Page 1

E12327-00

™

BIG BERTHA

X

XS

S

M

M

30

30" Extreme Strip

and Scrub Machine

Operator and Parts

Manual

1001 Brown Avenue • Toledo, Ohio 43607-0127

Customer Service: 888-GO-BETCO • Fax: 800-445-5056 • Technical Service: 877-856-5954 • www.betco.com

1

Page 2

TABLE OF CONTENTS

CARBON MONOXIDE WARNING ...................................... 3

SAFETY ............................................................................ 4

TANK USE AND STORAGE ...............................................5

STARTING AND STOPPING THE HONDA ENGINE ............ 5

OPERATOR PREPARATION ..............................................6

MAJOR ASSEMBLIES ......................................................7

HANDLE BAR ..............................................................8 - 9

LOWER HANDLE SUPPORT ....................................10 - 13

REGULATOR ASSEMBLY ........................................14 - 15

12V STARTER SWITCH ...........................................14 - 15

KAWASAKI ENGINE ASSEMBLY ..............................16 - 17

DECK ASSEMBLY ....................................................18 - 19

MAIN DRIVE SYSTEM .............................................20 - 21

PIVOT BRACKET ASSEMBLY ..................................22 - 25

BRUSH PLATE ASSEMBLY ......................................26 - 27

ENGINE MAINTENANCE ................................................. 28

ELECTRICAL SCHEMATIC .............................................. 29

MAIN DRIVE BELT .........................................................30

BRUSH DRIVE PLATE AND BELT ...................................31

BRUSH CHANGE ............................................................ 32

TROUBLESHOOTING .....................................................33

EMISSIONS WARRANTY ........................................34 - 35

WARRANTY.................................................................... 36

2

Page 3

WARNING - CARBON MONOXIDE

LETHAL EXHAUST GAS

- MUST READ THIS! -

Never Run The Engine In A Closed Building Or Confined Area

Exhaust gases contain poisonous carbon monoxide.

Carbon monoxide is odorless, colorless, and can cause death if inhaled.

Carbon Monoxide Poisoning Symptoms

Train your employees to know the warning signs of carbon monoxide poisoning.

Mild carbon monoxide poisoning may cause any of the following:

Headache, drowsiness, faintness, poor coordination, nausea, and vomiting.

Turn the engine off and immediately get to fresh air if you have any of these symptoms.

Do not run the machine until it is given an emissions test and repairs made by an authorized distributor.

• Local emissions testing is available at a fork-lift service department.

Moderate or severe carbon monoxide poisoning causes confusion, unconsciousness, chest pain, shortness of breath, and

coma. Thus, most victims are not able to move themselves and must be rescued. Severe poisoning is often fatal.

Carbon monoxide is dangerous because a person may not recognize drowsiness as a symptom of poisoning. Consequently,

someone with mild poisoning can go to sleep and continue to breathe the carbon monoxide until severe poisoning or death

occurs. Some people with long-standing, mild carbon monoxide poisoning caused by furnaces or

heaters may mistake their symptoms for other conditions, such as the flu or other viral infections.

Carbon Monoxide Detectors

CO detectors are a must for safe operation of your equipment. Various types are available. A “CO” carbon monoxide detector

detects carbon monoxide before it reaches dangerous levels. Detectors are a must for those who run propane powered

equipment. The CO Detector is for everyone’s protection against Carbon Monoxide Poisoning.

• Carbon Monoxide Detector - Passive

– Effective for 30 days after package has been opened.

– Write the date opened on the detector.

– Mount with self-adhesive strip on the machine handle.

– Train machine operator to check detector regularly.

– If the orange disk changes to gray or black - your Carbon Monoxide Levels are

at a Dangerous Level.

– If the orange disk changes to gray or black you must turn your buffer off immediately and return it to your nearest

authorized distributor for an emissions test.

– Do Not Restart the machine until the emissions have been checked and corrected.

– This is for your protection as well as your customers. CO detectors are a must for safe operation and maximum

efficiency of your equipment.

– For replacement CO detectors, contact your distributor. Ask for the carbon monoxide detector,

part# E012426.

• Carbon Monoxide Detector - battery operated with alarm

– Available from various sources

3

Page 4

SAFETY

lmportant Safety Information

All LPG (Liquid Propane Gas) powered engines, including this engine, produce Carbon Monoxide (CO). It is a

Lethal Poison that is colorless, odorless, tasteless, and non-irritating gas. You must read “Danger: Lethal Exhaust Gas”

information below.

Keep hands, feet, and loose clothing away from all moving parts while the machine is in operation. The exhaust system

gets very hot so keep hands, clothing and any items that can burn away from the engine, engine manifold, and muffler.

These machines are tough and durable, however do not abuse the machine. With proper care and maintenance this unit

will give you years of trouble free operation.

Carbon Monoxide Safety Information

Engine exhaust gases contain poisonous carbon monoxide. Carbon monoxide is odorless, colorless, tasteless, and

can cause death if inhaled. Failure to provide proper venting of CO, failure to properly maintain the engine, or failure to

properly train personnel of the dangers and warning signs of carbon monoxide exposure may result in Serious Injury Or

Death to the operator and others in the area.

• Any equipment with the potential to produce carbon monoxide presents a significant hazard when used indoors.

They must be used with great caution. Opening a door or window, or running an exhaust fan will not necessarily

supply adequate ventilation. Avoid inhaling exhaust fumes and never run the engine in a closed building or

confined area without proper ventilation.

• Do not allow engine to run unattended.

• If you have any indication that the engine is not running properly, immediately shut the machine off and have it

checked over and repaired by qualified maintenance personnel.

• Workers should be trained to recognize the hazards of carbon monoxide and the early symptoms of carbon

monoxide poisoning.

• A carbon monoxide detector and alarm should be available to alert workers of emissions.

• Have a carbon monoxide detector attached to machine handle or have machine operator wear a carbon monoxide

detector. (See carbon monoxide detector page).

• Use only as described in this manual.

• Use only manufacturer’s recommended components.

• Maintenance and repairs must be done by qualified personnel.

• Only trained operators should be allowed to operate propane powered floor machines.

• If the machine is not working properly, have it serviced by an authorized service center.

• Install fuel cylinder in a well ventilated place.

• Be aware of possible leaks of propane gas if odor is present.

• If the machine is stored inside a building, remove the fuel cylinder and store properly outside.

• Secure fuel cylinders when being transported.

• If tank is left attached to the machine then valve should be OFF.

• Never store fuel cylinders in a vehicle, building, or area where they may exposed to high temperature.

• Do not operate the machine with any openings blocked.

• Keep openings free of debris that may reduce airflow.

• Remove fuel cylinder and disconnect battery before servicing.

4

Page 5

TANK USE AND STORAGE

Propane Tank Use

We use the Worthington gas cylinders designed for vapor withdrawal. The fuel lock offs, regulators, and engines are

also designed for vapor withdrawal.

• We recommend that you use the OPD (Overflow Protection Device) vapor withdrawal type cylinder. These style

tanks have a triangle shaped valve handle.

• Do not overfill - the best gauge is a scale - never allow tank to weigh over 36 pounds for an aluminum tank and

43 pounds for a steel tank.

• Connect fuel cylinder to machine in a well ventilated place.

