Page 1

IN-LINE BLOWERS

READ AND SAVE THESE INSTRUCTIONS

MODELS ILB9 ILB11

Page 1

!

FOR DOMESTIC COOKING ONLY

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If

you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel

and lock the service disconnecting means to prevent power from

being switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s

guideline and safety standards such as those published by the

National Fire Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. T o reduce the risk of fire, use only metal ductwork.

8. If this unit is to

as appropriate for the application and be connected to a GFCI

(Ground Fault Interrupter) - protected branch circuit.

9. Never place a switch where it can be reached from a tub or

shower.

10. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef

Flambe’).

3. Clean ventilating fans frequently. Grease should not be allowed

to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for the

size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO PREVENT

BURNS. If the flames do not go out immediately, EVACUATE AND

CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent

steam explosion will result.

be inst

alled over a tub or shower, it must be marked

!

WARNING

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already

know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. Yo u can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. Fo r general ventilating use only. Do not use to exhaust hazardous

or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

3. If ventilator is installed in an unconditioned space (such

as an attic): Surround the ventilator with thermal insulation - to

minimize possible condensation.

4. Please read specification label on product for further information

and requirements.

TABLE OF CONTENTS

This manual is divided into sections as follows:

“TYPICAL INSTALLATION”

This section shows a common installation.

- Mounting (New Frame Construction)

- Mounting (Existing Frame Construction)

- Mounting Using Hanger Kit (included)

- Ducting (Horizontal blower discharge)

- Wiring

“MOUNTING OPTIONS”

“WIRING PLATE POSITION”

“DUCTING OPTIONS”

- Blower Discharge Positions

- Ducting (Vertical blower discharge)

“USE AND CARE”

“SERVICE PARTS”

“WARRANTY”

Installer: Leave this manual with

the homeowner.

Homeowner: Use and Care

information on page 4.

!

Page 2

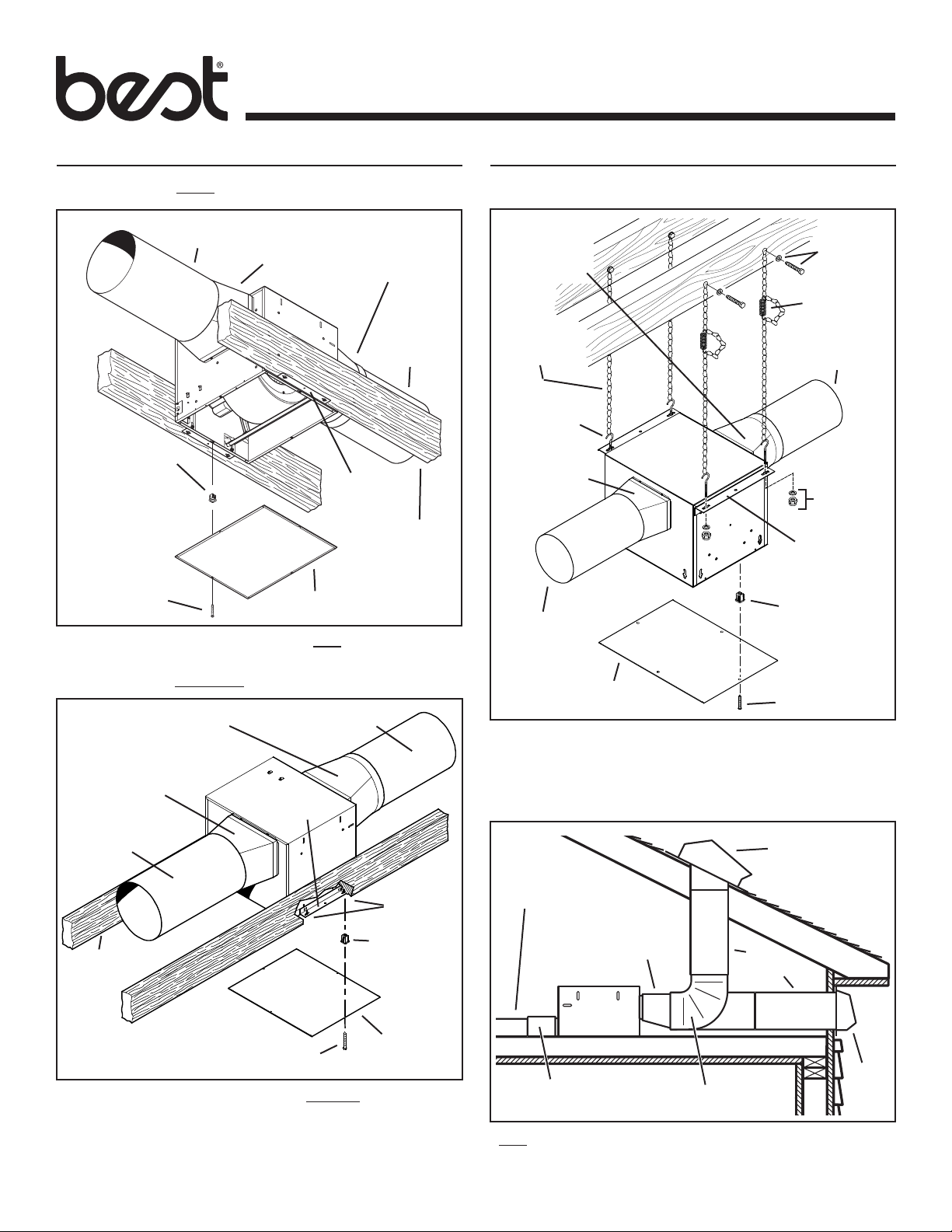

TYPICAL INSTALLATION

MODELS ILB9 ILB11

Page 2

TYPICAL INSTALLATION

MOUNTING (New Frame Construction)

10” ROUND DUCT

(OUTLET)

GRILLE NUT

(Install into square

holes in housing)

Ventilator

factory-shipped

in straight-through

discharge position.

ACCESS

PANEL

SCREW

8” X 12” TO

10” ROUND

TRANSITION

(MALE)

ACCESS PANEL

Factory-shipped unit installed in new construction.

8” X 12” TO

10” ROUND

TRANSITION

(FEMALE)

10” ROUND

MOUNTING

BRACKETS

(24” centers

DUCT

(INTAKE)

CEILING

JOIST

shown)

MOUNTING USING HANGER KIT (included)

8” X 12” TO

10” ROUND

TRANSITION

(FEMALE)

HANGER

KIT CHAIN

HANGER KIT

EYE-BOLT

8” X 12” TO

10” ROUND

TRANSITION

(MALE)

10” ROUND

DUCT

(OUTLET)

square holes in

HANGER

KIT BOLT

& WASHER

EXTENSION

SPRING

10” ROUND

DUCT (INTAKE)

HANGER

KIT NUT &

WASHER

MOUNTING

BRACKET

GRILLE NUT

(Install into

housing)

MOUNTING (Existing Frame Construction)

8” X 12” TO 10” ROUND

TRANSITION (FEMALE)

8” X 12” TO

10” ROUND

TRANSITION

(MALE)

10” ROUND

DUCT

(OUTLET)

CEILING

JOIST

(24” cen-

ters

shown)

Ventilator factory-shipped

in straight-through

discharge position.

PANEL SCREW

Factory-shipped unit installed in existing construction.

10” ROUND

DUCT (INTAKE)

MOUNTING

BRACKETS

ACCESS

MOUNTING

SCREWS

GRILLE NUT

(Install into

square

holes in hous-

ing)

ACCESS

PANEL

IMPORTANT: Remove shipping tape from damper

Remove the shipping tape from the damper flap and make sure that

damper flap opens and closes freely inside the ductwork. Use duct

tape to make ductwork connections secure and air-tight.

ACCESS

PANEL

ACCESS

PANEL SCREW

Blower factory-shipped in straight-through

discharge position.

DUCTING (Horizontal blower discharge)

ROOF CAP

10”

ROUND

DUCT

8” X 12” TO 10” ROUND

TRANSITION (FEMALE)

Two ways to connect ductwork to a factory-shipped unit.

