Page 1

WTT32I3 Series

HB0103

In USA - BEST® Hartford, Wisconsin

REGISTER YOUR PRODUCT ONLINE AT : www.BestRangeHoods.com/register

For additional Information visit www.BestRangeHoods.com

Page 2

READ AND SAVE THESE INSTRUCTIONS

!

!

INTENDED FOR DOMESTIC COOKING ONLY

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSON(S)

OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer at the address or telephone number listed

in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock

service disconnecting means to prevent power from being switch on accidentally.

When the service disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by qualified personnel

in accordance with all applicable codes and standards, including fire-rated

construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases

through the flue (chimney) of fuel burning equipment to prevent backdrafting.

Follow the heating equipment manufacturer’s guidelines and safety

standards such as those published by the National Fire Protection

Association (NFPA), the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) and the local code authorities.

5. This product may have sharp edges. Be careful to avoid cuts and abrasions

during installation and cleaning.

6. When cutting or drilling into wall or ceiling, do not damage electrical wiring and

other hidden utilities.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only steel ductwork.

9. Do not use this unit with any other solid-state speed control device.

10. Do not operate any fan with a damaged cord or plug. Discard fan or return to

an authorized service facility for examination and/or repair.

11. GROUNDING INSTRUCTION: The appliance must be grounded. In the event

of an electrical short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. The appliance is equipped with

a cord having a grounding wire with a grounding plug. The plug must be plugged

into an outlet that is properly installed and grounded. WARNING: Improper

grounding can result in a risk of electric shock. Consult a qualified electrician if

the grounding instructions are not completely understood, or if doubt exists as

to whether the appliance is properly grounded. Do not use an extension cord. If

the power supply cord is too short, have a qualified electrician install an outlet

near the appliance.

- 2 -

Page 3

!

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers cause smoking

and greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when cooking flaming foods

(i.e. Crêpes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed to accumulate

on fan or filters.

d) Use proper pan size. Always use cookware appropriate for the size of the

surface element.

TO REDUCE THE RISK OF INJURY TO PERSON(S) IN THE EVENT OF A RANGE

TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn

off the burner. BE CAREFUL TO PREVENT BURNS. IF THE FLAMES DO NOT

GO OUT IMMEDIATELY, EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN – You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels – This could cause

a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you know how to

operate it.

B. The fire is small and contained in the area where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust hazardous or explosive

materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced impeller, keep

drywall spray, construction dust, etc. off power unit.

4. Your hood motor has a thermal overload which will automatically shut off the

motor if it becomes overheated. The motor will restart when it will cool down. If

the motor continues to shut off and restart, have the hood serviced.

5. The bottom of the hood MUST NOT BE LESS than 24” and at a maximum of

30” above cooktop for best capture of cooking impurities.

6. Two installers are recommended because of the size of this hood.

7. To reduce risk of fire and to properly exhaust air, be sure to duct air outside. Do

not exhaust air into spaces within walls or ceilings or into attics, crawl spaces,

or garages.

8. Be careful when installing the decorative flue and hood, they may have sharp

edges.

9. Please read specification label on product for further information and

requirements.

- 3 -

Page 4

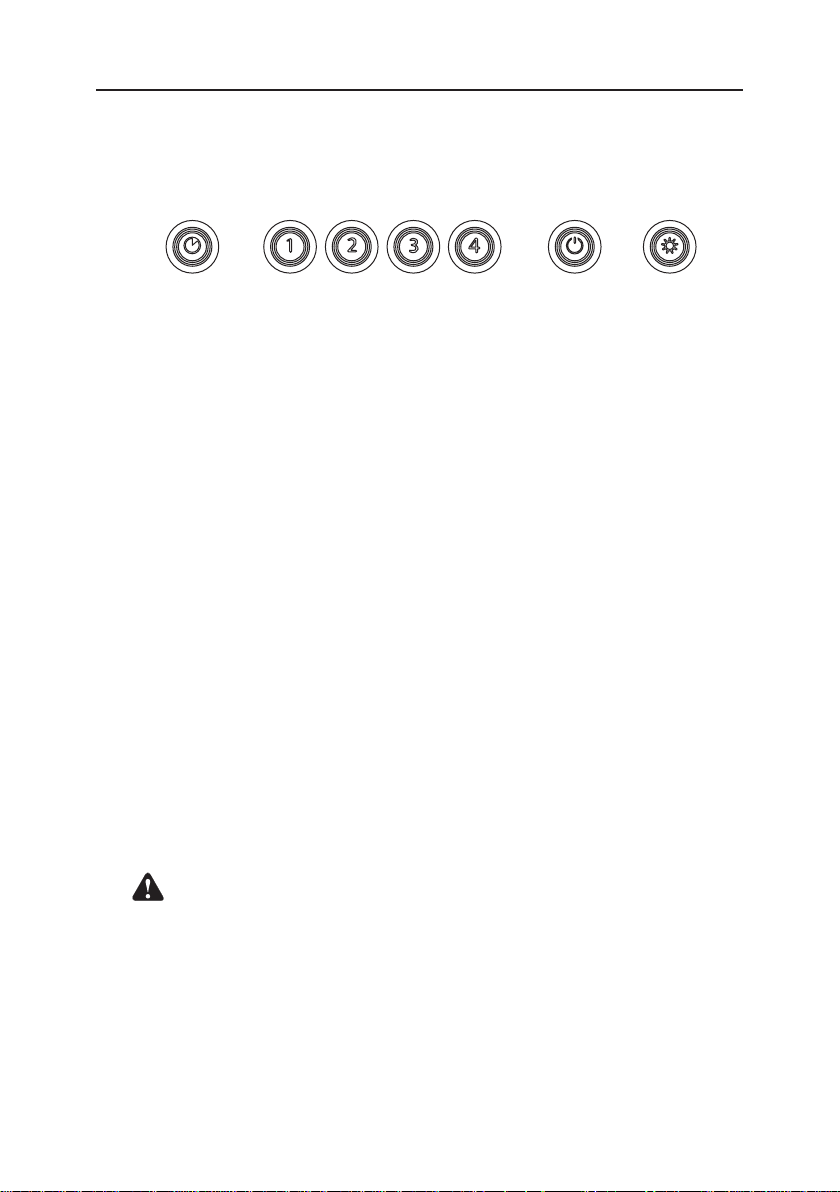

OPERATION

Always turn your hood on before you begin cooking to establish an air flow in the

kitchen. Let the blower run for a few minutes to clear the air after you turn off the

range.

The hood is operated using the push buttons on the front panel.

A B C D

A. DELAY SWITCH

When a blower speed is selected, press this switch to activate the delay func-

tion. The delay button will illuminate to indicate this function is activated. The

blower will continue to operate for 5 minutes and will stop automatically. To

cancel the delay function, press the delay switch once again.

B. START / STOP / SPEED SELECTION SWITCHES

Press the switch corresponding to the desired blower speed (from 1 for low

speed to 4 for high speed). The chosen switch will light. To turn off the blower,

press once more on the corresponding blower speed switch; the switch light

will shut off.

C. MASTER OFF / FILTER MAINTENANCE / HEAT SENTRY™

(TRIPLE FUNCTION SWITCH)

To turn off the blower and the light simultaneously, press this switch once. After

25 hours of operation, this switch will light to indicate the filters and the blower

wheel(s) need to be cleaned in order to maintain efficient operation of the unit.

The switch light will stay on until the function is reset by pressing this switch for

3 seconds. The light indicator is used for the Heat Sentry function as well.

HEAT SENTRY: When an excessively high temperature is detected, the Heat

Sentry takes control over the blower and sets it on speed 3. The triple-function

switch will flash.The blower will remain on until the heat condition is back to

normal. It will then return to the speed previously selected.

WARNING: The Heat Sentry can start the blower even if the hood is

turned off. When this situation occurs, it is impossible to turn the blower

off using the push buttons. If you must stop the blower, do it from the

main electrical panel.

D. LIGHT SWITCH

This switch allows three different lighting levels according to your needs. Press

once for nightlight, twice for normal or three times to obtain full intensity. To

shut off the lights without turning off the blower, press once more.

- 4 -

Page 5

CLEANING & MAINTENANCE

For performance, appearance, and health reasons, clean filter, fan and grease-laden

surfaces regularly. Use only a clean cloth and mild detergent solution on stainless and

painted surfaces.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of

the filter may occur if using phosphate detergents, or as a result of local water conditions but this will not affect filter performance. This discoloration is not covered by the warranty.

Clean the non-duct recirculating filter surfaces frequently with a damp cloth and a mild

detergent. DO NOT immerse filters in water or put in dishwasher. Change the nonduct recirculating filters every 6 months. For replacement non-duct recirculating filters

- purchase S97018968 or Model AFCWTT32 (for 30” wide hood) or S97019039 or Model

AFCWTT326 (for 36” and 42” wide hoods).

The motor is permanently lubricated and never needs oiling. If the motor bearings

make excessive or unusual noise, replace the blower assembly with an exact service

replacement.

LIGHT BULBS

WARNING:

Bulbs may be hot.

Always allow bulbs

to cool down before

removing them.

Use (2) Halogen Bulbs

(included with hood) 120 V, 50 W, shielded

halogen bulbs - MR16

with GU10 base. (3

bulbs for 42” hood.)

NOTE:

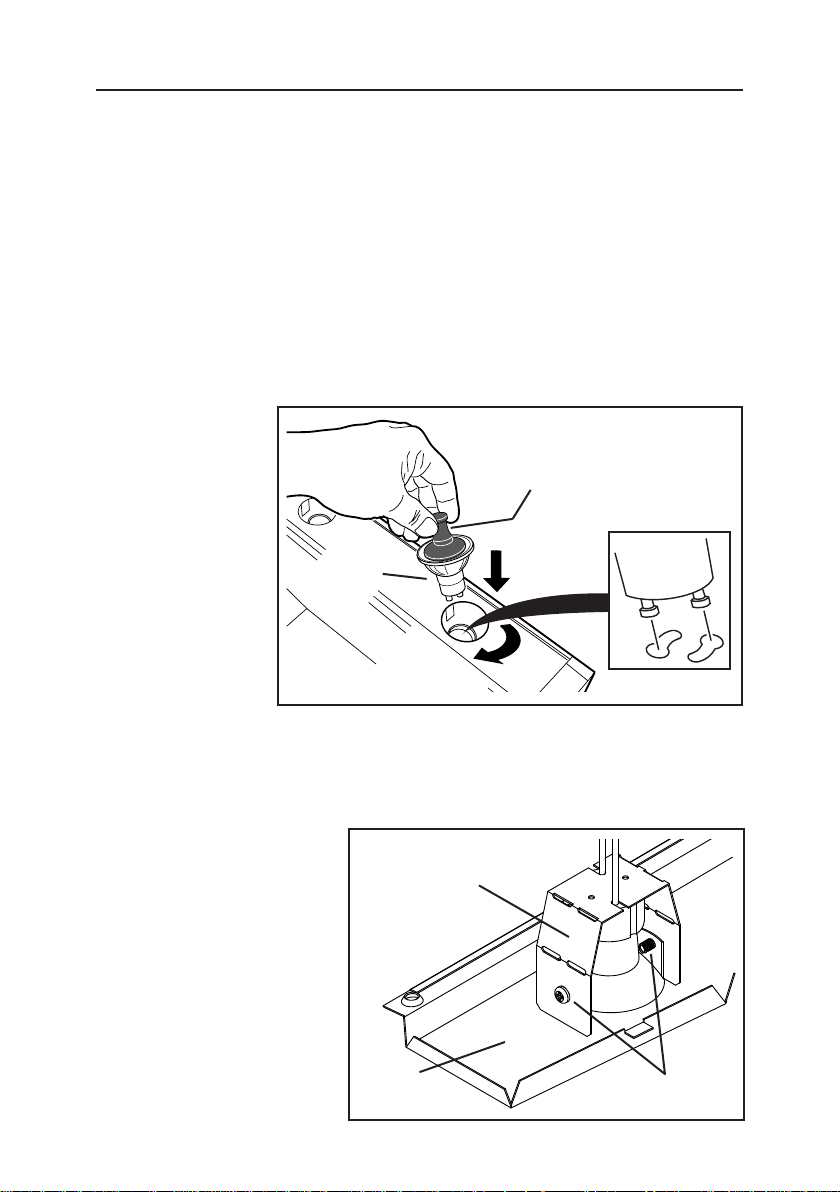

Suction Cup Tool

(included with

hood) can be used to install and remove light bulbs. Align pins on bulb with large

diameter opening on socket, then push bulb in towards hood and rotate clockwise until

firmly seated. The position of the bulb socket (depth) is adjustable and may require

adjustment when: a) certain brands of bulbs are difficult to install. b) the bulb protrudes

too far below the light panel.

To change the depth of bulb

sockets:

- Remove screws on light

panel – set screws aside

- Remove Light Panel.

- Loosen 2 Screws holding

Lamp Socket Bracket to Light

Panel.

- Adjust socket/bracket to

desired depth.

- Re-tighten screws securely.

- Re-attach light panel with

screws that were previously

set aside.

