Bewator 5PQXX500 Proximity Readers Handbook

Proximity

Readers Handbook

HB00117 Issue 1

Applicability

This handbook applies to the PR500 Proximity Reader,

the HD500-2 Heavy Duty Proximity Reader, the SP500 Switch Plate

Proximity Reader and the PM500 Panel Mount Proximity Reader

© BEWATOR LTD JULY 2003

This handbook is based on the best information available to Bewator at the time of publication.

Although every effort is made to keep our documentation up to date, small changes which arise from

the Company's policy of continuing product improvement are not necessarily incorporated. Some

products are not available in all countries. All orders are accepted only on the Company's standard

Conditions of Sale, copies of which are available on request.

Bewator Ltd, Albany Street, Newport, South Wales, NP20 5XW, UK

Tel: +44 (0)1633 821000 Fax: +44 (0)1633 850893

Email: sales@bewator.co.uk Website: www.bewator.co.uk

NOTE: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Safety

This equipment must be powered by a supply which is suitably insulated

from the mains. The supply should be classed as SELV under the terms

of EN60950.

The power supply must be connected to safety earth. A mains isolation

switch should be provided by the installer. Any third party equipment

connected must also be suitably insulated from the mains supply.

Any fuses which are replaced must be of the recommended rating and

type.

Wiring connected by the installer must be adequate. The use of

inadequate wiring may present a fire hazard.

Except where specified the equipment is not suitable for outside use.

Except where specified this equipment is not for use in safety critical

applications.

Contents

Chapter 1 Introduction

Reader types............................................................................................1-1

Data output .............................................................................................1-1

Interrogation of cards and tags................................................................. 1-2

Setting up the Reader...............................................................................1-2

Chapter 2 Installing and connecting

PR500- 2 Proxim it y Reader........................................................................2-1

HD500-2 Heavy Duty Proximity Reader.....................................................2-3

SP500 Switch Plate Proximity Reader........................................................2-6

PM500 Panel Mount Proximity Reader ...................................................... 2-8

Configuring and testing the Reader...............................................2-10

Chapter 3 Setting up

Configuring the Reader.............................................................................3-1

The configuration card.............................................................................3-1

The DC/SC card......................................................................................3-2

Programming the configuration card.........................................................3-2

0xxs (secondary code swap) 3-2

xbff (ASCII in t er face pr ot ocol and bau d rate).....................................3-3

xxxh (Data Hold input signal polarity)................................................3-3

xxhe (horn configuration) 3-4

hhhh (hold- off time) ........................................................................3-4

pxxx (calculation of leading parity bit for 26-bit Wiegand interfaces)....3-5

xxrg (inter n al/external con t r ol ofre d an d gr een LEDs)........................3-5

crrrrrrr (Secondary Code check disable,

and repeat data delay - RDD) ..................................................... 3-6

iiiiiiii (interface number) 3-6

Note to existing users of PR500 and HD5 0 0....................................3-6

Programming the DC/SC card.................................................................. 3-7

Presenting configuration card and DC/SC card to the Reader....................3-7

Changing the Secondary Code or Distributor Code....................................3-7

Examples of working out what to program i nto the

configuration card in 63-bit mode on the Programmer...............................3-8

Example 1.........................................................................................3-8

Example 2.........................................................................................3-9

i

Proximit y R ead ers Han db ook

Chapter 4 Data interfaces

Electrical characteristics of outputs from the Reader.................................4-1

Data Hold input.......................................................................................4-2

Wiegand ..................................................................................................4-2

Connections......................................................................................4-2

Electrical char act er ist ics....................................................................4-2

Data format.......................................................................................4-3

Card data......................................................................................4-3

Interface settings...............................................................................4-4

Magnetic Stripe........................................................................................4-5

Connections......................................................................................4-5

Electrical char act er ist ics....................................................................4-5

ASCII data output - TTL voltage levels .......................................................4-7

Connections......................................................................................4-7

Electrical char act er ist ics....................................................................4-7

Data format.......................................................................................4-8

Protocol ............................................................................................ 4-8

4101/4010 Controller interface..........................................................4-8

Chapter 5 Operation

LEDs.......................................................................................................5-1

Card interr ogat ion....................................................................................5-1

Standard in t er r ogat ion rout in e...........................................................5-1

Using cards .............................................................................................5-2

Looking after a card...........................................................................5-2

ii

Chapter 1

Introduction

The

PR500, HD500-2, SP500

designed to read the codes contained in Cotag coded cards and tags

and to pass these codes, if valid, to a host system. These Readers are

primaril y for use by OEMs to provi de proxi mity reading for their own

proprietary access control systems.

