Page 1

Downdraft Ventilators

MODEL WIDTH BLOWER

Page 1

DD0130SS 30" 500 cfm Interior

DD0136SS 36" 500 cfm Interior

DD0148SS 48" 500 cfm Interior

DDEX30SS 30" Models EB6, EB9, EB12, or EB15 Exterior (purchase separately) or Models ILB3, IILB6, ILB9 or ILB 11 In-Line (purchase separately)

DDEX36SS 36" Models EB6, EB9, EB12, or EB15 Exterior (purchase separately) or Models ILB3, ILB6, ILB9 or ILB 11 In-Line (purchase separately)

DDEX48SS 48" Models EB6, EB9, EB12, or EB15 Exterior (purchase separately) or Models ILB3, ILB6, ILB9 or ILB 11 In-Line (purchase separately)

WARNING - To reduce the risk of burns or ignition of clothing by reaching across burners, the downdraft remote control MUST

be mounted in the countertop - at least 4" from the burners. See "INSTALL COOKTOP" section on page 8.

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. To reduce the risk of fire, use only metal ductwork.

8. Do not install this product

behind a burner or element. Minimum distance between the

switch and the edge of the burner should be 4 inches.

9. Loose-fitting or hanging clothing should never be worn when

operating this appliance. They may be ignited by burners/

elements on cooktop.

10. Children should not be left alone or unattended in the area

where this appliance is in use.

11. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

cooking flaming foods.

c) Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate

for the size of the surface element.

INSTALLER:

Save this manual for Electrical

Inspector and Homeowner to use.

with the

activating switch directly

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immedi-

ately, EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - a

violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher, and you

already know how to operate it.

B. The fire is small and contained in the area where it

started.

C. The fire department is being called.

D . Yo u can fight the fire with your back to an exit.

a

Based on “Kitchen Firesafety Tips” published by NFPA.

CAUTION

1. Fo r indoor use only.

2. For general ventilating use only. Do not use to exhaust hazardous

or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power unit.

4. Clean filters and grease-laden surfaces frequently.

5. Do not repair or replace any part of this appliance unless specifically recommended in this manual. All other servicing should be

done by a qualified technician.

6. Please read specification label on product for further

and requirements.

7. To reduce the risk of fire and electric shock, install this downdraft

only with Best by Broan blower models shown below. Other blower

models cannot be substituted. (Blowers sold separately).

MODEL WIDTH BLOWER

DD0130SS 30" 500 cfm Interior

DD0136SS 36" 500 cfm Interior

DD0148SS 48" 500 cfm Interior

DDEX30SS 30" Models EB6, EB9, EB12, or EB15 Exterior

(purchase separately) or Models ILB3, ILB6,

ILB9 or ILB 11 In-Line (purchase separately)

DDEX36SS 36" Models EB6, EB9, EB12, or EB15 Exterior

(purchase separately) or Models ILB3, ILB6,

ILB9 or ILB 11 In-Line (purchase separately)

DDEX48SS 48" Models EB6, EB9, EB12, or EB15 Exterior

(purchase separately) or Models ILB3, ILB6,

ILB9 or ILB 11 In-Line (purchase separately)

Register your product online at: www.BestRangeHoods.com

a

:

!

ormation

inf

Page 2

PLANNING

Downdraft Ventilators

Page 2

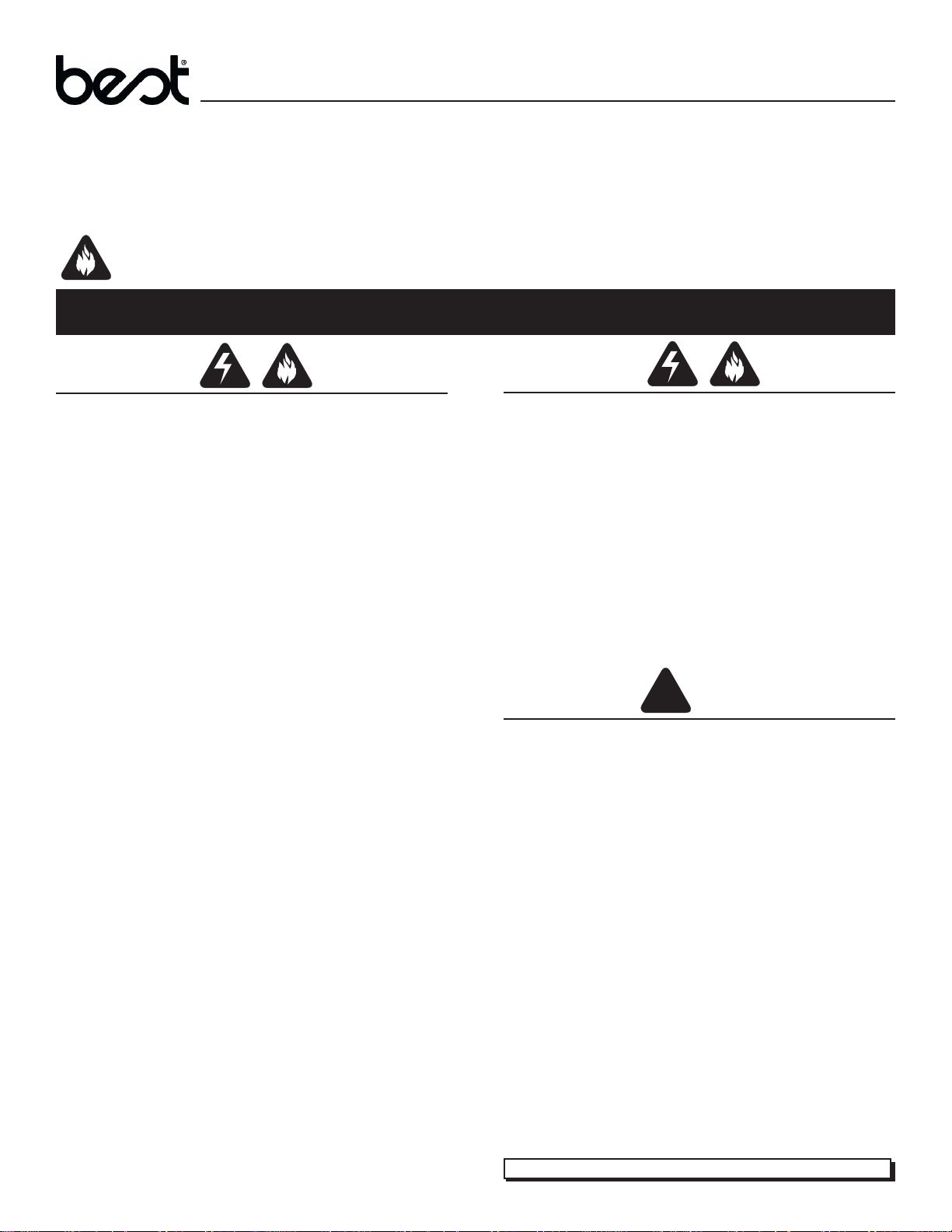

Interior Blower Installation

This downdraft blower system is

designed to be used to exhaust

airborne contaminants when

cooking with a variety of gas

or electric cooktops. It can be

mounted in island, peninsula,

or conventional wall locations.

This unit can be easily installed

following these basic steps:

Cut out the countertop open-

ing.

Mount the unit in the cabinet.

Connect the ductwork and

electrical.

Install the cooktop.

Note: the high level of air flow

of this appliance may effect the

gas flame on some types of gas

cooktops. This is NORMAL and

will cause no harm, but can be

corrected by lowering the speed

of the blower.

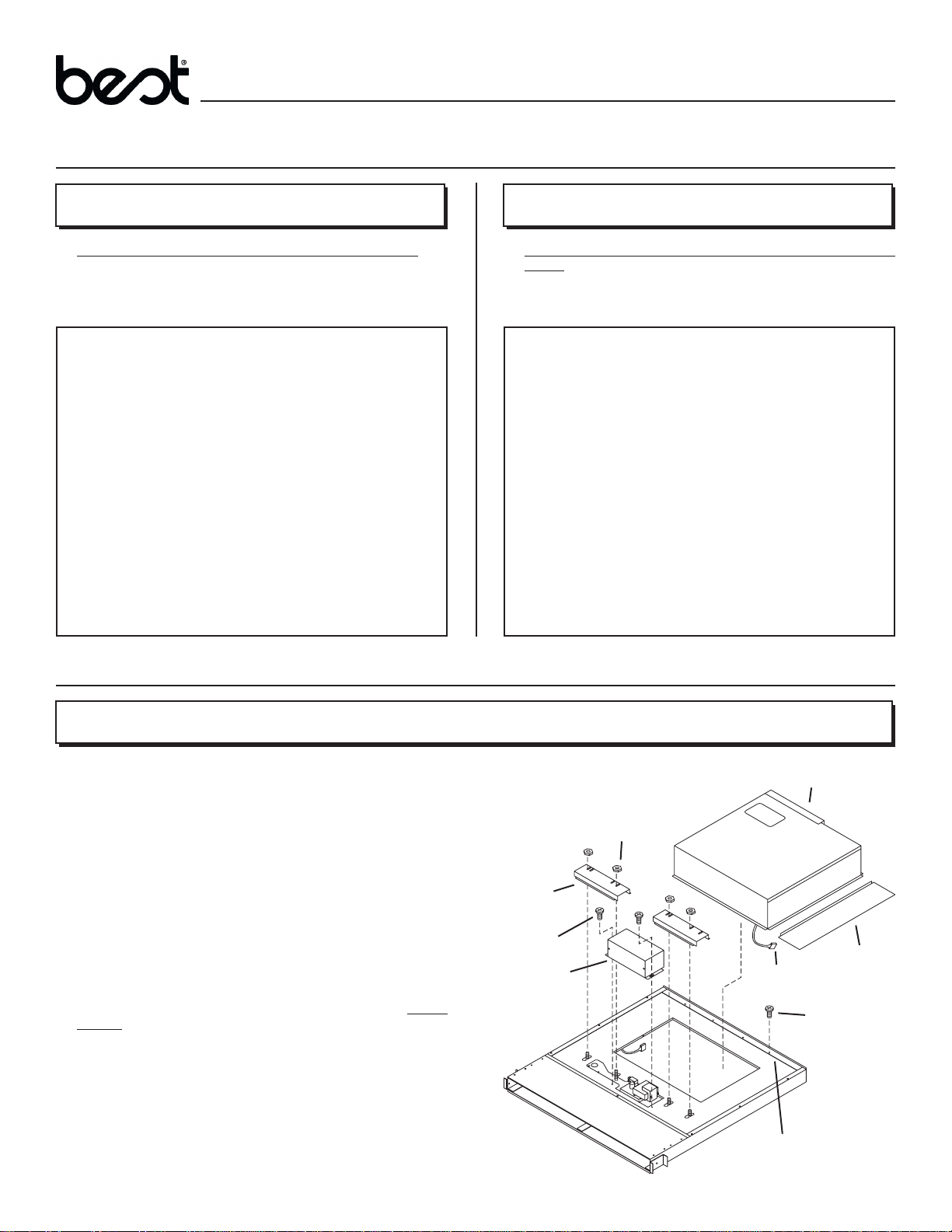

TYPICAL INSTALLATION

COUNTER

TOP

BLOWER

COOK TOP

GEAR

MOTOR

COVER

BOX

CHIMNEY TOP

3-1/4" X 10"

DUCT CONNECTOR

ELECTRICAL

SPECIFICATIONS

120 VAC • 60 Hz • 4.0 A

AIR

VENT

120 VAC

GROUNDED

OUTLET

Exterior or In-Line Blower Installation

This downdraft blower system

is designed to be used to exhaust airborne contaminants

when cooking with a variety

of gas or electric cooktops.

It can be mounted in island,

peninsula, or conventional wall

locations.

This unit can be easily installed

following these basic steps:

Cut out the countertop

opening.

Mount the unit in the cabi-

net.

Install Model EB6, EB9,

EB12, EB15 External

Blower or ILB3, ILB6,

ILB9, ILB11In-Line

Blower

Connect the ductwork and

electrical.

Install the cooktop.

Note: the high level of air flow of this appliance may effect the

gas flame on some types of gas cooktops. This is NORMAL and

will cause no harm, but can be corrected by lowering the speed

of the blower.

