Page 1

Multi-Port Actuator

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Release: Mar 2013

Page 2

WARNING:

Use caution when working on, with, or around valves and actuators. High pressures, forces, voltages, and

flammable media can be present.

WARNING

Read this manual in its entirety before installing, operating, or performing maintenance on the MPA valve

actuator.

WARNING

Failure to follow instructions for proper electrical wiring, storage, setup, and maintenance may cause

serious injury, damage equipment, or void the warranty. Refer to Manual E796 for instructions on storage,

electrical hook-up, and maintenance.

Ensure that the installation is carried out in accordance with EN 60079-14 and IEC 60079-14.

Regulatory information:

EEx d IIB T4 or EEx d IIB 120 degrees C (T4)

Tamb-20degress C to +60 degrees C

Revision N

Copyright © 2013

Emerson Process Management

All rights reserved.

II 2GD

Emerson Process Management

Valve Actuation LLC

13840 Pike Road

1-800-679-1561

(281) 499-1561 FAX (281) 499-8445

Page 3

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Table of Contents

Section 1: Introduction ........................................................ 1

Section 2: Features ...............................................................2

Section 3: Mechanical and Electrical Installation .................. 5

Section 4: Wiring ................................................................. 6

4.1 Power Wiring ................................................................................................ 6

4.2 Network Wiring ............................................................................................ 6

4.3 Monitor Relay Wiring..................................................................................... 6

4.4 Local ESD Wiring (Emergency Shutdown) ...................................................... 6

4.5 Optional Remote Display Module (RDM) Wiring ............................................ 7

Table of Contents

Mar 2013

Section 5: Local Display Module ........................................... 8

5.1 Description ................................................................................................... 8

5.2 Operation ..................................................................................................... 9

5.3 Local Operation ............................................................................................. 9

5.4 Operational Display ....................................................................................... 9

5.5 Display Blanking .......................................................................................... 10

5.6 Alarms Display ............................................................................................ 10

Section 6: Field Setup Using MPA Config Software .............. 12

6.1 CommSetUp ............................................................................................... 12

6.2 User Setup Menus ....................................................................................... 13

6.3 Selecting New Home Port (HP command using Control Knob setup) ........... 14

6.4 Home Port LED Function ............................................................................. 15

6.5 Home Port Calibration (HC command using Control Knob setup) ................ 15

6.6 Factory SetUp Menus .................................................................................. 16

6.7 Motor Type ................................................................................................. 16

6.8 Control Screen ............................................................................................ 18

Section 7: Field Setup Using Local Controls ......................... 20

7.1 Alarm History Display .................................................................................. 20

7.2 Setup Mode Display Sequence .................................................................... 20

Table of Contents

Section 8: Field Diagnostics ................................................ 23

8.1 Fd Fault Codes ............................................................................................. 23

Section 9: Remote Network Control ................................... 25

9.1 Modbus RTU ............................................................................................... 25

9.2 Foundation Fieldbus (FF) ............................................................................. 27

9.3 Probus DP Reduntant Networks with Redcom ........................................... 29

9.4 DeviceNet ................................................................................................... 30

I

Page 4

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Appendix A: EC Declaration of Conformity Certificate ......... 31

Appendix B: Wiring Diagrams ............................................ 32

B.1 Three Phase Power ...................................................................................... 32

B.2 Single Phase Power ......................................................................................33

B.3 24 VDC Power ............................................................................................. 34

Table of Contents

Mar 2013

II

Table of Contents

Page 5

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Section 1: Introduction

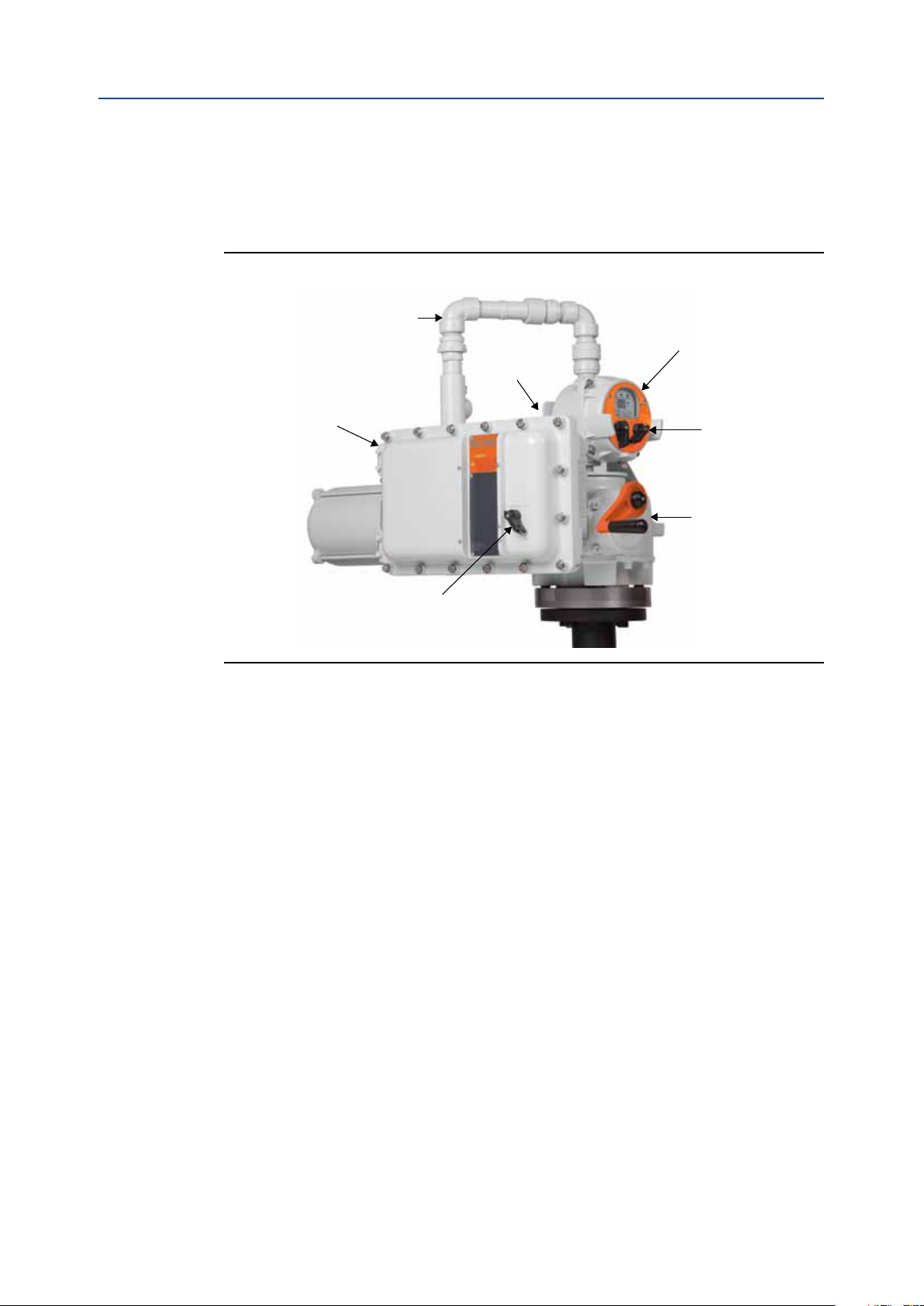

The Multi-Port Actuator is an single turn actuator for control of multi-port ow selectors

(MPFS) with 3 to 8 ports. A typical application is oil or gas well selection for well production

testing as shown in Figure 1. Typically the MPA is the actuator of a Multi-Port Flow Selector

as shown in Figure 2. There are applications in other processes where control of multi-port

valves is required.

Figure 1 Typical Well Test Application

Section 1: Introduction

Mar 2013

Figure 2 MPA mounted on 6"x16" MPFS

Introduction

1

Page 6

Section 2: Features

Low Voltage

Interfaces between

CPU and TBM

Electrical Enclosure with

Motor Starter, Control

Transformer, DC Power

Supplies, Power Entry,

Termination Panel, User

Wiring, I/O Interfaces,

Torque Encorder

Integral

Disconnect

BETTIS 3000 Ft-Lb Gearbox

Geared for 1.5 RPM

Position Encorder

Coupling to MPFS Stem

Local Display Module (LDM)

with Display & Status LEDs,

Selector & Control Knobs,

CPU Module,

Network Communications,

Position Encoder

Motor

(not shown)

Mar 2013

Section 2: Features

The actuator features several assemblies as shown in Figure 3. Unique features of the

actuator are listed below.