HALOGEN

BULB

(2)

ROTATE

CLOCKWISE

LAMP SOCKET

BRACKET

LIGHT

PANEL

SUCTION

CUP TOOL

(1)

PUSH IN

SCREWS

- 5 -

Page 6

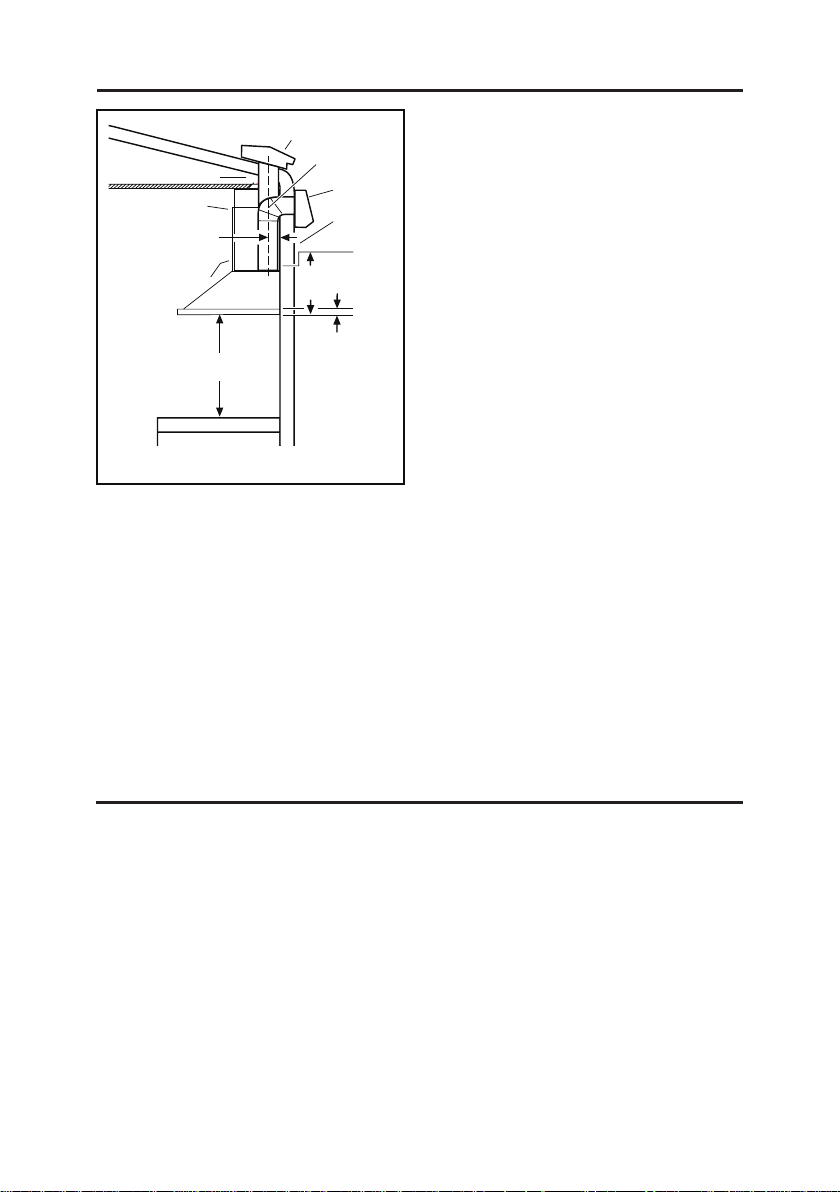

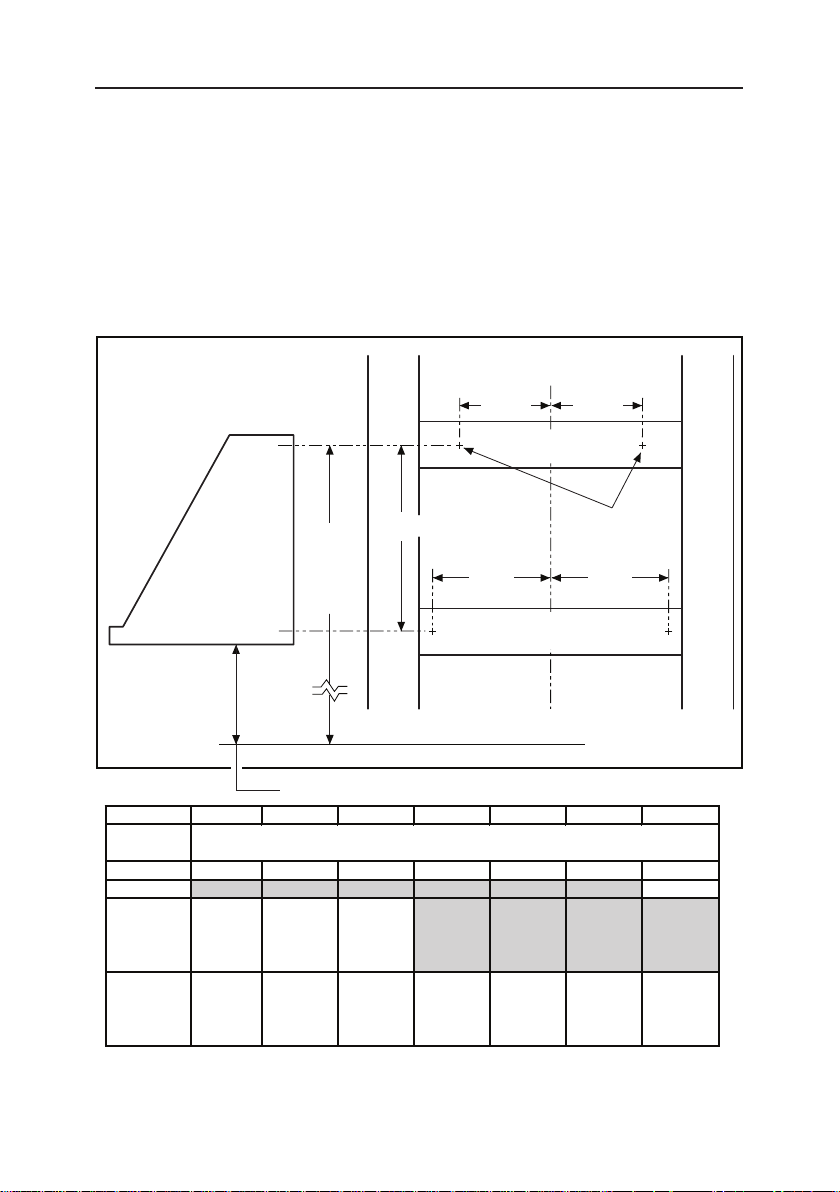

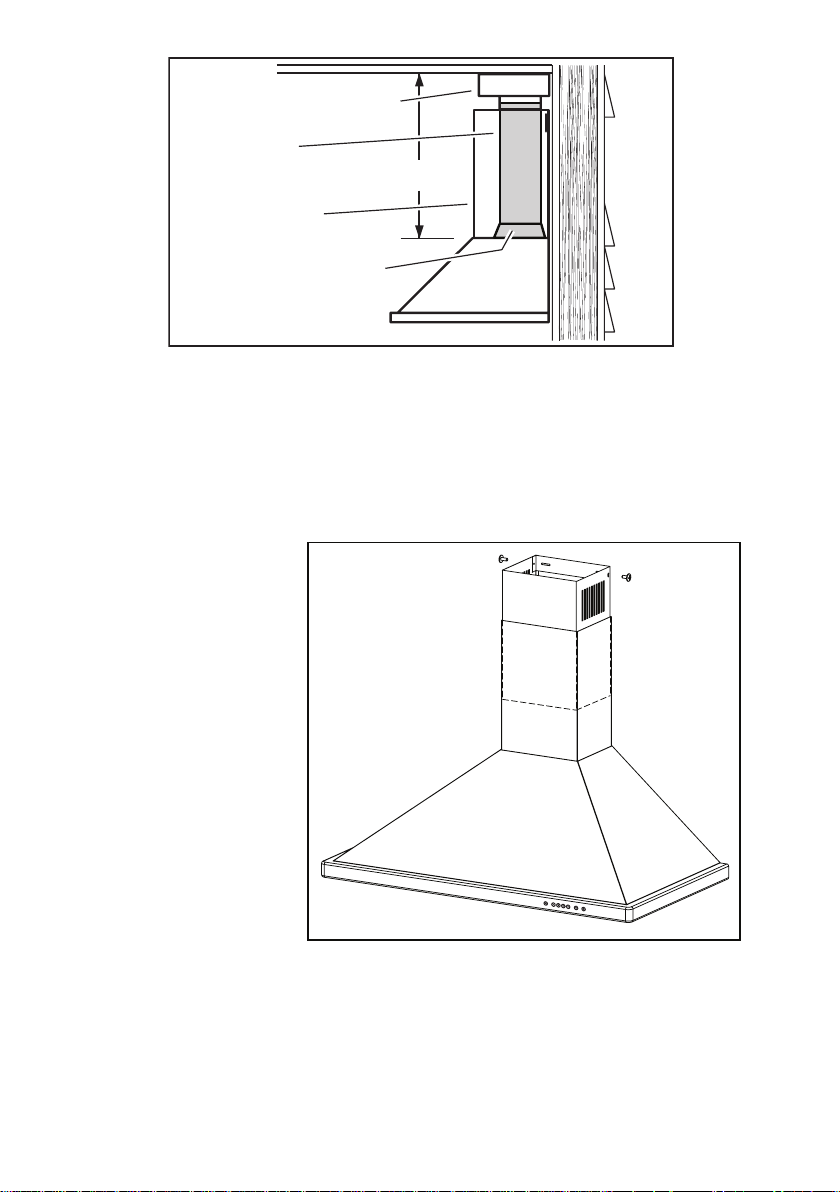

MEASURE THE INSTALLATION

MOUNTING

CAP

ROOF

ROUND

8” ROUND DUCT

DECORATIVE

FLUE

4 3/8” FROM WALL TO

CENTER

LINE OF DUCT

DECORATIVE FLUE

HOOD

24” TO 30” ABOVE

SURFACE

COOKING

The minimum hood distance above cooktop MUST NOT BE LESS than 24”.

A maximum of 30” above cooktop is highly recommended for best capture of

cooking impurities.

Distances over 30” are at the installer and users discretion; providing that the

ceiling height permits.

ELBOW

WALL CAP

HOOD

BRACKET

13 1/8” TO CENTER

OF

UPPER MOUNTING

HOLES

1 3/8” TO CENTER

LOWER HOOD

OF

CHASSIS

HOLES

INSTALL THE DUCTWORK

(Ducted Hoods Only)

1. Decide where the ductwork will run between the hood and the outside.

2. A straight, short duct run will allow the hood to perform most efficiently.

3. Long duct runs, elbows and transitions will reduce the performance of the

hood. Use as few of them as possible. Larger ducting may be required for best

performance with longer duct runs.

4. Install wall cap or roof cap. Connect round metal ductwork to cap and work back

towards the hood location. Use duct tape to seal the joints between ductwork

sections.

- 6 -

Page 7

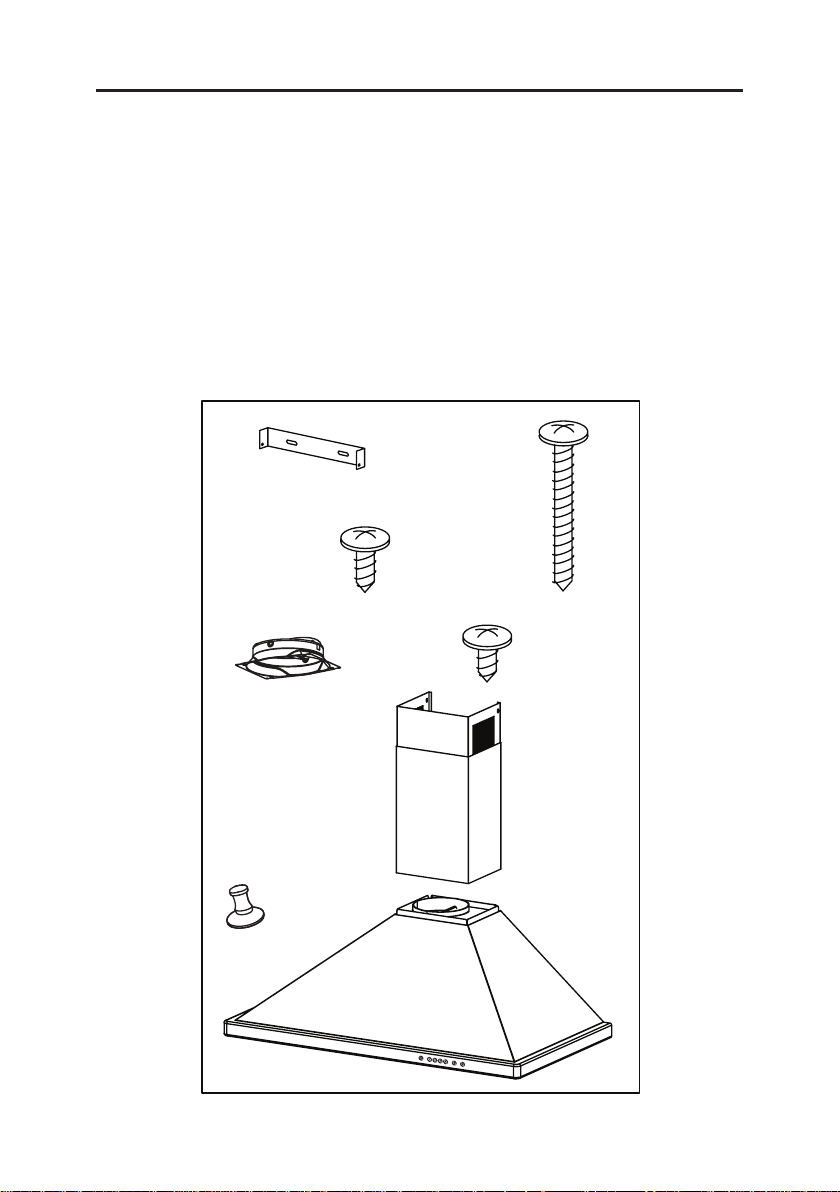

PREPARE THE HOOD

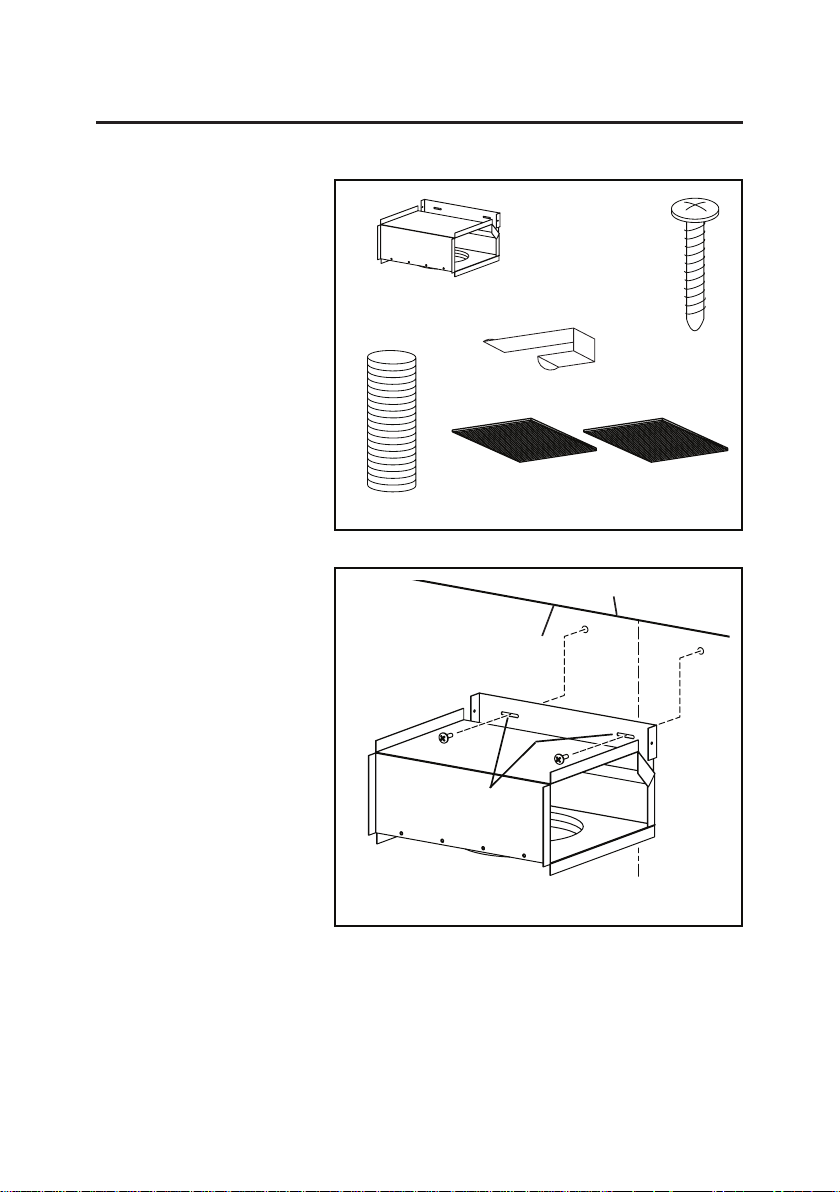

Unpack hood and check contents. You should receive:

1 - Hood Assembly

1 - Decorative Flue Assembly (consisting of upper and lower flue)

1 - Upper Flue Mounting Bracket

2 - Aluminum Grease Filters (installed on hood)

2 - 50W MR16 GU10 Halogen Lamps (installed on hood) (3 - on 42” model)

1 - 8” Damper / Duct Connector

1 - Parts Bag containing:

6 - Mounting Screws (4mm x 38mm Cross Recessed Pan Head)

2 - Mounting Screws (4mm x 12mm Cross Recessed Pan Head)

4 - Mounting Screws (4mm x 8mm Cross Recessed Pan Head)

1 - Suction Cup Tool (for bulb installation / removal)

6 MOUNTING

SCREWS

UPPER

FLUE MOUNTING

BRACKET

1 - DAMPER/DUCT

CONNECTOR

(8” diameter)

(4mm x 38mm

Cross Recessed

Pan Head)

2 MOUNTING

SCREWS

(4mm x 12mm

Cross Recessed

Pan Head)

4 MOUNTING

SCREWS

(4mm x 8mm

Cross Recessed

Pan Head)

BULB

SUCTION

CUP TOOL

- 7 -

DECORATIVE

FLUE

ASSEMBLY

HOOD

ASSEMBLY

Page 8

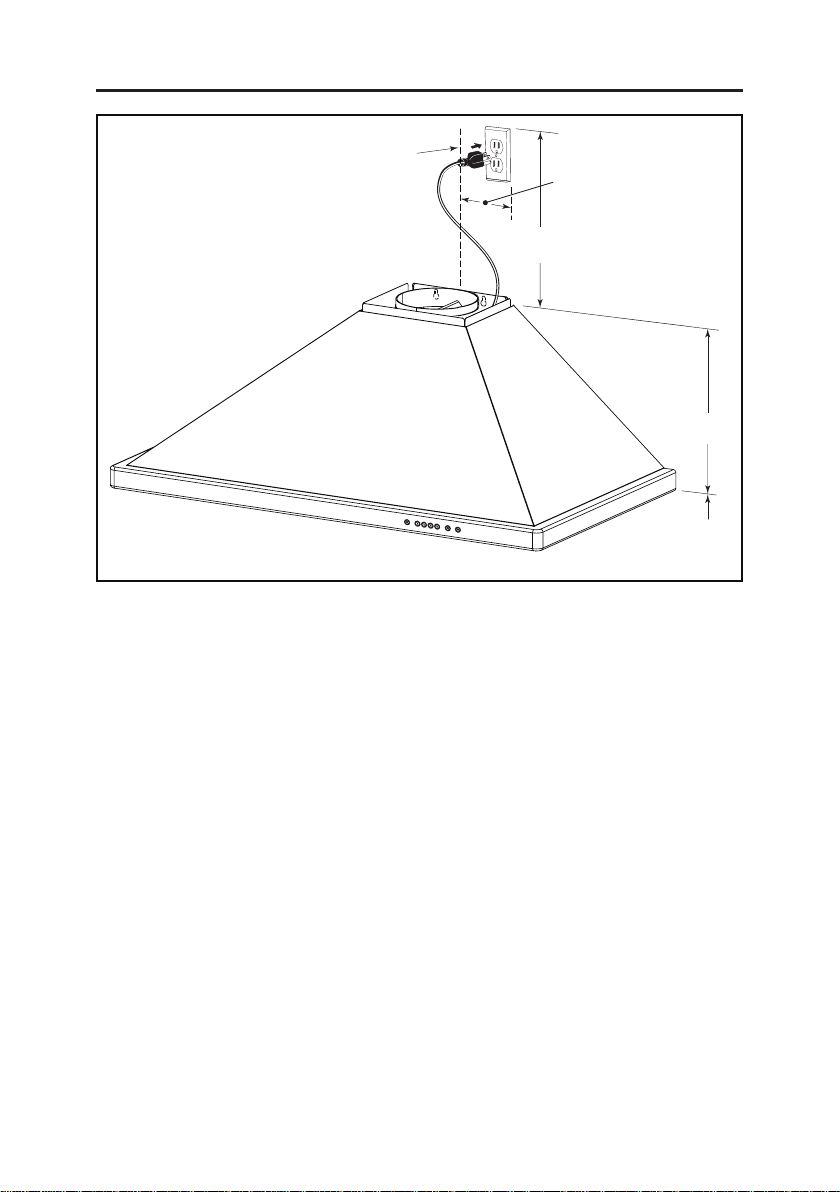

”

TOP

INSTALL THE WIRING

HOOD

CENTERLINE

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire for the

electric current. This appliance is equipped with a cord having a grounding wire

with a grounding plug. The plug must be plugged into an outlet that is properly

installed and grounded.

Position the electrical outlet within the space covered by the decorative flue and

where it will not interfere with the round duct. Make sure the outlet is no further than

24” from the top of the hood chassis, and that the outlet does not interfere with a

mounting bracket fastening area or where the decorative flue touches the wall.

NOTE: A clock outlet can be used to minimize clearance related issues with the

range hood plug.

24”

MAX.

3

4

/

4

”

3

12

/

8

24” TO 36”

ABOVE

COOK

- 8 -

Page 9

INSTALL THE HOOD MOUNTING SUPPORT

L

36” HIGH COOKTOP

Ceiling

Height

** For non-duct installation, use upper flue from AEWTT32SB and lower flue from standard hood.

Desired Hood Distance (Above 36" High Cooktop)

1. Construct structural wall framing that is flush with interior surface of wall studs.

Make sure the framing is centered over installation location.

NOTE

Hood distance above cooktop is: Minimum 24”, Maximum 30”. 9-ft. and 10-ft.

ceilings may require Flue Extension, Model AEWTT32SB, depending on

installation height (purchase separately). See charts below for additional

installation height information.

2. After wall surface is finished, fasten (2) 4mm x 38mm screws at the locations

shown below. DO NOT TIGHTEN screws all the way - leave approximately 1/4”

between screw head and wall.

C

4 3/4 ”

STRUCTURAL

FRAMING

11 3/4 ”

HOOD

24" 25"26" 27" 28"29" 30"

Upper Mounting Screws Location (Distance above 36" High Cooktop)

8 Feet 37-1/8" 38-1/8" 39-1/8" 40-1/8"41-1/8"*42-1/8"*43-1/8"

9 Feet

9 Feet

with

AEWTT32SB

**37-1/8" **38-1/8" **39-1/8"

A

SEE

CHART

BELOW

6 3/8 ”

STRUCTURAL

FRAMING

4 3/4 ”

4mm x 38mm

SCREWS

HERE

6 3/8 ”

(Dimension “A”)

43-1/8"

10 Feet

with

AEWTT32SB

* Not applicable for non-duct installation.

37-1/8" 38-1/8" 39-1/8" 40-1/8"41-1/8"42-1/8" 43-1/8"

- 9 -

Page 10

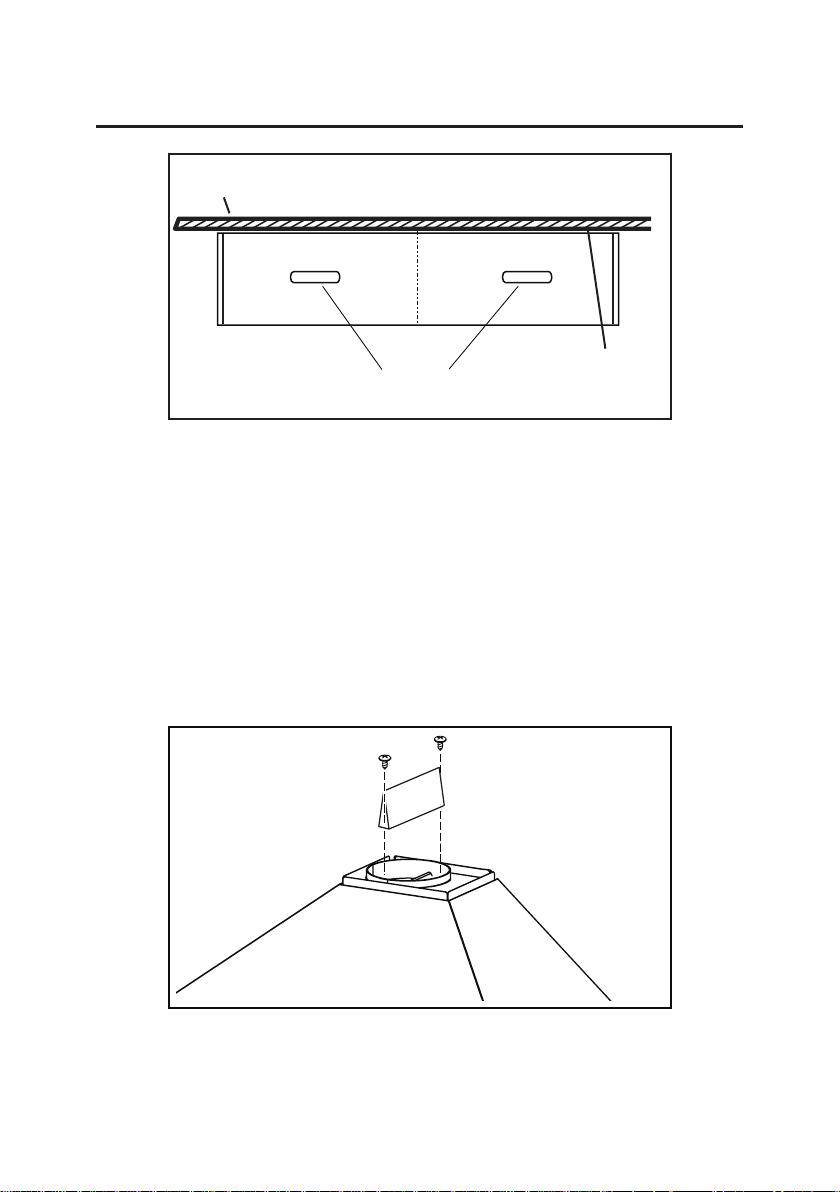

INSTALL THE HOOD

(Ducted Hoods Only)

Ceiling

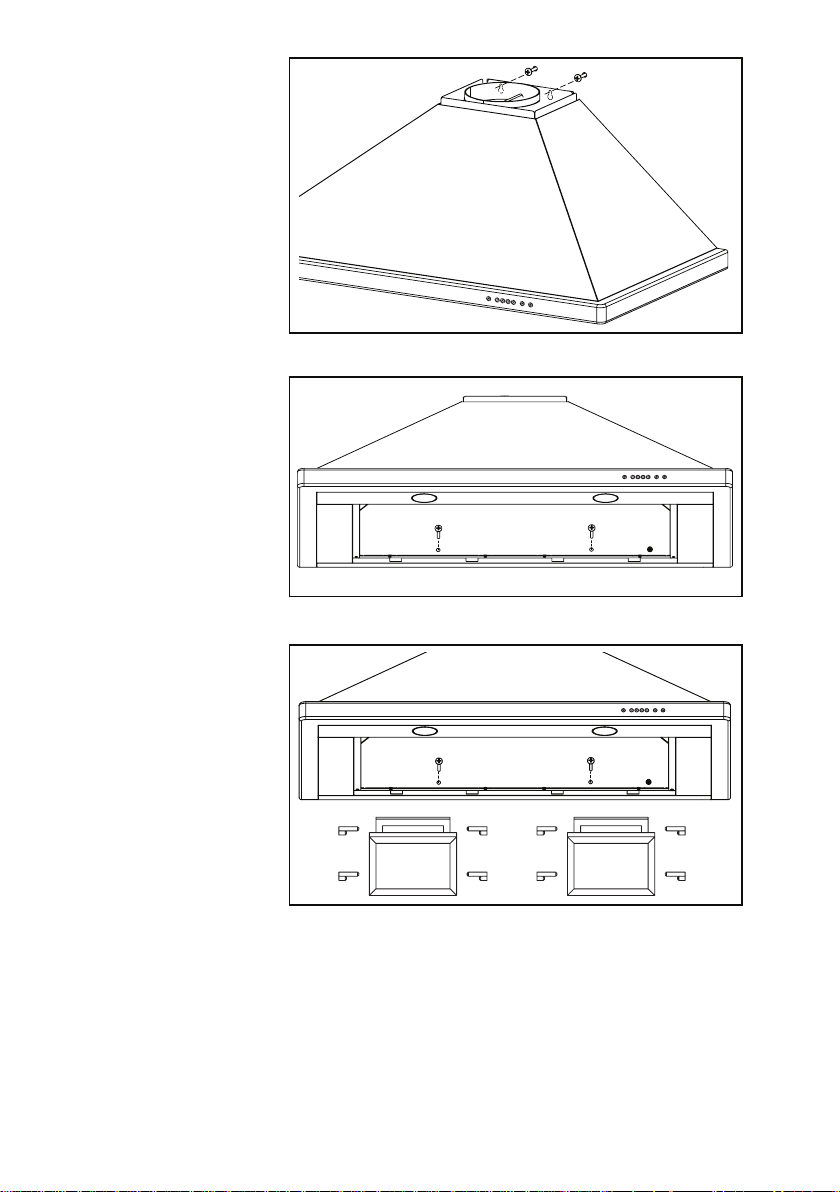

1. Center the flue mounting bracket over the hood location and flush with the

ceiling. Secure the upper flue bracket to the wall using (2) 4mm x 38mm

mounting screws. Note: Drywall anchors may be required (not included).

2. Tighten the screws completely. Make sure that the bracket is tight against the

wall and ceiling.

3. Remove the protective plastic film covering the decorative flue and the hood at

this time.

4. Remove the grease filters by pulling down the metal latch tab and tilting filters

downward to remove.

5. Remove all internal foam fillers that support the blower assembly inside the

hood.

