Best E5-1.5G/2.2P-T4-B5, E5-2.2G/3.7P-T4-B5, E5-5.5G/7.5P-T4-B5, E5-7.5G/11P-T4-B6, E5-15G/18.5P-T4-C4 User Manual

...Page 1

E5 SERIS

USER MANUAL

High-Performance Frequency Inverter

Page 2

Preface

Thank you for choosing E5 series multi-functional high performance product.

To gain a better performance of the inverter, it’s strongly recommended you

read this manual carefully before using the inverters and keep it well for

future use.

If during usage you encounter any problems which you cannot solve,please

cntact us at any time.Considering your safety,please make sure the inerters

are debugged and revbised by specialized electrical engineers with

qualifications. There are Danger Caution symbols to remind you of

the safety matters during moving, installing, operating and inspecting

inverter. Please comply with them so you can use inverter more safely.

Page 3

Page 4

Table of Contents

Preface ........................................................................................................................................ 1

Chapter 1 Summarize ............................................................................................................. 1

1.1 Inspection and safty Precautions ...................................................................................... 1

1.2 Precification Table ............................................................................................................. 6

1.3 Precification Unit and Braking Resistor ............................................................................ 8

1.4 Technical Characteristics .................................................................................................. 9

Chapter 2 Installation and connection ................................................................................ 11

2.1 Case Structure and Dimensioon ..................................................................................... 11

2.2 Installation Requirement ................................................................................................. 12

2.3 Connection Guidelines .................................................................................................... 13

2.4 Connection Instruction .................................................................................................... 14

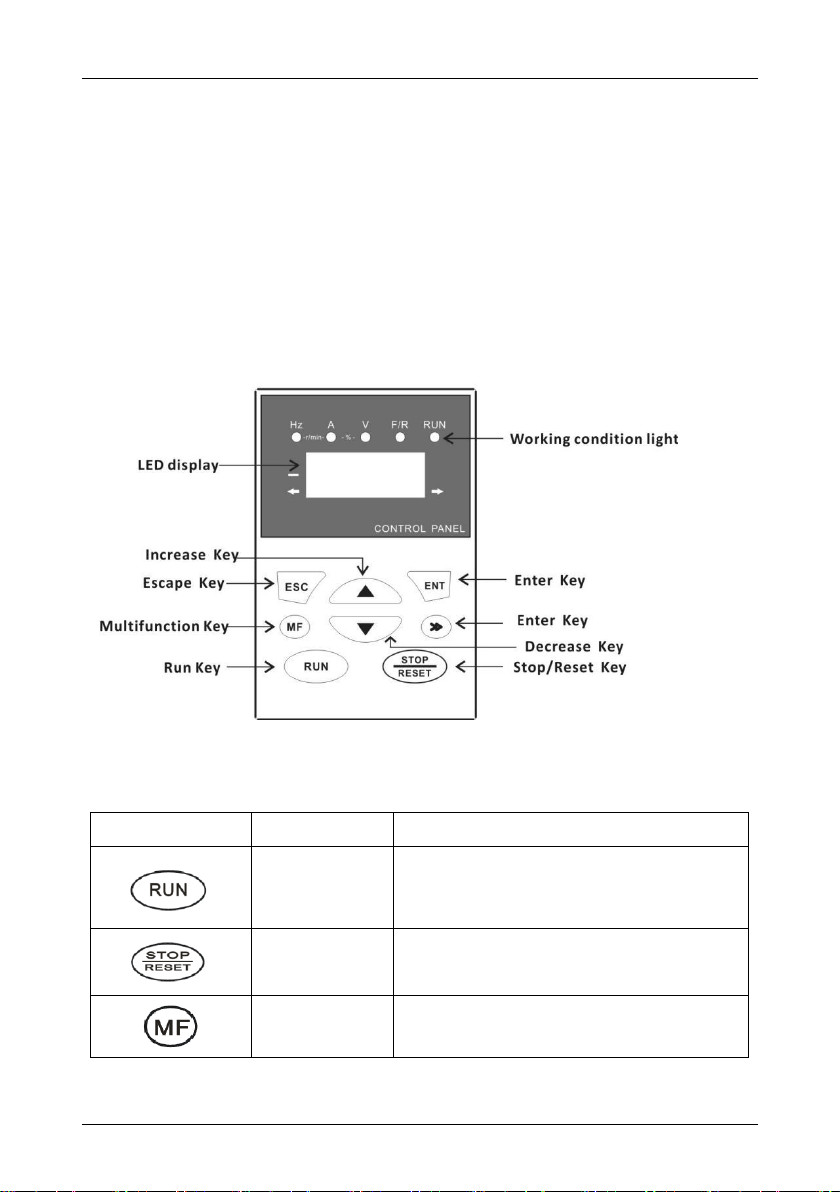

Chapter 3 Keypad Operation ............................................................................................... 23

3.1 Operation of keypad........................................................................................................ 23

3.2 Operation keypad Explanation........................................................................................ 23

3.3 Display Content Explanation ........................................................................................... 24

3.4 Parameter Modification Method ...................................................................................... 25

Chapter 4 List of Parameters ............................................................................................... 27

Chapter 5 Specification of Parameters ............................................................................... 71

Chapter 6 Trouble shooting Easures ................................................................................ 177

6.1 Maintenance Inspection Precautions ............................................................................ 177

6.2 Periodie Inspection Precautions ................................................................................... 177

6.3 Fault Information and Troubleshooting ......................................................................... 177

6.4 Diagnostics.................................................................................................................... 185

6.5 Frequent Anomalies and Solutions ............................................................................... 186

Chapter 7 Modbus Maintenance ........................................................................................ 189

Page 5

E5 User Manual Chapter 1 Summarize

Chapter 1 Summarize

1.1 Inspection and Safety Precautions.

E5 series inverters have gone through strict testing and quality inspection before sales.

When you receive the cargo, please check:

Whether the package is well or damaged by careless shipping;

Whether the product model and parameter are same with your order details.

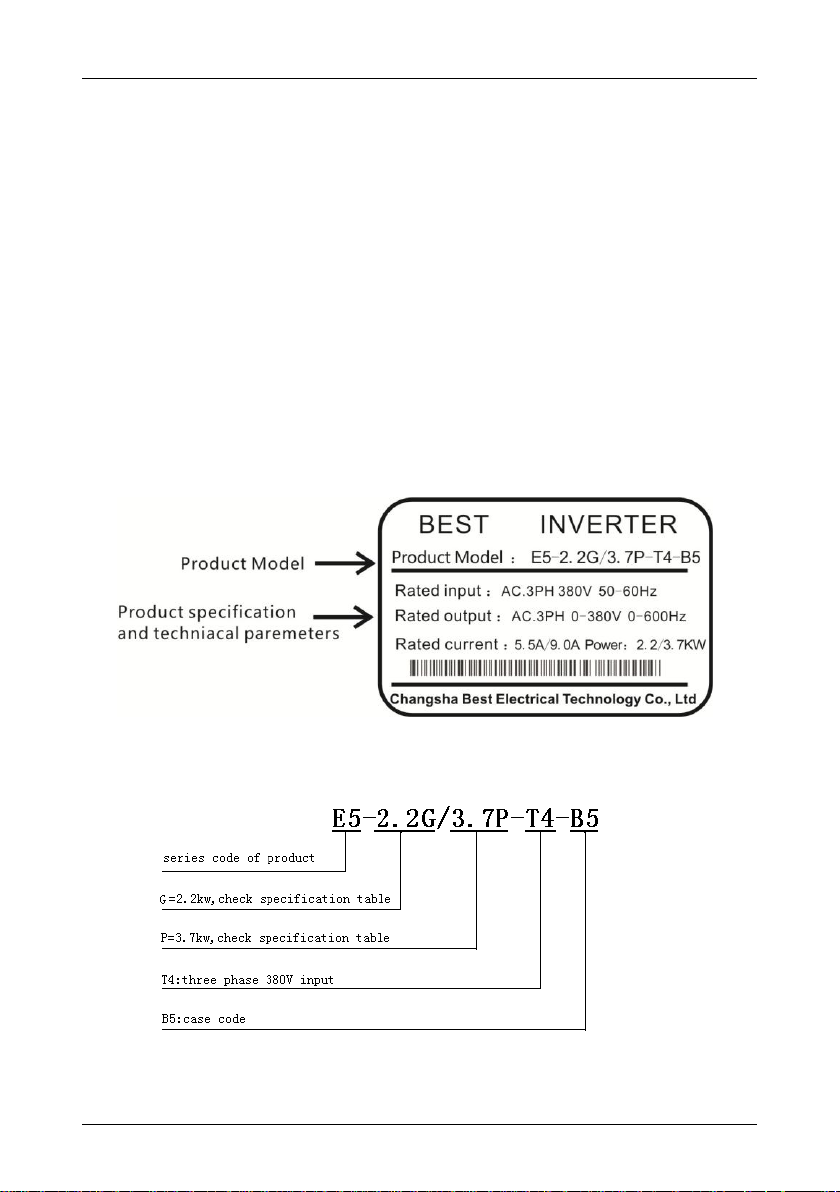

1.1.1 Inspection after Unpacking

Each inverter is packed with one manual, one warrantee card, and one certification

card inside;

Check the nameplate on the profile of inverter, to confirm the model received is the

right one.

Inverter Nameplate:

Model Explanation:

- 1 -

Page 6

Chapter 1 Summarize E5 User Manual

WARNING indicates the situation in which the failure to follow operating

requirements may result in fire or serious personal injury or even death.

ATTENTION indicates the situation in which the failure to follow operating

requirements may damage to inverter or equipment system.

WARNING

Make sure the power is off before wiring.

Within 10 minutes after turning off AC power supply, there’s high voltage still inside

inverter, which is extremely dangerous. DO NOT touch the electric circuit or any

spare part inside.

When inverter is under working, DO NOT inspect the spare part or signal on electric

circuit.

DO NOT dismount or change the inside wiring, electric circuit or spare part by

yourself.

DO NOT operate inverter with a wet had in case of electric shock.

Ierter ground terminals must be correctly grounded.

It is prohibited to reassemble or change control board and spare parts, otherwise

there will be dangers such as electric shock, explosion, etc.

NEVER open inverter cover or touch the spare parts on circuit board when inverter is

power-on. There is high voltage on these parts. Beware of electric shock which

results death!!!

ATTENTION

DO NOT carry out puncture test on the accessories inside the inverter, for they are prone

to be damaged by high voltage.

NEVER connect the output terminal U.V.W to AC power supply.

When power is on or has been cut off just for a short while, inverter and braking resistor

stay in high temperature, DO NOT touch them in case of being scalded.

The voltage on each terminal must comply with the indication on manual, to prevent

crack and damage.

Inverter main electric board CMOS, IC are prone to be influenced and damaged by static

electricity.

Only qualified specialized persons are permitted to install, debug and maintain the

inverters.

Dump the inverters as industrial waste. Burning is not allowed.

After the inverter being kept aside for long time, inspection and commissioning are

required before using.

Inverters can be set for high speed running easily. Please check whether the motor and

1.1.2 Safety Precautions

Notice: Based on different situations, “CAUTION” issue may also cause severe

consequences. Please comply with above two grade issues, which are both vital to our

individual safety.

- 2 -

Page 7

E5 User Manual Chapter 1 Summarize

mechanic properties are competent before revising the settings.

1.1.3 Other Cautions

Input Power Supply

This series of inverters are not applicable to applications out the range of operating voltage as

set forth in this manual. If necessary, please use booster to rise or drop the voltage to regulated

voltage range.

This series of inverters only apply to AC three-phase 380V input voltage. AC two-phase voltage

input will cause faults even damage to the inverters.

Surge Protection

This series of inverters are furnished with surge suppressor that has certain resistance to

lightning induction. However, users in areas with frequent occurrence of lightning need to

mount an external surge suppressor in front of the inverter power input side.

Operation of Contactor

As to the configuration of peripheral devices recommended by this manual, it is necessary to

mount a contactor between the power supply and this drive input side. Such a contactor should

not be used as a control device for start and stop of the inverter, as frequent charging &

discharging shall reduce the service life of internal electrolytic capacitors.

When it is necessary to mount a contactor between the drive output and the motor, it

should be ensured the drive is in a non-output status before switch-on/switch-off of such a

contactor. Failure to comply may result in inverter damage.

Output Filter

Since the inverter output is PWM high frequency chopping voltage, mounting filter devices such

as an output filter and an output AC reactor between the motor and the inverter shall effectively

reduce output noise, avoiding interference to other surrounding equipments.

If the length of cable between the inverter and the motor exceeds 100m, an output AC reactor

is recommended to use with the purpose of preventing drive fault as a result of overcurrent

caused by excessive distributed capacitance. An output filter is optional depending on field

requirements.

Be sure not to mount phase-shifting capacitor or surge absorber at output side of the inverter

since this may result in inverter damage as a result of over-temperature.

Insulation of the Motor

In view of the fact that the inverter output is PWM high frequency chopping voltage

accompanied by higher harmonics, the noise, temperature rise and vibration of the motor is

higher compared with sinusoidal voltage. Particularly this debases motor insulation. Therefore,

the motor should be subjected to insulation inspection before initial use or reuse after being

stored for a long period of time. The motor in regular service should also be subjected to

regular insulation inspection so as to avoid the inverter damage as a result of motor insulation

- 3 -

Page 8

Chapter 1 Summarize E5 User Manual

ATTENTION

While moving the inverter, please DO NOT directly hold up the front cover, instead, shall

hold the inverter from the pedestal, in case that the front cover slips off or inverter falls

down, even causing damages to human or inverter.

Install the inverter on nonflammable material like metal, to avoid fire disaster.

Choose a proper and safe place to install the inverter, where there is non high

temperature or direct sunlight, to avoid moisture and water drops.

Prevent children or unconcerned people from approaching the inverter.

This inverter can only be used in the areas which are approved by our company,

unapproved performance environment may result in fire disaster, gas explosion,

electrification, etc.

If several inverters are installed in one common control cabinet, please install extra

cooling fans to keep the inside temperature below 40℃, in order to avoid overheat, fire

disaster, etc.

Please at first make sure the power is off then dismount or install the operation keypad,

and fasten the front cover, in case of poor contact which may cause operation fault or non

display.

DO NOT place the inverter in the environment where there is explosive gas, otherwise it

will result in danger of explosion.

In the areas 1000m above sea level, since the heat dissipation of the inverter becomes

worse, please select one grade higher model.

On output side please DO NOT install contactor or other capacitor, varistor related

accessories, otherwise it will cause inverter faults or device damages.

On output side please DO NOT install switching devices such as air switch and contactor.

If these have to be installed at the place due to some technology reason or else, then

please make sure the inverter has NO output action during switch turning on or off. In

addition, it is prohibited to install capacitor with power improving function or

lightning-proof varistor, otherwise, it may result in inverter faults, tripping to protection or

damage to components.

damage. A 500V voltage mode mega-ohmmeter is recommended to use for the measurement

of the motor insulation, during which, it is essential to

disconnect the motor from the inverter. Normally, the insulation resistance of the motor should

be bigger than 5MΩ.

Derating

Due to the thin air in high-altitude areas, the radiating performance of the inverter with forced

air cooling may degrade while the electrolyte of electrolytic capacitors is more volatile, which

can result in reduction in product life. Inverter should be derated when used in an area at the

altitude above 1000 meters. It is recommended to derated 1% for every 100m when the altitude

is above 1000 meters.

- 4 -

Page 9

E5 User Manual Chapter 1 Summarize

Please connect inverter to an independent power supply, definitely NEVER share a

power supply with machines like electric welder, otherwise it may cause inverter to trip for

protection or even damaged.

