Page 1

Installation, Operation and Maintenance Manual

Bettis RPE-Series

Rack and Pinion Pneumatic Actuators

DOC.IOM.BE.EN Rev. 9

March 2019

Page 2

Page 3

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Table of Contents

Section 1: Before You Start

1.1 Installation, Operation and Maintenance Reference Documents ................... 1

1.2 Warehouse Storage ...................................................................................... 1

1.3 On-Site Storage ............................................................................................ 2

Section 2: Introduction

2.1 Identification ................................................................................................ 3

2.2 Intended Use ................................................................................................. 5

2.3 Specifications ................................................................................................ 5

Section 3: Configuration Code

Table of Contents

March 2019

Section 4: Installation

4.1 Before You Start ............................................................................................9

4.2 Actuator Rotation Direction .......................................................................... 9

4.2.1 Valve Rotation .................................................................................... 9

4.2.2 Position After Failure ........................................................................ 10

4.3 Principles of Operation ................................................................................ 10

4.3.1 Solenoid Valve .................................................................................. 10

4.3.2 Ingress Protection (IP) rating ............................................................ 11

4.3.3 Double-Acting Actuators .................................................................. 12

4.3.4 Spring-Return Actuators ................................................................... 13

4.4 Actuator Assembly Codes ........................................................................... 14

4.5 Actuator to Valve Installation ...................................................................... 15

4.6 Mounting of control and feedback accessories ............................................ 18

4.7 Recommended Tubing Sizes ....................................................................... 18

Section 5: Mechanical Stroke Adjustment

5.1 Travel Stop Adjustment ............................................................................... 20

5.1.1 Double-Acting Actuators .................................................................. 20

5.1.2 Spring-Return Actuators ................................................................... 20

5.1.3 Angular Displacement ......................................................................21

Section 6: Maintenance

6.1 Normal Maintenance .................................................................................. 22

6.2 Inspection and Repair .................................................................................. 23

6.2.1 Service Kits .......................................................................................23

6.2.2 Spring-Return Actuator ....................................................................23

Table of Contents

Section 7: Decommission (Out of Service)

7.1 Before You Start ..........................................................................................24

7.2 Removing the actuator from the valve ........................................................ 25

I

Page 4

Table of Contents

March 2019

Section 8: Disassembly

Section 9: Reassembly

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

8.1 Removing End Caps (Sizes 25 to 600) .......................................................... 27

8.2 Removing End Caps (Sizes 950 to 4000) ...................................................... 29

8.3 Removing Spring Cartridges or Springs ....................................................... 30

8.4 Removing of Limit Stop ...............................................................................31

8.5 Removing Pistons ....................................................................................... 31

8.6 Removing Pinion .........................................................................................32

8.7 Cleaning the Components .......................................................................... 33

9.1 Grease Instructions .....................................................................................35

9.2 Reassembly of the pinion ............................................................................ 36

9.3 Reassembly of the pistons ........................................................................... 37

9.4 Reassembly and settings of the limit stops .................................................. 39

9.5 Reassembly of the end caps ........................................................................ 40

9.5.1 Double-Acting actuators .................................................................. 40

9.5.2 Spring-Return actuators ................................................................... 41

9.5.3 Spring-Return actuators - Size 950 to 4000 ...................................... 42

9.6 Basic function and Air Leak Test .................................................................. 45

Section 10: Troubleshooting

10.1 Mechanical Problems ..................................................................................46

10.2 Pneumatic Problems ...................................................................................47

10.3 Electrical Problems ...................................................................................... 48

Section 11: Parts List and Spare Parts Recommendations

11.1 Actuator sizes RPE25 to RPE600 ..................................................................49

11.2 Actuator sizes RPE950 to RPE2500 .............................................................. 50

11.3 Actuator size RPE4000 ................................................................................ 51

Appendix A: Spring Load Removal

A.1 Spring load relief ......................................................................................... 52

Appendix B: Tool & Torque Table

Appendix C: Full Stroke Adjustment Option

C.1 Full Stroke Adjustment Option .................................................................... 56

C.2 Convert a Standard Actuator into a Full Stroke Adjustment Version ............ 57

11.3.1 Procedure ........................................................................................ 58

C.3 Full Stroke Adjustment Setting .................................................................... 59

11.3.2 Factory Setting Procedure ................................................................ 59

11.3.3 Setting the Full Stroke Adjustment Screw to the Required Angle ...... 60

II

Table of Contents

Page 5

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 1: Before You Start

This section explains:

• Base safety procedures.

• Where to find detailed information relating safety.

• Storage guidelines.

Installation, adjustment, putting into service, use, assembly, disassembly and maintenance

of the pneumatic actuator must be performed by qualified personnel.

NOTICE

Failure to follow the above guidelines will void warranty.

WARNING

Section 1: Before You Start

March 2019

Actuator must be isolated both pneumatically and electrically before any (dis)assembly

starts. Before mounting or (dis)assembly, the actuator consult the relevant sections of this

manual.

1.1 Installation, Operation and Maintenance Reference Documents

Before you start, read the following documents:

• All chapters in this manual.

• Safety Guide (Document No. DOC.SG.BE.1).

For Safety Instrumented Systems application, read the following document:

• SIL Safety Manual Bettis RPE-Series (Document No. DOC.SILM.BE.EN).

NOTICE

Failure to read the Safety Guide will void the warranty.

Not following the instructions of the Safety Guide can lead to failure of the product and

harm to personnel or equipment.

1.2 Warehouse Storage

• All actuators should be stored in a clean, dry warehouse, free from excessive

vibration and rapid temperature changes.

• All actuators should not be stored directly to the floor surface - it must be placed

in racks/shelves or use a pallet.

Before You Start

1

Page 6

Section 1: Before You Start

March 2019

1.3 On-Site Storage

• All actuators should be stored in a clean, dry warehouse, free from excessive vibra-

tion and rapid temperature changes.

• Prevent moisture or dirt from entering the actuator. Plug or seal both air connec-

tion ports.

NOTICE

Failure to follow the above guidelines (Warehouse and On Site Storages) will void warranty.

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

2

Before You Start

Page 7

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 2: Introduction

This section explains:

• How to identify the received product.

• The intended use of the product.

• Construction details.

• Actuator specifications.

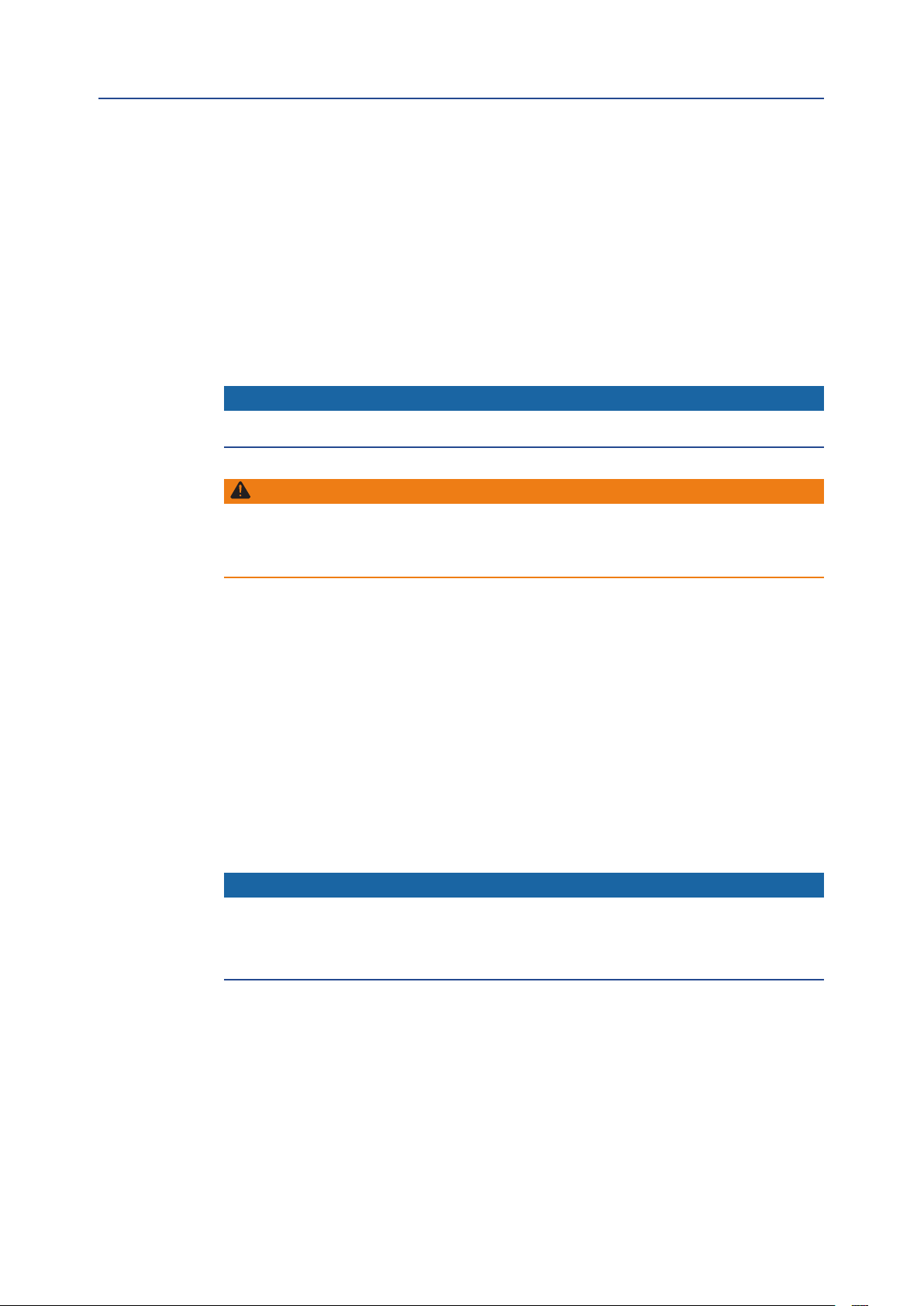

2.1 Identification

The Bettis™ RPE-Series Rack and Pinion actuators are available as double-acting or

spring-return versions. 12 models are available, ranging from 23 Nm to 4041 Nm

(206 to 35765 lbf.in)nominal torque output.

The Bettis RPE-Series uses standardized interfaces for solenoid, switchbox or positioner

mounting (VDI/VDE3845; NAMUR). The valve interface is equipped with an insert in the

pinion bottom that allows both ISO5211 or DIN3337 mounting.

Section 2: Introduction

March 2019

The springs in the spring-return version allow a fail action in case of loss of air supply

pressure (Fail-to-Close or Fail-to-Open).

As from size RPED150 double-acting versions have flat end caps to reduce actuator length

and internal air volume.

