Bettis Manual: Bettis RPE-Series Installation, Operation and Maintenance Manual Manuals & Guides

Installation, Operation and Maintenance Manual

Bettis RPE-Series

Rack and Pinion Pneumatic Actuators

DOC.IOM.BE.EN Rev. 9

March 2019

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Table of Contents

Section 1: Before You Start

1.1 Installation, Operation and Maintenance Reference Documents ................... 1

1.2 Warehouse Storage ...................................................................................... 1

1.3 On-Site Storage ............................................................................................ 2

Section 2: Introduction

2.1 Identification ................................................................................................ 3

2.2 Intended Use ................................................................................................. 5

2.3 Specifications ................................................................................................ 5

Section 3: Configuration Code

Table of Contents

March 2019

Section 4: Installation

4.1 Before You Start ............................................................................................9

4.2 Actuator Rotation Direction .......................................................................... 9

4.2.1 Valve Rotation .................................................................................... 9

4.2.2 Position After Failure ........................................................................ 10

4.3 Principles of Operation ................................................................................ 10

4.3.1 Solenoid Valve .................................................................................. 10

4.3.2 Ingress Protection (IP) rating ............................................................ 11

4.3.3 Double-Acting Actuators .................................................................. 12

4.3.4 Spring-Return Actuators ................................................................... 13

4.4 Actuator Assembly Codes ........................................................................... 14

4.5 Actuator to Valve Installation ...................................................................... 15

4.6 Mounting of control and feedback accessories ............................................ 18

4.7 Recommended Tubing Sizes ....................................................................... 18

Section 5: Mechanical Stroke Adjustment

5.1 Travel Stop Adjustment ............................................................................... 20

5.1.1 Double-Acting Actuators .................................................................. 20

5.1.2 Spring-Return Actuators ................................................................... 20

5.1.3 Angular Displacement ......................................................................21

Section 6: Maintenance

6.1 Normal Maintenance .................................................................................. 22

6.2 Inspection and Repair .................................................................................. 23

6.2.1 Service Kits .......................................................................................23

6.2.2 Spring-Return Actuator ....................................................................23

Table of Contents

Section 7: Decommission (Out of Service)

7.1 Before You Start ..........................................................................................24

7.2 Removing the actuator from the valve ........................................................ 25

I

Table of Contents

March 2019

Section 8: Disassembly

Section 9: Reassembly

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

8.1 Removing End Caps (Sizes 25 to 600) .......................................................... 27

8.2 Removing End Caps (Sizes 950 to 4000) ...................................................... 29

8.3 Removing Spring Cartridges or Springs ....................................................... 30

8.4 Removing of Limit Stop ...............................................................................31

8.5 Removing Pistons ....................................................................................... 31

8.6 Removing Pinion .........................................................................................32

8.7 Cleaning the Components .......................................................................... 33

9.1 Grease Instructions .....................................................................................35

9.2 Reassembly of the pinion ............................................................................ 36

9.3 Reassembly of the pistons ........................................................................... 37

9.4 Reassembly and settings of the limit stops .................................................. 39

9.5 Reassembly of the end caps ........................................................................ 40

9.5.1 Double-Acting actuators .................................................................. 40

9.5.2 Spring-Return actuators ................................................................... 41

9.5.3 Spring-Return actuators - Size 950 to 4000 ...................................... 42

9.6 Basic function and Air Leak Test .................................................................. 45

Section 10: Troubleshooting

10.1 Mechanical Problems ..................................................................................46

10.2 Pneumatic Problems ...................................................................................47

10.3 Electrical Problems ...................................................................................... 48

Section 11: Parts List and Spare Parts Recommendations

11.1 Actuator sizes RPE25 to RPE600 ..................................................................49

11.2 Actuator sizes RPE950 to RPE2500 .............................................................. 50

11.3 Actuator size RPE4000 ................................................................................ 51

Appendix A: Spring Load Removal

A.1 Spring load relief ......................................................................................... 52

Appendix B: Tool & Torque Table

Appendix C: Full Stroke Adjustment Option

C.1 Full Stroke Adjustment Option .................................................................... 56

C.2 Convert a Standard Actuator into a Full Stroke Adjustment Version ............ 57

11.3.1 Procedure ........................................................................................ 58

C.3 Full Stroke Adjustment Setting .................................................................... 59

11.3.2 Factory Setting Procedure ................................................................ 59

11.3.3 Setting the Full Stroke Adjustment Screw to the Required Angle ...... 60

II

Table of Contents

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 1: Before You Start

This section explains:

• Base safety procedures.

• Where to find detailed information relating safety.

• Storage guidelines.

Installation, adjustment, putting into service, use, assembly, disassembly and maintenance

of the pneumatic actuator must be performed by qualified personnel.

NOTICE

Failure to follow the above guidelines will void warranty.

WARNING

Section 1: Before You Start

March 2019

Actuator must be isolated both pneumatically and electrically before any (dis)assembly

starts. Before mounting or (dis)assembly, the actuator consult the relevant sections of this

manual.

1.1 Installation, Operation and Maintenance Reference Documents

Before you start, read the following documents:

• All chapters in this manual.

• Safety Guide (Document No. DOC.SG.BE.1).

For Safety Instrumented Systems application, read the following document:

• SIL Safety Manual Bettis RPE-Series (Document No. DOC.SILM.BE.EN).

NOTICE

Failure to read the Safety Guide will void the warranty.

Not following the instructions of the Safety Guide can lead to failure of the product and

harm to personnel or equipment.

1.2 Warehouse Storage

• All actuators should be stored in a clean, dry warehouse, free from excessive

vibration and rapid temperature changes.

• All actuators should not be stored directly to the floor surface - it must be placed

in racks/shelves or use a pallet.

Before You Start

1

Section 1: Before You Start

March 2019

1.3 On-Site Storage

• All actuators should be stored in a clean, dry warehouse, free from excessive vibra-

tion and rapid temperature changes.

• Prevent moisture or dirt from entering the actuator. Plug or seal both air connec-

tion ports.

NOTICE

Failure to follow the above guidelines (Warehouse and On Site Storages) will void warranty.

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

2

Before You Start

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 2: Introduction

This section explains:

• How to identify the received product.

• The intended use of the product.

• Construction details.

• Actuator specifications.

