XT3

2

1

E12601-00

21

XT3

2

1

Battery Burnisher

©2007 Betco Corporation. All Rights Reserved. 1001 Brown Avenue Toledo, Ohio 43607-0127 888-GO-BETCO www.betco.com

Operators Manual

Parts Schematic

Table of Contents

Page

Description

2

Table of Contents

3,4

Safety Instructions - Very Important - Must Read

5

XT 21 Product Specifications

6

Procedures for Loading, Transporting, and Unloading Machine

7

Operating Instructions

8

Battery Charging

9

Battery Charger Operation

10

Battery Maintenance

11

Battery Charger Settings

12

Battery Discharge Indicator (BDI) & Hour Meter

13

Pad Changing Instructions

14

Machine Balancing Set Up

15

Belt Tensioning

16,17

Covers & Handle Parts

18,19

Frame & Deck Parts

20,21

Belt Drive Parts

22,23

Pad Driver Parts

24,25

Battery & Electrical Parts

26

Electrical Layout

27

Wiring Ladder Diagram

28

Troubleshooting Guide

29 30

Warranty

Page 2 of 30

SAFETY INSTRUCTIONS

Page 3 of 30

Hazard Level Explanation or Description of Hazard Level

Failure to follow safety instructions labeled

injury or death to the machine operator or others.

the machine operator or others. Also, machine or property damage could

occur.

Failure to follow safety instructions labeled

to the machine or other property.

could result in damage

could result in severe

could result in injury to

This manual contains important information about your

machine. Read and understand all instructions before

operating the machine. Failure to read and follow the

instructions could result in injury to the person operating the

machine or injury to others. Damage to the machine or other

property could occur if instructions are not followed.

Do not operate this machine around any solvents, thinners, or other

flammable liquids or materials. Electrical sparks can cause a fire or even an

explosion.

Do not smoke around the machine. Also, keep all sparks and flames away

from the batteries. The batteries generate gases that can cause an

explosion.

Special care needs to be used when working on or near the batteries. Wear

eye protection. Do not lay tools on batteries, as they may short out battery

terminals. Do not wear metal jewelry, as it may short out battery terminals.

Charging batteries can be dangerous. Be aware that the battery charger

may have a relatively low voltage output, but the current output is very high

and therefore dangerous. Do not operate the charger if any parts of the

charger or charger cords are damaged. Do not stand on a wet floor when

connecting or disconnecting charger to the power outlet or to the

machine.

Safety Instructions are continued on the next page

SAFETY INSTRUCTIONS

Page 4 of 30

Battery acid is dangerous. Wear eye and face protection, hand protection,

and body protection when working on and around batteries. If you get acid

on your skin, wash off immediately. If you get acid on your clothing, remove

clothing and wash any skin that was in contact with the clothing. Baking

soda mixed with water will help to neutralize the acid on your skin.

The machine is very heavy, so be very careful when loading, transporting,

and unloading the machine.

Keep all body parts, clothing, and objects away from moving parts.

Operate machine from the rear, not from the side.

Disconnect a wire to the batteries before working on the machine.

Do not operate machine with charger plugged in.

Do not operate machine with any parts damaged or missing.

Do not operate close to stairs, loading docks, or other drop-offs. Do not park

machine in such a manner that it could roll, forward or backward, off a

drop-off.

Authorized personnel must perform maintenance and repairs. Do not alter or

modify the machine, unless authorized by the manufacturer.

Do not expose the electrical components to water or excessive moisture.

Always put caution signs around the areas that are being cleaned.

Do not use machine as a “ladder”. Do not use machine as a “forklift” to

push stuff around. Do not ride or let anyone ride on the machine.

Your machine warranty may be voided if parts other than PowerBuff parts

are used.

XT3 - 21 Product Specifications

Page 5 of 30

Burnish path: 21”

Pad size: 21”

Motor: Maintenance Free, brushless, rated at 5 hp.

Motor controller: Monitors and maintains consistent pad speed and torque

Motor speed: 2000 rpm

Pad pressure: Approx. 25 lbs.

Pad driver: Flexible, Flex Lock III

Center lock: Threaded, for easy installation

Noise level: 70 dB (at operator)

Voltage: 36 volt system

Batteries: (3) Maintenance free, 12 volt, 135 Amp Hour, AGM

Run time: Up to 2.5 hours

Charger: Onboard, high frequency computer controlled

Battery/hour meter gauge: Yes, BDI (battery discharge indicator) computer controlled

Key switch: Yes.

Main power light: Yes, bright red

Safety switch: Yes, spring loaded handle assembly

Length: 56”

Width: 24.5”

Height: 40.5”

Weight: 484 lbs.

Tank Construction: Polyethylene

Deck Construction: Cast Aluminum

Wheels: (2) 6” heavy duty, non-marking, sealed bearings

Casters: (2) 3” heavy duty, non-marking

Productivity: Up to 24,000 sq.ft/hr.

Procedures for Loading, Transporting, and

Page 6 of 30

Unloading Battery Burnisher

DANGER: The machine is very heavy, so be very careful when loading,

transporting, and unloading the machine. Use at least two

people to load or unload the machine.

• Loading Procedure Using a Ramp

a) It is not recommended that the battery burnisher be loaded using a ramp with

an incline of more than 7 degrees. The machine is not self-propelled and

therefore it is not able to assist itself up a ramp. It is too heavy to manually

push up a steep incline.

b) If you must load with a ramp, the incline must be no more than 7 degrees. (This

would permit a height of no more than one foot for an 8-foot ramp).

c) Ramp must be secured to vehicle, and be clean and dry.

d) Machine must be pushed or pulled straight up the ramp and never at an angle.

• Loading Procedure Using a Lift Gate

a) Lift gate must have ample capacity to lift the burnisher.

b) Wheels must be firmly chocked to prevent burnisher from rolling off the lift gate.