Introduction

3

Page 8

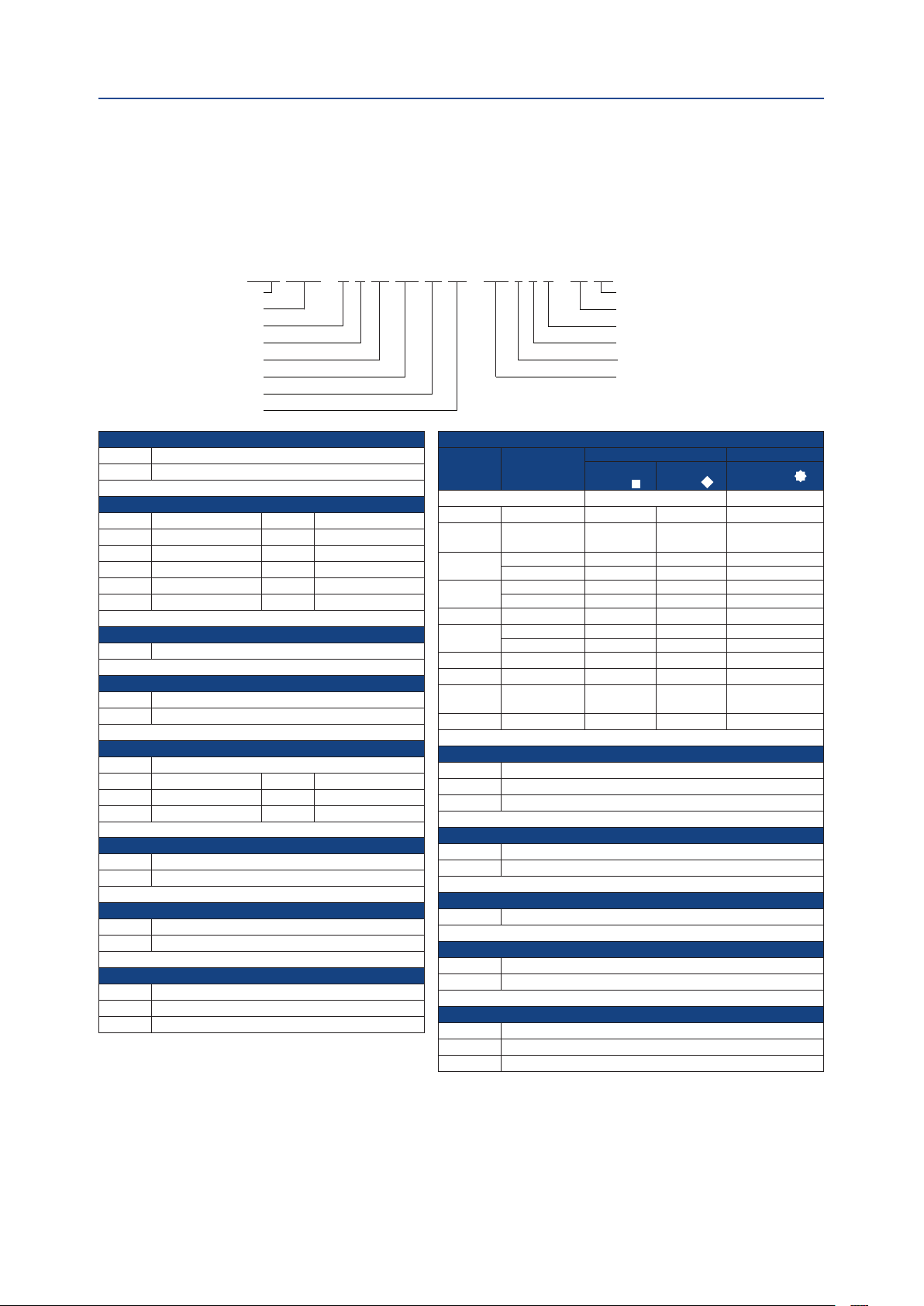

25 100

150 -

600

4000

Size End cap design

5

Spring design

6

Pinion bottom /

Insert design

2

950 -

2500

SR

Maximum 12

spring cartridges

Maximum 6

loose springs

Left

Right

Left Right

Left Right

DA

SR DA

SR DA

SR DA

Maximum 12

spring cartridges

Maximum 6

loose springs

Left Right

Notes

1. Top auxilliaries and Solenoid interface (VDI/VDE 3845; NAMUR) for size 25 to 4000.

2. Valve interface availalable according ISO5211 or DIN 3337.

Actuator sizes 25 to 2500 can be fitted with drive inserts with various inner shapes.

Actuator size 4000 is fitted with a double square; parallel and diagonal.

3. Spring-Return actuators: - with springs

4. Double-Acting actuators: - no springs

5. Actuator sizes 25 to 100 have high end caps for double-acting and spring-return models.

Actuator sizes 150 to 4000 have low end caps for double-acting models and high end caps

for spring return models.

6. Actuator sizes 25 to 600 are fitted with a maximum of 12 spring cartridges.

Actuator sizes 950 to 4000 are fitted with a maximum of of 6 loose springs.

1

2

3 4

Section 2: Introduction

March 2019

Figure 1 Identification

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

4

Introduction

Page 9

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

2.2 Intended Use

The Bettis RPE Rack and Pinion actuators are intended for the automation and operation of

quarter-turn valves like Butterfly, Ball and Plug valves.

Rack and Pinion actuators can also be used to operate dampers or any other quarter-turn

applications.

2.3 Specifications

Table 1. Pressure Range

Actuator Type Pressure

Double-Acting 0.2 to 8 bar (2.9 to 116 psi)

Spring-Return

Table 2. Operating Media

6 to 8 bar (87 to 116 psig), with maximum spring set

3 to 8 bar (43.5 to 116 psig), reduced spring quantity

Section 2: Introduction

March 2019

Actuator Type Operating Media

Air, dry or lubricated and inert gases

Dew point at least 10K below ambient temperature

Double-Acting and Single Acting

1. Recommended air quality according ISO 8573-1 for normal operation: 7-5-4.

For sub-zero applications, take appropriate measures

Mentioned pressure levels are "gauge pressures".

Gauge pressure is equal to absolute pressure minus

atmospheric pressure.

NOTE:

Use of filters, pressure regulators, lubricator and an oil/water separator mounted in the air

supply line, will allow a smooth and durable operation of the actuator.

For lubricated supply air, it is recommended to use a non-detergent oil without aggressive

additives, VG32, group 2 (ISO 3448).

Table 3. Temperature Range

Actuator Type Temperature

Standard -20°C to 80°C (-4°F to +176°F)

Option: Low Temperature -40°C to +80°C (-40°F to +176°F)

Option: High Temperature -10°C to +120°C (+14°F to +250°F)

Introduction

5

Page 10

A

B

Section 2: Introduction

March 2019

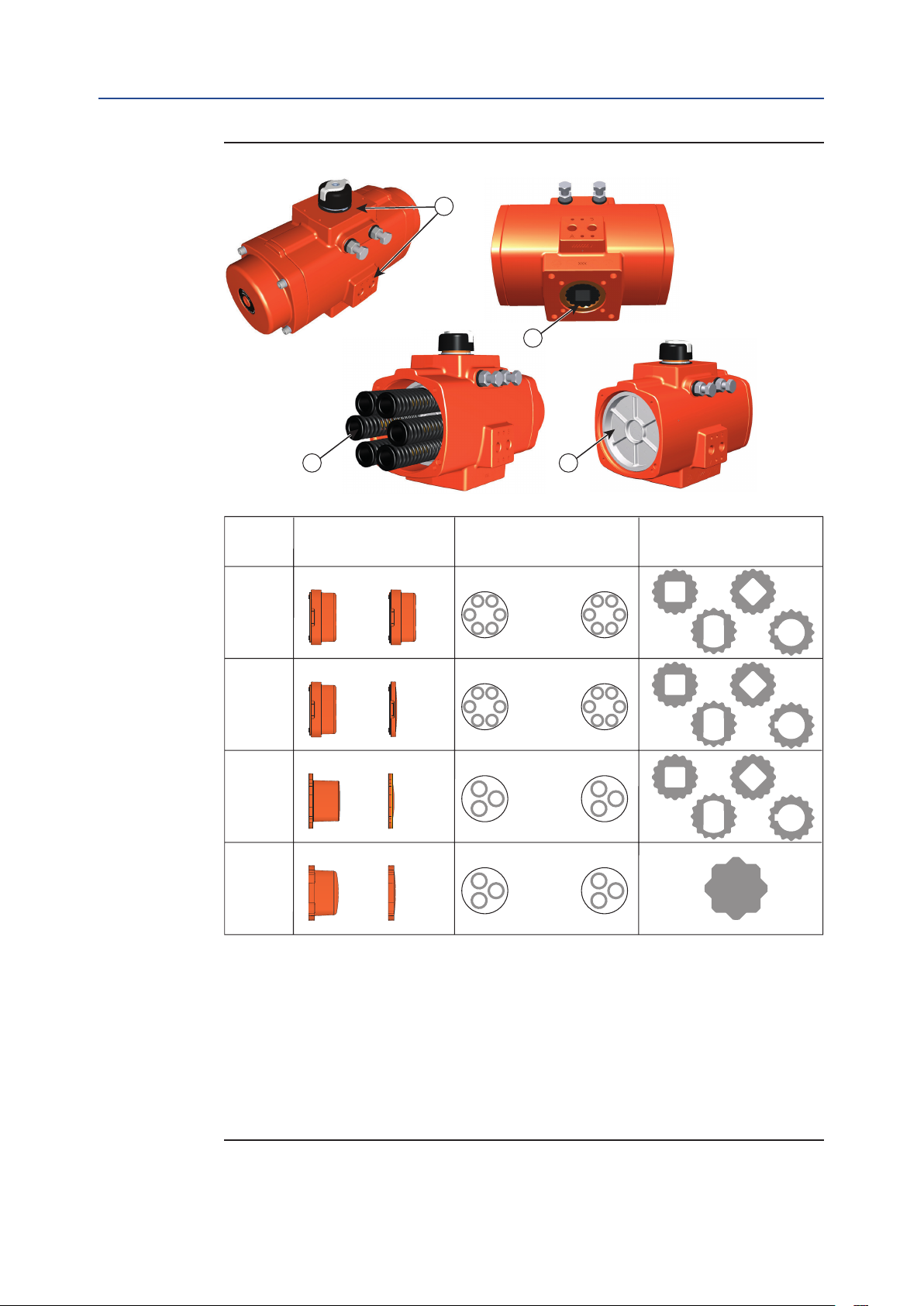

Table 4. Air Volumes and Consumption

Actuator

model

RPE 0025 0.14 0.20 0.08 0.36 0.64 1.2 0.48 0.88 1.7

RPE 0040

RPE 0065 0.40 0.56 0.22 1.02 1.8 3.4 1.3 2.4 4.7

RPE 0100 0.6 0.9 0.3 1.5 2.7 5.0 2.0 3.8 7.2

RPE 0150 1.0 0.8 0.5 2.4 4.3 8.1 2.1 3.6 6.7

RPE 0200

RPE 0350

RPE 0600 3.6 3.3 2.1 9.4 17 31 8.7 15 28

RPE 0950

RPE 1600 7.9 7.3 5.4 21 37 69 20 35 64

RPE 2500 12.6 11.9 8.3 34 59 109 32 56 104

RPE 4000 21.7 19.0 13.5 57 100 187 52 89 165

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Actuator volumes:

Maximum volume (in liters) Outward Stroke Inward Stroke

Central

chamber

1

End cap

chamber

2

Displaced

3

volume

Double-Acting

and Spring-Return

2 4 8 2 4 8

0.26 0.37 0.15 0.67 1.2 2.2 0.89 1.6 3.1

1.3 1.0 0.7 3.2 5.7 11 2.8 4.9 9.1

2.1 1.9 1.2 5.5 9.8 18 5.0 8.8 16

4.9 4.6 3.2 13 23 43 12 22 40

Consumption per stoke

(in liters, pressure in barg)

Double-Acting only

Consumption per stoke

(in Cu.in., pressure in psig)

Double-Acting only

Actuator

model

Actuator volumes:

Maximum volume (Cu.in.) Outward Stroke Inward Stroke

Central

chamber

1

End cap

chamber

2

Displaced

3

volume

Double-Acting

and Spring-Return

40 80 120 40 80 120

RPE 0025 8.5 12.2 4.7 28 52 75 38 72 106

RPE 0040

RPE 0065

15.9 23 8.9 53 96 140 71 133 196

24 34 13.5 81 148 215 107 200 294

RPE 0100 36 53 19.9 118 216 314 165 310 455

RPE 0150 58 47 32 192 352 512 163 293 424

RPE 0200 76 64 44 255 466 676 220 397 573

RPE 0350 131 115 76 436 796 1157 392 709 1025

RPE 0600 222 201 129 742 1354 1967 683 1237 1790

RPE 0950 301 279 196 1025 1854 2682 966 1735 2505

RPE 1600 484 447 328 1662 2997 4331 1560 2792 4024

RPE 2500 769 728 508 2630 4751 6873 2515 4523 6530

RPE 4000 1324 1159 825 4477 8130 11782 4022 7219 10416

Notes:

1. Pistons at 90° outward position.

2. Pistons at 0° inward position.

3. Stroke is 90°.

Figure 2 Actuator air volumes

Central air chamber volume

Double-Acting and Spring-Return

6

End cap air chamber volume

Double-Acting only

Introduction

Page 11

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 3: Configuration Code

This section explains:

• How to create the configuration code for a actuator.

RPES 0150 - N U 40 CW AL TN - L19 S K A - 00 XX

Type

Size

Rotation angle

Threads

Spring set

Rotation

Pinion material

Valve interface

Section 3: Configuration Code

March 2019

Miscellaneous options

Internal code 1

Color / finish

Visual indicator

Temperature

Valve stem connection

Type

RPED Double Acting

RPES Spring Return

Size

0025 Size 0025 0350 Size 0350

0040 Size 0040 0600 Size 0600

0065 Size 0065 0950 Size 0950

0100 Size 0100 1600 Size 1600

0150 Size 0150 2500 Size 2500

0200 Size 0200 4000 Size 4000

Rotation angle

N 90° rotation angle

Threads

M Metric ISO 5211

U UNC/NPT/Imperial

Spring Set

00 Double Acting (no springs)

10 Spring Set 10 40 Spring Set 40

20 Spring Set 20 50 Spring Set 50

30 Spring Set 30 60 Spring Set 60

Rotation direction

CW Spring to Close/Clock Wise

CC Spring to Open/Counter Clock Wise

Pinion Material

AL High Grade Aluminium, Hard anodized

SS Stainless steel ASI 316 (+ A4-70 SS fasteners)

Valve Interface

TN Standard ISO 5211 interface

SY Small interface with center plate (DIN3337)

LY Large interface with center plate (DIN3337)

(2

Notes:

See next page.

