Page 1

SERVICE &

INSTALLATION

MANUAL

ICE CREAM

DIPPING

CABINETS

R-404A Refrigerant

1/2003 51-1468-01

CARRIER COMMERCIAL REFRIGERATION, INC.

Providing BEVERAGE-AIR • FRIGIDAIRE • KELVINATOR • UNIVERSAL NOLIN Products/Services

Page 2

If additional information is necessary, call the factory.

Our toll free number is 1-800-684-1199.Technical

assistance engineers are willing to assist you in any way

possible. Office hours are from 8:00a.m. to 5:30 p.m.,

Eastern Standard Time.

Important information is contained in this manual which should

be retained in a convenient location for future reference.

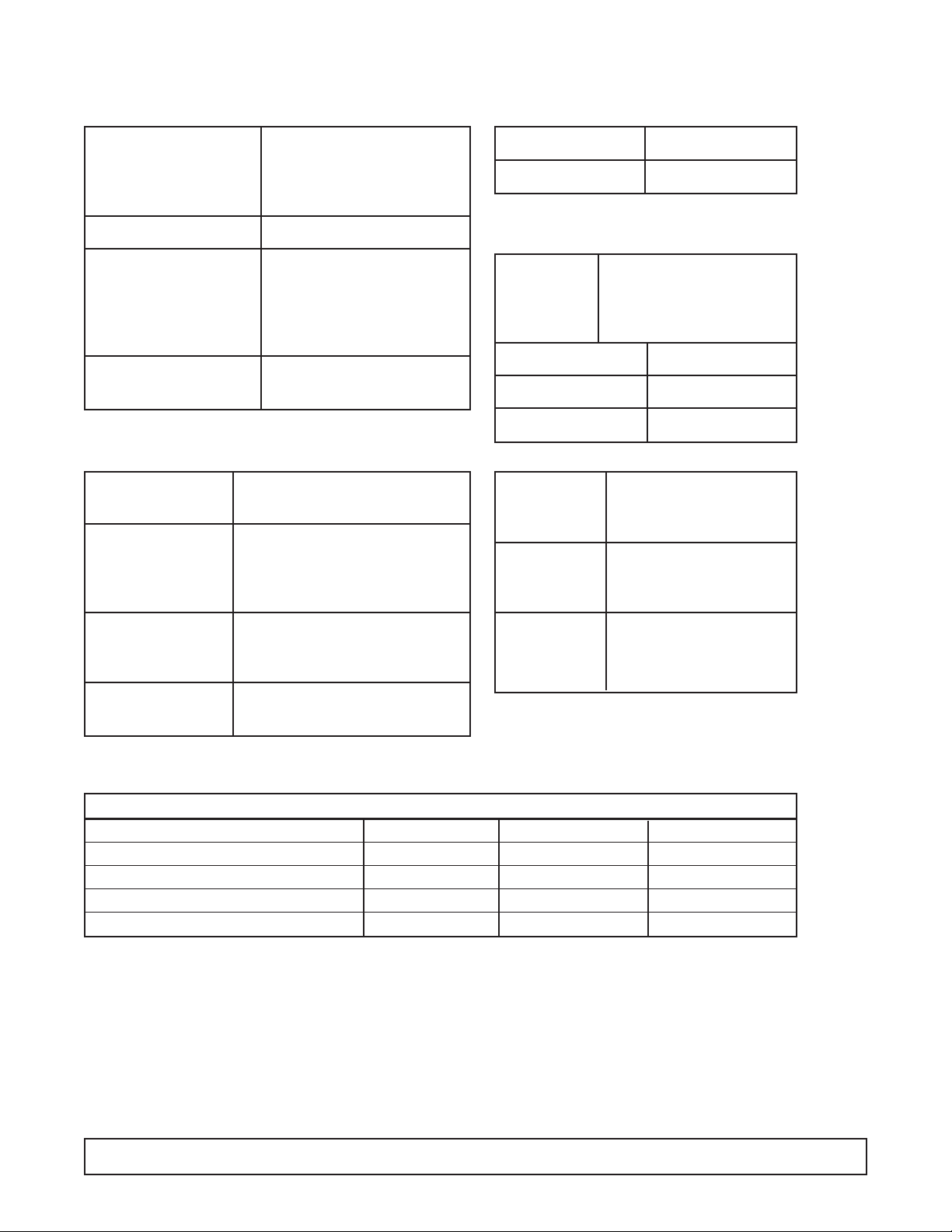

MODEL DESIGNATION INFORMATION

115V, 60HZ

PART # MODEL # DATA PLATE

52-1961-35 BRT-68 BRT68

52-2077-02 BRT68P BRT68

52-2077-04 BRT68W BRT68

52-1961-36 BRT90 BRT90

52-2077-03 BRT90P BRT90

52-2077-05 BRT90W BRT90

EXPORT 220V, 50HZ

PART # MODEL # DATA PLATE

52-1961-31 EBRT-68 EBRT68

52-1961-41 EBRT68P EBRT68

52-1961-32 EBRT90 EBRT90

52-1961-42 EBRT90P EBRT90

EXPORT 220V, 60HZ

PART # MODEL # DATA PLATE

52-1961-33 KBRT-68 KBRT68

52-1961-34 KBRT90 KBRT90

Manual effective for models produced January, 2003. Starting ser ial number 6527372.

Page 3

SECTION I

Introduction

Page 4

blank

Page 5

Dipping Cabinets - Introduction

These Dipping Cabinets are designed to merchandise ice

cream or yogurt-type products.Dipping cabinets are

produced in three sizes: 8,12,and 16 facings of ice cream

containers.The cabinet systems contain CFC free refr igerant,

metered into the system by a capillary tube.The evaporator

is a cold wall which has the refrigerant lines strapped to the

inner liner of the cabinet.The condenser is a bare tube

mounted on a pullout machinery compartment tray for ease

of servicing. All electrical controls are easily accessible for

repair.The temperature within the cabinet is controlled

thermostatically, allowing for maintenance of correct dipping

temperatures.

Mechanical equipment may require repair at times.This

manual presents information that is helpful in maintaining,

diagnosing,and repairing these cabinets .

The high level of quality built into these units will allow for

many years of trouble-free operation.

INTRODUCTION 3

Page 6

TABLE OF CONTENTS

4TABLE OF CONTENTS

Due to Frigidaire’s policy of continuous quality improvement, specifications are subject to change without notice.

INTRODUCTION

Introduction ........................................................................ 3

Table of Contents ................................................................4

Cabinet Specifications / Dimensional Data: BRT-68 ............ 5

Cabinet Specifications / Dimensional Data: BRT-90 ............ 6

Handling & Installation ...................................................... 7

PRINCIPLES OF OPERATION

General Information - Refrigeration Systems.................... 11

BRT-68 Electrical & Refrigeration Information .................. 13

BRT-90 Electrical & Refrigeration Information .................. 14

EBRT-68 & KBRT-68 Electrical &Refrigeration Info ........ 15

EBRT-90 & KBRT-90 Electrical &Refrigeration Info ........ 16

BRT-68 & BRT-90 Wiring Diagram .................................. 17

EBRT/KBRT-68 & 90 Wiring Diagram .............................. 18

MAINTENANCE & REPAIR

Pre-Service Check List ...................................................... 21

General Maintenance Information .................................... 22

Compressor Installation / Diagnostics .............................. 24

Cleaning & Maintenance .................................................. 26

Cleaning the Lid ................................................................ 27

Lid Seal Replacement ...................................................... 28

Lid Gasket Replacement .................................................. 29

Lid Pivot Bushing Assembly Replacement ...................... 30

Center & End Pivot Rod Replacement .............................. 31

Fluorescent Lamp Holder/Light Starter Socket Replac. .... 32

Fluorescent Bulb & Starter Replacement .......................... 33

Thermostat Replacement .................................................. 34

Master Power Supply Switch / Light Switch Removal ...... 35

Condenser Fan Motor Replacement .................................. 36

Ballast Replacement ........................................................ 37

Metering Device / Heat Exchanger Replacement .............. 38

Cabinet Troubleshooting Guide ........................................ 39

Compressor Troubleshooting Guide ................................ 42

Fluorescent Lamp Troubleshooting Guide ........................ 45

PARTS LISTS

Cabinet Parts .................................................................. 48

Lamp Assembly Parts ...................................................... 50

Condensing Unit Parts ...................................................... 52

Electrical Parts .................................................................. 54

Lid Parts .......................................................................... 56

