Beverage Air IM101S Installation Manual

3077860

BLAST CHILLER AND FREEZING

CELLULES DE REFRIFERATION RAPIDE ET CELLULES MIXTES

ABATEDORES DE TEMPERATURA

USE AND INSTALLATION MANUAL

MANUEL D’UTILISATION ET D’INSTALLATION

MANUAL DE US

Rev.1 02/2007

GB

FR

P

Carefully read the instructions contained in the handbook. You may find important safety instructions and

recommendations for use and maintenance.

Please retain the handbook for future reference.

The Manufacturer is not liable for any change s to this handbook, which may be altered w ithout prior

notice.

Lire avec attention les instructions contenues dans ce livret car elles fournissent d'importants renseignements

pour ce qui concerne la sécurité, l'emploi et l'entretien.

Garder avec soin ce livret pour des consultations ultérieures de différents opérateurs.

Le constructeur se réserve le droit d'apporter des modifications à ce manuel, sans préavis ni

responsabilité d'aucune sorte.

Leia com atenção as advertências contidas neste manual pois fornecem importantes indicações para a

segurança, a utilização e a manutenção do aparelho.

O construtor reserva-se o direito de modificar o manual sem dar aviso prévio e sem nenhuma

responsabilidade.

-

I

N

D

E

X

-

-

I

N

D

-

I

N

1st PART INSTRUCTION MANUAL …………………………………3

2st PART INSTALLATION MANUAL ………………………………31

0 INFORMATION FOR THE READER ………………………………………………3

1 GENERAL INSTRUCTIONS ON DELIVERY ……………………………………3

• GENERAL INSTRUCTIONS ……………………………… ……………………………………3

• TECHNICAL DATA ………………………………………………………………………………3

• LIST OF REGULATION REFERENCES ……………………………………………………3

• GENERAL INSTRUCTIONS ……………………………… ……………………………………3

• SETTING UP ………………………………………………………………………………………4

• TESTING …………………………………………………………………………………………4

2 CONTROL PANEL …………………………………………………………………7

• DESCRIPTION OF CONTROLS ………………………………………………………………7

• CORE PROBE ……………………………………………………………………………………8

• GENERAL SETTING ……………………………………………………………………………8

3 WORKING …………………………………………………………………………11

• QUICK COOLING CYCLE ……………………………………………………………………11

• STORING CYCLE ………………………………………………………………………………21

• MEMORIZING PROGRAMMES ……………………………………………………………… 23

• USING MEMORIZED PROGRAMMES ………………………………………………………23

• USING RECOMMENDED PROGRAMMES …………………………………………………24

• DEFROSTING …………………………………………………………………………………24

4 ACCESSORIES ……………………………………………………………………26

• PRINTING MEMORIZED CYCLES ………… …………………………………………………26

5 MAINTENANCE ……………………………………………………………………27

• MAINTENANCE AND CLEANING ……………………………………………………………27

MACHINE LOADING …………………………………… ……………………………………………………………5

POSITION OF TRAYS ………………………………………………………………………………………………5

LENGTH ………………………………………………………………………………………………………………5

LANGUAGE …………………………………………………………………………………………………………8

CLOCK ………………………………………………………………………………………………………………9

TEMPERATURE UNIT OF MEASUREMENT ……………………………………………………………………9

PRE-COOLING CYCLE ………… ……… ………… ……… ………… ……… ………… ……… ………… ………1 1

IFR POSITIVE QUICK COOLING CYCLE ………………………………………………………………………13

CORE PROBE POSITIVE QUICK COOLING CYCLE …………………………………………………………14

CORE PROBE NEGATIVE QUICK COOLING CYCLE ………………………………………………………15

TIME-CONTROLLED POSITIVE QUICK COOLING CYCLE …………………………………………………16

TIME-CONTROLLED NEGATIVE QUICK COOLING CYCLE ………………… ………… ……… ………… …17

CORE PROBE HARD QUICK COOLING CYCLE ………………………………………………………………18

TIME-CONTROLLED HARD QUICK COOLING CYCLE ………………………………………………………19

POSITIVE STORING CYCLE ……………………………………………………………………………………21

NEGATIVE STORING CYCLE ……………………………………………………………………………………22

CLEANING THE CABINET …………………………………………………………………………………………27

CLEANING THE AIR CONDENSER ……………………………………………………………………………28

STAINLESS-STEEL MAINTENANCE ……………………………………………………………………………28

DISCONTINUED USE ………………………………………………………………………………………………29

D

E

E

X

X

-

-

-

I

N

D

E

X

-

-

I

N

D

-

I

N

D

E

E

X

X

-

-

• INSTALLATION ……………………………………………………………………………… …31

• GENERAL SETTING ……………………………………………………………………………34

•

• SERVICE FUNCTIONS …………………………………………………………………………36

• ALARMS AND FAULT ANALYSIS …………………………………………………………40

• DISPLAYING INPUTS/OUTPUTS STATE …………………………………………………41

• DISPLAYING THE LATEST DEFROST CYCLES …………………………………………42

• DISPLAYING DOOR OPENINGS ……………………………………………………………42

