BETTCHER INDUSTRIES 1850M2-S, 1850M2, 1880M2, 1000M2, 1300M2 Operating Instructions And Spare Parts Lists

...

BETTCHER

Industries, Inc.

750M2 (F/N *183000) Bone Trimmer

OPERATING INSTRUCTIONS AND SPARE PARTS LISTS

LARGE MODULAR SERIES II TOOLS

Models :

850M2 (F/N *183001) Defatting Machine

880M2-B&S (F/N *183002) Primal Fat Shaper

1850M2 (F/N *183003) Defatting Machine

1880M2 (F/N *183004) Primal Fat Shaper

1000M2 (F/N *183005) Defatting Machine

1300M2 (F/N *183006) Primal Fat Shaper

1400M2 (F/N *183007) Ham Finisher

1500M2 (F/N *183008) Skinning Machine

1930M2 (F/N *185000) Defatting Machine

1932M2 (F/N *185086) Defatting Machine

1933M2 (F/N *185001) Defatting Machine

1940M2 (F/N *185002) Defatting Machine

1942M2 (F/N *185087) Defatting Machine

1943M2 (F/N *185003) Slicing Machine

MANUAL #183130

Re-Issued : October 29, 2001

TMC #756

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

Information in this document is subject to change without notice.

No part of this document may be reproduced or transmitted in any form or any

means, electronic or mechanical, for any purpose, without the express written

permission of Bettcher Industries Inc.

Written permission to reproduce in whole or part is herewith granted to the legal

owners of the Whizard Trimmer with which these Operating Instructions have

been supplied.

Operating Instructions in other languages are available on request. Additional

copies of Operating Instructions are available by calling or writing the local

Representative or by contacting :

BETTCHER INDUSTRIES INC.

6801 State Route 60

Birmingham, Ohio 44889

U.S.A.

Telephone : 1-440-965-4422

(In The U.S.A.) : 1-800-321-8763

Fax : 1-440-965-4900

The Infomation Provided In These Operating Instructions Are

Important To Your Health, Comfort And Safety. For Safe

And Proper Operation, Read This Entire Manual

Before Using This Equipment.

Copyright 1999 By Bettcher Industries, Inc.

All Rights Reserved

Original Instructions

Page i

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

Table Of Contents

SECTION 1.0 Machine Specifications 1

SECTION 2.0 Designated Use 1

2.1 Warning 1

2.2 Recommended Operation 2

SECTION 3.0 Function 5

3.1 Machine Function Description 5

3.2 Safety Recommendations And Warnings 5

SECTION 4.0 Safety Features 7

SECTION 5.0 Ergonomics & Environment 8

5.1 Ergonomic Features 8

5.2 Noise And Vibration Levels 8

SECTION 6.0 Unpacking 9

6.1 Safety First 9

6.2 Included With Your Machine 9

SECTION 7.0 Installation 9

SECTION 8.0 Instructions For Operation 10

8.1 Optional Thumb Support And Handle Size Selection 10

8.2 Handle - Assembly & Adjustments 10

8.3 Proper Use/Operating Procedures 16

8.4 Fault Detection And Correction 22

Page ii

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

Table Of Contents

(Continued)

SECTION 9.0 Maintenance 24

9.1 Disassembly Of Handpiece 24

9.2 Daily Inspections & Maintenance 27

9.3 Blade Sharpening 34

9.4 Assembly 35

9.5 Preventative Maintenance 39

SECTION 10.0 Cleaning 40

10.1 Periodic Cleaning During Use 40

10.2 Daily Cleaning 40

10.3 Cleaning Solutions 40

SECTION 11.0 Spare Parts List 41

11.1 Head Assembly - 750M2 42

11.2 Head Assembly - 850M2 44

11.3 Head Assembly - 880M2-B 46

11.4 Head Assembly – 880M2-S 48

11.5 Head Assembly - 1850M2 50

11.6 Head Assembly – 1880M2 52

11.7 Head Assembly - 1000M2 54

11.8 Head Assembly - 1300M2 56

11.9 Head Assembly - 1400M2 58

11.10 Head Assembly - 1500M2 60

11.11 Head Assembly - 1930M2 62

11.12 Head Assembly - 1932M2 64

11.13 Head Assembly - 1933M2 66

11.14 Head Assembly - 1940M2 68

11.15 Head Assembly - 1942M2 70

11.16 Head Assembly - 1943M2 72

Page iii

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

Table Of Contents

(Continued)

11.17 Flex Shaft & Casing 74

11.18 Post Handle (Optional) 76

11.19 Optional Equipment Available 78

Lubrication and Lubrication Equipment 78

Optional Blades 78

Blade Sharpening and Steeling Equipment 78

Covers and Depth Gauges 78

Tools 79

Cleaning Equipment 79

Cleaning Solution 79

11.20 Handle Options 79

SECTION 12.0 About These Operating Instructions 80

12.1 Other Languages 80

12.2 Document Identification 80

12.3 Software & Duplication 80

SECTION 13.0 Contact Addresses & Phone 81

Page iv

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

SECTION 1.0 Machine Specifications

Bettcher Modular Series II Whizard tools are highly effective for use in the meat industry,

designed with the highest possible standards for safety, ergonomics and production. These

versatile machines, with their carefully engineered and durable cutting edge, bring uniformity and

consistent yield control to all operations. This Operating Instruction covers the following models:

Model Main Application

750M2 Bone Trimmer

850M2 Defatting Machine

880M2-B&S Primal Fat Shaper

1850M2 Defatting Machine

1880M2 Primal Fat Shaper

1000M2 Defatting Machine

1300M2 Primal Fat Shaper

1400M2 Ham Finisher

1500M2 Skinning Machine

1930M2 Defatting Machine

1932M2 Defatting Machine

1933M2 Defatting Machine

1940M2 Defatting Machine

1942M2 Defatting Machine

SECTION 2.0 Designated Use

2.1 Warning

1943M2 Slicing Machine

Modular Series II Whizard tools are used for removal of fat and tissue, the recovery of lean meat

from fat, and as a universal cutting tool in the meat industry. Any use in applications other than

those for which the Whizard trimmer was designed and built may result in serious injuries.

WARNING

THE MANUFACTURER ASSUMES NO LIABILITY FOR ANY

UNAUTHORIZED DESIGN CHANGES, MODIFICATIONS, OR USE OF

PARTS NOT SUPPLIED BY THE MANUFACTURER

OR

THE USE OF PARTS NOT DESIGNED FOR USE ON THAT SPECIFIC

MODEL, INCLUDING CHANGES IN OPERATING PROCEDURES MADE BY

THE OWNER OR ANY OF HIS PERSONNEL.

THE USE OF PARTS OTHER THAN THOSE LISTED IN THE PARTS LIST

FOR THE SPECIFIC MODEL MAY CAUSE BLADE LOCK-UP RESULTING

IN AN UNSAFE OPERATING CONDITION.

Page 1

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

2.2 Recommended Operations

Modular Series II Whizard tools are made for several recommended operations. Ensure that you

are using the correct tool for your specific application. The following recommendation list is not

intended to be a total and comprehensive listing, but is offered as a guide. Additional applications

are possible.

MODEL 750M2

PORK CUT PORK KILL FOAM INDUSTRY

Remove diaphragm lean

Removal of picnic hearts

Remove cheek meat

Remove blood clots from

jowls

Remove defects

Flash trimming

MODELS 850M2/1850M2

POULTRY BEEF PORK PROCESSING

Defatting turkey skins

Defatting turkey thighs

PORK KILL

Removing leaf lard

Recover lean from fat

Trim lean from rib caps

Trim beef tripe

External ham defatting

Internal ham defatting

Defat pork loins

Remove oyster meat

MODEL 880M2-B/1880M2 WITH ADJUSTABLE DEPTH GAUGE

BEEF BONING/FABRICATING

Removing Dirt and Hair

- Slaughter Floor

- Prior to Loading

- Upon Receiving

- Prior to Fabrication

Final Trim on Primal Fat Shaping

MODEL 880M2-S/1880M2 WITH ADJUSTABLE DEPTH GAUGE

HOG KILL/HOG CUT/HAM PROCESSING

Remove skin or hair patches

Trimming pork loins and Canadian backs

Internal and external defatting of hams

TOP ROUNDS/BOTTOM ROUNDS/BRISKETS/CUBE STEAK MATERIAL

Removing membranes and light fat covering

DEFATTING TURKEY THIGHS

Page 2

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

2.2 Recommended Operations (Continued)

MODEL 1000M2

HOG CUT

Defat hams, picnics and butts

Removing lean from:

- Picnic Face

- Clear Plates

Jowls shoulder end of belly

Belly (Wire muscle – Pickle pocket)

Plate Trim

- Fat Backs

- Bootjack

BEEF SLAUGHTER

Defatting hot beef externally & internally

Kidney fat, heart fat, pelvic fat & cod fat

MODEL 1300M2

BEEF KILL

Pizzle cord removal

Removing external fat

BEEF BONING/

FABRICATION

Primal Fat Shaping:

- Strips

- Sirloin Butts

HAM BONING

External defat of hams

External defat of pork shoulders

- Ribs

Defat navels (Pastrami)

MODEL 1400M2 WITH ADJUSTABLE DEPTH GAUGE

PORK PROCESSING

Defatting:

- Whole Hams

- Shoulders

- Canadian Backs

Removing Beater Marks

Scraping Leaf Lard

BEEF PROCESSING

Carcass hair & dirt removal

Defatting:

- New York strips & sirloin butts

- Rounds and ribeyes

MODEL 1500M2 WITH ADJUSTABLE DEPTH GAUGE

PORK PROCESSING

Removing skin patches from bellies

Defatting:

- Whole Hams

- Pork Loins

BEEF SLAUGHTER

Defatting hot beef externally

Hair and dirt removal

Page 3

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

2.2 Recommended Operations (Continued)

MODEL 1930M2

BEEF SLAUGHTER

Defatting Hot Beef

MODEL 1932M2 WITH ADJUSTABLE DEPTH GAUGE

BEEF PROCESSING

Defatting Strips

MODEL 1933M2 WITH ADJUSTABLE DISC GAUGE

BEEF PROCESSING

Defatting Strips

MODEL 1940M2

BEEF SLAUGHTER

Defatting Hot Beef

MODEL 1942M2 WITH ADJUSTABLE DEPTH GAUGE

BEEF PROCESSING

Defatting Strips

MODEL 1943M2 WITH ADJUSTABLE DISC GAUGE

BEEF PROCESSING SALMON PROCESSING

Defatting Strips Slicing

Page 4

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

SECTION 3.0 Function

3.1 Machine Functions

Modular Series II Whizard tools are durable and efficient, promoting higher yields for

meat and poultry trimming. The Modular Series II Whizard tools are superbly designed

for ease of handling while reducing operator fatigue. Modular Series II Whizard tool

blades maintain accurate and continued sharpness.

A vertically hung motor drives a flexible shaft. The flexible shaft drives a rotating blade in

the handpiece via a gear and pinion. The force to cut through meat and fat is now provided

by the drive motor and no longer by the worker. Forces applied by the worker are greatly

reduced and limited to guiding the rotating knife blade.

3.2 Safety Recommendations And Warnings

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

Modular Series II Whizard tools have been designed to obtain the highest possible

degree of safety. The Trimmer contains sharp knife blades. Handle this equipment with

caution as you would with any sharp object. In particular, read and apply the following

safety recommendations :

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

PROPER PROTECTION OF HANDS, A PROTECTIVE

FOR

GLOVE SHOULD BE USED WHEN OPERATING THIS

EQUIPMENT AND DURING THE HANDLING OF BLADES.

METAL MESH GLOVES ARE RECOMMENDED

THE FREE HAND.

FOR

Page 5

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

3.2 Safety Recommendations And Warnings (Continued)

WARNING

KEEP HANDS AWAY FROM MOVING BLADE!

WARNING

ALWAYS TURN OFF THE MOTOR AND PLACE THE HANDPIECE IN THE

HANGER BRACKET. NEVER LAY THE HANDPIECE DOWN ON THE

WORKSTATION OR LET IT HANG FREE BY THE FLEX SHAFT CASING.

NEVER PLACE THE HANDPIECE IN THE HANGER WHILE THE BLADE IS

STILL REVOLVING!

WARNING

ALWAYS DISCONNECT THE POWER AND REMOVE THE TOOL FROM

THE FLEX SHAFT CASING PRIOR TO SERVICING!

WARNING

IF AT ANY TIME THIS MACHINE DOES NOT APPEAR TO OPERATE

NORMALLY OR EXHIBITS A MARKED CHANGE IN PERFORMANCE, IT

SHOULD BE IMMEDIATELY SHUT DOWN, UNPLUGGED, AND TAGGED AS

"UNSAFE" UNTIL SUCH TIME AS PROPER REPAIRS ARE MADE AND THE

MACHINE AGAIN OPERATES NORMALLY.

WARNING

AFTER SERVICE OF THE UNIT, ALWAYS CHECK TO ENSURE THAT THE

BLADE IS FREE TO ROTATE IN THE MACHINE PRIOR TO STARTING. IF

THE BLADE DOES NOT ROTATE FREELY, IT MAY CAUSE THE

HANDPIECE TO ROTATE IN THE HAND.

Page 6

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

3.2 Safety Recommendations And Warnings (Continued)

WARNING

LENGTHY OR REPEATED USE OF VARIOUS POWER TOOLS VIBRATING

EXCESSIVELY IS SUSPECTED OF CONTRIBUTING TO CERTAIN HAND,

WRIST OR FOREARM DISORDERS IN SUSCEPTIBLE INDIVIDUALS. IF

EXCESSIVE VIBRATION OCCURS, IT IS AN INDICATION THAT THERE ARE

WORN PARTS THAT NEED REPLACEMENT.

WARNING

IF YOUR WHIZARD TRIMMER DEVELOPS UNUSUAL VIBRATION, DO NOT

CONTINUE TO USE IT WITHOUT FIRST UNDERTAKING CORRECTIVE

ACTION AS OUTLINED IN THE TROUBLESHOOTING GUIDE IN THIS

OPERATING INSTRUCTION.

WARNING

AVOID USE OF THIS MACHINE IN STANDING WATER.

WARNING

USE ONLY REPLACEMENT PARTS MANUFACTURED BY BETTCHER

INDUSTRIES, INC. USE OF SUBSTITUTE PARTS WILL VOID THE

WARRANTY AND MAY CAUSE INJURY TO OPERATORS AND DAMAGE TO

EQUIPMENT.

SECTION 4.0 Safety Features

All Modular Series II Whizard tools have been designed for use with an optional

Disconnect which will stop blade rotation when the trigger/lever is released. This

trigger/lever has been designed in such a way that minimal grip force is required for

operation, using three fingers.

Page 7

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

SECTION 5.0 Ergonomics And Environment

5.1 Ergonomic Features

Handles – X-Small, Small, Medium, and Large Handle sizes are available to help improve

the operator’s grip and comfort. Fitting the correct size handle to the worker's hand is a

very important step. The Modular Series II Whizard tools have been manufactured in

both right and left handed configurations. All handles are also available without flanges, to

allow for more freedom of movement where space is limited.

Optional Thumb Support - An adjustable Thumb Support is available to ensure a proper

and comfortable fit while providing added control and stability of the tool during use.

Whizard Hand Strap - This Strap has been designed to allow the user to relax the fingers

between work cycles while maintaining control of the Trimmer.

NOTE: The Whizard® handstrap can not be

used with the flangeless handles.

5.2 Noise And Vibration Levels

The force to cut through meat and fats is now provided by the drive motor and no longer

by the worker. Forces applied by the worker are greatly reduced and limited to guiding the

rotating knife blade.

The noise emission value is less than 70 dB(A)

Vibration of the handpiece is less than 1 m/sec2

No negative side effects have been reported.

Page 8

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

SECTION 6.0 Unpacking

6.1 Safety First

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

UNPACK THE WHIZARD TRIMMER CAREFULLY.

6.2 Included With Your Machine

The following parts are included with each Modular Series II Whizard tool. Please

check when unpacking and advise your local Bettcher Industries representative if the

delivery is incomplete.

Part Number Description Qty.

100642 Whizard® Special Steel 1

100660 Special Stone 1

113415 Grease Gun (for 8 oz. tube of Whizard® Grease) 1

100608 8 oz. Tube Whizard® Grease 1

143631 14 oz. Cartridge of Special Whizard® Grease 1

183130 Operating Instructions and Spare Parts List 1

SECTION 7.0 Installation

The work station for each operator should be designed so that the operator's movements in

performing the job are natural and easy. A sideways sweeping motion with the Modular

Series II Whizard tool is preferable to a reaching motion. Long reaching motions and

high muscle strain should be avoided if possible. Also, a proper working height is needed

to avoid excessive shoulder and back exertion. Refer to the Whizard Motor Manual for

instructions on the proper placement and installation of the motor.

Page 9

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

SECTION 8.0 Instruction For Operation

8.1 Optional Thumb Support And Handle Size Selection

Your Modular Series II Whizard® tool has been supplied with a spacer ring and an optional thumb

support. If using the optional thumb support, the operator’s thumb should be fully supported and

rest comfortably in the support. The thumb support has been optimized to fit most hands

comfortably.

Fitting the correct size handle to the grip of an operator’s hand is a very important step when

trying to reduce risks associated with cumulative trauma disorders. The Trimmers are

available in right and left handed configurations. Once it has been determined that an operator

is right or left handed and the appropriate model of Trimmer has been selected, choosing the

proper handle size can be accomplished in the following manner. The handles have been

color-coded for size as follows:

Tan

Turquoise

Grey

Blue

Green

Here is a very simple procedure to determine correct handle size:

STEP 1 - Assemble four (4) knives each with a different size handle. (See Section 8.2 for

complete assembly instructions).

STEP 2 - Allow the user to hold the knife and apply the grip pressure normally used during

the job operation.

If the operator normally wears a glove, this process

should be done with the glove(s) used in normal operation.

We do not recommend the use of Nitrile gloves in direct

contact with the Whizard® handles because

the gloves may become slippery.

The operator should choose the handle that is most comfortable. Allow the operator to work

with this handle on a tool for several days. If the operator is not comfortable with the handle

selection, try a different size.