Valve Stem Connection

Actuator

size

0025 11mm / 0.433" L11 D11 Q11

0040 &

0065

0100

0150

0200 22mm / 0.866" L22 D22 Q22

0350

0600 27mm / 1.063" L27 D27 Q27

0950 36mm / 1.417" L36 D36 Q36

1600 &

2500

4000 (355mm / 2.165" Q55 Q55 Q55

Temperature Range

S Standard: -20°C to +80°C (-4°F to +176°F)

H High: -10°C to +120°C (+14°F to +250°F)

L Low: -40°C to +80°C (-40°F to +176°F)

Visual Indication Code

K Standard (Knob)

N No Visual Indication

Finish

(7

B Standard coating (Bettis Orange)

Internal code 1

00 Standard

10 Stainless steel AISI316 (A4-70) end cap screws

Miceleanuous options

XX Standard

H1 1/2" High Flow plate

P1 1/2" Porting according EN 15714-3 (only sizes 950-4000)

Square

No insert 000 Not applicable

14mm / 0.551" L14 D14 Q14

17mm / 0.669" D17 Q19

19mm / 0.748" L19

17mm / 0.669" D17 Q22

19mm / 0.748" L19

22mm / 0.866" D22 Q27

27mm / 1.063" L27

46mm / 1.811" L46 D46 Q46

Aluminum Stainless Steel

Parallel

drive

Diagonal

drive

Star drive

(7

(4

Configuration Code

7

Page 12

Section 3: Configuration Code

March 2019

Notes:

1. The options, listed here, are all options available. Not all options apply to all configurations.

2. Valve Interface: Option "S"; Small Interface with Center Plate (DIN3337) is not

available for size 0025, 0950 and 4000. Option "L"; Large Interface with Center

Plate (DIN3337) is not available for size 1600 and 2500.

3. Size 4000 does not have inserts but has two inner squares (diagonally and parallel

oriented) directly in the bottom of the pinion.

4. Actuators with stainless steel pinions do not have inserts but have two inner

squares (diagonally and parallel oriented aka "Star Drive") directly in the bottom of

the pinion.

5. Contact you local Bettis representative for additional insert options.

6. PED Group 1 Label only available up to size 950.

7. Actuators with the default hard anodized pinions, come with stainless steel grade

A2 (AISI304) end cap screws.

Optional, the actuator is available with stainless steel grade A4-70 (AISI316) end

cap screws.

Select option 10 in the "Internal code 1" segment in case stainless steel grade A4

(AISI316) end cap screws are required.

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

8

Configuration Code

Page 13

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 4: Installation

This section explains:

• The actuator rotation direction.

• In which position the actuator will end after a failure.

• Principles of operation:

— Solenoid operation.

— Double acting and Spring return operation.

• Assembly codes.

• Actuator to valve assembly.

4.1 Before You Start

Section 4: Installation

March 2019

SAFETY

In case of an air or electrical failure, it is important to know the behavior of the actuator.

Before mounting the actuator on a valve, consult the following sections below.

4.2 Actuator Rotation Direction

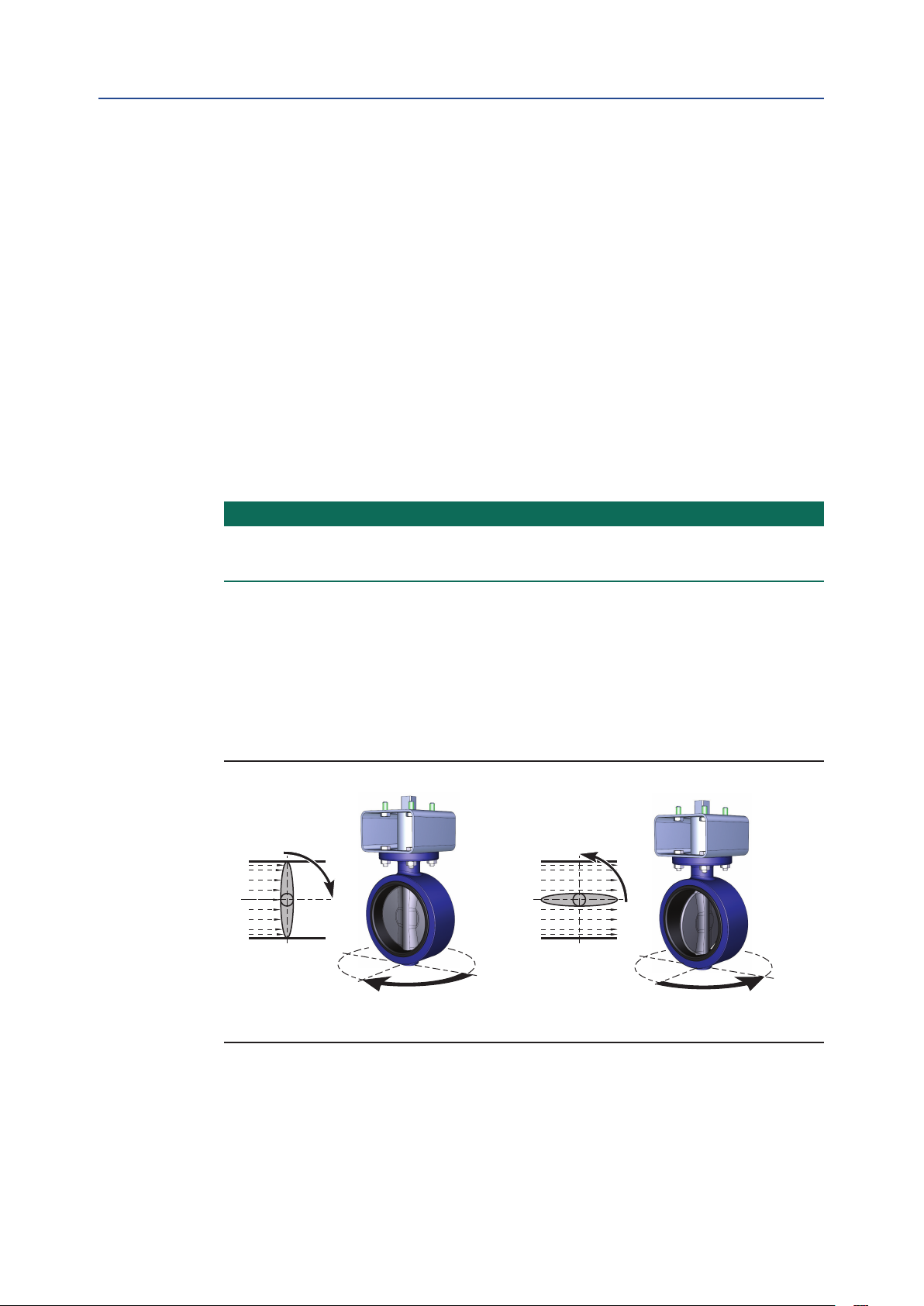

4.2.1 Valve Rotation

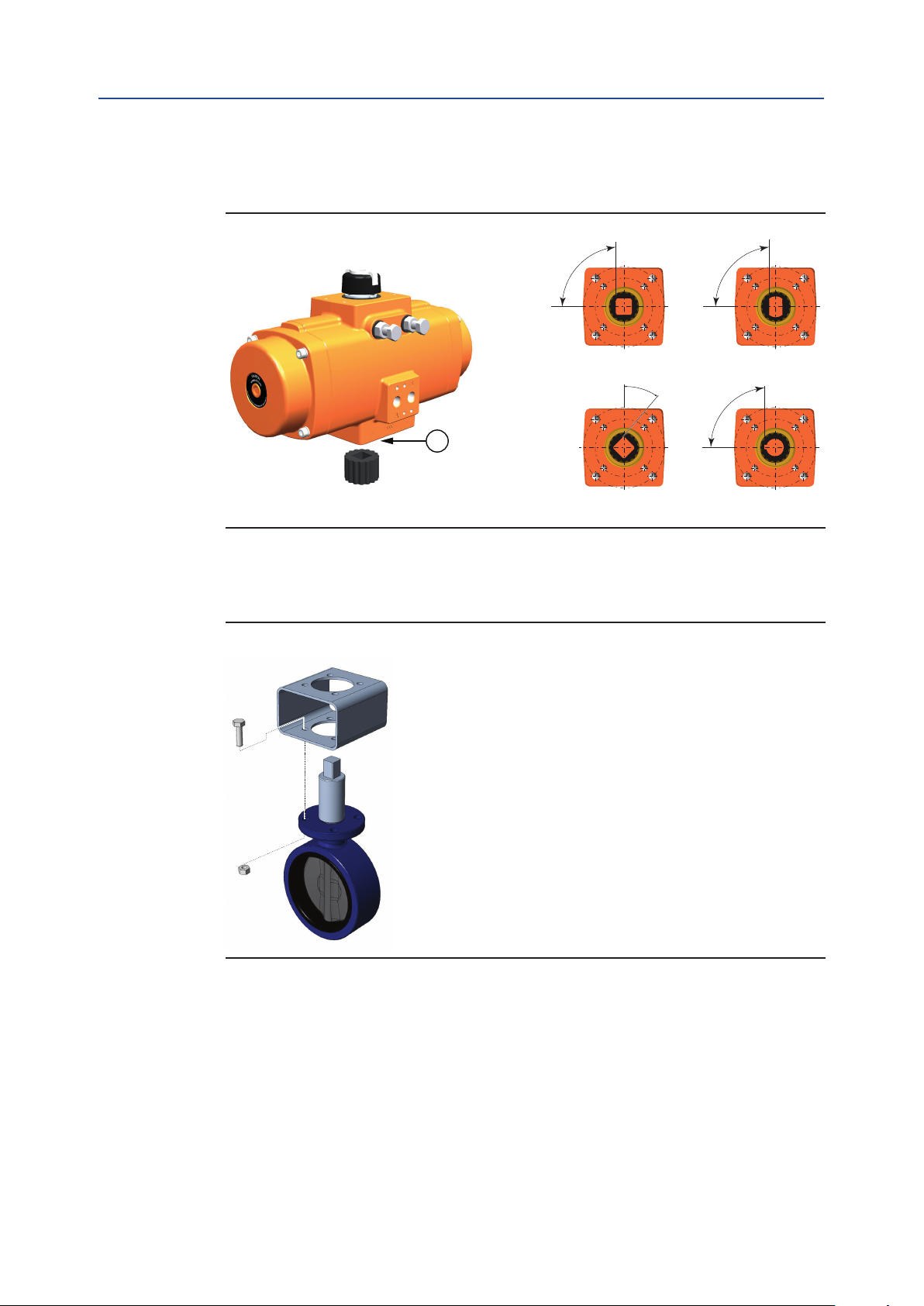

For the following paragraphs we assume that valves rotate as indicated in figure 3.

Figure 3 Normal valve rotation

Installation

The valve is closed after

a clockwise rotation.

The valve is open after

a counterclockwise rotation.

9

Page 14

A

BA

Section 4: Installation

March 2019

4.2.2 Position After Failure

The position of the actuator after a failure depends on the:

1. Principle of operation (see paragraph 4.3)

2. Assembly codes (see paragraph 4.4)

3. Kind of failure. Refer to the table below.

Table 5. Position After Failure

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Principle of

Operation

Assembly Code Kind of Failure Position

CW

Double-Acting

Actuator

Single-Acting

CW

(Spring-Return)

Actuator

4.3 Principles of Operation

4.3.1 Solenoid Valve

All actuators can be either piped with solid or flexible tubing with the solenoid valve

mounted remotely from the actuator or by mounting a VDI/VDE 3845 (NAMUR) designed

solenoid valve DIRECTLY onto the NAMUR mounting pad on the side of the actuator.

