Page 1

Model EB6

Model EB9

For use with compatible

Best by Broan range hoods.

See hood manual for suitability.

BEST BY BROAN, P.O. BOX 140 HARTFORD, WI 53027

Page 2

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended

by the manufacturer. If you have questions, contact the manufacturer at the

address or telephone number listed in

the warranty.

2. Before servicing or cleaning unit, switch

power off at service panel and lock the

service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten

a prominent warning device, such as a

tag, to the service panel.

3. Installation work and electrical wiring must

be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through

the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety standards such as those

published by the National Fire Protection

Association (NFPA), and the American

Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE),

INSTALLER: Leave This Manual With The Homeowner.

HOMEOWNER: Use And Care Information On Page 4.

WARNING

5. When cutting or drilling into wall, or ceiling, do not damage electrical wiring or

other hidden utilities.

6. Ducted fans must always be vented to

the outdoors.

7. To reduce risk of fire, use only metal

ductwork.

8. This unit must be grounded.

CAUTION

1. For general ventilating use only. Do not

use to exhaust hazardous or explosive

material and vapors.

2. To avoid motor bearing damage and

noisy and/or unbalanced impellers, keep

drywall spray, construction dust, etc. off

power unit.

3. Please read specification label on product for further information and requirements.

4. Electrical circuit, including speed control, (if used), must be rated 6 AMPS

minimum for Model EB9 or 3 AMPS

minimum for Model EB6.

SPECIFICATIONS

MODEL VOLTS AMPS CFM DUCT SIZE

EB6 120 2.4 600 10 " DIA.

EB9 120 5.7 900 10" DIA.

PLAN THE INSTALLATION

ALL INSTALLATIONS

1. Locate the blower so the length of the

duct run and number of elbows are kept

to a minimum.

2. Where possible, blower should be centered between wall studs or roof rafters.

PLAN THE INSTALLATION

3. Avoid pipes, wires, or other ductwork that

may be running through the wall.

4. Attach mounting plate to top of hood.

5. Install 10” dia. ductwork and 120 VAC

house wiring between blower location

and hood location.

2

Page 3

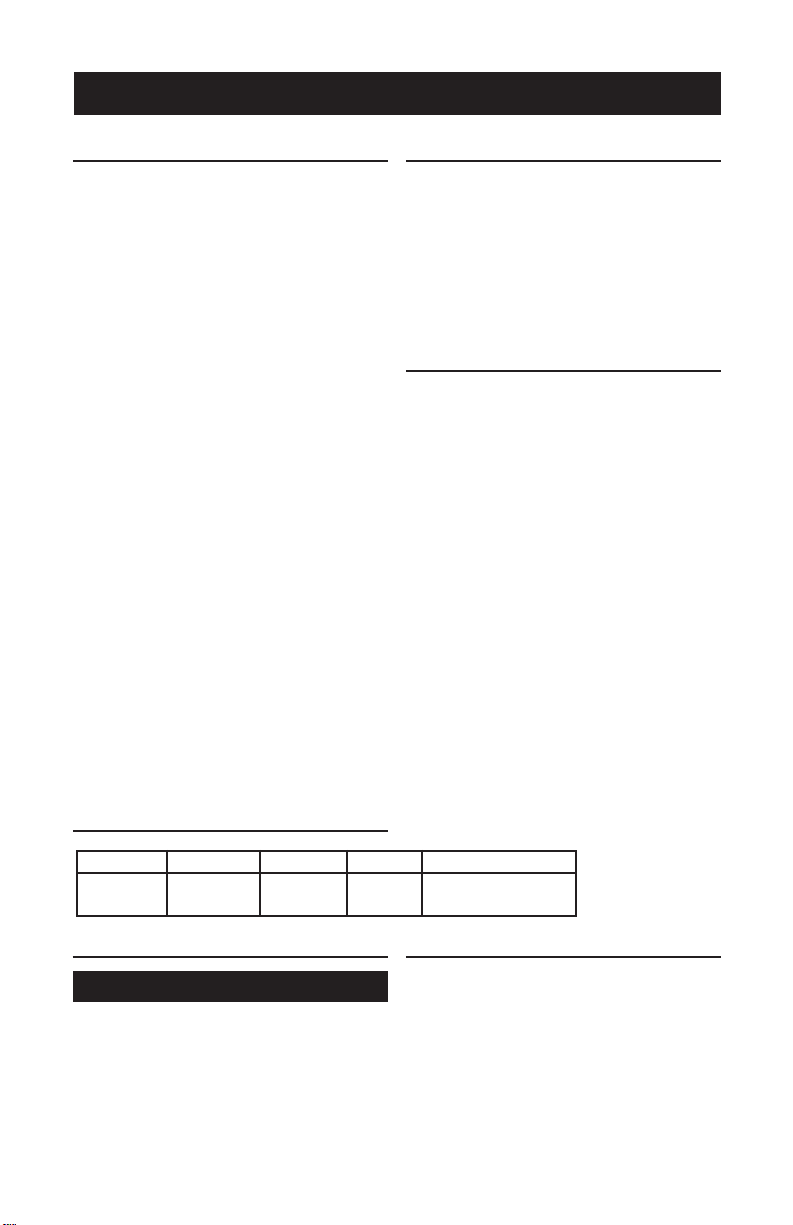

11" dia.

hole

29 ½"

1¼"

dia. hole

127/8"

10 ¾"

25 "

7¼ "

91/8"

Wa ll Stu d

Wa ll Stu d

REMOVE

SIDING

8½ "

Pilot

Hole

OUTSIDE - WALL VIEW

20 ½"

11"

dia.

hole

103/8"

1¼"

dia. hole

8½"

20 ¾"

7¼"

91/8"

REMOVE

SHINGLES

Pilot

Hole

OUTSIDE - ROOF VIEW

PREPARE THE

INSTALLATION LOCATION

PREPARE THE

INSTALLATION LOCATION

ROOF INSTALLATIONS

1. Locate the blower on the rear slope of the

roof. Place it in a location to minimize

duct run. The location should be free of

obstacles (T.V. leads, electrical lines,

etc.). Bear in mind, if the blower top is

level with the roof peak, it will not be seen

from the street. Keep this approximate

location in mind as you work from within

the attic.

Figure 1

REMOVE

103/8"

SHINGLES

Roof Rafter

dia. hole

From inside the attic space:

2. Drill a PILOT HOLE up through the roof,

8½" from the inside edge of a ROOF

RAFTER.

From outside - on the roof:

Measure and mark the 20¾" x 20½" rect-

3.

angle.

Cut and remove only the shingles

inside this rectangle.

Measure and mark the 11" DIAMETER

4.

HOLE and the 1¼" DIAMETER HOLE.

Cut these holes all the way through the

roof.