TYPICAL INSTALLATION

COUNTER

TOP

BLOWER

COOK TOP

GEAR

MOTOR

COVER

BOX

CHIMNEY TOP

AIR

VENT

120 VAC

GROUNDED

OUTLET

3-1/4" X 14"

DUCT CONNECTOR

ELECTRICAL

SPECIFICATIONS

120 VAC • 60 Hz • 6.0 A (max.)

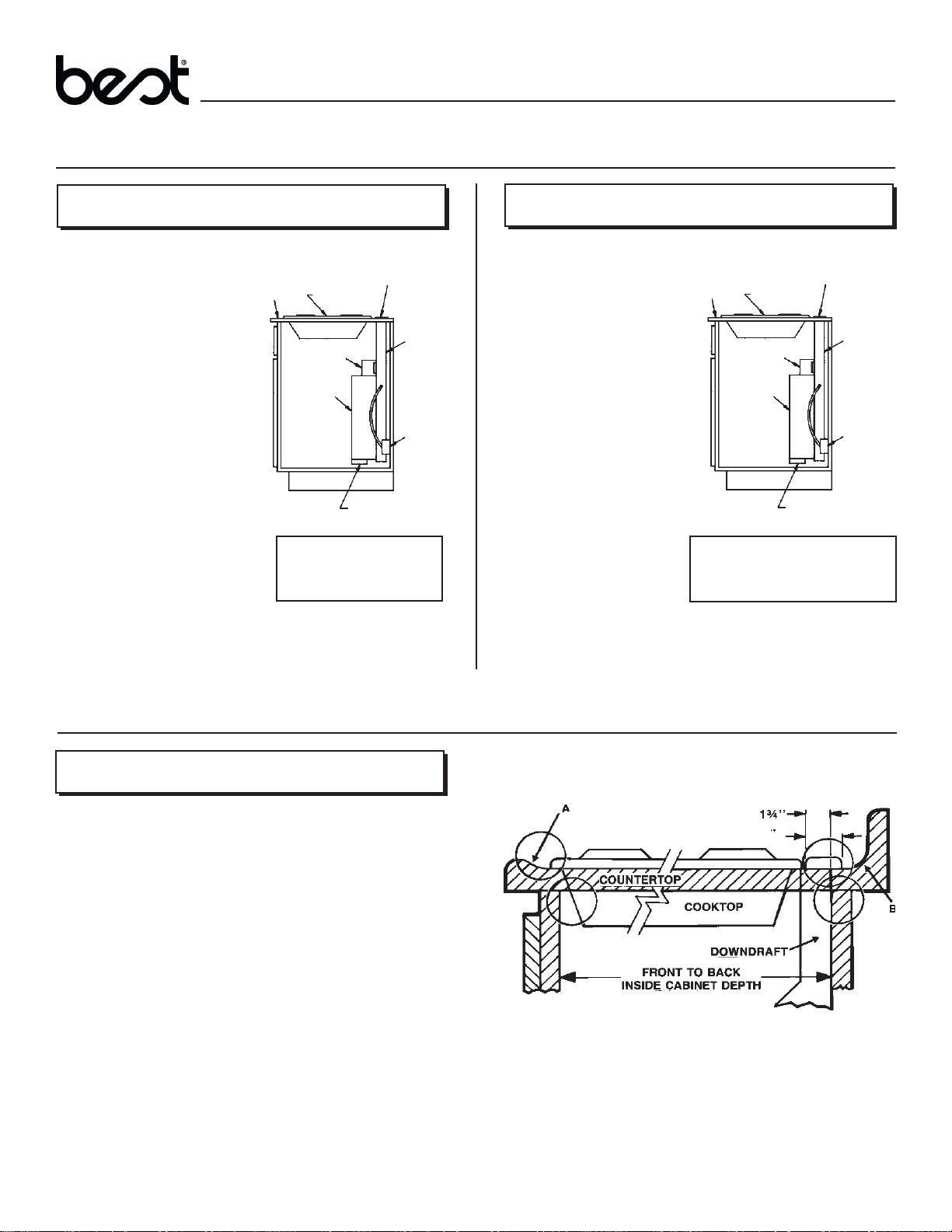

TAKE MEASUREMENTS

All Units

1. Refer to the cooktop installation instructions for dimensions

of cooktop, countertop cut-out, and cabinet requirements.

Models DD0130SS & DDEX30SS will fit in most 30" wide

cabinets. Models DD0136SS & DDEX36SS will fit in most

36" wide cabinets. Models DD0148SS & DDEX48SS will fit

in most 48" wide cabinets. However, it is recommended that

oversized cabinets be used for easier installation.

2. Cooktop depth can vary greatly from one to another. This may

cause the fit of these two appliances to be rather tight.

Pay special attention to the areas of potential interference highlighted above. A countertop with (A) a raised lip and/or (B) a

backsplash may not allow enough flat countertop for a proper

installation. Note that 2" of flat countertop is required behind

cooktop and that 1-3/4" is necessary between the back edge of

the cooktop and the inside of cabinet back.

2

Page 3

TAKE MEASUREMENTS (CONTINUED)

Downdraft Ventilators

Page 3

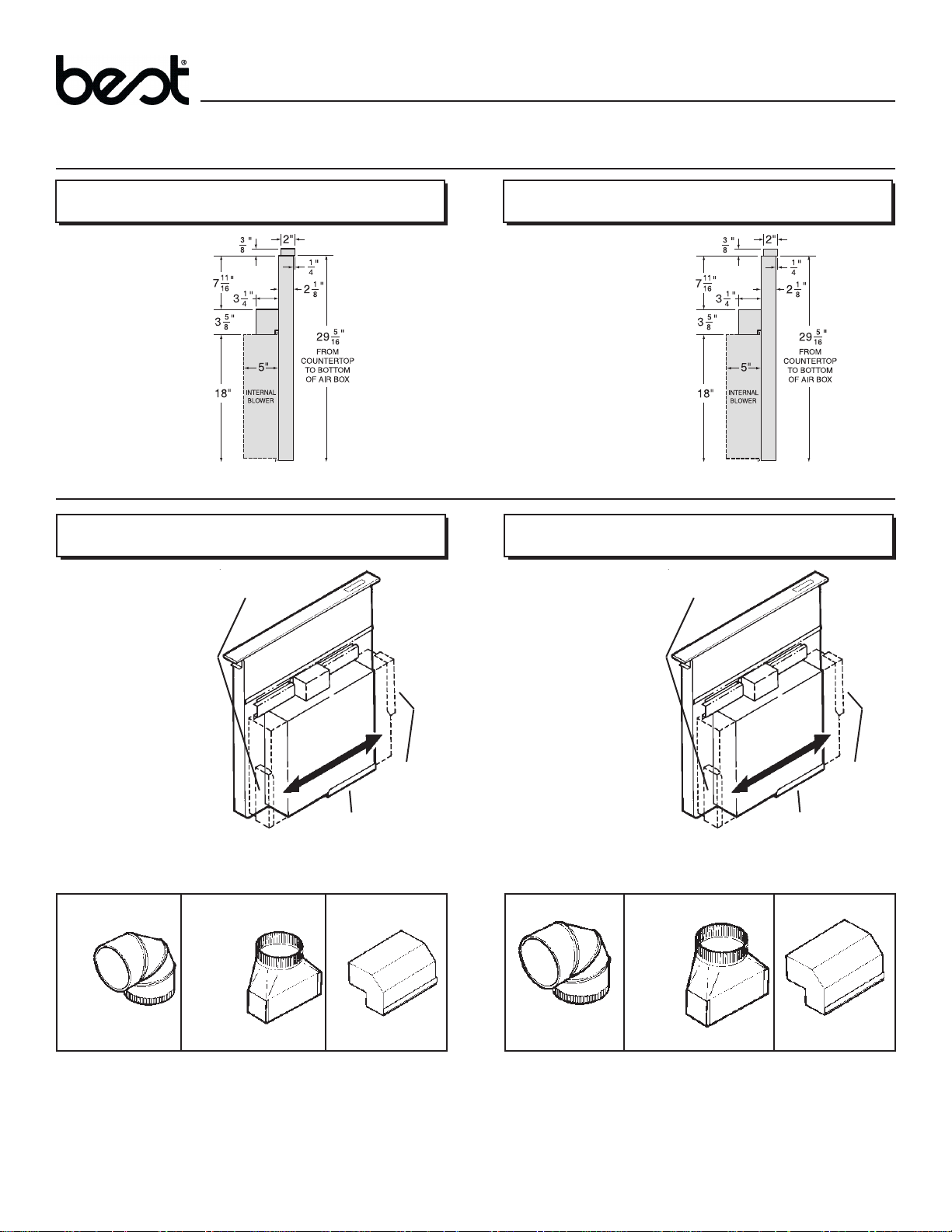

Interior Blower Installation

SIDE VIEW

OF DOWNDRAFT

PLAN THE DUCTWORK

Interior Blower Installation

1. The interior downdraft blower system is

designed for use with

3-1/4" x 10" ductwork

(can be transitioned

to 6" round). Three

different discharge

directions are available with side-toside adjustment for

accurate alignment of

ductwork.

2. For best performance:

Choose the ducting

option which allows

the shortest length

of ductwork and a

minimum number of

elbows and transitions. Check location of floor joists, wall studs, electrical

wiring or plumbing for possible interference.

LEFT

DISCHARGE

DISCHARGE

DOWN DISCHARGE

RIGHT

Exterior or In-Line Blower Installation

SIDE VIEW

OF DOWNDRAFT

Exterior or In-Line Blower Installation

1. The interior downdraft blower system is

designed for use with

3-1/4" x 14" ductwork

(can be transitioned

to 8" or 10" round).

Three different discharge directions are

available with side-toside adjustment for

accurate alignment of

ductwork.

2. For best performance:

Choose the ducting

option which allows

the shortest length

of ductwork and a

minimum number of

elbows and transitions. Check location of floor joists, wall studs, electrical

wiring or plumbing for possible interference.

LEFT

DISCHARGE

RIGHT

DISCHARGE

DOWN DISCHARGE

6" ROUND

ELBOW

EQUALS 8 FT. OF

STRAIGHT DUCT

3. The system will operate most efficiently when the ductwork

does not exceed 40 feet of equivalent duct. The chart, above,

shows equivalent feet of elbows and transitions. The number

of feet of straight duct plus the equivalent feet of transitions

and/or elbows to be used should equal 40 feet or less.

NOTE: The equivalent feet of various roof and wall caps has

been taken into consideration. Do not include them in this

calculation.

3-1/4" X 10" TO 6" RD.

TRANSITION

EQUALS

2 FT. OF

STRAIGHT DUCT

3-1/4" X 10"

90O ELBOW

EQUALS 14 FT. OF

STRAIGHT DUCT

8" ROUND ELBOW

EQUALS 11 F T. OF

STRAIGHT DUCT

3. The system will operate most efficiently when the ductwork

does not exceed 40 feet of equivalent duct. The chart, above,

shows equivalent feet of elbows and transitions. The number

of feet of straight duct plus the equivalent feet of transitions

and/or elbows to be used should equal 40 feet or less.

NOTE: The equivalent feet of various roof and wall caps has

been taken into consideration. Do not include them in this

calculation.

3-1/4" X 14" TO 8" RD.

TRANSITION

EQUALS

5 FT. OF

STRAIGHT

DUCT

3-1/4" X 14" 90O

ELBOW

EQUALS 19 FT. OF

STRAIGHT DUCT

Page 4

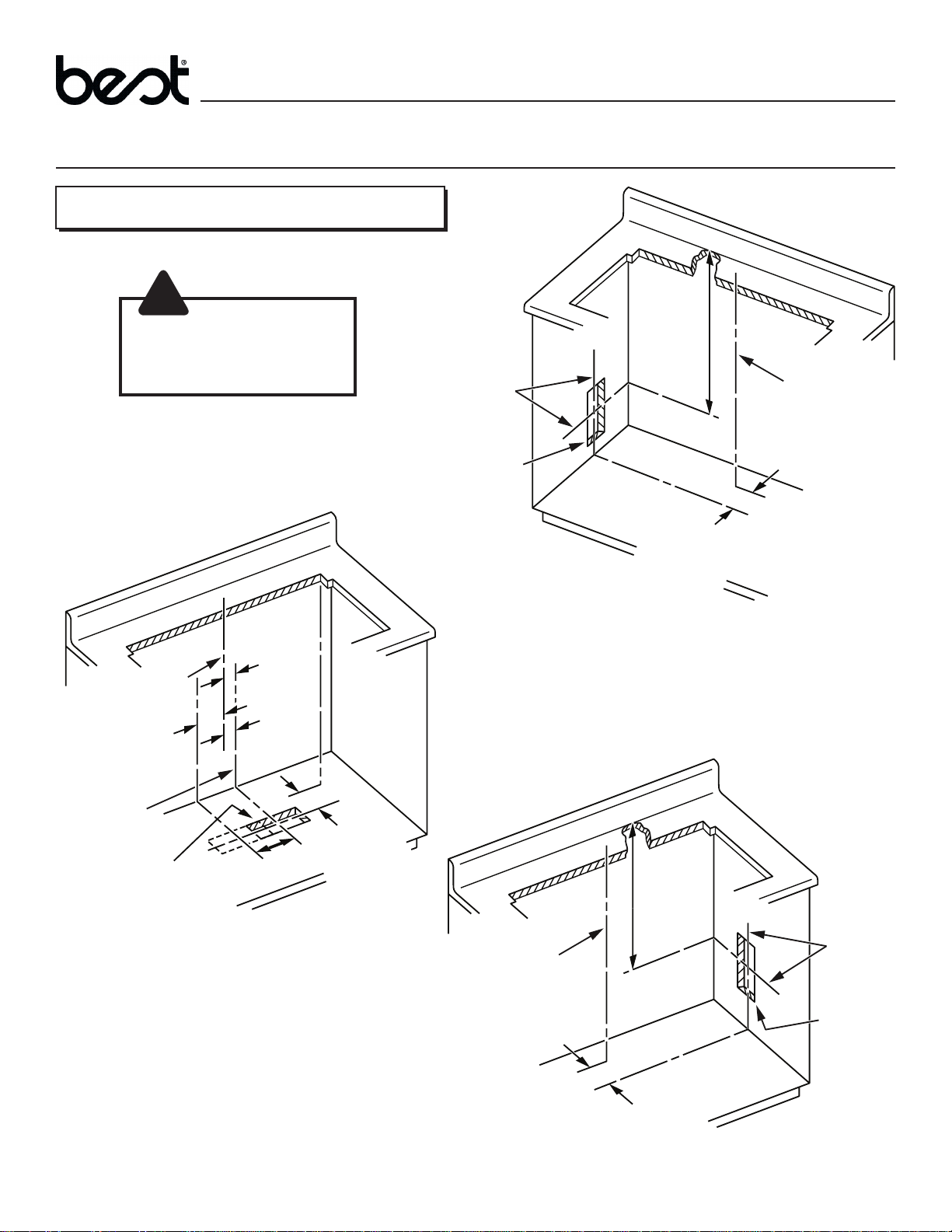

PLAN THE CABINET CUTOUTS

Downdraft Ventilators

Page 4

Blower Installation

!

BEFORE CUTTING HOLE IN

CABINET FOR DUCTWORK,

check for interference with floor

joists, wall studs, electrical wir-

BOTTOM

DISCHARGE

CAUTION:

ing, or plumbing.

CENTER

LINES OF

DUCT CUTOUT

10¼" x 3½"

CUTOUT

(14¼" x 3½"

FOR

EXTERNAL

BLOWER)

22

1

/

(19"

8

FOR

EXTERNAL

BLOWER)

5½"

(4¼" FOR

EXTERNAL

BLOWER)

LEFT SIDE

DISCHARGE

"

CENTER LINE

OF COUNTER

CUTOUT

CENTER LINE

OF COUNTER

CUTOUT

(5" MAX.