• Securing Battery Burnisher

a) Burnisher must be secured, so that it will not roll or turn over. Use chocks and

tie downs to secure.

b) Please be aware that the battery burnisher is very heavy, and that a metal

bulkhead in a van may not contain equipment in the event of an accident. The

equipment in a van can be more dangerous than the accident itself.

• Unloading Procedure Using a Ramp

a) Ramp must be long enough so that removal can be controlled. Use same ramp

incline restrictions as used for loading burnisher.

b) Ramp must be secured to vehicle, and be clean and dry.

c) Machine must be taken straight down the ramp and never at an angle.

d) Do not let machine run over you or anyone else as it comes off ramp.

OPERATING INSTRUCTIONS

Page 7 of 30

SAFETY LEVER

KEY SWITCH

ROCKER SWITCH

TO START BUFFING:

# 1 - TURN ON KEY SWITCH

# 2 - TURN ON ROCKER SWITCH

# 3 - DEPRESS SAFETY HANDLE

AND BEGIN BUFFING

TO END BUFFING:

# 1 - RELEASE SAFETY HANDLE

# 2 - TURN OFF ROCKER SWITCH

# 3 - TURN OFF KEY SWITCH

AFTER EACH USE:

PLUG CHARGER CORD

INTO 110 VOLT WALL OUTLET

BATTERY CHARGING

Page 8 of 30

REFER TO NEXT THREE PAGES FOR

BATTERY CHARGER OPERATION

AND BATTERY MAINTENANCE

Become familiar with and follow the instructions issued by the charger

•

manufacturer.

Batteries should be charged after each period of use. Lead acid batteries

•

do not develop a memory and need not be fully discharged before

recharging.

The charger is factory set to properly charger the size and type batteries

•

that were supplied with your machine.

Charge only in well-ventilated area. Keep sparks or flames away from a

•

charging battery.

Do not get the charger wet.

•

Do not remove battery caps, the caps are vented. Caps on standard wet

•

cell batteries. No caps on AGM batteries.

Do not charge machine in a wet area.

•

Do not stand in a wet area when plugging in charger to the 110 volt

•

receptacle.

Plug in the charger to a properly grounded 110 volt receptacle.

•

Lights will indicate the charging status.

•

Charger will shut off automatically when batteries are fully charged.

•

TO CHARGE BATTERIES:

OPEN DOOR•

REMOVE ELECTRICAL CORD

•

PLUG INTO 11O VOLT OUTLET

•

BATTERIES WILL BEGIN CHARGING

•

figure 2

Page 9 of 30

WATER

LEVEL

IN THIS

CELL IS

TOO HIGH

WATER

LEVEL

IN THIS

CELL IS

TOO LOW

CHECK ELECTROLYTE

LEVEL IN ALL CELLS

WATER

LEVEL

IN THIS

CELL IS

GOOD

DO NOT OVERFILL.

DO NOT FILL ABOVE

THE BOTTOM OF THE TUBE

THAT EXTENDS INTO BATTERY.

KEEP ABOUT 1/4" BELOW

BOTTOM OF TUBE.

ADD DISTILLED WATER, AS NEEDED,

SO THAT ELECTROLYTE LEVEL

IS ABOUT 1/2" ABOVE PLATES.

KEEP ELECTROLYTE LEVEL

ABOVE TOP OF PLATES.

BATTERY CHARGER OPERATION

Page 10 of 30

OPERATION

• PLUG THE CORD FROM THE CHARGER INTO A 110 VOLT OUTLET

• Batterie s should now start charging.

• A test is run o n the battery voltage to decide if the charging process should be started or not. If the

battery is not connected to the battery charger, the display will show the word “bat”. The word will

stay on, even if the test is failed (for instance, reversed polarities or incorrect battery connection). If

the test is passed, the display will show the battery voltage for approximately 5 seconds and the

battery will begin to be charged. The charging cycle progress will be shown by red, yellow, and

green LED indicators. At the end of the charge, when the green indicator is on, unplug the cord from

the socket and operate the machine.

• NOTE: THE MACHINE WILL NOT POWER ON IF THE CHARGER IS STILL PLUGGED IN TO

THE 110 VOLT OUTLET.

INDICATOR LIGHTS

• Red indicator shows that the charging cycle has started.

• Yellow indicator shows that the final phase of the charging cycle has

started.

• Green indicator shows that the charging cycle has finished.

DISPLAY

Press button “S” (for Selection) to display:

• A = the charging current,

• U = the batte ry voltage,

• h = the charging time,

• C = the charging ampere-hours [Ah],

• E = the energ y used [KWh].

CAUTION - CHARGER SETTINGS MUST BE

CHANGED IF BATTERY TYPE IS CHANGED

(SEE NEXT PAGE FOR SETTINGS)

THIS BATTERY CHARGER IS FACTORY SET FOR THE TYPE OF BATTERIES THAT CAME WITH

YOUR MACHINE. IF YOU SWITCH BATTERY TYPES (FOR EXAMPLE GO FROM AGM TYPE

BATTERIES TO STANDARD WET CELL BATTERIES), THEN THE BATTERY CHARGER MUST BE

REPROGRAMMED. SEE NEXT PAGE “HOW TO SET THE CHARGER FOR DIFFERENT SIZES AND

TYPES OF BATTERIES” FOR INSTRUCTION.

GENERAL INFORMATION AND WARNINGS

• READ SAFETY INSTRUCTIONS ON PAGES 4 AND 5

• This is a state-of-the-art electronic high frequency automatic battery charger with microprocessor.

• It is suitable for any battery type, if the charger has the proper settings. (Call manufacturer of

machine on how to set the charger for different batteries than were supplied with your machine)..

• Never disconnect the battery while charging, since this could cause sparks.

• Never use the equipment in the rain, in areas used for washing, or in wet or damp areas.

