LaserSpeed LS9000

OPERATOR GUIDE

- for daily operation -

Manual Part Number: 93296 • Manual Drawing Number: 0921-01419 • English • Revision F • © Copyright Feb 2013

www.betalasermike.com

Declaration of Conformity

LaserSpeed 9000 Operator Guide

Declaration of Conformity

Part No. 93296 / Drawing No. 0921-01419 Page 2 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

Contents

Declaration of Conformity ....................................................................... 2

Contents ................................................................................................... 3

Proprietary Statement .............................................................................. 4

European Commission Requirements .................................................... 5

Safety Information .................................................................................... 6

Intended Use ........................................................................................................ 6

Laser Classification .............................................................................................. 7

Laser Safety Precautions ..................................................................................... 8

Labels and Safety Features ................................................................................. 9

Introduction .............................................................................................11

Quick Start ...............................................................................................11

LaserTrak Software .................................................................................12

LaserTrak for Windows ...................................................................................... 12

Gauge Alignment ................................................................................................ 12

Contents

Servicing and Returning Your Equipment .............................................16

Part No. 93296 / Drawing No. 0921-01419 Page 3 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

Note:

For

information

about

servicing and

returning your

equipment,

see the

section at the

end of this

manual.

Proprietary Statement

Manufacturer/Distributor

Beta LaserMike, 8001 Technology Blvd., Dayton, OH 45424, USA

About This Manual

This manual contains descriptions, drawings, and specifications for a Beta LaserMike product. Equipment or

products made prior to or subsequent to the publication date of this manual may have parts, features, options, or

configurations that are not covered by this manual. Specifications contained herein are subject to change by Beta

LaserMike without prior notice. Beta LaserMike is not responsible for errors or omissions that may be contained

herein or for incidental or consequential damages in connection with the furnishing or use of this information.

Comments or suggestions for possible improvements to the manual are appreciated. Please email us at

manualfeedback@betalasermike.com.

The information contained in this manual is the property of Beta LaserMike. The information disclosed in this

document is furnished in confidence and upon the condition that individual and corporate intellectual rights, whether

patented or not, will be respected. If this document is supplied on removable media (e.g. CD), an electronic copy

(stored on-site) and one printout is permitted. If this document is supplied in printed form, no part of this document

may be reproduced or scanned without the prior written consent of Beta LaserMike. This document may not be

distributed or circulated to third parties.

Proprietary Statement

Limited Warranty

Beta LaserMike will correct by repair, or at Beta LaserMike‘s option, by replacement, F.O.B Beta LaserMike’s plant,

any defect in workmanship or material in any equipment manufactured by Beta LaserMike which appears under

normal and proper use within twelve months from the date of shipment (eighteen months for OEM’s), provided Beta

LaserMike is given reasonable opportunity to inspect the alleged defective equipment at the place of its use and

under conditions of its use.

EXCLUSIONS: This warranty does not cover products which have been modified, altered, or repaired by any other

party than Beta LaserMike or its authorized agents. Furthermore, any product which has been, or is suspected of

being damaged as a result of negligence, misuse, incorrect handling, servicing, or maintenance; or has been

damaged as a result of excessive current/voltage or temperature; or has had its serial number(s), any other

markings, or parts thereof altered, defaced, or removed will also be excluded from this warranty.

WARRANTY SERVICE AT CUSTOMER SITE: Warranty service performed at the customer’s facility will be free of

charge for parts and labor; however, the customer will be liable for transportation and living expenses of personnel

dispatched to effect such repair. A purchase order or other written confirmation of the acceptance of these charges,

signed by an authorized individual, will be required prior to commencement of repairs. Additional charges may be

assessed the customer if: 1) The equipment is not made available on a timely basis, 2) The equipment is found to

be without fault, and/or 3) It is determined the equipment is not under warranty, whether by expiration of the

warranty or any act which voids the warranty.

OTHER THAN AS SET FORTH HEREIN, BETA LASERMIKE MAKES NO WARRANTIES, EXPRESSED OR

IMPLIED, OF MERCHANTABILITY AS TO THE EQUIPMENT MANUFACTURED BY IT, AND THERE ARE NO

EXPRESSED OR IMPLIED WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

THEREOF. Beta LaserMike’s obligation to correct defects in such equipment by repair or replacement in

accordance with the foregoing provisions is in lieu of any other warranties, expressed or implied, and in no event

shall Beta LaserMike be liable for incidental or consequential damages. No service of Beta LaserMike’s equipment

is permitted during the warranty period without the specific written consent of Beta LaserMike.

