IP29M SERIES

INTENDED FOR DOMESTIC COOKING ONLY

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

HOMEOWNER: USE AND CARE AND OPERATION INFORMATION

ON PAGES 12 TO 15.

SV08072 rev. I

INSTALLATION INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

!

!

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800-558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.com 866-737-7770

REGISTER YOUR PRODUCT ON LINE AT: www.BestRangeHoods.com/register

HB0063

WARNING WARNING

- 2 -

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address or telephone number

listed in the warranty.

2. Before servicing or cleaning unit, switch power

off at service panel and lock service disconnecting

means to prevent power from being switched on

accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be

done by qualified personnel in accordance with all

applicable codes and standards, including fire-rated

construction codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of

fuel burning equipment to prevent backdrafting.

Follow the heating equipment manufacturer’s

guidelines and safety standards such as those

published by the National Fire Protection

Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any additional solid-state

speed control device.

8. To reduce the risk of fire, use only steel ductwork.

9. This unit must be grounded.

10. When applicable local regulations comprise

more restrictive installation and/or certification

requirements, the aforementioned requirements

prevail on those of this document and the installer

agrees to conform to these at his own expenses.

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

a) Never leave surface units unattended at high

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low or

medium settings.

b) Always turn hood ON when cooking at high heat or

when flambeing food (i.e.: Crêpes Suzette,

Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should

not be allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate

for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS

IN THE EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie

sheet or metal tray, then turn off the burner.

BE CAREFUL TO PREVENT BURNS. IF THE

FLAMES DO NOT GO OUT IMMEDIATELY,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN—You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or

towels—This could cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and you

know how to operate it.

B. The fire is small and contained in the area

where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

!

!

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray,

construction dust, etc. off power unit.

4. Your hood motor has a thermal overload which will

automatically shut off the motor if it becomes

overheated. The motor will restart when it will be

cooled down. If the motor continues to shut off and

restart, have the hood serviced.

5. For best capture of cooking impurities, the bottom

of the hood should be at a minimum of 30” and at

a maximum of 36” above the cooking surface.

6. Two installers are recommended because of the

large size and weight of this hood.

7. To reduce the risk of fire and to properly exhaust

air, be sure to duct air outside—Do not exhaust air

into spaces within walls or ceiling or into attics,

crawl space or garage.

8. This product is equipped with a thermostat which

may start blower automatically. To reduce the risk

of injury and to prevent power from being switched

on accidentally, switch power off at service panel

and lock or tag service panel.

9. Because of the high exhausting capacity of this

hood, you should make sure enough air is entering

the house to replace exhausted air. Use an appropriate

make-up air device or open a window close to or in

the kitchen.

10. To reduce the risk of fire and electric shock, the

Best IP29M Series hood must be installed with

Best interior blower models

P6 or P12; Best exterior

blower models

EB6, EB9, EB12 or EB15; Best

in-line blowers models ILB3, ILB6, ILB9, ILB11.

Other blowers cannot be substituted. (Blowers sold

separately.)

11. Please read specification label on product for

further information and requirements.