• Be aware of possible leaks of propane gas if odor is present.

• Use propane tanks designed for vertical use only.

• New tanks must be purged of air at first filling.

Propane Tank Storage

• Store tanks outside in a well-ventilated area.

• Never store fuel cylinders in a vehicle, building, or area where they may exposed to high temperature.

• If the machine is stored inside a building, remove the fuel cylinder and store properly outside.

• Secure fuel cylinders when being transported.

• If tank is left attached to the machine then valve should be OFF.

• Store tanks in the upright position (valves up).

• Be aware of possible leaks of propane gas if odor is present.

STARTING AND STOPPING

THE KAWASAKI ENGINE

Starting The Kawasaki Engine

The Kawasaki engine is equipped with a 12 volt starter and a key switch start.

1. Place propane tank into handle assembly and close propane tank strap clamp to secure tank.

2. Attach propane hose coupling and fully tighten.

3. Start the Extreme Strip machine with the brushes in the running position, flat on the floor.

4. Open propane tank valve (turn counterclockwise) and check for any leaks.

5. Turn the ignition - Start switch to the 'start' position and hold it there until the engine starts. Do not crank for

more than 20 seconds at a time and wait at least one minute between tries when cranking. See the troubleshooting guide if the engine does not start after several tries.

6. After engine starts, set the throttle so that the centrifugal clutch will not engage until the engine has warmed

up. Do not operate the machine until the engine has warmed up sufficiently (3 to 5 minutes).

7. Check for frost on the regulator and fuel line. Frost will indicate that the machine is drawing liquid propane

from an overfilled or incorrect tank.

Stopping The Kawasaki Engine

1. Turn propane tank valve to the closed position (turn clockwise) and allow the engine to continue running until

it runs out of fuel. This can be done with the centrifugal engaged or not engaged.

2. Turn key to the off position.

In an emergency, immediately turn the key to the 'off' position.

Backfiring may occur when using this method.

5

Page 6

OPERATOR PREPARATION

Before Starting the Machine

Read the Owner’s Manual and the Engine Operation Manual.

Your machine is shipped ready for operation; however there is no fuel in the tank. When having the tank filled, you

must make sure the tank is never over-filled.

• The best way to do this is to tell the filling station to weigh the tank full. On an aluminum tank, it should

weigh no more than 36 pounds and on a steel tank no more than 43 pounds. (See more information at “Tank

Storage and Maintenance” page.)

Adjust the handle for comfortable operation. Remove detent pins from handle and adjust to the hole alignment that

gives the most comfortable height. Replace detent pins. Tighten nuts and bolts if needed.

Check Oil Level: Starting the engine without the proper amount of oil will cause severe engine damage. Always keep

the engine oil level between the full and add marks on the dipstick. Do not loosen oil fill cap or remove dipstick while

engine is running.

• Park your machine on a level surface.

• Turn the oil fill cap counter clockwise and then lift from the fill tube.

• Wipe the dip stick clean and push it back into the oil fill tube until the cap seats and then withdraw it to

check: the oil level. (Do not screw cap on to check oil). Add if necessary. If the oil level is low, add API Class

SM oil having a SAE viscosity grade appropriate for the expected temperatures as indicated in the Operators

Manual (Usually a HD30 or 10W30).

• Important Note: Do Not Overfill

• Replace oil cap.

Inspect fuel hoses and fittings for wear and leaks. Have all worn hoses and leaks repaired before operating.

Look and listen for exhaust leaks. Have all leaks repaired before operating.

Check the carburetor filter and air filter for debris. Clean and replace if necessary.

Connect fuel hose to tank by screwing the hose fitting to tank. You must tighten all the way down to make fuel

connection. Turn tank knob slowly until you hear the flow of fuel into fuel system.