ATTENTION

Before power on

The power supply voltage adopted must comply with the rated input voltage of the

inverter.

PE symbol means ground terminal. Please make sure to ground the motor and inverter

correctly to ensure safety.

When there is contactors installed between power supply and inverter, please Do Not use

contactor to control the running and stopping of inverter, otherwise it will reduce inverter’s

service life.

Main loop must be wired correctly. R.S.T(L.N) is power supply input terminal, NEVER

connect this terminal with U.V.W, otherwise it will cause inverter damage when power is

on.

During power on

When power is on, NEVER insert or pull the contactors on the inverter, in case that the

surge caused from the inserting or pulling enters into the control mother board and

results in inverter damage.

During Running

When inverter is running, it is prohibited to add or disconnect the motor group, otherwise

it will cause the inverter to over-current trip, or even burn down the main loop of inverter.

DO NOT take off the front cover when power is on, in case it result in human injury or

death.

When fault restart function is turned on, the motor will restart automatically after stop.

Please DO NOT approach the machine to avoid accidents.

Stop switch function is not valid if it is not set before, which is not the same with

emergency stop switch. Please use it carefully.

- 5 -

Page 10

Chapter 1 Summarize E5 User Manual

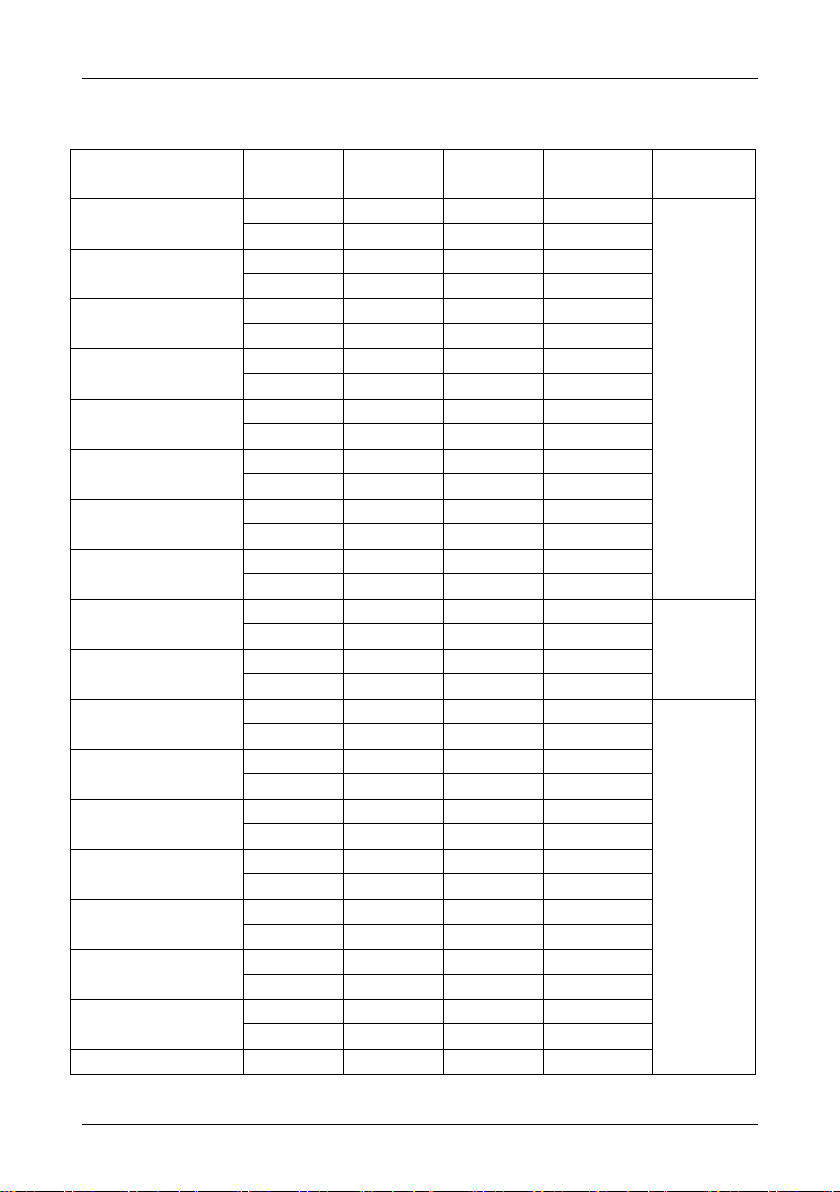

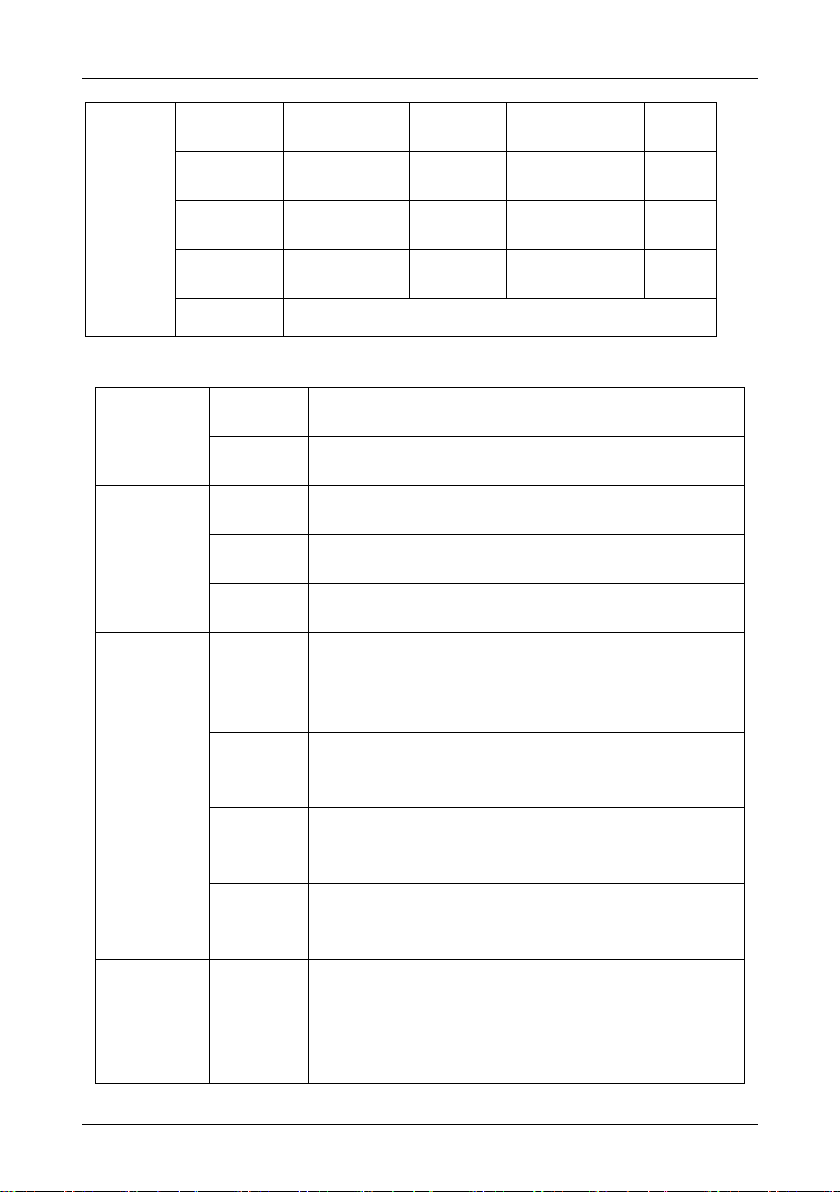

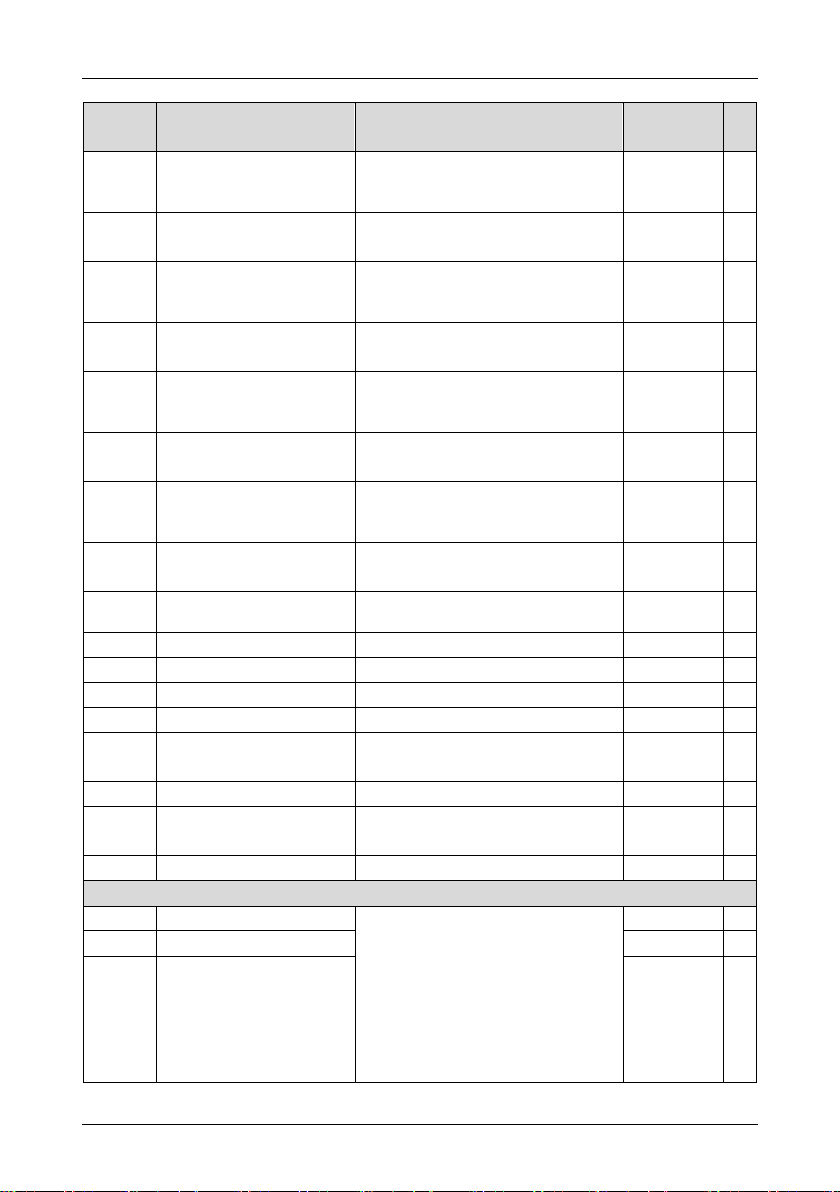

Inverter Model

Power grade

Output

current

Input current

Adapted Motor

Braking unit

E5-0.75G/1.5P-T4-B5

0.75G

2.5

3.4

0.75

built-in

1.5P

3.8

5.1

1.5

E5-1.5G/2.2P-T4-B5

1.5G

3.8

5.1

1.5

2.2P

5.5

9.2

2.2

E5-2.2G/3.7P-T4-B5

2.2G

5.5

9.2

2.2

3.7P 9 14.9

3.7

E5-3.7G/5.5P-T4-B5

3.7G 9 14.9

3.7

5.5P

13

21.5

5.5

E5-5.5G/7.5P-T4-B5

5.5G

13

21.5

5.5

7.5P

17

27.9

7.5

E5-7.5G/11P-T4-B6

7.5G

17

27.9

7.5

11P

24

39

11

E5-11G/15P-T4-B6

11G

24

39

11

15P

30

50.3

15

E5-15G/18.5P-T4-C4

15G

30

50.3

15

18.5P

39

60

18.5

E5-18.5G/22P-T4-C6

18.5G

39

60

18.5

optional

22P

45

69.3

22

E5-22G/30P-T4-C6

22G

45

69.3

22

30P

60

86

30

E5-30G/37P-T4-C7

30G

60

86

30

Externally

Mounted

37P

75

104

37

E5-37G/45P-T4-C7

37G

75

104

37

45P

91

124

45

E5-30G/37P-T4-C8

30G

60

86

30

37P

75

104

37

E5-37G/45P-T4-C8

37G

75

104

37

45P

91

124

45

E5-45G/55P-T4-C9

45G

91

124

45

55P

112

150

55

E5-55G/75P-T4-C9

55G

112

150

55

75P

150

201

75

E5-45G/55P-T4-C10

45G

91

124

45

55P

112

150

55

E5-55G/75P-T4-C10

55G

112

150

55

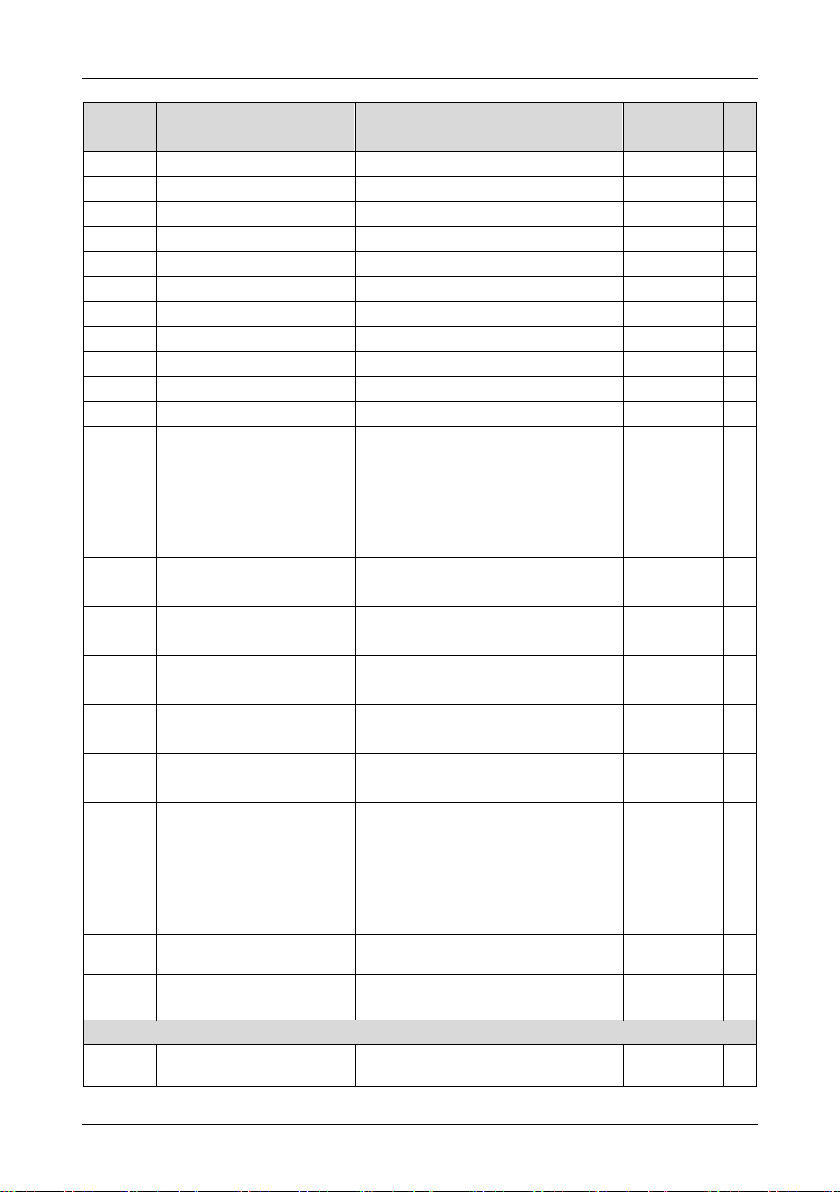

1.2 Pecification Table

- 6 -

Page 11

75P

150

201

75

Externally

Mounted

E5-75G/90P-T4-C11

75G

150

201

75

90P

176

236

90

E5-90G/110P-T4-C11

90G

176

236

90

110P

210

281

110

E5-75G/90P-T4-C12

75G

150

201

75

90P

176

236

90

E5-90G/110P-T4-C12

90G

176

236

90

110P

210

281

110

E5-110G/160P-T4-C13

110G

210

281

110

132P

253

339

132

E5-132G/160P-T4-C13

132G

253

339

132

160P

310

415

160

E5-110G/160P-T4-C14

110G

210

281

110

132P

253

339

132

E5-132G/160P-T4-C14

132G

253

339

132

160P

310

415

160

E5-160G/185P-T4-C15

160G

310

415

160

185P

350

469

180

E5-185G/200P-T4-C15

185G

350

469

180

200P

380

509

200

E5-160G/185P-T4-C16

160G

310

415

160

185P

350

469

180

E5-185G/200P-T4-C16

185G

350

469

180

200P

380

509

200

E5-200G/220P-T4-C18

200G

380

509

200

220P

430

576

220

E5-220G/250P-T4-C18

220G

430

576

220

250P

470

629

250

E5-250G/280P-T4-C20

250G

470

629

250

280P

520

696

280

E5-280G/315P-T4-C20

280G

520

696

280

315P

590

790

315

E5-315G/355P-T4-C22

315G

590

790

315

