Page 1

LCD Television

Service Manual

Chassis: MSD1328

Product: LTDN32k316AM、LTDN42K310WAM

Ver 1.0

Hisense Electric Co.,Ltd.

July,2012

Page 2

Contents

Contents.......................................................................................................................................................................- 2 -

Service Manual ...........................................................................................................................................................- 3 -

1. Precautions and notices.....................................................................................................................................- 3 -

1.1 Warning...................................................................................................................................................- 4 -

1.2 Notes.......................................................................................................................................................- 7 -

2. Product Specifications:...................................................................................................................................- 10 -

2.1Main Board:...........................................................................................................................................- 10 -

2.2 Following products are Chassis MSD1328: .........................................................................................- 11 -

3. Factory/Service OSD Menu and Adjustment..................................................................................................- 12 -

3.1 T o enter the Factory OSD Menu...........................................................................................................- 12 -

3.2 Factory OSD Menu...............................................................................................................................- 12 -

4. Software updating...........................................................................................................................................- 14 -

4.1 Upgrading Mboot software with the ISP-Tool......................................................................................- 14 -

4.2 Upgrading main software with Tftp32、securecrt ...............................................................................- 18 -

4.3 Upgrading with the USB disk...............................................................................................................- 21 -

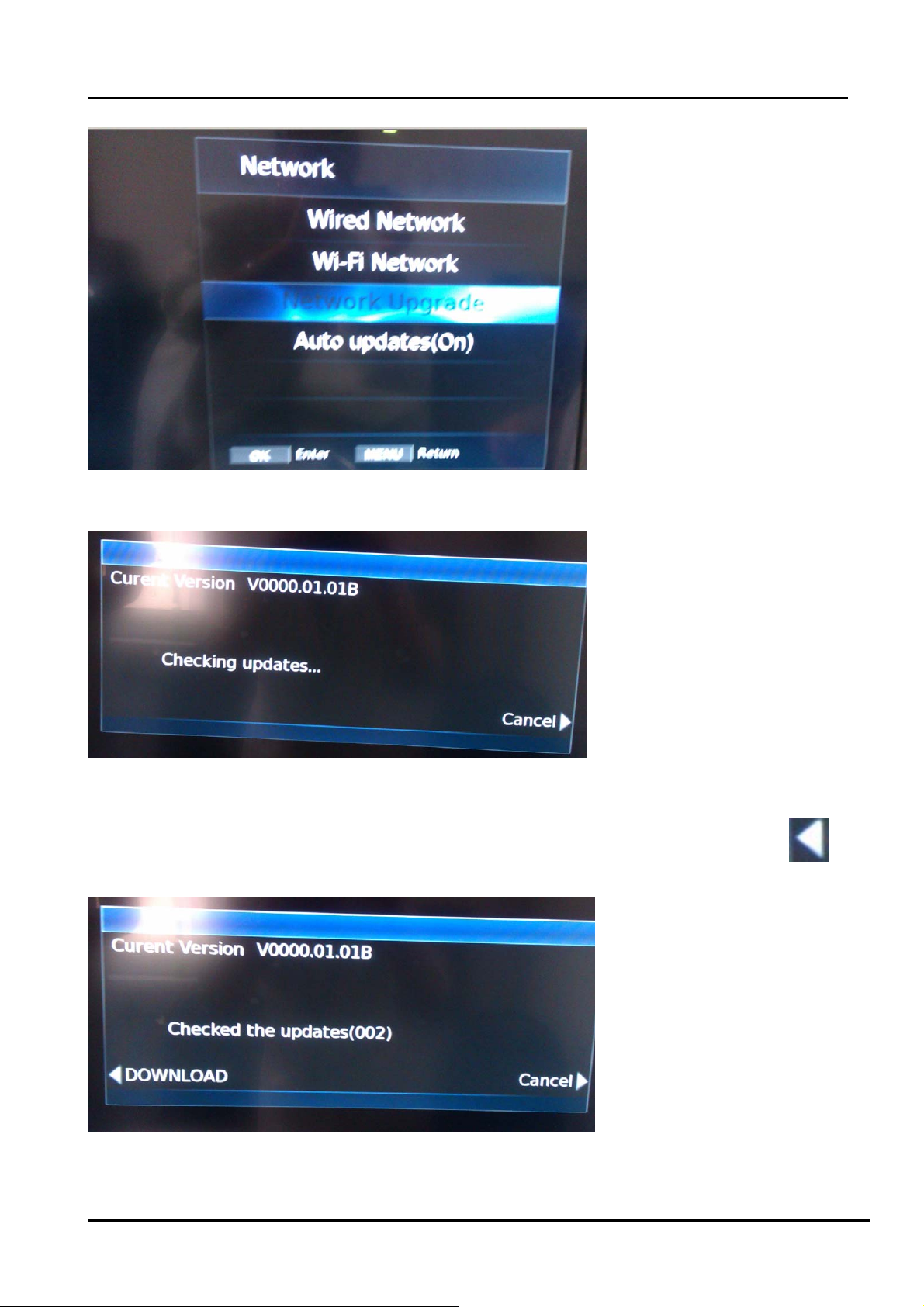

4.4 Network online updating ......................................................................................................................- 22 -

5. Circuit instruction...........................................................................................................................................- 26 -

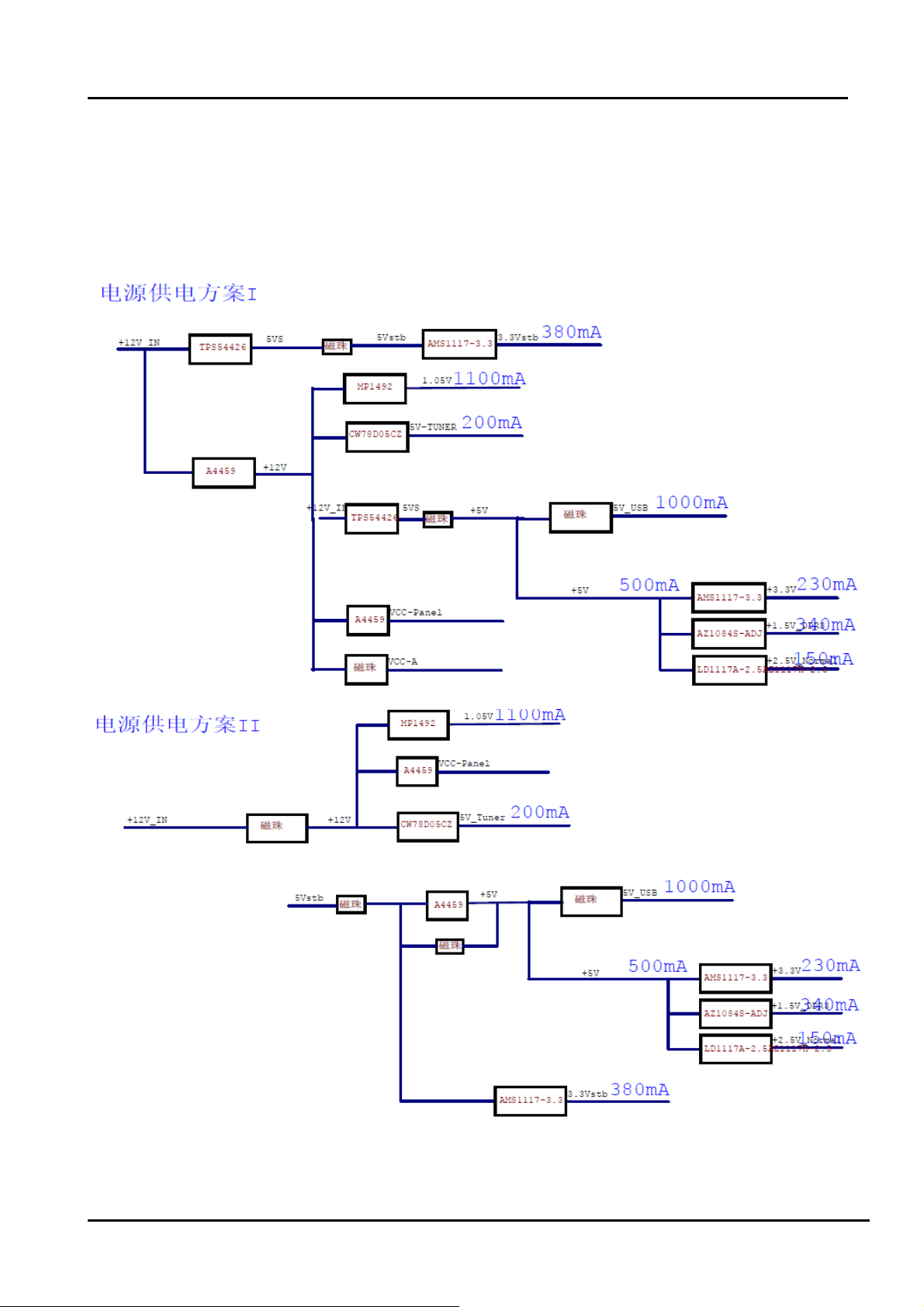

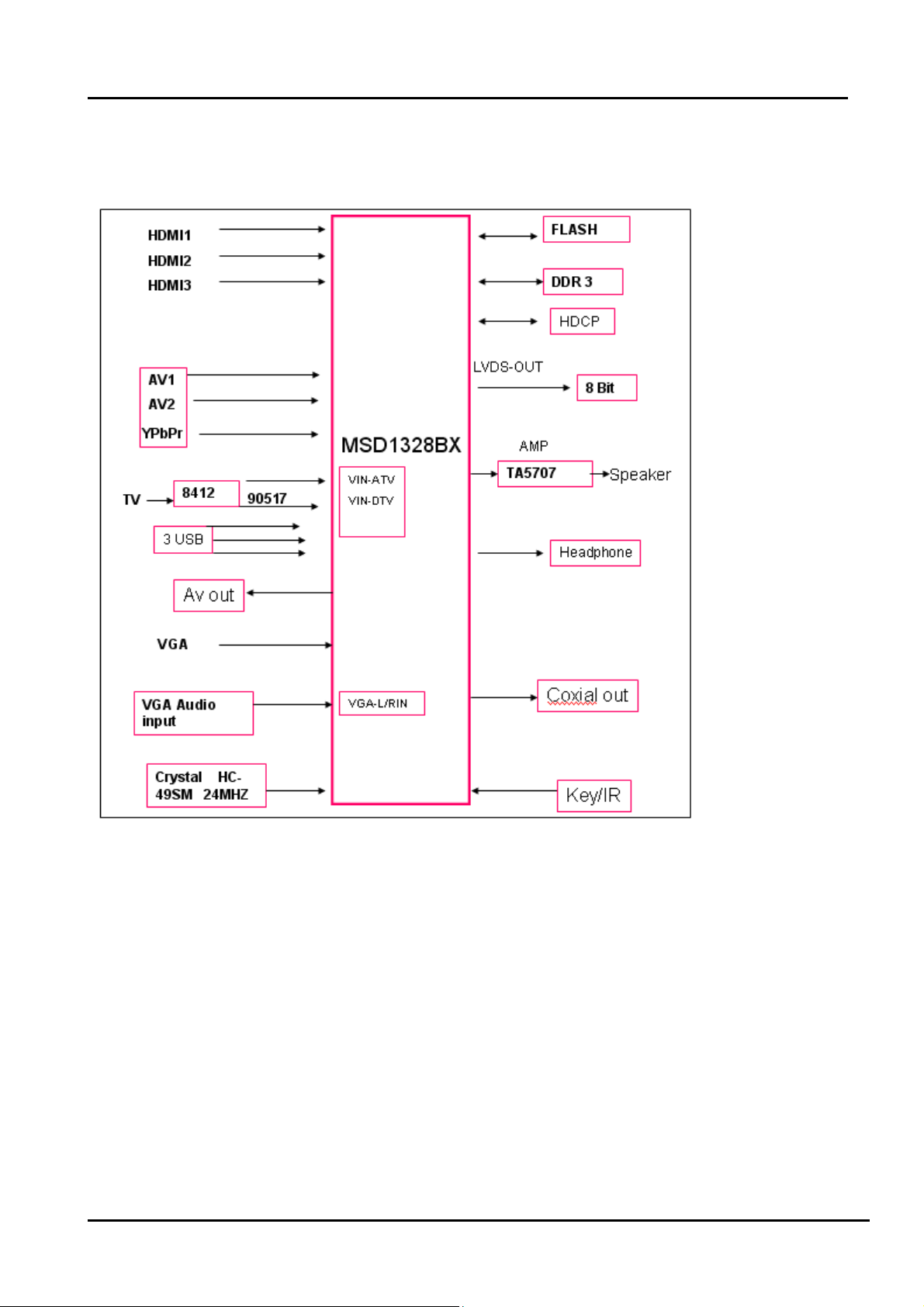

5.1 Power assign and block diagram ..........................................................................................................- 26 -

5.2 Main board signal process....................................................................................................................- 27 -

5.3 Troubleshooting....................................................................................................................................- 28 -

6. Schematic circuit diagram..............................................................................................................................- 35 -

7. Explode View..................................................................................................................................................- 35 -

- 2 -

Page 3

Service Manual

1. Precautions and notices

BEFORE SERVICING THE LCD TV, READ THE SAFETY PRECAUTIONS IN

THIS MANUAL.

WHEN REPLACEMENT PARTS ARE REQUIRED, BE SURE TO USE

REPLACEMENT PARTS SPECIFIED BY THE MANUFACTURER.

Proper service and repair is important to the safe, reliable operation of all Hisense

Electric Co., Ltd Equipment. The service procedures recommended by Hisense and

described in this Service Guide are effective methods of performing service operations.

Some of these service operations require the use of tools specially designed for the

purpose. The special tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES

which should be carefully read in order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service methods may damage the

equipment. It is also important to understand that these CAUTIONS and NOTICES ARE

NOT EXHAUSTIVE. Hisense could not possibly know, evaluate and advise the service

trade of all conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, Hisense has not undertaken any

such broad evaluation. Accordingly, a serviceman that uses a service procedure or tools,

- 3 -

Page 4

which are not recommended by Hisense, must first satisfy himself thoroughly that

neither his safety nor the safe of the equipment will be jeopardized by the service

method selected.

Hereafter throughout this manual, Hisense Electric Co., Ltd will be referred to as

Hisense.

1.1 Warning

1.1.1

Critical components having special safety characteristics are identified with a by the

Ref. No. in the parts list. Use of substitute replacement parts, which do not have the

same specified safety characteristics, may create shock, fire, or other hazards.

Under no circumstances should the original design be modified or altered without

written permission from Hisense. Hisense assumes no liability, express or implied,

arising out of any unauthorized modification of design. Serviceman assumes all liability.

DANGER CAUTION

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY

ORIGINAL MANUFACTURER'S REPLACEMENT PARTS, WHICH ARE LISTED WITH

THEIR PART NUMBERS IN THE PARTS LIST SECTION OF THIS SERVICE GUIDE.

1.1.2.

All ICs and many other semiconductors are susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life drastically. When repairing, make sure

- 4 -

Page 5

that you are connected with the same potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this same potential.

1. Never replace modules or other components while the unit is switched on.

2. When making settings, use plastic rather than metal tools. This will prevent any

short circuits and the danger of a circuit becoming unstable.

1.1.3

To prevent electrical shock, do not use this polarized ac plug with an extension cord,

receptacle, or the outlet unless the blades can be fully inserted to prevent blade exposure.

To prevent electrical shock, match wide blade or plug to wide slot, fully insert.

1.1.4

When replacement parts are required, be sure to use replacement parts specified by the

manufacturer or have the same characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock, or other hazards.

1.1.5

Safety regulations require that after a repair the set must be returned in its original

condition. In particular attention should be paid to the following points.

-Note: The wire trees should be routed correctly and fixed with the mounted cable

clamps.

-The insulation of the mains lead should be checked for external damage.

1.1.6

(1) Do not touch Signal and Power Connector while this product operates. Do not

- 5 -

Page 6

touch EMI ground part and Heat Sink of Film Filter.

(2) Do not supply a voltage higher than that specified to this product. This may damage

the product and may cause a fire.

(3) Do not use this product in locations where the humidity is extremely high, where it

may be splashed with water, or where flammable materials surround it. Do not install

or use the product in a location that does no satisfy the specified environmental

conditions. This may damage the product and may cause a fire.

(4) If a foreign substance (such as water, metal, or liquid) gets inside the panel module,

immediately turn off the power. Continuing to use the product may cause fire or

electric shock.

(5) If the product emits smoke, and abnormal smell, or makes an abnormal sound,

immediately turn off the power. Continuing to use the product, it may cause fire or

electric shock.

(6) Do not disconnect or connect the connector while power to the product is on. It

takes some time for the voltage to drop to a sufficiently low level after the power has

been turned off. Confirm that the voltage has dropped to a safe level before

disconnecting or connecting the connector.

(7) Do not pull out or insert the power cable from/to an outlet with wet hands. It may

cause electric shock.

(8) Do not damage or modify the power cable. It may cause fire or electric shock.