6

Page 7

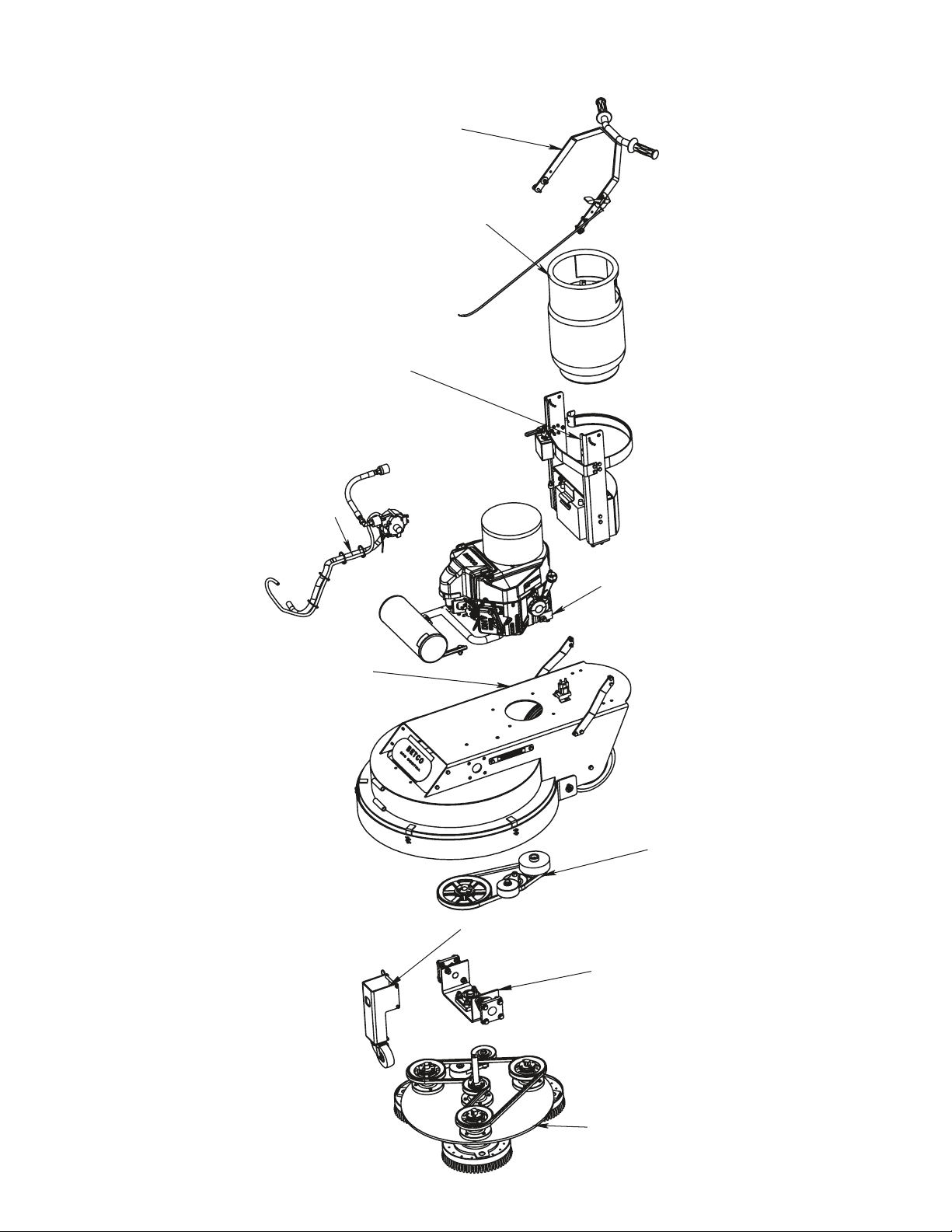

MAJOR ASSEMBLIES

HANDLE BAR ASM

OPD PROPANE TANK

LOWER HANDLE SUPPORT

REGULATOR ASM

STRIP MACHINE DECK

ENGINE ASM

BRUSH DRIVE

TRANSPORT WHEEL ASM

PIVOT BRACKET

BRUSH DECK ASM

7

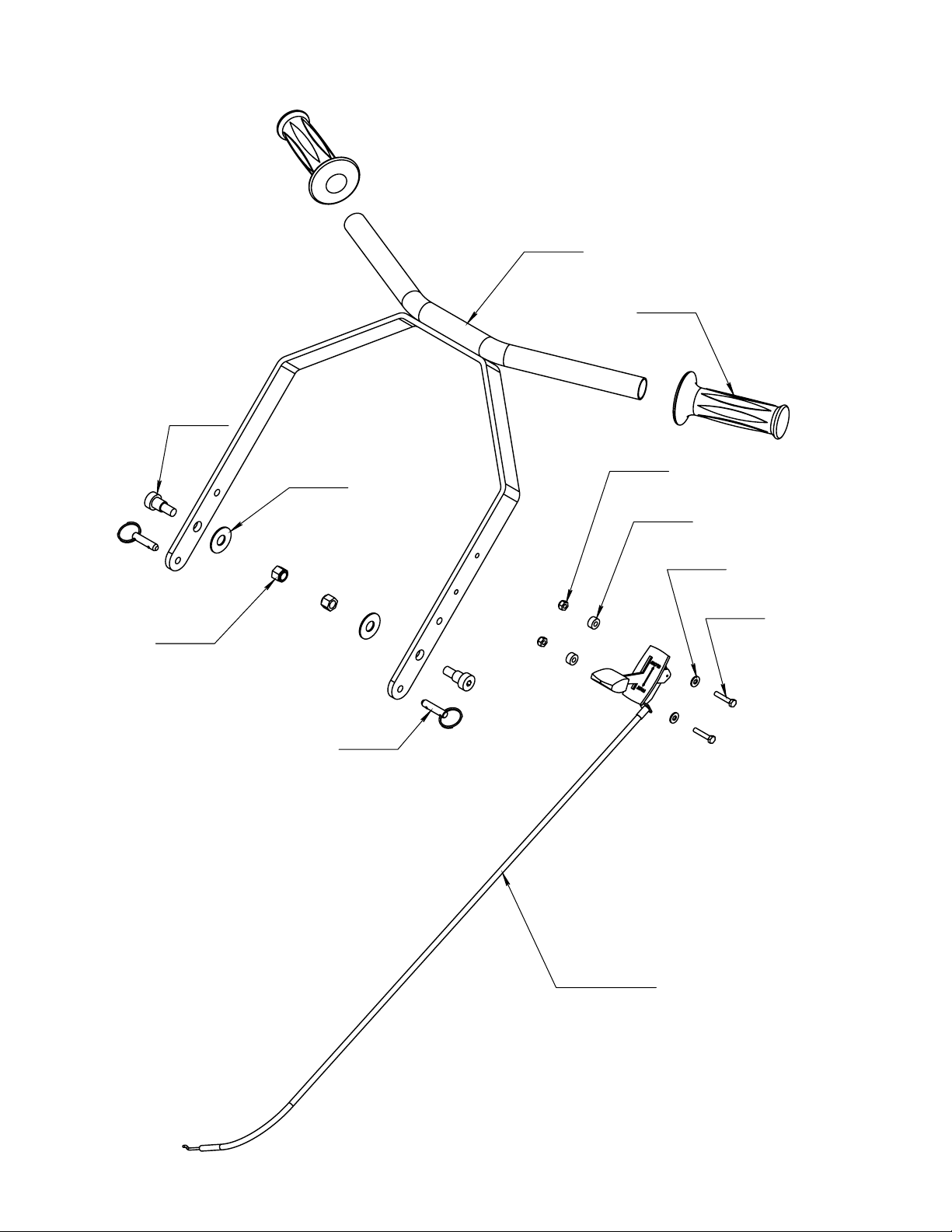

Page 8

HANDLE BAR

E12476

E88808

E12696

E10120

E83145

E86228

E11146

E11420

E86125

E87986

E86114 (38")

8

Page 9

PART

NUMBER

E10120

E11146

E11420

E12476

E12696

E83145

E86114

E86125

E86228

E87986

E88808

Nut, #10-32, Nylon Lock, Grade 5, Zinc

Nut, 3/8"-16, Nylon Lock, Grade 5, Zinc

Washer, #10 SAE, Zinc

Screw, Shoulder 1/2" x 1/2" Socket Head

Hand Grip

Washer, Nylon 1/2" ID X 1.25" OD

Kawasaki Throttle Cable 38" L

Screw, #10-32 x 1.000 Hex Head, Zinc

Spacer, #10 ID x 1/2" OD x 1/4" Long, Black Nylon

Pin, 5/16" x 3/4" Detent with Ring

Handle Bar Weldment

Note: Not available for purchase assembled.

Description

QTY.