FOR EXTERNA

BLOWER)

CENTER LINE

OF DUCT

CUTOUT

10¼" x 3½"

CUTOUT

FOR EXTERNAL BLOWER)

(14¼" x 3½"

L

¼" to 7¾"

(2½" MAX.

FOR

EXTERNAL

BLOWER)

5½"

(4¼" FOR

EXTERNAL

BLOWER)

CENTER LINE

OF COUNTER

CUTOUT

"

3

8

/

16

(21½" FOR

EXTERNAL

BLOWER)

5½"

(4¼" FOR

EXTERNAL

BLOWER)

RIGHT SIDE

DISCHARGE

CENTER

LINES OF

DUCT

CUTOUT

10¼" x 3½"

CUTOUT

(14¼" X 3½"

FOR

EXTERNAL

BLOWER)

Page 5

PLAN THE WIRING

Downdraft Ventilators

Page 5

Interior Blower Installation

1. The Interior Downdraft Blower system draws 4 AMPS and

requires a 120 VAC, 60 Hz circuit.

2. The unit has a 18 in. long power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will allow

the unit’s power cord to reach.

IMPORTANT - LOCATION OF ELECTRICAL OUTLET:

If Model DD0130SS is being installed in a 30" wide

cabinet...

o r Model DD0136SS is being installed in a 36" wide

cabinet...

o r Model DD0148SS is being installed in a 48" wide

cabinet...

...the outlet cannot be located on the back

wall of cabinet.

In these cases, the width of the downdraft covers nearly

the entire width of the back wall of the cabinet. So you

must either:

• mount the electrical box to a side wall or cabinet floor

- at least 12 inches from the back wall.

• mount the electrical box to a wall stud behind

the cabinet - where it will not be covered by the

downdraft. Then provide a clearance hole in the

back wall of the cabinet.

Exterior or In-Line Blower Installation

1. The Exterior or In Line Downdraft Blower system draws 6

AMPS and requires a 120 VAC, 60 Hz circuit.

2. The unit has a 18 in. long power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will allow

the unit’s power cord to reach.

IMPORTANT - LOCATION OF ELECTRICAL OUTLET:

If Model DDEX30SS is being installed in a 30" wide

cabinet...

o r Model DDEX36SS is being installed in a 36" wide

cabinet...

o r Model DDEX48SS is being installed in a 48" wide

cabinet...

...the outlet cannot be located on the back

wall of cabinet.

In these cases, the width of the downdraft covers nearly

the entire width of the back wall of the cabinet. So you

must either:

• mount the electrical box to a side wall or cabinet floor

- at least 12 inches from the back wall.

• mount the electrical box to a wall stud behind the

cabinet - where it will not be covered by the down

draft. Then provide a clearance hole in the back wall

of the cabinet.

PREPARE THE DOWNDRAFT

Blower Duct Connection Installation (all blowers)

The downdraft is shipped with duct connector pointing toward the

bottom of the unit. If you wish to change this orientation, follow

the steps below:

1. Place the downdraft on its back on a table of flat work surface.

2. Remove the 4 nuts and 2 clamp channels.

3. Remove 2 screws and the gear motor cover.

4. Carefully position the blower under the bottom flange of

the downdraft with the 3¼" x 10" discharge (3¼" x 14" for

exterior or in-line blower) pointed in the desired direction.

5. Connect motor plug.

6. Replace the gear motor cover and 2 sheet metal screws.

7. Replace the 2 clamp channels and start the 4 nuts, do not

tighten.

8. Slide blower left of right to desired position. Use cover plate

(supplied) to close up any open space.

9. Tighten 4 nuts to secure top of blower. Use additional screws

(supplied) through bottom flange to secure bottom in blower.

CLAMP

CHANNELS

SCREWS

GEARMOTOR

COVER

3¼" X 10" DISCHARGE

(3¼" X 14" FOR EXTERIOR OR IN-LINE BLOWER)

NUTS

BLOWER

COVER

MOTOR

PLUG

PLATE

ADDITIONAL

SCREWS

BOTTOM

FLANGE

Page 6

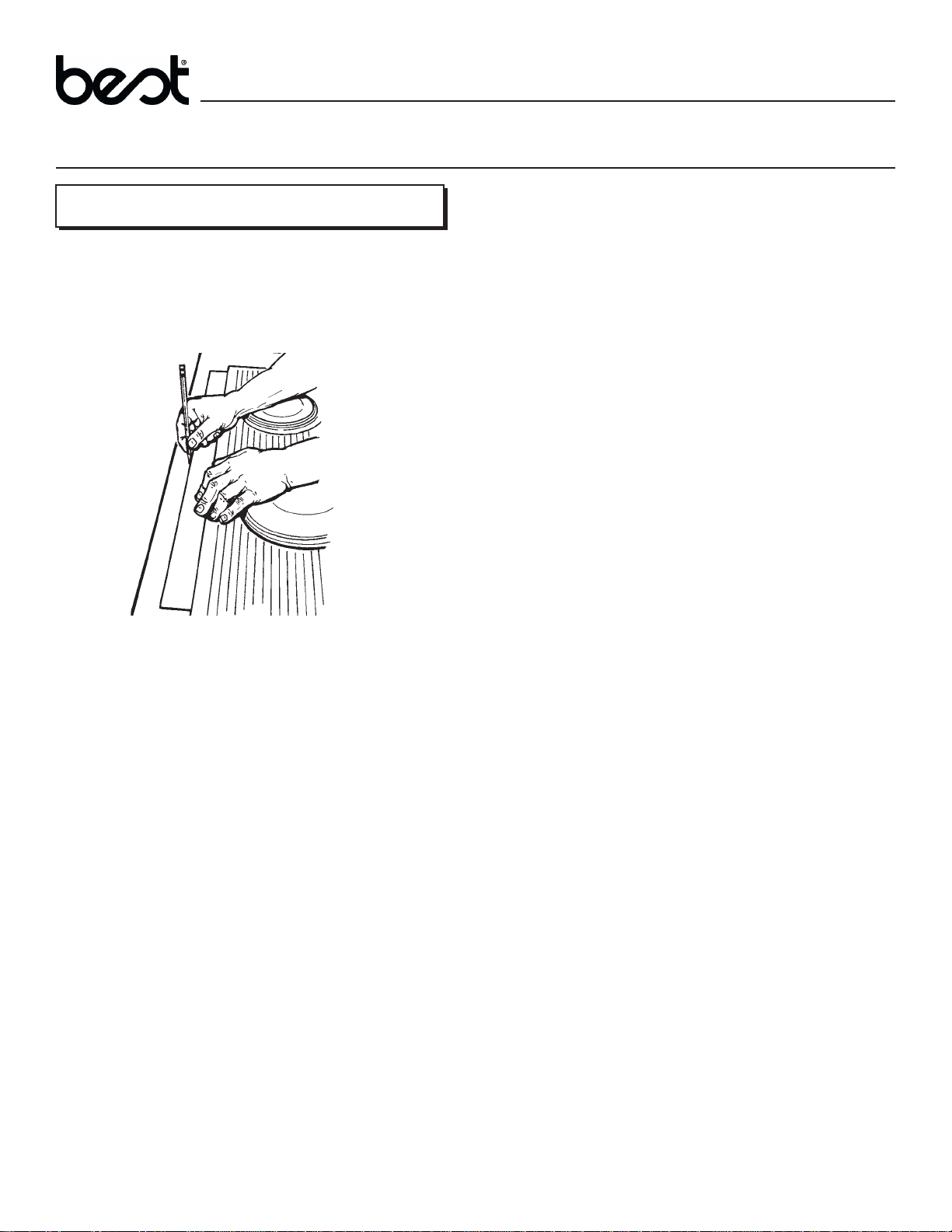

CUT COUNTERTOP OPENING

All Units

1. La y out and cut the cooktop cut-out far enough FORWARD so

downdraft will fit behind it.

2. Set cooktop in place and slide it as far forward as possible.

Center and square it with edges of countertop.

Downdraft Ventilators

Page 6

3. Place the plastic template against the back flange of the cook-

top and center it. Trace around template to mark the downdraft

opening.

4. Remove cooktop from countertop.

5. Cut downdraft opening. Be careful not to chip edges of coun-

tertop.

Page 7

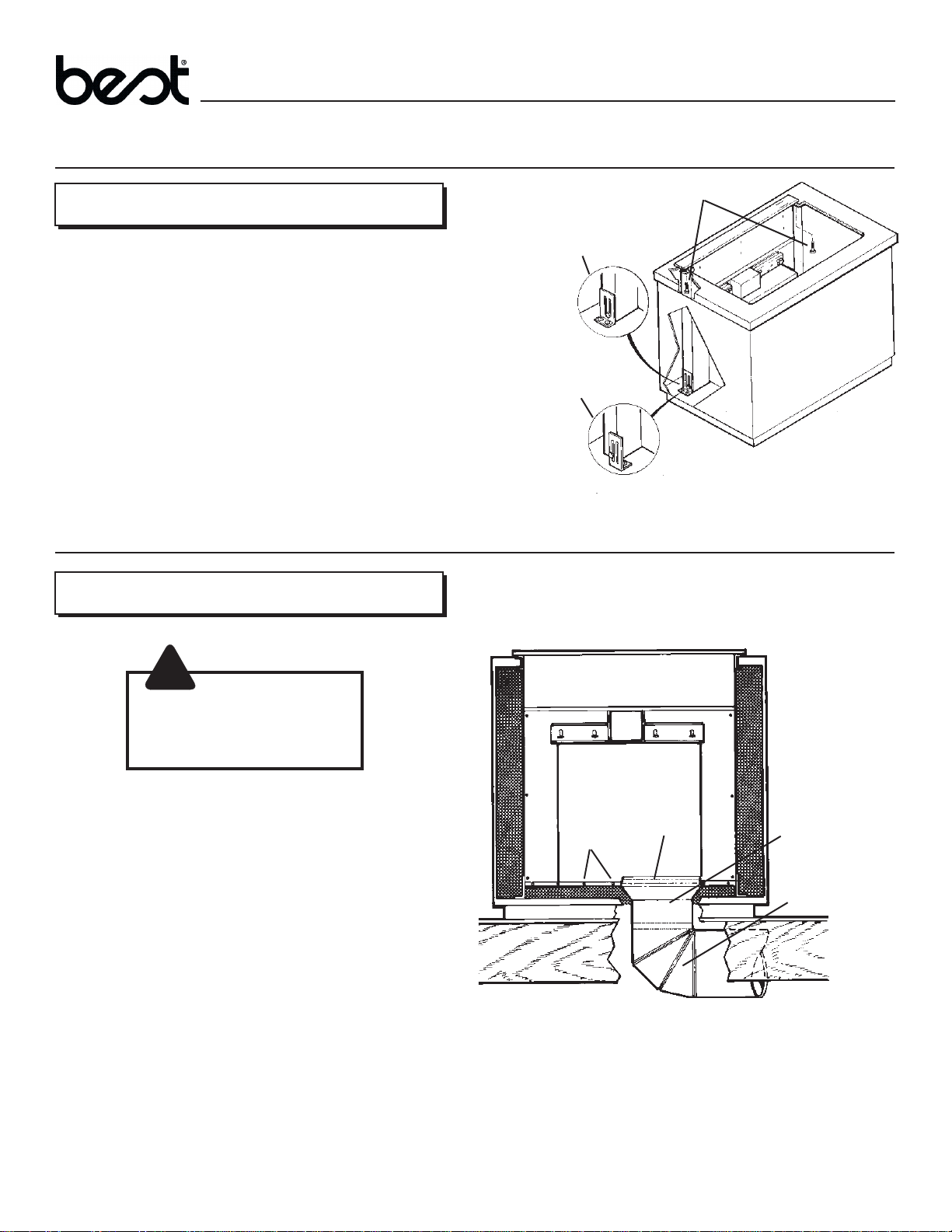

MOUNT THE UNIT

All Units

1. Set downdraft into opening. Extend leveling brackets to floor

of cabinet so downdraft sits straight. (Note: Leveling brackets

can be removed and re-attached in other positions. Bottom

flange may have to face inward in tight cabinet installations.)

2. Secure the downdraft to the countertop as follows: Hold the

downdraft against the back of countertop cut-out and tightening the two mounting screws (one on each end of unit) on

underside of countertop. Use a wood shim between screw

and underside of granite countertops.

3. Screw leveling brackets to bottom of cabinet. Tighten screws

holding leveling bracket to unit on each side.

Downdraft Ventilators

Page 7

MOUNTING SCREWS

LEVELING BRACKET -

FLANGE FACING OUT

LEVELING BRACKET -

FLANGE FACING IN

INSTALL DUCTWORK

Blower Installation

!

BEFORE CUTTING HOLE IN

CABINET FOR DUCTWORK,

check for interference with floor

joists, wall studs, electrical wir-

1. Cut hole in cabinet as well as holes in wall or floor as necessary.

2. Mount the roof or wall cap and work back towards the cabinet,

attaching all ductwork, elbows and transitions as previously

planned. Tape all ductwork connections to make them secure

and air tight.

3. Connect ductwork (and transition, if required) to downdraft.

If necessary, LOOSEN nuts and screws that hold the blower

in place, and slide blower left or right to meet ductwork. Retighten screws and nuts.

Note: A 3¼" x 10" collar (3¼" x 14" collar for exterior or in-line

blower) is provided for installers who prefer to rivet the ductwork to

the unit. This will allow blower to be removed and replaced easily

in service situations without disturbing ductwork.

CAUTION:

ing, or plumbing.

BLOWER

COLLAR

SCREWS

3¼" X 10"

TO 6" RD.

