Page 1

Model U102E

ENGLISH.....................................2

FRANÇAIS..................................16

ESPAÑOL..................................30

BEST BY BROAN P.O. Box 140, Hartford, WI 53027

REGISTER YOUR PRODUCT ONLINE AT www.bestbybroan.com/register

99043487B

Page 2

READ AND SAVE THESE INSTRUCTIONS

!

INTENDED FOR DOMESTIC COOKING ONLY

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions,

contact the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock service

panel to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction codes

and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s guidelines and safety standards such as those published by the

National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other

hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes

Suzette, Cherries Jubilee, Peppercorn Beef Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or

filter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface

element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam explosion will

result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know how to operate

it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

- 2 -

Page 3

!

CAUTION

1. To reduce risk of fire and to properly exhaust air, be sure to duct air outside. Do not vent

exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

2. Take care when using cleaning agents or detergents.

3. Avoid using food products that produce flames under the Range Hood.

4. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

5. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall

spray, construction dust, etc. off power unit.

6. Your hood motor has a thermal overload which will automatically shut off the motor if it

becomes overheated. The motor will restart when it cools down. If the motor continues

to shut off and restart, have the hood serviced.

7. For best capture of cooking impurities, the bottom of the hood should be a minimum of

22-1/2" above the cooking surface.

8. Three installers are recommended because of the large size and weight of this hood.

9. This product is equipped with a thermostat which may start blower automatically. To

reduce the risk of injury and to prevent power from being switched on accidentally,

switch power off at service panel and lock or tag service panel.

10. To reduce the risk of fire and electric shock, the Best U102E Series hood must be

installed with blower models EB6, EB9, EB12, EB15,

Other blowers cannot be substituted. (blowers sold separately).

11. Use with approved cord-connection kit only.

12. Please read specification label on product for further information and requirements.

13. Automatically operated device. To reduce the risk of injury, disconnect power before

servicing.

ILB3, ILB6, ILB9 or ILB11 only.

- 3 -

Page 4

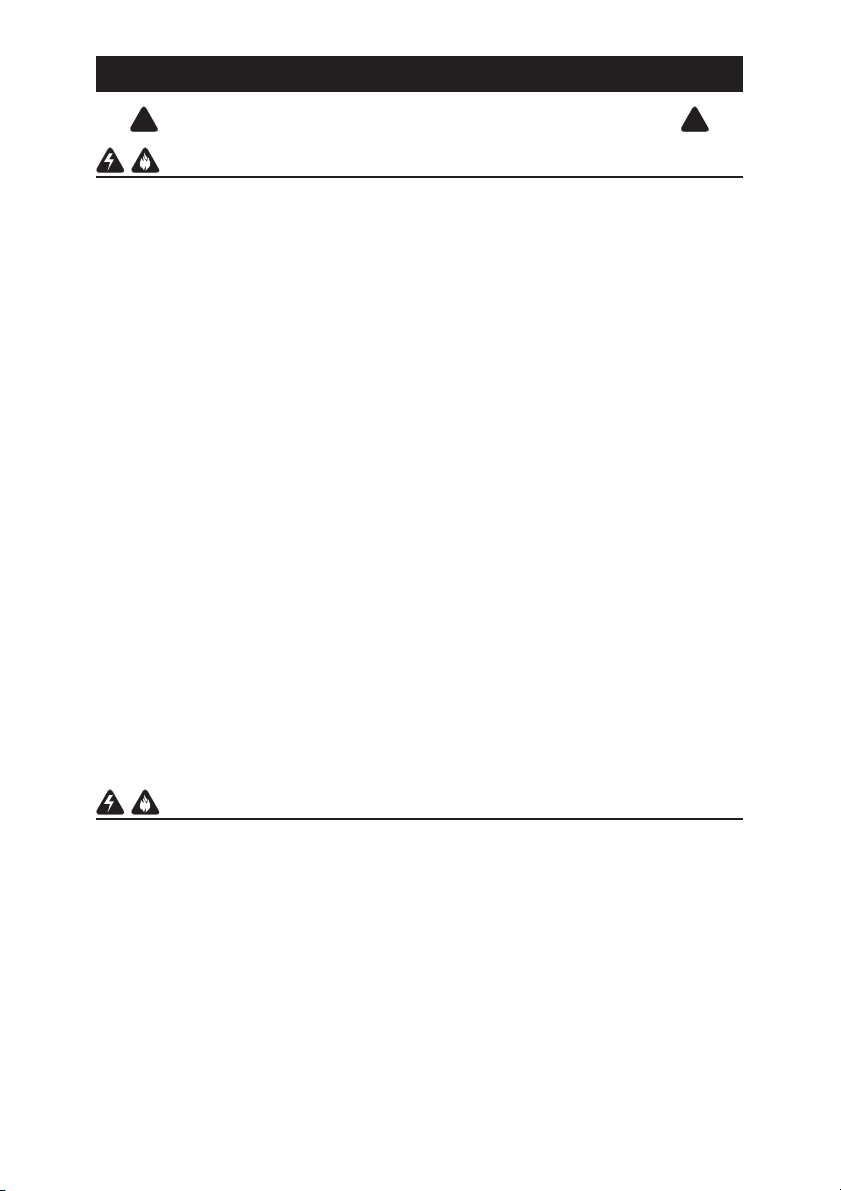

OPERATION

For quiet operation and best capture of smoke, steam and other cooking

impurities, always operate this unit with the slide-out visor fully open.

Controls

The hood is operated using the (5) push buttons located on the slide-out visor.

The Light Off/On switch turns the lights on to low intensity and turns them off.

The Light Dimmer switch alternates light intensity from low to high.

The Blower Off/Speed switch turns the blower off and changes blower speed to four

different speed settings: high, medium-high, medium-low and low speed.

Depress and hold the button for 2 seconds to turn the blower off.

The Blower On/Speed switch turns the blower on to four different speed settings:

Low, medium-low, medium-high and high speed. The visor must be open for the

blower to be operational.

The LED Display:

Indicates blower speed selection from 1 (lowspeed) to 4 (high speed).

Flashes the blower speed when the 10-minutes delay off has been activated.

After 30 hours of operation, the center segment of the display blinks and remains

lit, indicating that filters need to be cleaned.

The Time Delay switch activates a delay off feature. When pushed, the blower will

continue to operate at the current speed setting for 10-minutes before automatically

turning itself off.

The Filter Alarm Reset switch is used to reset the 30-hour filter timer. After filters

are cleaned or replaced, press this switch once to reset the filter clean alarm.

HEAT SENTRY™

Your hood is equipped with a HEAT SENTRY™ thermostat. This thermostat is a

device that will turn on or speed up the blower if it senses excessive heat above

the cooking surface.

1) If blower is OFF - it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting - it turns blower up to HIGH speed.

When the temperature level drops to normal, the blower will return to its original

setting.

WARNING : The HEAT SENTRY thermostat can start the blower even if

the hood is turned OFF. When this occurs, it is impossible to turn the blower

OFF with its switch. If you must stop the blower, do it from the main electrical

panel.

- 4 -

Page 5

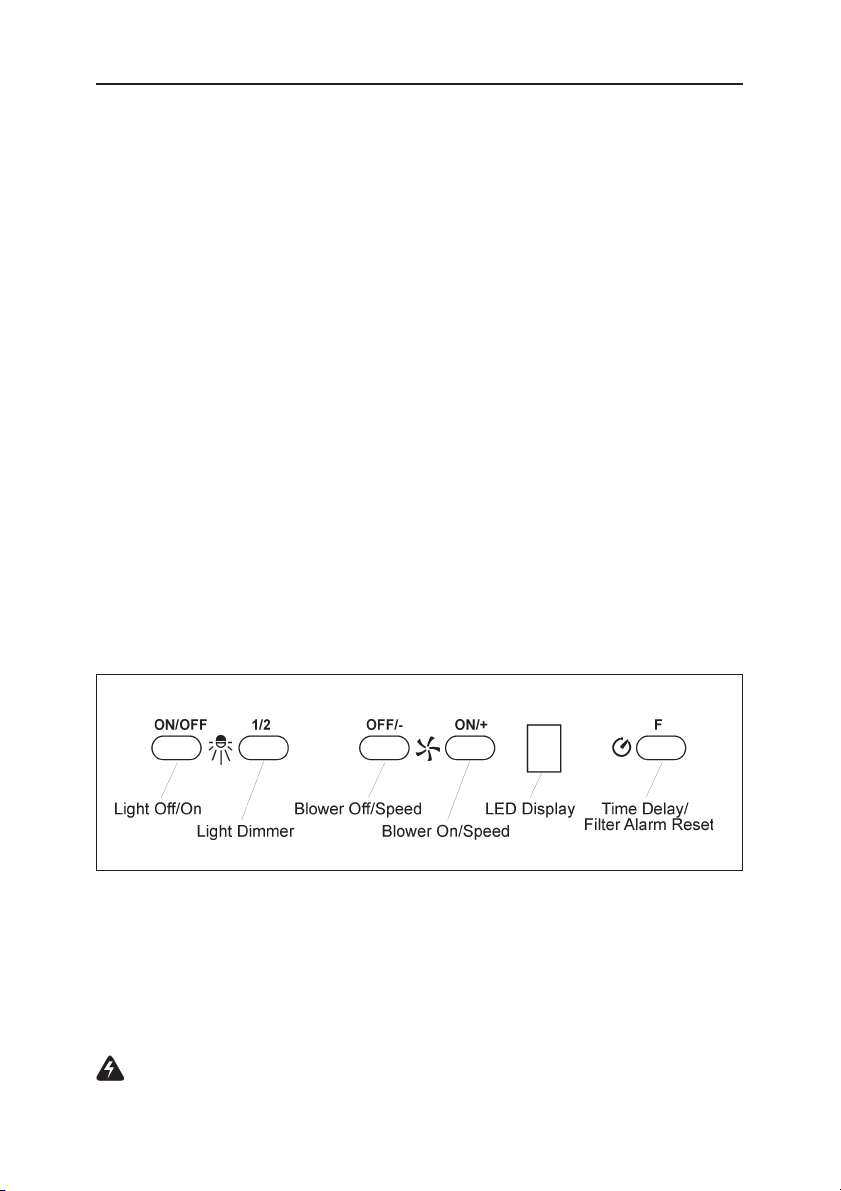

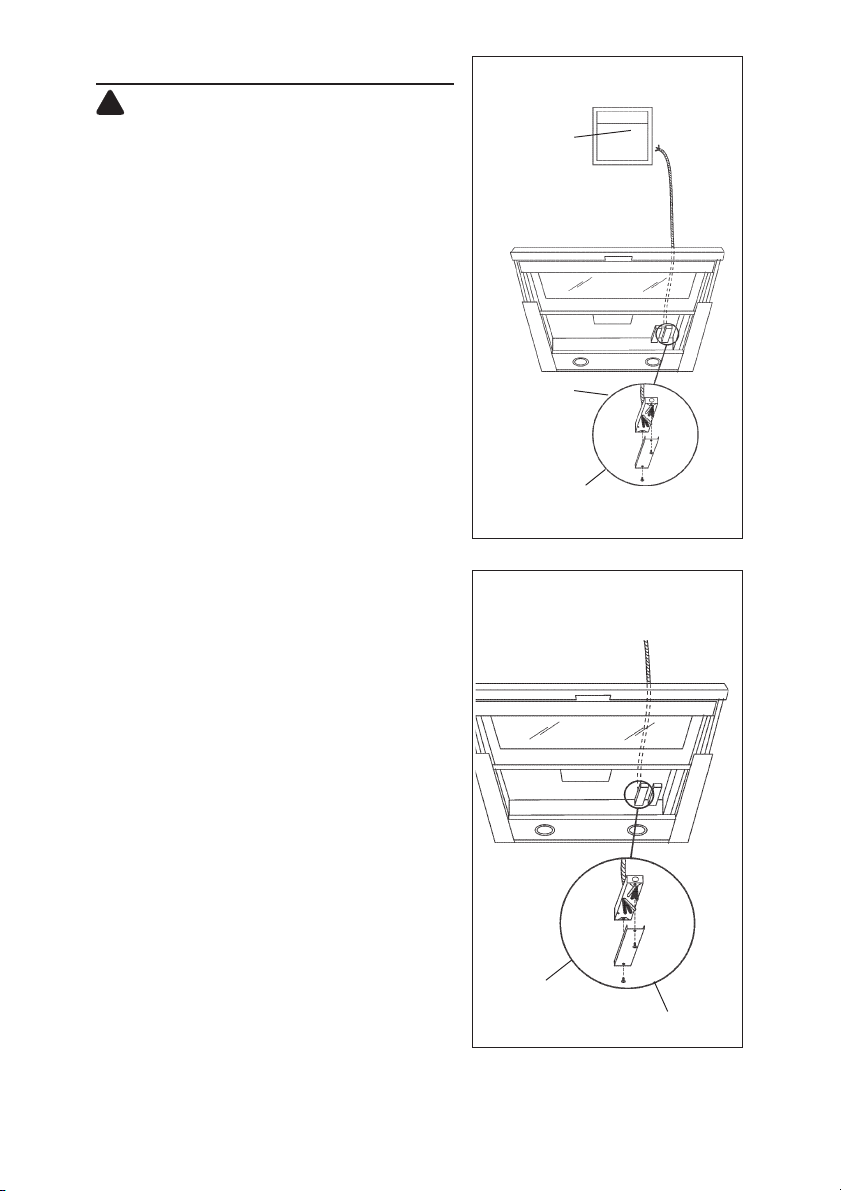

HALOGEN BULBS

This range hood requires two halogen bulbs (Type

T3, 12Volt, 20Watt Max, G-4 Base).

WARNING: Always switch off the

electricity supply before carrying out any

operations on the appliance.

To change bulbs:

1. Open the cover by prying from the proper slots.

- DO NOT ROTATE.

!

CAUTION: Bulb may be hot.