Pressure Not defined

Signal Closed

Supply Voltage Closed

Pressure Not defined

Signal Open

Supply Voltage Open

Pressure Closed

Signal Closed

Supply Voltage Closed

Pressure Open

Signal Open

Supply Voltage Open

10

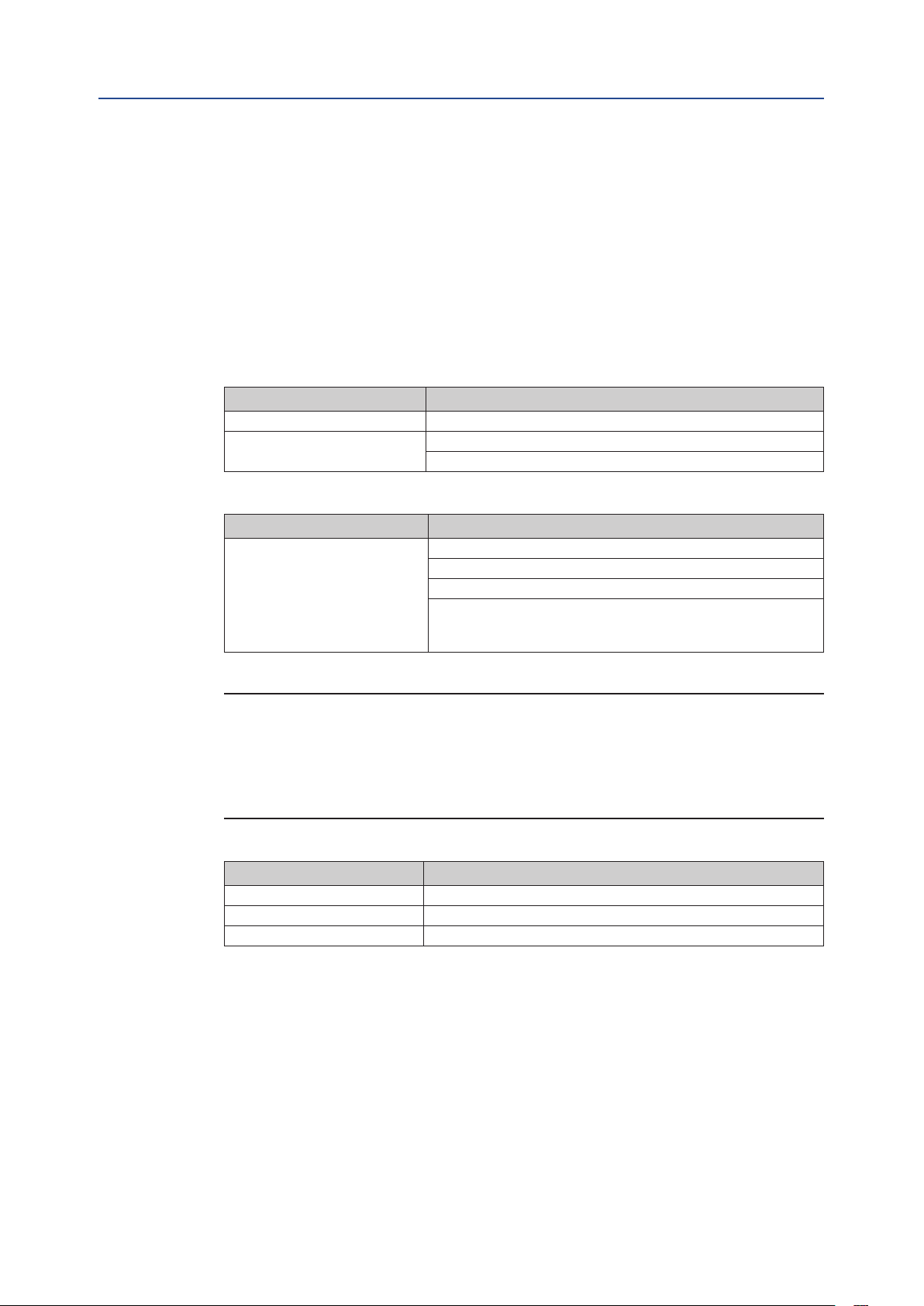

Figure 4 Typical solenoid operation

Spring-Return Operation Double-Acting Operation

Installation

Page 15

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

The table below represents the cycle time (operating time) per different Actuator sizes:

Table 6. Operating Speed

Cycle time in seconds

Actuator

size

25 0.5 0.4 0.5 0.4

40 0.6 0.5 0.6 0.5

65 0.7 0.5 0.6 0.6

100 0.8 0.6 0.8 0.7

150 1.0 0.8 0.9 0.8

200 1.3 0.9 1.0 1.0

350

600 3.2 1.9 2.2 2.2

950 6.6 2.2 2.4 2.0

1600 10.6 3.5 3.6 3.3

2500 16.9 5.7 5.8 5.2

4000 29.1 9.2 9.2 9.0

Operating time is average with actuator under load and solenoid valve fitted.

pressurized

Spring-Return Double-Acting

A-port

1.9 1.3 1.4 1.5

Spring

stroke

Section 4: Installation

A-port

pressurized

March 2019

B-port

pressurized

Test conditions:

1. Solenoid with flow capacity: 0.6 m3/hr

2. Pipe diameter: 6mm

3. Medium: clean air

4. Supply pressure: 5.5 bar (80psi)

5. Load: with average load

6. Stroke: 90°

7. Temperature: Room temperature

4.3.2 Ingress Protection (IP) rating

Bettis RPE actuators are IP66/IP67 rated. In case of IP66 or IP67 requirements, take

precautions that comply with the IP66/IP67 requirements to prevent moisture or dust

from entering the actuator through the open air exhaust port(s), either directly on the

actuator or at the exhaust ports of the connected solenoid valve.

We recommend to connect tubing to the exhaust(s) and lead this into a dry and dust free

area, or to use check valves in the exhaust.

Installation

11

Page 16

A

BA

A

B

B

Section 4: Installation

March 2019

Installation, Operation and Maintenance Manual

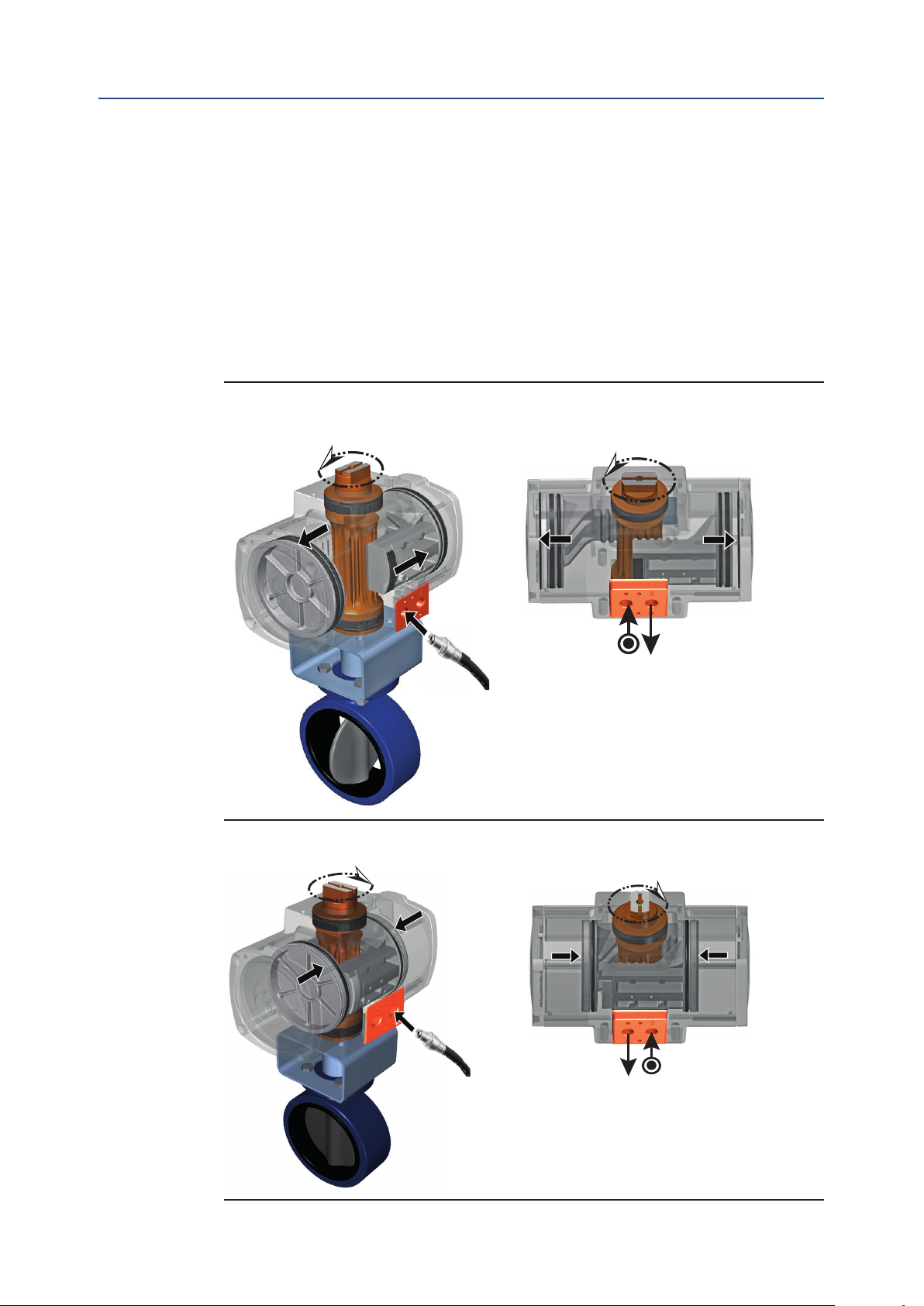

4.3.3 Double-Acting Actuators

The operating principle, as explained here, is applicable for actuators with assembly code

CW (direct acting).

• Applying supply pressure to port A will move the pistons outward to the "Open"

position of the valve.

• Applying supply pressure to port B will move the pistons inward to the "Close"

position of the valve.

• For assembly codes CC, the operating principle is reversed (reverse acting).

Figure 5 Double-Acting Operation

Outward Stroke

DOC.IOM.BE.EN Rev. 9

12

Inward Stroke

Installation

Page 17

Installation, Operation and Maintenance Manual

A

A

B

A

DOC.IOM.BE.EN Rev. 9

4.3.4 Spring-Return Actuators

The operating principle, as explained here, is applicable for actuators with assembly code

CW (direct acting).

• Applying supply pressure to port A will move the pistons outwards to the "Open"

position of the valve.

• Venting the supply pressure from port A will cause the springs to move the pistons

inwards to the "Close" position of the valve.

• For assembly codes CC, the operating principle is reversed (reverse acting).

Figure 6 Stroke Movements

Outward Stoke

Section 4: Installation

March 2019

Installation

Inward Stroke

13

Page 18

AB

A

B

A

B

A

B

Pinion and

cam position

Dot in

pinion slot

Default

pistons position

Reversed

pistons position

Pinion 90°

rotated

AB

A

B

A

BA

B

Pinion and

cam position

Dot in

pinion slot

Default

pistons position

Reversed

pistons position

Springs

Pinion 90°

rotated

Section 4: Installation

Installation, Operation and Maintenance Manual

March 2019

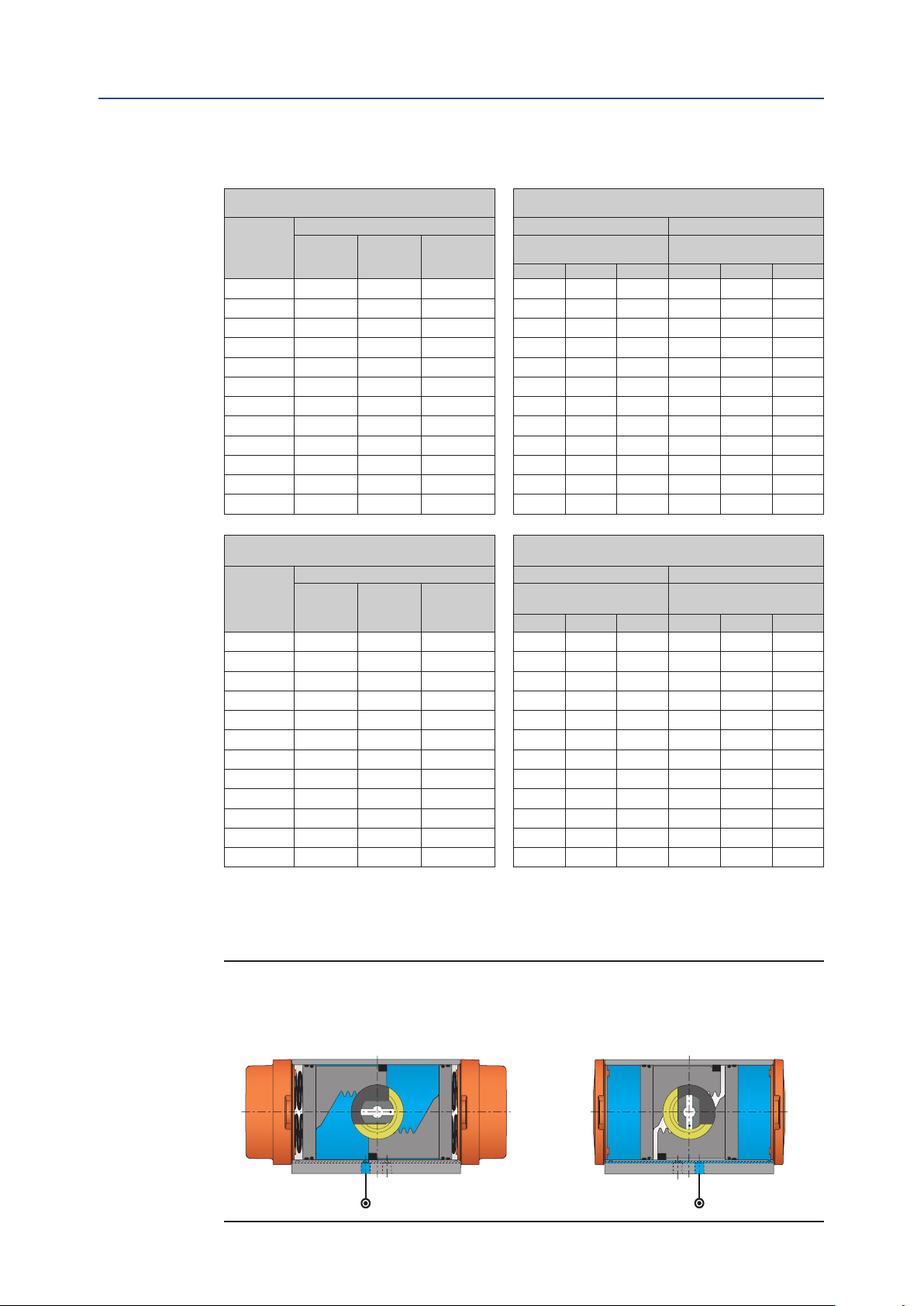

4.4 Actuator Assembly Codes

Figure 7 Assembly Code - Double-Acting

Assembly code: CW Assembly code: CC

= Standard, Clockwise-to-Close rotation = Reverse, Counterclockwise-to-Open

= Fail-to-Close = Fail-to-Open

DOC.IOM.BE.EN Rev. 9

A = Rotation when central air chamber is pressurized.