- 3 -

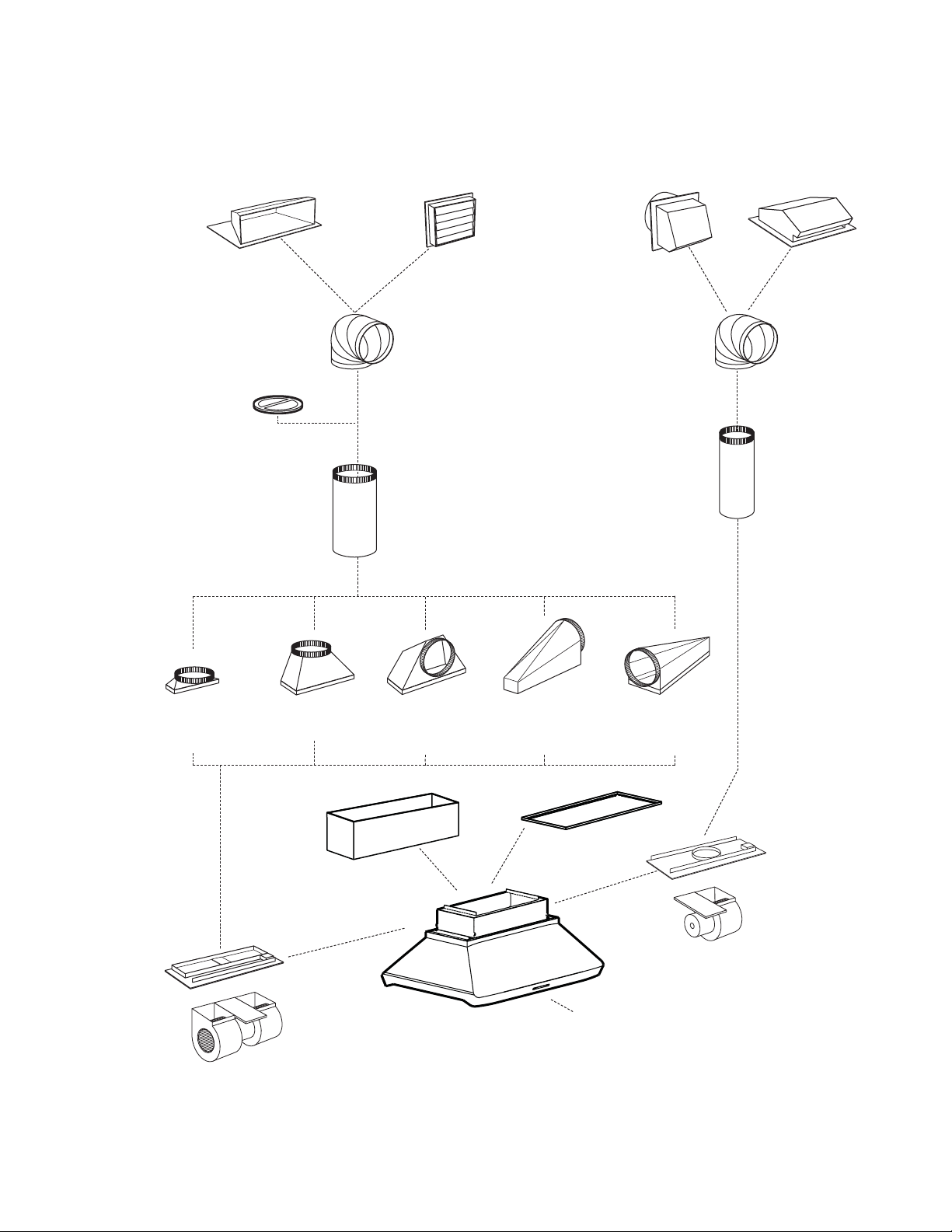

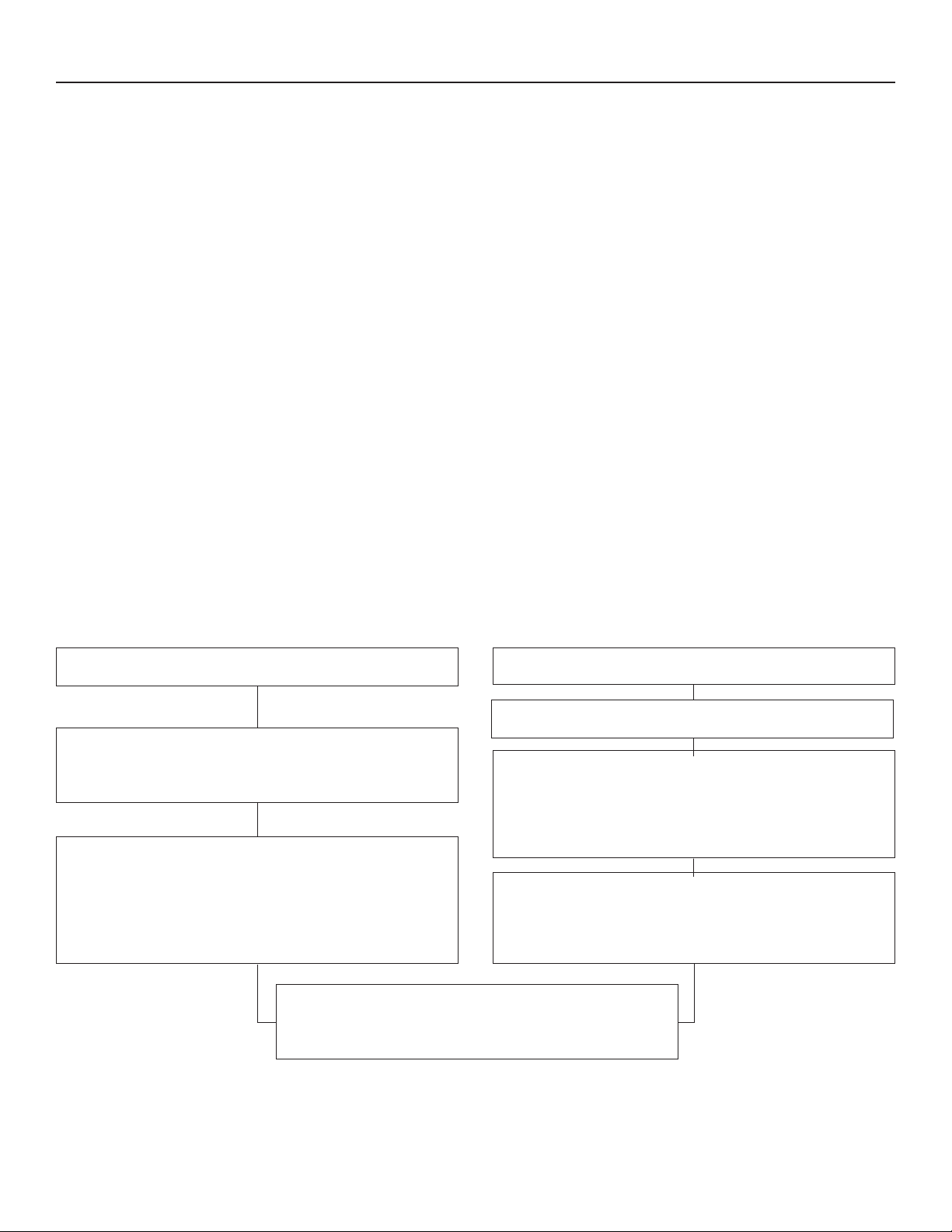

Model 415

(7” round adjustable elbow)

Model 427

(4½” x 18½”

to 10” Round,

6” high - lateral

Model 423

(4½” x 18½” to

10” Round - vertical

Model 424

(4½” x 18½” to

10” Round - horiz.

front/rear

Model 454

(4½” x 18½”

to 10” Round -

horiz. /right

Model 453

(4½” x 18½”

to 10” Round -

horiz. /left

IP29M SERIES

HOOD

(Canopy with

blower controls

& lighting.

Required for all

installations.)

OPTIONAL

DECORATIVE FLUE

AEIP SERIES

OPTIONAL

DRYWALL TRIM

ATDIP SERIES

- IP29M SERIES RANGE HOOD SYSTEM -

INTERIOR BLOWERS

Model 437

(High capacity roof cap)

Model 441

(10’’ Round wall cap)

Model 634 or 644

(roof cap)

Model 647

(7” Round wall cap)

Model 407

(7” round duct—2 ft. sections)

Model 410

(10” round duct—2 ft. sections)

MODEL P6

BLOWER/ROUGH-IN KIT

(600 cfm interior blower &

rough-in plate)

MODEL P12

BLOWER/ROUGH-IN KIT

(1200 cfm interior blower

& rough-in plate)

Model 418

(10” round adjustable elbow)

Model 421

(10” Round Vertical

In-line damper —

Optional)

HL0091

- 4 -

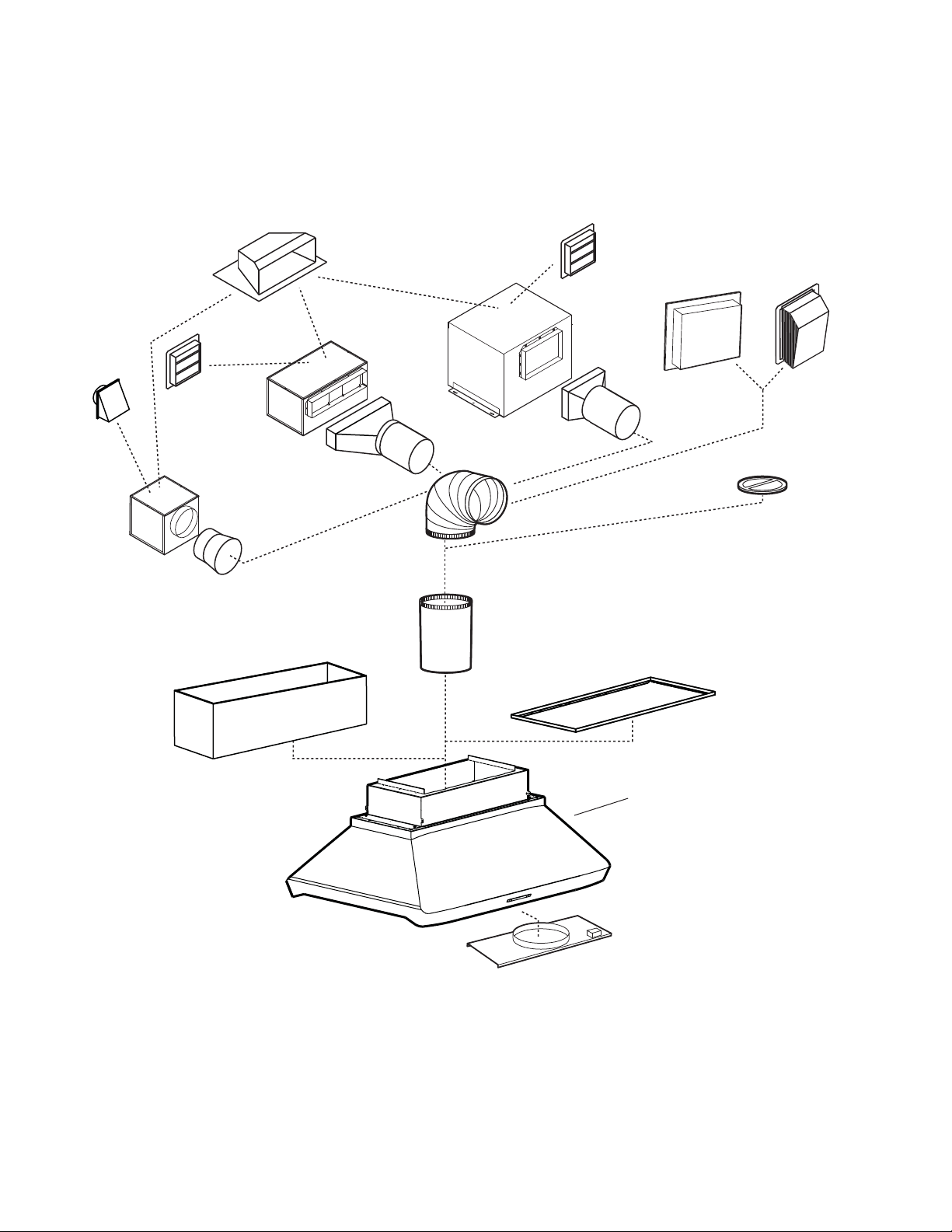

- IP29M SERIES RANGE HOOD SYSTEM -

IN-LINE AND EXTERIOR BLOWERS

In-line and exterior blower rough-in kit

(included with EB6, EB9, EB12, EB15,

ILB3, ILB6, ILB9 and ILB11 blowers.)

Model 418

10” Round

adjustable elbow

(optional)

Model ILB3 (280 cfm)

in-line blower

(includes one 8” to 10”

round transition)

Model EB6 (600 cfm)

or EB9(900 cfm)

exterior blower

Model EB12 (1200 cfm)

or EB15 (1500 cfm)

exterior blower

Model 441

(10” Round

wall cap)

Model 437

(High capacity roof cap)

Model 441

(10” Round wall cap)

Model 421

(10” Round vert.

in-line damper)

Recommended

for use with

exterior blowers

Model 410

(10” Round duct

—2ft. sections)

Model ILB6 (600 cfm)

in-line blower

(includes two 4½” x 18½”

to 10’’ round transitions)

Model ILB9 (800 cfm)

or ILB11 (1100 cfm)

in-line blower

(includes two 8” x 12” to

10’’ round transitions)

IP29M SERIES

HOOD

(Canopy with

blower controls

& lighting.

required for all

installations.)