2. Replace with a Type T3, 12Volt, 20Watt Max,

G-4 Base bulb. Do not touch replacement bulb

with bare hands!

DO NOT use bulbs greater than 20 Watts.

Bulbs greater than 20 Watts will cause the

fuse to open.

FUSE REPLACEMENT

IF LIGHTS FAIL TO OPERATE, DISCONNECT

POWER AT THE SERVICE ENTRANCE. CHECK

THE FUSE AND REPLACE IF NECESSARY.

1.Remove the grease filter and pull the visor open.

2.Locate the fuse holder on the top right hand side

of the light housing.

3.Unscrew the fuse holder cap and remove the

fuse.

4.Replace the fuse with the same size and

amperage (5 x 20mm, 4 amp, 125 volt).

DO NOT use fuses greater than 4 Amps. Fuses

greater than 4 Amps may damage the

transformer.

5.Reinstall the fuse cap and grease filter.

6.Reconnect power at the service entrance.

- 5 -

Page 6

MAINTENANCE

Proper maintenance of the Range Hood will assure proper performance of the

unit.

Before Servicing Or Cleaning Unit, Switch Power Off At Service Panel And Lock

Service Disconnecting Means To Prevent Power From Being Switched On

Accidentally.

When The Service Disconnecting Means Cannot Be Locked, Securely Fasten

A Prominent Warning Device, Such As A Tag, To The Service Panel.

Grease Filters

The grease filters should be cleaned when the LED Display flashes when

the blower is off (i.e. 30 hours of operation). Use a warm detergent

solution to clean filters. Filters are dishwasher safe. See page 13 for filter

removal and installation instructions.

Hood Cleaning

Stainless steel is one of the easiest materials to keep clean. Occasional care will

help preserve its fine appearance.

Cleaning tips:

1. Hot water with soap or detergent is all that is usually needed.

2. Follow all cleaning by rinsing with clear water. Wipe dry with a clean, soft cloth to

avoid water marks.

3. For discolorations or deposits that persist, use a non-scratching household cleanser

or stainless steel polishing powder with a little water and a soft cloth.

4. For stubborn cases, use a plastic scouring pad or soft bristle brush together with

cleanser and water. Rub lightly in direction of polishing lines or "grain" of the

stainless finish. Avoid using too much pressure which may mar the surface.

5. DO NOT allow deposits to remain for long periods of time.

6. DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere

to the surface causing rust.

7. DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to

remain in contact with stainless steel for extended periods. Many of these compounds contain chemicals which may be harmful. Rinse with water after exposure and wipe dry with a clean cloth.

Painted surfaces should be cleaned with warm water and mild detergent only.

- 6 -

Page 7

PREPARE THE HOOD

Unpack hood and check contents.

You should receive:

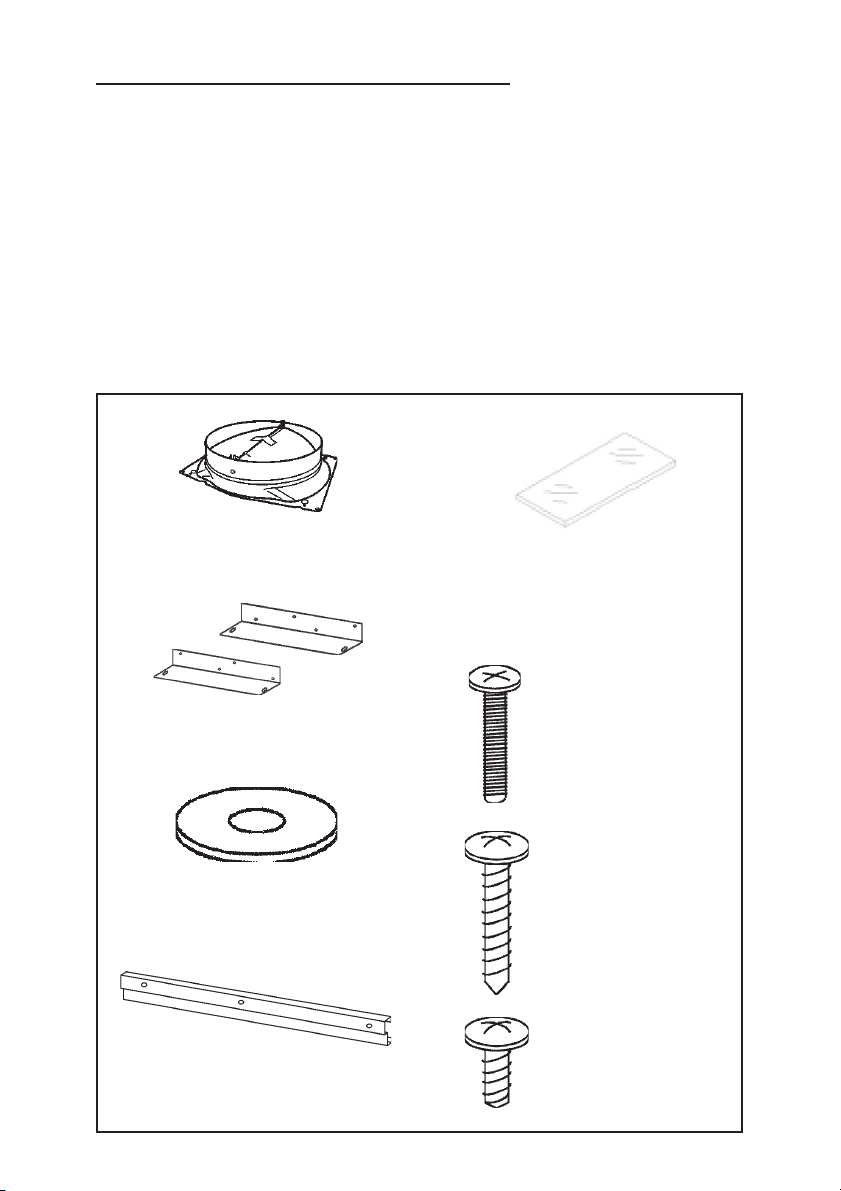

1 - Hood

1 - 8” Damper / Duct Connector

1 - Glass Visor

1 - Decorative Spacer

1 - Parts Bag containing:

2 - Mounting Brackets

4 - Machine Screws (M4 x 30mm Pan Head)

7 - Mounting Screws (3.9 x 9.5mm Pan Head)

4 - Flat Washers (4 mm diameter)

8 - Screws (4.2 x 15mm Pan Head)

1 - Installation Instructions

8” DAMPER/DUCT CONNECTOR

GLASS VISOR

2 MOUNTING BRACKETS

4 FLAT WASHERS

DECORATIVE SPACER

- 7 -

4 MACHINE SCREWS

(M4 x 30mm PAN HEAD)

8 MOUNTING SCREWS

(4.2 x 15mm PAN HEAD)

7 MOUNTING SCREWS

(3.9 x 9.5mm PAN HEAD)

Page 8

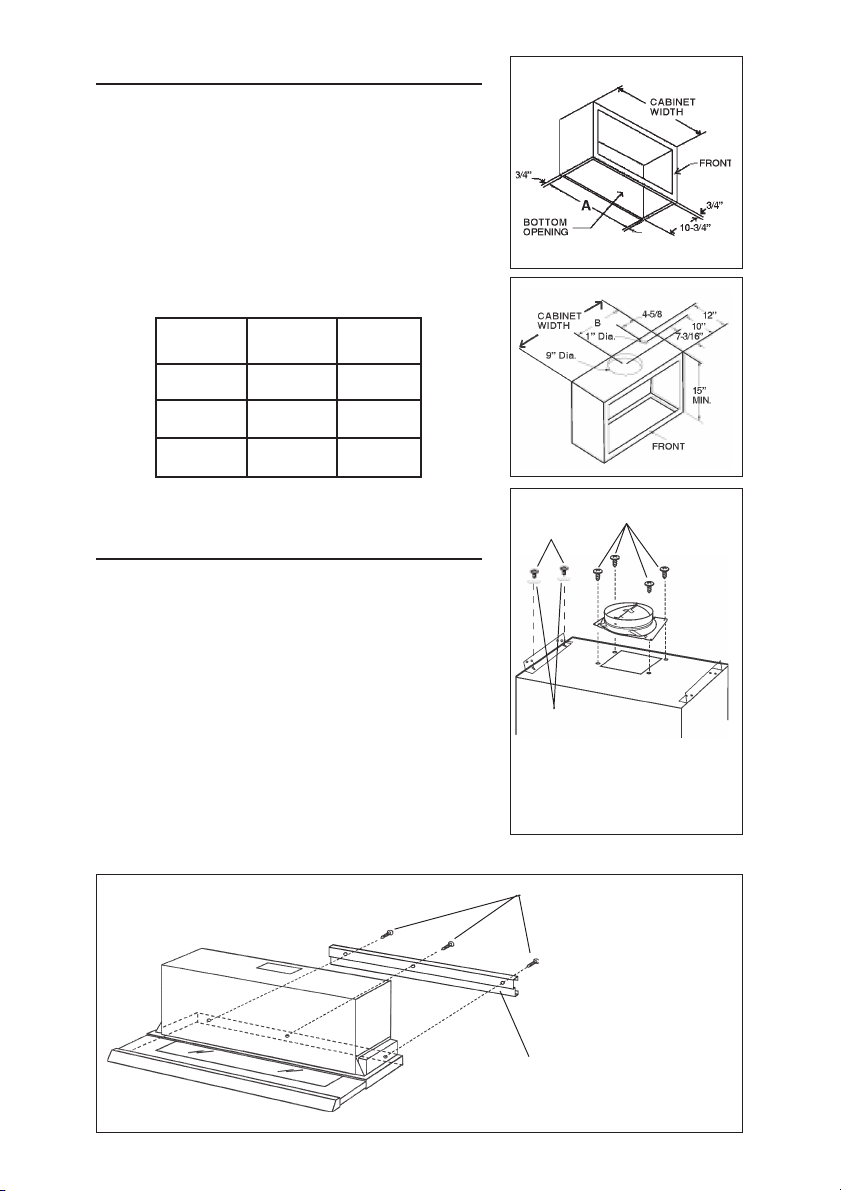

PREPARE WALL CABINET

1. Prior to wall cabinet installation, remove doors

and door mounting hardware.

2. Cut an opening into the bottom panel to the

dimensions shown.

3. Cut out openings for the duct and electrical

wiring.

4. Install cabinet on the wall and secure per cabinet

manufacturer’s recommendations. The cabinet

must be securely fastened to studs and framing

behind the drywall prior to hood installation.

Cabinet-

Widht

30”

36”

42”

“A”

28-1/2”

34-1/2”

40-1/2”

“B”

15”

18”

21”

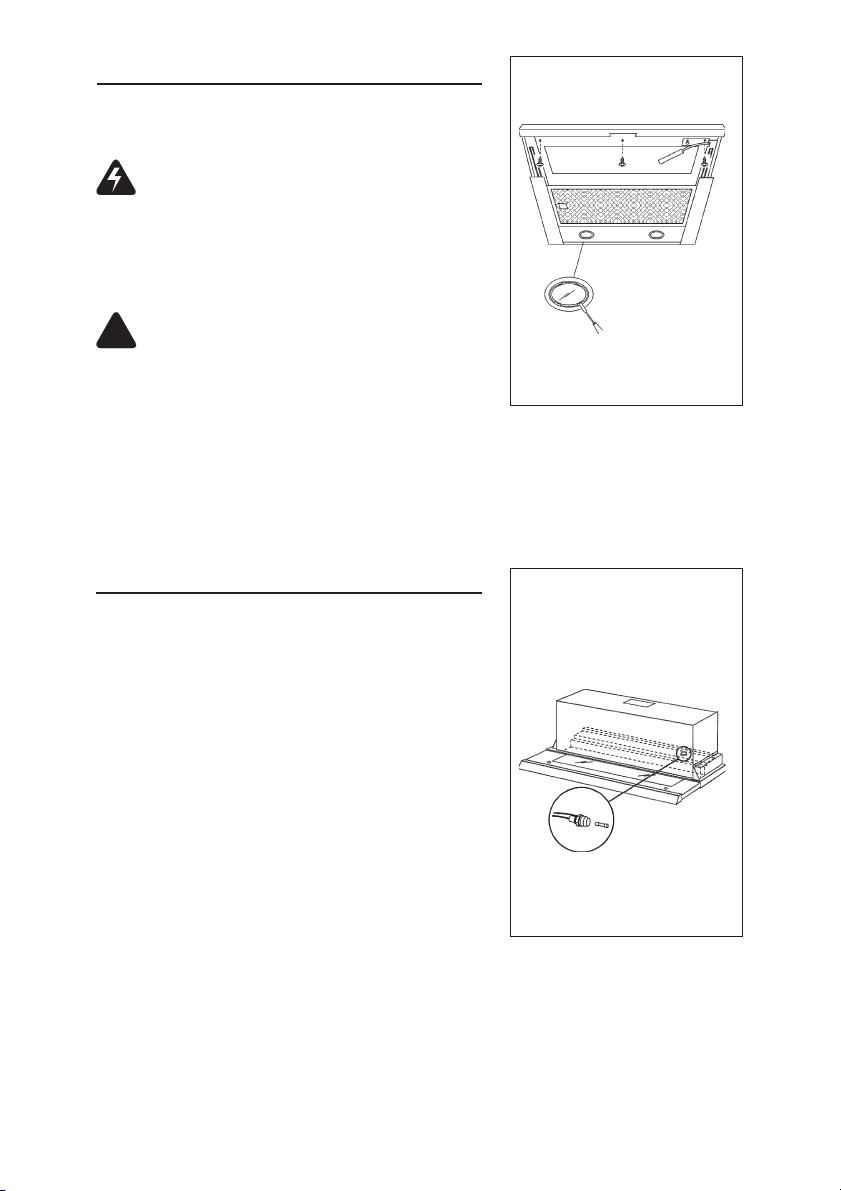

PREPARE THE HOOD

1. Loosley assemble both mounting brackets to

the hood using M4 x 30mm machine screws

and flat washers.

