Multi-Port Actuator

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Release: Mar 2013

WARNING:

Use caution when working on, with, or around valves and actuators. High pressures, forces, voltages, and

flammable media can be present.

WARNING

Read this manual in its entirety before installing, operating, or performing maintenance on the MPA valve

actuator.

WARNING

Failure to follow instructions for proper electrical wiring, storage, setup, and maintenance may cause

serious injury, damage equipment, or void the warranty. Refer to Manual E796 for instructions on storage,

electrical hook-up, and maintenance.

Ensure that the installation is carried out in accordance with EN 60079-14 and IEC 60079-14.

Regulatory information:

EEx d IIB T4 or EEx d IIB 120 degrees C (T4)

Tamb-20degress C to +60 degrees C

Revision N

Copyright © 2013

Emerson Process Management

All rights reserved.

II 2GD

Emerson Process Management

Valve Actuation LLC

13840 Pike Road

1-800-679-1561

(281) 499-1561 FAX (281) 499-8445

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Table of Contents

Section 1: Introduction ........................................................ 1

Section 2: Features ...............................................................2

Section 3: Mechanical and Electrical Installation .................. 5

Section 4: Wiring ................................................................. 6

4.1 Power Wiring ................................................................................................ 6

4.2 Network Wiring ............................................................................................ 6

4.3 Monitor Relay Wiring..................................................................................... 6

4.4 Local ESD Wiring (Emergency Shutdown) ...................................................... 6

4.5 Optional Remote Display Module (RDM) Wiring ............................................ 7

Table of Contents

Mar 2013

Section 5: Local Display Module ........................................... 8

5.1 Description ................................................................................................... 8

5.2 Operation ..................................................................................................... 9

5.3 Local Operation ............................................................................................. 9

5.4 Operational Display ....................................................................................... 9

5.5 Display Blanking .......................................................................................... 10

5.6 Alarms Display ............................................................................................ 10

Section 6: Field Setup Using MPA Config Software .............. 12

6.1 CommSetUp ............................................................................................... 12

6.2 User Setup Menus ....................................................................................... 13

6.3 Selecting New Home Port (HP command using Control Knob setup) ........... 14

6.4 Home Port LED Function ............................................................................. 15

6.5 Home Port Calibration (HC command using Control Knob setup) ................ 15

6.6 Factory SetUp Menus .................................................................................. 16

6.7 Motor Type ................................................................................................. 16

6.8 Control Screen ............................................................................................ 18

Section 7: Field Setup Using Local Controls ......................... 20

7.1 Alarm History Display .................................................................................. 20

7.2 Setup Mode Display Sequence .................................................................... 20

Table of Contents

Section 8: Field Diagnostics ................................................ 23

8.1 Fd Fault Codes ............................................................................................. 23

Section 9: Remote Network Control ................................... 25

9.1 Modbus RTU ............................................................................................... 25

9.2 Foundation Fieldbus (FF) ............................................................................. 27

9.3 Probus DP Reduntant Networks with Redcom ........................................... 29

9.4 DeviceNet ................................................................................................... 30

I

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Appendix A: EC Declaration of Conformity Certificate ......... 31

Appendix B: Wiring Diagrams ............................................ 32

B.1 Three Phase Power ...................................................................................... 32

B.2 Single Phase Power ......................................................................................33

B.3 24 VDC Power ............................................................................................. 34