2.1 Identification

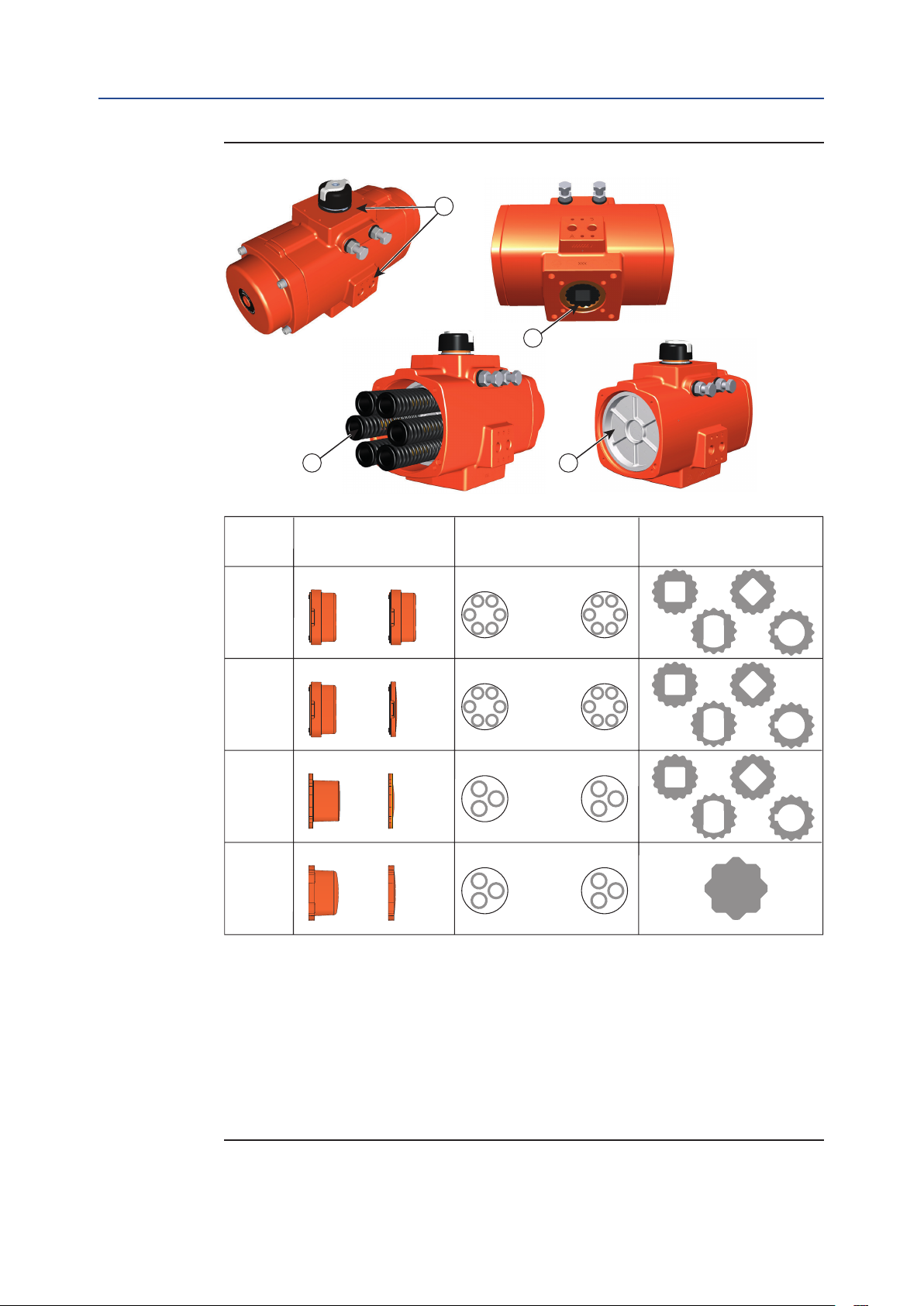

The Bettis™ RPE-Series Rack and Pinion actuators are available as double-acting or

spring-return versions. 12 models are available, ranging from 23 Nm to 4041 Nm

(206 to 35765 lbf.in)nominal torque output.

The Bettis RPE-Series uses standardized interfaces for solenoid, switchbox or positioner

mounting (VDI/VDE3845; NAMUR). The valve interface is equipped with an insert in the

pinion bottom that allows both ISO5211 or DIN3337 mounting.

Section 2: Introduction

March 2019

The springs in the spring-return version allow a fail action in case of loss of air supply

pressure (Fail-to-Close or Fail-to-Open).

As from size RPED150 double-acting versions have flat end caps to reduce actuator length

and internal air volume.