• Use battery charg ers only in well ventilated areas.

FOR LEAD ACID BATTERIES:

• Control the water level after each ch arging process. (See “Battery Maintenance” page).

• Refill with distilled water only.

• Caution! The gases generated during charging are explosive. Do not smoke in the vicinity of the

batteries. When working with cables and electrical equipment, avoid open flame s and sparks.

• Attention: Use prote ctive glasse s and gloves during battery maintenance. Battery acid causes

injuries. In case of contact with battery acid, wash the affected parts with a lot of fresh water and

consult a doctor if necessary.

HOW TO SET THE CHARGER

Page 11 of 30

FOR DIFFERENT SIZES AND TYPES OF BATTERIES

THE INFORMATION THAT FOLLOWS IS PROVIDED SHOULD YOU EVER

CHANGE THE TYPE OR SIZE OF BATTERIES IN YOUR MACHINE. CONSULT

WITH THE EQUIPMENT MANUFACTURER BEFORE YOU MAKE ANY CHANGES

TO THE CHARGER SETTINGS. DAMAGE COULD OCCUR TO THE BATTERIES

AND MORE SERIOUS, IF THE BATTERIES ARE CHARGED TO THE INCORRECT

AMPERAGE OR VOLTAGE, THE BATTERIES COULD EXPLODE.

UP IS ON

DOWN IS OFF

DIP SWITCHES ARE LOCATED UNDER LABEL

DIP 1, DIP 2, DIP 3, AND DIP 4 ARE FOR SELECTING THE CHARGING CURVE

DIP 1 DIP 2 DIP 3 DIP 4 CHARGING

CURVE

OFF ON ON ON WET BATTERIES

OFF ON OFF ON AGM BATTERIES

PLEASE CONSULT EQUIPMENT MANUFACTURER BEFORE CHANGING

DIP 5 AND DIP 6 ARE CONTROL THE CHARGING CURRENT

DIP 5 DIP 6 AMPERAGE

ON ON 15 A

OFF ON 20 A

ON OFF 25 A

OFF OFF 30 A

DIP 7 AND DIP 8 CONTROL THE BATTERY CHARGING VOLTAGE

DIP 7 DIP 8 VOLTAGE

ON ON 12 V

OFF ON 24 V

ON OFF 36 V

OFF OFF 48 V

BATTERY DISCHARGE INDICATOR (BDI) AND HOUR METER

Page 12 of 30

0

7

1

Connector pin configuration (B)

1: hour meter input 2: key +

3: relay +

4: relay –

5: battery –

6: not used

7: not used

8: battery +

A. Shutoff voltage rotary dipswitch. Factory set to 4 (32.76 volts). This is the voltage at which the

batteries are 80% discharged. Do not set below this voltage or battery life will be shortened.

B. Connections to meter (molex connector)

C. Hour meter (display is always on, but only counts time when negative voltage is applied to pin 1)

D. Low voltage shutoff LED

E. Battery condition LED’s. (1 through 7 with 7 being fully charged batteries)

6

1

5

2

A

3

5

4

2

3

4

B

6

8

7

D

C

E

BACK FRONT

POSITION 0 1 2 3

VOLTS PER CELL 1.63 1.68 1.73 1.76

TOTAL VOLTS 29.34 30.24 31.14 31.68

BDI DISPLAY

When the machine is turned on, the battery level indicator is switched on and the LED (D or E)

corresponding to the position currently held by the rotary dipswitch will turn on. Position 0 (zero)

corresponds to the red LED (D), position 1 corresponds to the first yellow LED (row of 7 LED’s (D), and

so on. After that, all the LED’s turn on for a few seconds (lamp test) and then ordinary operation is

started. The battery level indicator features two voltage thresholds: the stopping threshold and the

resetting threshold. The stopping threshold corresponds to the value of the voltage at the end of

discharge and depends on the position of the rotary dipswitch (A) located at the back side of the

indicator. The resetting threshold corresponds to the reset-point threshold of the device (this value

varies along with the discharging current selected by the dipswitch (A) and is close to the battery

nominal value). When the voltage value corresponding to the stopping threshold is reached, the last

yellow LED will flash for 15 seconds, then the red LED will turn on, and the blocking relay will open. To

reset, switch off the battery level indicator, charge the batteries, and then switch on the machine.

BDI OPERATION

When the battery level indicator is switched on, the battery voltage is measured, and:

• If the voltage is below the stopping voltage, the machine will not run.

• If the voltage is higher than the resetting threshold, all the LED’s will turn on again and the battery

level indicator will reset and the machine will run.

• If the voltage ranges b etween the stopping voltage and the resetting voltage, the LED’s will turn on

rapidly according to the condition prior to the switching off. If the previous condition was a stop, the

last yellow LED will flash.

4

1.82

32.76

5 6 7

1.84 1.86 1.89

33.12 33.48 34.02

PAD CHANGING INSTRUCTIONS

Page 13 of 30

TILT MACHINE BACK AND

REMOVE FRONT COVER

USE 3/4" OPEN END

WRENCH TO SECURE

SHAFT AND SPIN

PAD DRIVER OFF

SHAFT BY HAND

DO

NOT

TILT MACHINE ON ITS SIDE

DETAIL A

SCALE 1 : 6

A

CENTER THE PAD ON PAD HOLDER

AND TIGHTEN CENTER LOCK

USE THE HI-SHINE LIGHT BURNISH PAD

21" IS PART NUMBER F084621 (5 PER CASE)

27" IS PART NUMBER F084627 (5 PER CASE)

NOTE: PAD CAN BE CHANGED ON THE MACHINE WITHOUT REMOVING PAD DRIVER,

BUT YOU MUST GET ON THE FLOOR AND BE SURE THAT PAD IS CENTERED ON PAD DRIVER.