2. Place the 8” damper/duct connector on top of

the range hood discharge opening. Remove

tape from damper flaps.

Secure with (4) 3.9 x 9.5mm screws.

3. Assemble wall spacer to the hood with (3) 3.9 x

9.5mm screws.

NOTE: The spacer is designed to fill a 5/8” gap

between the wall and the back of the hood. If

the gap is larger, a non-combustible material

that is in compliance with local building codes

must be used to fill this gap.

MACHINE

SCREWS

(M4x30mm)

WASHERS

MOUNTING SCREWS

(3.9x9.5mm)

MOUNTING SCREWS

(3.9x9.5mm)

- 8 -

WALL

SPACER

Page 9

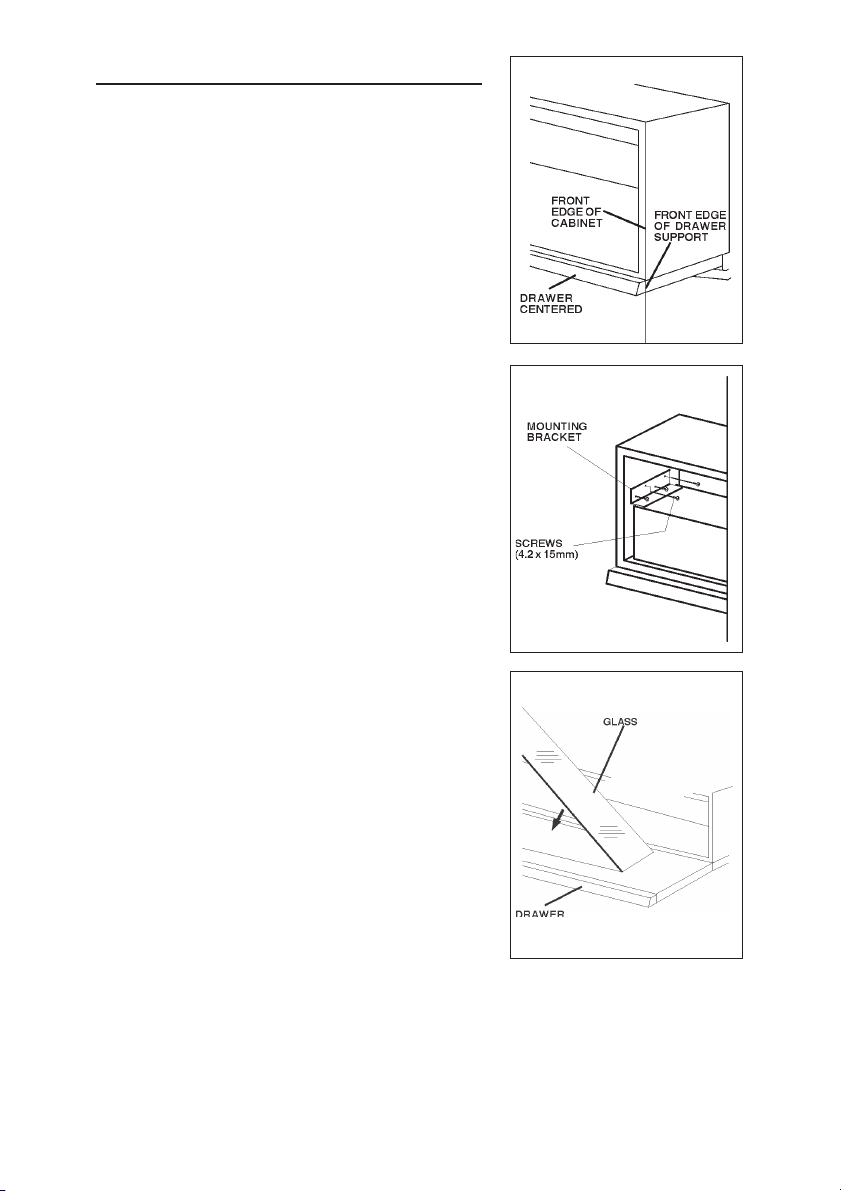

INSTALL THE HOOD

NOTE: At least three people will be required to

mount the hood.

1. Raise the hood up into the wall cabinet. Adjust

brackets to contact inside walls of the cabinet.

2. Make sure the front edge of the hood drawer

support is aligned with the front of the wall

cabinet. Center the hood on the wall cabinet.

3. Tighten the (4) mounting bracket machine

screws previously installed.

4. Fasten the hood to the cabinet with (8) 4.2 x

15mm pan head screws.

Make sure that screws will not penetrate finished

cabinet side walls.

5. Open the slide out drawer. Place the glass panel

into the open recessed area of the drawer.

6. Slide glass left or right until it is centered in the

opening and securely retained.

- 9 -

Page 10

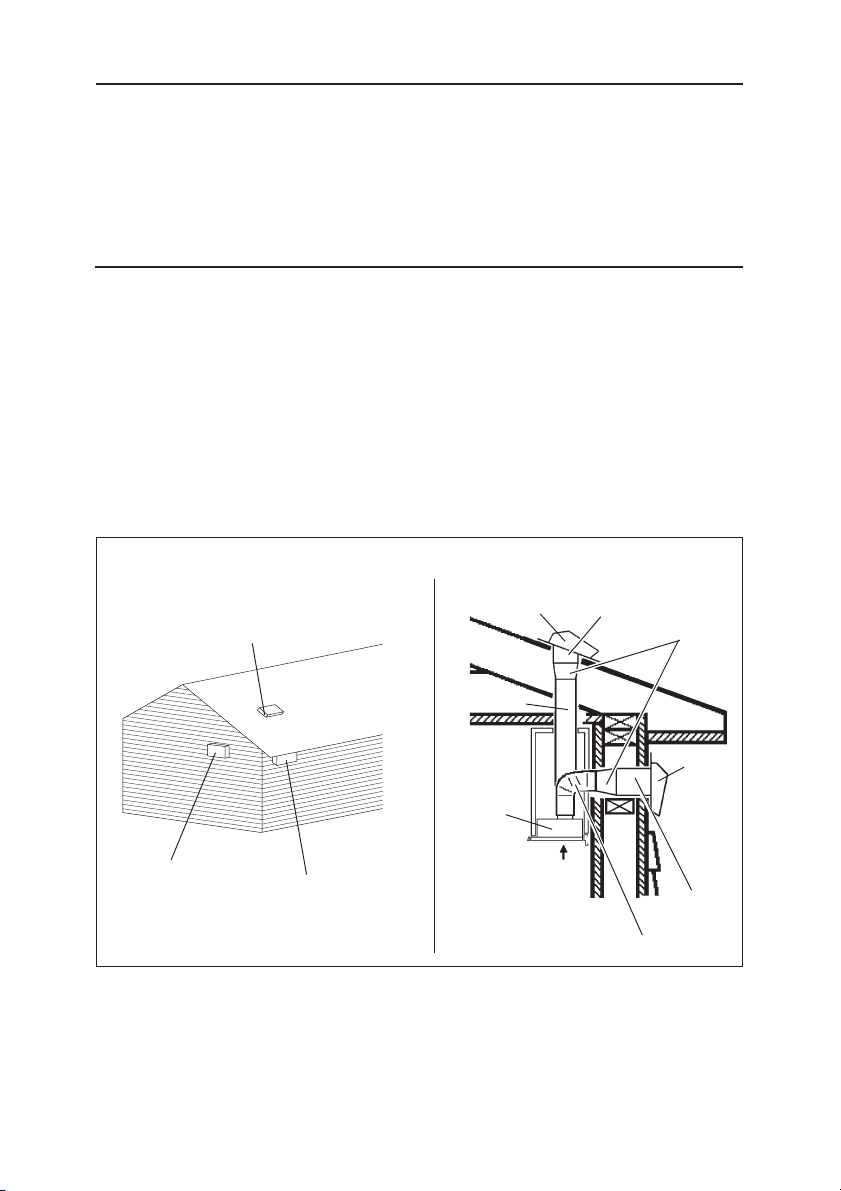

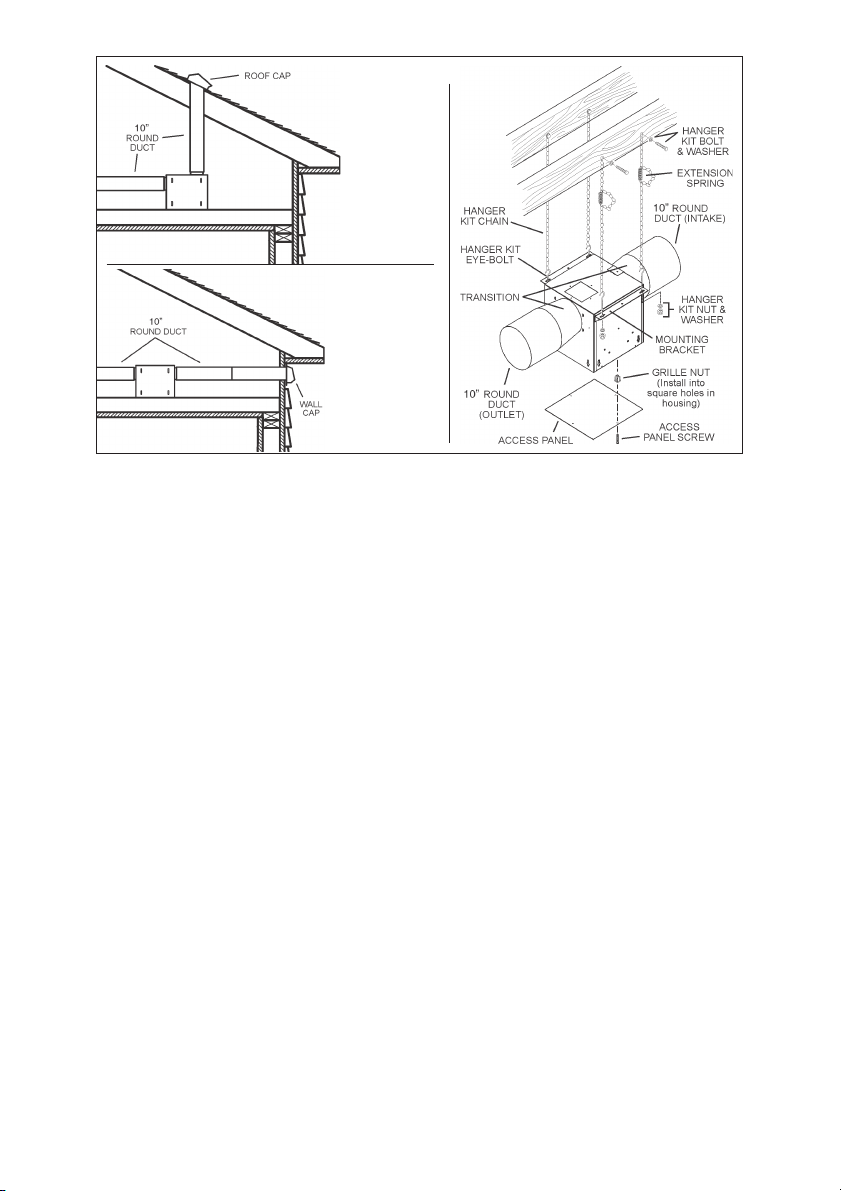

EXTERIOR OR IN-LINE BLOWER SELECTION

CAUTION: Either an exterior blower or in-line blower may be used with this hood.

The U102E hood must be installed with blower models EB6, EB9, EB12, EB15,

ILB3, ILB6, ILB9, or ILB11 only. Other Blowers cannot be substituted (Blowers sold

separately).

The blower must be UL listed for Canadian and U.S. use, and evaluated for use with

solid state speed control, rated 120V, 60 Hz, 6.0 A max.

INSTALL THE DUCTWORK

NOTE: To reduce the risk of fire, use only metal ductwork.

1. Choose the location where the Exterior or In-Line Blower will be mounted. See

illustrations below for mounting location suggestions and restrictions.

2. A straight, short duct run will allow the hood to perform most efficiently.

3. Long duct runs, elbows and transitions will reduce the performance of the

hood. Use as few of them as possible. Larger ducting may be required for best

performance with long duct runs.

4. After the Exterior or In-Line Blower has been installed, connect round metal

ductwork and work back towards the hood location. Use duct tape to seal joints

between ductwork sections.

5. An 8” round to 10” round transition (Model 414) is required. For best air

performance, install the transition as close to the range hood as possible.

EXTERIOR BLOWER

SUGGESTED MOUNTING LOCATIONS

OK

OK

CAUTION: MAY NOT FIT

UNDER EAVES OF SINGLE

STORY HOMES

- 10 -

EXTERIOR

BLOWER

8” ROUND

DUCT

HOOD

22-1/2”

ABOVE

COOKING

SURFACE

10” ROUND

DUCT

8” ROUND

ELBOW

8” TO 10”

ROUND

TRANSITION

EXTERIOR

BLOWER

10”

ROUND

DUCT

Page 11

IN-LINE BLOWER

- 11 -

Page 12

WIRING

!

CAUTION: All electrical wiring should

be done by a qualified person (s) in

accordance with all applicable codes and

standards. This range hood must be

properly grounded.

Do not turn power on at service panel until

all wires have been connected.

Blower connection at hood:

1. Run 2-wire plus ground power cable from

the Exterior or In-Line Blower to the hood’s

wiring box marked “motor connection”.

2. Remove the cover from the wiring box and

remove one knockout.

3. Secure the conduit to the wiring box through

a conduit connector.

4. Make electrical connections at the hood.

Connect white-to-white, red-to-black and

green-to-ground.

5. Replace the wiring box cover and screws.

make sure wires are not pinched between

the cover and box.

Exterior or In-line blower connection:

1. Make electrical connections at the exterior

or in-line blower (see instructions provided

with the exterior or in-line blower).