Externally

mounted

355P

650

871

355

E5-355G/400P-T4-C22

355G

650

871

355

400P

725

971

400

E5-400G/450P-T4-C24

400G

725

971

400

450P

820

1098

450

E5 User Manual Chapter 1 Summarize

- 7 -

Page 12

Chapter 1 Summarize E5 User Manual

E5-450G/500P-T4-C24

450G

820

1098

450

500P

860

1152

500

E5-500G/560P-T4-C26

500G

860

1152

500

560P

950

1273

560

E5-560G/630P-T4-C26

560G

950

1273

560

630P

1100

1474

630

E5-630G-T4-C28

630G

1100

1474

630 - - - -

E5-110G/132P-T4-C14

110G

210

281

110

132P

253

339

132

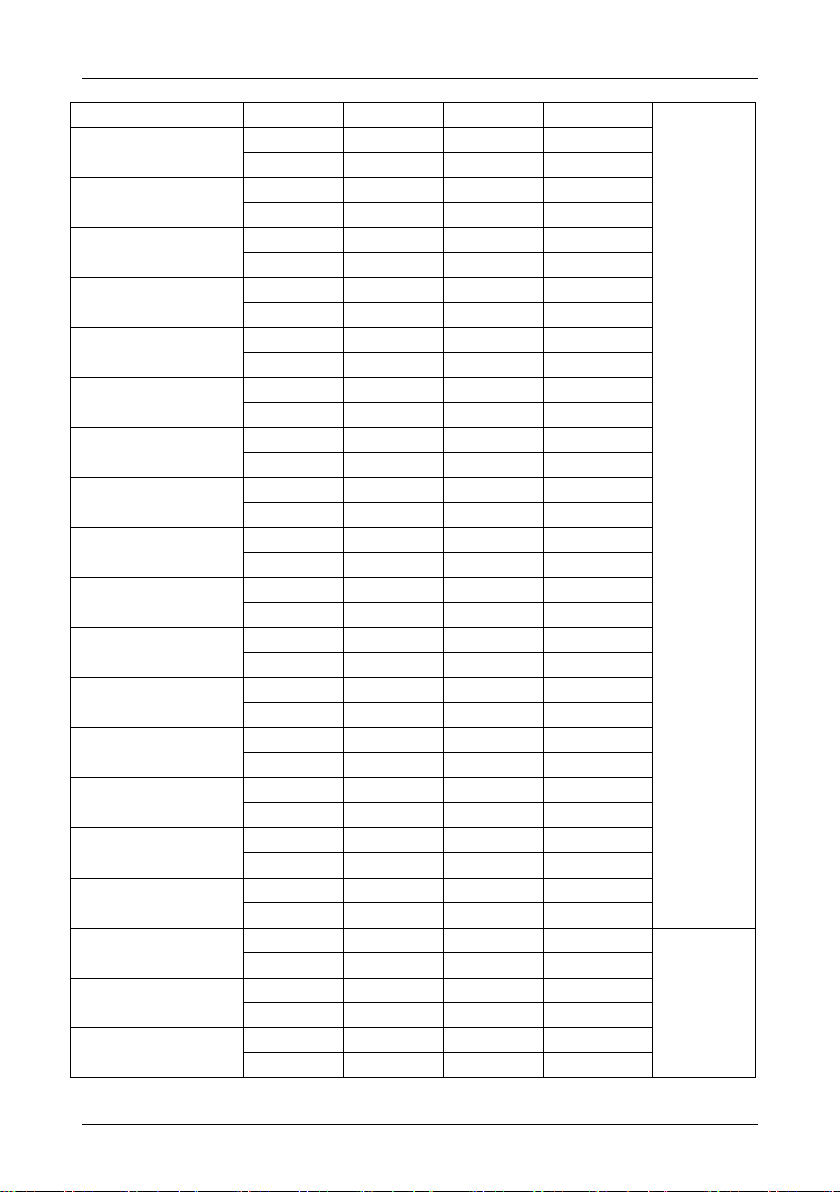

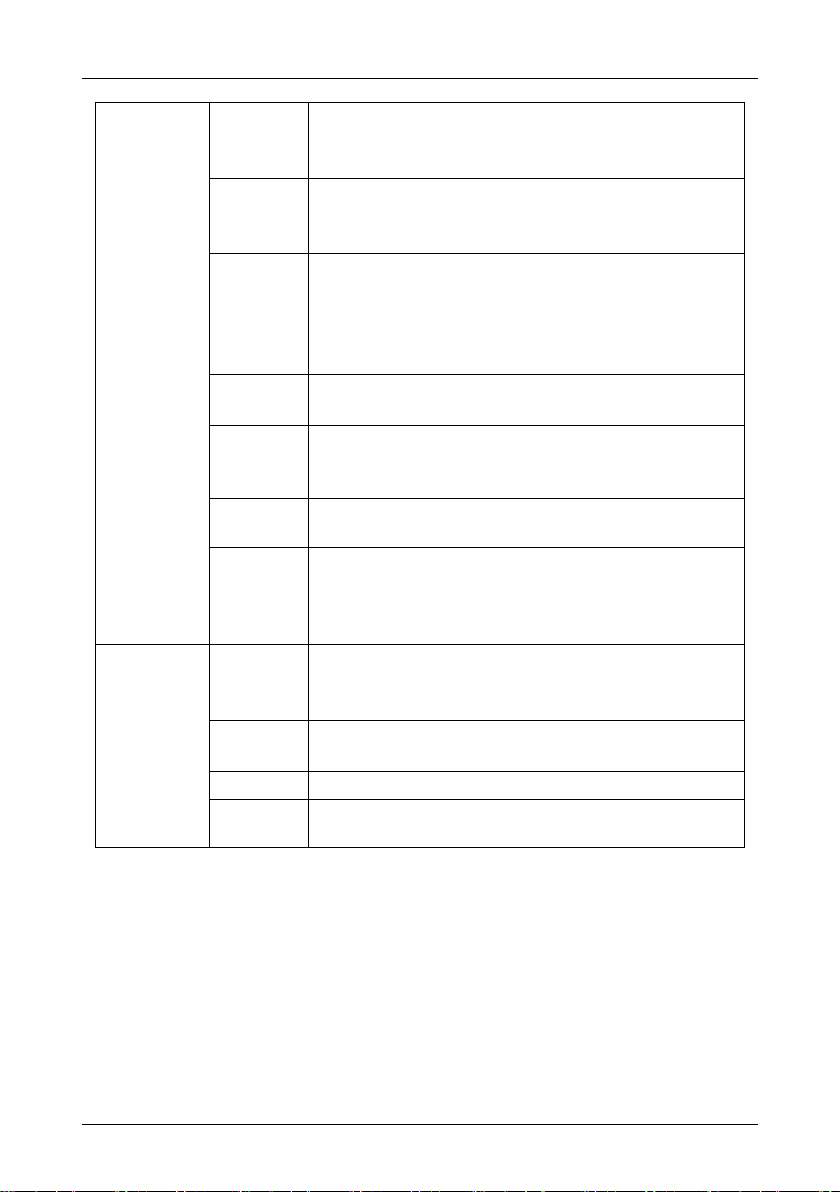

inverter

Braking unit Braking resistor

voltage

power KW

configuration

configuration

specification

quantity

3 ph 380V

0.75

built-in

externally

mounted

150W /400Ω

1

1.5

built-in

externally

mounted

200W/300Ω

1

2.2

built-in

externally

mounted

250W/200Ω

1

3.7

built-in

externally

mounted

400W/150Ω

1

5.5

built-in

externally

mounted

500W/90Ω

1

7.5

built-in

externally

mounted

800W/60Ω

1

Notes:

1. Maximum adapted motor means the maximum power light load engine for the drive of the

certain inverter model, by the standard of four-pole motor.

2. Rated output current means the output current when output voltage is 380V (or 220V).

3. Overload capacity is represented by the percentage of the overcurrent to the rated current.

When using it repeatedly, please wait till the temperature of inverter and motor decrease

below the temperature under 100% load.

4. Maximum output voltage cannot exceed power supply voltage. Below power supply voltage,

any output voltage can be set freely(voltage peak value of inverter output terminal is DC

voltage).

5. Power supply capacity changes according to the value of impedance (including input reactor

and cable ) on the side of power supply.

1.3 Braking Unit and Braking Resistor

- 8 -

Page 13

E5 User Manual Chapter 1 Summarize

11

built-in

externally

mounted

1000W/47Ω

1

15

built-in

externally

mounted

1500W/47Ω

1

18.5

Built-in optional

externally

mounted

2000W/40Ω

1

22

Built-in optional

externally

mounted

2500W/33Ω

1

30-630

selection as per braking unit requirements and

recommendation

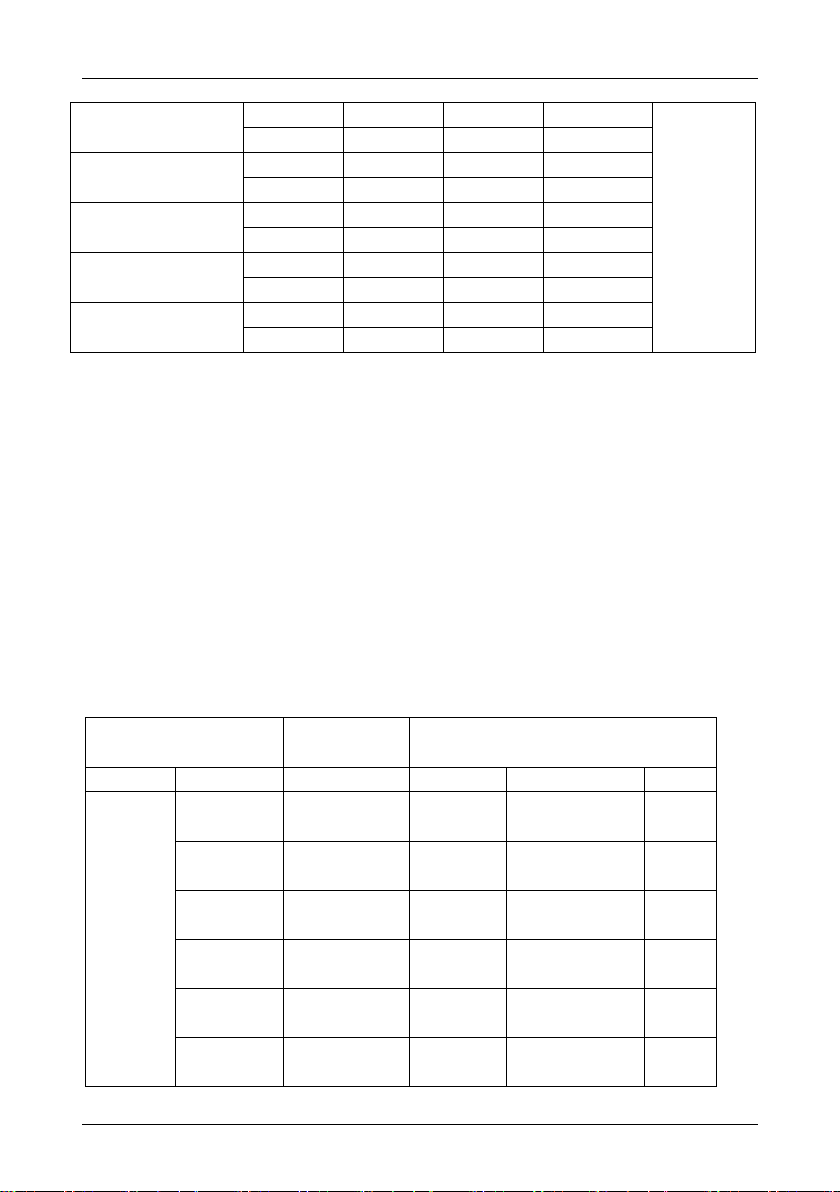

Power input

Rated

voltage

Three phase AC380V±10%

rated

equency

50Hz/60Hz, tolerance ±5%

Power output

output

voltage

Three phase 0~rated input voltage, error within ±3%

output

requency

0.00~600.00Hz, unit: 0.01Hz

overload

apacity

150% 1min;180% 10S;200% 0.5S

Control

Characteristics

control

method

V/F control

V/F separation control

Non-PG vector control 1

Non-PG vector control 2

Speed

control range

1:100 (V/F control)

1:100 (Non-PG vector control 1)

1:200(Non-PG vector control 2)

Speed

control

precision

±0.5% (V/F control)

±0.2% (Non-PG vector control 1)

±0.2% (Non-PG vector control 2)

Starting

torque

0.5Hz:180%(V/F control)

0.5Hz:180%(Non-PG vector control 1)

0.25Hz:180%(Non-PG vector control 2)

Basic Functions

Frequency

setting

digital setting + operation keypad ∧/∨

digital setting + terminal UP/DOWN setting

terminal pulse setting

analog setting (AI1/AI2)

RS485 communication setting

1.4 Technical Characteristics

- 9 -

Page 14

Chapter 1 Summarize E5 User Manual

Starting

method

start under starting frequency

start after DC braking

start in tracking speed

Stopping

method

deceleration stop

free stop

deceleration stop + DC braking

Dynamic

braking

capacity

0.75KW~7.5KW optional built-in braking unit

11KW ~ 15KW standard configuration including built-in

braking unit

18.5KW~22KW optional built-in braking unit

≥30KW, externally mounted braking unit required

input terminal

6 pcs of multi-functional terminals, X6 can be set as high

speed pulse input; 2 analog input

output

terminal

1 analog output;