TRANSITION

(3¼" X 14" TO 8"

RD. TRANSITION

FOR EXTERIOR

OR IN-LINE

BLOWER

8" RD. ELBOW

& DUCTWORK

Page 8

INSTALL ELECTRICAL WIRING

!

!

Downdraft Ventilators

Page 8

Interior Blower Installation

CAUTION: All electrical wiring should be done

by a qualified person(s) in accordance with all

applicable codes and standards.

1. Mount a standard wiring box, with 3-pronged receptacle, inside

the cabinet. Make sure the downdraft's power cord can easily

reach it.

2. Run appropriate power cable into cabinet and connect it to

receptacle.

3. Plug the downdraft's power cord into the outlet. Make sure that

the power cord is routed away from the heat generated by the

cooktop.

INSTALL COOKTOP

All Units

Exterior or In-Line Blower Installation

CAUTION: All electrical wiring should be done

by a qualified person(s) in accordance with all

applicable codes and standards.

1. Mount a standard wiring box, with 3-pronged grounded receptacle, inside the kitchen cabinet. Make sure the unit's power

cord can easily reach it.

2. Run appropriate power cable into cabinet and connect it to

electrical box and receptacle.

3. Exterior or in-line blower may not exceed 6.0 Amp rating.

4. Run 2-wire plus ground power cable from the exterior or inline blower to wiring box on adaptor plate. Remove wiring box

cover.

5. Connect wiring harness to power cable from exterior or in-line

blower. Wire black to black, white to white, and green to green

or bare wire.

6. Replace wiring box cover.

7. Plug the downdraft's power cord into outlet. Make sure that

the power cord is routed away from the heat generated by the

cooktop.

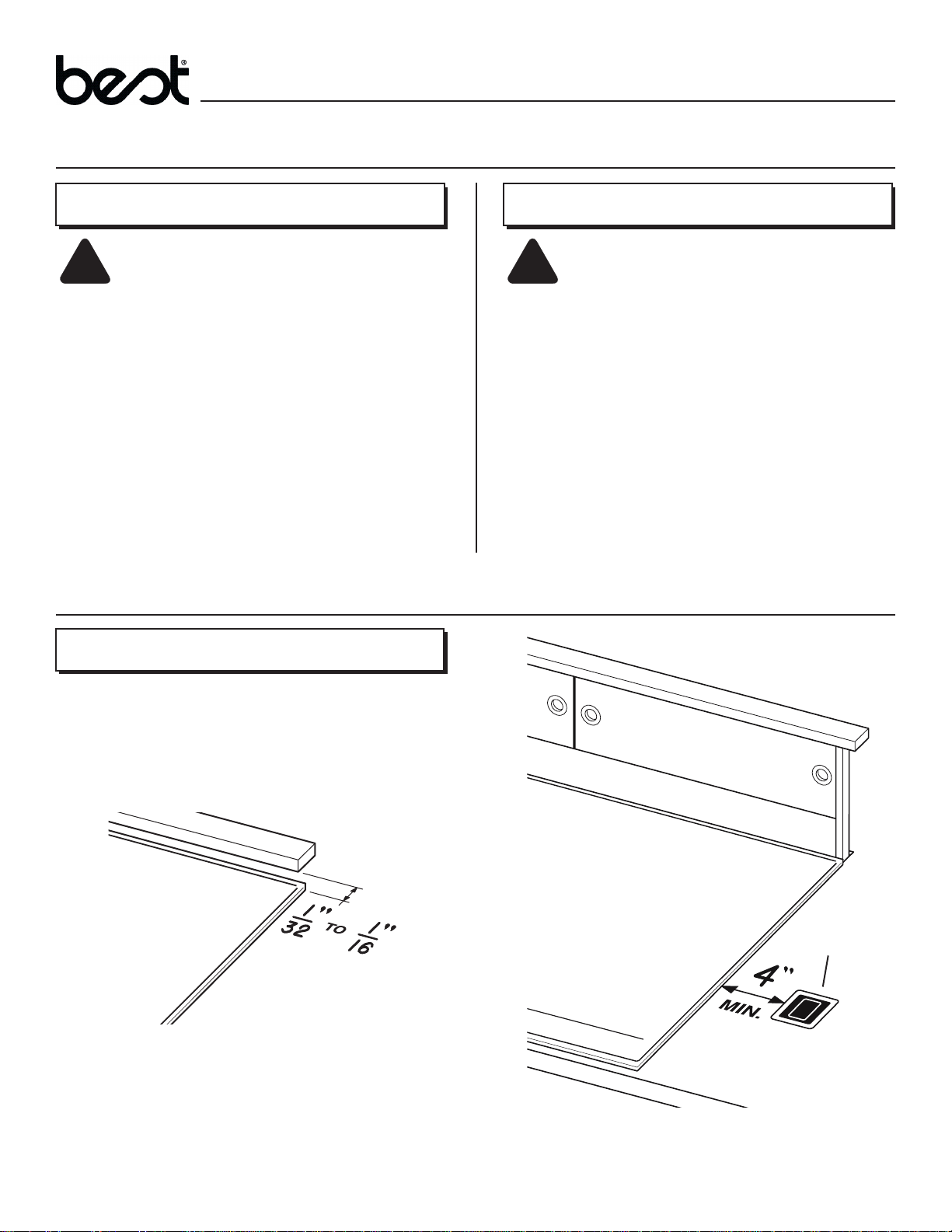

1. Align the cooktop with the downdraft and fasten cooktop in

place.

Note: Accurate alignment of cooktop and downdraft is necessary

to ensure that there is no interference when air vent is raised and

lowered. There should be a gap of 1/32" - 1/16" between the back

of the cooktop and the front of the downdraft cover.

COOKTOP

UP / DOWN

CONTROL

COUNTERTOP

Note:

The downdraft up/down control must be mounted into the coun-

tertop, at least 4" from the cooktop.

Page 9

Downdraft Ventilators

REMOTE UP/DOWN CONTROL INSTALLATION (OPTIONAL)

All Units

When to use the Remote UP/DOWN Control

The Remote UP/DOWN Control should be used when your cooktop

has a burner that is within 4 inches of the UP/DOWN Button on

the downdraft chimney.

The Remote UP/DOWN Control can be used for convenient UP/

DOWN operation of the downdraft chimney (even when a burner

is more than 4 inches from the UP/DOWN Button of the downdraft

chimney).

Page 9

How to use the Remote UP/DOWN Control

Do not place the remote control where it will interfere with cooking, where hot pans could be set, or where hot liquids could be

spilled on the control.

The Remote UP/DOWN Control disables the UP function of the

UP/DOWN Button on the downdraft chimney.

Installation

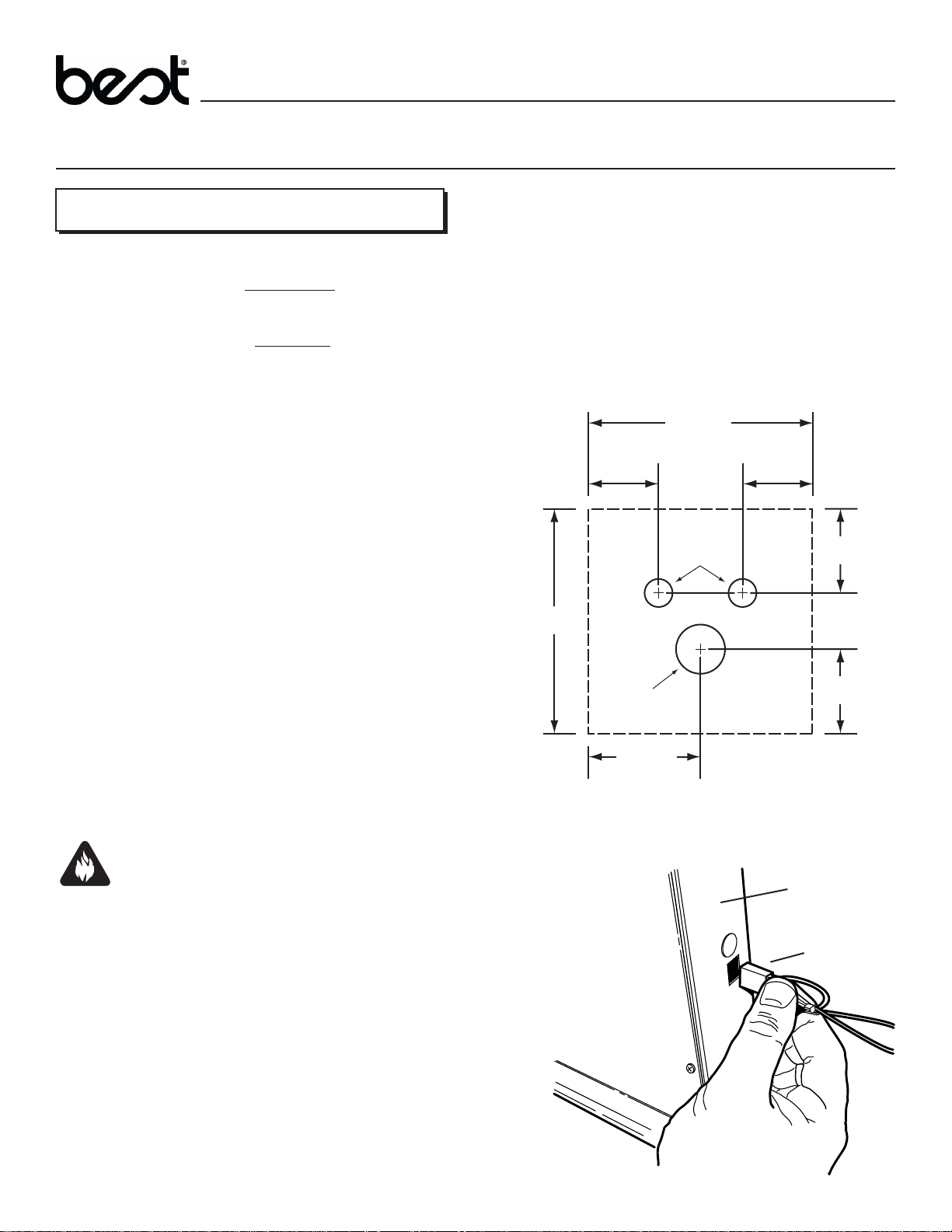

1. Using the template at right, lay out the 3-hole pattern on the

counter top. Mark the centers of the three holes to be drilled.

2. Carefully drill the three holes through the counter top. Be careful

not to damage or chip the counter top surface when drilling

the holes.

3. Remove the control from the plastic bag. Line the control up

with the three holes and position the control so it is parallel

with the front of the counter top.

4. Remove the two nylon thumbnuts from the plastic bag and

thread onto the two studs on the control from below the counter

top. Hand tighten only.

WARNING: To reduce the risk of burns or ignition

of clothing by reaching across burners, the remote

control must be mounted at least 4" away from any

cook top burner.

2.000

2.000

.625

.250 DIA.

HOLES

.438

DIA.

HOLE

1.000

CUT OUT

ON DOTTED LINE

.625

.750

.750

LOWER

RIGHT SIDE

OF DOWNDRAFT

5. Remove cable from the plastic bag and plug into back of control

from below counter top. Route cable through cabinet to lower

right hand corner of downdraft. Plug other end of cable into

the downdraft unit as shown.

6. Stuff excess cable out of the way and secure the cable so it

is not damaged by items stored in the cabinet.

REMOTE

CABLE

CABINET

FLOOR

Page 10

USE AND CARE

All Units

WARNING: Always disconnect electric power

supply before cleaning and/or servicing unit.

Downdraft Ventilators

Page 10

Cleaning

Use a mild detergent suitable for painted surfaces. DO NOT USE

ABRASIVE CLOTH, STEEL WOOL PADS, OR SCOURING POWDERS. Vacuum blower to clean. Do not immerse blower in water.

Wash the 2 aluminum/stainless steel grease filters in a mild detergent solution or a dishwasher. Remove them from the air vent

by grasping the tab at the top of each filter.

Always turn the downdraft blower on before you begin cooking

to establish an air flow in the kitchen. Let the blower run for a few

minutes to clean the air after you turn the cooktop off. This will

keep the whole kitchen cleaner and brighter. The activating switch

is pressed and the air vent rises.

BACKSIDE OF

REMOTE SWITCH

TEMPLATE

Servicing

It may be necessary to remove the downdraft blower system from

the cabinet in order to service components such as the blower

motor or air vent mechanism.

Disconnect power to the cooktop and remove it first. Reverse the

steps under “MOUNT THE UNIT” to remove the downdraft from

the cabinet.