8” X 12” TO

10” ROUND

TRANSITION

(MALE)

10”

ROUND

DUCT

WALL

10” ROUND

ELBOW

CAP

Page 3

MODELS ILB9 ILB11

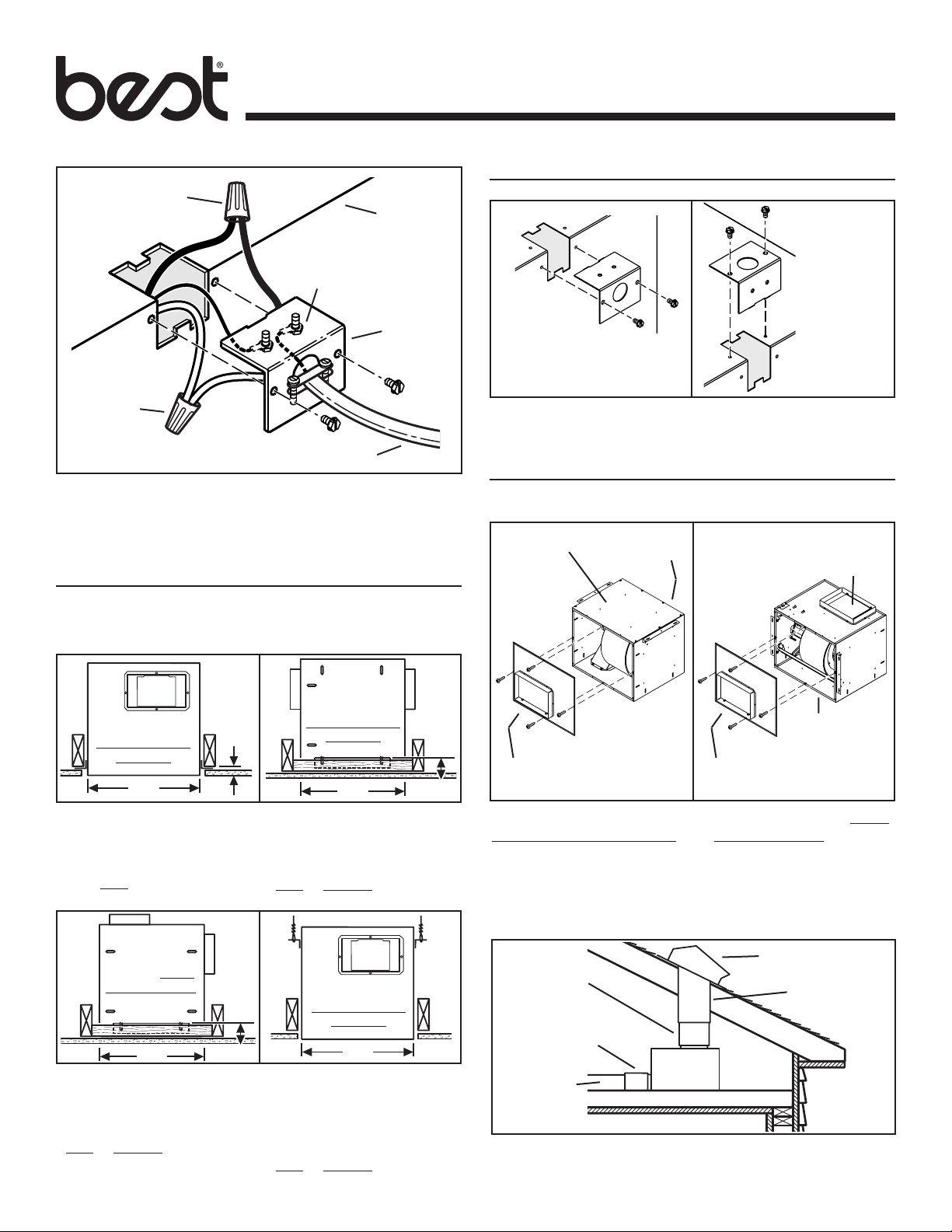

WIRING

BLACK

TO

BLACK

GROUND TO

WIRING PLATE

WHITE

TO

WHITE

120 VAC LINE IN

(from range hood)

EDGE

OF HOUSING

WIRING

PLATE

Ventilator can be wired from outside of housing.

Use UL approved connectors to wire per local codes.

MOUNTING OPTIONS

¼-20 hex nuts secure mounting brackets to housing. Loosen and

re-tighten or remove and replace nuts as necessary for desired

mounting bracket position.

WIRING PLATE POSITION

VERTICAL

POWER CABLE

CONNECTION

HORIZONTAL POWER

CABLE CONNECTION

Wiring plate mounts to side or top of housing.

DUCTING OPTIONS

BLOWER DISCHARGE POSITIONS

MOVABLE

PANEL

DUCT

CONNECTOR

(outlet)

Housing

rotated & movable panel covers previous

open side.

CONNECTOR

Page 3

DUCT

(outlet)

1

Factory-Shipped

Straight-Through

Discharge

22"

1

MAX.

Mounting brackets in

factory-shipped position mounted directly to joists.

(Outlet parallel to joists.)

(New construction)

Housing Con-

verted to Right-

Angle Discharge

18"

1½"

2½"

Mounting brackets ipped

over and mounted to ad-

ditional framing.

(Outlet vertical.)

(New or Existing construction)

Factory-Shipped

8

/

"

Straight-Through

Discharge

18"

Mounting brackets ipped

over and mounted to ad-

ditional framing.

(Outlet perpendicular to joists.)

(New or Existing construction)

to

Factory-Shipped

Straight-Through

Discharge

22"

Mounting brackets ipped

over and mounted to top of

housing. Housing secured

with cables.

(Outlet parallel to joists.)

(New or Existing construction)

1½"

to

2½"

MOVABLE

PANEL

DUCT

CONNECTOR

(intake)

Ventilator shown in

straight-through discharge

position. (Factory shipped)

DUCT

CONNECTOR

(intake)

Ventilator shown in right-

angle discharge position.

(Change movable panel to

(Change to this

location)

new location as shown.)

DUCTING (Vertical blower discharge)

8” X 12” TO

10” ROUND

TRANSITION

(MALE)

8” X 12” TO 10”

ROUND

TRANSITION

(FEMALE)

10” ROUND

DUCT

Typical ductwork connection to a ventilator converted to

right-angle discharge.