B = Rotation when end cap air chambers are pressurized.

All views are from above. Pistons are shown in inward position.

Figure 8 Assembly Code - Spring-Return

Assembly code: CW Assembly code: CC

= Standard, Clockwise-to-Close rotation = Reverse, Counterclockwise-to-Open

= Fail-to-Close = Fail-to-Open

14

Installation

Page 19

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

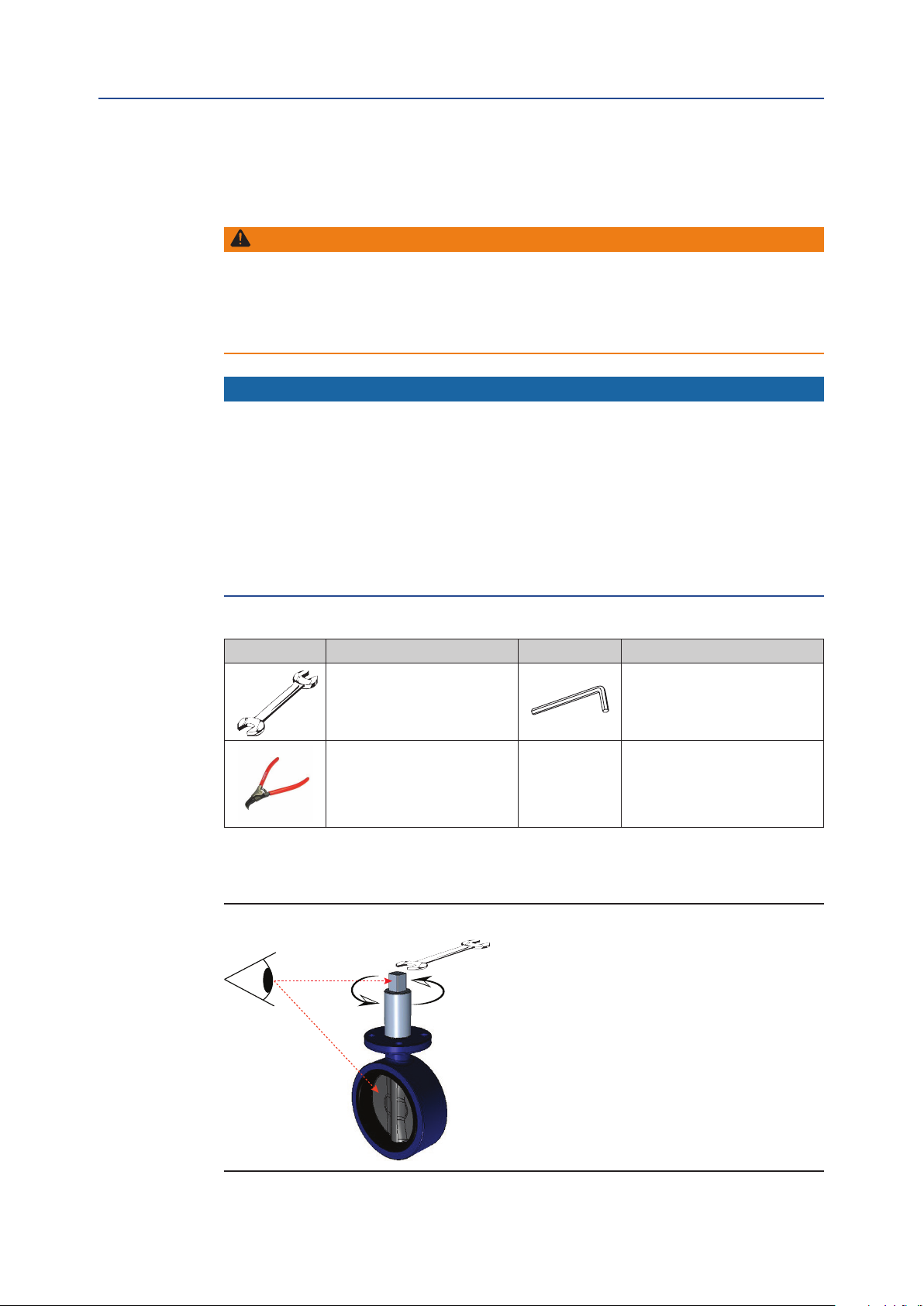

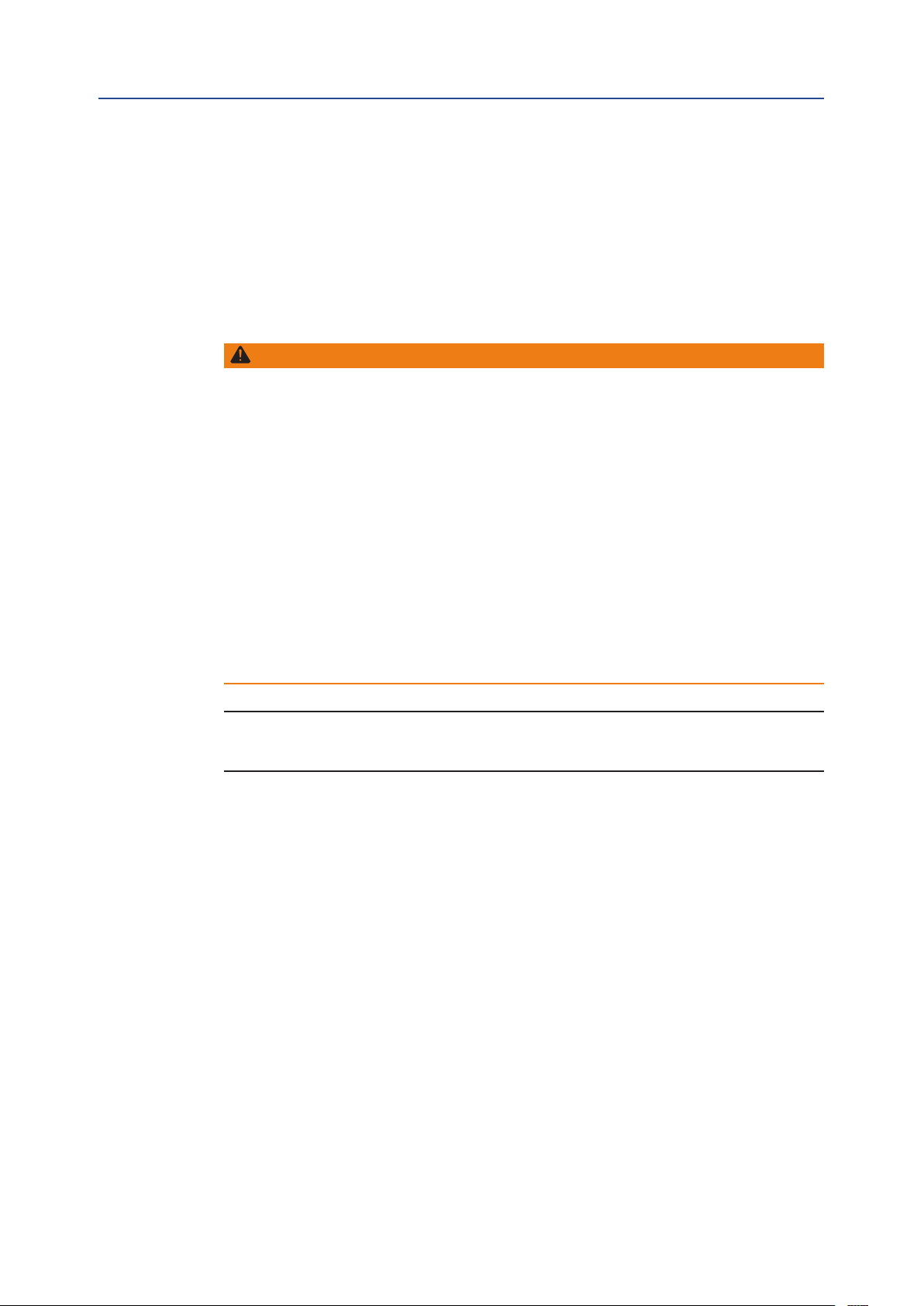

4.5 Actuator to Valve Installation

WARNING: MOVING PARTS

Actuator must be isolated pneumatically and electrically before any (dis)assembly starts.

Stay away from moving parts to prevent serious injuries. When test cycling the actuator

and valve assembly by applying pressure to the A or B port, be aware that there are moving

parts like pinion top, actuator to valve coupling and the valve- blade, ball, plug, etc.

NOTICE

The actuator is designed to be installed, commissioned and maintained using generic tools

like wrenches, Allen keys and screwdrivers. For the removal of inserts, a special extractor

tool can be supplied on request.

During assembly to the valve, do not hit with hammer on pinion top. This can damage the

pinion top washer and cause premature failure.

Section 4: Installation

March 2019

Before mounting the actuator on the valve or valve bracket, be sure that both the

actuator and the valve are in the same closed or open position.

Refer to Appendix B, Tool and Torque tables, for using the right size tool.

Table 7. Tool Table

Symbol Tool Symbol Tool

Wrench – All types and sizes.

Metric and Imperial

Circlip Pliers

1. Remove handle nut, handle, lock washer, and etc. from the valve if required.

2. Visually check to make sure the valve is CLOSED.

Figure 9 Valve handle removal

Allen key

Installation

15

Page 20

Section 4: Installation

March 2019

3. When required, check if the insert drive (23) is mounted. If not, use a plasticmallet

Figure 10 Insert drive Installation

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

and tap slightly until the reducer square is in the required position.

90°

90°

Parallel

square

45°

Flat head

90°

23

Diagonal

square

Round with

key way

4. Install the bracket to the valve flange. Tighten all bolts and nuts and apply the correct torque.

Figure 11 Bracket Installation

16

Installation

Page 21

Installation, Operation and Maintenance Manual

Indicator mounting “In-line”

DOC.IOM.BE.EN Rev. 9

5. Install the actuator to the bracket. Tighten all bolts and apply the correct torque

(refer to Table 8).

Table 8. Bottom flange torque values

Section 4: Installation

March 2019

Actuator size ISO Pattern

25

40, 65, 100

150, 200, 350

600

950

1600, 2500

4000

F03 inner pattern M5 2.0 3.0 10-24UNC 1.5 2.2

F05 outer pattern M6 4.5 5.0 1/4"-20 3.3 3.7

F05 inner pattern M6 4.5 5.0 1/4"-20 3.3 3.7

F07 outer pattern M8 10.5 12.5 5/16"-18 7.7 9.2

F07 inner pattern M8 10.5 12.5 5/16"-18 7.7 9.2

F10 outer pattern M10 21.0 24.5 3/8"-16 15.5 18.1

F10 inner pattern M10 21.0 24.5 3/8"-16 15.5 18.1

F12 outer pattern M12 34.5 43.0 1/2"-13 25.4 31.7

F10 inner pattern M10 21.0 24.5 3/8"-16 15.5 18.1

F14 outer pattern M16 90.0 104.0 5/8"-11 66.4 76.7

F16 inner pattern M20 170.0 204.0 3/4"-10 125.4 150.5

F25* outer pattern 4x M16 90.0 104.0 4x 5/8"-11 66.4 76.7

F16 inner pattern M20 170.0 204.0 3/4"-10 125.4 150.5

F25 outer pattern 8x M16 90.0 104.0 8x 5/8"-11 66.4 76.7

Torque (Nm) Torque (lbf.ft)

Thread Min. Max. Thread Min. Max.

6. When required, mount or adjust the visual indicator (26).

Figure 12 Actuator to valve mounting

Size 12 - 350 Size 600 - 4000

26 26

90°

90°

Indicator mounting “Across Line”

90°

Installation

17

Page 22

Section 4: Installation

March 2019

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

4.6 Mounting of control and feedback accessories

Solenoid valve and or switch boxes can now be mounted to the actuator. Check

the instructions as shipped with these components for installation, operating and

maintenance instructions.

We recommend to test-cycle the complete assembly to check correct operation.

4.7 Recommended Tubing Sizes

In case the solenoid valve is mounted remotely (i.e. in a central solenoid cabinet) and in

order to supply sufficient flow of air supply to the actuator, the following tubing sizes are

recommended.