Page 11

Downdraft Ventilators

Page 11

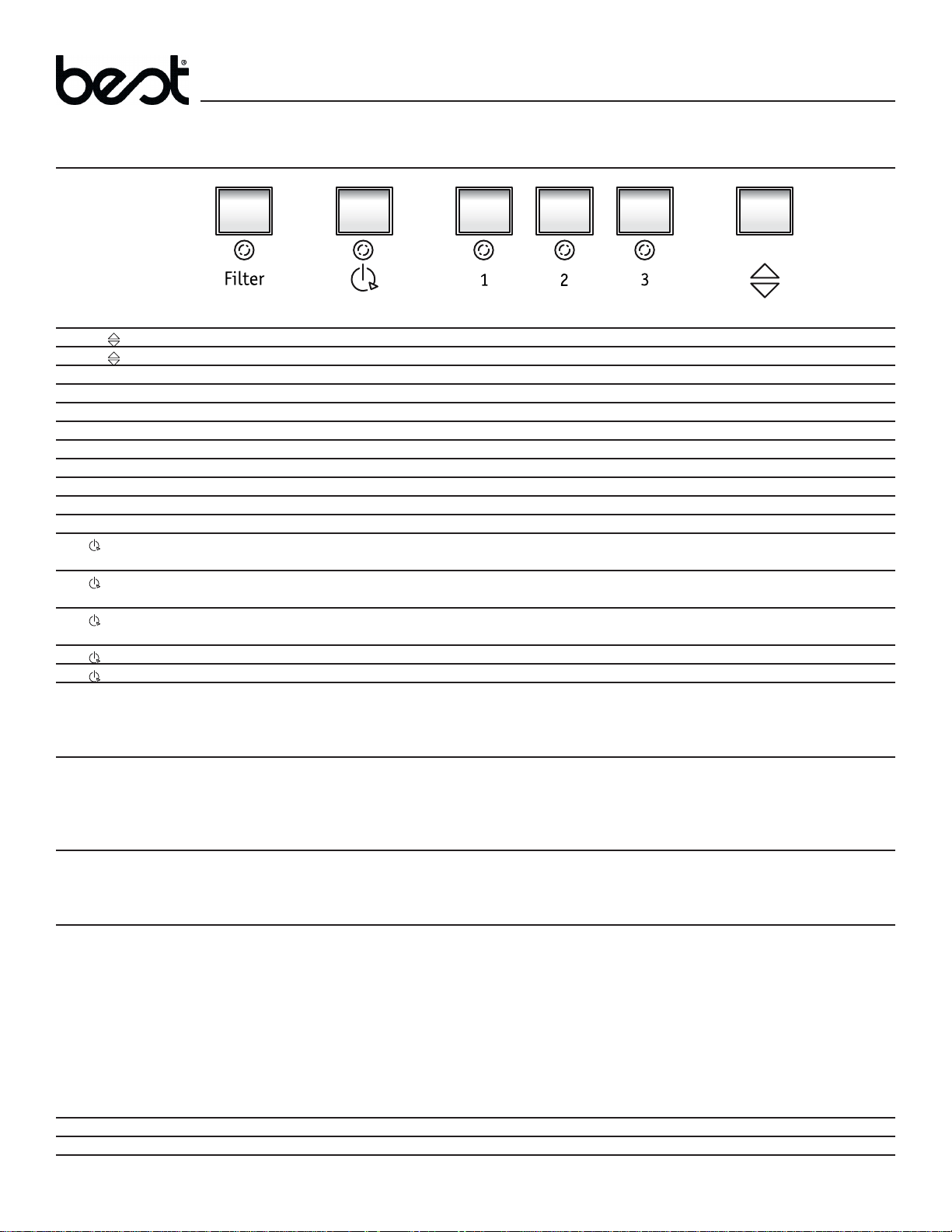

OPERATION

BUTTONS

LED's

ICONS

Press this BUTTON… when CHIMNEY is… and BLOWER is… RESULT

Up/Down Down Off Chimney rises / Blower turns On to last speed used

Up/Down Up On or Off Chimney lowers / Blower turns Off

High [ 3 ] Up On / Low or Med Blower speed to High.

High [ 3 ] Up On / High Blower turns Off / Chimney remains Up

High [ 3 ] Down Off No action

Med [ 2 ] Up On / Low or High Blower speed to Med

Med [ 2 ] Up On / Med Blower turns Off / Chimney remains Up

Med [ 2 ] Down Off No action

Low [ 1 ] Up On / Med or High Blower speed to Low

Low [ 1 ] Up On / Low Blower turns Off / Chimney remains Up

Low [ 1 ] Down Off No action

Delay * Up On / High Blower on High 5 min. > Low 5 min. > Off

Chimney remains Up / Delay LED flashes & Speed LED’s illuminate

Delay * Up On / Med Blower on Med 5 min. > Low 5 min. > Off

Chimney remains Up / Delay LED flashes & Speed LED’s illuminate

Delay * Up On / Low Blower on Low 5 min. > Off (all LED’s Off)

Chimney remains Up / Delay LED flashes & Low LED illuminates

Delay * Up On / in Delay Mode Delay Mode cancelled

Delay * Up or Down Off No action

* Heat Sentry is disabled in Delay mode

When this BUTTON

LED is illuminated… and CHIMNEY is… and BLOWER is… RESULT

Filter Up or Down On or Off Filter LED illuminates as a reminder to clean Filters (approx. every 30

hours).

Pressing Filter Button turns Off illuminated Filter LED and resets Filter-

use timer.

Press this BUTTON… when CHIMNEY is… and BLOWER is… RESULT

Filter Up or Down On or Off Pressing Filter button when Filter LED is not illuminated - No action

When this BUTTON

LED is ashing… and CHIMNEY is… and BLOWER was… RESULT

Med [ 2 ] or High [ 3 ] Up On / Low or Med a. Exhaust temperature is higher than anticipated - Heat Sentry mode

activated. LED flashing b. Blower increases to next highest speed.

c. Blower speed LED flashes on / off.

d. Blower speed may increase, decrease, or stay at current speed based

on exhaust air temperature.

e. When Blower speed returns to original setting - Blower speed LED

stops flashing.

f. Unit no longer in active Heat Sentry mode.

Press this BUTTON

and hold for 1 second… when LED is… and BLOWER is… RESULT

Med [ 2 ] Flashing On / any speed Heat Sentry mode disabled. **

High [ 3 ] Flashing On / any speed Heat Sentry mode disabled. **

** Press any button to re-active Heat Sentry.

Page 12

Downdraft Ventilators

Page 12

SERVICE PARTSWARRANTY

ONE YEAR LIMITED WARRANTY

FOR BEST

Broan-NuTone LLC (Broan-NuTone) warrants to the

original consumer purchaser of BEST

such products will be free from defects in materials

or workmanship for a period of one year from the

date of original purchase. THERE ARE NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, IMPLIED WARRANTIES

OR MERCHANT ABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its

option, repair or replace, without charge, any product

or part which is found to be defective under normal use

and service.

THIS WARRANTY DOES NOT EXTEND TO

FLUORESCENT LAMP STARTERS, TUBES,

HALOGEN AND INCANDESCENT BULBS, FUSE,

FILTERS, DUCTS, ROOF CAPS, WALL CAPS

AND OTHER ACCESSORIES FOR DUCTING. This

warranty does not cover (a) normal maintenance

and service or (b) any products or parts which

have been subject to misuse, negligence, accident,

improper maintenance or repair (other than by BroanNuTone), faulty installation or installation contrary to

recommended installation instructions.

The duration of any implied warranty is limited to the

one-year period as specified for the express warranty.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply

to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR

REPLACE, AT BROAN-NUTONE’S OPTION, SHALL

BE THE PURCHASER’S SOLE AND EXCLUSIVE

REMEDY UNDER THIS WARRANTY. BROANNUTONE SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING

OUT OF OR IN CONNECTION WITH PRODUCT USE

OR PERFORMANCE. Some states do not allow the

exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not

apply to you.

This warranty gives you specific legal rights, and you

may also have other rights, which vary from state to

state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify

Broan-NuTone at the address stated below or telephone

number stated below, (b) give the model number and

part identification and (c) describe the nature of any

defect in the product or part. At the time of requesting

warranty service, you must present evidence of the

original purchase date.

In USA:

®

BEST

, 926 West State Street, Hartford, Wisconsin

53027 800-558-1711

In Canada:

®

BEST

, 550 Bd Lemire, Drummondville, QC J2C 7W9

866-737-7770

www.BestRangeHoods.com

®

PRODUCTS

®

products that

KEY 30N 36N 48N

NO. WIDTH WIDTH WIDTH DESCRIPTION

1 97015866 97015867 97015868 TOP COVER

2 99140195 99140195 99140195 FILTER SPRING

3 99230345 99230345 99230345 POP RIVET

4 97015970 97015971 97015972 CHIMNEY WELDMENT

5 98009357 98009357 98009357 END CAP RH

6 98009358 98009358 98009358 END CAP LR

7 97015973 97015973 97015973 MACHINED CHIMNEY SLIDE

8 98010013 98010013 98010013 MACHINED AIRBOX SLIDE

9 99160421 99160421 99160421 SCREW RHM 10-24 x .375

10 99160419 99160419 99160419 SCREW 10-24 x .375 PH FLHD

11 99271218 99271218 99271218 GROUND WIRE

12 99150471 99150471 99150471 SCREW 10-32 x .500 TYP CA PH

13 97015753 97015754 97015755 FILTER

14 99710032 99710032 99710032 SPACER

15 99111184 99111184 99111184 SLIDE STRIPS

16 97015974 97015975 97015976 AIRBOX WELDMENT

17 99271210 99271210 99271210 CORD SET

18 99400060 99400060 99400060 STRAIN RELIEF BUSHING

19 99271303 99271303 99271303 WIRE HARNESS

20 99271294 99271294 99271294 HEAT SENSOR HARNESS

21 99271289 99271289 99271289 CONTROL BOARD

22 97015674 97015674 97015674 CRANK ASSEMBLY

23 97017023 97017023 97017023 GEAR MOTOR BRACKET

24 97017051 97017047 97017049 GEAR MOTOR KIT INTERNAL

BLOWER MODELS (INCLUDES

ITEM 23 & 27 ON 36N & 48N

MODELS)

97017052 97017048 97017050 GEAR MOTOR KIT EXTERNAL

BLOWER MODELS (INCLUDES

ITEM 23 & 27 ON 36N & 48N

MODELS)

25 97015692 97015692 97015692 REMOTE CONTROL ASSEMBLY

26 98009802 97017024 97017040 FRONT AIRBOX BOTTOM

27 97017057 97017053 97017055 GEAR MOTOR COVER

INTERNAL BLOWER MODELS

97017058 97017054 97017056 GEAR MOTOR COVER

EXTERNAL BLOWER MODELS

28 98008158 98008158 98008158 AIRBOX OPENING COVER

29 98009773 98009773 98009773 AIRBOX CLAMP

30 99260488 99260488 99260488 WHIZ NUT 10-24

31 97017025 97017025 97017025 SCROLL BOX ASSEMBLY

32 98008150 98008150 98008150 SCROLL BOX COVER

33 98008157 98008157 98008157 CAPACITOR CLAMP

34 98008167 98008167 98008167 EXT - SCROLL BOX WELDMENT

35 99080362 99080362 99080362 MOTOR W/CAPACITOR

36 99020247 99020247 99020247 BLOWER WHEEL

37 99100484 99100484 99100484 MOTOR MOUNT ISOLA

38 99260477 99260477 99260477 WHIZ NUT 1/4-20

39 99271293 99271293 99271293 HEAT SENSOR

40 97016974 97016974 97016974 ADAPTOR PLATE

41 98010005 98010005 98010005 OUTLET PLATE

42 99271304 99271304 99271304 WIRE HARNESS

43 99400042 99400042 99400042 STRAIN RELIEF BUSHING

44 97015983 97015983 97015983 USER INTERFACE

TOR

Page 13

SERVICE PARTS

Downdraft Ventilators

Page 13

Page 14

Ventiladores de tiro descendente

MODELO ANCHO VENTILADOR

Página 14

DD0130SS 76,2 cm (30") interior de 500 pcm

DD0136SS 91,4 cm (36") interior de 500 pcm

DD0148SS 122 cm (48") interior de 500 pcm

DDEX30SS 76,2 cm (30") exterior, modelo EB6, EB9, EB12, o EB15 (se compra por separado) o modelo ILB3, ILB6, ILB9, ILB11 en línea

(se compra por separado)

DDEX36SS 91,4 cm (36") exterior, modelo EB6, EB9, EB12, o EB15 (se compra por separado) o modelo ILB3, ILB6, ILB9, ILB11 en línea

(se compra por separado)

DDEX48SS 122 cm (48") exterior, modelo EB6, EB9, EB12, o EB15 (se compra por separado) o modelo ILB3, ILB6, ILB9, ILB11 en línea

(se compra por separado)

ADVERTENCIA. Para reducir el riesgo de quemaduras o que se incendie la ropa al atravesarse sobre de los quemadores, el

control remoto del tiro invertido se DEBE montar en la superficie del gabinete, a una distancia mínima de 10,2 cm (4”) de los

quemadores. Consulte la sección “INSTALE LA ESTUFA” en la página 21.

LEA Y CONSERVE ESTAS INSTRUCCIONES

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS ELÉCTRICAS O

LESIONES PERSONALES OBSERVE LAS SIGUIENTES PRECAUCIONES:

1. Use la unidad sólo de la manera indicada por el fabricante.Si tiene pregun-

tas, comuníquese con el fabricante a la dirección o el número telefónico

que se incluye en la garantía.

2. Antes de dar servicio o limpiar la unidad, interrumpa el suministro eléctrico

en el panel de servicio y bloquee los medios de desconexión del servicio

para evitar que la electricidad se reanude accidentalmente. Cuando no sea

posible bloquear los medios de desconexión del servicio, fije firmemente

en el panel de servicio un dispositivo de advertencia prominentemente

visible, como por ejemplo una etiqueta.

3. Una o más personas calificadas deben realizar el trabajo de instalación

y el cableado eléctrico, de acuerdo con todos los códigos y normas correspondientes, inclusive los códigos y normas de construcción específicos

sobre protección contra incendios.

4. Se necesita suficiente aire para que se lleve a cabo una combustión adec-

uada y para la descarga de los gases a través del tubo de humos (chimenea)

del equipo quemador de combustible a fin de evitar las contracorrientes.

Siga los lineamientos y las normas de seguridad del fabricante del equipo

de calentamiento, como aquellos publicados por la Asociación Nacional de

Protección contra Incendios (National Fire Protection Association, NFPA),

y

la Sociedad

Aire Acondicionado (American Society for Heating, Refrigeration and Air

Conditioning Engineers, ASHRAE), y las autoridades de los códigos locales.

5. Al cortar o perforar a través de la pared o del cielo raso, no dañe el cableado

eléctrico ni otros servicios ocultos.

6. Los ventiladores con conductos siempre se deben conectar hacia el exterior.

7. P a r a reducir el riesgo de incendio, use solamente conductos metálicos.

8. No instale este producto con el conmutador de activación directamente

detrás de un quemador o elemento. La distancia mínima entre el conmutador y el borde del quemador debe ser de 10 cm (4").

9. Cuando se opere este electrodoméstico nunca se debe usar ropa holgada

o colgante. Este tipo de ropa se puede incendiar con los quemadores o

elementos de la estufa.