SPIN PAD DRIVER BACK ONTO SHAFT

AND REPLACE COVER

BALANCING INSTRUCTIONS

Page 14 of 30

TO ACHIEVE PROPER MACHINE BALANCE

SHIFT SHIMS FROM FRONT TO BACK OR

BACK TO FRONT OF BATTERIES

For best operation and maximum battery life, the XTG3 battery burnisher must have the

correct pad pressure. The burnisher should require only minor adjustments to the balance. Only the

battery shims should be adjusted. The wheel axel positions are factory set and are in the proper

locations in the wheel brackets.

Tilt the burnisher back. Remove front cover.

Tilt burnisher to upright position.

With a new pad, the burnisher should hesitate and then barely fall back.

With a worn pad, the burnisher should barely sit upright.

If burnisher falls back easily, then the batteries need to be moved forward.

Remove several battery spacers from front of batteries

•

Slide batteries forward

•

Add spacer(s) to rear of batteries

•

Slide batteries tight against rear spacers (can be done by tilting machine back quickly)

•

Replace remaining spacers in front of batteries (batteries should now be “locked” into position)

•

If burnisher sits upright easily, then the batteries need to be moved back.

Remove some battery spacer(s) from rear of batteries

•

Slide batteries back

•

Replace remaining spacers in front of batteries (batteries should now be “locked” into position)

•

If batteries are moved as far as possible and proper balance cannot be achieved,

then one of the wheels may be moved to achieve balance. The burnisher is factory balanced,

so this is usually not necessary unless different batteries are installed by the customer. Most of the time,

only one wheel needs to be moved. Any stagger of the wheels should have the left wheel in front (to the

front of the machine) of the right wheel.

XT3-21 BELT TENSIONING INSTRUCTIONS

Page 15 of 30

fig. 1

TENSIONER BOLT

USE 9/16"

WRENCH

OR SOCKET

TEST TENSION BY

PUSHING OR PULLING

ON BELT. WITH BELT

PROPERLY TENSIONED,

THE PULLEY ON THE

TENSIONER ARM

SHOULD MOVE ONLY

ABOUT AN INCH.

figure 2

DETAIL VIEW OF BELT AND TENSIONER

USE 15/16 SOCKET WITH EXTENSION

TO TIGHTEN TENSIONER IN DIRECTION

SHOWN TO PUSH INSIDE OF BELT OUT

TO TIGHTEN THE BELT TENSIONER

(Tensioner may have slipped, or belt may have stretched)

Tilt machine back and remove front cover

1.

Using a 3/4" open end wrench, secure the top of the shaft and remove

2.

pad driver assembly. (see "Pad Changing Instructions" page)

On the top of the deck, use a 9/16” wrench or socket to loosen tensioner

3.

bolt. Leave a little snug to help hold tensioner in place after adjustment.

(location shown in fig. 1)

Using a 15/16” socket with an extension, fully tighten tensioner from the

4.

underside of deck, and back off 10 to 15 degrees. This will be about 2

inches at the end of the socket handle. (Note: This is about one mark on

the tensioner. There are five marks on the side of the tensioner, which are

difficult to see with the tensioner in place. Each mark is equal to about 15

degrees. This leaves the tensioner at about 60 degrees of tightness.)(see

figure 2)

While holding position tensioner in this proper location, fully tighten the

5.

tensioner bolt from the top. TIGHTEN SECURELY!

Make sure tensioner did not slip by pushing or pulling on side of belt away

6.

from tensioner. Belt should be tight and move the tensioner arm 10 to 15

degrees (about 1 ").