Table of Contents

Mar 2013

II

Table of Contents

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Section 1: Introduction

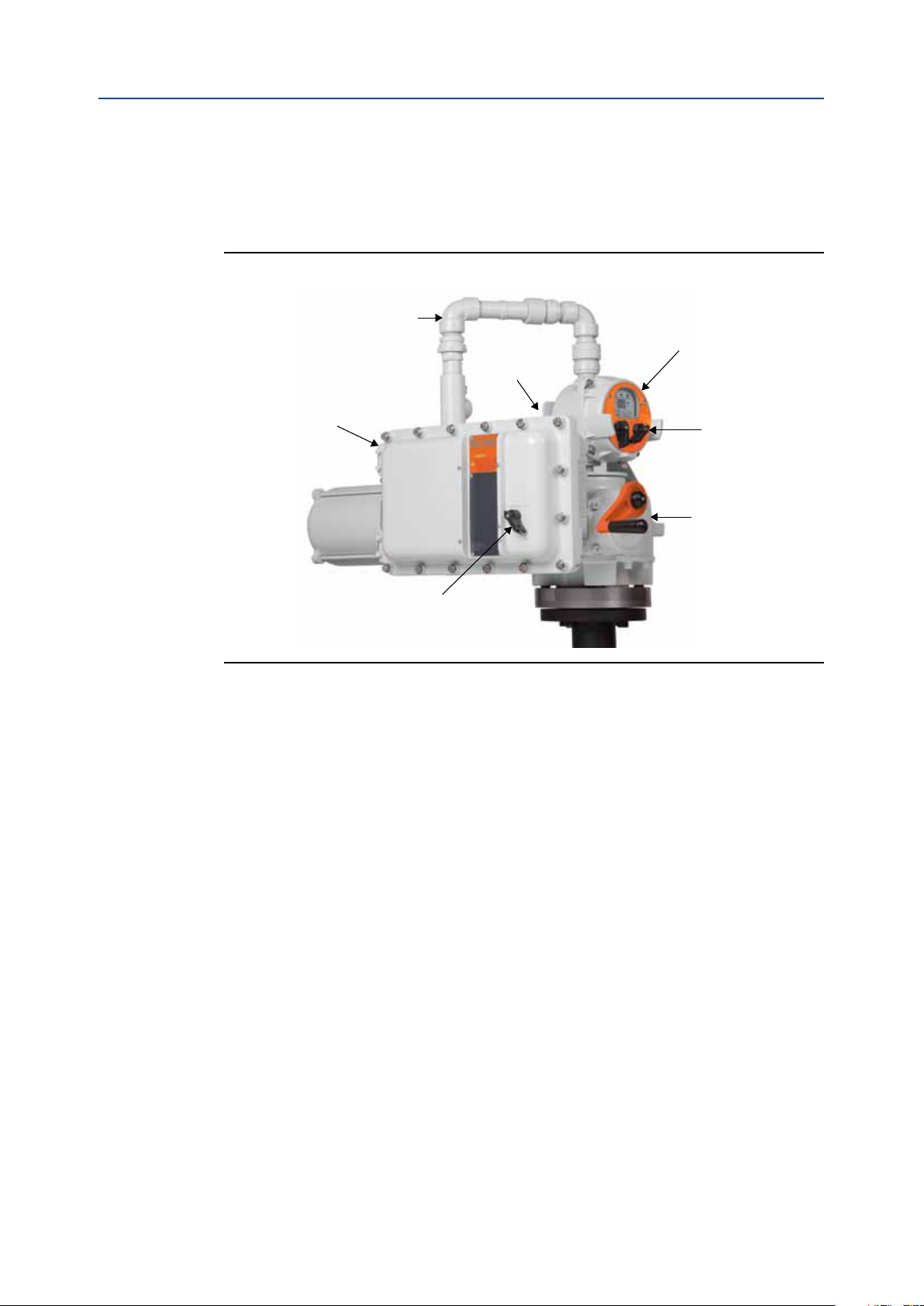

The Multi-Port Actuator is an single turn actuator for control of multi-port ow selectors

(MPFS) with 3 to 8 ports. A typical application is oil or gas well selection for well production

testing as shown in Figure 1. Typically the MPA is the actuator of a Multi-Port Flow Selector

as shown in Figure 2. There are applications in other processes where control of multi-port

valves is required.

