Page 1

Model DC54MSB

ENGLISH............................................3

FRANÇAIS.......................................17

ESPAÑOL.........................................33

In USA - BEST Hartford, Wisconsin

In CANADA - BEST Drummondville, QC, Canada

REGISTER YOUR PRODUCT ONLINE AT : www.BestRangeHoods.com/register

For additional Information visit www.BestRangeHoods.com

Page 2

- 2 -

Page 3

READ AND SAVE THESE INSTRUCTIONS

INTENDED FOR DOMESTIC COOKING ONLY

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions,

contact the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock service panel

to prevent power from being switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent warning device, such as a tag, to

the service panel.

3. Installation work and electrical wiring must be done by a qualifi ed person(s) in accordance

with all applicable codes and standards, including fi re-rated construction codes and stan-

dards.

4. Suffi cient air is needed for proper combustion and exhausting of gases through the fl ue

(chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment

manufacturer’s guidelines and safety standards such as those published by the National

Fire Protection Association (NFPA), and the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fi re, use only metal ductwork.

9. This unit must be grounded.

10. When applicable local regulations comprise more restrictive installation and/or certifi cation

requirements, the aforementioned requirements prevail on those of this document and the

installer agrees to conform to these at his own expenses.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low or medium settings.

B. Always turn downdraft ON when cooking at high heat or when cooking fl ambeing foods.

(i.e. Crêpes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or

fi lter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface ele-

ment.

E. For use with electrical and induction cook tops only. No gas applications.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fi tting lid, cookie sheet, or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. IF THE FLAMES DO NOT GO OUT IMMEDIATELY, EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - This could cause a violent

steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and you know how to operate it.

B. The fi re is small and contained in the area where it started.

C. The fi re department has been called.

D. You can fi ght the fi re with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

- 3 -

Page 4

CAUTION

1. For indoor use only.

2. To reduce risk of fi re and to properly exhaust air, be sure to duct air outside. Do not

vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or

garages.

3. Take care when using cleaning agents or detergents.

4. Avoid using food products that produce fl ames near downdraft.

5. For general ventilating use only. Do not use to exhaust hazardous or explosive

materials and vapors.

6. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall

spray, construction dust, etc. off power unit.

7. Please read specifi cation label on product for further information and require-

ments.

8. Automatically operated device. To reduce the risk of injury, disconnect power before

servicing.

9. ATTENTION: This device has not been designed for gas cookers.

The power supply cord has to be routed beneath the appliance and routed away

10.

from heat generated by the cooktop.

CAUTION : To Reduce The Risk Of Fire And Electric Shock, Install This Down-

11.

draft Only With Downdraft integral Blower Manufactured by Best, Model(s) PF6

or PF3. Other blowers cannot be substituted. (Blower shipped separately)

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of an electrical short-circuit, grounding

reduces the risk of electric shock by providing an escape wire for the electric current.

This appliance is equipped with a cord having a grounding wire with a grounding plug.

The plug must be plugged into an outlet that is properly installed and grounded.

WARNING — Improper grounding can result in a risk of electric shock.

Consult a qualifi ed electrician if the grounding instructions are not completely

understood, or if doubt exists as to whether the appliance is properly grounded. Do

not use an extension cord. If the power supply cord is too short, have a qualifi ed

electrician install an outlet near the appliance.”