XX-Small

X-Small

Small

Medium

Large

NOTE

Page 10

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.1 Optional Thumb Support And Handle Size Selection (Continued)

Short

Groove

8.2 Handle - Assembly And Adjustment

The Modular Series II Whizard tools have been designed to allow the head of the tool to

be rotated relative to the handle. In this way, the tool can be adjusted to position the blade

properly to the product while the handle can be set to allow the operator to have a

comfortable position for the wrist.

The position which is selected will vary based on the individual work station, product, and

operator. To determine the proper position, it will be necessary to observe the operator

while trying various positions. Select the position in which the operator's wrist appears to

maintain the most neutral position and which is comfortable to the operator.

Note that left handed heads are available for left handed users. Do not assign a knife

designed for a right handed person to a left handed user. Possible exposure to increased

muscle stress may result.

Page 11

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.2 Handle - Assembly And Adjustment (Continued)

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

STEP 1

Pick up the Whizard Trimmer

Pick up a spacer ring or optional thumb support

If the optional thumb support is used, align the

thumb support tab with one of the notches

on the underside of the frame

The optional thumb support should be located

on the opposite side of the grease cup

Frame

Notches

STEP 2

While holding the Trimmer, pick up a handle and align the four (4) handle tabs with the four

notches located on the threaded portion of the frame tube

Firmly push the handle towards the bottom of the spacer ring or optional thumb support, and

align the handle tabs with the notches on the front of the tube as shown

For the initial adjustment position, the short groove on the handle should be on top, as shown.

STEP 3

Screw on the handle retaining knob.

Tighten firmly, but take care not to overtighten or the handle will be damaged.

Short Groove

Optional

Thumb Support

Handle

Tabs (4)

Handle

Retaining

Knob

Frame Tube Threads

Frame Notches

Page 12

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.2 Handle - Assembly And Adjustment (Continued)

The Whizard Hand Strap has been designed to allow the user to relax the fingers of the

hand between work cycles while maintaining control of the Trimmer.

NOTE: The Whizard® handstrap can not be

used with the flangeless handles.

Installation Of The Hand Strap

Remove the grease cup from the tool.

Push the grease cup thread through the round grommet end of the strap. Be sure that

the ribbed surface of the strap is on top as shown.

Reinstall the grease cup.

Weave the end of the strap down and back up through the slots in the flange of the

handle. The strap may be pulled through the slots to adjust for size.

An optional secondary strap has been provided with your Modular Series II Whizard

tool. To install the secondary strap :

Weave the secondary strap end through the opposite handle slots similar to the method

used to install the primary hand strap.

Bring the loose end of the strap across the tool and snap closed.

Primary

Hand

Strap

Optional

Secondary

Hand Strap

Page 13

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.2 Handle - Assembly And Adjustment (Continued)

The Disconnect Casing

Connect the casing to the Bettcher Industries motor as described in the motor manual.

Hold the trimmer in the hand you will use in operation, and with the other hand, grasp the

casing and push it into the end of the tool through the handle retaining knob.

Push the casing in until the latch catches the casing.

The disconnect lever rotates freely around the handle.

Align the disconnect lever in the notched-out area of the handle. Slightly open the fingers on

the hand holding the trimmer. Push the casing inward and hold the lever down in the handle

groove with the normal operating hand.

Check to see that the lever is seated completely flat within the groove.

Release the lever and the casing should pop out and stop the blade from turning. The motor

will continue to operate.

Handle Retaining Knob

Handle Groove

Disconnect Lever

NEVER

ALWAYS

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

LAY THE HANDPIECE DOWN ON THE WORK STATION OR LET IT HANG BY THE

FLEX SHAFT CASING.

TURN OFF AND PLACE THE HANDPIECE IN THE HANGER BRACKET.

NEVER

PLACE THE HANDPIECE IN THE HANGER WHILE THE BLADE

IS STILL REVOLVING!

Page 14

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.2 Handle - Assembly And Adjustment (Continued)

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

WHILE WEARING A PROTECTIVE GLOVE, ALWAYS CHECK TO ENSURE

THAT THE BLADE IS FREE TO ROTATE IN THE MACHINE PRIOR TO

STARTING. IF THE BLADE DOES NOT ROTATE, IT MAY CAUSE THE

HANDPIECE TO ROTATE IN THE HAND.

With the handpiece held in your operating hand, stand at your normal work position and

move your hand and the handpiece over your normal work area to check that there are no

binds or sharp bends in the flex shaft and casing assembly.

With your other hand, turn on the motor switch. While the blade is rotating, press the

rubber cap of the grease cup on the handpiece with your thumb. Press only until a light

coating of lubricant appears on the blade in the gear tooth area.

During daily use, the grease cup rubber cap should be depressed every 30 minutes. Refill

when empty.

WHIZARD SPECIAL GREASE COMPLIES WITH

USDA H1 STANDARDS FOR USE IN FEDERALLY

INSPECTED MEAT AND POULTRY PLANTS AND IS

AUTHORIZED BY AGRICULTURE AND AGRI-FOOD CANADA

FOR USE IN FOOD PLANTS.

DO NOT USE A SUBSTITUTE TYPE LUBRICANT.

USE OF SUBSTITUTE LUBRICANTS COULD

RESULT IN DAMAGE TO THE UNIT.

Prior to placing the tool in operation, refer to the guidelines for tool adjustment and handle

size selection. It is critical to use the proper size handle and that the tool be properly

adjusted in order to gain the full benefit of the

Modular Series II Whizard tool design

concept.

You are now ready to put the Modular Series II Whizard® tool into operation.

Page 15

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.3 Operating Procedure

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

NEVER

ALWAYS

Always hold the handpiece of the Modular Series II Whizard® tool with your thumb

extended. Let the handpiece rest naturally in the palm of the hand in a relaxed manner.

Each person should be allowed to hold the handpiece in a position that is most comfortable

to them.

The most-used motion is a long sweeping or gliding stroke across the trimming surface.

Hold the blade surface as flat to the trim surface as possible. A scooping action, such as

dipping ice cream, should be used around the vertebra.

On flat bones, such as backbones or blades, use a long, quick gliding stroke.

During the cutting operation do not try to pull the blade out of a cut. Let the blade do the

work as you would any other cutting tool. Finding the proper angle for Whizard

trimming will become easy after experience and use of the tool.

As with any meat cutting tool, your speed and efficiency is only as good as the blade

sharpness.

In order to achieve maximum unit and operator efficiency, it is recommended that sharp

blades be installed at each shift break. For this reason, it is suggested that extra blades be

kept on hand. For example, if 4 units are being used and there are 3 shift breaks, 16 blades

would be required. This would provide a sharp blade for start up and one for each break.

When following this procedure, steeling of the blade is virtually eliminated, and blades

need only be sharpened once a day with the use of a Whizard Model 210 Universal Blade

Sharpener, Bettcher® AutoEdge, or by hand stoning.

If blades are not changed at each shift break, it may be required to steel the blade.

HOLD THE PRODUCT BEING TRIMMED IN YOUR HAND.

LAY THE PRODUCT FLAT ON THE WORK SURFACE.

Page 16

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.3 Operating Procedure (Continued)

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

PROPER PROTECTION OF HANDS, A PROTECTIVE GLOVE

FOR

SHOULD BE USED WHEN OPERATING THIS EQUIPMENT AND

DURING THE HANDLING OF BLADES.

ALWAYS

DISCONNECT THE POWER AND REMOVE THE TOOL FROM

THE FLEX SHAFT CASING PRIOR TO SERVICING.

For Models 880M2-S&B,1880M2, 1400M2, 1500M2, 1932M2 and 1942M2 Only :

These tools are equipped with an adjustable Depth Gauge for setting a controlled product trim

thickness. The Depth Gauge can be adjusted for cuts up to ¼” thick. A Depth Gauge Setting

Device is also available. To adjust depth :

Hold the handpiece with the blade facing downward.

Loosen the attachment screws at the base of the plastic depth gauge.

Adjust the gauge setting by sliding it up or down to the desired height.

Retighten the attachment screws.

Depth Gauge Adjustment Range :

Slide to Adjust

Moving Up = Thicker Cut

Moving Down = Thinner Cut

Attachment

Screws

Model 880M2-B Model 1400M2

Page 17

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.3 Operating Procedure (Continued)

Optional Adjustable Fat (F) and Skinner (S) Disc Gauges

(850M2, 1000M2, 1300M2, 1933M2 and 1943M2):

Hold the handpiece with the blade facing

downward.

Adjustments – Turn the adjustment knob

clockwise for a thicker cut, or counterclockwise

Adjustment

Blade

Disc

Knob

Attachment

Screws (2)

for a thinner cut. Take care not to turn too far

as the depth control hub may disengage from

the shaft.

Model 1000M2-S

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

OR PROPER PROTECTION OF HANDS, A PROTECTIVE GLOVE SHOULD

F

BE USED WHEN OPERATING THIS EQUIPMENT AND DURING THE

HANDLING OF BLADES.

LWAYS DISCONNECT THE POWER AND REMOVE THE TOOL FROM THE

A

FLEX SHAFT CASING PRIOR TO SERVICING.

Steeling For All Models Except 750M2:

Use the Whizard Special Steel anytime you feel the edge of the blade needs to be raised for

better cutting action.

Use the Whizard Special Steel against the flat ground surface on the outside surface of the

blade. Be sure to hold the "steel" flat and across the centerline of the blade to prevent "rounding

off" or rolling of the edge.