Page 7

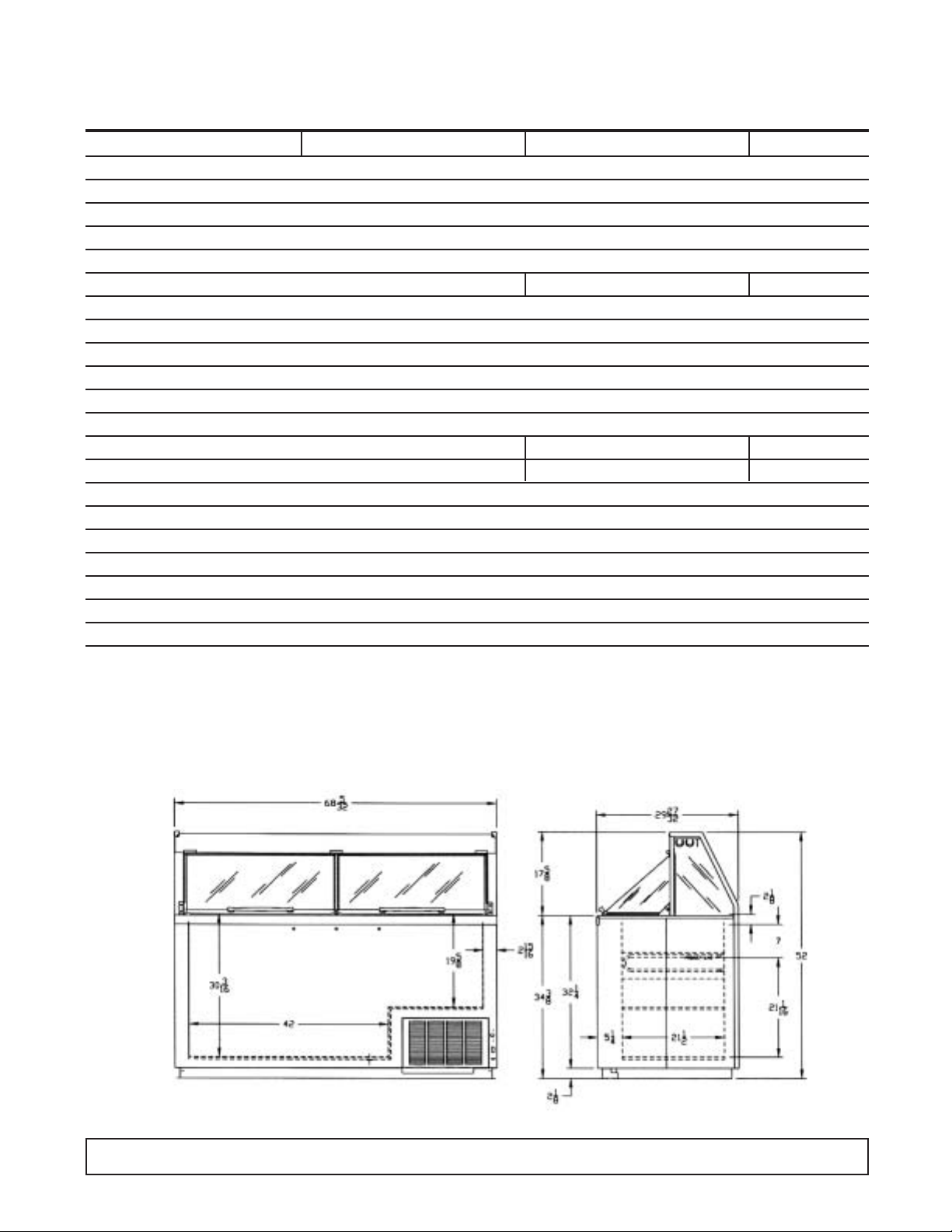

INTRODUCTION 5

CABINET SPECIFICATIONS

BRT68 EBRT68 KBRT68

Temp. Range +10°F to -8°F

Capacity 19.1 Cu. Ft.

Capacity (3 Gal. Tubs) 20

Facings (3 Gal. Tubs) 12

Storage (3 Gal. Tubs) 8

Compressor Size 1/3 Hp. 3/4 Hp. 3/4 Hp.

Shipping Weight (App.) 644 lbs.

Condenser Type Bare Tube

Evaporator Type Cold Wall - Refrigerated Cross Bars

Refrigerant R-404A

Refrigerant Control Capillary Tube

Defrost System Manual

Rated Amps 8.0 4.1 4.1

Electrical Specs. 115V, 60 Hz., 1 Ph. 220V, 50 Hz., 1Ph 220V, 60 Hz., 1 Ph.

Power Cord No. 16AWG

NSF Listing NSF1

Canopy Construction S.S. Top with Glass Ends Straight or Curved Front Glass

Lids (Plexiglass) 2 Lids

Interior Finish White Baked Enamel on Galvanized Steel

Exterior Finish White Baked Enamel

Lighting Two 40 Watt Bulbs

DIMENSIONAL DATA

REAR VIEW END VIEW

Page 8

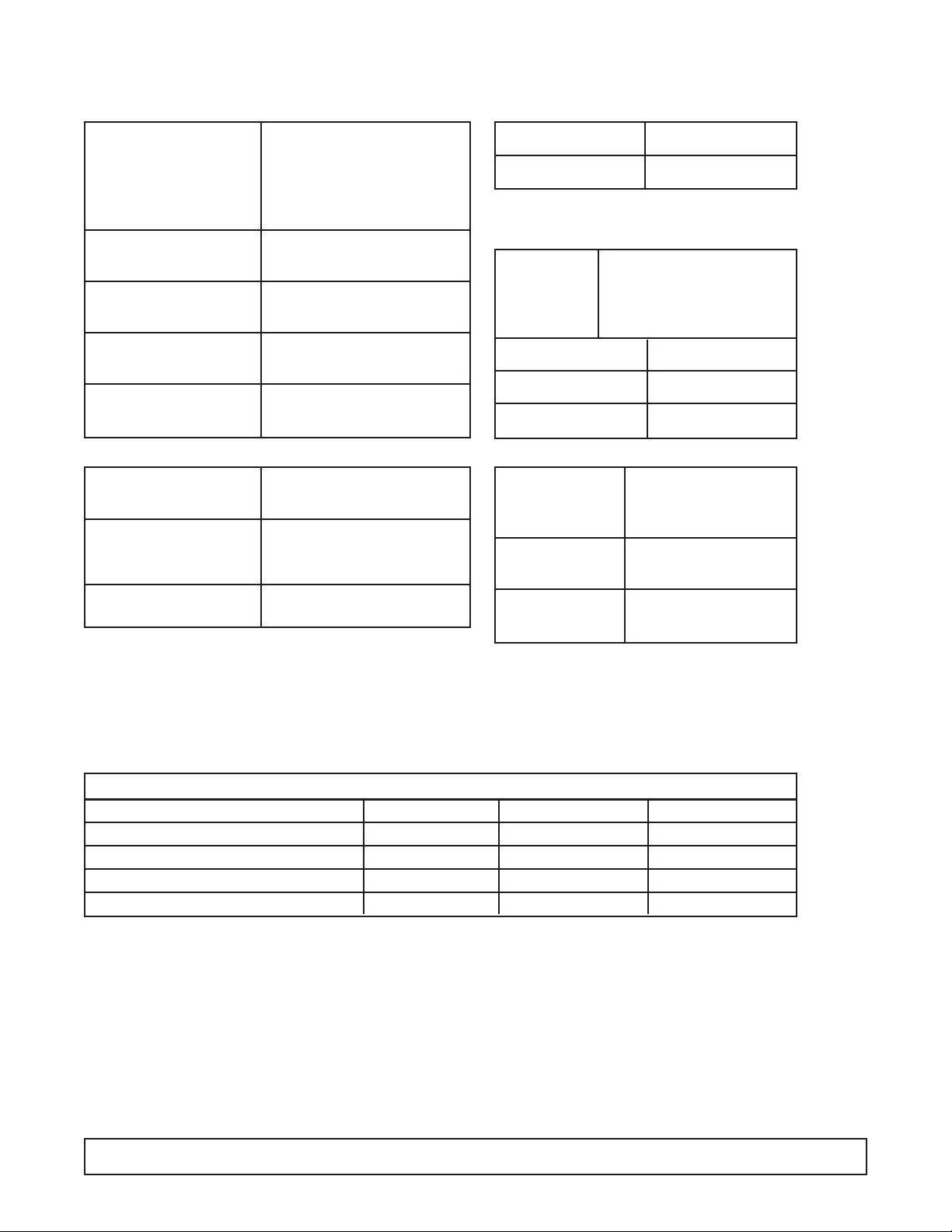

6 INTRODUCTION

CABINET SPECIFICATIONS

BRT90 EBRT90 KBRT90

Temp. Range +10°F to -8°F

Capacity 24.4 Cu. Ft.

Capacity (3 Gal. Tubs) 28

Facings (3 Gal. Tubs) 16

Storage (3 Gal. Tubs) 12

Compressor Size 1/3 Hp. 3/4 Hp. 3/4 Hp.

Shipping Weight (App.) 754 lbs.

Condenser Type Bare Tube

Evaporator Type Cold Wall - Refrigerated Cross Bars

Refrigerant R-404A

Refrigerant Control Capillary Tube

Defrost System Manual

Rated Amps 8.0 4.1 4.1

Electrical Specs. 115V, 60 Hz., 1 Ph. 220V, 50 Hz., 1Ph 220V, 60 Hz., 1 Ph.

Power Cord No. 16AWG

NSF Listing NSF1

Canopy Construction S.S. Top with Glass Ends Straight or Curved Front Glass

Lids (Plexiglass) 2 Lids

Interior Finish White Baked Enamel on Galvanized Steel

Exterior Finish White Baked Enamel

Lighting Two 40 Watt Bulbs

DIMENSIONAL DATA

REAR VIEW END VIEW

Page 9

HANDLING & INSTALLATION-Illuminated Dipping Cabinets

INTRODUCTION 7

FREIGHT DAMAGES AND SHOR TAGES

IMPORTANT

The cabinet was inspected and packaged at the

factory, and should have arrived in excellent

condition. The transportation company or other

parties involved in the shipment are responsible for

loss and/or “damage.” Always make an inspection

before and after uncrating, pref erab ly at the point of

unloading by the transportation company.

INSPECTING FOR DAMAGES

Note:

Always use care when removing shipping tape,

blocks, pads, hardware or other material. Contact

your dealer or distributor if technical assistance

is required.

Check the cartons or containers. If these are damaged

in any way, open them and inspect the contents in the

driver’s presence. If damage is detected, do the

following:

1. Have the driver note the nature and extent of the

damage on the freight bill.

2. Notify the transportation company’s office to request

an inspection. Carrier claim policies usually require

inspections to be made within 15 days of delivery.

3. If damage is noticed, file a claim with the

transportation company.

FILING A CLAIM

File a claim for loss at once with the transportation

company for:

A. A cash adjustment B. Repairs C. Replacement

When filing your claim, retain all packaging materials

and receipts.

HANDLING THE CABINET

Note:

The refrigeration system of the cabinet is designed

to operate with the cabinet located on a flat surface.

Do not tilt the cabinet more than 30° to any side. If

the cabinet must be tilted on an angle for handling or

moving purposes, allow it to sit in an upright position

20 to 30 minutes prior to operating.

CHOOSE A LOCATION

This model cabinet should be situated to allow proper air

circulation. The cabinet must be installed on sturdy, level

floor and positioned so that it can be plugged into a

properly grounded three-prong electrical wall outlet. The

electrical outlet should not be controlled by a wall switch

which might be turned off accidentally.