Figure 1 Typical Well Test Application

Section 1: Introduction

Mar 2013

Figure 2 MPA mounted on 6"x16" MPFS

Introduction

1

Section 2: Features

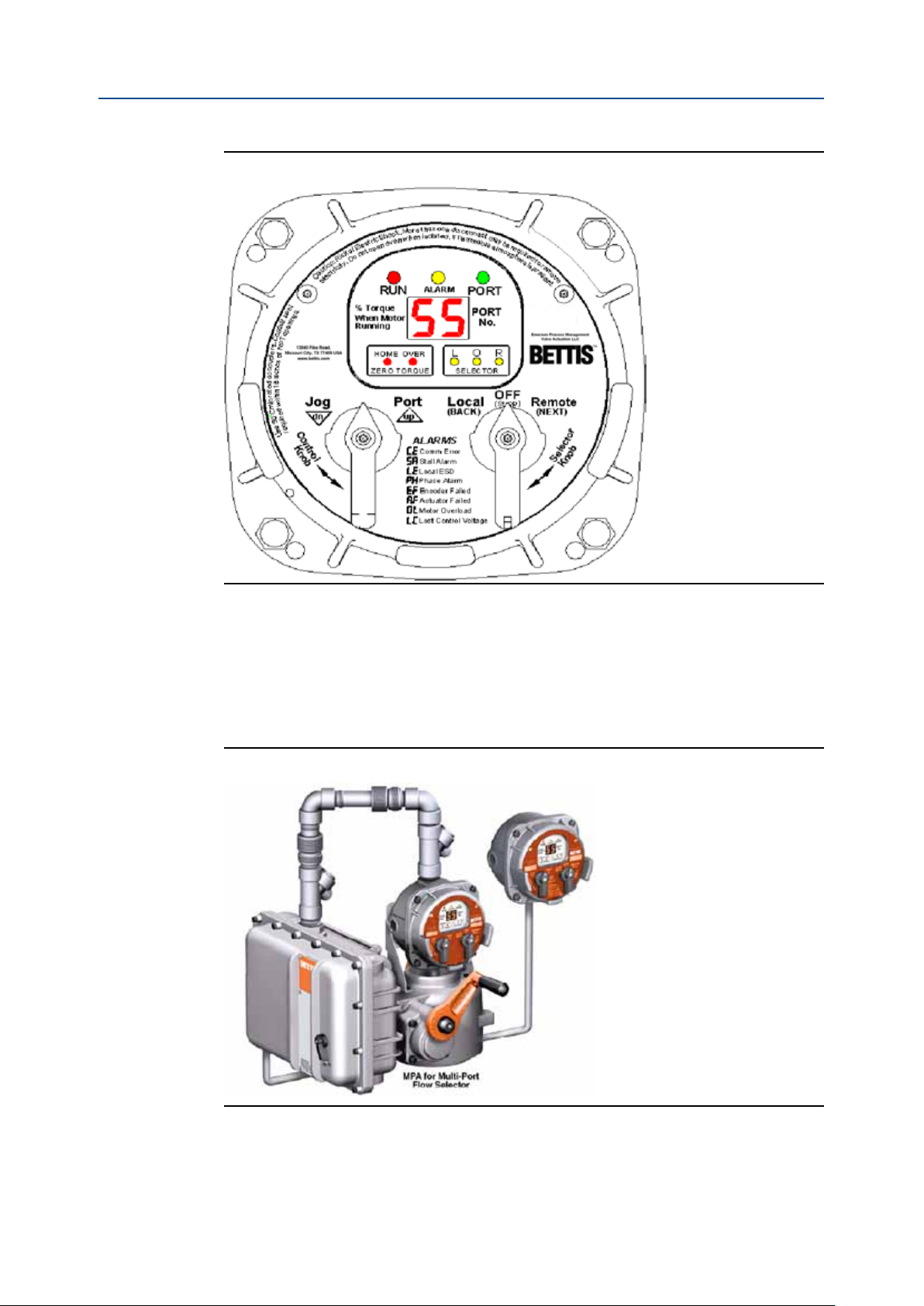

Low Voltage

Interfaces between

CPU and TBM

Electrical Enclosure with

Motor Starter, Control

Transformer, DC Power

Supplies, Power Entry,

Termination Panel, User

Wiring, I/O Interfaces,

Torque Encorder

Integral

Disconnect

BETTIS 3000 Ft-Lb Gearbox

Geared for 1.5 RPM

Position Encorder

Coupling to MPFS Stem

Local Display Module (LDM)

with Display & Status LEDs,

Selector & Control Knobs,

CPU Module,

Network Communications,

Position Encoder

Motor

(not shown)

Mar 2013

Section 2: Features

The actuator features several assemblies as shown in Figure 3. Unique features of the

actuator are listed below.