(9) If the power cable is damaged, or if the connector is loose, do not use the product:

- 6 -

Page 7

otherwise, this can lead to fire or electric shock.

(10) If the power connector or the connector of the power cable becomes dirty or dusty,

wipe it with a dry cloth. Otherwise, this can lead to fire.

(11) Use only with the cart, stand, tripod, bracket, or table specified by the

manufacturer, or sold with the apparatus. When a cart is used, use caution when

moving the cart/apparatus combination to avoid injury from tip-over.

1.2 Notes

Notes on Safe Handling of the LCD panel and during service

The work procedures shown with the Note indication are important for ensuring the

safety of the product and the servicing work. Be sure to follow these instructions.

• Before starting the work, secure a sufficient working space.

• At all times other than when adjusting and checking the product, be sure to turn OFF

the POWER Button and disconnect the power cable from the power source of the TV

during servicing.

• To prevent electric shock and breakage of PC board, start the servicing work at least 30

seconds after the main power has been turned off. Especially when installing and

removing the power board, start servicing at least 2 minutes after the main power has

been turned off.

• While the main power is on, do not touch any parts or circuits other than the ones

specified. If any connection other than the one specified is made between the measuring

- 7 -

Page 8

equipment and the high voltage power supply block, it can result in electric shock or

activation of the leakage-detection circuit breaker.

• When installing the LCD module in, and removing it from the packing carton, be sure

to have at least two persons perform the work.

• When the surface of the panel comes into contact with the cushioning materials, be

sure to confirm that there is no foreign matter on top of the cushioning materials before

the surface of the panel comes into contact with the cushioning materials. Failure to

observe this precaution may result in, the surface of the panel being scratched by foreign

matter.

• When handling the circuit board, be sure to remove static electricity from your body

before handling the circuit board.

• Be sure to handle the circuit board by holding the large parts as the heat sink or

transformer. Failure to observe this precaution may result in the occurrence of an

abnormality in the soldered areas.

• Do not stack the circuit boards. Failure to observe this precaution may result in

problems resulting from scratches on the parts, the deformation of parts, and

short-circuits due to residual electric charge.

• Routing of the wires and fixing them in position must be done in accordance with the

original routing and fixing configuration when servicing is completed. All the wires are

routed far away from the areas that become hot (such as the heat sink). These wires are

fixed in position with the wire clamps so that the wires do not move, thereby ensuring

- 8 -

Page 9

that they are not damaged and their materials do not deteriorate over long periods of time.

Therefore, route the cables and fix the cables to the original position and states using the

wire clamps.

• Perform a safety check when servicing is completed. Verify that the peripherals of the

serviced points have not undergone any deterioration during servicing. Also verify that

the screws, parts and cables removed for servicing purposes have all been returned to

their proper locations in accordance with the original setup.

The lightning flash with arrowhead symbol, within an equilateral

triangle is intended to alert the user to the presence of uninsulated

dangerous voltage within the products enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

The exclamation point within an equilateral triangle is intended to alert

the user to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the set.

- 9 -

Page 10

2. Product Specifications:

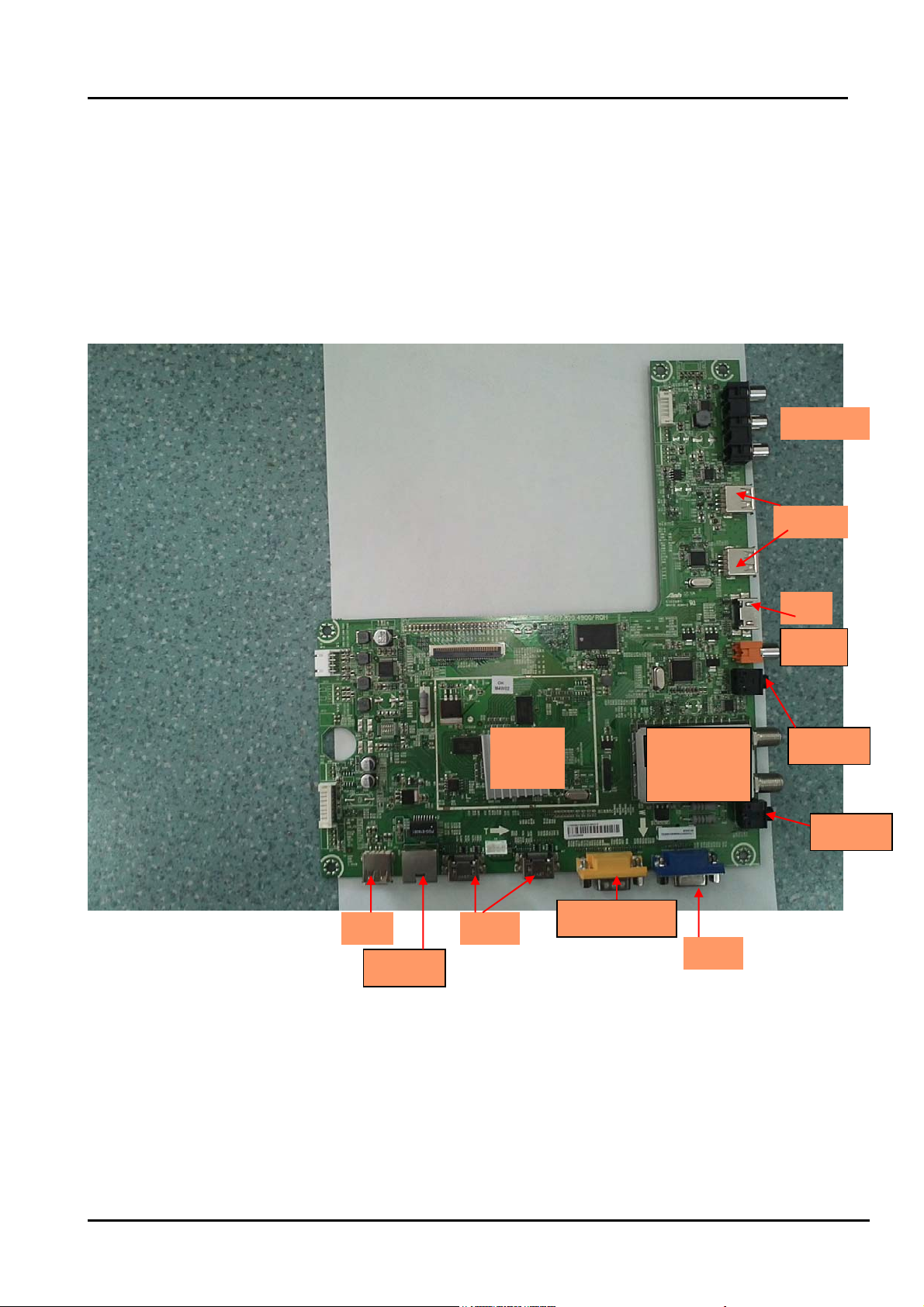

2.1Main Board:

Take LTDN32k316AMmain board(4900)for example:

Top

AV OTU

HDMI

USB

Coaxial

IC

MSD1328

Tuner

Cable Air

Earphone

PC Audio

USB HDMI

Ethernet

Comp/AV1/AV2

VGA

- 10 -

Page 11

Bottom:

Note:

Above “Main board image”is only for LTDN32k316AM, other products please look for the actual

units to determine the boards.

2.2 Following products are Chassis MSD1328:

Model Panel Mode LVDS(Main-Panel)

LTDN32k316AM HE315FH-E58\PW1\ROH FFC-30-367\ROH

LTDN42K310WAM

HE420FF-B57(1000)\ROH HX2-2x22KLB450P-CMO\ROH

- 11 -

Page 12

3. Factory/Service OSD Menu and Adjustment

3.1 To enter the Factory OSD Menu

a. With factory RC (remote control)

1. Press “M” button and enter factory mode.(Note1)

2. Press “Menu” button and enter factory OSD menu.

3. Press “CH+”/“CH-” button select the function menu, press “VOL+”/“VOL-” enter the selected

function menu. Press “VOL+”/“VOL-” button adjust values in the menu.

4. Press “M” button exit factory mode in the factory OSD menu.

When TV outgoing factory, user can not enter factory OSD menu with Factory Remote

Note:

1. In the “Factory Menu”, item “Function”->”TOFAC” ,you can select “M” or “U”, default is “U”.

----M-Means you can enter factory mode with factory RC or user RC.

----U-Means you can enter factory mode only with user’s RC.

2. Mode “M” is only used for factory production.

b. With user’s RC

Power on the TV.

1. Press “Menu” button and call up User OSD Menu.

2. Select “ Sound” -> “Balance” item.

3. Press number key 1->9->6 ->9 in sequence when “Balance” item is focused.

Note: If necessary, re-do number keys.

4. Factory OSD appears.

Note: Press the standby button then AC turn off and restart the TV, which can exit factory OSD menu.

3.2 Factory OSD Menu

The Factory OSD Menu comprises Factory Menu and Design Menu .

3.2.1、Factory Menu

- 12 -

Page 13

Factory Menu

White Balance

Auto Calibration

Option

Init

Test Pattern

Version

White Balance

R-DRV:

G- DRV:

B- DRV

R-CUT:

G- CUT:

B- CUT:

Color Temp: Medium

Panel Set : B1

Option

TO FAC : M or U

LOGO: Hisense

OSD language: English

Power Mode Memory

Set MAC_ADDR

PVR_RecordALL Off

HDCP EEP

Uart enable On

WDT On

C1 Key Null

3.2.2、Design Menu

Design Menu

Picture Mode

Audio Mode

Picture Curve

Audio Curve

SSC Adjust

Saving Mode

Overscan

Not Stand

Note:

The above “Factory/Service OSD Menus” are re ference on ly, please ref er to t he ac tual unit

to determine the appearances.

- 13 -

Page 14

4. Software updating

Software Upgrading includes MBoot and main software. Usually first update MBoot then main

software. With ISP_Tools、Tftp and SecureCRT upgrading Tools.

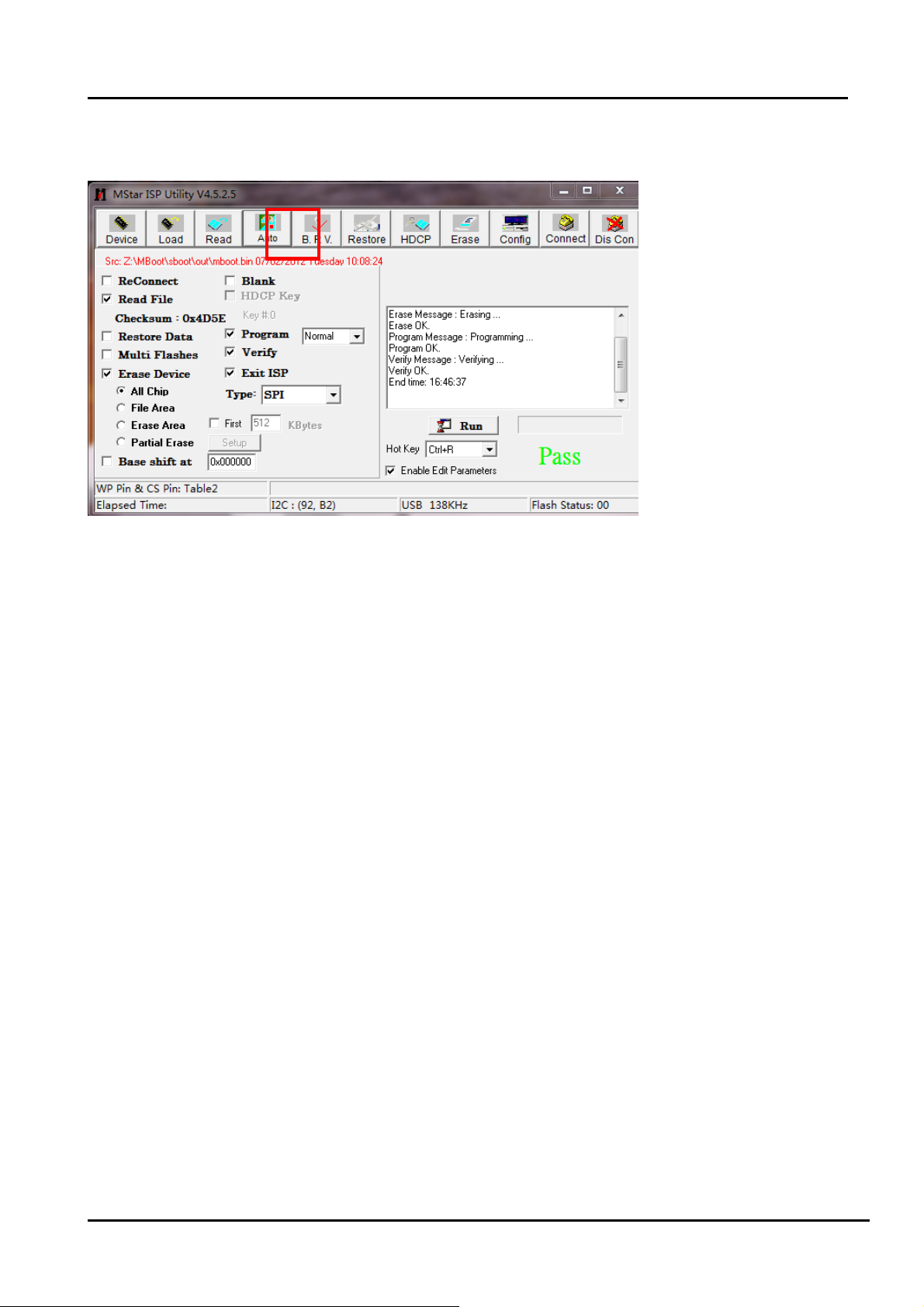

4.1 Upgrading Mboot software with the ISP-Tool

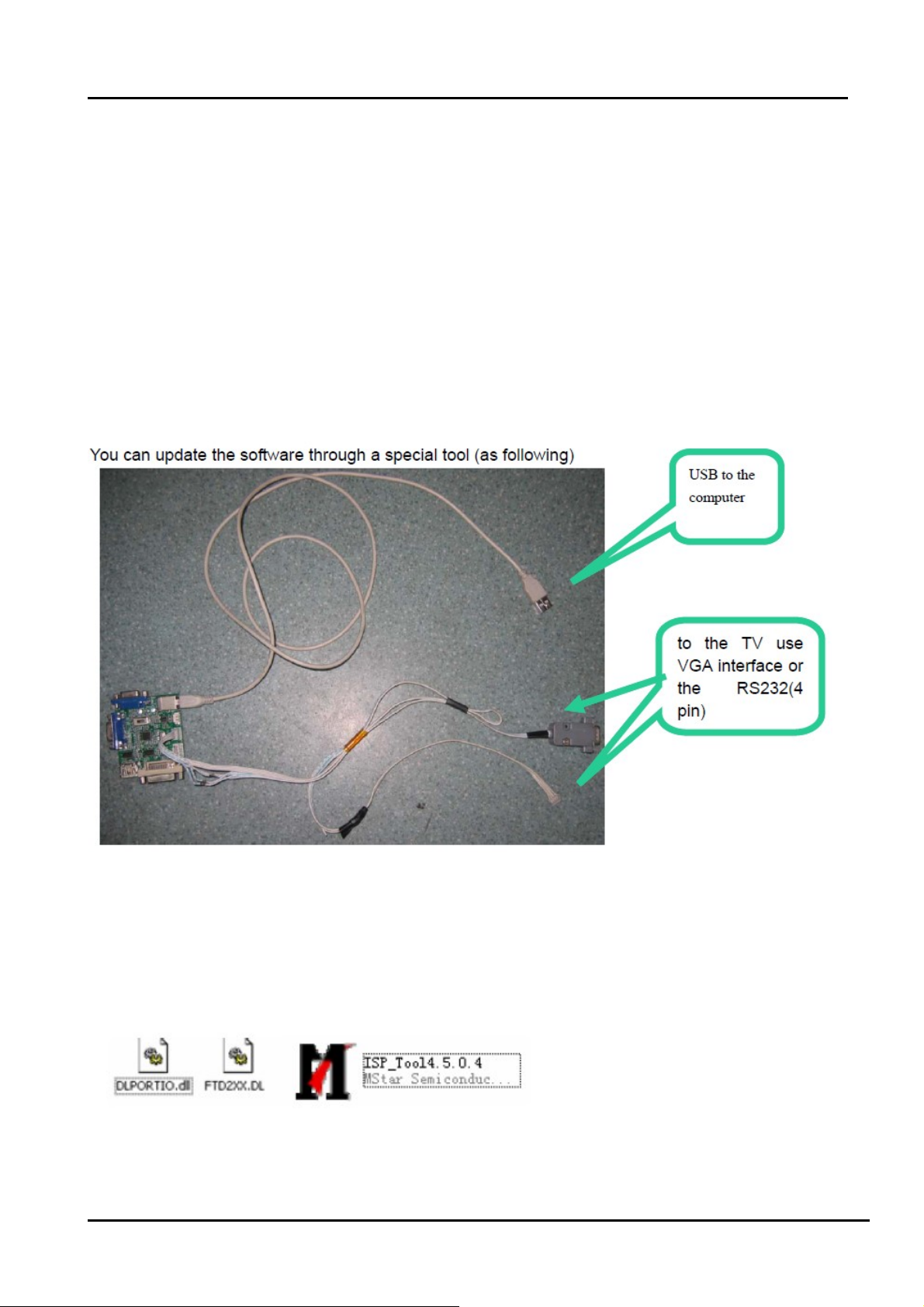

4.1.1 Hardware connecting

You can update the software through a special tool (as following)

Connect the Debug board to the TV use the RS232 (4 pin), the other USB port to the PC.