10. No se debe dejar niños solos o desatendidos en el área en la que se usa

este electrodoméstico.

11. Es ta unidad se debe conectar a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO POR GRASA

EN LA ESTUFA:

a) Nunca deje las unidades de la superficie desatendidas en ajustes altos de

calor. Los alimentos en ebullición causan derrames grasosos y con humo

que se pueden inflamar. Caliente el aceite lentamente en ajustes de calor

bajo o medio.

b) Siempre ENCIENDA la campana cuando cocine a calor

cocine alimentos inflamables.

c) Limpie frecuentemente los ventiladores. No se debe permitir la acumulación

de grasa en el ventilador ni en el filtro.

d) Use una cacerola del tamaño adecuado. Siempre use utensilios de cocina

apropiados para el tamaño del elemento de la superficie.

PARA LA PERSONA QUE REALIZA LA INSTALACIÓN:

Registre su producto en línea en: www.BestRangeHoods.com

Americana de Ingenieros en Calefacción, Refrigeración y

alt

Conserve este manual que lo use el

inspector eléctrico y el propietario.

o o cuando

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES PERSONALES EN EL CASO

DE QUE SE INCENDIE LA GRASA DE LA ESTUFA, OBSERVE LAS

SIGUIENTES PRECAUCIONES

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una charola para

galletas o una bandeja de metal, luego apague el quemador. TENGA

CUIDADO PARA PREVENIR QUEMADURAS. Si las llamas no se apagan

inmediatamente, EVACÚE EL ÁREA Y LLAME AL DEPARTAMENTO DE

BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA, se puede quemar.

3. NO USE AGUA ni toallas húmedas, - ya que provocará una violenta explosión

de vapor.

4. Use un extintor SÓLO si:

A. Sabe que tiene un extintor clase ABC, y ya sabe cómo usarlo.

B. El incendio es pequeño y está confinado en el área en la que se inició.

C. Va a llamar al Departamento de Bomberos.

D. Puede combatir el incendio con la espalda hacia una salida.

a

Basado en “Kitchen Firesafety Tips” (Sugerencias para la seguridad contra

incendios en la cocina) publicado por NFPA.

PRECAUCIÓN

1. Pa ra el use de interior solamente.

2. Sólo para uso en ventilación general. No se use para descargar materiales

o vapores peligrosos o explosivos.

3. Para evitar daños a los cojinetes del motor y rotores ruidosos y/o no

equilibrados, mantenga el rocío de yeso, el polvo de la construcción, etc.

alejado de la unidad de accionamiento.

4. Limpie frecuentemente los filtros y las superficies con grasa.

5. No repare ni reemplace ninguna pieza de est

que así se recomiende específicamente en este manual. Todas las demás

operaciones de servicio las debe realizar un técnico calificado.

6. Por favor lea la etiqueta de especificaciones que tiene el producto para

ver información y requisitos adicionales.

7. P a r a reducir el riesgo de incendios y descargas eléctricas, instale este

ventiladore de tiro descendente solamente con ventiladores de Best by

Broan demostrado abajo. Otros modelos del ventilador no pueden se

substituidos. (Ventiladores vendidos por separado).

MODELO ANCHO VENTILADOR

DD0130SS 76,2 cm (30") interior de 500 pcm

DD0136SS 91,4 cm (36") interior de 500 pcm

DD0148SS 122 cm (48") interior de 500 pcm

DDEX30SS 76,2 cm (30") exterior, modelo EB6, EB9, EB12, o EB15

DDEX36SS 91,4 cm (36") exterior, modelo EB6, EB9, EB12, o EB15

DDEX48SS 122 cm (48") exterior, modelo EB6, EB9, EB12, o EB15

(se compra por separado) o modelo

ILB3, ILB6, ILB9, ILB11 in-line (se compra

por separado)

(se compra por separado) o modelo ILB3,

ILB6, ILB9, ILB11 in-line (se compra por

separado)

(se compra por separado) o modelo ILB3,

ILB6, ILB9, ILB11 in-line (se compra por

separado)

a

:

!

e electrodoméstico a menos

Page 15

PLANIFICACIÓN

Ventiladores de tiro descendente

Página 15

Instalación del ventilador interior

El sistema de ventilación de tiro

descendente está diseñado para

descargar los contaminantes

transportados por el aire cuando

se cocina en una variedad de

estufas a gas o eléctricas. Se

puede montar en unidades de

isla, península o convencionales

de la pared.

Esta unidad se puede instalar

fácilmente siguiendo estos pasos

básicos:

Haga la abertura en la

•

superficie del gabinete.

Monte la unidad en el gabi-

•

nete.

Conecte los conductos y el

•

sistema eléctrico.

Instale la estufa.

•

Nota: el flujo de aire de alto

nivel de este electrodoméstico

puede afectar la llama de gas

en algunos tipos de estufas

a gas. Esto es NORMAL y no

causará daño, pero se puede

corregir reduciendo la velocidad

del ventilador.

INSTALACIÓN TÍPICA

SUPERFICIE DEL

GABINETE

ESTUFA

CUBIERTA DEL

MOTOR DE

ENGRANAJE

SISTEMA DE

VENTILACIÓN

CONECTADOR DE

CONDUCTO DE

3-1/4" X 10"

ESPECIFICACIONES

ELÉCTRICAS

120 VCA • 60 Hz • 4.0 A

PARTE SUPERIOR

DE LA CHIMENEA

TOMACORRIENTE

DE 120 VCA

CONECTADA

A TIERRA

CAJA DEL

VENTILADOR

Instalación del ventilador exterior o en línea

Este sistema de ventilación de

tiro descendente está diseñado

para descargar contaminantes

transportados por el aire

cuando se cocina en una

variedad de estufas a gas y

eléctricas. Se puede montar

en unidades de isla, península

o convencionales de la pared.

Esta unidad se puede instalar

fácilmente siguiendo estos

pasos básicos:

Haga la abertura en la

•

superficie del gabinete.

Monte la unidad en el

•

gabinete.

Instale el ventilador ex-

•

terno modelo EB6, EB9,

EB12, EB15 o ILB3, ILB6,

ILB9, IB11 ventilador en

línea.

Conecte los conductos y el

•

sistema eléctrico.

Instale la estufa.

•

Nota: el flujo de aire de alto nivel de este electrodoméstico puede

afectar la llama de gas en algunos tipos de estufas a gas. Esto es

NORMAL y no causará daño, pero se puede corregir reduciendo la

velocidad del ventilador.

INSTALACIÓN TÍPICA

PARTE SUPERIOR

SUPERFICIE DEL

GABINETE

CUBIERTA DEL

MOTOR DE

ENGRANAJE

SISTEMA DE

VENTILACIÓN

DE LA CHIMENEA

ESTUFA

CAJA DEL

VENTILADOR

TOMACORRIENTE

DE 120 VCA

CONECTADA

A TIERRA

CONECTADOR DE

CONDUCTO DE

3-1/4" X 14"

ESPECIFICACIONES

ELÉCTRICAS

120 VCA • 60 Hz • 6.0 A (máx.)

TOME MEDIDAS

Todas las unidades

1. Consulte las instrucciones de instalación de la estufa para ver las

dimensiones de la estufa, la abertura en la superficie del gabinete

y los requerimientos del gabinete. Los modelos DD0130SS y

DDEX30SS cabrán en la mayoría de los gabinetes de 76,2 cm

(30") de ancho. Los modelos DD0136SS y DDEX36SS cabrán en la

mayoría de los gabinetes de 91,4 cm (36") de ancho. Los modelos

DD0148SS y DDEX48SS cabrán en la mayoría de los gabinetes

de 122 cm (48") de ancho. Sin embargo, se recomienda que se

usen gabinetes de mayor tamaño para facilitar la instalación.

2. La profundidad de las diferentes estufas varía grandemente. Esto

puede ocasionar que estos dos electrodomésticos queden muy

ajustados.

Preste atención especial a las áreas de posible interferencia que se

indicaron anteriormente. Es posible que un gabinete que tenga (A)

un reborde elevado y/o (B) un protector contra salpicaduras no tenga

suficiente superficie plana para realizar una instalación adecuada.

Note que el gabinete necesita tener una superficie plana de 5,08 cm

(2") en detrás de la estufa, y que se requiere una distancia 4,45 cm

(1-3/4") entre el borde posterior de la estufa y el interior de la parte

posterior del gabinete.

4,45 cm (13/4")

5,08 cm (2")

SUPERFICIE DEL GABINETE

ESTUFA

TIRO DESCENDENTE

PROFUNDIDAD DEL INTERIOR

DEL GABINETE DEL FRENTE

HACIA ATRÁS

Page 16

TOME MEDIDAS (CONTINUACIÓN)

Ventiladores de tiro descendente

Página 16

Instalación del ventilador interior

5 cm (2")

Instalación del ventilador exterior o en línea

2"

1

"

7 mm

4

(1/4")

1

"

5,4 cm

2

8

(2-1/8")

5

74,6 cm (29-5/16")

"

29

DESDE LA

16

SUPERFICIE DEL

FROM

GABINETE HASTA LA

COUNTERTOP

PARTE INFERIOR DE

TO BOTTOM

LA CAJA DE AIRE

OF AIR BOX

VISTA LATERAL

DEL TIRO

DESCENDENTE

VISTA LATERAL

DEL TIRO

DESCENDENTE

19,5 cm

(7-11/16")

7

9,2 cm

3

(3-5/8")

45,7 cm

18"

(18")

0,95 cm

1"

(3/8")

11

"

8,2 cm

16

(3-1/4")

1

"

3

4

5

"

8

12,7

5"

cm

(5")

VIDV500

INTERNAL

BLOWER

PLANEE EL SISTEMA DE CONDUCTOS

Instalación del ventilador interior

1. E l sistema de ventilación de tiro descendente interior está

diseñado para usarse

con conductos de 8,3

cm x 25,4 cm (3¼" x

10") (puede hacerse

una transición a un

conducto redondo de

15,3 cm (6”)) Están

disponibles tres direcciones diferentes de

descarga con ajuste

de lado a lado para la

alineación adecuada del

sistema de conductos.

2. Para obtener el mejor

rendimiento: Seleccione

el sistema de conductos

de la longitud más corta

y un número mínimo de codos y transiciones. Revise el área de la

instalación para asegurarse de que no haya interferencia de vigas

del piso, montantes de la pared, cableado eléctrico o tuberías.

CODO REDONDO

DE 15,3 cm (6")

EQUIVALE A 2,4 m

(8 PIES) DE

CONDUCTO RECTO

3. El sistema funcionará de manera más eficiente cuando los conductos

no excedan el equivalente a 12,2 m(40 pies) de longitud. La tabla de

arriba muestra la longitud equivalente en pies de codos y transiciones. El número de pies de conducto recto más la longitud equivalente

en pies de transiciones y/o codos que se use debe ser de 12,2 m (40

pies) o menos.

NOTA: Se ha tomado en consideración la longitud equivalente en

pies de varias tapas de techo y pared. No las incluya en este cálculo.

DESCARGA

DERECHA

TRANSICIÓN

REDONDA DE

8,3cm x

25,4cm (3¼"

x 10") A 6"

EQUIVALE

A 0, 61 m

(2 PIES) DE

CONDUCTO

RECTO

DESCARGA

IZQUIERDA

DESCARGA

DESCENDENTE

CODO DE 90°

DE 8,3 cm x 25,4

cm (3¼"

x10")

EQUIVALE A 4,3 m

(14 PIES) DE

CONDUCTO RECTO

Instalación del ventilador exterior o en línea

1. E l sistema de ventilación

de tiro descendente interior está diseñado para

usarse con conductos de

8,3 cm x 35,6 cm (3¼" x

14") (puede hacerse una

transición a un conducto

redondo de 20,3 o 25,4

cm (8” o 10")) Están disponibles tres direcciones

diferentes de descarga

con ajuste de lado a

lado para la alineación

adecuada del sistema de

conductos.

2. Para obtener el mejor

rendimiento: Seleccione

el sistema de

conductos de la longitud

más corta y un número

mínimo de codos y transiciones. Revise el área de la instalación

para asegurarse de que no haya interferencia de vigas del piso,

montantes de la pared, cableado eléctrico o tuberías.

CODO REDONDO

DE 20,3 cm (8")

EQUIVALE A 3,4 m

(11 PIES) DE

CONDUCTO RECTO

3. El sistema funcionará de manera más eficiente cuando los conductos

no excedan el equivalente a 12,2 m (40 pies) de longitud. La tabla de

arriba muestra la longitud equivalente en pies de codos y transiciones. El número de pies de conducto recto más la longitud equivalente

en pies de transiciones y/o codos que se use debe ser de 12,2 m (40

pies) o menos.

NOTA: Se ha tomado en consideración la longitud equivalente en

pies de varias tapas de techo y pared. No las incluya en este cálculo.

5 cm (2")

0,95 cm

1"

(3/8")

19,5 cm

11

"

7

16

9,2 cm

5

3

(3-5/8")

8

45,7 cm

18"

(18")

3

"

8,2 cm

(3-1/4")

1

"

4

12,7

5"

cm

(5")

VIDV500

INTERNAL

BLOWER

(7-11/16")

DESCARGA

DERECHA

TRANSICIÓN

REDONDA DE 8,3 cm x

35,6 cm

(3¼" x 14")

A 20,3 cm

(8")

EQUIVALE

A 1,5 m (5 PIES) DE

CONDUCTO RECTO

2"

1

"

7 mm

4

(1/4")

1

"

5,4 cm

2

8

(2-1/8")

5

74,6 cm (29-5/16")

"

29

DESDE LA

16

SUPERFICIE DEL

FROM

GABINETE HASTA LA

COUNTERTOP

PARTE INFERIOR DE

TO BOTTOM

LA CAJA DE AIRE

OF AIR BOX

DESCARGA

IZQUIERDA

DESCARGA

DESCENDENTE

CODO DE 90°

DE 8,3 cm x 35,6

cm (3¼"

x 14")

EQUIVALE A 5,8 m

(19 PIES) DE

CONDUCTO RECTO

Page 17

Ventiladores de tiro descendente

PLANEE LAS ABERTURAS DEL GABINETE

Instalación del ventilador

!