Power connection at hood:

1. Run 120 VAC electrical power cable to the

hood wiring box marked “120VAC input”.

2. Remove the cover from the wiring box and

remove one knockout.

3. Secure the conduit to the wiring box through

a conduit connector.

4. Make electrical connections at the hood.

Connect white-to-white, black-to-black

and green-to-ground.

5. Replace the wiring box cover and screws.

Make sure wires are not pinched between

the cover and box.

BLOWER CONNECTION AT

Exterior or

In-Line blower

BOX MARKED

“MOTOR

CONNECTION”

CONNECT: WHITE-TO-WHITE,

GREEN-TO-GROUND.

POWER CONNECTION AT HOOD

HOOD

RED-TO-BLACK,

120 Volt 60Hz

LINE-IN

- 12 -

CONNECT:

WHITE-TO-WHITE,

BLACK-TO-BLACK,

GREEN-TO-GROUND.

BOX MARKED

“120 VAC INPUT”

Page 13

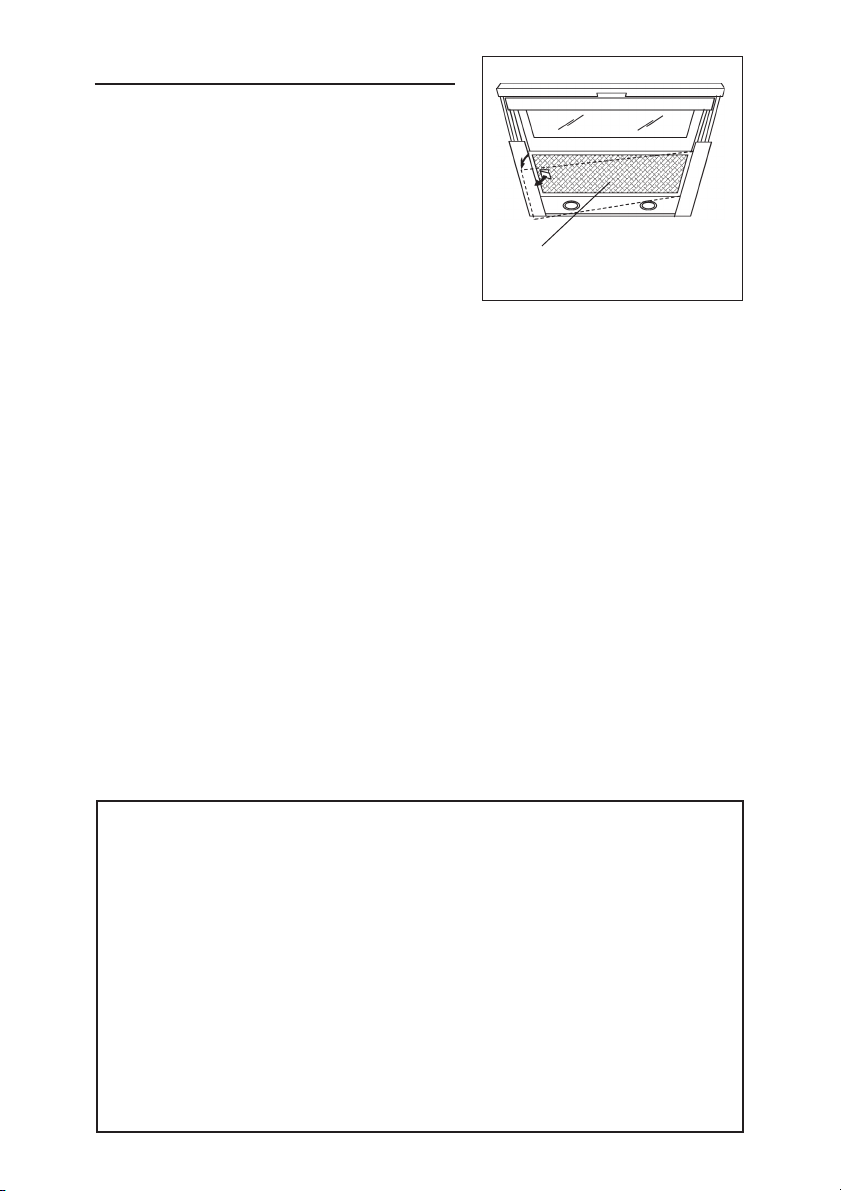

INSTALL FILTERS

To install the GREASE filter, grip the latch tab

and pull it down. This will disengage the filter

from the hood.

To remove the GREASE filter, align filter tabs

on the side of the filter with slots in the hood

drawer. Pull latch tab down, push filter up into

place and release the tab.

Make sure the filter is securely engaged after

assembly.

GREASE

FILTER

WARRANTY

Broan warrants to the original consumer purchaser of its products that such products will be free from defects in materials

or workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan will, at its option, repair or replace, without charge, any product or part which is found to

be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND

INCANDESCENDT BULBS. This warranty does not cover (a) normal maintenance and service or (b) any products or parts

which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by Broan), faulty

installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do

not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN’S OPTION, SHALL BE THE PURCHASER’S SOLE AND

EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty

supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan at the address stated below or telephone: 1-800-637-1453, (b) give

the model number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting

warranty service, you must present evidence of the original purchase date.

BEST BY BROAN, P.O. Box 140 Hartford, Wisconsin 53027

BROAN ONE YEAR LIMITED WARRANTY

- 13 -

Page 14

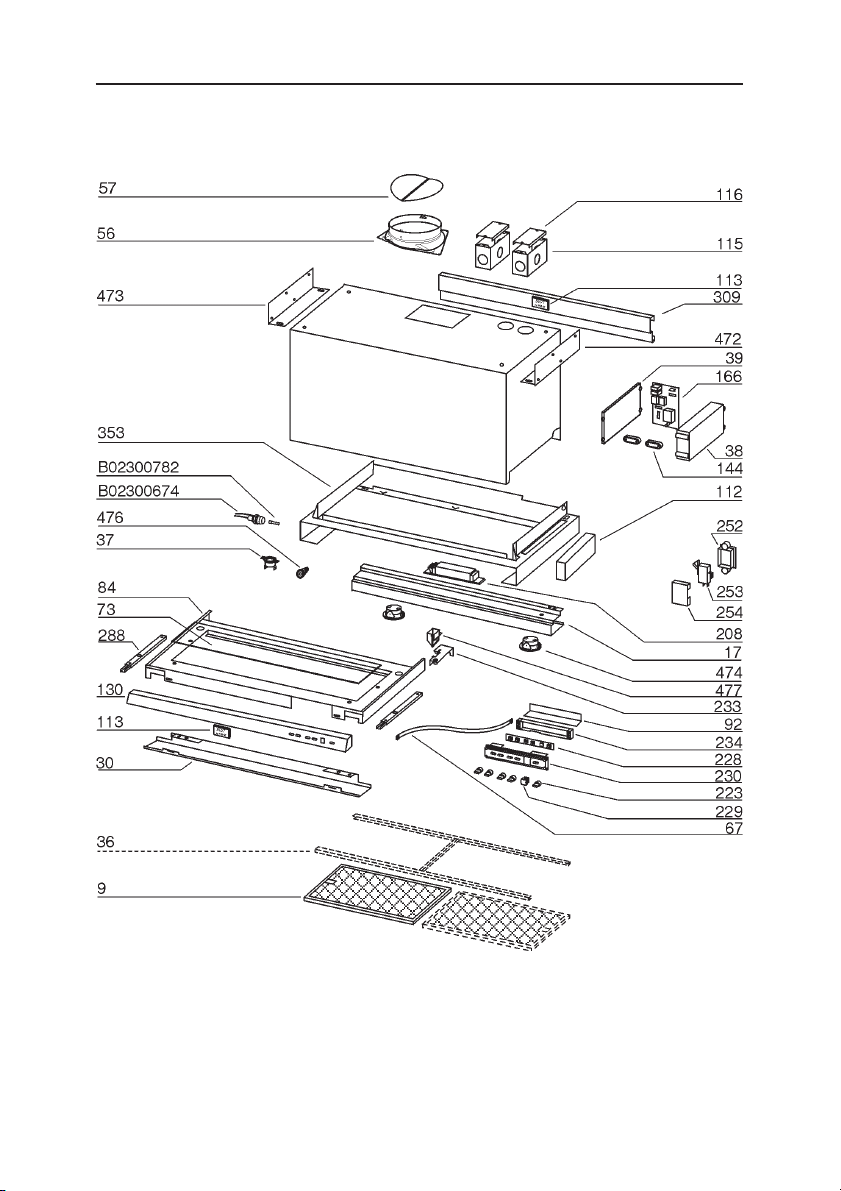

SERVICE PARTS

MODEL U102E

- 14 -

Page 15

SERVICE PARTS

MODEL U102E- Parts for stainless steel models shown. For service parts for black,

white, polished brass, or brushed copper models, call Broan Customer Service.

KEY NO. PART NO. DESCRIPTION

9 B08087077 Grease filter (36” model)

9 B08087016 Grease filter (30” model)

9 B08087017 Grease filter (42” model)

17 BE3347241 Halogen Support (36” model)

17 BE3347372 Halogen Support (30” model)

17 BE3347378 Halogen Support (42” model)

30 BE3347340 Controls protection (36” model)

30 BE3347370 Controls protection (30” model)

30 BE3347259 Controls protection (42” model)

36 BE3403716 Filter Frame (36” model)

36 BE3403765 Filter Frame (42” model)

37 B02300804 Heat Sentry

38 B03292357 Electrical Box

39 B03294033 Electrical Box Cover

73 B02005069 Glass (36” model)

73 B02005070 Glass (30” model)

73 B02005071 Glass (42” model)

84 BE3403714 Display visor (36” model)

84 Be3403752 Display visor (30” model)

84 Be3403762 Display visor (42” model)

112 B03294746 Wiring Protection

113 B02011284 Name Plate

115 BE3334250 Wiring Box

116 BE3334252 Wiring Box Cover

130 B003101208 Front Panel (36” model)

130 B003101220 Front Panel (30” model)

130 B003101227 Front Panel (42” model)

144 B03292287 Wire Clamp

166 B08086701 Wiring Board

208 B02300783 Transformer

223 B03294171 Switch botton

233 B03294740 Closing

252 B03292349 Microswitch box

253 B02300620 Microswitch

254 B03292350 Microswitch box cover

288 B020111650 Runner ball

309 B003101216 Spacer (36” model)

309 B003101222 Spacer (30” model)

309 B003101228 Spacer (42” model)

353 BE3403713 Display support (36” model)

353 BE3403751 Display support (30” model)

353 BE3403761 Display support (42” model)

472 BE3347252 Right Bracket

473 BE3347251 Left Bracket

474 B02300733 Halogen Lamp

476 B03292203 Spacer Panel

477 B03294785 Upper Closing

998 B080810599 Hardware Package

ARU B08092501 Flange + Non Return Flap Assembly (56,57)

* B06108277 Switch Box Assembly:

- B02300782 Fuse

- B02300674 Fuse Holder

* Not shown assembled.

includes Key Nos. 234, 228, 223, 229, 67,

230, 92)

- 15 -

Page 16

LISEZ ET CONSERVEZ CES INSTRUCTIONS

!

POUR USAGE DOMESTIQUE SEULEMENT

!

AVERTISSEMENT

POUR REDUIRE LES RISQUES D’INCENDIE, DE DECHARGES ELECTRIQUES OU DE

DOMMAGES AUX PERSONNES, OBSERVEZ LES INSTRUCTIONS SUIVANTES:

1. N’utilisez cet appareil que comme cela est indiqué par le constructeur. Si vous avez des

problèmes, contactez le fabriquant à l’adresse ou au numéro de téléphone indiqués dans

la garantie.

2. Avant de pourvoir à l’entretien ou au nettoyage de votre appareil, éteignez-le au tableau

des commandes ou bloquez le tableau des commandes afin d’éviter de le mettre en marche

accidentellement. Si vous ne pouvez pas bloquer le système permettant d’éteindre votre

appareil, appliquez un avertissement extérieur d’une façon sure, comme par exemple un

panneau, sur le tableau des commandes.

3. L’assemblage et la connexion électrique doivent être faits par des personnes qualifiées

en respectant les normes et règlements en vigueur, y compris les normes et règlements

concernant les possibilités d’incendie.

4. Il est indispensable qu’il y ait suffisamment d’air pour que la combustion et l’évacuation des

gaz à travers le tuyau du brûleur du combustible ait lieu sans retour de flamme. Suivez

les indications données par le fabricant du brûleur ainsi que les normes de sécurité comme

celles qui sont publiées par l’Association Nationale pour la Protection contre les Incendies

National Fire Protection Association (NFPA) et la American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), et les autorités locales en matière de normes.

5. Quand vous coupez ou percez des trous dans le mur ou le plafond, n’abîmez pas les fils

électriques ou autres.

6. Le ventilateur canalisé doit toujours évacuer l’air vers l’extérieur.

7. N’utilisez pas cet appareil avec un appareil contrôlant la vitesse à état solide.

8. Afin de diminuer tout risque d’incendie n’utilisez que des conduits en métal.

9. Votre appareil doit être relié à la terre.

ATTENTION - POUR REDUIRE LES RISQUES D’INCENDIE DES MATIERES GRASSES

QUI SONT EN TRAIN DE CUIRE:

A. Ne laissez jamais ni vos éléments chauffants, ni vos casseroles ou poêles sur le feu

sans les contrôler si vous réglez l’apport de chaleur sur une position élevée. Si vos

casseroles ou poêles débordent cela provoque de la vapeur et des éclaboussures de

graisse qui peuvent prendre feu. Chauffez les huiles lentement à feu bas ou moyen.

B. Faites toujours fonctionner votre hotte quand vous cuisez à des températures élevées

ou quand vous cuisinez des plats flambés. (par ex. crêpes Suzette, Cerises “Jubilé”,

Steack au poivre flambé).