UNCRATING THE CABINET

The cabinet should be moved as close as possible to

the operating location before removing the skid. Be

sure to follow the steps in the “INSPECTING FOR

DAMAGES” instructions.

INSTALLING THE CABINET

Whenever possible leave the crate skid on the cabinet

until it is moved close to the final position. When it is

necessary to move the cabinet through a doorway, it

may be necessary to remove the crate skid.

Run the cabinet down to storage temperature before

adding product.

CAUTION

A. Do not locate cabinet where sunlight or drafts from

fans, air conditioners or open doors can affect product

temperature.

B. Run cabinet before building in or attaching panels or

accessories.

C. Employee side access panel must be kept clear for

adjustments and service.

D. Cabinet must be installed on the finished floor to

assure rear raceway cover and condensing unit

(employee side) can be pulled or removed for service.

DO NOT seal in with cover molding or caulking in the

area where condensing unit pulls out.

E. Do not use extension cords to power this equipment.

Run any necessary electrical, water supply and drain

lines before setting the cabinet in position. Shim under

the cabinet as necessary to level it. N.S.F. approval

requires sealing the cabinet to the floor. This can be

done by applying a bead of mastic sealer between the

cabinet bottom flange and the floor.

Should several cabinets be set up in a row, space is

provided in the rear toe space for routing electrical and

plumbing lines.Access to this space requires removing

screws and the metal cover which runs the length of the

cabinet.

Rivnuts are provided on the operator's side for

mounting dipperwell and other accessories.

CABINET START-UP

Once the cabinet has been located in its permanent

location and the proper power and grounding have

been provided, the following items must be checked or

completed:

A. Cut and remove the compressor hold-down band (if

applicable) so the compressor “floats” freely.

Page 10

B. Check for traces of oil on the compressor pan which

could mean a broken or leaking refrigeration line.

UNDER NO CIRCUMSTANCE SHOULD THE

COMPRESSOR BE STARTED WHEN OIL IS

PRESENT UNTIL INSPECTED BY A SERVICE

TECHNICIAN.

C. INSPECT THE FACTORY WIRING FOR TERMINALS

THAT MIGHT HAVE VIBRATED LOOSE IN

SHIPPING. TIGHTEN ALL SCREW TYPE

TERMINALS.

D. Check the refrigeration lines to see that they are

“free” and no damage was done during shipping.

E. Check fan blade for free operation.

F. Turn on the main po wer s witch.Once the compressor

starts, the voltage should be checked at the

compressor terminals to determine if there is proper

voltage to the compressor. The voltage should not

exceed the 10% above or below the rated

compressor voltage.

EXAMPLE: If the voltage reads 115 volts with no load

and it drops below 103 volts when the compressor

starts, it may indicate that the supply wiring is too small

or that the wire run is too long.

G. Listen for any unusual noise such as lines vibrating,

etc. Correct the problem by tightening screws,

slightly bending tubing, etc.

H.The temperature control thermostat which is located

in the rear post is factory set for average conditions.

A customer adjustment requires a coin or

screwdriver to turn the slotted shaft.A numbered dial

makes it easy to keep track of adjustments. #1 is

warmest setting and #7 is coldest setting. An “OFF”

position is provided for your convenience in

defrosting the cabinet.

I. Allow the cabinet to pull down and cycle prior to

loading with product (Approx. 24 hours).

GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong

(grounding) plug for your protection against shock

hazards.The appliance should be plugged directly into

a properly grounded three-prong receptacle.

Where a two-prong wall receptacle is encountered, it

must be replaced with a properly grounded three-prong

receptacle in accordance with the National Electrical

Code and local codes and ordinances. The work must

be done by a licensed electrician.

IMPORTANT

Do not, under any circumstance, cut or remove the

round grounding plug from the appliance plug.

WARNING

Consult a licensed electrician if you have any doubt

about the grounding of your wall receptacle. Only a

licensed electrician can determine the polarization of

your wall receptacle. Only a properly installed threepronged wall receptacle assures the proper

polarization with the appliance plug.

IMPORTANT USAGE INSTRUCTIONS

Dipping Cabinet

The cabinet must be located in an area free from air

drafts created by open doors, air conditioning ducts,

and fans. The cabinet should not be located in the

direct sunlight.

The rear grill must be clear of any obstructions so the

intake and exhausting of air f or the condensing unit can

move freely.

Dipping cabinets are designed for use in an air

conditioned store. This cabinet is designed for

merchandising, not hardening of the product.

High humidity can cause fogging of the lid and front glass.

High temperatures, installation of warm product and

heavy usage can cause the product to soften. This

condition will be more noticeable at the top of the cans.

The corners of the cabinets are the coldest areas.

These areas should be used for product that is more

difficult to keep firm.

Frost and ice act as insulators.The need for defrosting

will depend on usage and product firmness.

If the frost is scraped daily with a plastic scraper,

intervals between complete defrosting may be

extended.

Thermostat adjustments should be made one

increment warmer or colder allowing 24 hours between

adjustments to allow the product to stabilize.

8 INTRODUCTION

Page 11

SECTION II

Pr inciples of

Operation

Page 12

blank

Page 13

GENERAL INFORMATION - REFRIGERATION SYSTEMS

PRINCIPLES OF OPERATION 11

FIGURE 1

Basic refrigeration is based upon the Second Law of

Thermodynamics … “Heat will always flow from a warm

object to and be absorbed by an object of substance of

colder temperature.”

The purpose of a mechanical refrigeration system is to

provide for efficient and continuous cooling.

In order for this to take place, the system must provide

a means to transfer heat from the products being

refrigerated to an area that will not affect the product

(See Figure 1).

This is accomplished through the circulation of

refrigerant contained in conductive tubing, past the area

where the products are stored.

The refrigerant absorbs the heat from the product area

and transports it to where the heat can be dissipated

into the air outside the cabinet. Four essential

components are needed in a simple refrigeration

system:

An Evaporator

A Compressor

A Condenser

and a Refrigerant Flow Metering Device

The purpose of the evaporator is to draw the heat from

the product or storage area. As low temperature, low

pressure liquid refrigerant enters the evaporator, it

begins to boil or vaporize as it absorbs the heat of the

product and cabinet interior.

The vaporized refrigerant is drawn through the

evaporator by the compressor , in addition to causing the

necessary flow of refrigerant within the circuit.

The compressor also increases the pressure of the

vaporized refrigerant flowing from the compressor to the

condenser.

The increased pressure causes the temperature of the

refrigerant to rise above the ambient temperature of the

room.

This condition allows the heat in this vaporized high

pressure refrigerant to be released into the room’s

ambient environment.

As heat is released, the vaporized refrigerant returns to

a liquid state.

If there is a large amount of heat to be released, this

heat transfer is increased by using a fan to ensure a

constant flow of cooler ambient air through the

condenser coil.

Page 14

The cooled liquid refrigerant leaves the condenser

under high pressure and travels to the refrigerant flow

metering device.

This device regulates the flow of refrigerant into the

evaporator.

By restricting this flow, the liquid refrigerant mo ves to the

evaporator under low pressure.(See FIGURE 1)

This lower pressure is necessary for the refrigerant to

have the capability to vaporize and absorb heat.

The cycle will continue until the desired temperature

within the product area is reached.

At this point, the compressor shuts off and the

refrigerant cycle is interrupted until further cooling is

required.

This simple refrigeration system is known as a single

stage system. It is the most common refrigeration

system and is used for applications where the product

area temperatures do not exceed -20° Fahrenheit.

The single stage system is used on product dipping

cabinets.

Product dipping cabinets utilize a cold wall evaporator.

(See FIGURE 2).

Here the refrigerant lines actually contact the product

area’s inner wall. Heat is transferred through the wall

and into the refrigerant.

To understand how the refrigerant system creates cold

temperatures, it is important to understand how the

temperatures of the area into which the heat will be

dissipated affect the system’s performance.

Simply stated, a refrigerant system’s ability to cool a

product area is dependent upon the unit’s ambient

environment.

For example, a single stage system dissipating heat

throught its condenser into a 60°F ambient environment

is capable of cooling a cabinet’s interior to a lower

temperatue than an identical system operaing in an

80°F ambient environment.

To understand the complete heat transfer and extraction

process in systems, let’s discuss the function of the

major system components.

There are three components in each system used for

transferring heat. They are the Evaporator, the

Compressor, and the Condenser.

Heat is transferred through the refrigerant lines by the

compressor. This heated refrigerant arrives at the

condenser for dissipation.

The heat transfers to the e vapor ator because it is colder .

The heat then moves through the compressor and

leaves the cabinet at the condenser, where it transfers

or dissipates into the cooler room air.

This heat transfer continues until the system has

absorbed all the heat it is capable of removing, and has

pulled down to the coldest temperature possible, or it

has reached its thermostatic set point and shuts off.

On product dipping cabinets, the copper evaporator

lines are strapped to the inner tank walls to form a cold

wall evaporator.

This is foamed into place with two inches of urethane

instulation to form a rigid bond between the outer shell

and inner liner, which is another metal barrier used for

strength and insulation separation.

The direction of the refrigerant flow is from the top to the

bottom.

The cold wall evaporator is not serviceable within the

walls of the cabinet because of the foam construction.

FIGURE 2

12 PRINCIPLES OF OPERATION

Page 15

PRINCIPLES OF OPERATION 13

SYSTEM INFORMATION - BRT-68

ELECTRICAL

REFRIGERATION -

Refrig.Charge: R-404A / 25 oz./ 708.75 grams / No.4 Stat Position

Compressor Manufacturer: Americold

Model: HP-127-1

Ph.: 1 Hz.: 60

Volts: 115 Amps: 4.2

Overload Protector Manufacturer: Americold

Start Relay Manufacturer: Americold

Start Capacitor V.: 125 M.F.: 189-227

Run Capacitor VAC: 370 M.F.: 20

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:5KSM51GG3784

Condenser Diameter: 9.5" # Blades: 3

Fan Blade Width of Blades:1 29/32"

Power Cord A.W.G.: 16

A.: 15 V.: 125

Light Ballast Manufacturer: G.E.

