Page 1

Model WM34I

ENGLISH.................................... 2

FRANÇAIS.................................17

ESPAÑOL.................................. 33

In USA - BEST Hartford, Wisconsin

In CANADA - BEST Drummondville, QC, Canada

REGISTER YOUR PRODUCT ONLINE AT : www.BestRangeHoods.com/register

For additional Information visit www.BestRangeHoods.com

Page 2

- 2 -

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions,

contact the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock service

panel to prevent power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such

as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the

flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating

equipment manufacturer’s guidelines and safety standards such as those published

by the National Fire Protection Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other

hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electrical shock by providing an escape wire for the electric current.

This appliance is equipped with a cord having a grounding wire with a grounding plug.

The plug must be plugged into an outlet that is properly installed and grounded.

WARNING - Improper grounding can result in a risk of electric shock.

Consult a qualified electrician if the grounding instructions are not completely understood,

or if doubt exists as to whether the appliance is properly grounded.

Do not use an extension cord. If the power supply cord is too short, have a qualified

electrician install an outlet near the appliance.

!

INTENDED FOR DOMESTIC COOKING ONLY

!

Page 3

- 3 -

!

CAUTION

1. For indoor use only.

2. To reduce risk of fire and to properly exhaust air, be sure to duct air outside. Do not

vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or

garages.

3. Take care when using cleaning agents or detergents.

4. Avoid using food products that produce flames under the Range Hood.

5. For general ventilating use only. Do not use to exhaust hazardous or explosive

materials and vapors.

6. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall

spray, construction dust, etc. off power unit.

7. Your hood motor has a thermal overload which will automatically shut off the motor

if it becomes overheated. The motor will restart when it cools down. If the motor

continues to shut off and restart, have the hood serviced.

8. For best capture of cooking impurities, the bottom of the hood should be a minimum

of 20” and a maximum of 30” above the cooking surface. See “Install Mounting

Bracket” section for mounting restrictions.

9. Two installers are recommended because of the large size and weight of this hood.

10. This product is equipped with a thermostat which may start blower automatically. To

reduce the risk of injury and to prevent power from being switched on accidentally,

switch power off at service panel and lock or tag service panel.

11. Please read specification label on product for further information and requirements.

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes

Suzette, Cherries Jubilee, Peppercorn Beef Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan

or filter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface

element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off

the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam explosion

will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know how to oper-

ate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

Page 4

- 4 -

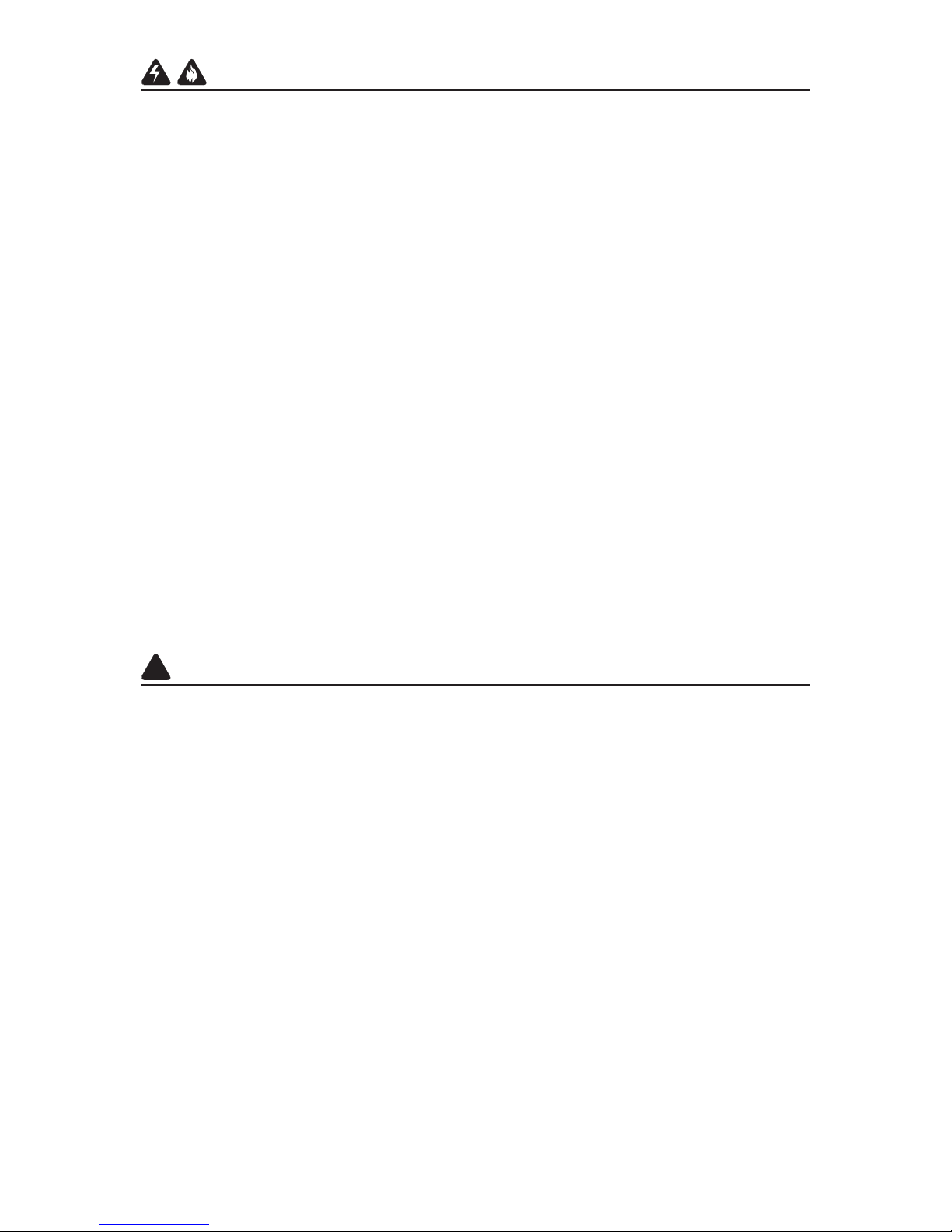

OPERATION

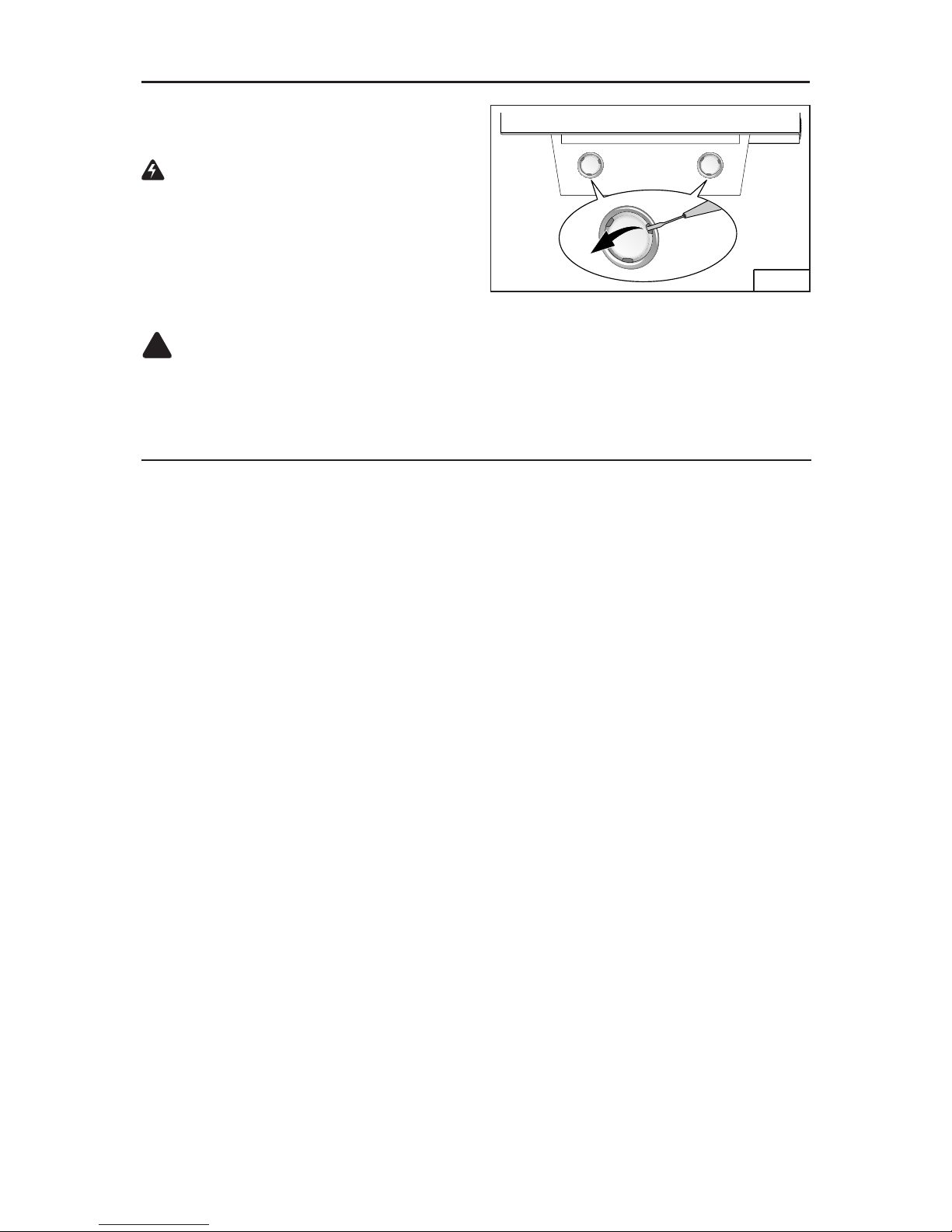

CONTROLS (FIG. 1)

Speed display:

PU5: ON/OFF Motor 4

th

speed

PU4: ON/OFF Motor 3

rd

speed

PU3: ON/OFF Motor 2

nd

speed

PU2: ON/OFF Motor 1

st

speed

PU1: HI/LOW/OFF Lights

10-minute timer function:

Pressing PU2, PU3 or PU4 for two seconds when the motor

is set to the corresponding speed, activates the 10-minute

timer function.

The corresponding LED starts blinking to display this function.

After ten minutes of operation the motor is turned off. If you

change the speed while the timer is running, the function

is NOT deactivated. To deactivate the function, press the

blinking key for two seconds.

FIG. 1

NOTE – the 10-minute timer function can be activated for the normal speeds

only (1st, 2nd, 3rd).

Filter alarm:

After 30 hours of motor operation, the grease filter alarm is activated (all the

LEDs come on). The alarm is activated when the motor is off and remains

displayed for 30 minutes. To deactivate the alarm, press one of the keys for 2

seconds during alarm display. After 120 hours of motor operation, the charcoal

filter alarm is activated (all the LEDs blink). The alarm is activated when the motor

is off and remains displayed for 30 minutes. To deactivate the alarm, press one of

the keys for 2 seconds during alarm display.

HEAT SENTRY™

Your hood is equipped with a HEAT SENTRY™ thermostat. This thermostat is a

device that will turn on or speed up the blower if it senses excessive heat above

the cooking surface.

1) If blower is OFF - it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting - it turns blower up to HIGH speed.

When the temperature level drops to normal, the blower will return to its original

setting.

WARNING

The HEAT SENTRY thermostat can start the blower even if the hood is turned

OFF. When this occurs, it is impossible to turn the blower OFF with its switch.

If you must stop the blower, do it from the main electrical panel.

Page 5

- 5 -

HALOGEN BULBS

This range hood requires two halogen

bulbs (Type T4, 120Volt, 25Watt Max,

G9 Base).

WARNING: Always switch off the

electrical supply before carrying out

any operation on the appliance.

To change bulbs:

1. Open the cover by prying from the

proper slots. Fig. 2.

2. Remove the bulbs by pulling sideways. (DO NOT ROTATE).

!

CAUTION: Bulbs may be hot.

3. Replace with Type T4, 120Volt, 25Watt Max, G9 Base halogen bulbs. Do not

touch replacement bulbs with bare hands!

FIG. 2

CLEANING AND MAINTENANCE

Proper maintenance of the Range Hood will assure proper performance of the unit.

Motor

The motor is permanently lubricated and never needs oiling. If the motor bearings make

excessive or unusual noise, replace the motor with the exact service motor. The impeller

should also be replaced.

Grease Filter

The grease filter should be cleaned frequently. Use a warm detergent solution. Grease filter

is dishwasher safe.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of

the filter may occur if using phosphate detergents, or as a result of local water conditions

- but this will not affect filter performance. This discoloration is not covered by the warranty.

See “INSTALL FILTERS” section for removal and installation instructions.

Non-ducted Recirculation Filter

The non-ducted recirculation filter should be changed every 6 months. Replace more often if

your cooking style generates extra grease, such as frying and wok cooking. See “INSTALL

FILTERS” section for removal and installation instructions.

Stainless Steel Cleaning

DO:

• Regularly wash with clean cloth or rag

soaked with warm water and mild soap

or liquid dish detergent.

• Always clean in the direction of original

polish lines.

• Always rinse well with clear water (2 or 3

times) after cleaning. Wipe dry completely.

• You may also use a specialized household

stainless steel cleaner.

DON’T:

•

Use any steel or stainless steel wool or any

other scrapers to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction

residues reach the hood. During construction/renovation, cover the range hood to

make sure no dust sticks to the stainless

steel surface.

Avoid: When choosing a detergent

• Any cleaners that contain bleach will attack stainless steel

• Any products containing: chloride, fluoride, iodide, bromide will deteriorate surfaces rapidly.

• Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc.,

are highly explosive and should never be used close to a range.

Page 6

- 6 -

PREPARE THE HOOD

Unpack hood and check contents.