Introduction

3

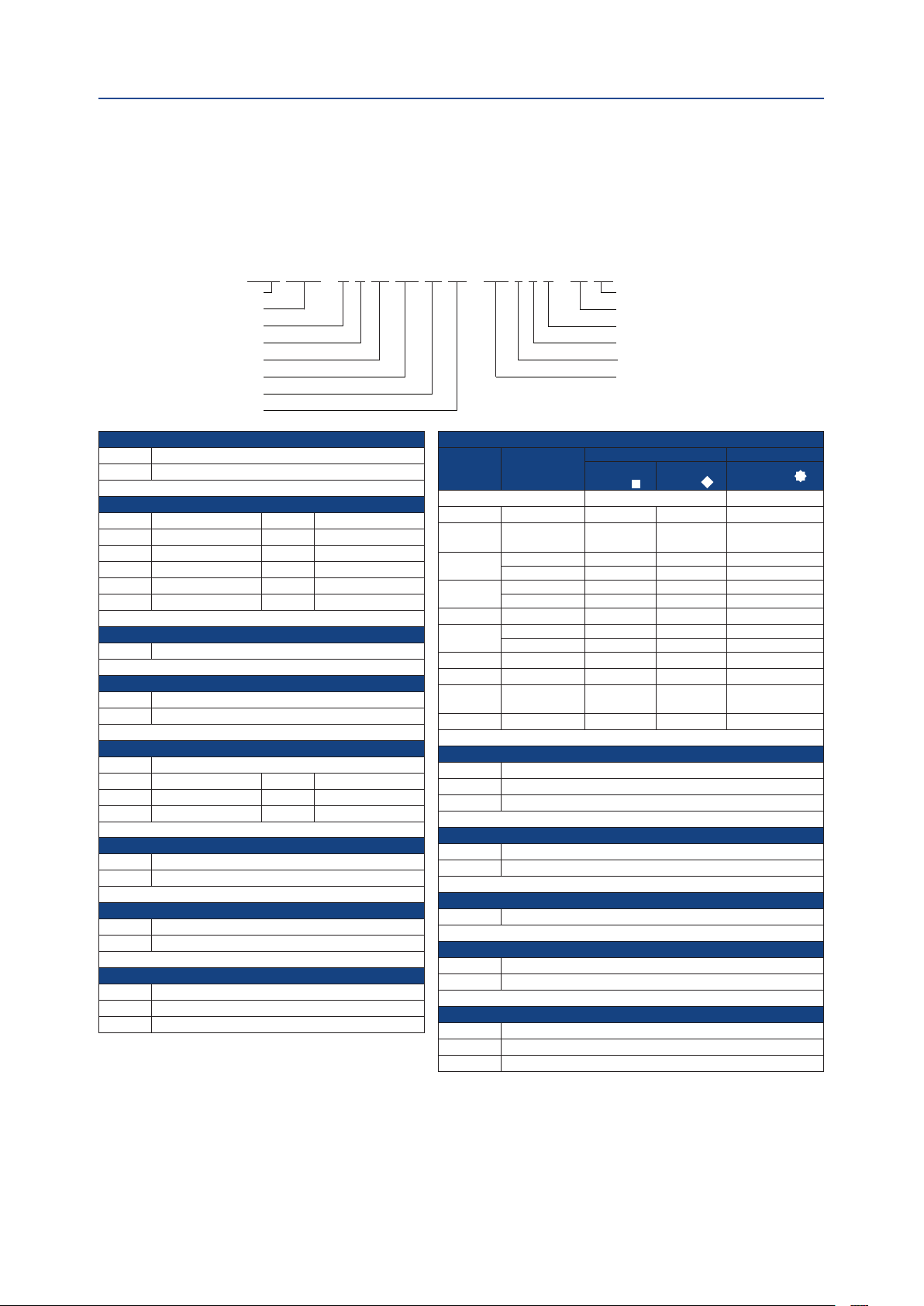

25 100

150 -

600

4000

Size End cap design

5

Spring design

6

Pinion bottom /

Insert design

2

950 -

2500

SR

Maximum 12

spring cartridges

Maximum 6

loose springs

Left

Right

Left Right

Left Right

DA

SR DA

SR DA

SR DA

Maximum 12

spring cartridges

Maximum 6

loose springs

Left Right

Notes

1. Top auxilliaries and Solenoid interface (VDI/VDE 3845; NAMUR) for size 25 to 4000.

2. Valve interface availalable according ISO5211 or DIN 3337.

Actuator sizes 25 to 2500 can be fitted with drive inserts with various inner shapes.

Actuator size 4000 is fitted with a double square; parallel and diagonal.

3. Spring-Return actuators: - with springs

4. Double-Acting actuators: - no springs

5. Actuator sizes 25 to 100 have high end caps for double-acting and spring-return models.

Actuator sizes 150 to 4000 have low end caps for double-acting models and high end caps

for spring return models.

6. Actuator sizes 25 to 600 are fitted with a maximum of 12 spring cartridges.

Actuator sizes 950 to 4000 are fitted with a maximum of of 6 loose springs.

1

2

3 4

Section 2: Introduction

March 2019

Figure 1 Identification

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

4

Introduction

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

2.2 Intended Use

The Bettis RPE Rack and Pinion actuators are intended for the automation and operation of

quarter-turn valves like Butterfly, Ball and Plug valves.

Rack and Pinion actuators can also be used to operate dampers or any other quarter-turn

applications.

2.3 Specifications

Table 1. Pressure Range

Actuator Type Pressure

Double-Acting 0.2 to 8 bar (2.9 to 116 psi)

Spring-Return

Table 2. Operating Media

6 to 8 bar (87 to 116 psig), with maximum spring set

3 to 8 bar (43.5 to 116 psig), reduced spring quantity

Section 2: Introduction

March 2019

Actuator Type Operating Media

Air, dry or lubricated and inert gases

Dew point at least 10K below ambient temperature

Double-Acting and Single Acting

1. Recommended air quality according ISO 8573-1 for normal operation: 7-5-4.

For sub-zero applications, take appropriate measures

Mentioned pressure levels are "gauge pressures".

Gauge pressure is equal to absolute pressure minus

atmospheric pressure.

NOTE:

Use of filters, pressure regulators, lubricator and an oil/water separator mounted in the air

supply line, will allow a smooth and durable operation of the actuator.

For lubricated supply air, it is recommended to use a non-detergent oil without aggressive

additives, VG32, group 2 (ISO 3448).

Table 3. Temperature Range

Actuator Type Temperature

Standard -20°C to 80°C (-4°F to +176°F)

Option: Low Temperature -40°C to +80°C (-40°F to +176°F)

Option: High Temperature -10°C to +120°C (+14°F to +250°F)

