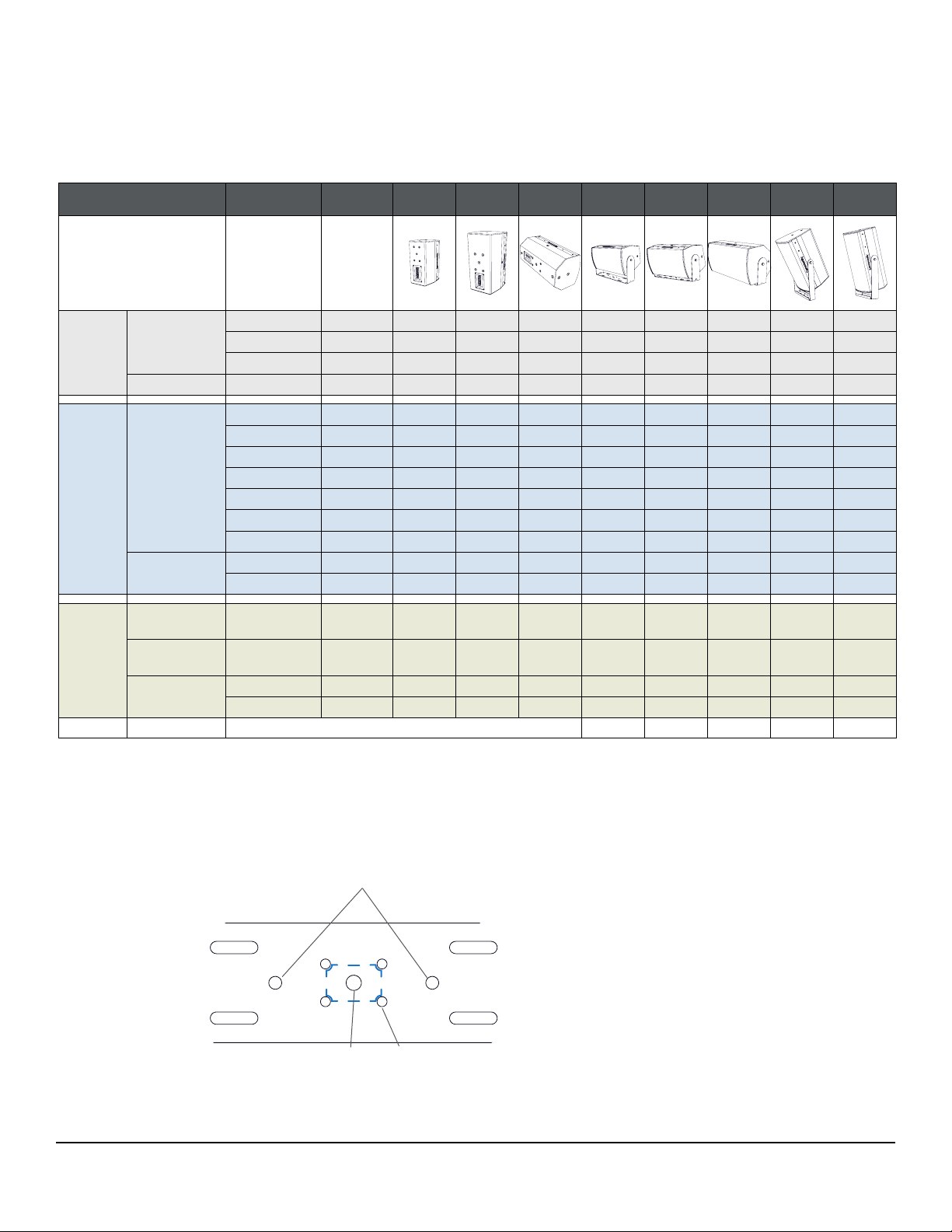

ACCESSORIES - U-BRACKET ATTACHMENT

The U-Brackets will allow rotation of the loudspeaker around the long axis.

APPLICATION: Suspend and aim single loudspeakers from ceilings, walls,

trusses, or use with BalancePoint™ Flyware rails and frames.

Before assembly: Adhere the rubber washers to the inside of the yoke (aligned

with cabinet mounting point - see arrow in Figure 1).

Notes:

1. Since the primary orientation of the IC6-1082 is vertical (portrait), it is suggested that the horn

be rotated to maintain its stated coverage pattern if mounted horizontally.

