Page 1

A: 9300 S.W. Gemini Drive Beaverton, OR 97008 USA W: www.biamp.com

COMMERCIAL LOUDSPEAKERS

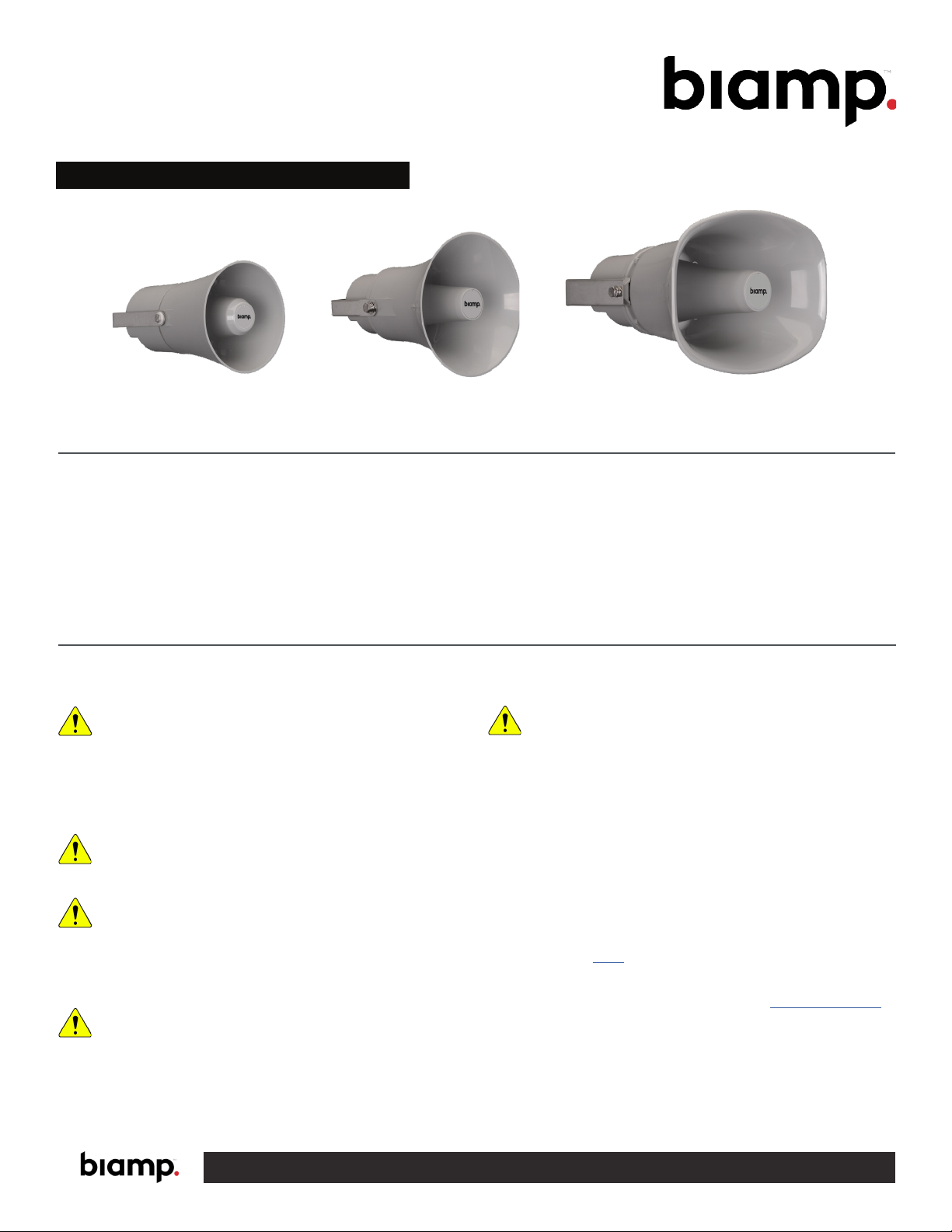

H10-G / H20-G / H30LT-G PAGING HORNS

Installation and Operation Guide

H10-G H30LT-GH20-G

PRODUCT DESCRIPTION

• Powerful weatherproof, industrial horn loudspeakers with compression drivers oering high

sound pressure.

• Suited for speech and reproduction of alarm signals.

• Ideal for long-distance and outdoor use.

• 70V/100V transformer with ve power tap and 8-ohm low impedance settings.

Rigging and Electrical Safety

DANGER: The loudspeakers described in this manual are designed

and intended to be suspended using a variety of rigging hardware,

means, and methods. Installation of loudspeakers should only be

performed by trained and qualied personnel. It is strongly recommended

that a licensed and certied professional structural engineer approve the

mounting design. Severe injury and/or loss of life may occur if these products

are improperly installed! All electrical connections must conform to applicable

city, county, state, and national (NEC) electrical codes.

