Beverage Air E8FR-13 Service Manual

SERVICE &

INSTALLATION

MANUAL

Chest

Freezers

51-1371-04

02/03

CARRIER COMMERCIAL REFRIGERATION, INC.

Providing BEVERAGE-AIR • FRIGIDAIRE • KELVINATOR • UNIVERSAL NOLIN Products/Services

If additional information is necessary, call the factory.

Our toll free number is 1-800-684-1199.Technical assis-

tance engineers are willing to assist you in any way possible. Office hours are from 7:30 a.m. to 5:30 p.m.,

Eastern Standard Time.

Important information is contained in this manual which should

be retained in a convenient location for future reference.

All data and information in this manual is subject to change without notice.

MODEL DESIGNATION INFORMATION

115V, 60HZ

PAR T N O. MODELS

52-1904-21 2SF-13

52-1904-22 4SF-13

52-1904-23 4DF-13

52-1904-24 6DF-13

52-1904-25 8DF-13

52-1904-33 8FR-13

52-1904-26 10DF-13

52-1904-27 14DF-13

52-2034-01 DI4-2

EXPORT 220V, 50HZ

PAR T N O. MODELS

52-1904-34 E2SF-13

52-1904-35 E4SF-13

52-1904-36 E4DF-13

52-1904-37 E6DF-13

52-1904-38 E8DF-13

52-1904-39 E8FR-13

SECTION I

General

Maintenance

& Repair

Ice Cream Cabinets

Except for routine cleaning, these chest freezers

require little maintenance. In the unusual event

that repair should be necessary , this manual presents information that is helpful in maintaining,

diagnosing, and repairing these cabinets.

Table of Contents

GENERAL MAINTENANCE & REPAIR

Installation/Operation .......................................................... 3

Grounding Instructions ...................................................... 4

Cleaning Instructions .......................................................... 5

Defrosting Instructions ...................................................... 6

2SF / 4DF / 4SF / DI4 Specs. & Drawings .......................... 7

6DF / 8DF / 10DF / 14DF Specs. & Drawings .................... 8

8FR Specs. & Drawings ...................................................... 9

General Operations Information ........................................ 10

Cabinet Construction ........................................................ 10

Cooling Tank Assembly .................................................... 10

Chamber Guards .............................................................. 10

Replacing Chamber Guards .............................................. 11

Lids .................................................................................. 11

Replacing Stainless Steel Top Cap .................................... 11

Refrigerating Systems ...................................................... 11

Condenser ........................................................................ 11

Filter Drier ........................................................................ 12

Capillary Tube .................................................................. 12

Heat Exchanger ................................................................ 12

Replacing Heat Exchanger ................................................ 12

Refrigerant Cycle - Condenser & Evaporator .................. 13

Electrical Service .............................................................. 14

Thermostat ...................................................................... 14

Condensate Heater ............................................................ 15

Motor & Relay .................................................................. 16

Checking For Electrical Trouble ........................................ 17

Refrigeration Service: Compressor Installation ................ 17

Refrigerant Service .......................................................... 17

Cleaning System After Burnout ........................................ 19

Wiring Diagram: Chest Models ........................................ 20

ELECTRICAL & REFRIGERATION

SPECIFICATIONS

2SF-13 & 4SF-13 (R-404A) .............................................. 21

4DF-13 & 6DF-13 (R-404A) .............................................. 22

8DF-13 / 8FR-13 & 10DF-13 (R-404A) ............................ 23

14DF-13 & DI4-1 (R-404A) .............................................. 24

PAR TS LISTS

Cabinet Parts Illustration (R-404A) .................................. 26

Cabinet Parts Listing (R-404A) ........................................ 27

Cabinet Parts Listing (R-404A) Export................................28

Condensing Unit Comp. Listing (R404A) Export ................29

Condensing Unit Compartment Illustration (R404A) ..........30

Condensing Unit Compartment Listing (R404A) ................31

Condensing Unit Compartment Illustration & Listing

Model DI4-1........................................................................32

8FR Parts Listing (R-404) & Accessory Mounting .......... 33

Cleaning Chocolate & Syrup Pumps ................................ 33

Accessory Mounting Limitations ...................................... 34

Caster Assembly Installation ............................................ 35

2TABLE OF CONTENTS

Installation & Operation Instructions

These instructions include information which is intended

to assure the operator of correct installation, operation,

and service. Before attempting installation, adjustment

or maintenance, be certain of the following:

1.That you have read and fully understand the instructions.