Figure 3 MPA Features

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

• MPA uses Bettis’s heavy duty gearbox with capacity of 3000’ lbsThreaded Valve

Stem

— Wide range of motors available for any voltage and torque

• Congurable for multi-port ow selectors from 3 to 8 ports

— Any port may be selected as home port and any port(s) may be skipped

— Actuator calibrated at factory for exact match to alignment of ow

selector ports

— Calibration parameters stored in nonvolatile memory and available to DCS

• 12-bit magnetic encoder coupled directly to valve stem for precision position

feedback

— Provides position measurement resolution of 0.088 degrees

• BETTIS’s exclusive solid-state motor starter and control software provides precise

positioning of ow selector within +1 degree of selected port

• High performance microcontroller updates motor control output every 4mS for

precision motor control

• 12-bit magnetic encoder coupled directly to torque pinion for torque feedback

— Provides torque measurement resolution of 0.146% of full torque

2

Features

Page 7

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

• MPA supports all network protocols available with all other Bettis actuators

• I/O and alarm monitoring include:

• Four models support ve 8-port MPFS (Also see motor type, Table 4)

Section 2: Features

Mar 2013

— Modbus RS485 Bus or E>Net ring available

— Probus Redundancy with Redcom

— Foundation Fieldbus

— DeviceNet

— Ethernet Modbus TCP/IP

— Integral circuit breaker/disconnect

— Motor overload and motor thermal

— Loss of control voltage

— Encoder failure

— Stall detection and alarming (detects mechanical faults)

— 3-Phase monitoring and phase correction to insure correct motor rotation

— ESD to send selector to home port (also goes to home port on fault)

— Monitor relay for hardwired relay contact status on fault

Table 1. Four models support five 8-port MPFS

Model MPFS

MPA 150 2x4 150 203 1.0 1.0 1.0 0.79

MPA 650 3x6 650 881 0.7 1.0 0.5 0.49

MPA 800 4x8 & 4x10 800 1085 0.6 0.9 0.5 0.40

MPA1500 6x16 1500 2034 0.3 0.5 0.3 0.26

Note: Accuracy based on worst case tests at 38% of maximum torque.

Capacity RPM Accuracy

Lb/Ft Nm 1Ph 3Ph DC Degrees

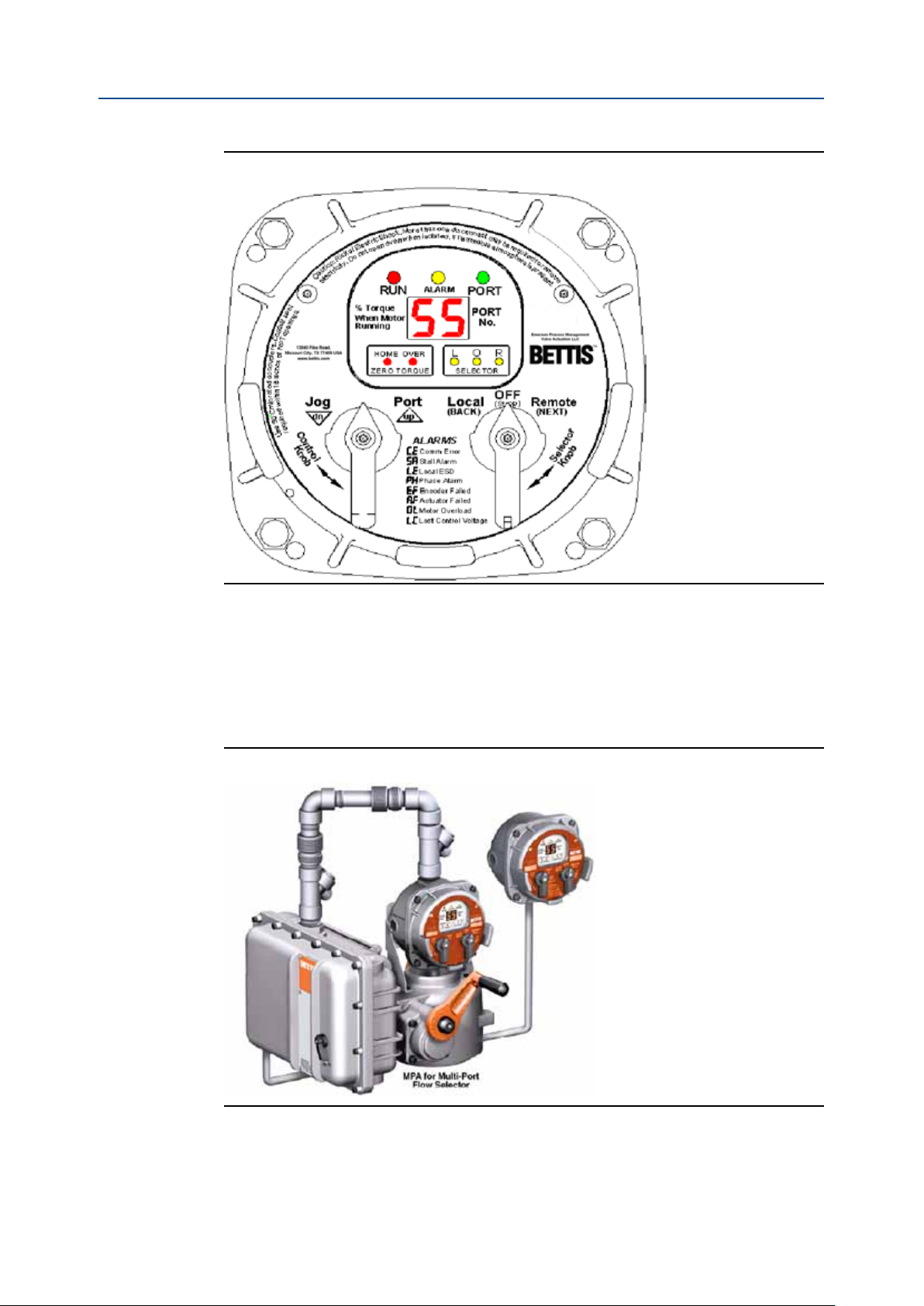

• MPA includes local display module (LDM) standard

— Uses rugged, high visibility LED display for port number, torque, and

alarms (also displays setup menus and setup parameters)

— Multiple color LEDs display

— Port position within 1° of port

— Port position within 2° of port

— Motor running

— Over torque

— Position within 0.25° of home port

— Local mode |

Features

— Off mode | Combined detection logic for two

selector switches

— Remote mode |

— Includes Local Off Remote selector switch

— Local control knob for Port selection and Jog control when enabled by

User

3

Page 8

Section 2: Features

Mar 2013

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

Figure 4 Local Display Module (LDM)