Introduction

5

A

B

Section 2: Introduction

March 2019

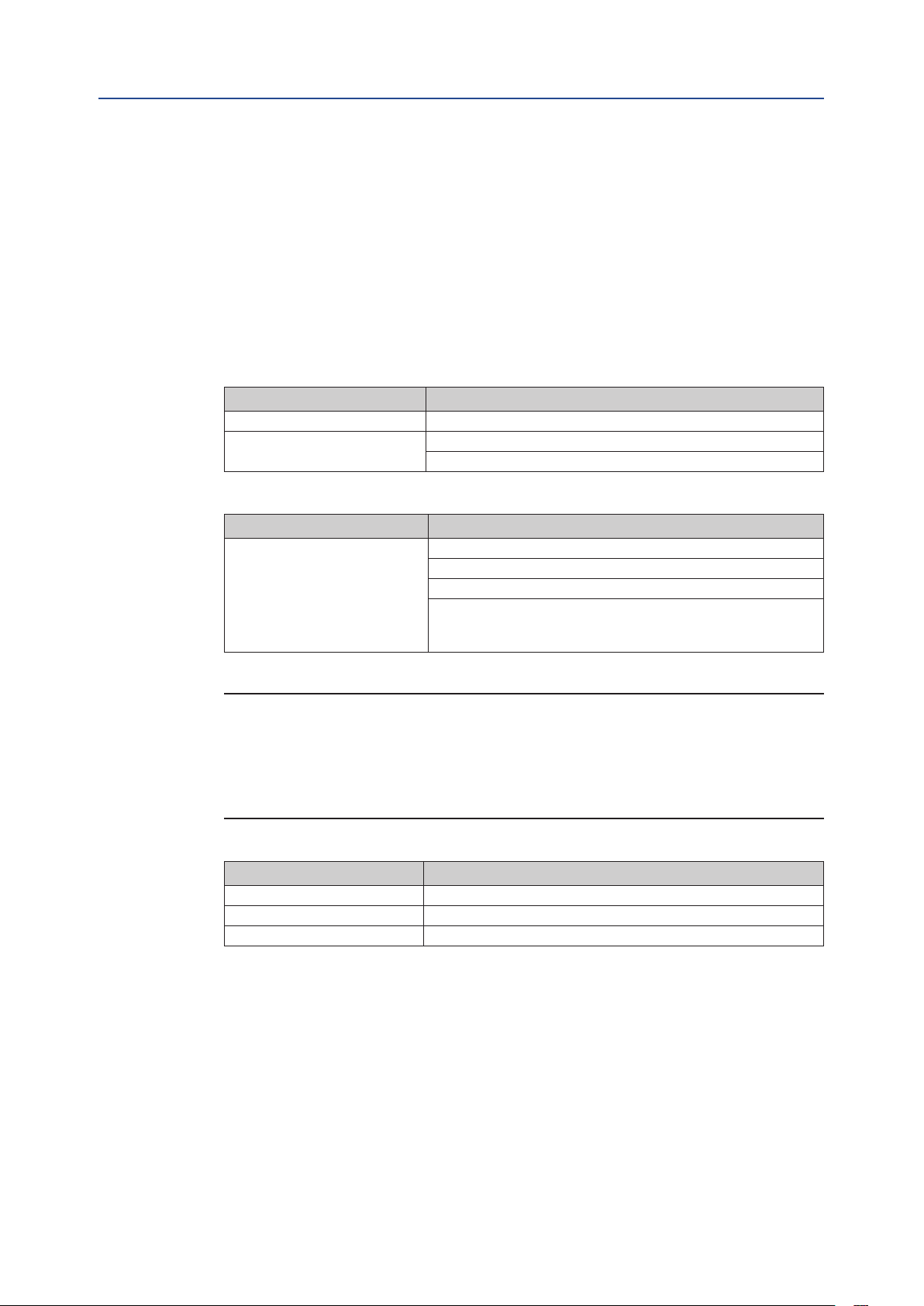

Table 4. Air Volumes and Consumption

Actuator

model

RPE 0025 0.14 0.20 0.08 0.36 0.64 1.2 0.48 0.88 1.7

RPE 0040

RPE 0065 0.40 0.56 0.22 1.02 1.8 3.4 1.3 2.4 4.7

RPE 0100 0.6 0.9 0.3 1.5 2.7 5.0 2.0 3.8 7.2

RPE 0150 1.0 0.8 0.5 2.4 4.3 8.1 2.1 3.6 6.7

RPE 0200

RPE 0350

RPE 0600 3.6 3.3 2.1 9.4 17 31 8.7 15 28

RPE 0950

RPE 1600 7.9 7.3 5.4 21 37 69 20 35 64

RPE 2500 12.6 11.9 8.3 34 59 109 32 56 104

RPE 4000 21.7 19.0 13.5 57 100 187 52 89 165

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Actuator volumes:

Maximum volume (in liters) Outward Stroke Inward Stroke

Central

chamber

1

End cap

chamber

2

Displaced

3

volume

Double-Acting

and Spring-Return

2 4 8 2 4 8

0.26 0.37 0.15 0.67 1.2 2.2 0.89 1.6 3.1

1.3 1.0 0.7 3.2 5.7 11 2.8 4.9 9.1

2.1 1.9 1.2 5.5 9.8 18 5.0 8.8 16

4.9 4.6 3.2 13 23 43 12 22 40

Consumption per stoke

(in liters, pressure in barg)

Double-Acting only

Consumption per stoke

(in Cu.in., pressure in psig)

Double-Acting only

Actuator

model

Actuator volumes:

Maximum volume (Cu.in.) Outward Stroke Inward Stroke

Central

chamber

1

End cap

chamber

2

Displaced

3

volume

Double-Acting

and Spring-Return

40 80 120 40 80 120

RPE 0025 8.5 12.2 4.7 28 52 75 38 72 106

RPE 0040

RPE 0065

15.9 23 8.9 53 96 140 71 133 196

24 34 13.5 81 148 215 107 200 294

RPE 0100 36 53 19.9 118 216 314 165 310 455

RPE 0150 58 47 32 192 352 512 163 293 424

RPE 0200 76 64 44 255 466 676 220 397 573

RPE 0350 131 115 76 436 796 1157 392 709 1025

RPE 0600 222 201 129 742 1354 1967 683 1237 1790

RPE 0950 301 279 196 1025 1854 2682 966 1735 2505

RPE 1600 484 447 328 1662 2997 4331 1560 2792 4024

RPE 2500 769 728 508 2630 4751 6873 2515 4523 6530

RPE 4000 1324 1159 825 4477 8130 11782 4022 7219 10416

Notes:

1. Pistons at 90° outward position.

2. Pistons at 0° inward position.

3. Stroke is 90°.

Figure 2 Actuator air volumes

Central air chamber volume

Double-Acting and Spring-Return

6

End cap air chamber volume

Double-Acting only

Introduction

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 3: Configuration Code

This section explains:

• How to create the configuration code for a actuator.

RPES 0150 - N U 40 CW AL TN - L19 S K A - 00 XX

Type

Size

Rotation angle

Threads

Spring set

Rotation

Pinion material

Valve interface

Section 3: Configuration Code

March 2019

Miscellaneous options

Internal code 1

Color / finish

Visual indicator

Temperature

Valve stem connection

Type

RPED Double Acting

RPES Spring Return

Size

0025 Size 0025 0350 Size 0350

0040 Size 0040 0600 Size 0600

0065 Size 0065 0950 Size 0950

0100 Size 0100 1600 Size 1600

0150 Size 0150 2500 Size 2500

0200 Size 0200 4000 Size 4000

Rotation angle

N 90° rotation angle

Threads

M Metric ISO 5211

U UNC/NPT/Imperial

Spring Set

00 Double Acting (no springs)

10 Spring Set 10 40 Spring Set 40

20 Spring Set 20 50 Spring Set 50

30 Spring Set 30 60 Spring Set 60

Rotation direction

CW Spring to Close/Clock Wise

CC Spring to Open/Counter Clock Wise

Pinion Material

AL High Grade Aluminium, Hard anodized

SS Stainless steel ASI 316 (+ A4-70 SS fasteners)

Valve Interface

TN Standard ISO 5211 interface

SY Small interface with center plate (DIN3337)

LY Large interface with center plate (DIN3337)

(2

Notes:

See next page.

Valve Stem Connection

Actuator

size

0025 11mm / 0.433" L11 D11 Q11

0040 &

0065

0100

0150

0200 22mm / 0.866" L22 D22 Q22

0350

0600 27mm / 1.063" L27 D27 Q27

0950 36mm / 1.417" L36 D36 Q36

1600 &

2500

4000 (355mm / 2.165" Q55 Q55 Q55

Temperature Range

S Standard: -20°C to +80°C (-4°F to +176°F)

H High: -10°C to +120°C (+14°F to +250°F)

L Low: -40°C to +80°C (-40°F to +176°F)

Visual Indication Code

K Standard (Knob)

N No Visual Indication

Finish

(7

B Standard coating (Bettis Orange)

Internal code 1

00 Standard

10 Stainless steel AISI316 (A4-70) end cap screws

Miceleanuous options

XX Standard

H1 1/2" High Flow plate

P1 1/2" Porting according EN 15714-3 (only sizes 950-4000)

Square

No insert 000 Not applicable

14mm / 0.551" L14 D14 Q14

17mm / 0.669" D17 Q19

19mm / 0.748" L19

17mm / 0.669" D17 Q22

19mm / 0.748" L19

22mm / 0.866" D22 Q27

27mm / 1.063" L27

46mm / 1.811" L46 D46 Q46

Aluminum Stainless Steel

Parallel

drive

Diagonal

drive

Star drive

(7

(4

Configuration Code

7

Section 3: Configuration Code

March 2019

Notes:

1. The options, listed here, are all options available. Not all options apply to all configurations.

2. Valve Interface: Option "S"; Small Interface with Center Plate (DIN3337) is not

available for size 0025, 0950 and 4000. Option "L"; Large Interface with Center

Plate (DIN3337) is not available for size 1600 and 2500.