Center of

installation

C

L

Upper flue mounting

bracket slots

Flush with

the ceiling

6. Attach the damper / duct connector using (4) 4mm x 8mm mounting screws.

- 10 -

Page 11

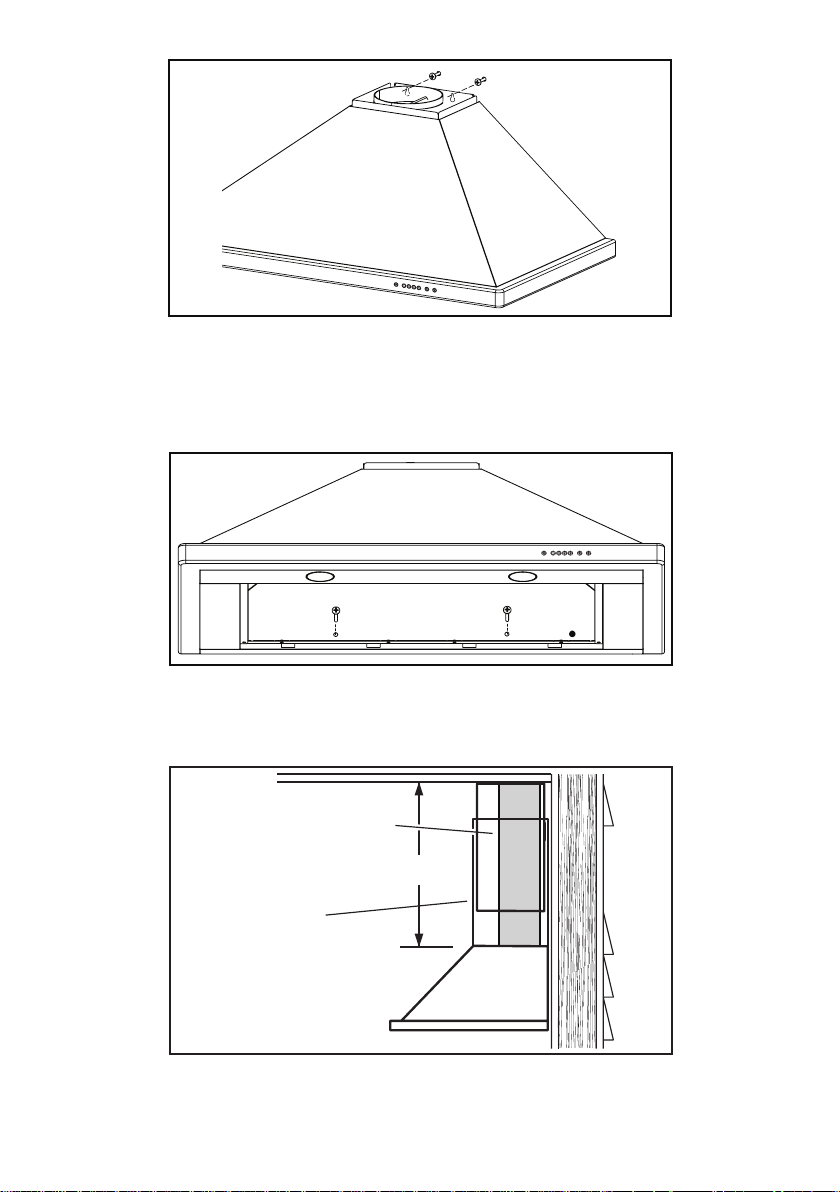

7. Align the two outer keyhole slots on the hood with the mounting screws that

were partially tightened into the wall framing. Ensure that hood is seated entirely

on mounting screws and that hood is level. Then tighten screws completely.

8. Install (2) 4mm x 38mm long screws into the holes inside the hood and tighten

them securely.

9. Reinstall grease filters by aligning rear filter tabs with slots in the hood. Pull

down the metal latch tab, push filters into position and release. Make sure

filters are securely engaged after installation.

8” ROUND STEEL DUCT

DUCT LENGTH

DECORATIVE

FLUE

10. Measure and install steel ductwork to hood duct connector and ductwork

rough-in on ceiling or wall. Use duct tape to make all joints secure and air tight.

11. Plug power cord into wall outlet.

- 11 -

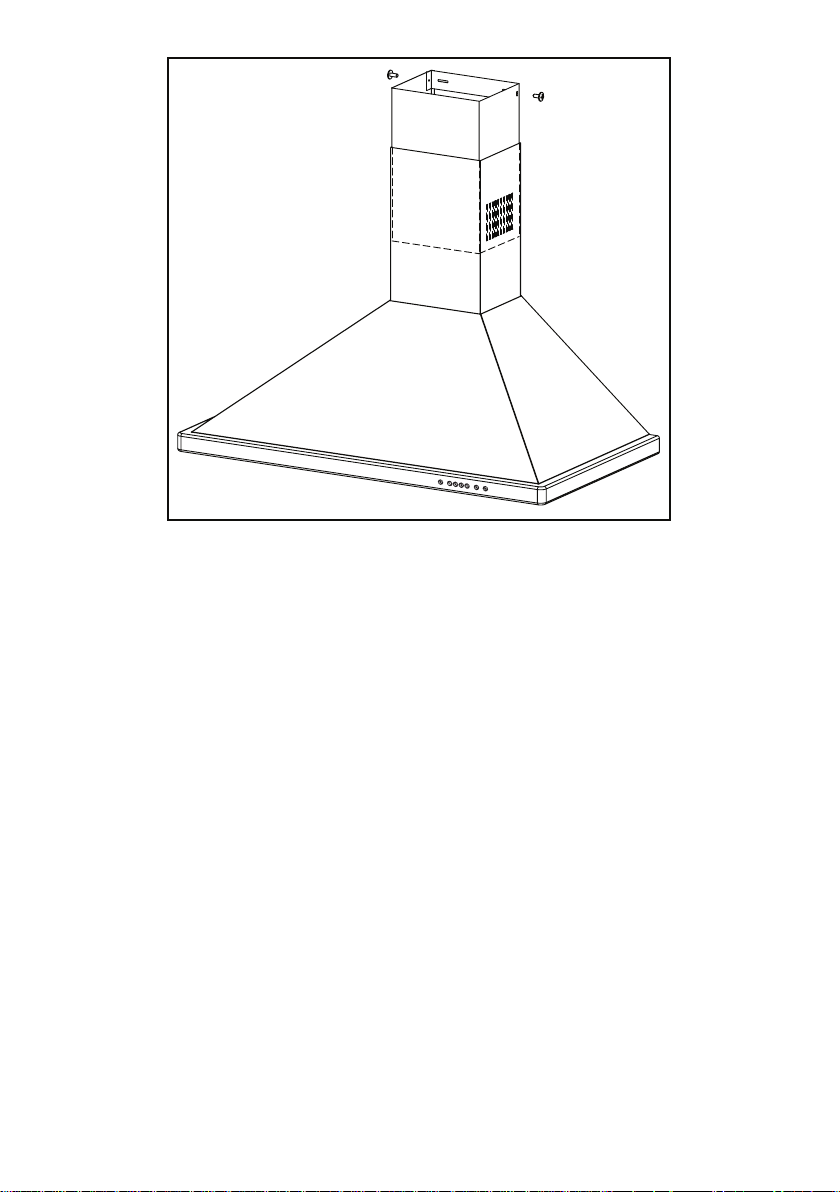

Page 12

12. Slide the upper decorative flue section into the lower decorative flue section.

NOTE

For ducted applications, the louvers on the upper flue should be hidden by

positioning the louvers down, inside of the lower flue.

13. Carefully place the upper/lower flue assembly into the recessed area of the

hood.

14. Slide the upper flue upward until it is aligned with its mounting bracket. The

bracket should be inside the flue. Secure the upper flue to the upper flue

mounting bracket using (2) 4mm x 12mm mounting screws.

NOTE

9-10 ft. ceilings may require Flue Extension Model AEWTT32SB, depending

on installation height (purchase separately). Discard the upper and lower flues

supplied with your hood and replace them with Flue Extensions.

- 12 -

Page 13

INSTALL THE HOOD

L

(Non-Ducted Hoods Only)

NON-DUCT KIT MODEL ANKWTT320 OR ANKWTT326 CONTENTS

NOTE

Non-ducted installations

require Non-Duct Kit,

Model ANKWTT320 (for

30” wide hood) or Model

ANKWTT326 (for 36” or 42”

wide hood).

NON-DUCT PLENUM

ASSEMBLY

FLEXIBLE DUCT

8 FILTER CLIPS

NON-DUCTED RECIRCULATION FILTERS

2 MOUNTING

SCREWS

(4mm x 38mm

Cross Recessed

Pan Head)

1. Center the non-duct

plenum over the hood

Ceiling

location and flush with

the ceiling. Secure the

non-duct plenum to the

wall using (2) 4mm x

Flush with

the ceiling

38mm mounting screws.

Note: Drywall anchors

may be needed (not

included).

2. Tighten the screws

completely. Make

sure that the non-duct

plenum is tight against

Upper flue mounting

bracket slots

the wall and ceiling.

3. Remove damper flaps

from damper / duct

connector and discard

flaps.

Center of

installation

C

4. Remove the protective

plastic film covering the decorative flue and the hood at this time.

5. Attach the 8” round duct connector to the top of the hood using (4) 4mm x

8mm mounting screws.

6. Remove the grease filters by pulling down the metal latch tab and tilting filters

downward to remove.

7. Remove all internal foam fillers that support the blower assembly inside the

hood.

- 13 -

Page 14

8. Align the two

outer keyhole

slots on the hood

with the mounting

screws that were

partially tightened

into the wall

framing. Ensure

that hood is

seated entirely on

mounting screws

and that hood is

level. Then tighten

screws completely.

9. Install (2) 4mm

x 38mm long

screws into the

holes inside the

hood and tighten

them securely.

10. Attach non-

ducted filters to

grease filter using

(8) filter clips.

11. Reinstall grease/

non-duct filter

assembly by

aligning rear filter

tab with slots in

the hood. Pull

down the metal

latch tab, push

filters into position and release. Make sure filters are securely engaged after

installation.

- 14 -

Page 15

NON-DUCT

8” ROUND

FLEXIBLE

METAL DUCT

DECORATIVE

FLUE

DAMPER / DUCT

12. Measure and install section of flexible metal ductwork (included with

ANKWTT320 or ANKWTT326) to damper/duct connector and bottom of nonduct plenum. Use duct tape to make all joints secure and air tight.

CAUTION

Do not use plastic duct.

13. Plug power cord into wall outlet.

14. Slide the upper decorative flue section into the lower decorative flue section.

NOTE

For non-ducted

applications, the

upper flue should

be oriented so the

louvers are towards

the ceiling.

15. Carefully place the

upper/lower flue

assembly into the

recessed area of

the hood.

16. Slide the upper

flue upward until it

is aligned with the

non-duct plenum.

The non-duct

plenum should

be inside the flue.

Secure the upper

flue to the non-duct

plenum using (2) 4mm x 12mm mounting screws.

NOTE

9-10 ft. ceilings may require Flue Extension Model AEWTT32SB depending

on installation height (purchase separately). Discard the upper and lower

flues supplied with your hood and replace them with Flue Extension Model

AEWTT32SB.