C. Nettoyez régulièrement les ailes de vos ventilateurs. Ne permettez pas que la graisse

s’accumule sur le ventilateur ou sur le filtre.

D. Utilisez des casseroles de taille appropriée. Utilisez toujours des ustensiles de cuisson

dont la taille est appropriée à la surface de votre élément de cuisson.

AVERTISSEMENT

POUR REDUIRE LES RISQUES DE DOMMAGES AUX PERSONNES AU CAS OÙ VOTRE

CUISINIERE PRENDRAIT FEU, OBSERVEZ LES INSTRUCTIONS SUIVANTES:*

1. ETEINDRE LES FLAMMES à l’aide d’un couvercle le plus hermétique possible, une

plaque à gâteaux, ou un plateau en métal, puis éteindre le brûleur. ATTENTION à NE

PAS VOUS BRÛLER. Si les flammes ne s’éteignent pas immédiatement, SORTEZ ET

APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS EN MAIN UNE POÊLE OU UNE CASSEROLE QUI A PRIS FEU

- Vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni torchons ou serviettes mouillés - vous provoqueriez une

violente explosion de vapeur.

- 16 -

Page 17

4. Utilisez un extincteur SEULEMENT si:

A. Vous savez que vous avez un extincteur Classe ABC, et vous en connaissez déjà le

mode d’emploi.

B. Ce n’est pas un très gros incendie et qu’il se limite à l’endroi où il a explosé.

C. Vous êtes en train d’avertir les pompiers.

D. Vous avez la possibilité d’essayer d’éteindre l’incendie en ayant le dos tourné vers

une issue.

* D’après les “Suggestions concernant la Sécurité contre les incendies des cuisines”

publiées par NFPA.

!

ATTENTION

1. Pour réduire tout risque d’incendie et pour évacuer correctement l’air, assurez-vous de

prévoir un conduit de ventilation extérieur. Ne videz pas l’air dans les espaces limités

par des murs ou des plafonds, les combles, les passages étroits ou les garages.

2. Faites très attention quand vous utilisez des produits de nettoyage ou des détergents.

3. Évitez d’utiliser des aliments pouvant s’enflammer sous la Range Hood.

4. N’utilisez cet appareil que pour une ventilation générale. Ne l’utilisez pas pour évacuer

des matières ou des vapeurs dangereuses ou qui peuvent exploser.

5. Pour éviter de causer des dommages au moteur et de rendre les rotors bruyants et/ou

non équilibrés, évitez que les sprays pour murs secs, la poussière de construction

entrent en contact avec la partie électrique.

6. Le moteur de votre hotte a un thermostat qui éteindra automatiquement le moteur s’il est

surchauffé. Le moteur se remettra en marche lorsqu’il se sera refroidi. Si le moteur

continue à s’éteindre et à se remettre en marche, faites vérifier votre hotte.

7. Pour mieux capturer les impuretés de cuisine, le bas de votre hotte devrait être à une

distance minimum de 22-1/2” (57.1 cm) au-dessus du plan de cuisson.

8. Vu que cette hotte est grande et lourde, il est recommandé de confier l’installation de

cette hotte à 3 personnes.

9. Ce produit est doté d’un thermostat qui active automatiquement le moteur. Pour

réduire le risque de dommages et éviter l’activation accidentelle, positionner l’interrupteur

du panneau de service sur la position OFF et bloquer le panneau de service ou mettre

un avertissement externe, par exemple une plaquette.

10. Pour réduire les risques d'incendie et de choc électrique, la hotte Série Best U102E doit

uniquement être installée avec les ventillateurs de modèle EB6, EB9, EB12, EB15,

ILB3,

ILB6, ILB9 ou ILB11. Aucun autre ventillateur ne peut être substitué. (Ventillateur

vendu séparément.)

11. Utiliser uniquement avec un kit de connexion pour alimentation homologué.

12. Nous vous recommandons de lire l’étiquette indiquant les caractéristiques de votre

hotte pour de plus amples informations et exigences.

13. Appareils avec fonctionnement automatique. Pour réduire les risques de décharges,

débrancher avant l’entretien.

- 17 -

Page 18

FONCTIONNEMENT

Pour l’opération silencieuse et la meilleure capture de la fumée, la vapeur et

d’autres impuretés à cuire, actionnent toujours cette unité avec glissent-dehors

la visière coulissante entièrement ouvert.

Commandes

La hotte fonctionne à l’aide de cinq (5) boutons-poussoirs situés sur la visière

coulissante.

L’interrupteur d’Éclairage Marche/Arrêt allume les lumières à la plus faible intensité

et les éteint.

Le Gradateur d’éclairage fait passer l’éclairage de faible à intense.

L’interrupteur de Ventilateur Arrêt/Régime arrête le ventilateur ou change sa vitesse

selon quatre régimes différents : élevé, moyen-élevé, moyen-faible et faible régime.

Si l’on maintient le bouton enfoncé pendant 2 secondes, le ventilateur s’arrête.

L’interrupteur de Ventilateur Marche/Régime actionne le ventilateur ou change sa

vitesse selon quatre régimes différents : faible, moyen-faible, moyen-élevé et élevé.

La visière doit être ouverte pour que le ventilateur fonctionne.

L’Indicateur DEL :

Il indique la vitesse du ventilateur de 1 (régime faible) à 4 (régime élevé). Il

indique en clignotant la vitesse du ventilateur lorsque la minuterie de 10 minutes

est activée.

Après 30 heures d’utilisation, le segment central de l’indicateur clignote puis

demeure allumé, indiquant que les filtres doivent être nettoyés.

L’Interrupteur de minuterie actionne un dispositif de minuterie qui se trouvait

désactivé. Lorsque l’on appui sur ce bouton, le ventilateur continue à fonctionner

pendant 10 minutes au régime réglé, puis s’arrête automatiquement.

Le bouton de Réamorçage de l’alerte de filtre remet le compteur de 30 heures à

zéro pour les filtres. Après avoir nettoyé ou remplacé les filtres, appuyez une fois sur

ce bouton pour remettre l’alerte à zéro.

HEAT SENTRY

MC

Votre hotte est munie d’un thermostat HEAT SENTRYMC. Ce thermostat est un

dispositif qui actionnera ou augmentera la vitesse du ventilateur s’il détecte une

chaleur excessive au-dessus de la surface de cuisson.

1) Si le ventilateur n’est pas en marche - il actionnera le ventilateur en haute

vitesse.

2) Si le ventilateur fonctionne en basse vitesse - le ventilateur tournera en haute

vitesse.

Lorsque la température revient à la normale, le ventilateur retourne à sa vitesse

d’origine.

MC

AVERTISSEMENT : Le thermostat HEAT SENTRY

peu actionner la

hotte même si la hotte est arrêtée. Si tel est le cas, il est impossible de

l’arrêter avec l’interrupteur. Si vous devez arrêter le ventilateur, faites-le à

partir du panneau électrique principal.

- 18 -

Page 19

AMPOULES HALOGENES

Cette hotte requiert deux ampoules halogènes

(Type T3, 12Volt, 20Watt Max, G-4 Base).

AVERTISSEMENT : Coupez toujours

l’alimentation électrique avant d’effectuer

tous travaux sur l’appareil.

Pour remplacer les ampoules :

1. Ouvrez le couvercle en faisant levier dans les

fentes appropriées. NE LE TOURNEZ PAS.

!

!

ATTENTION : L’ampoule peut être très

chaude.

2. Remplacez-la par une ampoule halogène de

type T3, 12Volt, 20Watt Max, G-4 Base. Ne

touchez pas l’ampoule de rechange avec les

mains nues !

N’employez pas watts plus grands que

d’ampoules les 20. Watts plus grands que

d’ampoules les 20 feront ouvrir le fusible.

REMPLACEMENT DU FUSIBLE

SI LES LUMIÈRES NE S’ALLUMENT PAS,

COUPEZ LE COURANT AU PANNEAU

D’ALIMENTATION ÉLECTRIQUE. VÉRIFIEZ LE

FUSIBLE ET REMPLACEZ-LE, LE CAS

ÉCHÉANT.

1. Enlevez le filtre à graisse et ouvrez la visière.

2. Repérez le porte-fusible du côté supérieur droit

du boîtier d’éclairage.

3. Dévissez le capuchon du porte-fusible et retirez

le fusible.

4. Remplacez-le par un fusible de même taille et

de même intensité (5 x 20 mm, 4 ampères, 125

volts).

N’utilisez pas les fusibles 4 ampères plus

grands que. Les fusibles 4 ampères plus

grands que peuvent endommager le

transformateur.

5. Replacez le capuchon du porte-fusible et le filtre

à graisse.

6. Rétablissez le courant au panneau électrique.

- 19 -

Page 20

ENTRETIEN

Un entretien adéquat de la hotte assurera son bon fonctionnement.

Filtres à graisse

Les filtres à graisse doivent être nettoyés lorsque l’Indicateur DEL clignote

quand le ventilateur est à l’arrêt (c.-à-d. après 30 heures de fonctionnement).

Utilisez une solution tiède de détergent pour les nettoyer. Ces filtres peuvent

aller au lave-vaisselle. Voir comment enlever et installer les filtres à la page 27.

Nettoyage de la hotte

L’acier inoxydable est l’un des matériaux les plus faciles à nettoyer. Quelques

soins contribueront à préserver sa belle apparence.

Conseils de nettoyage :

1. Il suffit habituellement d’utiliser de l’eau chaude savonneuse ou additionnée

de détergent.

2. Après le nettoyage, rincez toujours à l’eau claire. Essuyez la surface avec un

chiffon propre et doux pour éviter les stries.

3. Pour les ternissures ou les dépôts tenaces, utilisez un nettoyant domestique

non-abrasif ou une poudre à polir l’acier inoxydable avec un peu d’eau et un

chiffon doux.

4. Pour la saleté rebelle, utilisez un tampon à récurer en plastique ou une brosse

à poils doux avec un nettoyant et de l’eau. Frottez doucement dans le sens

des lignes de polissage ou du “ grain ” de l’acier. Évitez de trop appuyer au

risque de gâcher la surface.

5. NE LAISSEZ PAS les dépôts s’accumuler trop longtemps.

6. N’UTILISEZ PAS une laine d’acier ordinaire ou une brosse d’acier. De petites

particules d’acier risqueraient d’adhérer à la surface et de la faire rouiller.

7. NE LAISSEZ PAS une solution saline, un désinfectant, de l’eau de javel ou

tout autre produit détachant rester longtemps en contact avec l’acier

inoxydable. Bon nombre de ces nettoyants contiennent des produits pouvant

en altérer la surface. Après l’utilisation du nettoyant, rincez la surface à l’eau

et essuyez-la avec un chiffon propre.

Nettoyez les surfaces peintes uniquement à l’eau tiède avec un détergent doux.

- 20 -

Page 21

PRÉPARATION DE LA HOTTE

Déballez la hotte et vérifiez le contenu de la boîte.

Celle-ci doit contenir les éléments suivants :

1 - Hotte

1 - Clapet / Raccord de conduit de 20,3 cm (8 po)

1 - Visière de verre

1 - Cale décorative

1 - Sac de pièces contenant :

2 - Brides de montage

4 - Vis mécanique (M4 x 30 mm - à tête cylindrique)

7 - Vis de montage (3.9 x 9,5 mm - à tête cylindrique)

4 - Rondelles (de 4 mm de diamètre)

8 - Vis (4.2 x 15 mm - à tête cylindrique)

1 - Directives d’installation

CLAPET / RACCORD DE CONDUIT

DE 20,3 CM (8 PO)

VISIÈRE DE VERRE

2 BRIDES DE MONTAGE

4 RONDELLES

CALE DÉCORATIVE

- 21 -

4 VIS MÉCANIQUES

(M4 X 30 MM - À TÊTE

CYLINDRIQUE)

8 VIS MÉCANIQUES

(4.2 X 15 MM - À TÊTE

CYLINDRIQUE)

7 VIS DE MONTAGE

(3.9 X 9.5 MM - À TÊTE

CYLINDRIQUE)

Page 22

PRÉPARATION DE L’ARMOIRE

1. Avant d’installer l’armoire, enlevez les portes et

les charnières.

2. Découpez une ouverture dans le fond

conformément aux dimensions illustrées.

3. Découpez les ouvertures requises pour les

conduits et le câblage électrique.

4. Installez l’armoire au mur et fixez-la

conformément aux recommandations du

fabricant. L’armoire doit être solidement fixée

aux montants du mur et à la charpente derrière

la cloison sèche avant d’installer la hotte.

LARGEUR

DE L’ARMOIRE

30 po

36 po

“A”

28 1/2 po

34 1/2 po

“B”

15 po

18 po

42 po

40 1/2 po

21 po

PRÉPARATION DE LA HOTTE

1. Assemblez les brides de montage sur la hotte

sans les serrer à l’aide des vis mécaniques M4

x 30 mm et des rondelles.

2. Placez le clapet / raccord de conduit de 20,3 cm

(8 po) sur l’ouverture de sortie du dessus de la

hotte. Enlevez le ruban qui retient les volets du

clapet. Fixez-le avec (4) vis de 3,9 x 9,5 mm.

3. Assemblez la cale sur la hotte avec trois (3) vis

de 3,9 x 9,5 mm.

REMARQUE : La cale est conçue pour

remplir l’espace de 1,5 cm (5/8 po) entre le

mur et l’arrière de la hotte. Si l’espace est

plus grand, utilisez un matériau non

combustible conforme aux codes de

construction locaux pour remplir l’espace.

VIS DE MONTAGE

VIS

MÉCANIQUES

(M4x30mm)

RONDELLE

VIS DE MONTAGE

(3.9x9.5mm)

(3.9x9.5mm)

- 22 -

CALE

Page 23

INSTALLATION DE LA HOTTE

REMARQUE : L’installation de la hotte nécessite

au moins trois personnes.