Figure 2

2"

24¾"

5. For flat roof installations, build a curb that

will mount the blower at a minimum pitch of

2/12. See Figure 2. Discharge end of the

blower should be pointed away from prevailing winds.

20¾"

8½"

Pilot

Pilot

Hole

Hole

1¼"

7¼"

OUTSIDE - ROOF VIEW

11"

dia.

hole

Roof Rafter

91/8"

2"

28¼"

20½"

6¾"

WALL INSTALLATIONS

1. Choose a position on the outside wall.

Make sure that no wall studs, pipes or

wires run through the opening area.

Figure 3

127/8"

Wall Stud

24¾"

10¾"

8½"

Pilot

Pilot

Hole

Hole

1¼"

dia. hole

OUTSIDE - WALL VIEW

REMOVE

SIDING

7¼"

11" dia.

hole

91/8"

Wall Stud

From inside the wall:

2. Drill a PILOT HOLE through the wall, 8½"

from the inside edge of a WALL STUD.

From outside - on the wall:

3. Measure and mark the 24¾" x 28¼"

rectangle.

Cut and remove only the sid-

ing inside this rectangle.

4. Measure and mark the 11" DIAMETER

HOLE and the 1¼" DIAMETER HOLE.

Cut these holes all the way through the

wall.

PREPARE THE BLOWER

ALL INSTALLATIONS

1. Unpack the blower assembly.

2. Remove the cover and screws.

3. Remove and discard cardboard from blower

wheel.

4. Remove the wiring box cover and screws.

5. Attach an appropriate U.L. approved cable

connector in the hole at the rear of the wiring

box.

3

28¼"

Page 4

INSTALL THE BLOWER

INSTALL THE BLOWER

ROOF INSTALLATIONS

1. Remove roofing nails from the upper 2/3

of the shingles around the cutout area

and carefully lift the shingles to allow the

back flashing sheet on the blower housing to fit under them.

2. Center the blower ring in the 11" diameter hole, making sure that the 1-1/4"

diameter electrical wiring hole aligns with

the hole in the wiring box.

3. Attach the blower to the roof with the six

screws provided. All six holes in the back

panel must be filled, or any moisture that

may get inside the housing could leak

into the house.

4. Using a good grade of roofing cement,

seal all of the shingles around the housing and flashing sheet as well as the

mounting screw heads.

5. Bring electrical wiring (from hood) through

the hole in the wiring box and secure it

according to local codes.

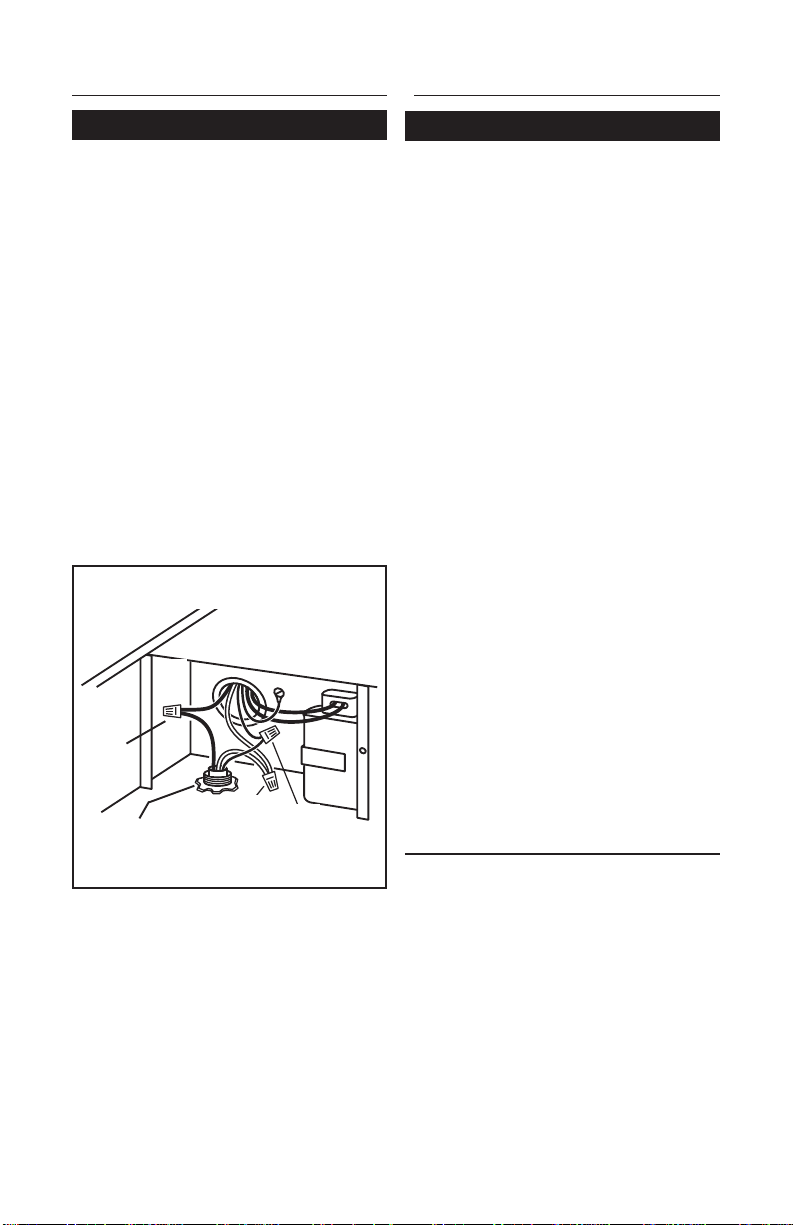

Figure 4

BLACK

TO

BLACK

BLACK

TO

BLACK

120 VAC

LINE IN

120 VAC

WIRING

FROM HOOD

6. Make the electrical connections with the

proper connector for the type of wiring

being used. Connect white to white, black

to black, and the green or bare wire to

green. See Figure 4, as well as the wiring

label on the hood’s mounting plate.

7. Replace wiring box cover and screws.

Do not pinch wiring under the cover.

8. Check for free movement of the damper

before installing housing cover and

screws.

9. Turn on power and check operation of

the blower.

WHITE

WHITE

TO

TO

WHITE

WHITE

GREEN

GREEN

TO

GREEN

TO

GREEN

WALL INSTALLATIONS

1. Place a large bead of caulk on the back

side of the housing along the outer edge.

2. Center the blower ring in the 11" diameter hole, making sure that the 1-1/4"

diameter electrical wiring hole aligns with

the hole in the wiring box.

3. Attach blower to the wall with the six

screws provided. All six holes in the back

panel must be filled, or any moisture that

may get inside the housing could leak

into the house.

4. Using a good grade of caulk, seal all

around the mounting screw heads.

5. Bring electrical wiring through the hole in

the wiring box and secure it according to

local codes.

6. Make the electrical connections with the

proper connector for the type of wire

being used. Connect white to white, black

to black, and green or bare wire to green.