4.1.2 Install the ISP_TOOL4.5.0.4-------only for the first time update.

1、The software is upgraded by a burning tool- ISP_TOOL.exe

2、Find the folder where the ISP_TOOL4.5.0.4 lies in.

There are three folders/files in this folder together.

DLPORTIO.dll and FTD2XX.DLL must be in the same folder

- 14 -

Page 15

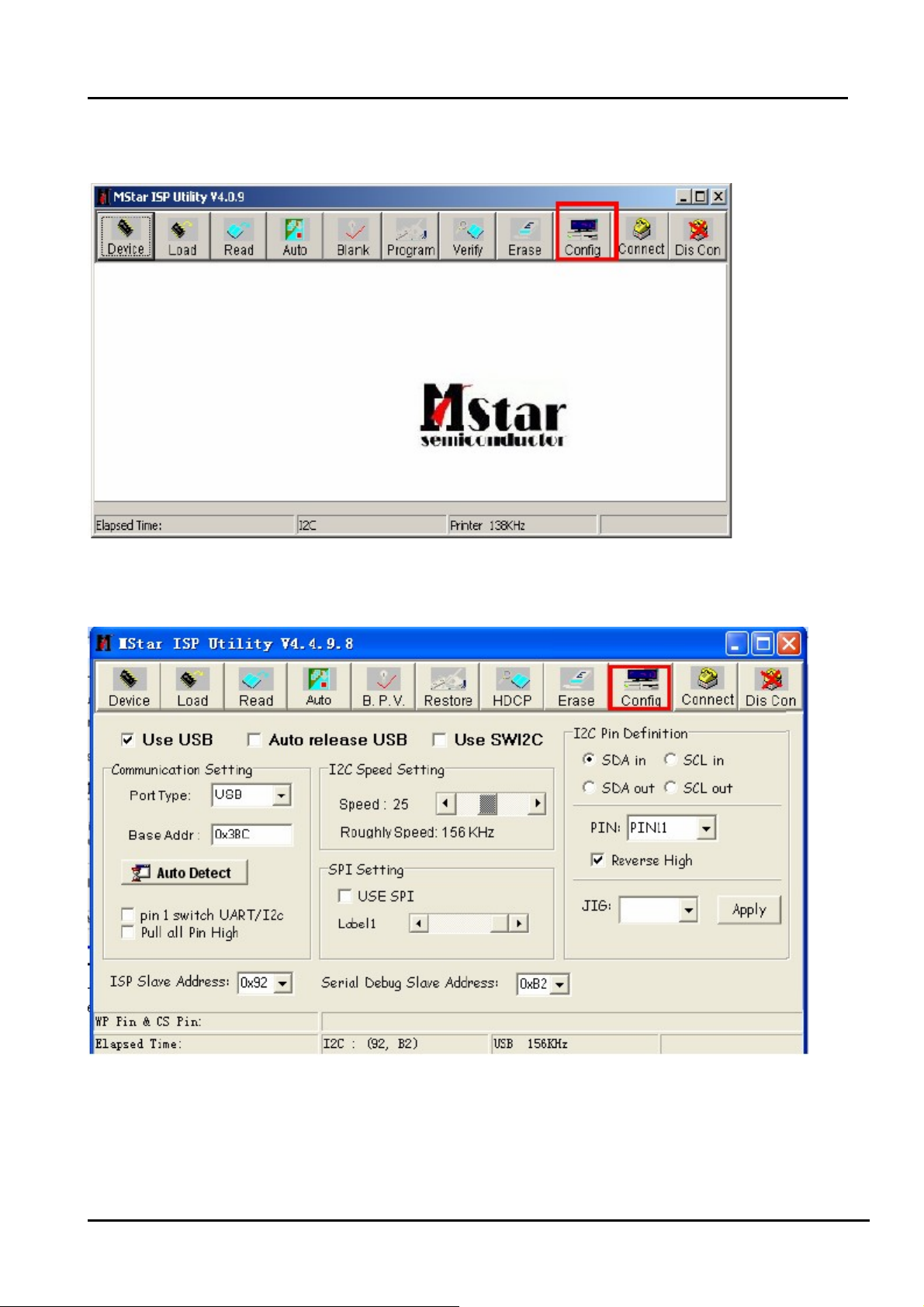

3、Double click the ISP_TOOL4.5.0.4 icon, and then a dialog window will show as below.

4、Click the” Config “button. And then a dialog window will show as below.

Draw on the front of “Use USB”

Port Type setting is USB

Base Addr setting is 0x38C

ISP Slave Address choose 0x92

Serial Debug Slave Address choose 0xB2,

- 15 -

Page 16

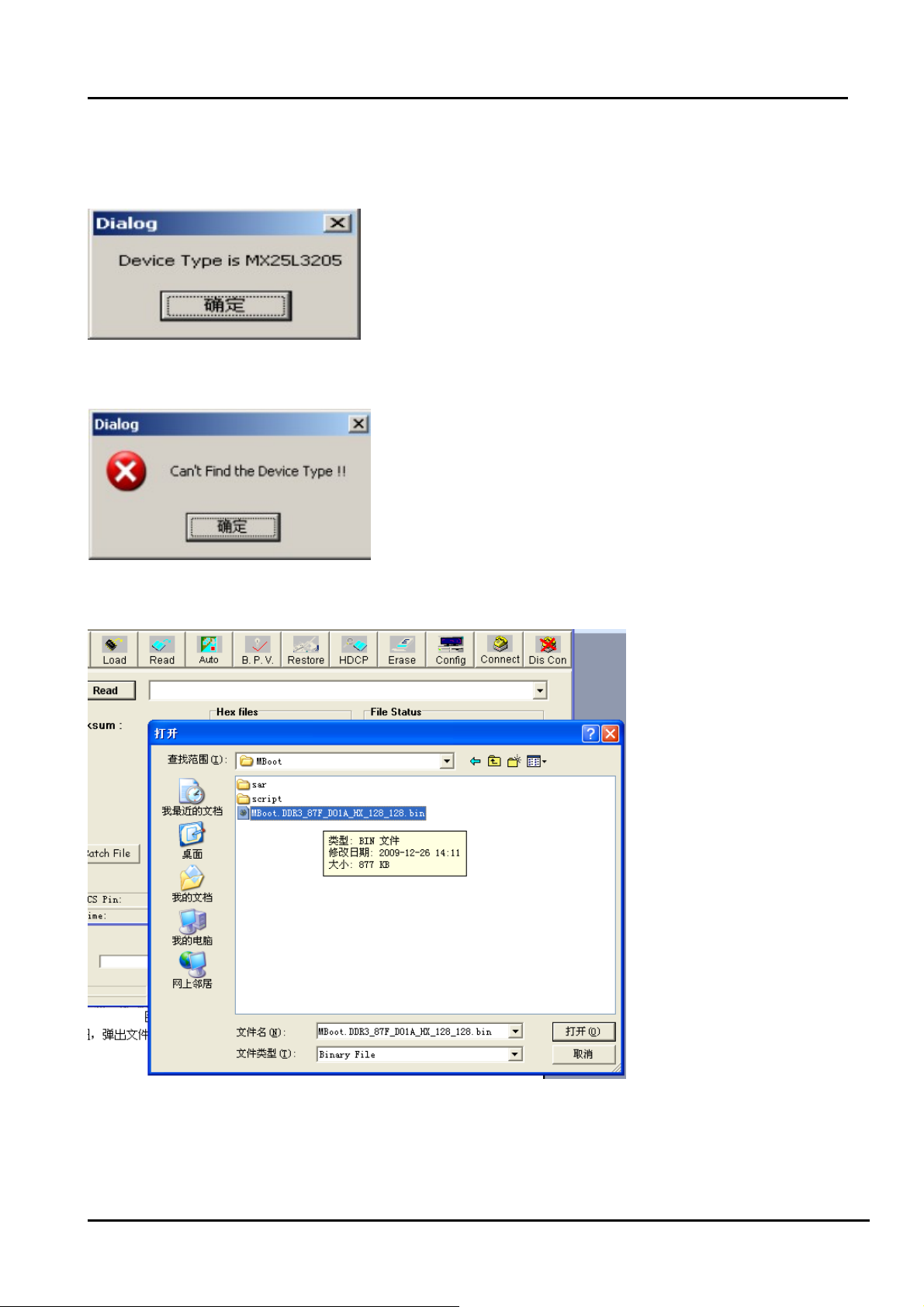

5、Click the “Connect”button,if appear the following figure, It indicates that the ISP_TOOL has

connected.(According to the tv set,”Device Type” maybe different.)

If appear the following figure,It indicates that the ISP_TOOL has not connected. Please click

the“DisCon”button and “Connect”button to connect..

6、Click the“Read ”button,Choose the correct update file。

- 16 -

Page 17

7、After the update file has been chosen successfully。

Click the“Auto”button and choose parameters as following。

8、Click the “Run” button and wait update end.

If show any error message ,then do “Dis Con” >> “Connect”,and click the “Run” button

again,till show the following dialog window.

- 17 -

Page 18

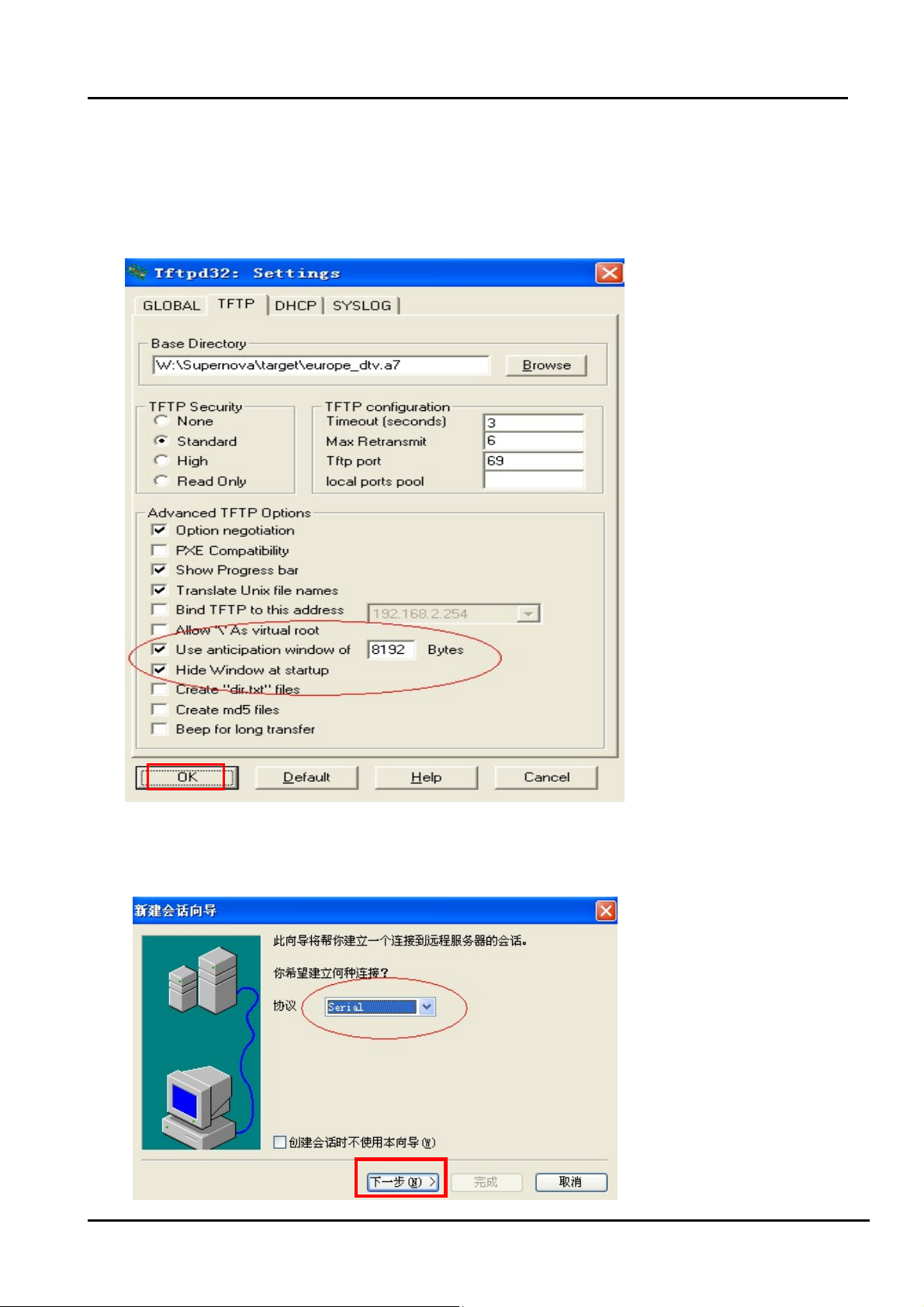

4.2 Upgrading main software with Tftp32、securecrt

a) Run Tftpd32.exe. Browse the Base Directory file “*_dtv.a7”

Settings as following, late click “OK”.

b) Run Securecrt.exe to set up a serical seccion.

Select FileConnectNew seccion

- 18 -

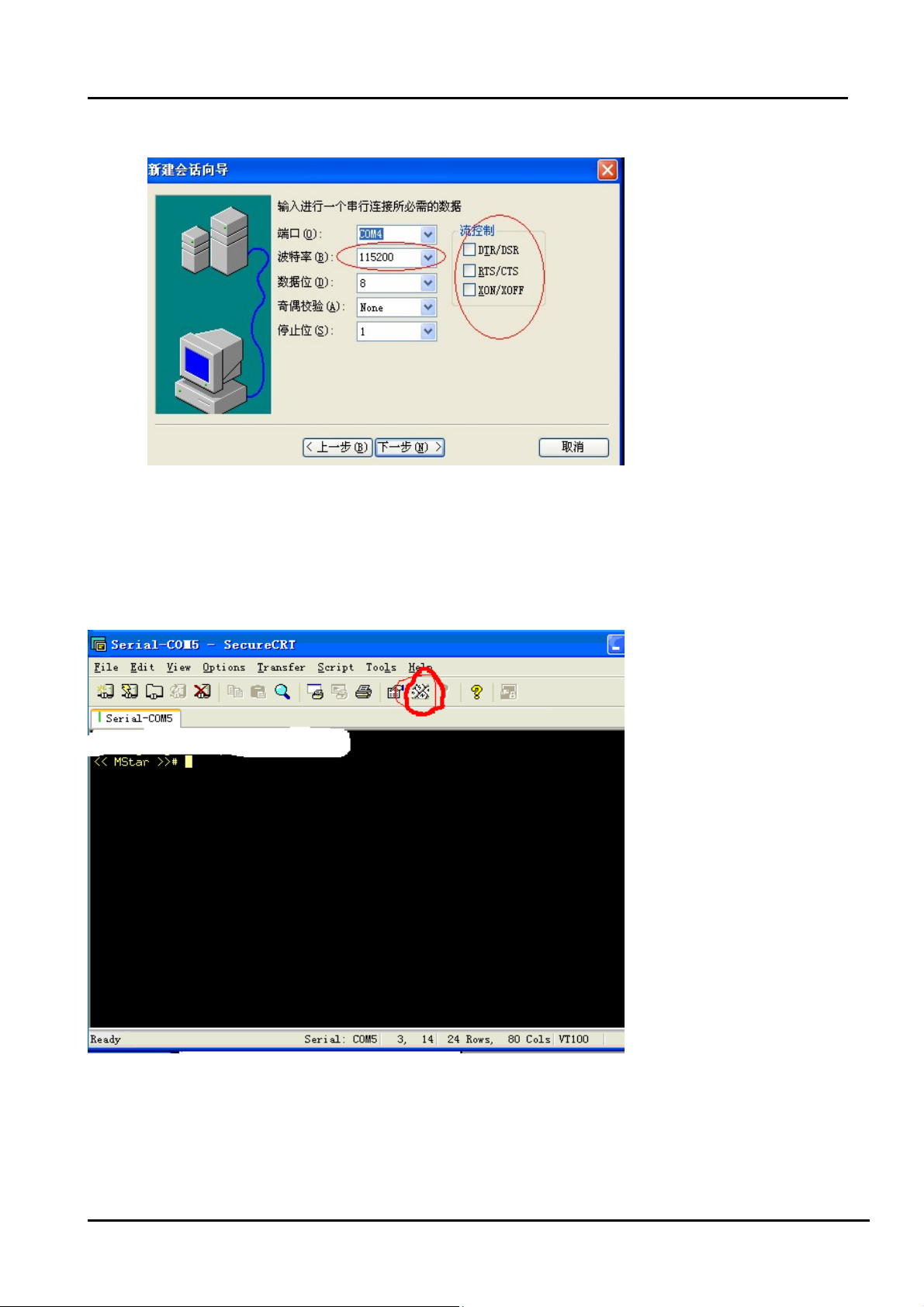

Page 19

AC power off the TV, this time the mouse must lies on the Securecrt interface. then AC

power on the TV, at the same time press “enter” key. you will see“<<mstar>>#”on the

Securecrt interface.