Table 9. Tubing Sizes

Actuator size

1.2 meters 4 feet 1.2 meters 4 feet

25, 40, 65 6 mm 1/4 inch 6 mm 1/4 inch

100, 150, 200,

350, 600

950, 1600, 2500,

4000

Runs up to Runs over to

6 mm 1/4 inch 8 mm 5/16 inch

6 mm 1/4 inch 10 mm 3/8 inch

18

Installation

Page 23

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 5: Mechanical Stroke Adjustment

Section 5: Mechanical Stroke Adjustment

This section explains:

• What mechanical stroke adjustment is.

• What the factory settings are.

• How to adjust the travel stops.

Bettis RPE actuators have two stroke adjustment stops for adjusting accurately the stroke

of the actuator/valve assembly in open and closed position.

The factory setting of the stroke is 90°. Most quarter-turn valve applications will not require

readjustment of these settings.

If required the stroke can be adjusted by means of two-stroke adjustment bolts.

Figure 13 Factory Setting

March 2019

80°

95°

Open

90°

Closed

Size 950 - 4000Size 25 - 600

Closed

-5°10°

90°

80°

93°

Open

-3°10°

Limit Stop 2Limit Stop 1

Mechanical Stroke Adjustment

19

Page 24

Stop 1

Stop 2

Stop 1

Stop 2

Section 5: Mechanical Stroke Adjustment

March 2019

Installation, Operation and Maintenance Manual

5.1 Travel Stop Adjustment

CAUTION: PRESSURIZED ACTUATOR

Do not turn out the travel stops completely when the actuator is pressurized.

When adjusting the travel stops and the actuator is still pressurized, the travel stops can be

“shot” away when completely turned out.

5.1.1 Double-Acting Actuators

1. Operate valve/actuator assembly to the required "Closed" position.

2. Remove air supply.

3. Slacken locknut on the “closed” stop (2).

DOC.IOM.BE.EN Rev. 9

Figure 14

4. Turn the “closed” stop clockwise to reduce or counterclockwise to increase the

travel. Consult chapter 5.1.3 (angular displacement of the pinion), to define how

far the limit stop must be turned in or out.

5. Tighten the lock nut.

6. Connect air and cycle the actuator to check that the position is correct. If not

repeat from 2.

7. Remove air supply.

8. For adjusting the open position repeat steps 1 to 7, but now for the open position

and “open” stop (1).

5.1.2 Spring-Return Actuators

20

1. Connect air supply to the A port. Actuator will move to the open position.

2. Slacken locknut (24) on the “closed” stop (2).

Figure 15

Mechanical Stroke Adjustment

Page 25

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

3. Turn the “closed” stop clockwise to reduce or counterclockwise to increase the

travel. Consult chapter 5.1.3 (angular displacement of the pinion), to define how

far the limit stop must be turned in or out.

4. Remove air supply. Actuator will move to the closed position.

5. Check whether the actuator valve assembly is in the required position.

If not repeat steps 1 to 5.

6. Remove air supply.

7. For adjusting the open position repeat steps 1 to 6, but now for the open position

and "open" stop (1).

Table 10. Limit stop dimensions

Actuator size Thread Bolt wrench size (mm) Nut wrench size (mm)

25 M6 10 10

40 M8 13 13

65 M10 17 (16)* 17 (16)*

100 M10 17 (16)* 17 (16)*

150 M10 17 (16)* 17 (16)*

200 M12 19 (18)* 17 (18)*

350 M16 24 24

600 M20

950 M 22

1600 M 24 14 36

2500 M 27 17 41

4000 M 22 12 32

1. Default dimension according DIN933 standard.

2. Dimensions in brackets according ISO4017 standard.

Section 5: Mechanical Stroke Adjustment

March 2019

30

12

30

32

5.1.3 Angular Displacement

Below table identifies, per actuator size, what the angular displacement of the pinions is,

when using the limit stop screws.

— Turn the limit stop clockwise reduces the stroke.

— Turn the limit stop counteclockwise to increase the stroke.

Table 11. Angular Displacement limit stops

Actuator size

25 0.7 7.1°

40 0.8 6.3°

65 0.6 8.3°

100 0.7 7.1°

150 1.2 4.2°

200 1.0 5.0°

350 0.8 6.3°

600 0.8 6.3°

950 1.1 4.7°

1600 1.3 4.1°

2500 1.5 3.4°

4000 3.2 1.6°

NOTICE

Turns for 5° adjustment of

the pinion:

360° revolution of limit

stop screw will adjust

In case of air leakage over the limit stop bolts, turn the lock nut of the limit stop bolts

tighter, until leakage stops.

Mechanical Stroke Adjustment

21

Page 26

Section 6: Maintenance

March 2019

Installation, Operation and Maintenance Manual

Section 6: Maintenance

This section explains:

• When and how to do maintenance.

— Normal maintenance.

— Extraordinary maintenance.

• What to do when replacing springs.

• What the availability is of spare parts, action conversion kits and temperature

conversion kits.

WARNING

Actuator must be isolated pneumatically and electrically before any (dis)assembly starts. Before mounting or (dis)assembling the actuator, consult the relevant sections of this manual.

DOC.IOM.BE.EN Rev. 9

6.1 Normal Maintenance

Bettis RPE actuators are designed to operate without maintenance for their normal

working life. Normal working life is 500,000 cycles* for sizes up to RPE1600 and 250,000

for sizes RPE2500 and RPE4000.

For actuators with the optional low temperature silicon seals, we advise to replace these

seals after 250.000 cycles*.

NOTE:

* 1 Cycle = one open stroke and one close stroke.

We recommend regular inspections to make certain that the actuator / valve assembly

operates smoothly and to check that there are no visible or audible defects. We advise to

perform the following checks upon each proof test interval complying with the rules and

regulations of the country of final installation:

• Visually check the entire actuator as well as the control system (where foreseen).

• Ensure there are no leaks on the actuator parts under pressure.

• Check pneumatic connections for leaks. Tighten tube fittings as required.

22

• Check if manual override (where foreseen) is regular.

• Check if pneumatic filter cartridge (where foreseen) is sound and filter bowl

(where foreseen) has been cleaned properly.

• Check the setting of the relief valves (where foreseen).

• Verify that the power fluid supply pressure value is within the required range.

• Remove built-up dust and dirt from all actuator surfaces.

Maintenance

Page 27

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

• Inspect actuator paint work for damages to ensure continued corrosion protection.

Touch-up as required in accordance with the applicable paint specification.

• Operate the Actuator/Valve assembly for 2 complete open/close cycles with com-

plete closing of the valve.

• Verify the correct performing of open – close operations (e.g. check locally,

or automatically via Logic solver, the correct movement of the actuator).

All actuators are supplied with sufficient lubrication for their normal working life.

If required, see Section 9.1 (Grease instructions) for the recommended grease.

For mounting the parts of the repair kit follow the instruction of the Decommission,

Disassembly and Reassembly chapters of this manual.

6.2 Inspection and Repair

Replacement of internal seals and bearings allows to you extend the normal working

life. Service kits, containing all necessary spare parts (like seals, bearings, grease and

instructions) can be obtained through authorized Emerson – Actuation Technologies

distributors.

Section 6: Maintenance

March 2019

6.2.1 Service Kits

All soft seals, bearings, and nonreusable parts are included in the recommended service

kit. The service kit is identical for both the double-acting and the spring-return models.

6.2.2 Spring-Return Actuator

For the spring-return models, we recommend a set of spare springs for each different

model in addition to the recommended spare parts kit.

On spring-return actuators, the spring cartridges can be replaced. SPRING CARTRIDGES

SHOULD ALWAYS BE REPLACED IN COMPLETE SETS. Spring kits are available through

authorized Emerson – Actuation Technologies distributors.

Maintenance

23

Page 28

Section 7: Decommission (Out of Service)

March 2019

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 7: Decommission (Out of Service)

This section explains:

• How to decommission an actuator in a safe way.

7.1 Before You Start

WARNING: MOVING PARTS

Actuator must be isolated pneumatically and electrically before any (dis)assembly starts.

Before mounting or (dis)assembling the actuator consult the relevant sections of this

manual.

Actuator can move when removing supply pressure and/or electrical control signal of

actuators. If not already there, a spring-return actuator will cycle to its fail position.

When removing any ball valve or plug valve assemblies from a pipe system, isolate the

piping system on which the Actuator is installed and relieve any media pressure that may

be trapped in the valve cavities before removing the actuator for maintenance.

A spring-return actuator mounted on a valve, which is stuck in mid stroke, contains a

high spring load which will cause a sudden rotation of the actuator versus the valve or

valve bracket during disassembly. This can cause serious injury to personnel or damage

to property.

Refer to Appendix A for instructions to safely remove the spring load before disassembling

the spring-return actuator from valve or bracket.

Important

Refer to the Safety Guide for Lifting Instructions.

24

Decommission (Out of Service)

Page 29

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 7: Decommission (Out of Service)

7.2 Removing the actuator from the valve

1. Disconnect all air supply hoses (Ports A and B or solenoid).

2. Disconnect all electrical wirings of the switch box.

3. Disconnect the electrical wiring of the solenoid valve.

4. Remove the bolts and nuts from the valve flange.

5. Remove the bracket from the actuator.

6. Remove the switch box and solenoid valve. Refer to the documentation of the

switch box and solenoid valve for safe disassembly.

Figure 16 Removing actuator from valve

3

1

March 2019

2

4

Decommission (Out of Service)

25

Page 30

Section 8: Disassembly

March 2019

Installation, Operation and Maintenance Manual

Section 8: Disassembly

This section explains:

• How to disassemble an actuator safely.

Tip

The instructions of this section can be used for maintenance or reconfiguration like spring

set change or maintenance.

Reference numbers for components refer to the exploded view in section 11.

In case of maintenance, discard all the used soft parts like O-ring seals, guide bands,

wear strips and circlip.

WARNING

Actuator must be isolated pneumatically and electrically before any (dis)assembly starts.

DOC.IOM.BE.EN Rev. 9

Before mounting or (dis)assembling the actuator consult the relevant sections of this

manual.

CAUTION: PRESSURIZED ACTUATOR

Spring-return actuators contain springs in a compressed state. Follow these instructions to

release the spring force safely.

The end caps of spring-return actuators sizes 25 to 600 should be free of the spring load

after 10 full turns (crosswise relaxing) of the end cap screws. If there is still spring load on

the end cap, this might indicate a broken spring cartridge. Stop this disassembly procedure

immediately. Continuing might cause the end cap to be “shot” away causing serious injury.

Spring return actuator size 950 to 4000 have long end cap screws to release the spring load

safely.

Refer to Appendix A for instructions to safely remove the spring load before disassembling

the end cap of a spring-return actuator with a broken spring cartridge.

NOTICE

The actuator is designed to be installed, commissioned and maintained using generic tools

like wrenches, Allen keys and screwdrivers.

26

Disassembly

Page 31

Installation, Operation and Maintenance Manual

2

6

8

6

11

6

5

10

8

10

11

2

DOC.IOM.BE.EN Rev. 9

Section 8: Disassembly

Refer to the tables in this section or refer to Appendix B Tool and Torque tables.

8.1 Removing End Caps (Sizes 25 to 600)

1. For Double-Acting actuators, do the following:

a. Remove the screws (8) and washers (10) of the end caps (6).

b. Remove the o-ring (11) and "B" port seal (2). Discard these parts.

Figure 17 Double-Acting End Caps Removal

March 2019

Double acting end caps (6) are fitted with a white warning sticker. Spring return end

caps (5) are fitted with a black warning sticker.

Actuator sizes 25 to 100 have high end caps for double-acting and spring-return models.

Disassembly

27

Page 32

Section 8: Disassembly

March 2019

Actuator sizes 150 to 4000 have low end caps for double-acting models and high end

caps for spring return models.

2. For Spring-Return actuators, do the following:

Figure 18 Spring-Return End Caps Removal

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

a. Tip: For actuators with assembly code CW, turn back the right hand limit

stop screw (30) 2 full turns.

For actuators with assembly code CC, turn back the left hand limit stop

screw (30) 2 full turns.

This will lower the spring force on the end cap and reduces the screw out

length of the end cap screws.

b. Uniformly loosen the screws (9) of the end caps (5) 1/4-1/2 turns at a

time, in sequence, as per figure 18, to relieve the pre-load of the springs.

c. Remove the o-rings (11) and "B" port seals (2). Discard these parts.

28

Disassembly

Page 33

Installation, Operation and Maintenance Manual

3

1

4

5

11

2

30

5

9

11

10

2

9

10

2

6

2

11

6

8

10

8

10

2

11

DOC.IOM.BE.EN Rev. 9

Section 8: Disassembly

8.2 Removing End Caps (Sizes 950 to 4000)

1. For Double-acting actuators, do the following:

a. Remove the screws (8) and washers (10) of the end caps (6).

b. Remove the o-ring (11) and "B" port seal (2). Discard these parts.

March 2019

Figure 19 Double-Acting End Caps Removal sizes 950 to 4000

2. For Spring-return actuators, do the following:

a. Tip: For actuators with assembly code CW, turn back the right hand limit

stop screw (30) 2 full turns.