See Figure 4.

7. Replace wiring box cover and screws.

Do not pinch wiring under cover.

8. Check for free movement of the damper

before installing housing cover and

screws.

9. Turn on power and check operation of

the blower.

10.Top and side flanges of the back plate

may be covered with trim strips. Do not

block grille opening at bottom with trim. It

will adversely affect performance of the

blower.

USE AND CARE

Disconnect electrical power supply and lockout service panel before cleaning or servicing this unit.

CLEANING

Remove cover and carefully vacuum blower

and inside of housing. Be careful not to

bend or otherwise damage blower wheel.

MOTOR LUBRICATION

The motor is permanently lubricated. Do

not oil or disassemble motor.

4

Page 5

WARRANTY

BROAN ONE YEAR LIMITED WARRANTY

Broan warrants to the original consumer purchaser of its products that such

products will be free from defects in materials or workmanship for a period of one

year from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

During this one-year period, Broan will, at its option, repair or replace, without

charge, any product or part which is found to be defective under normal use and

service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS AND TUBES. This warranty does not cover (a) normal maintenance and

service or (b) any products or parts which have been subject to misuse,

negligence, accident, improper maintenance or repair (other than by Broan),

faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as

specified for the express warranty. Some states do not allow limitation on how

long an implied warranty lasts, so the above limitation may not apply to you.

BROAN’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN’S OPTION,

SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER

THIS WARRANTY. BROAN SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan at the address or

telephone number below, (b) give the model number and part identification and

(c) describe the nature of any defect in the product or part. At the time of

requesting warranty service, you must present evidence of the original purchase date.

Best by Broan

P.O. Box 140

Hartford, WI 53027

5

Page 6

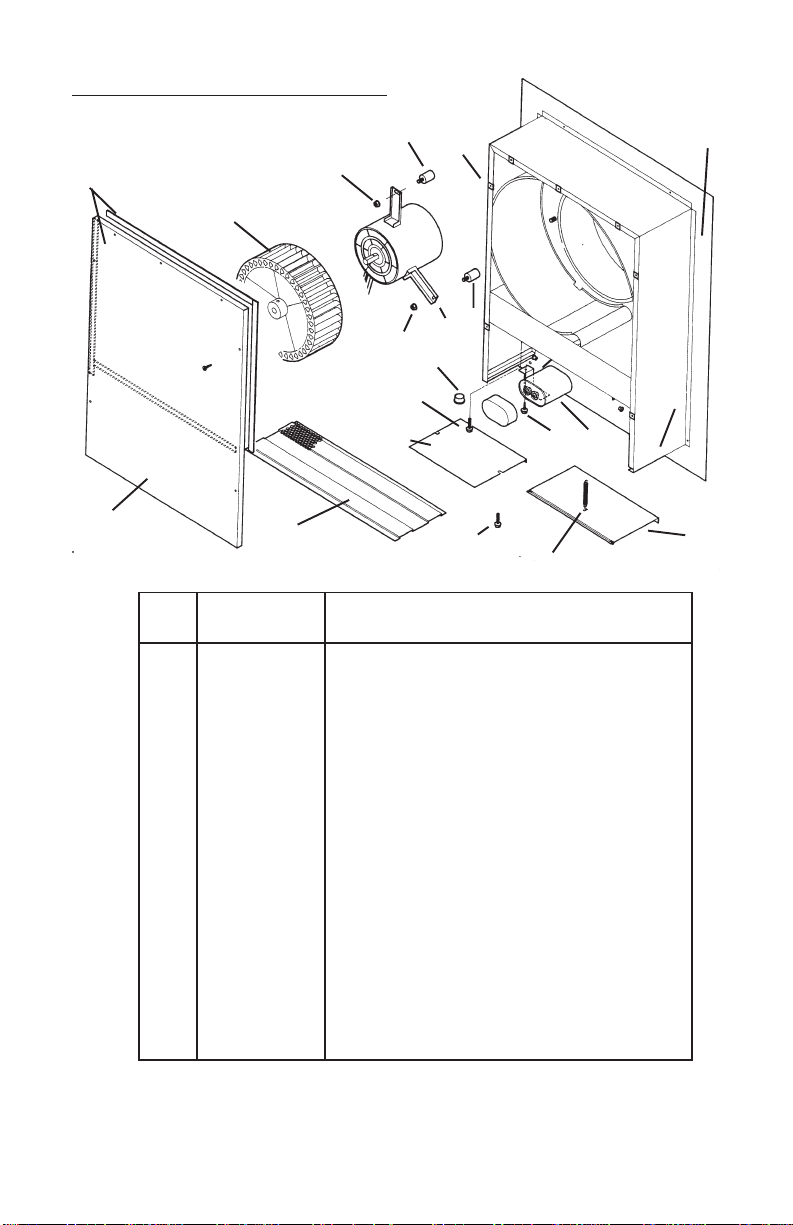

SERVICE PARTS

MODELS EB6 & EB9

16

13

4

5

3

4

8

5

15

1

11

17

10

12

KEY

NO. PART NO. DESCRIPTION

1 97011795 Airbox Assembly

2 98008507 Damper

3 93260454 Sheet Metal Nut, #8-18 U-Type (7 req.)*

4 99100484 Isolator (3 req.)

5 99260477 Whiz Nut, 1/4" - 20 (3 req.)*

6 98008511 Grille

7 99100379 Heyco Damper (2 req.)

8 99080396 Motor W/Capacitor (Model EB9)

10 98008509 Wiring Box Cover

11 98008588 Capacitor Clamp

12 98008510 Airbox Cover

13 99020263 Blower Wheel (Model EB9)

14 99140145 Damper Spring

15 99400055 Heyco

16 99100517 Foam Seal (4 req.)

17 99150471 Hex Screw, #10 - 32 x 1/2"*

18 99150535 Hex Screw, #8-16 x 3/8 (2 Req.)*

19 99271110 Capacitor 15 MFD

6

99080397 Motor W/Capacitor (Model EB6)

99020264 Blower Wheel (Model EB6)

18

14

18

19

7

2

* Standard Hardware - May be purchased locally.

Always order replacement parts by Part No., not Key No.

6

Page 7

Modelo EB6

Modelo EB9

Para el uso con las campanas

compatibles de Best by Broan.

V ea el manual de la campana p ara la

conveniencia.

BEST BY BROAN, P.O. BOX 140 HARTFORD, WI 53027

Page 8

LEA Y CONSER VE ESTAS INSTRUCCIONES

ADVERTENCIA

Para reducir el riesgo de incendio, descarga eléctrica, o lesiones a personas,

cumpla los siguientes puntos:

1. Solamente use esta unidad de la manera

propuesta por el fabricante. Si tiene

alguna pregunta, póngase en contacto

con el fabricante en la dirección o teléfono

anotados en la garantía.