Part No. 93296 / Drawing No. 0921-01419 Page 4 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

European Commission Requirements

European Commission Requirements

This equipment is intended for use in a heavy industrial environment. The equipment generates, uses and

can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to other equipment. There is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to other equipment the user is

encouraged to try to correct the interference by one or more of the following measures:

- Re-orientate or relocate the equipment.

- Increase the separation between the pieces of equipment.

- Connect the pieces of equipment on separate mains circuits.

- Ensure that the relevant items of equipment are properly and securely earthed to a common earth point

using adequately sized cable or other means of connection.

Where supplied or specified, shielded interconnection cables must be employed with this equipment to

ensure compliance with the pertinent RF limits. Changes or modifications not expressly approved by the

company could void the user’s authority to operate the equipment.

This product has been rigorously tested to comply with the European EMC (Electromagnetic Compatibility)

Directive. With regard to this, Beta LaserMike recommends that any non-Beta LaserMike peripheral

equipment is CE marked for the Heavy Industrial environment (EN50082-2). Beta LaserMike also

recommends that any cables not supplied by Beta LaserMike, but used for powering Beta LaserMike

equipment, be built using good EMC practices (i.e. cables with braided shield, and connectors with 360

termination of the braid to a metal/metalised shell connector at both ends). If you have any questions

regarding this, contact the Beta LaserMike Service Department.

Part No. 93296 / Drawing No. 0921-01419 Page 5 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

Safety Information

Under NO circumstances should the earth safety connections

be broken – internal damage to sensitive electronic components

may occur and at worst electrocution to personnel may result.

This equipment must be earthed/grounded.

Relays and associated wiring are rated for SELV levels i.e. 60

VDC & 30 VAC RMS. These levels must not be exceeded.

Maintenance, repairs and electrical connections should be

performed by a suitably qualified person for the country of

installation.

Input power to the equipment is of direct current type

designated by the symbol on equipment housing and shown

below.

Safety Information

Reference: IEC 60417-5031

The equipment contains a slow blow type fuse to protect against

input power overloads and is not user replaceable.

Intended Use

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Part No. 93296 / Drawing No. 0921-01419 Page 6 of 16 Revision F (Feb 2013)

Laser Classification

The Model LS9000 Non-contact Length and Speed

Gauge (Model LS9000) is classified as a IIIb laser device.

This category contains infrared and visible laser devices

with powers up to 500 mW. The optical gauge in the

system uses a 50 mW solid-state laser device operating

between 760 and 800 nm (near infrared region of the

spectrum).

A class IIIb product must have the following safety

features:

A 5-second delay after power-up before laser

radiation is emitted from the gauge.

An indicator light to inform personnel near the

gauge that laser radiation is being emitted.

LaserSpeed 9000 Operator Guide

Safety Information

A mechanical device to physically block the laser

beam from exiting the gauge.

An interlock circuit to shut off the laser when the

circuit is opened.

All hazards must be properly identified with warning labels.

These basic safety features are incorporated to promote safe operation of the

laser.

A class IIIb laser must also have a key switch to power the laser, ensuring that

only trained personnel can operate the instrument. Because the location of the

gauge can often make it difficult to access a key switch, the key switch needs

to be installed by the final user. It should be placed in a location that will be

readily accessible to the operators. For more information on installing the laser

key switch, see the Installing the System section of the Instruction Handbook.

The user of a laser device must comply with a different set of regulations.

Many countries and individual states have passed legislation regarding the use

of laser products.

Part No. 93296 / Drawing No. 0921-01419 Page 7 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

Maximum Laser Power

0.050 watt

Laser Wavelength

0.785 micrometer

Minimum Laser Spot Size

(Elliptical)

5 x 3 millimeters

Beam Divergence

0.5 milliradians

Pulse Rate

Continuous wave

Maximum radiance (power

divided by spot-size area)

0.050 Watt / 0.1 cm2

[0.5 W/cm2]

The following system specifications will help establish appropriate safety

measures.

Laser Safety Precautions

The laser beam in the optical gauge is very powerful and can permanently

damage eyes not protected by laser safety glasses. To avoid exposing

yourself to hazardous radiation, you must take these precautions:

Safety Information

Never look into the laser beam. If you must look at the beam,

view it from an angle and in the direction in which the beam is

travelling.

The beams emitted from the Model LS9000 are invisible to the

unaided eye. Return the beam shutter to the closed position

when the system is not in use or during setup.

Ensure that all direct reflections are blocked.