ROOF CAP

10” ROUND

DUCT

Page 4

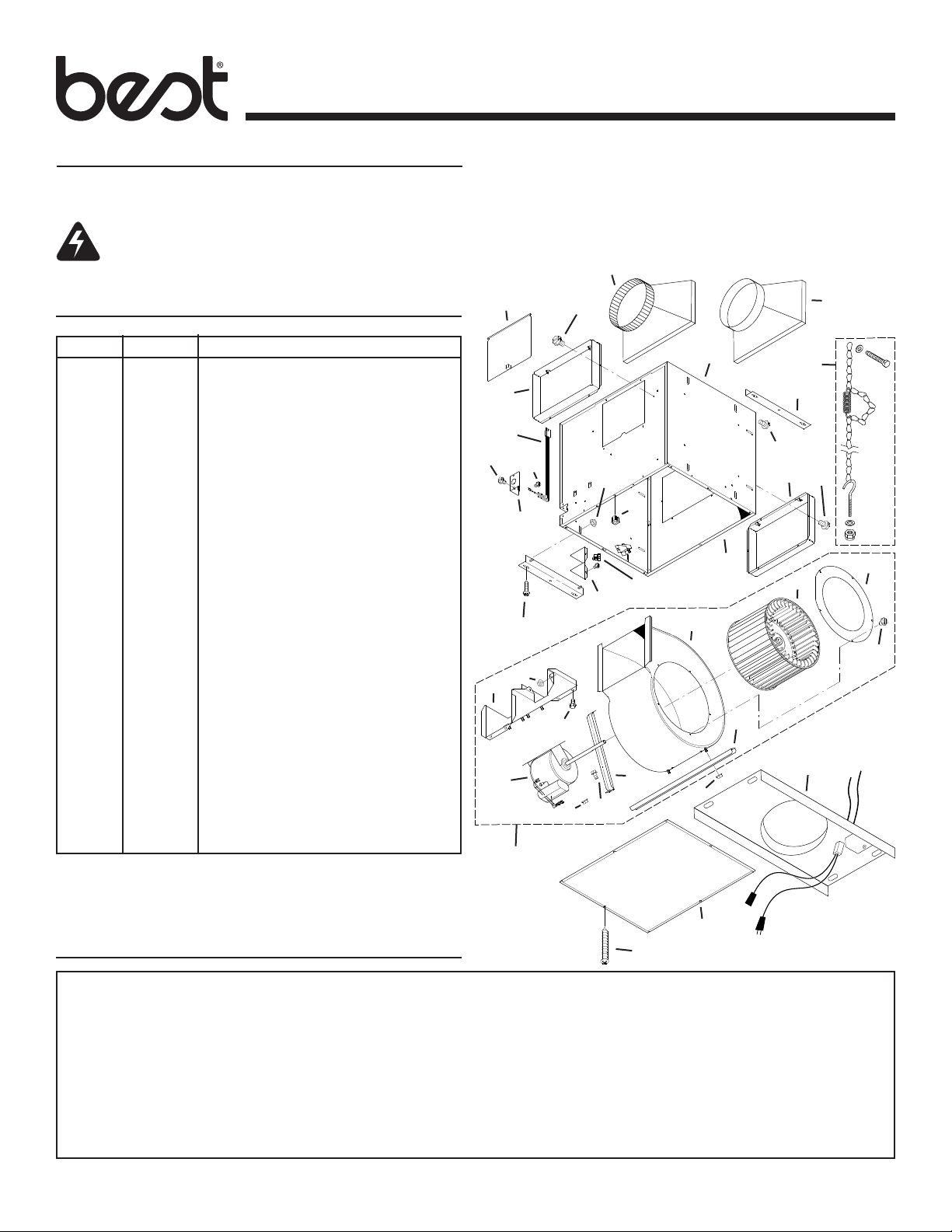

USE AND CARE

Follow wiring instructions packed with range hood, and adhere to

all local and state codes, and the National Electrical Code.

WARNING: To reduce the risk of electric shock,

disconnect from power supply before servicing.

MODELS ILB9 ILB11

Page 4

To clean blower assembly: Remove access panel, unplug blower

from housing, remove blower mounting nuts, and carefully remove

blower from housing. Use appropriate vacuum attachment or a soft

cloth and mild soap or detergent to clean blower discharge area and

wheel. DO NOT ALLOW WATER TO ENTER MOTOR. Make sure

blower assembly is completely dry before reinstalling.

Motor is permanently lubricated. Do not oil or disassemble motor.

29

SERVICE PARTS

KEY NO. PART NO. DESCRIPTION

1 97014853 Damper Flap

2 99150415 Screw, #8B x ¼* (16 req.)

3 98009520 Duct Connector (2 req.)

4 97014784 Housing Assembly

5 97014728 Mounting Bracket (2 req.)

6 99150591 Mounting Screw, #10-12 x .625 (4 req.)

7 97006142 Wiring Harness

8 99150471 Ground Screw, #10-32 x ½* (2 req.)

9 98005512 Wiring Adapter Plate

10 99420470 Access Panel Nut (4 req.)

11 98009531 Movable Housing Panel

12 93150487 Screw, #10-24 x .375* (8 req.)

13 98005513 Outlet Box Cover

14 99400035 Strain Relief Bushing

15 97014788 Motor Bracket

16 99260477 Whiz Nut, ¼-20* (11 req.)

17 99200202 Screw, ¼-20 x ½* (5 req.)

18 97014785 Blower Scroll

19 99080490 Motor (ILB9)

99080491 Motor (ILB11)

20 93260447 Nut, Hex Flange 5/16-18* (5 req.)

21 98009516 Support Bracket

22 99020286 Blower Wheel

23 98009514 Inlet Ring

24 99150417 Screw, #8-18 x ¼* (5 req.)

25 98009513 Scroll Support Channel

+ 97016794 Blower Assembly Complete (ILB9)

(Includes Key Nos. 15 thru 25)

+ 97016795 Blower Assembly Complete (ILB11)

(Includes Key Nos. 15 thru 25)

26 98009532 Access Cover

27 99150472 Access Cover Screw (4 req.)

28 97016791 Hanger Kit

29 99610015 Transition, 8” x 12” to 10” Round, Male

30 99610028 Transition, 8” x 12” to 10” Round, Female

31 97014597 Rough-In Kit

Order replacement parts by PA RT NO. - not by KEY NO.

* Standard hardware - may be purchased locally.

+ Not shown assembled.

1

3

7

2

8

9

6

16

15

19

BLOWER

ASSEMBLY

17

20

2

4

30

28

5

12

3

16

2

10

14

11

22

23

13

18

24

25

21

31

16

17

26

WARRANTY

Broan-NuTone LLC (Broan-NuTone) warrants to the original consumer purchaser of Best products that such products will be free from defects in materials or workmanship for a period of one year from the date of

original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENT BULBS, FUSE, FILTERS, DUCTS, ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES

FOR DUCTING. This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence, accident, improper maintenance or repair (other

than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL

NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number stated below, (b) give the model number and part identification and (c) describe the nature of any defect

in the product or part. At the time of requesting warranty service, you must present evidence of the original purchase date.

In USA: BEST

®

, 926 W. State Street, Hartford, Wisconsin 53027 800-558-1711 In Canada: BEST® , 550 Lemire Blvd., Drummondville (Quebec) Canada J2C 7W9 866-737-7770 www.BestRangeHoods.com

ONE YEAR LIMITED WARRANTY FOR BEST PRODUCTS

27

99043703E

Page 5

ILB9 ILB11

!

VENTILADORES PARA MONTAJE EN LÍNEA

LEA Y CONSERVE ESTAS INSTRUCCIONES

MODELOS

Página 5

!

PARA COCINAR EN CASA SOLAMENTE

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, GOLPE ELÉCTRICO, O LESIÓN

A PERSONAS, OBSERVE LO SIGUIENTE:

1. Use esta unidad solamente de la manera indicada por el fabricante. Si

tiene preguntas, póngase en contacto con el fabricante a la dirección o

teléfono que aparecen en la garantía.

2. Antes de limpiar o de poner en servicio la unidad, apague el interruptor

en el panel de servicio, y asegure el panel de servicio para evitar que se

encienda accidentalmente. Cuando el dispositivo para desconectar el

servicio eléctrico no puede ser cerrado con algún tipo de traba, sujete

fuertemente al panel de servicio, una etiqueta de advertencia prominente.

3. El trabajo de instalación y cableado eléctrico deben estar hechos por

personal capacitado de acuerdo con todos los códigos y estándares

aplicables, incluyendo códigos y estándares de construcción a prueba

de incendios.

4. Se necesita suficiente aire para la combustión y extracción de gases por

la chimenea del equipo que quema combustible para evitar la retrogresión

de las llamas. Siga las directrices del fabricante y estándares de seguridad

como los publicados por la Asociación Nacional de Protección Contra

Incendios (o por sus siglas en inglés NFPA), y la Sociedad Americana de

Ingenieros de Calefacción, Refrigeración, y Aire Acondicionado (o por

sus sigles en inglés ASHRAE), y los códigos de las autoridades locales.

5. Cuando corte o taladre en una pared o cielo raso, no dañe cableado

eléctrico o instalaciones no visibles.

6. Ventiladores con conductos siempre deben extraer hacia el exterior.

7. Para reducir el riesgo de incendio, use sólo ductos de metal.

8. Si esta unidad va a instalarse sobre una bañera o ducha, debe marcársela

como correcta para dicha aplicación y debe conectarse a un protegido

GFCI (Cortacicuito Accidental a Tierra).