(the following image).

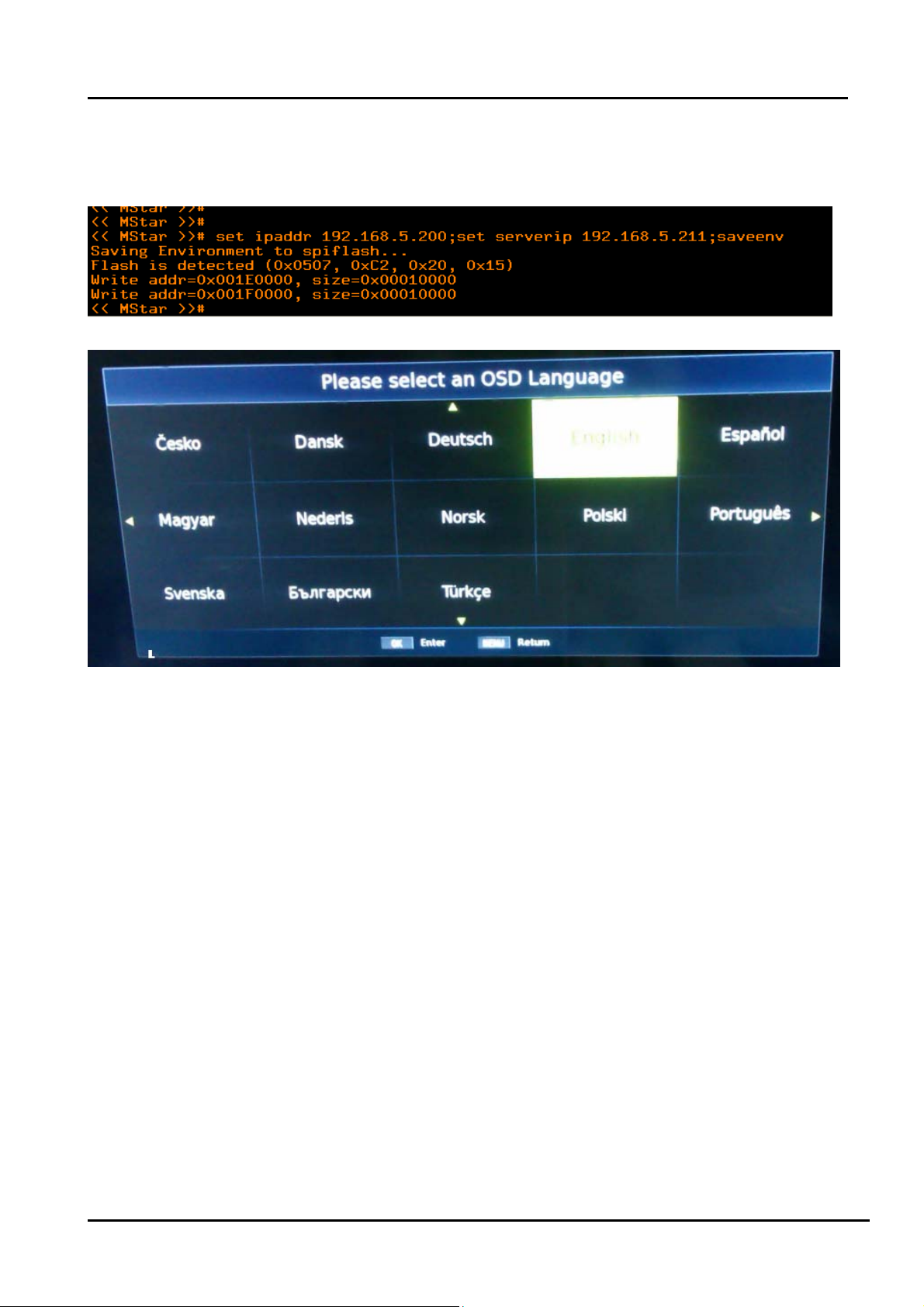

Next input : set ipaddr 192.168.5.200;set serverip 192.168.5.211;saveenv ,then press

- 19 -

Page 20

“enter” key. late input: “mstar mscript/auto_update.txt”to update (the following

image).note1

After software update has finished, the TV OSD appears following.

Note:

1) Serverip “192.168.5.211”is PC LAN IP address. When update the main software,you

must replace you PC IP address with 192.168.5.211,and net mask with 255.255.255.0 .

- 20 -

Page 21

4.3 Upgrading with the USB disk

4.3.1 TV in normal state

1. Copy the “USBUpgrade.bin” file that MBoot and main software named to the root directory of

two USB disks respectively.

2. Insert the USB disk into the USB slot of the TV SET.

3. Press “Menu” button of remote control and call up User OSD Menu, choose " OPTION

"->”Software Update(USB)” item.

- 21 -

Page 22

4. Press “OK”, it will show a confirm message box, Press [◀] button to select “yes” in the

confirm message box, TV will restart and start automatic update.

5. Then it will update the software automatically, Please don’t power off during the updating

process.

6. After update succeeds, TV SET will restart automatically.

7. First update the MBoot software, second update the main software. In order to convenience,

prepare two USB disks to save different software respectively.

4.3.2 TV in abnormal state

If the method of 4.3.1 can not update successfully or TV can not power on normally . You will

adopt the force update method. Insert the USB disk with USBUpgrade.bin into the USB slot of

the TV. AC power on the TV , at the moment ,press the” menu “key of TV keypad. Longer about

5 seconds. Then the TV will automatically update. If defeat, try again.

Note:

After updating, you must confirm the software version in the “Factory Menu” and you'd better

do a " UnProtected Clear" in the “Factory Menu”.

4.4 Network online updating

First, correctly connect network. Open the network setting image. “MENU””OPTION”

Second, Press right or OK key to enter the subpage of network settings menu. And select

“Network Upgrade” item and then press “OK” key to download the new firmware.

- 22 -

Page 23

Third, Checking if there is new firmware..

If there is new firmware on our server, you will see the dialog below and press arrow to

continue firmware download..Note2

- 23 -

Page 24

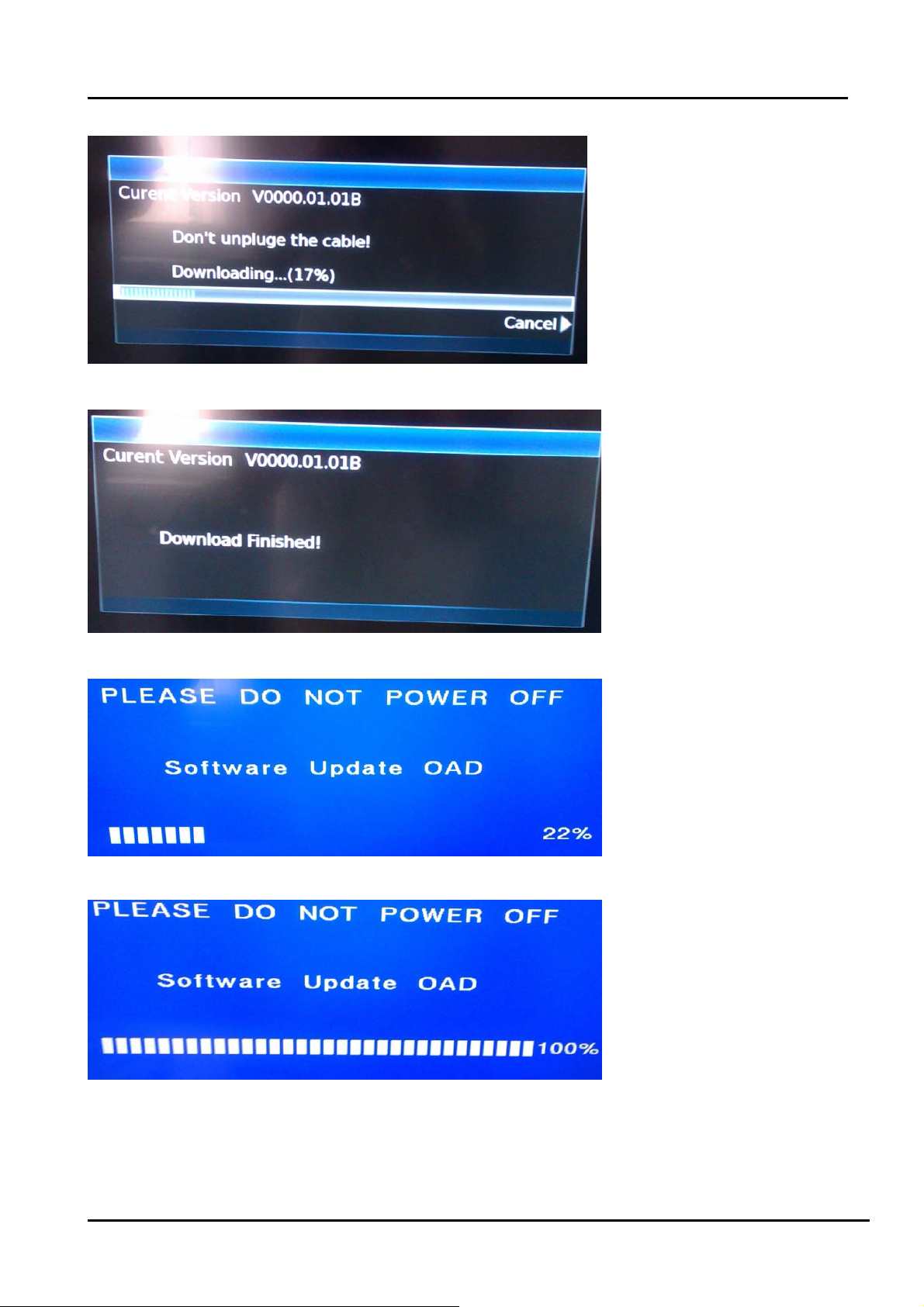

Next

This time download has finished, next to automatically update the firmware.

Note:

1) It will take sometimes to complete the upgrade. The time depend on your network speed.

- 24 -

Page 25

Don’t Turn off TV during upgrading.

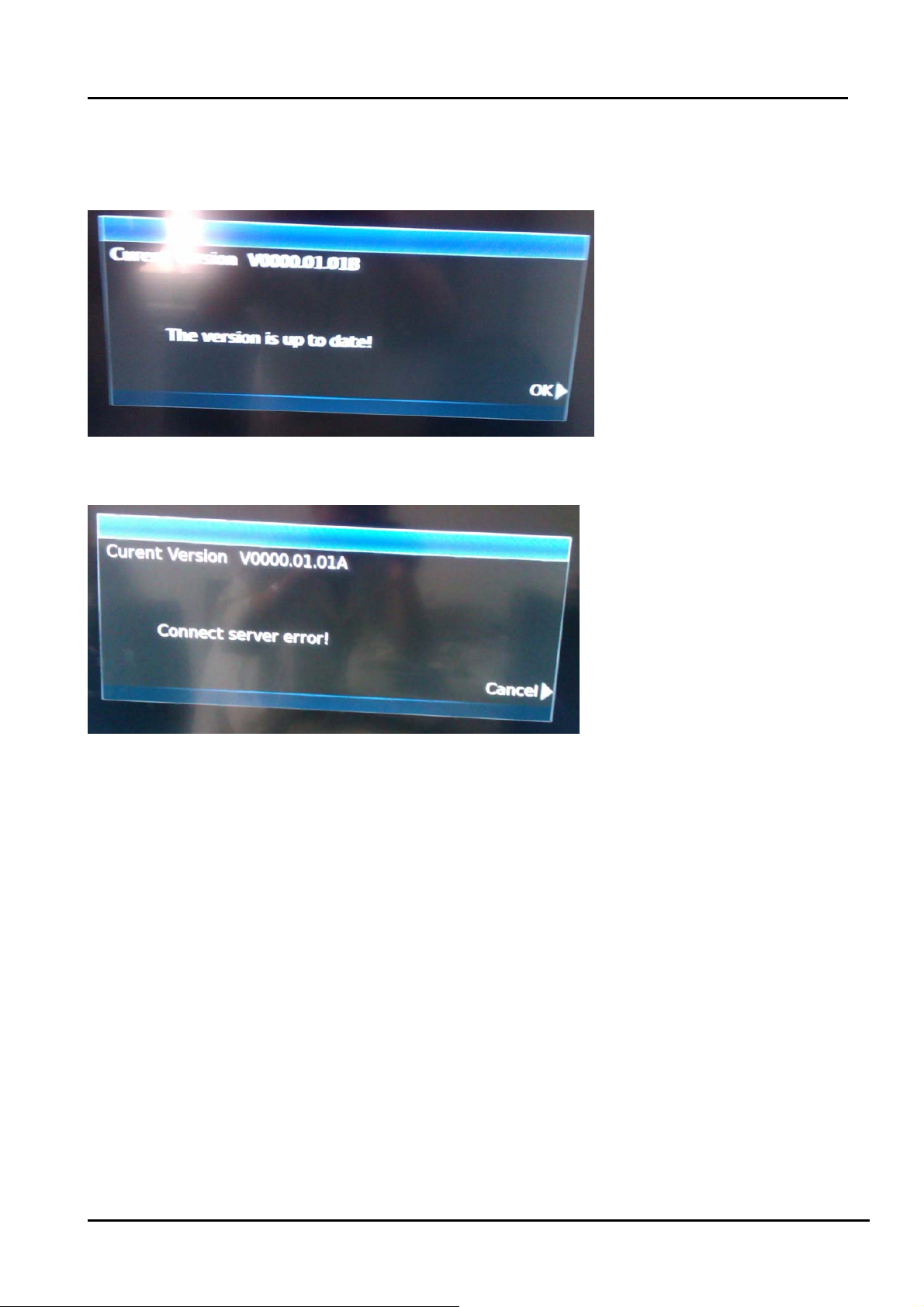

2) If there is no new firmware on our server, see the dialog below.

3) If there is no network or not correctly connected it. See the below dialog below.