You should receive:

1 - Hood

1 - Decorative Flue Assembly

1 - Parts Bag containing:

2 - Mounting Brackets

1 - Discharge Collar

1 - Flue Mounting Bracket

8 - Mounting Screws (4.8 x 38mm Pan Head)

2 - Mounting Screws (3.9 x 9.5mm Pan Head)

8 - Drywall Anchors

1 - Installation Instructions

2 MOUNTING

BRACKETS

DISCHARGE

COLLAR

FLUE MOUNTING

BRACKET

8 MOUNTING SCREWS

(4.8 x 38mm Pan Head)

8 DRYWALL

ANCHORS

2 MOUNTING

SCREWS (3.9 x

9.5mm Pan Head)

DECORATIVE

FLUE

FIG. 3

Page 7

- 7 -

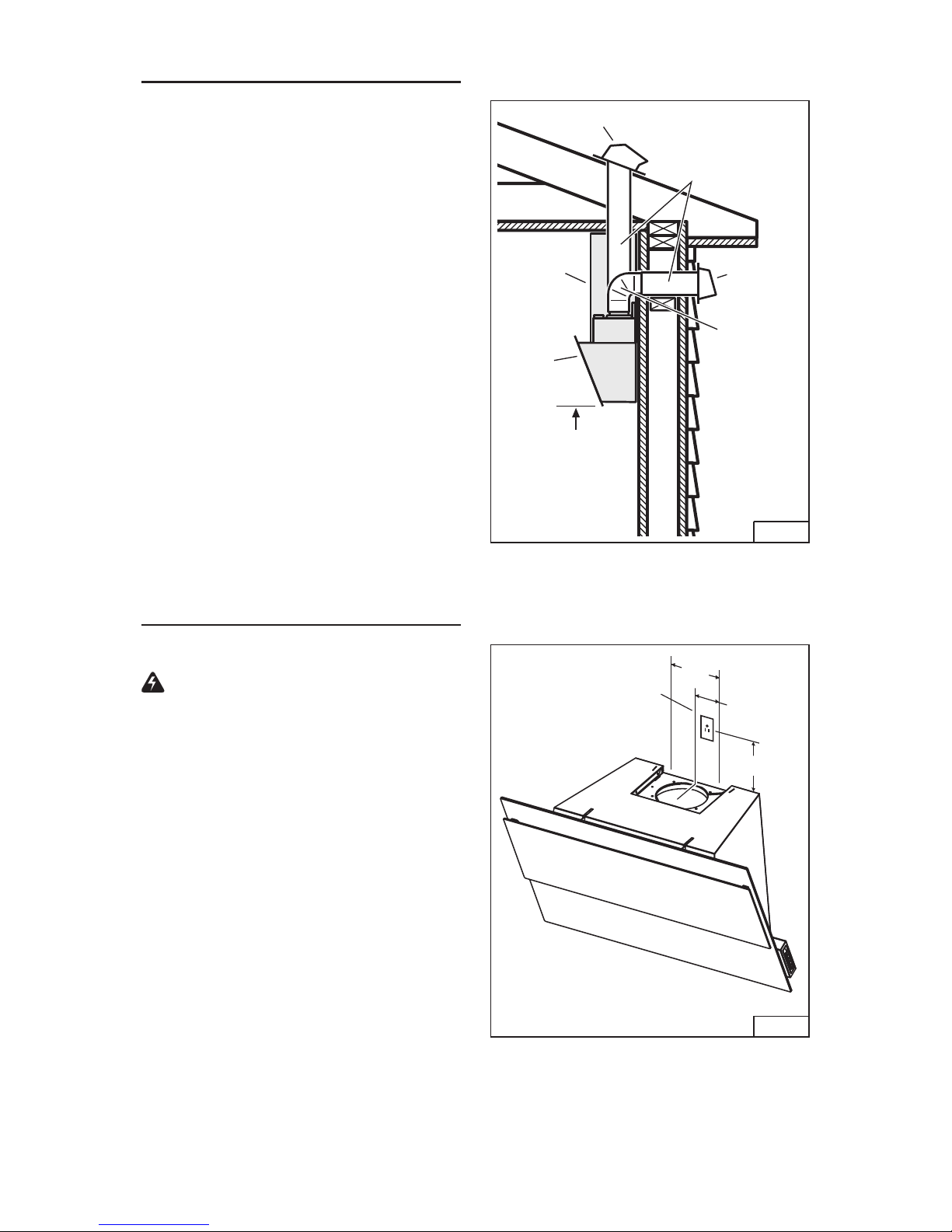

INSTALL THE DUCTWORK

DUCTED HOODS ONLY

CAUTION: To reduce the risk of fire,

use only metal ductwork.

1. Decide where the ductwork will run

between the hood and the outside.

Fig. 4.

2. A straight, short duct run will allow

the hood to perform most efficiently.

3. Long duct runs, elbows, and transitions will reduce the performance of

the hood. Use as few of them as possible. Larger ducting may be required

for best performance with longer duct

runs.

4. Install a roof or wall cap. Connect

round metal ductwork to cap and

work back towards hood location. Use

duct tape to seal the joints between

ductwork sections.

INSTALL ELECTRICAL

DUCTED and NON-DUCTED HOODS

WARNING : Electrical wiring must

be done by a qualified person(s) in

accordance with all applicable codes

and standards. This range hood must

be properly grounded. Turn off electrical power at service entrance before

wiring.

1. Plan where the hood will be located

above the cook top. Refer to the

“INSTALL MOUNTING BRACKET”

section for hood mounting height

options.

2. Install a standard 2” x 4” wall outlet

box and 3-blade 125 volt, 15 Amp

grounded receptacle.

3. Mount the center of the wall outlet 5”

to

8” above the bottom of the hood.

Fig. 5.

4. Locate the box and the receptacle

within boundary shown and off center

of the ductwork (to allow for power

cord plug and flue clearance).

FIG. 4

FIG. 5

6" ROUND

DUCT

ROOF CAP

6" ROUND

ELBOW

20" TO 30" ABOVE

COOKING SURFACE

(see “INSTALL

MOUNTING

BRACKETS”

section for mounting

restrictions)

WALL CAP

HOOD

DECORATIVE

FLUE

8

5

”

to

4¼”

8½”

CENTERLINE

OF HOOD

”

Page 8

- 8 -

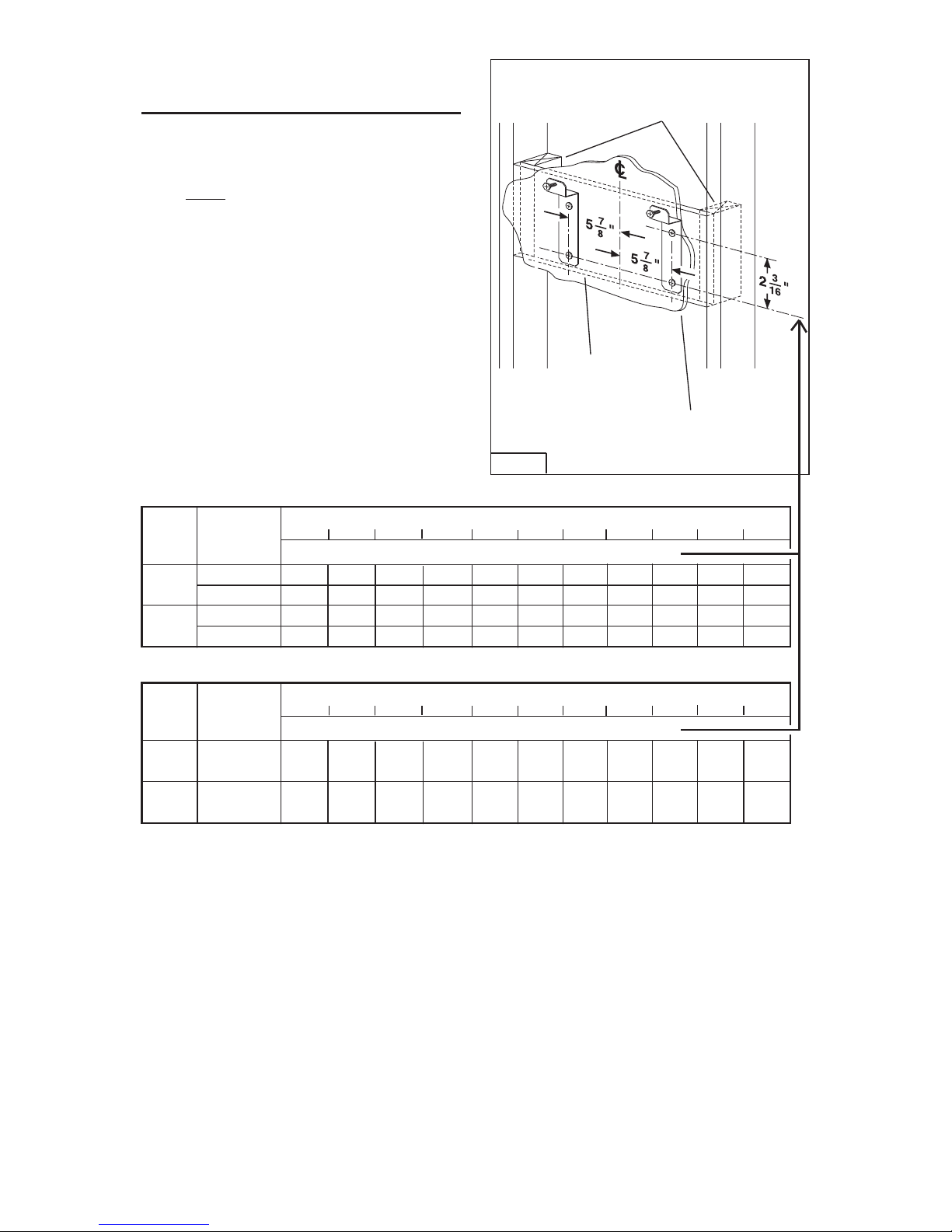

HOOD DISTANCE ABOVE 36” HIGH COOK TOP (see note below)

26”

MOUNTING BRACKET LOCATION ABOVE 36” HIGH COOK TOP

CEILING

HEIGHT

8 FEET

20” 21” 22” 23” 24” 25”

34-1/2” 35-1/2” 36-1/2” 37-1/2”

DUCTED

NON-DUCTED

DUCT

METHOD

34-1/2” 35-1/2”

9 FEET

DUCTED

NON-DUCTED

35-1/2” 36-1/2” 37-1/2”

38-1/2” 39-1/2” 40-1/2”

41-1/2”

42-1/2” 43-1/2” 44-1/2”

30”27” 28” 29”

38-1/2” 39-1/2” 40-1/2”

41-1/2”

42-1/2” 43-1/2” 44-1/2”

INSTALL MOUNTING

BRACKET

DUCTED and NON-DUCTED HOODS

1. Construct wood wall framing that

is flush with interior surface of wall

studs. Fig. 6.

Make sure:

a) the framing is centered over in-

stallation location.

b) the height of the framing will al-

low the mounting brackets to be

secured to the framing within the

dimensions shown.

2. After wall surface is finished, secure each mounting bracket to framing with (2) 4.8 x 38 mm mounting

screws. See chart below for mounting

bracket location.

FRAMING BEHIND

WOOD CROSS

SUPPORT

WOOD CROSS

SUPPORT BEHIND

DRYWALL

DRYWALL

FIG. 6

INSTALLATIONS WITH FLUE

HOOD DISTANCE ABOVE 36” HIGH COOK TOP (see note below)

26”

MOUNTING BRACKET LOCATION ABOVE 36” HIGH COOK TOP

CEILING

HEIGHT

20” 21” 22” 23” 24” 25”

34-1/2”

35-1/2”

36-1/2”

37-1/2”

NON-DUCTED

DUCT

METHOD

30”27” 28” 29”

38-1/2”

39-1/2”

40-1/2”

41-1/2”

42-1/2”

43-1/2”

44-1/2”

8 or

9 FEET

NON-DUCTED INSTALLATIONS WITHOUT FLUE (WITH BLADE GUARD ONLY)

Note: Minimum hood distance above cook top must not be less than 20". A maximum of 30" above cook top is highly recommended for best capture of cooking

impurities. Distance over 30" are the installer and user's discrection; and if ceiling

height and flue lenght permit.