9. Nunca instale un interruptor donde se pueda alcanzar desde una bañera

o ducha.

10. Esta unidad se debe conectar a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO DEBIDO A GRASA ACUMULADA

EN LAS HORNILLAS:

1. Nunca deje sin atender las unidades de superficie cuando tengan ajustes

altos. Los reboses pueden provocar humo y derrames grasosos que se

pueden incendiar. Caliente lentamente el aceite en un ajuste bajo o medio.

2. Siempre ENCIENDA la campana cuando cocine con alta temperatura o

cuando cocine alimentos que se puedan incendiar.

3. Limpie con frecuencia los ventiladores. No debe permitir que la grasa

se acumule en el ventilador ni en el filtro.

4. Utilice un sartén de tamaño adecuado. Siempre utilice el utensilio adecuado al tamaño del elemento de superficie.

PARA REDUCIR EL RIESGO DE LESION A PERSONAS RESULTADO DE UN

INCENDIO DEBIDO A GRASA ACUMULADA EN LAS HORNILLAS, PROCURE

LO SIGUIENTE:*

1. AHOGUE LAS LLAMAS con una tapa ajustada o charola de metal, después

apague la hornilla. TENGA CUIDADO A FIN DE EVITAR QUEMADURAS. Si

las llamas no se apagan de inmediato, EVACUE Y AVISE A LOS BOMBEROS.

2. NO LEVANTE NUNCA UNA SARTEN QUE ESTE EN LLAMAS - Usted se

podrá quemar.

3. NO UTILICE AGUA, incluyendo toallas de cocina mojadas - puede resultar

una explosión de vapor violenta.

!

ADVERTENCIA

4. Utilice un extinguidor SOLAMENTE si:

A. Usted sabe que tiene un extinguidor de clas ABC y lo sabe utilizar.

B. El incendio es pequeño y contenido dentro del área donde se inició.

C. Los bomberos han sido avisados.

D. Usted puede combatir el incendio con una salida a su espalda.

* Basado en las recomendaciones para “Seguridad en la Cocina” publicadas

por la NFPA de los EEUU.

CUIDADO

1. Para uso de ventilación general solamente. No lo use para extraer

materiales o vapores peligrosos o explosivos.

2. Para evitar daño a los cojinetes del motor y hélices ruidosas y/o

desequilibradas, mantenga la unidad de potencia lejos de rocíos de yeso,

polvo de construcción, etc.

3. Si el ventilador se instala en un área sin acondicionamiento (como por

ejemplo en un ático): Rodee el ventilador con material de aislamiento

térmico para minimizar la posible condensación.

4. Para más información y requisitos favor leer la etiqueta de especificaciones

del producto.

CONTENDIO

Este manual consiste en las siguientes secciones:

• “INSTALACIÓN TÍPICA”

Esta sección muestra una instalación común en una estructura nueva y

en una existente.

- Montaje (estructura nueva)

- Montaje (estructura existente)

- Montaje el usar kit de suspender (incluido)

- Colocación de conductos (descarga horizontal por del ventilador)

- Cableado

• “OPCIONES DE MONTAJE”

• “COLOCACIÓN DE LA PLACA DE CONEXIONES”

• “OPCIONES PARA LA COLOCACIÓN DE CONDUCTOS”

- Posiciones de la descarga del ventilador

- Colocación de conductos (descarga vertical por del ventilador)

• “USO Y CUIDADO”

• “PIEZAS DE SERVICIO”

• “GARANTÍA”

Instalador: Deje este manual con el

dueño de casa.

Dueño de casa: Información del uso y

mantenimiento en la página 8.

Page 6

INSTALACIÓN TÍPICA

MODELOS

ILB9 ILB11

Página 6

INSTALACIÓN TÍPICA

MONTAJE (Estructura nueva)

TRANSICIÓN 8” X 12”

(20,3 X 30,5 cm) A

REDONDO DE 10”

(25,4) (MACHO)

CONDUCTO

REDONDA DE

10” (25,4 cm)

(salida)

Ventilador,

enviado de

fábrica en

posición de

descarga

derecha por

del ventilador

TUERCA

DE PARILLA

(Instale en

los agujeros

cuadros en la

cubierta)

TORNILLO DE

PANEL DE

ACCESO

PANEL DE ACCESO

Unidad enviada de fábrica instalada en una estructura nueva.

TRANSICIÓN

8” X 12”

(20,3 X 30,5 cm) A

REDONDO DE 10”

(25,4) (HEMBRA)

CONDUCTO

REDONDA DE

10” (25,4 cm)

(entrada)

ABRAZA-

DERAS DE

MONTAJE

VIGUETA DEL

TECHO

(centros de 24”

61 cm)

MONTAJE (Estructura existente)

MONTAJE EL USAR KIT DE SUSPENDER

(incluido)

TRANSICIÓN

DE 8” X 12” A

10” REDONDA

(20,3 x 30,5 cm

a 25,4 cm

redonda)

(Hembra)

CADENA DE

KIT DE SUS-

PENDER

TORNILLO DE

OJO DE KIT DE

SUSPENDER

TRANSICIÓN

DE 8” X 12” A

10” REDONDA

(20,3 x 30,5 cm a

25,4 cm redonda)

(Macho)

CONDUCTO

REDONDA DE 10”

(25,4 cm) (salida)

TORNILLO Y

ARANDELA

DE KIT DE SUS-

PENDER

RESORTE

EXTENCIÓN

CONDUCTO

REDONDA DE 10”

(25,4 cm) (entrada)

TUERCA Y

ARANDELA DE

KIT DE SUS-

PENDER

ABRAZADERAS

DE MONTAJE

TUERCA DE

PARILLA (Instale

en los agujeros

cuadros en la

cubierta)

TRANSICIÓN

8” X 12”

(20,3 X 30,5 cm) A

REDONDO DE 10”

(25,4) (MACHO)

CONDUCTO

REDONDA DE 10”

(25,4 cm) (salida)

VIGUETA

DEL TECHO

(centros de 24”

61 cm)

Ventilador, en-

viado de fábrica en

posición de descar-

ga ángulo recto del

ventilador

TORNILLO DE PANEL DE ACCESO

TRANSICIÓN 8” X 12”

(20,3 X 30,5 cm) A

REDONDO DE 10”

(25,4) (HEMBRA)

DERAS DE

MONTAJE

ABRAZA-

PANEL DE

ACCESO

CONDUCTO

REDONDA DE 10”

(25,4 cm) (entrada)

TORNILLOS

DE ABRAZA-

DERAS DE

MONTAJE

TUERCA

DE PARILLA

(Instale en

los agujeros

cuadros en

la cubierta)

Unidad enviada de fábrica instalada en una estructura existente.

IMPORTANTE: Quite la cinta del envío de apagador

Asegúrese de quitar la cinta que fija la pestaña del regulador durante

la transportación, y de que esta pestaña abra y cierre libremente

dentro del conducto. Utilice cinta de conductos para asegurar y

hermetizar las conexiones de los conductos.

PANEL DE ACCESO

TORNILLO DE PANEL

DE ACCESO

Ventilador, enviado de fábrica en posición de descarga

derecha por del ventilador

COLOCACIÓN DE CONDUCTOS (descarga

horizontal por del ventilador)

CONDUCTO

DE 10”

(25,4 cm)

(entrada)

TRANSICIÓN 8” X 12”

(20,3 X 30,5 cm) A REDONDO

DE 10” (25,4) (HEMBRA)

TRANSICIÓN

8” X 12”

(20,3 X 30,5 cm) A

REDONDO DE 10”

(25,4) (MACHO)

CODO

REDONDO

DE 10” (25,4 cm)

Dos formas de conectar los conductos a una unidad envia-

da de fábrica.

VENTILACIÓN

EN EL ALERO

CONDUCTO DE

10” (25.4 cm)

(salida)

TAPA

DE

PARED

Page 7

MODELOS

ILB9 ILB11

CONEXIONES ELECTRICAS

NEGRO A

NEGRO

TIERRA A LA PLACA DE CONEXIO-

BLANCO

A

BLANCO

El ventilador se puede conectar desde el exterior del alo-

jamiento.