- 25 -

Page 26

5. Circuit instruction

5.1 Power assign and block diagram

- 26 -

Page 27

5.2 Main board signal process

- 27 -

Page 28

5.3 Troubleshooting

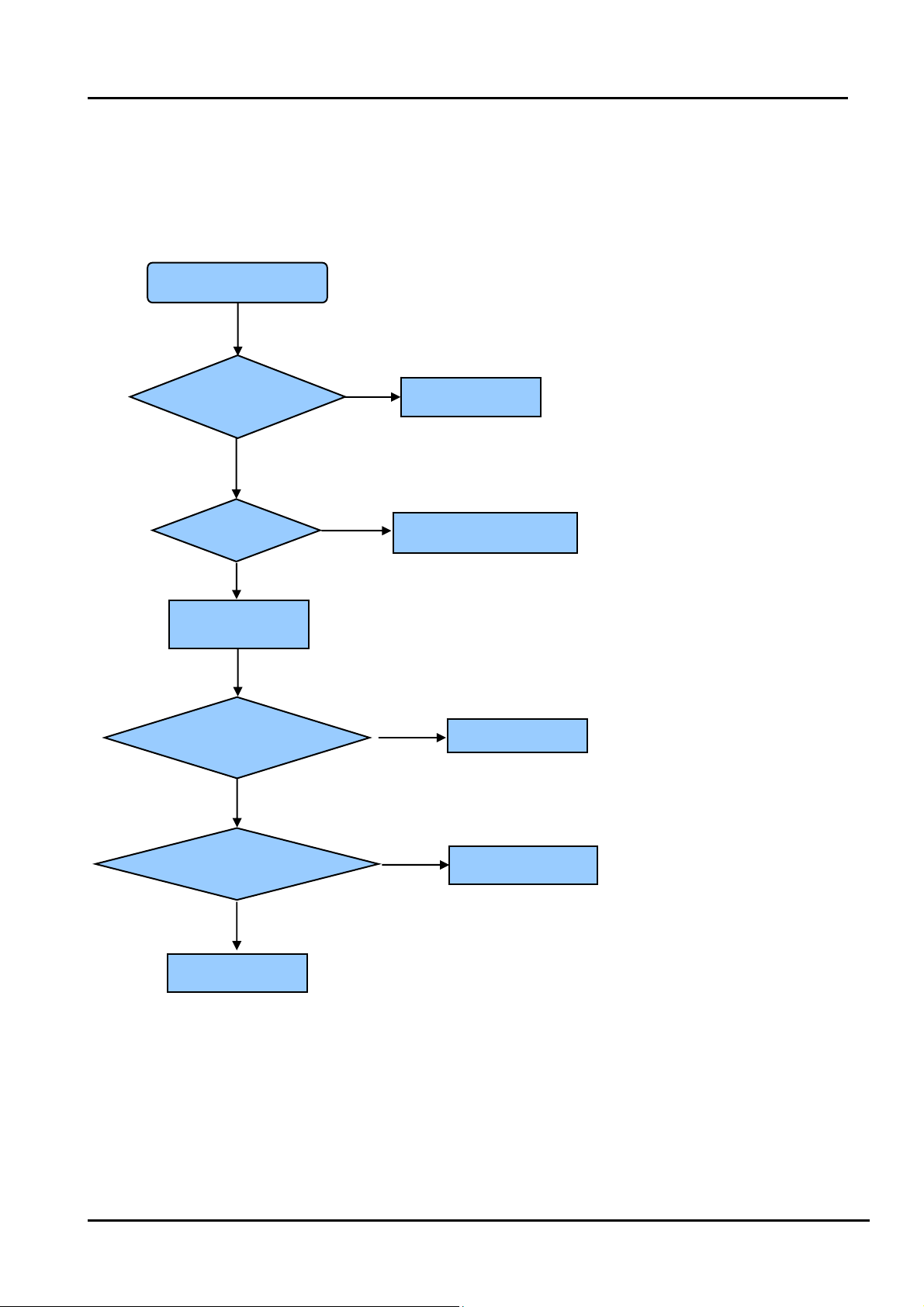

5.3.1 Troubleshooting for Remote Control

Remote control does not work

Try new batteries

NO

Replace RC

Check IR receiver

YES

YES

Replace battery

Replace remote control

Change Led & IR board

NO

Change Led & IR cable

NO

Replace main board

YES

Replace Led & IR BD

YES

Replace Led & IR cable

- 28 -

Page 29

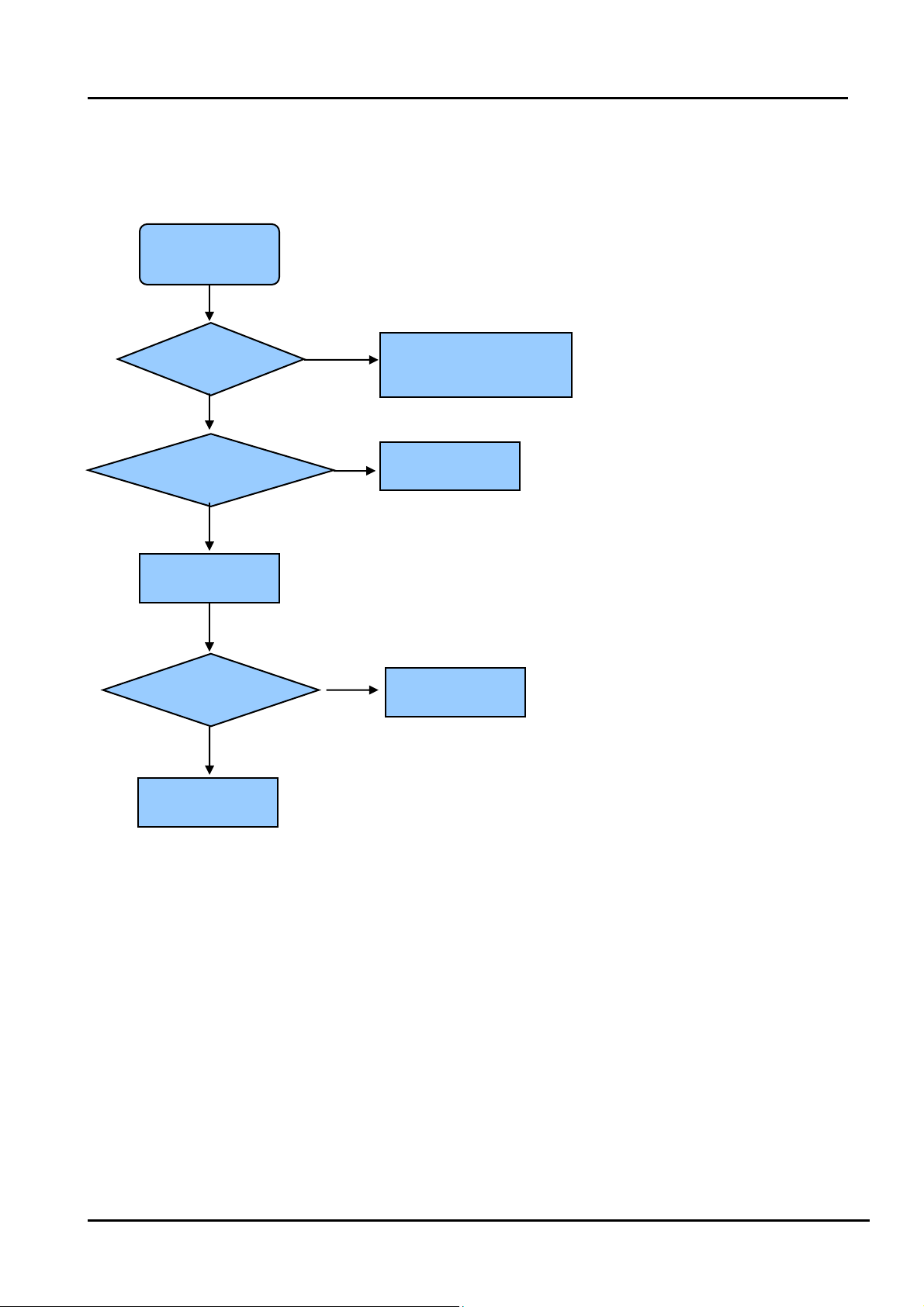

5.3.2 Troubleshooting for Function Key

Buttons does not work

Check switches

YES

Check solder connections and

see if any switches are stuck.

NO

Check key board

NO

Check Key BD cable

YES

Replace Key BD

YES

Change Key BD

OK

NO

Replace main board

- 29 -

Page 30

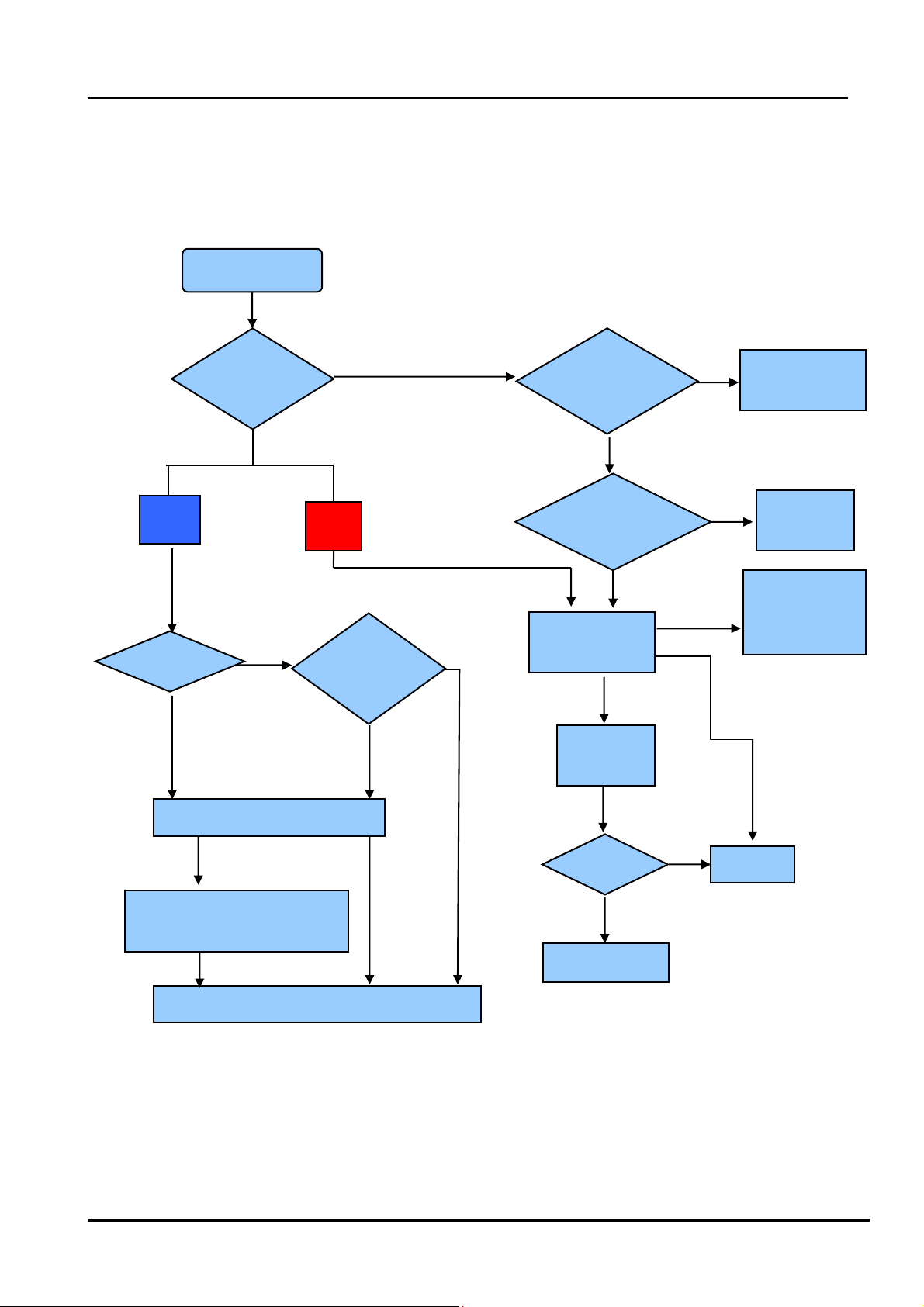

5.3.3 TV won’t Power On

TV won’t power on

Is LED

light?

NO

Check Power

Output

YES

Make Sure Power

source is live

YES

NO

BLUE

RED

Panel Bright

NO

YES

Check signal

Source

YES

NO

Check Power

Cord

NO

Try Power on by

RC and Button

Neither

works

Replace Main

BD

YES

Only

one works

Both

Work

Replace

Power Cord

Check/replace IR

BD or Keypad

PCA

NO

(to contact Hisense tech support.)

Replace Main BD

Replace Panel

OK

YES

Power on

NO

Replace Power BD

YES

OK

- 30 -

Page 31

5.3.4 Troubleshooting for Audio

No sound

Check connecter

YES

Reconnect

NO

Check speaker wire

NO

Check speaker set

YES

YES

Replace speaker wire

Replace speaker set

NO

Replace main board

NO

YES

OK

Power Supply Board

- 31 -

Page 32

5.3.5 Troubleshooting for TV/VGA/HDMI input

No picture on the screen

NO

Check Signal Source

Make sure signal

source is available

YES

Check connect

NO

YES

Check cab l e

NO

Replace main board

Reconnect

Replace cable

- 32 -

Page 33

5.3.6 Troubleshooting for YPbPr input

No picture on the screen

Check Source work or not

YES

Check connect

NO

Check Wires (Green Blue, Red)

NO

Replace main board

NO

YES

YES

Check Source Device

Reconnect

Replace wires

- 33 -

Page 34

5.3.7 Troubleshooting for Video input

No picture on the screen

Check Source work or not

YES

Check connect

NO

Check Cable/ Wires

NO

Replace main board

NO

YES

YES

Check Signal Source

Reconnect

Replace Cable/Wires

- 34 -

Page 35

6. Schematic circuit diagram

7. Explode View

- 35 -

Page 36

5

LTDN32k316AM<DN42K310WAM main board:4900

4

3

2

1

TO Inverter Board

100n/16V/NCC5100n/16V/NC

R443 0R/NCR443 0R/NC

R409

R409

10k/NC

10k/NC

C34

C34

100n/16V

100n/16V

N11

N11

3

2

C43

C43

100n/16V

100n/16V

LD1117A-3.3AZ1117H-3.3/NC

LD1117A-3.3AZ1117H-3.3/NC

AP1084D33GAZ1084D-3.3

AP1084D33GAZ1084D-3.3

3

C53

C53

100n/16V

100n/16V

3

C86

C86

100n/16V

100n/16V

3.3Vstb

R60RR6

0R

R12

R12

1

4.7k/NC

4.7k/NC

C5

R18 10kR18 10k

100n/16V/NCC9100n/16V/NC

C292

C292

100n/16V

100n/16V

+3.3V

R440

R440

10k

10k

3

V29

V29

1

2SCR523EB

2SCR523EB

2

C291

C291

100n/16V

100n/16V

N12

N12

VOUT

VIN

Vout

Vin

VOUT

ADJ

ADJ

1

1

VOUT

VIN

VOUT

ADJ

LD1117A-2.5AZ1117H-2.5

LD1117A-2.5AZ1117H-2.5

1

VIN

ADJ

LD1117A-2.5AZ1117H-2.5

LD1117A-2.5AZ1117H-2.5

1

R50

R50

0R/NC

0R/NC

R7 10kR7 10k

V1

V1

2SCR523EB/NC

2SCR523EB/NC

2 3

R54

R54

0R/NC

0R/NC

R418

R418

47k

47k

R417 22kR417 22k

R439 10kR439 10k

4

3

2

N15

N15

4

2

N16

N16

VOUT

VOUT

R1

4.7k/NCR14.7k/NC

Power Input

兼容老电源板规范接口标准

XP18XP18

1

2

XP1XP1

5Vstb

R434

R434

10k

10k

V6

2SCR523EB V62SCR523EB

2 3

STPB2012-121PT/NC

STPB2012-121PT/NC

3

4

1

2

3

4

5

BL-ON/OFF

6

7

8

9

10

11

12

STANDBY

13

INV_12V

R59

R59

4.7k

4.7k

5Vstb

+12V_S

for 32" 37" only

for 40"/46"/55"

5Vstb

for 32" 37" only

+5V

for 40"/46"/55"

D D

C C

B B

For 32"/37"

7

6

5

4

BL-ON/OFF

3

2

1

XP2XP2

POWER_SW

HI = > OFF

LO = > ON

STANDBY

R210R R210R

BL-ADJUST

INV_12V

+12V

+5V_S

INV_12V

R444

R444

47k

47k

R435

R435

0R/NC

0R/NC

R442

R442

4.7k

4.7k

L37

L37

L41

L41

L38

L38

L39

L39

1

STPB2012-121PT

STPB2012-121PT

STPB2012-121PT/NC

STPB2012-121PT/NC

STPB2012-121PT

STPB2012-121PT

C515

C515

10u/16V

10u/16V

VVV

R15 0RR15 0R

+12V

STPB2012-121PT

STPB2012-121PT

1

STPB2012-121PT

STPB2012-121PT

BL-ADJUST

5Vstb

L59

L59

100n/16V

100n/16V

L36

L36

R53

R53

4.7k

4.7k

+12V

C514

C514

10u/16V

10u/16V

C140

C140

V8

2SCR523EB V82SCR523EB

2 3

Power Input

新电源板规范接口标准

BL-ADJUST BL-ON/OFF

STANDBY

5Vstb

C137

C137

R291

R291

100n/16V

100n/16V

22k

22k

R60

R60

10k

10k

C129

C129

100n/16V

100n/16V

1

R102

R102

47k

47k

R229

R229

10k

10k

V7

2SCR523EB V72SCR523EB

2 3

C132

C132

100n/16V

100n/16V

1

2

3

XP20XP20

1 2

3

R270R R270R

5

7

9

11

5Vstb

C13

C13

10u/10V

10u/10V

N40

N40

S1

D11

G1

D12

S2

D21

G24D22

IRF7314/AO4801/3

IRF7314/AO4801/3

C12

C12

100n/16V

100n/16V

8

7

6

5

Standby

VBLCTRL-P2

4

6

INV_12V

8

10

VVVVVV

12

+12V

C90

C90

C210

10u/16V

10u/16V

C210

C211

C211

C320

C320

10u/16V

10u/16V

100n/16V

100n/16V

100u/16V/NC

100u/16V/NC

STANDBY

100n/16VC3100n/16V

STANDBY:

HIGH->NORMAL

LOW->STANDBY

C3

5Vstb 3.3Vstb

R2

R9 100RR9 100R

R13

R13

4.7k/NC

4.7k/NC

4.7kR24.7k

V3

2 3

2SCR523EB V32SCR523EB

R10

R10

4.7k

4.7k

1

C6

100n/16V/NCC6100n/16V/NC

R3

10kR310k

V4

2 3

2SCR523EB V42SCR523EB

R11

R11

0R/NC

0R/NC

R14

R14

1

4.7k

4.7k

C7

4.7u/10V/NCC74.7u/10V/NC

R4

10kR410k

POWER_SW 2

1.2V FOR 1328BX CORE POWER

STPB2012-121PT/NC

STPB2012-121PT/NC

+5V

L16

L16

+12V

L7

L7

STPB2012-121PT

C10

C10

100n/16V

100n/16V

10u/16V

10u/16V

STPB2012-121PT

C29

C29

C26

C26

10u/16V

10u/16V

+5V

STANDBY

R20 220kR20 220k

C230 100n/16VC230 100n/16V

R22 100kR22 100k

R24 100k/NCR24 100k/NC

C25

C25

100n/16V

100n/16V

+5V

+12V

N8

1

SW

IN

8

BYP

FREQ

6

BST

EN

7

GND

FB

MP1492 N8MP1492

3

5

4.7u/10V

4.7u/10V

4

1u/25V

1u/25V

2

VCC_VSENSE3

L8 2.2 uHL8 2.2 uH

R35

R35

R330RR33

C30

C30

C31

C31

180k

180k

0R

R34

R34

22R

22R

C32

C32

1n/50V

1n/50V

VCC_VSENSE

C414

C414

220p/50V

220p/50V

C231

C231

100n/16V

100n/16V

R920RR92

R171 100RR171 100R

R36 16.9kR36 16.9k

R37

R37

36k

36k

0R

VCC1V

C232

C232

C28

C28

22u/6.3V

22u/6.3V

22u/6.3V

22u/6.3V

C413

C413

R38

R38

100n/16V

100n/16V

10k/NC

10k/NC

VBLCTRL-P22

BRI_ADJ-PWM2

BRI_ADJ-PWM22,8

Power for Panel

L13 STPB2012-121PTL13 STPB2012-121PT

+12V

L14

L14

+5V

STPB2012-121PT/NC

STPB2012-121PT/NC

H:OFF

L:ON

1 2

L9

L9

R4111kR411

1k

VD2

VD2

MBR0520LT1/B0520LW

MBR0520LT1/B0520LW

C33

C33

2.2u/10V

2.2u/10V

ON_PANEL2

3.3V Power_Standby only for AVDD_MPLL and IR

5Vstb

BLM18PG181SN1/NC

BLM18PG181SN1/NC

CORE POWER 1.2V, 1.16V<=VDDC<=1.24V

1.5V Power_DDR3(1105681)

C39

C39

22u/6.3V

22u/6.3V

L3 4.7 uHL3 4.7 uH

R23

R23

22R/NC

22R/NC

C18

C18

+1.5V_DDR3

C40

C40

22u/6.3V

22u/6.3V

C41

C41

100n/16V

100n/16V

C16

C16

330u/6V/NC

330u/6V/NC

C47

C47

22u/6.3V

22u/6.3V

3.3V Power_Normal

+5V

L11

L11

BLM18PG181SN1

BLM18PG181SN1

C42

C42

2.2u/10V

2.2u/10V

2.5V FOR 1328BX

+5V

L12

+5V_S

R26

R26

C66

C66

130k

130k

22p/50V

22p/50V

R25

R25

R136

R136

22k

22k

10k/NC

10k/NC

C513

C513

220u/16V/NC

220u/16V/NC

C14

C14

22u/6.3V

22u/6.3V

C22

C22

22u/6.3V

22u/6.3V

C21

C21

100n/16V

100n/16V

C15

C15

22u/6.3V/NC

22u/6.3V/NC

L12

BLM18PG181SN1

BLM18PG181SN1

+5V

L15

L15

BLM18PG181SN1

BLM18PG181SN1

C52

C52

2.2u/10V

2.2u/10V

2.2u/10V

2.2u/10V

C92

C92

+12V_S

L4

L4

STPB2012-121PT

STPB2012-121PT

+5V

R40 2R/2WR40 2R/2W

+5V FOR SYS

C19

C19

10u/16V

10u/16V

C20

C20

C17

C17

100n/16V

100n/16V

10u/16V

10u/16V

+5V_S

R1660RR166

0R

10n/50V

10n/50V

N10

3

2.2u/10V/NC

2.2u/10V/NC

EN

PG

VIN

C46

C46

10

11

12

7

6

3

8

N10

4

VOUT

2

VOUT

ADJ

1

Vout=0.765*(1+R1/R2)

C64 100n/25VC64 100n/25V

C508 100n/16VC508 100n/16V

R127 100kR127 100k

R165 100k/NCR165 100k/NC

1 2

R167

R167

LM3Z5V6T1G

LM3Z5V6T1G

100k/NC

100k/NC

VD13

VD13

C63

C63

1u/25V

1u/25V

R411kR41

1k

R42

R42

R603

R603

220R

220R

220R/NC

220R/NC

1n/50V/NC

1n/50V/NC

VDD_DDR

C37

C37

C38

C38

100n/16V

100n/16V

10u/10V

10u/10V

AZ1084S-ADJ

AZ1084S-ADJ

N7

N7

13

VIN1

SW1

VIN214SW2

4

SS

VBST

1

VO

2

VFB

5

VREG5

GND

9

PGND1

PGND2

PwPd

TPS54426-HX

TPS54426-HX

C65

C65

15

R490RR49

0R

+5V

R16

R16

4.7k

4.7k

1

V5

2SCR523EB V52SCR523EB

2 3

C9

C306

C306

1u/16V

1u/16V

V30

V30

1

R441

R441

10k

10k

VOUT=0.8*(1+R598/R599) V

C430

C430

22u/6.3V

22u/6.3V

C55

C55

10u/10V

10u/10V

4

2

+5V

1

N6

2

3

2SCR523EB

2SCR523EB

2

+2.5V_Normal

100n/16V

100n/16V

C91

C91

10u/10V

10u/10V

R5

4.7kR54.7k

V2

2SCR523EB V22SCR523EB

2 3

R17 1kR17 1k

R19

R19

10k

10k

AO3401LN6AO3401L

1

N87 AP2127K-ADJN87 AP2127K-ADJ

1

3

+3.3V

C44

C44

22u/6.3V

22u/6.3V

L48

L48

BLM18PG121SN1/NC

BLM18PG121SN1/NC

C54

C54

C85

C85

100n/16V

100n/16V

R80RR8

BL-ON/OFF

0R

R43

R43

10k/NC

10k/NC

BL-ADJUST

C8

4.7u/10VC84.7u/10V

VCC-Panel

3

C288

C288

10u/16V

10u/16V

VIN

VOUT

ShutD

ADJ

GND

2

C45

C45

100n/16V

100n/16V

C62

C62

100n/16V

100n/16V

L53

L53

BLM18PG121SN1

BLM18PG121SN1

C4

2.2u/10V/NCC42.2u/10V/NC

C301

C301

100n/16V

100n/16V

5

4

BL-ADJUST 8

R598

R598

22k

22k

R599

R599

6.8k

6.8k

C60

C60

100n/16V

100n/16V

C61

C61

100n/16V

100n/16V

3.3Vstb

C35

C35

10u/10V

10u/10V

2.5V_Demod

C36

C36

100n/16V

100n/16V

M2

M1

A A

5

4

3

NC/MARKM1NC/MARK

M3

NC/MARKM3NC/MARK

NC/MARKM2NC/MARK

M4

NC/MARKM4NC/MARK

Q1

Q1

12345

E1

E1

RSAG7.308.107

RSAG7.308.107

1

RSAG7.070.178

RSAG7.070.178

6

Title

Title

Title

MSD1328BX

MSD1328BX

MSD1328BX

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

A2

A2

A2

System Power

System Power

System Power

Thursday, December 29, 2011

Thursday, December 29, 2011

Thursday, December 29, 2011

Date: Sheet of

Date: Sheet of

2

Date: Sheet of

1

1

1

1

1.0

1.0

1.0

12

12

12

Page 37

USB

LTDN32k316AM<DN42K310WAM main board:4900

XP12XP12

VCC

GND_4

XP13XP13

VCC

D D+

GND

6

XP17XP17

VCC

D D+

GND

6

D D+

GND5GND

GND5GND

GND_55GND_6

6

5V_USB

1

2

3

4

5V_USB

1

2

3

4

5V_USB_WIFI

C93 100n/16VC93 100n/16V

C99 10u/16VC99 10u/16V

1

2

3

4

C94 100n/16VC94 100n/16V

C102 10u/16VC102 10u/16V

C96 100n/16VC96 100n/16V

C143 10u/16VC143 10u/16V

100u/16V/NC

100u/16V/NC

VD50

VD50

4

Vp

GND

3

I/O2

ESDA6V8UBA

ESDA6V8UBA

VD51

VD51

4

Vp

GND

3

I/O1

I/O2

ESDA6V8UBA

ESDA6V8UBA

VD52

VD52

4

Vp

GND

3

I/O1

I/O2

ESDA6V8UBA

ESDA6V8UBA

USB POWER

+5V

C277

C277

C56

C56

10u/10V

10u/10V

I/O1

1

2

1

2

C57

C57

100n/16V

100n/16V

1

2

C75

C75

10u/10V

10u/10V

R70 5.1RR70 5.1R

R71 5.1RR71 5.1R

C67

C67

100n/16V

100n/16V

USB_DM1

USB_DP1

USB_DM2

USB_DP2

F1

F1

nanoSMDC200F-2

nanoSMDC200F-2

F2

F2

nanoSMDC200F-2

nanoSMDC200F-2

USB0_DM 2

USB0_DP 2

12

12

5V_USB

5V_USB_WIFI

HUB 1_8V

HUB 1_8VHUB 1_8V

C517

C517

100n/16V

100n/16V

PIN 3 PIN 29

HUB 3_3V HUB 3_3V HUB 3_3V HUB 3_3V

C520

C520

100n/16V

100n/16V

PIN 19 PIN 32 PIN 41PIN 27

PIN 13

Bypass CAP , close to each indicated pin

of FE1.1, and should not be removed.

C518

C518

100n/16V

100n/16V

HUB 3_3V

C521

C521

100n/16V

100n/16V

100n/16V

100n/16V

X'TAL 12MHZ

16~20pF/30~50ppm

C522

C522

Z2

Z2

1 2

JAM12D

JAM12D

BLM18PG121SN1

BLM18PG121SN1

L44

L44

C523

C523

100n/16V

100n/16V

100n/16V

100n/16V

5V_USB

HUB 1_8V

VD_PLL

VS_PLL

C524

C524

R70910k R70910k

PIN 9

VD_PLL

C519

C519

100n/16V

100n/16V

Close to pin39

C525

C525

10n/50V

10n/50V

N9

N9

1

OVCB2

2

PWRB2

3

VD18_3

4

PWRB3

5

OVCB3

6

VSS

7

FE1_QFP48

FE1_QFP48

OVCB4

8

PWRB4

9

VD_PLL

10

VS_PLL

11

XOUT

12

XIN

USB_DM2

USB_DP2

48

OVCB1

13

HUB 3_3V

47

46

PWRB1

C235

C235

10u/16V

10u/16V

FE1.1-HX

FE1.1-HX

DP415DM414VD33_13

16

42

LED143LED244LED345LED4

HUB 3_3V

DRV

HUB 3_3V

500mA

C224

C224

Close to pin38(VD5_IN)

HUB 3_3V

38

41

37

39

40

VD33

TEST

VD5_IN

DIS_REG

VD33_OUT

VD33_32

VD18_29

VREG18

DP124DM123VSS_22

DP221DM220VD33_1919DP318DM317VSS_16

22

10u/16V

10u/16V

BUS_B

VBUSM

XRSTJ

VSS_33

DPU

DMU

REXT

VD3_IN

VS_A

500mA

L17 STPB2012-121PTL17 STPB2012-121PT

R31, R29, C1 are close to pin 35 (VBUSM).

HUB 3_3V

36

35

34

33

32

31

30

29

28

27

26

25

USB_DP1

USB_DM1

BUS_B

HUB 3_3V

R44

R44

R28

100k

100k

HUB 3_3V

HUB 1_8V

R28

100k

100k

300mA

300mA

R30

R30

2.7k

2.7k

2.7K+-1% close to pin 28

* 5 couples of DP, DM, must be at least

1500 mil with 15 of 45-degree-angle (USB-IF).

+5V

R29

R29

100k

100k

R702 5.1RR702 5.1R

R700 5.1RR700 5.1R

HUB 3_3V

HUB 1_8V

C1

C1

100n/16V

100n/16V

USB1_DP

USB1_DM

HUB 1_8V

C237

C237

10u/16V

10u/16V

signal only 8 mil

R31

R31

10k

10k

USB1_DP 2

USB1_DM 2

Close to pin26

+5V

Page 38

5

N89C

N89C

J2

C78

C78

2.2u/10V

2.2u/10V

3D_RL

SPDIF_OUT

VGA_RIN+

VGA_GIN+

VGA_BIN+

VGA_HSYNC

VGA_VSYNC

PR

PR5

Y

Y5

PB

PB5

SPI_CSN_1

SPI_SCK

SPI_SDI

SPI_SDO

C139

C139

C138

C138

2.2u/10V

2.2u/10V

SPI_SCK

SPI_SDI

R505 0RR505 0R

R506 0RR506 0R

R518 0R/NCR518 0R/NC

L67

L67

BLM18PG181SN1/NC

BLM18PG181SN1/NC

UART-RX

UART-TX

HDMI1-RX0N

HDMI1-RX0P

HDMI1-RX1N

HDMI1-RX1P

HDMI1-RX2N

HDMI1-RX2P

HDMI1-CLKN

HDMI1-CLKP

HDMI1-SCL

HDMI1-SDA

HDMI1-HPDIN

HDMI2-RX0N

HDMI2-RX0P

HDMI2-RX1N

HDMI2-RX1P

HDMI2-RX2N

HDMI2-RX2P

HDMI2-CLKN

HDMI2-CLKP

HDMI2-SCL

HDMI2-SDA

HDMI2-HPDIN

HDMI3-RX0N

HDMI3-RX0P

HDMI3-RX1N

HDMI3-RX1P

HDMI3-RX2N

HDMI3-RX2P

HDMI3-CLKN

HDMI3-CLKP

HDMI3-SCL

HDMI3-SDA

HDMI3-HPDIN

3.3Vstb

C87

C87

220p/50V

220p/50V

R75 22RR75 22R

R142 22RR142 22R

R144 22RR144 22R

R497 22RR497 22R

R131 1kR131 1k

7

6

5

3.3Vstb

HDMI1-RX0N4

HDMI1-RX0P4

HDMI1-RX1N4

HDMI1-RX1P4

HDMI1-RX2N4

HDMI1-RX2P4

HDMI1-CLKN4

HDMI1-CLKP4

HDMI1-SCL4

HDMI1-SDA4

HDMI1-HPDIN4

D D

HDMI2-RX0N4

HDMI2-RX0P4

HDMI2-RX1N4

HDMI2-RX1P4

HDMI2-RX2N4

HDMI2-RX2P4

HDMI2-CLKN4

HDMI2-CLKP4

HDMI2-SCL4

HDMI2-SDA4

HDMI2-HPDIN4

HDMI3-RX0N4

HDMI3-RX0P4

HDMI3-RX1N4

HDMI3-RX1P4

HDMI3-RX2N4

HDMI3-RX2P4

HDMI3-CLKN4

HDMI3-CLKP4

HDMI3-SCL4

HDMI3-SDA4

HDMI3-HPDIN4

HDMI-A_ARC4

HDMI-CEC4

SPDIF_OUT5

C C

VGA_RIN+5

VGA_GIN+5

VGA_BIN+5

VGA_HSYNC5

VGA_VSYNC5

Boot Loader SPI Flash

B B

3.3Vstb

100n/16V

100n/16V

XP7XP7

4

3

2

1

A A

Debug port

1

2

3

4

XP8XP8

A_RX0N

J1

A_RX0P

J3

A_RX1N

K1

A_RX1P

K2

A_RX2N

K3

A_RX2P

H2

A_RXCN

H3

A_RXCP

K6

DDCDA_CK/GPIO23

L7

DDCDA_DA/GPIO24

L6

HOTPLUGA/GPIO19

AC8

C_RX0N

AE8

C_RX0P

AD8

C_RX1N

AC9

C_RX1P

AD9

C_RX2N

AC10

C_RX2P

AD7

C_RXCN

AE7

C_RXCP

AA9

DDCDC_CK/GPIO27

AA8

DDCDC_DA/GPIO28

AB8

HOTPLUGC/GPIO21

F2

D_RX0N

F1

D_RX0P

F3

D_RX1N

G1

D_RX1P

G2

D_RX2N

G3

D_RX2P

E2

D_RXCN

E3

D_RXCP

J4

DDCDD_CK/GPIO29

J5

DDCDD_DA/GPIO30

K4

HOTPLUGD/GPIO22

R550RR55

K5

PAD_ARC0

0R

G5

CEC/GPIO5

H4

SPDIF_IN/GPIO152

U6

SPDIF_OUT/GPIO153

C88

C88

220p/50V

220p/50V

Close to MST IC

with wide trace

R73

R73

68R

68R

R74 33RR74 33R

R76

R76

68R

68R

R83 33RR83 33R

R85

R85

68R

68R

R87 33RR87 33R

R90 0RR90 0R

R95

R95

68R

68R

R96 33RR96 33R

R99

R99

68R

68R

R101 33RR101 33R

R104

R104

68R

68R

R107 33RR107 33R

R106 0RR106 0R

SPI-CS1N

SPI-SCK

SPI-SDI

SPI-SDO

FLASH-WPN1FLASH_WPN1

MX25L1605D-SST25VF016B

MX25L1605D-SST25VF016B

VCC8CS#

LOLD#

SCLK

SI/SIO0

N2

N2

R931MR93

1M

LED_CTL_IR

R114

R114

10k

10k

SO/SIO1

WP#/ACC

R941MR94

1M

KEYPAD-KEY1

KEYPAD-KEY0

5Vstb

R115

R115

10k

10k

1

2

3

4

GND

C115

C115

100n/16V

100n/16V

C133

C133

1n/50V

1n/50V

5

HDMI

HDMI

Audio

Audio

Analog

Analog

I2S_OUT_BCK/GPIO156

I2S_OUT_MCK/GPIO154

I2S_OUT_WS/GPIO155

I2S_OUT_SD/GPIO157

I2S_IN_BCK/GPIO150

I2S

I2S

MSD1328

N2

RIN0N

C103 47n/16VC103 47n/16V

C105 47n/16VC105 47n/16V

C107 47n/16VC107 47n/16V

C108 47n/16VC108 47n/16V

C109 47n/16VC109 47n/16V

C110 47n/16VC110 47n/16V

C112 1n/50VC112 1n/50V

C117 47n/16VC117 47n/16V

C119 47n/16VC119 47n/16V

C120 47n/16VC120 47n/16V

C123 47n/16VC123 47n/16V

C124 47n/16VC124 47n/16V

C126 47n/16VC126 47n/16V

C128 1n/50VC128 1n/50V

RIN0

GIN0N

GIN0

BIN0N

BIN0

SOGIN0

RIN2N

RIN2

GIN2N

GIN2

BIN2N

BIN2

SOGIN2

N1

M3

M1

L3

L2

M2

L4

L5

T1

R3

R1

R2

P2

N3

P3

T2

T3

W2

W1

V3

V1

U3

U2

V2

*100MHz, No any VIA hole!