PRECAUCIÓN:

ANTES DE HACER LA ABERTURA

EN EL GABINETE PARA EL

SISTEMA DE CONDUCTOS, revise

que no exista la interferencia de

vigas del piso, montantes de la

pared, cableado eléctrico ni tubería.

DESCARGA

INFERIOR

LÍNEAS

CENTRALES

CENTER

DEL CORTE

LINES OF

PARA EL

DUCT CUTOUT

CONDUCTO

CORTE DE

10¼" x 3½"

26 CM x 8,9 CM

(10¼” x 3½”) (36,2

(14¼” x 3½”) PARA

CUTOUT

(14¼" x 3½"

CM x 8,9 CM

VENTILADORES

EXTERIORES O

FOR

EXTERNAL

BLOWER)

EN LÍNEA)

56,2 CM

(221/ 8")

22

1

/

(19"

(48,3 CM

8

"

FOR

EXTERNAL

(19") PARA

VENTILADORES

BLOWER)

EXTERIORES

O EN LÍNEA)

14 CM (5½")

(10,8 CM (4¼")

PARA VENTILA-

DORES EXTE-

EXTERNAL

RIORES O EN

BLOWER)

5½"

(4¼" FOR

LÍNEA)

Página 17

DESCARGA

DE LADO

IZQUIERDO

LÍNEA CENTRAL

CENTER LINE

DEL CORTE DEL

OF COUNTER

GABINETE

CUTOUT

LÍNEA CENTRAL DEL

CENTER LINE

CORTE DEL GABINETE

OF COUNTER

CUTOUT

12,7 CM (5")

MAX. PARA VENTILA-

(5" MAX.

DORES EXTERIORES O

EN LÍNEA

FOR EXTERNA

BLOWER)

LÍNEA CENTRAL

DEL CORTE PARA

EL CONDUCTO

CENTER LINE

OF DUCT

CUTOUT

LADORES EXTERIORES O EN

CORTE DE

26 CM X 8,9 CM

10¼" x 3½"

(10¼” x 3½”)

CUTOUT

(36,2 CM X 8,9 CM

(14¼” x 3½”) PARA VENTI-

LÍNEA)

0,6 CM A

19,7 CM

¼" to 7¾"

(¼" A 7¾")

(2½" MAX.

6,4 CM (2½")

FOR

MAX. PARA

EXTERNAL

L

VENTILADORES

BLOWER)

EXTERIORES

O EN LÍNEA

DESCARGA

14 CM (5½”)

5½"

(10,8 CM (4¼”)

PARA

(4¼" FOR

EXTERNAL

RIORES

VENTILADORES EXTE-

BLOWER)

O EN LÍNEA)

LÍNEA CENTRAL

CENTER LINE

DEL CORTE DEL

OF COUNTER

GABINETE

CUTOUT

41,6 CM

"

3

8

/

(16 -3/ 8")

16

(21½" FOR

(54,6 CM (21½”)

EXTERNAL

PARA VENTILADO-

BLOWER)

RES EXTERIORES

O EN ÍNEA)

5½"

14 CM (5½”)

(4¼" FOR

(10,8 CM (4¼”) PARA

EXTERNAL

VENTILADORES

BLOWER)

EXTERIORES

O EN LÍNEA)

DEL LADO

DERECHO

LÍNEAS

CENTRALES

CENTER

DEL CORTE

LINES OF

PARA EL

DUCT

CONDUCTO

CUTOUT

10¼" x 3½"

CORTE DE

CUTOUT

26 CM X 8,9 CM

(14¼" X 3½"

(10¼” x 3½”)

(36,2 CM X 8,9

FOR

CM (14¼” x 3½”)

EXTERNAL

PARA VENTILA-

BLOWER)

DORES EXTERIORES O EN LÍNEA)

Page 18

PLANEE EL CABLEADO ELÉCTRICO

Ventiladores de tiro descendente

Página 18

Instalación del ventilador interior

1. El sistema de ventilación de tiro descendente interior requiere

4 AMPERIOS y un circuito de 120 VCA y 60 Hz.

2. La unidad tiene un cordón eléctrico de 45,7 cm (18") con una

clavija de tres patas. Planee colocar un tomacorriente con

conexión a tierra en un lugar que el cordón eléctrico de la

unidad pueda alcanzar.

IMPORTANTE: UBICACIÓN DEL TOMACORRIENTE

ELÉCTRICO:

Si el modelo DD0130SS se va a instalar en un gabinete de 76,2

cm (30”) de ancho…cabinet...

o el modelo DD0136SS se va a instalar en un gabinete

de 91,4 cm (36”) de ancho…

o el modelo DD0148SS se va a instalar en un gabinete

de 122 cm (48”) de ancho…

...el tomacorriente no se puede instalar en la pared

posterior del gabinete.

En estos casos, la anchura del tiro descendente cubre casi la

totalidad de la anchura de la pared posterior del gabinete. Debe

hacer cualquiera de lo siguiente:

• montar la caja eléctrica en una pared lateral o en

el piso del gabinete

- a una distancia mínima de 30 cm (12") de la pared posterior.

• montar la caja eléctrica al montante de la pared que está

detrás del gabinete, en donde no quedará cubierto

por el tiro descendente. Luego proporcione un orificio de

separación en la pared posterior del gabinete.

1. El sistema de ventilación de tiro descendente exterior o en línea

2. La unidad tiene un cordón eléctrico de 45,7 cm (18") con una

Si el modelo DDEX30SS se va a instalar en un gabinete de 76,2

o el modelo DDEX36SS se va a instalar en un gabinet de

o el modelo DDEX48SS se va a instalar en un gabinete de

122 cm (48”) de ancho…

...el tomacorriente no se puede instalar en la pared

posterior del gabinete.

En estos casos, la anchura del tiro descendente cubre casi la

• montar la caja eléctrica en una pared lateral o en

- a una distancia mínima de 30 cm (12") de la pared posterior.

• montar la caja eléctrica al montante de la pared que está

e n la pared

PREPARE EL TIRO DESCENDENTE

Instalación del ventilador exterior o en línea

requiere 6 AMPERIOS y un circuito de 120 VCA y 60 Hz.

clavija de tres patas. Planee colocar un tomacorriente con conexión a tierra en un lugar que el cordón eléctrico de la unidad

pueda alcanzar.

IMPORTANTE: UBICACIÓN DEL TOMACORRIENTE

ELÉCTRICO:

cm (30”) de ancho…cabinet...

91,4 cm (36”) de ancho…

totalidad de la anchura de la pared posterior del gabinete. Debe

hacer cualquiera de lo siguiente:

el piso del gabinete

detrás del gabinete, en donde no quedará cubierto por el tiro

descendente. Luego proporcione un orificio de separación

posterior del

gabinete.

Instalación de la conexión del conducto (todos los ventiladores)

El tiro descendente se envía con el conectador del conducto

orientado hacia el fondo de la unidad. Si desea cambiar esta

orientación siga los pasos que se indican a continuación:

1. Coloque el tiro descendente sobre su parte posterior sobre

una mesa o una superficie de trabajo plana.

2. Quite las 4 tuercas y los 2 canales de sujeción.

3. Quite 2 tornillos y la cubierta del motor de engranaje.

4. Cuidadosamente coloque el ventilador debajo del reborde

inferior del tiro descendente con la descarga de 8,3 x 25,4

cm (3¼" x 10") (8,3 x 35,6 cm (3¼" x 14") para ventiladores

exteriores o en línea) orientada hacia la dirección deseada.

5. Conecte el enchufe del motor.

6. Vuelva a colocar la cubierta del motor de engranaje y los 2

tornillos autorroscantes.

7. Vuelva a colocar los 2 canales de sujeción y apriete ligeramente

las 4 tuercas, no las apriete totalmente.

8. Deslice el ventilador a la izquierda o a la derecha hasta la

posición deseada. Use la placa de cubierta (suministrada)

para cerrar cualquier espacio abierto.

9. Apriete las 4 tuercas para fijar la parte superior del ventilador.

Coloque tornillos adicionales (se suministran) a través del

reborde inferior para fijar la parte inferior en el ventilador.

DESCARGA DE 8,3 x 25,4 cm (3¼” X 10") (8,3 x 35,6 cm

(3¼” X 14") PARA VENTILADORES EXTERIORES O EN LÍNEA)

TORNILLOS

VENTILADOR

CANALES DE

FIJACIÓN

TUERCAS

CUBIERTA DEL

MOTOR DE

ENGRANAJE

ENCHUFE DEL

MOTOR

REBORDE

INFERIOR

PLACA DE

CUBIERTA

TORNILLOS

ADICIONALES

Page 19

Ventiladores de tiro descendente

HAGA LA ABERTURA DE LA SUPERFICIE DEL GABINETE

Todas las unidades

1. Trace y haga el corte para la estufa lo suficientemente HACIA

DELANTE como para que el tiro descendente quepa detrás de

la estufa.

2. Coloque la estufa en su lugar y deslícela tan adelante como sea

posible. Céntrela y escuádrela con los bordes de la superficie del

gabinete.

Página 19

3. Coloque la plantilla de plástico contra el reborde posterior de la

estufa y céntrela. Trace alrededor de la plantilla para marcar la

abertura del tiro descendente.

4. Quite la estufa de la superficie del gabinete.

5. Haga la abertura del tiro descendente. Tenga cuidado de no astillar

los bordes de la superficie del gabinete.

Page 20

MONTE LA UNIDAD

!

Ventiladores de tiro descendente

Página 20

Todas las unidades

1. Coloque el tiro descendente en la abertura. Extienda los soportes de

nivelación al piso del gabinete para que el tiro descendente quede

recto. (Nota: Los soportes de nivelación se pueden quitar y volver

a poner en otra posición. Es posible que el reborde inferior deba

quedar orientado hacia el interior en instalaciones muy ajustadas en

los gabinetes.)

2. Fije el tiro descendente en la superficie del gabinete de la siguiente

manera: Sujete el tiro descendente contra la parte posterior de la

abertura de la superficie del gabinete y apriete los dos tornillos de

montaje (uno en cada extremo de la unidad) en la parte interna de

la superficie del gabinete. Coloque una cuña de madera entre el

tornillo y la parte interior de superficies de gabinete de granito.

3. Atornille los soportes de nivelación en la parte inferior del gabinete.

Apriete los tornillos que fijan los soportes de nivelación a la unidad

en cada lado.

SOPORTE DE NIVEL-

ACIÓN, REBORDE ORI-

ENTADO HACIA AFUERA

SOPORTE DE NIVEL-

ACIÓN, REBORDE

ORIENTADO HACIA

ADENTRO

INSTALE EL SISTEMA DE CONDUCTOS

Instalación del ventilador

TORNILLOS DE MON-

TAJE

ANTES DE HACER LA ABERTURA

PRECAUCIÓN:

EN EL GABINETE PARA EL

SISTEMA DE CONDUCTOS, revise

que no exista la interferencia de

vigas del piso, montantes de la

pared, cableado eléctrico ni tubería.

1. Haga el orificio en el gabinete así como los orificios en la pared o el

piso según sea necesario.

2. Monte la tapa de techo o de pared y trabaje hacia atrás, hacia el

gabinete, conectando todos los conductos, codos y transiciones

como se planeó previamente. Encinte todas las conexiones de

los conductos para fijarlas y hacerlas herméticas al aire.

3. Conecte el sistema de conductos (y las transiciones, si se requieren) al tiro descendente. Si es necesario, AFLOJE las tuercas

y los tornillos que fijan el ventilador en su lugar, y deslice el

ventilador hacia la izquierda o hacia la derecha para que se una

con los conductos. Vuelva a apretar los tornillos y las tuercas.

Nota: Se proporciona un collar de 8,3 x 25,4 cm (3¼" x 10") (un collar

de 8,3 x 35,6 cm (3¼" x 14") para ventiladores exteriores o en

lÍnea) para los instaladores que prefieran remachar los conductos a la

unidad. Esto permitirá que el ventilador se quite y reemplace fácilmente

en situaciones de servicio sin alterar el sistema de conductos.

VENTILADOR

COLLAR

TORNILLOS

TRANSICIÓN

REDONDA DE 8,3

x 25,4 cm (3¼" x

10") A 15,2 cm (6").

(TRANSICIÓN

REDONDA DE

8,3 x 35,6 cm

(3¼" x 14") A 20,3

cm (8") PARA

VENTILADORES

EXTERIORES O

EN LÍNEA)

CODO REDONDO

DE 15,2 cm (6").

(20,3 cm

(8") PARA

VENTILADORES

EXTERIORES)

Page 21

INSTALE EL CABLEADO ELÉCTRICO

Ventiladores de tiro descendente

Página 21

Instalación del ventilador interior

PRECAUCIÓN: Una o más personas calificadas deben

realizar el trabajo de cableado eléctrico, de acuerdo

!

con todos los códigos y normas correspondientes.

1. Monte una caja de cableado estándar, con un receptáculo para

tres patas, dentro del gabinete. Asegúrese de que esté al alcance

del cordón eléctrico.

2. Tienda el cable eléctrico apropiado en el gabinete y conéctelo en

el receptáculo.

3. Conecte el cordón eléctrico del tiro descendente en el tomacorriente. Asegúrese de que el cordón eléctrico esté tendido lejos

del calor generado por la estufa.

!

INSTALE LA ESTUFA

Todas las unidades

Instalación del ventilador exterior o en línea

PRECAUCIÓN: Una o más personas calificadas deben

realizar el trabajo de cableado eléctrico, de acuerdo

!

con todos los códigos y normas correspondientes.

1. Monte una caja de cableado estándar, con un receptáculo para

tres patas conectado a tierra, dentro del gabinete. Asegúrese de

que esté al alcance del cordón eléctrico de la unidad.