1 high speed pulse output, 1 normally open normally close

output

simple PLC

control

able to set 0~15 section running speeds & time

Swing

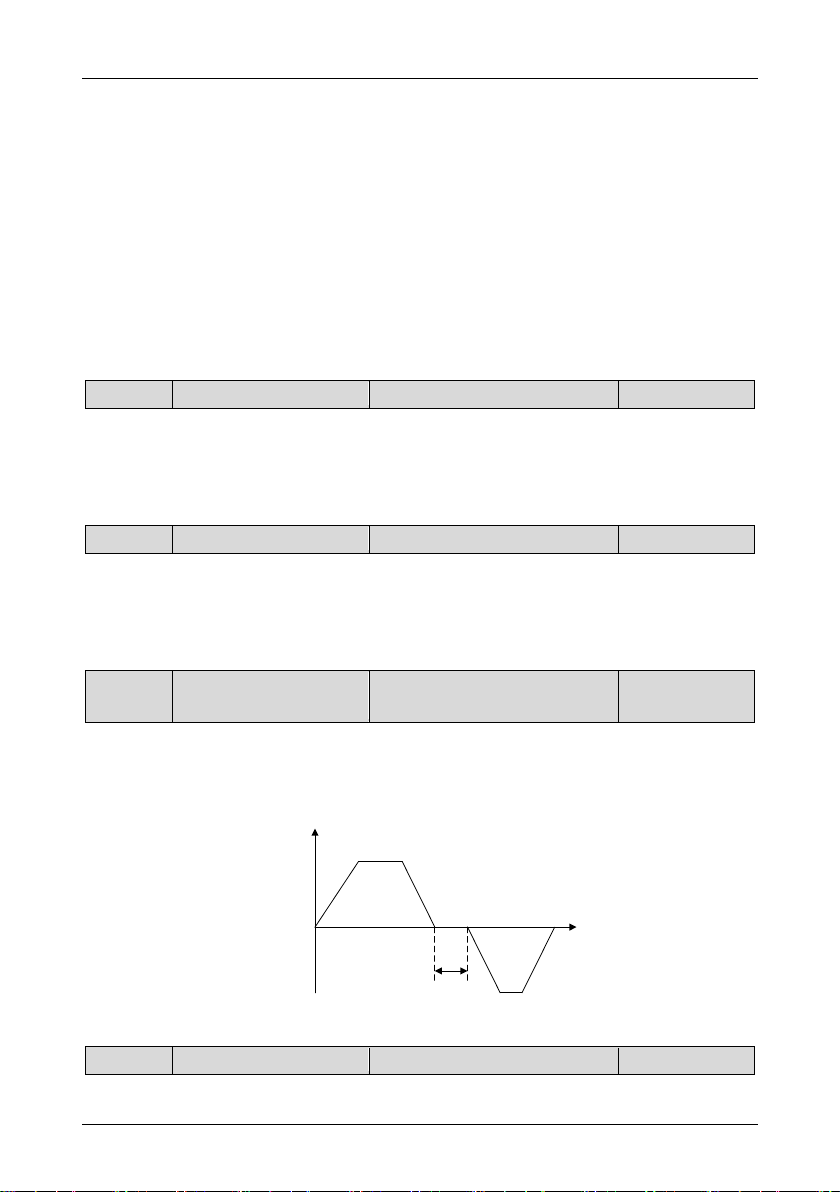

frequency

running

function

applicable to textile industry

others

efficiency

under rated power

7.5kW and below:≥93%

11~45kW:≥95% 55kW and above:≥98%

installation

method

Wall-mounted, cabinet type

IP grade

IP20

cooling

method

forced-air cooling

- 10 -

Page 15

E5 User Manual Chapter 2 Installation and Connection

Chapter 2 Installation and Connection

This chapter indicates basic “installation and connection”, before using please read all the

notices in this chapters carefully.

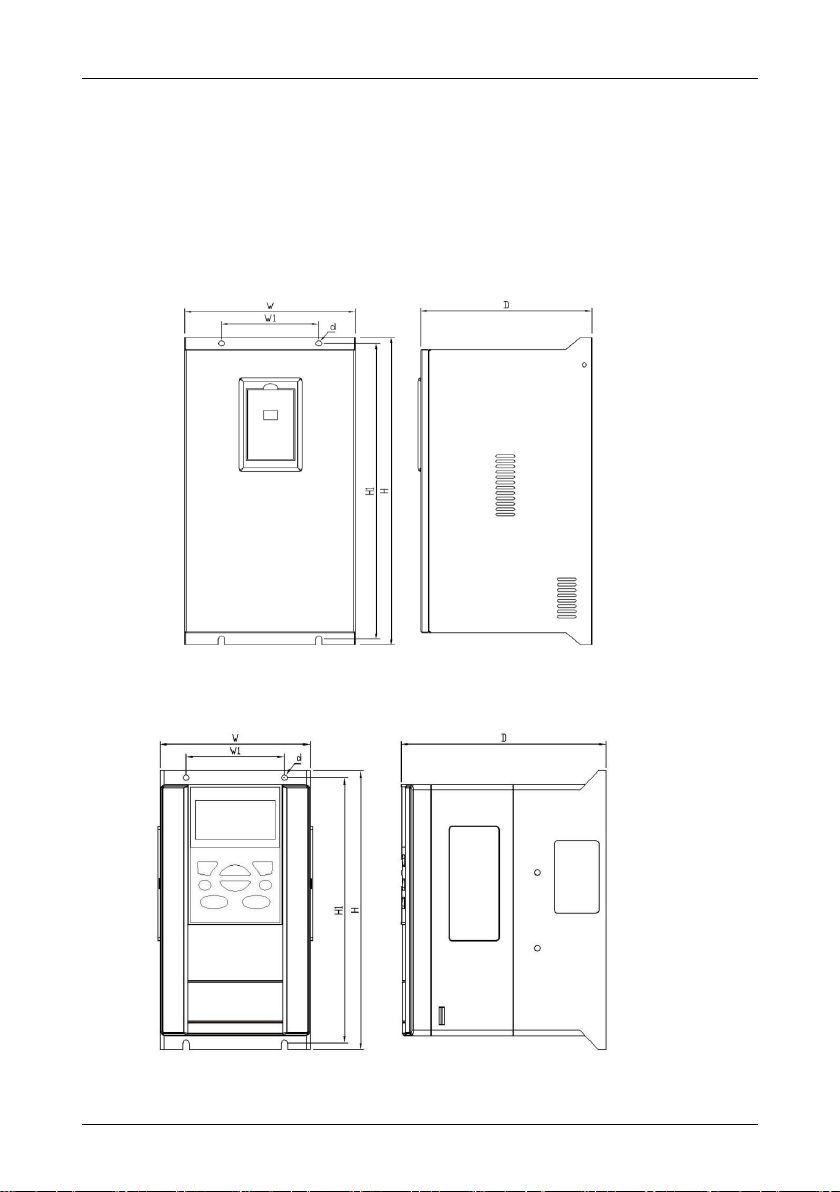

2.1 Case Structure and Dimension

E5 iron Configuration:

E5 plastic Configuration:

- 11 -

Page 16

Chapter 2 Installation and Connection E5 User Manual

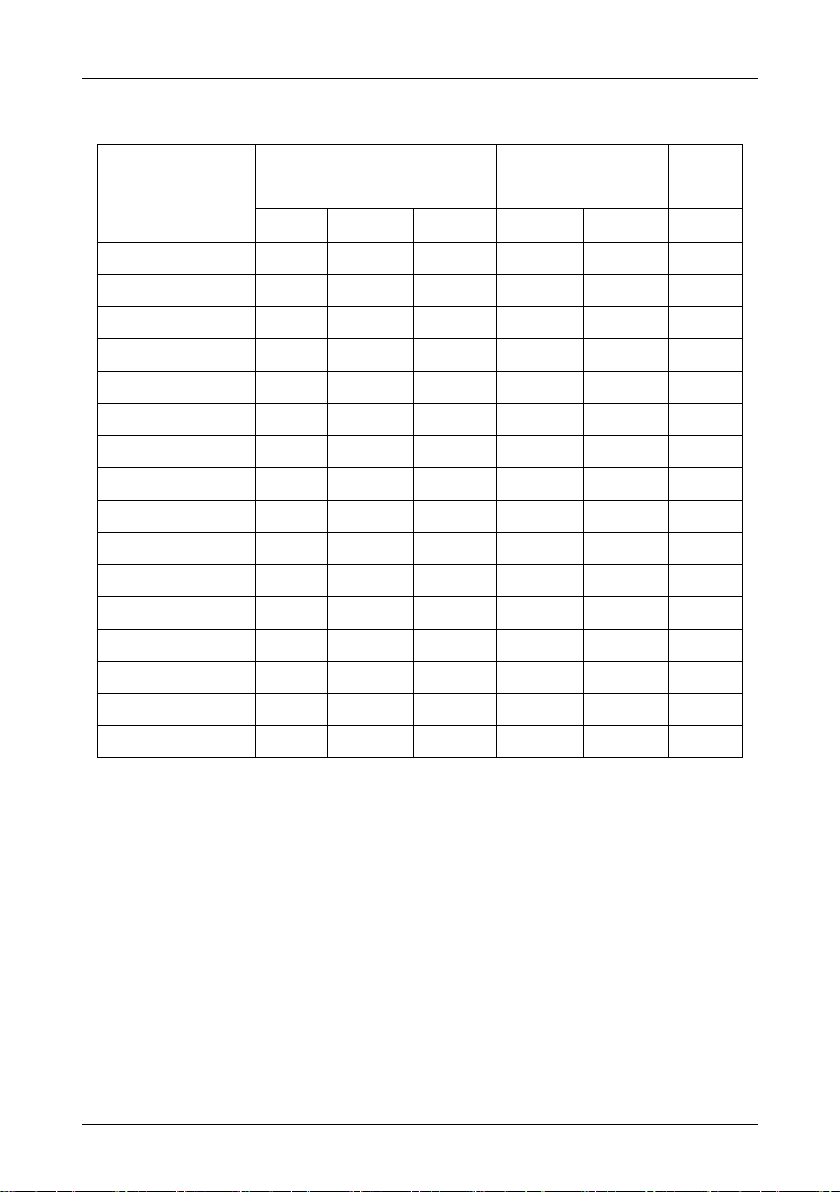

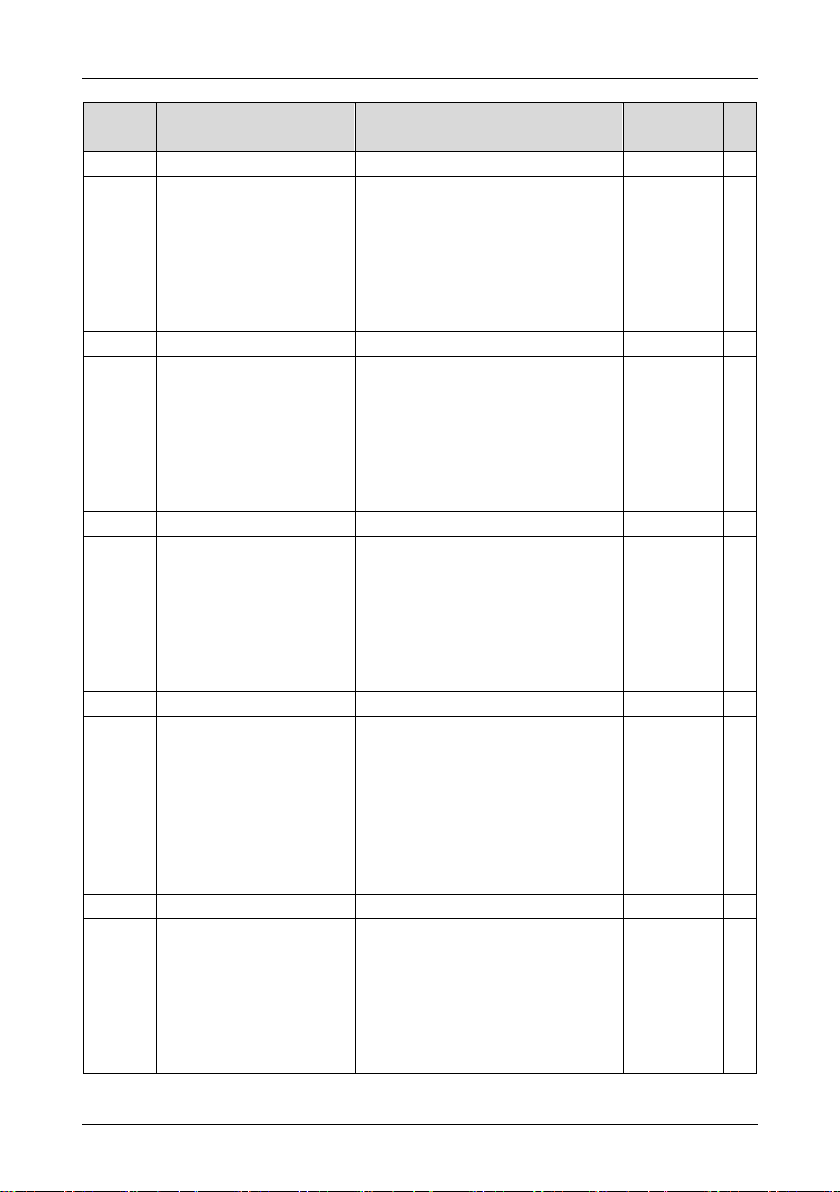

Inverter Model

External dimensions

installation dimensions

Mounting

hole dia.

W(mm)

H(mm)

D(mm)

W1(mm)

H1(mm)

d(mm)

B5

107

200

145

70

190

4.5

B6

140

280

192

100

267 6 C4

210

338

194

192

319 7 C6

257

417

203

160

400

8

C8

262

577

262

150

555

10

C9

388

596

252

280

572

10

C10

285

645

258

150

625

10

C11

498

666

278

350

642

10

C12

372

770

310

240

726

12

C13

400

811

303

340

787

12

C14

393

852

302

270

824

12

C15

465

920

325

320

894

10

C16

453

1005

322

320

1005

20

C18

650

970

350

420

970

20

C20

700

1000

355

420

970

26

C22

810

1040

372

560

1010

26

Dimensions of E5 series inverters:

2.2 Installation requirement

Inverter is one kind of precise power electronic products, so the working environment directly

influences the performance and service life of inverter. Therefore, please follow the below:

Check whether the inverter installation position environment comply with 1.2.3 instructions, if

not, please DO NOT install it, otherwise it will cause damage to inverter.

1. Inverter adopts plastic parts, please do not exert a big force on the cover plate. Install

carefully in case of any damage.

2. If conditions allow please openly install the backside plate and cooling fins out of control

cabinet, to effectively decrease the temperature in the electrical control cabinet.

3. Install inverter in clean place if possible, or inside of the enclosed type shield board which

- 12 -

Page 17

E5 User Manual Chapter 2 Installation and Connection

prevents all the floating material.

4. Inverter shall be installed in vertical direction solidly on the installation board with screws.

5. Pay attention to the heat dissipation method of the inverter which is installed in a control

cabinet: under the condition that there are two or more inverters and ventilation fan are

installed together into one electrical control cabinet, please pay attention to select a

proper installation position, for ensuring the temperature surround the inverter is within

the permissible value. If the installation position is not correct, it will cause the

surrounding temperature to rise and the ventilation effect worse.

6. Please install inverter on a nonflammable surface. Inverter temperature may reach a

rather high value (about 80 °C). Meanwhile, in order to facilitate heat dissipation, please

reserve enough space around.

2.3 Connection Guidelines

1. Separate power supply line and control line while installing the wires, e.g. adopt

independent trunking. If control electrical circuit linking must across the cable, they should

be wired in 90°angle.

2. When using shield wire or twisted pair to connect control electric circuit, make sure the

unshielded part as short as possible, if conditions allow, please adopt cable sleeve.

3. Avoid the inverter gravity line(input and output line) and signal line to be parallel-wired or

clustered-wired but should be crossed-wired separately.

4. Please use twisted pair shield wire for connection line of detector and signal line for control.

The sheath of shield wire connects to COM terminal.