2

2

2

2

2

2

1

2

2

2

1

9

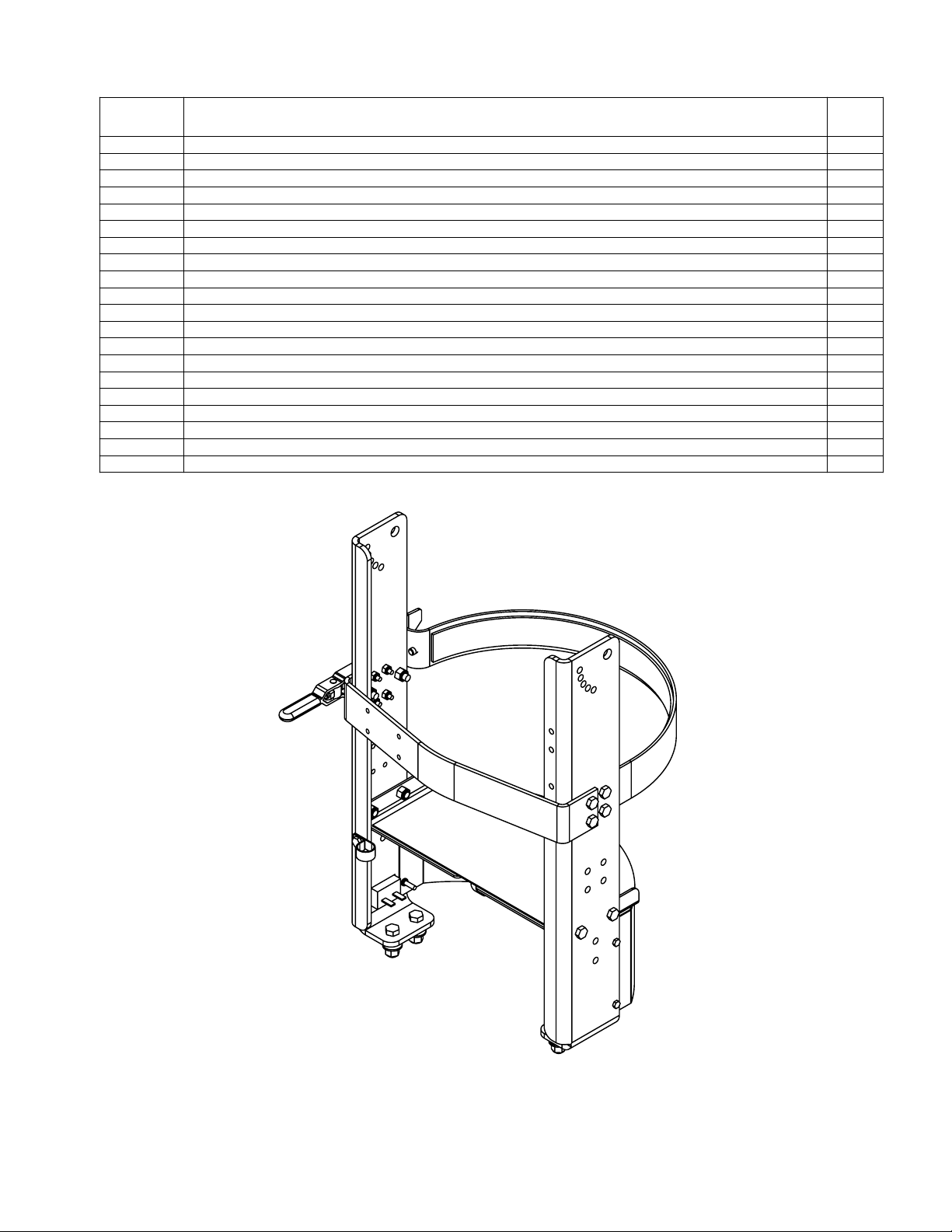

Page 10

LOWER HANDLE SUPPORT

(For Serial Numbers Before 6999)

E86125

E81072

E81089

E86125

E86119

E10457 (4")

E11702

E88806

E10120

E86120

E10457 (13")

E10761

E81063

E88316

E81072

10

E11353

E10734

E88807

E88319

E83629

E81062

E11146

E81089

E88805

E86125

Page 11

PART

NUMBER

E10120

E10457

E10734

E10761

E11146

E11353

E11702

E81062

E81063

E81072

E81089

E83629

E86119

E86120

E86125

E88316

E88319

E88805

E88806

E88807

Nut, #10-32, Nylon Lock, Grade 5, Zinc

Felt, 1.500 W x 0.125 Thick, Adhesive Back

Screw, 1/4"-20 x 0.625 Hex Head, Grade 5, Zinc

Rubber Propane Tank Shelf Pad

Nut, 3/8"-16, Nylon Lock, Grade 5, Zinc

Tube Clamp 3/4" (COV-1309)

Propane Tank Strap Latch

Washer, 5/16" USS, Zinc

Nut, 5/16"-18, Nylon Lock, Grade 5, Zinc

Screw,5/16"-18 x 1.000 Hex Head, Grade 5, Zinc

Screw, 5/16"-18 x 0.750 Hex Head, Grade 5, Zinc

Screw, 3/8"-16 x 1.250 Hex Head, Grade 5, Zinc

Hour Meter, SenDEC 5-80V

Propane Tank Strap Back

Screw, #10-32 x 1.000 Hex Head, Zinc

Battery Cover

Propane Tank Shelf

Lower Handle Leg Left

Lower Handle Leg Right

Propane Tank Strap Front

Note: Not available for purchase assembled.

Description

QTY.

4

2

1

1

4

1

1

4

10

4

6

4

1

1

8

1

1

1

1

1

11

Page 12

LOWER HANDLE SUPPORT

(For Serial Numbers 7000 and Greater)

E89825

E86120

E10457 (13")

E86125

E81089

E86119

E10457 (4")

E88807

E11702

E89823

E10141

E89822

E10120

E81072

E89826

12

E11353

E10734

E81062

E81062

E89824

E11146

E89827

Page 13

Note: Not available for purchase assembled.

13

Page 14

REGULATOR ASSEMBLY

E10751

E12359

E10243 (Emissions)

E10246

E88803 (36")

E10084

E88804

E11321

E11353

E88510 (24")

E10746

E10734

E88509

12V STARTER SWITCH

E12290

E86125

E10550

E10449

E86121

E10204

14

Page 15

PART

NUMBER

E10084

E10243

E10246

E10734

E10746

E10751

E11321

E11353

E12359

E88509

E88510

E88803

E88804

Fitting, 3/8 MJIC x 3/8 MNPT, 90 Elbow, Brass

In Line Fuel Shut Off Valve Model 152 (With Emissions)

In Line Fuel Shut Off Valve Model 151

Screw, 1/4"-20 x 0.625 Hex Head, Grade 5, Zinc

Fuel Regulator Model 60E

Propane Tank Coupling 7141F

Screw #10 x 5/8" Sheet Metal, Pan Head, Phillips, Black

Tube Clamp 3/4" (COV-1309)

Propane Tank Hose 1/4" MNPT - 3/8" MJIC 16.50" L

Fitting, Hose Barb 3/8" MNPT x 1/2" Barb, Brass

1/2" ID Braided Gasoline Fuel Hose (24")

Hose, 3/16" ID Vacuum

Fitting, 1/4"-28 Thread, 1/4" OD, 0.046 Wall,0.700 L, Brass

Note: Not available for purchase assembled.

Description

QTY.

1

1

1

2

1

1

1

1

1

1

1

1

1

PART

NUMBER

E10204

E10449

E10550

E12290

E86121

E86125

Wire Clamp, 3/8" Romex Connector

5 Wire Keyed Ignition Switch

Decal, OFF/ON/START

Ignition Switch Key

Key Switch Box

Screw, #10-32 x 1.000 Hex Head, Zinc

Note: Not available for purchase assembled.

Description

QTY.

1

1

1

1

1

4

15

Page 16

KAWASAKI ENGINE ASSEMBLY

Full Throttle = 3600

E10242 - Emission Kit (E10248

& E10249)

E10245 - Bung Plug M18 x 1.5mm

E10337 - Valve Oil Seal

E10544 - Decal, Clutch

E12426 - CO Detection Badge

E12525 - Drive Shaft Oil Seal

E85461 - Oil Drain Hose ASM

E88326 - Spark Plug

E88327 - Ignition Coil ASM

E88328 - Air Intake Manifold

E88468 - Head Gasket

E88469 - Cylinder 1 Head ASM

E88470 - Cylinder 2 Head ASM

E88471 - Valve Cover Gasket

E88472 - Intake Valve

E88473 - Exhaust Valve

E88476 - Dipstick Tube O-Ring

E88511 - Voltage Regulator

EP50146 - LP Ready Kawasaki

Engine ASM

With Emission Kit

(E10242)