2. Tienda el cable eléctrico apropiado en el gabinete y conéctelo en

la caja eléctrica y en el receptáculo

3. La capacidad nominal del ventilador exterior no puede exceder

o en línea 6.0 amperios.

4. Tienda un cable eléctrico de dos hilos y conexión a tierra desde

el ventilador exterior o en línea hasta la caja de cableado en una

placa adaptadora. Quite la cubierta de la caja del cableado.

5. Conecte el colector de cables al cable eléctrico desde el ventilador

exterior o en línea. Conecte negro con negro, blanco con blanco

y verde con verde o con el hilo desnudo.

6. Vuelva a colocar la cubierta de la caja.

7. Conecte el cordón eléctrico del tiro descendente en el tomacorriente. Asegúrese de que el cordón eléctrico esté tendido lejos

del calor generado por la estufa.

1. Alinee la estufa con el tiro descendente y fije la estufa en su lugar.

Nota: Es necesario alinear exactamente la estufa y el tiro descendente

para asegurarse de que no haya interferencia cuando el sistema de

ventilación se eleve o baje. Debe haber una distancia de 1 a 2 mm

(1/32" a 1/16") entre la parte posterior de la estufa y la parte frontal

de la cubierta del tiro descendente.

0,8 mm

(1/32")

à

1,6 mm

(1/16")

ESTUFA

CONTROL DE

ELEVACIÓN /

10 cm

DESCENSO

(4")

MÍN

SUPERFICIE

DEL GABINETE

Nota:

El control de ascenso/descenso del tiro descendente debe montarse

en la supercie del gabinete, a una distancia mínima de 10 cm (4”)

de la estufa.

Page 22

Ventiladores de tiro descendente

Página 22

INSTALACIÓN DEL CONTROL REMOTO DE ASCENSO/DESCENSO (OPCIONAL)

Todas las unidades

Cuándo usar el control remoto de ASCENSO/DESCENSO

El control remoto de ASCENSO/DESCENSO se debe usar cuando

la estufa tiene un quemador que está a una distancia de 4 pulgadas

o menos del botón de ASCENSO/DESCENSO de la chimenea del

tiro descendente.

El control remoto de ASCENSO/DESCENSO se puede usar para

el ASCENSO/DESCENSO conveniente de la chimenea del tiro

descendente (aún cuando un quemador esté a una distancia mayor

de 4 pulgadas del botón de ASCENSO/DESCENSO de la chimenea

del tiro descendente.

2.000

Cómo usar el control remoto de ASCENSO/DESCENSO

No coloque el control remoto en un lugar en el que interfiera con

sus actividades en la estufa, en donde se vayan a colocar cacerolas

calientes, ni en donde se puedan derramar líquidos calientes sobre

el control.

El control remoto de ASCENSO/DESCENSO desactiva la función

de ASCENSO del botón de ASCENSO/DESCENSO de la chimenea

del tiro descendente.

1,59 CM

.625

(5/8")

5,1 CM

(2")

ORIFICIOS

.250 DIA.

DE 6,35 MM

(0,250 PO)

HOLES

1,59 CM

(5/8")

.625

1,91 CM

.750

(3/4")

Instalación

1. Usando la plantilla que aparece a la derecha, trace el patrón de tres

orificios en el gabinete. Marque el centro de los tres orificios que se

van a hacer.

2. Cuidadosamente haga con un taladro los tres orificios en la

superficie del gabinete. Tenga cuidado de no dañar ni astillar la

superficie del gabinete cuando haga los orificios.

3. Saque el control de la bolsa de plástico. Alinee el control con los

tres orificios y colóquelo de manera que quede paralelo con la

parte frontal de la superficie del gabinete.

4. Saque las dos tuercas de mariposa de nilón de la bolsa de plástico

y enrósquelas en los dos pernos del control desde debajo del

gabinete. Apriete las tuercas sólo con los dedos.

ADVERTENCIA: Para reducir el riesgo de quemadoras

o de que se incendie la ropa al tratar de atravesarse

sobre los quemadores, el control remoto se debe

montar a una distancia mínima de 10 cm (4”) de

cualquier quemador de la estufa.

5. Saque el cable de la bolsa de plástico y enchúfelo en la parte

posterior del control desde abajo del gabinete. Tienda el cable

a través del gabinete hasta la esquina inferior derecha del tiro

descendente. Conecte el otro extremo del cable en la unidad del

tiro descendente como se muestra.

6. Acomode el exceso de cable donde no estorbe y fije el cable para

que no resulte dañado por los artículos que se almacenan en el

gabinete.

5,1 CM

2.000

(2")

.438

ORIFICIOS

DE

DIA.

11,13 MM

(0,438")

HOLE

1.000

2,54 CM

(1")

RECORTE SOBRE

LA LÍNEA PUNTEADA

1,91 CM

.750

(3/4")

LADO DERECHO

INFERIOR

DEL TIRO

DESCENDENTE

CABLE

REMOTO

PISO DEL

GABINETE

Page 23

USO Y CUIDADO

Todas las unidades

ADVERTENCIA: Siempre desconecte el suministro

eléctrico antes de limpiar y/o dar servicio a la unidad.

Siempre encienda el ventilador del tiro descendente antes de comenzar a

cocinar para establecer un flujo de aire en la cocina. Después de apagar

la estufa, deje que el ventilador funcione durante unos minutos para

limpiar el aire de la cocina. Así mantendrá toda la cocina más limpia y

brillante. El conmutador de activación se presiona y el sistema de

ventilación se eleva.

Ventiladores de tiro descendente

Página 23

Limpieza

Use un detergente suave adecuado para superficies pintadas. NO

USE PAÑOS ABRASIVOS, ALMOHADILLAS DE LANA DE ACERO NI

POLVOS ABRASIVOS. Limpie por aspiración. No sumerja el ventilador

en agua.

Lave los dos filtros de aluminio/acero inoxidable, para grasa, en una

solución suave de detergente o en el lavaplatos. Sáquelos del sistema

de ventilación sujetando la lengüeta que se encuentra en la parte

superior de cada filtro.

Servicio

Es posible que sea necesario quitar el sistema de ventilación de tiro

descendente del gabinete para dar servicio a componentes tales como

el motor del ventilador o el mecanismo del sistema de ventilación.

Desconecte el suministro eléctrico a la estufa y primero quítela. Invierta

los pasos contenidos en la sección “MONTE LA UNIDAD” para quitar

el tiro descendente del gabinete.

PARTE

POSTERIOR DE

LA PLANTILLA DEL

CONMUTADOR

REMOTO

Page 24

OPERACIÓN

BOTONES

LED

Ventiladores de tiro descendente

Página 24

ICONOS

Presione este BOTÓN... cuando la CHIMENEA esté.. y el VENTILADOR esté... RESULTADO

Ascenso/Descenso Abajo Apagado La chimenea se eleva / El ventilador se enciende a la última velocidad usada

Ascenso/Descenso Arriba Encendido o apagado La chimenea desciende / El ventilador se apaga

Alto [3] Arriba Encendido / Bajo o medio La velocidad del ventilador cambia a alta.

Alto [3] Arriba Encendido / Alto El ventilador se apaga / La chimenea permanece arriba

Alto [3] Abajo Apagado No pasa nada

Med [ 2 ] Arriba Encendido / Bajo o alto La velocidad del ventilador cambia a media.

Med [ 2 ] Arriba Encendido / Med El ventilador se apaga / La chimenea permanece arriba

Med [ 2 ] Abajo Apagado No pasa nada

Bajo [1] Arriba Encendido / Medio o alto La velocidad del ventilador cambia a baja.

Bajo [1] Arriba Encendido / Bajo El ventilador se apaga / La chimenea permanece arriba

Bajo [1] Abajo Apagado No pasa nada

Demora

La chimenea permanece arriba / el LED de demora destella y el LED de velocidad se

ilumina

Demora * Arriba Encendido / Med El ventilador se enciende en medio 5 minutos > bajo 5 minutos > se apaga

La chimenea permanece arriba / el LED de demora destella y el LED de velocidad se

ilumina

Demora * Arriba Encendido / Bajo El ventilador se enciende en bajo 5 minutos > se apaga (todos los LED se apagan)

La chimenea permanece arriba / el LED de demora destella y el LED de baja se ilumina

Demora * Arriba Encendido /en modalidad Modalidad de demora cancelada

de demora

Demora * Arriba o abajo Apagado No pasa nada

* La modalidad Heat Sentry se desactiva en la modalidad de demora

Cuando este BOTÓN

LED esté iluminado... y la CHIMENEA esté... y el VENTILADOR esté.. RESULTADO

Filtro Arriba o abajo Encendido o apagado

Cuando se presiona el botón de filtro se apaga el LED del filtro iluminado y serestablece el

temporizador de uso del filtro.

* Arriba Encendido / Alto El ventilador se enciende en alto 5 minutos > bajo 5 minutos > se apaga

Filtro

El LED del filtro se ilumina como recordatorio para limpiar los filtros (aprox. Cada 30 horas).

Presione este BOTÓN... cuando la CHIMENEA esté... y el VENTILADOR esté... RESULTADO

Filtro Arriba o abajo Encendido o apagado Cuando se presiona el botón del filtro cuando el LED del filtro no está iluminado, no

pasa nada

Cuando este BOTÓN

LED esté destellando... y la CHIMENEA esté... y el VENTILADOR esté... RESULTADO

Med [ 2 ] o Alto [ 3 ] Arriba Encendido / Bajo o medio a. La temperatura de descarga es mayor que la anticipada. Modalidad Heat Sentry

LED destellando activideo.

b. El ventilador pasa ala siguiente velocidad más alta.

c. El LED de velocidad del ventilador se enciende y apaga.

d. La velocidad del ventilador puede aumentar, disminuir o permanecer a la velocidad

actual dependiendo de la temperatura del aire de descarga.

e. Cuando la velocidad del ventilador regresa al ajuste original, el LED de velocidad

del ventilador deja de destellar.

f. La unidad ya no está en la modalidad Heat Sentry.

Presione este BOTÓN

y manténgalo presionado

por 1 segundo… cuando el LED esté... y el VENTILADOR esté... RESULTADO

Med [2] Destellando Encendido / cualquier velocidad Modalidad Heat Sentry desactivada. **

Alto [3] Destellando Encendido / cualquier velocidad Modalidad Heat Sentry desactivada. **

**Presione cualquier botón para reactivar la modalidad Heat Sentry.

Page 25

Ventiladores de tiro descendente

Página 25

PIEZAS DE SERVICOGARANTIA

GARANTIA BROAN-NUTONE LIMITADA POR UN AÑO

Broan-NuTone LLC (Broan-NuTone) garantiza al consumidor

comprador original de sus productos de BEST® que dichos

productos carecerán de defectos en materiales o en mano de

obra por un período de un año a partir de la fecha original de

compra. NO EXISTEN OTRAS GARANTIAS, EXPLICITAS O

IMPLICITAS, INCLUYENDO, PERO NO LIMITADAS A, GARANTIAS IMPLICITAS DE COMERCIALIZACION O APTITUD

PARA UN PROPOSITO PARTICULAR.

Durante el período de un año, y a su propio criterio, BroanNuTone reparará o reemplazará, sin costo alguno cualquier

producto o pieza que se encuentre defectuosa bajo condiciones normales de servicio y uso.

LA PRESENTE GARANTÍA NO CUBRE LOS TUBOS FLUORESCENTES NI SUS ARRANCADORES, BOMBILLAS DE

HALÓGENO E INCANDESCENTES, FUSIBLES, FILTROS,

CONDUCTOS, TAPONES DE TECHO O PAREDES Y DEMÁS

ACCESORIOS PARA CONDUCTOS. Esta garantía no cubre

(a) mantenimiento y servicio normales o (b) cualquier producto o piezas que hayan sido utilizadas de forma errónea,

negligente, que hayan causado un accidente, o que hayan

sido reparadas o mantenidas inapropiadamente (por otras

compañías que no sean Broan-NuTone), instalación defectuosa, o instalación contraria a las instrucciones de instalación

recomendadas.

La duración de cualquier garantía implícita se limita a un

período de un año como se especifica en la garantía expresa.

Algunos estados no permiten limitaciones en cuanto al tiempo

de expiración de una garantía implícita, por lo que la limitación

antes mencionada puede no aplicarse a usted.

LA OBLIGACION DE BROAN-NUTONE DE REPARAR O

REEMPLAZAR, SIGUIENDO EL CRITERIO DE BROANNUTONE, DEBERA SER EL UNICO Y EXCLUSIVO RECURSO LEGAL DEL COMPRADOR BAJO ESTA GARANTIA.

BROAN-NUTONE NO SERA RESPONSABLE POR DAÑOS

INCIDENTALES, CONSIGUIENTES, O POR DAÑOS ESPECIALES QUE SURJAN A RAIZ DEL USO O DESEMPEÑO

DEL PRODUCTO. Algunos estados no permiten la exclusión

o limitación de daños incidentales o consiguientes, por lo que

la limitación antes mencionada puede no aplicarse a usted.

Esta garantía le proporciona derechos legales específicos, y

usted puede también tener otros derechos, los cuales varían

de estado a estado. Esta garantía reemplaza todas las garantías anteriores.

Para calificar en la garantía de servicio, usted debe (a) notificar

a Broan-NuTone al domicilio o al número de teléfono que se

menciona abajo, (b) dar el número del modelo y la identificación

de la pieza, y (c) describir la naturaleza de cualquier defecto

en el producto o pieza. En el momento de solicitar servicio

cubierto por la garantía, usted debe de presentar evidencia

de la fecha original de compra.

En los E.E.U.U. :

BEST®, 926 West State Street, Hartford, Wisconsin 53027

800-558-1711

En Canada:

BEST

866-737-7770

www.BestRangeHoods.com

PARA LOS PRODUCTOS DE BEST

®

, 550 Bd Lemire, Drummondville, QC J2C 7W9

®

76,2 cm 91,4 cm 122 cm

CLAVE (30") (36") (48")