3. Size 4000 does not have inserts but has two inner squares (diagonally and parallel

oriented) directly in the bottom of the pinion.

4. Actuators with stainless steel pinions do not have inserts but have two inner

squares (diagonally and parallel oriented aka "Star Drive") directly in the bottom of

the pinion.

5. Contact you local Bettis representative for additional insert options.

6. PED Group 1 Label only available up to size 950.

7. Actuators with the default hard anodized pinions, come with stainless steel grade

A2 (AISI304) end cap screws.

Optional, the actuator is available with stainless steel grade A4-70 (AISI316) end

cap screws.

Select option 10 in the "Internal code 1" segment in case stainless steel grade A4

(AISI316) end cap screws are required.

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

8

Configuration Code

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 4: Installation

This section explains:

• The actuator rotation direction.

• In which position the actuator will end after a failure.

• Principles of operation:

— Solenoid operation.

— Double acting and Spring return operation.

• Assembly codes.

• Actuator to valve assembly.

4.1 Before You Start

Section 4: Installation

March 2019

SAFETY

In case of an air or electrical failure, it is important to know the behavior of the actuator.

Before mounting the actuator on a valve, consult the following sections below.

4.2 Actuator Rotation Direction

4.2.1 Valve Rotation

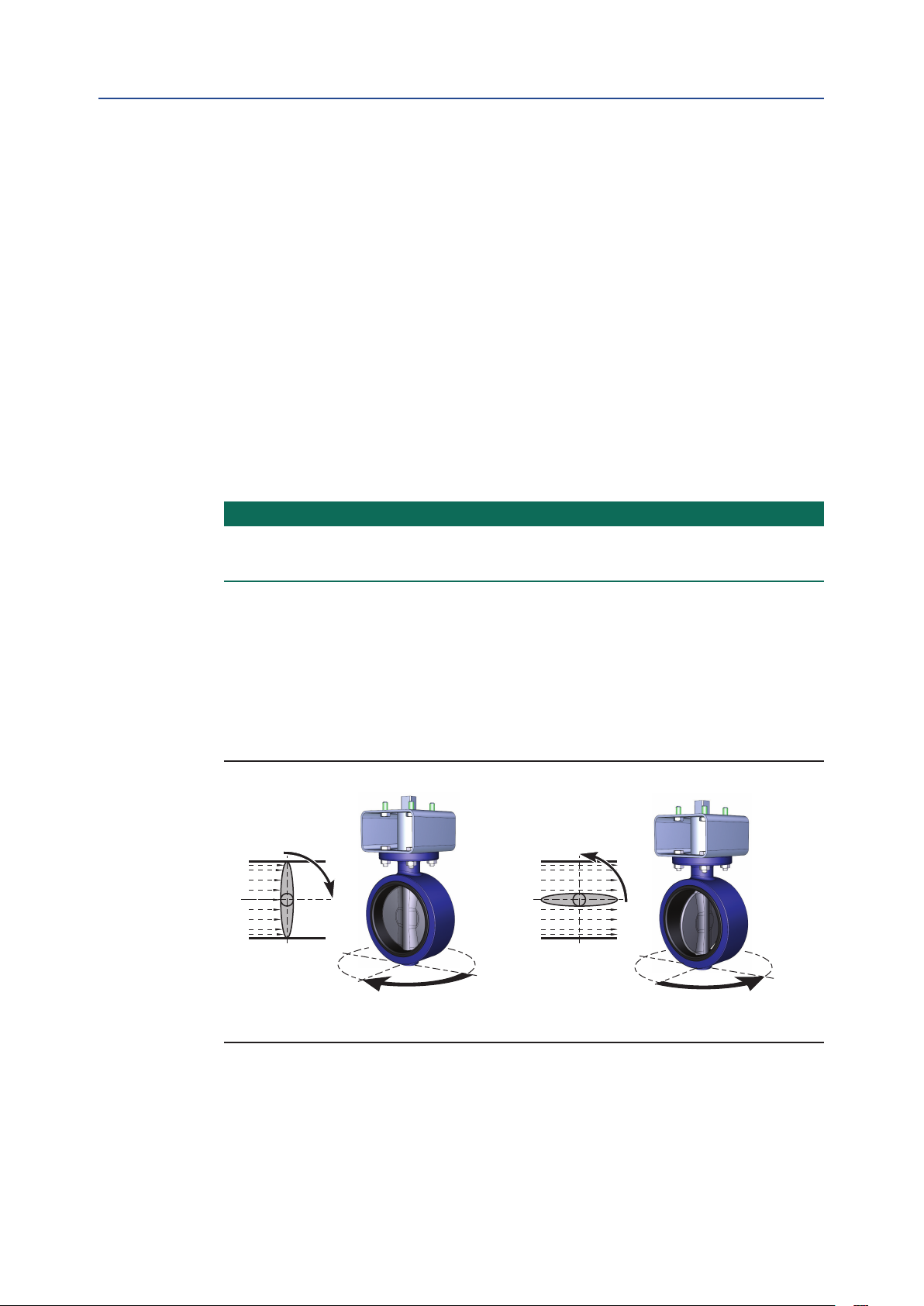

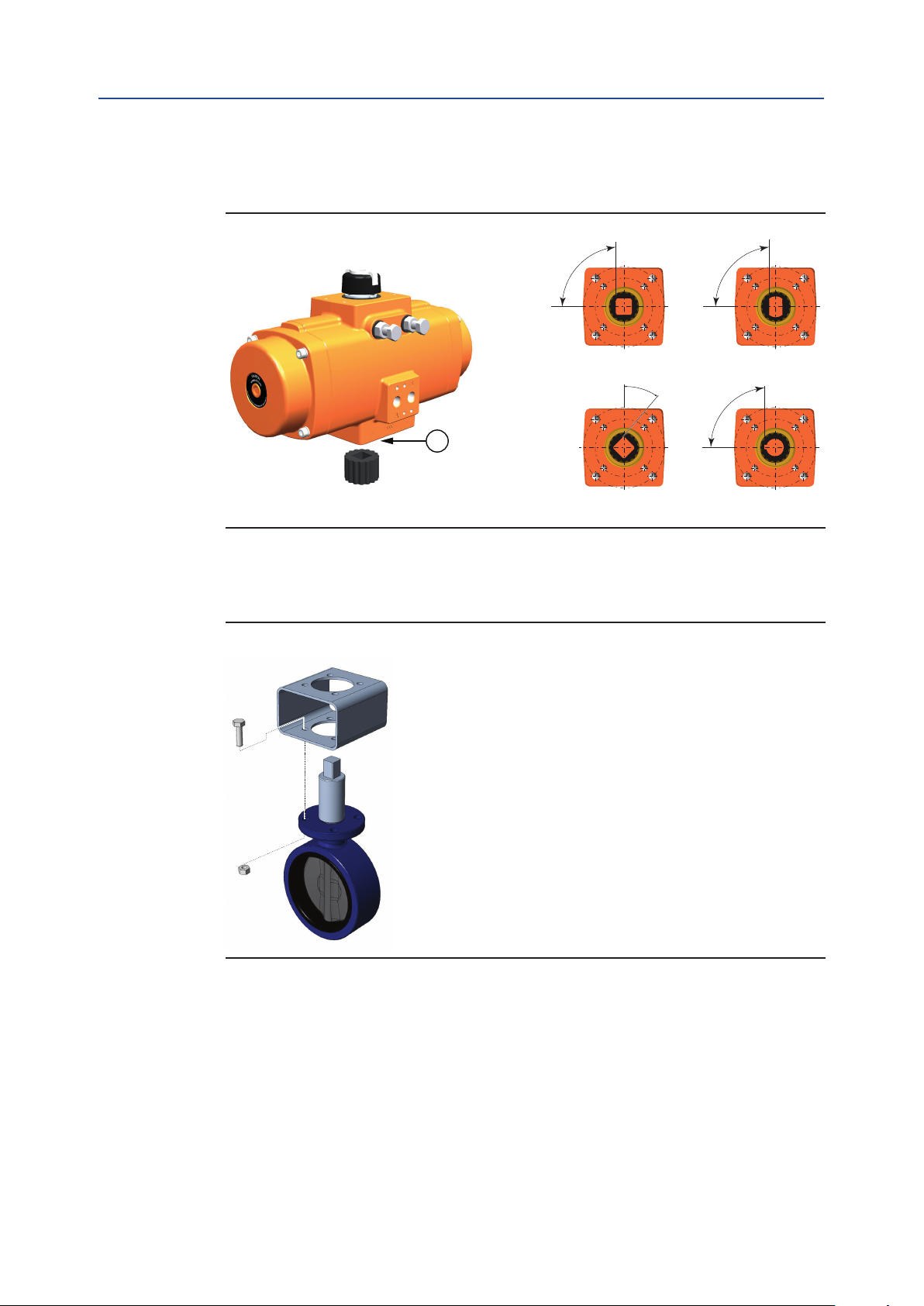

For the following paragraphs we assume that valves rotate as indicated in figure 3.

Figure 3 Normal valve rotation

Installation

The valve is closed after

a clockwise rotation.

The valve is open after

a counterclockwise rotation.

9

A

BA

Section 4: Installation

March 2019

4.2.2 Position After Failure

The position of the actuator after a failure depends on the:

1. Principle of operation (see paragraph 4.3)

2. Assembly codes (see paragraph 4.4)

3. Kind of failure. Refer to the table below.

Table 5. Position After Failure

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Principle of