OPTIONAL

DECORATIVE FLUE

AEIP SERIES

OPTIONAL

DRYWALL TRIM

ATDIP SERIES

Model 643

(8” Round

wall cap)

HL0090

- 5 -

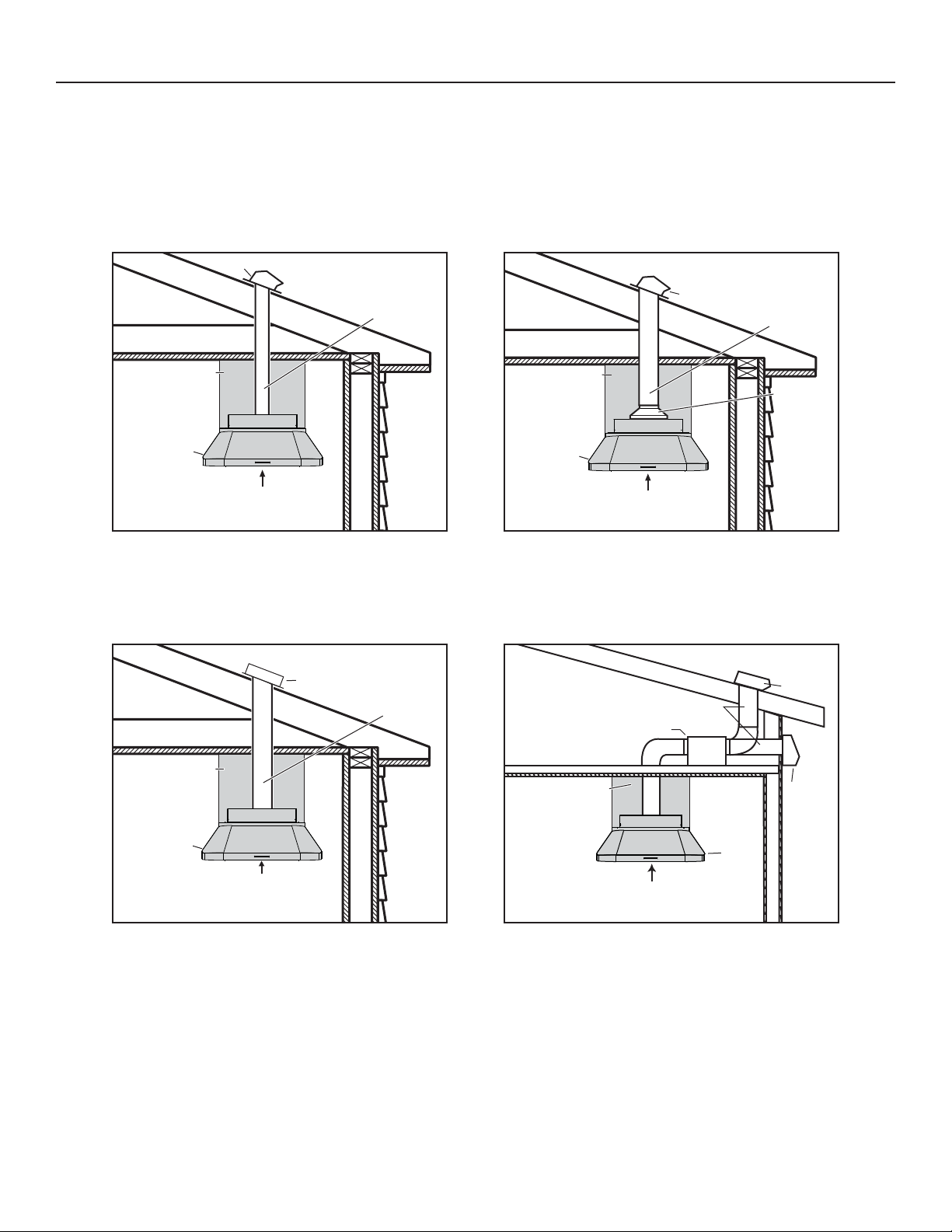

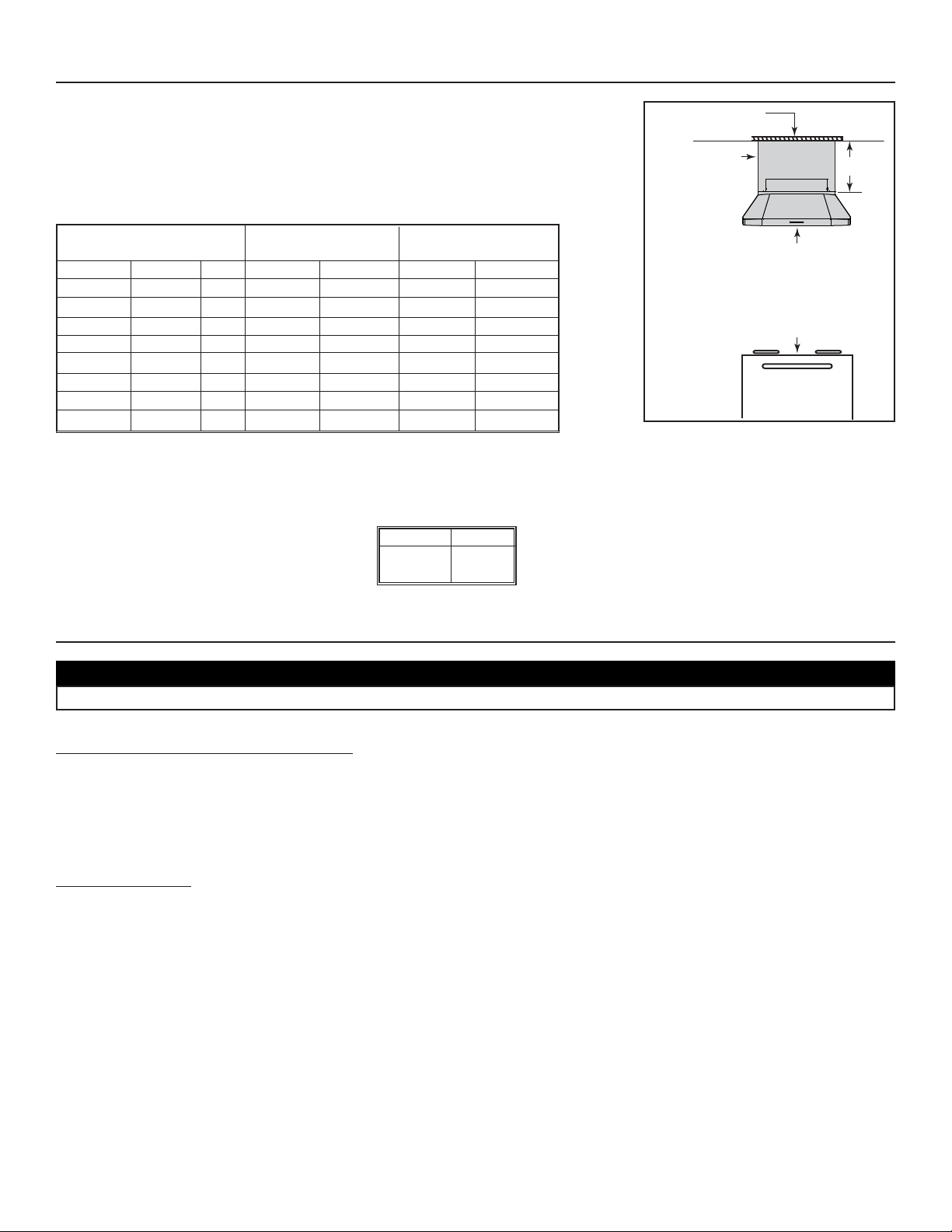

1. SELECT BLOWER OPTION AND INSTALLATION TYPE

Either an interior or an exterior blower or in-line blower may be used with this hood. The Best IP29M Series must be installed with

blower models P6, P12, ILB3, ILB6, ILB9, ILB11, EB6, EB9, EB12 or EB15 only. Other blowers cannot be substituted. (Blowers

sold separately.)

Plan where and how the ductwork will be installed.

If installing in-line blower, refer to instructions packed with in-line blower and follow steps 1 up to 9, 11 to 15, 17 and up of

this manual.

Install proper-sized ductwork, elbows and roof or wall cap for the type of blower you are installing. Use metal duct tape to seal duct joints.

7” (178) ROUND DUCT

ROOF CAP

30” TO 36” (762 to 914)

ABOVE COOKING SURFACE

HOOD

DECORATIVE

FLUE

12”, 18”, 24” or 30”

(305, 457, 610 or 762)

or TRIM

HH0080A

NOTE: Dimensions in ( ) are in mm.

MODEL P6 SINGLE INTERIOR BLOWER

TYPICAL DUCTWORK

10” (254) ROUND DUCT

ROOF CAP

30” TO 36” (762 to 914)

ABOVE COOKING SURFACE

HOOD

DECORATIVE

FLUE

12”, 18”, 24” or 30”

(305, 457, 610 or 762)

or TRIM

HH0081A

NOTE: Dimensions in ( ) are in mm.

ROUND

TRANSITION

4½” x 18½”

to 10”

(114 x 470

to 254)

(see page 3)

MODEL P12 DUAL INTERIOR BLOWER

TYPICAL DUCTWORK

10” (254)

ROUND DUCT

EXTERIOR

BLOWER

30” TO 36” (762 to 914)

ABOVE COOKING SURFACE

HOOD

DECORATIVE

FLUE

12”, 18”, 24” or 30”

(305, 457, 610 or 762)

or TRIM

HH0082A

NOTE: Dimensions in ( ) are in mm

MODEL EB6, EB9, EB12 OR EB15

EXTERIOR BLOWER TYPICAL DUCTWORK

IN-LINE BLOWER

HH0083A

30” TO 36 ” [762 to 914]

ABOVE COOKING SURFACE

ROOF CAP

WALL

CAP

HOOD

NOTE: Dimensions in [ ] are in mm.