For actuators with assembly code CC, turn back the left hand limit stop

screw (30) 2 full turns.

This will lower the spring force on the end cap and reduces the screw out

length of the end cap screws.

b. Uniformly loosen the screws (9) of the end caps (5) 1/4-1/2 turns at a

time, in sequence, as per figure 20, to relieve the pre-load of the springs.

c. Remove the o-rings (11) and "B" port seals (2). Discard these parts.

Disassembly

29

Page 34

7

7

Section 8: Disassembly

March 2019

Figure 20 Spring-Return End Caps Removal sizes 950 to 4000

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

10

9

3

6

1

4

5

2

5

11

2

11

2

30

8.3 Removing Spring Cartridges or Springs

3. Remove the spring cartridges or springs (7).

Figure 21 Removing Spring Cartridges size 25 to 600

5

10

9

30

Disassembly

Page 35

Installation, Operation and Maintenance Manual

7

7

DOC.IOM.BE.EN Rev. 9

Figure 22 Removing Springs size 950 to 4000

8.4 Removing of Limit Stop

1. Remove the limit stop screws (30), limit stop nuts (31), limit stop washers (32) and

limit stop o-rings (33). Discard the o-rings.

Section 8: Disassembly

March 2019

Figure 23 Limit Stop Removal

33 30

32

8.5 Removing Pistons

1. Use a wrench and turn the pinion counterclockwise until the pistons (14) come

out of the body.

2. Remove the piston bearings (15), piston rack bearing strips (17) and piston o-ring

seals (16). Discard these parts.

31

Disassembly

31

Page 36

Section 8: Disassembly

March 2019

8.6 Removing Pinion

1. Remove the circlip (27) and thrust bearing (23) on top of the pinion assembly.

For sizes 950 to 4000 remove also the top pinion bearing (19).

2. Remove the pinion (18) by pushing it downwards. For Size 4000, remove the

backup ring (29), O-ring pinion top (21) the cam (24) and cam thrust washer (25)

through the main bore of the housing.

3. Remove the pinion O-ring seals (21/22) and the pinion bearings (19/20).

For Size 950 to 2500, remove also the backup ring (29).

4. Discard all of these parts.

Figure 25 Pinion Removal

Sizes 25 to 600

23

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

19

19

27

Sizes 950, 1600, and 2500

23

27

19

Size 4000

23

27

19

21

29 25

25

18

29 19 18

24

18

21

2221

20

22

20

32

Table 12. Recommended circlip pliers according DIN 5254 (or equal) for circlips.

Actuator

size

25 - 100 22 mm 0.866" A2 1600 75 mm 2.953" A3

150 - 350 36 mm 1.417" A3 2500 95 mm 3.74" A4

600 55 mm 2.165" A3 4000 96 mm 3.78" A4

950 65mm 2.559" A3

Pinion top

diameter

Pliers according

DIN 5254

Actuator

size

Pinion top

diameter

Pliers according

DIN 5254

Disassembly

Page 37

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

8.7 Cleaning the Components

In case of maintenance, use a clean dry cloth and thoroughly wipe clean and remove old

grease from:

• The inside and outside of the body including thread holes and crevices/grooves

• The pinion gears.

• The pistons.

Figure 24 Removing Pistons

14

17

14

16

15

16

17

Section 8: Disassembly

15

March 2019

Disassembly

33

Page 38

Section 9: Reassembly

March 2019

Section 9: Reassembly

This section explains:

• Which parts and how to grease them.

• How to reassemble a complete actuator.

• How to set the stroke adjustment bolts after reassembly.

• How to do a basic function and air leak test.

Tip

The instructions of this section can be used for maintenance or reconfiguration like spring

set change or maintenance.

Reference numbers for components refer to the exploded view in section 11.

In case of maintenance, discard all used soft parts like O-ring seals, guide bands and wear

strips and circlip and replace them with the parts as supplied in the repair kit.

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

In case of reconfiguration replace the parts as supplied in the conversion kit

(see also chapter 6).

Refer to the Safety Guide for Lifting Instructions.

NOTICE

The actuator is designed to be installed, commissioned and maintained using generic tools

like wrenches, Allen keys and screwdrivers.

Refer to the tables in this section or refer to Appendix B Tool and Torque tables.

34

Reassembly

Page 39

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

9.1 Grease Instructions

Check the product coding on the product labels and chapter 3 of this manual, to define

which type of grease to use.

— For standard actuators (-20°C to +80°C / -4°F to +176°F):

Castrol High Temperature grease (or equivalent).

— For low temperature operation (-40°C to +80°C / -40°F to +176°F):

Castrol Tribol GR TT 1 PD (previously known as Castrol OPTITEMP TT1) or

LG2 grease (or equivalent).

— For high temperature operation (-10°C to +120°C / +14°F to +250°F):

Castrol High Temperature grease (or equivalent).

We recommend using a suitable sized paint brush to apply the required amount of grease

on the parts as per Table 12 and Figure 23.

Table 13. Grease Instructions

Part Section of part Amount of grease

O-rings:

Housing Parts:

Piston Parts:

Piston Parts:

A Completely

B Piston bore Light film

C Top pinion bore Light film

D Bottom pinion bore Light film

E

O-ring & bearing groove

F Rack teeth Half the teeth depth full with grease

G Piston bearing Light film on outside

H Piston rack bearing strip Light film

J

Pinion bottom & O-ring groove Light film

K Pinion top & O-ring groove Light film

L Gear teeth Half the teeth depth

M Pinion top bearing Light film (inside and out)

N Pinion bottom bearing Light film (inside and out)

Section 9: Reassembly

March 2019

Light film

Light film

Reassembly

Figure 26 Grease Instructions

A

M

K

L

J

N

A

B

A

E

C

F

G

A

H

A

A

D

35

Page 40

Section 9: Reassembly

Installation, Operation and Maintenance Manual

March 2019

9.2 Reassembly of the pinion

1. Grease the pinion parts according to chapter 9.1.

2. Install the pinion bearings (19/20) and the O-ring seals (21/22) on the pinion (18).

For Size 950 to 2500, install also the the backup ring (29).

3. Insert the pinion (18) in the housing. For size 4000: mount first the cam (24), cam

thrust washer (25), pinion top O-ring (21) and backup ring (29) through the mainbore onto the pinion (18).

4. For sizes 950 to 4000 install first the top pinion bearing (19). For all sizes, install

the thrust washer (23) and mount the circlip (27) on the pinion top.

— Install the new circlip onto its mating groove on the top shaft extension

and with the non-sharp edge (2) towards the housing and the sharp edge

(1) towards the top of the shaft.

Figure 27 Reassemble the pinion

2

Sizes 25 to 600

23

1

19

DOC.IOM.BE.EN Rev. 9

19

27

1

1

Sizes 950, 1600, and 2500

2

23

27

19

Size 4000

2

23

27

19

21

29 19

24

29 25

21

18

18

18

21

2221

20

22

20

36

Table 14. Recommended circlip pliers according DIN 5254 (or equal) for circlips.

Reassembly

Page 41

Installation, Operation and Maintenance Manual

17

14

16

16

17

14

15

15

DOC.IOM.BE.EN Rev. 9

Section 9: Reassembly

March 2019

Actuator

size

25 - 100 22 mm 0.866" A2 1600 75 mm 2.953 A3

150 - 350 36 mm 1.417" A3 2500 95 mm 3.74 A4

600 55 mm 2.165" A3 4000 96 mm 3.78 A4

950 65mm 2.559" A3

Pinion top

diameter

Pliers according

DIN 5254

Actuator

size

9.3 Reassembly of the pistons

NOTICE

Before reassembling the pistons, check the required assembly code (see section 4.2).

1. Grease the piston parts according to step 9.1.

2. Install the piston rack bearing strips (17) and piston O-ring seals (16) on the pistons (14). Ensure all these parts are kept in place during assembly.

Figure 28 Reassemble the pistons

Pinion top

diameter

Pliers according

DIN 5254

Reassembly

3. Align the pinion (see Figure 26) so that the teeth on the pinion will pick up the pistons rack teeth when turning the pinion. Note the position of the pinion top slot

and the cam on the pinion top:

— For standard or Spring-to-Close: Assembly Code CW.

— For reverse or Spring-to-Open: Assembly Code CC.

37

Page 42

90°

90°

Assembly code CW Assembly code CC

(Standard; Spring-to-Close) (Reverse; Spring-to-Open)

A

B

A

B

C

C

Section 9: Reassembly

March 2019

4. Slightly push the pinion inward to engage with the pinion.

5. When the pistons are moved 90° inwards (see figure 26), check that the pinion slot

6. If not, turn pinion to move the pistons outward until they disengage from the

7. Move the pistons outward so that just the bearing groove sticks out of the hous-

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

— Ensure that smooth movement and 90-degree operation can occur with-

out moving the pistons out of the actuator body.

— For larger pistons, use a rubber mallet and slightly hitting the pistons

inward to engage with the pinion.

on the pinion top is:

— Perpendicular to the length centre line of the house for assembly code CW.

— In line to the length centre line of the house for assembly code CC.

pinion. Shift one tooth of the pinion, reassemble and check again.

ing. Fold the piston bearings (15) around the piston and hold the bearing ends in

place while moving the pistons inwards.

— For larger pistons, use a rubber mallet and slightly hitting the pistons

inward to engage with the pinion.

Figure 29 Position of the slot and the cam on the pinion top

38

A = Position of cam

B = Position of slot and dot in pinion.

C = Final position of pinion dot.

Reassembly

Page 43

Installation, Operation and Maintenance Manual

33 30

31

32

DOC.IOM.BE.EN Rev. 9

NOTE:

When the pistons are completely moved inwards, the pinion top will show a 5° over travel.

Section 9: Reassembly

9.4 Reassembly and settings of the limit stops

1. Install the limit stop screws (30), limit stop nuts (31), limit stop washers (32) and

limit stop O-rings (33).

Figure 30 Install Limit Stop Bolts

March 2019

2. Move the pistons inward until the slot in the top of the pinion is perpendicular to

3. Double check if the position of the slot and the cam on the pinion top is in the cor-

4. Move the pistons outward until the slot in the top of the pinion is in line with the

5. Screw in the left hand travel stop until it comes into contact with the pinion stop

centerline of the housing.

rect position (see figure 26). Screw in the right hand travel stop until it comes into

contact with the pinion stop face.

centerline of the housing.

face.

— For accurate travel stop adjustment of the actuator on the valve,

see section 5.

Reassembly

39

Page 44

2

6

9

6

11

6

5

10

9

10

11

2

Section 9: Reassembly

March 2019

Installation, Operation and Maintenance Manual

9.5 Reassembly of the end caps

9.5.1 Double-Acting actuators

1. Grease the O-ring seals (11) and B port seals (2) according to step 9.1.

2. Ensure that O-ring seals (11) and B port seals (2) are kept in place during assembly.

3. Install the end caps (6) and tighten the end cap screws (8).

Refer to Table 15 for the correct torque.

Figure 31 Double-Acting end cap assembly

DOC.IOM.BE.EN Rev. 9

Double acting end caps (6) are fitted with a white warning sticker. Spring return end

caps (5) are fitted with a black warning sticker.

Actuator sizes 25 to 100 have high end caps for double-acting and spring-return models.

Actuator sizes 150 to 4000 have low end caps for double-acting models and high end

caps for spring return models.

Table 15. End cap Screw Torque

Actuator

size

25 M5

40 M5 SW 4 2.0 1.6 3.0 1.5 1.2 2.2

65 M5 SW 4 2.0 1.6 3.0 1.5 1.2 2.2

100 M5 SW 4 2.0 1.6 3.0 1.5 1.2 2.2

150 M6 SW 5 3.3 2.6 5.1 2.4 1.9 3.8

200 M6 SW 5 3.3 2.6 5.1 2.4 1.9 3.8

350 M8 SW 6 8.4 6.7 12.2 6.2 4.9 9.0

600 M10 SW 8 15.3 12.2 24.8 11.3 9.0 18.3

950 M12 SW10 24.3 19.4 41.6 17.9 14.3 30.7

1600 M12 SW10 24.3 19.4 41.6 17.9 14.3 30.7

2500 M12 SW10 24.3 19.4 41.6 17.9 14.3 30.7

4000 M14 SW12 43.5 34.8 66.4 32.1 25.7 49.0

Thread Tool Size

Allen Key

SW 4 2.0 1.6 3.0 1.5 1.2 2.2

Torque (Nm) Torque (lbf.ft)

Target Min. Max. Target Min. Max.

40

Reassembly

Page 45

Installation, Operation and Maintenance Manual

1

2 3

4

56

A

B

1

2

3

4

56

1

23

4

56

N = 10

N = 20

N = 30

1

2 3456

1

23

4

5

6

1

23

4

5

6

N = 40

N = 50

N = 60

DOC.IOM.BE.EN Rev. 9

9.5.2 Spring-Return actuators

Important

Bettis RPE-Series Spring return actuators are supplied with springs on each side of the

actuator. Throughout the RPE-Series size range, there are two different spring designs:

— Sizes RPE25 to RPE600 have 6 springs on each side (see figure below).