Operation

Assembly Code Kind of Failure Position

CW

Double-Acting

Actuator

Single-Acting

CW

(Spring-Return)

Actuator

4.3 Principles of Operation

4.3.1 Solenoid Valve

All actuators can be either piped with solid or flexible tubing with the solenoid valve

mounted remotely from the actuator or by mounting a VDI/VDE 3845 (NAMUR) designed

solenoid valve DIRECTLY onto the NAMUR mounting pad on the side of the actuator.

Pressure Not defined

Signal Closed

Supply Voltage Closed

Pressure Not defined

Signal Open

Supply Voltage Open

Pressure Closed

Signal Closed

Supply Voltage Closed

Pressure Open

Signal Open

Supply Voltage Open

10

Figure 4 Typical solenoid operation

Spring-Return Operation Double-Acting Operation

Installation

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

The table below represents the cycle time (operating time) per different Actuator sizes:

Table 6. Operating Speed

Cycle time in seconds

Actuator

size

25 0.5 0.4 0.5 0.4

40 0.6 0.5 0.6 0.5

65 0.7 0.5 0.6 0.6

100 0.8 0.6 0.8 0.7

150 1.0 0.8 0.9 0.8

200 1.3 0.9 1.0 1.0

350

600 3.2 1.9 2.2 2.2

950 6.6 2.2 2.4 2.0

1600 10.6 3.5 3.6 3.3

2500 16.9 5.7 5.8 5.2

4000 29.1 9.2 9.2 9.0

Operating time is average with actuator under load and solenoid valve fitted.

pressurized

Spring-Return Double-Acting

A-port

1.9 1.3 1.4 1.5

Spring

stroke

Section 4: Installation

A-port

pressurized

March 2019

B-port

pressurized

Test conditions:

1. Solenoid with flow capacity: 0.6 m3/hr

2. Pipe diameter: 6mm

3. Medium: clean air

4. Supply pressure: 5.5 bar (80psi)

5. Load: with average load

6. Stroke: 90°

7. Temperature: Room temperature

4.3.2 Ingress Protection (IP) rating

Bettis RPE actuators are IP66/IP67 rated. In case of IP66 or IP67 requirements, take

precautions that comply with the IP66/IP67 requirements to prevent moisture or dust

from entering the actuator through the open air exhaust port(s), either directly on the

actuator or at the exhaust ports of the connected solenoid valve.

We recommend to connect tubing to the exhaust(s) and lead this into a dry and dust free

area, or to use check valves in the exhaust.