DANGER: It is possible to experience severe electrical shock from a

power amplier. Always make sure that all power ampliers are in the

“OFF" position and unplugged from an AC Mains supply before

performing electrical work.

IMPORTANT: All electrical installation connections for loudspeaker

lines are subject to all applicable governmental building and re

codes. The selection of appropriate electrical hardware to interface

with the loudspeaker lies solely with the installation professional. Biamp

recommends that an appropriately licensed engineer, electrician, or other

qualied professional identify and select the appropriate conduit, ttings, wire,

etc. for the installation.

DANGER: The output power capabilities of audio ampliers present a

danger to installers. To minimize the risk of electric shock from

loudspeaker connecting cables, conrm that the power ampliers are

turned “o" before connecting loudspeaker cable(s) to the loudspeaker or

amplier. Always follow local electrical codes and proper electrical safety

procedures.

WARNING: After wiring the amplier(s) to the loudspeaker(s), rst

power-up all devices that are upstream of the amplier, such as

mixers, equalizers, compressor/limiters, etc., before powering-up the

amplier. This is to avoid passing any clicks or pops that may originate in the

upstream devices to the loudspeakers. The amplier should initially be

powered-up with its gain controls turned all the way down. After making sure

that a continuous signal is present, such as a CD playing, slowly raise the level

of the gain controls to establish that the wiring has been installed correctly.

Only then should the loudspeaker be operated at normal output levels.

Wiring and Electrical Safety

All standard paging horns come with attached SJOW-rated input cables

(length 1m [3.3']). The cable exits the enclosure through a weather-resistant

nut. The other end of the cable is un-terminated. The designer must account

and compensate for cable losses between the amplifier and the loudspeaker

system. Refer to this article on Cornerstone for more information on cable loss

calculations. Do not remove the rear enclosure or tamper with the cable nut,

as this will compromise the weather integrity of the enclosure. Please contact

the Customer Support for additional assistance (email: support@biamp.com)

Wire the loudspeaker. A typical installation method is to bring the cable

into a junction box (J-box). Connections within the J-box may be made with

appropriate wire connectors. Terminate per your local electrical code or

requirements.

NOTE: Be sure to read the loudspeaker safety guide included in

the carton with the loudspeakers.

Page 2

PRODUCT REPRESENTATION

U-bracket

Horn

Tap Switch Access Cover

Integrated Water-Tight

Gland Nut

Figure 1. Typical horn (H10- G shown)

Cable

Figure 2. H20-G

Figure 3. H3 0LT- G

page 2 Installation and Operation Guide H10-G/H20-G/H30LT-G

Page 3

INSTALLATION

H10-G / H20-G / H30LT-G Horn Loudspeakers

These installation instructions apply to the H10-G, H20-G, and H30LT-G. Each loudspeaker comes

with an attached stainless-steel U-bracket for easy surface installation. The installer must provide

the appropriate hardware for the application. The horn and cable egress are watertight and may be

installed indoor or in outdoor applications.

1. Determine where the loudspeaker is to be installed.

2. Attach the loudspeaker to the structure or surface using the holes in the U-bracket (hardware not

provided).

NOTE: It saves time to adjust the tap setting before installation. See page 4.

3. Attach a safety cable (not shown) to one of the unused holes in the U-bracket (refer to safety

note at the bottom of this page.

NOTE: The U-bracket can be removed and pre-installed. Reserve the hardware for reattachment of the

horn.

4. Aim the loudspeaker to the desired angle and tighten the bolts on either side to hold it in place.

Figure 4. Position horn

NOTE: The safety cable and associated hardware are not included. Consult all applicable codes for your application.

Confer with a structural engineer for the appropriate cable / hardware for the load, application, and locale. If required,

the safety cable must be secured to a suitable load-bearing point separate from the array mounting, with as little slack as

possible, so as not to develop undue kinetic force if the primary mount were to fail.

H10-G/H20-G/H30LT-G Installation and Operation Guide page 3

Page 4

SET LOUDSPEAKER TAPS

1. Remove the small black cap at the back of the horn to access the

tap switch as shown in Figure 5.

2. Use a small at screwdriver to turn the shaft to the appropriate

setting.

3. Replace the cap and make sure that it is fully seated to ensure

weather-resistance.

Figure 5. Typical horn (H10-G shown)

Figure 6. Tap settings for each model

page 4 Installation and Operation Guide H10-G/H20-G/H30LT-G

Page 5

WIRING

The loudspeaker comes with an attached cable with 2 conductors white (+) / black (–) as seen below

in Figure 7.