• ALARMS AND USER PROGRAMMES CANCELLATION ………………………………43

• RESTORING PRE-SET PARAMETERS ……………………………………………………44

• MAINTENANCE OF PANEL BOARD ………………………… ……………………………45

• WIRING DIAGRAM PLATE …………………………………………………………………46

• CONTROL AND SAFETY SYSTEMS ………………………………………………………46

• DISPOSAL ………………………………………………………………………………………46

• REFRIGERANT MATERIAL SAFETY DATA SHEET …..…………………………………47

• DIMENSIONS …………………………………………………………………………………48

ANNEXES …………………………………………………………………………49

INTRODUCTION ……………………………………………………………………………………………………31

MAX ROOM TEMPERATURE ……………………………………………………………………………………31

POSITIONING ………………………………………………………………………………………………………31

WIRING ………………………………………………………………………………………………………………3 3

PLEASE USE CERTIFIED APPROVED MATERIALS …………………………………………………………33

REFRIGERATING CONNECTION …………………….…………………………………………………………33

CONNECTION TO CONDENSATE DRAIN ………………………………………………………………………33

TESTING ……………………………………………………………………………………………………………34

LANGUAGE …………………………………………………………………………………………………………34

CLOCK ………………………………………………………………………………………………………………35

TEMPERATURE UNIT OF MEASUREMENT ……………………………………………………………………35

PRINTER INSTALLATION ……………………………………………………………………36

CHANGING PARAMETERS ………………………………………………………………………………………36

DESCRIPTION OF PARAMETERS ………………………………………………………………………………37

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

INFORMATION FOR THE READER CHAPTER 0

This manual is subdivided into two parts.

1st part: covers all the information

necessary to the user.

GENERAL INSTRUCTIONS ON DELIVERY CHAPTER 1

GENERAL INSTRUCTIONS

Make sure that the consignment has not been tampered with or damaged during transport.

After unpacking the cooling cabinet make sure all sections or components have been included and

specifications and conditions are as to your order.

If not, please inform the retailer immediately.

We assure you have made the best choice in purchasing our products and hope you will be fully satisfied

with our their performance. To this purpose, we recommend you strictly comply with the instructions and

regulations contained in this handbook.

Please remember that no reproductions of this handbook are allowed. Due to our constant technological

updating and research, the features described in this handbook may be altered without prior notice.

TECHNICAL DATA

Please refer to the technical data of your own appliance. (tab.1a-1b)

LIST OF REGUALATION REFERENCES

The cooling cabinet we manufacture fully complies with the following regulations:

UL Listed for electrical safety

NSF standard 7 for sanitation

GENERAL INSTRUCTIONS

The quick cooler is a refrigerating appliance which can cool cooked foodstuffs to a temperature of +38 [°F]

(positive quick cooling) and to 0 [°F] (negative quick cooling).

Machine capacity as to the quantity to be cooled depend on the model purchased.

2nd part: covers all the information necessary to

the qualified operators authorized to move,

transport, install, service, repair and demolish the

appliance.

While users are instructed to refer to the 1st part

only, the 2ndpart is addressed to skilled

operators. They may also read the1st part for a

more complete picture of the information provided

if necessary.

U

A

A

L

L

-

-

3

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

SETTING UP

Before setting to operation thoroughly clean the cooling cabinet with a suitable detergent or sodium bycarb

dissolved in lukewarm water. Clean the appliance inside to remove any condensate caused by the

Manufacturer's final testing.

Cooling and freezing speed depends on the following factors:

a) container shape, type and material;

b) whether container lids are used;

c) foodstuff features (density, water contents, fat contents);

d) starting temperature;

e) thermal conduction inside the foodstuffs

Positive /Negative quick cooling time depends on type of foodstuffs to be processed.

Full-speed cycle is recommended for high-density or large-sized foodstuffs. However, the following limits

should never be exceeded : a 7.1 pounds load for 12”x20”x2-1/2” or 14 pounds load for 18”x26”, a 2”

thickness or freezing and an 3” thickness for cooling (tab.2).