2.That you have all the tools required and are trained to

use them.

3.That you have met all installation and usage restrictions and are familiar with the functions and operation

of the unit.

4.That you follow all instructions exactly as given.

All fittings, measurements, procedures and recommendations are significant. Substitutions and approximation

must be avoided. Improper handling, maintenance,

installation and adjustment or service attempted by anyone other than a qualified technician, may void the

future warranty claims and cause damage to the unit

and/or result in injury to the operator and/or bystanders.

Record for Service

Model No. __________________________________

Serial No. ____________________________________

Installation Date ______________________________

Invoice Date__________________________________

Start-up Date ________________________________

Telephone for Service __________________________

INSTALLATION INSTRUCTIONS

Thermostat will maintain approximately zero degrees on

the original factory setting. Turn the adjusting screw

clockwise for colder and counterclockwise for warmer.

IMPORTANT: Turning control counterclockwise to the

stop shuts cabinet "OFF".

For storage of package ice cream, turn thermostat to

coldest position. Limit top layer of package to a height

consistent with cabinet usage and turn over of product.

LOCATION

Select a location for the cabinet which will be most convenient for the customer and which will allow adequate

air circulation.Restricted air flow will result in higher condensing pressures and operating costs.

Provide at least a 1-inch space around the exterior of

the cabinet. The outside shell is the condenser and

depends on the natural convection of room air for dissipation of its heat. Stainless or formica facing sheets

applied to the cabinet exterior should be in tight contact

with the cabinet's outer walls to improve the heat flow.

When a cabinet is built into a counter or back-bar and

space is allowed between the counter and the cabinet

walls, provide holes or louvers along the top edge f or hot

air to escape.Holes should be screened to keep insects

and rodents out.

IMPORTANT: Before building any piece of equipment

in, run it to be sure the operation is satisfactory.

BE SAFE. SEE ILLUSTRATION ABOVE.

