BEYMA LA10-3V, SUB218 User Manual

BEYMA LINE ARRAY SYSTEM PROJECT

BEYMA LINE ARRAY SYSTEM PROJECT

BEYMA LINE ARRAY SYSTEM PROJECTBEYMA LINE ARRAY SYSTEM PROJECT

LA10

LA10----3V AND SUB218

LA10LA10

3V AND SUB218

3V AND SUB2183V AND SUB218

BEYMA LINE ARRAY SYSTEM PROJECT

LA10-3V AND SUB218

1º PRESENTATION OF THE SYSTEM. LA3V210

The system that we are going to describe is a three-way Line Array system. It is made up of:

- A LF via that mounts the Beyma model 10G40.

- A MF via that mounts the model Beyma 10MI100.

- And a HF via composed by two WL4 waveguides and a diffuser specially designed for its

specific use in this application, the TDWL4. The profile of the horn has been calculated thru

numerical methods to optimize the dispersion and transient response of the WL4 units.

Beyma Line Array Project Page 2

BEYMA LINE ARRAY SYSTEM PROJECT

LA10-3V AND SUB218

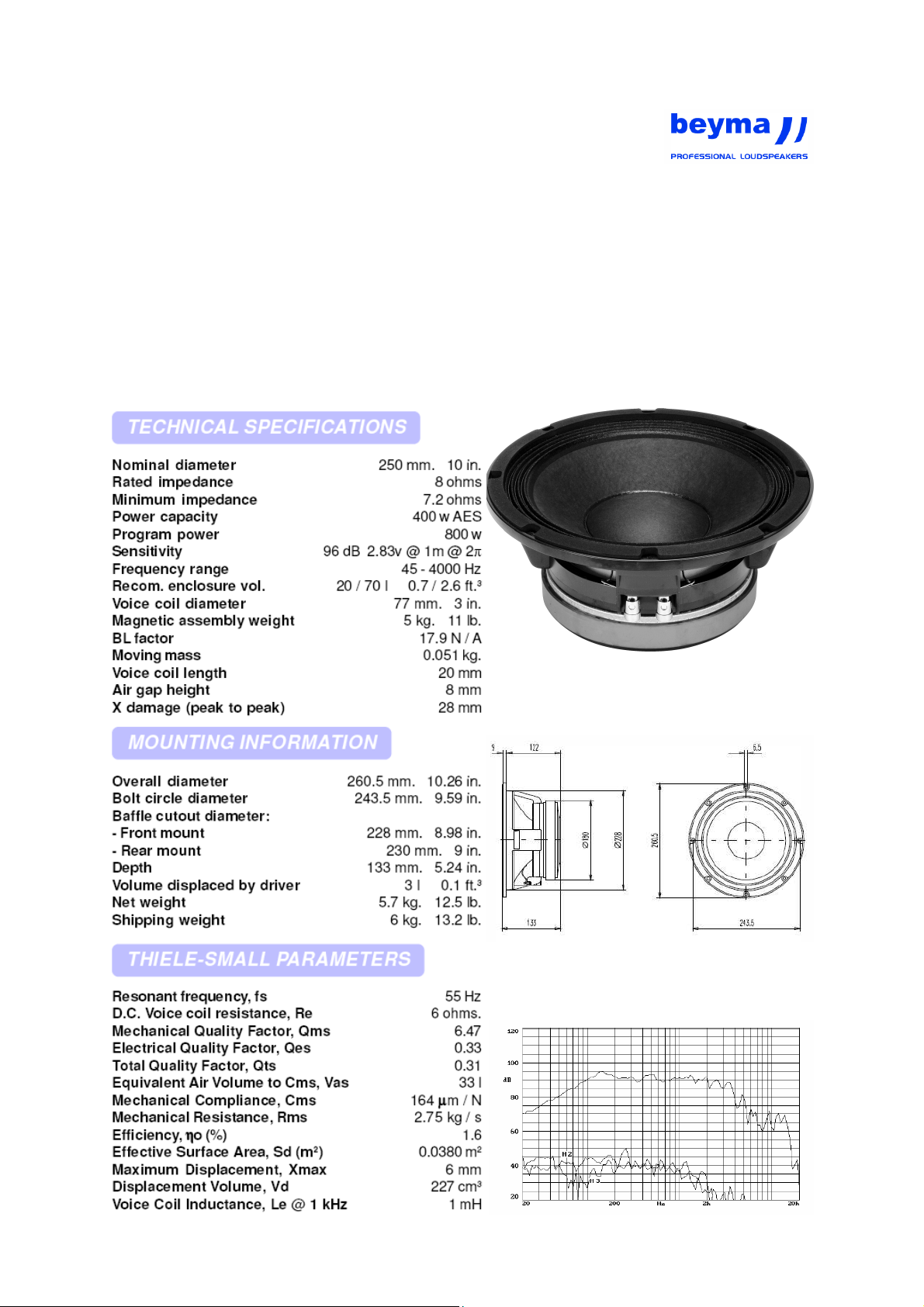

2º LF VIA: 10G40

This low frequency transducer is specially intended for the most demanding applications. Its design

concept arises from the need of achieve a more resistant loudspeaker that matches the more and

more power given by ultimate amplification systems.

In order to accomplish that, almost every component of the speaker has been reconsidered: its voice

coil has the benefits of an improved manufacturing process, made with the highest quality materials

and the diaphragm has been carefully developed to give an extremely flat, smooth response. These

characteristics make its integration in compact systems covering the low frequency range a straightforward task. Moreover, its parameters has been optimized to obtain an excellent bass response

when used in small bass-reflex cabinets.

.