Model: 89G457

Fluorescent Manufacturer: G.E.

Lamp F40T12CW

Evaporator Cold Wall

Capillary Tube 7' of .042

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 120/250 L.R.A.: 100

Warm Cut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Suction Pressure - C.O. PSIG/Kpa 9 / 62 10 / 69 11 / 76

Discharge Pressure - C.O. PSIG/Kpa 198 / 1365 230 / 1586 268 / 1848

Compressor Amps 4.2 4.2 4.3

Total Cabinet Amps 6.1 6.1 6.2

Cavity Temperature 0°F / -17°C 1°F / -17°C 2°F / -16°C

Page 16

14 PRINCIPLES OF OPERATION

SYSTEM INFORMATION - BRT-90

ELECTRICAL

REFRIGERATION -

Refrig.Charge: R-404A / 27 oz./ 765.45 grams / No.4 Stat Position

Compressor Manufacturer: Americold

Model: HP-127-1

Volts: 115 Amps: 4.2

L.R.A.: — Ph.: 1 Hz.: 60

Overload Protector Americold #1456-3321

Start Relay Americold #1456-3374

Start Capacitor V.: 125 M.F.: 189-227

Run Capacitor V: 370 M.F.: 20

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:5KSM51GG3784

Condenser Diameter: 9.5" # Blades: 3

Fan Blade Width of Blades:1 29/32"

Power Cord A.W.G.: 16

A.: 15 V.: 125

Light Ballast Manufacturer: G.E.

Model: 8G3706

Fluorescent Manufacturer: G.E.

Lamp F40T12CW

Evaporator Cold Wall

Capillary Tube 7' of .042

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 120/240 L.R.A.: 100

Warm Cut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CONTROL SETTINGS #4 C.S. #4 C.S. #4 C.S.

Suction Pressure - C.O. PSIG/Kpa 9 / 62 10 / 69 12 / 82

Discharge Pressure - C.O. PSIG/Kpa 207 / 1427 234 / 1613 262 / 1806

Compressor Amps 3.8 3.8 3.9

Total Cabinet Amps 6.3 6.3 6.3

Cavity Temperature -0.5°F / -18°C -0.3°F / -17.9°C -1.2°F / -18.4°C

Page 17

PRINCIPLES OF OPERATION 15

SYSTEM INFORMATION -

EBRT-68

(220V / 50 Hz)

ELECTRICAL KBR T-68 (220V / 60 Hz)

REFRIGERATION -

Refrig.Charge: R-404A / 25 oz./ 708.75 grams / No.4 Stat Position

Compressor Mfg: Copeland (3/4 HP)

Model: KAMB-007E-CAV

Phase: 1 Hz.:50

Overload Protector Model No.: 071-0092-29

Start Relay G.E. 3ARR3CT3E5

Pick up: 340-360

Drop out: 45-115

Model No.: 040-0001-03

Start Capacitor V: 220

M.F.: 145-174

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model: KSM51GG3705

Condenser Diameter: 91⁄2

"# Blades: 3

Fan Blade Width of Blades: 1

29

⁄32"

High Pressure Ranco

Switch Preset 400 PSIG Diff 100 PSIG

Power Cord A.W.G.: 16

Amp: 15

Light Ballast Mfg:Vossloh Schwabe

Model: L36.291 (50 Hz)

Robertson: 1-4026 (60 Hz)

Fluorescent Manufacturer: G.E.

Lamp F40T12CW

Evaporator Cold Wall

Capillary Tube 9' of .042

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 125/250 L.R.A.: 100

Warm Cut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CAVITY TEMPERATURE 2°F / -17°C 4°F / -16°C 6°F / -14°C

Suction Pressure - C.O. PSIG/Kpa 8 / 55 10 / 69 12 / 82

Discharge Pressure - C.O. PSIG/Kpa 188 / 1296 225 / 1551 253 / 1744

Compressor Amps 7.2 7.1 7.1

Total Cabinet Amps 9.5 9.3 9.4

Page 18

16 PRINCIPLES OF OPERATION

SYSTEM INFORMATION -

EBRT-90

(220V / 50 Hz)

ELECTRICAL KBR T-90 (220V / 60 Hz)

REFRIGERATION -

Refrig.Charge: R-404A / 27 oz./ 765.45 grams / No.4 Stat Position

Compressor Mfg: Copeland (3/4 HP)

Model: KAMB-007E-CAV

Phase: 1 Hz.:50

Overload Protector Copeland

Model No.: 071-0092-20

Start Relay G.E. 3ARR3CT3E5

Start Capacitor V: 220

M.F.: 145-174

Run Capacitor V: 370

M.F.: 10

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model: KSM51GG370E

115V / 60 Hz. / Ph. 1

Condenser Diameter: 91⁄2

"# Blades: 3

Fan Blade Width of Blades: 1

29

⁄32"

High Pressure Ranco

Switch Preset 400 PSIG Diff 100 PSIG

Power Cord A.W.G.: 16

V.: 220 Amp: 15

Light Ballast Mfg:Vossloh Schwabe

Model: L36.291 (50 Hz)

Robertson: 1-4025 (60 Hz)

Fluorescent Manufacturer: G.E.

Lamp F40T12CW

Evaporator Cold Wall

Capillary Tube 9' of .049

Thermostat Manufacturer: Ranco

Model No.: 9540N46

F.L.A.: 25

V.: 125/250 L.R.A.: 100

Warm Cut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CAVITY TEMPERATURE 2°F / -17°C 4°F / -16°C 7°F / -14°C

Suction Pressure - C.O. PSIG/Kpa 8 / 55 10 / 69 12 / 82

Discharge Pressure - C.O. PSIG/Kpa 228 / 1572 257 / 1772 284 / 1958

Compressor Amps 7.4 7.5 8

Total Cabinet Amps 9.5 9.3 10

Page 19

WIRING DIAGRAM 17

WIRING DIAGRAM - BR T-68 & BRT-90

SUPPLY

FAN MOTOR

(BLUE)

WHITE

SWITCH

(BROWN)

BLACK

(115/60 ONLY)

BALLAST

LIGHT

SWITCH

MOTOR PROTECTOR

PROTECTOR

CONTROL

R

C

FAN MOTOR

COMPRESSOR

WIRE DIAGRAM

KDC67/87-BRT68/90

00-2368-00 Rev B

S

1

2

(PTCR)

3

4

RUN CAP.

START CAP.

S

LAMP

MOTOR

TEMP.

(PTCR)

1

2

4

3

TERMINAL BOX

COMPRESSOR

BLUE

S

LAMP

WHITE

BLUE

LAMP

S

BLUE

(BLACK-220)

BLUE

(BLACK-220)

BALLASTBALLAST

NOTE: 115/60

NOTE: 115/60

SHOWN

SHOWN

220/60

220/60

WHITE LEAD.

SAME LESS

WHITE LEAD.

SAME LESS

BLUE

BLACK

YELLOW

WHITE

(115/60 ONLY)

BLACK

TEMP.

BLK.BLK.

CONTROL

BLACK

BLACK

START CAP.

BLACK

BLACK

LIGHT

SWITCH

( SEE NOTES)

(115/60 ONLY)

BLACK

RUN CAP.

BLACK (BROWN)

WHITE (BLUE)

SWITCH

SUPPLY

BOARD

TERMINAL

1

3

5

BLACK

L1

BLACK

(BROWN)

WHITE

RED (EXTRA)

2

4

6

WHITE

(BLUE)

(L2) N

BLACK

BLUE

BLUE

WHITE

220 VAC. 60 Hz.-10

POWER SUPPLY

115 VAC. 60 Hz.-10

POWER SUPPLY FOR

EXPORT MODELS ONLY

ELECTRICAL INFORMATION.

SEE SERIAL PLATE FOR

Page 20

WIRING DIAGRAM - EBR T-68 / EBRT-90

KBR T-68 / KBRT-90

18 WIRING DIAGRAM

SWITCH

SUPPLY

FAN MOTOR

(BLUE)

WHITE

GFCIFUSE

(BROWN)

LIGHT

BLACK

CONTROL (NC)

HIGH PRESSURE

(USED ON BRT-90

AND H-16 MODELS

SWITCH

ONLY.)

BALLAST

R

C

CAPACITOR. SEE COMPRESSOR

TERMINAL BOX.

S

PROTECTOR

+

+

-

P

CONTROL

HIGH PRESSURE

OPEN 350 20

CLOSE 250 20

NOTE; BLUE WIRE CONNECTS

TO #2 ON COMPRESSOR

TERMINAL BOARD WHEN

HIGH PRESSURE CONTROL

IS NOT USED.

FAN MOTOR

-

COMPRESSOR

WIRING DIAGRAM

00-C-2342-00 B

EKDC/KKDC-67/87 &

EBRT/KBRT-68/90

ONLY ON MODELS WITH RUN

CAPACITOR. SEE COMPRESSOR

TERMINAL BOX.

RELAY

1

5

S

RUN CAP.

BLEED RESISTOR

2

CONTROL

TEMP.

TERMINAL BOX

COMPRESSOR

ONLY ON MODELS WITH RUN

MOTOR

BLUE

START CAP.

POTENTIAL

S

LAMP

P

2

1

2

1

3

R

C

BLUE

LAMP

BLUE

BLACK

WHITE

LAMP

S

BLACK

BLACK

S

BALLAST

BALLAST

BLACK

YELLOW

BLACK

CONTROL

TEMP.

BLACK

POTENTIAL

BLACK

RELAY

125

BLACK

LIGHT

SWITCH

WHITE

BLACK

WHITE

BLACK

RUN CAP.

WHITE

FUSE

(SOME MODELS)

WHITE

TERMINAL

ELB

(SOME MODELS)

START CAP.