• Remote display module (RDM) option available

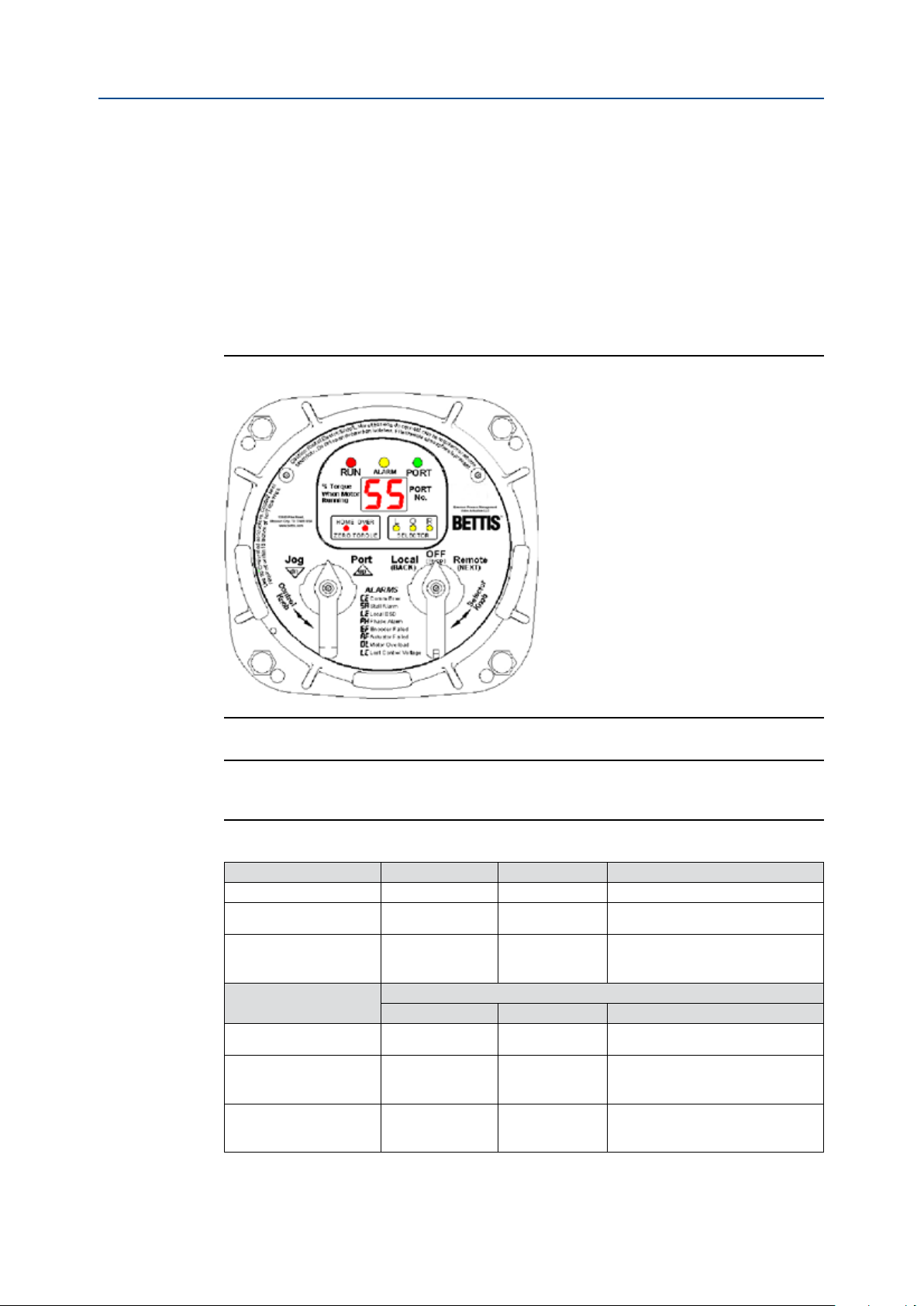

— RDM displays identical information and performs identical control as LDM

— BETTIS’s patented combined switch logic allows detection of selector

switch position on LDM and RDM

— Allows remote control up to 4,000 feet (1,220 meters) away

— Alarming includes loss of communication with RDM

Figure 5 MPA with Remote Display Module (RDM)

4

Features

Page 9

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Section 3: Mechanical and Electrical Installation

Section 3: Mechanical and Electrical

Installation

Do not connect power until you have gone through the following checklist

1. Does the information given on the nameplate correspond with the application?

2. Have all wire terminations and the equipotential bonding system been connected

correctly?

3. EEx d applications: are the cable entries, plugs and adaptors EEx d approved?

4. Are all cable entries of the correct internal diameter providing a good seal around

the cable?

5. Do the ambient and process temperatures correspond to the ratings on the

nameplate as shown below?

Mar 2013

Mechanical and Electrical Installation

5

Page 10

Section 4: Wiring

Mar 2013

Section 4: Wiring

All user wiring terminations are made inside the Electrical Enclosure shown in Figure 3 on

Page 2. Refer to wiring diagram located at the back of this manual for wiring connections.

High voltage power connections are made to the disconnect/circuit breaker located inside

the electrical enclosure. All low voltage connections, including network wiring, are made

to the Termination Board Module (TBM) located inside the electrical enclosure. Use conduit

and seals in accordance with National Electric Code (NEC) and local codes for all wiring

entering the electrical enclosure.

4.1 Power Wiring

Connect power voltage leads to the circuit breaker located in the main electrical enclosure.

Power wires must enter the electrical enclosure at the conduit entry on the lower right side

of the enclosure to prevent water from entering. The controller provides automatic phase

correction in case three-phase power is connected in the wrong phase rotation.

4.2 Network Wiring

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

If a single bus network connection, such as Foundation Fieldbus, is being made,

connect to Network Port A at TBM terminals 24 (-) and 25 (+). If the cable is shielded,

connect shield to TBM terminal 23. If redundant or repeater network connections such

as Bettis E>Net are being made, connect the second network to Network Port B at TBM

terminals 23 (+) and 24 (-). Connect cable shield of Port B to TBM terminal 25. Cable

shields are isolated from earth in the actuator. Connect shields to only one earth ground

point in the network, normally the host location.

4.3 Monitor Relay Wiring

The Monitor Relay is used for hard-wiring an indication of availability of the actuator for

remote control. When the selector switch is placed in the Remote mode and if there are no

alarms present that prevent operation, the Monitor Relay is energized. If an alarm occurs

or the selector switch is moved from the Remote position, the relay is de-energized. The

Monitor Relay is a Form C relay with both normally open (N.O.) and normally closed (N.C.)

contacts. Wire to either TBM terminals 31 and 32 if N.O. contacts are desired. Wire to TBM

terminals 32 and 33 if N.C. contacts are desired. The relay is shown on the wiring diagram

in the de-energized state, meaning that the actuator is not available for remote control.

4.4 Local ESD Wiring (Emergency Shutdown)

Remove jumper between TBM terminals 27 and 28. Connect Normally Closed (N.C.) dry

contacts to terminals 27 and 28. When the contacts open, ESD is activated, causing the

actuator to go to Home Port. The actuator will remain at the Home Port until the ESD

contacts are closed and a new command is received from either Local or Remote control.

The ESD circuit is a closed loop failsafe circuit. It the circuit is opened for any reason, broken

wire, bad contact, 24VDC power supply failure, etc., the ESD function is activated. The

closed loop circuit is powered by 24VDC from the actuator.

6

Wiring

Page 11

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Section 4: Wiring

Mar 2013

4.5 Optional Remote Display Module (RDM) Wiring

Connect twisted pair RS485 cable from the RDM to TBM terminals 18 (-) and 19 (+). If

the RDM is being powered from the actuator 12VDC supply, wire the power wires from

the RDM to TBM terminals 16 (-) and 17 (+). The RDM is polarity protected, preventing

damage, but will not operate if polarity is reversed.

Wiring

7

Page 12

Section 5: Local Display Module

Mar 2013

Operation and Maintenance

Section 5: Local Display Module

5.1 Description

Contains microprocessor controller, position encoder, and network interface. This is the

main controller used to setup and operate the actuator.

This module displays operating parameters, port position, torque, and alarms. It also

provides a means to congure the actuator by using the local controls.

Figure 6 Local Display Module

Part Number: MPA-0400-0313, Rev. N

To use the Local Control and Selector Knobs refer to Table 2.

NOTE:

Actuator moves in only the counterclockwise direction.

Table 2. Selector/Control Knob Function

Selector Knob (right) Rotate Function Results

OFF (Stop) [return position] Stop movement Prevents motor operation.

REMOTE (Auto) Clockwise Remote control

LOCAL (Hand) Counter-clockwise Hand Operation

Control

Knob (left)

Spring return Neutral position No operation

PORT (up) Clockwise

Jog (dn) Counter-clockwise

(while selector is in LOCAL (Hand) mode)

Rotate Function Results

Local command

to go to next

port

Local command

to micro-step

Allows control from remote

location.

Allows from the local control knob

or the control knob of the RDM, if

connected.

Releases a local command when

Local control is used.

Commands actuator to move to

the next port. Momentary knob

control.

Commands actuator to move only

whileknob is being held, i.e. maintained knob control.

8

Local Display Module

Page 13

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

5.2 Operation

Place the “Selector Knob” in the desired operating position

1. LOCAL – hands on operation at the actuator by manipulation of Control Knob.

2. REMOTE – used within the context of plant operation, i.e. Remote Control Panel,

PLC, DCS, etc. See wiring diagram for typical user wiring for remote control.

3. OFF (Stop) – to prevent local or remote operation.

Figure 7

Section 5: Local Display Module

Mar 2013

5.3 Local Operation

Place the “Selector Knob” in the “Local” position. If a remote display is connected, the

remote selector switch must not be in the “Off” position. Verify that the selector “L” amber

light is on. The actuator may now be operated using the port and jog Control Knobs. Jog

control is normally disabled and must be enabled in the setup menu.

To jog or micro-step the actuator toward the next port, rotate the control knob in the

counterclockwise direction. Jog to position and release when the desired position is

reached. When using jog for calibrating the actuator, always stop short of the desired port

and use the hand wheel to complete accurate positioning to center of the port.

To move only to the next port, momentarily rotate the control knob in the clockwise

direction to the Port position and release.

To Stop or prevent actuator movement, move Selector knob to the OFF (Stop) position.

5.4 Operational Display

Operational indicators for RUN / ALARM / PORT position use long lasting LED’s. Run torque

and port position are shown on the digital readout during normal operation. Torque in

percent of maximum is displayed as a 2-digit number only while the motor is running. Port

position is displayed as a single digit when the motor stops. If the actuator stops between

two ports, the two corresponding port numbers will alternate. Torque less than 10% is

displayed as 0% because torque between 0 and 10% cannot be accurately measured.

Local Display Module

9

Page 14

Section 5: Local Display Module

Mar 2013

1. RUN LED ashes Green while the actuator is moving to the next port and ashes

Red while running within 2° of the selected port position.

2. PORT LED ashes Green when the actuator is within 2° and outside 1° prior to the

setpoint of the selected port. The port LED ashes Red when within 2° and outside

1o beyond the setpoint. The port LED illuminates steady Green while within 1° of

the selected port position.

3. ALARM (Yellow) LED ashes when any alarm is present, otherwise it remains off.

4. OVER TORQUE alarm condition is indicated when a torque alarm occurs in mid-

travel. The over torque LED will ash so long as the over torque condition exists.