DECORATIVE

FLUE

12”, 18”, 24” or 30”

[305, 457, 610 or 762]

or TRIM

10” [254] ROUND DUCT

(except ILB3, 8’’ [203] ROUND DUCT)

MODEL ILB3, ILB6, ILB9 OR ILB11

IN-LINE BLOWER TYPICAL DUCTWORK

Remove the installation kit from inside the hood.

Make sure that the following items are included:

- Installation manual

- Accessories including:

• 3 Evolution™ hybrid baffle filters

• Shielded halogen lights (GU10 type base, 120 V, 50 W) (6 for 42” width hoods, 8 for 54” width hoods)

• Bag of parts including:

(10) steel wood screws no. 10 x 1.5’’, (10) steel washer no. 10, (6) screws no. 8 x 3/8’’ (additional screws provided)

Parts sold separately:

- Interior blower Model P6 (includes rough-in kit).

- Interior blower Model P12 (includes rough-in kit).

- In-line blower assembly ILB3, ILB6, ILB9 or ILB11 (all include transition and rough-in plate)

- Exterior blower assembly EB6, EB9, EB12 or EB15 (all include rough-in plate).

- Transitions, duct, elbows, dampers, wall and roof caps. Refer to pages 3 and 4 for a complete list of venting options and model numbers.

- Optional decorative flue cover AEIP Series, 12’’, 18”, 24” or 30” height and 42” or 54” width.

- Optional dry wall trim ATDIP Series, 42” or 54” width.

- 6 -

3. PREPARE THE INSTALLATION

2. MEASURE INSTALLATION

Dimensions for the most common installation are shown beside.

The minimum hood distance above cooktop must not be less than 30’’. A maximum of

36” above cooktop is highly recommended for best capture of cooking impurities.

Distances over 36” are at the installer and users discretion.

Since framework must be flush to ceiling, 4 decorative flue covers have been created to fit

both hood widths and different ceiling heights. Refer to table below to choose the model that

fits your needs.

If a drywall box will be built instead of installing decorative flue cover, use drywall trim to hide hood and drywall junction. Refer to table

below to find the appropriate model for your hood width.

L

INKLOGIC® ENABLED HOOD

This hood includes the LinkLogic system which allows communication over ordinary household electrical wiring to other LinkLogic

devices including the Broan Smart Sense Fan system. If you intend to use this hood with another LinkLogic device, follow the instructions

found in section 21 along with the instructions that come with the LinkLogic device you plan to use.

MINIMUM AND MAXIMUM DISTANCE

OVER COOKTOP

CAUTION

When performing installation, servicing or cleaning the unit, it is recommended to wear safety glasses and gloves.

DECORATIVE FLUE COVER

8’ CEILING 9’ CEILING

DISTANCE FROM COOKTOP DISTANCE FROM COOKTOP

MODEL A (HEIGHT)WIDTH 30” 36” 30” 36”

AEIP422 12” 42” X

AEIP542 12” 54” X

AEIP428 18” 42” X

AEIP548 18” 54” X

AEIP424 24” 42” X

AEIP544 24” 54” X

AEIP420 30” 42” X

AEIP540 30” 54” X

MODEL WIDTH

ATDIP42 42”

ATDIP54 54”

NOTE: For ceilings over 9’, decorative flues are not available.

Framework

flush to ceiling

Decorative flue

cover or drywall

with trim

A

Minimum distance between

the hood and cooktop:

30’’ (762 mm)

Recommended maximum

distance between the hood

and cooktop: 36’’ (914 mm)

HH0084A

Standard 36”

(914 mm)