Page 9

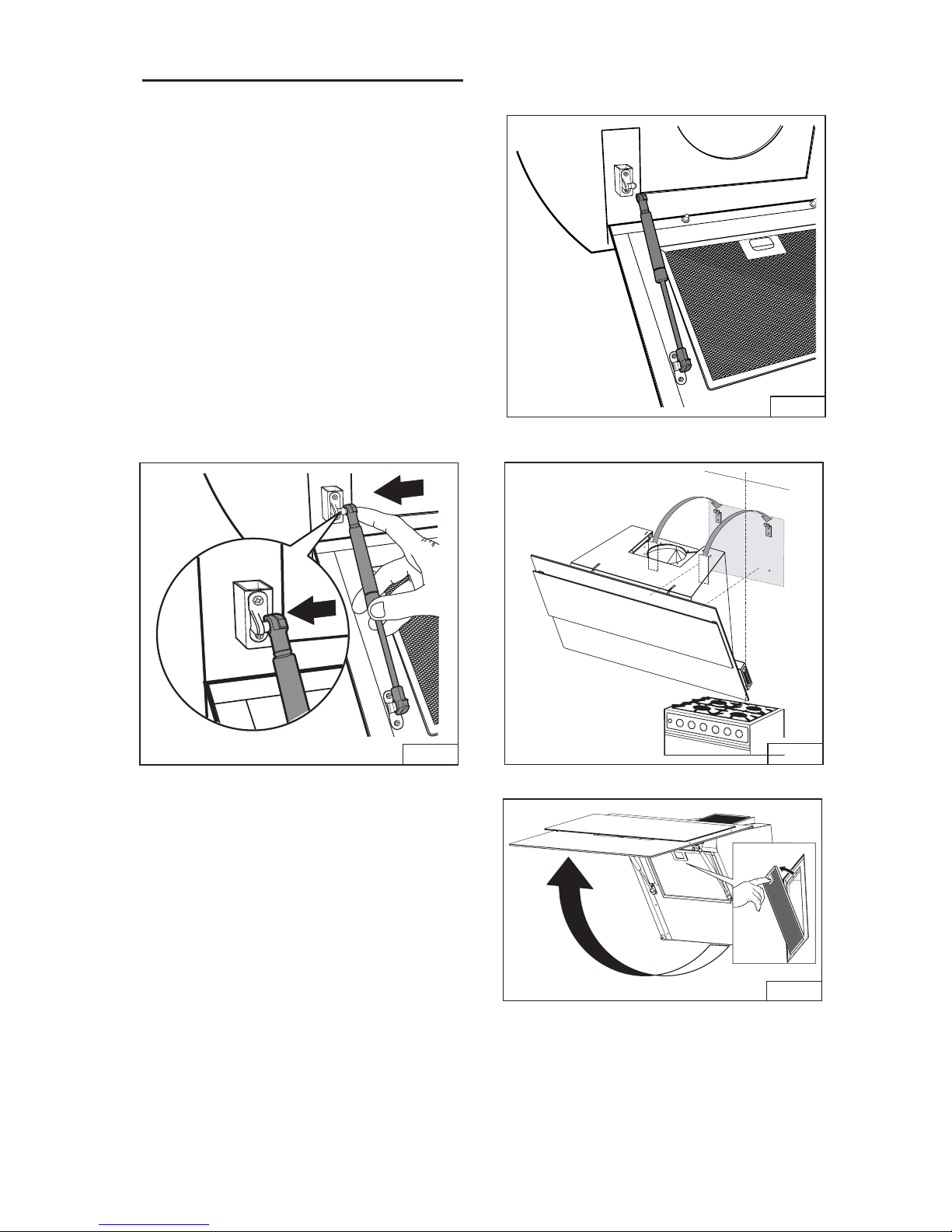

INSTALL THE HOOD

Note: Remove the plastic protective

film from all exterior surfaces,

decorative flues and filters, prior to

final insallation.

DUCTED and NON-DUCTED

INSTALLATION

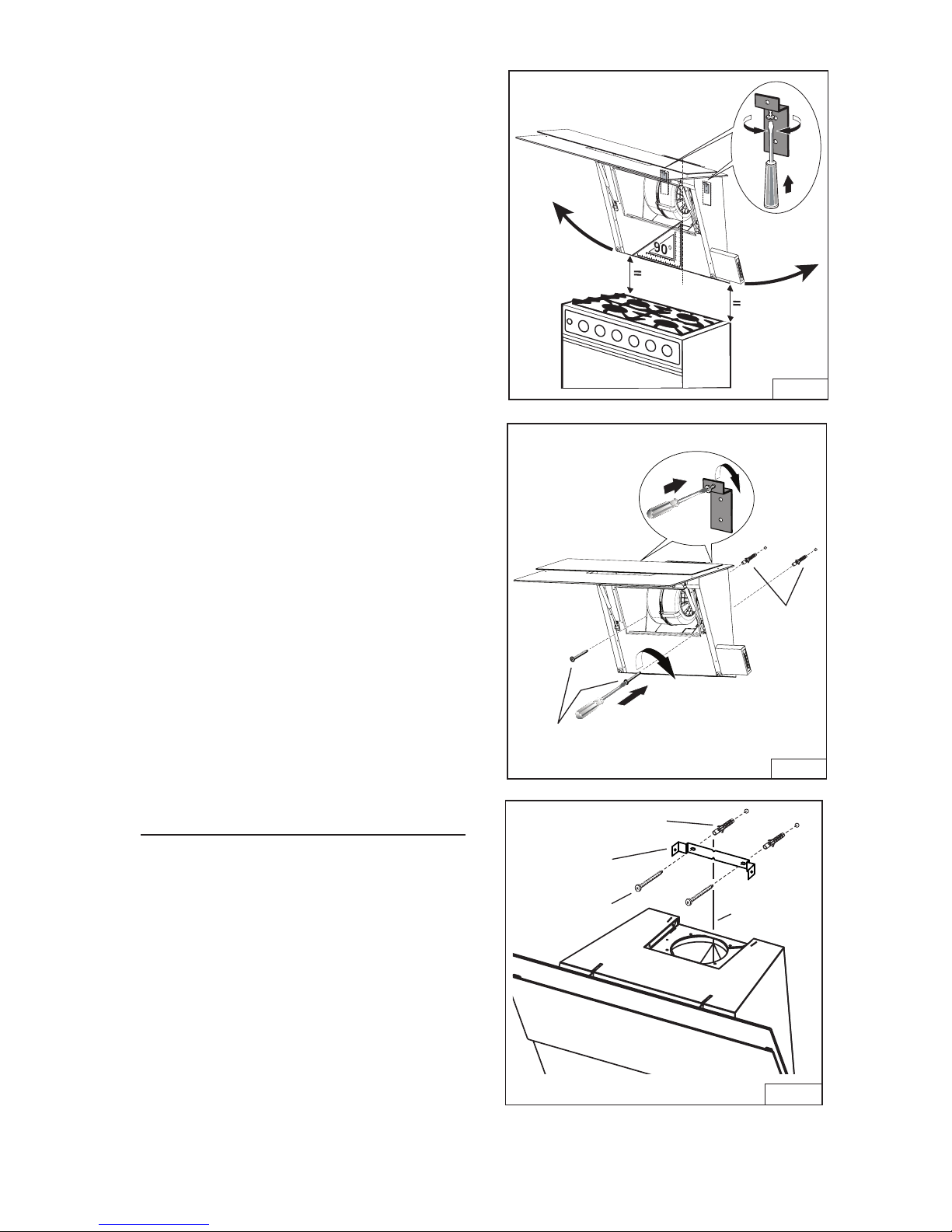

1. Open the front glass panel and

remove shipping tape from both air

cylinders.

2. Pull each cylinder to extend its lenght.

Fig.7

3. Align end of cylinder with mounting

bracket and push in to engange. Fig.8

4. Install hood onto (2) wall mounting

brackets. Make sure hood is level with

floor. Fig.9

5. Lift glass front panel and remove

grease filter.Fig 10.

FIG.

Click!

8

0

FIG.1

FIG. 7

FIG. 9

- 9 -

Page 10

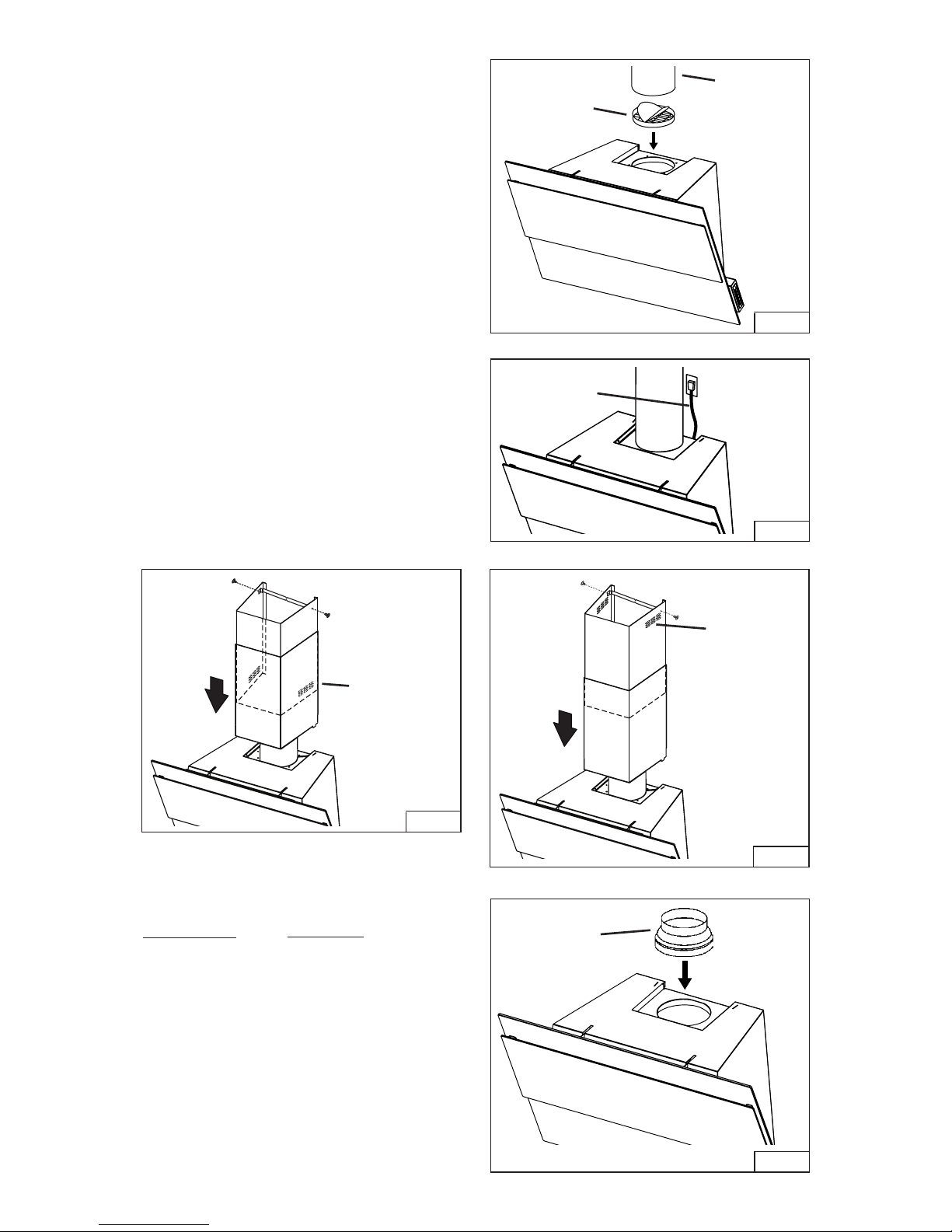

6. Use adjustment screws on wall

brackets to level hood. Fig.11

7. From inside the hood, locate (2) holes

for drywall anchors. Mark their location

on the wall.

8. Remove hood from the wall and drill

(2) 5/16” holes. Install drywall anchors as

shown. Fig.12

9. Lift hood back onto wall mounting

brackets. Secure hood to the wall with

(2) 4.8 x 38mm mounting screws.

DUCTED AND NON-DUCTED

INSTALLATION WITH FLUE CONTINUE TO “INSTALL FLUE

MOUNTING BRACKET” SECTION

ON PAGE 10

NON-DUCTED INSTALLATIONS

WITHOUT FLUE SKIP TO “INSTALL BLADE GUARD”

SECTION ON PAGE 14

INSTALL FLUE MOUNTING

BRACKET

DUCTED OR NON-DUCTED HOOD

WITH FLUE

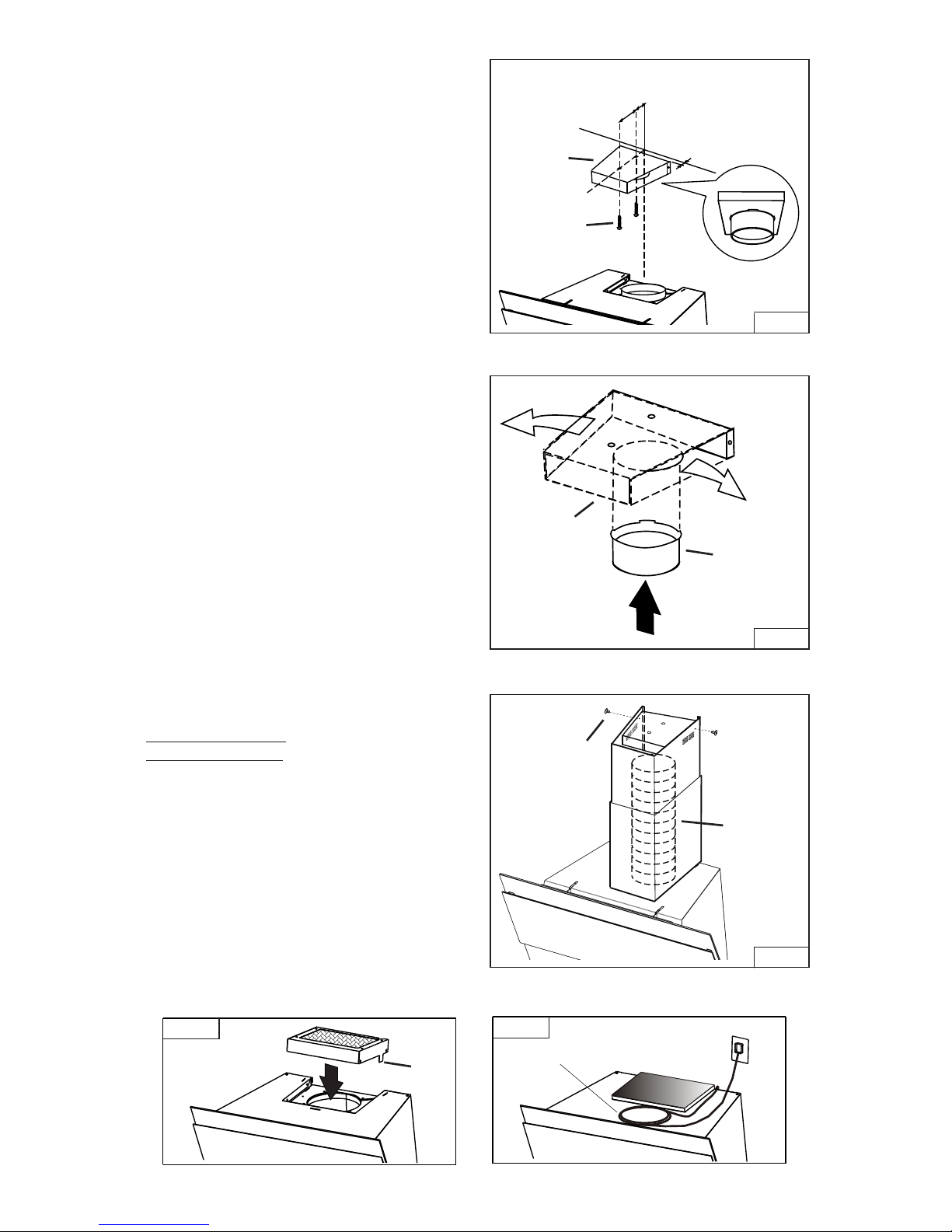

1. Center the mounting bracket directly

over the range hood location.