Use conectores aprobados por UL en la conexión en cum-

plimiento con los códigos locales.

PARTE SUPERIOR/POSTERIOR DEL ALOJA-

ENTO

MI

NES

PLACA DE

CONEXIONES

LÍNEA DE

ENTRADA DE

120 VCA

(de la campana)

OPCIONES DE MONTAJE

Las tuercas hexagonales de ¼ x 20 aseguran las abrazaderas de

montaje en el alojamiento. Afloje y vuelva a apretar o quite y reemplace las tuercas según sea necesario para colocar las abrazaderas

de montaje en la posición deseada.

11/8”

(28,6 mm)

Fábrica

descarga

derecha por del

ventilador

22"

22” (55,9 cm)

Max.

1

MAX.

1

/

Abrazaderas de montaje

en la posición ajustada en

fábrica.

(La salida queda paralela a las

viguetas)

(Estructura nueva)

Cubierta

convertido a

descarga ángulo

recto del venti-

lador

18” (45,7 cm)

18"

1½”

a 2½”

(38,1 a

1½"

63.5 mm)

to

2½"

Abrazaderas de montaje

volteadas y montadas a la

armazón addicional.

(La salida ángulo recto.)

(Estructura nueva o existente)

Fábrica

8"

descarga

derecha por del

ventilador

18” (45,7 cm)

18"

Abrazaderas de montaje

volteadas y montadas a la

armazón addicional.

(La salida queda perpendicular

a las viguetas)

(Estructura nueva o existente)

Fábrica

descarga

derecha pro del

ventilador

22” (55,9 cm)

22"

Abrazaderas de montaje

volteadas y montadas a la

tapa de la cubierta. Cubier-

ta asegurada con los cables.

(La salida queda paralela a las

viguetas)

(Estructura nueva o existente)

1½” a

2½”

(38,1 a

1½"

63.5 mm)

to

2½"

Página 7

COLOCACIÓN DE LA PLACA

DE CONEXIONES

CONEXIÓN

VERTICAL DEL

CABLE DE ALI-

CONEXIÓN

HORIZONTAL

DEL CABLE DE

ALIMENTACIÓN

MENTACIÓN

La placa de conexiones se monta a los lados o en la parte

superior del alojamiento.

OPCIONES PARA LA

COLOCACIÓN DE CONDUCTOS

POSICIONES DE LA DESCARGA DEL VENTILADOR

CONECTOR

PANEL

MOVIBLE

CONECTOR DEL

CONDUCTO

(entrada)

DEL CONDUCTO

(salida)

Ventilador mostrado en

la posición de descarga

derecho por del ventilador.

(Fábrica)

El alojamiento rotado y el

panel movible cubre la

cara abierta

anterior.

CONECTOR DEL

CONDUCTO

(entrada)

Ventilador mostrado en la

posición de ángulo recto del

ventilador. (Cambie el panel

movible a la nueva posición,

según lo mostrado.)

COLOCACIÓN DE DUCTOS (Descarga vertical

por del ventilador)

TRANSICIÓN 8” X 12”

(20,3 X 30,5 cm) A

REDONDO DE 10”

(25,4) (MACHO)

TRANSICIÓN 8” X 12”

(20,3 X 30,5 cm) A REDONDO

DE 10” (25,4) (HEMBRA)

CONDUCTO

REDONDO DE

10” (25.4 cm)

(entrada)

Conexión típica de los conductos al ventilador cambiado a

posición de descarga ángulo recto por del ventilador.

CONECTOR

DEL CONDUCTO

(salida)

PANEL

MOVIBLE

(cambie a esta

localización)

VENTILACIÓN EN EL

ALERO

CONDUCTO

REDONDO DE

10” (25.4 cm)

(salida)

Page 8

USO Y CUIDADO

Siga las instrucciones para las conexiones eléctricas que vienen empacadas con el campana, y observe todos los códigos locales y estatales

y el Código Eléctrico Nacional.

ADVERTENCIA: Para reducir el riesgo de sufrir una descarga eléctrica, antes de dar servicio al ventilador desconéctelo del suministro eléctrico.

PIEZAS DE SERVICIO

MODELOS

ILB9 ILB11

Página 8

Para limpiar el conjunto del ventilador: Quite el panel de acceso,

desconecte el ventilador del alojamiento, quite las tuercas de montaje

del ventilador y cuidadosamente saque el ventilador del alojamiento.

Use el aditamento apropiado de la aspiradora o un paño suave y jabón

o detergente suave para limpiar el área de descarga y la rueda del

ventilador. NO PERMITA QUE ENTRE AGUA AL MOTOR. Asegúrese

de que el conjunto del ventilador esté completamente seco antes de

volverlo a instalar.

El motor está permanentemente lubricado. No lubrique ni desmonte

el motor.

1

29

2

30

CLAVE Nº. PIEZA Nº. DESCRIPCIÓN

1 97014853 Solapa del regulador

2 99150415 Tornillo, #8B x ¼* (se req. 16)

3 98009520 Conjunto del regulador (se req. 2)

4 97014784 Conjunto del alojamiento

5 97014728 Abrazadera de montaje (se req. 2)

6 99150591 Tornillo de montaje, #10-12 x .625 (se req. 4)

7 97006142 Arnés de alambre

8 99150471 Tornillo de conexión a tierra, #10-32 x ½*

(se req. 2)

9 98005512 Placa de conexiones

10 99420470 Tuerca del panel de acceso (se req. 4)

11 98009531 Panel de cubierta movible

12 93150487 Tornillo, #10-24 x .375* (se req. 8)

13 98005513 Cubierta de la caja de conexiones

14 99400035 Buje de alivio de tensión

15 97014788 Abrazadera del motor

16 99260477 Tuerca, ¼-20* (se req.11)

17 99200202 Tornillo, ¼-20 x ½* (5 req.)

18 97014785 Conjunto del caracol

19 99080490 Motor (ILB9)

99080491 Motor (ILB11)

20 93260447 Tuerca, Hex Flange 5/16-18* (se req. 5)

21 98009516 Abrazadera del soporte

22 99020286 Rueda del ventilador (Incluye clave Nº. 22)

23 98009514 Anillo de entrada

24 99150417 Tornillo, #8-18 x ¼* (se req. 5)

25 98009513 Abrazadera de soporte del caracol

+ 97016794 Conjunto del ventilador, completo

(Incluye art. clave Nº. 15-26)

+ 97016795 Conjunto del ventilador, completo (ILB11)

(Incluye art. clave Nº. 15-26)

26 98009532 Panel de acceso

27 99150472 Tornillo del panel de acceso (se req. 4)

28 97016791 Kit de suspender

29 99610015 Transición, 20,3 x 30,5 a 25,4 cm redondo

(8 x 12 a 10 po redondo) (macho)

30 99610028 Transición, 20,3 x 30,5 a 25,4 cm redondo

(8 x 12 a 10 po redondo) (hembra)

31 97014597 Kit de placa del ventilador

Pida las piezas de repuesto por Nº.

* Herraje estándar, se puede comprar localmente.

+ No mostrado ensamblado.

DE PIEZA, no por Nº. DE CLAVE

(ILB9)

GARANTIA

3

7

2

8

9

6

16

15

17

19

CONJUNTO

DEL

VENTILADOR

20

13

17

16

10

21

14

27

18

16

26

4

28

5

12

3

2

11

23

22

24

25

31

Broan-NuTone LLC (Broan-NuTone) garantiza al consumidor comprador original de sus productos que dichos productos carecerán de defectos en materiales o en mano de obra por un período de un año a partir de la fecha

original de compra. NO EXISTEN OTRAS GARANTIAS, EXPLICITAS O IMPLICITAS, INCLUYENDO, PERO NO LIMITADAS A, GARANTIAS IMPLICITAS DE COMERCIALIZACION O APTITUD PARA UN PROPOSITO PARTICULAR.