high cooktop

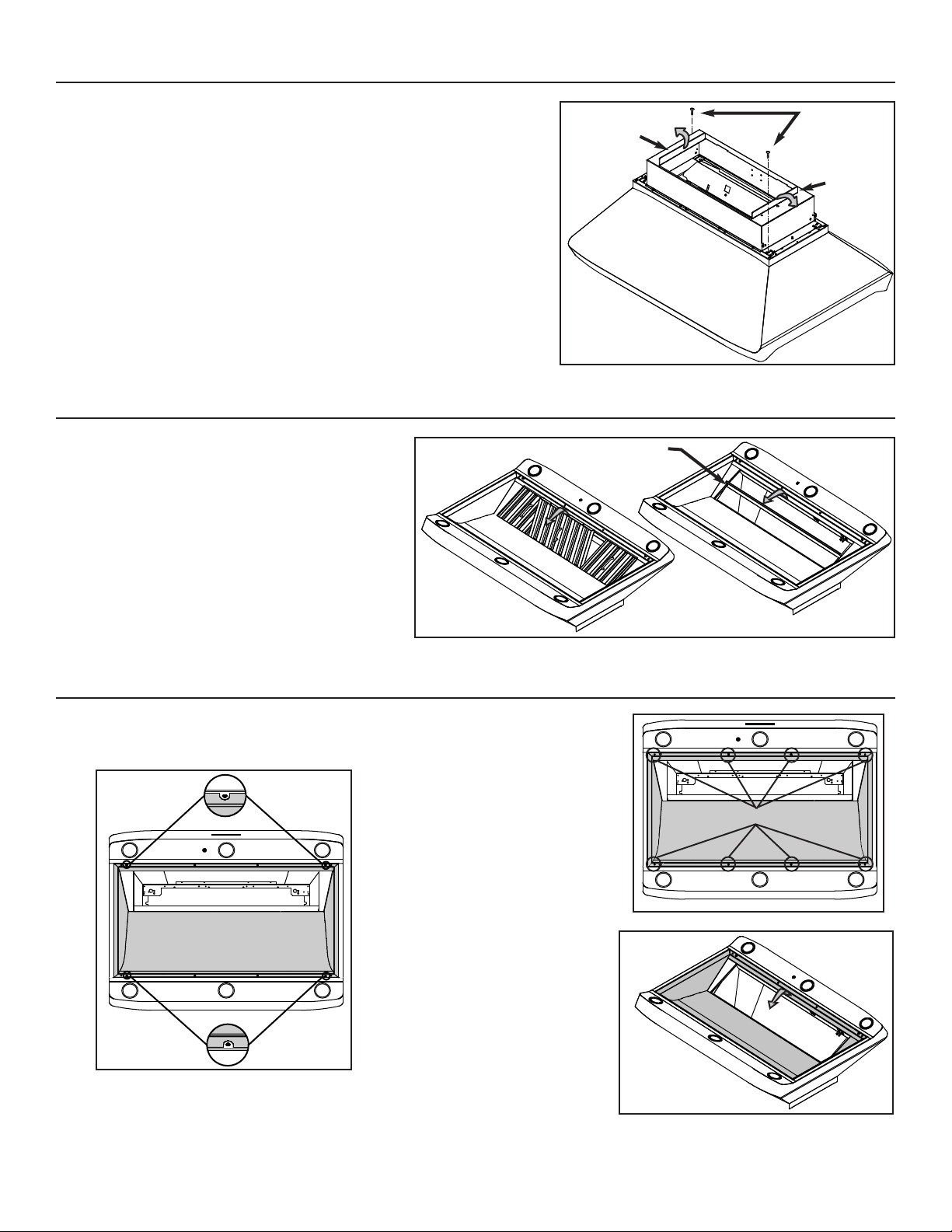

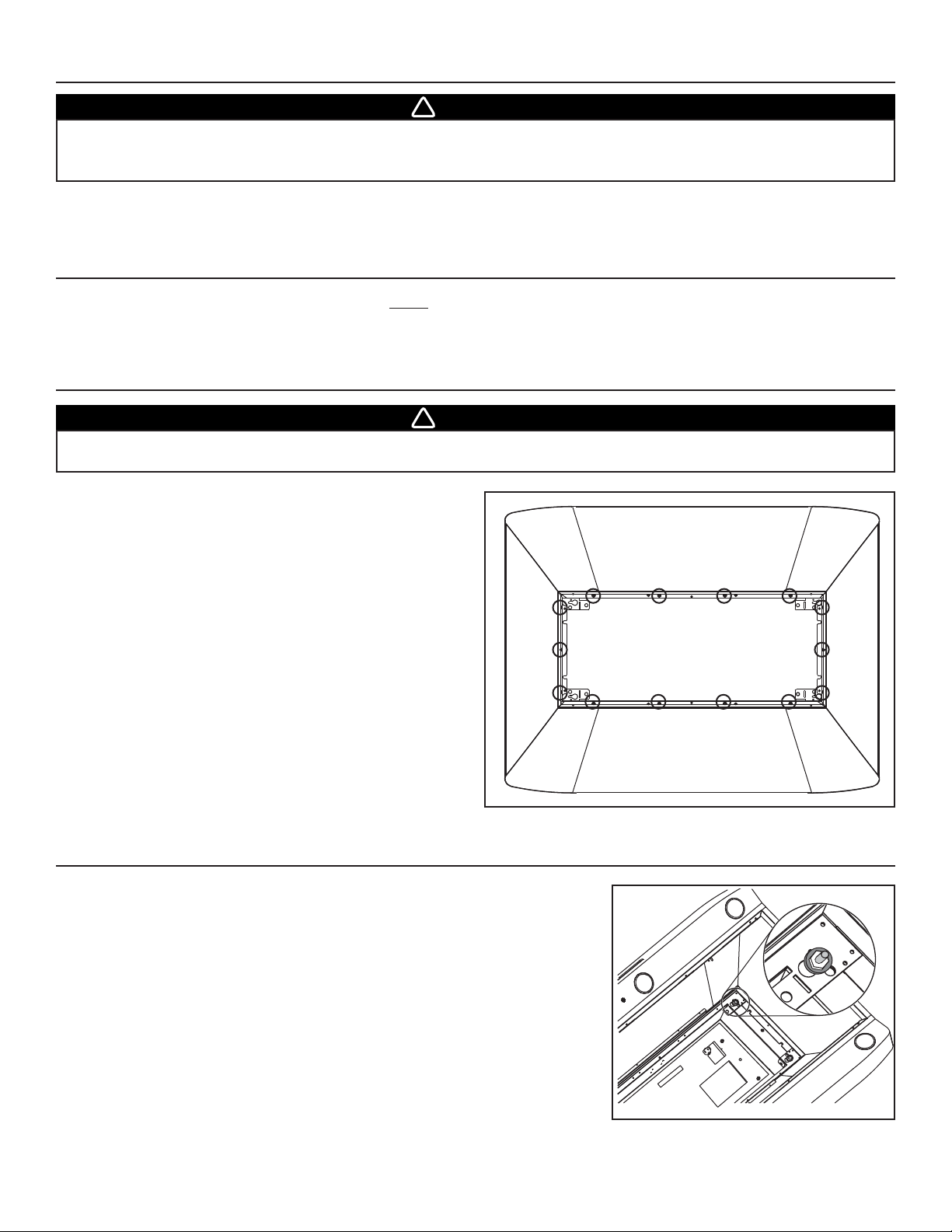

Using a Phillips no. 2, remove 8 screws

retaining the pan (shaded part on

illustration beside) to the hood.

Remove the pan and set aside.

- 7 -

5. REMOVE THE FILTERS AND THE GREASE DRIP RAIL

A. Remove tape on filters. Remove filters from hood and

set aside.

NOTE: It is recommended to start with the central one.

B. Remove tape on grease drip rail (1).

Lift out grease drip rail and set aside.

6. REMOVE THE PAN

NOTE: Do not remove the 4 screws located on the

notched parts of the pan (A on figure below).

1

A

A

4. PREPARE THE BLOWER HOUSING

Detach the blower housing from the hood by removing its both retaining screws (A).

Keep the screws for further use.

Fold up its both flanges (B). The flanges must be perpendicular to the top of the

blower housing.

A

B

B

RETAINING SCREWS LOCATION

HD0229

HD0222

HD0224

HD0223

HD0238

- 8 -

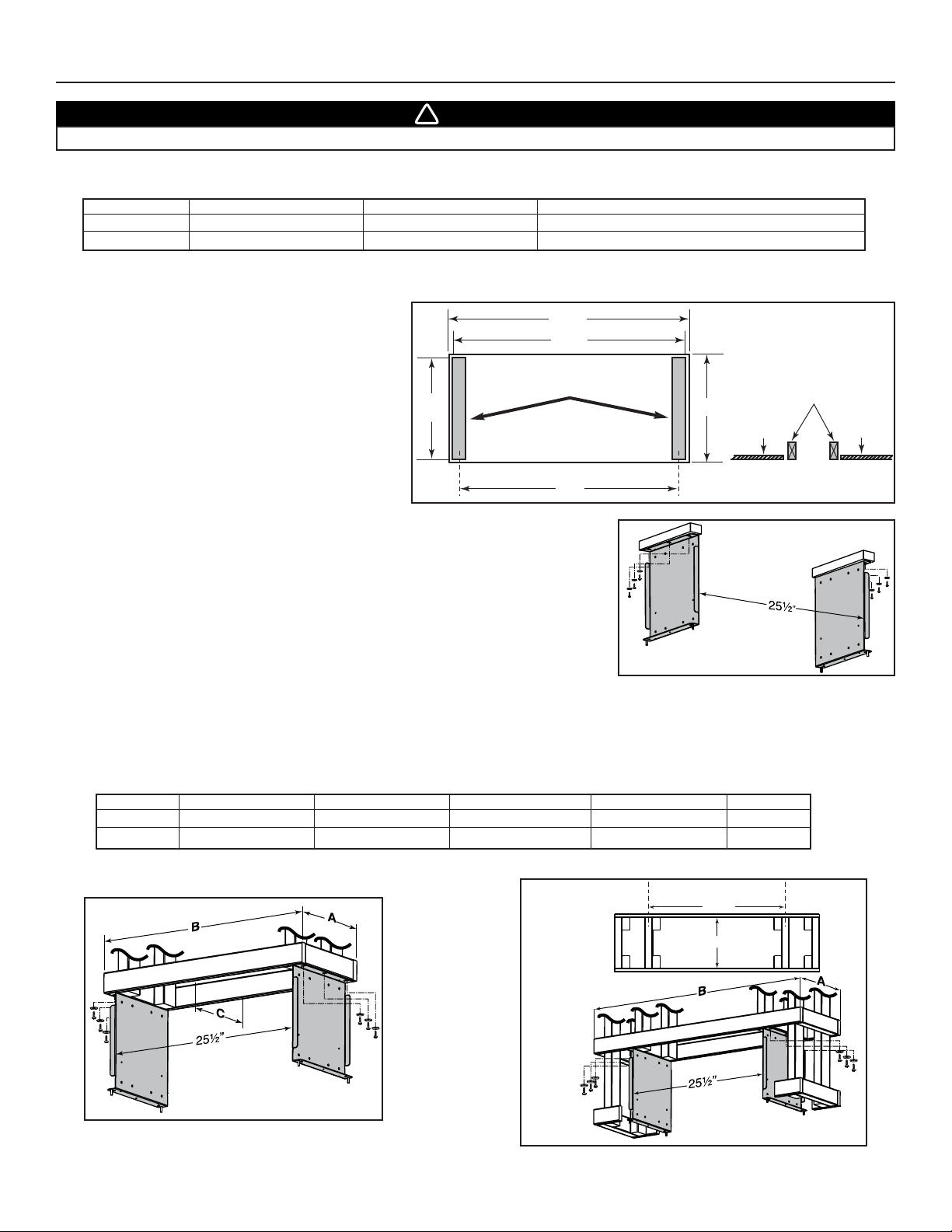

In the ceiling material, cut-out a 28¾” x 12½” max.

opening over the installation location. Install two

supporting studs inside the cut-out at dimensions

shown beside.

7. BUILD THE FRAMEWORK

7.1 SUGGESTED FRAMEWORK FOR INSTALLATION WITH DECORATIVE FLUE COVER AEIP SERIES

7.2 SUGGESTED FRAMEWORK FOR INSTALLATION WITH DRYWALL TRIM ATDIP SERIES

FRAMEWORK 54’’ HOOD

FRAMEWORK 42’’ HOOD

WARNING

When building framework, always follow all applicable construction codes and standards.

!

The framework must be sized to support the total weight of the hood. Refer to the table below for total weight of the hood, according to the

type of blower chosen.

HOOD WIDTH WITH P6 INTERIOR BLOWER WITH P12 INTERIOR BLOWER WITH IN-LINE OR EXT. BLOWER (ROUGH-IN PLATE ONLY)

42” 71 LB 84 LB 52 LB

54” 86 LB 99 LB 67 LB

SUPPORTING STUDS

Using provided wood screws no. 10 x 1.5” and washers, assemble both mounting brackets

(included with the optional decorative flue cover) to the framework. See illustration beside.

Below is the suggested framework for both 42” and 54” width hoods to be installed with drywall trim ATDIP Series. Refer to the table and

illustrations below for the dimensions according to the hood width. Using provided wood screws no. 10 x 1.5” and washers, assemble

both mounting brackets (included with the optional drywall trim) to the framework.

HOOD WIDTH A WITH 5/8” DRYWALL A WITH 1/2” DRYWALL B WITH 5/8” DRYWALL B WITH 1/2” DRYWALL C

42” 11

5

⁄8”11

7

⁄8”28

5

⁄8”28

7

⁄8” 10” MINIMUM

54” 115⁄8”11

7

⁄8”40

5

⁄8”40

7

⁄8” 10” MINIMUM

FRAMEWORK

TOP VIEW

28¾”

28½”

12½”

max.