The low-speed cycle is suitable to process delicate foodstuffs, such as vegetables, creamy products, creamy

desserts or low-thickness products.

We recommend making sure that any positive quick cooling cycles, up to +38 [°F] to the core of the product,

do not last over 90 minutes, and that negative quick cooling cycles, up to 0 [°F] to the core of the product,

do not last over 4 hours.

The processing room is to be pre-cooled before starting the positive and /or negative quick cooling cycle.

Moreover, avoid covering the foodstuffs during the cycle, which would increase the cycle length.

We recommend using the core probe in order to have the exact core temperature reading. Do not stop the

cycle before reaching a temperature of +38 [°F] during positive quick cooling and 0 [°F] during negative quick

cooling.

Tab.2

Name and Surname Address Tel./fax no.

Model Max. output/cycle Capacity

IM51M-IM51C 44[lb] 24[lb]

IR51M-IR51C 40[lb] -

IM101L-IM101S 93[lb] 55[lb]

IR101L-IR101S 80[lb] -

IM72S 115[lb] 55[lb]

IR72S 113[lb] -

IM102S 220[lb] 110[lb]

+160[°F]÷+38[°F] +160[°F]÷+0[°F]

TESTING

A

U

A

n° max

5 12“x20“x1,5“

4 12“x20“x2,5“

5 12“x20“x1,5“

4 12“x20“x2,5“

14 12“x20“x1,5“

8 12“x20“x2,5“

14 12“x20“x1,5“

8 12“x20“x2,5“

26 12“x20“x1,5“

14 12“x20“x2,5“

13 18“x26“x1,5“

7 18“x26“x2,5“

26 12“x20“x1,5“

14 12“x20“x2,5“

13 18“x26“x1,5“

7 18“x26“x2,5“

32 12“x20“x1,5“

20 12“x20“x2,5“

16 18“x26“x1,5“

10 18“x26“x2,5“

L

L

-

-

4

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

-

I

N

S

T

R

U

C

T

I

O

N

M

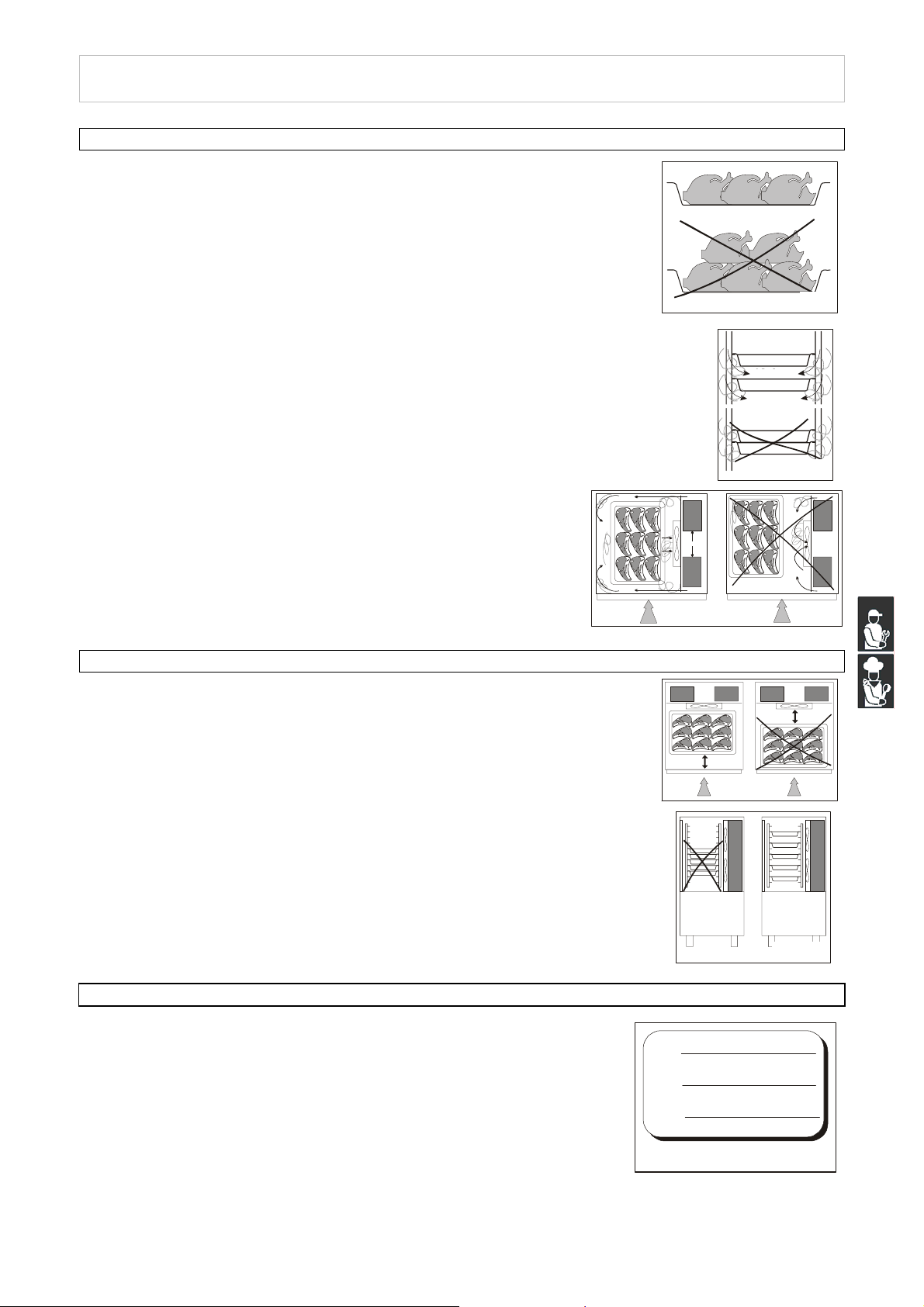

MACHINE LOADING

Do not pile up foodstuffs to be cooled. Thickness should be lower than 2” in

negative quick cooling and lower than 3” in positive quick cooling. (pict.1)

Make sure air circulation is not hampered between food trays. (pict.2)

The grid-holding frame (included in those models which include

trolleys) is to be located at the centre of the cabinet. (pict.3)

POSITION OF TRAYS

Place the trays as close to the evaporator as possible. (pict.4)

If the cabinet is not full place the trays at equal distance from one another. (pict.5)

LENGTH

Cooled or frozen processed foodstuffs may be stored in a refrigerator for 5

days of processing with no quality alterations.

For best results we recommend keeping temperature constant throughout the