2. Antes de limpiar o de poner en servicio la

unidad, apague el interruptor en el panel

de servicio, y asegure el panel de servicio

para evitar que se encienda

accidentalmente. Cuando el dispositivo

para desconectar el servicio eléctrico no

puede ser cerrado con algún tipo de

traba, sujete fuertemente al panel de

servicio, una etiqueta de advertencia

prominente.

3. El trabajo de instalación y el alambrado

eléctrico deben llevarse a cabo por personal calificado de acuerdo con todos

los códigos y las normas aplicables,

incluyendo los códigos y normas de construcción contra incendios.

4. Se requiere una cantidad de aire suficiente para la combustión y escape de

gases por la chimenea del equipo de

quemado de combustible para evitar

salirse de las especificaciones y estándares de seguridad del fabricante, tales

como los publicados por la Asociación

nacional de protección contra incendios

(NFPA por sus siglas en Inglés), y la

Sociedad americana de ingenieros de

calefacción, refrigeración y aire acondicionado (ASHRAE por sus siglas en Inglés), y los códigos de las autoridades

locales.

ADVERTENCIA

5. Cuande corte o taladre en una pared o

techo, no dañe los cables eléctricos ni

otras instalaciones ocultas.

6. Los ventiladores con ductos siempre

deben de ventilar hacia el exterior.

7. Para reducir el riesgo de incendio, use

solamente conductos de metal.

8. Esta unidad se debe conectar a tierra.

PRECAUCION

1. Sólo para uso de ventilación general. No

se use para extraer materiales o vapores

peligrosos o explosivos.

2. Para evitar daños al cojinete del motor y/

o impulsores ruidosos o desequilibrados, mantenga la fuente de potencia

lejos de rocíos de pared seca, de polvo

de construcción, etc.

3. Lea la etiqueta de especificaciones en el

producto para mayor información y requisitos.

4. El circuito, incluyendo el control de la

velocidad (si lo usa), debe tener

capacidad de 6 AMPS mínimo para el

Modelo EB9 o 3 AMPS mínimo para el

Modelo EB6.

INSTALADOR: Deje este manual con

el usuario.

USUARIO: Uso y información sobre el

cuidado en la página 4.

ESPECIFICACIONES

MODELO VOLTIOS AMPS CFM TAMAÑO DUCTO

EB6 120 2.4 600 25 cm de DIA.

EB9 120 5.7 900 25 cm de DIA.

PLANEAMIENTO DE LA

INSTALACION

TODAS LAS INSTALACIONES

1. Ubique el ventilador de manera que la

longitud del ducto y el número de

codos se reduzcan al mínimo.

2. Cuando sea posible el ventilador

deberá centrarse entre los montantes

de la pared o las vigas del techo.

PLANEAMIENTO DE LA

INSTALACION

3. Evite tubos, cables u otros ductos que

puedan estar tendidos a lo largo de la

pared.

4. Conecte la placa de montaje en la

parte superior de la campana.

5. Instale un ducto de 10” de diámetro y

cables domésticos de 120 VCA entre

la ubicación del ventilador y la

ubicación de la campana.

8

Page 9

PREPARE EL SITIO PARA

20 ½"

11"

dia.

hole

103/8"

1¼"

dia. hole

8½"

20 ¾"

7¼"

91/8"

REMOVE

SHINGLES

Pilot

Hole

OUTSIDE - ROOF VIEW

11" dia.

hole

29 ½"

1¼"

dia. hole

127/8"

10 ¾"

25 "

7¼ "

91/8"

Wal l Stu d

Wal l Stu d

REMOVE

SIDING

8½ "

Pilot

Hole

OUTSIDE - WALL VIEW

LA INSTALACION

PREPARE EL SITIO PARA

LA INSTALACION

INSTALACIONES DE TECHO

1. Coloque el ventilador en la gradiente trasera

del techo. Ubíquelo en lugar que no requiera

largo ducto. No debe haber obstáculos

(Alambres de T.V., líneas eléctricas, etc.).

Tenga en cuenta que si el tope del ventilador

está a nivel de la cúspide del techo, no se

lo verá desde la calle. Recuerde la ubicación

aproximada mientras trabaja en el ático.

Figura 1

264 mm

(10 3/

8

103/8"

plg.)

Viga del techo

Roof Rafter

Desde el interior del espacio del ático:

2. Haga un ORIFICIO PILOTO a través del

techo, a una distancia de 21.6 cm (8 ½”) del

borde interior de una VIGA DEL TECHO.

Desde el exterior, en el techo:

3. Mida y marque el rectángulo de 52.7 x 52.1

cm (20 ¾” x 20 ½”).

tejas que se encuentran dentro de este

rectángulo.

4. Mida y marque el ORIFICIO DE 27.9 CM

(11") y el ORIFICIO DE 3.2 CM (1 1/4") de

DIÁMETRO. Haga estos orificios

totalmente a través del techo.

Figura 2

51 mm

5. Para instalar un ventilador sobre un techo

(2 plg.)

2"

628.7mm

24¾"

(24¾plg.)

plano, construya un bastidor para soportar

el ventilador, con una pendiente mínima de

2/12. El extremo de descarga del ventilador

debe apuntar en dirección contraria a los

vientos dominantes.

527 mm

20¾"

(20¾ plg.)

216 mm

8½"

(8½ plg.)

Orificio

Pilot

Pilot

piloto

Hole

Hole

Orificio de 279 mm

(11 plg.) de diám.

184 mm

7¼"

(7 ¼ plg.)

dia.

hole

232mm

Roof Rafter

91/8"

(91/8plg.)

Viga del techo

11"

QUITE LAS

REMOVE

TEJAS

SHINGLES

Orificio de

32 mm

(1¼ plg.) de

1¼"

diám.

dia. hole

OUTSIDE - ROOF VIEW

EXTERIOR - VISTA DEL TECHO

Corte y quite sólo las

51mm

(2plg.)

2"

28¼"

717.6mm

(28¼plg.)

171.5mm

(6¾plg.)

521 mm

20½"

(20½ plg.)

6¾"

INSTALACIONES DE PARED

1. Escoja un sitio en la pared exterior.

Cerciórese que no hay montantes, tubería

o alambres en dicho punto.

Figura 3

327mm

127/8"

(127/8plg.)

628.7 mm

24¾"

(24¾ plg.)

273mm

10¾"

(10¾ plg.)

216mm

8½"

(8½plg.)

Wall S tud

Orificio de

32 mm

Montante de la pared

1¼"

(1¼ plg.) de

dia. hole

diám.

EXTERIOR - VIST A DE LA P ARED

REMOVE

QUITE EL

SIDING

FORRADO

Pilot

Pilot

Orificio

Hole

Hole

piloto

184mm

7¼"

(7¼plg)

OUTSIDE - WALL VIEW

Orificio de

11" dia.