SAR1

SAR0

3.3Vstb

R139

R139

10k/NC

10k/NC

XP6XP6

SPI_CSN_1

SPI_SDO

R98 1kR98 1k

R103 1kR103 1k

C134

C134

1n/50V

1n/50V

C116

C116

2.2u/10V

2.2u/10V

I2S_IN_WS/GPIO149

I2S_IN_SD/GPIO151

SPDIF

SPDIF

N89E

N89E

RIN0M

RIN0P

GIN0M

GIN0P

BIN0M

BIN0P

SOGIN0

HSYNC0

VSYNC0

RIN1M

RIN1P

GIN1M

GIN1P

BIN1M

BIN1P

SOGIN1

HSYNC1

VSYNC1

RIN2M

RIN2P

GIN2M

GIN2P

BIN2M

BIN2P

SOGIN2

R152

R152

10k

10k

IRKEY PAD

1

2

3

4

5

6

7

8

9

LINE_IN_0L

LINE_IN_0R

LINE_IN_1L

LINE_IN_1R

LINE_IN_2L

LINE_IN_2R

LINE_IN_3L

LINE_IN_3R

HP_OUT_1L

HP_OUT_1R

LINE_OUT_0L

LINE_OUT_0R

LINE_OUT_2L

LINE_OUT_2R

IRINT

RESET

XTALIN

XTALOUT

TESTPIN

MSD1328

W3

Y2

Y3

AA2

AA1

AA3

AA5

AB5

AB4

AC4

AB3

AC2

AC3

AD1

AA4

VRP

AB2

VAG

AB1

VRM

D5

D4

E5

E4

U4

U5

E7

G4

C4

AE2

AE3

K8

RGB

RGB

3.3Vstb

5

4

74HC1G08GW-HX/NC

74HC1G08GW-HX/NC

100n/16V/NC

100n/16V/NC

IR_IN

LED_CTL_IR

R508 0RR508 0R

R517 0RR517 0R

C83 2.2u/10VC83 2.2u/10V

C77 2.2u/10VC77 2.2u/10V

C68 2.2u/10VC68 2.2u/10V

C69 2.2u/10VC69 2.2u/10V

C70 2.2u/10VC70 2.2u/10V

C71 2.2u/10VC71 2.2u/10V

C72 2.2u/10VC72 2.2u/10V

C74 2.2u/10VC74 2.2u/10V

AUVRP

AUVAG

AUVRM

I2S-OUT_BCK

I2S-OUT_MCK

I2S-OUT_WS

I2S-OUT_SD

LD-EN

3D-EN

IRIN

System-RST

XTALI

XTALO

PAD_GPIO19

PAD_GPIO20

CVBS3P

CVBS2P

CVBS1P

CVBS0P

CVBS PHYUSB

CVBS PHYUSB

VCOM0

CVBS_OUT1

CVBS_OUT2

N90

N90

VCC

GND3Y

C415

C415

KEYPAD-KEY0

KEYPAD-KEY1

DM_P0

DP_P0

DM_P1

DP_P1

R1260R R1260R

B

A

COMP_AUL2

COMP_AUR2

VGA_AU_IN_L

VGA_AU_IN_R

RCA_AU_IN_3L

RCA_AU_IN_3R

MUTE_DRV632 9

AUVRM

AUVRP

AUVAG

C79

C79

4.7u/10V

4.7u/10V

Ethernet

A2

RN

B2

RP

B1

TN

C2

TP

C3

C1

A4

B4

AD10

AE10

T6

P6

P5

P4

R6

T4

T5

1

FLASH_WPN1

2

3.3Vstb

L66

L66

BLM18PG181SN1/NC

BLM18PG181SN1/NC

4

C80

C80

1u/10V

1u/10V

Close to IC

with width

trace

LAN-LED0

LAN-LED1

C118 47n/16VC118 47n/16V

C121 47n/16VC121 47n/16V

C125 47n/16VC125 47n/16V

2SCR523EB

2SCR523EB

4

RCA_AU_IN_0L 5

RCA_AU_IN_0R 5

COMP_AUL2 5

COMP_AUR2 5

VGA_AU_IN_L 5

VGA_AU_IN_R 5

RCA_AU_IN_3L 5

RCA_AU_IN_3R 5

I2S-OUT_MCK9

I2S-OUT_BCK9

C81

C81

100n/16V

100n/16V

LAN-LED0 7

LAN-LED1 7

USB0_DM 5

USB0_DP 5

USB1_DM 5

USB1_DP 5

SC_CVBS_OUT

3.3Vstb

R132

R132

2.2k

2.2k

V24

V24

2 3

5Vstb

C122

C122

100n/16V

100n/16V

EARPHONE_OUTL 9

EARPHONE_OUTR 9

AU_LOUT 9

AU_ROUT 9

I2S OUT

I2S-OUT_MCK

I2S-OUT_BCK

I2S-OUT_WS

I2S-OUT_WS9

I2S-OUT_SD

I2S-OUT_SD9

C82

C82

10u/10V

10u/10V

BLM18PG181SN1

BLM18PG181SN1

L19

L19

R558

R558

R545

R545

R546

R546

49.9R

49.9R

49.9R

49.9R

49.9R

49.9R

C435

C435

100n/16V

100n/16V

GNDGND

Close to MST IC

SC_CVBS-IN

R97 33RR97 33R

CVBS2-RCA

R100 33RR100 33R

VCOM0

R105 68RR105 68R

1

System-RST

R163 10kR163 10k

5Vstb 5Vstb

IR_IN

LED

C136

C136

100n/16V

100n/16V

PF_ALE

PF_AD_15

PF_CE0Z

PF_CE1Z

PF_OEZ

PF_WEZ

F_RBZ

R559

R559

49.9R

49.9R

C432

C432

100n/16V

100n/16V

SC_CVBS_OUT 5

R108

R108

4.7k/NC

4.7k/NC

R113 1k/NCR113 1k/NC

C135

C135

20p/50V

20p/50V

3.3Vstb

10k/NC

10k/NC

SC_CVBS-IN 5

CVBS2-RCA 5

R118

R118

R116

R116

PCM_A0

R299 22RR299 22R

PCM_A1

R301 22RR301 22R

PCM_A2

R302 22RR302 22R

PCM_A3

R303 22RR303 22R

PCM_A4

R304 22RR304 22R

PCM_A5

R305 22RR305 22R

PCM_A6

R306 22RR306 22R

PCM_A7

R307 22RR307 22R

R397 22RR397 22R

R308 22RR308 22R

R310 22RR310 22R

R311 22RR311 22R

R309 22RR309 22R

R398 22RR398 22R

R312 22RR312 22R

C443

C443

33p/50V

33p/50V

+3.3V

R134

R134

R137

R137

R140

R140

R143

R143

R147

R147

R150

R150

R153

R153

R154

R154

R156

R156

R157

R157

R109

R109

1k/NC

1k/NC

V11

V11

2SCR523EB/NC

2SCR523EB/NC

2 3

R120

R120

4.7k/NC

4.7k/NC

R112

R112

0R/NC

0R/NC

1

4.7k/NC

4.7k/NC

4.7k

4.7k

4.7k/NC

4.7k/NC

4.7k

4.7k

4.7k

4.7k

4.7k/NC

4.7k/NC

4.7k/NC

4.7k/NC

4.7k

4.7k

4.7k/NC

4.7k/NC

4.7k

4.7k

5Vstb

V12

V12

2SCR523EB

2SCR523EB

2 3

IRIN

靠近主

R110

R110

10k

10k

RXN 7

RXP 7

TXN 7

TXP 7

Mode Selection

1

R119

R119

100R

100R

10k

10k

N89B

N89B

AA20

PCM_D0

AC19

PCM_D1

AA21

PCM_D2

AC18

PCM_D3

AC16

PCM_D4

AD16

PCM_D5

AD17

PCM_D6

AC17

PCM_D7

AA19

PCM_A0

AB20

PCM_A1

Y20

PCM_A2

Y17

PCM_A3

Y19

PCM_A4

AD18

PCM_A5

AC20

PCM_A6

AE20

PCM_A7

AB17

PCM_A8

Y16

PCM_A9

AE16

PCM_A10

AB16

PCM_A11

AD19

PCM_A12

AA18

PCM_A13

Y18

PCM_A14

AD20

PCM_RESET

AB21

PCM_IRQA_N

AA17

PCM_IOWR_N

AC15

PCM_OE_N

AA16

PCM_IORD_N

AE17

PCM_CE_N

AE19

PCM_WE_N

AB22

PCM_CD_N

AB19

PCM_REG_N

AC21

PCM_WAIT_N

AE14

PCM_NAND_ALE

AC14

PCM_NAND_WPZ

AA15

PCM_NAND_CEZ

AD15

PCM_NAND_CLE

AA14

PCM_NAND_REZ

AD14

PCM_NAND_WEZ

Y15

PCM_NAND_RBZ

C442

C442

33p/50V

33p/50V

IC

GPIO PULL HIGH

6M30_RST8

3D_RL8

RF_AGC_SW6

MUTE_AMP9

I2C-SCL6,8

I2C-SDA6,8

POWER_SW1

UART-TX5

UART-RX5

ON_PANEL1

VBLCTRL-P21

BRI_ADJ-PWM21,8

Demod_RST#6

LED

I2S-OUT_BCK

I2S-OUT_MCK

PWM1

PWM0

LD-EN

R328

R328

47k

47k

3D-EN

R198

R198

47k

47k

LED_CTL_IR

3

MSD1328

6M30_RST

3D_RL

LD-EN

RF_AGC_SW

MUTE_AMP

I2C-SCL

I2C-SDA

POWER_SW

UART-TX

UART-RX

ON_PANEL

VBLCTRL-P2

BRI_ADJ-PWM2

Demod_RST#

EEPROM

1

1

3

R123 10kR123 10k

R124 10kR124 10k

R331 10kR331 10k

R133 10kR133 10k

R130 10kR130 10k

R146 10kR146 10k

R148 10kR148 10k

R151 10kR151 10k

1

A0

A12WP

A23SCL

4

GND

+3.3V

R327

R327

2.2k/NC

2.2k/NC

V13

V13

2SCR523EB

2SCR523EB

2 3

+3.3V

R330

R330

2.2k/NC

2.2k/NC

V15

V15

2SCR523EB

2SCR523EB

2 3

TS1_CLK

TS1_VLD

TS1_SYNC

TS0_CLK

TS0_VLD

TS0_SYNC

RF_TAGC

TGPIO0/UPGAIN

TGPIO2/ I2C_CLK

TGPIO3/ I2C_SDA

+3.3V

3.3Vstb

N18

N18

VCC

SDA

AT24C32N-10SI-2.7

AT24C32N-10SI-2.7

R569 0RR569 0R

R574 0RR574 0R

AC12

R535 22RR535 22R

TS1_D0

AD13

R536 22RR536 22R

TS1_D1

AD12

R537 22RR537 22R

TS1_D2

AC11

R538 22RR538 22R

TS1_D3

AD11

R539 22RR539 22R

TS1_D4

AA10

R540 22RR540 22R

TS1_D5

AB14

R541 22RR541 22R

TS1_D6

AA12

R542 22RR542 22R

TS1_D7

Y13

R543 22RR543 22R

AC13

R544 22RR544 22R

AE11

R565 22RR565 22R

AB13

TS0_D0

Y14

TS0_D1

AA11

TS0_D2

AB11

TS0_D3

AA13

TS0_D4

Y9

TS0_D5

AB10

TS0_D6

AE13

TS0_D7

Y10

Y12

Y11

AD5

IP

IP

AC6

IM

IM

AC5

VIFP

AE5

VIFM

AE4

IFAGC

IFAGC

AD4

TAGC

AD2

Demod_RST#

AD3

RF_AGC_SW

TGPIO1

AD6

R284 22RR284 22R

AC7

R296 22RR296 22R

I2C address at A0.

