Better Pack® 755e Series

Model 755eMA

Electronic Tape Dispenser

BP755eMA OPERATING MANUAL

B

ETTER PACKAGES

4 Hershey Drive Ansonia, CT 06401

Web Site: www.betterpackages.com

BP P/N: MAN-755eMA-OPR File Name: BP755eMA-OPERATING MANUAL-21July14.doc

®

1

This manual is a non-controlled document.

Information in this manual does not constitute a warranty of performance. Futhermore Better Packages

reserves the right to revise this publication and make changes in its content from time to time.

Better Packages ASSUMES NO LIABILITY WHATSOEVER FOR ANY LOSSES OR DAMAGES

INCURRED AS A RESULT OF INFORMATION CONTAINED IN THIS MANUAL

Proprietary Notice

This publication contains information proprietary and confidential to Better Packages. Any reproduction,

disclosure, or use of this publication is expressly prohibited except as Better Packages may otherwise

authorize in writing.

Better Packages

4 Hershey Drive

Ansonia, CT 06401

Telephone: (800) 237-9151 or (203) 926-3700

Fax: (203) 926-3706

Web Site: http://www.betterpackages.com

2

Safety Precautions

Technical Data

Unpacking .

Preparing the Machine for Operation

Operating Instructions .

Recommended Maintenance . .

Warranty Statement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

. . . . . . . . . . . . . . . . Page 7

. . . . . . . . . . . . . . . . . . . . . . . . Page 11

. . . . . . . . . . . . . . . . . . Page 12

. . . . . . . . . . . . . . . . . . . . . . . . . . Page 14

3

SAFETY PRECAUTIONS

This must be read before servicing equipment.

Always unplug the machine before performing any maintenance or repair.

Line voltages may be present even with power switch in Off position.

This machine is designed for sealing cartons with water activated tape. Any other use will void all

warranties and any responsibility or liability of Better Packages, Inc.

Read all Safety Precautions and Operating Instructions before powering on and using the machine.

Any operator of this machine must be fully trained in the operation and safety.

In the event of a malfunction or breakdown, grounding provides a low resistance path for electric

current to reduce the risk of electric shock. This machine is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Before connecting the machine to the power mains, verify that the electrical ratings of the machine

match the electrical supply intended for connection. If not, do not connect. If the correct power is not

available, contact the reseller.

The electrical safety of this machine is guaranteed only when it is correctly connected to a grounded

electrical system as prescribed by the present electrical safety rules.

Before maintenance or repair, disconnect the power cords from the electrical supply and protect the

cables from any possible accidental connection carried out by unauthorised personnel.

Keep the machine away from children and from personnel who are not authorised or adequately

instructed in its use.

4

TECHNICAL DATA

Size: 21” L x 10.5” W x 9.5” H

Dispensing Speed: Up to 32” per second

Water Bottle Capacity: 2 quarts

Tape Width: 1” to 4” Wide

Maximum Roll Size: Up to 600 ft. of tape

Up to 7.5” diameter roll

Tape Lengths Dispensed: Adjustable from 6” to 100 ”

Shipping Weight: 42 lbs.

Power Requirements: 115 volts, 60 Hz, 4 Amps

All specifications are subject to change without notice.