The inside edge of the blade should be steeled only with the Special Steeling Device mounted on

the inside diameter of the blade housing. This is accomplished as follows :

Page 18

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.3 Operating Procedure (Continued)

Hold the Whizard Special Steel on the bottom edge of the blade and the handpiece in your

normal operating hand with the blade down, or away from you.

With your thumb, lightly push down on the push button of the steeling device. DO NOT hold

the steeling device against the rotating blade steadily, but rather lightly contact the blade edge.

Whizard

Special Steel

Push Button

Special Steeling

Device

While steeling the inside edge,

use the Whizard Special Steel

to steel the bottom edge.

Models 850M2/880M2-S&B/

1850M2 and 1880M2

Whizard

Special

Steel

Whizard

Special Steel &

Push Button

Models 1000M2/1300M2/1400M2/1500M2

Replace or sharpen the blade (see Section 9.3 for complete instructions) if this procedure does not

improve the cutting action.

Steeling For Models 750M2 Only :

Use the Whizard Special Steel any time you feel the blade needs to be raised for better cutting

action. Be sure to hold the steel at the actual angle of the blade edge. Running the steel at an angle

greater than the factory ground angle will round over the edge and make resharpening more

difficult.

Cross-Section View Of Steeling

Inside Blade Edge

Cross-Section View Of Steeling

Outside Blade Edge

Whizard Special Steel

Use the steel lightly and always make the last pass of the steel on the blade on the inside surface of

the blade.

Page 19

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.3 Operating Procedure (Continued)

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

PROPER PROTECTION OF HANDS, A PROTECTIVE

FOR

GLOVE SHOULD BE USED WHEN OPERATING THIS

EQUIPMENT AND DURING THE HANDLING OF BLADES.

ALWAYS

DISCONNECT THE POWER AND REMOVE THE TOOL

FROM THE FLEX SHAFT CASING PRIOR TO SERVICING.

The Modular Series II Whizard tools have been designed in such a way as to allow the blades to

be quickly removed and reinstalled.

Blade Changing

Hold the tool in your hand.

Loosen only the left cover retaining screw (Item #1)

With a screwdriver held in the opposite hand, insert the screwdriver in the housing slot (Item

#2). Note: The 1000M2-1500M2 tools have two slots in the housing. Using the frame as the

support point (Item #3), spread open the housing. The blade should fall out.

NOTE:

A slight tension on the left cover screw will allow

To Re-Install The Blade :

Turn the tool over so the blade side is up.

Spread open the blade housing with a screwdriver.

Insert a new blade in the housing.

Loosen the left cover screw so the housing will close.

Adjust the housing for proper running clearance. The blade should turn freely with a slight

side-to-side motion. This leaves room for the grease.

B

E CERTAIN THAT THE BLADE IS FREE TO ROTATE IN THE HOUSING. IF THE BLADE DOES NOT

TURN FREELY

Tighten the left cover screw to 35 in-lb. (4 N-m). Use of the Bettcher torque wrench kit is

recommended.

Re-check the running clearance.

, IT MAY CAUSE THE TOOL TO ROTATE IN THE HAND.

the blade housing to stay open on its own.

NOTE:

Leave a slight tension on the left cover screw

so the blade housing will stay open on its own.

Page 20

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.3 Operating Procedure (Continued)

To Re-Install The Blade : (Continued)

If the blade is too tight in the housing, adjustments can be made by loosening the left cover

retaining screw and slightly spreading open the housing. Check again for proper running

clearance. Retighten the left cover retaining screw.

If the blade is too loose in the housing, adjustments can be made by slightly loosening the

left cover screw and squeezing the housing lightly.

Check the housing for proper running clearance and retighten the left cover screw to

35 in-

lb. (4 N-m). Use of the Bettcher torque wrench kit is recommended.

#2

Housing Slot

#3

Frame

Support

Point

#1

Left Cover

Retaining

Screw

#2

#1

#3

Page 21

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.4 Fault Detection And Correction

PROBLEM PROBABLE CAUSE REMEDY

Inside bore of handpiece frame worn out Replace frame

Worn handpiece bearing Replace

Worn pinion gear Replace

Worn teeth on blade or pinion gear Replace

Handpiece

Vibration

Handpiece

Hot

Adjust blade housing. If still

Blade too loose in blade housing

too loose, try a new blade in

the housing.

Blade too tight in the housing Adjust blade housing

Inside of flex shaft casing worn Replace casing

Clean flex shaft and casing as

No lubrication on flex shaft or casing

described in Section 9.2 and

relubricate properly

Clean corrosion from the

Pinion gear tight in handpiece bearing

handpiece bearing and

lubricate

Blade tight in blade housing Adjust blade housing

Handpiece bearing not installed correctly

(No clearance between face of pinion gear

and blade housing) causing mechanical

bind

Reinstall bearing correctly.

With handpiece removed

from flex shaft, you should

be able to rotate the blade

freely by hand.

Page 22

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

8.4 Fault Detection And Correction

PROBLEM PROBABLE CAUSE REMEDY

Rapid Flex Shaft

Wear or Breakage

Dull Blade

Optional Thumb

Support Rotates

Improper cleaning and lubrication of flex

shaft and casing.

Inside of flex shaft casing worn, allowing

flex shaft to “wind-up” inside the casing

Refer to Section 9.2

Replace flex shaft casing

With handpiece removed

Mechanical bind in handpiece

from flex shaft, blade should

rotate freely by hand.

Correct any mechanical bind.

Sharpening can best be

accomplished by use of a

Improperly sharpened blades will cause

loss of production, increase wear of parts,

and operator fatigue

Whizard® Model 210

Universal Blade Sharpener,

or Bettcher® AutoEdge.

However, the blades can be

sharpened by hand. See

Section 9.3

Anti-rotation rib has broken off Replace

Spring Lost from

Flex Shaft Casing

Blade Skips or

Will Not Rotate

Refer to note in section 11.5

Improper Assembly

flex shaft and casing of

service parts list for assembly

instructions

Handpiece bearing too tight Check/Replace bearing

Flex shaft worn Replace shaft

Motor Adapter worn Replace adapter

Loose ferrule on shaft Replace shaft

Page 23

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

SECTION 9.0 Maintenance

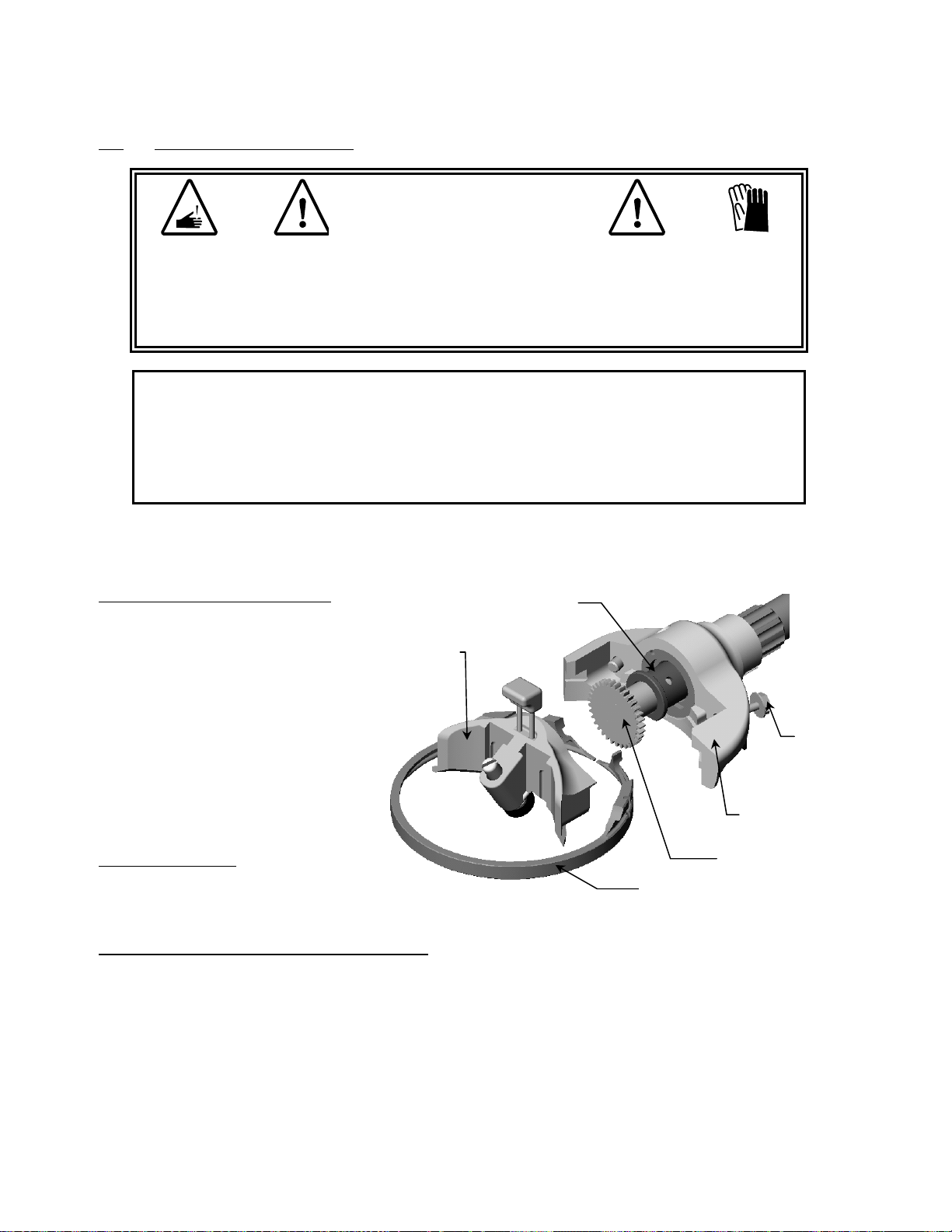

9.1 Disassembly Of Handpiece

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

PROPER PROTECTION OF HANDS, A PROTECTIVE

FOR

GLOVE SHOULD BE USED WHEN OPERATING THIS

EQUIPMENT AND DURING THE HANDLING OF BLADES.