Beyma Line Array Project Page 3

BEYMA LINE ARRAY SYSTEM PROJECT

LA10-3V AND SUB218

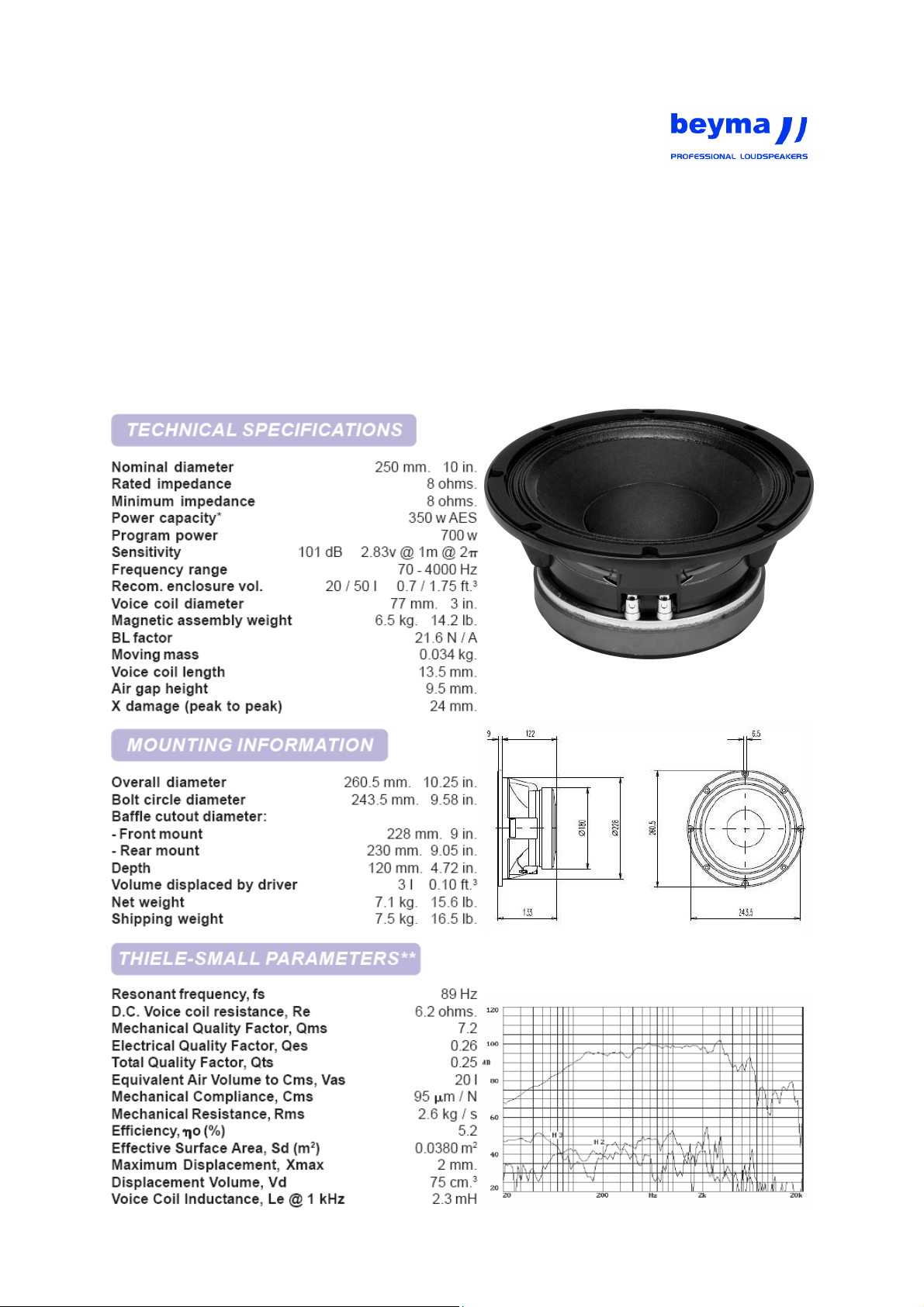

3º MF VIA: 10MI100

This low-mid frequency transducer offers three main points of interest: a high efficiency (5.2 %), an

extremely linear frequency response and a low harmonic distortion. These characteristics make it

suitable for high quality sound reinforcement systems, especially for live applications.

Beyond its frequency response advantages, this loudspeaker offers more: it takes profit of the improvements achieved in our low frequency-high power transducers. Thus, it incorporates a high quality voice coil and a large magnetic assembly to provide efficient heat dissipation. Thanks to this design concept of strongness, the 10 MI100 reaches a considerable power handling (350 WAES).