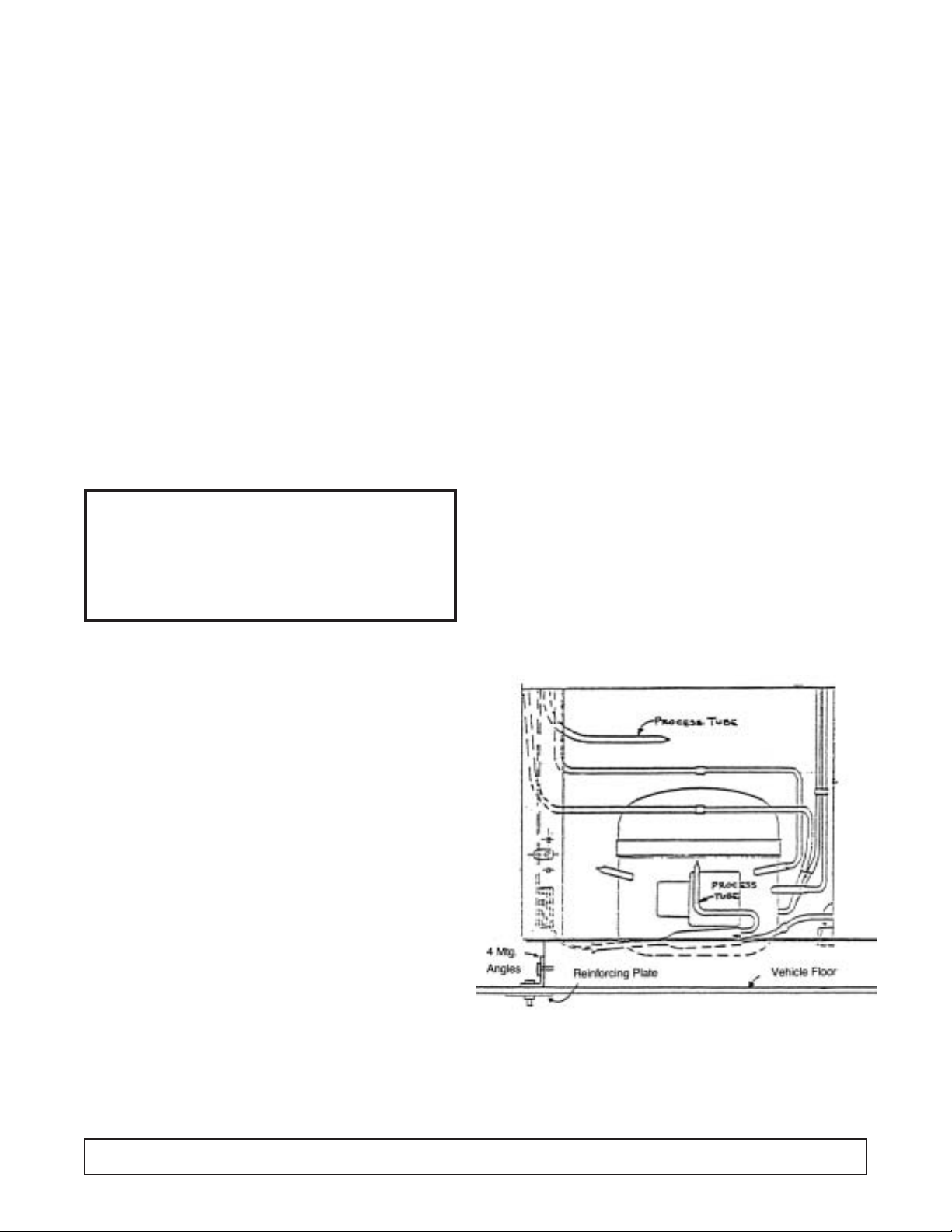

When a cabinet is installed in a moving vehicle, use the

original crate mounting angles or equivalent to securely

bolt the cabinet to the vehicle floor so it won't move

going around corners or during sudden starts and stops.

INSTALLATION & OPERATION 3

Important information is contained in

these instructions which should be

retained in a convenient location for

future reference.

Grounding Instructions

This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazards.The

appliance should be plugged directly into a properly

grounded three-prong receptacle.

Where a two-prong wall receptacle is encountered, it

must be replaced with a properly grounded three-prong

receptacle in accordance with the National Electrical

Code and local codes and ordinances. The work must

be done by a licensed electrician.

IMPORTANT

Do not, under any circumstances cut or remove the

round grounding prong from the appliance plug.

WARNING

Consult a licensed electrician if you have any

doubt about the grounding of your wall

receptacle. Only a licensed electrician can

determine the polarization of your wall

receptacle. Only a properly installed threeprong wall receptacle assures the proper

polarization with the appliance plug.

4 GROUNDING INSTRUCTIONS

20 Amp

15 Amp

15 Amp

20 Amp

FIG. 2

Cleaning Instructions

DIRECTIONS FOR PROPER CARE &

CLEANING

1.Wipe up spilled foods promptly.

2. Use lukewarm detergent solution for cleaning the

cabinet interior, exterior, and lids.Follow with a clean,

damp cloth and then wipe dry.

3. Protect the exterior enamel finish and plastic lid frame

with automotive type cleaner and wax.

4. Protect all stainless steel surfaces with a commercial

silicone emulsion type cleaner.This cleaner is excellent for all stainless steel surfaces. It leaves a protecting film that prevents fingermarking and the adherence of food particles.

5. CAUTION:

a. Never use naptha or solvent type cleaner on plas-

tic parts or lid frames.

b. Never u se harsh abrasive polishes on plastic parts

or plastic lid frames.

c. Do not blow steam or dash excessively hot water

against plastic materials when cleaning the tank or

defrosting, as damage to plastic parts may occur.

6.When the cabinet is taken out of service for more than

a short period:

a. Remove lids. (DO NOT replace them on the cabi-

net until the cabinet is again refrigerated.)

b. Defrost cabinet and remove any spilled ice cream

from the chamber guards.

c.Wash and dry chamber guards and cabinet interi-

or.(See Item 2 above.)