storing (32[°F] to 38[°F]), according to the various commodities.

Storing time may be increased to approx. two weeks by using vacuum

processing.

After a negative quick cooling cycle, foodstuffs may be stored safely for 3 to 18

months, according to the type of foodstuff processed.

We strongly recommend keeping storing temperature at 0[°F] or below.

A

N

N

U

U

A

A

A

L

L

L

-

-

-

Pict.1

0.5 - 2 cm.

0,19”-0,79”

Pict.2

Pict.3

Pict.4

Pict.5

A

B

C

Pict.6

5

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

-

I

N

S

T

R

U

C

T

I

O

N

M

A

Table 3 shows the storing time rates for a few examples of frozen food.

Do not leave cooked products at room temperature before quick cooling.

Avoid any loss of moisture, which will affect food freshness.

The cooled product should be wrapped in a specific film for foodstuffs (better

still, vacuum stored) and provided with a sticker reporting the content [A], date

of processing [B] and expiry date [C] written in permanent type ink (pict.6).

Tab.3

Foodstuff Storing tmperature

Pork 0 6

Beef 0 9

Poultry 0 10

Fat fish 0 2

Lean fish 0 4

Peas 0 12

Strawberries 0 12

Spinach 0 6

[°F]

Recommended storing time

N

U

U

A

A

L

L

L

-

-

-

6

O

ON/OFF KEY

-

-

-

ENTER KEY

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

L

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

I

N

S

T

R

U

C

T

I

O

N

M

A

N

CONTROL PANEL CHAPTER 2

DESCRIPTION OF CONTROLS

MENU KEY DOWN KEYS

ON/OFF key

Pressing the key for 5 sec the controller turns off and the sign blinks on the

display

Pressing the key again the controller restarts in the Stand-By mode.

Enter key

Allows access to a menu or parameter selection.

Manual defrost

Menu key

Allows access to the main menu or return to the previous menu.

IFR Quick cooling

Up e Down keys

Allow to scroll the different menus or change parameter values.

FF

: press the key fro 5 s

: press the key for 5 s

U

A

A

L

-

L

-

UP KEYS

START/STOP KEY

Quick cooling pos.

Quick cooling neg.

Keyboard lock

Start/Stop key

Allow to start/stop a quick cooling cycle.

: press the key for 5 s

: press the key for 5 s

: press the keys for 5s

7

-

S

Languag

e

L

I

S

P

S

p

I

N

S

T

R

U

C

T

I

O

N

-

I

N

S

T

R

U

C

T

I

-

I

N

S

T

R

U

C

For proper position of the probe, refer to the following pictures.