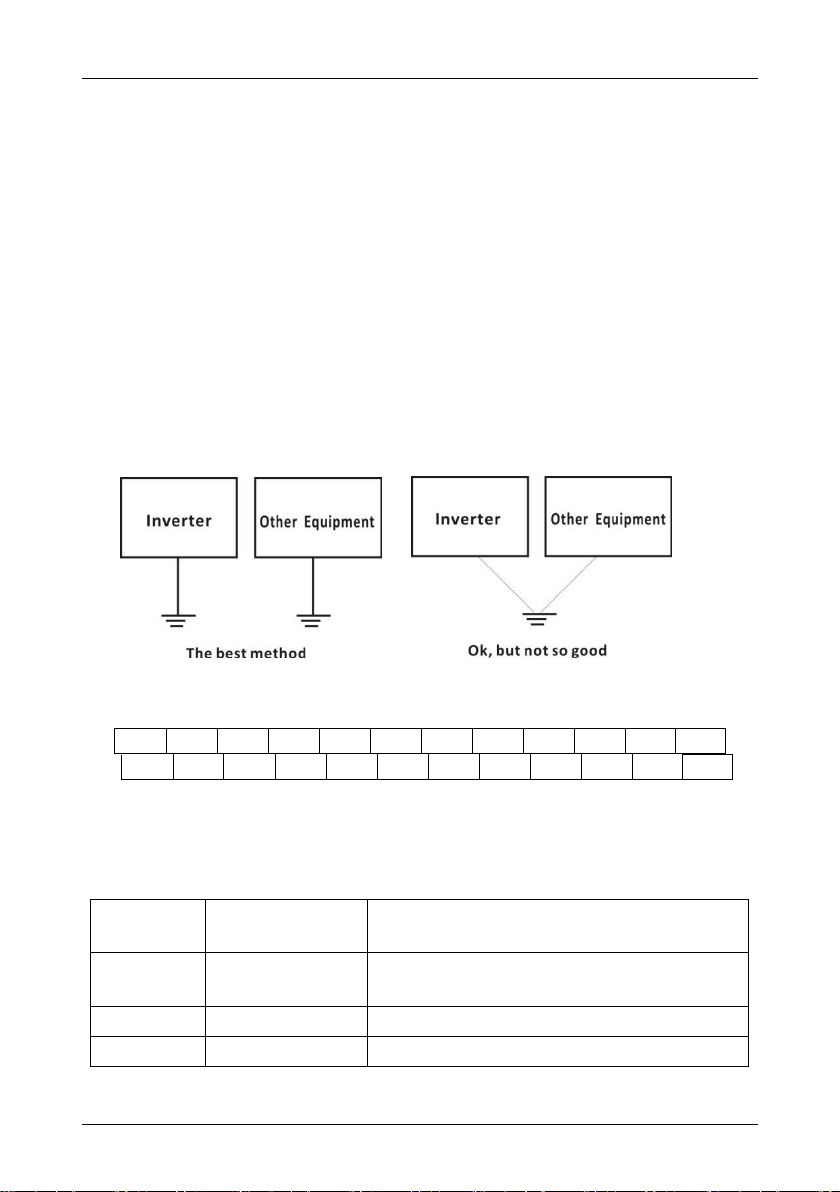

5. The ground wires of inverter and motor shall be connected on a common point.

6. Install data line filter onto signal line.

7. The shield layer of connector line of detector and control signal line must be grounded by

cable metal clamp.

- 13 -

Page 18

Chapter 2 Installation and Connection E5 User Manual

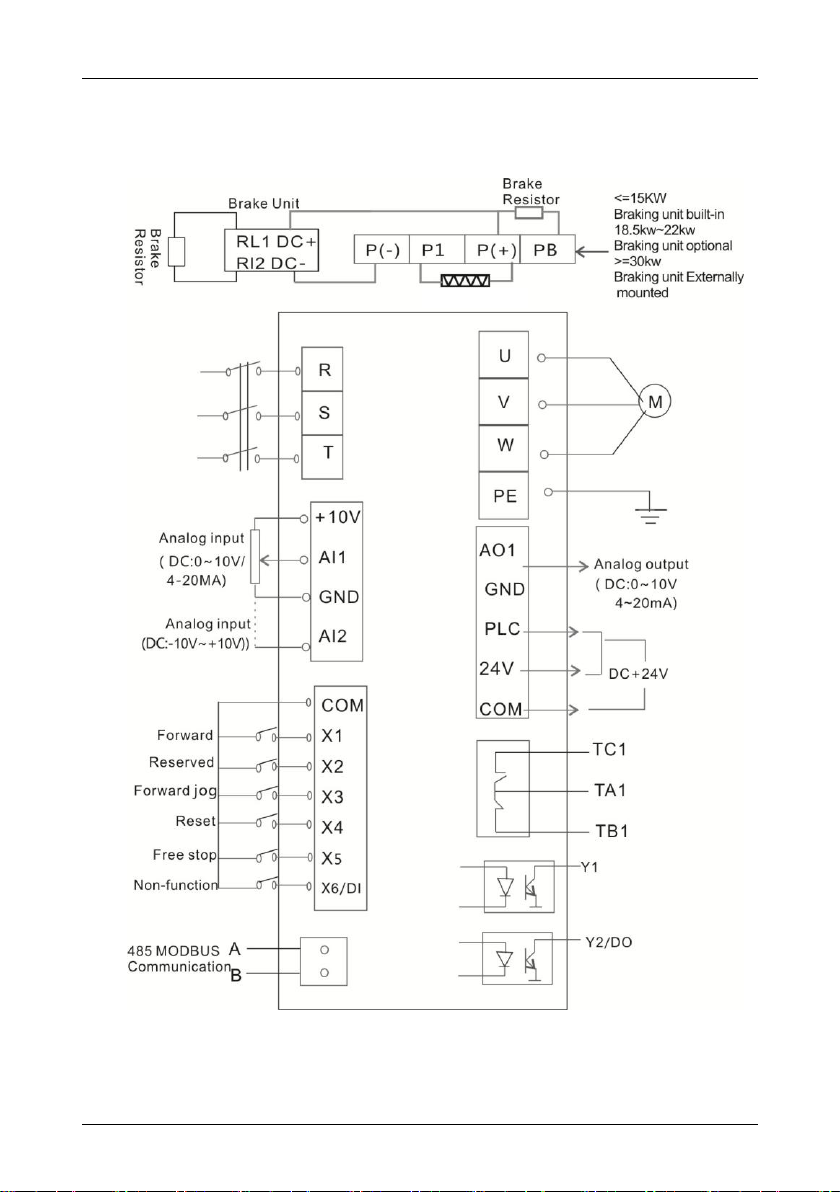

Braking Resistor

2.4 Connection Instruction

- 14 -

Page 19

E5 User Manual Chapter 2 Installation and Connection

P+

PB R S T PE

P-

P+ R S T U V W

PB

PE

R S T

PB

P+ U V W PE

P-

P+

PB R S T U V W

PE

PE R S T

P1

P+

P- U V

W

Cable must be of 75°C copper.

Screw with proper strength. Loose screwing will lead to short circuit or wrong

operation, while over-tight screwing will result in damages to screws and terminals, and

short circuit or wrong operation too.

U V W

2.4.1 Inverter Main Loop Terminal Row:

0.75KW-11KW, three-phase 380V:

15KW,three-phase 380V:

18.5KW-22KW, three-phase 380V:

11KW-15KW, three-phase 380V:

30KW-630KW, three-phase 380V:

Notes:

Different models may have some changes, please in kind prevail!

Inverter terminals (P+ , P-) shall be in accordance with braking unit terminal symbol during

wiring, damage will caused if wrongly connected.

The wire distance between braking unit and braking resistor unit shall be kept within 5

meters, or within 10 meters if using twisted pair.

If the transistor in braking unit is damaged (short circuit), resistor will be very hot which is

easy to cause fire. Therefore, installing electromagnetic contactor on inverter input terminal

is recommended because it allows cutting off power when fault occurs.

2.4.2 Main Loop Terminals

- 15 -

Page 20

Chapter 2 Installation and Connection E5 User Manual

Terminal Mark

Terminal Name

Explanation

R, S, T

Three-phase AC input

terminals

Connect to the power frequency supply

380V 50-60Hz

U, V, W

Inverter output

Connect to three phase asynchronous

motor

P+, PB

Connect to braking resistor

Connect braking resistor between P+ and

PB

PE

Grounding

Inverter grounding, must be properly

grounded

Terminal Mark

Terminal Name

Explanation

R, S, T

Three-phase AC input

terminals

Connect to the power frequency supply

380V 50-60Hz

U, V, W

Inverter output

Connect to three phase asynchronous

motor

P+, PB

Resistor connection

terminals

Connect to braking resistor

P+,P-

DC power supply input

terminals

DC input terminals of externally mounted

brake unit

PE

Grounding

Inverter grounding, must be properly

grounded

Terminal Mark

Terminal Name

Explanation

R, S, T

Three-phase AC input

terminals

Connect to the power frequency supply

380V 50-60Hz

U, V, W

Inverter output

Connect to three phase asynchronous

motor

P+, PB

Resistor connection

terminals

Connect to braking resistor

PE

Grounding

Inverter grounding, must be properly

grounded

0.75KW-11KW:

15KW:

18.5KW-22KW:

Above 30KW :

- 16 -

Page 21

E5 User Manual Chapter 2 Installation and Connection

Terminal Mark

Terminal Name

Explanation

R, S, T

Three-phase AC input

terminals

Connect to the power frequency supply

380V 50-60Hz

U, V, W

Inverter output

Connect to three phase asynchronous

motor

P1, P+

DC reactor connection

terminals

Connected with a jumper as factory default

P+,P-

DC power supply input

terminals

DC input terminals of externally mounted

brake unit

PE

Grounding

Inverter grounding, must be properly

grounded

Inverter Capacity

Below 11KW

15-110KW

Above 132KW

Non-ultra-low noise

mode

100m

150m

200m

Ultra-low noise

mode

50m

80m

100m

2.4.3 Main Loop Connection

1. The crimping terminals for power supply or motors must be with insulation tube.

2. Keep in mind that NEVER connect power supply to output terminals of inverter (U, V, W),

otherwise it will damage inverter.

3. After wiring is finished, odd wires must be cleaned up, otherwise they may cause abnormal

performance, failure or fault. When boring on control stand, be aware to prevent the

fragments and powders from entering into inverter.

4. To keep the voltage drop within 2%, please use proper electric wires for wiring. When the

distance between inverter and motor is long, especially under the condition of low frequency,

motor torque will decline due to the decrease of main loop wire voltage.

5. Maximum line distance is 500m, especially for long-distance wiring. Because the parasitic

capacitor generates surge current, which may cause current protection, there will be the

abnormal performance and faults of the devices connected to output terminal. Therefore,

please refer to the maximum wiring distance as below (when inverter connects two or more

motors, wiring distance shall be within 500m):

6. It is recommended to connect optional braking resistor between P+ and B- terminals.

7. Electromagnetic wave interference: there is harmonic wave in inverter input & output

circuits. In high-demanding circumstances please install wireless noise filter on input

terminal, to minimize the interference.

8. On inverter output terminal, DO NOT install power capacitor, surge suppressor or wireless

- 17 -

Page 22

Chapter 2 Installation and Connection E5 User Manual

Terminal

Mark

Terminal Name

Explanation

+10V

Analog input

reference voltage

The resistance of external potentiometer should be

during 4.7KΩ~10KΩ

AI1

Analog input 1

Input 0-10V, PID setting or feedback

AI2

Analog input 2

Input 4-20mA, PID setting or feedback

AI1

AI2

10V

GND

COM

X1

X3

X5

PLC

Y2

24V

TA1 A B

GND

AO1

COM

X2

X4

X6

Y1

COM

TB1

TC1

noise filter, which will lead to inverter fault or component damage.

9. When wiring change is required while power is on or inverter is running, inverter operation

must be stopped then wait for over 10 minutes after power is cut off. Check the voltage by

multi-meter then make the wiring change. There is still dangerous high voltage on capacitor

within a period after power is cut.

10. Ground terminal must be well grounded.

▲Since there is leakage current in inverter, in order to avoid electric shock, inverter and

motor must be grounded.

▲Use independent terminal for inverter grounding. DO NOT just use screw on shell or

chassis instead.

▲ It is recommended to adopt thick cable with demanded diameter no smaller then in the

attached form. Grounding wire should be near inverter, and ground wire be as short as

possible.

▲ When the motor is grounded on inverter side, please use one core of the four-core cable

to ground, with the same size to input wire.

2.4.4 Inverter Control Loop Terminal Row

Notes: Different models may have some changes, please in kind prevail!

2.4.5 Control Loop Terminal Explanation

- 18 -

Page 23

E5 User Manual Chapter 2 Installation and Connection

AO1

Analog output

Switch on control board for jumping from 0~20mA

and 0~10V, factory default: 0~10V

GND

Analog ground

Isolated from COM interiorly

COM

Digital ground

Isolated from GND interiorly

X1

Multi-function

terminal 1

Function defined by value of parameter P20.01,

factory default: “forward”

X2

Multi-function

terminal 2

Function defined by value of parameter P20.02,

factory default : “reverse”

X3

Multi-function

terminal 3

Function defined by value of parameter P20.03,

factory default :“stop”

X4

Multi-function

terminal 4

Function defined by value of parameter P20.04,

factory default: “multi-step speed 1”

X5

Multi-function

terminal 5

Function defined by value of parameter P20.05,

factory default is “multi-step speed 2”

X6(DI)

Multi-function

terminal 6

Function defined by value of parameter P20.06,

factory default is “multi-step speed 3”

A、B

RS485

commumication

Rate: 4800/9600/19200/38400/57600/115200bps

Maximum distance: 500m (use standard network

cable)

Y1

Open collector

output

Range of voltage: 0~24V;Range of current:

0~50mA

Y2(DO)

Open collector

output /Pulse

output

Open collector output: same as Y1;

Pulse output: 0~50kHz

TA1、TB1、

TC1

Relay contactor

output

TA1and TC1 are normally open contactors,TA1

and TB1 are normally closed contactors.

PLC

Digital input

Common terminal

Used for switching between high and low levels,

short-circuited with +24V at delivery, i.e. low value

of digital input valid; External power input

24V

Auxiliary power

supply

24V±10%, Isolated from GND interiorly;

Maximum load: 50mA

2.4.6 Control Loop Connection

1. “COM” is the control signal common terminal , do not public grounded.

2. ”GND” is the Analog signal input/output common terminal, do not public grounded.

- 19 -

Page 24

Chapter 2 Installation and Connection E5 User Manual

3. The wiring of control loop should adopt shielded wire or twisted wire, meanwhile, it must be

wired separately from main loop and strong electricity loop.

4. Because the frequency input signal of control loop is tiny current, please use two

side-by-side contacts or twin contacts to avoid poor contact.