Beyma Line Array Project Page 4

BEYMA LINE ARRAY SYSTEM PROJECT

LA10-3V AND SUB218

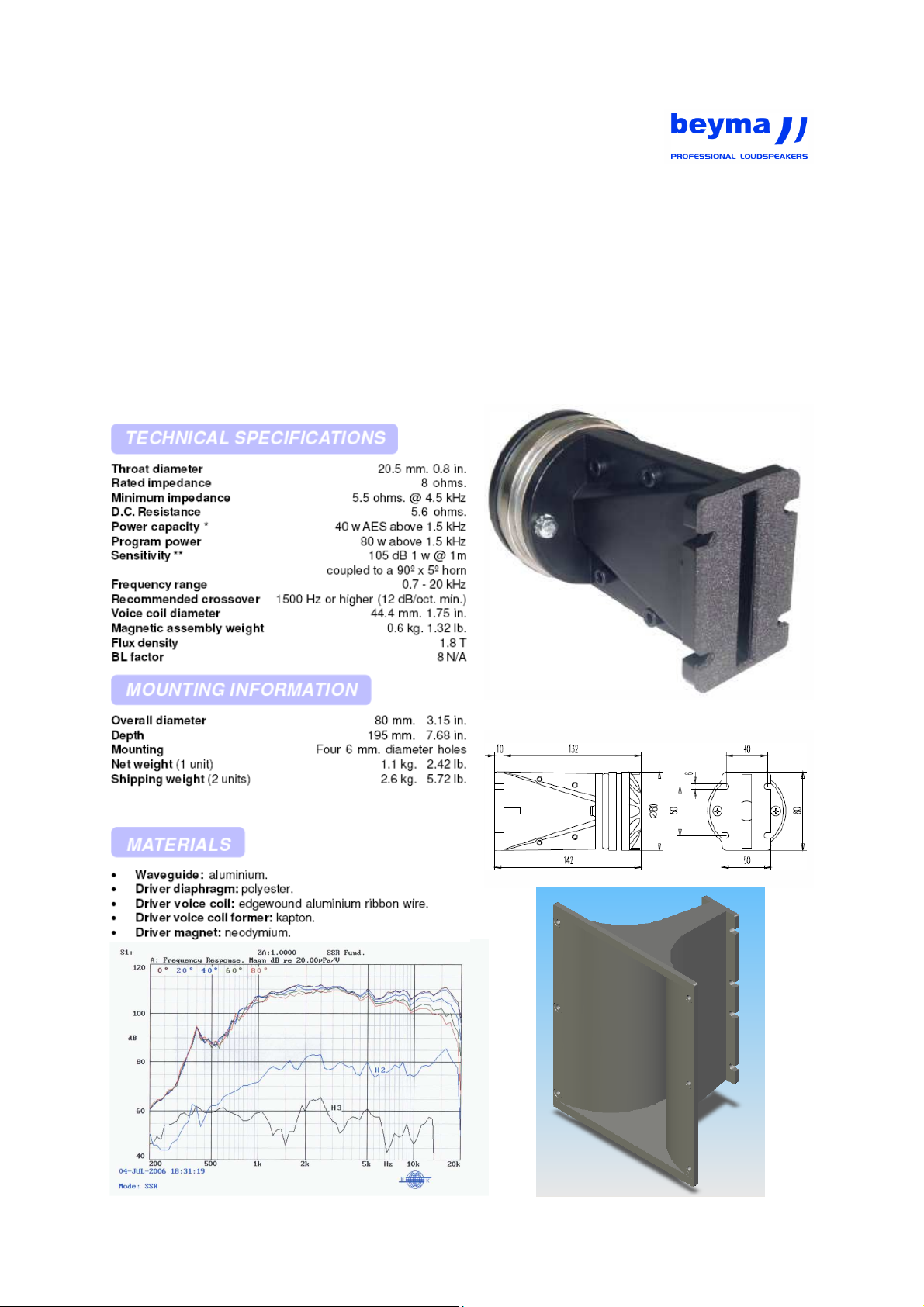

4º HF VIA: WL4 + TDWL4

This combination of high power neodymium compression driver with wave guide gives a straightforward solution to build a Line Array System, solving the difficult problem of achieving an optimum coupling between adjacent high frequency transducers. Instead of using expensive and complicated

wave-shaping devices, a simple but effective wave guide transforms the circular aperture of the compression driver into a rectangular surface, without excessive angle aperture to provide low curvature

to the acoustic wave front, arriving to fulfil the curvature requirement for optimal acoustic coupling

between adjacent sources until 18 kHz. This is achieved with the minimum possible length for low

distortion, but without being excessively short, which would cause strong high frequency interferences. This waveguide can be combined with loudspeakers of different diameters but it specially

matches with 8”, 6” and 5” loudspeakers.