Figure 3 MPA Features

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

• MPA uses Bettis’s heavy duty gearbox with capacity of 3000’ lbsThreaded Valve

Stem

— Wide range of motors available for any voltage and torque

• Congurable for multi-port ow selectors from 3 to 8 ports

— Any port may be selected as home port and any port(s) may be skipped

— Actuator calibrated at factory for exact match to alignment of ow

selector ports

— Calibration parameters stored in nonvolatile memory and available to DCS

• 12-bit magnetic encoder coupled directly to valve stem for precision position

feedback

— Provides position measurement resolution of 0.088 degrees

• BETTIS’s exclusive solid-state motor starter and control software provides precise

positioning of ow selector within +1 degree of selected port

• High performance microcontroller updates motor control output every 4mS for

precision motor control

• 12-bit magnetic encoder coupled directly to torque pinion for torque feedback

— Provides torque measurement resolution of 0.146% of full torque

2

Features

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

• MPA supports all network protocols available with all other Bettis actuators

• I/O and alarm monitoring include:

• Four models support ve 8-port MPFS (Also see motor type, Table 4)

Section 2: Features

Mar 2013

— Modbus RS485 Bus or E>Net ring available

— Probus Redundancy with Redcom

— Foundation Fieldbus

— DeviceNet

— Ethernet Modbus TCP/IP

— Integral circuit breaker/disconnect

— Motor overload and motor thermal

— Loss of control voltage

— Encoder failure

— Stall detection and alarming (detects mechanical faults)

— 3-Phase monitoring and phase correction to insure correct motor rotation

— ESD to send selector to home port (also goes to home port on fault)

— Monitor relay for hardwired relay contact status on fault

Table 1. Four models support five 8-port MPFS

Model MPFS

MPA 150 2x4 150 203 1.0 1.0 1.0 0.79

MPA 650 3x6 650 881 0.7 1.0 0.5 0.49

MPA 800 4x8 & 4x10 800 1085 0.6 0.9 0.5 0.40

MPA1500 6x16 1500 2034 0.3 0.5 0.3 0.26

Note: Accuracy based on worst case tests at 38% of maximum torque.

Capacity RPM Accuracy

Lb/Ft Nm 1Ph 3Ph DC Degrees

• MPA includes local display module (LDM) standard

— Uses rugged, high visibility LED display for port number, torque, and

alarms (also displays setup menus and setup parameters)