2. Secure the bracket to the wall using

(2) 4.8 x 38mm mounting screws and

drywall anchors. Fig7. Make sure the

bracket is tight against the wall and

centered over the hood. Fig.13

FIG.13

4.8 x 38 mm

SCREWS

DRYWALL

ANCHORS

CENTERLINE

OF HOOD

4.8 x 38 mm

SCREWS

DRYWALL

ANCHORS

MOUNTING

BRACKET

FIG.11

FIG.12

- 10 -

Page 11

- 11 -

FIG.14

FIG.15

FIG.16

DUCTED INSTALLATION ONLY

10. Press the discharge collar into the

duct connector of the range hood.

Fig. 14.

11. Run 6” diameter metal ductwork

to the outside location. Install an

appropriate wall or roof cap with

damper to exhaust air to the outside.

12. Tape all duct joints with aluminum

duct tape.

13. Plug power cord into wall outlet. Fig.

15.

14. Install upper and lower decorative

flues onto the range hood.

- Vents are concealed on 8-foot

ceilings. Fig. 16

- Vents are exposed on 9-foot ceilings. Fig. 17.

15. Secure upper flue to flue mounting

bracket with (2) 3.9 x 6 mm screws.

DISCHARGE

COLLAR

6” ROUND

DUCT

POWER

CORD

FIG.17

VENTS

CONCEALED

8 FT. CEILING

VENTS

EXPOSED

9 FT. CEILING

NON-DUCTED INSTALLATION

WITH FLUE AND PLENUM ONLY

Note: Purchase Model ANKWM34 Nonducted Recirculation Kit.

10. Do not install discharge collar

supplied with the range hood.

11. Attach the 5”-to-6” adapter to

blower discharge and tape joint with

aluminum duct tape. Fig. 18.

FIG.18

5” TO 6”

ADAPTER

Page 12

- 12 -

12. Center the plenum over the hood.

Fig. 19.

13. Attach plenum to the ceiling using

(2) drywall anchors and (2) 4.8 x 38

mm screws, as shown.

14. Press duct connector into the

plenum until it snaps into place. Fig.

20.

15. Attach 5-inch dia. expandable

ducting to the plenum and tape joint

with aluminum duct tape.

16. Stretch expandable duct, attach it to

the 5”-to-6” adapter and tape duct

joints. Fig. 21.

1 7. Plug power cord into wall outlet.

18. Position upper and lower flues onto

the hood.

19. Align tabs on bottom edge of lower

flue with slots on top of the range

hood.

20. Make sure recirculation slots on the

upper flue are exposed, as shown.

2 1. Lift upper flue up until mounting

holes align with holes in the plenum.

22. Install (2) 3.9 x 9.5 mm mounting

screws to secure upper flue to

plenum.

FIG.20

FIG.19

FIG.21

5-7/8”

1-3/8”

3/8”

4.8 x 38mm

SCREWS

PLENUM

PLENUM

DUCT

CONNECTOR

3.9 x 6mm

SCREWS

5” DIA.

EXPANDABLE

DUCT

NON-DUCTED INSTALLATION

WITHOUT FLUE AND

BLADE GUARD ONLY

10. Install blade guard. Align tabs of the

guard with slots on top of the hood.

Fig.22

11. From inside the hood , bend tabs

over to secure the blade guard to the

hood.

12. Plug power cord into 120 VAC

receptacle . Fig.23

13. Coil and tape remaining power cord

to the top of the range hood.

FIG.22

TABS

FIG.23

TAPE

Page 13

- 13 -

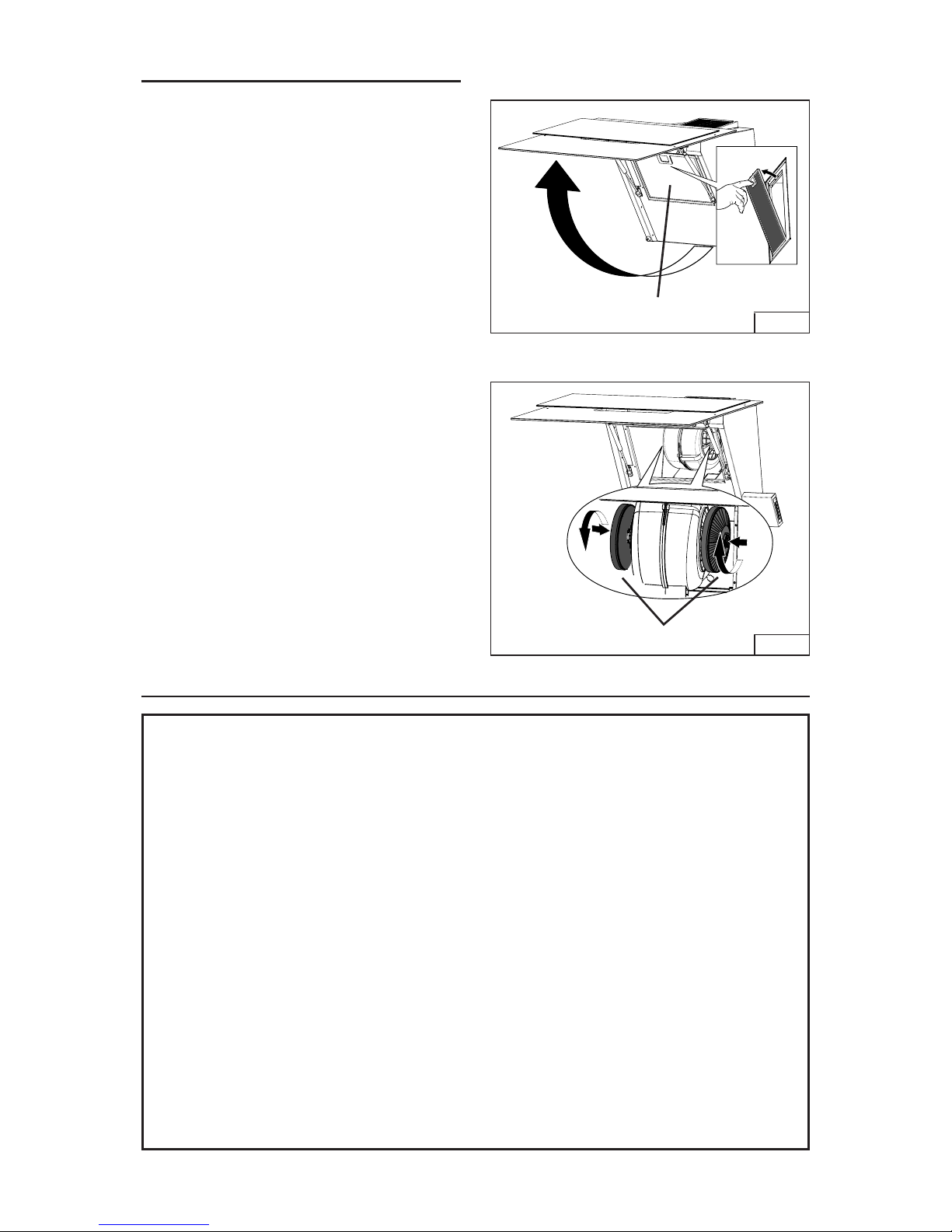

INSTALL FILTERS

DUCTED AND NON-DUCTED HOODS

1. To remove the GREASE filter, push in

latch tab to disengage the filter from

the hood. Tilt the filter downward and

remove. Fig. 24.

2. To install the GREASE filter, align rear

filter tabs with slots in the hood. Push

latch tab in, push filter into position

and release. Make sure the filter is

securely engaged after installation.

NOTE: Prior to use, remove protective

film from the filter frame.

NON-DUCTED HOODS ONLY

1. Lift glass front panel and remove

the grease filter.

2. Install (2) charcoal filters to the

blower, as shown. Fig. 25

3. Re-install grease filter and close the

front panel.

WARRANTY

ONE YEAR LIMITED WARRANTY FOR BEST PRODUCTS

Broan-NuTone LLC (Broan-NuTone) warrants to the original consumer purchaser of Best products that such products

will be free from defects in materials or workmanship for a period of one year from the date of original purchase. THERE

ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which

is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENT BULBS, FUSE, FILTERS, DUCTS, ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES FOR DUCTING.

This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject

to misuse, negligence, accident, improper maintenance or repair (other than by Broan-NuTone), faulty installation or

installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states

do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE

PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH

PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This

warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address stated below or telephone number stated

below, (b) give the model number and part identification and (c) describe the nature of any defect in the product or part.

At the time of requesting warranty service, you must present evidence of the original purchase date.

In USA - Best®, 926 W. State Street, Hartford, WI 53027 (800-558-1711)

In Canada - Best®, 550 Lemire Blvd., Drummondville, QC J2C 7W9 (866-737-7770)

www.BestRangeHoods.com

FIG.25

CHARCOAL FILTERS

FIG.24

GREASE FILTER

Page 14

- 14 -

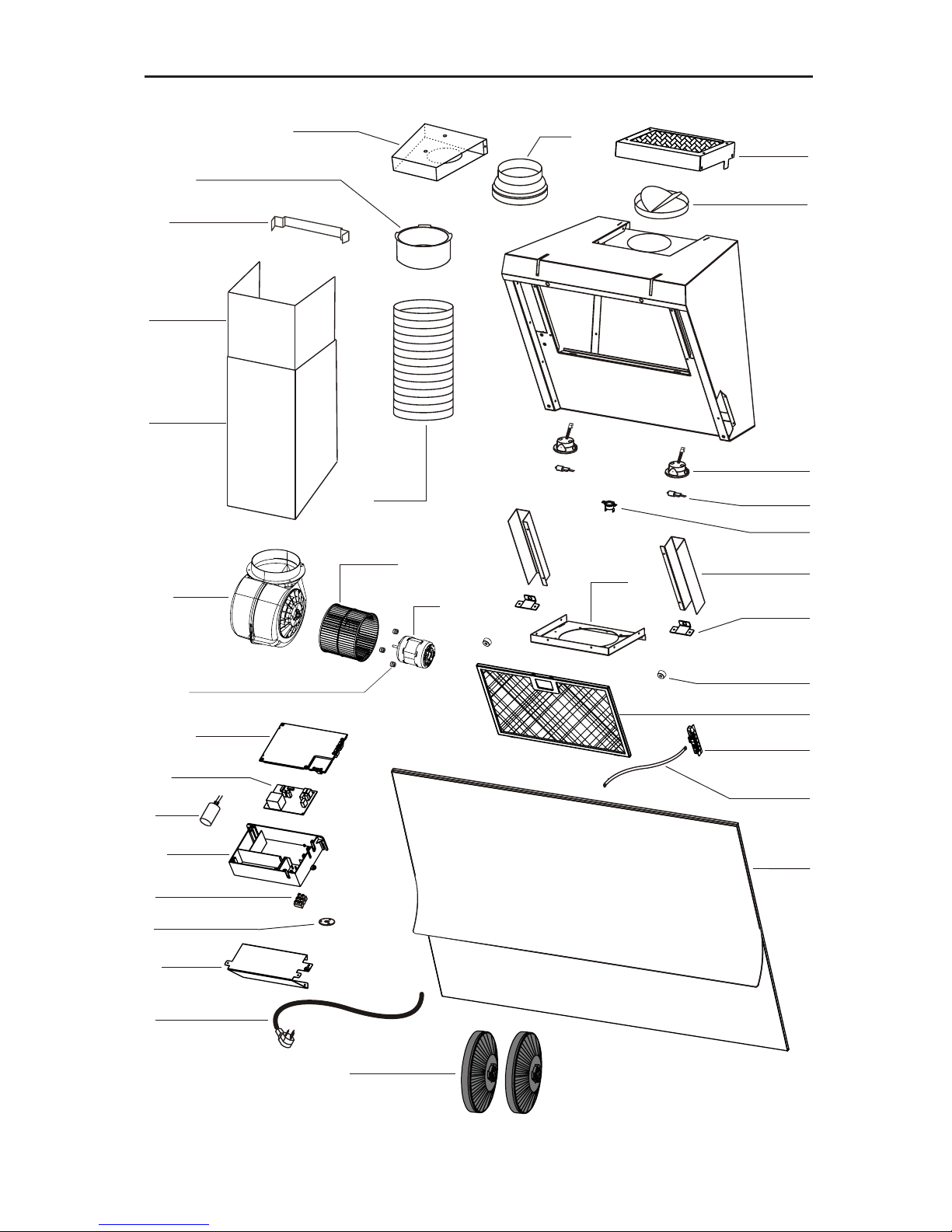

KEY NO.