Remove all rings, watches, or jewellery from your hands when

working on or near the gauge—can cause hazardous reflections.

Never install the instrument at eye level.

Operate the system only with people who have been instructed

in laser safety.

Post warning signs and lights that are active when laser is

operating.

If your country or state has no regulations governing the safe use of lasers,

Beta LaserMike recommends that you follow the guidelines specified by the

American National Standard for the safe use of lasers (ANSI Z136.1–1986).

For a copy of this document, write to:

Laser Institute of America

13501 Ingenuity Drive, Suite 128

Orlando, Florida 32826

1-800-345-2737

Part No. 93296 / Drawing No. 0921-01419 Page 8 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

IDENTIFICATION

LABEL

LASER

WARNING

LABEL

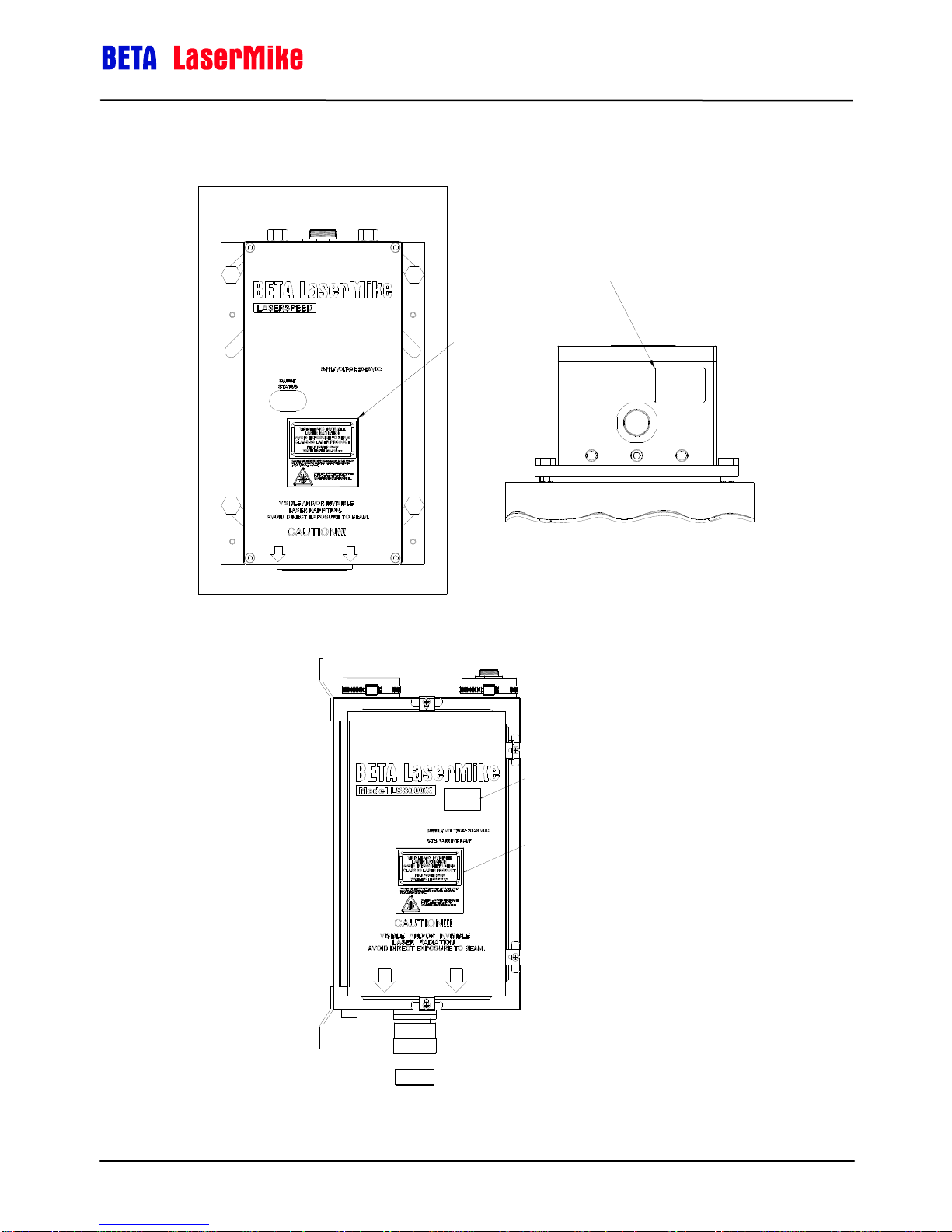

Labels and Safety Features

This section acquaints you with the advisory and identification labels on the

instrument and the safety features incorporated into the design of the

instrument. The following figures show the advisory and identification labels

on the Model LS9000.