Each Reader requires a power supply, but can usually share the

same supply as the door lock.

Reader types

The PR500 Proximity Reader is a general purpose proximity reader

which is small and slim and can be mounted on a wall or door frame.

The HD500-2 Heavy Duty Proximity Reader has a stainless steel

frame, held in place by four tamper-resistant screws, which covers

the mounting screws. This makes it suitable for applications where

vandalism could be a problem.

The SP500 Switch Plate Proximity Reader fits a standard single

surface-mount or flush fitting back box, either metal or plastic, such

as is used for light switches and mains plug sockets2-hole mounting

for screwing it to a standard single-way back box.

and

PM500 Proximity Readers

are

The PM500 Panel Mount Proximity Reader can be mounted within a

sheet metal or plastic panel using four screws.

Data output

The Readers provide Wiegand or Magnetic Stripe format data output,

or ASCII data output at TTL voltage levels (0V and +5V). (The Readers

are available in AB format if you require BCLINK data output, but

this option is not described in this handbook.)

For some OEM systems, the data lines from two Readers can be

connected in parallel, the host polling each Reader in turn using the

Data Hold input. When this input is held low, the Reader buffers the

data from one

and read the message before the next card is read, or else the

message is discarded by the Reader.

1-1

transaction. The host must release the Data Hold line

Proximity Read er s Han d book

Interrogation of cards and tags

The Reader uses “standard interrogation” which reads the card code

just once and outputs the data in a little under half a second for

standard cards and tags, or in one tenth of a second for fast cards

and tags. If there is too much electrical noise to read a card or tag,

the amber LED indicator on the unit flashes.

The interrogation routine checks both the Distributor Code and the

Secondary Code* of a card or tag and sends data to the host system

only if both are valid.

*Note that the Secondary Code check can be disabled with some

interfaces - see chapter 3 for details.

Setting up the Reader

You configure the Reader by presenting it with two coded cards. The

first card (the configuration card) defines the type of data interface,

and various other features*. The second card (any of the ordinary

Distributor Coded cards which will be used with the system) teaches

the Reader its Distributor and Secondary Codes. Note that you

cannot teach the Reader its Distributor and Secondary Codes without

first presenting the configuration card.

When the Reader is powered up, it waits 4 seconds for a

configuration card to be presented. If it doesn’t read a configuration

card in this time, it enters the configured operating mode.

*All the features which can be set using the configuration card are

listed on the first p age of c hapter 3.

read and understand chapter 3 of this handbook before you

attempt to install a Reader

.

It is most importa nt that you

1-2

Chapter 2

Installing and connecting

PR500 Proximity Reader

The Reader is supplied with the cover separate. If the cover has been

fitted for any reason, remove it by pushing in the lug on its lower

edge using a suitable screwdriver.

1. Choose a suitable position to mount the Reader near the door.

The Rea der has a maximum range o f 30cm (12in) so it must be

mounted in a position where the card or tag can easily be

brought within this distance. We recommend it is mounted

approximately one metre (3.5ft) above the ground. Also

consider ease of access to the door once the card or tag has

been read, for example, it is better to mount the Reader near

the opening side of the door rather than the hinge side.

2. The Reader should be mounted with the LEDs at the top left.

Mark out and drill the two mounting holes. Don’t fix the

Reader to the wall yet. The holes accept 4mm machine screws

or No 8 wood screws.