E12625

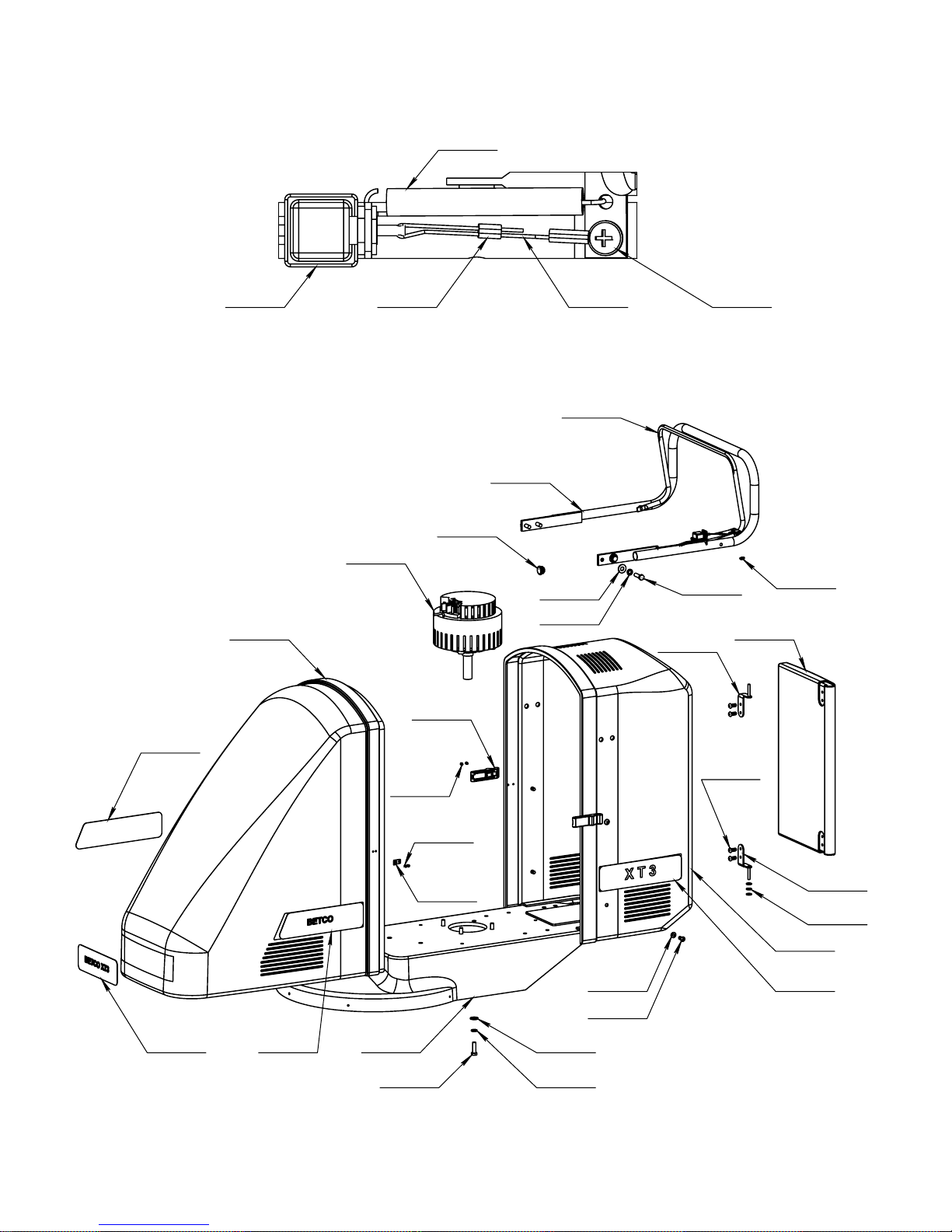

Covers & Handle Parts

Page 16 of 30

E12197

E11565

E10259

E12638

E11553E12215 E12221 E11122

E12639

E10135

E81066

E83629

E12641

E12242

E12632

E88152

E88151 E88153

E12633

E12676

E12676

E12633

E12653 E12447

E81066E83629

E11834

E11833

E11833

E12640

E11834

E12625

E88150

PART

Covers & Handle Parts

Page 17 of 30

NUMBER

E10135

E10259

E11122

E11407

E11553

E11565

E11833

E11834

E12197

E12215

E12221

E12242

E12399

E12447

E12625

E12632

E12633

E12634

E12635

E12638

E12639

E12640

E12641

E12653

E12676

E81066

E83629

E88150

E88151

E88152

E88153

Washer, 3/8" USS, Zinc

Plug, 1" Tube

Screw 1/4" x .500 Pan Head Phillips

Screw, 5/16"-18 x 3.250 Eyebolt with Nut, Zinc

Lanyard 3/64" x 6" XT Safety Switch

Spring, Extension 0.080 Wire, 1/2" OD x 3.850 L

Screw 1/4" - 20 x 0.750 Pan Head Phillips Black

Washer, SAE 1/4" Black

Motor, 36VDC, Brushless

Switch, Safety Shut Off

Crimp Sleeve, Cable, 3/8" L, Aluminum

Locknut, Flange 0.250 - 20

Dust Skirt, 21"

Washer, 7/16" SAE, Zinc

XT Gen 3 Cover

XT Gen 3 Cover Door

Latch Rubber Body

Battery & Electrical Frame XT21

Mounting Bracket, Handle to Deck XT21

XT Gen 3 Handle Weldment

Shutoff Handle Weldment

Hinge Right

Hinge Left

Deck 21" Aluminum Casting

Rivet, 5/32"

Washer, 3/8" Split Lock, Zinc

Screw, 3/8"-16 x 1.250 Hex Head, Grade 5, Zinc

Decal, XT3 Rear

Decal, XT3 Front

Decal, XT3 Right

Decal, XT3 Left

Note: Not available for purchase assembled.

Description

QTY.

4

2

1

1

1

1

8

11

1

1

1

1

1

4

2

1

6

1

2

1

1

1

1

1

12

8

8

2

1

1

1

E12399 - Dust Skirt 21"

Page 18 of 30

Frame & Deck Parts

E12204

E12584 is supplied

with the machine.

After removing the 5/16"

eye bolt (E11407)

insert it into the hole,

use a hammer to seat.

E12634

E10135

E12653

E81087

E10135

E12635

E10122

E81713

E11833

E12643

E10122

E81713

E10122

E81713

E12237

E12242

E10705 53"

E12584

E11432

Serial # Location

On Opposite Side

E12242

E81713

E12656

E12242

E12447

E12644

E10902

E12689

E10141

E10202

PART

Page 19 of 30

Frame & Deck Parts

NUMBER

E10122

E10135

E10141

E10202

E10705

E10902

E11407

E11432

E11833

E12204

E12237

E12242

E12447

E12584

E12634

E12635

E12643

E12644

E12653

E12656

E12689

E81087

E81713

Screw, 1/4"-20 x 1.000 Hex Head, Grade 5, Zinc

Washer, 3/8" USS, Zinc

Nut, 5/16"-18, Slim, Nylon Lock, Grade 5, Zinc

Rivet, 3/16" OD x 0.700" L with 0.600" Head

Bumper, Red (21" Deck = 53", 24" Deck = 63", 28" Deck = 75")

Screw, 5/16"-18 x 2.500 Hex Head, Grade 5, Zinc

Screw, 5/16"-18 x 3.250 Eyebolt with Nut, Zinc

Locknut, Flange 0.375 - 16

Screw 1/4" - 20 x 0.750 Pan Head Phillips Black

Rubber Flange Extrusion

Caster, 3" 4 Bolt

Locknut, Flange 0.250 - 20

Washer, 7/16" SAE, Zinc

Rivet, 5/16" Drive (Hammer In)

Battery & Electrical Frame XT21

Mounting Bracket, Handle to Deck XT21

Cord Wrap

Wheel Bracket XT

Deck 21" Aluminum Casting

Chain, Static Dispersion

Wheel, 6" with Sealed Ball Bearings, Non-Marking

Screw, 3/8"-16 x 1.500 Hex Head, Grade 5, Zinc

Washer, 1/4" SAE, Zinc

Note: Not available for purchase assembled.