279 mm

hole

(11 plg.)

de diám.

232mm

91/8"

(91/8 plg)

Wall S tud

Montante de la pared

717.6mm

(28¼ plg.)

Desde el interior de la pared:

2. Haga un ORIFICIO PILOTO a través de

la pared, a una distancia de 21.6 cm (8 ½”)

del borde interior de un MONTANTE DE

LA PARED.

Desde el exterior, en la pared:

3. Mida y marque el rectángulo de 62.9 x

71.8 cm (24¾" x 28¼”).

Corte y quite

sólo el forrado que se encuentra dentro

de este rectángulo.

4. Mida y marque el ORIFICIO DE 27.9

CM (11") y el ORIFICIO DE 3.2 CM (1

1/4") de DIÁMETRO. Haga estos

orificios totalmente a través de la pared.

PREPARE EL VENTILADOR

TODAS LAS INSTALACIONES

1. Desempaque el conjunto del ventilador

2. Quite la cubierta y los tornillos.

3. Quite y deseche el cartón de la rueda del

ventilador.

4. Quite la cubierta de la caja de conexiones

y los tornillos.

5. Coloque un conectador de cables

apropiado, aprobado por U.L., en el orificio

que se encuentra en la parte posterior de

la caja de conexiones.

9

28¼"

Page 10

INSTALE DEL

VENTILADOR

INSTALE DEL

VENTILADOR

INSTALACIONES DE TECHO

1. Saque los clavos de techo de las 2/3

partes del revestimiento alredeador de

área del corte y cuidadosamente levante

las tablillas para permitir que las

tapajuntas de la caja del ventilador

encajen debajo.

2. Centre el anillo del ventilador en el agujero

de 28 cm cerciorándose que el agujero

de 32 mm de diámetro quede alineado

con el agujero de la caja de conexiones.

3. Asegure el ventilador al techo con los

seis tornillos provistos. Todos seis

agujeros del panel posterior deben

sellarse, o cualquier humedad que

pudiera entrar en la caja podrá también

infiltrarse en la casa.

4. Use cemento para techo de buena calidad

para sellar todas las tablillas alrededor

de la caja y el tapajuntas asi como también

las cabezas de los tornillos.

5. Pase los cables eléctricos (desde la

campana) a través del agujero de la caja

y asegúrelos de acuerdo con los códigos

locales.

BLACK

TO

A

120 VCA

BLACK

120 VAC

LINE IN

WHITE

TO

BLANCO

WHITE

A

BLANCO

NEGRO

NEGRO

CABLES DE

DESDE LA

CAMPANA

6. Haga las conexiones eléctricas con el

conector apropiado para el tipo de cables

que está usando. Conecte el cable

blanco con el blanco, el negro con el

negro y el verde o alambre desnudo con

el verde. Consulte la Figura 4 y la

etiqueta de cableado que se encuentra

en la placa de montaje de la campana.

7. Reemplace la tapa de la caja y tornillos.

No apriete el alambre bajo la tapa.

8. Verifique que el registro se mueve

libremente antes de poner la tapa y los

tornillos.

9. Prenda la electricidad y verifique el

funcionamiento del ventilador.

Figura 4

GREEN

VERDE

TO

GREEN

A

VERDE

INSTALACIONES DE PARED

1. Ponga una gota gruesa de masilla de

calafateo en la parte posterior de la caja

a lo largo del borde exterior.

2. Centre el anillo del ventilador en el agujero

de 28 cm de diámetro queda alineado

con el agujero de la caja.

3. Asegure el ventilador a la pared con los

seis tornillos provistos. Todos seis

agujeros del panel posterior deben

sellarse, o cualquier humedad que

pudiera entrar en la caja se infiltrará en la

casa.

4. Use una masilla de calafateo de calidad

para sellar bien alrededor de las cabezas

de los tornillos de montaje.

5. Pase el alambre eléctrico por el agujero

en la caja y asegúrelo de acuerdo con los

códigos locales.

6. Haga las conexiones eléctricas con el

conector apropiado al alambre que

emplea. Conecte blanco a blanco, negro

a negro, y verde o alambre desnudo a

verde. Vea la Figura 4.

7. Reemplace la tapa de la caja y tornillos.

No apriete el alambre bajo la tapa.

8. Verifique que el registro se mueve

libremente antes de poner la tapa y los

tornillos.

9. Prenda la electricidad y verifique el

funcionamiento del ventilador.

10.Las bridas del tope y los costados de la

plancha trasera pueden cubrirse con

tiritas de guarnición. No bloquee la

entrada de la rejilla con la parte baja de

la guarnición. Afectará grandemente el

rendimiento del ventilador.

USO Y CUIDADO

Desconecte la fuerza eléctrica y bloquee el

panel de servicio antes de limpiar o hacer el

servicio en la unidad.

LIMPIEZA

Saque la tapa y con cuidado limpie con la

aspiradora el ventilador y el interior de la

caja. Tenga cuidado de no torcer o causar

daño a los rodetes del ventilador.

LUBRICACION DEL MOTOR

El motor tiene lubricación permanente. No

lo enaceite o desarme.

10

Page 11

GARANTIA

GARANTÍA BROAN LIMITADA POR UN AÑO

Broan garantiza al consumidor comprador original de sus productos que

dichos productos carecerán de defectos en materiales o en mano de obra por

un período de un año a partir de la fecha original de compra. NO EXISTEN

OTRAS GARANTÍAS, EXPRESAS O IMPLÍCITAS, INCLUYENDO, PERO NO

LIMITADAS A, GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN O APTITUD PARA UN PROPÓSITO PARTICULAR.

Durante el período de un año, y a su propio criterio, Broan reparará o

reemplazará, sin costo alguno cualquier producto o pieza que se encuentre

defectuosa bajo condiciones normales de servicio y uso.

ESTA GARANTÍA NO SE APLICA A TUBOS Y ARRANCADORES DE LÁMPARAS FLUORESCENTES. Esta garantía no cubre (a) mantenimiento y

servicio normales o (b) cualquier producto o piezas que hayan sido utilizadas

de forma errónea, negligente, que hayan causado un accidente, o que hayan

sido mantenidas o reparadas inapropiadamente(por otras compañías que no

sea Broan), instalación defectuosa, o instalación contraria a las instrucciones

de instalación recomendadas.

La duración de cualquier garantía implícita se limita a un período de un año

como se especifica en la garantía expresa. Algunos estados no permiten

limitaciones en cuanto al tiempo de expiración de una garantía implícita, por lo

que la limitacíon antes mencionada puede no aplicarse a usted.