ALWAYS

DISCONNECT POWER AND REMOVE TOOL FROM

FLEX SHAFT CASING PRIOR TO SERVICING.

To remove the casing from the handpiece, push the metal plate on the handle retaining knob in

and the tool should pop off.

Removal Of The Blade From The Tool :

Hold the tool in your hand.

Loosen only the left cover retaining

screw (Item #1)

With a screwdriver held in the opposite

hand, insert the screwdriver in the housing

slot (Item #2). Note: The 1000M2-1500M2

tools have two slots in the housing. Using

the frame as the support point (Item #3),

spread open the housing. The blade

should fall out.

Unscrew the grease cup.

Removal Of The Handle From The Tool :

Remove the handle retaining knob by turning counterclockwise.

While holding the trimmer, pull the handle and align the four (4) handle tabs with the four

notches located on the threaded portion of the frame tube.

Pull the handle off the tube.

Remove the handle spacer ring or optional thumb support.

#2

#3

#1

Page 24

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.1 Disassembly Of Handpiece (Continued)

Removal/Disassembly Of The Depth Gauge From The Cover:

Loosen the two attachment screws located inside the depth gauge. It is not necessary to

remove the screws.

Slide the gauge upward until the depth gauge clamps come out of the cover plate grooves.

Cover

Plate Grooves

Cover

Plate

Grooves

Depth

Gauge

Clamps

Depth

Gauge

Clamps

Model 880M2-B

Attachment Screws

(2)

Depth Gauge

Model 1400M2

Attachment Screws

(2)

Depth Gauge

Cover Plate

Grooves

Depth Gauge

Attachment Screws (2)

Model 1000M2-F

Removal Of The Blade Housing And Cover:

Loosen cover retaining screws until the

cover is free.

NOTE:

Pinion

Cover Plate

Frame

The screws will stay in the frame.

Remove the blade housing.

Pull the pinion out of the frame.

Blade

Housing

Cover Retaining

Screws (2)

Page 25

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.1 Disassembly Of Handpiece (Continued)

Removal Of The Bearing From The Frame :

The bearing is pulled out from the

front of the tool.

Use a screwdriver to reach into the

bearing and catch the bearing

grease groove.

While pulling upward, try to rotate

the bearing back and forth. Since

the bearing is not a press-fit, this

will work in most cases.

If the bearing will not come out, it

may be necessary to run a tap

into the bearing and pull on the

tap. If this is done, then the

Bearing

bearing must be replaced due

to damage.

The handpiece is now completely disassembled except for the cover retaining screws and

finger guard.

Finger Guard

(For Models 750M2 -1880M2 Only)

Cover Retaining Screws

NOTE:

The cover retaining screws do not normally need to removed. If they do need to be

removed, turn the screw while pulling down to engage the thread in the frame.

Page 26

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.2 Daily Inspections & Maintenance

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

ALWAYS DISCONNECT POWER AND REMOVE THE TOOL FROM THE

FLEX SHAFT CASING PRIOR TO SERVICING.

See Disassembly And Reassembly of Handpiece

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

AFTER SHARPENING, ALL ABRASIVE DUST MUST BE COMPLETELY

REMOVED FROM THE HANDPIECE. DISASSEMBLE THE UNIT AND

CAREFULLY WASH EACH PIECE WITH HOT, SOAPY WATER AND A

SMALL BRUSH.

Be Sure To Clean All Lubricant Out Of The

Inside Of Handpiece. Rinse And Dry Each Piece.

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

DO NOT ADJUST HANDLE OR THUMB SUPPORT WITH THE TRIMMER

RUNNING OR WITH BLADE INSTALLED.

Blade

Inspect the cutting edge height with Bettcher Blade Gauge.

Check for worn or chipped teeth.

Check for damage to the cutting edge.

Page 27

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.2 Daily Inspections & Maintenance (Continued)

Blade Housing Wear – For Models 750M2-1880M2

Inspect the inner diameter of the housing for wear.

Look for evidence of the blade rubbing the outer wall of the housing.

When holding the housing with a new blade installed, if the split in the housing touches the other side,

and the blade is still loose, the housing needs to be replaced. If a gap is seen, the housing is

acceptable.

Housing is Acceptable

Gap –

No Gap - Housing is Not

Acceptable

Blade Housing Wear – For Models 1000M2-1500M2

Inspect the inner diameter of the housing for wear.

When the housing wears to a point where the segments (grooves) are gone, the housing needs to be

replaced.

Segments

Page 28

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.2 Daily Inspections & Maintenance (Continued)

Pinion Gear

Check for worn or chipped teeth. Worn out teeth are indicated by rounded off and pointed tops on the teeth.

Bearing

Install a new pinion and move the pinion side to side.

If the bearing feels egg-shaped, it should be replaced.

As a rule of thumb, the bearing should be replaced at 500 hours of use or sooner.

Cover Plate

Look for signs of corrosion or wear on the cover.

Pay special attention to the area covering the gear teeth.

If the edge of the cover is worn, exposing the pinion and blade teeth, the cover should be replaced.

Hand Strap

Inspect the strap for hardening and cracks.

If any fibers, cuts, or cracks are showing, the strap should be replaced.

Knob

Inspect for cracks.

Make sure spring tension in the metal plate is adequate.

Make sure the metal plate is clean and moves freely.

Frame

Inspect the frame surfaces where the housing mounts.

Look for corrosion and any nicks or burrs that may prevent proper housing seating.

Inspect the housing locating key for damage.

Steeling Device

Inspect the surface condition of the carbide steel. If chipped or cracked it should be replaced.

Make sure the steeling device and the plunger are free to move.

The plunger and steel should be cleaned and oiled with mineral oil in order to keep free movement

and prevent build-up of dirt.

Depth Gauge and Depth Gauge Clamps

Inspect the depth gauge for wear or damage.

Make sure the depth gauge clamps are not bent.

Page 29

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.2 Daily Inspections & Maintenance (Continued)

Flex Shaft And Casing

Bearing

Inspect the casing for any cracks, tears, or

other wear. If any damage is found, replace

the casing.

Remove the flex shaft from the casing and

check for any flex shaft damage, such as

broken wires or kinking. If any damage is

detected, replace the flex shaft.

Reinsert the flex shaft into the casing, making

certain the flange of the flex shaft is pressed

against the bearing inside the casing.

Check the extension of the flexible shaft

driver at the motor end. The flexible shaft

driver should extend past the motor end

fitting. If the shaft extends less than 5/64”,

replace the casing.

Motor End

Fitting

Flex Shaft

Driver

Casing

Page 30

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.2 Daily Inspections & Maintenance (Continued)

Casing Replacement

When the casing needs to be replaced, the drive end assembly may be retained and reused.

Hold the casing (#1) in a vise.

Unscrew the drive end assembly (#4) by turning counterclockwise using the wrench flats on the drive

end assembly.

Unscrew and remove the nylon washer (#3), casing latch collar (#2) or lever mounting collar (#5)

from the casing.

Discard the casing but retain and reuse the drive end assembly (#4), the nylon washer (#3),

the casing latch collar (#2) – or the lever mounting collar (#5) and disconnect lever (#6).

7

1

2

5

3

4

6

To Reassemble the Drive End Assembly to a New Casing

If using the casing disconnect, place the disconnect lever (#6) onto the lever mounting collar (#5).

Slip the casing latch collar (#2) or lever mounting collar (#5) with disconnect lever (#6) onto the new

casing.

Thread the nylon washer (#3) onto the new casing.

Clean the threads of the new casing assembly and apply Loctite #242 Threadlocker or equivalent.

Screw the drive end assembly (#4) on the new casing.

Tighten by hand and then with a wrench while holding the casing by hand.

NOTE:

DO NOT hold the new casing in a vise or use pliers as

damage will occur. It is not necessary to over-tighten this joint.

Page 31

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.2 Daily Inspections & Maintenance (Continued)

Drive End Assembly Inspection And Replacement

Removal of the driver assembly

With one hand, pull the spring (#1) back to expose the knurled cap (#2) at the end of the tube.

Using the other hand, grip the knurled cap (#2) with a pair of pliers.

Using a 7/16” open end wrench, hold the flats on the drive end assembly (#3) and turn the knurled cap

(#2) counterclockwise.

Unscrew the knurled cap (#2) until the threads are free from the tube.

Pull the driver assembly (#4) out of the tube.