5. It is recommended to use 0.75mm cable for wiring control loop.

6. High voltage CANNOT be input into control loop, otherwise it will damage inverter.

- 20 -

Page 25

E5 User Manual Chapter 2 Installation and Connection

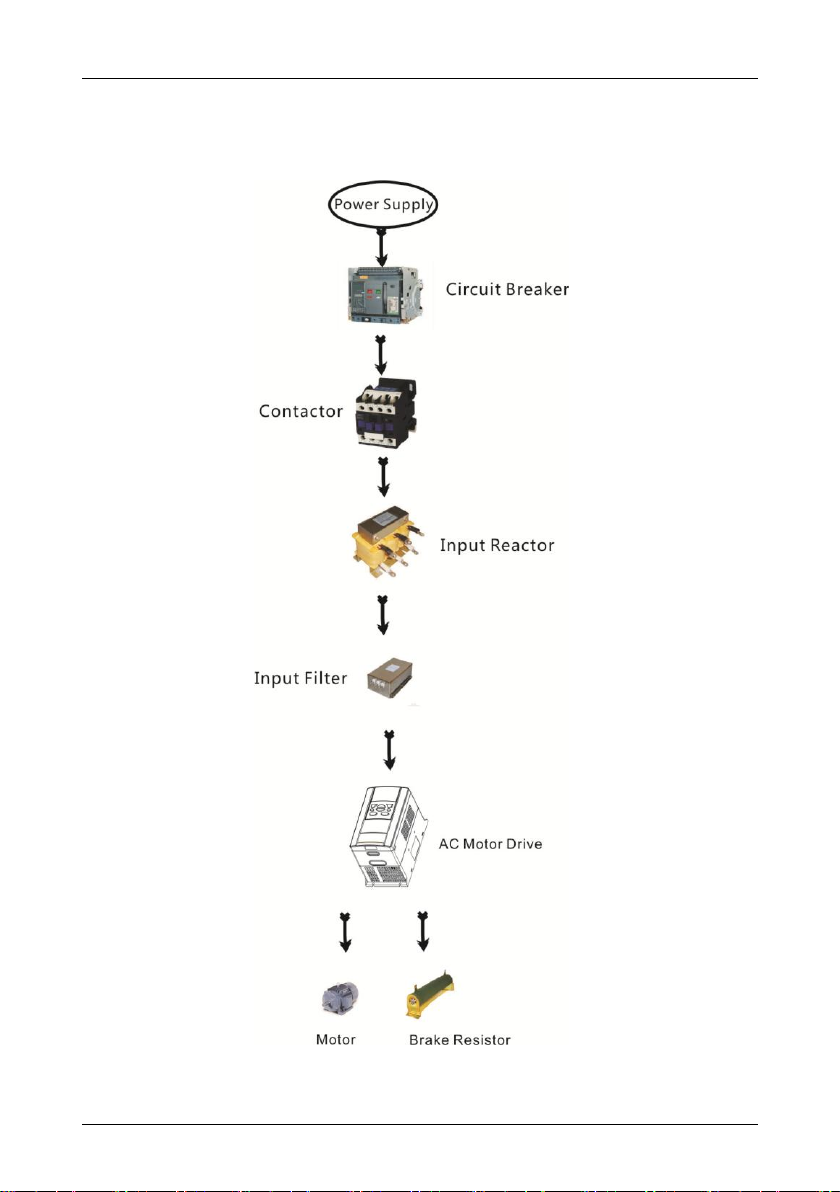

2.4.7 Standard Configuration of Peripheral Devices

- 21 -

Page 26

Chapter 2 Installation and Connection E5 User Manual

Device

Instructions

Power

supply

Input three-phase AC power supply should be in the range as specified in

this manual

Circuit

breaker

Purpose: disconnect power supply and protect the equipments in case of

abnormal over current occurs

Type selection: breaking current of circuit breaker is defined to be 1.5~2

times the rated current of the drive

Breaking time characteristic of circuit breaker should be selected based on

overload protection time characteristic of the drive

RCD

Purpose: since the drive outputs PWM HF chopping voltage, HF leakage

current is inevitable

Type selection: type B dedicated RCD is recommended

Contactor

For safety's sake, do not frequently close and break the contactor since this

may bring about equipment faults

Do not control the start & stop of the drive directly through switch on and off

the contactor since this will result in a reduction on the product life

Input AC

reactor or

DC choke

Improve power factor

Reduce the impact of imbalanced three-phase input AC power supply on

the system

Suppress higher harmonics and reduce the conducted and radiated

interference to peripheral devices

Restrict the impact of impulse current on rectifier bridges

Input filter

Reduce conducted interference from power supply to the drive, improve the

immunity of the drive from noise

Reduce conducted and radiated interference of the drive to peripheral

devices

Brake unit

and

braking

resistor

Purpose: consume motor feedback energy to attain quick brake

Type selection: Contact GTAKE technical personnel for type selection of

brake unit. Refer to type selection of braking resistor in Table 1.3 Type

Selection of Peripheral Devices.

Output filter

Reduce conducted and radiated interference of the drive to peripheral

devices

Output AC

reactor

Avoid the motor insulation damage result from harmonic voltage

Reduce frequent protection from the drive caused by leakage current

In case the cable connecting drive and motor is over 100 meters, output AC

reactor recommended

Motor

Should match the drive

2.4.8 Instructions of Peripheral Devices

- 22 -

Page 27

E5 User Manual Chapter 3 Keypad Operation

Symbol

Key Name

Function

Run key

Inverter starts running once this key is pressed.

This key is invalid when inverter is in external

control mode.

Stop/Reset Key

Inverter stops running when this key is pressed;

Reset inverter by this key under fault alarm.

Multifunction key

Refer to parameter P70.00.

Chapter 3 Keypad Operation

This chapter provides guidance for basic “running operation”, please read it carefully in detail

before using the inverter.

3.1 Operation of Keypad

Operation Keypad is the connector for communication between human and equipment, which

is composed of key part and display part. User inputs control commands through keys, and

display part shows parameter information and different running conditions. Keypad

appearances are as below:

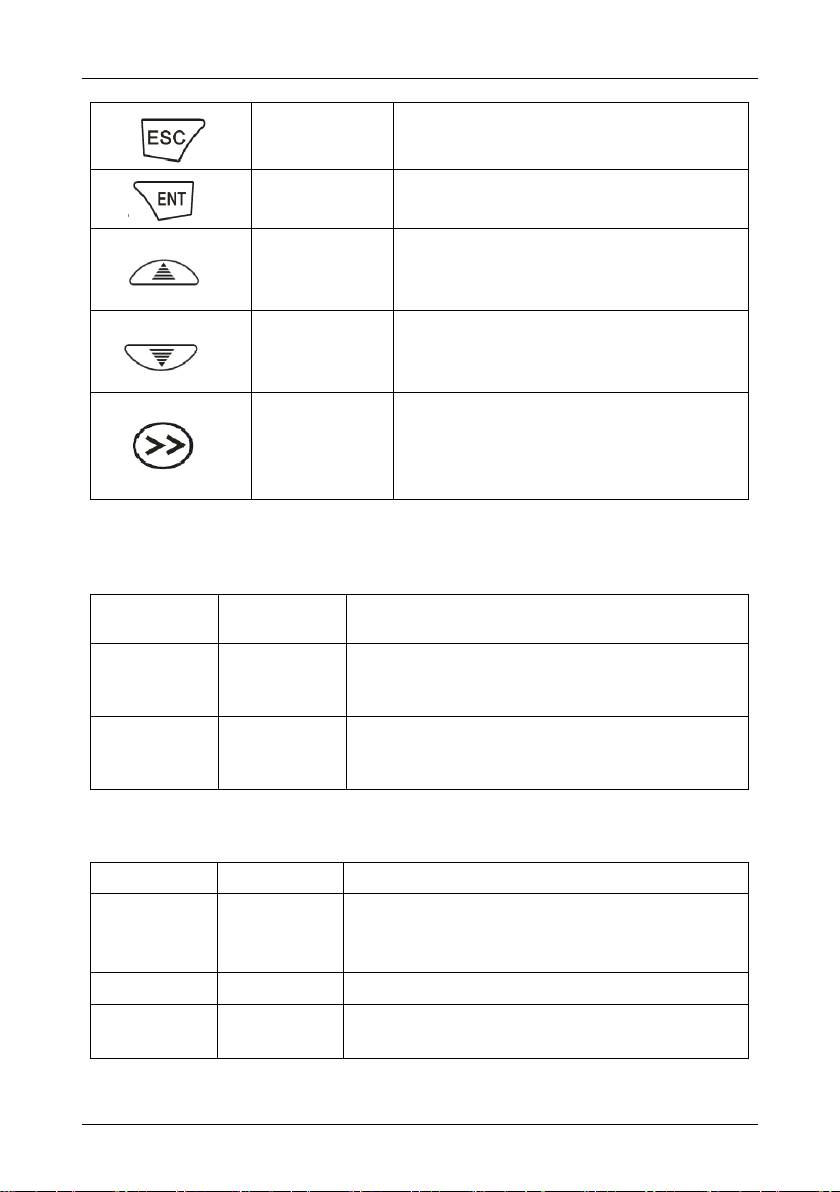

3.2 Operation Keypad Explanation

- 23 -

Page 28

Chapter 3 Keypad Operation E5 User Manual

Escape Key

Escape function setting condition.

Enter Key

Function parameter edition enter;

Confirmation/saving of parameter setting.

Increase Key

Increase of selected function code value;

Increase of selected parameter code value;

Increase of set frequency.

Decrease key

Decrease of selected function code value;

Decrease of selected parameter code value;

Decrease of set frequency.

Shift key

Selection of function code value;

Selection of parameter value;

Selection of stop/run status display parameters;

Refer to 3.3 for details.

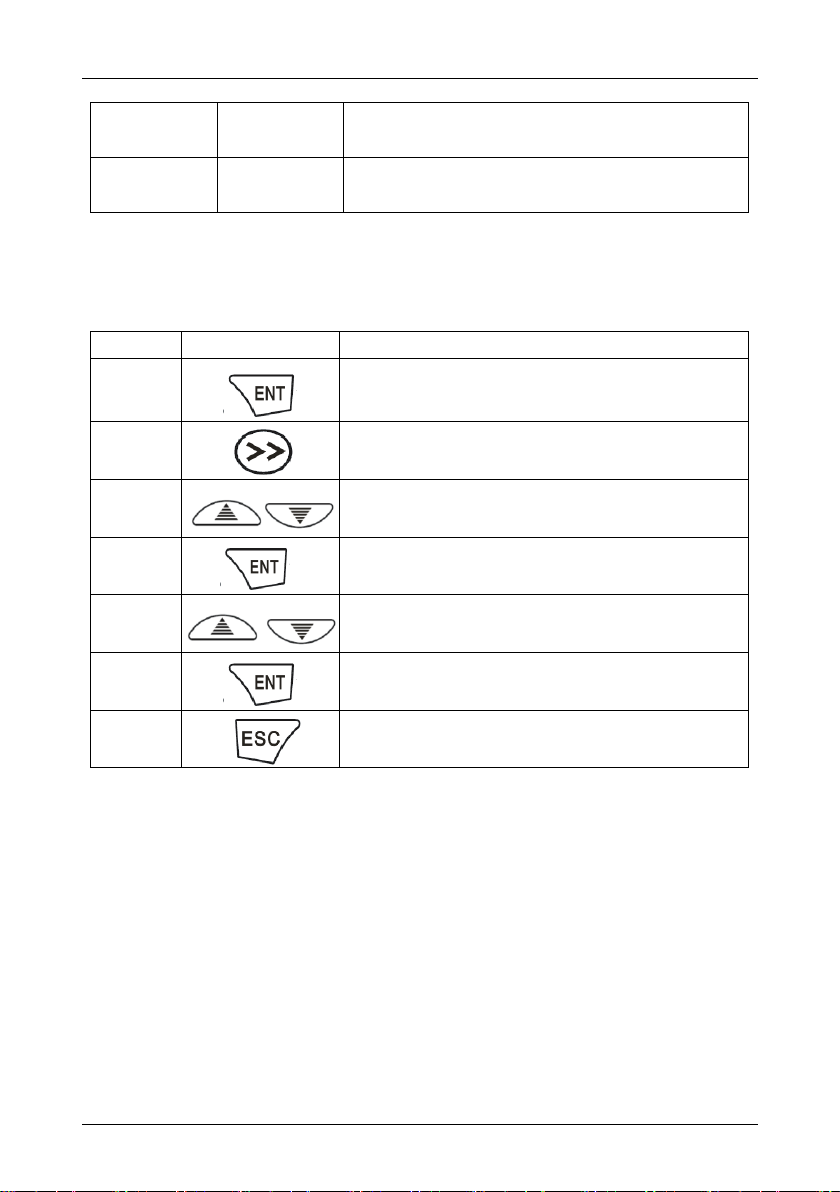

Condition

Light

Light Name

Explanation

RUN

Running

condition

Indication

ON: Run

OFF: Stop

Flash: Stopping

F/R

Reverse

Indication

ON: Reverse command initiates under stop condition;

Inverter reverses under running condition.

Flash: Shifting from Reverse to Forward.

Condition Light

Name

Explanation

Hz

Frequency

Indication

ON: Present displayed parameter is running frequency

or present function unit is frequency;

Flash: Present displayed parameter is set frequency.

A

Current Display

ON: Present displayed parameter is current.

V

Voltage

Indication

ON: Present displayed parameter is voltage.

3.3 Display Content Explanation

3.3.1 Condition Light Explanation

3.3.2 Unit Light Explanation

- 24 -

Page 29

E5 User Manual Chapter 3 Keypad Operation

Hz+A

Rotating Speed

Indication

ON: Present displayed parameter is rotating speed;

Flash: Present displayed is set rotating speed.

A+V

Percentage

Indication

ON: Present displayed parameter is percentage.

Sequence

Operation

Explanation

1

Enter into parameter menu, e.g. P00-00, inverter

displays present parameter’s first level menu.

2

Adjust to the parameter which requires modification,

e.g. P00-00.

3

Adjust to the required parameter code, e.g. P10-00.

4

Inverter displays the value of present parameter, e.g.

“0”.

5

Adjust to the required value, e.g. “1”.

6

Confirm this operation, save information.

7

Exit parameter setting condition, back to standby or

running condition.

3.4 Parameter Modification Method

If parameters need modification, first you shall enter into the function code which requires

modification, then reset the parameter. Refer to details as below:

Note: When setting parameters, pressing “ESC” key can exit parameter setting state and back

to standby mode.

3.5 Commissioning

3.5.1 Important inspection Before Running

Whether exists wrong wiring, especially check whether the power supply is wrongly

connected to U.V.W terminal;

Please pay attention: power supply should be input from R.S.T(L.N) terminals;

Whether there are metal chips or wires, which may cause short-circuit, left on inverter base

board and wiring terminals;

Whether screws are tightly screwed, whether connectors are loose;

- 25 -

Page 30

Chapter 3 Keypad Operation E5 User Manual

Whether there is short-circuit or short-to-ground on output part.

3.3.2 Commissioning Method

Because the control method of E5 series is set as control panel method before out of factory,

therefore, commissioning can be carried out by operating JOG key on the panel. Normally

commissioning is operated under 5.0Hz.