Description

QTY.

11

14

2

5

1

2

1

8

2

2

2

11

12

1

1

2

1

2

1

1

2

8

12

21" & 28" Deck Shimming:

Page 20 of 30

Belt Drive Parts

Place 2 of the E83269 &

1 of the E12447 between

E12709 & aluminum deck

at this bolt location.

E10116

E10117

E83629

E81066

E12447

E12709

E12459

E12401 -- 21" Deck

E10428 -- 28" Deck

E12400

E10135

E10459

E11289

E12663

E12662

E81078

E81078

E81064

E11135

E10725

E10107

PART

Page 21 of 30

Belt Drive Parts

NUMBER

E10107

E10116

E10117

E10135

E10459

E10725

E11135

E11289

E12400

E12401

E12447

E12459

E12662

E12663

E12709

E81064

E81066

E81078

E83269

E83629

Belt, BX40

Screw, 7/16"-14 x 1.250 Hex Head, Grade 5, Zinc

Washer, 7/16" Split Lock, Zinc

Washer, 3/8" USS, Zinc

Belt Tensioner

Screw, 1/4"-20 x 1.500 Hex Head, Grade 5, Zinc

Washer, 3/4" SAE, Zinc

Key 1/4" x 1/4" x 1.500"

Bushing, QT 25mm Taper Lock

Pulley, BK75H - 7.25 OD

Washer, 7/16" SAE, Zinc

Key 8mm x 7mm x 30mm

Motor Pulley BK45QT

Bushing, QT 1.0" Taper Lock

Pad Driver Alum Bearing Assembly with Shaft

Screw, 1/4"-20 x 0.750 Hex Head, Grade 5, Zinc

Washer, 3/8" Split Lock, Zinc

Washer, 1/4" Split Lock, Zinc

Washer, 1/2" ID x 0.020" T, Spring

Screw, 3/8"-16 x 1.250 Hex Head, Grade 5, Zinc

Note: Not available for purchase assembled.

Description

QTY.

1

4

4

1

1

2

1

1

1

1

5

1

1

1

1

2

1

4

2

1

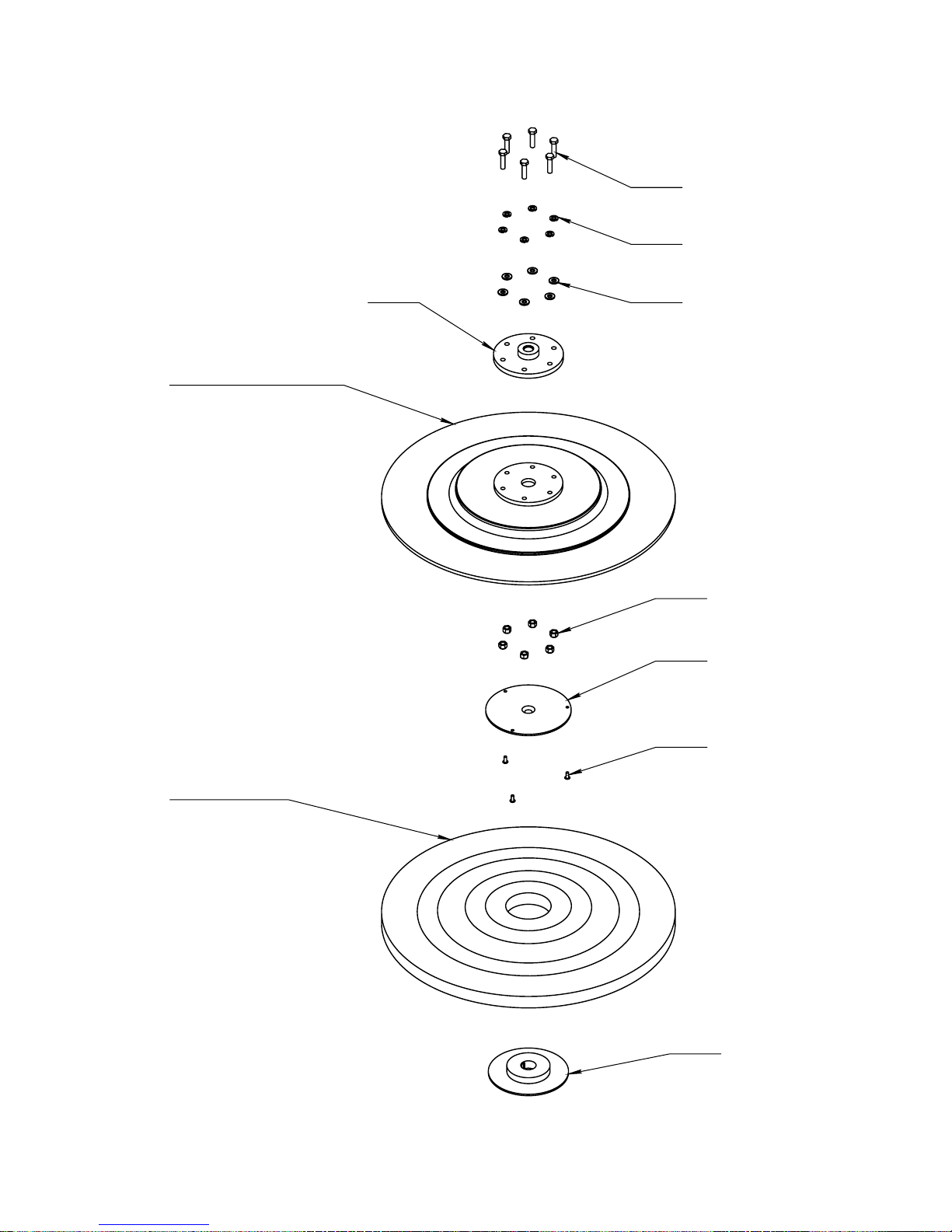

EP50028 -- 21" Pad Drive Assembly

Page 22 of 30

Pad Driver Parts

EP50040 -- 27" Pad Drive Assembly

E10112

E81067

E10250 -- 21" Pad Driver

E10252 -- 27" Pad Driver

E10586

E12444

E81063

E12517

2 Piece Set

E10850

84621 -- 24" Pad

84627 -- 27" Pad

E12517

2 Piece Set

PART

Page 23 of 30

Pad Driver Parts

NUMBER

84621

84627

E10112

E10250

E10252

E10586

E10850

E12444

E12517

E81063

E81067

EP50028

EP50040

NOTE: Pad driver assembly comes without pad.