1. Soulevez la hotte dans l’armoire. Ajustez les

brides pour qu’elles touchent les parois de

l’armoire.

2. Assurez-vous que le bord avant de la hotte est

aligné avec l’avant de l’armoire. Centrez la hotte

sur l’armoire.

3. Serrez les quatre (4) vis mécaniques des brides

préalablement installées.

4. Fixez la hotte à l’armoire avec huit (8) vis de 4.2

x 15 mm à tête cylindrique. Assurez-vous que

les vis ne pénètrent pas le fini des parois de

l’armoire.

5. Ouvrez la visière coulissante. Placez le panneau

de verre dans l’ouverture encastrée.

6. Glissez la vitre à gauche ou à droite jusqu’à ce

qu’elle soit centrée dans l’ouverture et

solidement retenue.

- 23 -

Page 24

CHOIX DE VENTILATEUR EXTERNE OU “IN-LINE”

ATTENTION: avec cette hotte, on peut utiliser soit un ventilateur externe soit “InLine”. La hotte U102E doit être installée avec un ventilateur des modèles suivants

EB6, EB9, EB12, EB15, ILB3, ILB6, ILB9, ou ILB11 uniquement. On ne peut pas

utiliser d’autres ventilateurs (les ventilateurs sont vendus séparément).

Le ventilateur doit être compris dans la liste UL pour l’utilisation au Canada et aux

USA et approuvée pour l’utilisation avec un “dispositif de contrôle de la vitesse” à

l’état solide, dont les données sur la plaque sont 120V, 60 Hz, 6.0 A max.

POSE DU CONDUIT

REMARQUE : Pour réduire les risques d’incendie, utilisez seulement des conduits

en métal.

1. Choisissez l’endroit où le ventillateur doit être monté à l’extérieur. Voir les

illustrations ci-dessous pour les restrictions et les suggestions s’appliquant au

lieu de montage.

2. Un tracé droit et court permet à la hotte d’être plus efficace.

3. Des conduits longs, des coudes et des transitions réduisent l’efficacité de la hotte.

N’en utilisez que le moins possible. Pour plus d’efficacité, des conduits plus gros

peuvent être nécessaires si le parcours est trop long.

4. Après avoir installé le ventillateur extérieur, connectez un conduit rond en métal

en progressant vers la hotte.

Scellez les joints avec du ruban entre chaque section de conduit.

5. Un raccord de transition rond (Modèle 414) de 20,3 cm (8 po) à 25,4 cm (10 po)

est nécessaire. Pour plus d’efficacité, installez l’adapteur aussi proche que

possible de la hotte.

VENTILATEUR EXTERIEUR

EMPLACEMENTS SUGGERES

OK

OK

ATTENTION : RISQUE DE NE

PAS S’INSERER SOUS

L’AVANT-TOIT D’UNE MAISON

SANS ETAGE SUPERIEUR

CONDUIT ROND

20.3 CM (8 PO)

- 24 -

CONDUIT ROND

25.4 CM (10 PO)

VENTILATEUR

EXTERIEUR

HOTTE

57.1 CM (22-1/2 PO)

AU-DESSUS DE LA

SURFACE DE

CUISSON

ADAPTATEUR

25.4 CM (10

COUDE

ROND 20.3

CM (8 PO)

ROND DE

20.3 CM (8

PO) À

PO)

VENTILATEUR

EXTERIEUR

CONDUIT

ROND

25.4 CM

(10 PO)

Page 25

VENTILATEUR IN-LINE

- 25 -

Page 26

INSTALLATION ELECTRIQUE

ATTENTION : Les travaux d’électricité

doivent être effectués par des personnes

qualifiées en respectant les codes et les

normes en vigueur. Cette hotte de cuisine

doit être correctement mise à la terre.

Ne pas rétablir le courant du panneau

d’électricité avant que tous les câbles

aient été connectés.

Raccordement du ventilateur à la hotte :

1. Acheminez un câble électrique à deux fils

(plus un fil de terre) du ventilateur extérieur

(ou ventilateur “In-Line”) jusqu’à la boîte

de câblage de la hotte marquée “ motor

connection ” (“connexion du moteur”).

2. Enlevez le couvercle du boîtier de câblage.

3. Fixer le “conduit” au boîtier de connexion

à l’aide d’un connecteur approprié pour

ce “conduit”.

4. Effectuez les connexions électriques de la

hotte. Branchez les fils blancs ensemble,

les fils rouges aux noirs et le fil vert avec

le fil de terre.

5. Replacez le couvercle du boîtier de

câblage et les vis. Assurez-vous qu’aucun

des câbles n’est coincé entre le couvercle

et le boîtier.

CONNEXION DU VENTILATEUR

VENTILATEUR

EXTÉRIEUR OU

BOÎTE MARQUEE

CONNECTION”

CONNECTER: BLANC AVEC BLANC

L’ALIMENTATION DE LA HOTTE

À LA HOTTE

«IN-LINE»

“MOTOR

ROUGE AVEC NOIR

VERT AVEC FIL DE TERRE

CONNEXION DE

ENTRÉE 120 Volt 60Hz

Connexion du ventilateur extérieur

ou

«in-Line»:

1. Effectuez les branchements électriques du

ventilateur extérieur ou “In-Line” (voir les

instructions fournies avec le ventilateur).

Connexion de l’alimentation de la hotte :

1. Acheminez un câble électrique de 120

VCA au boîtier de câblage de la hotte

portant l’inscription “ 120VAC input ” (“

entrée de 120 VCA ”).

2. Enlevez le couvercle du boîtier de câblage.

3. Fixer le “conduit” au boîtier de connexion

à l’aide d’un connecteur approprié pour

ce “conduit”.

4. Effectuez les connexions électriques de la

hotte. Branchez les fils blancs ensemble,

les fils noirs ensemble et le fil vert avec le

fil de terre.

5. Replacez le couvercle du boîtier de

câblage et les vis. Assurez-vous qu’aucun

des câbles n’est coincé entre le couvercle

et le boîtier.

- 26 -

CONNECTER:

BLANC AVEC

BLANC

NOIR AVEC NOIR

VERT AVEC FIL DE

TERRE

BOÎTE MARQUEE

“120 VAC INPUT”

Page 27

INSTALLATION DES FILTRES

Pour enlever le filtre à GRAISSE, tirez la

languette vers le bas. Le filtre se dégagera

de la hotte.

Pour installer le filtre à GRAISSE, alignez les

pattes du côté du filtre dans les fentes de la

visière de la hotte. Tirez la languette vers le

bas, poussez le filtre en place et relâchez la

languette. Vérifiez si le filtre est bien fixé une

fois replacé.

FILTRES À GRAISSE

GARANTIE

Broan-NuTone LLC garantit à l’acheteur original que les produits vendus en vertu de la présente sont libres de tout vice de

matériau ou de fabrication pour une période d’un an à compter de la date d’achat originale. CETTE GARANTIE NE

COMPORTE AUCUNE AUTRE GARANTIE, EXPRESSE OU TACITE, Y COMPRIS, MAIS SANS S’Y LIMITER,

LES GARANTIES TACITES DE VALEUR MARCHANDE OU D’ADAPTATION À UN

USAGE PARTICULIER.

Durant cette période d’un an, Broan-NuTone LLC réparera ou remplacera gratuitement, à sa discrétion, tout produit ou toute

pièce jugés défectueux dans des conditions normales d’utilisation.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS, NI AUX AMPOULES

HALOGÈNES OU INCANDESCENTES. Cette garantie ne couvre pas (a) les frais d’entretien ou de service normaux ni

(b) tout produit ou toute pièce soumis à un abus, une négligence, un accident, un entretien ou une réparation inadéquats

(autres que ceux effectués par Broan-NuTone LLC), une mauvaise installation ou une installation contraire aux instructions

recommandées.

La durée de toute garantie tacite est limitée à la période d’un an stipulée pour la garantie expresse. Certains territoires ou

provinces interdisent les restrictions relatives à la durée d’une garantie implicite. La restriction susmentionnée peut donc

ne pas s’appliquer dans votre cas.

L’OBLIGATION POUR BROAN-NUTONE LLC DE RÉPARER OU DE REMPLACER LE PRODUIT, À SA DISCRÉTION,

CONSTITUE LE SEUL RECOURS DE L’ACHETEUR EN VERTU DE CETTE GARANTIE. BROAN-NUTONE LLC NE

PEUT ÊTRE TENUE RESPONSABLE DE TOUT DOMMAGE INDIRECT, CONSÉCUTIF OU ACCESSOIRE

DÉCOULANT DE L’UTILISATION OU DU RENDEMENT DU PRODUIT. Certains territoires ou provinces interdisent

l’exclusion ou la restriction des dommages indirects ou consécutifs. La restriction susmentionnée peut donc ne pas s’appliquer

dans votre cas.

La présente garantie vous confère des droits spécifiques reconnus par la loi. D’autres droits pourraient également vous être

accordés selon la législation locale en vigueur.

La présente garantie remplace toutes les autres garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan-NuTone LLC à l’adresse mentionnée ci-dessous ou au numéro

de téléphone suivant : 1 800 637-1453, (b) indiquer le numéro de modèle et d’identification de la pièce et (c) décrire la

défectuosité

du produit ou de la pièce. Lors de votre demande de garantie, vous devez présenter une preuve de la date d’achat originale.

BEST BY BROAN, P.O. Box 140 Hartford, Wisconsin 53027

GARANTIE LIMITÉE D’UN AN BROAN-NUTONE LLC

- 27 -

Page 28

PIECES DE RECHANGE

MODÈLE U102E

- 28 -

Page 29

PIECES DE RECHANGE

MODÈLE U102E- Pièces indiquées pour les modèles en acier inoxydable. Pour

les pièces des modèles noirs, blancs, laiton poli ou cuivre brossé, veuillez appeler

le Service à la clientèle Broan.

REPÈRE N° de PIÈCE DESCRIPTION

9 B08087077 Filtre à graisse (modèle 91,5 cm / 36 po)

9 B08087016 Filtre à graisse (modèle 76,2 cm / 30 po)

9 B08087017 Filtre à graisse (modèle 106,7 cm / 42 po)

17 BE3347241 Support halogène (modèle 91,5 cm / 36 po)

17 BE3347372 Support halogène (modèle 76,2 cm / 30 po)

17 BE3347378 Support halogène (modèle 106,7 cm / 42 po)

30 BE3347340 Protection des commandes

30 BE3347370 Protection des commandes

30 BE3347259 Protection des commandes

36 BE3403716 Cadre de filtre (modèle 91,5 cm / 36 po)

36 BE3403765 Cadre de filtre (modèle 106,7 cm / 42 po)

37 B02300804 Thermostat Heat Sentry

38 B03292357 Boîtier électrique

39 B03294033 Couvercle du boîtier électrique

73 B02005069 Visière en verre (modèle 91,5 cm / 36 po)

73 B02005070 Visière en verre (modèle 76,2 cm / 30 po)

73 B02005071 Visière en verre (modèle 106,7 cm / 42 po)

84 BE3403714 Visière d’affichage (modèle 91,5 cm / 36 po)

84 BE3403752 Visière d’affichage (modèle 76,2 cm / 30 po)

84 BE3403762 Visière d’affichage (modèle 106,7 cm / 42 po)

112 B03294746 Protection du câblage

113 B02011284 Plaque signalétique

115 BE3334250 Boîtier de câblage

116 BE3334252 Couvercle du boîtier de câblage

130 B003101208 Panneau avant (modèle 91,5 cm / 36 po)

130 B003101220 Panneau avant (modèle 76,2 cm / 30 po)

130 B003101227 Panneau avant (modèle 106,7 cm / 42 po)

144 B03292287 Attache de câble

166 B08086701 Circuit de câblage

208 B02300783 Transformateur

223 B03294171 Bouton d’interrupteur

233 B03294740 Fermoir

252 B03292349 Boîte de mini-interrupteur

253 B02300620 Mini-interrupteur

254 B03292350 Couvercle de boîte de mini-interrupteur

288 B020111650 Glissière de visière

309 B003101216 Cale (modèle 91,5 cm / 36 po)

309 B003101222 Cale (modèle 76,2 cm / 30 po)

309 B003101228 Cale (modèle 106,7 cm / 42 po)

353 BE3403713 Support d’affichage (modèle 91,5 cm / 36 po)

353 BE3403751 Support d’affichage (modèle 76,2 cm / 30 po)

353 BE3403761 Support d’affichage (modèle 106,7 cm / 42 po)

472 BE3347252 Bride de montage droite

473 BE3347251 Bride de montage gauche

474 B02300733 Lampe halogène

476 B03292203 Panneau d’épaisseur

477 B03294785 Fermeture supérieure

998 B080810599 Accessoires de quincaillerie

ARU B08092501 Ensemble de bride et de clapet anti-retour

* B06108277 Ensemble de boîte d’interrupteur : comprend

- B02300782 Fusible

- B02300674 Porte-fusible

repères n° 234, 228, 223, 229, 67, 230, 92

(modèle 91,5 cm / 36 po)

(modèle 76,2 cm / 30 po)

(modèle 106,7 cm / 42 po)

(56, 57)

* Illustré démonté.

- 29 -

Page 30

LEA Y CONSERVE ESTAS INSTRUCCIONES

!

INDICADA SOLAMENTE PARA COCINAR EN CASA

!

ADVERTENCIA

PARA EVITAR EL RIESGO DE INCENDIO, CORTOCIRCUITO O DAÑO PARA LAS

PERSONAS, OBSERVE ATENTAMENTE LAS SIGUIENTES NORMAS:

1. Use esta unidad solamente de la manera indicada por el fabricante; si tiene dudas,

póngase en contacto con éste a la dirección o teléfono indicados en la garantía.

2. Antes de hacer una revisión o de limpiar la unidad, desconéctela de la red para evitar

que se encienda de manera accidental. En el caso de que éste no pueda ser desactivado, se indicará nel panel de servicio.