EP50147 - LP Ready Kawasaki

Engine ASM

E88478

E88465

E88464

E88484

E10545

E88328

E12360

E88859

E88480

E88482

E88121

E11321

E10248

E88481

E88474

E88504

E88502

E88503

E88501

E88483

Engine RPM

E88325

E10895

E88477

E88479

EP50154

E10116

E10135

E10249

E11819

E12405

E10549

E88475

E10137

E88486

E88466

E81066

E81087

Idle = 1700 - 1780

16

E11418

Page 17

PART

NUMBER

E10116

E10135

E10137

E10242

E10245

E10248

E10249

E10337

E10544

E10545

E10549

E10895

E11321

E11418

E11819

E12360

E12405

E12426

E12525

E81066

E81087

E85461

E88121

E88325

E88326

E88327

E88328

E88464

E88465

E88466

E88468

E88469

E88470

E88471

E88472

E88473

E88474

E88475

E88476

E88477

E88478

E88479

E88480

E88481

E88482

E88483

E88484

E88486

E88501

E88502

E88503

E88504

E88511

E88859

EP50146

EP50147

EP50154

Description

Screw, 7/16"-14 x 1.250 Hex Head, Grade 5, Zinc

Washer, 3/8" USS, Zinc

Clamp, Tube 1/2" (COV-0909)

Emissions Kit (E10248, E10249)

Bung Plug M18 x 1.5mm

O2 Sensor Electrical Control Box

O2 Sensor

Valve Oil Seal

Decal, Clutch

Decal, Read Oners Manual

Decal, Caution Oil Pressure Switch

Gasket, Carburetor to Air-Fuel Hub

Screw #10 x 5/8" Sheet Metal, Pan Head, Phillips, Black

Nut, 7/16"-14, Nylon Lock, Grade 5, Zinc

Stud, 8mm x 18mm L

Cooling Air Intake Filter

Oil Pressure Switch

CO Detector Badge

Drive Shaft Oil Seal

Washer, 3/8" Split Lock, Zinc

Screw, 3/8"-16 x 1.500 Hex Head, Grade 5, Zinc

Oil Drain Hose Accessory

Decal, Emissions Warning Light

Air Intake Filter Paper

Spark Plug

Ignition Coil ASM

Air/Fuel Intake Manifold

O-Ring 12.5mm ID x 3.4mm T

Air Filter Thumb Nut

12V Starter

Head Gasket

Cylinder 1 Head ASM

Cylinder 2 Head ASM

Valve Cover Gasket

Intake Valve

Exhaust Valve

Oil Dipstick

Oil Filter

O-Ring

Stud, 6mm x 95mm L

Air Intake Filter Foam

Muffler Gasket

Cooling Air Intake Guard

Decal, Emissions

Decal, Air Filter Cover

Muffler, Catalytic, & Manifold Kawasaki FS481V

Air Filter Cover

Kawasaki Engine Gasoline Ready 16HP

Carburetor Intake Neck

Air Intake Elbow

Air Intake Elbow to Neck Clamp

Air Intake Elbow to Filter Clamp

Voltage Regulator

Rivet, Push, Cooling Air Intake Guard, FS481V ASM

LP Ready Kawasaki Engine Assembly With Emission Kit (E10242)

LP Ready Kawasaki Engine Assembly

Carburetor, LP Gas FS481V

QTY.

1

1

1

1

1

1

1

4

1

1

1

2

2

1

4

1

1

1

1

4

4

1

1

1

2

2

1

2

2

1

2

1

1

2

2

2

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

17

Page 18

DECK ASSEMBLY

E11772

E10734

E81089

E81067

E88320

E11164

E81089

E88315

E81089

E81067

E10120

E81063

E81063

E88314

E81067

E81089

E81089

E81067

E81089

E12693

E88323

E11165

E11501

E12476

E81066

E12483

E11339

E11170

E11420

E10120

E11420

E11335

E11340

E11351

E10120

E11163

E11420

E86125

E11416

E11135

E81066

E83629

18

Page 19

DECK PARTS

PART

NUMBER

E10120

E10734

E11135

E11163

E11164

E11165

E11170

E11335

E11339

E11340

E11351

E11416

E11420

E11501

E11772

E12476

E12483

E12693

E81063

E81066

E81067

E81089

E83629

E86125

E88314

E88315

E88320

E88323

DESCRIPTION

NYLOC HEX NUT 10-32

HEX HEAD BOLT 1/4-20 x 5/8 LG

WASHER, 3/4" SAE, ZINC

DECAL TENSIONER ACCESS

DECAL, BELT PATH

SPLASH SKIRT, 30 INCH

TENSIONER ACCESS COVER

WHEEL 10 INCH DIA x 2.50 WIDE

SPLASH SKIRT HANGER

WHEEL AXLE 3/4 OD

SHAFT COLLAR 3/4 ID

RUBBER SPLASH GUARD

FLAT WASHER #10 ZINC

WASHER, 7/16 USS, ZINC

SOLENIOD 12 VDC

SHOULDER SCREW 3/8-16 x 1/2 DIA x 1/2 LG

FLAT HEAD SCREW 10-32 x 5/8 LG

DECAL, BIG BERTHA

NYLOC HEX NUT 5/16-18 ZINC

SPLIT LOCK WASHER .375

LOCK WASHER 5/16

HEX HEAD BOLT 5/16-18 x 3/4 LG

HEX HEAD BOLT 3/8-16 x 1-1/4 LG

HEX HEAD BOLT, 10-32 x 1.00 LG

HANDLE SUPPORT LEFT

HANDLE SUPPORT RIGHT

EXTREME STRIP FRAME 30 ASSEMBLY

FRONT ACCESS PANEL

QTY.

12

2

2

1

1

1

1

2

4

1

2

1

14

2

1

2

8

1

4

4

10

14

2

3

1

1

1

1

E81088

PART

NUMBER

E81088

E86118

E87989

E87990

TRANSPORT

WHEEL ASSEMBLY

E87989

E87990

E86118

DESCRIPTION

NYLOC JAM NUT 1/2-13

3 INCH SWIVEL CASTER

TRANSPORT WHEEL

BRACKET

DETENT PIN 3/8 x 4.0, RING

QTY.

1

1

1

2

19

Page 20

MAIN DRIVE SYSTEM

E81064

E81078

E86232

E12434

E11289

E12400

E12459

E11350

E11501

E12447

E10117

E10598

E12406

E12409

E11501

E11417

20

E11345

Page 21

PART

NUMBER

E10117

E10598

E11289

E11345

E11350

E11417

E11501

E12400

E12406

E12409

E12434

E12447

E12459

E81064

E81078

E86232

Washer, 7/16" Split Lock, Zinc

Screw 7/16"-20 x 1.750 Hex Head, Grade 5, Zinc

Key 1/4" x 1/4" x 1.500"

Belt, B44 V-Belt, 44"

Pulley, BK90H - 8.75 OD

Tensioner Large For Engine

Washer, 7/16" USS, Zinc

Bushing, QT 25mm Taper Lock

Screw, 1/2"-13 x 1.750 Hex Head, Grade 5, Zinc

Washer, 1/2" Split Lock, Zinc

Clutch, Centrifugal 1750 RPM 4" Dia.

Washer, 7/16" SAE, Zinc

Key 8mm x 7mm x 30mm

Screw, 1/4"-20 x 0.750 Hex Head, Grade 5, Zinc

Washer, 1/4" Split Lock, Zinc

Spacer, Clutch Strip Kaw Top 1.000 ID x 0.470 L

Note: Not available for purchase assembled.