5

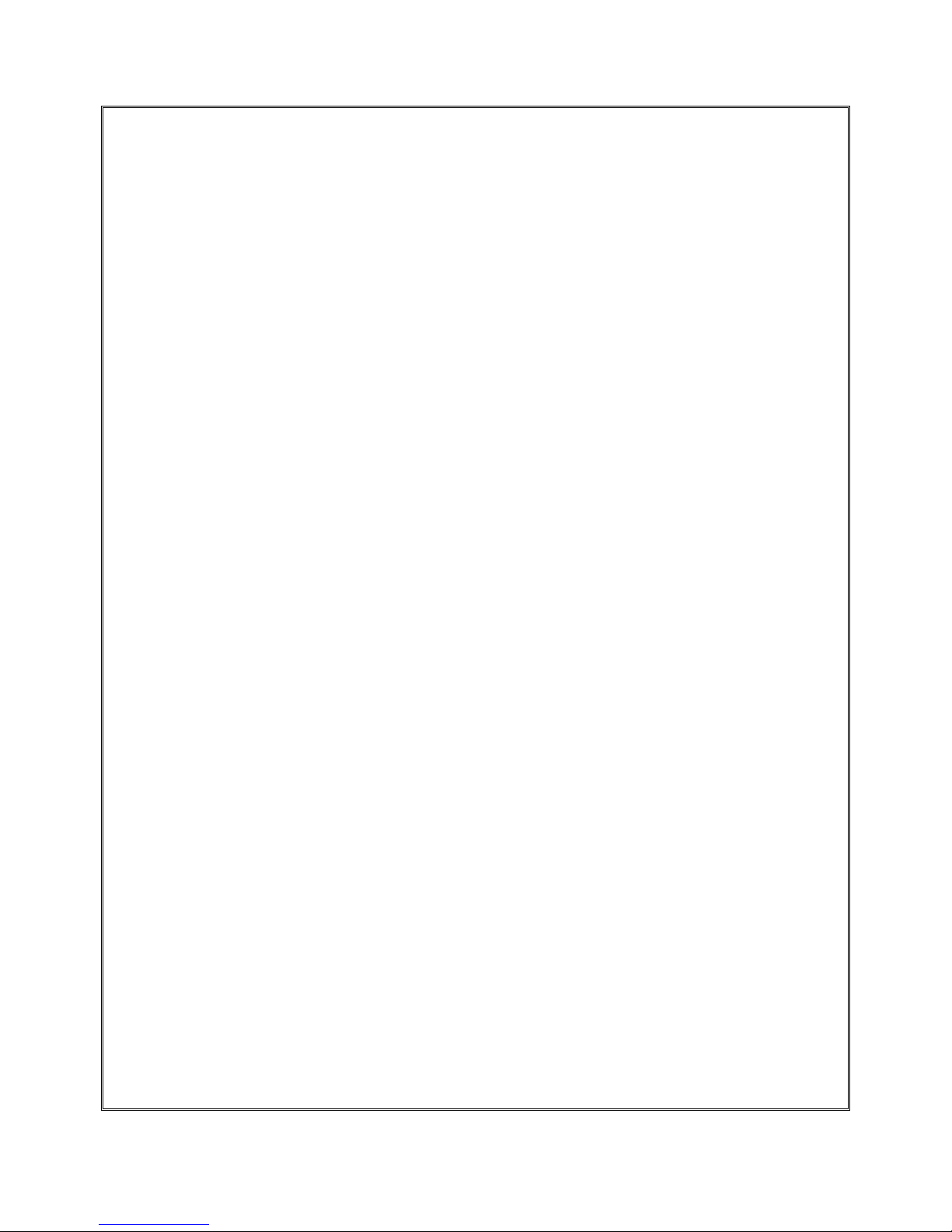

UNPACKING

Water Bottle

ty-rap

When unpacking your new Better Pack Tape Dispenser, check to make sure you have the following items

before discarding packing material:

• Operating Manual

• Power Cord

• Upper Tape Plate

• Water Bottle

• Water Tank and 2 Brushes

Note: The upper tape plate is held in position by packing materials, but may have been dislodged in

shipping. (see page 7, “Checking the Upper Tape Plate” if this has occurred.) Remove all packing

material before using the machine.

Power Cord

`

Cut off and remove the plastic ty-rap used to secure the blade during shipping.

Cut and remove

Upper Tape Plate

Water Tank

& Brushes

6

PREPARING THE MACHINE FOR OPERATION

1. ADJUSTING TAPE ROLL GUIDES

Adjust tape roll guides located inside the rear of the machine to accommodate the width for your

tape. The guides should be adjusted to minimize roll movement from side to side, but should not be

tight against the sides of the roll, which could create excessive drag.

Using the thumbscrew, adjust the width between the guides slightly wider than the tape width. If the

adjustment is more than ¼” or so, lift the back of the guides out of their slots, so they do not bind

while turning the thumbscrew, then insert the guides back into the slots.

Place the roll of tape into the machine and adjust the thumbscrew so the front end of the guides has

approximately 1/16” of clearance on each side of the tape.