12 /

5

8”

Studs flush

with ceiling material

Ceiling

material

Ceiling

material

C

L

HD0227A

C

L

27”

HD0228A

C

L

27¼”

C

C

L

HD0235A

HD0237A

- 9 -

INSTALLATION WITH

DRY WALL TRIM ATDIP SERIES

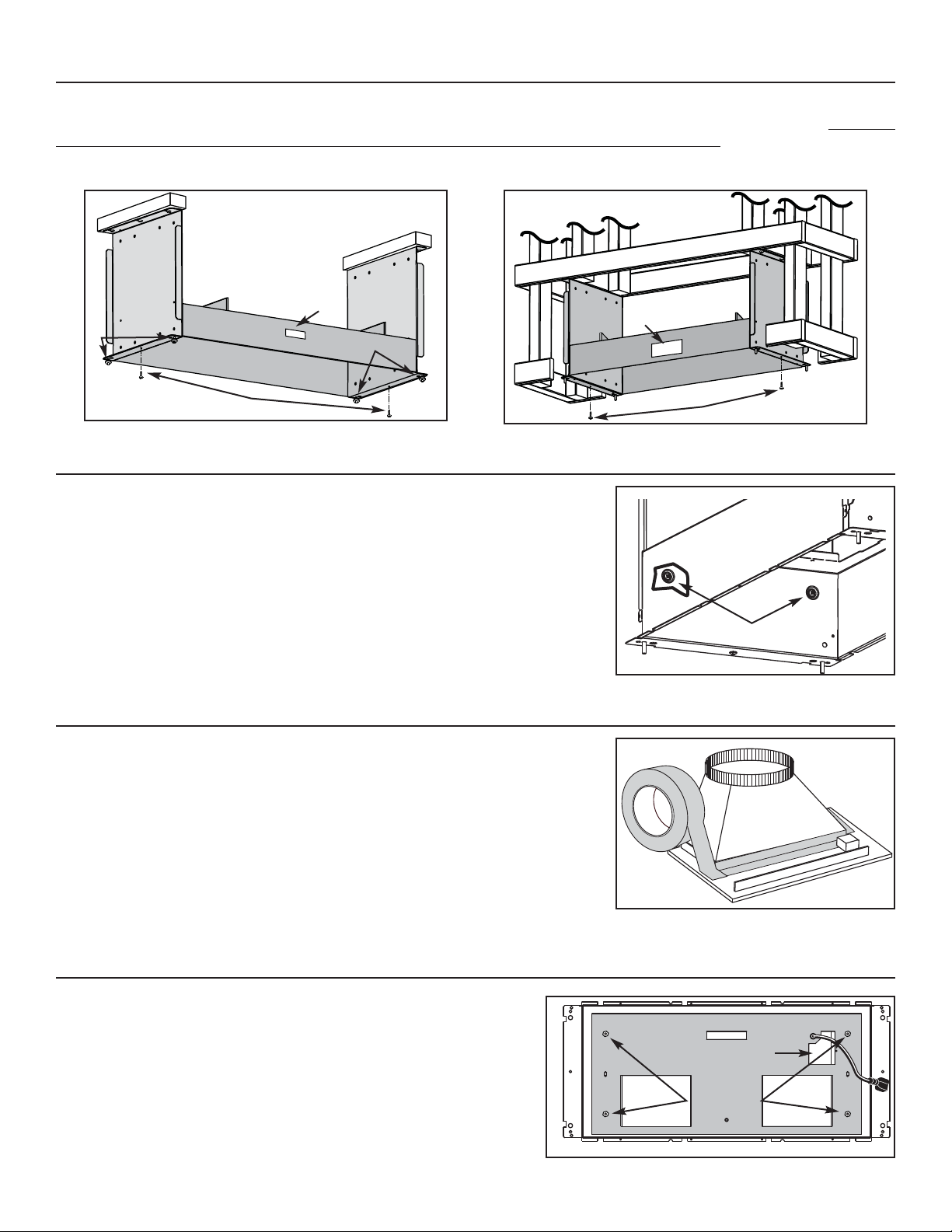

8. INSTALL BLOWER HOUSING

Use both screws (A) previously removed in step 4 to assemble the blower housing to the mounting brackets. For installation with decorative

flue cover AEIP Series only, place 4 nuts (B) (from flue cover parts bag) on the pem studs, leaving 1/4” for the hood installation. The blower

housing must be installed in such a way that its label (C) will be on the same side as the hood control side. See illustrations below.

INSTALLATION WITH

DECORATIVE FLUE COVER AEIP SERIES

A

B

B

Model 423, 424, 427 453, or 454

Attach transition (if required) to blower rough-in plate.

Use metal duct tape to make all joints secure and air-tight.

NOTE: Model P6 blower plate connects directly to 7’’ round ductwork without a transition.

10. INSTALL TRANSITION TO ROUGH-IN PLATE (INTERIOR BLOWER ONLY)

11. INSTALL THE ROUGH-IN PLATE IN THE BLOWER HOUSING

Run power cable to installation location. Refer to the instructions included with

the selected blower/rough-in kit (sold separately) for details on installing the

rough-in plate. Install the rough-in plate so that the wiring box is located on the

right side when facing the hood, as specified on the blower housing label.

Connect transition or rough-in plate to ductwork. Use metal duct tape to make

all joints secure and air-tight.

C

C

WIRING COVER

LOCK NUTS

A

From the inside, secure the blower housing to mounting brackets, using 2 no. 8 x 3/8”

screws per side.

Screws must be installed in embossed sections, see details beside.

9. SECURE BLOWER HOUSING TO BRACKETS

RETAINING SCREWS LOCATION

HD0230

HD0231

HO0100

HO0086

HD0232

- 10 -

15. INSTALL THE HOOD

15.1INSTALLATION WITH DECORATIVE FLUE COVER AEIP SERIES

Assemble the hood assembly to the mounting brackets by aligning keyholes with

4 nuts previously installed in step 8 (2 nuts per side). While holding the hood,

remove one nut and install a washer (included in parts bag) on each pem

stud, then reinstall the nut and tighten it. See illustration beside.

15.2INSTALLATION WITH DRY WALL TRIM ATDIP SERIES

Align hood keyholes with pem studs on brackets. Secure the hood to the brackets

using washers and nuts (included in parts bag). See illustration beside.

14. MOUNT THE DECORATIVE FLUE COVER OR THE DRY WALL TRIM ON THE HOOD

14.1INSTALLATION WITH DECORATIVE FLUE COVER

AEIP SERIES

Remove the protective plastic film covering the decorative flue

cover AEWP Series. Assemble the flue cover on top of hood

using (14) no. 8 x 3/8” screws (provided with decorative flue

cover). See illustration beside to locate mounting screws from

top of hood.

NOTE: Ensure edges fit perfectly before tightening completely

the mounting screws.

14.2INSTALLATION WITH DRY WALL TRIM ATDIP SERIES

Remove the protective plastic film covering the dry wall trim

ATDPI Series. Assemble the dry wall trim on the top of the

hood using (14) no. 8 x 3/8” screws (provided with dry wall

trim). See illustration beside to locate mounting screws from

top of hood.

NOTE: Ensure edges fit perfectly before tightening completely

the mounting screws.

WARNING

The decorative flue cover AEIP Series and the dry wall trim ATDIP Series may have sharp edges. Be careful when

handling and installing these metal parts.

!

MOUNTING SCREWS LOCATION

13. FINISH THE DRYWALL BOX (INSTALLATION WITH DRY WALL TRIM ATDIP SERIES ONLY)

Finish the drywall box. Check fitting with dry wall trim before mounting it to the hood.

12. CONNECT THE WIRING

Remove wiring cover from rough-in plate and set aside.

Connect BLACK to BLACK, WHITE to WHITE and GREEN or bare wire under GREEN ground screw. Reinstall wiring cover.

WARNING

Risk of electrical shock. Electrical wiring must be done by qualified personnel in accordance with all applicable

codes and standards. Before connecting wires, switch power off at service panel and lock service disconnecting

means to prevent power to be switched on accidentally.

!

HD0233

HD0234

17. REINSTALL THE PAN

Using a Phillips no. 2 or Robertson no. 2 screwdriver and the retaining screws, reinstall the pan

(previously removed in step 6) inside the hood (shaded part on illustration beside).

RETAINING SCREWS LOCATION

Reinstall grease drip rail (1). The illustration beside shows how to reinsert the

grease drip rail(s) into the range hood.

18. REINSTALL GREASE DRIP RAIL AND BAFFLE FILTERS

Reinstall Evolution™ hybrid baffle filters on

the hood.

It is recommended to install side filters first

and finish with center one.

1. Insert one end of Evolution™ hybrid baffle

filter into the front channel of the hood.

2. Raise the other end toward the inside of

hood and insert in the grease drip rail of

the hood.

Replacement filters are available from your

dealer. See label inside hood for size and

part number.

CAUTION

Remove protective plastic film covering Evolution™ hybrid baffle filters before installing them.

1

- 11 -

16. INSTALL THE BLOWER (INTERIOR OR EXTERIOR BLOWER)

Refer to instructions included with blower.

Once the blower is installed, plug the blower cord (A) into the female receptacle and the

power supply cord (B) onto the male connector inside the hood.

HE0078

WARNING

Do not plug the two cords into each other.

!