5

9

14

16

26

37

38

45

48

49

53

58

60

67

76

86

118

119

120

122

147

166

167

195

332

415

472

474

503

AQI

-

-

-

-

PART NUMBER

B03115314

B08087827

B02300233

BE3350518

B02300890

B02300804

B03295595

BW0000021

B02310260

B03295071

B03204177

B03293180

B03295018

B02300249

B02300961

B08093024

B08088378

B03292300

BE3350842

BE3350841

BE3349246

B08093104

BR2300132

B08080852

B03295596

BE3351278

B03115207

B03202454

BE3350520

B02300918

B02011452

B06103891

B06002157

B06145125

B080810939

B03300495

DESCRIPTION

BLADE GUARD

GREASE FILTER

CAPACITOR

ELECTRICAL BOX SUPPORT

LAMP BULB

THERMOSTAT

ELECTRICAL PRINTED CIRCUIT BOARD BOX

BLOWER

MOTOR (CLOCKWISE)

FAN (CLOCKWISE)

RUBBER WASHER

RUBBER WASHER

OUTLET REDUCTION

FEEDER CABLE

WIRES

TOP GLASS

OUTLET FLANGE

OUTLET FLANGE

BOTTOM DUCTEXT.

UPPER DUCT EXT.

TELESCOPIC DUCT UPPER BRACKET

PLENUM

JUNCTION CLAMP

ELECTRICAL PRINTED CIRCUIT BOARD

ELECTRICAL BOX COVER

BRACKET

COVER

FAIRLEAD

BRACKET

HALOGEN LAMP

EXPANDABLE DUCT

SWITCH BOX ASSEMBLY

BLOWER ASSEMBLY (INCLUDES KEY NO. 46,

48, 49, 53)

ELECTRICAL INSTALLATION ASSEMBLY

(INCLUDES KEY NO.14,38,60,67,147,166,167)

FITTING SET

NON-DUCT FILTERS (2)

SERVICE PARTS

Page 15

474

26

332

472

195

(03293180) 53

9

167

14

166

38

415

147

16

503

AQI

67

76

120

119

118

60

37

45

49

48

53 (03204177)

122

86 (03292300)

(08088378) 86

58

5

NON-DUCT

FILTERS

SERVICE PARTS

- 15 -

Page 16

- 16 -

C

99044731C

04308265/1

Page 17

- 17 -

Modèle WM34I

ENGLISH.................................... 2

FRANÇAIS.................................17

ESPAÑOL.................................. 33

Aux États-Unis – BEST Hartford, Wisconsin

Au CANADA – BEST Drummondville, QC, Canada

ENREGISTREZ VOTRE PRODUIT EN LIGNE À L’ADRESSE : www.BestRangeHoods.com/register

Pour en savoir plus, visitez le site www.BestRangeHoods.com

Page 18

- 18 -

VEUILLEZ LIRE ET CONSERVER CES INSTRUCTIONS

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE, D’ÉLECTROCUTION OU DE

BLESSURES PHYSIQUES, RESPECTEZ LES INSTRUCTIONS CI-DESSOUS :

1. Utilisez cet appareil uniquement de la manière prévue par le fabricant. Si vous avez des

questions, contactez le fabricant à l’adresse ou au numéro de téléphone indiqués dans la

garantie.

2. Avant d’effectuer l’entretien ou le nettoyage de l’appareil, mettez-le hors tension sur le

panneau de service et verrouillez ce dernier pour éviter que l’appareil soit mis sous tension

par inadvertance. S’il n’est pas possible de verrouiller le dispositif de déconnexion, apposez

un avertissement bien visible (par exemple une étiquette) sur le panneau de service.

3. L’installation et le raccordement électrique doivent être effectués par du personnel qualifié

conformément à toutes les réglementations et normes en vigueur, y compris celles concernant

les constructions cotées pour leur résistance au feu.

4. Afin d’éviter un refoulement lors de l’utilisation d’équipements à combustible, une quantité d’air

suffisante est nécessaire pour assurer une combustion et un échappement adéquats des gaz

à travers le conduit (la cheminée). Suivez les consignes du fabricant de l’équipement chauffant

et les normes de sécurité publiées, entre autres, par l’Association nationale de protection

contre l’incendie (NFPA) et l’American Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), ainsi que les réglementations locales.

5. Quand vous effectuez une découpe ou un forage dans un mur ou un plafond, veillez à ne pas

endommager des câblages électriques ou d’autres équipements non visibles.

6. Les soufflantes canalisées doivent toujours être dirigées vers l’extérieur.

7. N’utilisez pas cet appareil avec un dispositif de commande de vitesse transistorisée séparé.

8. Pour réduire les risques d’incendie, utilisez uniquement des canalisations en métal.

INSTRUCTIONS DE MISE À LA TERRE

Cet appareil doit être mis à la terre. En cas de court-circuit électrique, la mise à la

terre réduit le risque d’électrocution grâce à un fil permettant au courant électrique de

s’échapper. Cet appareil est doté d’un cordon ayant un fil de terre, ainsi que d’une fiche de

mise à la terre. La fiche doit être branchée dans une prise bien installée et mise à la terre.

AVERTISSEMENT – Une mise à la terre inappropriée peut donner lieu à un risque

d’électrocution.

Consultez un électricien qualifié si vous ne comprenez pas parfaitement les instructions

de mise à la terre ou si vous n’êtes pas certain(e) que l’appareil est mis à la terre comme

il se doit.

N’utilisez pas de rallonge. Si le cordon est trop court, demandez à un électricien d’installer

une prise près de l’appareil.

!

CONÇUE POUR LES CUISINES PRIVÉES UNIQUEMENT

!

Page 19

- 19 -

!

ATTENTION

1. Uniquement pour l’utilisation intérieure.

2. Pour réduire le risque d’incendie et obtenir un échappement d’air adéquat, veillez à bien

canaliser l’air vers l’extérieur. Ne ventilez pas l’air d’échappement vers des espaces confinés,

des plafonds, des combles, des vides sanitaires ou des garages.

3. Soyez prudent(e) quand vous utilisez des agents de nettoyage ou des détergents.

4. Évitez d’utiliser sous la hotte de cuisine des denrées alimentaires produisant des flammes.

5. À utiliser uniquement pour la ventilation générale. N’utilisez pas la hotte pour l’échappement

de matériaux ou de vapeurs comportant un danger ou un risque d’explosion.

6. Pour éviter que le roulement moteur s’endommage et que des hélices deviennent bruyantes

ou déséquilibrées, faites en sorte que le bloc d’alimentation n’entre pas en contact avec un

atomiseur pour cloisons sèches, de la poussière de construction, etc.

7. Le moteur de la hotte est doté d’un rupteur thermique qui éteint automatiquement le moteur

en cas de surchauffe. Le moteur redémarrera après avoir refroidi. Si le moteur s’éteint et se

rallume constamment, faites réparer la hotte.

8. Pour mieux capturer les impuretés de cuisson, la partie inférieure de la hotte doit se trouver

au minimum à 60 cm (20 po) et au maximum à 75 cm (30 po) au-dessus de la surface de

cuisson. Consultez la section « Installation du support de montage » pour connaître les

restrictions de montage.

9. Étant donné la taille et le poids de la hotte, il est conseillé d’avoir recours à deux personnes

pour la monter.

10. Ce produit est doté d’un thermostat qui peut activer la soufflante automatiquement. Pour éviter

les risques de blessure et l’allumage accidentel de la hotte, mettez-la hors tension sur le

panneau de service et verrouillez ce dernier ou fixez-y une étiquette d’avertissement.

11. Pour en savoir plus et connaître les exigences sur le produit, veuillez lire l’étiquette des

spécifications.

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE D’UN FEU DE FRITURE SUR LA TABLE DE CUISSON :

A. Ne laissez jamais les appareils de surface sans surveillance quand ils sont sur un réglage

élevé. Les débordements peuvent provoquer de la fumée et des déversements gras risquant

de prendre feu. Chauffez les huiles lentement sur un réglage bas ou moyen.

B. ALLUMEZ toujours la hotte quand vous cuisinez à une chaleur élevée ou quand vous flambez

des aliments (p. ex. des crêpes Suzette, des cerises jubilé ou du bœuf au poivre flambé).

C. Nettoyez souvent les ventilateurs d’aération. Évitez que de la graisse s’accumule sur le

ventilateur ou le filtre.

D. Utilisez des poêles de la taille appropriée. Utilisez toujours des ustensiles de cuisine adaptés

à la taille de l’élément de surface.

POUR RÉDUIRE LE RISQUE DE BLESSURES PHYSIQUES EN CAS DE FEU DE

FRITURE SUR LA TABLE DE CUISSON, VEUILLEZ PROCÉDER COMME SUIT : *

1. ÉTOUFFEZ LES FLAMMES avec un couvercle hermétique, une plaque à biscuits ou un

plateauen métal, puis éteignez le brûleur. SOYEZ PRUDENT(E) AFIN D’ÉVITER LES

BRÛLURES. Siles flammes ne s’éteignent pas immédiatement, ÉVACUEZ LE LIEU ET

APPELEZ LE SERVICE DES POMPIERS.

2. NE SAISISSEZ JAMAIS UNE POÊLE ENFLAMMÉE, vous risquez de vous brûler.

3. N’UTILISEZ JAMAIS D’EAU ni de torchons ou serviettes mouillé(e)s : cela donnerait lieu à une

violente explosion de vapeur.

4. Utilisez un extincteur UNIQUEMENT si :

A. Vous savez qu’il s’agit d’un extincteur de Classe ABC et savez déjà comment vous en

servir.

B. L’incendie est de petite taille et confiné à l’endroit où il a commencé.

C. Le service des pompiers a été averti.

D. Vous pouvez éteindre l’incendie en ayant une sortie derrière vous.

* Basé sur « Kitchen Fire Safety Tips », publié par la NFPA.

Page 20

- 20 -

FONCTIONNEMENT

COMMANDES (FIG. 1)

Affichage de vitesse :

PU5 : MARCHE/ARRÊT Moteur 4

e

vitesse

PU4 : MARCHE/ARRÊT Moteur 3

e

vitesse

PU3 : MARCHE/ARRÊT Moteur 2

e

vitesse

PU2 : MARCHE/ARRÊT Moteur 1

e

vitesse

PU1 : Ampoules HAUTE/BASSE/ARRÊT

Fonction de la minuterie 10 minutes :

Enfoncer PU2, PU3 ou PU4 pendant deux secondes lorsque le moteur est réglé à la vitesse correspondante, active

la fonction de minuterie de 10 minutes.

La DEL correspondante commence à clignoter pour afficher

cette fonction.

Après dix minutes de marche, le moteur s’éteint. Si vous

changez la vitesse pendant que la minuterie fonctionne, la

fonction N’est PAS désactivée. Pour désactiver cette fonction,

appuyez sur la touche clignotante pendant deux secondes.

FIG. 1

REMARQUE – la fonction de la minuterie 10 minutes peut être activée pour

les vitesses normales seulement (1e, 2e, 3e).

Alarme du filtre :

Après 30 heures de fonctionnement du moteur, l’alarme du filtre à graisse s’active

(toutes les DEL s’allument). L’alarme est activée lorsque le moteur est éteint et

reste affichée pendant 30 secondes. Pour désactiver l’alarme, appuyez sur l’une

des touches pendant 2 secondes durant l’affichage de l’alarme. Après 120 heures

de fonctionnement du moteur, l’alarme du filtre à charbon est activée (toutes les

DEL clignotent). L’alarme est activée lorsque le moteur est éteint et reste affichée

pendant 30 secondes. Pour désactiver l’alarme, appuyez sur l’une des touches

pendant 2 secondes durant l’affichage de l’alarme.

HEAT SENTRY™

La hotte est équipée d’un thermostat HEAT SENTRY™. Ce dispositif active ou accélère

la soufflante s’il détecte une chaleur excessive au-dessus de la surface de cuisson.

1) Si la soufflante est ARRÈTÉE, il l’ALLUME en HAUTE vitesse.

2) Si la soufflante est ALLUMÉE à une vitesse basse, il la fait passer à la vitesse HAUTE.

Quand la température redevient normale, la soufflante revient au réglage d’origine.

AVERTISSEMENT

Le thermostat HEAT SENTRY peut activer la soufflante même si la hotte est

ÉTEINTE. Dans ce cas, il est impossible de DÉSACTIVER la soufflante avec

le commutateur d’arrêt. Si vous devez arrêter la soufflante, faites-le depuis le

panneau électrique principal.

Page 21

- 21 -

AMPOULES HALOGÈNES

Cette hotte de cuisine nécessite deux ampoules

halogènes (Type T4, 120 V, 25 W max., base G9).

AVERTISSEMENT : Désactivez toujours

l’alimentation avant d’effectuer toute

opération sur l’appareil.

Pour changer les ampoules :

1. Ouvrez le couvercle en faisant levier sur les

fentes prévues à cet effet. Fig. 2.

2. Retirez les ampoules en les tirant vers le côté.

(NE LES TOURNEZ PAS).

!

ATTENTION : Il est possible que les ampoules soient chaudes.

3. Remplacez-les par des ampoules halogènes de type T4, 120 V, 25 W max., base G9.

Netouchez pas les ampoules de rechange à mains nues!

FIG. 2

NETTOYAGE ET ENTRETIEN

Pour assurer les performances de l’appareil, entretenez-le de manière appropriée.

Moteur

Le moteur est lubrifié en permanence et aucun graissage n’est nécessaire. Si les roulements du

moteur font un bruit excessif ou inhabituel, remplacez le moteur par une pièce de rechange identique.

Remplacez aussi les hélices.

Filtre à graisse

Le filtre à graisse doit être nettoyé souvent. Vous pouvez utiliser une solution détergente chaude. Le

filtre peut être mis dans le lave-vaisselle.

Nettoyez tous les filtres en métal dans le lave-vaisselle avec un détergent sans phosphate. Si vous

utilisez un détergent phosphaté ou selon le type d’eau, il est possible que le filtre se décolore, mais

cela n’affectera aucunement ses performances. Cette décoloration n’est pas couverte par la garantie.

Consultez la section « INSTALLATION DES FILTRES » pour connaître les instructions de retrait et

d’installation.