5. HOME PORT LED will light when the actuator is within 0.25° of the user selected

Home Port position.

Selector switch LEDs are also made available for operational use in the bottom right corner.

The selector LEDs are important when using a Remote Display Module (RDM) because

these LEDs indicate the combined logic of the two selector switches, i.e. the selected mode

of operation of the actuator. All three LOR LEDs ash while the actuator is in setup mode.

5.5 Display Blanking

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

The user has the option to have the display blank out (turn off) when not in use. This is

a very important feature for solar power applications because power consumption is

minimized. Option to enable or disable display blanking timeout is available by setup using

MPA Cong or the control knobs. See the eld setup section for selecting the option. When

control knobs are used for setup, the parameter is C9 as shown in the table on Page 21. The

default setting is display blanking timeout enabled for 24VDC versions and disabled for AC

versions. If display blanking is enabled, the display will blank out after 60 seconds when left

unattended while the selector switch is in Remote mode. The display will blank out after 3

minutes when left unattended while the selector switch is in Local mode. The display will

not blank out while in setup mode. When selected, display blanking applies to both local

(LDM) and remote (RDM) displays.

5.6 Alarms Display

When an alarm occurs, it is automatically displayed by the two character LED display.

The yellow ALARM LED will ash while any alarm is present. The display will alternate

between the current port position and the active alarm(s) except when stopped between

parts. If more than one alarm is active, the display will cycle through a sequence of Port

Position, newest alarm, Port Position, next oldest alarm and so on until all active alarms

are displayed. The cycle is continuously repeated until all alarms are cleared. Each alarm

is recorded in an Alarm History. The alarm history may be viewed by entering setup mode

(see next section).

All possible alarms that may be displayed are listed on the name plate of the Local Display

Module (LDM). Following are denitions of the listed alarms.

10

Local Display Module

Page 15

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

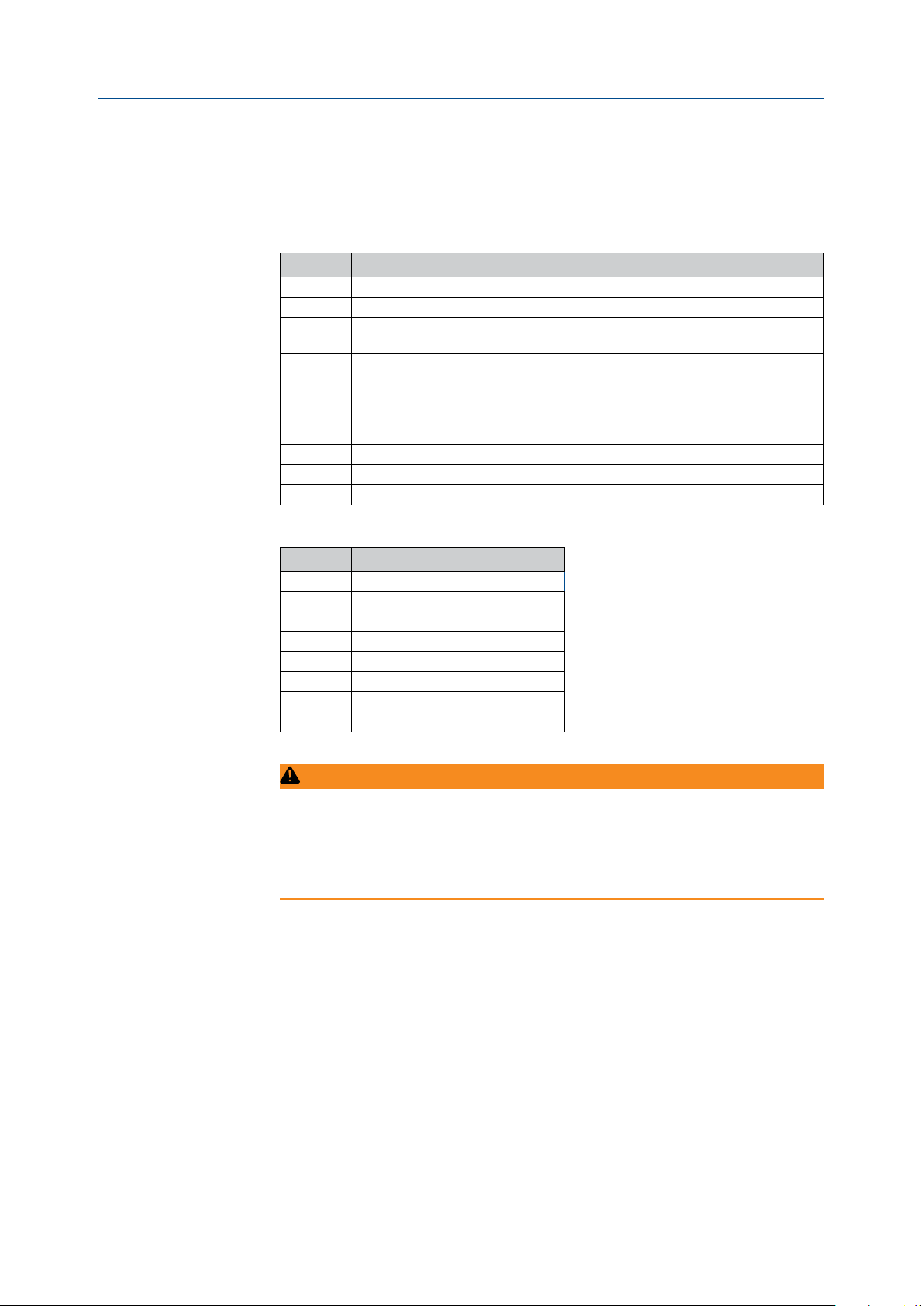

Table 3. Alarm List

Alarm Definition Details

CE Communication Error

SA Stall Alarm

LE Local ESD Hardwired Local Emergency Shut Down is active.

PH Phase Alarm Loss of one phase when congured for 3-Phase.

EF Encoder Failed Failure of either the position or torque encoders.

AF Actuator Failed

OL Motor Overload Motor thermals or motor overload relay has tripped.

LC Lost Control Voltage

NOTE:

Over torque alarm is displayed by dedicated LED. See Operational Display section above.

Section 5: Local Display Module

Mar 2013

Lost communication with the Remote Display Module (RDM) when

congured.

Actuator failed to move within 8 seconds after commanded by

either local or remote controls.

A fault is detected by hardware electronics fault monitor. This is a

non-recoverable condition that requires actuator service.

Loss of power to the motor control circuits. The control voltage

supply has an automatic resetting fuse.

Local Display Module

11

Page 16

Section 6: Field Setup Using MPA Config Software

Mar 2013

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

Section 6: Field Setup Using MPA Cong

Software

MPA Cong is a Windows application for conguration, calibration, test, and operation of

the MPA. MPA Cong is compatible with Windows XP, Windows 7, and Vista. Connection

to the MPA requires a RS485 link. It may be necessary to use a USB to RS485 converter

for connection of a PC to the RDM port of the actuator. RDM port is TBM terminals 18 (-)

and 19 (+). Load the software to a laptop or other compatible PC device and connect the

RS485 link to the TBM in the electrical enclosure. If opening the enclosure is undesirable,

conguration may be performed using the local control knobs of the actuator as

described in the next section of this manual. If the system is congured for Modbus

networking, the PC may be connected to the local area network at any location in the

network. The MPFS factory uses this software to congure and calibrate the MPA and

saves the conguration to a “.mpa” le by MPFS serial number. Should loss of factory

conguration or port calibration occur due to failure of a CPU module or user error, a copy

of the le may be obtained from the MPFS factory and loaded to the actuator using MPA

Cong Software.

6.1 CommSetUp

First select the CommSetUp screen shown in Figure 8 to congure the network

communication link.

Figure 8

12

If connected to the RDM port, set the computer Baud Rate to 9600, Parity None and Stop

Bits to 1. Set the Slave Address to 254. The RDM port conguration of the MPA is x at

9600,N,8,1, address 254 and may not be changed by the user.

Field Setup Using MPA Config Software

Page 17

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

If connected to a Modbus local area network, the baud rate and slave address congured

for the actuator must be known in order to setup the computer communication port.

Default conguration for the MPA network port is 19,200 baud and slave address 254.

There are two universal addresses of 99 and 254. Addresses 1-98 and 100-254 are unique.

HELP: Clicking the ? button at the top of the screen and then passing the cursor across

each button will cause a description of that button to be displayed.

6.2 User Setup Menus

To congure the actuator, select the User Setup Menus tab shown in Figure 9.

Figure 9

Section 6: Field Setup Using MPA Config Software

Mar 2013

From this screen Alarm History of the last eight accumulated alarms may be

viewed. Conguration may also be viewed without a passcode. In order to change

conguration, a valid passcode must be entered. Click on “Enter User Password” button

near the bottom of the screen and the screen shown in Figure 9 will display. Enter the 4-

digit passcode and click Enter. You may now edit conguration, including a new passcode

as shown in Figure 9. If the passcode is changed, be sure it is recorded and kept in a safe

place. The default passcode is 0000.