LS9000 Labels

Safety Information

Part No. 93296 / Drawing No. 0921-01419 Page 9 of 16 Revision F (Feb 2013)

IDENTIFICATION

LABEL

LASER

WARNING

LABEL

IDENTIFICATION

LABEL

LASER

WARNING

LABEL

LS9000E Labels

LaserSpeed 9000 Operator Guide

Safety Information

LS9000X Labels

Part No. 93296 / Drawing No. 0921-01419 Page 10 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

Power Connection

The sensor requires 24 VDC of power at 1.5 amps. Connect +24 VDC

to input pins 24 and 25 (+24V Power Input) on the 25-pin D-sub

connector on the back of the LS9000 sensor. Connect the power

ground to pins 12 and 13 (Power Ground for 24V Input) on the 25-pin

D-sub connector on the LS9000 sensor.

Shutter Control

Connect pin 17 (Shutter Control) to pin 11 (Signal Ground). This will

open the shutter and permit the laser beams to exit the sensor.

Laser Interlock

Connect pin 16 (Laser Interlock) to pin 21 (Signal Ground). This will

power the laser. With +24 VDC connected and pin 16 (Laser Interlock)

and pin 17 (Shutter Control) grounded, the laser will be visible on

paper held in front of the LS9000 sensor.

RS232 Interface

For 9-Pin D-sub Computer

Serial Port

Connect the RS232 Cable from the 9 pin “D” connector on the

Breakout terminal strip to the Comm port on your computer. The cable

is a straight through cable without any pin reversal. The male end

connects to the 9 pin connector on the terminal strip for the gauge and

the female end connects to the computer.

Introduction

This manual describes the daily routine usage of the LaserSpeed 9000 Gauge.

For installation and setup, see the LaserSpeed 9000 Instruction Handbook.

The Model LS9000 LaserSpeed® Non-Contact Length and Speed Gauge is an

industrial, laser-based instrument that measures the velocity and length of

moving material. Due to the nature of the laser-based measurement, there is

no physical contact with the material.

Quick Start

The following will help you set up and operate the LS9000 for the first time.

You can also use this information to check for possible connection problems

during troubleshooting.

Introduction

Run the LaserTrak system software. Check for proper RS232 connection at a

baud rate of 115,200. If the interface fails, perform a search with the LS9000

software to make the connection. If the search fails, re-check all RS232

connections and search again. If the RS232 still is not working, try another

computer. Some computers do not support a baud rate of 115,200.

Part No. 93296 / Drawing No. 0921-01419 Page 11 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

LaserTrak Software

LaserTrak® is a Windows®-based software program, which allows you to

acquire and display the Length, Velocity, Quality Factor, and Gauge Status in

real time. The LaserTrak software configures the gauge’s operating

parameters, displays data, and collects data, which can be stored on a

computer hard drive. This LaserSpeed series of non contact speed and length

gauges provide a set of versatile tools that are applicable for a wide variety of

process measurement schemes. LaserTrak allows you to take full advantage

of this versatility in a straightforward, easy to understand manner.

There are several features available with the LaserTrak software. LaserTrak

mimics a chart recorder output on the screen and monitor the speed, length

and Quality Factor in real time and presents a time history depiction of the

data. LaserTrak can acquire and store data, and load and display stored data

from a previously acquired data file.

LaserTrak Software

LaserTrak also allows the configuration of the gauge operating parameters to

optimize the gauge’s performance for each application. The gauge can

emulate any mechanical pulse tachometer by using the gauge configuration

feature. To configure the pulse outputs or any other parameter of the gauge,

Click on “tools”, then click on “LaserSpeed Configuration”. Change the

operating parameters to match your operating conditions and then save the

parameters to the gauge by clicking on close. Once the parameters have been

saved to the gauge you do not need the LaserTrak software to operate the

gauge. However, LaserTrak software can be a very useful tool in getting

familiar with the gauge’s operation and performance. It can be useful to

monitor the gauge's operation until you are comfortable with the gauge’s

performance.

LaserTrak for Windows

Note: LaserTrak Version 4.0 or later must be used with the LS9000 gauge.

1) Make sure the RS232 cable is properly connected to the gauge and the

computer. See the LS4000-3 Instruction Handbook if more information

is needed.

2) Make sure the power is applied to the gauge.