Description

QTY.

1

1

1

1

1

1

4

1

1

1

1

1

1

2

2

1

21

Page 22

PIVOT BRACKET ASSEMBLY

(For Serial Numbers Before 6999)

E11418

E12447

E11347

E11418

E88321

E87987

E11501

E10117

E11347

E12447

E12447

E11347

E12447

E86234

E86224

22

E11430

Page 23

PART

NUMBER

E10117

E11347

E11418

E11430

E11501

E12447

E86224

E86234

E87987

E88321

Washer, 7/16" Split Lock, Zinc

Flange Bearing AMI UCF 205 Set Screws 2.75 Bolt Spacing

Nut, 7/16"-14, Nylon Lock, Grade 5, Zinc

Screw, 7/16"-14 x 2.250 Hex Head, Grade 5, Zinc

Washer, 7/16" USS, Zinc

Washer, 7/16" SAE, Zinc

Axle, Pivot, 25mm OD x 2.0" L

Screw, 7/16"-14 x 1.500 Hex Head, Grade 5, Zinc

Screw, 7/16"-14 x 1.000 Hex Head, Grade 5, Zinc

Pivot Bracket

Note: Not available for purchase assembled.

Description

QTY.

2

4

12

4

2

24

2

8

2

1

23

Page 24

PIVOT BRACKET ASSEMBLY

(For Serial Numbers 7000 and Greater)

E11418

E12447

E89818

E89828

E11347

E11418

E10117

E12447

E11347

E89816

E89817

E12447

E86234

E11418

E10117

E12447

E89782

E12447

E86234

E12447

E89819

24

Page 25

PART

NUMBER

DESCRIPTION

QTY.

E10117

E11347

E11418

E12447

E86234

E89782

E89816

E89817

E89818

E89819

E89828

Note: Not available for purchase assembled.

SPLIT LOCK WASHER 7/16

FLANGE BEARING AMI UCF 205 SET SCREWS 2.75 BOLT SPACING

NYLOC NUT 7/16-14

FLAT WASHER, 7/16, SAE

HEX HEAD SCREW 7/16-14 x 1-1/2

PIVOT BASE ASM

FLANGE-MOUNTED STEEL BALL BEARING, 1" SHAFT DIAMETER

BRONZE THRUST BEARING 1" I.D. X 1-1/2" OD X 1/16" T

CENTER SHAFT SPACER

HEX BOLT 0.4375-14 x 2.75 LG

PIVOT BRACKET

12

2

16

32

12

2

2

2

1

4

1

25

Page 26

BRUSH PLATE ASSEMBLY

E12444

E11501

E81072

E81067

E10458

E12400

E12459

E11350

E12400

E12459

E11346

E12427

E11343

E12400

E12459

E11348

E12427

E11344

E11349

26

E11336

E11501

E12409

E12406

E10117

E10116

E83641

E11342

E11414

E12444

E81063

Page 27

PART

NUMBER

E10116

E10117

E10458

E11336

E11342

E11343

E11344

E11346

E11348

E11349

E11350

E11414

E11501

E12400

E12406

E12409

E12427

E12444

E12459

E81063

E81067

E81072

E83641

DESCRIPTION

HEX HEAD SCREW 7/16-14 x 1-1/4 LG

SPLIT LOCK WASHER 7/16

TENSIONER LARGE FOR BRUSHES

BRUSH MOUNTING PLATE

BRUSH MOUNTING PLATE LH

STRIPPER CENTER DRIVE HUB ASSEMBLY

STRIPPER BRUSH DRIVE HUB ASSEMBLY

PULLEY, BK47H - 4.45 OD

PULLEY, BK62H - 5.95 OD

BELT, BB77 DOUBLE V-BELT 77"

PULLEY, BK90H - 8.75 OD

STRIP BRUSH 11" FLARED 2" HOLE

WASHER, 7/16 USS, ZINC

BUSHING, PULLEY, D25MM QT25MM

HEX HEAD BOLT 1/2-13 x 1-3/4 Lg

WASHER, 1/2 SPLIT LOCK

WASHER 1 ID x 14 GAUGE

FLAT WASHER, 5/16" SAE

MACHINE KEY 8mm x 7 mm x 30mm

NYLOC HEX NUT 5/16-18 ZINC

LOCK WASHER 5/16

HEX HEAD SCREW 5/16-18 x 1.00 Lg

HEX HEAD BOLT, 5/16-18 x 1-1/2 Lg

QTY.

16

16

1

1

3

1

3

1

3

1

1

3

2

5

1

1

8

10

5

9

1

1

9

Note: Not available for purchase assembled.

27

Page 28

ENGINE MAINTENANCE

KAWASAKI FS481V

PERIODIC MAINTENANCE

PLEASE REFER TO ENGINE OWNERS MANUAL

FOR MORE INFORMATION

Check engine oil level and add if needed

Check and clean engine intake foam and intake paper filter

Check and clean engine cooling air intake filter

General check for loose or lost nuts, screws, oil leakage,

fuel hose connection, etc.

Clean air intake foam filter

Clean air intake paper filter

Check belt tension

Change engine oil

Change oil filter

DAILY

*

*

*

*

EVERY

25

HOURS

*

*

*

EVERY

50

HOURS

*

EVERY

100

HOURS

*

EVERY

200

HOURS

Clean dust and dirt from cylinder and cylinder head

cooling fins

Tighten nuts and screws

Clean and regap sparkplugs

Replace air intake foam filter

Replace air intake paper filter

Replace spark plugs

Check and adjust valve clearance

Clean combustion chamber

Clean and lap valve seating surface

IMPORTANT NOTES:

1) Change engine oil and oil filter after first 8 hours of operation

2) Maintenance should be done by qualified personnel only

3) Change foam and paper air intake filters and spark plugs after first 25 hours of operation

*

*

*

*

*

*

*

*

*

28

Page 29

ELECTRICAL SCHEMATIC

E10248

O2 Sensor Electrical Control Box

EP50034

LP Ready 17HP Kawasaki

Engine Assembly

With Emission Kit (E10242)

Black Wire

Green Wire

E10243

In Line Fuel Shut Off Valve Model 152

E86119

Hour Meter, SenDEC 5-80V

-

+

E10553

Black 14 Gauge Wire

Blue

Wire

Red Wire

Blue

14 Gauge

Wire

E10553

Black 14 Gauge Wire

Green

14 Gauge Wire

E10249 O2 Sensor

E12405 Oil Pressure Switch

Red

14 Gauge Wire

Black

14 Gauge Wire

E10449 Ignition Switch

Yellow

14 Gauge Wire

E88511 Voltage Regulator

E12381

Black 6 Gauge Wire

-

+

E88324 Battery, 12V,12AH, 35CCA, AGM

E12380

Red 6

Gauge

Wire

Red

14 Gauge Wire

E88466

12V Starter

E12380

Red 6

Gauge

Wire

E11772 Solenoid, 12V

29

Page 30

MAIN DRIVE BELT

Removal

Remove main drive belt tensioner access plate.

1.

Remove front access panel bolts and panel.

2.

Loosen main drive belt tensioner bolt using a 3/4" wrench.

3.

Through the front access slip the belt up over the main drive pulley of the brush drive plate.

4.