2. The U-Bracket can be attached to the building structure and then the loudspeaker can be

installed later. It is also compatible with BalancePoint™ Flyware rails and frames as well as

third party stand adapter brackets (See reference table on page 15).

3. Order IUB1062 for IC6-1062, IUB1082 for IC6-1082, or IUB2082 for IC6-2082. There are WR

(weather-resistant) versions of each if needed for the WR or WT Compact I SERIES models.

Parts:

UB

UB: U-Bracket (IUB1062 shown)

Hardware:

IUB1062

Qty

Code Description

2 HH 6 x 35 mm Hex Hd Bolts

2 HW 6 mm Flat Washers

2 HL 6 mm Lock Washers

2 HW-R

IUB1082 / IUB2082:

Qty

Code Description

2 HH 10 x 40 mm Hex Hd Bolts

2 HW 10 mm Flat Washers

2 HL 10 mm Lock Washers

2 HW-R

Kit Weights:

IUB1062: 4.6 lbs (2.1 kg)

IUB1062WR: 4.4 lbs (2.0 kg)

IUB1082: 6.3 lbs (2.9 kg)

IUB1082WR: 6.0 lbs (2.7 kg)

IUB2082: 6.8 lbs (3.1 kg)

IUB2082WR: 6.5 lbs (2.9 kg)

Note: Weather-resistant U-Bracket kits contain

stainless steel hardware

6mm ID x 50mm OD

Rubber Washer

8mm ID x 40mm OD

Rubber Washer

1

UB

HW

HH

HL

HW-R

Figure 1. Remove middle cabinet bolts and attach yoke to cabinet

2

Figure 2. Adjust angle

and fully tighten all

connections

MODELS

Match your loudspeaker model and color

Indoor - black

IUB1062B, IUB1082B, IUB2082B

Indoor - white

IUB1062W, IUB1082W, IUB2082W

Weather-resistant - grey

IUB1062WR, IUB1082WR, IUB2082WR

(custom colors may be ordered as a

CTO option)

Page 12 Quick Start Guide I SERIES Compact 600

Page 13

ACCESSORIES - VERTICAL YOKE ATTACHMENT

The IVY1082 and IVY2082 will allow panning and tilting of the IC6-1082 and

IC6-2082 models respectively.

APPLICATION: Suspend and aim single loudspeakers vertically (in portrait

orientation) from ceilings, walls, trusses, third party speaker stand adapters, or

use with BalancePoint™ Flyware rails and frames.

Before assembly: Adhere the rubber washer to the inside of the yoke (aligned

with cabinet mounting hole - see arrow in Figure 1).

Notes:

1. Since the primary orientation of the IC6-2082 is horizontal (landscape), it is suggested that the

horn be rotated to maintain its stated coverage pattern when mounted vertically.

2. The yoke can be attached to the building structure and then the loudspeaker can be installed

later.

Parts:

VY

VY: Vertical Yoke (IVY1082 shown)

Hardware:

Qty

Code Description

2 HH1-4 10 x 40 mm Hex Hd Bolts

2 HW1 10 mm Flat Washers

2 HL1 10 mm Lock Washers

2 HW-R 2" OD Rubber Washer

Kit Weights:

IVY1082: 4.0 lbs (1.8 kg)

IVY2082: 6.2 lbs (2.8 kg)

HH1-4

1

VY

HL1

HW1

HW-R

Figure 1. Remove side cabinet bolts and attach yoke to cabinet

MODELS

Match your loudspeaker model and color

Indoor - black

2

IVY1082B, IVY2082B

Indoor - white

IVY1082W, IVY2082W

(custom colors may be ordered as a

CTO option)

Figure 2. Adjust angle and

fully tighten all connections

I SERIES Compact 600 Quick Start Guide Page 13

Page 14

PERFORMANCE AND SPECIFICATIONS

USE A DIGITAL SIGNAL PROCESSOR

For best performance, loudspeaker protection and system longevity, a

digital signal processor (DSP) must be used with all I SERIES loudspeakers.

Community's dSPEC226 processor(s) and Resyn® software contain all of the

information (high pass filters, limiters, factory tunings) and DSP settings

to fully optimize your system. For more information on installing and

operating your I SERIES loudspeaker, please refer to Community’s website

at communitypro.com, or contact our Technical Applications Group (TAG) at

tagteam@communitypro.com, or by phone at 610-876-3400 or toll-free (within

the US and Canada) at 800-523-4934.