3. El montaje y la instalación eléctrica debe hacerlos un técnico especializado siguiendo

las normas estándar e incluyendo aquellas de construcción anti incendio.

4. Necesita aire suficiente para una apropiada combustión y escape de gases a través del

tubo del depósito de quema de combustible. Para evitar que el humo aspirado vuelva a

la cocina, siga las directivas del fabricante y las normas estándar de siguridad así como

las normas publicadas por la Asociación de prevención de incendios (NFPA) y la Sociedad americana de especialistas en cale-facción, refrigeración y aire acondicionado y

además las normas de las autoridades locales.

5. Hacer un corte o un taladro en la pared o en el techo no debe dañar la instalación

eléctrica u otras instalaciones ocultas en la pared.

6. Los conductos ventiladores deben siempre desalojar al exterior.

7. No use esta unidad con dispositivo de control de la velocidad a estado sólido.

8. Para evitar el riesgo de incendio, use solamente conductos de metal.

9. Esta unidad tiene que ser conectada a tierra.

PARA EVITAR EL RIESGO DE FUEGO POR ALTO NIVEL DE GRASA:

A. Nunca abandone los quemadores con el fuego alto. La cocción causa humo y restos

de grasa que pueden arder. Caliente el aceite a fuego medio o bajo.

B. Encienda siempre la campana cuando cocine a fuego alto o cuando cocine alimentos

fácilmente inflamables. (por ejemplo Crepes Suzette, Cerezas Jubilee, Ternera

flambeada con granos de pimienta).

C. Limpie con frecuencia los ventiladores. No se debe acumular grasa en el ventilador o

en el filtro.

D. Usa el tamañp de cazuela apropiado. Use siempre utensilios de cocina de tamaño y

material adecuados.

ADVERTENCIA

PARA EVITAR EL RIESGO DE DAÑOS A PERSONAS EN CASO DE FUEGO POR ALTO

NÍVEL DE GRASA, TENGA EN CUENTA LO SIGUIENTE:*

1. SOFOQUE LA LLAMA con una tapadera apropiada, una bandeja metálica ó un utensilio

de cocína que pueda cubrirla, despues, apague el quemador. ACTÚE CON

PRECAUCÍON PARA EVITAR QUEMADURAS. Si la llama no se extingue inmediatamente, SALGA Y LLAME A LOS BOMBEROS.

2. NUNCA COJA UNA SARTEN EN LLAMAS, porque corre el riesgo de quemarse.

3. NO USE AGUA ni paños o toallas húmidas porque puede provocarse una violenta

humareda.

4. Use un extintor SOLAMENTE si:

A. Posee un extintor de clase ABC y sabe perfectamente cómo usarlo.

B. El fuego es pequeño y está controlado en el mismo sitio en que empezó.

C. Ha llamado con anterioridad a los bomberos.

D. Puede combatir el fuego retrocedíendo hacia la salida.

* Basado en “Seguridad antifuego en la cocína” publicado por NFPA.

- 30 -

Page 31

!

ADVERTENCIA

1. Para reducir el riesgo de incendios y para evacuar correctamente los humos, asegurarse

de haber realizado una conducción del aire hasta el exterior. No expulsar los humos en

espacios cerrados por paredes o techos, áticos, espacios angostos o garajes.

2. Prestar la máxima atención al utilizar productos de limpieza o detergentes.

3. Evitar el uso de productos alimentarios que puedan inflamarse bajo la campana.

4. Sólo para ventilación total. No use gases de escape peligrosos o materiales y vapores

explosivos.

5. Para evitar daños en el funcionamiento del motor e impulsores ruidosos y/o desequi-

librados, mantenga alejados de la unidad de encendido pulverizadores en seco o polvo.

6. El motor tiene un nivel de sobrecarga térmica que apaga automáticamente el motor

cuando se ha recalentado excesivamente. El motor se pone de nuevo en fincionamento

cuando la temperatura baja. Si el motor comienza a encenderse y a apagarse, deberá

hacer una revisión de éste.

7. Para limpiar mejor las impurezas al cocinar, la distancia entre la parte inferior de la

campana y la zona de cocción debe ser mínimo 22-1/2 pulg (57.1 cm).

8. Debido a su gran tamaño y peso, se recomienda su montaje por parte de 3 técnicos

esperializados.

9. Este producto está dotado de un termostato que pone en marcha automáticamente el

motor. Para reducir el riesgo de daños y evitar que se encienda accidentalmente,

colocar el interruptor del panel de servicio en la posición OFF y bloquear el panel de

servizio o colocar una advertencia externa como por ejemplo un letrero o una chapita.

10. Para reducir el riesgo de incendio o de descargas eléctricas, se debe instalar la campana

Best de la serie U102E únicamente con los modelos de ventiladores EB6, EB9, EB12,

ILB3, ILB6, ILB9 o ILB11. No se pueden utilizar otros ventiladores. (Los

EB15,

ventiladores se venden por separado.)

11.Use solamente con juego de conexión para alimentación aprobado.

12. Se recomienda leer la placa de caracteristicas del producto para ulterior información.

13. Aparato con automatismo. Para evitar el riesgo de daños, colocar el interruptor del

panel de servicio en la posición OFF antes de mantenimiento.

- 31 -

Page 32

OPERACIÓN

Para la operación reservada y la mejor captura del humo, el vapor y otras

impurezas que cocinan, funcionan siempre esta unidad con el visor deslizante

completamente abierto.

Controles

La campana se opera mediante los 5 botones pulsadores que se encuentran en

el visor deslizante.

El interruptor de apagado/encendido de la luz enciende las luces a una intensidad

baja y las apaga.

El interruptor del reductor de intensidad de la luz alterna la intensidad de la luz,

de baja a alta.

El interruptor de apagado/velocidad del ventilador apaga el ventilador y cam-

bia su velocidad a cuatro ajustes: alta, mediana-alta, mediana-baja y baja. Para

apagar el ventilador, apriete el botón sin aflojarlo durante 2 segundos.

El interruptor de encendido/velocidad del ventilador enciende el ventilador en

cuatro ajustes de velocidad: baja, mediana-baja, mediana-alta y alta. Para que

el ventilador funcione, el visor debe estar abierto.

La pantalla LED:

Indica la selección de la velocidad del ventilador: desde 1 (velocidad baja)

hasta 4 (velocidad alta). La velocidad del ventilador aparece intermitente en

la pantalla una vez que se activa el apagado demorado de 10 minutos.

Después de 30 horas de funcionamiento, el segmento central de la pantalla

destellará y permanecerá encendido; esto indica que es necesario limpiar

los filtros.

El interruptor de retardo temporal activa la función de apagado demorado. Al

apretarlo, el ventilador continuará funcionando a la velocidad presente durante

10 minutos antes de apagarse automáticamente.

El interruptor de reinicio de alarma del filtro sirve para reiniciar el temporizador

de 30 horas del filtro. Después de limpiar o cambiar los filtros, apriete este

interruptor una vez para reiniciar la alarma del filtro limpio.

HEAT SENTRY™

La campana está equipada con un termostato HEAT SENTRY™. Este termostato es un dispositivo que encenderá el ventilador o aumentará su velocidad si

detecta un calor excesivo sobre la superficie de cocinado.

1. Si el ventilador está apagado: enciende el ventilador a ALTA velocidad.

2. Si el ventilador está encendido a una velocidad menor: pone el ventilador a

ALTA velocidad.

Cuando la temperatura disminuye a valores normales, el ventilador regresa a

su posición original.

ADVERTENCIA: El termostato HEAT SENTRY puede activar el

ventilador aunque la campana esté APAGADA. Cuando esto ocurre, es

imposible APAGAR el ventilador con el interruptor. Si debe apagar el

ventilador, hágalo desde el panel eléctrico principal.

- 32 -

Page 33

BOMBILLAS DE HALÓGENO

Esta campana de estufa requiere dos bombillas

de halógeno (tipo T3, 12Volt, 20Watt Max, G-4

Base).

ADVERTENCIA: Siempre apague el

suministro eléctrico antes de realizar cualquier

operación en el electrodoméstico.

Para cambiar las bombillas:

1. Haga palanca desde las ranuras apropiadas y

abra la cubierta. NO GIRE LA BOMBILLA.

!

! PRECAUCIÓN: La bombilla puede estar

caliente.

2. Cámbiela por una bombilla tipo T3, 12Volt,

20Watt Max, G-4 Base.

¡No toque la bombilla de reemplazo con las

manos desnudas!

No utilice los bulbos mayor de 20 vatios. Los

bulbos mayor de 20 vatios harán el fusible

abrirse.

REEMPLAZO DEL FUSIBLE

SI LAS LÁMPARAS NO FUNCIONAN,

DESCONECTE LA ENERGÍA EN LA ENTRADA

DEL SERVICIO. REVISE EL FUSIBLE Y

REEMPLÁCELO SI ES NECESARIO.

1. Quite el filtro de grasa y hale y abra el visor.

2. El portafusibles se encuentra en la parte superior

derecha de la cubierta de la lámpara.

3. Desenrosque la tapa del portafusibles y saque

el fusible.

4. Reemplace el fusible con otro del mismo

tamaño y amperaje (5 x 20 mm, 4 A, 125 V).

No utilice los fusibles mayor de 4 amperios.

Los fusibles mayor de 4 amperios pueden

dañar el transformador.

5. Vuelva a colocar la tapa del portafusibles y el

filtro de grasa.

6. Vuelva a conectar la energía en la entrada de

servicio.

- 33 -

Page 34

MANTENIMIENTO

El mantenimiento correcto de la campana de la estufa asegurará el funcionamiento

adecuado de la unidad.

Filtros de grasa

Los filtros de grasa deben limpiarse cuando destelle la pantalla LED cuando el

ventilador se apague (a las 30 horas de funcionamiento). Limpie los filtros con una

solución tibia de detergente y agua. Los filtros se pueden lavar en lavaplatos. En la

pág. 41 encontrará las instrucciones de desmontaje y montaje del filtro.

Limpieza de la campana

El acero inoxidable es unos de los materiales más fáciles para mantener limpios.

Un cuidado ocasional ayudará a mantener su buen aspecto.

Consejos útiles de limpieza:

1. Normalmente todo lo que se necesita es agua caliente con detergente.

2. Enjuague bien con agua clara después de limpiar. Seque con un trapo limpio y

suave para no dejar marcas de agua.

3. Si persisten las descoloraciones o los depósitos, use un limpiador casero que no

deje arañazos o un polvo de pulir para acero inoxidable con un poco de agua y

un trapo suave.

4. En los casos más persistentes, use una esponja desengrasadora o un cepillo de

cerdas suaves junto con el limpiador y agua. Frote ligeramente en la misma

dirección de las líneas de pulido o “grano” del acabado de acero inoxidable. No

aplique demasiada presión porque podría desgastar la superficie.

5. NO deje que se acumulen depósitos durante tiempos largos.

6. NO use cepillos ordinarios de lana de acero o acero. Se podrían adherir pequeños

trozos de acero a la superficie y hacer que se oxide.

7. NO permita el contacto prolongado del acero inoxidable con soluciones salinas,

desinfectantes, blanqueadores o compuestos de limpieza. Muchos de estos

compuestos contienen productos químicos que pueden ser dañinos.

Enjuague con agua después de la exposición a estos compuestos y seque con

un trapo limpio.

Las superficies pintadas deben limpiarse solamente con agua tibia y un detergente

suave.

- 34 -

Page 35

PREPARACIÓN DE LA CAMPANA

Desempaque la campana y revise el contenido del paquete.

Debe contener lo siguiente:

1 campana

1 conectador del regulador de tiro/conducto de 8 pulg.

1 visor de vidrio

1 separador ornamental

1 bolsa de piezas con:

2 soportes de montaje

4 tornillos de máquina (M4 x 30 mm, cabeza troncocónica)

7 tornillos (3.9 x 9.5 mm, cabeza troncocónica)

4 arandelas planas (4 mm de diámetro)

8 tornillos (4.2 x 15 mm, cabeza troncocónica)

1 folleto de instrucciones de instalación

CONECTADOR DEL REGULADOR

DE TIRO/CONDUCTO DE 8 PULG.

VISOR DE VIDRIO

2 SOPORTES DE MONTAJE

4 ARANDELAS PLANAS

SEPARADOR ORNAMENTAL

- 35 -

4 TORNILLOS DE

MÁQUINA

(M4 x 30 mm, CABEZA

TRONCOCÓNICA)

8 TORNILLOS

(4.2 x 15 mm, CABEZA

TRONCOCÓNICA)

7 TORNILLOS DE

MONTAJE

(3.9 x 9.5 mm, CABEZA

TRONCOCÓNICA)

Page 36

PREPARE EL GABINETE DE

LA PARED

1. Antes de la instalación del gabinete de pared,

saque las puertas y los herrajes de montaje de

la puerta.

2. En el panel inferior recorte una abertura de las

dimensiones mostradas.

3. Recorte las aberturas para el conducto y el

cableado eléctrico.

4. Instale el gabinete en la pared y asegúrelo

según las recomendaciones del fabricante.

Antes de instalar la campana, es necesario fijar

el gabinete firmemente en los montantes y en

la estructura detrás de la placa de yeso.

ANCHO DEL

GABINETE

30 pulg.

36 pulg.

“A”

28 1/2 pulg.

34 1/2 pulg.

“B”

15 pulg.

18 pulg.

42 pulg.

40 1/2 pulg.

21 pulg.

PREPARACIÓN DE LA CAMPANA

1. Instale (sin apretar) ambos soportes de montaje

en la campana mediante los tornillos de

máquina M4 x 30 mm y las arandelas planas.

2. Coloque el conectador del regulador de tiro/

conducto de 8 pulg. por encima de la abertura

de descarga de la campana. Quite la cinta de

las aletas del regulador de tiro. Asegure con

(4) tornillos de 3.9 x 9.5 mm.