1

BOARD

3

5

WHITE

WHITE

WHITE

RED (EXTRA)

2

4

6

SUPPLY

SWITCH

BLUE

BLACK

L1

(BROWN)

BLUE

WHITE

(L2) N

(BLUE)

OR

220 VAC. 60 Hz.-10

POWER SUPPLY FOR

220 VAC. 50 Hz.-10

EXPORT MODELS ONLY

SEE SERIAL PLATE FOR

ELECTRICAL INFORMATION.

Page 21

SECTION III

Maintenance

& Repair

Page 22

WARNING:

To avoid the possibility of an electrical shock,

turn OFF thermostat and unplug the power cord

of the cabinet before cleaning or touching

electrical connections or parts.

Page 23

PRE-SERVICE CHECK LIST

MAINTENANCE & REPAIR 21

You may avoid the cost and inconvenience of an

unnecessary service call by first reviewing this check

list of the most frequently encountered situations that

are not the result of system component failure.

COMPRESSOR RUNS TOO MUCH

1. A refrigerated cabinet automatically compensates for

service loading by running longer and more often.

Before calling for service, check running time for at

least one hour the first thing in the morning (before

store traffic starts).

2. Be sure doors seal. A faulty gasket seal will cause

increased running time.

3. Check the room temperature.The warmer the room,

the more the compressor will run.

4. Check the condenser to be sure the face is clean.

Dirt and lint will raise the pressures and increase

running time. Use a brush or vacuum to clean the

condenser.

5. Check to see that condenser fans are running.

6. If product is too hard, (cold) try setting the

temperature control (thermostat) warmer. This will

result in warmer cabinet temperature and reduced

running time.

CABINET DOES NOT OPERATE

1. Be sure the cabinet is plugged in.

2. Check that the breakers or fuses are good and all

switches in the supply line are ON.

3. Be sure that cabinet Master Supply Switch is ON.

4. If you are in an area with voltage problems, try

shutting off all non-essential electric equipment.

LIGHT IS OFF

1. If the cabinet is operating, be sure the lamp is

properly seated in sockets.

2. If the cabinet is not running, check that Master Supply

Switch of cabinet is ON, fuses are okay, no switch in

the supply is off and the cabinet is plugged in.

CUSTOMER COMPLAINT

OR STORED PRODUCT

1. Check cleaning solutions used inside cabinet.

2. Check cleaning solutions, paint or other contaminants used in store maintenance.

3. Sometimes the ingredients used in some products or

containers will contaminate other products.

4. Be sure to follow a weekly schedule for cleaning

cabinet interior.

SERVICE

In the event of a malfunction, damage to the cabinet, or

if the cabinet requires service beyond the items in the

“Pre-Service Check List,” contact your local

refrigeration service company or the dealer or

distributor you purchased the unit from.

POWER FAILURE

Do not open the cabinet doors unnecessarily if power is

cut off due to electrical failure.The cabinet will star t up

if the power supply returns, but will require sufficient

time to reach maximum cold storage performance.

CABINET FAILURE

1. If the cabinet has stopped operating, check that the

cabinet is securely plugged in and turned on.Contact

a licensed electrician to locate and correct any power

supply problems.

2. Do not open the cabinet lids unnecessarily.

3. Provisions for other storage of the product may be

required to prevent spoilage.

If you call us for service, describe the problem and give

the information from the following list to the service

representative:

Cabinet Model ______________________________

Part Number ________________________________

Serial Number ______________________________

(These are located on a serial number rating plate

inside of the machinery compar tment of the cabinet.)

Page 24

SECTION III

MAINTENANCE & REPAIR

22 MAINTENANCE & REPAIR

TOOLS:

To provide full service diagnostics and repairs on these

cabinets the following tools are needed:

A V olt Meter

An Amp Meter

An Ohm Meter or tiplet meter to handle all three functions

An Electronic Leak Detector

An Electronic Micron Gauge

A Vacuum Pump capable of pulling to 50 microns

Four Hand Valves

A Refrigerant Reclaimer

A Compound Gauge Set

A cylinder of nitrogen with a regulator capable of 10 to

400 pounds.

Standard refrigeration hand tools like:wrenches, tubing

cutter, swage and flare tools, wire strippers, wire

crimpers, wire cutters, standard and phillips head

screwdrivers.

PRODUCT HISTORY

The first rule in accurately servicing a refrigeration

system is to determine if the problem is an electrical or

mechanical failure within the refrigeration system.

First, try to obtain the product’s history of operation

from the customer.This will help identify the source of

the problem.

Good facts from the cabinet user can help identify

whether the problem is electrical, within the

refrigeration system, or a “misapplication by the user.”

Get the history of operation and failure by asking these

questions:

1) Were there any brown-outs or power outages that

they are aware of?

2) Is the cabinet on a dedicated circuit?

3) Has any other equipment in this area had

operational problems?

4) When was the last time the cabinet’s operation was

confirmed as working properly?

5) When was a problem noticed?

6) How long has the equipment run without this

problem? (Years? Weeks? Days? Hours?)

7) Was anything tried prior to your arrival?

8) Was the warm-up fast, as in three to six hours, or

over a prolonged time, as in three to five days?

9) If the cabinet was running for a long time, was the

temperature recovery after entering the cabinet

always within an hour, or did it appear as though

recovery time was longer as usage went on?

The refrigeration system should only be entered if it is

absolutely necessary. It is critical that a clean,

uncontaminated system be maintained.

If a system is unable to reach the proper operating

temperature, a test of the unit’s mechanical

refrigeration components is required.

COMPRESSOR EFFICIENCY TEST

If the cabinet has a semi-hermetic compressor, begin

by testing the compressor’s efficiency.

To test a semi-hermetic compressor, place compound

gauge on the compressor’s suction port.

While the compressor is running, close off the suction

line so that only the port and valve are part of the

compressor’s low side.

When the valve is closed and v acuum has started, time

how long it takes to pull the compressor’s low side to its

lowest possible vacuum.

Compressors used on these cabinets should be

capable of pulling at least 20 to 22 inches of vacuum in

less than 40 seconds.

Next, shut off the compressor and watch the gauge. A

one or two inch rise in pressure is acceptable, since a

small amount of freon may remain on the low side of the

compressor, after which the reading should stabilize.

If the pressure continues to rise, the discharge reeds in

the valve head are bad, allowing high pressure gas to

return to the compressor.

If the compressor pulls less than 20 inches, the suction

reeds are bad in the valve head.

If it takes longer than 40 seconds to pull the

compressor, to its ultimate low vacuum, one or both

cylinders are not functioning as they should. Any

reading less than these will require replacement of the

compressor.

Page 25

MAINTENANCE & REPAIR 23

ENTERING THE SYSTEM

Entering the system should only be done as a last

resort. Extreme care must be used no matter what the

reason is for entering the system. Of course there are

times it cannot be avoided, such as component or

compressor replacement, or a leak within the system.

The system must also be entered any time you need to

obtain the operating pressures. Again, use extreme

caution to avoid any possible contamination.

Cabinets that use semi-hermetic compressors allow

easy access through the valve ports.

Cabinets using hermetic compressors do not have

valve ports, this product has process stubs for both

suction and discharge sides of the system.

Line taps should only be used to obtain pressure

readings, and not for reprocessing a system. The

opening of a line tap is too restrictive for pressure of

vacuum procedures.

Install hand valves at the process stub ends. Hand

valves will be less restrictive to flo w because of a larger

opening. They will also be easier to use during repair

procedures.

EVACUATION

Once the system has been cleaned and components

have been replaced, you are ready to initiate the final

servicing procedures necessary to achieve proper

cabinet operation.

Pull an evacuation to approximately 50 microns. You

can be sure that any contaminants that can affect the

system’s operation are now removed.

Use this time to check any joints for potential leaks.

CHARGING

You should use a charging cylinder to measure in the

the correct amount of refrigerant. The charging

methods are:

1) Add the refrigerant to the system until you reach a

predetermined balanced pressure.This will give you

an approximate static charge.

2) Weigh in the refrigerant using a scale calibrated in

ounces.

The cabinet’s operation is now ready to be tested. A

final check of the refrigeration lines should be made

before running the cabinet.

Be sure the refrigeration lines are not kinked or rubbing

against each other.

Also check that the door seals properly. An air leak will

affect proper operation, and the cabinet’s ability to

reach its coldest temperature.

Run the cabinet a both 100% run and also at a cycling

temperature for at least one da y. If the temperature and

pressures are correct, the system can be considered

repaired.

Hermetic systems should now have their process stubs

pinched off, hand valves removed and the ends brazed

shut.

Page 26

COMPRESSOR INSTALLA TION & MAINTENANCE / DIAGNOSTICS

24 MAINTENANCE & REPAIR

HOLD DOWN BOLTS

All models with Copeland compressors have hold down

bolts. The compressor has a metal hold down band

strapping it tightly to the cabinet body. This band should

be removed and discarded upon installation. If

compressor does not float freely, keep backing off all of

the retaining nuts until it does.

CHECKING COMPRESSOR THAT WON’T

START ON CORD CONNECTED CABINETS

1. Check that the supply plug is in wall outlet and that

outlet has the proper voltage.

2. Check that the cabinet thermostat is on a numerical

setting.

If items 1 & 2 are OK:

3. Pull condensing unit out of the cabinet and remove

compressor terminal cover. Check proper voltage at

terminals.

TO CHANGE THE COMPRESSOR:

1. Disconnect the power supply to the cabinet.

2. Disconnect power supply leads at the compressor.

3. Disconnect the wires to the relay and capacitors.

4. Remove the rela y and starting capacitor and install on

the new compressor.

5. Remove the defective compressor from the

condensing unit base.

6. Set the new compressor in place.

7. Reconnect the relay and capacitor wires.

8. Reconnect the power supply lead.

9. Leak test, evacuate, and weigh in charge.

TO CHANGE THE DRIER

If flare connected, make sure flares and faces of

fittings on new drier are clean and in good condition

before installing new drier.

Cut tubing only with tube cutters, not hacksaw’ s , to av oid

metal filings from entering the system. Driers must be

replaced any time you enter the system, except when

you are obtaining operating pressures.