You can finish removing the main drive belt through the rear opening of the machine under the handle.

5.

Installation

Insert the new main drive belt through the rear opening of the machine under the handle.

1.

Place the main drive belt around the clutch while ensuring the main drive belt tensioner pulley is in the

2.

correct location.

Put the opposite end of the main drive belt on top of the main drive belt pulley of the brush drive plate.

3.

Through the front access finish inserting the main drive belt into the main drive belt pulley groove.

4.

Tensioning

Insert a 1" wrench into the tensioner access slot onto the main drive belt tensioner hex on the main

1.

drive belt tensioner body.

Pull the wrench toward the front of the machine to tension the main drive belt.

2.

While holding the 1" wrench in place tighten the main drive belt tensioner bolt with a 3/4" wrench.

3.

Reposition the 1" wrench to add more tension to the main drive belt.

4.

While holding the 1" wrench in place then loosen the main drive belt tensioner bolt with the 3/4" wrench.

5.

Repeat steps 2 and 3.

6.

Repeat steps 5 and 6 until the main drive belt is tensioned properly. (2 or 3 repetitions)

7.

Main Drive Belt

Tensioner

Access Plate

Main Drive Belt

Tensioner Bolt

Main Drive

Belt

Main Drive

Belt Pulley

Clutch

Main Drive Belt

Tensioner Pulley

Main Drive Belt

Tensioner Bolt

Main Drive Belt

Tensioner Body

30

Page 31

BRUSH PLATE & BELT

Brush Drive Plate Removal

Remove front access panel bolts and panel.

1.

Loosen main drive belt tensioner bolt using a 3/4" wrench.

2.

Through the front access slip the main drive belt up over the main drive pulley of the brush drive plate.

3.

Remove pivot bracket axle bolts.

4.

Slide pivot bracket axles out from both sides.

5.

Tilt machine back at handle and pull backward until it clears the brush drive unit.

6.

Brush Drive Belt Removal

Loosen brush drive belt tensioner pulley bolt, located on brush side of plate, using a 3/4" wrench.

1.

Slide the belt off one of the three brush pulleys.

2.

Finish removing the belt from the rest of the pulleys.

3.

Brush Drive Belt Installation

Place the new belt around the center pulley as shown below.

1.

Now route the belt around each of the brush drive pulleys as shown below.

2.

Brush Drive Belt Tensioning

Place a 1" wrench on the tensioner hex on the top of the brush drive belt tensioner body.

1.

Pull the wrench toward the brush drive belt tensioner pulley to tension the belt.

2.

While holding the 1" wrench in place tighten the brush drive belt tensioner bolt, on the brush side of the

3.

plate, using a 3/4" wrench.

Front Access

Panel Bolts

Front Access

Panel

Engine Tensioner

Pulley Bolt

Pivot Bracket

Axle Bolts

Main Drive

Belt Pulley

Brush Drive Belt Path

Main Drive

Belt

Main Drive Belt

Tensioner Bolt

Brush Drive

Belt Tensioner

31

Page 32

BRUSH CHANGE

Remove propane tank.

1.

Remove front access panel to gain access to the brush drive shaft tops.

2.

Lay the machine on its side with the brush drive plate installed.

3.

The brush drive shaft and brush mount plate are LEFT HAND THREADS.

4.

Using a 3/4" open end wrench place it on the wrench flats of the brush drive shaft top.

5.

Place an 1 1/4" socket in the center of the brush mount plate on the bristle side.

6.

Unscrew the brush mount plate from the brush drive shaft while securing the brush drive shaft with the 3/4"

7.

wrench.

Now you'll need to remove the brush from the brush mount plate.

8.

Using a 1/2" wrench and 1/2" socket unscrew the nuts which hold the brush onto the brush mount plate.

9.

Note: When reassembling brush and brush mounting plate place bolts in through the brush mount plate

down through brush and put nuts on the bristle side of the brush.

Brush Drive

Shaft Top

Brush Mount

Plate Bottom

Brush Mount

Plate Top

See Note

Front Access

Panel

32

Page 33

TROUBLESHOOTING

PROBLEM CAUSE POSSIBLE SOLUTION

Battery is dead Recharge battery or replace if necessary

Loose wire or bad connection Check wires and connections

Engine will not turn over

Engine turns over, but will

not start

Hard to start

Engine stops suddenly

and will not restart

Engine overheats

Can't remove brushes

Poor stripping

performance or leaves

wax on the floor

Bad electrical component Replace bad component

Fuel system problem

Propane tank shut off valve in off

position

Low oil Add oil

Fuel system problem

Propane tank empty Fill propane tank

Engine problem

Throttle lever in slow position Push throttle lever to fast position

Propane tank shut off valve not

fully open

Some type of engine problem

Out of propane Replace propane tank with full propane tank

Low oil Add oil

Intake air filter is dirty Remove air intake filter and clean

Incorrect oil level Add or remove oil to achieve proper oil level

Turning brushes the wrong

direction

Brushes worn and have 3/4"

bristle length or less

Brush or main drive belt slipping Tension belts or replace belts if worn out

Problem with stripper Check dilution ratio or try alternative stripper

Refer to engine owner’s manual and read

IMPORTANT below

Open propane tank shut off valve completely

Refer to engine owner’s manual and read

IMPORTANT below

Refer to engine owner’s manual and read

IMPORTANT below

Open propane tank shut off valve completely

Refer to engine owner’s manual and read

IMPORTANT below

Turn clockwise to remove. Threads are LEFT HAND

Change the brushes

Excessive splashing Splash guard too high off floor Adjust splash guard down

Solution pushed by

splash guard

Brushes not turning,

turning slow or smell

burning rubber

Lacks power Some type of engine problem

Engine stops and will

restart, but stops again

Nothing here fixes the

problem

Splash guard too low Adjust splash guard up

Brush or main drive belt slipping Tension belts or replace belts if worn out

Floor too rough to overcome

friction, may happen on rough

concrete surface

Emission shut-down system

engaged

Problem could have several

causes

Check belts for proper tensioning or for excessive

wear and ensure there is plenty of liquid on the floor.

Refer to engine owner’s manual and read

IMPORTANT below

Refer to engine owner’s manual and read

IMPORTANT below

Read IMPORTANT below

IMPORTANT: Propane fueled combustion engines produce dangerous gases and must be serviced by authorized

service personnel trained specifically to service propane fueled engines and fuel systems. The troubleshooting

tips are not intended to take the place of authorized service personnel. If you are unsure of what to do contact an

authorized service personnel. Before working on this machine you must be familiar with the safety instructions in

this manual.

33

Page 34

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Betco Corporation are pleased to explain the emissions control system warranty on

your small off-road engine (SORE). In California and the other 49 States, new SORE must be designed, built and equipped

to meet stringent anti-smog standards. Betco Corporation must warrant the emission control system on your SORE for the

period of time listed below provided there has been no abuse, neglect or improper maintenance of your SORE.

Your emission control system may include parts such as the carburetor, fuel-injection system, the ignition system, catalytic

converter, fuel tanks, fuel lines, fuel caps, valves, canisters, filters, vapor hoses, clamps, connectors, and other associated

emission-related components.

Where a warrantable condition exists, Betco Corporation will repair your SORE at no cost to you including diagnosis, parts

and labor.