Roll Guide Slots

Tape Roll Guides

Thumbscrew for roll

guide adjustment

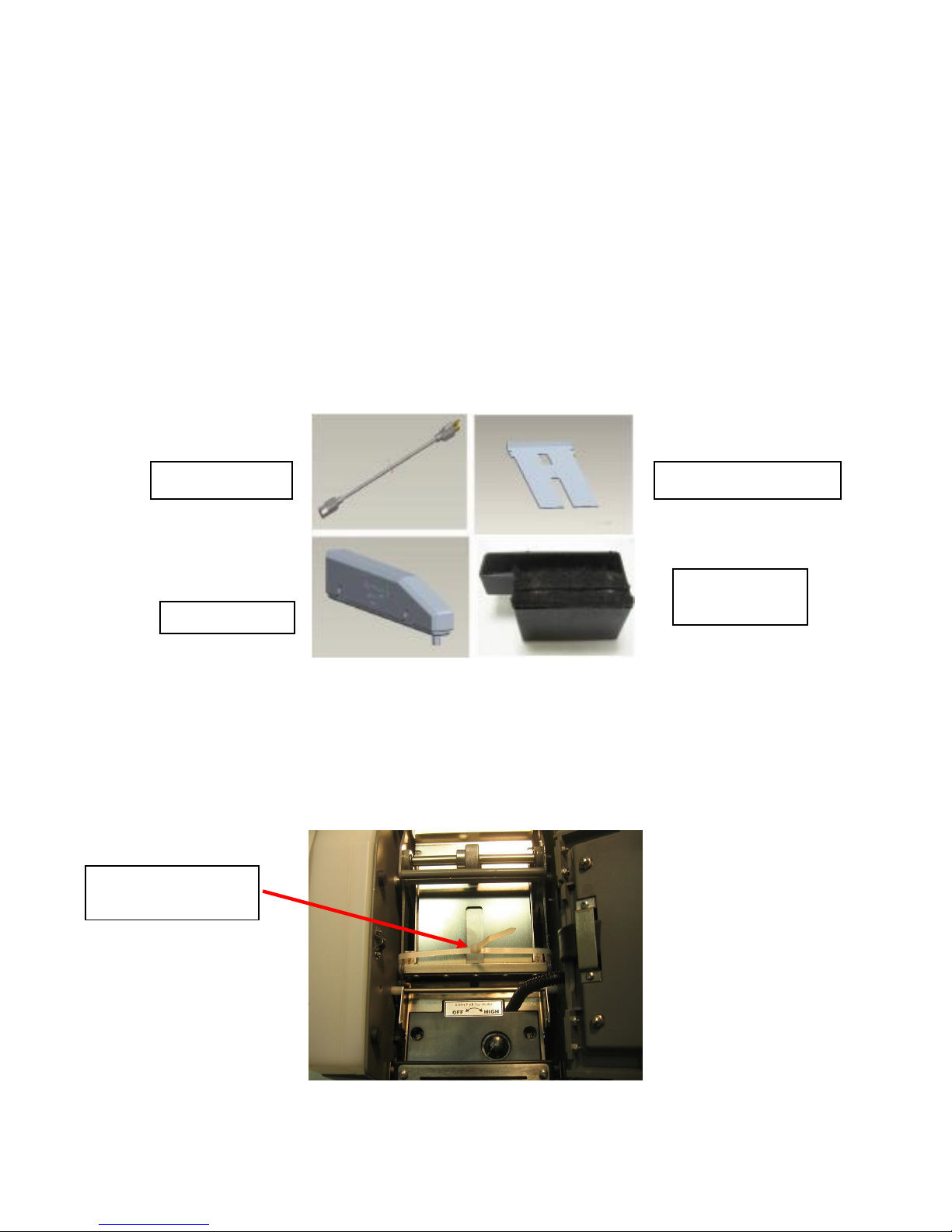

2. CHECKING THE UPPER TAPE PLATE

If the upper tape plate has been dislodged in shipping, reposition it as follows: slide the tape plate under

the feed wheel, by placing the slotted edge behind the feed wheel and sliding it down and forward. Move

it all the way forward until the rectangular cutout is centered under the feed wheel. The rear sides of the

upper tape plate should be positioned under the retaining tabs of the lower tape plate.

Plate Retaining Tabs

Feed Wheel

Upper Tape Plate

7

Water Tank

Brushes

3. LOADING TAPE (wound adhesive side in).

Take the roll and unwind about 12". Place the roll in the machine so that the strip unwinds off the rear

of the roll as the leading end is brought up toward the front of the machine with the adhesive side

down.

Thread tape between the tape guide adjustment screw and the roller below it. Lift the rear of the tape

plate slightly and slide the tape leading edge forward under it and the upper feed wheel until it can be

seen in the slot of the upper tape plate.

Tape Guide Adj. Screw

Upper Tape Plate

Upper Feed Wheel

4. PREPARING THE MOISTENING BRUSHES

Remove the water tank and brushes. Wash brushes thoroughly in warm water and soap or mild

detergent. Place brushes back into the water tank. Note: the two brushes are beveled; place them

into the tank, being sure each brush is positioned with the high side toward the front of the tank. Place

tank and brushes back into the machine.