SERVICE V ALVES

The compressors on some cabinets have service valves

for measuring suction and discharge pressures. Two

types are used.The first type is connected directly to the

compressor body or shell and back seats to connect

gauges to the access port. The second (Schrader type)

is on the end of a process tube and requires a gauge or

charging line with a depressing pin to open valve when

the connection is made.

CAUTION

This type valve should be tightly capped except

when making the gauge connection.

TO CHECK FOR OPEN WINDINGS

Use a multimeter. Measure ohms between “C” and “R”

and between “C” and “S”.

If windings are OK, multimeter will show a resistance

reading between terminals.

If there is no reading, the compressor, winding or

windings are open and the compressor should be

replaced.

TO CHECK FOR GROUNDED COMPRESSOR

Use multimeter.Touch probe from each terminal to an

unpainted surface of compressor body. If there is no

ground, there will be no change of the meter.

WARNING: Be Careful Not to Touch

Uninsulated Parts of the Meter Probes.

A reading indicates a ground and the compressor

should be replaced.

If there is voltage at the compressor terminals and the

compressor tries, but does not run, check voltage at the

compressor terminals while attempting to start the

compressor.If the voltage at the compressor terminal is

below 90% of the nameplate voltage, it is possible the

motor may not have developed sufficient torque to start.

Check to determine if:

A.Wire sizes are adequate.

B. Electrical connections are loose.

C. The circuit is overloaded.

D. The power supply is adequate.

A defective relay or capacitor may prevent the

compressor starting.

TO CHECK OUT THE RELAY

1. Disconnect the cabinet from the power supply.

2. Remove the wires from the relay.

3. Touch probes to the terminals. Meter should show

infinity if closed.

4.Touch probes to the terminals of coil. The meter

should show a resistance reading.

If items 3 & 4 are OK, the relay is good. If items 3 & 4

are not as indicated, change the relay.

Page 27

MAINTENANCE & REPAIR 25

COMPRESSOR INSTALLA TION & MAINTENANCE / DIAGNOSTICS

TO CHECK CAPACITORS

1. Disconnect the cabinet from the power supply.

2. Make sure the capacitors are discharged before

checking. (Shunt across the terminal of capacitor

with a heavy insulated wire.)

3. Remove the wires from the capacitors.

4. Any capacitor found to be bulging, leading, or

damaged should be replaced.

5. Use a multimeter to check the run and start

capacitors for shorts or open circuits.

A. Set ohmmeter to X1000 scale.

B. Standardize equipment

C. Touch probes to capacitor terminals.

1. With a good capacitor, the indicator should

first move to zero and then gradually increase

to infinity.

2. If there is no movement of the ohmmeter, an

open circuit is indicated.

3. If the ohmmeter indicator moves to zero, and

remains there or on a low resistance reading,

a short circuit is indicated.

On run capacitor, touch probes to metal case and each

terminal. If meter shows any deflection, a ground is

indicated. All defective capacitors should be replaced.

Page 28

CLEANING & MAINTENANCE

26 MAINTENANCE & REPAIR

CLEANING THE CABINET EXTERIOR

Wipe the exterior occasionally with a cloth dampened in

mild detergent water; r inse, and wipe dry with a soft,

dry cloth. Do not use abrasive or caustic cleaners or

scouring pads.

CLEANING THE CONDENSER - FIG. 1A

Periodic cleaning of the condenser can be easily

accomplished by brushing the coils with a soft brush

and/or using a vacuum cleaner with a brush

attachment.

Be sure that dirt, dust and collection of other debris do

not build up to a point air circulation through the

condenser is restricted.

CLEANING THE STORAGE COMPAR TMENT

1. Remove product and store it in another suitable

cabinet, if possible.Be sure to prevent spoilage of

the product which may occur if it is left at room

temperature.

2. Tur n OFF the ther mostat and unplug the cabinet.

3. Remove the can skirts.

4. Defrost completely prior to cleaning.

5. Wash the can skirts and the entire interior storage

area with warm water and baking soda solution —

about a tablespoon of baking soda per quart of

water. Rinse thoroughly with clean water and wipe

dry. This procedure can also be used for cleaning

door gaskets.

6. A drain hose (FIG.1B) is provided in the compressor

compartment. Connection is made to fit a standard

garden hose for ease of draining water from inside

of the tank area.

IMPORTANT: Do not use any objects or cleaner which

may leave residues, odors, or particles. Avoid the use

of strong chemicals or abrasive cleaners which may

damage the interior surfaces and contaminate product

within the storage area.

7. Wash, rinse, and dry the can skirts while they are

outside of the cabinet, using the same procedure as

described for the storage area.

8. Be sure to correctly reinstall the can skirts, plug in the

cabinet, set the temperature control and allow time for

cooling of the storage area before storing product.

A

B

FIG. 1

WARNING:

To avoid the possibility of an electrical shock,turn OFF thermostat and

unplug the electric cord of the cabinet before cleaning or touching

electrical connections or parts .

Page 29

CLEANING THE LID

MAINTENANCE & REPAIR 27

If the lid has been removed from the cabinet, wash with

plenty of non-abrasive soap or detergent and water.

Use the bare hand to feel and dislodge any caked soil.

Rinse thoroughly with clean water. Do not use hard,

rough cloths that will scratch the surface of the plastic

lid. Dry with a clean, damp chamois.

If the lid is on the cabinet where water cannot be used

freely, it should first be lightly dusted (not wiped) with a

soft, clean cloth.Then the surface can be wiped carefully

with a wet cloth or chamois.The cloth or chamois should

be kept free of grit by frequent rinsing in clean water.

Do not use solvents such as acetone, alcohol,

benzene, carbon tetrachloride, fire extinguisher fluid,

dry-cleaning fluid, and lacquer thinners, since they

attack the plastic part of the lid. Do not use window

sprays or kitchen scouring compounds.

Page 30

28 MAINTENANCE & REPAIR

LID SEAL REPLACEMENT

1. Remove lids from the cabinet.

2. Remove the stainless steel end trim located on each

end of the cabinet. This will allow access to the

screws that hold the stainless steel top in place.

3. Remove the six (6) screws on the underside of the

stainless top on the server side of the cabinet.

4. Remove the stainless top from the cabinet.

5. Slide the lid seal off of the top channel.

6. Replace the lid seal with new correct part number.

Seal needs to be cut to fit the cabinet width. Use

double back tape or spray adhesive to hold the new

seal in place.

7. Replace the stainless steel top with the lid seal

attached.

8. Replace the six (6) screws under the stainless

steel top server side.

9. Replace the four (4) screws located on each end

of the canoy top.

10. Replace lids on the cabinet.

The lid seal is located on the server side of the cabinet,

attached to the underside of the stainless steel top.

Page 31

MAINTENANCE & REPAIR 29

1. Remove the lid from the cabinet.

2. Set the lid on a flat, protected surface.

3. Rotate lid upside down.

4. Slide old gasket from the aluminum lid

frame.

5. Install new gasket in the groove

provided. See end detail.

6. Reinstall lid in cabinet.

LID GASKET REPLACEMENT

Page 32

LID PIVOT BUSHING ASSEMBLY REPLACEMENT

MAINTENANCE & REPAIR 30

Old Style

New Style

The pivot pin bushing is located on the outside edge of

each lid.

1. Remove the lid from the cabinet. Lay the lid on a

smooth, non-scratch surface.

2. Remove the two acorn nuts from the outside edge

of the lid assembly.

3. Remove the shake-proof washer, flat washer, pivot

bushing retainer, and pivot pin bushing.

4. Replace assembly with the correct new part number.

5. Replace the shake-proof washer, flat washer, pivot

bushing retainer, and pivot pin bushing.

6. Replace the two acorn nuts attaching the assembly

to the lid.Tighten nuts to 20" lbs. torque.

7. Replace the lid onto the cabinet.

Remove lid from cabinet. Lay the lid on a

smooth, non-scratch surface. Simply

unsnap lid pivot assembly and replace with

a new part.

Page 33

CENTER/END PIVOT ROD REPLACEMENT

MAINTENANCE & REPAIR 31

Remove lids from the cabinet.

Remove 2 mounting screws from the mounting bracket.

Replace the pivot bracket with correct new part number.

Reinstall lid assembly.

The 4-hole and 8-hole dipping cabinets have end pivot pins only.The 12- and 16-hole

dipping cabinets have end and center pivot brackets.

Page 34

FLUORESCENT LAMP HOLDER &

LIGHT STARTER SOCKET REPLACEMENT

32 MAINTENANCE & REPAIR

1. Disconnect the power to the cabinet.

2. Remove the lids from the cabinet.

3. Remove the fluorescent bulbs.

4. Remove the end trim located on each end

of the cabinet.This will expose the screws

that hold the top in place.Remove the four

(4) screws on the top and the six (6)

screws located underneath the stainless

steel top (on the server side FIG. 1).

5. Lift the stainless steel top off of the

cabinet. Set it aside.

6. For both the lamp holder and the starter

socket, remove the screws holding the

part in place. (FIG. 4-D) Remove the tape

holding the wires to the channel frame.

(FIG. 2)

7. Disconnect the lead wires at the butt

splice connector.(FIG.2-C)

8. Replace part with correct new part

number.

9. Replace screws removed in Step 4.

(FIG. 4-D)

10. Connect white and blue lead wires to

main wire with butt connectors. Replace

the tape holding the wires to the lamp

channel.

11. Replace the stainless steel top (FIG. 1)

using screws removed in Step 4.

12. Replace the starter.

13. Replace the bulbs (fluorescent).

14. Reconnect the power to the cabinet.

FIG. 1

FIG. 2

FIG. 3

FIG. 4

The lamp holder and the light starter socket

are located on the lamp channel assembly.

Page 35

FLUORESCENT BULB & STARTER REPLACEMENT

MAINTENANCE & REPAIR 33

BULB REPLACEMENT

1. Turn light switch off on the cabinet.

2. Pull down on the socket (A).

3. Remove the plastic outer lamp shield (B) and bulb

(C).