- 26 -

Page 31

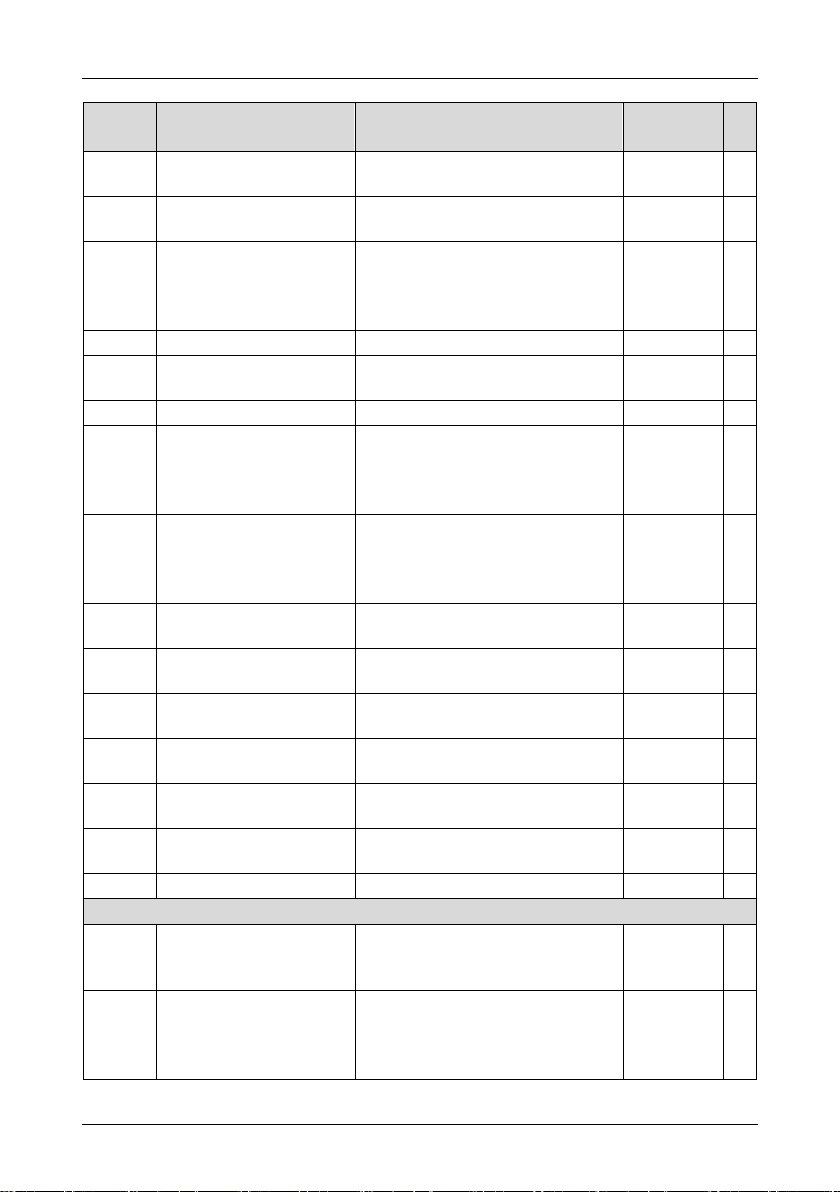

E5 User Manual Chapter 4 List of Parameters

Chapter 4 List of Parameters

ATTENTION:

Change attribute:

"○" means the value of this parameter can be modified in stop and running status of drive;

"●" means the value of this parameter can not be modified when drive is running;

"×" means this parameter is a measured value that cannot be modified;

Factory default value: The value when restored to factory default. Neither measured

parameter value nor recorded value will be restored.

Scope: the scope of setting and display of parameters;

- 27 -

Page 32

Chapter 4 List of Parameters E5 User Manual

Param.

Designation

Scope

Factory

Default

Attr

Group P00: System Parameters

P00.00

Setting of User

Password

0~FFFF

0000

○

P00.01

Display of Parameters

0: Display all parameters

1: Only display parameters P00.00

and P00.01

2: Reserved

A1-00~A1-19

3: Only display P00.00, P00.01,

and the

parameters different with factory

default

0

○

P00.02

Parameter Protection

0: All parameter programmable

1: Only P00.00 and this parameter

programmable

0

●

P00.03

Parameter Initialization

0: No operation

1: Clear fault record

2: Restore all parameters to

factory default (excluding motor

parameters)

3: Restore all parameters to

factory default (including motor

parameters)

4: Restore all parameters to

backup parameters

0

●

P00.04

Parameter Backup

0: No operation

1: Backup all parameters

0

●

P00.06

The inverter model

0:G type (adopted to the constant

torque load)

1: L type (adopted to the fan pump

load)

0

●

P00.07

Reserved

Reserved

Reserved

●

P00.08

Selection of Motor

1/motor 2

0: Motor 1

1: Motor 2

0

●

P00.09

Motor Control Pattern

Unit's place: Control pattern of

motor 1

0: V/f control

1: Sensor-less vector control 1

2: Sensor-less vector control 2

Decade: control pattern of motor 2

0: V/f control

1: Sensor-less vector control 1

Model

defined

●

- 28 -

Page 33

E5 User Manual Chapter 4 List of Parameters

Param.

Designation

Scope

Factory

Default

Attr

2: Sensor-less vector control 2

Group 10: Frequency Command

P10.00

Frequency Command

Pattern

0: Master frequency command

1: Master & auxiliary computation

result

2: Switch between master and

auxiliary command

3: Switch between master

frequency command, and master

& auxiliary computation result

4: Switch between auxiliary

frequency command, and master

& auxiliary computation result

0

●

P10.01

Master Frequency

Command Source

0: Digital setting (P10.02) +

keypad ∧/∨ adjustment

1: Digital setting (P10.02) +

terminal UP/DOWN adjustment

2: Analog input AI1

3: Analog input AI2

4: Reserved

5: X6/DI pulse input

6: Process PID output

7: PLC

8: Multi-step speed

9: Communication

0

●

P10.02

Digital Setting of Master

Frequency

Lower limit frequency ~ Upper limit

frequency

50.00Hz

○

P10.03

Auxiliary Frequency

Command Source

0: No command

1: Digital setting (P10.04) +

Keypad ∧/∨ adjustment

2: Digital setting (P10.04) +

terminal UP/DOWN adjustment

3: Analog input AI1

4: Analog input AI2

5: Reserved

6: X6/DI pulse input

7: Process PID output

8: PLC

9: Multi-step speed

10: Communication

00

●

P10.04

Digital setting of auxiliary

frequency

Lower limit frequency ~ upper limit

frequency

0.00Hz

○

- 29 -

Page 34

Chapter 4 List of Parameters E5 User Manual

Param.

Designation

Scope

Factory

Default

Attr

P10.05

Range of auxiliary

frequency

0: Relative to maximum frequency

1: Relative to master frequency

0

●

P10.06

Coeff of auxiliary

frequency

0.0%~100.0%

100.0%

●

P10.07

Computation of master

and auxiliary frequency

command

0: Master + auxiliary

1: Master - auxiliary

2: Max {master, auxiliary}

3: Min {master, auxiliary}

0

●

P10.08

Maximum frequency

Upper limit frequency ~600.00Hz

50.00Hz

●

P10.09

Upper limit frequency

Lower limit frequency ~ maximum

frequency

50.00Hz

●

P10.10

Lower limit frequency

0.00Hz~upper limit frequency

0.00Hz

●

P10.11

Operation when

command frequency

lower than lower limit

frequency

0: Run at lower limit frequency

1: Run at 0 Hz

2: Stop

0

●

P10.12

Time-delay of stop when

command frequency

lower than lower limit

frequency

0.0s ~ 6553.5s

0.0s

●

P10.13

Lower limit of skip

frequency band 1

0.00Hz~upper limit frequency

0.00Hz

●

P10.14

Upper limit of skip

frequency band 1

0.00Hz~upper limit frequency

0.00Hz

●

P10.15

Lower limit of skip

frequency band 2

0.00Hz~upper limit frequency

0.00Hz

●

P10.16

Upper limit of skip

frequency band 2

0.00Hz~upper limit frequency

0.00Hz

●

P10.17

Lower limit of skip

frequency band 3

0.00Hz~upper limit frequency

0.00Hz

●

P10.18

Upper limit of skip

frequency band 3

0.00Hz~upper limit frequency

0.00Hz

●

P10.19

Jog frequency

0.00Hz~upper limit frequency

5.00Hz

○

Group 11: Start/Stop Control

P11.00

Run command

0: Keypad control

1: Terminal control

2: Communication control

0

●

P11.01

Binding of run command

and frequency command

Unit's place: frequency command

source bundled under keypad

control:

0: No binding

000

●

- 30 -

Page 35

E5 User Manual Chapter 4 List of Parameters

Param.

Designation

Scope

Factory

Default

Attr

1: Digital setting (P10.02) +

keypad ∧/∨ adjustment

2: Digital setting (P10.02) +

terminal UP/DOWN adjustment

3: Analog input AI1

4: Analog input AI2

5: Reserved

6: X6/DI pulse input

7: Process PID output

8: Simple PLC

9: Multi-step frequency

A: Communication input

Decade: frequency command

source bundled under terminal

control (same as unit's place)

Hundreds place: frequency

command source bundled under

communication control (same as

unit's place)

P11.02

Running direction

0: Forward

1: Reverse

0

○

P11.03

Reverse-proof action

0: Reverse enabled

1: Reverse disabled

0

●

P11.04

Dead time between

forward and reverse

0.0s~3600.0s

0.0s

○

P11.05

Start Mode

0: From start frequency

1: DC injection braking at start

2: Flying start

0

●

P11.06

Start frequency

0.00Hz~upper limit frequency

0.00Hz

●

P11.07

Holding time of start

frequency

0.0s~3600.0s

0.0s

○

P11.08

DC braking current at

start

0.0%~100.0%

0.0%

○

P11.09

DC braking time at start

0.00s~30.00s

0.00s

○

P11.10

Flying Start Current

0.0~200.0%

100.0%

●

P11.11

Flying Start Decel Time

0.1s~20.0s

2.0s

●

P11.12

V/f coefficient at flying

start

20.0~100.0%

100.0%

●

P11.13

Stop mode

0: Ramp to stop

1: Coast to stop

2: Ramp to stop + DC brake

0

●

- 31 -

Page 36

Chapter 4 List of Parameters E5 User Manual

Param.

Designation

Scope

Factory

Default

Attr

P11.14

Start frequency of DC

injection braking stop

0.00Hz~upper limit frequency

0.00Hz

●

P11.15

Current of DC injection

braking stop

0.0%~100.0%

0.0%

○

P11.16

Time of DC injection

braking stop

0.00s~30.00s

0.00s

○

P11.17

Overexcitation brake

0: Disabled

1: Enabled

1

●

P11.18

Dynamic brake

0: Disabled

1: Enabled

0

●

P11.19

Dynamic brake threshold

voltage

650V~750V

720V

●

P11.20

Auto restart when power

up again after power

loss

0: Disabled

1: Enabled

0

●

P11.21

Waiting time of auto

restart when power up

again

0.0s~10.0s

0.0s

○

Group P12: Accel/Decel Parameters

P12.00

Accel/Decel time

resolution

0:0.01s

1:0.1s

2:1s

1

●

P12.01

Accel time 1

0s~600.00s/6000.0s/60000s

6.0s

○

P12.02

Decel time 1

0s~600.00s/6000.0s/60000s

6.0s

○

P12.03

Accel time 2

0s~600.00s/6000.0s/60000s

6.0s

○

P12.04

Decel time 2

0s~600.00s/6000.0s/60000s

6.0s

○

P12.05

Accel time 3

0s~600.00s/6000.0s/60000s

6.0s

○

P12.06

Decel time 3

0s~600.00s/6000.0s/60000s

6.0s

○

P12.07

Accel time 4

0s~600.00s/6000.0s/60000s

6.0s

○

P12.08

Decel time 4

0s~600.00s/6000.0s/60000s

6.0s

○

P12.09

Decel time at emergency

stop

0s~600.00s/6000.0s/60000s

6.0s

○

P12.10

Jog Accel time

0s~600.00s/6000.0s/60000s

6.0s

○

P12.11

Jog Decel time

0s~600.00s/6000.0s/60000s

6.0s

○

P12.12

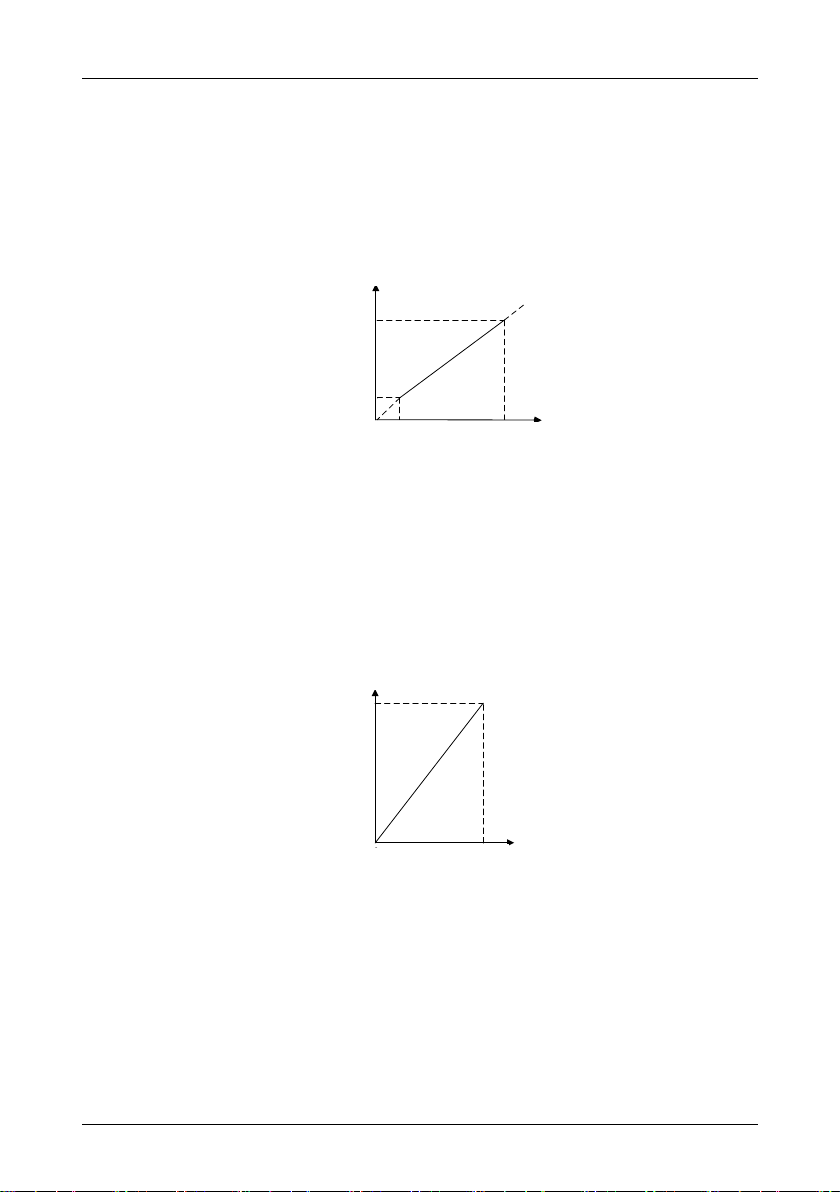

Accel/Decele curve

0: Linear Accel/Decel

1: Broken-line Accel/Decel

2: S-curve Accel/Decel A

3: S-curve Accel/Decel B

4: S-curve Accel/Decel C

0

●

P12.13

Accel time switching

0.00Hz~maximum frequency

0.00Hz

○

- 32 -

Page 37

E5 User Manual Chapter 4 List of Parameters

Param.

Designation

Scope

Factory

Default

Attr

frequency of broken-line

Accel/Decel

P12.14

Decel time switching

frequency of broken-line

Accel/Decel

0.00Hz~maximum frequency

0.00Hz

○

P12.15

Time of initial segment of

Accel S-curve

0.00s~60.00s (S-curve A)

0.20s

○

P12.16

Time of last segment of

Accel S-curve

0.00s~60.00s (S-curve A)

0.20s

○

P12.17

Time of initial segment of

Decel S-curve

0.00s~60.00s (S-curve A)

0.20s

○

P12.18

Time of last segment of

Decel S-curve

0.00s~60.00s (S-curve A)

0.20s

○

P12.19

Proportion of initial

segment of Accel

S-curve

0.0%~100.0% (S-curve B)

20.0%

○

P12.20

Proportion of last

segment of Accel

S-curve

0.0%~100.0% (S-curve B)

20.0%

○

P12.21

Proportion of initial

segment of Decel

S-curve

0.0%~100.0% (S-curve B)

20.0%

○

P12.22

Proportion of last

segment of Decel

S-curve

0.0%~100.0% (S-curve B)

20.0%

○

Group P20 Digital Input

P20.00

Enabled condition of run

command terminals when

power up

0: Trigger edge detected + ON

detected

1: ON detected

0

●

P20.01

Function of terminal X1

0: No function

1: JOG forward

2: JOG reverse

3: Running forward (FWD)

4: Running reverse (REV)

5: Three-wire control

6: Running suspended

7: External stop

8: Emergency stop

9: Stop command + DC brake

10: DC injection braking stop

11: Coast to stop

03

●

P20.02

Function of terminal X2

04

●

P20.03

Function of terminal X3

01

●

P20.04

Function of terminal X4

23

●

P20.05

Function of terminal X5

11

●

P20.06

Function of terminal X6

0

●

P20.07

Reserved

Reserved

●

P20.08

Function of terminal AI1

(Digital enabled)

0

●

P20.09

Function of terminal AI2

(Digital enabled)

0

●

- 33 -

Page 38

Chapter 4 List of Parameters E5 User Manual

Param.