8

Water Bottle

5. PREPARING THE WATER BOTTLE

Fill bottle with water and place in bottle holder so that the spout of the bottle is in the tank.

6. ELECTRICAL CONNECTION

a. Attach power cord to the receptacle in the rear of the machine.

b. Plug machine into a standard power outlet (115Vac - 60 Hz current only).

WARNING

FOR YOUR SAFETY all the metal parts of this machine are electrically grounded through a 3-

wire power supply cord and a 3-prong grounding type plug which must be plugged into a 3-wire

grounded type receptacle.

If you are not sure the electrical system in your building is properly grounded, call a licensed

electrician.

c. When all connections have been made, turn on the power switch at the right front of machine.

The power light should be illuminated and indicates the machine is ready for operation.

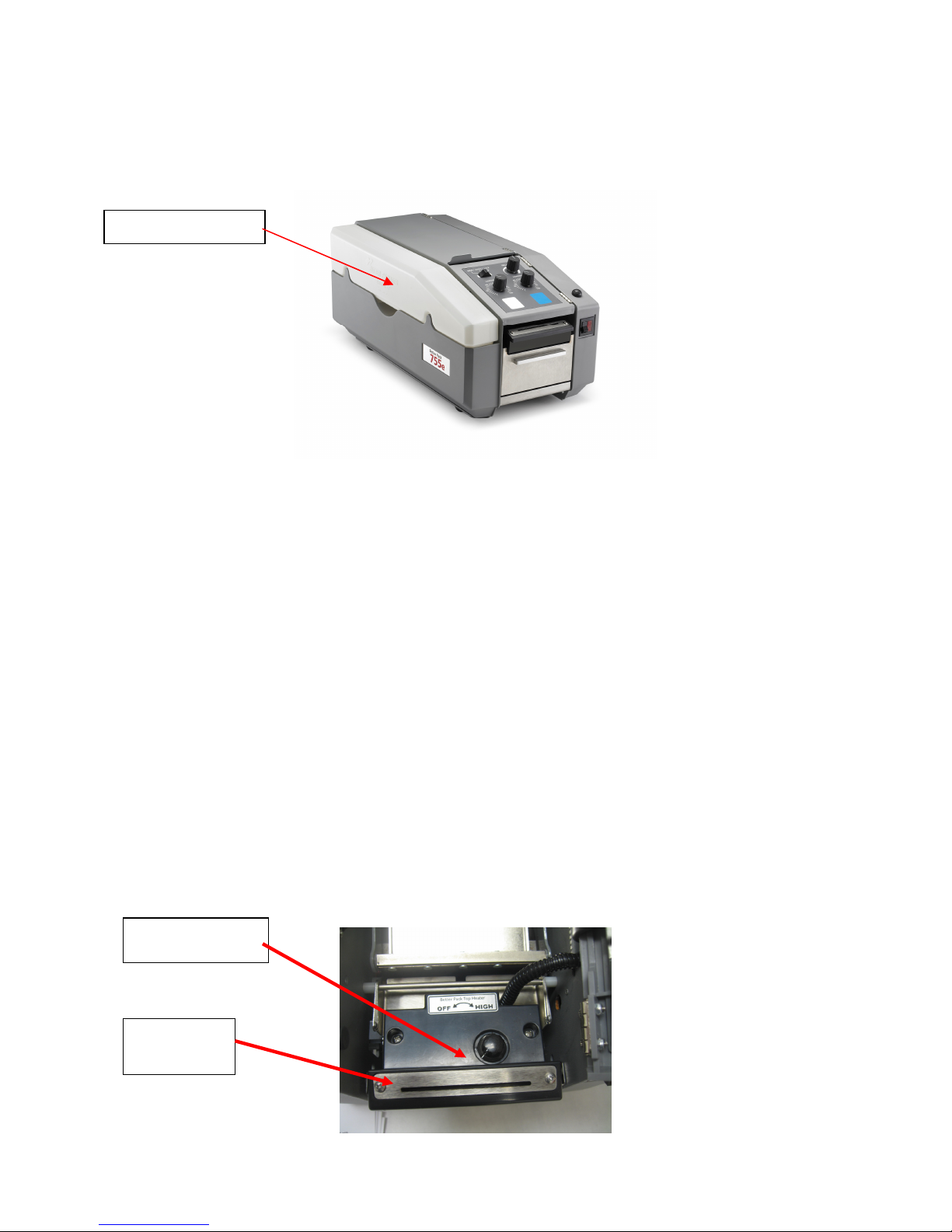

7. TOP HEATER SETTING

Finding the correct setting for the tape you are using is a matter of simple testing. Turn the

adjustment knob (clockwise) to the highest setting, then while using the machine, incrementally back

off the control to the lowest temperature setting that best meets your needs.