Installation

11

A

BA

A

B

B

Section 4: Installation

March 2019

Installation, Operation and Maintenance Manual

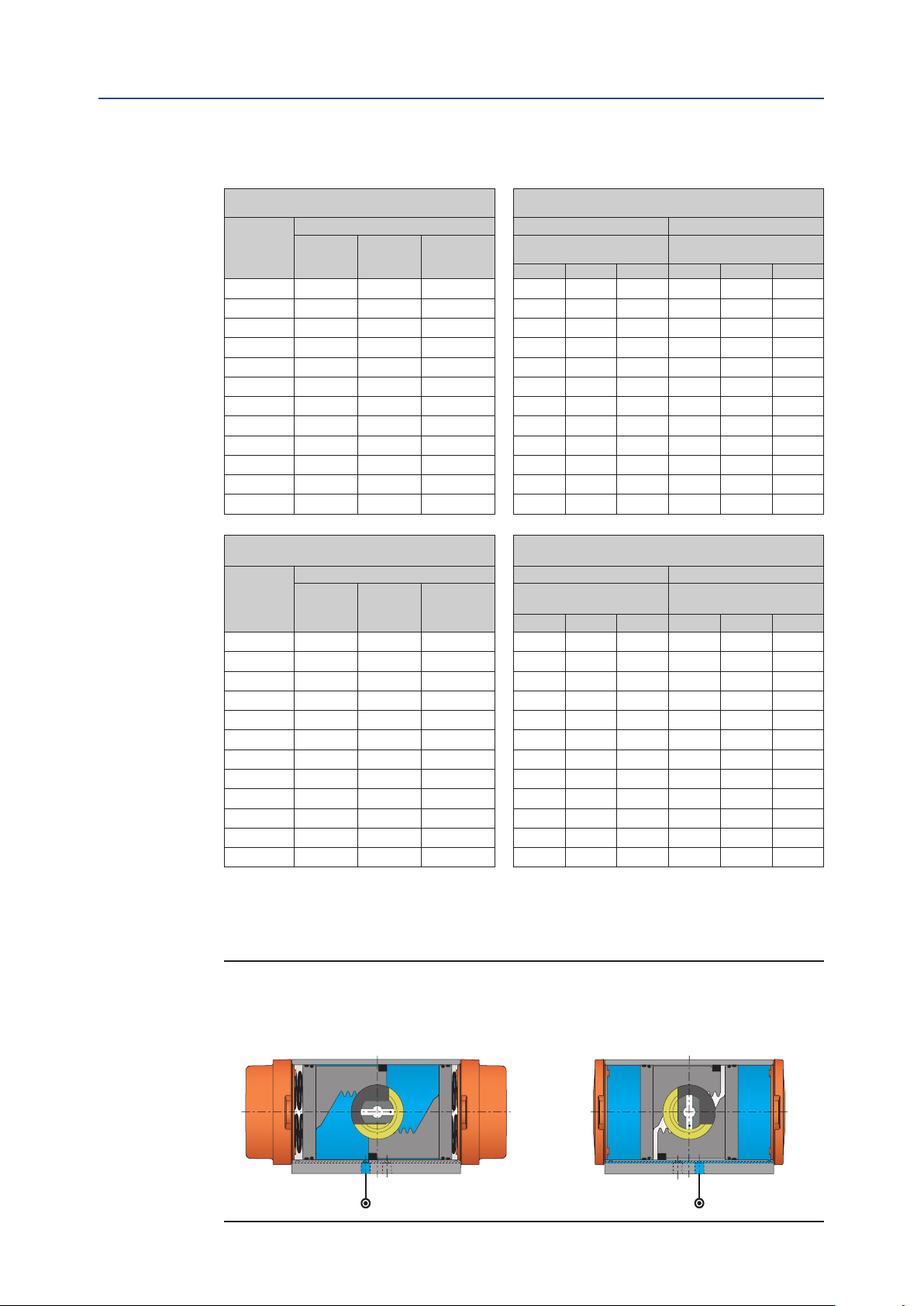

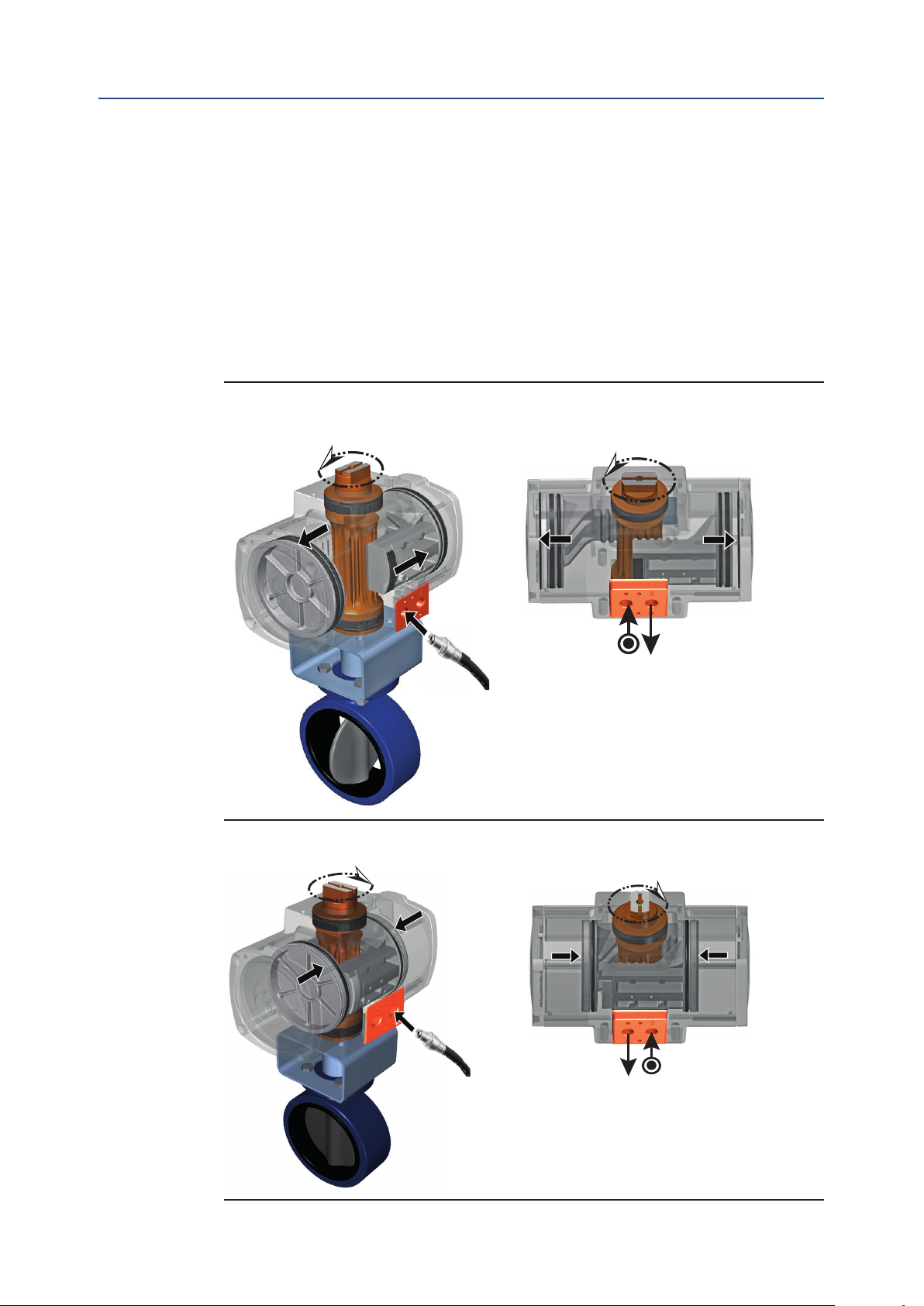

4.3.3 Double-Acting Actuators

The operating principle, as explained here, is applicable for actuators with assembly code

CW (direct acting).

• Applying supply pressure to port A will move the pistons outward to the "Open"

position of the valve.

• Applying supply pressure to port B will move the pistons inward to the "Close"

position of the valve.

• For assembly codes CC, the operating principle is reversed (reverse acting).

Figure 5 Double-Acting Operation

Outward Stroke

DOC.IOM.BE.EN Rev. 9

12

Inward Stroke

Installation

Installation, Operation and Maintenance Manual

A

A

B

A

DOC.IOM.BE.EN Rev. 9

4.3.4 Spring-Return Actuators

The operating principle, as explained here, is applicable for actuators with assembly code

CW (direct acting).

• Applying supply pressure to port A will move the pistons outwards to the "Open"

position of the valve.

• Venting the supply pressure from port A will cause the springs to move the pistons

inwards to the "Close" position of the valve.