NOTE: Never use pliers on the tube as damage to the internal parts may occur.

3

1

2

4

Inspection of the driver assembly (See Figure Below)

Wipe off excess grease.

Inspect the split bearing (#5) for wear or damage. Replace if required.

Slide the knurled cap (#6) forward against the driver (#7).

Wiggle the bushing (#8) sideways to check for excessive movement. Movement

should be minimal.

7

6 8

5

Slide the bushing (#8) and washer (#9) forward

toward the driver (#7). If the gap is 1/16” or

greater, the driver should be replaced.

9

10

Check the coupling cross pin (#10). If there is any free play or movement, replace the driver

assembly.

Page 32

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.2 Daily Inspections & Maintenance (Continued)

Drive End Assembly Inspection And Replacement

Replacement of the Driver Assembly

Clean the threads on the tube and knurled cap.

Apply Whizard special grease to split bearing (#3) and bushing (#2).

Apply a small amount of Loctite #242 Threadlocker or equivalent to the threads on the

knurled cap (#1).

Pull the spring (#4) on the drive end assembly back with one hand and insert the driver

assembly in the tube.

Push in and tighten the knurled cap until it is flush with the end of the tube. Pliers may be

used for this however it is not necessary to tighten beyond hand tight.

Allow ½ hour dry time for the threadlocker before the assembly is put in service.

1

2

3

4

Replacement of the Split Bearing (#3)

Remove the driver assembly as described above.

Insert a small screwdriver into the split in the bearing.

Spread the bearing and slide over the shoulder on the driver.

Clean the surface of the coupling and apply Whizard special grease.

Hold the bearing with the inside cone facing the end of the coupling.

Push the bearing on until it snaps into position.

Install the driver assembly as described above.

Page 33

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.3 Blade Sharpening – Daily

CORRECT POSITION OF

STONE OR STEEL FOR

SHARPENING

BLADE CUTTING EDGE

WARNING

AFTER SHARPENING, ALL ABRASIVE DUST MUST BE COMPLETELY

REMOVED FROM THE HANDPIECE. DISASSEMBLE THE UNIT AND

CAREFULLY WASH EACH PIECE WITH HOT, SOAPY WATER AND A

SMALL BRUSH.

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

FOR PROPER PROTECTION OF HANDS, A PROTECTIVE GLOVE SHOULD

BE USED WHEN OPERATING THIS EQUIPMENT AND DURING THE

HANDLING OF BLADES.

The blade should be stoned or sharpened on a Whizard Model 210 Universal Blade

Sharpener or Bettcher® AutoEdge at the end of each work day. Be sure to clean the blade

first to remove all grease or meat particles which could coat the stone and greatly reduce its

effectiveness. In the event the stone becomes coated, simply scrub it using hot, soapy

water.

HAND STONING – Models 850M2/880M2/1000M2-1500M2/1850M2/1880M2:

With the motor running, apply the flat side of the stone to the outside of the blade as shown

in the illustration. The stone should be applied with the flat part of the stone resting on the

flat part of the blade edge to be ground, using a "back and forth" motion.

Use the Special Whizard steel to finish sharpening as described in the Operating Section.

Page 34

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.4 Assembly Of Handpiece

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

PROPER PROTECTION OF HANDS, A PROTECTIVE GLOVE SHOULD

FOR

BE USED WHEN OPERATING THIS EQUIPMENT AND DURING THE

HANDLING OF BLADES.

CAUTION

INSPECTION OF ALL PARTS FOR EXCESSIVE WEAR IS CRITICAL TO ENSURE

PROPER AND SAFE OPERATION. VIBRATION OR LOCK-UP MAY OCCUR AS

A RESULT OF THE USE OF EXCESSIVELY WORN PARTS.

Prior to assembly, be sure all parts are clean and have been inspected for wear per Section 9.2.

Handpiece Bearing Installation

Bearing

Push the handpiece bearing in

the frame bore and align the

bearing flat with the frame flat.

The bearing should go in with

Cover

Plate

minimal effort and not require

pressing.

Do not force the bearing in. If

it does not go in, check frame

Cover

Retaining

Screw

and bearing for damage or

build-up.

Frame

Pinion Installation

The pinion should fit freely into

Blade Housing

Pinion

the bearing.

Blade Housing And Cover Plate Installation

Set the blade housing on the frame and put the cover plate on.

While holding the cover plate firmly against the housing and frame start the two cover

retaining screws.

Tighten the screws lightly.

Page 35

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.4 Assembly Of Handpiece (Continued)

Grease Cup

Pick up the Whizard Trimmer

Pick up a spacer ring or optional thumb support

If the optional thumb support is used, align the thumb

support tab with one of the notches on the underside of

the frame

The optional thumb support should be located on the

opposite side of the grease cup

Frame

Notches

While holding the Trimmer, pick up a handle and align the four (4) handle tabs with

the four notches located on the threaded portion of the frame tube

Firmly push the handle towards the bottom of the spacer ring or optional thumb support,

and align the handle tabs with the notches on the front of the tube as shown

For the initial adjustment position, the short groove on the handle should be on top, as

shown.

NOTE: The handle can be adjusted to suit the operator and the work station by pulling the

handle back away from the frame and re-locating it on another set of notches on the frame

tube.

Screw on the handle retaining knob.

Tighten firmly but take care not to overtighten or the handle will be damaged.

Optional

Thumb

Support

Short Groove

Handle Tabs (4)

Page 36

Frame Tube Threads

And Notches

Handle

Retaining

Knob

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.4 Assembly Of Handpiece (Continued)

Installation Of The Hand Strap And Grease Cup

Push the threaded end of the grease cup through the round grommet end of the strap.

Be sure that the ribbed surface of the strap is on top as shown.

Reinstall the grease cup.

Weave the end of the strap down and back up through the slots in the flange of the

handle. The strap may be pulled through the slots to adjust for size.

An optional secondary strap has been provided with your Modular Series II Whizard

tool. To install the secondary strap :

Weave the secondary strap end through the opposite handle slots similar to the method

used to install the primary hand strap.

Bring the loose end of the strap across the tool and snap closed.

Optional

Secondary

Hand Strap

Primary

Hand

Strap

Page 37

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.4 Assembly Of Handpiece (Continued)

Installation Of The Depth Gauge

(For 880M2-S&B, 1880M2, 1400M2, 1500M2, 1932M2 and 1942M2 Only)

Cover Plate

Grooves

Slide the depth gauge downward

along the cover plate grooves until

the depth gauge clamps catch in

Depth

Gauge

Clamp

position.

Final height adjustment can be

made after the blade is installed.

Attachment

Screws (2)

Tighten the two attachment screws.

Model 880M2-B

Depth Gauge

Attachment

Screws (2)

Cover Plate

Grooves

Depth

Gauge

Model 1400M2

Depth

Gauge

Clamp

Installation Of The Adjustable Disc Gauge

(For 850M2, 1000M2 and 1300M2)

Slide the depth gauge downward along the

Cover

Plate

Grooves

cover plate grooves until the depth gauge

clamps catch in position.

Final height adjustment can be made after

the blade is installed.

Tighten the two attachment screws.

Attachment

Screws (2)

Model 1000M2-F

Page 38

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

9.4 Assembly Of Handpiece (Continued)

Installation of the Blade :

Turn the tool over so the blade side is up.

Spread open the blade housing with a screwdriver.

NOTE:

Leave a slight tension on the left cover screw so the blade housing will stay open on its own.

Insert a new blade in the housing.

Loosen the left cover screw so the housing will close.

BE CERTAIN THAT THE BLADE IS FREE TO ROTATE IN THE HOUSING. IF THE BLADE DOES NOT

ROTATE FREELY

Adjust the housing for proper running clearance. For more information, refer to section 8.3,

Operating Procedures.

, IT MAY CAUSE THE TOOL TO ROTATE IN THE HAND.

9.5 Preventive Maintenance

CAUTION

USE ONLY BETTCHER WHIZLUBE

At least once each week, more frequently for multi-shift operation, the flex shaft casing should be

cleaned, inspected and lubricated as follows:

Exterior Of Casing – Clean the exterior of the casing with a mild detergent. For best results, use

Whizard® EXTRA Heavy Duty Cleaner, diluted according to the directions on the container.

Flex Shafts - Clean the shaft after 20 hours of operation by wiping off the old grease with a dry

cloth. Avoid the use of any liquids on the shaft. Spray the shaft with a generous amount of

Bettcher WhizLube as it is pushed back into the casing. Inspect the casing support for wear,

cracks, or chips.

CAUTION

DO NOT USE ANY HYDROCARBON SOLVENTS OR MINERAL OIL ON, OR IN, THE

CASING.

Page 39

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

SECTION 10.0 Cleaning

CAUTION

CASINGS, FLEX SHAFTS, AND HANDPIECES SHOULD BE REMOVED

RIOR TO AREA CLEANUP.

P

10.1 Periodic Cleaning During Use

Remove meat particles and rinse with warm soapy water. Wash the Whizard Trimmer

with warm cleaning solution. For best results, clean the Whizard® Trimmer with E

XTRA

Heavy Duty Cleaner, diluted according to the directions on the container. Rinse

thoroughly with water.

10.2 Cleaning After Daily Use

Disassemble and clean thoroughly daily.