Heater Knob

Top

Heater

9

7. SETTING WATER LEVEL

The water level is factory preset to provide proper moistening of the tape adhesive for most types of

tape and should not need to be adjusted unless the tape is not sticking to the box properly. If more or

less water is needed for optimum performance of your tape, then the water level may need to be

adjusted. The water level in the tank is controlled by the position of the water bottle nozzle which can

be raised or lowered with the bottle bracket. To adjust the water level, loosen the thumb screw on the

bracket slightly, then slide the bracket up for more water or down for less and retighten the

thumbscrew.

Bottle Bracket

Thumb screw

10

OPERATING INSTRUCTIONS

Mode Selector

Switch

Dispense Delay

Control

Length Control

1

Dispense Key

1

Length Control

2

Dispense Key

2

Random Button

Power Switch

1. After following the machine preparation instructions, including loading the roll of tape, you are now

ready to operate the machine.

2. To dispense tape, adjust the length control dial for the length of tape you wish to dispense, lightly

press the dispense key below dial. There are two adjusting dials so that you can program two

different lengths of tape at one time. This allows you to prepare an “H” pattern for the length and

width of the carton.

3. RANDOM LENGTHS - The button at the right front of the machine is for visually measured lengths

of tape. As the button is held down, tape is dispensed. With a little practice, the operator can

quickly develop his "time" sense and dispense lengths with considerable accuracy.

4. OPERATOR MODE SELECTION – Choose the operating mode for the machine by positioning the

mode selector switch to MAN (manual), AUTO (automatic), or 1-2-2, as appropriate.

11

Tape Sensor

5. DELAY CONTROL – Set the delay time so that the machine waits before automatically dispensing

the next length of tape. The delay can be set from approximately 1 to 30 seconds. Delay is for use

in Auto or 1-2-2 mode only.

6. MANUAL MODE – Tape is dispensed immediately each time a dispense key is pressed.

7. AUTO MODE – The automatic mode dispensing sequence is started by depressing a dispense key.

The tape length is set by the length dial above the key pressed. The machine waits the set delay

time after the operator removes tape and then automatically dispenses the next piece of tape. The

same length is repeated until either the other dispense key is pressed or the mode is changed.

8. 1-2-2 MODE – The 1-2-2 mode dispensing sequence is started by moving the mode selector switch

from MAN to the 1-2-2 position and then depressing the left dispense key. The 1-2-2 dispensing

sequence begins by dispensing a length set by the left length dial and then 2 lengths of tape set with

the right length dial. The dispenser waits the set delay time after the operator removes the tape and

then automatically dispenses the next piece of tape. The 1-2-2 sequence repeats until the mode is

changed.

Note: If the machine does not dispense tape when in “Auto’ or “1-2-2” modes, check to make

certain there is no tape stuck in the machine under the tape sensor. The tape sensor is

located under the rear of the heater cover and sees the tape through a hole in the heater

plate. Remove the tape piece to fix the problem. Check for a tape obstruction by lifting up the

heater to view the tape sensor. There should not be any tape visible in the hole area.

Bottom view of Heater

12

Recommended Maintenance

To ensure ongoing performance of your 755e tape dispensing machine, regular maintenance is

important. Maintenance is quite simple and just takes minutes. Without regular maintenance, the

efficiency of your equipment will be undermined. The frequency of maintenance depends on many

factors, including the volume of machine use. Frequencies indicated below are “standard”…your

frequency may vary.

Warning: Be sure the dispenser is UNPLUGGED before performing any cleaning procedures.

Clean Brushes – Weekly

Clean the brushes on a weekly basis or when adhesive build up effects proper moistening of the

tape. The adhesive can prevent sufficient and even water flow to the tape causing poor

moistening of the tape. Regular cleaning will extend the life of the brushes and insure that

adhesive build-up will not cause performance to deteriorate.

Procedure:

1. Unplug power from the machine! Remove the water bottle and water tank.

Caution: Heater may stay hot for a period after machine is off.

2. Remove the brushes from the tank to remove any dried adhesive. Notice how the brushes

are positioned in the tank because they must be replaced correctly.