Designation

Scope

Factory

Default

Attr

P20.10

Reserved

12: Terminal UP

13: Terminal DOWN

14: UP/DOWN (including ∧/∨

key) adjustment clear

15: Multi-step frequency terminal 1

16: Multi-step frequency terminal 2

17: Multi-step frequency terminal 3

18: Multi-step frequency terminal 4

19: Accel/Decel time determinant 1

20: Accel/Decel time determinant 2

21: Accel/Decel disabled(ramp

stop not inclusive)

22: External fault input

23: Fault reset (RESET)

24: Pulse input (valid only for

X6/DI)

25: Motor 1/2 switchover

26: Reserved

27: Run command switched to

keypad control

28: Run command switched to

terminal control

29: Run command switched to

communication control

30: Frequency command pattern

shift

31: Master frequency command

switched to digital setting P10.02

32: Auxiliary frequency command

switched to digital setting P10.04

33: PID adjustment direction

34: PID paused

35: PID integration paused

36: PID parameter switch

37: Count input

38: Count clear

39: Length count

40: Length clear

41~62: Reserved

63: Simple PLC paused

64: Simple PLC disabled

65: Clear simple PLC stop memory

0

●

- 34 -

Page 39

E5 User Manual Chapter 4 List of Parameters

Param.

Designation

Scope

Factory

Default

Attr

66: Start wobble frequency

67: Clear wobble frequency status

68: Running prohibited

69: DC injection braking at running

70~99: Reserved

P20.11

Filtering time of digital

input terminal

0.000s~1.000s

0.010s

○

P20.12

Delay time of terminal

X1

0.0s~3600.0s

0.0s

○

P20.13

Delay time of terminal

X2

0.0s~3600.0s

0.0s

○

P20.14

Digital input terminal

enabled status setting 1

Unit's place: X1

0: Positive logic

1: Negative logic

Decade: X2 (same as unit's place)

Hundreds place: X3 (same as

unit's place)

Thousands place: X4 (same as

unit's place)

0000

●

P20.15

Digital input terminal

enabled status setting 2

Unit's place: X5

0: Positive logic

1: Negative logic

Decade: X6 (valid as ordinary

terminal, same as unit's place)

Hundreds place: reserved)

Thousands place: reserved

0000

●

P20.16

Digital input terminal

enabled status setting 3

Unit's place: AI1

0: Positive logic

1: Negative logic

Decade: AI2 (same as unit's place)

Hundreds place: Reserved

Thousands place: reserved

0000

●

P20.17

Terminal UP/DOWN

frequency adjustment

control

Unit's place: action when stop

0: Clear

1: Holding

Decade: action on power loss

0: Clear

1: Holding

Hundreds place: integral function

0: No integral function

1: Integral function enabled

0000

○

- 35 -

Page 40

Chapter 4 List of Parameters E5 User Manual

Param.

Designation

Scope

Factory

Default

Attr

P20.18

Terminal UP/DOWN

frequency change step

size

0.00Hz/s~100.00Hz/s

0.03 Hz/s

○

P20.19

FWD/REV terminal

control mode

0: Two-wire mode 1

1: Two-wire mode 2

2: Three-wire mode 1

3: Three-wire mode 2

0

●

P20.20

Option of virtual input

terminal

000~77F

0: Actual terminal in effect

1: Virtual terminal in effect

Unit's place: BIT0~BIT3: X1~X4

Decade: BIT4~BIT6: X5~X6,

Hundreds place: BIT8~BIT10:

AI1~AI2

000

●

Group P21 Digital Output

P21.00

Y1 output function

0: No output

1: Drive undervoltage

2: Drive running preparation

completed

3: Drive is running

4: Drive in 0Hz running (no output

at stop)

5: Drive in 0Hz running (output at

stop)

6: Running direction

7: Frequency attained

8: Upper limit frequency attained

9: Lower limit frequency attained

10: Frequency higher than FDT 1

11: Frequency higher than FDT 2

12: Reserved

13: Torque being constrained

(speed control mode)

14: Fault output

15: Alarm output

16: Drive (motor) overloaded alarm

17: Drive thermal alarm

18: Zero current detection

19: X1

20:X2

21: Motor 1/ 2 indication

22: Set count value attained

0

○

P21.01

Y2/DO output function

(when used as Y2)

0

○

P21.02

Relay 1 output function

14

○

P21.03

Reserved

15

○

- 36 -

Page 41

E5 User Manual Chapter 4 List of Parameters

Param.

Designation

Scope

Factory

Default

Attr

23: Designated count value

attained

24: Length attained

25: Consecutive running time

attained

26: Accumulative running time

attained

27: Contracting brake control

28: Reserved

29: Positioning approaching

30: PLC step completed

31: PLC cycle completed

32: Wobble frequency attains to

upper or lower limit frequency

33~99: Reserved

P21.04

Y1 output delay time

0.0s~3600.0s

0.0s

○

P21.05

Y2 output delay time

0.0s~3600.0s

0.0s

○

P21.06

Relay 1 output delay

time

0.0s~3600.0s

0.0s

○

P21.07

Reserved

Reserved

Reserved

○

P21.08

Enabled state of digital

output

Unit's place: Y1

0: Positive logic

1: Negative logic

Decade: Y2 (same as unit's place)

Hundreds place: Relay 1 output

(same as unit's place)

Thousands place: Relay 2 output

(same as unit's place)

0000

●

P21.09

Detective object of

frequency doubling

technology(FDT)

Unit's place: FDT1 detective object

0: Set value of speed (frequency

after Accel/Decel)

1: Detected speed value

Decade: FDT2 detective object

0: Set value of speed (frequency

after Accel/Decel)

1: Detected speed value

00

○

P21.10

FDT1 upper bound

0.00Hz~maximum frequency

50.00Hz

○

P21.11

FDT1 lower bound

0.00Hz~maximum frequency

49.00Hz

○

P21.12

FDT2 upper bound

0.00Hz~maximum frequency

25.00Hz

○

P21.13

FDT2 lower bound

0.00Hz~maximum frequency

24.00Hz

○

P21.14

Detection width of

0.00Hz~maximum frequency

2.50Hz

○

- 37 -

Page 42

Chapter 4 List of Parameters E5 User Manual

Param.

Designation

Scope

Factory

Default

Attr

frequency attained

P21.15

Zero current detection

level

0.0%~50.0%

5.0%

○

P21.16

Zero current detection

time

0.01s~50.00s

0.50s

○

Group P22 Analog and Pulse Input

P22.00

Analog input curve

Unit's place: AI1 input curve

0: Curve 1 (2 points)

1: Curve 2 (4 points)

2: Curve 3 (4 points)

Decade: AI2 input curve

(same as unit's place)

Hundreds place: Reserved

Thousands place: reserved

000

●

P22.01

Maximum input of

curve1

Minimum input of curve 1 ~110.0%

100.0%

●

P22.02

Corresponding set value

of maximum input of

curve 1

-100.0%~100.0%

100.0%

●

P22.03

Minimum input of curve

1

-110.0% ~ maximum input of curve

1

0.0%

●

P22.04

Corresponding set value

of minimum input of

curve 1

-100.0%~100.0%

0.0%

●

P22.05

Maximum input of curve

2

Input of inflection point A of curve

2~110.0%

100.0%

●

P22.06

Set value corresponding

to maximum input of

curve 2

-100.0%~100.0%

100.0%

●

P22.07

Input of inflection point A

of curve 2

Input of inflection point B of curve

2 ~ maximum input of curve 2

0.0%

●

P22.08

Set value corresponding

to input of inflection point

A of curve 2

-100.0%~100.0%

0.0%

●

P22.09

Input of inflection point B

of curve 2

Minimum input of curve 2 ~ Input

of inflection point A of curve 2

0.0%

●

P22.10

Set value corresponding

to input of inflection point

B of curve 2

-100.0%~100.0%

0.0%

●

P22.11

Minimum input of curve

2

-110.0%~ input of inflection point B

of curve 2

0.0%

●

- 38 -

Page 43

E5 User Manual Chapter 4 List of Parameters

Param.

Designation

Scope

Factory

Default

Attr

P22.12

Set value corresponding

to minimum input of

curve 2

-100.0%~100.0%

0.0%

●

P22.13

Maximum input of curve

3

Input of inflection point A of curve

3~110.0%

100.0%

●

P22.14

Set value corresponding

to maximum input of

curve 3

-100.0%~100.0%

100.0%

●

P22.15

Input of inflection point A

of curve 3

Input of inflection point B of curve

3~ maximum input of curve 3

0.0%

●

P22.16

Set value corresponding

to Input of inflection point

A of curve 3

-100.0%~100.0%

0.0%

●

P22.17

Input of inflection point B

of curve 3

Minimum input of curve 3~ input of

inflection point A of curve 3

0.0%

●

P22.18

Set value corresponding

to Input of inflection point

B of curve 3

-100.0%~100.0%

0.0%

●

P22.19

Minimum input of curve

3

-110.0%~ input of inflection point B

of curve 3

0.0%

●

P22.20

Set value corresponding to

minimum input of curve 3

-100.0%~100.0%

0.0%

●

P22.21

AI1 terminal filtering time

0.000s~10.000s

0.01s

○

P22.22

AI2 terminal filtering time

0.000s~10.000s

0.01s

○

P22.23

Reserved

Reserved

Reserved

P22.24

DI maximum input

P22.26~50.0kHz

50.0kHz

●

P22.25

Set value corresponding

to DI maximum input

-100.0%~100.0%

100.0%

●

P22.26

DI minimum input

0.0kHz~P22.24

0.0kHz

●

P22.27

Set value corresponding

to DI minimum input

-100.0%~100.0%

0.0%

●

P22.28

DI filtering time

0.000s~1.000s

0.001s

○

Group P23 Analog and Pulse Output

P23.00

AO1 output function

0: No output

1: Command frequency

2: Output frequency

3: Output current

4: Output torque

5: Output voltage

6: Output power

7: Bus voltage

2

○

P23.01

AO2 output function

1

○

P23.02

Y2/DO output function

(when used as DO)

2

○

- 39 -

Page 44

Chapter 4 List of Parameters E5 User Manual

Param.

Designation

Scope

Factory

Default

Attr

8: Reserved

9: Torque current

10: Magnetic flux current

11:AI1

12:AI2

13: Reserved

14: Reserved

15:DI

16:Communication input

percentage

17: Output frequency before

compensation

18~99: Reserved

P23.03

AO1 offset

-100.0%~100.0%

0.0%

●

P23.04

AO1 gain

-2.000~2.000

1.000

●

P23.05

AO1 filtering time

0.0s~10.0s

0.0s

○

P23.06

Reserved

Reserved

Reserved

P23.07

Reserved

Reserved

Reserved

P23.08

Reserved

Reserved

Reserved

P23.09

DO maximum output

pulse frequency

0.1kHz~50.0kHz

50.0kHz

○

P23.10

DO output center point

0: No center point

1: Center point is (P23.09)/2, and

the corresponding parameter value

is positive when frequency is higher

than center point

2: Center point is (P23.09)/2, and

the corresponding parameter

value is positive when frequency is

lower than center point

0

●

P23.11

DO output filtering time

0.00s~10.00s

0.01s

○

Group P24 Automatic Correction of Analog Input

P24.00

Analog corrected

channel

0: No correction

1:Correct AI1

2:Correct AI2

3: Reserved

0

●

P24.01

Sampling value of

calibration point 1 of AI1

0.00V~10.00V

1.00V

×

P24.02

Input value of calibration

point 1 of AI1

0.00V~10.00V

1.00V

●

- 40 -

Page 45

E5 User Manual Chapter 4 List of Parameters

Param.

Designation

Scope

Factory

Default

Attr

P24.03

Sampling value of

calibration point 2 of AI1

0.00V~10.00V

9.00V

×

P24.04

Input value of calibration

point 2 of AI1

0.00V~10.00V

9.00V

●

P24.05

Sampling value of

calibration point 1 of AI2

0.00V~10.00V

1.00V

×

P24.06

Input value of calibration

point 1 of AI2

0.00V~10.00V

1.00V

●

P24.07

Sampling value of

calibration point 2 of AI2

0.00V~10.00V

9.00V

×

P24.08

Input value of calibration

point 2 of AI2

0.00V~10.00V

9.00V

●

P24.09

Reserved

Reserved

Reserved

P24.10

Reserved

Reserved

Reserved

P24.11

Reserved

Reserved

Reserved

P24.12

Reserved

Reserved

Reserved

Group P30 Parameters of Motor 1

P30.00

Type of motor 1

0: Ordinary asynchronous motor

1: Variable frequency

asynchronous motor

0

●

P30.01

Power rating of motor 1

0.4kW~6553.5kW

Model

defined

●

P30.02

Rated voltage of motor 1

0V~480V

380V

●

P30.03

Rated current of motor 1

0.0A~6553.5A

Model

defined

●

P30.04

Rated frequency of

motor 1

0.00Hz~600.00Hz

50.00Hz

●

P30.05

Pole pairs of motor 1

1~80

4

●

P30.06

Rated speed of motor 1

0~65535r/min

Model

defined

●

P30.07

Stator resistance R1 of

async motor 1

0.001Ω~65.535Ω

Model

defined

●

P30.08

Leakage inductance L1

of async motor 1

0.1mH~6553.5mH

Model

defined

●

P30.09

Rotor resistance R2 of

async motor 1

0.001Ω~65.535Ω

Model

defined

●

P30.10

Mutual inductance L2 of

asynchronous motor 1

0.1mH~6553.5mH

Model

defined

●

- 41 -

Page 46

Chapter 4 List of Parameters E5 User Manual

Param.

Designation

Scope

Factory

Default

Attr

P30.11

No-load current of async

motor 1

0.0A~6553.5A

Model

defined

●

P30.12

Field weakening coeff 1

of async motor 1

0.0000~1.0000

Model

defined

●

P30.13

Field weakening coeff 2

of async motor 1

0.0000~1.0000

Model

defined

●

P30.14

Field weakening coeff 3

of async motor 1

0.0000~1.0000

Model

defined

●

P30.15

Reserved

Reserved

Reserved

P30.16

Reserved

Reserved

Reserved

P30.17

Reserved

Reserved

Reserved

P30.18

Reserved

Reserved

Reserved

P30.19

Reserved

Reserved

Reserved

P30.20

Reserved

Reserved

Reserved

P30.21

Reserved

Reserved

Reserved

P30.22

Autotuning of motor 1

0: No autotuning

1: Static autotuning of async motor

2: Rotary autotuning of async

motor

0

●

P30.23

Overload protection

mode of motor 1

0: No protection

1: Judged from motor current

2: Judged from temperature

transducer

1

●

P30.24

Overload protection

detection time of motor 1

0.1min~15.0min

5.0min

●

P30.25

Input source of

temperature transducer

signal of motor 1

0: AI1

1: AI2

2: Reserved

1

●