Figure 7. Wire / cable

1. Route the cable to a junction box (J-box). Outdoor installations should utilize weatherproof boxes

and connectors to consistent operation.

2. Connect the cable in the J-box with barrel-type crimp connectors, wire nuts, solder and heat-

shrink, or terminal strips.

NOTE: Biamp recommends using barrel-type crimp connectors that are crimped with a forged

crimp or a ratcheting tool, as this method, when properly executed, results in a gas-tight

connection that is easy to accomplish.

3. Terminate connections per the local electrical requirements.

4. After all of the horns are installed and connected to the appropriate DSP/amplier equipment,

power and test the system.

Amplier power per channel must be higher than total power of all speakers on that channel.

120 Watt Amplier

120 W ≥ 20W + 20W + 20W + 20W + 10W + 10W

Figure 8. Typical amp & loudspeaker tap settings

H10-G/H20-G/H30LT-G Installation and Operation Guide page 5

Page 6

OPTIONAL ACCESSORIES

Conduit Adapter Kit (SPA-HCA100)

The Conduit Adapter attaches to the rear enclosure and provides a

sealed connection for 1/2" NPT conduit use.

1. Thread the cable through the adapter and attach with included

hardware as shown in Figure 10.

2. Fully tighten the adapter hardware as shown in Figure 11.

M3 Lock Washer

M3 Flat Washer

Do not loosen or remove the integrated gland nut.

It must remain in place when using this accessory to

maintain the water-tight wire ingress to the speaker.

M3x10 Screw

Figure 9. Adapter

Figure 10. Attach adapter to horn

Figure 11. Adapter installed

Figure 12. Typical application (with exible

conduit and the SPA-HM B10 0)

page 6 Installation and Operation Guide H10-G/H20-G/H30LT-G

Page 7

OPTIONAL ACCESSORIES CONTINUED

Dual Gang Box Mounting Bracket Kit (SPA-HMB100)

The bracket provides attachment from the horn's U-bracket to a

standard 4-square or dual gang junction box cover (North America

only).

1. Attach the bracket to the horn as shown in Figure 14.

2. Keep connection loose to allow horn rotation.

1/4-20 x 5/8" Screw

1/4" Flat Washer

3/8" Lock Washer

1/4"-20 Lock Nut

Figure 14. Bracket install

Figure 13. Bracket

Figure 15. Secure bracket to yoke

H10-G/H20-G/H30LT-G Installation and Operation Guide page 7

Page 8

OPTIONAL ACCESSORIES CONTINUED

Dual Gang Box Mounting Bracket Kit (SPA-HMB100)

3. Partially install screws (not included) holding the cover on the box as shown in Figure 16.

4. Slide the bracket slot onto the lower screw (a) shown in Figure 17.

5. Rotate and capture the upper bracket keyhole on the top screw (b) in Figure 17.

Figure 16. Loosen screws

Figure 17. Securely attach bracket to the box

page 8 Installation and Operation Guide H10-G/H20-G/H30LT-G

Page 9

OPTIONAL ACCESSORIES CONTINUED

Dual Gang Box Mounting Bracket Kit (SPA-HMB100)

6. Rotate the bracket down to fully capture the screw (circled) in Figure 18.

7. Fully tighten the screws to secure the bracket to the box.

NOTE: Vertically mounted boxes must have the straight bracket slot at the bottom for security/safety.

Figure 18. Bracket installed

Figure 19. Typical placements

H10-G/H20-G/H30LT-G Installation and Operation Guide page 9

Page 10

OPTIONAL ACCESSORIES CONTINUED

BEAM CLAMP KIT (SPA-HBC100

)

This beam clamp has a 125 lb. (56.6 kg) load capacity.

1. Attach clamp to beam or building structure.

2. Beam clamp supports 1/4" threaded rod as shown in Figure

22. (rod and horn mounting hardware not included).

3. One or two clamps may be used to suspend the horn. One

clamp in the center position is shown in Figure 22.

4. Position and secure beam clamp to the beam or support

structure by tightening the bolt.

5. Secure horn bracket to the rod.

6. Aim the horn and secure the angle by tightening the

side bolts.

7. Install the safety cable to a secondary mounting point.

Figure 20. Beam clamp

Figure 21. Beam clamp attached

CONTACT US

Email: support@biamp.com

Web: support.biamp.com

Warranty: biamp.com/legal/warranty-information

A: 9300 S.W. Gemini Drive Beaverton, OR 97008 USA W: www.biamp.com

Figure 22. Rod attachment

Figure 23. Typical assembly

(H20- G shown)

28MAR2023

Loading...

Loading...