LA OBLIGACIÓN DE BROAN DE REPARAR O REEMPLAZAR, SIGUIENDO

EL CRITERIO DE BROAN, DEBERÁ SER EL ÚNICO Y EXCLUSIVO RECURSO LEGAL DEL COMPRADOR BAJO ESTA GARANTÍA. BROAN NO SERÁ

RESPONSABLE POR DAÑOS ACCIDENTALES, CONSIGUIENTES, O POR

DAÑOS ESPECIALES SURGIDOS O EN CONEXIÓN CON EL USO O EL

RENDIMIENTO DEL PRODUCTO. Algunos estados no permiten la exclusión

o limitación de daños accidentales o consiguientes, por lo que la limitación antes

mencionada puede no aplicarse a usted. Esta garantía le proporciona derechos

legales específicos, y usted puede también tener otros derechos, los cuales

varían de estado a estado. Esta garantía reemplaza todas las garantías

anteriores. Para calificar en el servicio de garantía, usted debe (a) notificar a

Broan al domicilioo o al número de telefono abajo, (b) dar el número del modelo

y la identificación de la pieza y (c) describir la naturaleza de cualquier defecto

en el producto o pieza. En el momento de solicitar servicio cubierto por la

garantía, usted debe presentar evidencia de la fecha original de compra.

Best by Broan

P.O. Box 140

Hartford, WI 53027

11

Page 12

PARTES DE SERVICIO

MODELOS EB6 & EB9

16

13

4

5

3

4

8

5

15

1

11

17

12

10

6

18

18

19

14

CLAVE

NO. PARTE NO. DESCRIPCION

1 97011795 Conjunto Aireador

2 98008507 Registro

3 93260454 Tuerca para Chapa, #8-18 Tipo U (se nec. 7)*

4 99100484 Aislante (se nec. 3)

5 99260477 Tuerca Rápida, 1/4" - 20 (se nec. 3)*

6 98008511 Rejilla

7 99100379 Registro Heyco (se nec. 2)

8 99080396 Motor con Condensador (Modelo EB9)

10 98008509 Tapa Caja de Conexiones

11 98008588 Grapa de Condensador

12 98008510 Tapa de Aireador

13 99020263 Rodete de Ventilador (Modelo EB9)

14 99140145 Resorte de Registro

15 99400055 Heyco

16 99100517 Sellante de Espuma (se nec. 4)

17 99150471 Tornillo Hexag., #10 - 32 x 1/2"*

18 99150535 Tornillo Hexag., #8-16 x 3/8 (se nec. 2)*

19 99271110 Condensador 15 MFD

99080397 Motor con Condensador (Modelo EB6)

99020264 Rodete de Ventilador (Modelo EB6)

7

2

* Tornillería estandar - Pueden comprarse localmente.

Siempre pida repuestos dando el No. de Parte, No la Clave.

12

Page 13

Modèle EB6

Modèle EB9

Pour utilisation avec les hottes

compatibles de Best by Broan.

Voir le manuel de la hotte pour la convenance.

BEST BY BROAN, P.O. BOX 140 HARTFORD, WI 53027

Page 14

LIRE ET CONSERVER CES INSTRUCTIONS

AVERTISSEMENT

POUR RÉDUIRE LES RISQUE

D’INCENDIE, D’ÉLECTROCUTION OU

DE BLESSURES CORPORELLES,

OBERVEZ CE QUI SUIT:

1. N’utilisez cet appareil que selon la

manière prévue par le fabricant. Si vous

avez des questions, contactez le fabricant

à l’adresse ou au numéro de téléphone

indiquée dans la garantie.

2. Avant de réparer ou de nettoyer l’appareil,

éteindre ce dernier au panneau de service afin d’éviter sa remise en marche

accidentelle. Si le panneau de service ne

peut être verrouillé, y fixer un

avertissement en évidence.

3. Le travail d’installation et de branchement

des fils électriques doit être effectué par

une ou des personnes qualifées selon

tous le codes et toutes les normes en

vigueur, y compris ceux et celles

concernant les constructions étalonnées

contre le feau.

4. Il faut suffisamment d’air pour qu’une

bonne combustion et un bon

échappement des gaz se produisent par

le conduit de cheminée de l’equipement

pour empêcher un refoulement d’air.

Suivre les suggestions et les normes de

sécurité du tabricant de l’équipement de

chauffage telles que celles publiêes par

le NFPA (Association Nationale de Protection contre le Feau), et L’ASHRAE

(Société américaine des ingénieurs du

chauffage, de la réfrigération et de la

climatisation, et les autorités localaes en

matière de normes).

INSTALLATEUR: Donner ce manuel au propriétaire.

PROPRIÉTAIRE DE LA MAISON: Information d’usage et d’entretien à la page 3.

AVERTISSEMENT

5.Lorsque vous coupez dans un mur ou

loursque vous le percez, ne pas

endommager les fils électiques et les

autres éléments utilitaires qui s’y touvent.

6.Les ventilateurs à conduit doivent

toujours avoir leu sortie à l’extérier.

7. Pour réduire le rissque d’incendie,

n’utiliser que des conduits en acier.

8. Cet appareil doit être relié à terre.

ATTENTION

1. A n’utiliser que pour une ventilation

générale. Ne pas utiliser pour évacuer

des matériaux et des vapeurs dangeuses

ou explosives.

2. Pour éviter des dégâts aux roulements

du moteur et aux hélices du ventilateur

bruyantes et/ou déséquilibrées, éviter

de pulvériser les plàtres près de l’appareil

et de contaminer celui-ci avec de la

poussiére, etc.

3. Veuillez lire l’étiquette de spécifications

se trouvant sur le produit pour de plus

amples infonnations et exigences.

4. Le circuit électrique, comprenant le

contrôle de vitesse (si celui-ci utilisé) doit

être étalonné à 6 AMPÈRES minimum

pour le modèle EB9 ou à 3 AMPÈRES

minimum pour le modèle EB6.

SPÉCIFICATIONS

MODÉLE VOLTS AMPÈRES CFM DIMENSIONS DES CONDUITES

EB6 120 2.4 600 10” (25cm) DE DIAMÉTRE

EB9 120 5.7 900 10” (25cm) DE DIAMÉTRE

PLANNIFICATION DE L’INSTALLATIONPLANNIFICATION DE L’INSTALLATION

TOUTES LES INSTALLATIONS

1. Placer le ventilateur de telle sorte que la

longueur des conduites et le nombre de

coudes et transitions soient gardés au minimum.

2. Chaque fois que possible, le ventilateur doit

être centré entre les poutres du mur ou les

chevrons du toit.

3. Éviter les tuyaux, les fils électriques ou

autre conduites qui se trouveraient dans le

mur.

4. Fixer la plaque de montage sur le dessus

de la hotte.

5. Installer un système de gaines de 10 pouces

de diamètre et des fils résidentiels de 120

v.c.a. entre l’emplacement du ventilateur et

celui de la hotte.