— Sizes RPE950 to RPE4000 have 3 springs on each side (see chapter 9.5.3).

Check below figures to see where to place the spring cartridges in case of

spring set conversion.

When replacing spring cartridges in a spring-return actuator, ensure that the cartridges are

replaced in their identical position from where they were removed.

Before assembling the spring cartridges and end caps, make sure that the pistons are

completely inwards.

Figure 32 Spring cartridge placement

Section 9: Reassembly

March 2019

Reassembly

A = Piston top view

B = Position of piston gear rack

1. Grease the O-ring seals (11) and B port seals (2) according to step 9.1.

2. Ensure that O-ring seals (11) and B port seals (2) are kept in place during assembly.

3. Place the spring cartridges in actuator as per required spring set (see Figure 32).

4. Put the end cap screw washer (10) on the end cap screw (9) and tighten each end

cap screw in small equal turns and in the sequence as per Figure 33. Refer to Table

15 for the correct torque. We recommend to use some grease on the screws for

easier fastening.

41

Page 46

3

1

4

5

11

2

30

5

9

11

10

2

9

10

2

Section 9: Reassembly

March 2019

Installation, Operation and Maintenance Manual

Figure 33 Spring Return End cap assembly size 25 to 600

9.5.3 Spring-Return actuators - Size 950 to 4000

DOC.IOM.BE.EN Rev. 9

Important

Bettis RPE-Series Spring return actuators are supplied with springs on each side of the

actuator. Throughout the RPE-Series size range, there are two different spring designs:

— Sizes RPE25 to RPE600 have 6 springs on each side (Chapter 9.5.2).

— Sizes RPE950 to RPE4000 have 3 springs on each side (see figure below).

Check below figures to see where to place the springs in case of spring set conversion.

When replacing springs in a spring-return actuator, ensure that the springs are replaced in

their identical position from where they were removed.

Before assembling the springs and end caps, make sure that the pistons are completely

inwards.

42

Reassembly

Page 47

Installation, Operation and Maintenance Manual

N = 10 N = 20 N = 30

DOC.IOM.BE.EN Rev. 9

Figure 34 Spring placement size F950 to F4000

Left RightLeftRight Left Right

B

A

1 spring 0 spring 1 spring 1 spring 2 springs1 spring

N = 40 N = 50 N = 60

Section 9: Reassembly

March 2019

Left

2 springs

Right Left RightLeft Right

2 springs 3 springs2 springs3 springs3 springs

Reassembly

43

Page 48

Section 9: Reassembly

March 2019

A = Piston top view

B = Position of gear rack

1. Grease the O-ring seals (11) and B port seals (2) according to step 9.1.

2. Ensure that O-ring seals (11) and B port seals (2) are kept in place during assembly.

3. Place the spring in actuator as per required spring set (see Figure 29).

4. Put the end cap screw washer (10) on the end cap screw (9) and tighten each end

Figure 35 Spring Return end cap assembly size 950 to 4000

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

cap screw in small equal turns and in the sequence as per Figure 35.

Refer to Table 15 for the correct torque. We recommend to use some grease on

the screws for easier fastening.

10

9

3

6

1

4

5

2

5

11

2

11

2

30

5

10

9

44

Reassembly

Page 49

Installation, Operation and Maintenance Manual

AB

DOC.IOM.BE.EN Rev. 9

9.6 Basic function and Air Leak Test

CAUTION: MOVING PARTS

Applying pressure to the actuator will cause the actuator/valve assembly to operate.

1. Apply pressure (max. 8 bar/120 psi) to ports A and B. Use some soap suds at the

indicated points: around pinion top (1), pinion bottom (2), the end caps (3) and

limit stops (4).

2. In case of leakage around:

a. The limit stop bolts: Turn the lock nut of the bolts tighter, until the leak-

age stops.

b. The end caps: Disassemble the end caps, replace o-rings and reassemble.

c. The pinion top or bottom and A- or B- port: Disassemble the complete

actuator, replace o-rings and reassemble.

Section 9: Reassembly

March 2019

Figure 36 Basic function and air leak test

1

4

B

A

3

2

3

Reassembly

45

Page 50

Section 10: Troubleshooting

March 2019

Installation, Operation and Maintenance Manual

Section 10: Troubleshooting

10.1 Mechanical Problems

Problem Possible error Solution Where to find

Feedback position and

actual position are not

the same.

Valve is in “Closed”

position, actuator is in

“Open” position and will

not move anymore.

Actuator and valve are

mounted 90° rotated in

relation to each other.

Limit stop screws are not

set correctly.

Remove actuator from

valve. Check assembly code

of actuator. Put both valve

and actuator in “Closed”

position. Mount actuator on

valve.

Readjust the limit stop

screws.

DOC.IOM.BE.EN Rev. 9

Section 4

Section 5

Valve does not reach the

completely “Closed” or

“Open” position.

Actuator rotates, valve

does not.

Actuator does not

rotate or does not rotate

smoothly.

Limit stop screws cannot

be turned out anymore.

Insert is not mounted

properly.

Pressure to low. Apply pressure as per sizing.

Sizing is wrong.

Pinion is mounted in the

wrong position.

No coupling between

actuator shaft and valve

spindle.

Broken gearing on

pistons or pinion.

Spring or Spring

cartridge is broken.

Limit stop screws is

bend.

Mount the insert in the right

position. Remark: Rotate

insert to one cam = 22.5°.

Check valve torque data

with actuator torque data.

Re assemble actuator. Section 9

Install a coupling between

actuator shaft and valve

spindle.

Contact nearest Bettis

representative to replace

actuator.

Contact nearest Bettis

representative to replace

actuator.

Contact nearest Bettis

representative to replace

actuator.

Section 4.5

Section 4.5

Appendix A.

46

Troubleshooting

Page 51

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

10.2 Pneumatic Problems

Problem Possible error Solution Where to find

Actuator does not react

to electrical control

signal.

Actuator does not

react good to electrical

control signal.

Air leakage between

actuator and solenoid

valve.

There is no supply

pressure at the

actuator.

There is sufficient

supply air pressure but

insufficient supply air

capacity.

Supply pressure too

low, causing pilot

operated solenoid

valve to fail.

Solenoid valve is not

mounted properly.

Speed control throttle

(if present) blocks air

flow.

Manual override

(if present) on the

Solenoid Valve is

locked.

Sealing between

solenoid valve and

actuator is not

mounted air tight.

Section 10: Troubleshooting

Supply the right

pressure to the

actuator.

Take care the supply

air tubing has the right

dimensions.

Check that supply

pressure at the

actuator and solenoid

is sufficient to operate

the actuator.

Check the solenoid

valve mounting.

Turn the speed control

more open.

Unlock manual

override on the

solenoid valve.

Reassemble solenoid

valve taking care, that

all seals are in place.

March 2019

Section 2.3

Check that the actual

supply pressure is

higher than the sizing

pressure.

Section 4.6

Section 2.3

Check that the actual

supply pressure is

higher than the sizing

pressure.

Instructions shipped

with the solenoid valve.

Instructions shipped

with the speed control

valve.

Instructions shipped

with the manual

override.

Instructions shipped

with the solenoid valve.

Double-acting actuator

will only move to

“open” position.

Leakage notice on the

actuator.

Actuator has wrong

solenoid valve

configuration.

Seals on the limit stops

screws are not air tight.

Seals on the end caps

are not air tight.

Seals on the pinion top

and bottom are not air

tight.

Mount a solenoid valve

suitable for doubleacting actuators

(4/2 or 5/2 function).

Check that conversion

plate on solenoids, that

have both 3/2 and 5/2

functions, is in the right

position.

Turn the lock nut of the

bolts tighter; until the

leakage stops.

Disassemble the end

caps, replace O-rings

and reassemble.

Consider to replace

all O-ring seals and

bearings.

Disassemble the

complete actuator,

replace O-rings and

reassemble. Consider

to replace all O-ring

seals and bearings.

Instructions shipped

with the solenoid valve.

Instructions shipped

with the solenoid valve.

Section 9.6

Section 9.6 or Section 6

Section 9.6 or Section 6

Troubleshooting

47

Page 52

Section 10: Troubleshooting

March 2019

Installation, Operation and Maintenance Manual

10.3 Electrical Problems

Problem Possible error Solution Where to find

Control wiring.

Power supply wiring or

feedback wiring are not

Actuator does not react

to control signals.

There are problems

with position feedback

after sending the

actuator to either the

“Open” or “Closed”

position.

right connected.

The power supply

voltage is not is not the

same as the voltage of

the applicable solenoid

valve.

The wiring of the

feedback signals may

be switched.

Connect all wiring in

the right way.

Connect the right

power supply voltage.

Connect the feedback

wiring in the right way.

DOC.IOM.BE.EN Rev. 9

Instructions of the

control or feedback

accessories.

Instructions of the

solenoid valve.

Instructions of the

feedback device.

48

Troubleshooting

Page 53

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

Section 11: Parts List and Spare Parts

March 2019

Section 11: Parts List and Spare Parts

Recommendations

11.1 Actuator sizes RPE25 to RPE600

23

27

26

21

19

18

6

30

33

31

32

1

16

15

14

17

19

21

3

28

2

7

11

12

8

10

5

13

9

10

Table 16. Parts List

Pos. Qty Notes Description Material

1 1 House Cast Aluminium alloy

2 2 1 B-port seal Nitrile rubber

3 1 Center plate (optional) Nylon PA6, Black

5 2 2 End cap SR (DA) Cast Aluminium alloy

6 2 2 End cap DA Cast Aluminium alloy

7 Max. 12 Spring cartridge Spring steel

8 8 End cap screw DA Stainless Steel

9 8 End cap screw SR Stainless Steel

10 8 End cap screw washer Stainless Steel

11 2 1 O-ring end cap Nitrile rubber

12 2 Warning sticker DA Polyester

13 2 Warning sticker SR Polyester

14 2 Piston Cast Aluminium alloy

15 2 1 Bearing piston PTFE 25% carbon-filled

16 2 1 O-ring piston Nitrile rubber

17 2 1 Bearing strip piston rack POM

18 2 Pinion High grade aluminium

19 2 1 Bearing pinion POM

21 2 1 O-ring pinion Nitrile rubber

23 1 1 Thrust bearing pinion POM, black UV stabilized

26 1 Indicator assembly ABS + stainless steel screw

27 1 1 Circlip Spring steel

28 1 Drive insert Aluminium

30 2 Limit stop screw Stainless steel

31 2 Limit stop nut Stainless steel

32 2 1 Limit stop washer PA66

33 2 1 O-ring limit stop Nitrile rubber

Notes:

1 Included in Service Kit.

2 Actuator sizes 25 to 100 have high end caps for double-acting and spring-return models. Actuator sizes

150 to 4000 have low end caps for double-acting models and high end caps for spring-return models.

Parts List and Spare Parts

49

Page 54

Section 11: Parts List and Spare Parts

Installation, Operation and Maintenance Manual

March 2019

11.2 Actuator sizes RPE950 to RPE2500

26

30

31

32

33

19

1

27

23

29

21

18

16

15

DOC.IOM.BE.EN Rev. 9

6

8

10

12

9

10

5

17

14

20

22

28

4

3

2

11

7

Table 17. Parts List

Pos. Qty. Notes Description Material

1 1 House Cast Aluminium alloy

2 2 1 B-port seal Nitrile rubber

3 1 Center plate (option) Nylon PA6, Black

4 12 Thread insert Steel

5 2 End cap SR Cast Aluminium alloy

6 2 End cap DA Cast Aluminium alloy

7 Max. 6 Springs Spring steel

8 12 End cap screw DA Stainless Steel

9 12 End cap screw SR Stainless Steel

10 12 End cap screw washer Stainless Steel

11 2 1 O-ring end cap Nitrile rubber

12 2 Warning sticker DA Polyester

13 2 Warning sticker SR Polyester

14 2 Piston Cast Aluminium alloy

15 2 1 Bearing piston PTFE 25% carbon-filled

16 2 1 O-ring piston Nitrile rubber

17 2 1 Bearing strip piston rack POM

18 1 Pinion High grade aluminium

19 2 1 Bearing pinion top POM

20 1 1 Bearing pinion bottom POM

21 1 1 O-ring pinion top Nitrile rubber

22 1 1 O-ring pinion bottom Nitrile rubber

23 1 1 Thrust bearing pinion POM, black UV stabilized

26 1 Indicator assembly ABS + stainless steel screw

27 1 1 Circlip Spring steel

28 1 Drive insert Aluminium

29 1 1 Backup ring POM

30 2 Limit stop screw Stainless steel

31 2 Limit stop nut Stainless steel

32 2 1 Limit stop washer PA66

33 2 1 O-ring limit stop Nitrile rubber

Notes:

1 Included in Service Kit.

13

50

Parts List and Spare Parts

Page 55

Installation, Operation and Maintenance Manual

DOC.IOM.BE.EN Rev. 9

11.3 Actuator size RPE4000