SPECIFICATIONS AND INFORMATION

Full product specifications and current documentation (manuals, sales

literature) is available at communitypro.com. Additional technical information

to assist you in operating and optimizing your system or understanding more

about loudspeaker operation is also available on the website or by contacting

the Technical Applications Group (TAG).

CUSTOMER SUPPORT

FOR MORE INFORMATION AND

APPLICATION ASSISTANCE

For more information on installing and

operating your I SERIES loudspeaker,

please refer to Community’s website at

www.communitypro.com.

For application support, service

or warranty information, refer to

Community’s website or contact

Community at 610-876-3400 or tollfree (within the US and Canada) at

800-523-4934.

WARRANTY INFORMATION

TRANSFERABLE WARRANTY “(LIMITED)” VALID IN THE USA ONLY

The I SERIES loudspeakers are designed and backed by Community Professional

Loudspeakers. For complete warranty information within the USA please refer

to www.communitypro.com/warranty-statement. Please call 610-876-3400

or visit the website to locate your nearest Authorized Field Service Station. For

Factory Service call 610-876-3400. You must obtain a Return Authorization (R/A)

number prior to the return of your product for factory service.

WARRANTY INFORMATION AND SERVICE

FOR COUNTRIES OUTSIDE THE USA

To obtain specific warranty information and available service locations for

countries other than the United States of America, contact the authorized

Community Distributor for your specific country or region.

SHIPPING DAMAGE / CLAIMS

If the product is damaged during transit you must file a damage claim directly

with the freight company. It’s very important to contact the freight company as

soon as possible after receiving your shipment, as most freight companies have

a short time limit within which they will investigate claims. Be sure to save the

carton and packing materials, as damage claims can be denied if these materials

are not retained. If evidence of physical damage exists upon arrival, be cautious

before signing the delivery acceptance receipt. Often, the fine print will waive

your right to file a claim for damage or loss after you sign it. Make sure that

the number of cartons shown on the freight documents have actually been

delivered.

Note: Every eort has been made to insure that the information contained in this manual was complete and

accurate at the time of printing. However, due to ongoing technical advances, changes or modifications may have

occurred that are not covered in this manual. The latest version is available at communitypro.com.

Page 14 Quick Start Guide I SERIES Compact 600

Page 15

THIRD PARTY MOUNTING BRACKET REFERENCE

I SERIES Compact enclosures and their accessories (U-Brackets, Vertical Yokes) are

compatible with several universal mounting options from other manufacturers.

Below is a quick reference table to choose from.

Ceiling

Mount

Wall

Mount

/

Pan-Tilt

Speaker

Stand

Adapter

Model

Adaptive

Technologies

(MultiMount)

K&M 24496* 55 (24.9) x x x

Adaptive

Technologies

(MultiMount)

K&M

Ultimate

Support

On-Stage

Stands

K&M

MM3RDX-18 60 (27.2) x x x

MM-3RDX-120 120 (54.4) x x

MM-018 60 (27.2) x x

MM-015 25 (11.3) x

MM-016-BT 25 (11.3) x

MM-022-BT 60 (27.2) x x x

MM-024-BT 60 (27.2) x x x

MM-060 60 (27.2) x x x

MM-120 120 (54.4) x x x

WM-0-15-60 60 (27.2) x x x

24471* 33 (15.0) x x

24481* 55 (24.9) x x x

BMB-200K 100 (45.4) x x x x x

EB-9760B NR x x x x x

195/8 NR x x x x x

19780* 33 (15.0) x x x

* Must use with 24352 or 24354 Adapter Plate

WLL

lbs (kg)

IC6-1062 IC6-1082 IC6-2082 IUB1062 IUB1082 IUB2082 IVY1082 IVY2082

MOUNTING COMPATIBILITY OF ALL IC6 U-BRACKETS OR VERTICAL YOKES

11mm holes - use for third party

speaker stand adapter brackets

13 mm hole for center bolt connec tion

to BalancePoint™ IAF40/55 frame

or other center suspension mounts

(4) 8.5mm holes can mount yoke to

BalancePoint™ Fly Rails

I SERIES Compact 600 Quick Start Guide Page 15

Page 16

©2018 Community Professional Loudspeakers # 114097 v:13JUL2018

Community Professional Loudspeakers

333 East Fifth Street, Chester, PA 19013-4511 USA

Phone (610) 876-3400 • Fax (610) 874-0190

www.communitypro.com

Loading...

Loading...