Durante el período de un año, y a su propio criterio, Broan-NuTone reparará o reemplazará, sin costo alguno cualquier producto o pieza que se encuentre defectuosa bajo condiciones normales de servicio y uso.

LA PRESENTE GARANTÍA NO CUBRE LOS TUBOS FLUORESCENTES NI SUS ARRANCADORES, BOMBILLAS DE HALÓGENO E INCANDESCENTES, FUSIBLES, FILTROS, CONDUCTOS, TAPONES DE TECHO O PAREDES

Y DEMÁS ACCESORIOS PARA CONDUCTOS. Esta garantía no cubre (a) mantenimiento y servicio normales o (b) cualquier producto o piezas que hayan sido utilizadas de forma errónea, negligente, que hayan causado un

accidente, o que hayan sido reparadas o mantenidas inapropiadamente (por otras compañías que no sean Broan-NuTone), instalación defectuosa, o instalación contraria a las instrucciones de instalación recomendadas.

La duración de cualquier garantía implícita se limita a un período de un año como se especifica en la garantía expresa. Algunos estados no permiten limitaciones en cuanto al tiempo de expiración de una garantía implícita,

por lo que la limitación antes mencionada puede no aplicarse a usted.

LA OBLIGACION DE BROAN-NUTONE DE REPARAR O REEMPLAZAR, SIGUIENDO EL CRITERIO DE BROAN-NUTONE, DEBERA SER EL UNICO Y EXCLUSIVO RECURSO LEGAL DEL COMPRADOR BAJO ESTA GARANTIA.

BROAN-NUTONE NO SERA RESPONSABLE POR DAÑOS INCIDENTALES, CONSIGUIENTES, O POR DAÑOS ESPECIALES QUE SURJAN A RAIZ DEL USO O DESEMPEÑO DEL PRODUCTO. Algunos estados no permiten

la exclusión o limitación de daños incidentales o consiguientes, por lo que la limitación antes mencionada puede no aplicarse a usted.

Esta garantía le proporciona derechos legales específicos, y usted puede también tener otros derechos, los cuales varían de estado a estado. Esta garantía reemplaza todas las garantías anteriores.

Para calificar en la garantía de servicio, usted debe (a) notificar a Broan-NuTone al domicilio o al número de teléfono que se menciona abajo, (b) dar el número del modelo y la identificación de la pieza, y (c) describir la

naturaleza de cualquier defecto en el producto o pieza. En el momento de solicitar servicio cubierto por la garantía, usted debe de presentar evidencia de la fecha original de compra.

En los Estados Unidos: BEST

®

, 926 W. State Street, Hartford, Wisconsin 53027 800-558-1711 En Canada: BEST® , 550 Lemire Blvd., Drummondville (Quebec) Canada J2C 7W9 866-737-7770 www.BestRangeHoods.com

GARANTIA LIMITADA POR UN AÑO PARA LOS PRODUCTOS DE BEST

®

99043703E

Page 9

VENTILATEURS MONTAGE DANS LIGNE

LIRE ET CONSERVER CES INSTRUCTIONS

MODÈLES

ILB9 ILB11

Page 9

!

POUR USAGE DOMESTIQUE SEULEMENT

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE D´INCENDIE, DE CHOC ÉLECTRIQUE OU DE

BLESSURES PERSONNELLES, OBSERVEZ CE QUI SUIT:

1. Utilisez cette unité seulement de la façon prévue par le fabricant. Pour

d´autres renseignements, contactez le fabricant à l´adresse ou au numéro

de téléphone qui se trouve dans la garantie.

2. Avant d’effectuer une réparation ou un entretien sur cet appareil, coupez

le courant au tableau d’alimentation et verrouillez celui-ci pour empêcher

que la tension soit remise accidentellement. Lorsque le verrouillage

de la déconnexion n’est pas possible, mettez bien en vue un signal

d’avertissement telle qu’une étiquette, sur le panneau d’alimentation.

3. L´installation et la pose des fils électriques doivent être effectuées par

une ou des personnes qualifiées conformément à tous les codes et

normes applicables, incluant les normes de construction en rapport aux

incendies.

4. Il faut suffisamment d´air pour une combustion appropriée et

l´échappement des gaz par le tuyau de la cheminée de l´équipement

brûlant du combustible pour prévenir un contre-courant. Suivez les

instructions du fabricant de l´équipement de chauffage et les normes

de sécurité telles que celles publiées par la National Fire Protection Association (NFPA) et l´American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE) et des autorités du code local.

5. Lors de la coupe ou du perçage dans un mur ou un plafond, prenez soin de

ne pas endommager les fils électriques et les autres utilités dissimulées.

6. La décharge des ventilateurs à conduit par l´évent doit toujours se faire

à l´extérieur.

7. Pour réduire le rsque d’incendie, utilisez seulement des donduits de

ventilation en métal.

8. Si cette unité doit être installée au-dessus d’une baignoire ou d’une

douche, elle doit être marquée comme étant appropriée pour l’application

et être connectée à un circuit dérivé protége GFCI (interrupteur de circuit

en cas de défaut de mise à la terre du neutre).

9. Ne placez jamais un interrupteur dans un endroit où il peut être rejoint

d’une baignoire ou d’une douche.

10. Cette unité doit être mise à la terre.

AFIN DE DIMINUER LES RISQUES D’INCENDIE POUVANT SE DÉCLENCHER

SUR LA SURFACE DE CUISSON:

1. Ne jamais laisser sans surveillance des unités de surface réglées à feu

vif. En plus de générer de la fumée, les débordements de graisse peuvent

prendre feu. Chauffer les huiles lentement à feu doux ou moyen.

2. Toujours mettre en marche la hotte durant la cuisson à feu vif ou la

cuisson d’aliments à flamber.

3. Nettoyer régulièrement les ventilateurs d’aération. On ne doit tolérer

aucune accumulation de graisse sur le ventilateur ou sur le filtre.

4. Utiliser une casserole de grosseur appropriée. Toujours utiliser une

batterie de cuisine proportionnelle à l’élément de surface.

AFIN DE DIMINUER LES RISQUES DE BLESSURES POUVANT SURVENIR

LORSQU’UN FEU SE DÉCLENCHE SUR LA SURFACE DE CUISSON, SUIVEZ

CES DIRECTIVES:

1. ÉTOUFFEZ LES FLAMMES avec un couvercle hermétique, une tôle à biscuits ou un plateau en métal puis éteignez la cuisinière. PRENEZ GARDE

AUX BRÛLURES. Si vous ne parvenez pas à éteindre immédiatement les

flammes, ÉVACUEZ LES LIEUX ET CONTACTEZ VOTRE POSTE LOCAL

DE LUTTE CONTRE LES INCENDIES.

2. NE VOUS EMPAREZ JAMAIS D’UN PLAT QUI S’EST ENFLAMMÉ – Vous

risqueriez de vous brûler.

!

AVERTISSEMENT

3. N’UTILISEZ JAMAIS D’EAU, incluant les linges à vaisselles ou serviettes

mouillés car cela peut provoquer une violente explosion de vapeur.

4. Utilisez un extincteur SEULEMENT si:

A. Il s’agit d’un extincteur de classe ABC et que vous savez comment

vous en servir.

B. Il s’agit d’un petit feu qui ne se propage pas ailleurs que sur la

cuisinière.

C.Vous avez appelé votre poste local de lutte contre les incendies.

D. Vous pouvez combattre le feu tout en ayant accès à une sortie.

* Basé sur “Kitchen Fire Safety Tips” édité par NFPA.

ATTENTION

1. Pour ventilation générale seulement. Ne l´utilisez pas pour évacuer les

vapeurs ou matériaux dangereux ou que peuvent exploser.

2. Pour éviter d´endommager les coussinets du moteur et des turbines

bruyantes et/ou mal équilibrées, assurez que l´unité motrice est exempte

de poussière provenant des murs en pierres sèches et la construction.

