Page 1

Service Instructions

Part Number: 153955, Rev. B

Release: May 2012

LCD PAK Seal Installation for CBA Series

Actuators

Page 2

Page 3

Service Instructions

Part Number:153955, Rev. B

Table of Contents

Section 1: Introduction

1.1 Purpose ......................................................................................................... 1

1.2 Denitions .................................................................................................... 1

1.3 Service Tool Information ............................................................................... 1

1.4 Lubrication Requirements ............................................................................. 1

1.5 Other Notes .................................................................................................. 1

Section 2: Installation

2.1 Tools Used..................................................................................................... 2

2.2 Kit Items ....................................................................................................... 2

2.3 Procedure ..................................................................................................... 3

Table of Contents

May 2012

Section 3: Document Revision

Revision Overview..................................................................................................10

Appendix A: List of Figures

List of Figures.........................................................................................................11

Table of Contents

I

Page 4

Page 5

Service Instructions

Part Number:153955, Rev. B May 2012

Section 1: Introduction

Section 1: Introduction

1.1 Purpose

The purpose of these instructions is to inform the reader/installer on the correct procedure for

installing CBA torque-shaft seals, using Installation Rings that are designed specically for this

task and are included in CBA service kits. If instructions are followed, the chance for seal damage upon installation should be eliminated.

1.2 Definitions

1.2.1 Installation Ring - A rubber ring that comes with the CBA service kit to be installed into

the snap ring groove of the torque-shaft prior to new seal installation.

1.2.2 LCD PAK Seal - A custom seal designed with a double sealing point surface. LCD stands

for “Lip Cut Double.” The term “PAK” received its name from the “PolyPak” seal which

is a combination of a PolyPak shell energized with an O-Ring expander. The LCD PAK

seal used for the CBA does not contain an O-Ring expander.

1.3 Service Tool Information

There are many ways to install the LCD PAK seals, because different tools can be used to do so.

In these instructions, basic shop tools that are commonly available were used to illustrate that

it is not needed or important to use special tools.

1.4 Lubrication Requirements

It is very important to not over-grease the seal upon installation. Over lubricating can cause

problems during installation by halting the seal from seating all the way in the groove (if too

much grease is between the seal and housing). As shown in the pictures below, use a light coat

of grease on the seals when installing.

1.5 Other Notes

The Installation Rings (or ller rings as commonly referred to), are disposable items as they only

need to be used one time and are contained in the CBA service kits. However, it is possible to

reuse them by picking instead of cutting them out of the rotor clip groove.

Introduction

1

Page 6

Section 2: Installation

May 2012

Section 2: Installation

WARNING: DANGEROUS GAS AND/OR LIQUIDS

It is possible, that the actuator may contain a dangerous gas and/or liquids. Ensure that

all proper measures have been taken to prevent exposure or release of these types of

contaminants before commencing any work.

2.1 Tools Used

(1) Plastic mallet

(2) Socket extension (see 1.3 above)

(3) Pick

Service Instructions

Part Number:153955, Rev. B

(4) Rotor Clip Pliers

2.2 Kit Items

(A) Grease

(B) Two Installation Rings

(C) Two LCD PAK seals

(D) Two Rotor Clips

Figure 1 Tools and Kit Items Needed

1

3

2

4

D

A

D

2

B

Installation

Page 7

Service Instructions

Part Number:153955, Rev. B May 2012

Section 2: Installation

2.3 Procedure

1. Remove the Rotor Clip on side 1 of actuator housing using Rotor Clip Pliers.

Figure 2 Rotor Clip Removal Side 1

2. Use the mallet to tap the torque-shaft inward with the use of an extension rod to expose the existing seal.

Figure 3 Exposing the Seal - Side 1

Installation

3

Page 8

Section 2: Installation

May 2012

3. Use the Pick to remove old seal and clear groove of old grease and debris.

Figure 4 Cleaning the groove - Side 1

Service Instructions

Part Number:153955, Rev. B

4. Turn actuator to second side (side 2) and use Rotor Clip Pliers to remove rotor clip, tap

shaft to expose seal, remove old seal and clean groove by repeating steps 1-3.