Figure 10

Field Setup Using MPA Config Software

13

Page 18

Section 6: Field Setup Using MPA Config Software

Mar 2013

The Network SetUp changes conguration only for the network ports. It does not affect

the RDM port. If a pipeline is not connected to any one or more ports, or if it is desirable to

skip any one or more ports, click on the “Delete Port” number. The deleted ports will be

skipped when a next port command is issued in either local or remote control modes.

NOTICE:

When conguration changes are made, click the “Write” button at the bottom of the

screen to transfer the new parameters to the actuator. The “Read” button may be used

to refresh the screen to verify the parameters have been properly written and stored in

the actuator. To ensure the new conguration values are written to EEPROM, click on the

Factory tab and then click Force EEPROM Write. Within several seconds the three LOR

LEDs will simultaneously ash slowly. This slow ash is a signal that all new values were

successfully written to EEPROM.

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

6.3 Selecting New Home Port (HP command using

Control Knob setup)

The User may select any port as the new “Home Port” in the eld. When a new home

port is selected, the new home port is identied as Port 0 or 8 and the MPA reassigns all

other port numbers (1-7) in a counterclockwise sequence around the MPFS. The MPA

recalculates the exact calibrated port position based on factory calibration values so no

accuracy is lost.

To select a new home port, click on the “Set Home Port” button shown in Figure 11. The

Pop-Up shown in Figure 9 will appear. Enter the new home port number 1-7 relative to the

factory calibrated port assignments and click “Enter”.

Figure 11

14

Field Setup Using MPA Config Software

Page 19

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

NOTE:

When a new home port is selected, it must be a port without piping connected and

must be tted with a blind cover to allow for future seal inspection and visual port

alignment. Selecting a new home port will cause the MPA to recalculate all calibration

parameters based on the factory calibration and store the new values to EEPROM.

Section 6: Field Setup Using MPA Config Software

6.4 Home Port LED Function

The home port LED on the LDM will now identify the newly selected home port position.

This LED is on when the actuator is within 0.25 degrees of the selected home port. When

the blind cover of the home port is removed in the eld to inspect the seals, the home zero

may be veried and corrected if an error is detected.

6.5 Home Port Calibration (HC command using

Control Knob setup)

Mar 2013

If maintenance is performed on the actuator that can cause loss of calibration, the home

port must be re-calibrated. Examples of maintenance that affect calibration are removal of

the actuator from the MPFS and replacement of the position encoder. If a MPA is removed

from one MPFS and installed on another or if a CPU module is replaced, the factory

conguration (.mpa) le for the MPFS must be loaded to the new actuator and the selected

home port calibrated. To calibrate the home port position, remove the blind cover from

the selected home port. Use the hand wheel of the MPA to position the plug seal over the

port as precisely as possible. Click on the “Cal Home Port” button shown in Figure 9. To

avoid accidental setting of a new home port, the user is required to enter a passcode of 43

to gain access. A Pop-Up will appear as shown in Figure 12, providing a warning and allow

entry of the passcode.

Figure 12

Field Setup Using MPA Config Software

15

Page 20

Section 6: Field Setup Using MPA Config Software

Mar 2013

Operation and Maintenance

6.6 Factory SetUp Menus

All factory settings may be viewed but some items in Factory Setup require a Factory

Password to change them. The protected items are, RDM Required, Motor Type, Reset User

Password, and Calibrate Ports. The user may load or save a “.mpa” conguration le from

or to a PC.

Figure 13

Part Number: MPA-0400-0313, Rev. N

For precise MPFS port alignment, the factory calibrates each actuator to each of the

ports of the mated MPFS. The calibrated values are displayed on this screen and may be

compared to the current position (Encoder Feedback) to determine accuracy. When a new

home port is selected by the user, these calibration values are recalculated and stored to

EEPROM.

6.7 Motor Type

Motor Type is entered at the factory for the type of MPFS, power supply and motor horse

power rating as shown in the table below. Motor type is displayed on the MPA Confg

Factory Setup Menu for information only and cannot be edited.

Table 4. Motor Type

Motor

MPFS

2X4 1/12 2 6 10 14 18 22 26 -------2x4 1/6 --------- --------- --------- --------- --------- --------- --------- 30

3X6 1/6 3 7 11 15 19 23 27 31

4X8 1/6 4 8 12 16 20 24 28 32

6X16 1/6 5 9 13 17 21 25 29 33

6X16 1.5 --------- --------- --------- --------- 1 --------- --------- --------

HP

1 PH

115

VAC

1 PH

230

VAC

3 PH

220/230

VAC

3 PH

380

VAC

3 PH

415

VAC

3 PH

460

VAC

3 PH

575

VAC

24

VDC

16

Field Setup Using MPA Config Software

Page 21

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

NOTE:

The user is not required to select motor type unless qualied to download rmware

upgrade to the MPA. If a new HEX le for rmware upgrade is loaded to the MPA in the

eld, the motor type must be congured before the actuator will operate. When power

is rst applied to the MPA after a rmware upgrade, in order to know how to initialize

the electronics, the Motor Type stored in the EEPROM will be examined. If a new HEX le

was just downloaded, it will not yet have a Motor Type (it will be ZERO). When rmware

sees that the Motor Type is ZERO, rmware will immediately go to the display entry in the

Factory Setup Menu for Motor Type. The user will NOT have to move the left control knob

back and forth to go to Setup Mode or enter a passcode. The user will see alternate display

of "F1" and "0". The "F1" is the abbreviation for Motor Type in the factory setup menu, and

the current value is 0. Then the user (who just now completed the hex le download) will

have to use the left hand control knob to increment the display number to the correct

Motor Type (from 1 to 33 shown in the Table 4). Then a move of the right hand selector

knob either left or right will force an exit out of the Setup Menu in this unusual one-time

circumstance after a HEX le download.

Now the rmware will examine the Motor Type and know how to initialize the electronics.

Section 6: Field Setup Using MPA Config Software

Mar 2013

Normally when power is applied to the MPA, if it is NOT after a new download of the HEX

le, the Motor Type will already be non-ZERO so the rmware will know how to initialize the

electronics without forcing the user to use the knobs.

Field Setup Using MPA Config Software

17

Page 22

Section 6: Field Setup Using MPA Config Software

Mar 2013

6.8 Control Screen

The control screen (see Figure 14) is a valuable tool for commissioning the system. All

functions of the system may be tested prior to commissioning with the DCS. This screen

may be used to troubleshoot any problems should they occur. Field diagnostic

messages are displayed in the “Field Diagnostics Information” box. All active alarms may

be viewed at a glance in the “Alarms” section of the Control Screen.

Figure 14

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

1. “Mode” displays the mode selected by the selector switch of the LDM or

combined logic of both LDM and RDM selector switches.

2. “Status” displays Running or Stop state of the actuator.

3. “At Port” displays the port number position of the actuator and whether the MPA

is at the port within 1 degree or within 2 degrees.

4. “Torque” is displayed as percentage of the full torque rating of the actuator. Torque

is displayed from 10% to 99% in 1% increments. Torque less than 10% is displayed

as zero because torque between 0% and 10% cannot be accurately measured.

5. “Encoder Value” is the 12-bit raw data from the position encoder in the range of

0 to 4095. This value is also displayed on the Factory Setup screen so it can be

compared to port calibration value of each port.

6. “Valve Control” allows commanding the actuator to go to the next port or go

to a desired port number. “Go to Port” is the new setpoint in the range of 0 to

7. “Current Setpoint” is the last commanded value stored in the actuator. Each

time the actuator is powered up or it torques out while moving, it loads an

invalid setpoint of 255 to the “Current Setpoint”. This prevents the actuator from

moving until a valid setpoint from 0 to 7 is entered in the “Go to Port” and sent to

the actuator. If “Next Port” button is clicked while 255 is in the “Current Setpoint”,

then the next higher port number from the current position will be loaded to the

current setpoint.

18

Field Setup Using MPA Config Software

Page 23

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Section 7: Field Setup Using Local Controls

Section 7: Field Setup Using Local Controls

Use the Local Control (left) knob and Selector (right) knob to enter setup mode and to

execute Setup functions. The table below (see Table 5) outlines the knob functions for

Setup mode.

To access the Field SETUP mode of operation ensure the Selector Knob is placed in the

OFF (Stop) position. Once set, rotate the Control Knob to the “UP” & then to the “DOWN”

position in right to left succession three times. Keep the knob in each position for at least

½ second but not more than 3 seconds. The display module will ash the (3) amber LOR

selector LED’s when the SETUP mode is enabled.

Figure 15

Mar 2013

Table 5. Selector / Control Knob Setup Function

Selector Knob (right) Setup Function Results

Allows entry to SETUP mode.