Filtre de recirculation non canalisé

Le filtre de recirculation non canalisé doit être changé tous les 6 mois. Si votre style de cuisine engendre

beaucoup de graisse, par exemple si vous faites souvent de la friture ou si vous utilisez un wok,

remplacez-le plus souvent. Consultez la section « INSTALLATION DES FILTRES » pour connaître les

instructions de retrait et d’installation.

Nettoyage de l’acier inoxydable

À FAIRE :

• Nettoyez régulièrement l’acier inoxydable avec

un chiffon ou un torchon enduit d’eau chaude

et de savon doux ou de liquide vaisselle.

• Nettoyez toujours dans le sens des lignes de

polissage d’origine.

• Rincez toujours à l’eau claire (2 ou 3 fois) après

le nettoyage. Essuyez complètement.

• Vous pouvez aussi utiliser un nettoyant spécial

pour acier inoxydable d’électroménagers.

À NE PAS FAIRE :

• N’utilisez pas de laine d’acier inoxydable ni

d’autres racloirs pour éliminer la saleté difficile

à éliminer.

• N’utilisez pas de produits de nettoyage durs

ou abrasifs.

• Ne laissez pas la poussière s’accumuler.

• Ne laissez pas la poussière de plâtre ou

d’autres résidus de construction se poser sur la

hotte. Pendant la construction/les rénovations,

couvrez la hotte afin d’éviter qu’aucune poussière

n’adhère aux surfaces en acier inoxydable.

À éviter quand vous choisissez un détergent :

• Tous les produits de nettoyage contenant de l’eau de Javel attaquent l’acier inoxydable.

• Tous les produits contenant du chlore, du fluor, de l’iode ou du bromure provoquent une détérioration

rapide des surfaces.

• Tous les produits combustibles utilisés pour le nettoyage, tels que l’acétone, l’alcool, l’éther, le benzène

sont extrêmement explosifs et ne doivent jamais être employés à proximité d’une table de cuisson.

Page 22

- 22 -

PRÉPARATION DE LA HOTTE

Déballez la hotte et vérifiez le contenu de l’emballage.

Il doit comprendre :

1 – Hotte

1 – Ensemble de carneau décoratif

1 – Sac de pièces contenant :

2 – Supports de montage

1 – Collet de refoulement

1 – Support de montage du carneau

8 – Vis de montage (à tête cylindrique de 4,8 x 38 mm)

2 – Vis de montage (à tête cylindrique de 3,9 x 9,5 mm)

8 – Ancrages pour cloison sèche

1 – Instructions d’installation

2 SUPPORTS

DE MONTAGE

COLLET DE

REFOULEMENT

SUPPORT

DE MONTAGE DU CARNEAU

8 VIS DE MONTAGE (à tête

cylindrique de 4,8 x 38 mm)

8 ANCRAGES

POUR CLOISON

SÈCHE

2 VIS DE MONTAGE

(à tête cylindrique de

3,9 x 9,5 mm)

CARNEAU

DÉCORATIF

FIG. 3

Page 23

- 23 -

INSTALLATION DE LA

CANALISATION

HOTTES CANALISÉES UNIQUEMENT

ATTENTION : Pour réduire les risques

d’incendie, utilisez uniquement des

canalisations en métal.

1. Décidez à quel endroit passera la

canalisation entre la hotte et l’extérieur.

Fig. 4.

2. Une canalisation droite et courte assurera

une performance optimale de la hotte.

3. Une canalisation longue, coudée et les

transitions réduiront la performance de

la hotte. Utilisez-les le moins possible.

Si la canalisation est plus grosse, il

peut s’avérer nécessaire d’utiliser une

canalisation plus longue.

4. Installez une protection de toit ou de paroi.

Raccordez la canalisation métallique

ronde à la protection et reculez vers

l’emplacement de la hotte. Utilisez du

ruban adhésif en toile pour étanchéiser

les joints entre les sections de la

canalisation.

INSTALLATION ÉLECTRIQUE

HOTTES CANALISÉES et NON CANA-

LISÉES

AVERTISSEMENT :

Le câblage électrique

doit être réalisé par une personne qualifiée,

conformément aux réglementations et

normes en vigueur. Cette hotte de cuisine

doit être mise à la terre de manière adéquate.

Avant d’effectuer le câblage, coupez le

courant à l’origine de l’installation électrique.

1. Prévoyez où la hotte sera placée audessus de la table de cuisson. Consultez

la section « INSTALLATION DU

SUPPORT DE MONTAGE » pour savoir

à quelle hauteur la hotte peut être montée.

2. Installez une boîte à prises murale de

5 x 10 cm (2 po x 4 po) et un prolongateur

à 3 broches de 125 V, 15 A mis à la terre.

3. Montez le centre de la prise murale entre

12,7cm et 20,3 cm

(

5

et

8

po)

au-dessus

du bas de la hotte. Fig. 5.

4. Placez la boîte et le prolongateur dans les

limites indiquées et de manière décentrée

par rapport à la canalisation (afin de

laisser l’espace pour la protection du

cordon et le carneau).

FIG. 4

FIG. 5

CANALISATION RONDE

DE 15,2 cm (6 po)

PROTECTION DE TOIT

COUDE ROND

DE 15,2 cm

(6 po)

PROTECTION

DE PAROI

HOTTE

CARNEAU

DÉCORATIF

50,8 à 76,2 cm (20 à 30 po)

AU-DESSUS DE LA

SURFACE DE CUISSON

(voir la section

« INSTALLATION DES

SUPPORTS DE MONTAGE »

pour connaître les restrictions

de montage)

10,8 cm

(4 ¼ po)

21,6 cm

(8 ½ po)

LIGNE CENTRALE

DE LA HOTTE

12,7cm (5po) à

20,3cm (8po)

Page 24

- 24 -

ÉVENTS DE

PLAFOND

CONNECTEUR

MÉTHODE

DISTANCE DE LA HOTTE À 90 CM (36 po) AU-DESSUS DE LA TABLE DE CUISSON (voir remarque ci-dessous)

50,8 cm

(20 po)

53,3 cm

(21 po)

55,9 cm

(22 po)

58,4 cm

(23 po)

61 cm

(24 po)

63,5 cm

(25 po)

66 cm

(26 po)

68,6 cm

(27 po)

71,1 cm

(28 po)

73,7 cm

(29 po)

76,2 cm

(30 po)

EMPLACEMENT DU SUPPORT DE MONTAGE À 90 CM (36 po) AU-DESSUS DE LA TABLE DE CUISSON

2,4 M

(8PI)

CANALISÉE

87,6 cm

(34 1/2 po)

90,2 cm

(35 1/2 po)

92,7 cm

(36 1/2 po)

95,3 cm

(37 1/2 po)

NON

CANALISÉE

87,6 cm

(34 1/2 po)

90,2 cm

(35 1/2 po)

2,75 M

(9PI)

CANALISÉE

97,8 cm

(38 1/2 po)

100,3 cm

(39 1/2 po)

102,9 cm

(40 1/2 po)

105 cm

(411/2 po)

108 cm

(421/2 po)

110 cm

(431/2 po)

113 cm

(441/2po)

NON

CANALISÉE

90,2 cm

(35 1/2 po)

92,7 cm

(36 1/2 po)

95,3 cm

(37 1/2 po)

97,8 cm

(38 1/2 po)

100,3 cm

(39 1/2 po)

102,9 cm

(40 1/2 po)

105 cm

(411/2 po)

108 cm

(421/2 po)

110 cm

(431/2 po)

113 cm

(441/2po)

14,9 cm

(

4 1/

po)

14,9 cm

(

4 1/

po)

5,5 cm

(

4 1/

po)

INSTALLATION DU

SUPPORT DE MONTAGE

HOTTES CANALISÉES et NON

CANALISÉES

1. Construisez une structure murale en

bois à niveau avec la surface intérieure

des poteaux de cloison. Fig. 6.

Assurez-vous :

a) que la structure est centrée sur

l’emplacement de l’installation.

b) que la structure soit placée à une

hauteur permettant d’y fixer les

supports de montage conformément

aux dimensions indiquées.

2. Une fois que la surface murale est

terminée, fixez chaque support de

montage à la structure avec (2) vis de

montage de 4,8 x 38 mm. Consultez

le tableau ci-dessous pour connaître

l’emplacement du support de montage.

STRUCTURE DERRIÈRE

LE SUPPORT EN BOIS

CROISÉ

SUPPORT EN

BOIS CROISÉ

DERRIÈRE LA

CLOISON SÈCHE

CLOISON

SÈCHE

FIG. 6

ÉVENTS DE

PLAFOND

CONNECTEUR

MÉTHODE

DISTANCE DE LA HOTTE À 90 CM (36 po) AU-DESSUS DE LA TABLE DE CUISSON (voir remarque ci-dessous)

50,8 cm

(20 po)

53,3 cm

(21 po)

55,9 cm

(22 po)

58,4 cm

(23 po)

61 cm

(24 po)

63,5 cm

(25 po)

66 cm

(26 po)

68,6 cm

(27 po)

71,1 cm

(28 po)

73,7 cm

(29 po)

76,2 cm

(30 po)

EMPLACEMENT DU SUPPORT DE MONTAGE À 90 CM (36 po) AU-DESSUS DE LA TABLE DE CUISSON

87,6 cm

(34 1/2 po)

NON

CANALISÉE

90,2 cm

(35 1/2 po)

92,7 cm

(36 1/2 po)

95,3 cm

(37 1/2 po)

97,8 cm

(38 1/2 po)

100,3 cm

(39 1/2 po)

102,9 cm

(40 1/2 po)

105 cm

(411/2 po)

108 cm

(421/2 po)

110 cm

(431/2 po)

113 cm

(441/2po)

Remarque : La distance minimum de la hotte au-dessus de la table de cuisson ne doit pas

être inférieure à 50,8 cm (20 po). Il est fortement recommandé de placer la hotte à 76 cm

(30 po) au maximum au-dessus de la table de cuisson pour qu’elle capture au mieux les

impuretés culinaires. L’installateur et l’utilisateur peuvent s’ils le souhaitent – et si la hauteur

de plafond et la longueur du carneau le permettent – placer la hotte à plus de 75 cm (30 po)

de la table de cuisson.

2,42,75 M

(8 - 9 PI)

INSTALLATION NON CANALISÉES SANS CONDUIT

(SEULEMENT AVEC LA GRILLE)

INSTALLATION AVEC CONDUIT

OU

Page 25

- 25 -

FIG. 8

INSTALLATION DE LA

HOTTE

Remarque : Avant l’installation finale,

retirez la pellicule en plastique de toutes

les surfaces extérieures, des carneaux

décoratifs et des filtres.

INSTALLATION D’UNE HOTTE

CANALISÉE OU NON CANALISÉE

1. Ouvrez le panneau de verre avant

etretirez le ruban d’expédition des

deuxcylindres pneumatiques.

2. Tirez chaque cylindre pour l’allonger.

Fig.7.

3. Alignez l’extrémité du cylindre avec le

support de montage et enfoncez pour

engager. Fig. 8.

4. Installez la hotte dans (2) supports de

montage mural. Vérifiez que la hotte est

parallèle au sol. Fig. 9.

FIG. 7

Cliquez!

FIG. 9

FIG. 10

5. Soulevez le panneau avant en verre et

retirez le filtre à graisse. Fig. 10.

Page 26

- 26 -

6. Mettez la hotte à niveau en utilisant les (2)

vis fournies sur les supports de montage.

Fig. 12.

7. Prenez les repères et installez (2) autres

ancrages pour cloison comme illustré.

Fig. 13.

8. Fixez la hotte de cuisine au mur avec (2)

vis de montage de 4,8 x 38 mm.

9. Resserrez les vis supérieures des

supports de montage jusqu’à ce que la

hotte soit bien serrée contre le mur.

INSTALLATION CANALISÉE –

PASSEZ À L’ÉTAPE 10 DANS LE HAUT DE

LA PAGE 27.

INSTALLATION NON-CANALISÉE –

PASSEZ À L’ÉTAPE 10 DANS LE BAS DE

LA PAGE 27.

FIG. 12

FIG. 13

VIS

4,8 x 38mm

ANCRAGES

POUR

CLOISON

SÈCHE

FIG. 7

LIGNE

CENTRALE

DE LA

HOTTE

VIS

3,9 x 6 mm

ANCRAGES POUR

CLOISON SÈCHE

SUPPORT DE

MONTAGE

INSTALLATION DU SUPPORT

DE MONTAGE DU CARNEAU

HOTTES CANALISÉES ET

NON-CANALISÉE AVEC CARNEAU

1. Centrez le support de montage directement au-dessus de l’emplacement de

la hotte de cuisine.

2. Fixez le support au mur en utilisant

(2) vis de montage de 4,8 x 38 mm

et des ancrages pour cloison sèche.

Fig. 7. Assurez-vous que le support

de montage est bien serré contre le

mur et centré sur la hotte. Fig.13

Page 27

- 27 -

FIG. 14

FIG. 15

FIG. 16

INSTALLATIONS CANALISÉES

UNIQUEMENT

10. Appuyez sur le collet de refoulement

dans le connecteur de la canalisation

de la hotte. Fig. 14.

11. Faites passer la canalisation en métal

de 15 cm (6 po) de diamètre vers

l’emplacement extérieur. Installez une

protection de paroi ou de toit appropriée

avec le collet de refoulement afin que

l’air s’échappe vers l’extérieur.

12. Collez tous les joints de la canalisation

avec de l’adhésif pour canalisation en

aluminium.

13. Branchez le cordon dans la prise

murale. Fig. 15.

14. Installez les carneaux supérieur et

inférieur sur la hotte de cuisine.

- Les évents sont cachés si le plafond

a une hauteur de 2,4 m (8 pi). Fig. 16

- Les évents sont exposés si le plafond

a une hauteur de 2,75 m (9 pi). Fig. 17.