SONDA A SING OLO

SINGLE-DETECTOR

RILEVAMENTO

PROBE

PRODUCT CORE

CUORE PROD OTTO

O

T

I

O

CORE PROBE

M

N

M

N

SONDA A MULTIPLO

MULTI-DETECTOR

RILEVAMENTO

PROBE

M

A

A

A

N

N

N

U

U

U

A

A

A

L

-

L

-

L

-

PRODUCT SURFACE

SUP ER FICIE PR OD OT TO

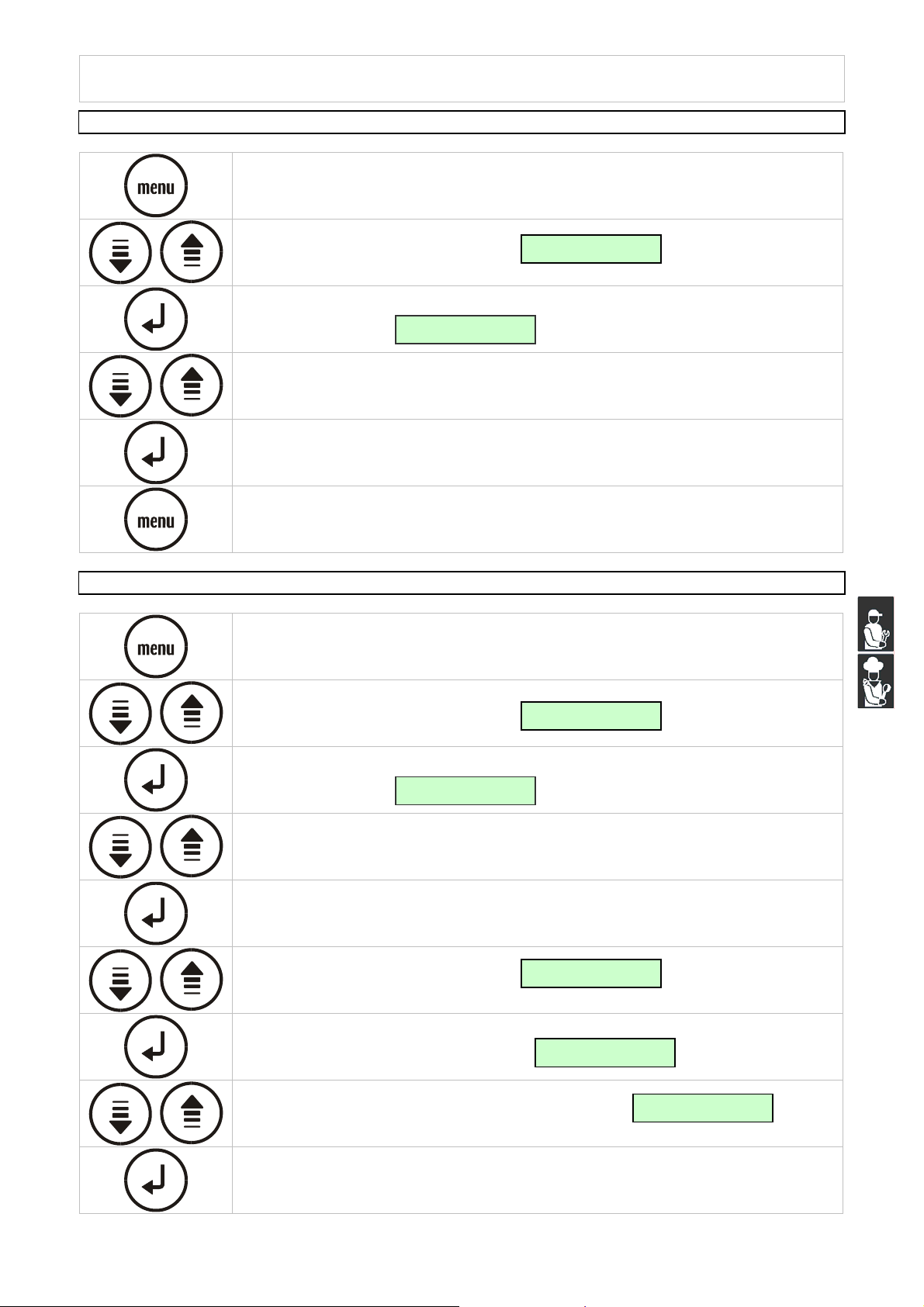

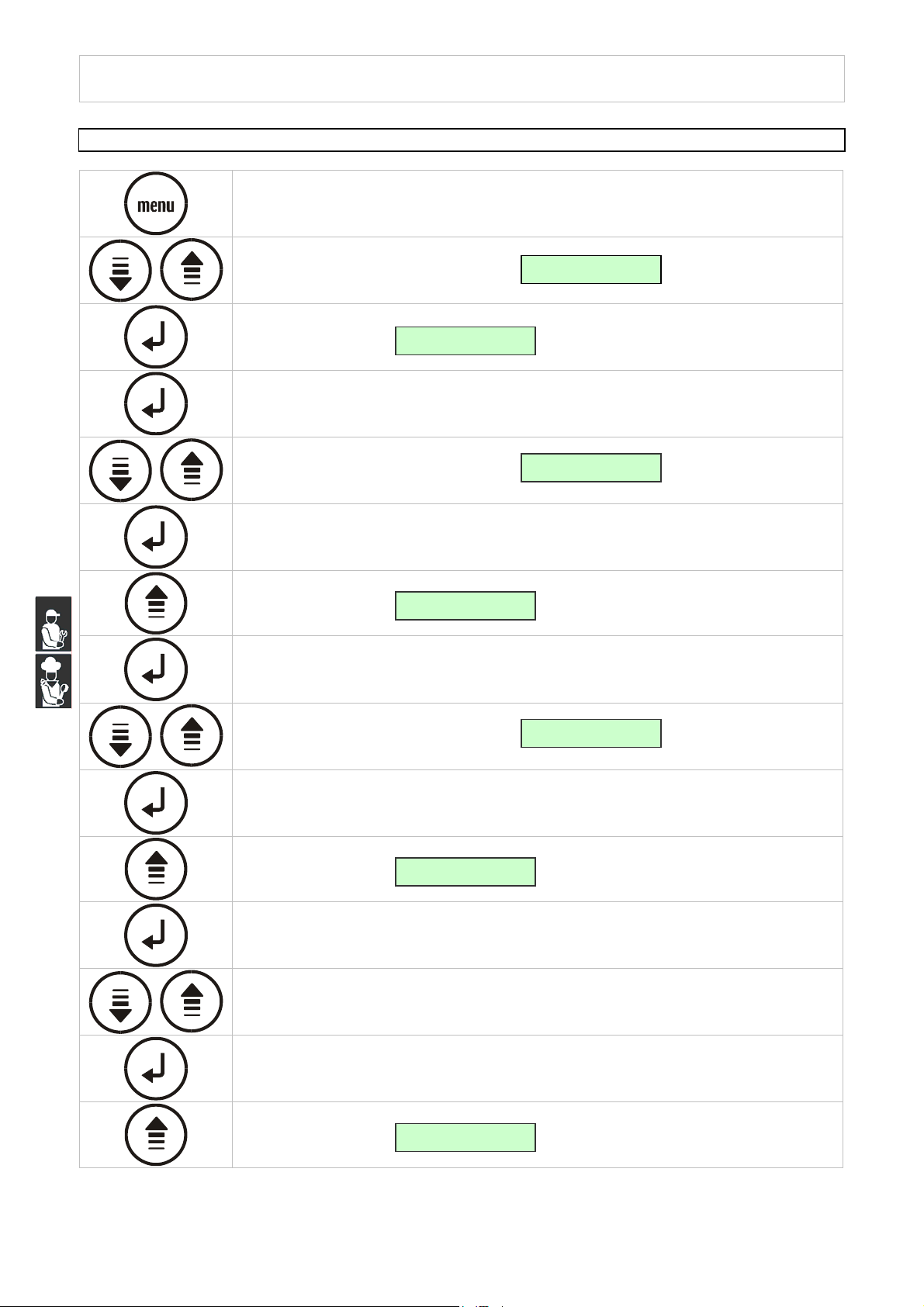

GENERAL SETTING

LANGUAGE

Press the menu key to select the desired menu

Use the keys up and down to display

Press the enter key to gain access to the setting submenus

The display shows

Use the keys up and down to select the password “-19”

Press enter to confirm your choice

Use the keys up and down to display

et Up

assword 0

Menu 05

et U

et Up 04

Press enter to display the first language available

Use the keys up and down to select the desired language

Press enter to confirm your choice

Press menu several times to exit

anguage

taliano

8

-

D

D

H

C

g

S

P

L

m

S

P

S

p

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

CLOCK

Press the menu key to select the desired menu

U

A

A

L

L

-

-

Use the keys up and down to display

Press enter to gain access to the clock setting mode

The display shows

Use the keys up and down to change the flashing digit

Press enter to confirm and pass to the next value

Press menu several times to exit

TEMPERATURE UNIT OF MEASUREMENT

Press the menu key to select the desired menu

ate: 06/11/05

our: 14:22:46

Menu 06

lock Settin

Use the keys up and down to display

Press the enter key to gain access to the setting submenus

The display shows

Use the keys up and down to select the password “-19”