Remove the blade and blade housing and clean them with a brush and cleaner. For best

results, clean the Whizard® Trimmer with E

XTRA Heavy Duty Cleaner, diluted according

to the directions on the container. Rinse thoroughly with water and dry.

Remove the hand strap from the handpiece per the instructions in Section 9.2 Clean these

in warm soapy water.

Before assembly, rinse well with clean water, dry, and assemble per instructions in Section

9.4.

10.3 Cleaning Solutions

Avoid the use of aggressive cleaning products as they will damage the aluminum handle

assembly.

Page 40

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

SECTION 11.0 Spare Parts List

Bettcher Industries, Inc. proudly manufactures

quality parts for your Bettcher equipment.

For optimum performance of your Bettcher

equipment, use only parts manufactured by

Bettcher Industries, Inc.

Page 41

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.1 Head Assembly – 750M2

2

3

1

13

11

4

10

12

5

6

8

7

9

Page 42

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.1 Head Assembly – 750M2

ITEM DESCRIPTION

Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 13)

XX-Small 183722 184580 183724 184581

X-Small 183386 184582 183390 184583

Small 183387 184584 183391 184585

Medium 183388 184586 183392 184587

Large 183389 184588 183393 184589

Disconnect Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 13)

XX-Small 183721 184806 183723 184807

X-Small 183378 184808 183382 184809

Small 183379 184810 183383 184811

Medium 183380 184812 183384 184813

Large 183381 184814 183385 184815

Head Assembly (Includes Items 3 - 10) 183021 183022

1 Handle Retaining Knob 183086 183086

2 Hand Strap – Primary 183065 183065

Hand Strap – Secondary

(Not Shown)

3 Grease Cup 173191 173191

Parts for Grease Cup (Not Shown)

Retainer Ring Only 173190 173190

Bulb and Washer 173208 173208

Base and Fitting 173187 173187

4 Frame Assembly 183896 183897

5 Bearing 183060 183060

6 Pinion 183063 183063

7 Cover 183088 183088

8 Blade Housing 183070 183070

9 Blade 183071 183071

10 Cover Retaining Screw (2 required) 183654 183654

11 Handle Spacer Ring 183120 183120

Handle Spacer Ring for XX-Small 163313 163313

12 Thumb Support (Gray) 163207 163207

13

See Section 11.20 for Handle Options

750M2 RH 750M2 LH

Flanged Flangeless Flanged Flangeless

183121 183121

Page 43

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.2 Head Assembly – 850M2

2

3

11

4

12

1

14

10

5

13a

13c

13d

13b

13

6

7

8

9

Page 44

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.2 Head Assembly – 850M2

ITEM DESCRIPTION

Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

XX-Small 183726 184590 183728 184591

X-Small 183402 184592 183406 184593

Small 183403 184594 183407 184595

Medium 183404 184596 183408 184597

Large 183405 184598 183409 184599

Disconnect Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

XX-Small 183725 184816 183727 184817

X-Small 183394 184818 183398 184819

Small 183395 184820 183399 184821

Medium 183396 184822 183400 184823

Large 183397 184824 183401 184825

Head Assembly (Includes Items 3 – 10)

1 Handle Retaining Knob 183086 183086

2 Hand Strap – Primary 183065 183065

Hand Strap – Secondary

(Not Shown)

3 Grease Cup 173191 173191

Parts for Grease Cup (Not Shown)

Retainer Ring Only 173190 173190

4

5

6

7

8

9

10

11

Frame Assembly 183896 183897

Bearing 183060 183060

Pinion 183063 183063

Cover with Special Steeling

Device

Blade Housing 183070 183070

Blade 183072 183072

Cover Retaining Screw (2

required)

Handle Spacer Ring 183120 183120

Handle Spacer Ring for XXSmall

12 Thumb Support (Gray) 163207 163207

13

13a

13b

13c

13d

14

Disc Gauge Kit 850M2-S

See Section 11.20 for Handle Options

Bulb and Washer 173208 173208

Base and Fitting 173187 173187

Repair Kit (Not Shown) 183474 183474

(Optional)

Parts for Disc Gauge

Knob 183791 183791

Frame 183798 183798

Spring 121635 121635

Disc Assembly 183799 183799

850M2 RH 850M2 LH

Flanged Flangeless Flanged Flangeless

183023 183024

183121 183121

183056 183056

183654 183654

163313 163313

183801 183801

Page 45

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.3 Head Assembly – 880M2-B

1

2

3

12

4

5

6

7

8

11

9

10

13

14

Page 46

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.3 Head Assembly – 880M2-B

ITEM DESCRIPTION

880M2-B RH 880M2-B LH

Flanged Flangeless Flanged Flangeless

Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 12, 13, 14)

XX-Small 183730 184600 183732 184601

X-Small 183418 184602 183422 184603

Small 183419 184604 183423 184605

Medium 183420 184606 183424 184607

Large 183421 184608 183425 184609

Disconnect Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 12, 13, 14)

XX-Small 183729 184826 183731 184827

X-Small 183410 184828 183414 184829

Small 183411 184830 183415 184831

Medium 183412 184832 183416 184833

Large 183413 184834 183417 184835

Head Assembly (Includes Items 3 - 11) 183025 183026

1 Handle Retaining Knob 183086 183086

2 Hand Strap – Primary 183065 183065

Hand Strap – Secondary (Not Shown) 183121 183121

3 Grease Cup 173191 173191

Parts for Grease Cup (Not Shown)

Retainer Ring Only 173190 173190

Bulb and Washer 173208 173208

Base and Fitting 173187 173187

4 Frame Assembly 183896 183897

5 Bearing 183060 183060

6 Pinion 183063 183063

7 Cover with Special Steeling Device 183056 183056

Repair Kit (Not Shown) 183474 183474

8 Depth Gauge Assembly 183075 183075

9 Blade Housing 183070 183070

10 Blade 183072 183072

11 Cover Retaining Screw (2 required) 183654 183654

12 Handle Spacer Ring 183120 183120

Handle Spacer Ring for XX-Small 163313 163313

13 Thumb Support (Gray) 163207 163207

14

See Section 11.20 for Handle Options

Page 47

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.4 Head Assembly – 880M2-S

2

3

12

4

13

1

14

5

6

7

8

11

9

10

Page 48

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.4 Head Assembly – 880M2-S

ITEM DESCRIPTION

880M2-S RH 880M2-S LH

Flanged Flangeless Flanged Flangeless

Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 12, 13, 14)

XX-Small 183734 184610 183736 184611

X-Small 183434 184612 183438 184613

Small 183435 184614 183439 184615

Medium 183436 184616 183440 184617

Large 183437 184618 183441 184618

Disconnect Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 12, 13, 14)

XX-Small 183733 184836 183735 184837

X-Small 183426 184838 183430 184839

Small 183427 184840 183431 184841

Medium 183428 184842 183432 184843

Large 183429 184844 183433 184845

Head Assembly (Includes Items 3 - 11) 183027 183028

1

Handle Retaining Knob 183086 183086

2

Hand Strap – Primary 183065 183065

Hand Strap – Secondary

(Not Shown)

3

Grease Cup 173191 173191

183121 183121

Parts for Grease Cup (Not Shown)

4

5

6

7

8

9

10

11

12

Frame Assembly 183896 183897

Bearing 183060 183060

Pinion 183063 183063

Cover with Special Steeling Device 183056 183056

Depth Gauge Assembly 183076 183076

Blade Housing 183070 183070

Blade 183072 183072

Cover Retaining Screw (2 required) 183654 183654

Handle Spacer Ring 183120 183120

Handle Spacer Ring for XX-Small 163313 163313

Retainer Ring Only 173190 173190

Bulb and Washer 173208 173208

Base and Fitting 173187 173187

Repair Kit (Not Shown) 183474 183474

13 Thumb Support (Gray) 163207 163207

14

See Section 11.20 for Handle Options

Page 49

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.5 Head Assembly – 1850M2

2

3

1

14

11

4

12

13a

5

10

6

13b

13c

13

8

13d

9

7

Page 50

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.5 Head Assembly – 1850M2

ITEM DESCRIPTION

1850M2 RH 1850M2 LH

Flanged Flangeless Flanged Flangeless

Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

XX-Small 183738 184620 183740 184621

X-Small 183450 184622 183454 184623

Small 183451 184624 183455 184625

Medium 183452 184626 183456 184627

Large 183453 184628 183457 184629

Disconnect Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

XX-Small 183737 184846 183739 184847

X-Small 183442 184848 183446 184849

Small 183443 184850 183447 184851

Medium 183444 184852 183448 184853

Large 183445 184854 183449 184855

Head Assembly (Includes Items 3 – 10) 183029 183030

1 Handle Retaining Knob 183086 183086

2 Hand Strap – Primary 183065 183065

Hand Strap – Secondary (Not

Shown)

183121 183121

3 Grease Cup 173191 173191

Parts for Grease Cup (Not Shown)

Retainer Ring Only 173190 173190

Bulb and Washer 173208 173208

Base and Fitting 173187 173187

4 Frame Assembly 183896 183897

5 Bearing 183060 183060

6 Pinion 183063 183063

7

Cover with Special Steeling Device

183053 183053

Repair Kit (Not Shown) 183476 183476

8 Blade Housing 183070 183070

9 Blade 183073 183073

10

Cover Retaining Screw

(2 required)