— Multiple color LEDs display

— Port position within 1° of port

— Port position within 2° of port

— Motor running

— Over torque

— Position within 0.25° of home port

— Local mode |

Features

— Off mode | Combined detection logic for two

selector switches

— Remote mode |

— Includes Local Off Remote selector switch

— Local control knob for Port selection and Jog control when enabled by

User

3

Section 2: Features

Mar 2013

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

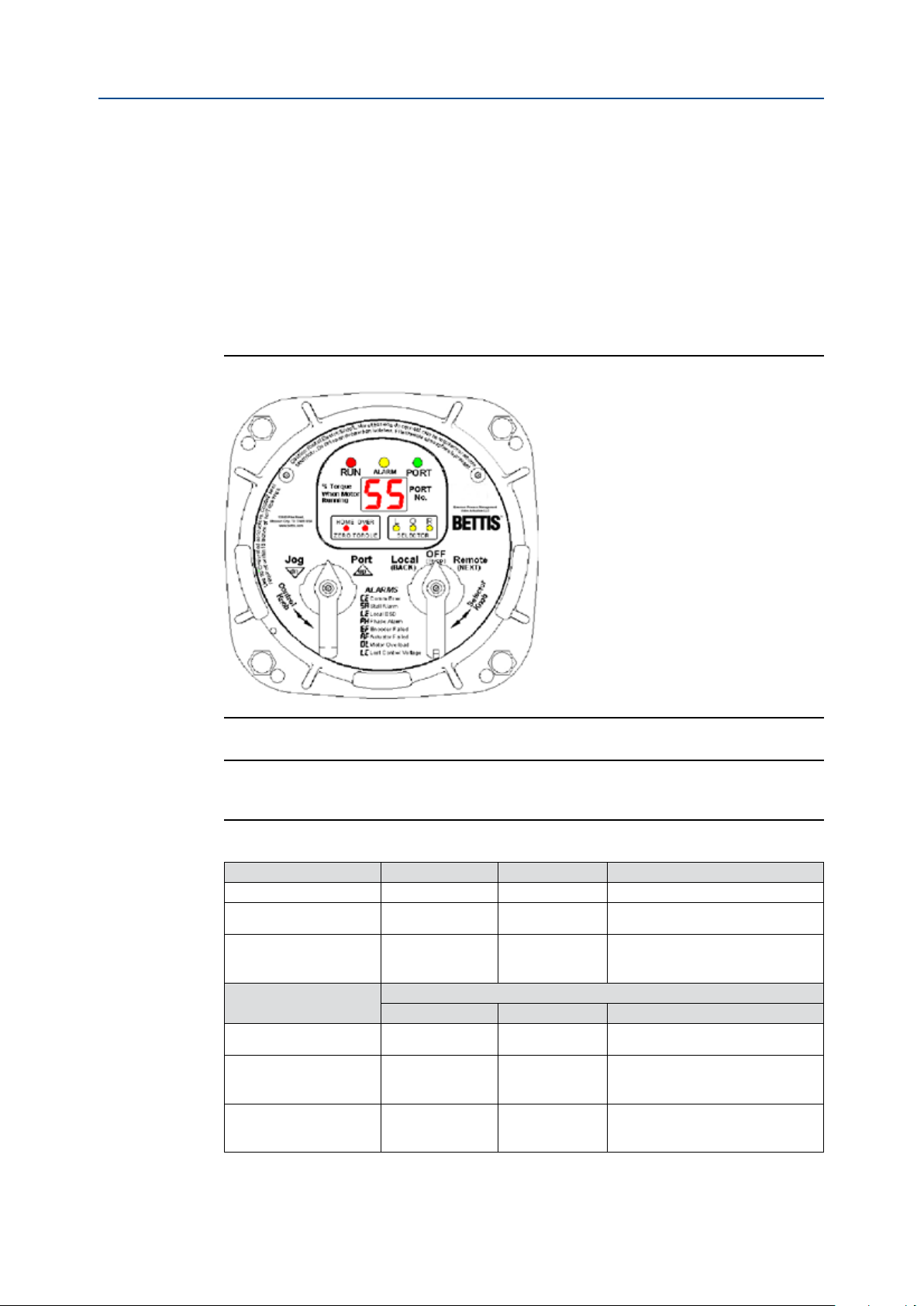

Figure 4 Local Display Module (LDM)

• Remote display module (RDM) option available

— RDM displays identical information and performs identical control as LDM

— BETTIS’s patented combined switch logic allows detection of selector

switch position on LDM and RDM

— Allows remote control up to 4,000 feet (1,220 meters) away

— Alarming includes loss of communication with RDM

Figure 5 MPA with Remote Display Module (RDM)

4

Features

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Section 3: Mechanical and Electrical Installation

Section 3: Mechanical and Electrical

Installation

Do not connect power until you have gone through the following checklist

1. Does the information given on the nameplate correspond with the application?

2. Have all wire terminations and the equipotential bonding system been connected

correctly?

3. EEx d applications: are the cable entries, plugs and adaptors EEx d approved?

4. Are all cable entries of the correct internal diameter providing a good seal around

the cable?

5. Do the ambient and process temperatures correspond to the ratings on the

nameplate as shown below?

Mar 2013

Mechanical and Electrical Installation

5

Section 4: Wiring

Mar 2013

Section 4: Wiring

All user wiring terminations are made inside the Electrical Enclosure shown in Figure 3 on

Page 2. Refer to wiring diagram located at the back of this manual for wiring connections.

High voltage power connections are made to the disconnect/circuit breaker located inside

the electrical enclosure. All low voltage connections, including network wiring, are made

to the Termination Board Module (TBM) located inside the electrical enclosure. Use conduit

and seals in accordance with National Electric Code (NEC) and local codes for all wiring

entering the electrical enclosure.