Beyma Line Array Project Page 5

BEYMA LINE ARRAY SYSTEM PROJECT

LA10-3V AND SUB218

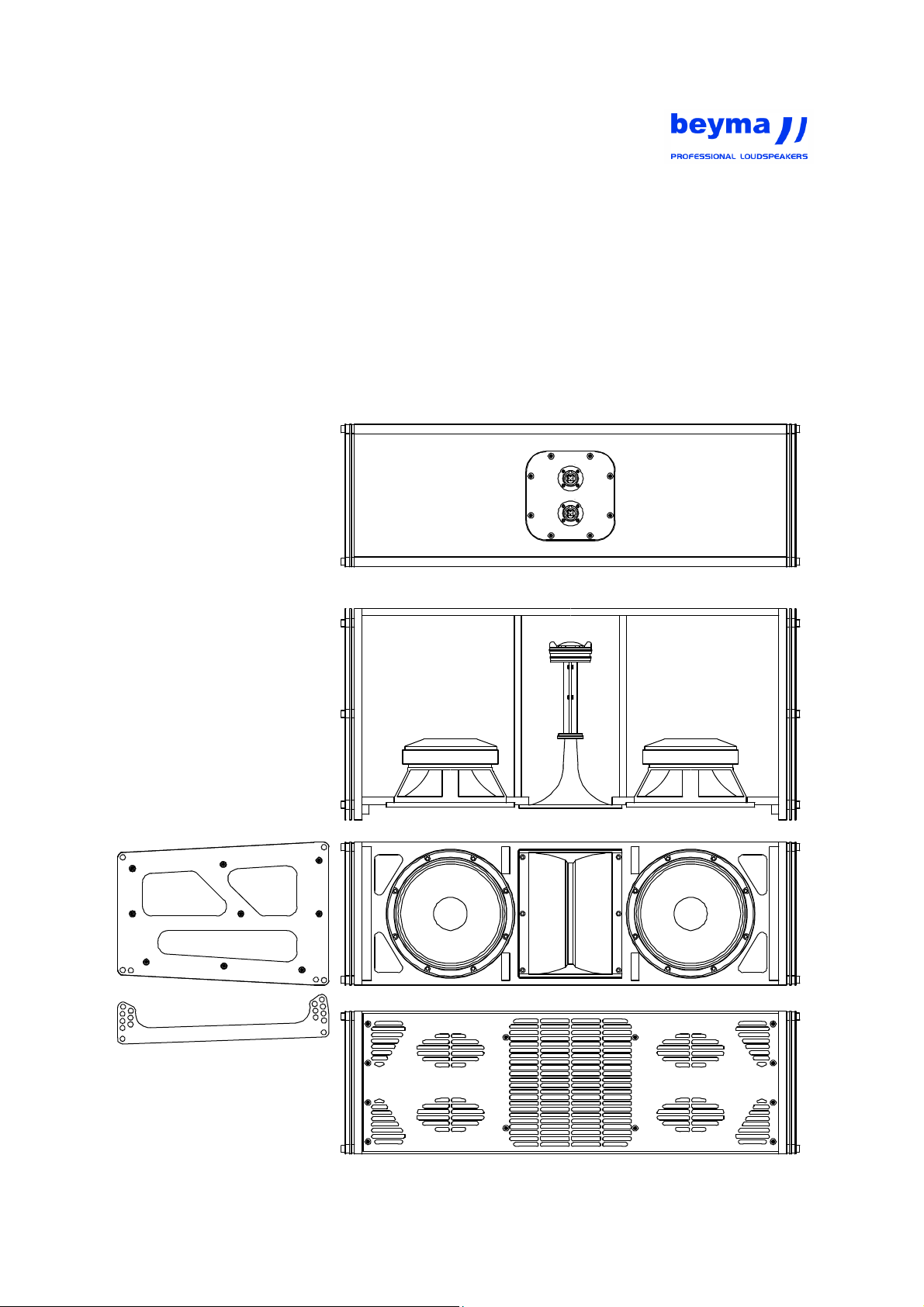

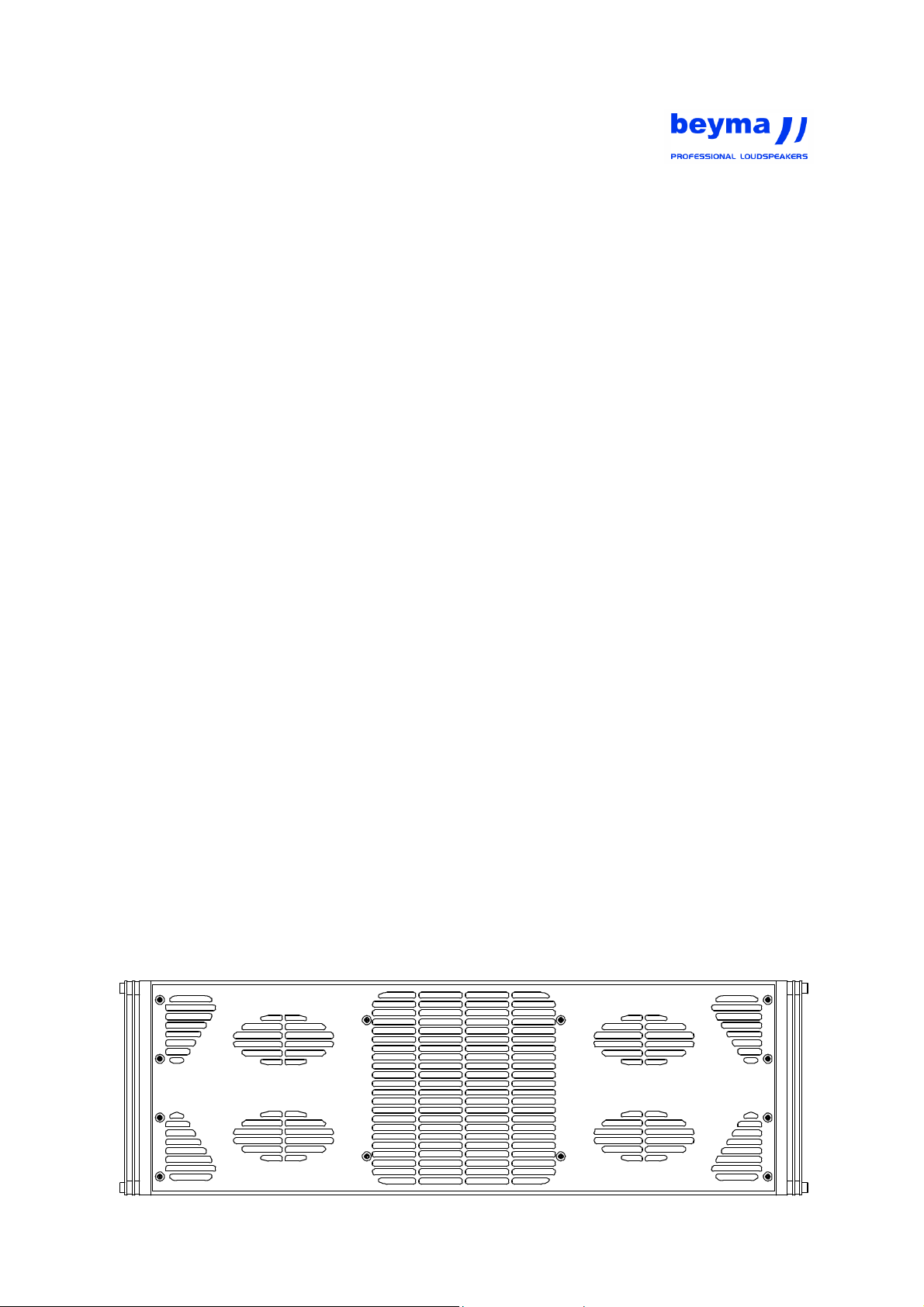

5º DESCRIPTION OF THE SYSTEM.

The beyma philosophy behind this system is as follows: :

1º So that the result of the sound system is comparable to other positioned systems is essential:

A) That it does not have appearance of "Kit" but of professional product.