8

EEP_Vcc

7

6

R86 100RR86 100R

R88 100RR88 100R

5

LD_EN 8

3D_EN 8

C378 10n/50V/NCC378 10n/50V/NC

C379 10n/50V/NCC379 10n/50V/NC

C385 10n/50VC385 10n/50V

C386 10n/50VC386 10n/50V

R77 0R/NCR77 0R/NC

R82 0RR82 0R

System-RST

C101

C101

R596

R596

100n/16V

100n/16V

10k

10k

E2PROM_WP

C113 10p/50VC113 10p/50V

C114 10p/50VC114 10p/50V

TS1_OUT_D0

TS1_OUT_D1

TS1_OUT_D2

TS1_OUT_D3

TS1_OUT_D4

TS1_OUT_D5

TS1_OUT_D6

TS1_OUT_D7

TS1_OUT_CLK

TS1_OUT_VLD

TS1_OUT_SYNC

+3.3V

R246

R246

4.7k

4.7k

R155 10kR155 10k

I2C-SCL

I2C-SDA

3.3Vstb

C496

C496

100n/16V

100n/16V

VIFP 6

VIFM 6

R56

R56

10k

10k

R267

R267

4.7k

4.7k

I2C-SCL-TUNER

I2C-SDA-TUNER

R72 4.7kR72 4.7k

RESET

3

VCC

APX810-29SAG-7

APX810-29SAG-7

2

1.Ball G7, Ball G8, Ball F7, Ball D6,

Ball E7 ONLY SOCKET BOARD HAVE,

不建议使用,会割地

TS1_OUT_D[7:0] 6

C73 10p/50V/NCC73 10p/50V/NC

TS1_OUT_CLK 6

TS1_OUT_VLD 6

TS1_OUT_SYNC 6

5V_Tuner

C84

C84

100n/16V

100n/16V

R570RR57

0R

C89

C89

22n/25V

22n/25V

Close to chip

I2C-SCL-TUNER 6

I2C-SDA-TUNER 6

+3.3V

R129

R129

2.2k

2.2k

1

V17

V17

2SCR523EB

2SCR523EB

2 3

EEP_Vcc

N19

N19

1

8

A0

VCC

2

7

A1

WP

3

6

A2

SCL

5

VSS4SDA

AT24C04N-10SU-2.7/NC

AT24C04N-10SU-2.7/NC

N85

N85

2

RST

1

GND

PWM0 ON_PCMCIA

PWM1

BRI_ADJ-PWM2

MUTE_AMP

LED

SAR0

SAR1

SAR2

TP8TP8

RST_AMP8

SPI-SCK

SPI-SDI

SPI-SDO

SPI-CS1N

HP_IN9

UART-RX

UART-TX

I2C-SCL

I2C-SDA

FLASH-WPN1

ON_PANEL

POWER_SW

VBLCTRL-P2

E2PROM_WP

C234

C234

2.2u/10V

2.2u/10V

RF_AGC 6

R122 0RR122 0R

1

PF_AD_15

2

I2C address at A4

R78

R78

4.7k

4.7k

R89 100RR89 100R

R91 100RR91 100R

R6371kR637

1k

R638

R638

100k

100k

2

R51 100RR51 100R

R52 100RR52 100R

6M30_RST

N88

N88

B

VCC

A

GND3Y

74HC1G08GW-HX/NC

74HC1G08GW-HX/NC

C106

C106

100n/16V

100n/16V

I2C-SCL

I2C-SDA

System-RST

Y21

Y22

AA22

V24

G6

E6

F4

F5

F6

C6

B6

B5

A5

C5

H5

U24

U23

G8

F7

G7

A3

B3

D3

D2

D1

D6

+3.3V

5

4

+3.3V

R81

R81

2.2k

2.2k

N89D

N89D

PWM0/GPIO66

PWM1/GPIO67

PWM2/GPIO68

PWM3/GPIO69

PWM_PM

SAR0/GPIO31

SAR1/GPIO32

SAR2/GPIO33

SAR3/GPIO34

PM_SPI_CK/GPIO1

PM_SPI_DI/GPIO2

PM_SPI_DO/GPIO3

PM_SPI_CS1/GPIO12/PM6

PM_SPI_CS2/GPIO16/PM10

J6

DDCA_CK/UART0_RX

DDCA_DA/UART0_TX

DDCR_CK/GPIO72

DDCR_DA/GPIO71

PAD_GPIO4/GPIO40

PAD_GPIO3/GPIO39

PAD_GPIO2/GPIO38

GPIO6/PM0/INT

GPIO7/PM1/PM_UART_TX

GPIO10/PM4

GPIO11/PM5/PM_UART_RX/INT

PM_SPI_WP2/GPIO14/PM8/INT

PM_SPI_CZ

MSD1328

NAND FLASH

FLH_3.3V

R169

R169

4.7k

4.7k

F_RBZ

PF_AD_15

R117

R117

FLH_3.3V

R121

R121

4.7k

4.7k

R135

R135

4.7k/NC

4.7k/NC

+3.3V

R79

R79

R80

R80

2.2k

2.2k

100R

100R

EEP_Vcc

C111

C111

2.2u/10V

2.2u/10V

1

两层板

2 7

W24

PWM

PWM

SAR

SAR

SPI GPIO

SPI GPIO

LVB0N/RLV6N

LVB0P/RLV6P

LVB1N/RLV7N

LVB1P/RLV7P

LVB2N/RLV8N

LVB2P/RLV8P

LVBCKN/LLVON

LVBCKP/LLVOP

LVB3N/LLV1N

LVB3P/LLV1P

LVB4N/LLV2N

LVB4P/LLV2P

LVA0N/LLV3N

LVA0P/LLV3P

LVA1N/LLV4N

LVDS

LVDS

LVA1P/LLV4P

LVA2N/LLV5N

LVA2P/LLV5P

LVACKN/LLV6N

LVACKP/LLV6P

LVA3N/LLV7N

LVA3P/LLV7P

LVA4N/LLV8N

LVA4P/LLV8P

RP10 10RRP10 10R

1

V23

4

W23

3 6

W25

Y24

2 7

RP11 10RRP11 10R

1

Y25

4

AA24

3 6

Y23

2 7

AB24

RP12 10RRP12 10R

1

AA23

4

AB23

3 6

AB25

AC24

2 7

RP13 10RRP13 10R

AC25

1

AD24

4

AD25

3 6

2 7

AC23

RP14 10RRP14 10R

1

AE24

4

AD23

3 6

AE23

2 7

AD22

RP15 10RRP15 10R

1

AE22

4

AD21

3 6

AC22

8

5

8

5

8

5

8

5

8

5

8

5

LVDS Block

C130

C130

10u/10V

10u/10V

C127

C127

100n/16V

100n/16V

NC_48

NC_47

NC_46

NC_45

NC_40

NC_39

NC_38

NC_35

NC_34

NC_33

NC_28

NC_27

NC_26

NC_25

FLH_3.3V

I/O7

I/O6

I/O5

I/O4

VCC

VSS

I/O3

I/O2

I/O1

I/O0

C131

C131

100n/16V

100n/16V

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

PCM_A7

PCM_A6

PCM_A5

PCM_A4

PCM_A3

PCM_A2

PCM_A1

PCM_A0

+3.3V

L21

L21

BLM18PG181SN1

BLM18PG181SN1

N3

N3

1

R111 0RR111 0R

F_RBZ

PF_OEZ

PF_CE0Z

FLH_3.3V FLH_3.3V

PF_CE1Z

PF_ALE

PF_WEZ

4.7k/NC

4.7k/NC

NC_1

2

NC_2

3

NC_3

4

NC_4

5

NC_5

6

NC_6

7

R/B

8

RE

9

CE

10

NC_10

11

NC_11

12

VCC

13

VSS

14

NC_14

15

NC_15

16

CLE

17

ALE

18

WE

19

WP

20

NC_20

21

NC_21

22

NC_22

23

NC_23

24

NC_24

HY27UF082G2B-TPCB

HY27UF082G2B-TPCB

System XTAL

XTALO

R68 0RR68 0R

XTALI

VD25

VD25

1 2

E2PROM_WPSystem-RST

1N4148W

1N4148W

Title

Title

Title

MSD1328BX

MSD1328BX

MSD1328BX

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Custom

Custom

Custom

MSD1328BX-MAIN

MSD1328BX-MAIN

MSD1328BX-MAIN

Thursday, December 29, 2011

Thursday, December 29, 2011

Thursday, December 29, 2011

Date: Sheet of

Date: Sheet of

Date: Sheet of2

R691MR69

1M

12

Z1

Z1

HC-49SM24MHZ

HC-49SM24MHZ

1

C98 20p/50VC98 20p/50V

C100 20p/50VC100 20p/50V

RXO0+ 8

RXO0- 8

RXO1+ 8

RXO1- 8

RXO2+ 8

RXO2- 8

RXOC+ 8

RXOC- 8

RXO3+ 8

RXO3- 8

RXO4+ 8

RXO4- 8

RXE0+ 8

RXE0- 8

RXE1+ 8

RXE1- 8

RXE2+ 8

RXE2- 8

RXEC+ 8

RXEC- 8

RXE3+ 8

RXE3- 8

RXE4+ 8

RXE4- 8

2

2

1.0

1.0

1.0

12

12

12

Page 39

5

4

3

2

1

R159 22RR159 22R

R160 22RR160 22R

1 8

RP2 22RRP2 22R

2

3

4 5

1 8

RP3 22RRP3 22R

2

3

4 5

1 8

RP4 22RRP4 22R

2

3

4 5

1 8

RP5 22RRP5 22R

2

3

4 5

1 8

RP9 22RRP9 22R

2

3

4 5

1 8

RP6 22RRP6 22R

2

3

4 5

1 8

RP8 22RRP8 22R

2

3

4 5

1 8

RP7 22RRP7 22R

2

3

4 5

1 8

RP19 22RRP19 22R

2

3

4 5

1 8

RP16 22RRP16 22R

2

3

4 5

1 8

RP18 22RRP18 22R

2

3

4 5

1 8

RP17 22RRP17 22R

2

3

4 5

R161 22RR161 22R

R162 22RR162 22R

1 8

RP23 22RRP23 22R

2

3

4 5

1 8

RP20 22RRP20 22R

2

3

4 5

1 8

RP22 22RRP22 22R

2

3

4 5

1 8

RP21 22RRP21 22R

2

3

4 5

1 8

RP27 22RRP27 22R

2

3

4 5

1 8

RP24 22RRP24 22R

2

3

4 5

1 8

RP26 22RRP26 22R

2

3

4 5

1 8

RP25 22RRP25 22R

2

3

4 5

1 8

RP31 22RRP31 22R

2

3

4 5

1 8

RP28 22RRP28 22R

2

3

4 5

1 8

RP30 22RRP30 22R

2

3

4 5

1 8

RP29 22RRP29 22R

2

3

4 5

A-DDR3_MCLK

A-DDR3_MCLKZA_DDR3_MCLKZ

7

A-DDR3-CKE

6

A-DDR3-A10

7

A-DDR3-A12

6

A-DDR3-BA1

7

A-DDR3-A4

6

A-DDR3-A6

7

A-DDR3-A1

6

A-DDR3-A8

7

A-DDR3-A11

6

A-DDR3-A14

7

A-DDR3-CASZ

6

A-DDR3-RASZ

7

A-DDR3-A0

6

A-DDR3-WEZ

7

A-DDR3-A9

6

A-DDR3-A2

7

A-DDR3-A7

6

A-DDR3-A13

7

A-DDR3-A5

6

A-DDR3-RESET

7

A-DDR3-BA2

6

A-DDR3-A3

7

A-DDR3-ODT

6

A-DDR3-BA0

B-DDR3_MCLKB_DDR3_MCLK

B-DDR3_MCLKZB_DDR3_MCLKZ

7

B-DDR3-CKE

6

B-DDR3-A10

7

B-DDR3-A12

6

B-DDR3-BA1

7

B-DDR3-A4

6

B-DDR3-A6

7

B-DDR3-A1

6

B-DDR3-A8

7

B-DDR3-A11

6

B-DDR3-A14

7

B-DDR3-CASZ

6

B-DDR3-RASZ

7

B-DDR3-A0

6

B-DDR3-WEZ

7

B-DDR3-A9

6

B-DDR3-A2

7

B-DDR3-A7

6

B-DDR3-A13

7

B-DDR3-A5

6

B-DDR3-RESET

7

B-DDR3-BA2

6

B-DDR3-A3

7

B-DDR3-ODT

6

B-DDR3-BA0

A-DDR3-A0

A-DDR3-A1

A-DDR3-A2

A-DDR3-A3

A-DDR3-A4

A-DDR3-A5

A-DDR3-A6

A-DDR3-A7

A-DDR3-A8

A-DDR3-A9

A-DDR3-A10

A-DDR3-A11

A-DDR3-A12

A-DDR3-BA0

A-DDR3-BA1

A-DDR3-BA2

A-DDR3-RASZ

A-DDR3-CASZ

A-DDR3-WEZ

A-DDR3-ODT

A-MVREFCA

A-DDR3-A13

A-DDR3-A14

B-DDR3-A0

B-DDR3-A1

B-DDR3-A2

B-DDR3-A3

B-DDR3-A4

B-DDR3-A5

B-DDR3-A6

B-DDR3-A7

B-DDR3-A8

B-DDR3-A9

B-DDR3-A10

B-DDR3-A11

B-DDR3-A12

B-DDR3-BA0

B-DDR3-BA1

B-DDR3-BA2

B-DDR3-RASZ

B-DDR3-CASZ

B-DDR3-WEZ

B-DDR3-ODT

B-MVREFCA

B-DDR3-A13

B-DDR3-A14

AVDD_DDR0

AVDD_DDR0

N3

A0

P7

A1

P3

A2

N2

A3

P8

A4

P2

A5

R8

A6

R2

A7

T8

A8

R3

A9

L7

A10

R7

A11

N7

A12

M2

BA0

N8

BA1

M3

BA2

L2

CS_34

J3

RAS_35

K3

CAS_36

L3

WE_37

K1

ODT

M8

VREFCA

J1

NC1

J9

NC2

L1

NC3

L9

NC4

M7

NC5

T3

A13

T7

NC7

ZQL8VSST9VSS1T1VSS2P9VSS3P1VSS4M9VSS5M1VSS6J8VSS7J2VSS8G8VSS9E1VSS10A9VSSQG9VSSQ1G1VSSQ2F9VSSQ3E8VSSQ4E2VSSQ5D8VSSQ6D1VSSQ7B9VSSQ8

R553

R553

240R

240R

N3

A0

P7

A1

P3

A2

N2

A3

P8

A4

P2

A5

R8

A6

R2

A7

T8

A8

R3

A9

L7

A10

R7

A11

N7

A12

M2

BA0

N8

BA1

M3

BA2

L2

CS_34

J3

RAS_35

K3

CAS_36

L3

WE_37

K1

ODT

M8

VREFCA

J1

NC1

J9

NC2

L1

NC3

L9

NC4

M7

NC5

T3

A13

T7

NC7

ZQL8VSST9VSS1T1VSS2P9VSS3P1VSS4M9VSS5M1VSS6J8VSS7J2VSS8G8VSS9E1VSS10A9VSSQG9VSSQ1G1VSSQ2F9VSSQ3E8VSSQ4E2VSSQ5D8VSSQ6D1VSSQ7B9VSSQ8

R293

R293

240R

240R

R1801kR180

1k

R1811kR181

1k

R1841kR184

1k

R1851kR185

1k

N89A

N89A

C11

A_DDR3_A0

U10

U11

U12

U13

U14

U15

U16

U17

U18

W19

W20

W21

W22

N89FN89F

VSENSE_VSS

DVDD

VDDP

R158 0RR158 0R

R17

VDDC

R18

VDDC

T18

VDDC

T19

VDDC

T20

VDDC

T21

VDDC

U19

VDDC

U20

VDDC

U21

VDDC

U22

VDDC

V22

VDDC

T22

VSENSE

R19

VSENSE_VSS

P17

DVDD

N15

AVDDL_MOD

M15

AVDD11_ETH

N16

AVDD1P1_ADC

P16

AVDDLV_USB

L8

DVDD_NODIE

AA7

AVDD25_DADC

Y7

AVDD25_REF

Y8

AVDD25_REF

W8

AVDD25_ETH

W9

AVDD_MOD

AB7

AVDD25_PGA

AB6

PGA_VCOM

M8

AVDD_DMPLL

M5

AVDD_NODIE

M6

AVDD_DVI

M7

AVDD_DVI

N5

AVDD_AU33

N6

AVDD_EAR33

M4

AVDD3P3_ADC_MPLL

N4

VDDP

N7

AVDD_LPLL

H17

AVDD_DDR0_D

H16

AVDD_DDR0_D

J16

AVDD_DDR0_D

J17

AVDD_DDR0_D

H15

AVDD_DDR0_C

K18

AVDD_DDR1_D

L17

AVDD_DDR1_D

L18

AVDD_DDR1_D

M18

AVDD_DDR1_D

K17

AVDD_DDR1_C

J8

GND_FU

F8

GND

U25

DDR_GND

A9

DDR_GND

A12

DDR_GND

A15

DDR_GND

F20

DDR_GND

C21

DDR_GND

D19

DDR_GND

C25

DDR_GND

E19

DDR_GND

F19

DDR_GND

E22

DDR_GND

F25

DDR_GND

J25

DDR_GND

L23

DDR_GND

D22

DDR_GND

D7

GND

D8

GND

D9

GND

D10

GND

D11

GND

D12

GND

D13

GND

D14

GND

D15

GND

D16

GND

E8

GND

E9

GND

E10

GND

E11

GND

E12

GND

E13

GND

E14

GND

E15

GND

E16

GND

F9

GND

F10

GND

F11

GND

F12

GND

F13

GND

F14

GND

F15

GND

F16

GND

G22

GND

G9

GND

G10

GND

G11

GND

G12

GND

G13

GND

G14

GND

G15

GND

G16

GND

G17

GND

G18

GND

GNDU7GNDU8GNDU9GND

GND

GND

GND

GND

GND

GND

GND

MSD1328

GND

GND

GND

GND

GND

GND

GNDW4GNDW5GNDW6GNDW7GND

GND

V9

C7

V10

V11

GND

V12

V13

V14

A20

W10

VDDC

D D

VCC_VSENSE1

TP13TP13

AVDDL_MOD

AVDD11_ETH

DVDD_NODIE

AVDD1P1_ADC

AVDDLV_USB

C145

C145

AVDD_ADC25

1u/10V

1u/10V

AVDD_REF25

AVDD_LAN

AVDD_MOD

AVDD25_PGA

PGA_VCOM

AVDD_DMPLL

AVDD_ALIVE

AVDD_DVI

AVDD_AU

AVDD_EAR

AVDD_MPLL

AVDD_LPLL

VDDIO_0

VDDIO_1

C C

B B

A A

V8

GND

GND

GND

GND

GND

GNDV5GNDV6GNDV7GND

H6

GND

H7

GND

H8

GND

H9

GND

H10

GND

H11

GND

H12

GND

H13

GND

H14

GND

H22

GND

J7

GND

V4

GND

J10

GND

J11

GND

J12

GND

J13

GND

J14

GND

J15

GND

J22

GND

K7

GND

K9

GND

K10

GND

K11

GND

K12

GND

K13

GND

K14

GND

K15

GND

K16

GND

K20

GND

K21

GND

K22

GND

L9

GND

L10

GND

L11

GND

L12

GND

L13

GND

L14

GND

L15

GND

L16

GND

J9

GND

R22

GND

L22

GND

F22

GND

M9

GND

M10

GND

M11

GND

M12

GND

M13

GND

M14

GND

W15

GND

M16

GND

M17

GND

AA6

GND

N8

GND

N9

GND

N10

GND

N11

GND

N12

GND

N13

GND

N14

GND

V15

GND

V16

GND

N17

GND

P25

GND

N19

GND

P7

GND

P8

GND

P9

GND

P10

GND

P11

GND

P12

GND

P13

GND

P14

GND

P15

GND

W16

GND

V17

GND

P18

GND

P19

GND

R7

GND

R8

GND

R9

GND

R10

GND

R11

GND

R12

GND

R13

GND

R14

GND

R15

GND

R16

GND

W17

GND

V18