3. Wash the brushes with warm water and soap.

4. Place the brushes back into the water tank. It is extremely important that they are positioned

correctly. The top of the brushes are cut at an angle. Shorter brushes go in the back. The longer

length bristles must be toward the front of the machine (tank).

Notice: Installing the brushes backwards will cause excessive tape jams.

Never cut the brush tips to remove adhesive as they are cut at a specific angled

and flagged to facilitate proper moistening. Cutting will most likely cause

poor performance.

Cleaning the Shear Blades

In order for this dispenser to cut the tape well, the blades need to be free of adhesive, dust or any other

materials. The adhesive that is laminated onto reinforced tape often accumulates on the dispenser’s

blades. Even single layer Kraft paper tape without reinforcing yarn can cause an accumulation of dust

and adhesive on the blades. These materials need to be cleaned off the blades. Use a scraper to remove

the accumulation of adhesive, but never scrape the cutting edge because the blade may become dull and

need replacement.

Coating the blade with a light grade oil can help slow down the accumulation of adhesive.

Caution: The blade is sharp and can cut easily, so be careful working around it.

13

General Machine Cleaning

The feed wheel pushes tape through the machine. Obstructions such as dirt or dried adhesive can divert

the tape and cause it to jam. Periodical cleaning of the tape path will mitigate tape jams.

Procedure

1. Remove the upper tape plate that sets on the tape next to the feed wheel. Pull tape off from the

lower tape plate if it hasn’t already been removed. Clean any dirt and adhesive from the upper

and lower tape plates.

2. Lift the heater up and clean the bottom of it. Under the heater is a lower plate that the tape rides

over. The lower plate and heater plate are separated by a small gap that helps the tape to move

under the heater and onto the brushes with minimal obstruction. Pull down on the front of the

lower plate to separate it from the heater plate. Clean between the plates the snap the lower plate

back onto the heater plate. Be careful not to bend the lower plate. A bent plate can be a cause of

tape jams.

LUBRICATION – Not Needed!

1.

All vital moving parts of this machine have oil retaining porous bushings and should not require

additional oil for the average life of the machine.

2. FEED WHEEL SHAFT -

internal parts.

Do not oil this shaft. Oil can creep in through the bearings and effect

14

Better Packages, Inc.

Warranty Information

The manufacturer warrants each new Better Packages machine and accessory to be free from defects in material

and workmanship under normal and proper use. Its obligation under this warranty being limited to replacing or

repairing any defective parts within the time period indicated for the specific model after delivery (at the company’s

discretion) to the customer. Wearable parts such as shear blades, water bottles and caps, water brushes and motor

brushes are not covered under the warranty. Machines used for any reason not intended by the manufacturer will not

be considered for warranty protection.

The company will replace or repair (at the company’s discretion) any defective parts within the warranty period, on a

no-charge basis. The Authorized Distributor/Service Center will furnish, without charge, within the time period

indicated for the specific model, necessary labor to service the machine.

If customer wishes, they may forward any machine listed below with authorization from Better Packages or an

Authorized Distributor/Service Center for warranty service. Any item shipped for warranty service must be shipped in

the original factory carton and properly packed with the original protective packaging inserts or a secure carton that

will properly protect the unit during transit. Units received improperly packed are subject to costs associated with

damage caused during transit. These costs will be the responsibility of the customer. All associated shipping or

freight costs related to items shipped for service are the sole responsibility of the customer.

For service under this warranty, call or write your nearest Better Packages Distributor/Service Center or Better

Packages, Inc. Ansonia, CT at 800-237-9151 (US only) or (203) 926-3700. To locate your local Authorized

Distributor/Service Center, visit www.betterpackages.com. Transportation charges on machines or parts returned

to Better Packages for service must be prepaid by the customer. Customers will be responsible for freight expenses

on parts or machines returned to them.

Better Packages’ ship-to address is: 4 Hershey Drive

Ansonia, Connecticut 06401

Product Warranty*

Model Parts Labor

Better Pack® 755e Series

Better Pack® 555e Series

Better Pack

®

500 Series 2 Years 6 Months

2 Years 6 Months

2 Years 6 Months

Better Pack® 333 Series 2 Years 6 Months

TapeShooter® 404 2 Years 6 Months

Packer® 3S 2 Years 6 Months

Better Pack® PS2A 1 Year 6 Months

*When servicing a Better Packages product, genuine Better Packages replacement parts should be

used. Any other parts used will void all existing warranties along with UL, CE and CSA

certifications and may create a safety hazard.

This warranty statement dated May 1, 2014 supersedes all other prior published statements.

15

Loading...

Loading...