B) That all the appearance of the system is solved, without the costumer must take pat of it.

C) And that the performance in terms of sonorous quality, as well as in the angle calibration of

the system are the necessary for a Line Array system.

2º That fulfills all and each one of the necessary requirements of a Line Array:

A) That the distance between the axes of the transducers is the correct one.

B) That the intermodulation distortion is as small as possible.

C) That the angle calibration between boxes is strictly exact.

3º That the assembly from the point of view of the client is easy, fast and without possibility of error,

for it:

A) All the complexity is in the "hardware", accessories and rest of components that are sup-

plied to the costumer.

B) the product once finished, is versatile, practical and of easy handling. In summary, a good

working tool.

• All the "hardware" of the system is cut by laser accurately of hundredth of millimetre.

• The frontal grid acts like a phase corrector to as much obtain greater sound pressure in the

mid via, as well as in the low frequency via. In addition, it solves the problem of the distance

between centres of the midrange via for the fulfilment of the coherent sum of the wave front

created by all the boxes, as well as providing excellent horizontal dispersion.

• All the accessories are constructed in F1 steel grade, that confers the maximum mechanical

resistance. Finished in satin black colour, with resistant painting to scratches and aging

• The "hardware" is calculated to support in series 20 units hung in vertical with a safety factor of

7 to 1.

• The pins are made of solid stainless steel, with a system of magnetic anchorage.

• The plate of connections mounts a double Speakon connector of 8 contacts in parallel with a

circuit plate that includes the internal wiring of the system.

• It includes all the screws, nuts and bolts and the necessary pieces for the complete assembly

of the system.

• The bumper or flown system frame is calculated to support 20 units suspended in series with a

safety factor of 7 to 1 and it is provided aside.