PLENUM

DUCT LENGTH

CONNECTOR

- 15 -

Page 16

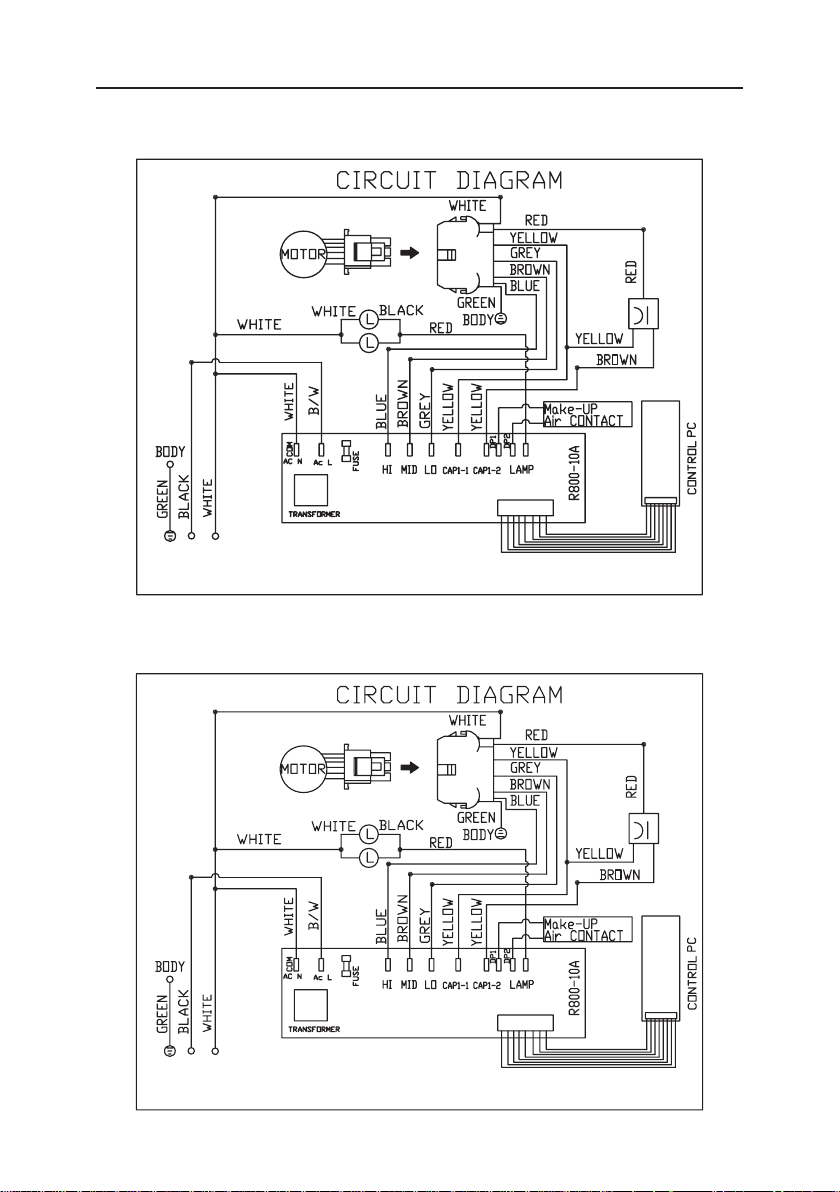

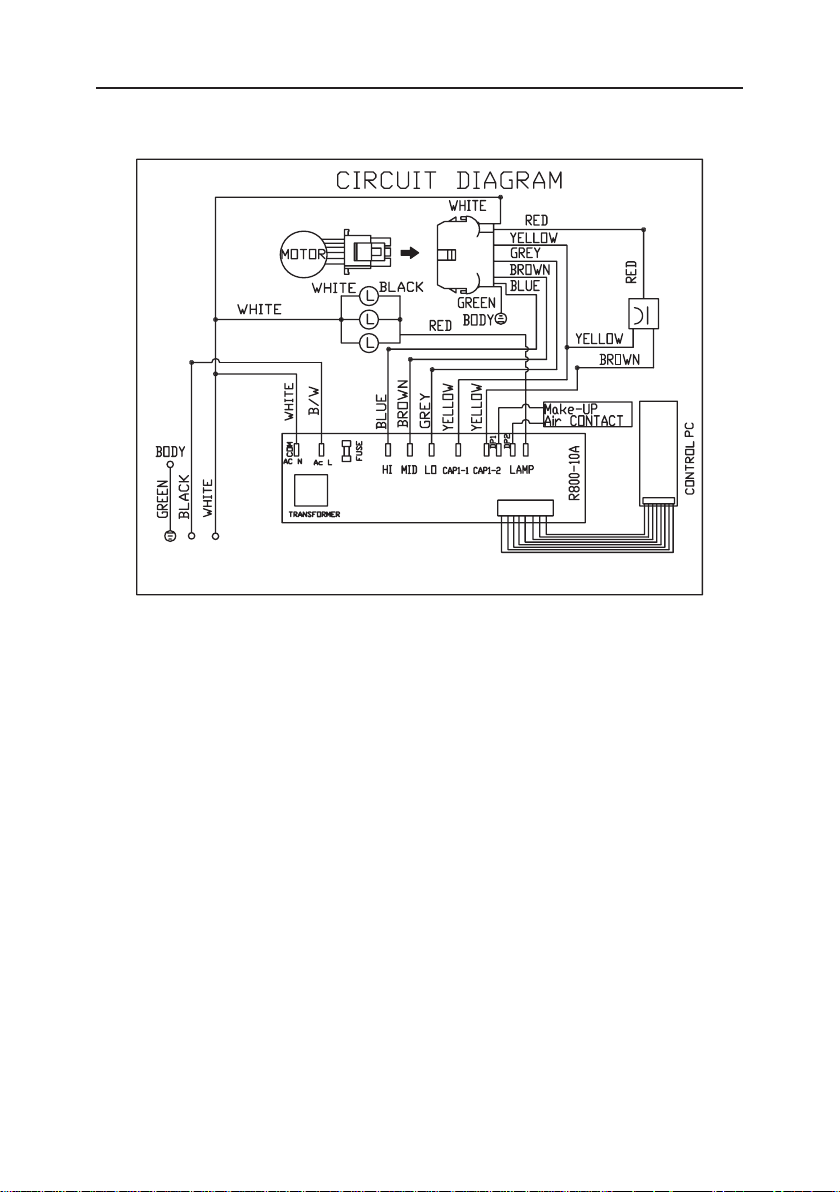

WIRING DIAGRAMS

MODEL WTT32I330SB

REMARKS/CONDENSER 3+2uF 250VAC FIT AC120V 60Hz

MODEL WTT32I336SB

REMARKS/CONDENSER 3+2uF 250VAC FIT AC120V 60Hz

- 16 -

Page 17

WIRING DIAGRAMS

MODEL WTT32I342SB

REMARKS/CONDENSER 3+2uF 250VAC FIT AC120V 60Hz

- 17 -

Page 18

SERVICE PARTS

KEY PART NO. DESCRIPTION QTY.

1 S99528405 Decorative Upper and Lower Flues 1

2 S99528891 Motor / Blower Assembly 1

3 S99528408 Light Socket (30” & 36” wide hoods) 2

(includes mounting hardware)

Light Socket (42” wide hood) 3

(includes mounting hardware)

4 S99528409 Light Socket Bracket (30” & 36” wide hoods) 2

(includes mounting hardware)

Light Socket Bracket (42” wide hood) 3

(includes mounting hardware)

5 S99528410 User Interface Assembly 1

6 S99528411 User Interface Cable 1

7 S99528412 Control Board 1

8 S99528414 Aluminum Grease Filter (30” wide hood) 2

S99528415 Aluminum Grease Filter (36” & 42” wide hoods) 2

9 S97018968 Non-Duct Recirculation Filter (30” wide hood) 2

S97019039 Non-Duct Recirculation Filter (36” & 42” wide hoods) 2

10 S99528418 8” Damper Assembly 1

11 S99528429 8” Dia. Expandable Flexible Aluminum Duct 1

12 S99528421 Non-Duct Plenum Assembly 1

13 S99528422 Upper Flue Mounting Bracket 1

14 V05921 50W MR16 GU10 Halogen Lamp (30” & 36” wide hoods) 2

50W MR16 GU10 Halogen Lamp (42” wide hood) 3

* S99528892 Capacitor 1

* S99528425 Parts Bag 1

* S99528518 Heat Sensor 1

* Not shown.

Order service parts by Part No. - not by Key No.

- 18 -

Page 19

SERVICE PARTS

13

7

14

6

5

1

1

10

4

3

12

11

Replacement parts can be

ordered on our website:

www.BestRangeHoods.com

2

9

8

- 19 -

Page 20

WARRANTY

ONE YEAR LIMITED WARRANTY FOR BEST PRODUCTS

Broan-NuTone LLC (Broan-NuTone) warrants to the original consumer purchaser

of Best products that such products will be free from defects in materials or workmanship for a period of one year from the date of original purchase. THERE ARE

NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace,

without charge, any product or part which is found to be defective under normal

use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS,

TUBES, HALOGEN AND INCANDESCENT BULBS, FUSE, FILTERS, DUCTS,

ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES FOR DUCTING. This

warranty does not cover (a) normal maintenance and service or (b) any products

or parts which have been subject to misuse, negligence, accident, improper

maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROANNUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE

REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE

FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT

OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address

stated below or telephone number stated below, (b) give the model number and

part identification and (c) describe the nature of any defect in the product or

part. At the time of requesting warranty service, you must present evidence of

the original purchase date.

In USA - BEST®, 926 W. State Street, Hartford, WI 53027 (800-558-1711)

In Canada - BEST®, 550 Lemire Blvd., Drummondville, QC J2C 7W9 (866-737-7770)

www.BestRangeHoods.com

- 20 -

99045953B

Page 21

HB0103

Série WTT32I3

Aux États-Unis - BEST® Hartford, Wisconsin

RENREGISTREZ VOTRE PRODUIT EN LIGNE À : www.BestRangeHoods.com/register

Pour de plus amples informations, visitez www.BestRangeHoods.com

Page 22

LIRE CES DIRECTIVES ET LES CONSERVER

!

!

POUR USAGE DOMESTIQUE SEULEMENT

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, DE DÉCHARGES ÉLECTRIQUES

OU DE BLESSURES CORPORELLES, VEUILLEZ OBSERVER LES DIRECTIVES

SUIVANTES :

1. N’utilisez cet appareil que de la manière prévue par le fabricant. Si vous avez

des questions, communiquez avec le fabricant à l’adresse ou au numéro de

téléphone indiqués dans la garantie.

2. Avant de procéder à l’entretien ou au nettoyage de l’appareil, coupez

l’alimentation du panneau électrique et verrouillez l’interrupteur principal afin

d’empêcher que le courant ne soit accidentellement rétabli. S’il est impossible de

verrouiller l’interrupteur principal, fixez solidement un message d’avertissement,

par exemple une étiquette, sur le panneau électrique.

3. L’installation et les branchements électriques doivent être effectués par un

personnel compétent, conformément aux normes et aux codes en vigueur,

ycompris les normes et les codes du bâtiment relatifs à la résistance au feu.

4. Pour éviter les refoulements, l’apport d’air doit être suffisant pour brûler les

gaz produits par les appareils à combustion et les évacuer dans le conduit

de fumée (cheminée). Respectez les directives du fabricant de l’appareil de

chauffage et les normes de sécurité, notamment celles publiées par la National

Fire Protection Association (NFPA), l’American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) et les codes des autorités locales.

5. Ce produit peut comporter des arêtes tranchantes. Prenez garde aux coupures

et aux éraflures lors de l’installation et du nettoyage.

6. Veillez à ne pas endommager le câblage électrique ou d’autres équipements

non apparents lors de la découpe ou du perçage du mur ou du plafond.

7. Les ventilateurs canalisés doivent toujours rejeter l’air à l’extérieur.

8. Pour réduire les risques d’incendie, utilisez seulement des conduits en acier.

9. N’utilisez pas de commande de régime à semi-conducteurs avec cet appareil.

10. Ne faites pas fonctionner le ventilateur si le cordon électrique ou la fiche est

endommagé. Jetez le ventilateur ou rapportez-le chez un réparateur agréé pour

le faire examiner et/ou réparer.

11. DIRECTIVES DE MISE À LA TERRE : Cet appareil doit être mis à la terre. Dans

l’éventualité d’un court-circuit, la mise à la terre réduit les risques de décharge

électrique en permettant au courant de s’échapper dans un fil. Cetappareil

comporte un cordon électrique muni d’un fil et d’une fiche de mise à la terre.

Cette fiche doit être branchée dans une prise de courant correctement installée

et mise à la terre. AVERTISSEMENT : Une mise à la terre incorrecte peut

entraîner un risque de choc électrique. Consultez un électricien qualifié si vous

ne comprenez pas complètement les directives de mise à la terre ou si vous

n’êtes pas sûr que l’appareil comporte une mise à la terre adéquate. N’utilisez

pas de rallonge électrique. Si le cordon électrique est trop court, demandez à

un électricien qualifié d’installer une prise de courant près de l’appareil.

- 22 -

Page 23

!

POUR RÉDUIRE LES RISQUES D’INCENDIE CAUSÉS PAR DE LA GRAISSE SUR

LE PLAN DE CUISSON :

a) Ne laissez jamais les éléments de surface allumés à haute température. Les

débordements peuvent causer de la fumée et occasionner des écoulements de

graisse inflammables. L’huile doit être chauffée graduellement à basse ou à moyenne

température.

b) Mettez toujours la hotte en MARCHE lors de la cuisson à feu vif ou lors de la cuisson

d’aliments à flamber (crêpes Suzette, cerises jubilé, bœuf au poivre flambé).

c) Nettoyez souvent la hotte. Ne laissez pas la graisse s’accumuler sur le ventilateur

ou les filtres.

d) Utilisez des casseroles de dimension appropriée. Utilisez toujours une batterie de

cuisine adaptée à la dimension de la surface chauffante.

OBSERVEZ LES CONSIGNES SUIVANTES AFIN DE RÉDUIRE LES RISQUES DE

BLESSURES CORPORELLES EN CAS D’INCENDIE CAUSÉ PAR DE LA GRAISSE

SUR LE PLAN DE CUISSON :*

1. ÉTOUFFEZ LES FLAMMES à l’aide d’un couvercle étanche, d’une tôle à biscuits

ou d’un plateau en métal puis éteignez le brûleur. FAITES ATTENTION DE NE PAS

VOUS BRÛLER. SI LES FLAMMES NE S’ÉTEIGNENT PAS IMMÉDIATEMENT,

QUITTEZ LES LIEUX ET APPELEZ LE SERVICE DES INCENDIES.

2. NE SOULEVEZ JAMAIS UNE CASSEROLE EN FLAMMES – vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni de linges ou de serviettes mouillés – une violente

explosion de vapeur pourrait survenir.

4. Utilisez un extincteur SEULEMENT si :

A. Vous savez qu’il est de classe ABC et vous connaissez déjà son mode de

fonctionnement.

B. L’incendie n’est pas très important et ne se propage pas.

C. Vous avez déjà téléphoné au service des incendies.

D. Vous pouvez combattre l’incendie en faisant dos à une sortie.

* Conseils tirés de la publication de la NFPA « Kitchen Fire Safety Tips ».

ATTENTION

1. Pour usage intérieur seulement.

2. Pour ventilation générale uniquement. N’utilisez pas cet appareil pour évacuer des

matières ou des vapeurs dangereuses ou explosives.

3. Pour ne pas endommager les roulements du moteur, déséquilibrer les pales ou les

rendre bruyantes, protégez l’appareil de la poussière de plâtre, de construction, etc.

4. Le moteur de la hotte est muni d’un dispositif de protection thermique qui coupe

automatiquement le moteur en cas de surchauffe. Il se remet en marche lorsqu’il a

refroidi. Faites réparer la hotte si le moteur continue à fonctionner par intermittence.

5. Pour mieux capter les vapeurs de cuisson, le bas de la hotte DOIT ÊTRE AU MINIMUM

à 61 cm (24 po) et au maximum à 76,2 cm (30 po) au-dessus de la surface de cuisson

6. Il est recommandé que les installateurs soient deux, compte tenu de la taille de cette hotte.

7. Pour réduire les risques d’incendie et évacuer l’air correctement, assurez-vous qu’il

est canalisé à l’extérieur. Ne pas évacuer l’air dans des espaces enfermés par des

murs ou un plafond ou dans un grenier, un vide sanitaire ou un garage.

8. Prenez garde en installant la cheminée décorative et la hotte, car elles peuvent

comporter des bords tranchants.

9. Veuillez lire l’étiquette de spécifications du produit pour obtenir plus de renseignements,

notamment sur les exigences.

- 23 -

Page 24

FONCTIONNEMENT

Mettez toujours la hotte en marche avant de cuisiner afin d’établir une circulation d’air

dans la cuisine. Laissez la hotte fonctionner quelques minutes après l’arrêt de la cuisinière

afin de nettoyer l’air.

La hotte fonctionne à l’aide de boutons-poussoirs situés sur la face avant.

A B C D

A. BOUTON DE MINUTERIE

Lorsqu’une vitesse de ventilateur est sélectionnée, appuyez sur ce bouton pour

activer la fonction d’arrêt différé. Le bouton d’arrêt différé s’illuminera pour indiquer

que cette fonction est activée. Le ventilateur continuera de fonctionner pendant cinq

minutes puis d’arrêtera automatiquement. Pour annuler la fonction d’arrêt différé,

appuyez de nouveau sur le bouton deminuterie.

B. BOUTONS MARCHE / ARRÊT DE SÉLECTION DE VITESSE

Appuyez sur le bouton correspondant à la vitesse de ventilateur voulue (1 pour lent

à 4 pour rapide). Le bouton choisi s’illuminera. Pour arrêter le ventilateur, appuyez

de nouveau sur le bouton correspondant à la vitesse du ventilateur; le bouton

s’éteindra.

C. BOUTON MAÎTRE D’ARRÊT / D’ENTRETIEN DU FILTRE / DE DÉTECTEUR

HEATSENTRY™ (BOUTON À TRIPLE FONCTION)

Pour arrêter le ventilateur et éteindre simultanément l’éclairage, appuyez une fois

sur ce bouton. Après 25 heures d’utilisation, ce bouton s’illuminera pour indiquer

que les filtres et la ou les roues à ailettes du ventilateur doivent être nettoyés pour

maintenir l’efficacité de la hotte. Le bouton restera allumé jusqu’à la remise à zéro

de cette fonction en appuyant sur le bouton pendant 3 secondes. Le voyant lumineux

indique également la mise en fonction du détecteur de chaleur Heat Sentry.

DÉTECTEUR DE CHALEUR HEAT SENTRY : Lorsqu’une température trop élevée

est détectée, la fonction Heat Sentry prend le contrôle du ventilateur et le règle à la

vitesse 3. L’interrupteur à triple fonction se met à clignoter. Le ventilateur demeurera

en marche jusqu’à ce que la chaleur soit revenue à la normale. Il reprendra alors la

vitesse préalablement choisie.