4. Raise the bulb up.Pull out of the socket.

5. Remove lamp shields and end caps (D).

6. Place the new bulb in the shield. Attach end caps.

7. Insert the bulb into the cabinet, push up an snap

into place.

8. Turn light switch back on.

BULB STARTER REPLACEMENT

(The fluorescent bulb starter is located on the lamp

channel assembly. One star ter is necessar y per bulb.)

1. Turn light switch off on the cabinet.

2. Remove the lid from the cabinet.

3. Grasp the starter (E), push in.

Turn counterclockwise.Pull the starter out of the

lamp channel assembly (F).

4. Replace the starter with the correct new part

number.

5. Grasp the starter, push into contact holes.Turn

the starter clockwise to seat properly.

6. Turn light switch back on.

Page 36

THERMOSTAT REPLACEMENT

34 MAINTENANCE & REPAIR

1. Disconnect the power to the cabinet.

2. Remove the grill.

3. Remove screws from the thermostat mount.

4. Pull the thermal bulb out of the cabinet.

5. Replace the thermostat with the correct new part

number .

6. Slide the capillary tube up the control well which

extends into the machinery compartment. (Be very

careful. Do not kink the thermal bulb capillary tube.)

7. Reattach the thermostat screws to mounting holes.

8. Replace the grill assembly.

9. Reconnect the power to the cabinet.

The thermostat is located on the server side of the

cabinet, directly behind the service grill. It functions

to control the temperature inside the cabinet. The

range on the thermostat dial is adjustable from 1 to 7

(7 being the coldest setting). The OFF position is

provided for defrosting the cabinet.

Page 37

MASTER POWER SUPPLY SWITCH &

LIGHT SWITCH REPLACEMENT

MAINTENANCE & REPAIR 35

The master supply switch (A) and the light

switch (B) are located behind the grill panel, on

the righthand server side of the unit.

1. Disconnect the power to the cabinet.

2. Remove the grill.

3. Remove screws holding the switch in place.

4. Detach the switch leads.

5. Remove the lock nut on exterior of switch.

6. Replace with new switch.

7. Reattach the electrical leads.

8. Replace the front grill.

9. Reconnect the power to the cabinet.

Page 38

CONDENSER FAN MOTOR REPLACEMENT

36 MAINTENANCE & REPAIR

The condenser fan motor is located in the

machinery compar tment, directly behind the

condenser coil.

1. Disconnect the power to the cabinet.

2. Remove the grill panel.

3. Remove the condensing tray hold

down bolts.

4. Pull the condenser tray out of the

cabinet. Disconnect the wire at the

compressor.

5. Remove the motor from the fan motor

mounting bracket.

6. Replace with correct motor.

7. Reconnect wires at the compressor.

8. Slide the tray back into the cabinet.

Replace hold down bolts.

9. Replace the front grill.

10. Reconnect the power to the cabinet.

Page 39

BALLAST REPLACEMENT

BALLAST REPLACEMENT 37

The ballast is located in the machinery

compartment inside the electrical box.

1. Disconnect the power to the cabinet.

2. Remove the front grill.

3. Remove the electrical wiring box.

4. Disconnect the leads to the ballast.

5. Replace the ballast with correct part.

6. Reconnect the leads to the ballast.

7. Replace the electrical box assembly.

8. Replace the front grill.

9. Reconnect the power to the cabinet.

Page 40

METERING DEVICE/HEAT EXCHANGER REPLACEMENT

38 MAINTENANCE & REPAIR

1. Disconnect power to the cabinet.

2. Pull out the condensing unit.

3. Disconnect the liquid line.

4. Disconnect the suction line at the compressor.

5. Cut off the evaporator inlet tube about five

inches down below the point where it comes out

of the cabinet.

6. Remove the capillary tube from the inside of the

evaporator inlet tube.

7. Connect the end of the capillary on the new heat

exchanger to the evaporator inlet tube.

8. Connect the suction line to the compressor valve

and the capillary line to the bottom of the drier.

Replace the drier.

9. Evacuate and recharge.

10. Secure short lengths of insulating tubing provided

around exposed tubing in place with tape and seal

to bottom of the cabinet with permagum which is

provided.

11. Reconnect power to the cabinet.

Page 41

TROUBLESHOOTING GUIDE

MAINTENANCE & REPAIR 39

TROUBLE COMMON CAUSE REMEDY

UNIT WILL NOT RUN.

CABINET IS

TOO WARM.

Blown Fuse.

Low V oltage .

Open motor or temperature control.

Open relay.

Open overload.

Open compressor.

Open service cord.

Broken lead to compressor or cold control.

Service cord not plugged in.

Thermostat position set to warm, not

allowing unit to operate often enough.

Fan motor not running.

Shortage of refrigerant.

Not enough air circulation around

cabinet.

Dirty condenser or obstructed

condenser ducts.

Thermostat control capillary not properly

installed.

Check power outlet for “”live” circuit.If outlet is “dead” but

building has power, replace the fuse.Try to determine the

cause of the overload or short circuit.

Check outlet with voltmeter, should check 115V plus or

minus 10%.

If circuit overloaded, either reduce load or have

electrician install separate circuit.

If unable to remedy any other way, install auto-transformer.

Jumper across terminals of control. If unit runs and

connections are all tight, replace control. Power element

may have lost charge or points may be dirty.Repair or

replace thermostat.

Check relay. Replace if necessary.

Check overload.Replace if necessary.

Check compressor.Replace if necessary.

Check with ohmmeter at unit. If no circuit and current is

indicated at outlet, replace or repair.

Repair or replace broken leads.

Plug in cord.

Turn knob to colder position.

Check and replace fan motor if necessary.

Check for leaks.Repair, evacuate and recharge system.

Relocate cabinet or provide clearance to allow sufficient

circulation.

Clean the condenser and the ducts.

Refer back to removal/installation instructions detailed

in this manual

Page 42

40 MAINTENANCE & REPAIR

TROUBLE COMMON CAUSE REMEDY

CABINET RUNS

CONTINUOUSLY.

UNIT CYCLES

ON OVERLOAD

Not enough air circulation around cabinet

or air circulation is restricted.

Cooling large quantities of product or heavy

loading.

Refrigerant charge.

Room temperature too warm.

Thermostat defective.

Loose flooring or floor not firm.

Tubing contacting cabinet or other tubing.

Cabinet not level.

Compressor mechanically grounded.

Fan hitting drain pan or mechanically

grounding.

Shipping bands rubbing.

Loose fan blades or motor.

Loose parts or refrigeration or electrical

lines out of place.

Short relay.

Weak overload protector.

Low voltage.

Short compressor.

Relocate cabinet or provide proper clearances around

cabinet. Remove restriction.

Explain to customer that heavy loading causes long

running time.

Undercharged or overcharged.Check, evacuate and

recharge with proper charge.

Ventilate room as much as possible.

Check control. If it allows unit to operate all the time,

replace control.

Tighten flooring or brace floor.

Move tubing gently!

Level cabinet.

Replace compressor mounts.

Move fan.

Make sure all shipping bands have been cut and

removed.

Tighten fan blades and/or motor.

Tighten all loose fittings. Move misplaced lines.

Replace relay.

Replace overload protector.

Check outlet with voltmeter. Under load, voltage should

be 115V plus or minus 10%. Check for several cabinets

on same circuit or extremely long or undersized cord

being used.

Check with meter and also ground before replacing.

NOISY OPERATION

Page 43

MAINTENANCE & REPAIR 41

TROUBLE COMMON CAUSE REMEDY

CABINET LIGHTS

WILL NOT WORK.

UNIT SHORT

CYCLES.

Light switch OFF or defective

Incorrect voltage.

Abnormally high, heavy use of cabinet.

Shortage of refrigerant. Unit must run

longer and will operate at a lower than

normal suction pressure.

Overcharge of refrigerant. Excessively cold

or frosted suction line results in lost

refrigeration effort.

Restricted air flow over condenser or

air or non-condensable gases in system.

High room temperature.

Compressor inefficient.

Thermostat setting too cold.

Cycling on overload because of high/low

line voltage with variance more or less than

10% from 115 volts.May also be caused by

head pressures too high.

Thermostat set too cold.

Thermostat bulb contact bad.

Room temperature abnormally low.

Thermostat set too warm.

Thermostat contact points dirty or burned.

Thermostat out of adjustment.

Excessive service load or abnormally high

room temperature.

Excessive frost accumulation.

Try new bulb or bulbs.Inspect lamp holders for signs of

bad connections.

Check voltage to compressor terminal board.Voltage

must be plus or minus 10% of nameplate voltage.

Heavy useage requires more operation. Check useage

and correct or explain.

Put in the normal charge and check for leaks.

Remove excess charge.

Correct the condition.

Check for temperature variance. Correct condition.

Replace.

Raise setting.

Check voltage, head pressure and air passages.

Repair and correct condition.

Set warmer.(Setting #1 is the warmest; #7 is the coldest.)

If the bulb contact is bad, the bulb temperature will lag

behind the sleeve temperature causing the unit to run

longer and make the cabinet too cold. Make sure bulb

makes good contact with the bulb well.

Correct conditions.

Set colder.(Setting #$1 is warmest; #7 the coldest.)

Clean or replace thermostat.

Readjust or change thermostat.

Educate customer about problems that are caused by

improper loading and excessive room temperature

fluctuations.

Defrost the cabinet.

COMPRESSOR WILL

NOT RUN.

UNIT RUNS

TOO MUCH.

PRODUCT TOO

COLD.

PRODUCT TOO

WARM.

Page 44

42 MAINTENANCE & REPAIR

TROUBLE COMMON CAUSE REMEDY

WON’T START.

WON’T HUM.

COMPRESSOR STARTS;

MOTOR WON’T GET

OFF STARTING

WINDING.

Open the circuit.

Protector open.

Control contacts open.

Open circuit in stator.

Improperly wired.

Low line voltage.

Open starting capacitor.

Relay contacts not closing.

Open circuit in start winding.

Stator winding grounded

(normally will blow fuse.)

High discharge pressure.

Tight compressor.

Weak starting capacitor or one weak

capacitor of a set.