Pad, 21" Hi-Shine Light Burnish Pad, 5/Case

Pad, 27" Hi-Shine Light Burnish Pad, 5/Case

Screw, 5/16"-18 x 1.250 Hex Head Grade 5, Zinc

21" Pad Driver

27" Pad Driver

3/4" Pad Driver Shaft Coupling

Rivet, 3/16" OD x 15/16" L with 3/8" Head

Washer, 5/16" SAE, Zinc

Pad Lock, Center Lok II ® RH Set Black

Nut, 5/16"-18, Nylon Lock, Grade 5, Zinc

Washer, 5/16" Split Lock, Zinc

Pad Drive Assembly 21" Without Pad

Pad Drive Assembly 27" Without Pad

Description

QTY.

1

1

6

1

1

1

3

6

2

6

6

1

1

E12691

Page 24 of 30

Battery & Electrical Parts

E12631

E12629

E12646

E12630

E11529

E11834E12219

E88149

E12690

E12543

E11096E12634

E10137

E12624

E88856

E12634

E12542

E12561

E11139

E12621

E12660

E12643

E12565

E11623

E10878E12564

E12628

E11833

E11353

E11834

PART

Page 25 of 30

Battery & Electrical Parts

NUMBER

E10137

E10878

E11096

E11139

E11353

E11407

E11529

E11623

E11833

E11834

E12219

E12242

E12542

E12543

E12561

E12564

E12565

E12592

E12621

E12624

E12625

E12628

E12629

E12630

E12631

E12634

E12642

E12643

E12646

E12660

E12690

E12691

E88149

E88853

E88856

Clamp, Tube 1/2" (COV-0909)

Anderson Plug, Grey

Nut, #10 - 32, Black

Cable, 4 AG, Red

Tube Clamp 3/4" (COV-1309)

Screw, 5/16"-18 x 3.250 Eyebolt with Nut, Zinc

SWITCH, ROCKER

Screw 1/4" - 20 x 0.750 Pan Head Phillips Zinc

Screw 1/4" - 20 x 0.750 Pan Head Phillips Black

Washer, SAE 1/4" Black

Screw #10 - 24 x 1.000 Pan Head Phillips Black

Locknut, Flange 0.250 - 20

Terminal Cover, Straight, Black

Terminal Cover, Straight, Red

Cable Tie, AF529, Black

Cable, 4 AWG, Red

Cable, 4 AWG, Black

Solenoid

Battery Strap

Battery Tray 3" height

XT Gen 3 Cover

Charger, On-Board

Switch, Keyed, SPE

Hour Meter, BDI

Heat Sink

Battery & Electrical Frame XT21

Battery Tray Bottom Plate

Cord Wrap

E12646 Lamp, 36VDC, LED

Shim, Plastic, 12" x 1.50" x 0.125"

Fuse, 200 AMP

Fuse Block

Decal, XT3 Dashboard

XT3 Gen 3 Controller

Battery, 12VDC, 135AH, AGM

Note: Not available for purchase assembled.

Description

QTY

1

1

2

2

1

1

1

2

11

11

8

2

2

2

6

1

1

1

1

1

1

1

1

1

1

1

1

1

1

14

1

1

1

1

3

E011835

Page 26 of 30

Electrical Layout

FUSE HOLDER

E011106

FUSE 10A

E088635

WIRE HARNESS

(INCLUDES ALL

CONTROL WIRING)

E011139

E081785

E081785

E012562

E012562

E012669

E012563

CHARGER

Wiring Ladder Diagram

Page 27 of 30

MOTOR

4

3

2

1

8

BDI

5

S

KEY

BLBR

Y

G

K - KEY SWITCH

5 15 17,26,29

M3

U

W

V

M2

MOTOR

CONTROL

M1

18 4 3 1 2,24

B-

B+

R - ROCKER SWITCH

S - SAFETY SWITCH

F - FUSE

C- SOLENOID

B - BLUE

BL - BLACK

Y - YELLOW

R - RED

G - GREEN

F

K

F

C

R

LED

BATTERY

TROUBLE-SHOOTING

Page 28 of 30

PROBLEM CAUSE POSSIBLE SOLUTION

No sign of power. No on

lamp, no BDI readout.

Powers on with key switch,

but solenoid does not “click”

with rocker switch.

Powers on, solenoid “clicks”,

but does not run

Pad “bogs down” Too much pad pressure Decrease pressure using directions on

Machine will not set upright

with cover on

Low runtime (a) Improper charge

Machine vibrates (a) Pad not centered

Noise coming from

underside of deck

Machine hard to push (a) Worn pad

Machine pulls left (a) Worn pad

Uneven floor buffing (right

side of pad polishes and left

side does not)

(a) Bad connection

(b) Bad connection to BDI

(c) On-board charger is

plugged in

(d) Batteries dead

(e) Charger plugged into

outlet

Bad connection Check all connections.

(a) Safety run switch

problem. Not pulling

plunger enough to

activate.

(b) Safety run switch wire

connectors may be loose

Too little pad pressure Increase pad pressure using directions on

(b) Old batteries or defective

cell in battery

(c) Too much pad pressure.