AB

CAUTION

Remove protective plastic film covering pan sides and tape over halogen lamps.

HD0224

HD0225

HD0226

12

- 12 -

20. USE AND CARE

Evolution™ Hybrid Baffle Filters

The Evolution™ hybrid baffle filters should be cleaned frequently. Use a warm detergent solution. Wash more often if your cooking style

generates greater grease—like frying foods or wok cooking.

Remove Evolution™ hybrid baffle filters by pushing them towards the back of hood and rotating filters downward. Slide out the

secondary micromesh filter from the back of each hybrid baffle filter before cleaning. Baffle filters are dishwasher safe. Clean secondary

filters with a warm detergent solution. Allow filters to dry completely before reinstalling them in the hood.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of the filter may occur if using phosphate detergent

or as a result of local water conditions—but this will not affect filter performance. This discoloration is not covered by the warranty.

Grease Drip Rail

The grease drip rail should be cleaned frequently. Lift it out from the hood and use a warm detergent solution. As for the baffle filters,

wash more often if your cooking style generates greater grease—like frying foods or wok cooking. Allow grease drip rail to dry completely

before reinstalling it in the hood.

Blower Cleaning

Remove the filters in order to access the blower. Vacuum blower to clean. Do not immerse in water. Refer to blower instruction manual

for more details.

Hood Cleaning

Stainless steel cleaning: How to maintain its “BRIGHT LOOK”

Do:

• Regularly wash with clean cloth or rag soaked with warm water and mild soap or liquid dish detergent.

• Always clean in the direction of original polish lines.

• Always rinse well with clear water (2 or 3 times) after cleaning. Wipe dry completely.

• You may also use a specialized household stainless steel cleaner.

Don’t:

• Use any steel or stainless steel wool or any other scrapers to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues reach the hood. During construction or renovation, cover the hood to make sure

no dust sticks to stainless steel surface.

Avoid: When choosing a detergent

• Any cleaners that contain bleach will attack stainless steel.

• Any products containing: chloride, fluoride, iodide, bromide will deteriorate surfaces rapidly.

• Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc., are highly explosive and should never be

used close to a range.

19. LIGHT BULBS REPLACEMENT

This hood must use 120 V, 50 W, MR16 with GU10 base or PAR16 with GU10 base, shielded halogen lamps (included).

WARNING

In order to prevent the risk of personal injury, do not install a lamp identified for use only in enclosed fixtures.

!

WARNING

In order to prevent the risk of personal injury, the halogen lamps must be cooled down before removing them.

!

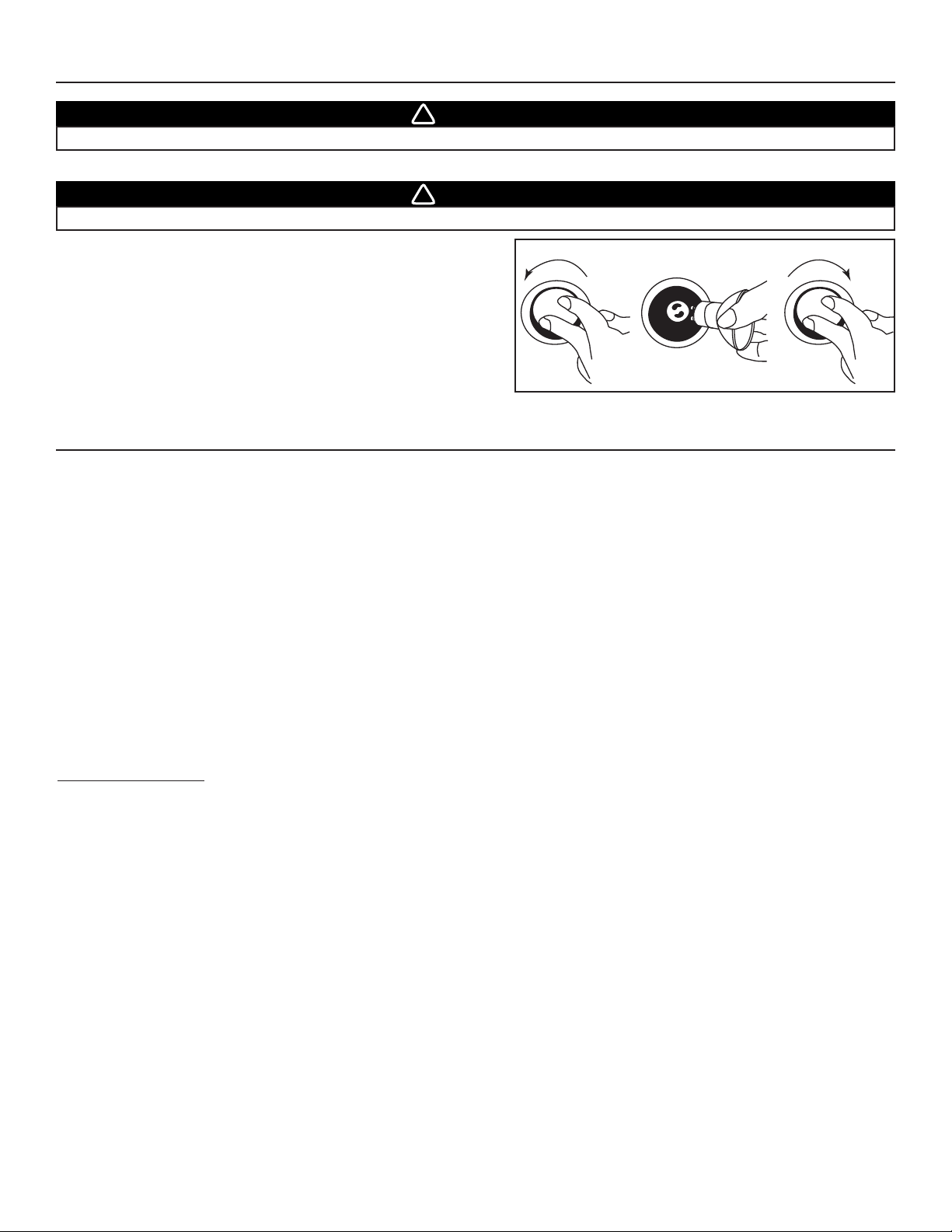

1. To remove lamps, gently push upwards and turn counterclockwise to

disengage bulb leads from their grooves.

NOTE: If need be, use a rubber dishwashing glove to add grip when

removing the bulb.

2. Install the new lamps by placing the bulb leads into their grooves in

the socket.

3. Gently push upwards and turn clockwise until secure.

12 3

HO0089

Always turn ON your hood before you begin cooking in order to establish an air flow in the kitchen. Let the blower run for a few minutes to

clear the air after you turn off the range. This will help keep the whole kitchen cleaner and brighter.

1. Halogen light push-button 6. Maximum blower speed icon

LinkLogic® Master Link Mode push-button 7. Particulates sensor icon

2. Blower push-button 8. Blower speed level/

3. Enable/Disable functions push-button/ LinkLogic® state icon

LinkLogic® Erase Link push-button 9. Air refresh function icon

4. Grease filter reset push-button/ 10. Blower speed icon

LinkLogic® Link Mode push-button 11. LinkLogic® icon

5. Grease filters maintenance icon

Cooktop Lighting (Halogen)

• The halogen lighting is controlled by the light push-button (item 1 on illustration above). Push once to turn ON the lights, and push a

second time to turn the lights ON to a brighter level. If the lights are at the highest level, pressing another time will set them to the

lowest intensity.

• Press on the push-button and maintain for 1 second to turn Off the lights and set the memorized intensity. When turned on, the

halogen bulbs will light cooktop at the previous setting.

• Use 120 V, 50 W, MR16 with GU10 base or PAR16 with GU10 base, shielded halogen lamps (included).

Blower

• The blower is controlled by the blower push-button (item 2 on illustration above). Push once to turn ON the blower, and push a

second time to set the blower speed to a higher level. If the blower speed is on maximum level, pressing another time will turn the

blower to the lowest speed.

• When power level 1 is activated from OFF, 100% of power level is activated during 0.3 second acting as a “kick-start”.

• Press on the push-button and maintain for 1 second to turn Off the blower and set the memorized speed. When turned ON, the

blower will operate at the previous setting.

• When the blower is ON, the speed level is shown by the center icon (item 8 on illustration above) while the icon 10 appears (the

speed of the rotational movement is proportional to the blower speed).

• When the blower is on the higher speed, the icon 10 shuts off and the icon 6 appears with “max” (the symbol has a rotational movement).

Functions

Pressing on Enable/Disable functions push-button (item 3 on illustration above) allows to control Particulate Sensor and Air Refresh

hood functions.

Particulates Sensor

• To activate the particulate sensor function, press on Enable/Disable functions push-button (item 3 on illustration above), the

particulates sensor icon (item 7 on illustration above) will appear.