Beyma Line Array Project Page 6

BEYMA LINE ARRAY SYSTEM PROJECT

LA10-3V AND SUB218

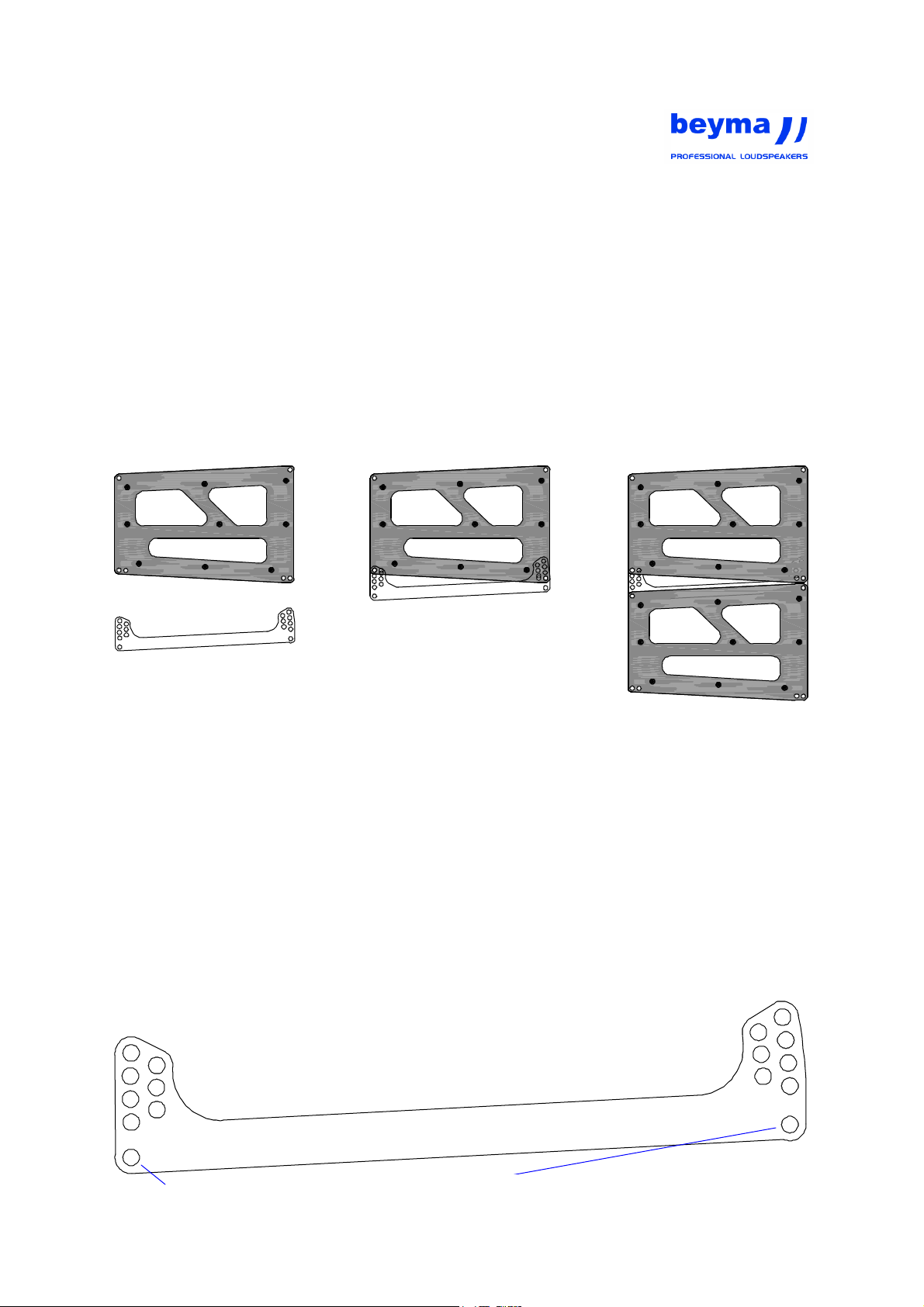

6º DESCRIPTION OF THE ALIGNMENT “HARDWARE”.

The alignment hardware for a LA10-3V box has to lateral steel plates and an alignment steel arm. In

every lateral side of the acoustic enclosure, we will find:

- Two lateral steel frames 3 mm. thick, F1 grade steel, to be tighten in the lateral side of the

box.

- One vertical alignment steel arm, 5 mm. Tic, F1 grade steel.

- Nine nº 10 harpoon nuts, inlaid in the inner said of the wooden box.

- Eighteen steel rings, 7 mm. Tic, to be fitted between the lateral steel frames and the lateral of

the box.

- Four solid stainless steel with magnetic securing system.

Marco lateral

Lateral frame Lateral frame with

Biela de angulación

Alignment arm

Marco lateral

con biela a "0º"

arm in 0º angle

Lateral frames with

2 marcos laterales

con biela a "0º"

arm in 0º angle

The vertical orientation system has a steel alignment arm, with 16 holes which are used as follows:

- For normal use, the front part of the arm should be used always with the pin in the 0º hole

(red color in the drawing).

- To regulate the angle between adjacent boxes in the vertical direction, the back part of the

arm should be used, by introducing the pin in the required hole, ranging from 0º to 6º angle

between boxes. (blue color in the drawing).

- For alternative applications, as p. instance as a front fill, the front pin can be used to open

the front angle of the box and direct the coverage of the box to a different audience area,

arriving to a maximum of 12º angle in the front.

CALIBRADO DE LOS ÁNGULOS VERTICALES ENTRE UNIDADES

VERTICAL ALIGNMENT ANGLE BETWEEN BOXES

0º

1º

2º

3º

4º

5º

6º

A

Taladros de anclaje de la unidad inferior

Holes for the attachement with the inferior box

6º

5º

4º

3º

2º

1º

0º

A

Beyma Line Array Project Page 7

Loading...

Loading...