Low line voltage.

Improperly wired.

Defective relay.

Running capacitor shorted.

Starting and running windings shor ted.

Starting capacitor weak or one of a set

open.

High discharge pressure.

Tight compressor.

Check wiring, fuses, receptacle.

Wait for reset — check current.

Check control, check pressures.

Replace stator or compressor.

Check wiring against diagram.

Check main line voltage, determine location of voltage

drop.

Replace starting capacitor.

Check by operating manually. Replace relay if defective.

Check stator leads.If leads are all right, replace

compressor.

Check stator leads.If leads are all right, replace

compressor.

Eliminate cause of excessive pressure.Make sure

discharge shut-off and receiver valves are open

if applicable.

Check oil level — correct binding condition, if possible.

If not, replace compressor.

Replace.

Bring up voltage.

Check wiring against diagram.

Check operation — replace relay if defective.

Check resistances.Replace capacitor if defective.

Check capacitance — replace if defective.

Check capacitance — replace if defective.

Check discharge shutoff valves. Check pressure.

Check oil level.Check binding. Replace compressor if

necessary.

WON’T START; HUMS

INTERMITTENTLY.

(cycling on protector.)

Page 45

MAINTENANCE & REPAIR 43

TROUBLE COMMON CAUSE REMEDY

COMPRESSOR STARTS

& RUNS BUT CYCLES

ON PROTECTOR.

STARTING

CAPACITORS

BURNT OUT.

Low line voltage.

Additional current passing through

protector.

Suction pressure too high.

Discharge pressure too high.

Protector weak.

Running capacitor defective.

Stator partially shorted or grounded.

Inadequate motor cooling.

Compressor tight.

Unbalanced line (three-phase).

Discharge valve leaking or broken.

Short cycling.

Prolonged operation on starting winding.

Relay contacts sticking.

Improper relay or incorrect relay setting.

Improper capacitor.

Capacitor terminals shorted by water.

Bring up voltage.

Check for added fan motors and pumps connected to

wrong side of protector.

Check compressor for proper application.

Check ventilation, restrictions and overcharge.

Check current — replace protector if defective.

Check capacitance.Replace if defective.

Check resistances; check for ground. Replace if

defective.

Correct cooling system.

Check oil level.Check for binding condition.

Check voltage of each phase.If not equal,

correct condition of unbalance.

Replace valve plate.

Reduce number of starts to 20 or less per hour.

Reduce starting load (install crankcase pressure limit

valve), increase voltage if low — replace relay if

defective.

Clean contacts or replace relay.

Replace relay.

Check parts list for proper capacitor rating — mfd. and

voltage.

Install capacitors so terminals won’t be wet.

Page 46

44 MAINTENANCE & REPAIR

TROUBLE COMMON CAUSE REMEDY

RUNNING

CAPACITORS

BURNT OUT.

Excessive line voltage.

High line voltage and light load.

Capacitor voltage rating too low.

Capacitor terminals shorted by water.

Low line voltage.

Excessive line voltage.

Incorrect running capacitor.

Short cycling.

Relay vibrating.

Incorrect relay.

Reduce the line voltage to not over 10% above rating of

motor.

Reduce voltage if over 10% excessive.

Install capacitors with recommended voltage rating.

Install capacitors so terminals will not be wet.

Increase voltage to not less than 10% under compressor

motor rating.

Reduce voltage to maximum of 10% above motor rating.

Replace running capacitor with correct mfd. capacitance.

Reduce number of starts per hour.

Mount relay rigidly.

Use relay recommended for specific motor compressor.

RELAY BURNT OUT.

Page 47

FLUORESCENT LAMPS - TROUBLESHOOTING GUIDE

MAINTENANCE & REPAIR 45

The manufacturer uses standard fluorescent lamps in all of its applications. Standard one- and two- lamp ballast circuits are used.

Replacement lamps should be purchased over the counter from a local electrical wholesaler. The table below indicates general problems that

may be encountered with fluorescent lighting applications, possible causes, and corrective maintenance suggestions.

TROUBLE COMMON CAUSE REMEDY

NORMAL END OF LIFE.

Lamp won’t operate. Flashes

momentarily and goes out or blinks

on and off. Ends probably blackened.

SHORT LIFE.

END BLACKENING.

Dense blackening at one end or

both, extending 2" to 3" from base.

Normal failure. Active material on

cathodes exhausted.

Wrong lamp type used.

Wrong type of starter.

Ballast not supplying the specified electrical values.

Wrong type of ballast used.

Too low or too high voltage.

Poor circuit contact.(likely at lampholders)

Ballast improperly or incompletely

connected.

Too many lamp starts.

Normal end of life.

Mercury deposit — generally within 1" of

lamp end.

Poor circuit contact likely at the lampholder.

Ballast improperly or incompletely

connected.

Wrong type lamp used.

Wrong type of starter or defective starter

causing on /off blinking or prolonged

flashing at each start.

Ballast intalled not supplying the specified

electrical values.

Line voltage too low or too high.

Ballast improperly or incompletely

connected.

Replace lamp promptly.

Replace with lamp type marked in owner’s manual.

Replace with correct starter.

Replace with correct ballast for rating for lamp size.

Replace ballast with proper type.

Check primary voltage with range specified on ballast

name plate.

Lampholders should be rigidly mounted and

lamp securely seated.

Study ballast label wiring diagram and check

connections.

Average life for most lamps is dependant on number of

starts and hours of operation.

Replace lamp promptly.

Should evaporate as lamp is operated.

Lampholders should be rigidly mounted and lamp

securely seated.

Study ballast wiring instructions and check

connections.

Replace with correct lamp type.

Replace with proper starter.

Replace with ballast of correct rating for lamp size.

Check line voltage with range specified on ballast plate.

Study ballast label wiring instuctions and check

connections.

Page 48

TROUBLE COMMON CAUSE REMEDY

NO STARTING EFFORT

OR SLOW STARTING.

DECREASED LIGHT

OUTPUT.

Full illumination of

bulbs requires correct assembly

of all components of lighting

system.

BLINKING ON/OFF.

Accompanied by shimmering effect

during “lighted” period.

Open lamp cathode circuit due to broken

cathode, air leak, or open weld.

Wrong lamp type used.

Starter at end of life.

Starter sluggish.

Ballast installed not supplying the specified

electrical values.

Temperature cold air contact to bulb.

Circuit voltage.

Temperature operation, cold air affects

lamp performance.

Circuit voltage.

Ballast improperly or incompletely

connected.

Dust or dirt on lamp or fixture.

Normal failure. Active material on cathodes

exhausted.

Possible lamp fault.

Wrong type of starter or defective starter.

Ballast installed not supplying the specified

electrical circuit.

Circuit voltage.

Loose circuit contact.

Wrong lamp type used.

Wrong ballast used.Wrong voltage rating.

Circuit voltage.

Ballast improperly or incompletely

connected.

If open, circuit is shown by continuity test or by viewing

end of bulb against a pinhole of light. Replace lamp.

Replace with lamp type indicated in owner’s manual.

Replace starter.

Replace starter.

Replace with certified ballast of correct rating for

lamp size.

Correct installation of lamp protection tubes, or

shields to prevent cold air effects.

Check voltage and correct if possible.

Properly install jacketed lamps where applicable.

Check voltage and correct if possible.

Study ballast label wiring instructions and

check connections.

Clean.

Replace lamp promptly.

Replace lamp.Investigate further if successive

lamps blink or flicker in same lampholders.

Replace with proper starter.

Replace with correct ballast with correct rating

for lamp size.

Check voltage and correct if possible.

Lampholders should be rigidly mounted and lamp

securely seated.

Replace with correct lamp number located in owner’s

manual.

Replace ballast.

Check voltage and correct to design specification.

Study ballast label. Correct if installed wrong.

46 MAINTENANCE & REPAIR

OVERHEATED BALLAST.

Page 49

SECTION IV

Parts List

Page 50

48 PARTS LIST

CABINET PAR TS

14

21

12

1

2

6

17

8

20

10

19

7

9

18

11

13

3

15

16

4

5

22

Page 51

PARTS LIST 49

CABINET PAR TS LIST

CABINET PARTS MISCELLANEOUS CABINET PARTS

Dipping Cabinets Not Shown

PART NUMBER

1 05-1188-* Canopy Top EA 1 -01 1 -02 137A04 Container Clamp Asm Complete

2 44-0862-06 Upper Lid Seal IN 1 - 1 -

3 51-1504-* Lamp Fixture As'y EA 1 -01 1 -02 33-0302 Can Clamp Frame

50-1078-00 Lower Front Trim Rail EA 1 - 137A05 Container Clamp Band Assy

4

137F02 Lower Front Trim Rail EA 1 - 137A0501 Band / Container Clamp

217F03 Lower Trim Filler EA 1 - 137A0201 Hinge / Container Clamp Band

5

137F03 Lower Trim Filler EA 1 - 33-0303 Band Lock Arm

6 05-1189-02 Outside Post, RH EA 1 - 1 - 356A09 Container Mtg Knob

7 05-1189-01 Outside Post, LH EA 1 - 1 -

8 10-1158-02 Pivot Bracket, RH EA 1 - 1 - 47-0064 Night Cover

9 10-1158-01 Pivot Bracket, LH EA 1 - 1 - 33-0245 Frost Shield Hook

10 10-1157-00 Pivot Bracket, Center EA 1 - 1 - 90-0125 Bottom Pad Insert

11 50-4010-01 Trim Support, LH EA 1 - 1 - 26-0632-00 Baskin Robbins Nameplate

12 50-4010-02 Trim Support, RH EA 1 - 1 - 26-6504-00 Double Sided Tape

13 137F0004-02 Trim, LH End EA 1 - 1 -

14 137F0005-02 Trim, RH End EA 1 - 1 -

15 42-0133 Glass, End EA 2 - 2 -

16 44-0913 Channel, Glass EA 2 - 2 -

17 20-0083-* Glass, Front EA 1 -01 1 -02

18 01-0986-00 Cover, Cold Plate EA 2 - 3 -