14

Page 15

PRÉPARATION DE

20 ½"

11"

dia.

hole

103/8"

1¼"

dia. hole

8½"

20 ¾"

7¼"

91/8"

REMOVE

SHINGLES

Pilot

Hole

OUTSIDE - ROOF VIEW

11" dia.

hole

29 ½"

1¼"

dia. hole

127/8"

10 ¾"

25 "

7¼ "

91/8"

Wal l Stu d

Wal l Stu d

REMOVE

SIDING

8½ "

Pilot

Hole

OUTSIDE - WALL VIEW

L’EMPLACEMENT POUR

L’INSTALLATION

PRÉPARATION DE

L’EMPLACEMENT POUR

L’INSTALLATION

INSTALLATIONS SUR LE TOIT

1. Positionnez le ventilateur sur la pente arrière du

toit. Placez-le dans un endroit qui minimisera la

longueur du conduit de ventilation. Cet endroit

doit être exempt d'obstacles (câble de

téléviseur, lignes électriques, etc.) Souvenezvous que si le dessus du ventilateur est à ras

de la pointe du toit, il ne sera pas vu de la rue.

Souvenez-vous de cet emplacement

approximatif pendant que vous travaillez de

l'intérieur de l'entre-toit.

ILLUSTRATION 1

3

/8po)

SHINGLES

Chevron

Orifice d’un

diamètre de

Roof Rafter

dia. hole

264mm

103/8"

(10

De l’intérieur du grenier

2. Percez un AVANT-TROU à travers le toit, à

une distance de 216 mm (8 ½ po) du rebord

intérieur d’un CHEVRON.

De l’extérieur –sur le toit :

3. Mesurez et tracez un rectangle de 527 mm

x 521 mm (20 ¾ po x 20 ½ po). Coupez et

retirez seulement les bardeaux qui se trouvent

à l’intérieur de ce rectangle.

4. Mesurez et tracez un ORIFICE D’UN

DIAMÈTRE DE 279 MM (11 PO) et un ORI-

FICE D’UN DIAMÈTRE DE 32 MM

(1 ¼ PO). Découpez ces orifices de part en

part du toit.

ILLUSTRATION 2

51 mm

(2 po)

2"

628.7mm

5. Pour les installations sur les toits plats,

24¾"

(24¾ po)

fabriquez une bordure qui inclinera le

ventilateur de 2/12 au minimum. Voir ill. 2.

L'extrémité de la décharge du ventilateur doit

pointer du côté opposé aux vents dominants.

527mm

20¾"

(20¾po)

216 mm

8½"

(8 ½ po)

ENLEVEZ

REMOVE

LES

BARDEAUX

Avant-

Pilot

Pilot

trou

Hole

Hole

32mm

1¼"

(1 ¼po)

OUTSIDE - ROOF VIEW

EXTÉRIEUR – VUE DU TOIT

Orifice d’un

diamètre de

279mm (11po)

184 mm

7¼"

(7 ¼ po)

51mm (2 po)

11"

dia.

hole

232mm

Roof Rafter

1

91/8"

/8po)

(9

Chevron

2"

28¼"

717.6mm

(28¼ po)

521mm

20½"

(20½po)

171.5mm

(6¾ po)

6¾"

INSTALLATION SUR UN MUR

1. Choisissez une position sur le mur extérieur.

Assurez qu'il n'y a pas de colombage,

tuyaux ou fils dans l'endroit qui sera ouvert.

ILLUSTRATION 3

327mm

127/8"

(127/8po)

Wall S tud

Poteau mural

629mm

24¾"

(24¾po)

273mm

10¾"

(10¾po)

Orifice d’un

diamètre

de 32mm

dia. hole

EXTÉRIEUR –VUE DU MUR

ENLEVEZ

216mm

8½"

(8½po)

1¼"

(1¼po)

REMOVE

SIDING

PAREMENT

Pilot

Pilot

Avant-

Hole

Hole

trou

184mm

7¼"

(7¼po)

OUTSIDE - WALL VIEW

LE

Orifice

d’un

11" dia.

diamètre

hole

de 279mm

(11po)

232mm

91/8"

(91/8po)

Wall S tud

Poteau mural

De l’intérieur du mur :

2. Percez un AVANT-TROU à travers le mur,

à une distance de 216 mm (8 ½ po) du

rebord intérieur d’un POTEAU

MURAL.TUD.

De l’extérieur –sur le mur :

3. Mesurez et tracez un rectangle de 629 mm

x 718 mm (24¾ po x 28¼ po). Coupez et

retirez seulement les bardeaux qui se

trouvent à l’intérieur de ce rectangle.

4. Mesurez et tracez un ORIFICE D’UN

DIAMÈTRE DE 279 MM (11 PO) et un

ORIFICE D’UN DIAMÈTRE DE 32 MM

(1 ¼ PO). Découpez ces orifices de part

en part du mur.

PRÉPAREZ LE

VENTILATEUR

TOUTES LES INSTALLATIONS

1. Déballez l'ensemble du ventilateur.

2. Enlevez le couvercle et les vis.

3. Enlevez et jetez le carton de la roue du

ventilateur.

4. Enlevez le couvercle de la boîte des fils et

les vis.

5. Attachez une pince de raccordement

appropriée approuvée par l'ACNOR dans

le trou à l'arrière de la boîte des fils.

15

28¼"

718mm

(28¼po)

Page 16

INSTALEZ DU VENTILATEUR

INSTALEZ DU VENTILATEUR

INSTALLATION SUR LE TOIT

1. Enlever les clous de toiture des deux-tiers

supérieurs des tuiles autour de la partie

coupée et soulever doucement les tuiles

pour que la tôle de revers du boîter du

ventilateur puisse se mettre sous celles-là.

2. Centrer l’anneau du ventilateur dans le trou

de 11” (28cm), en s’assurant que le trou de

1¼” (32mm) de diamètre pour les fils

électriques soit aligné avec le trou du boîter

des fils électriques.

3. Attacher le ventilateur au toit au moyen des

6 vis fournies. Les six trous du panneau

arrière doivent être bouchés, sinon de

l’humidité pourra entrer dans le boîter et

passer dans la maison.

4. Grâce à du ciment pour toit de bonne qualité,

rendre étanches les tuiles autour de boîter

et de la tôle du ventilateur ainsi que les têtes

de vis d’attache de celui-là.

5. Faire passer les fils électriques (de la hotte)

dans le trou du boîtier de fils électriques et

l’attacher en suivant les règlements locaux.

Figure 4

BLACK

TO

HOTTE

BLACK

120 VAC

LINE IN

WHITE

TO

BLANC

WHITE

AU

BLANC

GREEN

VERT

TO

GREEN

AU

VERT

DOS À

DOS

CÂBLAGE 120

V.C.A. DE LA

6. Faire les raccords électriques avec le

connecteur qui convient pour le genre de

fil utilisé. Relier le blanc au blanc, le noir au

noir et le vert ou le fil dénudé au vert. Voir

la figure 4, ainsi que l’étiquette du fil sur la

plaque de montage de la hotte.