Press enter to confirm your choice

Use the keys up and down to display

Press enter to gain access to the parameter programming mode

The first parameter is displayed

Use the keys up and down to display parameter D01

et Up

assword 0

Menu 05

et U

et Up 03

arameters

A01 = 23°F

ow Alar

01 = 0

Press enter to confirm your choice

9

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

Use the keys up and down to select the new value (0 Celsius, 1 Fahrenheit)

Press enter to confirm your choice

U

A

A

L

L

-

-

Press menu several times to exit

10

-

g

S

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

-

I

N

S

T

R

U

C

T

I

O

N

M

OPERATION CHAPTER 3

PRE-COOLING CYCLE

We recommend starting a pre-cooling cycle before selecting quick cooling cycles.

Press the menu key to select the desired menu

A

N

N

U

U

A

A

A

L

L

L

-

-

-

IFR POSITIVE QUICK COOLING CYCLE

Use the keys up and down to display

Press enter to gain access to the mode for setting quick cooling cy cles

Set

Use the keys up and down to pass to the next values

Set

Press enter to change the flashing values

Press the key start/stop to start the pre-cooling cycle immediately

Once the temperature of -4[°F] has been reached, press the key start/stop to interrupt

the pre-cooling cycle

Quick Cooling

Ne

ative

Quick Cooling

Time

QUICK COOLING CYCLE

Menu 01

et

: automatic cycle preventing the product surface (any

thickness and material) from freezing, while respecting the multi-detector core probe insertion.

CORE PROBE POSITIVE QUICK COOLING CYCLE

thickness lower than 1,5” using a room temperature of about +32[°F]. The cycle is controlled by the

core probe.

CORE PROBE NEGATIVE QUICK COOLING CYCLE

room temperature of about -22[°F]. The cycle is controlled by the core probe.

TIME-CONTROLLED POSITIVE QUICK COOLING CYCLE

thickness lower than 1,5” using a room temperature of about +32[°F]. The cycle is time-controlled.

TIME-CONTROLLED NEGATIVE QUICK COOLING CYCLE

using a room temperature of about -22[°F]. The cycle is time-controlled.

CORE PROBE HARD QUICK COOLING CYCLE

exceeding 1,5” using a room temperature ranging from -22[°F] to +23[°F]. The cycle is controlled by

the core probe.

: cycle suitable for cooling foodstuffs with thickness

: cycle suitable for cooling foodstuffs with

: cycle suitable for freezing foodstuffs using a

: cycle suitable for cooling foodstuffs with

: cycle suitable for freezing foodstuffs

11

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

A

L

L

-

-

TIME-CONTROLLED HARD QUICK COOLING CYCLE

thickness exceeding 1,5” using a room temperature ranging from -22[°F] to +23[°F]. The cycle is

time-controlled.

NOTE: At the end of the quick cooling phase, the device starts the storing phase (+28[°F] at the end of the

positive quick cooling; -7[°F] at the end of the negative quick cooling).

Cooling time

FOODSTUFF SHEET MAX. LOAD

Bechamel GN1/1 h60 0,21 cuft 1,5” 70 minutes HARD

Meat broth GN1/1 h110 0,28 cuft 2,7” 110 minutes HARD

Cannelloni GN1/1 h40 9 lbs 1,5” 40 minutes HARD

Vegetable soup GN1/1 h100 0,17 cuft 2” 100 minutes HARD

Fresh pasta GN1/1 h40 0,5 lbs 2” 20 minutes NEGATIVE

Meat and tomato

sauce

Bean soup GN1/1 h60 11 lbs 2” 100 minutes HARD

Fish soup GN1/1 h60 9 lbs 2” 110 minutes HARD

Roast pork GN1/1 h60 17,7 lbs 4” 110 minutes HARD

Braised beef GN1/1 h60 17,7 lbs 6” 110 minutes HARD

Boiler beef GN1/1 h60 13,24 lbs 6” 110 minutes HARD

Chicken breast GN1/1 h40 11 lbs 2” 30 minutes SOFT

Roast-beef GN1/1 h40 9 lbs 4” 80 minutes HARD

Baked grouper GN1/1 h40 6,5 lbs 2” 110 minutes HARD

Squill GN1/1 h40 4,4 lbs 1,2” 25 minutes HARD

Vacuum-stored

mussel

Fish salad GN1/1 h40 8,8 lbs 1,5” 30 minutes POSITIVE

Boiled polyp GN1/1 h60 11 lbs - 60 minutes HARD

Stewed cuttlefish GN1/1 h60 8,8 lbs 2” 60 minutes HARD

Carrots trifolate GN1/1 h60 8,8 lbs 2” 60 minutes HARD

Mushrooms trifolati GN1/1 h60 8,8 lbs 2” 60 minutes HARD

Zucchinis trifolate GN1/1 h60 6,6 lbs 2” 90 minutes HARD

Vanilla / chocolate

pudding

Creme anglaise GN1/1 h60 0,1 cuft 2” 100 minutes POSITIVE

Custard a GN1/1 h60 0,1 cuft 2” 100 minutes POSITIVE

Panna cotta

(single portion)