OFF (Stop) [return position] neutral position

Clockwise (REMOTE) (Auto) NEXT

Counter-clockwise (LOCAL)

(Hand)

BACK Backs up to the last menu item.

Completes NEXT, or BACK entry

cycle, except when knob is held for

scrolling through various menus.

Advances to the next menu item.

Displayed data is accepted.

Control Knob (left) Setup Function Results

Completes UP or Down entry Cycle

Spring Return to Center neutral position

Clockwise (CLOSE) UP Increments displayed data.

Counter-clockwise (OPEN) DOWN Decrements displayed data.

except when knob is held for

continuous data entry update.

Field Setup Using Local Controls

19

Page 24

Section 7: Field Setup Using Local Controls

Mar 2013

When the actuator LDM is placed in SETUP mode of operation it rst displays the Field

Diagnostics (Fd) menu item. The second menu item Alarm History (AH) menu. The eld

diagnostics and alarm history may be viewed without entering a passcode (See Field

Diagnostics and Alarm History Display section).

NOTE:

On any setup menu, use up/down to change a parameter and back/next to accept the

displayed parameter. All menus and all parameters are wrap around, meaning they will

advance from the highest or last value to the lowest or rst value.

To view or change setup parameters of the actuator, Rotate the Selector Knob to the

right or NEXT position to cycle through the alarm history display A1 through A8 until

P1is displayed. Alarm history (A1-A8) may be skipped by changing AH(1) to AH(0) and go

directly to passcode menu. Passcode menu is displayed as two, 2-digit entries, P1 and P2.

The actuator is shipped from the factory with the passcode disabled, meaning that the

passcode is 00 00. Until the passcode is changed by the user, the passcode of 00 00 may be

accepted by using the NEXT selector knob sequence to accept the passcode and continue

to the setup menus. You will now be able to display and/or edit setup data. If you forget

your congured passcode, factory trained technicians can reset the passcode back to 00

00.

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

NOTE:

While in the SETUP mode the actuator will not turn on the motor control circuits & disables

all control of discrete outputs until exiting the Setup Mode.

7.1 Alarm History Display

Setup always enters the main menu at the Field Diagnostics (Fd) and the next menu

item is Alarm History (AH). The user may view the alarm history without having to enter

a passcode. The AH menu will alternately display a value of 0 or 1. Use the Control Knob

up or down to change the selection from 0 to 1 or 1 to 0. If display of the alarm history is

desired, then the value must be 1. When AH with a value of 1 is displayed, use the Selector

Knob REMOTE (NEXT) to advance through the alarms. If it is desirable to skip the alarm

history and advance to the setup menus, use the control knob to select a value of 0 and

then the Selector Knob Remote (Next) to advance directly to the P1 passcode entry. Alarms

are displayed by a sequence number A1 through A8. The display alternates between the

alarm sequence number (A1-A8) and the recorded alarm. A1 is the newest alarm and A8 is

the oldest alarm. Use the NEXT and BACK selector positions to cycle through the alarms.

Blanks are displayed for fewer than 8 alarms. The alarm history is cleared by cycling power

to the actuator. If it is desirable to only display alarm history and not go into setup, use the

LOCAL(BACK) selection repeatedly to back out of the alarm history and return to normal

operating mode.

7.2 Setup Mode Display Sequence

20

The three (3) amber LED’s for the LOR section ash to indicate Setup Mode. When in setup

mode, the user must enter the REMOTE (NEXT) or LOCAL (BACK) within 120 seconds or the

display will revert back to the normal display mode.

Setup data may be changed by using the UP & Down entries of the Control Knob. The

UP and Down entries are active only after a valid pass-code is entered and the Selector

Switch is in the STOP position. The default pass-code is P1 00 and P2 00. Once the correct

passcode is entered and accepted at the actuator controls, the user will then be able to

Field Setup Using Local Controls

Page 25

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

advance thru the displays shown in the Main Menu table on the following page.

The table on the following page (see Table 6) shows the sequence of the setup menus.

It also shows the selections, units, and defaults. Each time the REMOTE (NEXT) selector

knob is selected, the display advances to the next menu item. Each time the LOCAL (BACK)

selector knob is selected, the display backs up to the previous menu item. The UP and

DOWN control knob is used to increment or decrement the value shown in the table.

Following is an example for changing the Torque Limit. In this example the current torque

value is the default value of 60%.

1) Enter setup mode – Selector knob Off – Rock control knob back and forth until

3 selector LEDs begin to ash and Fd is displayed. When using the selector knob

to advance to the next menu or back to the previous menu, always return the

selector to the Off position to complete the cycle.

2) Use control knob to change the value of AH to 0 – Rotate selector knob clockwise

to Remote (Next) to display P1 (1st passcode). The display will alternate between

P1 and the value (default is 00). If the passcode has been changed, rotate the

control knob clockwise to advance the display to the correct 1st passcode. Rotate

the selector knob clockwise to advance to the next display, P2. The display will

alternate between P2 and value of the 2nd passcode (default is 00). If the passcode

has been changed, rotate the control knob clockwise to increment the display to

the correct 2nd passcode.

3) Repeatedly cycle the selector knob clockwise to advance to the next menu item

until C2 is displayed. This is the torque limit setting as shown in the following table.

The display will alternate between C2 and the value of C2 which we have assumed

to be 60.

4) Rotate the control knob clockwise to the “up” position to increase the torque limit

setting. Rotate the control knob counterclockwise to the “dn” position to decrease

the torque limit setting.

5) Repeatedly cycle the selector knob to the Remote (Next) position and the Off

position to advance though the remaining menu items until the EP (Exit Program)

is displayed.

6) If it is desirable to exit, use the control knob “up” to display a 1 value. Use the

selector knob Remote (Next) to select exit. The system and display will return to

normal operating mode.

Section 7: Field Setup Using Local Controls

Mar 2013

NOTE:

Use Selector Knob to select Menu and Use Control Knob to select Units.

Table 6. Setup Mode Parameter Values

Menu Parameter Value Units Default

Fd Field diagnostics 0-27 Fault code 0

AH Display Alarm History? 0-1

A1 1st latest alarm Alarm None

A2 2nd older alarm Alarm None

A3 3rd older alarm Alarm None

A4 4th older alarm Alarm None

A5 5th older alarm Alarm None

A6 6th older alarm Alarm None

A7 7th older alarm Alarm None

A8 8th older alarm Alarm None

P1 1st passcode 00-99 None 00

Field Setup Using Local Controls

0=No, Skip to 1st Passcode

1=Yes, Display History

21

Page 26

Section 7: Field Setup Using Local Controls

Mar 2013

P2 2nd passcode 00-99 None 00

Table 6 continued......

Menu Parameter Value Units Default

C0 Control Mode 0-1

C1 ESD Action 0-1

C2 Torque Limit 15-99 Torque in % 27

C3 Network Node Address 1-99

C4 Network Baudrate 0-3

C5 Network Parity 0-2

C6 Network Stop Bits 1-2

C7

C8 Disable Jog Control 0-1 0=No, 1=Yes 1

C9 Disable Display Timeout 0-1 0=No, 1=Yes 1

CA Home Port Number (0 or 8) 0-1 0=0, 1=8 0

HP

HC Accept Home Port Calibration 0 or 43 0=No, 43=Yes 0

d1 Delete port 1 0-1 0=No, 1=Yes 0

d2 Delete port 2 0-1 0=No, 1=Yes 0

d3 Delete port 3 0-1 0=No, 1=Yes 0

d4 Delete port 4 0-1 0=No, 1=Yes 0

d5 Delete port 5 0-1 0=No, 1=Yes 0

d6 Delete port 6 0-1 0=No, 1=Yes 0

d7 Delete port 7 0-1 0=No, 1=Yes 0

E1 Edit 1st Passcode 00-99 None 00

E2 Edit 2nd Passcode 00-99 None 00

EP Exit Program? 0-1

Calibrate Motor

Characteristics

Home Port

(User selected)

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

0=Discrete

1=Network

0=Stop/Stayput

1=Go to Home Port

99 = selection of default address

254 for other protocol CAM

modules

0=4800 1=9600

2=19200 3=38400

0=None

1=Odd

2=Even

1=1 Stop bit

2=2 Stop bits

0-1 None 81

0-7 Port No. 1-7 0

0=No, Return to last menu

1=Yes, Exit

1

1

99

2

0

1

22

NOTE:

RDM port conguration is xed at 9600,N,8,1 address 254 and may not be changed by the

user. Only the network port conguration may be changed. The address programmed for

the network port will be accepted by the RDM port in addition to address 254.

Field Setup Using Local Controls

Page 27

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Section 8: Field Diagnostics

Should trouble occur, the Field Diagnostics feature may be used to help diagnose the

problem. Field diagnostics provides more detailed and denitive feedback than the alarms,

i.e. possible root cause(s) for the alarm. For example, there may be many causes for an

Actuator Fail alarm. Field diagnostics may be displayed by MPA Cong as shown in Figure

16 (highlighted in yellow).