MANUFACTURER'S WARRANTY COVERAGE

The emission control system is warranted for two years. If any emission-related part on your equipment is defective, the part

will be repaired or replaced by Betco Corporation.

OWNER'S WARRANTY RESPONSIBILITIES

As the small off-road engine (SORE) owner, you are responsible for the performance of the required maintenance listed in

your owner's manual. Betco Corporation recommends that you retain all receipts covering maintenance of your SORE engine,

but Betco Corporation cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all

scheduled maintenance.

As the SORE owner you should however be aware that Betco Corporation may deny your warranty if your SORE or its part has

failed due to abuse, neglect, improper maintenance or unapproved modification.

You are responsible for presenting your utility equipment engine to a Betco Corporation distribution center as soon as the

problem exists. The warranty repairs should be completed within a reasonable amount of time, not to exceed 30 days. If you

have any questions regarding your warranty rights and responsibilities, you should contact Betco Corporation at 1-888-GOBETCO (1-888-462-3826).

Betco Corporation

1001 Brown Ave.

P.O. Box 3127

Toledo, Ohio 43607

USA

GENERAL EMISSIONS WARRANTY COVERAGE

Betco Corporation warrants to the ultimate purchaser and each subsequent purchaser that the equipment is designed, built

and equipped so as to conform with all applicable regulations; and free from defects in materials and workmanship that cause

the failure of a warranted part to be identical in all material respects to that part as described in Betco Corporation’s application for certification.

The warranty period begins on the date the equipment is delivered to an ultimate purchaser or first placed into service. The

warranty period is two years.

Subject to certain conditions and exclusions as stated below, the warranty on emission-related parts is as follows:

1. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions supplied, is

warranted for the warranty period stated above. If the part fails during the period of warranty coverage, the part will be

repaired or replaced by Betco Corporation according to subsection (4) below. Any such part repaired or replaced under

warranty will be warranted for the remainder of the period.

2. Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the

warranty period stated above. Any such part repaired or replaced under warranty will be warranted for the remaining warranty period.

34

Page 35

EMISSION CONTROL WARRANTY STATEMENT

3. Any warranted part that is scheduled for replacement as required maintenance in the written instructions supplied is warranted for the period of time before the first scheduled replacement date for that part. If the part fails before the first scheduled

replacement, the part will be repaired or replaced by Betco Corporation according to subsection (4) below. Any such part

repaired or replaced under warranty will be warranted for the remainder of the period prior to the first scheduled replacement

point for the part.

4. Repair or replacement of any warranted part under the warranty provisions herein must be performed at a warranty station at

no charge to the owner.

5. Notwithstanding the provisions herein, warranty services or repairs will be provided at all of our distribution centers that are

franchised to service the subject engines or equipment.

6. The SORE owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective, emissionrelated warranted part, provided that such diagnostic work is performed at a warranty station.

7. Betco Corporation is liable for damages to other engine or equipment components proximately caused by a failure under

warranty of any warranted part.

8. Throughout the SORE warranty period stated above, Betco Corporation will maintain a supply of warranted parts sufficient to

meet the expected demand for such parts.

9. Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without

charge to the owner. Such use will not reduce the warranty obligations of Betco Corporation.

10. Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of any non-exempted

add-on or modified parts by the ultimate purchaser will be grounds for disallowing a warranty claims. Betco Corporation will

not be liable to warrant failures of warranted parts caused by the use of a non-exempted add-on or modified part.

WARRANTED PARTS

The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty

coverage if Betco Corporation demonstrates that the SORE has been abused, neglected, or improperly maintained, and that such

abuse, neglect, or improper maintenance was the direct cause of the need for repair or replacement of the part. That notwithstanding, any adjustment of a component that has a factory installed, and properly operating, adjustment limiting device is still

eligible for warranty coverage. The following emission warranty parts are covered:

1. Fuel system: carburetor, pressure regulator, and fuel lock off

2. Ignition system: spark plug, ignition coil assembly, and voltage regulator

3. Intake system: intake manifold and air filter

4. Exhaust system: exhaust manifold and catalytic converter

5. Miscellaneous items used in above systems: hoses, connectors, and assemblies.

35

Page 36

BETCO US WARRANTY POLICY

10 year coverage

Subject to the conditions stated below,

Betco warrants parts and labor on

rotationally molded polyethylene tanks/

housings and injection molded vacuum

head assemblies to be free from defects

in materials and workmanship for

a period of ten years to the original

purchaser.

Allowable Travel Time Warranty Reimbursement:

Eligible equipment: All battery and propane powered equipment products. Warranty period: 90 days from date of sale to the

original purchaser. A maximum 180 mile round trip at 50 cents per mile will be allowed for warranty consideration.

3 Year Coverage

Subject to the conditions stated below,

Betco warrants parts and labor on all

other Betco components to be free from

defects in materials and workmanship

for a period of three years to the original purchaser.

1 Year Coverage

Subject to the conditions stated below,

Betco offers a limited warranty on parts

and labor on the following equipment:

parts and accessories to be free from

defects in materials and workmanship

for a period of one year to the original

purchaser.

• HF14 Upright Vacuum: #E88820-00

• Bac Pac Lite Vacuum: #85903-00

• FiberPRO® Floor Dryer: #85507-00

• WORKMAN™ Series Vacuums:

#85024-00, #85025-00, #83012-00,

#85027-00

• CV100T Vacuum: #85023-00

• All Tools and Accessories

• All Battery Chargers

• All Batteries are pro-rated for 1 year

Propane Machine Warranty:

Kawasaki engines are warranted by Kawasaki for a period of 2 years against manufacturer defects. All other components

(except wear items)* are warranted by Betco for a period of 3 years.

*Wear Items exempt from Warranty consideration include but may not be limited to: power cords, transport wheels,

vacuum bags, belts, squeegee blades, pad drivers, clutch plates, handle grips, filters, screens, throttle cables, brushes

and carbon brushes.

Subject to the conditions and exceptions stated in this warranty, Betco warrants the Betco products to be free from defects in

material and workmanship, under normal use and service, for the periods listed under the warranty policy to the original purchaser. At any time during the warranty period, Betco will furnish replacement parts for the Betco parts to the original purchaser. Such parts will be furnished and charged including transportation costs, to the original owner through any Betco authorized

Service Distributor. If the original part is returned within the warranty policy period from date of delivery for inspection by

Betco and is found to be defective the owner will be credited for the cost of replacement parts plus shipping and handling.

Replacement parts that have become defective through wear or abuse are not included in this warranty.

This warranty does not apply to damage or defect caused by accident, misuse. Negligence, fire, or to any Betco product which

has been serviced or repaired by other than an authorized Betco Service Distributor or Betco factory personnel. This warranty

is void if products are used for any purpose other than that which was intended. There are no other warranties expressed or

implied. In no event shall Betco be liable for incidental or consequential damages or any damage to person or property. (Please

note some states do not allow the exclusion or limitations for incidental and consequential damages).

36

Customer Service: 888-GO-BETCO • Fax: 800-445-5056 • Technical Service: 877-856-5954 • www.betco.com

1001 Brown Avenue • Toledo, Ohio 43607-0127

E12327-94 Sept13R

Loading...

Loading...