Ice-cream cake grid 6,6 lbs 2,3” 50 minutes POSITIVE

Tiramisù GN1/1 h60 11 lbs 2” 45 minutes POSITIVE

GN1/1 h60 11 lbs 2” 90 minutes HARD

grid GN1/1 4,4 lbs max 2,5” 20 minutes HARD

GN1/1 h60 0,21 cuft 2” 90 minutes

grid 0,1 cuft 2,3” 60 minutes

FIRST COURSES

MEAT AND POULTRY

FISH

VEGETABLES

PASTRY/DESSERT

: cycle suitable for cooling foodstuffs with

PRODUCT

THICKNESS

QUICK COOLING

TIME

CYCLE

POSITIVE

POSITIVE

12

-

P

m

IFR

Prog

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

IFR POSITIVE QUICK COOLING CYCLE

U

A

A

L

L

-

-

The IFR is an innovative patented system of positive quick cooling which allows the cycle optimisation for

each type of foodstuffs by preventing superficial freezing.

Temperatures are detected by a three-sensor multipoint needle probe.

The position inside the foodstuff is determined univocally by a reference

disk located along the needle. (ref. pag 8, par. “core probe”).

Press the menu key to select the desired menu

Use the keys up and down to display

Press enter to gain access to the programme selecting mode

The display shows

Press enter to confirm your choice

rogra

Menu 03

rammes

Press the key start/stop to start the selected quick cooling cycle immediately

F

176

140

104

-40

100

50

0

F

176

140

104

-40

100

50

0

68

32

-4

68

32

-4

PRODUCT CORE

INTERMEDIATE

PRODUCT SURFACE

ROOM TEMPERATURE

ROOM VENTILATION SPEED

13

-

Q

g

S

Q

u

P

Q

T

Q

C

S

-

2

S

d

5

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

U

-

I

N

S

T

R

U

C

T

I

O

N

M

A

N

CORE PROBE POSITIVE QUICK COOLING CYCLE

Press the menu key to select the desired menu

U

A

A

L

L

-

-

Use the keys up and down to display

Press enter to gain access to the mode for setting quick cooling cy cles

The display shows

Press enter to change the flashing values

Use the keys up and down to display

Press enter to confirm your choice, the value stops flashing

Use the keys up and down to pass to the next values

The display shows

Press enter to change the flashing values

uick Cooling

ative

Ne

uick Cooling

ime

Menu 01

et

ick Cooling

ositive

Use the keys up and down to display

Press enter to confirm your choice, the value stops flashing

Use the keys up and down to pass to the next values

The display shows

Press enter to change the flashing values

Use the keys up and down to display the room temperature desired value

Press enter to confirm your choice, the value stops flashing

Use the keys up and down to pass to the next values

The display shows

et Point

5

pee

0%

uick Cooling

ore

14

-

Q

g

S

Q

T

Q

C

S

-

2

I

N

S

T

R

U

C

T

I

-

I

N

S

T

R

U

-

I

N

S

T

R

Press enter to change the flashing values

U

C

C

T

T

I

I

O

O

O

N

N

N

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

-

-

-

Use the keys up and down to display the desired value

Press enter to confirm your choice, the value stops flashing

Press the key start/stop to start the selected quick cooling cycle immediately

CORE PROBE NEGATIVE QUICK COOLING CYCLE

Press the menu key to select the desired menu

Use the keys up and down to display

Press enter to gain access to the mode for setting quick cooling cycle s

The display shows

Use the keys up and down to pass to the next values

The display shows

Press enter to change the flashing values

uick Cooling

ative

Ne

uick Cooling

ime

Menu 01

et

Use the keys up and down to display

Press enter to confirm your choice, the value stops flashing

Use the keys up and down to pass to the next values

The display shows

Press enter to change the flashing values

Use the keys up and down to display the desired value

Press enter to confirm your choice, the value stops flashing

et Point

5

uick Cooling

ore

15

Loading...

Loading...