183654 183654

11 Handle Spacer Ring 183120 183120

Handle Spacer Ring for XX-Small 163313 163313

12 Thumb Support (Gray) 163207 163207

13

Disc Gauge Kit 1850M2-K

(Optional)

184479 184479

Parts for Disc Gauge:

13a Knob 183791 183791

13b Frame 183798 183798

13c Spring 121635 121635

13d Disc Assembly 184481 184481

14

See Section 11.20 for Handle Options

Page 51

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.6 Head Assembly – 1880M2

2

3

12

4

13

1

14

5

6

7

8

11

9

10

Page 52

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.6 Head Assembly – 1880M2

ITEM DESCRIPTION

1880M2 RH 1880M2 LH

Flanged Flangeless Flanged Flangeless

Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 12, 13, 14)

XX-Small 183742 184630 183744 184631

X-Small 183466 184632 183470 184633

Small 183467 184634 183471 184635

Medium 183468 184636 183472 184637

Large 183469 184638 183473 184639

Disconnect Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

XX-Small 183741 184856 183743 184857

X-Small 183458 184858 183462 184859

Small 183459 184860 183463 184861

Medium 183460 184862 183464 184863

Large 183461 184864 183465 184865

Head Assembly (Includes Items 3 - 11) 183031 183032

1 Handle Retaining Knob 183086 183086

2 Hand Strap – Primary 183065 183065

Hand Strap – Secondary (Not Shown) 183121 183121

3 Grease Cup 173191 173191

Parts for Grease Cup (Not Shown)

Retainer Ring Only 173190 173190

Bulb and Washer 173208 173208

Base and Fitting 173187 173187

4 Frame Assembly 183896 183897

5 Bearing 183060 183060

6 Pinion 183063 183063

7 Cover with Special Steeling Device 183053 183053

Repair Kit (Not Shown) 183476 183476

8 Depth Gauge Assembly 183077 183077

9 Blade Housing 183070 183070

10 Blade 183073 183073

11 Cover Retaining Screw (2 required) 183654 183654

12 Handle Spacer Ring 183120 183120

Handle Spacer Ring for XX-Small 163313 163313

13 Thumb Support (Gray) 163207 163207

14

See Section 11.20 for Handle Options

Page 53

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

a

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.7 Head Assembly – 1000M2

1

2

14

3

11

4

12

10

5

6

13

13b

7

8

13c

9

13d

13

Page 54

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.7 Head Assembly – 1000M2

ITEM DESCRIPTION

Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

Disconnect Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

Head Assembly (Includes Items 3 – 10) 183169 183170

1 Handle Retaining Knob 183086 183086

2 Hand Strap – Primary 183065 183065

3 Grease Cup 173191 173191

4 Frame Assembly 184362 184363

5 Bearing 183060 183060

6 Pinion 183154 183154

7 Cover with Special Steeling Device 183163 183163

8 Blade Housing 183143 183143

9 Blade 183141 183141

10 Cover Retaining Screw (2 required) 183654 183654

11 Handle Spacer Ring 183120 183120

XX-Small

X-Small

Small

Medium

Large

XX-Small

X-Small

Small

Medium

Large

Hand Strap – Secondary (Not Shown) 183121 183121

Parts for Grease Cup (Not Shown)

Retainer Ring Only 173190 173190

Bulb and Washer 173208 173208

Base and Fitting 173187 173187

Repair Kit (Not Shown) 183477 183477

Handle Spacer Ring for XX-Small

1000M2 RH 1000M2 LH

Flanged Flangeless Flanged Flangeless

183746 184640 183748 184641

183185 184642 183189 184643

183186 184644 183190 184645

183187 184646 183191 184647

183188 184648 183192 184649

183745 184866 183747 184867

183177 184868 183181 184869

183178 184870 183182 184871

183179 184872 183183 184873

183180 184874 183184 184875

163313 163313

12 Thumb Support (Gray) 163207 163207

13 Disc Gauge Kit (Optional)

1000M2-S (Skinner) 183792 183792

1000M2-F (Fat) 183793 183793

1000M2-N (Special) 184365 184365

Parts for Disc Gauge

13a Knob 183791 183791

13b Frame Assembly 183784 183784

13c Spring 121635 121635

13d Disc Assembly (S) 183787 183787

Disc Assembly (F) 183788 183788

Disc Assembly (N) 184367 184367

14

See Section 11.20 for Handle Options

Page 55

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

11.8 Head Assembly – 1300M2

1

2

14

3

11

4

12

10

5

6

13a

7

8

13b

9

13d

13c

13

Page 56

TECHNICAL BETTCHER LARGE MODULAR SERIES II WHIZARD

MANUAL INDUSTRIES, INC. REV. June 28, 2012

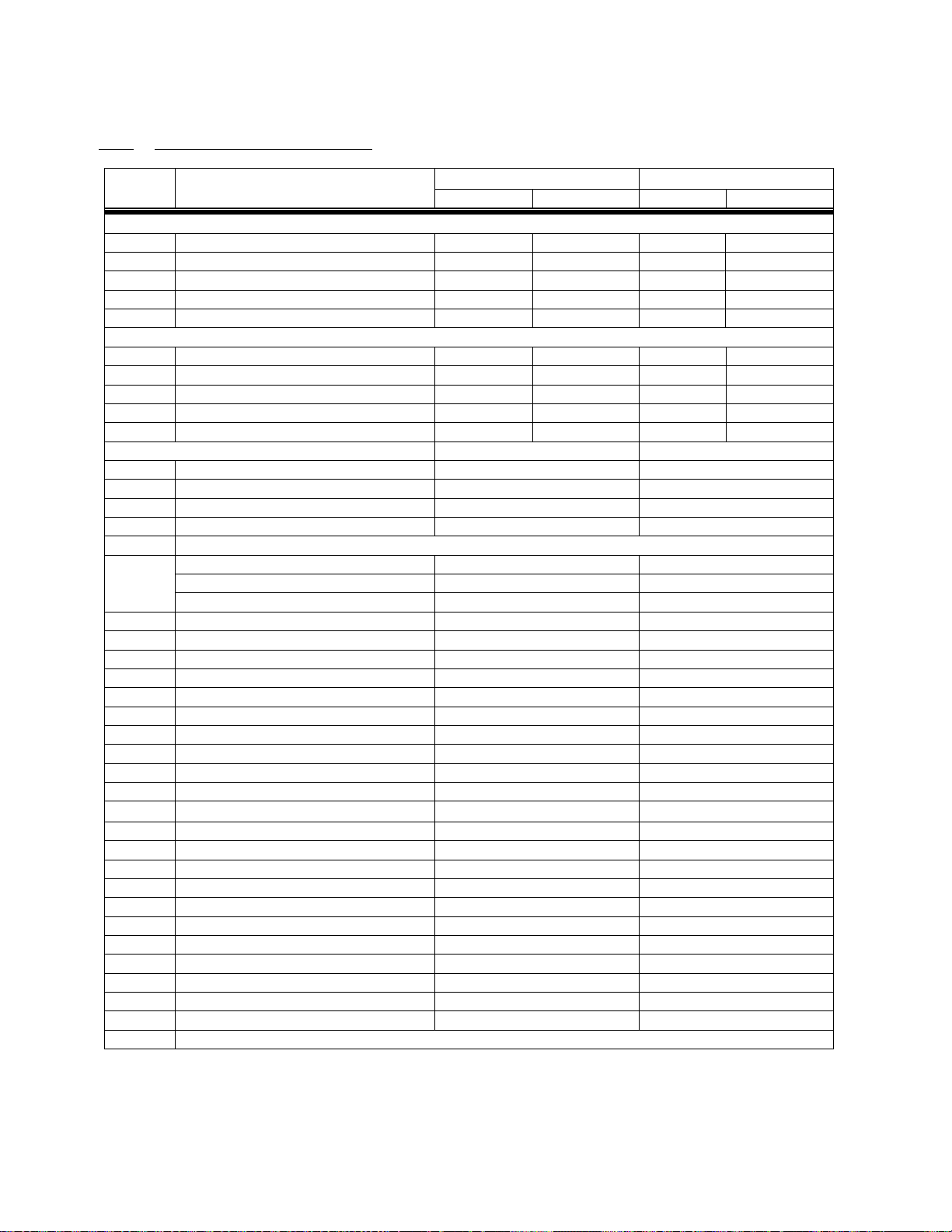

11.8 Head Assembly – 1300M2

ITEM DESCRIPTION

Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

XX-Small 183750 184650 183752 184651

X-Small 183201 184652 183205 184653

Small 183202 184654 183206 184655

Medium 183203 184656 183207 184657

Large 183204 184658 183208 184659

Disconnect Handpiece Assembly (Includes the Head Assy. Plus Items 1, 2 (Flanged Only), 11, 12, 14)

XX-Small 183749 184876 183751 184877

X-Small 183193 184878 183197 184879

Small 183194 184880 183198 184881

Medium 183195 184882 183199 184883

Large 183196 184884 183200 184885

Head Assembly (Includes Items 3 – 10) 183171 183172

1 Handle Retaining Knob 183086 183086

2 Hand Strap – Primary 183065 183065

Hand Strap – Secondary (Not Shown) 183121 183121

3 Grease Cup 173191 173191