AVERTISSEMENT : Le détecteur Heat Sentry peut faire démarrer

le ventilateur même si la hotte est arrêtée. Lorsque cela se produit,

ilest impossible d’arrêter le ventilateur en appuyant sur les boutons.

Sivous devez arrêter le ventilateur, coupez le disjoncteur du panneau

d’alimentationélectrique.

D. INTERRUPTEUR D’ÉCLAIRAGE

Cet interrupteur offre trois niveaux d’éclairage selon vos besoins. Appuyez une

fois pour la veilleuse de nuit, deux fois pour l’éclairage normal ou trois fois pour

l’intensité maximale. Pour éteindre les lumières sans arrêter le ventilateur, appuyez

une fois de plus.

- 24 -

Page 25

NETTOYAGE ET ENTRETIEN

Pour des raisons de santé, de performance et d’apparence, nettoyez régulièrement le filtre, le

ventilateur et les surfaces graisseuses. Utilisez seulement un chiffon propre et une solution de

détergent doux sur l’acier inoxydable et les surfaces peintes.

Nettoyez les filtres entièrement métalliques au lave-vaisselle avec un détergent sansphosphate.

Une décoloration du filtre peut se produire si des détergents phosphatés sont utilisés et selon

les conditions locales de l’eau, sans toutefois affecter le rendement du filtre. Cette décoloration

n’est pas couverte par la garantie.

Nettoyez souvent les surfaces des filtres de recirculation avec un linge humide et un

détergentdoux. NE PLONGEZ PAS les filtres dans l’eau et ne les mettez pas au lave-vaisselle.

Remplacez les filtres de recirculation sans conduit tous les six mois. Pour remplacer les filtres

de recirculation - veuillez acheter les filtres S97018968 ou Modèle AFCWTT32 pour les hottes

de 76,2 cm (30 po) de largeur, ou les filtres S97019039 ou Modèle AFCWTT326 pour les

hottes de 91,4 cm (36 po) ou de 106,7 cm (42 po) de largeur.

Le moteur est lubrifié en permanence et n’a pas besoin d’être huilé. Si les roulements du moteur sont

anormalement bruyants, remplacez l’ensemble du ventilateur exactement par le même modèle.

AMPOULES

AVERTISSEMENT :

Les ampoules peuvent

être très chaudes. Laissez

toujours les ampoules

refroidir avant de les

enlever.

Utilisez deux (2) ampoules

halogènes (fournies

AMPOULE

HALOGÈNE

avec la hotte) (ampoules

halogènes avec écran de

120 V, 50W - MR16 à culot

GU10. (3 ampoules pour le

hotte de 106,7cm (42 po).)

TOURNER DANS

LE SENS HORAIRE

(2)

REMARQUE :

Vous pouvez utiliser la ventouse (fournie avec la hotte) pour installer ou enlever les ampoules.

Alignez les bornes de l’ampoule sur la grande ouverture du socle, puis poussez l’ampoule

vers lahotte et tournez-la dans le sens horaire jusqu’à ce qu’elle soit bien appuyée. La position

du socle de l’ampoule (sa profondeur) est réglable et peut exiger un ajustement lorsque :

a) certainesmarques d’ampoule sont difficiles à installer. b) l’ampoule dépasse trop sous le

panneau d’éclairage.

VENTOUSE

(1)

ENFONCER

Pour changer la profondeur des

socles d’ampoule :

- Enlevez les vis du panneau

d’éclairage et mettez-les de côté.

- Enlevez le panneau d’éclairage.

- Desserrez les 2 vis retenant le

support du socle d’ampoule au

panneau d’éclairage.

- Réglez le support / socle à la

profondeur voulue.

- Resserrez les vis fermement.

- Fixez à nouveau le panneau

d’éclairage avec les vis que

vous avez mises de côté.

SUPPORT DE

SOCLED’AMPOULE

PANNEAU

D’ÉCLAIRAGE

- 25 -

VIS

Page 26

MESURES DE L’INSTALLATION

CAPUCHON DE TOIT

CONDUIT ROND

DE 20,3 CM (8 PO)

CONDUIT DÉCORATIF

11,1 CM (4 3/8 PO)

DU MUR À LA LIGNE

CENTRALE DU CONDUIT

CONDUIT DÉCORATIF

61 CM (24 PO) À 76,2 CM (30 PO)

AU-DESSUS DE LA SURFACE

HOTTE

DE CUISSON

La distance minimale de la hotte au-dessus de la surface de cuisson NE DOIT PAS

ÊTRE INFÉRIEURE à 61 cm (24 po).

Un maximum de 76,2 cm (30 po) est également fortement recommandé pour mieux

capter les vapeurs de cuisson.

Une distance de plus de 76,2 cm (30 po) est laissée à la discrétion de l’installateur et

des utilisateurs si la hauteur du plafond le permet.

COUDE ROND

CAPUCHON MURAL

BRIDE DE MONTAGE

DE HOTTE

33,3 CM (13 1/8 PO)

AU CENTRE DES TROUS

DE MONTAGE SUPÉRIEURS

3,5 CM (1 3/8 PO)

AU CENTRE DES

TROUS INFÉRIEURS

DU CHÂSSIS DE

LA HOTTE

POSE DU CONDUIT

(Hottes avec conduit seulement)

1. Planifiez la pose du conduit en déterminant son tracé entre la hotte et l’extérieur

dela maison.

2. Un tracé droit et court permet à la hotte d’être plus efficace.

3. Des conduits longs, des coudes et des transitions réduisent l’efficacité de la hotte.

N’en utilisez que le moins possible. Pour plus d’efficacité, des conduits plus gros

peuvent être nécessaires si le parcours est trop long.

4. Installez le capuchon mural ou de toit. Connectez un conduit rond en métal au

capuchon en progressant vers la hotte. Scellez les joints avec du ruban à conduit

àchaque section.

- 26 -

Page 27

PRÉPARATION DE LA HOTTE

Déballez la hotte et vérifiez le contenu de la boîte. Celle-ci doit contenir les éléments suivants:

1 - Ensemble de hotte

1 - Ensemble de conduit décoratif (sections supérieure et inférieure)

1 - Bride de montage de conduit décoratif supérieur

2 - Filtres à graisses en aluminium (installés dans la hotte)

2 - Ampoules halogènes de 50W MR16 GU10 (installées dans la hotte)

(3 – pour modèle de 106,7 cm)

1 - Clapet / raccord de conduit de 20,3 cm (8 po)

1 - Sac de pièces contenant :

6 - Vis de montage (4 mm x 38 mm à tête cylindrique cruciforme)

4 - Vis de montage (4mm x 8 mm à tête cylindrique cruciforme)

1 - Ventouse (pour la pose et l’enlèvement de l’ampoule)

6 TORNILLOS

DE MONTAJE

(4 x 38 mm de cabeza

SOPORTE

DE MONTAJE DEL TUBO

DE HUMOS SUPERIOR

1 - CONECTOR DEL

REGULADOR DE

TIRO/CONDUCTO

(8 pulg. (20.3 cm) de diám.

troncocónica ahuecada)

2 TORNILLOS

DE MONTAJE

(4 x 12 mm de cabeza

troncocónica ahuecada)

4 TORNILLOS

DE MONTAJE

(4 x 8 mm de cabeza

troncocónica ahuecada)

(6 para el modelo de

48 pulg. (121.9 cm))

HERRAMIENTA

DE VENTOSA

PARA BOMBILLAS

- 27 -

CONJUNTO

DEL TUBO

DE HUMOS

DECORATIVO

CONJUNTO DE

LA CAMPANA

Page 28

N

INSTALLATION DU CÂBLAGE

LIGNE CENTRALE

DE LA HOTTE

INSTRUCTIONS DE MISE À LA TERRE

Cet appareil doit être correctement mis à la terre. Dans l’éventualité d’un court-circuit,

la mise à la terre réduit les risques de décharge électrique en permettant au courant

de s’échapper dans un fil. Cet appareil comporte un cordon électrique muni d’un fil et

d’une fiche de mise à la terre. Cette fiche doit être branchée dans une prise de courant

correctement installée et mise à la terre.

Placez la prise de courant dans l’espace recouvert par le conduit décoratif de cheminée

et à un endroit où elle ne nuira pas au passage du conduit rond. Elle ne doit pas être à

plus de 61 cm (24 po) du dessus de la hotte et ne pas empiéter sur la zone de fixation

d’un support de montage et de l’endroit où le conduit décoratif touche au mur.

REMARQUE : Une prise de courant encastrée pour horloge peut être utilisée minimiser

les problèmes d’encombrement de la fiche de la hotte.

MAX. 61 CM

(24 PO)

12,1 CM (4

3

/4 PO)

31,4 CM

(12

61 CM (24 PO)

À 91,4 CM (36 PO)

AU-DESSUS DE LA

SURFACE DE CUISSO

3

/8 PO)

- 28 -

Page 29

INSTALLATION DE LA BRIDE DE MONTAGE

L

À 91,4 cm (36 po)

Hauteur

274 cm (9 pi)

avec

AEWTT32SB

305 cm (10 pi)

avec

AEWTT32SB

fumées de la hotte standard.

Distance requise pour la hotte au-dessus d’une surface de cuisson située à 91,4 cm (36 po)

DE LA HOTTE

1. Construisez une charpente de bois qui affleure la surface intérieure des montants

du mur. Centrez cette charpente avec l’emplacement d’installation.

REMARQUE : La distance de la hotte au-dessus de la surface de cuisson est : Au

minimum 61cm (24po), au maximum 76,2 cm (30 po). Les plafonds de 274 cm (9

pi) et 305 cm (10pi) peuvent nécessiter la rallonge de conduit décoratif, modèle

AEWTT32SB, selon la hauteur de l’installation (vendu séparément). Voir le tableau

ci-dessous pour de plus amples informations sur la hauteur de l’installation.

2. Une fois la surface du mur finie, fixez deux (2) vis de 4 mm x 38 mm aux endroits

indiqués ci-dessous. NE SERREZ PAS les vis jusqu’au bout - laissez environ 6,3

mm (1/4 po) entre la tête de la vis et le mur.

C

12,1 cm

3

/4 po)

(4

CHARPENTE

12,1 cm

3

(4

/4 po)

HOTTE

A

VOIR LE

TABLEAU

CI-DESSOUS

29,8 cm

3

(11

/4 po)

16,2 cm

3

/8 po)

(6

VIS DE

4 mm X 38 mm ICI

16,2 cm

3

(6

CHARPENTE

SURFACE DE CUISSON

61 cm (24 po) 63,5 cm (25 po) 66 cm (26 po) 68,6 cm (27 po) 71,1 cm (28 po) 73,7 cm(29 po) 76,2 cm (30 po)

du plafond

244 cm (8 pi)

274 cm (9 pi)

Position des vis de montage supérieures – distance au-dessus d’une surface de cuisson située

94,3 cm

(37-1/8 po)

**94,3 cm

(37-1/8 po)

94,3 cm

(37-1/8 po)

96,8 cm

(38-1/8 po)

**96,8 cm

(38-1/8 po)

96,8 cm

(38-1/8 po)

à 91,4 cm (36 po) (Dimension « A »)

99,4 cm

(39-1/8 po)

**99,4 cm

(39-1/8 po)

99,4 cm

(39-1/8 po)

101,9 cm

(40-1/8 po)

101,9 cm

(40-1/8 po)

104,5 cm

(41-1/8 po)

104,5 cm

(41-1/8 po)

*107 cm

(42-1/8 po)

107 cm

(42-1/8 po)

* Les évents de recirculation sans conduits sont exposés lors d'une installation avec conduits.

** Pour les non-conduit d'installation, utilisez Cheminée supérieure et inférieure de AEWTT32SB

/8 po)

*109,5 cm

(43-1/8 po)

109,5 cm

(43-1/8 po)

109,5 cm

(43-1/8 po)

- 29 -

Page 30

INSTALLATION DE LA HOTTE

(Hottes avec conduit seulement)

Plafond

1. Centrez la bride au-dessus de l’emplacement de la hotte au ras avec le plafond.

Fixez la bride supérieure au mur avec deux (2) vis de 4 mm x 38 mm. Remarque :

Des chevilles d’ancrage pour cloison sèche peuvent être nécessaires (non incluses).

2. Serrez complètement les vis. Assurez-vous que la bride est fermement appuyée

contre le mur et le plafond.

3. Enlevez la pellicule protectrice en plastique recouvrant la hotte et le conduit décoratif.

4. Enlevez les filtres à graisse en tirant vers le bas sur la languette métallique de

retenue et en basculant les filtres vers le bas.

5. Retirer toutes les charges internes en mousse qui supporte l’unité de ventilation à

l’intérieur de la hotte.

Centre de

l’installation

C

L

Fentes de la bride de

montage de conduit

décoratif supérieur

Au ras

duplafond

6. Fixez le clapet / raccord de conduit à l’aide de quatre (4) vis de montage de 4 mm x

8 mm.

- 30 -

Page 31

7. Alignez les deux fentes

extérieures en forme de trou

de serrure de la hotte sur

les vis partiellement vissées

dans la charpente du mur.

Glissez la hotte sur les têtes

de vis de sorte qu’elle soit

complètement appuyée sur

les vis de montage et qu’elle

est bien de niveau. Ensuite,

serrez complètement les vis.

8. Installez deux (2) vis de 4

mm x 38 mm dans les trous

situés à l’intérieur de la hotte

et serrez-les fermement.

9. Pour remettre les filtres à graisse, alignez les ergots arrière des filtres dans

les fentes de la hotte. Tirez la languette métallique vers le bas, poussez les

filtres en place et relâchez la languette. Vérifiez si les filtres sont bien fixés une

foisreplacés.

CONDUIT ROND EN

ACIER DE 20,3 cm (8 po)

LONGUEUR DU CONDUIT

CONDUIT

DÉCORATIF

10. Mesurez et installez le conduit en acier entre le raccord de conduit et le

connecteur du plafond ou du mur. Utilisez du ruban pour conduit afin de fixer

solidement tous les joints et assurer leur étanchéité.

11. Branchez le cordon électrique dans la prise de courant.

- 31 -

Page 32

12. Glissez soigneusement le conduit décoratif supérieur à l’intérieur du conduit

décoratif inférieur.

REMARQUE

Pour les applications avec conduits, les évents du conduit décoratif supérieur doivent

être masqués en les plaçant vers le bas, à l’intérieur du conduit décoratifinférieur.

13. Placez soigneusement l’ensemble de conduits décoratifs supérieur/inférieur dans

l’encastrement de la hotte.

14. Glissez le conduit décoratif supérieur vers le haut jusqu’à ce qu’il soit aligné avec

sa bride de montage. La bride doit être à l’intérieur du conduit décoratif. Fixez le

conduit supérieur à la bride supérieure avec deux (2) vis de 4 mm x 12 mm.