Figure 5 Rotor Clip Removal Side 2

4

Installation

Page 9

Service Instructions

Part Number:153955, Rev. B May 2012

Section 2: Installation

5. Place Installation Ring into Rotor Clip groove of side 1. Use a pick or similar tool to aid

installation. When shaft is tted with ring, lightly grease ring surface.

Figure 6 Ring Installation - Side 1

Make sure that the Installation

Ring is seated completely ush

with the surface of the torque-

shaft

Installation

5

Page 10

Section 2: Installation

May 2012

6. Tap side one inward to expose seal groove. Install new seal after lightly greasing.

Figure 7 New Seal Installation - Side 1

Service Instructions

Part Number:153955, Rev. B

1

2

When installing, insert the top of the seal rst, with the lip side inward towards shaft, then work

the sides in. When the seal is mostly in, invert the bottom of the seal (see photo #3) into a wave

like shape. When you release, the seal should seat itself smoothly into the groove. Press the seal

in from all angles with your nger to make sure it is ush with the housing bore (see photo #4).

3

4

6

Installation

Page 11

Service Instructions

Part Number:153955, Rev. B May 2012

Section 2: Installation

7. On side 2, place Installation Rings on torque-shaft. Lightly grease as per step 5.

Figure 8 Ring Installation - Side 2

8. Tap shaft inward to expose second seal groove. Install seal as per step 6.

Figure 9 New Seal Installation - Side 2

Installation

7

Page 12

Section 2: Installation

May 2012

9. Carefully tap torque-shaft back through housing and newly installed seals. If resistance

Figure 10 Re-installing torque shaft with newly installed seals

Service Instructions

Part Number:153955, Rev. B

is felt (a bouncy feeling especially), gently tap forward and backward until it becomes

easier.

10. Remove side 1 Installation Ring and discard.

Figure 11 Discard Installation Ring - Side 1

8

Installation

Page 13

Service Instructions

Part Number:153955, Rev. B May 2012

Section 2: Installation

11. On side 1, place Rotor Clip on torque-shaft. Tap this side towards the housing, pressing

the Rotor Clip against the housing This makes it easier to remove the side 2 Installation

Ring.