3. Instale el separador de pared en la campana

mediante los (3) tornillos de 3.9 x 9.5 mm.

NOTA: El separador está diseñado para llenar

una brecha de 5/8 de pulg. (1.5 cm) entre la

pared y la parte posterior de la campana. En

caso de que la brecha sea mayor, se deberá

rellenarla con un material no combustible que

cumpla con los códigos de construcción

locales.

TORNILLOS DE MONTAJE

TORNILLOS

DE MÁQUINA

(M4x30mm)

ARANDELA

TORNILLOS DE

MONTAJE

(3.9x9.5mm)

SEPARADOR DE PARED

(3.9x9.5mm)

- 36 -

Page 37

INSTALACIÓN DE LA CAMPANA

NOTA: Se requieren al menos tres personas

para montar la campana.

1. Eleve la campana hacia el gabinete de la pared.

Ajuste los soportes para que hagan contacto

con las paredes internas del gabinete.

2. Asegúrese de que el borde frontal del soporte

del cajón de la campana esté alineado con la

parte frontal del gabinete de la pared. Centre la

campana en el gabinete de la pared.

3. Apriete los (4) tornillos de máquina en los

soportes de montaje instalados previamente.

4. Asegure la campana al gabinete con (8) tornillos

de cabeza troncocónica de 4.2 x 15 mm. Tenga

cuidado de que los tornillos no penetren las

paredes laterales del gabinete terminado.

5. Abra el cajón deslizante. Coloque el panel de

vidrio en el área empotrada del cajón.

6. Deslice el vidrio hacia la izquierda o hacia la

derecha hasta que quede centrado en la

abertura y sujeto firmemente.

- 37 -

Page 38

SELECCIÓN DEL VENTILADOR EXTERIOR O DEL

VENTILADOR IN-LINE

PRECAUCIÓN: con este tipo de campana se deben utilizador tanto un ventilador

exterior como un ventilador in-line. La campana U102E debe instalarse

utilizando ventiladores de los modelos EB6, EB9, EB12, EB15, ILB3, ILB6, ILB9

o ILB11 únicamente. No pueden reemplazarse por otro tipo de ventiladores (los

ventiladores se venden por separado).

El ventilador tiene que estar incluido en la lista UL para el uso en Canadá y USA

y tiene que ser evaluada la utilización con “dispositivo de control de la velocidad”

en el estado sólido y los datos de su placa son 120 V, 60 Hz, 6.0 A máx.

INSTALACIÓN DEL SISTEMA DE CONDUCTOS

NOTA: Para reducir el riesgo de incendio,

use solamente conductos metálicos.

1. Elija la ubicación para el montaje del ventilador exterior. En las ilustraciones de

abajo se muestran sugerencias y restricciones para la ubicación del montaje.

2. Un conducto recto y corto permitirá que la campana funcione más eficientemente.

3. Los tramos largos de conductos, codos y transiciones reducirán el rendimiento

de la campana. Use tan pocos de ellos como sea posible. Es posible que se

requieran conductos más grandes de para un mejor funcionamiento con tramos

largos de conductos.

4. Una vez instalado el ventilador exterior, conecte el conducto metálico redondo y

trabaje hacia atrás, hacia la ubicación de la campana. Use cinta para conductos

para sellar las uniones entre las secciones de conductos.

5. Se requiere una transición redonda de 8 pulg. a 10 pulg. (modelo 414). Para

lograr el mejor rendimiento del aire, instale el adaptador tan cerca de la campana

de estufa como sea posible.

VENTILADOR EXTERIOR

CONDUCTO

REDONDO DE

UBICACIONES DE MONTAJE SUGERIDAS

ACEPTABLE

VENTILADOR

EXTERIOR

10 PULG. (25.4

CM)

ADAPTADOR

REDONDO

DE 8 (20.3

CM) A 10

PULG.(25.4

CM)

ACEPTABLE

PRECAUCIÓN: PODRÍA NO

CABER DEBAJO DEL ALERO

DE CASAS DE UN SOLO PISO

CONDUCTO

REDONDO DE 8

PULG.(20.3 CM)

CAMPANA

- 38 -

MÍNIMO DE 22 1/2

PULG. (57.1cm)

SOBRE LA

SUPERFICIE DE

COCINADO.

CODO REDONDO

DE 8PULG. (20.3

CM)

VENTILADOR

EXTERIOR

CONDUCTO

REDONDO

DE 10

PULG. (25.4

CM)

Page 39

VENTILADOR IN-LINE

- 39 -

Page 40

CABLEADO

PRECAUCIÓN: Una o más personas

calificadas deben realizar el trabajo de

cableado eléctrico, de acuerdo con todos

los códigos y normas correspondientes.

Esta campana debe estar

adecuadamente conectada a tierra.

No encienda la energía eléctrica en el

panel de servicio antes de conectar

todos los cables.

Conexión del ventilador en la campana:

1. Tienda un cable eléctrico de dos hilos y

conexión a tierra desde el ventilador

exterior o “In-Line” hasta la caja de

cableado marcada “motor connection”

(“conexión del motor”).

2. Quite la tapa de la caja de cableado.

3. Fije el “conduit” a la caja de conexión por

medio de un conector idóneo para el

“conduit”.

4. Haga las conexiones eléctricas en la

campana. Conecte blanco con blanco,

rojo con negro y verde con tierra.

5. Vuelva a colocar la cubierta de la caja de

conexiones y los tornillos.

Asegúrese de que los cables no queden

atrapados entre la cubierta y la caja.

Conexión del ventilador exterior o “InLine”:

1. Haga las conexiones eléctricas en el

ventilador exterior o “In-Line” (consulte las

instrucciones adjuntas a éste).

Conexión de energía eléctrica en la

campana:

1. Tienda el cableado de la casa de 120 VCA

a la caja de cableado de la campana

marcada “120VAC input” (“entrada de 120

VCA”).

2. Quite la tapa de la caja de cableado.

3. Fije el “conduit” a la caja de conexión por

medio de un conector idóneo para el

“conduit”.

4. Haga las conexiones eléctricas en la

campana. Conecte blanco con blanco,

negro con negro y verde con tierra.

5. Vuelva a colocar la cubierta de la caja de

conexiones y los tornillos. Asegúrese de

que los cables no queden atrapados entre

la cubierta y la caja.

CONEXIÓN DEL VENTILADOR

EN LA CAMPANA

VENTILADOR

EXTERIOR O

«IN-LINE»

CAJA MARCADA

“MOTOR

CONNECTION”

CONECTAR: BLANCO CON BLANCO

ROJO CON NEGRO

VERDE CON TIERRA

CONEXIÓN DE ENERGÍA

ELÉCTRICA EN LA CAMPANA

LÍNEA DE ENTRADA DE 120 V 60 HZ

CONECTAR:

BLANCO CON BLANCO

NEGRO CON NEGRO

VERDE CON TIERRA

CAJA MARCADA

“120 VAC INPUT”

- 40 -

Page 41

INSTALACIÓN DE FILTROS

Para instalar el FILTRO DE GRASA, sujete

la aleta de cierre y empújela hacia abajo.

Esto desprenderá el filtro de la campana.

Para quitar el FILTRO DE GRASA, alinee las

aletas del filtro (situadas en un lado del filtro)

con las ranuras que están en el cajón de la

campana. Apriete la aleta de cierre hacia

abajo, empuje el filtro hacia arriba y suelte la

aleta. Asegúrese de que el filtro esté

seguramente instalado después de la

instalación.

FILTRO DE GRASA

GARANTÍA

Broan-NuTone LLC garantiza al consumidor comprador original de sus productos que tales productos estarán libres de

defectos en materiales o mano de obra durante un período de un año a partir de la fecha de la compra original. NO EXISTEN

OTRAS GARANTÍAS, EXPRESAS NI IMPLÍCITAS, INCLUIDAS (PERO SIN LIMITARSE A) GARANTÍAS IMPLÍCITAS

DE COMERCIALIZACIÓN O IDONEIDAD PARA UN PROPÓSITO PARTICULAR.

Durante este período de un año, Broan-NuTone LLC, a su criterio, reparará o reemplazará, sin cargo alguno, cualquier pieza

o producto que se encuentre defectuoso bajo condiciones normales de uso y servicio.

ESTA GARANTÍA NO SE EXTIENDE A ARRANCADORES Y TUBOS DE LÁMPARAS FLUORESCENTES NI A

BOMBILLAS DE HALÓGENO E INCANDESCENTES. Esta garantía no cubre (a) mantenimiento y servicio normales ni

(b) ningún producto o piezas que se hayan sometido a uso inadecuado, negligencia, accidente, mantenimiento o reparación

inadecuada (no hecha por Broan-NuTone LLC), instalación incorrecta o instalación en contra de las instrucciones de

instalación recomendadas.

La duración de cualquier garantía implícita se limita al período de un año como se especifica para la garantía explícita.

Algunos estados no permiten la limitación de la duración de una garantía implícita, de manera que las limitaciones antedichas

pueden no aplicar a usted.

LA OBLIGACIÓN DE BROAN-NUTONE LLC DE REPARAR O REEMPLAZAR, A OPCIÓN DE BROAN-NUTONE LLC,

SERÁ EL ÚNICO Y EXCLUSIVO RECURSO DEL COMPRADOR BAJO ESTA GARANTÍA. BROAN-NUTONE LLC NO

SERÁ RESPONSABLE POR DAÑOS INCIDENTALES, RESULTANTES O ESPECIALES QUE SURJAN DE O EN

RELACIÓN CON EL USO O RENDIMIENTO DEL PRODUCTO.

Algunos estados no permiten la exclusión o la limitación de daños incidentales o resultantes, de manera que es posible que

la limitación antedicha no aplique en su caso.

Esta garantía le da derechos legales específicos, y usted puede tener otros derechos que varían entre estados. Esta garantía

sustituye a todas las garantías anteriores.

Para tener derecho al servicio cubierto por la garantía, debe (a) notificar a Broan-NuTone LLC a la dirección que se indica

abajo, o al teléfono: 1-800-637-1453, (b) dar el número de modelo y la identificación de la pieza y (c) describir la naturaleza

de cualquier defecto en el producto o pieza. En el momento de solicitar el servicio de la garantía, debe presentar comprobante

de la fecha de la compra original.

BEST BY BROAN, P.O. Box 140 Hartford, Wisconsin 53027

GARANTÍA LIMITADA DE UN AÑO DE BROAN-NUTONE LLC

- 41 -

Page 42

PIEZAS DE REPUESTO

MODELO U102E

- 42 -

Page 43

PIEZAS DE REPUESTO

MODELO U102E. Se muestran las piezas para los modelos de acero inoxidable. Si

desea información sobre piezas de servicios para los modelos negro, blanco, de

latón pulido o de cobre cepillado, llame al depto. de Servicio al cliente de Broan.

CLAVE N.° PIEZA N.° DESCRIPCIÓN

9 B08087077 Filtro de grasa (modelo de 36 pulg.)

9 B08087016 Filtro de grasa (modelo de 30 pulg.)

9 B08087017 Filtro de grasa (modelo de 42 pulg.)

17 BE3347241 Soporte de halógeno (modelo de 36 pulg.)

17 BE3347372 Soporte de halógeno (modelo de 30 pulg.)

17 BE3347378 Soporte de halógeno (modelo de 42 pulg.)

30 BE3347340 Protección de controles (modelo de 36 pulg.)

30 BE3347370 Protección de controles (modelo de 30 pulg.)

30 BE3347259 Protección de controles (modelo de 42 pulg.)

36 BE3403716 Bastidor del filtro (modelo de 36 pulg.)

36 BE3403765 Bastidor del filtro (modelo de 42 pulg.)

37 B02300804 Termostato Heat Sentry

38 B03292357 Caja de conexiones

39 B03294033 Cubierta de la caja de conexiones

73 B02005069 Visor de vidrio (modelo de 36 pulg.)

73 B02005070 Visor de vidrio (modelo de 30 pulg.)

73 B02005071 Visor de vidrio (modelo de 42 pulg.)

84 BE3403714 Visor de pantalla (modelo de 36 pulg.)

84 BE3403752 Visor de pantalla (modelo de 30 pulg.)

84 BE3403762 Visor de pantalla (modelo de 42 pulg.)

112 B03294746 Protección del cableado

113 B02011284 Etiqueta

115 BE3334250 Caja de conexiones

116 BE3334252 Cubierta de la caja de conexiones

130 B003101208 Panel frontal (modelo de 36 pulg.)

130 B003101220 Panel frontal (modelo de 30 pulg.)

130 B003101227 Panel frontal (modelo de 42 pulg.)

144 B03292287 Abrazadera de cables

166 B08086701 Tablero de conexiones

208 B02300783 Transformador

223 B03294171 Pulsador del interruptor

233 B03294740 Cierre

252 B03292349 Caja del microconmutador

253 B02300620 Microconmutador

254 B03292350 Cubierta de la caja del microconmutador

288 B020111650 Deslizador del cajón

309 B003101216 Separador (modelo de 36 pulg.)

309 B003101222 Separador (modelo de 30 pulg.)

309 B003101228 Separador (modelo de 42 pulg.)

353 BE3403713 Soporte de pantalla (modelo de 36 pulg.)

353 BE3403751 Soporte de pantalla (modelo de 30 pulg.)

353 BE3403761 Soporte de pantalla (modelo de 42 pulg.)

472 BE3347252 Soporte derecho

473 BE3347251 Soporte izquierdo

474 B02300733 Lámpara de halógeno

476 B03292203 Panel separador

477 B03294785 Cierre superior

998 B080810599 Paquete de herraje

ARU B08092501 Conjunto de aleta de no retorno y brida (56, 57)

* B06108277 Conjunto de la caja de interruptor: incluye las

- B02300782 Fusible

- B02300674 Portafusibles

* No se muestra montado.

piezas de clave n.° 234, 228, 223, 229, 67, 230,

92

- 43 -

Page 44

04307336/1N

Loading...