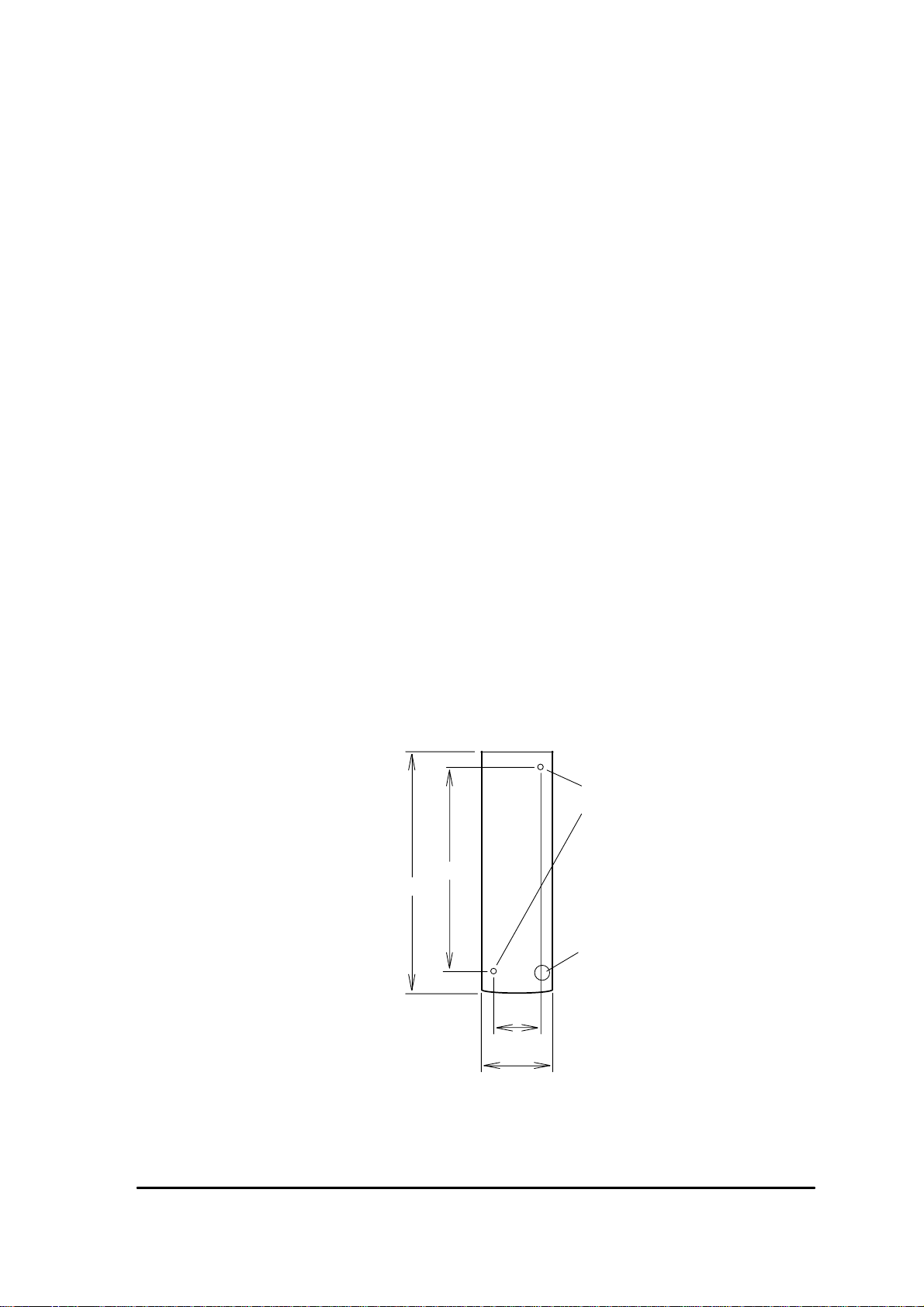

Fixing Dimensions (mm)

Fixing holes:

4.2 diameter

118

137.5

Cable entry hole

9mm diameter

20

37.5

The cover overlaps the base slightly on all sides so you must

allow a little extra room all round.

2-1

Proximity Read er s Han d book

3. Route the cables into the Reader: you can use either the cutout in the base or the one in the lower edge at the bottom of

the Reader.

The connections required for the Reader are power supply

connections (0V and +12V DC or +24V DC), data output

connections for Wiegand or Magnetic Stripe (D0, D1, DA) or

ASCII/TTL (

H , D0, DA), and a connection from the host to the

Data Hold input (

connected in parallel.

To promote EMC compliance we recommend you use 812

Cable as described here. Trim back and insulate the screens at

the PR500. Connect the screens at the host only: do not

connect the screens to the PR500.

4. When you have routed the cables into the Reader you can

screw it to the wall.

5. Make the connections shown in the following table:

Reader Function

V+ Power supply +12V unregulated or 24V battery-backed*

(absolute max 32V, m in 10.6V, 100mA max)

0V Power supply 0V (-ve)

(also ground reference for data output)

H

“CTS” for ASCII/TTL

D0 (D) “ Data Zero” f or Wiegand

“Data” for Mag Stri pe

“TXD” for ASCII/TTL

D1 “Data One” for W iegand

“Strobe” for Mag Stripe

DA “Data Available” for Wiegand

“Present” for Mag Stripe

“RTS” for ASCII/TTL

Horn (Adr) Horn - 0V to sound, +5V to turn off

R Red LED control - 0V for red LED

R/G Single wire LED control

0V for green LED, +5V for red LED

(C) “Data Hold” for Wiegand and Mag Stripe

H ) if data lines from two Readers are to be

*The PR500 is designed to be operated by 12V unregulated power supplies, or 24V

battery-backed power supplies. Operati ng vol tage range is 10. 6 to 32.0V. The upper

voltage is intended to be compatible with the charging of 24V lead-acid batteries.