3. Si le ventilateur est installé dans un endroit non conditionné (tel qu’un

grenier): Entourez le ventilateur d’un isolant thermique afin de réduire

toute condensation éventuelle.

4. Veuillez lire l´étiquette de spécifications sur le produit pour d´autres

renseignements et exigences.

TABLE DES MATIÈRES

Ce manuel se divise comme suit :

• INSTALLATION TYPIQUE

Cette section montre une installation standard dans un bâtiment en

cours de construction ou déjà construit.

- Montage (Construction en cours)

- Montage (Construction terminée)

- Montage en utilisant le kit de cintre (inclus)

- Installation des conduits (décharge horizontale de ventilateur)

- Câblage

• OPTIONS DE MONTAGE

• POSITION DE LA PLAQUE DE CÂBLAGE

• OPTIONS D’INSTALLATION DES CONDUITS

- Positions de la décharge de la soufflerie

- Installation des conduits (décharge vertical de ventilateur)

• UTILISATION ET ENTRETIEN

• PIÈCES DE RECHANGE

• GARANTIE

Installateur: Remetez ce manuel au

protpriétaire de maison.

Propriétaire de maison: Mode

d’utilisation et soin à la page 12.

!

Page 10

INSTALLATION TYPIQUE

MODÈLES

ILB9 ILB11

Page 10

INSTALLATION TYPIQUE

MONTAGE (Construction en cours)

CONDUIT CIRCULAIRE DE 10 po (25,4 cm) (sortie)

TRANSITION DE 8 x 12 po au

10 po circulaire (20,3 x 30,5 cm

au 25,4 cm circulaire) (mâle)

ÉCROU DE GRILLE

(Installez sur les

trous carrés dans le

logement.)

Soufflerie préas-

semblée en position

de décharge de

soufflerie

dans ligne

VIS DE

PANNEAU

D’ACCESS

Appareil installé dans un bâtiment en cours de construction.

TRANSITION DE

8 x 12 po au

10 po circulaire

(20,3 x 30,5 cm

au 25,4 cm

circulaire)

(femelle)

CONDUIT

CIRCULAIRE DE

10 po (25,4 cm)

(prise)

SUPPORTS

SOLIVE DE

PLAFOND

(24 po / 61 cm

centre)

PANNEAU D’ACCESS

MONTAGE (construction terminée)

SUPPORTS préassemblés pour plafonds de

½ po (1,27 cm) d’épaisseur.

TRANSITION DE 8 x 12 po au

10 po circulaire (20,3 x 30,5 cm

au 25,4 cm circulaire) (femelle)

TRANSITION DE 8 x 12

po au 10 po circulaire

(20,3 x 30,5 cm au 25,4

cm circulaire) (mâle)

CONDUIT CIRCULAIRE

DE 10 po (25,4 cm) (sortie)

Soufflerie préassemblée en position de

décharge de soufflerie droit angle.

VIS DE PANNEAU D’ACCESS

PANNEAU

D’ACCESS

Appareil installé dans un bâtiment déjà construit.

CONDUIT

CIRCULAIRE

DE 10 po

(25,4 cm)

(prise)

SOLIVE DE

PLAFOND

(24 po / 61 cm

centre)

VIS DE

SUPPORTS

ÉCROU DE

GRILLE

(Installez sur

les trous car-

rés dans le

logement.)

IMPORTANT: Retirez la bande d’expédition de l’amortisseur.

Veiller à retirer le ruban adhésif d’expédition du volet du registre et

s’assurer que ce dernier s’ouvre et se ferme librement à l’intérieur

du conduit. Utiliser du ruban adhésif pour assurer et étancher les

raccords des conduits.

MONTAGE EN UTILISANT LE KIT DE CINTRE (inclus)

TRANSITION DE

8 x 12 po au

10 po circulaire

(20,3 x 30,5 cm au

25,4 cm circulaire)

(femelle)

CHAÎNE

DE LE KIT

POUR

ACCROCHER

BOULON D’OEIL

DE LE KIT POUR

ACCROCHER

TRANSITION DE

8 x 12 po au 10 po

circulaire (20,3 x

30,5 cm au 25,4

cm circulaire)

(mâle)

CONDUIT

CIRCULAIRE DE

10 po (25,4 cm)

(SORTIE)

PANNEAU D’ACCESS

trous carrés dans le

VIS DE PANNEAU

Souferie préassemblée en position de décharge dans ligne.

VIS ET

RONDELLE DE

LE KIT POUR

ACCROCHER

RESSORT DE

PROLONGATION

CONDUIT

CIRCULAIRE DE

10 po (25,4 cm)

(ADMISSION)

VIS ET

RONDELLE DE

LE KIT POUR

ACCROCHER

SUPPORTS

ÉCROU DE PAN-

NEAU D’ACCESS

(Installez sur les

logement)

D’ACCESS

INSTALLATION DES CONDUITS (décharge

horizontale de ventilateur)

CONDUIT

CIRCULAIRE

DE

10 po

(25.4 cm)

TRANSITION CIRCULAIRE

8 x 12 po (20,3 x 30,5 cm) AU

10 po (25.4 cm) (FEMELLE)

TRANSITION

CIRCULAIRE

8 x 12 po (20,3 x

30,5 cm) AU

10 po (25.4 cm)

(MÂLE)

COUDE

CIRCULAIRE DE

10 po

(25.4 cm)

Deux manières de raccorder les conduits à un appareil

prémonté.

CHAPEAU DE TOIT

CONDUIT

CIRCULAIRE

DE 10 po

(25.4 cm)

CHAPEAU

DE MUR

Page 11

CÂBLAGE

MODÈLES

ILB9 ILB11

Page 11

POSITION DE LA

NOIR AU

NOIR

FIL DE TERRE À

PLAQUE DE CÂBLAGE

BLANC

AU

BLANC

DESSUS /

ARRIÈRE DU

BOÎTIER

PLAQUE

DE

CÂBLAGE

ENTRÉE

120 VCA

(du le hotte)

Le ventilateur peut être branché depuis l’extérieur du

boîtier. Utiliser des connecteurs homologués UL pour les

branchements, conformément aux codes locaux en vigueur.

OPTIONS DE MONTAGE

Des écrous à six pans ¼-20 fixent les supports au boîtier. Desserrer

et resserrer ou retirer et replacer les écrous si nécessaire, selon la

position désirée pour le support.

11/8 po

(28,6 mm)

Décharge

de soufflerie

dans ligne

présassemblée

22 po

22"

(55,9 cm)

Max.

1

MAX.

1

Supports en position préas-

semblée

(Sortie parallèle aux solives)

(Bâtiment en cours de con-

struction)

Décharge

de soufflerie

/

8"

dans ligne

présassemblée

18 po

18"

(45,7 cm)

Supports retournés et xés à

un cadre supplémentaire.

(Sortie perpendiculaire aux

(Construction neuve ou ex-

solives)

istante)

1½ au

2½

po

(38,1 a

1½"

63.5 mm)

to

2½"

PLAQUE DE CÂBLAGE

BRANCHEMENT

DU CÂBLE

D’ALIMENTATION

À LA VERTICALE

BRANCHEMENT DU

CÂBLE D’ALIMENTATION

À L’HORIZONTALE

La plaque de câblage se xe sur le côté ou sur le dessus du

boîtier.

OPTIONS D’INSTALLATION

DES CONDUITS

POSITIONS DE LA DÉCHARGE DE LA SOUFFLERIE

PANNEAU

AMOVIBLE

CONNECTEUR DU

CONNECTEUR

DU CONDUIT

(sortie)

CONDUIT

(prise)

Ventilateur illustré

en position de

décharge de souferie

dans ligne. (Préassemblé)

Le panneau

tourné et panneau amovibl

couvre le côté

ouvert précé-

dent.

CONNECTEUR

DU CONDUIT (prise)

Ventilateur illustré en

position de décharge de souf-

erie droit angle. (Changer la

position du panneau amovible

tel qu’illustré.)