15. Fixez le carneau supérieur au support

de montage du carneau avec 2 vis de

3,9 x 6 mm.

COLLET DE

REFOULEMENT

COLLAR

ROND DE

CONNECTEUR

15 cm (6 po)

CORDON

CORD

FIG. 17

CACHÉS

ÉVENTS

2,4 m (8 pi)

ÉVENTS DE

PLAFOND

VENTS

EXPOSÉS

2,7 m (9 pi)

ÉVENTS DE

PLAFOND

INSTALLATIONS NON CANALISÉES

AVEC CARNEAU ET COLLECTEUR

UNIQUEMENT

Remarque : Achetez le modèle ANKWM34

avec l’ensemble de recirculation non

canalisé.

10. N’installez pas le collet de refoulement

fourni avec la hotte de cuisine.

11. Fixez l’adaptateur 12 à 15 cm (5 po à

6 po) au refoulement de la soufflante

et collez le joint avec de l’adhésif pour

canalisation en aluminium. Fig. 18.

FIG. 18

12,7 cm (5 po) à

15,2 cm (6 po)

ADAPTATEUR

Page 28

- 28 -

12. Centrez le collecteur sur le hotte.

Fig.19.

13. Installez le collecteur du plafond en

utilisant (2) ancrages de cloisons

sèches et (2) vis de 4,8 x 38 mm,

comme indiqué.

14. Enfoncez le connecteur de la

canalisation dans le collecteur jusqu’à

ce qu’il s’enclenche en place. Fig. 20.

15. Fixez la canalisation extensible

de 12,7 cm (5 po) de diamètre au

collecteur et collez le joint avec de

l’adhésif en aluminium.

16. Étirez la canalisation extensible, fixez-la

à l’adaptateur 12,7 à 15,2 cm (5 po à

6 po) et appliquez de l’adhésif sur les

joints des canalisations. Fig. 21.

1 7. Branchez le cordon dans la prise

murale.

18. Placez les carneaux supérieur et

inférieur sur la hotte.

19. Alignez les languettes sur le bord

inférieur du carneau inférieur avec les

fentes sur le haut de la hotte de cuisine.

20. Assurez-vous que les fentes de

recirculation sur le carneau supérieur

sont exposées, comme illustré.

2 1. Relevez le carneau supérieur jusqu’à

ce que les trous de montage s’alignent

avec les trous du collecteur.

22. Installez (2) vis de montage de 3,9 x

9,5 mm pour fixer le carneau supérieur

au collecteur.

FIG. 20

FIG. 19

FIG. 21

14,9 cm

(5 7/8 po)

3,5 cm

(1 3/8 po)

0,9 cm

(3/8 po)

VIS

4,8 x 38 mm

COLLEC-

TEUR

COLLEC-

TEUR

CONNECTEUR

DE

CANALISATION

VIS

3,9 x 6 mm

12,7 cm (5 po)

DE DIAM.

CANALISATION

EXTENSIBLE

FIG.22

FIG.23

RUBAN ADHÉSIF

AILETTES

INSTALLATION NON-CANALISÉES

SANS CARNEAUX ET AVEC LA GRILLE

10. Installer la grille en alignant les ailettes de

la grille avec les rainures dans la partie

supérieure de la hotte. Fig.22.

11. De l’intérieur de la hotte, plier les ailettes

de la grille afin d’assurer la grille à la hotte.

12. Connecter le cordon d’alimentation à

brancher 120 VAC. Fig.23.

13. Enrouler le cordon d’alimentation et le fixer

avec du ruban adhésif à la partie supérieure

de la hotte.

Page 29

- 29 -

INSTALLEZ LES FILTRES

HOTTES CANALISÉES ET NON

CANALISÉES

1. Pour retirer le filtre à GRAISSE,

enfoncez la languette de blocage pour

dégager le filtre de la hotte. Inclinez le

filtre vers le bas et retirez-le. Fig. 24.

2. Pour installer le filtre à GRAISSE,

alignez les languettes arrière du

filtre avec les fentes de la hotte.

Poussez sur la languette de blocage

et enfoncez le filtre à sa position, puis

relâchez. Au terme de l’installation,

assurez-vous que le filtre est bien

engagé.

REMARQUE : Avant l’utilisation, retirez

la pellicule de protection du cadre du filtre.

HOTTES NON CANALISÉES

UNIQUEMENT

1. Soulevez le panneau avant en verre et

retirez le filtre à graisse.

2. Installez (2) filtres à charbon à la

soufflante, comme illustré. Fig. 25.

3. Réinstallez le filtre à graisse et fermez

le panneau avant.

FIG. 25

FILTRES À CHARBON

FIG. 24

FILTRE À GRAISSE

GARANTIE

GARANTIE LIMITÉE DE UN AN POR LES PRODUITS BEST

Broan-NuTone LLC (Broan-NuTone) garantit à l’acheteur consommateur original de produits Best qu’ils sont exempts de vice

de matériaux ou de fabrication pour une période d’un an à compter de la date d’achat original. IL N’Y A PAS D’AUTRES GARANTIES, EXPRIMÉES OU IMPLICITES, INCLUANT MAIS NON LIMITÉES AUX GARANTIES IMPLICITES DE QUALITÉ

MARCHANDE ET DE CONVENANCE DANS UN BUT PARTICULIER.

Durant cette période d’un an, Broan-NuTone, à sa discrétion, réparera ou remplacera gratuitement tout produit ou pièce qui

s’avèrera défectueux et ayant été utilisé normalement et d’une manière non abusive.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS, NI AUX AMPOULES

HALOGÈNES OU INCANDESCENTES, FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE TOIT, CAPUCHONS

MURAUX ET AUTRES ACCESSOIRES POUR CONDUITS. Cette garantie ne couvre pas (a) l’entretien et le service nor-Cette garantie ne couvre pas (a) l’entretien et le service normal ou (b) tout produit ou pièce endommagé à la suite d’un mauvais usage, d’une négligence, d’un accident, d’un entretien

inadéquat ou d’une réparation (autre que par Broan-NuTone), d’une mauvaise installation ou d’une installation non conforme

au mode d’installation recommandé.

La durée de toute garantie implicite est limitée à une période de un an tel que spécifié pour la garantie exprimée. Certains

États ou provinces ne permettent pas de limitation de la durée d’une garantie implicite. Cette condition ne s’applique donc

peut-être pas dans votre cas.

L’ENGAGEMENT DE BROAN-NUTONE À RÉPARER OU À REMPLACER, AU CHOIX DE BROAN-NUTONE, SERA LA

SEULE OBLIGATION EXCLUSIVE SOUS CETTE GARANTIE. BROAN-NUTONE NE SE TIENDRA PAS RESPONSABLE

DES DOMMAGES DIRECTS, INDIRECTS OU SPÉCIAUX AYANT UN LIEN DIRECT OU INDIRECT AVEC L’UTILISATION

OU LA PERFORMANCE DE SES PRODUITS. Certains États ou provinces ne permettent pas l’exclusion ou la limitation de

dommages directs ou indirects. Cette condition ne s’applique donc peut-être pas dans votre cas.

Cette garantie vous donne des droits spécifiques et il se peut que vous ayez d’autres droits qui varient d’une province à l’autre

ou d’un État à l’autre. Cette garantie annule toutes les garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan-NuTone à l’adresse ou numéro de téléphone mentionnée cidessous, (b) donner le numéro de modèle et l’identification de la pièce et (c) décrire la nature de tout défaut dans le produit

ou la pièce. Au moment de la demande de service sous garantie, vous devez présenter une preuve de la date d’achat original

du produit en question.

Au USA - BEST

®

Hartford, Wisconsin 800-558-1711

Au Canada - BEST

®

Drummondville, QC 866-737-7770

www.BestRangeHoods.com

Page 30

- 30 -

N°DE RÈF.

5

9

14

16

26

37

38

45

48

49

53

58

60

67

76

86

118

119

120

122

147

166

167

195

332

415

472

474

503

AQI

-

-

-

-

N° DE PIÈCE

B03115314

B08087827

B02300233

BE3350518

B02300890

B02300804

B03295595

BW0000021

B02310260

B03295071

B03204177

B03293180

B03295018

B02300249

B02300961

B08093024

B08088378

B03292300

BE3350842

BE3350841

BE3349246

B08093104

BR2300132

B08080852

B03295596

BE3351278

B03115207

B03202454

BE3350520

B02300918

B02011452

B06103891

B06002157

B06145125

B080810939

B03300495

DESCRIPTION

GRILLE

FILTRE À GRAISSE

CONDENSATEUR

SUPPORT DE BOÎTIER ÉLECTRIQUE

AMPOULE

THERMOSTAT

CARTE DE CIRCUITS IMPRIMÈS ÉLECTRIQUES

SOUFFLANTE

MOTEUR (SENS HORAIRE)

VENTILATEUR (SENS HORAIRE)

RONDELLE EN CAOUTCHOUC

RONDELLE EN CAOUTCHOUC

RÉDUCTION DE SORTIE

CÂBLE D’ALIMENTATION

FILS

VITRE SUPÉRIEURE

BRIDE DE SORTIE

BRIDE DE SORTIE

EXT. CANALISATION INFÉRIEURE

EXT. CANALISATION SUPÉRIEURE

SUPPORT SUPÉRIEURE DE CANALISATION

TÉLESCOPIQUE

PLENUM

COLLIER DE JONCTION

CARTE DE CIRCUITS IMPRIMÈS ÉLECTRIQUES

COUVERCLE DU BOÎTIER ÉLECTRIQUE

SUPPORT

COUVERCLE

GUIDE-CÂBLE

SUPPORT

AMPOULE HALOGÈNE

CANALISATION EXTENSIBLE

ENSEMBLE DE TABLEAU DE COMMANDE

ENSEMBLE DE VENTILATEUR (INCLUT LA CLÉ

N°. 46, 48, 49, 53)

INSTALLATION ÉLECTRIQUE ENSEMBLE

(INCLUT LA CLÉ N°.14,38,60,67,147,166,167)

JEU D’AJUSTEMENT

NON-CONDUITS FILTRES (2)

PIÈCES DE RECHANGE

Page 31

- 31 -

PIÈCES DE RECHANGE

474

26

332

472

195

(03293180) 53

9

167

14

166

38

415

147

16

503

AQI

67

76

120

119

118

60

37

45

49

48

53 (03204177)

122

86 (03292300)

(08088378) 86

58

5

NON-CONDUITS

FILTRES

Page 32

- 32 -

99044731C

04308265/1

Page 33

- 33 -

Modelo WM34I

ENGLISH.................................... 2

FRANÇAIS.................................17

ESPAÑOL.................................. 33

En EE.UU.: BEST Hartford, Wisconsin

En CANADÁ: BEST Drummondville, QC, Canadá

REGISTRE SU PRODUCTO EN LÍNEA EN: www.BestRangeHoods.com/register

Para obtener información adicional visite www.BestRangeHoods.com

Page 34

- 34 -

LEA Y CONSERVE ESTAS INSTRUCCIONES

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS ELÉCTRICAS O LESIONES

PERSONALES, RESPETE LO SIGUIENTE:

1. Utilice esta unidad sólo de la manera prevista por el fabricante. Si tiene preguntas,

comuníquese con el fabricante a la dirección o el número de teléfono que aparecen en

la garantía.

2. Antes de realizar el mantenimiento de la unidad o de limpiarla, desconecte la energía en

el panel de servicio y bloquéelo para evitar conectar la energía accidentalmente. Cuando

no se pueda bloquear el mecanismo de desconexión, fije firmemente un dispositivo de

advertencia que se destaque, como una etiqueta, en el panel de servicio.

3. Una persona capacitada debe realizar el trabajo de instalación y el cableado eléctrico

conforme a los códigos y estándares correspondientes, incluidos los códigos y estándares

de construcción de resistencia al fuego.

4. Es necesario que haya suficiente aire para que se produzca una combustión adecuada y los

gases de los equipos que consumen combustible se puedan evacuar a través del conducto

de humo (chimenea) para evitar el contratiraje. Siga las directrices y las normas de

seguridad del fabricante del equipo de calefacción como las publicadas por la Asociación

Nacional de Protección contra Incendios (National Fire Protection Association, NFPA) y la

Sociedad Americana de Ingenieros en Calefacción, Refrigeración y Aire Acondicionado

(American Society for Heating, Refrigeration and Air Conditioning Engineers, ASHRAE)

y las autoridades de códigos locales.

5. Cuando realice cortes o perforaciones en paredes o techos, no dañe el cableado eléctrico

ni otros servicios públicos ocultos.

6. Los ventiladores entubados siempre deben ventilarse hacia el exterior.

7. No utilice esta unidad con un dispositivo de control de velocidad de estado sólido

independiente.

8. Para reducir el riesgo de incendios, sólo utilice entubados de metal.

INSTRUCCIONES DE CONEXIÓN A TIERRA

Este artefacto se debe conectar a tierra. En caso de un cortocircuito eléctrico, la conexión

a tierra reduce el riesgo de descarga eléctrica al proporcionar un cable de escape para

la corriente eléctrica. Este artefacto está equipado con un cable que tiene un alambre de

conexión a tierra con una clavija de tierra. La clavija debe conectarse en un tomacorriente

que esté instalado y conectado a tierra correctamente.

ADVERTENCIA: la conexión a tierra incorrecta puede crear riesgo de descarga eléctrica.

Consulte a un electricista capacitado si no comprende por completo las instrucciones de

conexión a tierra o si tiene dudas sobre si el artefacto está conectado a tierra correctamente.

No utilice un alargador. Si el cable de alimentación eléctrica es demasiado corto, pida a un

electricista capacitado que instale un tomacorriente cerca del artefacto.

!

PARA COCINAS DOMÉSTICAS SOLAMENTE

!

Page 35

- 35 -

!