• When the sensor is activated, the blower turns ON automatically when some particulates, vapors or smokes caused by cooking

process, or abnormal gas emissions in the environment are detected. The blower speed is automatically set depending on the

particulates amount and the sensibility settings of the particulates sensor. See next paragraph.

• To stop the particulates sensor function, press on Enable/Disable functions push-button until particulates sensor icon turns off.

Particulates sensor sensibility settings

• Press on Enable/Disable functions push-button (item 3 on illustration above) to activate the particulate sensor function, this will light

up the particulates sensor icon (item 7 on illustration above). Then, press and maintain for 2 seconds the Enable/Disable functions

push-button: the sensor sensivity level will appear on center icon (item 8 on illustration above).

• Press again on this push-button to change the sensor sensitivity level (from 0 [minimum sensitivity] up to 9 [maximum sensitivity]).

• Press on the grease filter reset push button (item 4 on the illustration above) to confirm (or is confirmed automatically after 5 seconds).

Air Refresh

• To activate the air refresh function, press on Enable/Disable functions push-button (item 3 on illustration above), the air refresh function

icon (item 9 on illustration above) will appear.

• To stop the air refresh function, press on Enable/Disable functions push-button until air refresh icon turns off.

• Air refresh function activates only when blower is OFF. When activated, the blower hood recycles the air in the environment in

perfect silence, starting every 50 minutes (for 10 minutes, on first speed).

Grease filter reset

• Once the grease filter cleaning is done, press on the grease filter reset push-button (item 4 on control illustration) to reset the filter

maintenance timer. This will also shut off the grease filter maintenance icon (item 5 on control illustration).

- 13 -

21. OPERATION

1

2 5 6 7 8 9 10 11 3 4

max

HC0032

S

O

N

R

E

S

AIR

REFRESH

- 14 -

Grease filter maintenance indicator

• After 30 hours of operation, the grease filter maintenance icon (item 5 on control illustration) appears. This means filters need to

be cleaned.

• Once the grease filter cleaning is done, press on grease filter reset push-button to reset the filter maintenance timer.

Interface backlighting

• Off mode (Blower off, Particulates sensor and Air refresh modes disabled): Backlighting is off.

• Halogen lighting activated: does not affect backlighting.

• Blower turns on: Backlighting at maximum intensity.

• Particulates sensor and Air refresh mode activated: Backlighting at maximum intensity.

• Particulates sensor at sensitivity settings and Air refresh in activated mode: Backlighting at minimum intensity.

HEAT SENTRY™

This hood is equipped with a HEAT SENTRY™ thermostat. This thermostat is a device that will start or speed up the blower if it senses

excessive heat above the cooking surface.

• If blower is OFF—it turns the blower to speed 3 (blower speed icon shows H).

• If blower is ON—it turns the blower up to speed 3 (blower speed icon shows H).

NOTE: When Heat Sentry™ is activated, Air refresh mode and Particulate sensor are inactivated. Also, communication coming

from the LinkLogic® Module is disabled.

• When the temperature level drops to normal, the blower will return to its original setting (blower speed icon will show the original

blower speed).

• To turn off the blower when Heat Sentry™ is activated, press and hold the blower push-button (item 2 on illustration) for more

than 1 second.

21. OPERATION (CONT’D)

LinkLogic® Network compatibility

Your IP29M Series range hood can be linked to LinkLogic network, if installed in your house.

LINKLOGIC LINKING INSTRUCTIONS

A. ACTIVATE THE “LINK” MODE OF THE HOOD

Push the LinkLogic link mode push-button (item 4 on control illustration) for 2 seconds; the LinkLogic icon of the interface (item 11 on

control illustration) should be visible and backlighting is full intensity at that point.

LINK OF ANOTHER LINKLOGIC DEVICE

Go back to the appropriate first step if another LinkLogic device

needs to be linked. Otherwise, to exit “link” mode, go to

E

XIT LINK MODE OF THE HOOD.

LINK FOR SMARTSENSE™ OR MAKE-UP AIR MODULES

STA RT T H E “MASTER LINK” PROCESS OF THE HOOD

Push the LinkLogic master link mode push-button

(item 1 on illustration) to start the “Master Link” process,

flashing “L” should be visible (item 8 on control illustration) on

the hood interface, meaning that the hood is waiting for a

SmartSense™ or Make-Up Air module to link.

ACTIVATE THE “LINK” MODE OF THE LINKLOGIC DEVICE

Push the “link” button of the LinkLogic device

(see instructions of device for location) for a specific duration to

activate its link mode. Wait for the “L” to disappear from the

hood interface to do next step.

STA RT T H E “AUTO-LINK” PROCESS OF THE HOOD

Push the LinkLogic link mode push-button

(item 4 on illustration) to start the “Auto-Link” process,

flashing “A” should be visible (item 8 on control illustration)

on the interface until link is done.

NOTE: For some LinkLogic devices, no “A” will be flashing

because the linking duration is too short.

ACTIVATE THE “LINK” MODE OF THE LINKLOGIC DEVICE

Push the “link” button of the LinkLogic device for

a specific duration to activate its link mode

(see instructions of LinkLogic device).

B. EXIT LINK MODE OF THE HOOD

Press and hold LinkLogic link mode push-button (item 4 on control illustration) for 2 seconds to exit “link” mode. Link mode remains

activated for 4 minutes if no other operation is done.

GOTOSTEP22 (ON NEXT PAGE) TO CONFIGURE LINKLOGIC

BOARD JUMPERS BASED ON BLOWER PERFORMANCE

.

LINK FOR WALL REMOTE CONTROL, REMOTE CONTROL

OR

REMOTE BLOWER MODULES

- 15 -

21. OPERATION (CONT’D)

ERASE LINK PROCESS

A. ACTIVATE THE “LINK” MODE OF THE HOOD

Push the LinkLogic link mode push-button (item 4 on control illustration) for 2 seconds; the LinkLogic icon of the interface (item 11

on control illustration) should be visible and backlighting is full intensity at that point.

B. ERASE ALL LINKED LINKLOGIC DEVICES

Push the LinkLogic erase link push-button (item 3 on control illustration) for 2 seconds to start the “Erase Link” process, flashing “E”

should be visible (item 8 on control illustration) on the hood interface until links are erased.

C. EXIT “LINK” MODE OF THE HOOD

Press and hold LinkLogic link mode push-button (item 4 on control illustration) for 2 seconds to exit “link” mode. Link mode remains

activated for 4 minutes if no other operation is done.

NOTE: If during normal operation of the range hood, the LinkLogic Icon (item 11 on control illustration) starts blinking, an error occurred

while communicating with a linked LinkLogic device. To reset this error flag, customer needs to enter and exit the Linking mode

as explained previously. This will erase the error flag until it happens again. If the problem happens again, it is recommended

to erase all links and start back the whole linking process.

22. LINKLOGIC SYSTEM CONTROL BOARD JUMPERS

The LinkLogic system is designed to work with devices like the Broan Smart Sense Fan system that requires CFM output or this range

hood. If you are using this hood with a LinkLogic device that requires CFM information, please follow the simple instruction/matrix below

to configure the LinkLogic control board in the hood to provide the correct CFM information. To access the LinkLogic control board, remove

baffle filters, grease drip rail and hood pan (see steps 5 and 6). Remove both screws retaining the control panel to the hood. Rotate

carefully the control panel in order to see the LinkLogic board jumpers. Remove jumpers from current location on pins and reconfigure

based on blower performance.

WARRANTY

WARRANTY

If you are unsure if the LinkLogic accessory or device requires CFM data, please refer to the unit’s instructions.

LINKLOGIC BOARD JUMPERS

Pin 1 Pin 2 Pin 3 Maximum CFM value

000 0 CFM

001 300 CFM

0 1 0 500 CFM

0 1 1 600 CFM

Pin 1 Pin 2 Pin 3 Maximum CFM value

1 0 0 900 CFM

1 0 1 1000 CFM

1 1 0 1200 CFM

1 1 1 1500 CFM

0 = No jumper on pin. 0 = No jumper on pin.

1 = Jumper on pin. 1 = Jumper on pin.

ONE-YEAR LIMITED WARRANTY FOR BEST PRODUCTS

Broan-NuTone LLC (Broan-NuTone) warrants to the original consumer purchaser of Best products that such products will be free from

defects in materials or workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is found to be

defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENT BULBS,

FUSES, FILTERS, DUCTS, ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a)

normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence, accident, improper

maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states or provinces do

not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE

PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR

INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR

PERFORMANCE. Some states or provinces do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state or province to another.

This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address stated below or telephone number

stated below, (b) give the model number and part identification and (c) describe the nature of any defect in the product or part. At the time

of requesting warranty service, you must present evidence of the original purchase date.

In USA - Best

®

, 926 W. State Street, Hartford, WI 53027 (800-558-1711)

In Canada - Best

®

, 550 Lemire Blvd., Drummondville, QC, Canada, J2C 7W9 (866-737-7770)

www.BestRangeHoods.com

3

2

1

HE0089

Loading...

Loading...