CONNECTEUR

DU CONDUIT

(sortie)

PANNEAU

AMOVIBLE (à

placer ici)

1½ au

Boîtier converti

en décharge

de soufflerie

droit angle

18 po

18"

(45,7 cm)

2½

po

(38,1 a

1½"

63.5 mm)

to

2½"

Supports retournés et xés à

un cadre supplémentaire.

(Sortie droit angle.)

(Construction neuve ou ex-

istante)

Décharge

de soufflerie

dans ligne

présassemblée

22 po

22"

(55,9 cm)

Supports retournés et xés

en haut du boîtier. Boîtier

suspendu par des câbles.

(Sortie parallèle aux solives)

(Construction neuve ou ex-

istante)

INSTALLATION DES CONDUITS (décharge

vertical de ventilateur)

TRANSITION CIRCULAIRE

8 x 12 po (20,3 x 30,5 cm) AU

10 po (25.4 cm) (MÂLE)

TRANSITION CIRCULAIRE

8 x 12 po

(20,3 x 30,5 cm) AU

10 po (25.4 cm)

(FEMELLE)

CONDUIT

CIRCULAIRE

DE 10 po

(25.4 cm)

Raccordement de conduit typique à un ventilateur converti

en décharge verticale

CHAPEAU DE TOIT

CONDUIT

CIRCULAIRE

DE 10 po

(25.4 cm)

Page 12

UTILISATION ET ENTRETIEN

Suivre les instructions de câblage fournies avec le hotte et respecter

tous les codes locaux et provinciaux en vigueur, de même que le Code

national de l’électricité.

AVERTISSEMENT : Pour diminuer les risques de décharge

électrique, débrancher la source d’alimentation avant toute

opération d’entretien.

PIÈCES DE RECHANGE

LÉGENDE NO DE RÉF DESCRIPTION

1 97014853 Clapet

2 99150415 Vis, #8B x ¼* (16 oblig.)

3 98009520 Registre (2 oblig.)

4 97014784 Boîtier

5 97014728 Support (2 oblig.)

6 99150591 Vis, #10-12 x .625 (4 oblig.)

7 97006142 Harnais à fils

8 99150471 Vis de terre, 10-32 x ½* (2 oblig.)

9 98005512 Plaque de câblage

10 99420470 Écrou de panneau d’access (4 oblig.)

11 98009531 Panneau amovible du boîtier

12 93150487 Vis, #10-24 x .375* (8 oblig.)

13 98005513 Couvercle de la boîte de câblage

14 99400035 Réducteur de tension

15 97014788 Support de moteur

16 99260477 Écrou, ¼-20* (11 oblig.)

17 99200202 Vis, ¼-20 x ½* (5 oblig.)

18 97014785 Volute

19 99080490 Moteur (ILB9)

99080491 Moteur (ILB11)

20 93260447

21 98009516 Support

22 99020286 Roue de soufflerie (inclut no légende 22)

23 98009514 Bague d’arrivée

24 99150417 Vis, #8-18 x ¼* (5 oblig.)

25 98009513 Support de volute

+ 97016794 Soufflerie, ensemble (ILB9)

(inclut no légende 15 à 26)

+ 97016795 Soufflerie, ensemble (ILB11)

(inclut no légende 15 à 26)

26 98009532 Panneau de access

27 99150472 Vis de fixation de panneau de access

(4 oblig.)

28 97016791 Kit de accrocher

29 99610015

30 99610028

31 97014597 Kit de plaque de ventilateur

Commander les pièces de rechange par numéro de référence et non

à l’aide du numéro de légende.

* Visserie standard - peut être achetée localement.

+ Non montré assemblé.

Écrou hexagonal à collerette 5/16-18* (5 oblig.)

Transition de 8 x 12 po au 10 po circulaire

(20,3 x 30,5 cm au 25,4 cm circulaire) (mâle)

Transition de 8 x 12 po au 10 po circulaire

(20,3 x 30,5 cm au 25,4 cm circulaire) (femelle)

GARANTIE

MODÈLES

ILB9 ILB11

Page 12

Pour nettoyer la soufflerie : Retirer la panneau d’access, débrancher la

soufflerie du boîtier, retirer les écrous de fixation de la soufflerie et retirer

délicatement la soufflerie du boîtier. Utiliser un accessoire d’aspirateur approprié ou retirer la grille et nettoyer à l’aide d’un chiffon doux et de savon

ou de détergent doux pour nettoyer la zone de décharge de la soufflerie

et la roue. NE PAS LAISSER D’EAU S’INFILTRER DANS LE MOTEUR.

S’assurer que la soufflerie est complètement sèche avant de la réinstaller.

Le moteur est lubrifié en permanence. Ne pas lubrifier ou démonter le

moteur.

1

3

7

2

9

6

16

15

19

ENSEMBLE DE

SOUFFLERIE

29

2

4

30

28

5

12

8

16

3

2

10

11

14

22

13

18

17

21

25

31

16

17

20

26

27

23

24

Broan-NuTone LLC (Broan-NuTone) garantit à l’acheteur consommateur original de ses produits qu’ils sont exempts de vice de matériaux ou de fabrication pour une période d’un an à compter de la date

d’achat original. IL N’Y A PAS D’AUTRES GARANTIES, EXPRIMÉES OU IMPLICITES, INCLUANT MAIS NON LIMITÉES AUX GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET DE CONVENANCE DANS

UN BUT PARTICULIER.

Durant cette période d’un an, Broan-NuTone, à sa discrétion, réparera ou remplacera gratuitement tout produit ou pièce qui s’avèrera défectueux et ayant été utilisé normalement et d’une manière non abusive.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS, NI AUX AMPOULES HALOGÈNES OU INCANDESCENTES, FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE TOIT,

CAPUCHONS MURAUX ET AUTRES ACCESSOIRES POUR CONDUITS. Cette garantie ne couvre pas (a) l’entretien et le service normal ou (b) tout produit ou pièce endommagé à la suite d’un mauvais usage,

d’une négligence, d’un accident, d’un entretien inadéquat ou d’une réparation (autre que par Broan-NuTone), d’une mauvaise installation ou d’une installation non conforme au mode d’installation recommandé.

La durée de toute garantie implicite est limitée à une période de un an tel que spécifié pour la garantie exprimée. Certains États ou provinces ne permettent pas de limitation de la durée d’une garantie implicite.

Cette condition ne s’applique donc peut-être pas dans votre cas.

L’ENGAGEMENT DE BROAN-NUTONE À RÉPARER OU À REMPLACER, AU CHOIX DE BROAN-NUTONE, SERA LA SEULE OBLIGATION EXCLUSIVE SOUS CETTE GARANTIE. BROAN-NUTONE NE SE TIENDRA

PAS RESPONSABLE DES DOMMAGES DIRECTS, INDIRECTS OU SPÉCIAUX AYANT UN LIEN DIRECT OU INDIRECT AVEC L’UTILISATION OU LA PERFORMANCE DE SES PRODUITS. Certains États ou provinces

ne permettent pas l’exclusion ou la limitation de dommages directs ou indirects. Cette condition ne s’applique donc peut-être pas dans votre cas.

Cette garantie vous donne des droits spécifiques et il se peut que vous ayez d’autres droits qui varient d’une province à l’autre ou d’un État à l’autre. Cette garantie annule toutes les garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan-NuTone à l’adresse ou numéro de téléphone mentionnée ci-dessous, (b) donner le numéro de modèle et l’identification de la pièce et (c) décrire la

nature de tout défaut dans le produit ou la pièce. Au moment de la demande de service sous garantie, vous devez présenter une preuve de la date d’achat original du produit en question.

BEST®, 926 W. State Street, Hartford, Wisconsin 53027 800-558-1711

Aux E.U. :

GARANTIE LIMITÉE D’UN AN DE PRODUITS BEST

Au Canada :

BEST® , 550 Lemire Blvd., Drummondville (Quebec) Canada J2C 7W9 866-737-7770 www.BestRangeHoods.com

®

99043703E

Loading...

Loading...