4.1 Power Wiring

Connect power voltage leads to the circuit breaker located in the main electrical enclosure.

Power wires must enter the electrical enclosure at the conduit entry on the lower right side

of the enclosure to prevent water from entering. The controller provides automatic phase

correction in case three-phase power is connected in the wrong phase rotation.

4.2 Network Wiring

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

If a single bus network connection, such as Foundation Fieldbus, is being made,

connect to Network Port A at TBM terminals 24 (-) and 25 (+). If the cable is shielded,

connect shield to TBM terminal 23. If redundant or repeater network connections such

as Bettis E>Net are being made, connect the second network to Network Port B at TBM

terminals 23 (+) and 24 (-). Connect cable shield of Port B to TBM terminal 25. Cable

shields are isolated from earth in the actuator. Connect shields to only one earth ground

point in the network, normally the host location.

4.3 Monitor Relay Wiring

The Monitor Relay is used for hard-wiring an indication of availability of the actuator for

remote control. When the selector switch is placed in the Remote mode and if there are no

alarms present that prevent operation, the Monitor Relay is energized. If an alarm occurs

or the selector switch is moved from the Remote position, the relay is de-energized. The

Monitor Relay is a Form C relay with both normally open (N.O.) and normally closed (N.C.)

contacts. Wire to either TBM terminals 31 and 32 if N.O. contacts are desired. Wire to TBM

terminals 32 and 33 if N.C. contacts are desired. The relay is shown on the wiring diagram

in the de-energized state, meaning that the actuator is not available for remote control.

4.4 Local ESD Wiring (Emergency Shutdown)

Remove jumper between TBM terminals 27 and 28. Connect Normally Closed (N.C.) dry

contacts to terminals 27 and 28. When the contacts open, ESD is activated, causing the

actuator to go to Home Port. The actuator will remain at the Home Port until the ESD

contacts are closed and a new command is received from either Local or Remote control.

The ESD circuit is a closed loop failsafe circuit. It the circuit is opened for any reason, broken

wire, bad contact, 24VDC power supply failure, etc., the ESD function is activated. The

closed loop circuit is powered by 24VDC from the actuator.

6

Wiring

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Section 4: Wiring

Mar 2013

4.5 Optional Remote Display Module (RDM) Wiring

Connect twisted pair RS485 cable from the RDM to TBM terminals 18 (-) and 19 (+). If

the RDM is being powered from the actuator 12VDC supply, wire the power wires from

the RDM to TBM terminals 16 (-) and 17 (+). The RDM is polarity protected, preventing

damage, but will not operate if polarity is reversed.

Wiring

7

Section 5: Local Display Module

Mar 2013

Operation and Maintenance

Section 5: Local Display Module

5.1 Description

Contains microprocessor controller, position encoder, and network interface. This is the

main controller used to setup and operate the actuator.

This module displays operating parameters, port position, torque, and alarms. It also

provides a means to congure the actuator by using the local controls.

Figure 6 Local Display Module

Part Number: MPA-0400-0313, Rev. N

To use the Local Control and Selector Knobs refer to Table 2.

NOTE:

Actuator moves in only the counterclockwise direction.

Table 2. Selector/Control Knob Function

Selector Knob (right) Rotate Function Results

OFF (Stop) [return position] Stop movement Prevents motor operation.

REMOTE (Auto) Clockwise Remote control

LOCAL (Hand) Counter-clockwise Hand Operation

Control

Knob (left)

Spring return Neutral position No operation

PORT (up) Clockwise

Jog (dn) Counter-clockwise

(while selector is in LOCAL (Hand) mode)

Rotate Function Results

Local command

to go to next

port

Local command

to micro-step

Allows control from remote

location.

Allows from the local control knob

or the control knob of the RDM, if

connected.

Releases a local command when

Local control is used.

Commands actuator to move to

the next port. Momentary knob

control.

Commands actuator to move only

whileknob is being held, i.e. maintained knob control.

8

Local Display Module

Loading...

Loading...