INSTRUCTIONS FOR SEALING

CABINET TO FLOOR

The National Sanitation Foundation recommends these

cabinets be sealed to the floor to prevent w ater, dirt and

vermin, etc. from getting under the cabinet. The instructions below meet their requirements.

1. Position and level the cabinet.

2. Draw outline of the base on the floor.

3. Raise and block the front side of the cabinet as illustrated in FIG. 1.

4. Apply a bead of mastic (See approved list below) to

the floor one half inch inside the outline drawn. (See

FIG. 2.) Bead must be heavy enough to compress at

all points when the cabinet is set down.

5. Raise and block the rear of the cabinet as illustrated

in FIG. 1.

6. Apply mastic on the floor as outlined in step 4 on the

other three sides.

7. Examine to see that cabinet is sealed to floor around

entire perimeter.

NOTE. Asphalt floors are very susceptible to chemical

attack. A layer of tape on the floor prior to applying the

mastic will protect the floor.

APPROVED MASTICS

3M #EC800 ............................................................Caulk

3M #EC2185 ..........................................................Caulk

3M #EC1055 ..........................................................Bead

3M #EC1202 ..........................................................Bead

Armstrong Cork ........................................Rubber Caulk

Products Research Co.#5000..................Rubber Caulk

G.E. Silicone Sealer

CLEANING INSTRUCTIONS 5

FIG. 1

Defrosting Instructions

A drain fitting is located in the bottom of the storage

tank.To drain the defrost water:

1. Remove and store products in another freezer.

2. Loosen and remove any items such as ice cream,

nuts, berries, paper labels, etc., which could plug the

bottom drain.

3. Remove the cap from the drain hose fitting.

4. Connect a hose to the fitting and run it to a floor drain,

a shallow (2" high maximum) pan, or to a “Filordrain”

at the sink.

5. Disconnect the cabinet by pulling the plug or turning

the thermostat off to melt down the frost.You can hasten the defrost by using the “Filordrain” or a hose to

spray warm water on the cabinet walls. (Detailed

instructions for using the “Filordrain” for spraying the

frost and removing the accumulated water are available from your dealer.)

6. Recap hose fitting after defrosting is complete.

6 GROUNDING INSTRUCTIONS

COMPRESSOR COMPARTMENT

DRAIN IN LINER

DRAIN CAP

Specifications - Specifications Subject to Change without Notice.

DI4 2SF 4DF 4SF

Compressor Mount Front Front Front Front

Temperature Range 0° to -20°F (-18° to -29°C) 0° to -25° 0° to -25° 0° to -20°

Number of Lids 2 2 2 4

Lid Construction Stainless Steel, High Density, High Density, Foamed-in-Place High Density, Foamed-in-Place High Density, Foamed-in-Place

Foamed-In-Place Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets

Insulation w/ Vinyl Gaskets

Hinge Type Continuous Composition Continuous Composition Continuous Composition Continuous Composition

Insulation Polyurethane Foam Polyurethane Foam Polyurethane Foam Polyurethane Foam

Wall Thickness 2-1/4" 2-5/16" 2-5/16" 2-5/16"

Capacity 4.9 cu. ft. 5.4 cu. ft. 9.1 cu. ft. 11.3 cu. ft.

Capacity

3 gal. (9-

1

⁄2" I.D.) cans 6 4 9 10

2-

1

⁄2 gal. (9" I.D.) cans 6 5 10 13

2-

1

⁄2 gal.(9-1⁄4" I.D.) cans 6 5 12 15

1

⁄2 gal. packages — 63 116 136

Shipping Weight 210 lbs. 212 lbs. 247 lbs. 294 lbs.