Figure 16

Section 8: Field Diagnostics

Mar 2013

Field diagnostic may be displayed by the local display by entering setup mode. In Setup

Mode, the rst entry is Field Diagnostics having visible code “Fd”. Its value is 0 if there is no

fault. If there is a fault, its code is from 1 to 28. If there are multiple faults, only the rst of

those faults in the following list will be seen. When that fault is corrected, the next fault will

display if present.

8.1 Fd Fault Codes

1. MCP23 Chip will not initialize (pertains to a three phase AC motor type)

2. Motor is wired to turn in the wrong direction

3. Self-detected wiring fault (Emergency Shut Down - LE)

4. Host transmitted ESD command (Emergency Shut Down - LE)

5. Lost Phase, pertains to a three phase AC motor type - PH

6. Motor has over-heated (Motor overload - OL)

7. Stall Alarm. No motor movement after excess time of power applied - SA

8. Lost Control Voltage (Loss of power for motor control - LC)

9. Contactor is engaged, but there is no AUX feedback (= Control Failure)

Field Diagnostics

23

Page 28

Section 8: Field Diagnostics

Mar 2013

10. SPI communication failure for GPA chip

11. AUX feed-back alarm (= Incorrect AUX feedback from contactor)

12. Three consecutive overshoots of the port

13. RDM is not communicating and is required (Communication Error - CE)

14. No input from Torque Encoder. Check for cable connection problems or encoder

15. Torque OCF bit is low. Power supply to the Torque Encoder is likely at fault

16. Encoder reports that Torque Encoder value is invalid

17. Torque Encoder Parity error

18. Torque Encoder Magnet is out of range

19. Over-Torque. Torque value is greater than the Torque Limit

20. Value from the Torque Encoder is out of range (invalid instead of over-torque)

21. No input from Position Encoder. Check for cable connection problems or encoder

22. Position OCF bit is low. Power supply to the Position Encoder is likely at fault

23. Encoder reports that Position Encoder value is invalid

24. Position Encoder Parity error

25. Position Encoder Magnet is out of range

26. Encoder Position inconsistent consecutive times. Expect Position Encoder problem

27. Stopped between ports (non-critical)

28. Home Port is the last port reached (stopped at Home Port, non-critical and may be

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

failure

failure

normal operation)

24

Field Diagnostics

Page 29

Operation and Maintenance

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Part Number: MPA-400-0711, Rev. N

Section 9: Remote Network Control

Section 9: Remote Network Control

9.1 Modbus RTU

The native language of the MPA is Modbus RTU. If other network protocols such as

Foundation Fieldbus are used, a Communication Adapter Module (CAM) module is installed

to translate between the selected protocol and Modbus. The controller supports Modbus

function codes 01,02,03,04,05,06,15,16. Following are the memory maps for discrete I/O

and unsigned 16-bit Holding registers used in this application. All memory maps shown are

zero based, i.e. register 1 = holding register 40002. reading Input Bit 0 using FC02 = 10001.

9.1.1 Discrete Input Map (Valve Status) and Alarms

Table 7. Discrete Input Map (Valve Status) and Alarms

Bit Input Detail

0 16 At commanded port within 1 degree

1 17 At commanded port within 2 degrees

2 18 Flow selector moving

3 19 Wrong direction alarm

4 20 Selector switch Local/Manual Mode

5 21 Selector switch Remote/Auto Mode

6 22 Over torque alarm

7 23 Stop between ports alarm

8 24 Flow selector stall alarm

9 25 Power monitor alarm

A 26 Motor thermal overload alarm

B 27 Phase monitor alarm

C 28 Local ESD alarm

D 29 Actuator fail alarm

E 30 No input (always zero)

F 31 Unit alarm (above alarms are OR’ed)

Mar 2013

Remote Network Control

These same status and alarm bits are duplicated in Modbus Registers 01, 06, 09

(40002, 40007, 40010) in the same bit sequence shown above.

9.1.2 Coil Map (Discrete Network Control)

There are only two coils used for discrete network control as follows. When Coil 10

is set by the host, the actuator resets the coil automatically when the command is

executed. When Coil 11 is set, the host must reset the coil before the actuator will

respond to any other command.

Table 8. Coil Map (Discrete Network Council)

Coil Detail

10 Go to next port

11 Host ESD command, Go to Home Port

2525

Page 30

Section 9: Remote Network Control

Mar 2013

9.1.3 Holding Register Map

These are the recommended registers to use. Other registers are active but the

user is cautioned not to use the data or write to any other registers.

Table 9. Monitor and Control Registers

Register Detail

01 Actuator status and alarms in the bit sequence shown for the input map

06 Actuator status and alarms in the bit sequence shown for the input map

07

09 Actuator status and alarms in the bit sequence shown for the input map

11

13 Raw 12-bit position encoder value (0-4095)

14 Port position (0-4095)

15 Torque (0-4095)

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

Last Port position reached (0-7 or 1-8)

(See CA Home port number on Page 22)

Port position Setpoint (0-7 or 1-8)

(Data must be a single digit between 0 and 7 or 1 and 8 depending on Home

conguration) (See CA Home port number on Page 22) (MPA returns 255

(0xFF) in register 11 when the commanded port is reached)

Table 10. Configuration and Calibration Registers

Register Detail

211 Port 0 calibration value (0-4095)

212 Port 1 calibration value (0-4095)

213 Port 2 calibration value (0-4095)

214 Port 3 calibration value (0-4095)

215 Port 4 calibration value (0-4095)

216 Port 5 calibration value (0-4095)

217 Port 6 calibration value (0-4095)

218 Port 7 calibration value (0-4095)

Note: After the HC command is executed,

Register 211 will be zero and remain zero.

WARNING

Extreme caution must be used when writing port calibration values to registers

211 through 218 (40212 thru 40219). Only values read from these registers shall

be written to them. The purpose of these registers is to allow the network host to

store the port calibration values and then write them back to the actuator in case

of replacement of the CPU module.

2626

Remote Network Control

Page 31

Operation and Maintenance

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Part Number: MPA-400-0711, Rev. N

9.2 Foundation Fieldbus (FF)

The MPA uses a CAM18 to convert between Modbus and Foundation Fieldbus. Refer to

M2CP CAM18 & TEC2000 CAM218 Installation, Operation and Instruction Manual for

installation and setup of the FF link. Relations between the Modbus and FF maps are

identied as follows:

Foundation Fieldbus

Modubus Discrete Input

Map

Input DI PV / Out_D

16 At port within 1 degree 1

17 At port within 1 degree 2

18 Flow selector moving 4

19 Wrong direction alarm 5

Modubus Discrete Input Map Actuator Status (Channel 5)

Note: Channel 5 has only 1 discrete value and depends upon Selector Switch

position.

Input AUTO OFF LOCAL

SS Local/Manual 3

20

Selector Switch Off 2

21 SS Remote/Auto 0

22 Over torque alarm 56 58 59

23 Stop between ports alarm 52 54 55

24 Flow selector stall alarm 9 11 12

25 Power monitor alarm 12 14 15

26 Motor thermal overload alarm 20 22 23

27 Phase monitor alarm 76 78 79

28 Local ESD alarm 40 42 43

29 Actuator fail alarm 44 46 47

Actuator Readback (Channel 2)

Note: Channel 2 has only 1 value

DI PV / Out_D

Section 9: Remote Network Control

Mar 2013

Remote Network Control

Coil Map (Discrete Network Control) Actuator Command (Channel 1)

Coil DO SP / Out_D

10 Go to Next Port 1

Coil Map (Discrete Network Control) ESD Command (Channel 10)

Coil DO SP / Out_D

11 Host ESD Command 1

Monitor and Control Registers Analog input / Output Channels

Register

11 Port Position Setpoint (0-7 or 1-8) Setpoint AO (Channel 3) SP / OUT

14 Port position (0-4095) Position AI (Channel 4) SP / OUT

15 Torque (0-99%) Torque AI (Channel 18) SP / OUT

2727

Page 32

Section 9: Remote Network Control

Mar 2013

Modbus Foundation Fieldbus

Configuration and Calibration Registers MAO (Channel 19) MAI (Channel 20)

Register Parameter Parameter

211 Port 0 calibration IN_1 OUT_1

212 Port 1 calibration IN_2 OUT_2

213 Port 2 calibration IN_3 OUT_3

214 Port 3 calibration IN_4 OUT_4

215 Port 4 calibration IN_5 OUT_5

216 Port 0 calibration IN_6 OUT_6

217 Port 0 calibration IN_7 OUT_7

218 Port 0 calibration IN_8 OUT_8

NOTE:

Input and Output parameters are the number of hardware registers that are connected to

the I/O block. They dene the transducers to be used going to or from the physical world.