PRECAUCIÓN

1. Sólo para uso en interiores.

2. Para reducir el riesgo de incendios y eliminar el aire correctamente, asegúrese de dirigir

el aire hacia afuera. No ventile el aire de escape en espacios dentro de paredes o techos

ni en áticos, sótanos o garajes.

3. Tenga cuidado cuando use agentes de limpieza o detergentes.

4. Evite usar productos alimenticios que produzcan llamas debajo de la campana para cocina.

5. Sólo para uso de ventilación general. No utilice para purgar materiales y vapores

explosivos o peligrosos.

6. Para evitar causar daños en el cojinete del motor y que los propulsores queden

desbalanceados o ruidosos, mantenga el polvillo de paredes de yeso, polvo de

construcción, etc. alejados de la unidad motriz.

7. El motor de la campana tiene relés térmicos que se apagan automáticamente si el motor

se sobrecalienta. El motor se reiniciará cuando se enfríe. Si el motor se sigue apagando

y reiniciando, realice el mantenimiento de la campana.

8. Para capturar mejor las impurezas de la cocina, la parte inferior de la campana debe

tener un espacio de como mínimo 20" y como máximo 30" por encima de la superficie

de cocción. Consulte la sección “Instalación del Soporte de Montaje” para obtener las

restricciones de montaje.

9. Se recomienda que haya dos instaladores debido al gran tamaño y peso de esta campana.

10. Este producto está equipado con un termostato que puede iniciar el soplador

automáticamente. Para reducir el riesgo de lesiones y evitar conectar la energía

accidentalmente, desconecte la energía en el panel de servicio y bloquéelo o etiquételo.

11. Lea la etiqueta de especificación en el producto para obtener más información y requisitos.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS POR GRASA EN LA COCINA:

A. Nunca deje las unidades de superficie sin cuidado en graduaciones altas. Los derrames

por ebullición generan humos y derrames grasosos que pueden encenderse. Caliente

aceites lentamente en una graduación baja o media.

B. Siempre ENCIENDA la campana cuando cocine con mucho calor o cuando flambea

alimentos (por ejemplo crepes Suzette, cerezas jubileo, filete flambeado a la pimienta).

C. Limpie los ventiladores con frecuencia. No se debe dejar acumular grasa en el ventilador

ni en el filtro.

D. Utilice una cacerola del tamaño adecuado. Siempre utilice utensilios de cocina apropiados

para el tamaño del elemento de la superficie.

PARA REDUCIR EL RIESGO DE LESIONES PERSONALES EN CASO DE UN INCENDIO

POR GRASA EN LA COCINA, RESPETE LO SIGUIENTE: *

1. SOFOQUE LAS LLAMAS con una tapa bien ajustada, una bandeja para hornear o una

bandeja metálica y luego apague el quemador. TENGA LA PRECAUCIÓN DE EVITAR

QUEMADURAS. Si las llamas no se apagan inmediatamente, SALGA Y LLAME A LOS

BOMBEROS.

2. NUNCA TOQUE UNA CACEROLA EN LLAMAS: puede quemarse.

3. NO USE AGUA, incluso toallas o repasadores húmedos. Se producirá una explosión de

vapor violenta.

4. Utilice un extintor de incendios SÓLO si:

A. Sabe que tiene un extintor de incendios Clase ABC y ya sabe utilizarlo.

B. El fuego es pequeño y está contenido en el área donde comenzó.

C. Se está llamando a los bomberos.

D. Puede combatir el incendio de espaldas hacia una salida.

* Según los “Consejos de Seguridad para Incendios en la Cocina” publicado por la NFPA.

Page 36

- 36 -

FUNCIONAMIENTO

CONTROLES (FIG. 1)

Visualización de velocidad:

PU5: ENCENDIDO/APAGADO Motor de 4

ª

velocidad

PU4: ENCENDIDO/APAGADO Motor de 3

ª

velocidad

PU3: ENCENDIDO/APAGADO Motor de 2

ª

velocidad

PU2: ENCENDIDO/APAGADO Motor de 1

ª

velocidad

PU1: Luces de ALTA/BAJA/APAGADO

Función de temporizador de 10minutos:

Si presiona PU2, PU3 o PU4 durante 2segundos hasta que el

motor llegue a la velocidad que corresponde, activa la función

de temporizador de 10 minutos.

El LED correspondiente comienza a parpadear para visualizar

esta función.

Luego de diez minutos de funcionamiento, el motor se

apaga. Si cambia la velocidad durante el funcionamiento del

temporizador, la función NO se desactiva. Para desactivar la

función, presione la tecla parpadeante durante dossegundos.

FIG. 1

NOTA: la función del temporizador de 10minutos se puede activar para

velocidades normales solamente (1ª, 2ª y 3ª).

Alarma del filtro:

Luego de 30horas de funcionamiento del motor, la alarma del filtro de grasas se

activa (todos los LED se encienden). La alarma se activa cuando el motor se apaga

y se puede visualizar durante 30segundos. Para desactivar la alarma, presione una

de las teclas durante 2segundos durante la visualización de la alarma. Luego de

120horas de funcionamiento del motor, la alarma del filtro de carbón se activa (todos

los LED parpadean). La alarma se activa cuando el motor se apaga y se puede

visualizar durante 30segundos. Para desactivar la alarma, presione una de las teclas

durante 2segundos durante la visualización de la alarma.

HEAT SENTRY™

La campana está equipada con un termostato HEAT SENTRY™. Este termostato es un

dispositivo que encenderá o acelerará el soplador si detecta calor excesivo sobre

la superficie de cocción.

1) Si el soplador está APAGADO: ENCIENDE el soplador en velocidad ALTA.

2) Si el soplador está ENCENDIDO en un ajuste de velocidad bajo: cambia el soplador

a velocidad ALTA.

Cuando el nivel de temperatura descienda a normal, el soplador regresará a su ajuste

original.

ADVERTENCIA

El termostato HEAT SENTRY puede iniciar el soplador aún si la campana está

APAGADA. Cuando sucede esto, es imposible APAGAR el soplador con su

interruptor. Si debe detener el soplador, hágalo desde el panel eléctrico principal.

Page 37

- 37 -

FOCOS HALÓGENOS

Esta campana para cocina necesita dos

focos halógenos (Tipo T4, de 120Voltios,

25Vatios Máximos, G9 Base).

ADVERTENCIA: siempre desconecte

el suministro eléctrico antes de realizar

cualquier operación en el artefacto.

Para cambiar los focos:

1. Abra la tapa haciendo palanca desde las

ranuras correspondientes. Fig. 2.

2. Retire los focos tirando de los costados. (NO LOS HAGA GIRAR).

!

PRECAUCIÓN: los focos pueden estar calientes.

3. Reemplácelos por focos halógenos del Tipo T4, de 120Voltios, 25 Vatios Máximos,

G9Base. No toque los focos de repuesto con las manos sin protección.

FIG. 2

LIMPIEZA Y MANTENIMIENTO

El mantenimiento adecuado de la campana para cocina garantizará el rendimiento correcto de

la unidad.

Motor

El motor está constantemente lubricado y nunca necesita engrase. Si los cojinetes del motor

hacen un ruido excesivo o inusual, reemplace el motor con el mismo motor de servicio. También

se debe reemplazar el propulsor.

Filtro de Grasas

Se debe limpiar el filtro de grasas regularmente. Utilice una solución de detergente tibia. Elfiltro

de grasas es apto para lavavajillas.

Limpie los filtros que sean completamente de metal del lavavajillas con un detergente sin fosfato.

Es posible que se produzca una decoloración del filtro si se usan detergentes con fosfato o como

resultado del estado del agua local, pero esto no afectará el rendimiento del filtro. Esta decoloración

no está cubierta por la garantía. Consulte la sección “INSTALACIÓN DE FILTROS” para obtener

instrucciones de extracción e instalación.

Filtro de Recirculación Sin Entubar

El filtro de recirculación sin entubar se debe cambiar cada 6meses. Reemplácelo más seguido

si su estilo de cocina produce grasa adicional, como frituras y cocina en wok. Consulte la sección

“INSTALACIÓN DE FILTROS” para obtener instrucciones de extracción e instalación.

Limpieza del Acero Inoxidable

LO QUE SE DEBE HACER:

• Limpiar regularmente con un paño limpio o

un trapo empapado con agua tibia y jabón

suave o detergente líquido.

• Limpiar siempre en la dirección de las líneas

pulidas originales.

• Siempre enjuagar bien con agua limpia (2ó

3veces) después de la limpieza. Secar con

un trapo por completo.

• También se puede utilizar un limpiador de

acero inoxidable doméstico.

LO QUE NO SE DEBE HACER:

•

Usar esponjas de acero o acero inoxidable

o raspadores para eliminar la suciedad

persistente.

• Usar limpiadores agresivos o abrasivos.

• Permitir que se acumule suciedad.

• Dejar que el polvo de yeso u otro residuo de

construcción alcance la campana. Durante

una construcción/renovación, cubra la

campana para cocina para asegurarse de

que el polvo no se pegue en la superficie

de acero inoxidable.

Cuando elija un detergente, evite lo siguiente:

• Todos los limpiadores que contienen lejía, ya que atacarán el acero inoxidable.

• Todos los productos que contienen: cloruro, fluoruro, yoduro o bromuro, porque deteriorarán

las superficies rápidamente.

• Todos los productos combustibles usados para limpiar, como acetona, alcohol, éter, benzol, etc.,

puesto que son altamente explosivos y nunca se deben usar cerca de la cocina.

Page 38

- 38 -

PREPARACIÓN DE LA CAMPANA

Desembale la campana y revise el contenido.

Debe recibir:

1 - Campana

1 - Conjunto de Conducto de Humo Decorativo

1 - Bolsa de Piezas que contiene:

2 - Soportes de Montaje

1 - Collarín de Descarga

1 - Soporte de Montaje del Conducto de Humo

8 - Tornillos de Montaje (Cabeza Troncocónica 4.8 x 38mm)

2 - Tornillos de Montaje (Cabeza Troncocónica 3.9 x 9.5mm)

8 - Anclajes para Paredes de Yeso

1 - Instrucciones de Instalación

2 SOPORTES

DE MONTAJE

COLLARÍN DE

DESCARGA

SOPORTE DE MONTAJE

DEL CONDUCTO DE HUMO

8 TORNILLOS DE MONTAJE

(Cabeza Troncocónica 4.8 x 38mm)

8 ANCLAJES

PARA PAREDES

DE YESO

2 TORNILLOS DE

MONTAJE (Cabeza

Troncocónica 3.9 x

9.5mm)

CONDUCTO DE

HUMO DECORATIVO

FIG. 3

Page 39

- 39 -

INSTALACIÓN DE LOS

ENTUBADOS

SÓLO CAMPANAS ENTUBADAS

PRECAUCIÓN: Para reducir el riesgo de

incendios, sólo utilice entubados de metal.

1. Decida en qué lugar entre la campana y el

exterior colocará los entubados. Fig. 4.

2. Un tendido de conducto corto y recto

permitirá que la campana funcione con

la mayor eficiencia.

3. Los tendidos de conductos largos, los

codos y las transiciones reducirán el

rendimiento de la campana. Utilice

la menor cantidad posible de estos.

Esposible que se necesiten entubados

para mejorar el rendimiento con tendidos

de conductos más largos.

4. Instale un sombrerete para techo o pared.

Conecte un entubado de metal redondo

en el sombrerete y trabaje hacia atrás,

hacia la ubicación de la campana. Utilice

cinta adhesiva para sellar las juntas entre

las secciones del entubado.

INSTALACIÓN DEL

CABLEADO ELÉCTRICO

CAMPANAS ENTUBADAS y SIN ENTUBAR

ADVERTENCIA: una persona

capacitada debe realizar el trabajo

de instalación del cableado eléctrico

conforme a los códigos y estándares

correspondientes. Esta campana para

cocina debe estar correctamente

conectada a tierra. Desconecte la energía

eléctrica en la entrada de servicio antes

de instalar el cableado.

1. Planifique dónde ubicará la campana

encima de la cocina. Consulte la sección

“INSTALACIÓN DEL SOPORTE DE

MONTAJE” para obtener las opciones de

altura para el montaje de la campana.

2. Instale una caja de salida estándar para

pared de 2" x 4" y un receptáculo conectado

a tierra de 3patas, 125Voltios, 15Amperes.

3. Instale el centro de la caja de salida para

pared de 5" a 8" por encima de la par

te

inferior de la campana. Fig. 5.

4. Coloque la caja y el receptáculo dentro de

los límites que se muestran, descentrados

del entubado (para dejar margen para el

enchufe del cable de alimentación y el

conducto de humo).

FIG. 4

FIG. 5

CONDUCTO

CIRCULAR DE 6"

SOMBRERETE PARA EL TECHO

CODO

CIRCULAR

DE 6"

SOMBRERETE

PARA LA

PARED

CAMPANA

CONDUCTO DE

HUMO DECORATIVO

SUPERFICIE DE COCINA

DE 20" A 30" (Consulte la

sección “INSTALACIÓN DEL

SOPORTE DE MONTAJE”

para obtener las restricciones

de montaje)

4 ¼"

8 ½"

LÍNEA CENTRAL

DE LA CAMPANA

5 a 8"

Page 40

- 40 -

INSTALACIÓN DEL

SOPORTE DE MONTAJE

CAMPANAS ENTUBADAS y SIN

ENTUBAR

1. Construya un marco de madera para

la pared que esté nivelado con la

superficie interior de los puntales de

la pared. Fig. 6.

Asegúrese de lo siguiente:

a) Que el marco esté centrado sobre

el lugar de instalación.

b) Que la altura del marco permitirá

fijar los soportes de montaje al

marco dentro de las dimensiones

que se muestran.

2. Una vez terminada la superficie de la

pared, fije cada soporte de montaje al

marco con (2) tornillos de montaje de

4.8x38mm. Consulte la siguiente tabla

para obtener la ubicación del soporte