Charge methods vary, and may be temperatur e dependent. 32V max is intended to

be compatible with commonly used charging methods. If the upper operating

voltage is exceeded then permanent damage may be caused. Installers and systems

designers should check the max power supply voltage under all conditions. Do not

operate the PR500 using unregulated 24V supplies. The PR500 current consumption

can be significantly less than 100mA. The unloaded peak voltage from a nominal

24V unregulated supply will exceed the absolute max.

6.

Do not

configured it and tested it

fit the front cover to the Reader until you have

(see the end of this chapter).

2-2

Installin g an d con n ect in g

HD500-2 Heavy Duty Proximity Reader

1. Choose a suitable position to mount the Reader near the door.

The Rea der has a maximum range o f 25cm (10in) so it must be

mounted in a position where the card or tag can easily be

brought within this distance. We recommend it is mounted

approximately one metre (3.5ft) above the ground. Also

consider ease of access to the door once the card or tag has

been read, for example, it is better to mount the Reader near

the opening side of the door rather than the hinge side.

2. You can mount the Reader using any of the six mounting holes

in the black plastic enclosure - the diagram at the end of this

section shows the fixing dimensions and is drawn actual size

so you can use it as a template when drilling the holes.

The Reader should be mounted with the strip of LEDs at the

top left.

Note that you do not need the stainless steel frame when

mounting the Reader - you fasten it to the Reader afterwards

to prevent anyone undoing the mounting screws.

3. Mark out and drill the mounting holes, but

Reader to the wall yet

The holes accept 4mm machine screws or No 8 wood screws.

4. The connections required for the Reader are power supply

connections (0V and +12V DC or +24V DC), data output

connections for Wiegand or Magnetic Stripe (D0, D1, DA) or

ASCII/TTL (H, D0, DA), and a connection from the host to the

Data Hold input (H) if data lines from two Readers are to be

connected in parallel.

To promote EMC compliance we recommend you use 812

Cable as described here. Trim back and insulate the screens at

the HD500-2. Connect the screens at the host only: do not

connect any of the screens to the HD500-2.

.

don’t fix the

2-3

Proximity Read er s Han d book

Route the cables into the Reader from behind, then make the

connections shown in the table below.

Reader Function

V+ Power supply +12V unregulated or 24V battery-backed*

(absolute max 32V, m in 10.6V, 100mA max)

0V Power supply 0V (-ve)

(also ground reference for data output)

H (C) “Data Hold” for Wiegand and Mag Stripe

“CTS” for ASCII/TTL

D0 (D) “Data Zero” for W iegand

“Data” for Mag Stripe

“TXD” for ASCII/TTL

D1 “Data One” for Wi egand

“Strobe” for Mag Stripe

DA “Dat a Avai lable” for Wiegand

“Present” for Mag Stripe

“RTS” for ASCII/TTL

Horn (Adr) Horn - 0V to sound, +5V to t ur n of f

R Red LED control - 0V for red LED

R/G Single wire LED control - 0V for green LED, +5V for red LED

TAMPER Tamper circuit connection (hard wired link) #

*The HD500-2 is designed to be operated by 12V unregulated power supplies, or

24V battery-backed power supplies. Operating volt age range is 10.6 to 32.0V. The

upper voltage is intended to be compatible with the charging of 24V lead-acid

batteries. Charge methods vary, and may be temperature dependent. 32V max is

intended to be compatible with commonly used charging methods. If the upper

operating voltage is exceeded then permanent damage may be caused. Installers

and systems designers should check the max power supply voltage under all

conditions. Do not operate the HD500-2 using unregulated 24V supplies. The

HD500-2 current consumpti on can be significantly less than 100m A. The unloaded

peak voltage from a nom inal 24V unregulated supply will exceed the absolute max.

#Two term inals are provided for use with a system 24hour tamper protection circuit .

These terminals are hard wired together on the Reader’s circuit board. If you connect

cables to these terminals, an open circuit will indicate that the wires have been cut.

5. Route the cable neatly then fix the Reader to the wall or door

frame.

6.

Do not

have configured it and tested it

fit the stainless steel frame to the Reader until you

(see the end of this chapter).

7. When you have configured the Reader and tested it to make

sure that it is working correctly, you can fasten the Reader’s

stainless steel frame using the four “Resistorx” M4x12 screws

provided. These tamper-resistant screws can only be inserted

or removed using the correct tool which is not supplied with

2-4

Loading...

Loading...