REMARQUE

Les plafonds de 274 cm – 305 cm (9-10 pi) peuvent nécessiter la rallonge de conduit

décoratif AEWTT32SB, selon la hauteur de l’installation (vendus séparément). Jetez

les conduits décoratifs supérieur et inférieur fournis avec votre hotte et remplacez-

les par la rallonge de conduit décoratif.

- 32 -

Page 33

INSTALLATION DE LA HOTTE

L

(Hottes sans conduits seulement)

CONTENU DES ENSEMBLES POUR HOTTE SANS CONDUITS

MODÈLE ANKWTT320 OU ANKWTT326

REMARQUE

Les installations sans

conduits exigent l’ensemble

ANKWTT320 (pour

hottes de76,2 cm (30 po)

de largeur) ou modèle

ANKWTT326 (pour hottes

de91,4 cm (36po) ou

106,7cm (42 po) de largeur).

ENSEMBLE DE CAISSON

NON CANALISÉ

CONDUIT FLEXIBLE

à tête cylindrique

8 CLIPS DE FILTRE

FILTRES DE RECIRCULATION POUR

INSTALLATION SANS CONDUITS

2 VIS

DE MONTAGE

(4 mm x 38 mm

cruciforme)

1. Centrez le caisson non

canalisé au-dessus de

Plafond

l’emplacement de la hotte

au ras avec le plafond.

Fixez le caisson non

canalisé au mur à l’aide

Au ras

duplafond

de deux (2) vis de 4 mm

x 38 mm. Remarque:

Des chevilles d’ancrage

pour cloison sèche

peuvent être nécessaires

(nonincluses).

2. Serrez complètement

les vis. Assurez-vous

Fentes de la bride de

montage de conduit

décoratif supérieur

que le caisson est bien

appuyé contre lemur et

le plafond.

3. Enlevez les clapets

Centre de

l’installation

C

de l’ensemble clapet /

raccord de conduit et jetez-les.

4. Enlevez la pellicule protectrice en plastique recouvrant la hotte et le conduit décoratif.

5. Fixez le raccord de conduit rond de 20,3 cm (de 8 po) sur le dessus du boîtier de

la hotte à l’aide de quatre (4) vis de montage de 4 mm x 8 mm.

6. Enlevez les filtres à graisse en tirant vers le bas sur la languette métallique

deretenue et en basculant les filtres vers le bas.

7. Retirer toutes les charges internes en mousse qui supporte l’unité de ventilation à

l’intérieur de la hotte.

- 33 -

Page 34

8. Alignez les deux

fentes extérieures

en forme de trou

de serrure de

la hotte sur les

vis partiellement

vissées dans la

charpente du mur.

Assurez-vous

que la hotte est

complètement

appuyée sur les

vis de montage

et qu’elle est

bien deniveau.

Ensuite, serrez

complètement lesvis.

9. Installez deux(2)

vis de 4 mm x

38mm dans les

trous àl’intérieur

dela hotte

et serrez-les

fermement.

10. Fixez les filtres

pour hotte sans

conduits aux

filtres à graisse à

l’aide de huit (8)

attaches.

11. Replacez les filtres

à graisse / filtres

sans conduits

en alignant les

languettes à

l’arrière des filtres

dans les fentes de

la hotte.

Tirez la languette métallique vers le bas, poussez les filtres en place et relâchez

la languette. Vérifiez si les filtres sont bien fixés une foisreplacés.

- 34 -

Page 35

CAISSON NON

CANALISÉ

CONDUIT MÉTALLIQUE

FLEXIBLE ROND

DE 20,3 CM (8 PO)

LONGUEUR DU CONDUIT

CONDUIT

DÉCORATIF

CLAPET / RACCORD

DE CONDUIT

12. Mesurez et installez une section de conduit métallique flexible (inclus avec

ANKWTT320 ou ANKWTT326) entre le clapet / raccord de conduit et le bas du

caisson non canalisé. Utilisez du ruban pour conduit afin defixer solidement tous

les joints et assurer leur étanchéité.

ATTENTION

N’utilisez pas de conduits en plastique.

13. Branchez le cordon électrique dans la prise de courant.

14. Glissez soigneusement le conduit décoratif supérieur à l’intérieur du conduit

décoratifinférieur.

REMARQUE

Pour les applications

sans conduits, les

évents du conduit

décoratif supérieur

doivent être orientés

vers le plafond.

15. Placez soigneusement

l’ensemble de

conduit décoratif

supérieur/inférieur

dans l’encastrement

delahotte.

16. Glissez le conduit

décoratif supérieur

vers le haut jusqu’à

ce qu’il soit aligné

avec le caisson. Le

caisson doit être à

l’intérieur du conduit

décoratif. Fixez le

conduit décoratif supérieur sur le caisson non canalisé à l’aide de deux (2) vis de

montage de 4 mm x 12 mm.

REMARQUE

Les plafonds de 274 cm – 305 cm (9-10 pi) peuvent nécessiter la rallonge de conduit

décoratif AEWTT32SB selon la hauteur de l’installation (vendueséparément).

Jetezles conduits décoratifs supérieur et inférieur fournis avec votre hotte et

remplacez-les par la rallonge de conduit décoratif, modèleAEWTT32SB.

- 35 -

Page 36

SCHÉMAS DE CÂBLAGE

PC DE CONTRÔLE

PC DE CONTRÔLE

MODÈLE WTT32I330SB

SCHÉMA DE CIRCUIT

MOTEUR

MOTEUR

BLANC

BLANC

N/B

BLANC

CARROSSERIE

NOIR

VERT

BLANC

TRANSFORMATEUR

REMARQUES/CONDENSEUR 3+2uF 250VCA CONVIENT CA120V 60Hz

MODÈLE WTT32I336SB

NOIR

BLEU

FUSIBLE

ROUGE

GRIS

MARRON

BLANC

VERT

CAR.

JAUNE

JAUNE

GRIS

MARRON

BLEU

JAUNE

ROUGE

SUPPLÉMENTAIRE

JAUNE

MARRON

AMORTISSEUR

D'AIR

ROUGE

SCHÉMA DE CIRCUIT

BLANC

MOTEUR

MOTEUR

BLANC

BLANC

N/B

BLANC

NOIR

BLEU

ROUGE

GRIS

MARRON

CARROSSERIE

FUSIBLE

NOIR

VERT

BLANC

TRANSFORMATEUR

REMARQUES/CONDENSEUR 3+2uF 250VCA CONVIENT CA120V 60Hz

- 36 -

VERT

CAR.

JAUNE

JAUNE

MARRON

JAUNE

ROUGE

GRIS

BLEU

JAUNE

MARRON

AMORTISSEUR

D'AIR

SUPPLÉMENTAIRE

ROUGE

Page 37

SCHÉMAS DE CÂBLAGE

PC DE CONTRÔLE

MODÈLE WTT32I342SB

SCHÉMA DE CIRCUIT

MOTEUR

MOTEUR

BLANC

BLANC

N/B

BLANC

CARROSSERIE

NOIR

VERT

BLANC

REMARQUES/CONDENSEUR 3+2uF 250VCA CONVIENT CA120V 60Hz

TRANSFORMATEUR

NOIR

BLEU

FUSIBLE

ROUGE

GRIS

MARRON

BLANC

VERT

CAR.

JAUNE

JAUNE

GRIS

MARRON

JAUNE

ROUGE

BLEU

SUPPLÉMENTAIRE

JAUNE

MARRON

AMORTISSEUR

D'AIR

ROUGE

- 37 -

Page 38

PIÈCES DE RECHANGE

N° DE REPÈRE N° DE PIÈCE DESCRIPTION QTÉ

1 S99528405 Conduits décoratifs supérieur et inférieur 1

2 S99528891 Ensemble moteur / ventilateur 1

3 S99528408 Socle d’ampoule (hottes de 76,2 cm (30 po),

Socle d’ampoule (hottes de 106,7 cm (42 po) 3

4 S99528409 Support de socle d’ampoule 2

Support de socle d’ampoule (hottes de 106,7 cm 3

5 S99528410 Ensemble d’interface utilisateur 1

6 S99528411 Câble d’interface utilisateur 1

7 S99528412 Panneau de commande 1

8 S99528414 Filtre à graisses en aluminium 2

S99528415 Filtre à graisses en aluminium 2

9 S97018968 Filtre de recirculation pour installation 2

S97019039 Filtre de recirculation pour installation 2

10 S99528418 Ensemble de clapet / raccord de conduit 1

11 S99528429 Conduit d’aluminium flexible extensible 1

12 S99528421 Ensemble de caisson non canalisé 1

13 S99528422 Bride de montage de conduit décoratif supérieur 1

14 V05921 Ampoule halogène de 50W MR16 GU10 2

Ampoule halogène de 50W MR16 GU10 3

* S99528892 Condensateur 1

* S99528425 Sac de pièces 1

* S99528518 Détecteur de chaleur 1

91,4 cm (36 po) de largeur) (comprend la

quincaillerie de montage)

de largeur) (comprend la quincaillerie de montage)

(hottes de 76,2 cm (30 po), 91,4 cm (36 po)

de largeur) (comprend la quincaillerie

demontage)

(42 po) de largeur) (comprend la quincaillerie

de montage)

(hotte de 76,2 cm (30 po) de largeur)

(hottes de 91,4 cm (36 po) et 106,7 cm

(42 po) de largeur)

sans conduits (hotte de 76,2 cm (30 po)

de largeur)

sans conduits (hottes de 91,4 cm (36 po) et

106,7 cm (42 po) de largeur)

de 20,3 cm (8 po)

de 20,3 cm (8 po) de diamètre

(hottes de 76,2 cm (30 po), 91,4 cm (36 po)

de largeur))

(hottes de 106,7 cm (42 po) de largeur)

* Non illustré.

Veuillez commander les pièces par n° de pièce - et non par n° de repère.

- 38 -

Page 39

PIÈCES DE RECHANGE

13

7

14

6

5

1

1

10

4

3

12

11

Les pièces de rechange

peuvent être commandées

sur notre site :

www.BestRangeHoods.com

2

9

8

- 39 -

Page 40

GARANTIE

GARANTIE LIMITÉE D’UN AN DES PRODUITS BEST

Broan-NuTone LLC (Broan-NuTone) garantit à l’acheteur original que les produits

Best sont libres de tout vice de matériau ou de fabrication pour une période d’un an

à compter de la date d’achat originale. CETTE GARANTIE NE COMPORTE AUCUNE

AUTRE GARANTIE, EXPRESSE OU TACITE, Y COMPRIS, MAIS SANS S’Y LIMITER,

LES GARANTIES TACITES DE VALEUR MARCHANDE OU D’ADAPTATION À UN

USAGE PARTICULIER.

Durant cette période d’un an, Broan-NuTone réparera ou remplacera gratuitement,

à sa discrétion, tout produit ou toute pièce jugés défectueux dans des conditions

normales d’utilisation.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX

DÉMARREURS, NI AUX AMPOULES HALOGÈNES OU INCANDESCENTES,

FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE TOIT, CAPUCHONS MURAUX

ET AUTRES ACCESSOIRES POUR CONDUITS. Cette garantie ne couvre pas (a)

les frais d’entretien ou de service normaux ni (b) tout produit ou toute pièce soumis

à un abus, une négligence, un accident, un entretien ou une réparation inadéquats

(autres que ceux effectués par Broan-NuTone), une mauvaise installation ou une

installation contraire aux instructions recommandées.

La durée de toute garantie tacite est limitée à la période d’un an stipulée pour la

garantie expresse. Certains territoires ou provinces interdisant de limiter la durée

d’une garantie tacite, la limitation ci-dessus peut ne pas s’appliquer à votre situation.

L’OBLIGATION POUR BROAN-NUTONE DE RÉPARER OU DE REMPLACER

LEPRODUIT, À SA DISCRÉTION, CONSTITUE LE SEUL RECOURS DE

L’ACHETEUR EN VERTU DE CETTE GARANTIE. BROAN-NUTONE NE PEUT ÊTRE

TENUE RESPONSABLE DES DOMMAGES INDIRECTS OU CONSÉCUTIFS NI

DES DOMMAGES-INTÉRÊTS PARTICULIERS DÉCOULANT DE L’UTILISATION

OU DU RENDEMENT DU PRODUIT. Certains territoires ou provinces ne permettant

pas la limitation ou l’exclusion des dommages indirects ou consécutifs, la limitation

ci-dessus peut ne pas s’appliquer à votre situation.

La présente garantie vous confère des droits spécifiques reconnus par la loi. D’autres

droits pourraient également vous être accordés selon la législation locale en vigueur.

La présente garantie remplace toutes les autres garanties précédentes.

Pour vous prévaloir de cette garantie, vous devez (a) aviser Broan-NuTone à l’adresse

ou au numéro de téléphone indiqués ci-dessous, (b) donner le numéro de modèle du

produit et le numéro d’identification de la pièce et (c) décrire la nature de la défectuosité

du produit ou de la pièce. Lors de votre demande de garantie, vous devez présenter

une preuve de la date d’achat originale.

Aux États-Unis - BEST®, 926 W. State Street, Hartford, WI 53027 (800-558-1711)

Au Canada - BEST®, 550 Lemire Blvd., Drummondville, QC J2C 7W9

(866-737-7770)

www.BestRangeHoods.com

- 40 -

99045953B

Page 41

HB0103

Serie WTT32I3

En EE. UU. - BEST® Hartford, Wisconsin

REGISTRE SU PRODUCTO EN LÍNEA EN: www.BestRangeHoods.com/register

Si desea información adicional, visite www.BestRangeHoods.com

- 41 -

Page 42

LEA Y CONSERVE ESTAS INSTRUCCIONES

!

!

INDICADO SOLAMENTE PARA COCINAR EN CASA

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA OLESIONES

PERSONALES, OBSERVE LO SIGUIENTE:

1. Use la unidad solo de la manera indicada por el fabricante. Si tiene preguntas,

comuníquese con el fabricante a la dirección o al número telefónico que se incluye

en la garantía.

2. Antes de dar servicio o limpiar la unidad, interrumpa el suministro eléctrico en el

panel de servicio y bloquee los medios de desconexión del servicio para evitar que

la electricidad sea reanudada accidentalmente. Cuando no sea posible bloquear

los medios de desconexión del servicio, fije firmemente una señal de advertencia

(como una etiqueta) en un lugar visible del panel de servicio.

3. Solo personal calificado debe realizar el trabajo de instalación y el cableado eléctrico,

de acuerdo con todos los códigos y las normas correspondientes, incluidos los

códigos y las normas de construcción específicos sobre protección contra incendios.

4. Es necesario suficiente aire para que se lleve a cabo una combustión y una

extracción adecuadas de los gases a través del tubo de humos (chimenea) del

equipo quemador de combustible, con el fin de evitar el contratiro. Siga las directrices

y las normas de seguridad del fabricante del equipo de calefacción, como las

publicadas por la Asociación Nacional de Protección contra Incendios (National Fire

Protection Association, NFPA), la Sociedad Americana de Ingenieros en Calefacción,

Refrigeración y Aire Acondicionado (American Society for Heating, Refrigeration and

Air Conditioning Engineers, ASHRAE), y las autoridades de los códigos locales.