(d) BDI set to too high a

voltage

(b) Pad is torn or worn

excessively

Belt is loose and causing belt

tensioner to “chatter”.

(b) Worn wheel bearings

(c) Pad out of alignment

(b) Wrong pad

(c) Right side of pad needs a

little more contact than

the left so “pad assist”

can help pull machine

forward .

Right side of pad contacting

too much, therefore left side

is not contacting enough.

(a) Check all connections.

(b) Make sure connector is fully pushed into

BDI.

(c) Disconnect charger from wall outlet.

(d) Recharge or replace batteries as needed.

(e) Unplug charger from 110v outlet. Charger

has an “inhibit” circuit that prevents machine

from running if charger is plugged in.

(a) Cable may have slipped and sleeve needs

to be re-crimped or replaced.

(b) Push in connectors

“Balancing Instructions” page

“Balancing Instructions” page

(a) Make sure that batteries get a full charge

after each use.

(b) Replace batteries. Best to replace as a set.

(c) Balance machine. See “Balancing

Instructions” page.

(d) See BDI instruction page on how to set to a

value of 4 for optimal run time and battery

life

(a) Remove pad and re-center the pad

(b) Replace pad

Tighten belt. See page with “Belt tightening

instructions”.

(a) Replace pad.

(b) Replace bearings or replace wheels.

(c) See solution to next problem “Machine pulls

left”.

(a) Replace pad

(b) Replace pad with pad approved use with XT

burnisher.

(c) Add a small shim (.010 thick) between

bearing housing and deck on the right side.

This will “push” right side down toward floor.

(If there are too many shims, then left side

of pad will not contact properly).

The reverse of the previous procedure. Remove

one of the small shims (.010 thick) between

bearing housing and deck on the right side

Page 29 of 30

Page 30 of 30

BBeettccoo WWaarrrraannttyy EExxpprreessss PPrrooggrraamm™™

RReevviisseedd NNoovveemmbbeerr 11,, 22000066

10 Year Coverage

10 Year Coverage

Subject to the conditions stated

below, Betco Corporation

warrants parts and labor on

rotationally molded polyethylene

tanks/housings and injection

molded vacuum head assemblies

to be free from defects in

materials and workmanship for a

period of ten years to the original

purchaser.

3 Year Coverage

3 Year Coverage

Subject to the conditions stated

below, Betco Corporation

warrants parts and labor on all

other Betco components to be

free from defects in materials and

workmanship for a period of three

years to the original purchaser.

AAlllloowwaabbllee TTrraavveell TTiimmee WWaarrrraannttyy RReeiimmbbuurrsseemmeenntt::

Eligible equipment: All battery and propane powered equipment products.

Warranty period: 90 days from date of sale to the original purchaser. A maximum 60 mile round trip at 44

cents per mile will be allowed for warranty consideration.

PPrrooppaannee MMaacchhiinnee WWaarrrraannttyy::

Honda engines are warranted by Honda for a period of 2 years against manufacturer defect. Kawasaki

engines are warranted by Kawasaki for a period of 2 years against manufacturer defect. All other

components (except wear items)* are warranted by Betco Corporation for a period of 3 years.

**WWeeaarr iitteemmss eexxeemmpptt ffrroomm wwaarrrraannttyy ccoonnssiiddeerraattiioonn iinnccl

coorrddss,,

c

haannddllee

h

Subject to the conditions and exceptions stated in this warranty, Betco warrants the Betco products to be

free from defects in material and workmanship, under normal use and service, for the periods listed under

the warranty policy to the original purchaser. At any time during the warranty period, Betco will furnish

replacement parts for the Betco products to the original purchaser. Such parts will be furnished and charged

including transportation costs, to the original owner through any Betco authorized Service Distributor. If the

original part is returned within the warranty policy period from date of delivery for inspection by Betco and is

found to be defective, the owner will be credited for the cost of replacement parts plus shipping and

handling. Replacement parts that have become defective through wear or abuse are not included in this

warranty.

This warranty does not apply to damage or defect caused by accident, misuse, negligence, fire or to any

Betco product which has been serviced or repaired by other than an authorized Betco Service Distributor or

Betco factory personnel. This warranty is void if products are used for any purpose other than that which

was intended. There are no other warranties expressed or implied. In no event shall Betco be liable for

incidental or consequential damages or any damage to person or property. (Please note some states do not

allow the exclusion or limitations for incidental and consequential damages.)

p

ttrraannssp

oorrtt wwhheeeellss,, vvaaccuuuumm bbaaggss,, bbeellttss,, ssqquueeeeggeeee bbllaaddeess,, ppa

ggrriippss,, ffiilltteerrss,, s

s

ccrreeeennss,, tthhrroottttllee ccaabblleess,, bbrruusshheess aanndd ccaarrbboonn bbrruusshhees

1 Year Coverage

1 Year Coverage

Subject to the conditions stated

below, Betco Corporation offers a

limited warranty on parts and

labor on the following equipment,

parts and accessories to be free

from defects in material and

workmanship for a period of one

year to the original purchaser.

DM Series Vacuums:

●

#85506-00, #85507-00

●Bac Pac Lite Vacuum:

#85903-00

●FiberPRO® Floor Dryer:

#85507-00

●WORKMAN™ Series Vacuums:

#85024-00, #85025-00,

#85026-00, #85027-00

●CV100T Vacuum:

#85023-00

●All Tools and Accessories

●All Battery Chargers

●All Batteries are pro-rated for 1 year.

luuddee

bbuutt mmaayy nnoott bbee lliimmiitteedd ttoo:: ppoowweerr

add

ddrriivveerrss,, cclluuttcchh ppllaatteess,,

s..

©2006 Betco Corporation

All Rights Reserved.

1001 Brown Avenue

Toledo, Ohio 43607-0127

888-462-3826

www.betco.com

Loading...

Loading...