7. Remetre le couvercle et les vis du boîter de

fils électriques. Ne pas pincer les fils sous le

couvercle.

8. Vérifier que le registre se meut bien librement

avant de remettre le couvercle et les vis du

boîter.

9. Mettre sous tension et vérifier le

fonctionnement du ventilateur.

INSTALLATION AU MUR

1. Placer un large cordon de calfatage à

l’arrière du boîter le long du bord extérieur.

2. Centrer l’anneau du ventilateur dans le trou

de 11” (28cm) de diamètre, en s’assurant

que le trou de 1¼” (32mm) de diamètre pour

les fils électriques soit aligné avec le trou du

boîter des fils électriques.

3. Attacher le ventilateur au mur au moyen

des 6 vis fournies. Les six trous du panneau

arrière doivent être bouchés, sinon de

l’humidité pourra entrer dans le voîtier et

passer dans la maison.

4. Gràce à un calfatage de qualité rendre

étanche tout autour des têtes de vis

d’installation du ventilateur.

5. Faire passer les fils électriques dans le trou

du boîter de fils électriques et l’attacher en

suivant les reglements locaux.

6. Faire les raccords électriques avec le

connecteur qui convient pour le genre de fil

utilisé. Relier le blanc au blanc, le noir au

noir, et le vert ou le fil dénudé au vert. Voir

la figure 4.

7. Remettre le couvercle et les vis du boîter de

fils électiques. Ne pas pincer les fils sous le

couvercle.

8. Vérifier que le registre se meut librement

avant de remettre le couvercle et les vis du

boîter.

9. Mettre sous tension et vérifier le

fonctionnement du ventilateur.

10.Les rebords due haut et des côtés de la

plaque arrière doivent être couvertes avec

des bordures en bois. Ne pas bloquer

l’ouverture de la grille en bas avec une

bordure. Cela risquerait d’affecter les performances du ventilateur.

USAGE ET ENTRETIEN

Débrancher le courant et le panneau de service avant de nettoyer ou d’effectuer une

réparation ou un entretien dans ce ventilateur.

NETTOYAGE

Enlever le couvercle passer soigneusement à

l’aspirateur. Veillez à ne pas plier ou

endommager d’une manière quelconque la

roue du ventilator.

LUBRIFICATION DU MOTEUR

Le moteur est lubrifié en permanence. Ne pas

graisser ni démonter le moteur.

16

Page 17

GARANTIE LIMITÉE D´UN AN DE BROAN

Broan garantit à l´acheteur consommateur original de ses produits qu´ils sont

exempts de défauts dans les matières premières ou la main-d´oeuvre pour

une période d´un an à compter de la date d´achat original. IL N´Y A PAS

D´AUTRES GARANTIES, EXPRIMÉES OU IMPLICITES, INCLUANT LES MAIS

NON PAS LIMITÉES AUX GARANTIES IMPLICITES POUR FIN DE

COMMERCIALISATION ET DE CONVENANCE DANS UN EUT PARTICULIER.

Pendant oette période d´un an, Broan, à son choix, réparera ou remplacera,

gratuitement, tout produit ou pièce qui s´avère défectueux sous utilisation et

service normaux.

CETTE GARANTIE NE COUVRE PAS LES STARTERS DE LAMPES

FLUORESCENTES ET LES TUBES. Cette garantie ne couvre pas (a)

l´entretien et le service normaux ou (b) tout produit ou pièce endommagé par

suite de mauvais usage, négligence, accident, entretien inapproprié ou

réparation (autre que par Broan), mauvaise installation ou installation contraire

au mode d´installation recommandé.

La durée de toute garantie implicite est limitée à une période d´un an tel que

spécifié pour la garantie exprimée. Certains états et certaines provinces no

permettent pas la limitation de la durée d´une garantie implicite, la limitation

ci-dessus peut dono ne pas s´appliquer à vous.

L´ENGAGEMENT DE BROAN DE RÉPARER OU DE REMPLACER, AU CHOIX

DE BROAN, SERA LA SEULE OBLIGATION EXCLUSIVE SOUS CETTE

GARANTIE. BROAN NE SE TIENDRA PAS RESPONSABLE DES DOMMAGES

DIRECTS, INDIRECTS OU SPECIAUX SURVENENT À CAUSE DE OU EN

RAPPORT A L´UTILISATION OU LA PERFORMANCE DE SES PRODUITS.

Certains états et certaines provinces ne permettent pas l´exclusion ou le

limitation des dommages directs ou indirects, la limitation ou l´exclusion cidessus peut donc ne pas s´appliquer à vous.

Cette garantie vous donne des droits légaux spécifiques et il se peut que

vous ayez d´autres droits qui varient d´un état à un autre et d´une province à

une autre. Cette garantie annule toutes les garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan à l´adresse ou

numéro de telephone ci-dessous, (b) donner le numéro du modèle et

l´identification de la pièce et (c) décrire la nature de tout défaut dans le produit

ou la pièce. Au temps de demander la service sous garantie, vous devez

présenter une preuve de la date d´achat original.

Best by Broan

P.O. Box 140

Hartford, WI 53027

17

Page 18

PIÈCES DÉTACHÉES

MODÈLES EB6 & EB9

16

13

4

5

3

4

8

5

15

1

11

17

12

10

6

18

18

14

NO. NO. DE

D’ENTRÉE DE PIÈCES. DESCRIPTION

1 97011795 Ensemble Boîter Air

2 98008507 Registre

3 93260454 Écrou à tôle, #8-18 Type-U (7 néc.)*

4 99100484 Isolant (3 néc.)

5 99260477 Écrou Whiz, ¼”-20 (3 néc.)

6 98008511 Grille

7 99100379 Registre Heyco (2 néc.)

8 99080396 Moteur avec condesateur (Modèle EB9)

10 98008509 Couvercle de boîter de fils électriques

11 98008588 Serre-joint de condensateur

12 98008510 Couvercle de boîter air

13 99020263 Roue de ventilateur (Modèle EB9)

14 99140145 Ressort de registre

15 99400055 Heyco

16 99100517 Joint en mousse (4 néc.)

17 99150471 Vis à tête hex., #10-32 x ½**

18 99150535 Vis à tête hex., #8-16 x 3/8 (2 néc.)

19 99271110 Condensateur 15 MFG

99080397 Moteur avec condesateur (Modèle EB6)

99020264 Roue de ventilateur (Modèle EB6)

19

7

2

* Hardware standard - Peut être acheté localement.

Toujours commander des pièces détachées par leur NO. DE PIÈCES et non

par le NO. D’ENTRÉE.

18

Page 19

19

Page 20

99042680D

Loading...

Loading...