Compressor Size 1/5 HP 1/5 HP 1/5 HP 1/5 HP

Condenser Type Forced Convection No-clog, Wrap-around No-clog, Wrap-around No-clog, Wrap-around

Radiant Shell Radiant Shell Radiant Shell

Evaporator Type Cold Wall Cold Wall Cold Wall Cold Wall

Refrigerant Type R404A R-404A R-404A R-404A

Refrigerant Control Capillary Capillary Capillary Capillary

Defrost System Manual Manual Manual Manual

Amp Draw 2.0 2.0 2.0 2.0

Electrical Specs. (V/Hz/Ph) 115/60/1 115/60/1 115/60/1 115/60/1

NSF-7 (Ice Cream Storage) Yes Yes Yes Yes

UL & CUL Listed Yes Yes Yes Yes

Interior Finish Baked Enamel on Galvanized Steel Baked Enamel Baked Enamel Baked Enamel

Exterior Finish Unpainted Galvannealed Steel Baked Enamel Baked Enamel Baked Enamel

w/ Stainless Steel Cap w/ Stainless Steel Cap w/ Stainless Steel Cap w/ Stainless Steel Cap

Electrical Information Conduit Connected, Max. Fuse 15 Amp Service Cord 15 Amp Service Cord 15 Amp Service Cord

Size: 15 Amp, Circuit Ampacity: 15A NEMA 5-15P Plug NEMA 5-15P Plug NEMA 5-15P Plug

DI4 / 2SF / 4DF / 4SF SPECIFICATIONS 7

SF

Side View

DF

Side View

DI4 Front View

DI4 Side View

Model 2SF

Model 4DF Model 4SF

Thermostat

on Side

Handy

Box

10 7/8"

TYP.

1/2"

11 1/8"

13"

13"

Drain

12 1/8"

10 1/8"

25 1/2"

29 3/8"

Connector for

Drain Hose

27 3/4"

22 1/4"

SQ.

21 5/8"

Reach In Opening

2 1/4"

TYP.

8 6DF / 8DF / 10DF / 14DF SPECIFICATIONS

Specifications - Specifications Subject to Change without Notice.

6DF 8DF 10DF 14DF

Compressor Mount Front Front Front Front

Temperature Range 0° to -20°F 0° to -20° 0° to -20° 0° to -25°

Number of Lids 4 4 6 8

Lid Construction High Density, Foamed-In-Place High Density, Foamed-in-Place High Density, Foamed-in-Place High Density, Foamed-in-Place

Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets

Hinge Type Continuous Composition Continuous Composition Continuous Composition Continuous Composition

Insulation Polyurethane Foam Polyurethane Foam Polyurethane Foam Polyurethane Foam

Wall Thickness 2-5/16" 2-5/16" 2-5/16" 2-5/16"

Capacity 14.1 cu. ft. 18.6 cu. ft. 23.6 cu. ft. 31.5 cu. ft.

Capacity

3 gal. (9-

1

⁄2" I.D.) cans 16 21 29 40

2-

1

⁄2 gal. (9" I.D.) cans 19 25 33 47

2-

1

⁄2 gal.(9-1⁄4" I.D.) cans 21 30 40 56

1

⁄2 gal. packages 173 234 298 103

Shipping Weight 304 lbs. 353 lbs. 396 lbs. 598 lbs.

Compressor Size 1/3 HP 1/3 HP 1/3 HP (2) 1/3 HP

Condenser Type No-clog, Wrap-around No-clog, Wrap-around No-clog, Wrap-around No-clog, Wrap-around

Radiant Shell Radiant Shell Radiant Shell Radiant Shell

Evaporator Type Cold Wall Cold Wall Cold Wall Cold Wall

Refrigerant Type R-404A R-404A R-404A R-404A

Refrigerant Control Capillary Capillary Capillary Capillary

Defrost System Manual Manual Manual Manual

Amp Draw 3.0 3.0 5.5 6.0

Electrical Specs. (V/Hz/Ph) 115/60/1 115/60/1 115/60/1 115/60/1

NSF-7 (Ice Cream Storage) Yes Yes Yes Yes

UL & CUL Listed Yes Yes Yes Yes

Interior Finish Baked Enamel on Galvanized Steel Baked Enamel Baked Enamel Baked Enamel

Exterior Finish Unpainted Galvannealed Steel Baked Enamel Baked Enamel Baked Enamel

w/ Stainless Steel Cap w/ Stainless Steel Cap w/ Stainless Steel Cap w/ Stainless Steel Cap

Electrical Information 15 Amp Service Cord 15 Amp Service Cord 15 Amp Service Cord 15 Amp Service Cord

NEMA 5-15P Plug NEMA 5-15P Plug NEMA 5-15P Plug NEMA 5-15P Plug

Model 6DF

Model 8DF

Model 10DF

Model 14DF

8FR SPECIFICATIONS 9

Specifications - Specifications Subject to Change without Notice.