• For assembly codes CC, the operating principle is reversed (reverse acting).

Figure 6 Stroke Movements

Outward Stoke

Section 4: Installation

March 2019

Installation

Inward Stroke

13

AB

A

B

A

B

A

B

Pinion and

cam position

Dot in

pinion slot

Default

pistons position

Reversed

pistons position

Pinion 90°

rotated

AB

A

B

A

BA

B

Pinion and

cam position

Dot in

pinion slot

Default

pistons position

Reversed

pistons position

Springs

Pinion 90°

rotated

Section 4: Installation

Installation, Operation and Maintenance Manual

March 2019

4.4 Actuator Assembly Codes

Figure 7 Assembly Code - Double-Acting

Assembly code: CW Assembly code: CC

= Standard, Clockwise-to-Close rotation = Reverse, Counterclockwise-to-Open

= Fail-to-Close = Fail-to-Open

DOC.IOM.BE.EN Rev. 9

A = Rotation when central air chamber is pressurized.

B = Rotation when end cap air chambers are pressurized.

All views are from above. Pistons are shown in inward position.

Figure 8 Assembly Code - Spring-Return

Assembly code: CW Assembly code: CC

= Standard, Clockwise-to-Close rotation = Reverse, Counterclockwise-to-Open

= Fail-to-Close = Fail-to-Open

14

Installation

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

4.5 Actuator to Valve Installation

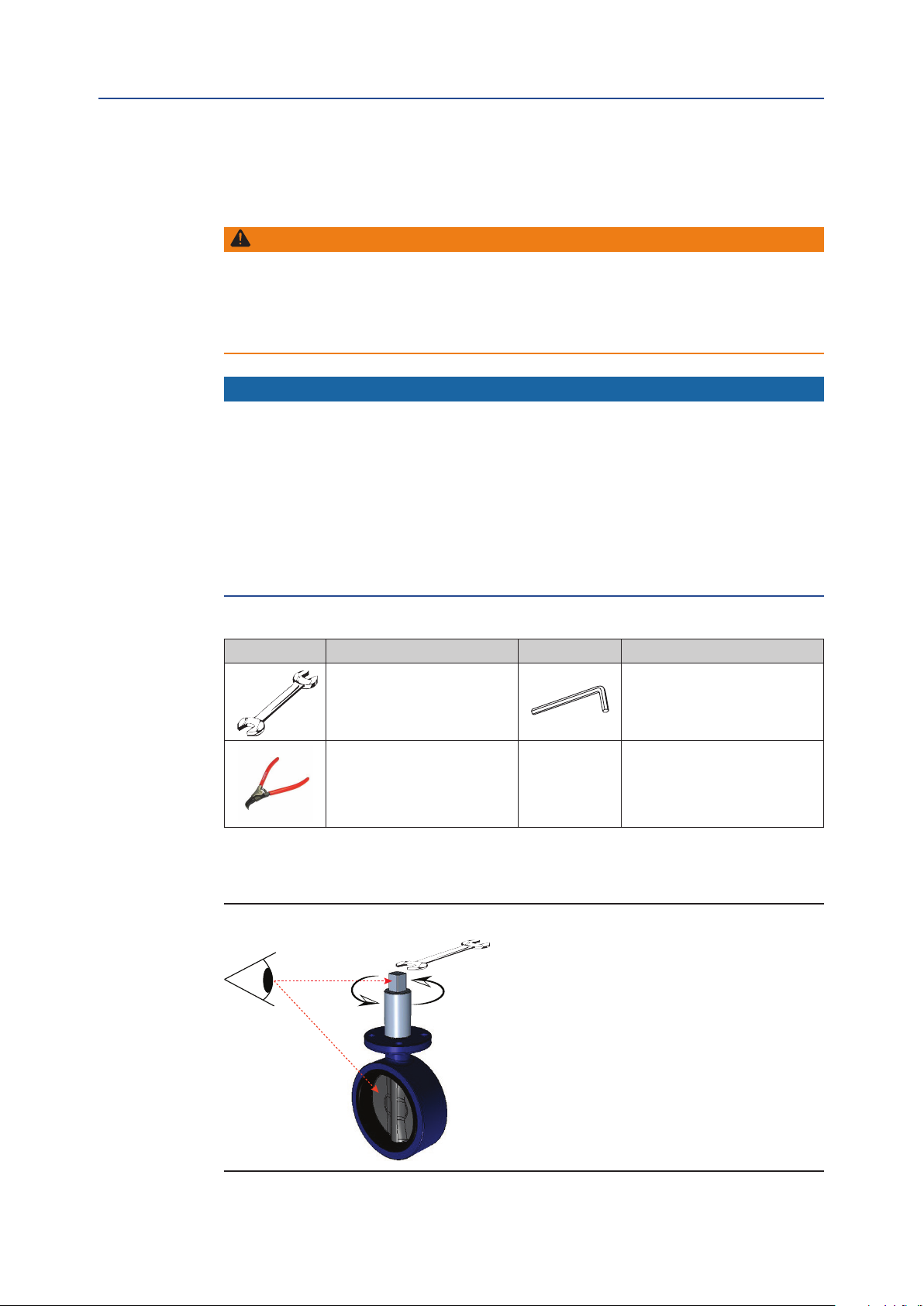

WARNING: MOVING PARTS

Actuator must be isolated pneumatically and electrically before any (dis)assembly starts.

Stay away from moving parts to prevent serious injuries. When test cycling the actuator

and valve assembly by applying pressure to the A or B port, be aware that there are moving

parts like pinion top, actuator to valve coupling and the valve- blade, ball, plug, etc.

NOTICE

The actuator is designed to be installed, commissioned and maintained using generic tools

like wrenches, Allen keys and screwdrivers. For the removal of inserts, a special extractor

tool can be supplied on request.

During assembly to the valve, do not hit with hammer on pinion top. This can damage the

pinion top washer and cause premature failure.

Section 4: Installation

March 2019

Before mounting the actuator on the valve or valve bracket, be sure that both the

actuator and the valve are in the same closed or open position.

Refer to Appendix B, Tool and Torque tables, for using the right size tool.

Table 7. Tool Table

Symbol Tool Symbol Tool

Wrench – All types and sizes.

Metric and Imperial

Circlip Pliers

1. Remove handle nut, handle, lock washer, and etc. from the valve if required.

2. Visually check to make sure the valve is CLOSED.

Figure 9 Valve handle removal

Allen key

Installation

15

Section 4: Installation

March 2019

3. When required, check if the insert drive (23) is mounted. If not, use a plasticmallet

Figure 10 Insert drive Installation

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

and tap slightly until the reducer square is in the required position.

90°

90°

Parallel

square

45°

Flat head

90°

23

Diagonal

square

Round with

key way

4. Install the bracket to the valve flange. Tighten all bolts and nuts and apply the correct torque.

Figure 11 Bracket Installation

16

Installation

Loading...

Loading...