Part No. 93296 / Drawing No. 0921-01419 Page 12 of 16 Revision F (Feb 2013)

®

Windows 98, NT 2000 and Windows XP are registered trademarks of Microsoft

Corporation.

LaserSpeed 9000 Operator Guide

LaserTrak Software

3) Check status lights on the gauge. The power light should be on and the

Laser on light should be on. This indicates that power has been applied

to the gauge and the Interlock is closed so the Laser power can be

applied.

4) Click on the LaserTrak Icon to start the LaserTrak Software.

a) The LaserTrak software should search all COM ports on the

computer and find the COM port that the gauge is connect to.

Check the LS4000-3 Instruction Handbook for more information

if the software does not find the gauge.

b) Once communication has been established between the

LaserTrak software and the gauge, the software will display the

Chart Recorder screen.

c) Click on “Tools” then “LaserSpeed Configuration” to go the

configuration screen.

d) Change the configuration settings to correspond to your

application.

e) Click Close and update the setting to the gauge.

f) The gauge is now ready to start measuring.

Part No. 93296 / Drawing No. 0921-01419 Page 13 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

Gauge Alignment

LaserSpeed gauges have a standoff distance and a depth of field the product

needs to stay within in order to make measurements. The last two digits of the

model number indicate the standoff distance. For example model LS9000-303,

the last two digits are 03 meaning 300 mm (11.8 inches). See the LS9000

Instruction Handbook for more details. The 300 mm (11.8 inch) standoff

means the product has to be 300 mm or 11.8 inches from the product. Model

LS9000-303 also has a 37 mm or 1.45 inch depth of field. This means the

product has to be 300 mm (11.8 inches) from the gauge ± 17.5 mm (±0.69

inches).

LaserTrak Software

The laser beam needs to get aligned to the center 20% on round product. For

flat products, the product just needs to be within the depth of field of the

gauge. Normally, the gauge will be aligned perpendicular to the product. See

the LS9000 Instruction Handbook for alignment error if not mounted

perpendicular to the product.

The gauge should be making accurate speed and length measurements once

the gauge has been mounted and aligned properly. The Speed and Length

measurements along with Quality Factor can be monitored using a computer

and the LaserTrak software.

Part No. 93296 / Drawing No. 0921-01419 Page 14 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

Speed Graph

Quality Factor Graph

The Chart Recorder Screen acquires Speed, Length, Quality Factor and

Status from the gauge and displays them on a chart recorder screen.

Chart Recorder Screen

LaserTrak Software

The Quality Factor represents how well the gauge is measuring the product.

Quality Factor ranges from 0 to 15, with 15 being the best. Always try to get

Quality Factor to equal 15. If Quality Factor is not 15, check the standoff

distance, the alignment, make sure the product does not have any water on

the surface. See the LS9000 Instruction Handbook for more details.

Part No. 93296 / Drawing No. 0921-01419 Page 15 of 16 Revision F (Feb 2013)

LaserSpeed 9000 Operator Guide

Servicing and Returning Your Equipment

Servicing and Returning Your Equipment

Your instrument was carefully inspected electrically and mechanically prior to

shipment. It should be free of surface mars and scratches, and it should be in

perfect working order upon receipt. If any indication of damage is found, file a

claim with the carrier immediately, prior to using the instrument. If no damage

is apparent, proceed by using this manual to install and setup this instrument.

Save the shipping carton and packing material for future storing or shipment of

the instrument. If, at some future time, the instrument must be returned to the

factory for service, include a full description of the instrument failure and the

mode of operation the instrument was in at the time of failure. Also include a

contact person to discuss the instrument failure.

When returning equipment for service, it is important to first obtain a Return

Material Authorization (RMA) number. The RMA number is needed for proper

handling of returned equipment.

To obtain an RMA, go to www.betalasermike.com

Select Service

Select Equipment Return / RMA from the drop-down menu. Follow

the instructions to obtain an RMA.

Ship the instrument in the original carton, or, if the original carton is

unavailable, ship in a carton providing sufficient protection. Send the

instrument to the Asia, Europe, or USA office (addresses listed in the supplied

Contacts/CE Compliance Manual), whichever is closest to you or to the office

indicated by your sales engineer. Place the RMA number on the outside of the

carton, and include a purchase order number and any other information

specific to your instrument. Field warranty service is available, if the customer

pays travel expenses by advance purchase order. All service operations

should be performed by skilled electronics technicians, who have been trained

by Beta LaserMike.

Part No. 93296 / Drawing No. 0921-01419 Page 16 of 16 Revision F (Feb 2013)

Loading...

Loading...