8FR

Compressor Mount Front

Temperature Range 0° to -20°F

Number of Lids 2

Lid Construction High Density, Foamed-In-Place

Insulation w/ Vinyl Gaskets

Hinge Type Continuous Composition

Insulation Polyurethane Foam

Wall Thickness 2-5/16"

Capacity 14.1 cu. ft.

Capacity

3 gal. (9-

1

⁄2" I.D.) cans 21 - 12 top / 9 bottom

2-

1

⁄2 gal. (9" I.D.) cans 25

2-

1

⁄2 gal.(9-1⁄4" I.D.) cans 30

1

⁄2 gal. packages 234

Shipping Weight (Approx.) 353 lbs.

Compressor Size 1/3 HP

Condenser Type No-clog, Wrap-around

Radiant Shell

Evaporator Type Cold Wall Shell

Refrigerant Type R404A

Refrigerant Control Capillary

Defrost System Manual

Amp Draw 3.0

Electrical Specs. (V/Hz/Ph) 115/60/1

NSF-7 (Ice Cream Storage) Yes

UL & CUL Listed Yes

Interior Finish Baked Enamel on Galvanized Steel

Exterior Finish Baked Enamel

w/ Stainless Steel Cap

Electrical Information 15Amp Service Cord

NEMA 5-15P Plug

8FR

Operation - General

All the chest freezer models are of the same basic

design consisting of a hot wall condenser cap tube fed

tank wrap evaporator. Ice formation on the walls over a

period of time is normal.This frost should be scraped off

periodically in order to maintain peak performance.

These cabinets are thermostatically controlled for various temperature requirements. The thermostat is

located post adjacent to the unit compartment and can

be accessed for adjustment by the user with a screwdriver or a dime. Thermostat position #1 being the

warmest and position #7 being the coldest.

These cabinets are manual defrost and a drain is provided for periodic cleaning. A garden hose can be

attached to the drain plug for draining any water that

may accumulate.This drain attachment is located in the

front base rail of the cabinet.

NOTE: The power supply cord must be disconnected

when cleaning or servicing these cabinets.

On initial cabinet pulldown, the hot wall condenser may

become warm to the touch until the normal operating

temperatures are achieved.

Refer top model serial data tag for cabinet amperage,

refrigerant charges and type.

CABINET CONSTRUCTION

The low side tank is lowered into the outer shell and

anchored to the sub top by a plastic extrusion and foam.

The space between the outer wrapper and the inner

tank is then filled with urethane foam insulation (2-1⁄4"

thick) forming a three-ply wall of single unit construction.

The low side tank then is not removab le and no repair of

the low side can be made.

The stainless steel top capping is of drawn one piece

construction. It is put in place after the inner tank is

assembled to the wrapper and is secured to the sides of

the cabinet with 1⁄8" pop rivets.

COOLING TANK ASSEMBLY

The low side assemblies are designed so that the sides

and the ends of the tank are refrigerated.

The evaporator coil assembly on the tank is different to

that on previous models. It is now a serpentine coil

arrangement.The new evaporator starts at the top of the

inner tank and spirals downward to the condensing unit.

The thermostat bulb well is located near the front of the

machine compartment in all models.

CHAMBER GUARDS

The one-piece vinyl chamber guard extends from the

top of the lid opening down into the inner tank.

Galvanized steel chamber guard retainers mounted in

the top of the tank frame hold the vinyl chamber guard

against the top stainless steel capping.A special sealing

compound laid on the inside angle of the retainers seals

the vinyl to the stainless steel capping. One-piece

retainer brackets along the low er edge of the tank frame

retain the lower edge of the vinyl chamber guard.

To remove the vinyl chamber guard, merely unhook

from lower edge of the brackets and the top edge of the

chamber guard retainers. (See below)

10 GENERAL OPERATIONS

Loading...

Loading...