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

WARNING

Extreme caution must be used when writing port calibration values to registers 211

through 218. Only values read from these registers shall be written to them. The purpose

of these registers is to allow the network host to store the port calibration values and then

write them back to the actuator in case of replacement of the CPU module.

NOTE:

The network host may write a Port Position Setpoint to Channel 3 (SP/OUT) as a 12-bit

unsigned integer analog value corresponding to 0% to 8% where the percentage relates to

the port number 0 to 8. The analog value is calculated as absolute value of Port Number /

100 * 4095. Example: Analog value for Port 6 = 6/100*4095=245.7 = 245. The actuator will

accept the percentage analog value within a tolerance as shown below:

Port 0 = 0 If CA is congured as 1 for Home Port = 8,

Port 1 = 39 – 42 the MPA will accept either 0 or 327 for setpoint

Port 2 = 79 – 82 of Home Port. The acceptable range for Port 8

Port 3 = 120 – 123 is 325 to 329. (see Page 22 for CA conguration)

Port 4 = 162 – 165

Port 5 = 203 – 206

2828

Port 6 = 244 – 247

Port 7 = 284 – 288

Remote Network Control

Page 33

Operation and Maintenance

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Part Number: MPA-400-0711, Rev. N

Section 9: Remote Network Control

Mar 2013

9.3 Profibus DP Reduntant Networks with Redcom

The MPA uses CAM20 to convert between Mosbus RTU and Probus DP. This section

describes the data mapping between the Probus DP host and MPA Modbus map. The

mapping allows the Probus DP host to control the Flow Selector and monitor the actuator

status. The control information is mapped directly to words in the Probus Output data

and status information is mapped directly to words in the Probus Input data.

Table 11. Output Data

Location Bit

Word Byte 7 6 5 4 3 2 1 0

1 1

1 2

2 3

2 4

3 5

3 6

Not

used

Not

used

Not used

Not

used

Not

used

Flow Selector Port Position Setpoint (0-7) Single Bit

Not

used

Host ESD

Command

Not used

Go to

Next Point

Not

used

Not

used

Table 12. Input Data

Location Bit

Word Byte 7 6 5 4 3 2 1 0

1 1

1 2 Not used

2 3

2 4

3 5

3 6

4 7

4 8

5 9

5 10

6 11

6 12

Not

used

Unit

Alarm

Stopped

Between

Ports

Not

used

Not used

Over

Torque

Alarm

Not

used

Not

used

Selector

Remote /

Auto

Flow Selector Position (0-7) Single Bit

Not

used

Not

used

Local ESD

Alarm

Selector

Local /

Manual

Torque (0-99%)

Not used

Not used

Not used

Host ESD

Monitor

Phase

Monitor

Alarm

Wrong

Direction

Alarm

Motor

Thermal

Alarm

Flow

Selector

Moving

Not used

Power

Monitor

Alarm

Within 2

degrees

of port

Actuator

Fail Alarm

Selector

Stall Alarm

Within 1

degree of

Flow

port

Remote Network Control

2929

Page 34

Section 9: Remote Network Control

Mar 2013

9.4 DeviceNet

The MPA uses CAM09 to convert between Modbus and DeviceNet. This section describes

the data mapping between the DeviceNet host and MPA Modbus map. The mapping

allows the DeviceNet host to control the Flow Selector and monitor actuator status. The

control information is mapped directly to words in the DeviceNet Output data and status

information are mapped directly to words in the DeviceNet Input data.

Table 13. Output Data

Location Bit

Word Byte 7 6 5 4 3 2 1 0

1

2

3

1 Not used

2 Not used

3

4

5

6

Operation and Maintenance

Part Number: MPA-0400-0313, Rev. N

Host ESD

Command

Flow Selector Port Position Setpoint (0-7) Single Bit

Not used

Go to

Next Point

Not used

Table 14. Input Data

Location Bit

Word Byte 7 6 5 4 3 2 1 0

0 Not used Not used Not used Not used Not used Not used Not used

1

1 Not used Not used Not used Not used Not used

Stopped

2

Between

Ports

2

Unit

3

Alarm

4

3

5

6

4

7

8

5

9

10

6

11

Over

Torque

Alarm

Not used

Selector

Remote /

Auto

Actuator

Fail Alarm

Flow Selector Position (0-7) Single Bit

Selector

Local /

Manual

Local ESD

Alarm

Torque (0-99%)

Not used

Not used

Wrong

Direction

Alarm

Phase

Monitor

Alarm

Flow

Selector

Moving

Motor

Thermal

Alarm

Within 2

Degrees

of port

Power

Monitor

Alarm

Within 1

Degree of

Selector

Alarm

port

Flow

Stall

3030

Remote Network Control

Page 35

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

Appendix

Mar 2013

Appendix A: EC Declaration of Conformity

Certicate

Appendix

31

Page 36

Appendix

Mar 2013

Appendix B: Wiring Diagrams

B.1 Three Phase Power

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

32

Appendix

Page 37

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

B.2 Single Phase Power

Appendix

Mar 2013

Appendix

33

Page 38

Appendix

Mar 2013

B.3 24VDC Power

Operation and Maintenance

Part Number: MPA-400-0313, Rev. N

34

Appendix

Page 39

Contact Us: Emerson Process Management, Valve Automation facilities at your nearest location:

North & South AmericA

19200 Northwest Freeway

Houston, TX 77065

T +1 281 477 4100

F +1 281 477 2801

2500 Park Avenue West

Mansfield, OH 44906

USA

T +1 419 529 4311

F +1 419 529 3688

13840 Pike Road

Missouri City, Texas 77489

USA

T +1 281 499 1561

F +1 281 499 8445

Av. Hollingsworth,

325, Iporanga Sorocaba,

SP 18087-105

Brazil

T +55 15 3238 3788

F +55 15 3228 3300

middle eASt & AfricA

P. O. Box 17033

Dubai

United Arab Emirates

T +971 4 811 8100

F +971 4 886 5465

P. O. Box 105958

Abu Dhabi

United Arab Emirates

T +971 2 697 2000

F +971 2 555 0364

P. O. Box 3911

Al Khobar 31952

Saudi Arabia

T +966 3 814 7560

F +966 3 814 7570

P. O. Box 10305

Jubail 31961

Saudi Arabia

T +966 3 340 8650

F +966 3 340 8790

P. O. Box 32281

Doha

Qatar

T +974 4 576777

F +974 4 315448

24 Angus Crescent

Longmeadow Business Estate

East P.O. Box 6908;

Greenstone; 1616

Modderfontein, Extension 5

South Africa

T +27 11 451 3700

F +27 11 451 3800

europe

Asveldweg 11

7556 BR Hengelo (O)

The Netherlands

T +31 74 256 1010

F +31 74 291 0938

Siemensring 112

47877 Willich

Germany

T +49 2154 499 660

F +49 2154 499 6613

25, Rue de Villeneuve

Silic – BP 40434

94583 Rungis

France

T +33 1 49 79 73 00

F +33 1 49 79 73 99

Via Montello 71/73

20038 Seregno (Milan)

Italy

T +39 0362 2285 207

F +39 0362 2436 55

6 Bracken Hill

South West Industrial Estate

Peterlee SR8 2LS

United Kingdom

T +44 191 518 0020

F +44 191 518 0032

2A Szturmowa Str

02-678 Warsaw

Poland

T +48 22 45 89 237

F +48 22 45 89 231

C/ Francisco Gervás, 1

28108 Alcobendas – Madrid

Spain

T +34 0913 586 000

F +34 0913 589 145

Letnikovskaya Str. 10-2

115114 Moscow

Russia and FSU

T +7 495 981 98 11

F +7 495 981 98 10

ASiA pAcific

No. 9 Gul Road

#01-02 Singapore 629361

T +65 6501 4600

F +65 6268 0028

9/F Gateway Building

No. 10 Ya Bao Road

Chaoyang District

Beijing 100020

P.R.China

T +86 10 8572 6666

F +86 10 8572 6888

No.1 Lai Yuan Road

Wuqing Development Area

Tianjin 301700

P.R.China

T +86 22 8212 3300

F +86 22 8212 3308

Lot 13112, Mukim Labu

Kawasan Perindustrian Nilai

71807 Nilai, Negeri Sembilan

Malaysia

T +60 6 799 2323

F +60 6 799 9942

471 Mountain Highway

Bayswater, Victoria 3153

Australia

T +61 3 9721 0200

F +61 3 9720 0588

Delphi B Wing, 601 & 602

6th Floor, Central Avenue

Powai, Mumbai – 400 076

India

T +91 22 6662 0566

F +91 22 6662 0500

Please visit our web site for up to date product data.

www.bettis.com

All Rights Reserved.

We reserve the right to modify or improve the designs or specifications of the products mentioned in this manual at any time without

notice. Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility

for proper selection, use and maintenance of any Emerson Process Management product remains solely with the purchaser.

©2013 Emerson Electric Co.

Loading...

Loading...