5. Este producto podría tener bordes afilados. Trabaje con cuidado para evitar cortes

y abrasiones durante la instalación y la limpieza.

6. Al cortar o perforar a través de la pared o del cielo raso, tenga cuidado de no dañar

el cableado eléctrico ni otros servicios ocultos.

7. Los ventiladores con conductos siempre deben ventearse hacia el exterior.

8. Para reducir el riesgo de incendio, use solamente conductos de acero.

9. No use esta unidad junto con ningún otro dispositivo de control de velocidad de

estado sólido.

10. No haga a funcionar ningún ventilador con el enchufe o el cable dañado. Deseche el

ventilador o regréselo a una instalación de servicio autorizada para que lo examinen

o lo reparen.

11. INSTRUCCIONES PARA LA PUESTA A TIERRA: Este aparato debe estar conectado

a tierra. En caso de un corto circuito eléctrico, la puesta a tierra reduce el riesgo de

una descarga eléctrica al suministrar un cable de escape para la corriente eléctrica.

El aparato está equipado con un cordón que tiene un cable con una clavija a tierra.

La clavija debe conectarse a un tomacorriente que esté instalado y conectado a

tierra adecuadamente. ADVERTENCIA: Una puesta inadecuada a tierra puede tener

el riesgo de una descarga eléctrica. Consulte a un electricista calificado si no se

entienden totalmente las instrucciones de puesta a tierra, o si tiene alguna duda en

cuanto a la conexión a tierra apropiada del aparato. No utilice una extensióneléctrica.

Si el cable de la fuente de alimentación es demasiado corto, solicite a un electricista

calificado que instale una toma eléctrica cerca del aparato.

- 42 -

Page 43

!

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO POR GRASA PRESENTE

EN LA ESTUFA:

a) Nunca deje desatendidas las unidades de la superficie cuando estén en ajustes altos

de calor. Los alimentos en ebullición provocan derrames grasosos y con humo que

se pueden incendiar. Caliente el aceite lentamente en ajustes de calor bajo omedio.

b) Siempre ENCIENDA la campana cuando esté cocinando a altas temperaturas

o flameando alimentos (por ejemplo crepas Suzette, cerezas Jubilee, bistec con

pimienta flameado).

c) Limpie frecuentemente los ventiladores. No permita la acumulación de grasa en el

ventilador ni en los filtros.

d) Use una cacerola del tamaño adecuado. Siempre use utensilios de cocina que sean

apropiados para el tamaño del elemento de la superficie.

PARA REDUCIR EL RIESGO DE LESIONES PERSONALES EN EL CASO DE QUE LA

GRASA DE LA ESTUFA SE INCENDIE, SIGA LAS SIGUIENTES PRECAUCIONES*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una charola para galletas o una

bandeja de metal, y después apague el quemador. PROCEDA CON CUIDADO PARA

EVITAR QUEMADURAS. SI LAS LLAMAS NO SE APAGAN INMEDIATAMENTE,

EVACÚE EL ÁREA Y LLAME AL DEPARTAMENTO DE BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA, se puede quemar.

3. NO USE AGUA ni toallas húmedas, ya que provocará una violenta explosión de vapor.

4. Use un extintor SOLO si:

A. El extintor es clase ABC y usted sabe cómo usarlo.

B. El incendio es pequeño y está confinado al área en la que se inició.

C. Se ha llamado al departamento de bomberos.

D. Puede combatir el incendio teniendo la espalda orientada hacia una salida.

* Basado en “Kitchen Fire Safety Tips” (Sugerencias para la seguridad contra incendios

en la cocina) publicado por NFPA.

PRECAUCIÓN

1. Solo debe usarse bajo techo.

2. Solo para usarse como medio de ventilación general. No debe usarse para la

extracción de materiales o vapores peligrosos o explosivos.

3. Para evitar daños a los cojinetes del motor y rotores ruidosos o desbalanceados,

mantenga la unidad de potencia protegida contra rociados de yeso, polvos de

construcción, etc.

4. Este motor de campana tiene una protección contra sobrecargas térmicas que

automáticamente apagará el motor en caso de sobrecalentamiento. El motor

reanudará su funcionamiento cuando se enfríe. Si el motor continúa apagándose y

encendiéndose, solicite servicio para la campana.

5. La parte inferior de la campana NO DEBE ESTAR A MENOS de 24 pulg. (61 cm)

ydebe estar a un máximo de 30 pulg. (76.2 cm) por arriba de la estufa, para captar

mejor las impurezas que surgen al cocinar.

6. Se recomienda que dos personas hagan la instalación debido al gran tamaño de

esta campana.

7. Para reducir el riesgo de incendio y para descargar adecuadamente el aire,

asegúresede dirigir el aire hacia el exterior. No descargue el aire en espacios

contenidos entre paredes o cielos rasos, ni en áticos, sótanos bajos ni en la cochera.

8. Tenga cuidado al instalar el tubo de humos decorativo y la campana; pueden tener

bordes afilados.

9. Lea la etiqueta de especificaciones del producto para ver información y requisitos

adicionales.

- 43 -

Page 44

FUNCIONAMIENTO

Encienda siempre la campana antes de comenzar a cocinar para establecer un flujo de

aire en la cocina. Deje el ventilador funcionando unos cuantos minutos para despejar

el aire después de apagar la estufa.

La campana se hace funcionar con los botones en el panel frontal.

A B C D

A. INTERRUPTOR DE RETARDO

Cuando seleccione una velocidad del ventilador, presione este interruptor para

activar la función de retardo. El botón de retardo destellará a fin de verificar que

se ha activado esta función. El ventilador seguirá funcionando durante 5 minutos

y se detendrá de formaautomática. Para cancelar la función de retardo, presione

de nuevo el interruptor de retardo.

B. INTERRUPTORES DE SELECCIÓN DE INICIO / APAGADO / VELOCIDAD

Presione el interruptor correspondiente a la velocidad deseada del ventilador

(del 1 para velocidad baja al 4 para velocidad alta). Se encenderá el interruptor

seleccionado. Presione otra vez el interruptor de velocidad correspondiente para

apagar el ventilador; la luz del interruptor se apagará.

C. MAESTRO DE APAGADO / MANTENIMIENTO DEL FILTRO / HEAT SENTRY™

(INTERRUPTOR DE TRIPLE FUNCIÓN)

Presione este interruptor una vez para apagar el ventilador y la lámpara al

mismotiempo. Después de transcurridas 25 horas de funcionamiento este

interruptor se encenderá para indicar que los filtros y las ruedas del ventilador

necesitan limpieza para mantener el funcionamiento eficiente de la unidad. La luz

del interruptor permanecerá encendida hasta que la función se vuelva a restablecer

presionando este interruptor durante tres segundos. El indicador de la lámpara se

usa también para la función Heat Sentry.

SISTEMA HEAT SENTRY: Cuando se detecta una temperatura excesivamente

elevada, el sistema Heat Sentry asume el control del ventilador y lo configura a la

velocidad 3. El interruptor de triple función destellará. El ventilador permanecerá

encendido hasta que la condición de calentamiento vuelva a lo normal y luego

regresará a la velocidad seleccionada anteriormente.

ADVERTENCIA: El sistema Heat Sentry puede activar el ventilador aunque

la campana esté apagada. Cuando esta situación ocurre, es imposible apagar

el ventilador mediante los botones. Si debe apagar el ventilador, hágalo desde

el panel eléctrico principal.

D. INTERRUPTOR DE LA LÁMPARA

Este interruptor permite tener tres diferentes niveles de iluminación según sus

necesidades. Presione una vez para lámpara de noche, dos para iluminación normal

o tres veces para toda la intensidad. Para apagar las luces sin apagar elventilador,

presione el interruptor una vez más.

- 44 -

Page 45

LIMPIEZA Y MANTENIMIENTO

Por motivos de desempeño, apariencia y salud, limpie periódicamente el filtro, el ventilador

y las superficies que tengan grasa. Utilice únicamente un trapo limpio y una solución de

detergente suave en superficies de acero inoxidable y pintadas.

Limpie los filtros completamente metálicos en el lavaplatos con un detergente sin fosfatos.

El filtro se puede decolorar si se utilizan detergentes con fosfatos o como resultado de la

condición del agua local, pero esto no afectará el desempeño del filtro. Esta decoloración

no está cubierta por la garantía.

Limpie frecuentemente las superficies del filtro de recirculación sin conducto con un paño

húmedo y un detergente suave. NO sumerja los filtros en agua ni los coloque en el lavaplatos.

Cambie los filtros de recirculación cada 6 meses. Para reemplazar los filtros de recirculación

para sistemas sin conductos, compre el S97018968 o el modelo AFCWTT32 (para la campana

de 30 pulg. [76.2 cm] de ancho) o el modelo AFCWTT326 (para las campanas de 36 y 42 pulg.

[91.4 y 106.7 cm] de ancho).

El motor está permanentemente lubricado y nunca necesitará ponerle aceite. Si los cojinetes

del motor hacen un

ruido excesivo o inusual,

reemplace el conjunto del

ventilador con el repuesto

de servicio exacto.

BOMBILLAS

ADVERTENCIA:

Las bombillas podrían estar

calientes. Siempre permita

que se enfríen antes de

BOMBILLA DE

HALÓGENO

cambiarlas.

Esta campana requiere dos

(2) bombillas dehalógeno

(incluidascon la campana),

bombillas de halógeno

(2) GIRAR EN

SENTIDO DE LAS

AGUJAS DEL RELOJ

blindadas de 120 V, 50W,

tipoMR16 con base GU10. (3bombillas para la campana de 42 pulg. (106.7cm).

NOTA: La herramienta de ventosa (incluida con la campana) sirve para instalar y quitar

bombillas. Alineelas clavijas de la bombilla con la abertura de diámetro grande en el

receptáculo, empujela bombilla hacia la campana y luego gire hacia la derecha hasta que

esté firmemente asentada. La posición del receptáculo de la bombilla (profundidad) es

ajustable, y podría necesitar ajuste en el caso de: a) ciertas marcas de bombillas que son

difíciles de instalar. b) que la bombilla sobresalga demasiado debajo del panel de luces.

HERRAMIENTA

DEVENTOSA

(1) EMPUJAR

HACIA ADENTRO

SOPORTE DEL RECEPTÁCULO

DE LA LÁMPARA

Para cambiar la profundidad de

los receptáculos de las bombillas:

- Quite los tornillos en el panel

de luces, déjelos a un lado.

- Retire el panel de iluminación.

- Afloje 2 tornillos que sostienen

el soporte del receptáculo

de la lámpara al panel

deiluminación.

- Ajuste el receptáculo/soporte

a la profundidad deseada.

PANEL DE

ILUMINACIÓN

TORNILLOS

- Vuelva a apretar los tornillos

con firmeza.

- Vuelva a fijar el panel de iluminación con los tornillos que dejó a un lado anteriormente.

- 45 -

Page 46

MIDA LA INSTALACIÓN

TAPA DE TECHO

CONDUCTO REDONDO

DE 8 PULG. (20.3 CM)

TUBO DE HUMOS

DECORATIVO

4 3/8 PULG. (11.1 CM)

DE LA PARED A LA LÍNEA

CENTRAL DEL CONDUCTO

TUBO DE HUMOS

DECORATIVO

CAMPANA

CODO REDONDO

TAPA DE PARED

SOPORTE DE MONTAJE

DE LA CAMPANA

13 1/8 PULG. (33.3 CM)

AL CENTRO DE LOS

ORIFICIOS DE MONTAJE

SUPERIORES

24 A 30 PULG.

(61 A 76.2 CM)

POR ARRIBA

DE LA SUPERFICIE

PARA COCINAR

1 3/8 PULG. (3.5 CM)

AL CENTRO DE LOS

ORIFICIOS INFERIORES

DEL CHASIS DE

LA CAMPANA

La distancia mínima de la campana sobre la superficie de la estufa NO DEBE SER

MENOR de 24 pulg. (61 cm).

Se recomienda enfáticamente una distancia máxima de 30 pulg. (76.2 cm) sobre la

superficie de la estufa para capturar mejor las impurezas resultantes del cocinado.

Utilizar distancias superiores a las 30 pulg. (76.2 cm) queda a discreción del usuario

ydel instalador, siempre y cuando lo permita la altura hasta el cielo raso.

INSTALACIÓN DEL SISTEMA DE CONDUCTOS

(Solo campanas para sistemas con conductos)

1. Decida dónde instalará el conducto entre la campana y el exterior.

2. Un conducto recto y corto permitirá que la campana funcione más eficientemente.

3. Los tramos largos de conductos, codos y transiciones reducirán el desempeño de

la campana. Use tan pocos de ellos como sea posible. Es posible que se requieran

conductos más grandes para un mejor funcionamiento con tramos más largos

deconductos.

4. Instale la tapa para pared o para techo. Conecte un conducto metálico redondo

en la tapa y trabaje hacia atrás, hacia la ubicación de la campana. Use cinta para

conductos para sellar las uniones entre las secciones de conductos.

- 46 -

Page 47

PREPARE LA CAMPANA

Desempaque la campana y revise el contenido del paquete. Debe contener lo siguiente:

1 - Conjunto de campana

1 - Conjunto de tubo de humos decorativo (contiene el tubo de humos superior e inferior)

1 - Soporte de montaje del tubo de humos superior

2 - Filtros de aluminio para grasa (instalados en la campana)

2 - Lámparas de halógeno MR16 GU10 de 50 W (instaladas en la campana) (3 en los

modelos de 42 pulg. (106.7 cm))

1 - Conector del regulador de tiro/conducto de 8 pulg. (20.3 cm)

1 - Bolsa de piezas con:

6 - Tornillos de montaje (4 x 38 mm de cabeza troncocónica ahuecada)

4 - Tornillos de montaje (4 x 8 mm de cabeza troncocónica ahuecada)

1 - Herramienta de ventosa (para instalar o quitar bombillas)

6 TORNILLOS

DE MONTAJE

(4 x 38 mm de cabeza

SOPORTE

DE MONTAJE DEL TUBO

DE HUMOS SUPERIOR

1 - CONECTOR DEL

REGULADOR DE

TIRO/CONDUCTO

(8 pulg. (20.3 cm) de diám.

troncocónica ahuecada)

2 TORNILLOS

DE MONTAJE

(4 x 12 mm de cabeza

troncocónica ahuecada)

4 TORNILLOS

DE MONTAJE

(4 x 8 mm de cabeza

troncocónica ahuecada)

(6 para el modelo de

48 pulg. (121.9 cm))

HERRAMIENTA

DE VENTOSA

PARA BOMBILLAS

- 47 -

CONJUNTO

DEL TUBO

DE HUMOS

DECORATIVO

CONJUNTO DE

LA CAMPANA