Figure 12 Rotor Clip Installation - Side 1

12. Remove and discard side 2 Installation Seal and then install a new Rotor Clip.

Figure 13 Discard Installation Ring and Rotor Clip Installation - Side 2

Installation

9

Page 14

Section 3: Document Revision

May 2012

Section 3: Document Revision

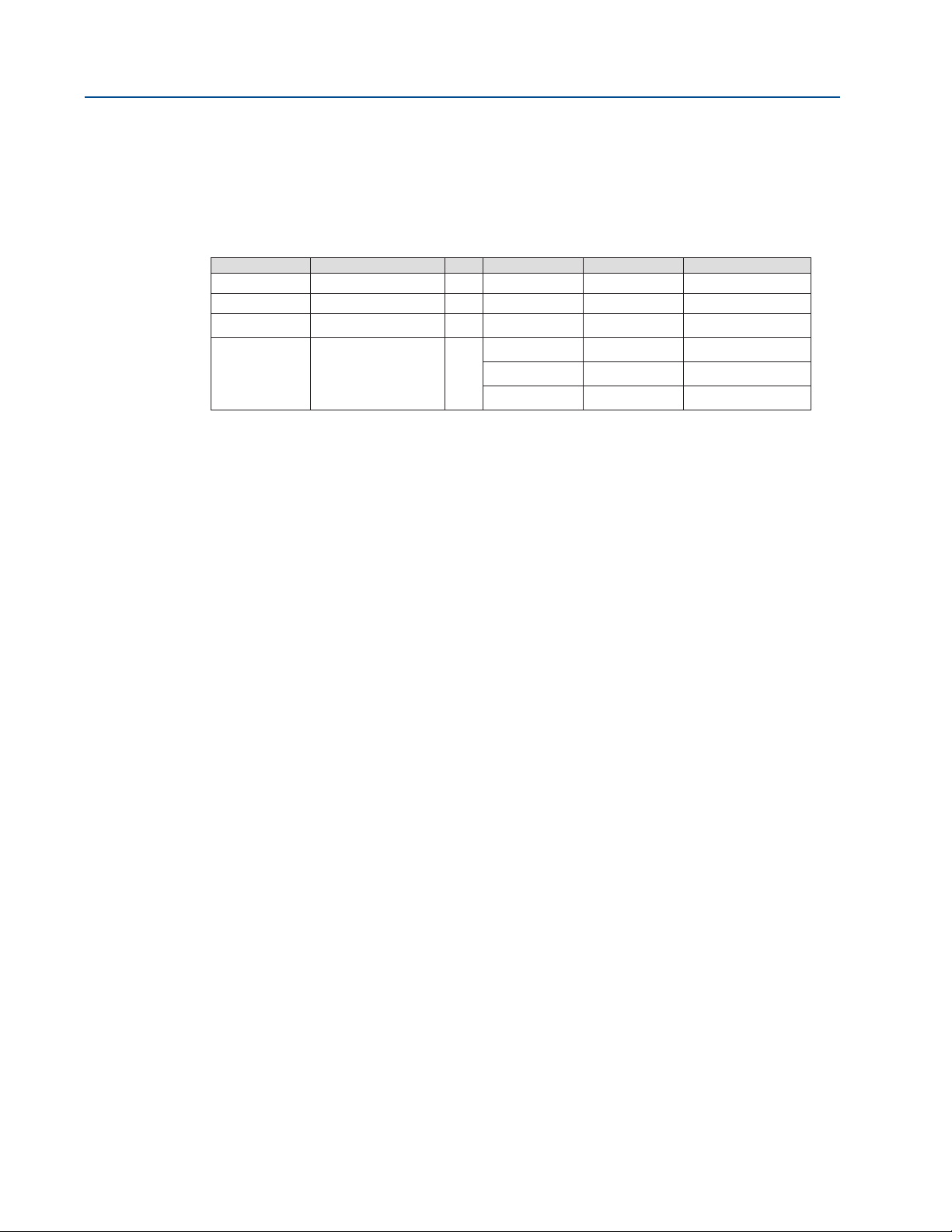

Table 1. Revision Overview

ECN DATE REV BY * DATE

Released 17 December 2001 A COMPILED B. Cornelius 17 December 2001

CHECKED B. Cornelius 17 December 2001

APPROVED R. Smith 17 December 2001

COMPILED A. Cruz 5/16/12

0526 001 May 2012 B

* Signatures on le Bettis Actuator & Controls, Waller, Texas

CHECKED B. Jumawan 8/21/12

APPROVED B. Jumawan 9/26/12

Service Instructions

Part Number:153955, Rev. B

10

Document Revision

Page 15

Service Instructions

Part Number:153955, Rev. B May 2012

Appendix

Appendix A: List of Figures

Figure 1 Tools and Kit Items Needed ................................................................................... 2

Figure 2 Rotor Clip Removal Side 1 ...................................................................................... 3

Figure 3 Exposing the Seal - Side 1 ...................................................................................... 3

Figure 4 Cleaning the groove - Side 1 .................................................................................. 4

Figure 5 Rotor Clip Removal Side 2 ...................................................................................... 4

Figure 6 Ring Installation - Side 1 ........................................................................................ 5

Figure 7 New Seal Installation - Side 1 ................................................................................. 6

Figure 8 Ring Installation - Side 2 ........................................................................................ 7

Figure 9 New Seal Installation - Side 2 ................................................................................. 7

Figure 10 Re-installing torque shaft with newly installed seals .............................................. 8

Figure 11 Discard Installation Ring - Side 1 ............................................................................ 8

Figure 12 Rotor Clip Installation - Side 1 ................................................................................ 9

Figure 13 Discard Installation Ring and Rotor Clip Installation - Side 2 .................................. 9

Appendix

11

Page 16

Contact Us: Emerson Process Management, Valve Automation facilities at your nearest location:

NORTH & SOUTH AMERICA

18703 GH Circle

PO Box 508

Waller, TX 77484

USA

T +1 281 727 5300

F +1 281 727 5353

2500 Park Avenue West

Mansfield, OH 44906

USA

T +1 419 529 4311

F +1 419 529 3688

9009 King Palm Drive

Tampa, FL 33619

USA

T +1 813 630 2255

F +1 813 630 9449

13840 Pike Road

Missouri City, Texas 77489

USA

T +1 281 499 1561

F +1 281 499 8445

Av. Hollingsworth,

325, Iporanga Sorocaba,

SP 18087-105

Brazil

T +55 15 3238 3788

F +55 15 3228 3300

MIDDLE EAST & AFRICA

P. O. Box 17033

Dubai

United Arab Emirates

T +971 4 811 8100

F +971 4 886 5465

P. O. Box 105958

Abu Dhabi

United Arab Emirates

T +971 2 697 2000

F +971 2 555 0364

P. O. Box 3911

Al Khobar 31952

Saudi Arabia

T +966 3 814 7560

F +966 3 814 7570

P. O. Box 10305

Jubail 31961

Saudi Arabia

T +966 3 340 8650

F +966 3 340 8790

P. O. Box 32281

Doha

Qatar

T +974 4 576777

F +974 4 315448

24 Angus Crescent

Longmeadow Business Estate

East P.O. Box 6908; Greenstone;

1616 Modderfontein, Extension 5

South Africa

T +27 11 451 3700

F +27 11 451 3800

EUROPE

Asveldweg 11

7556 BR Hengelo (O)

The Netherlands

T +31 74 256 1010

F +31 74 291 0938

Siemensring 112

47877 Willich

Germany

T +49 2154 499 660

F +49 2154 499 6613

25, Rue de Villeneuve

Silic – BP 40434

94583 Rungis

France

T +33 1 49 79 73 00

F +33 1 49 79 73 99

Via Montello 71/73

20038 Seregno (Milan)

Italy

T +39 0362 2285 207

F +39 0362 2436 55

6 Bracken Hill

South West Industrial Estate

Peterlee SR8 2LS

United Kingdom

T +44 191 518 0020

F +44 191 518 0032

2A Szturmowa Str

02-678 Warsaw

Poland

T +48 22 45 89 237

F +48 22 45 89 231

C/ Francisco Gervás, 1

28108 Alcobendas – Madrid

Spain

T +34 0913 586 000

F +34 0913 589 145

Letnikovskaya Str. 10-2

115114 Moscow

Russia and FSU

T +7 495 981 98 11

F +7 495 981 98 10

ASIA PACIFIC

No. 9 Gul Road

#01-02 Singapore 629361

T +65 6501 4600

F +65 6268 0028

9/F Gateway Building

No. 10 Ya Bao Road

Chaoyang District

Beijing 100020

P.R.China

T +86 10 5821 1188

F +86 10 5821 1100

No.15 Xing Wang Road

Wuqing Development Area

Tianjin 301700

P.R.China

T +86 22 8212 3300

F +86 22 8212 3308

Lot 13112, Mukim Labu

Kawasan Perindustrian Nilai

71807 Nilai, Negeri Sembilan

Malaysia

T +60 6 799 2323

F +60 6 799 9942

471 Mountain Highway

Bayswater, Victoria 3153

Australia

T +61 3 9721 0200

F +61 3 9720 0588

Delphi B Wing, 601 & 602

6th Floor, Central Avenue

Powai, Mumbai – 400 076

India

T +91 22 6662 0566

F +91 22 6662 0500

NOF, Shinagawa Konan Bldg

1-2-5, Higashi-shinagwa

Shinagwa-ku, Tokyo

140-0002 Japan

T +81 3 5769 6873

F +81 3 5769 6902

Please visit our web site for up to date product data.

www.EmersonProcess.com/BETTIS

All Rights Reserved.

We reserve the right to modify or improve the designs or specications of the products mentioned in this manual at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper

selection, use and maintenance of any Emerson Process Management product remains solely with the purchaser.

©2012 Emerson Electric Co.

Loading...

Loading...