- 4 -

Page 5

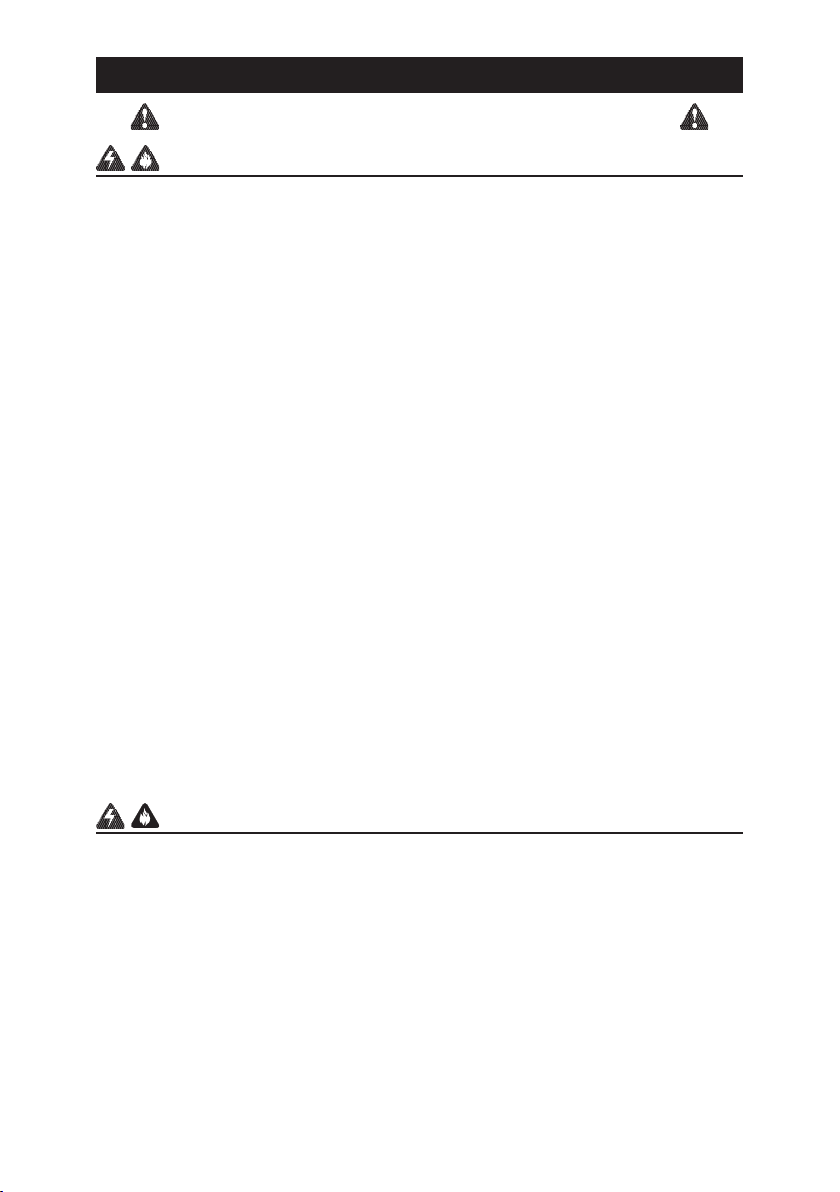

PREPARE THE HOOD

Unpack hood and check contents.

You should receive:

1 - Downdraft

1 - Parts Bag (B080811046) containing:

10 - Mounting Screws (3.9 x 6 mm Flat Head)

6 - Mounting Screws (4.2 x 15 mm)

2 - Mounting Brackets

2 - Transition Brackets

1 - Installation Instructions

2 TRANSITION

BRACKETS

10 MOUNTING SCREWS (3.9 x 6 mm)

6 MOUNTING SCREWS (4.2 x 15 mm)

2 MOUNTING

BRACKETS

- 5 -

Page 6

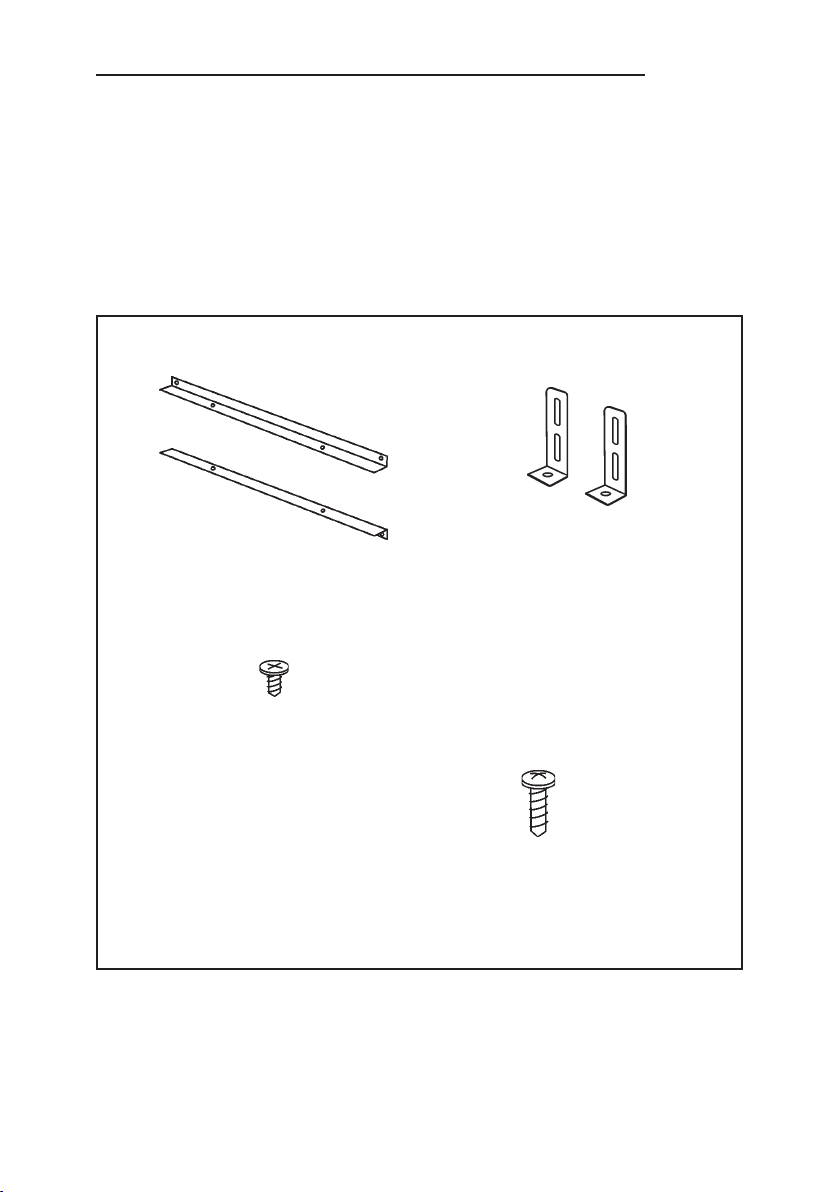

BEFORE YOU BEGIN

This unit can be installed following these basic

steps:

- Cut out the countertop opening.

- Mount the downdraft in the cabinet.

- Install the blower and electrical panel.

- Connect the ductwork and electrical.

- Install the cooking appliance.

PREPARATION

Preparation of the cabinet:

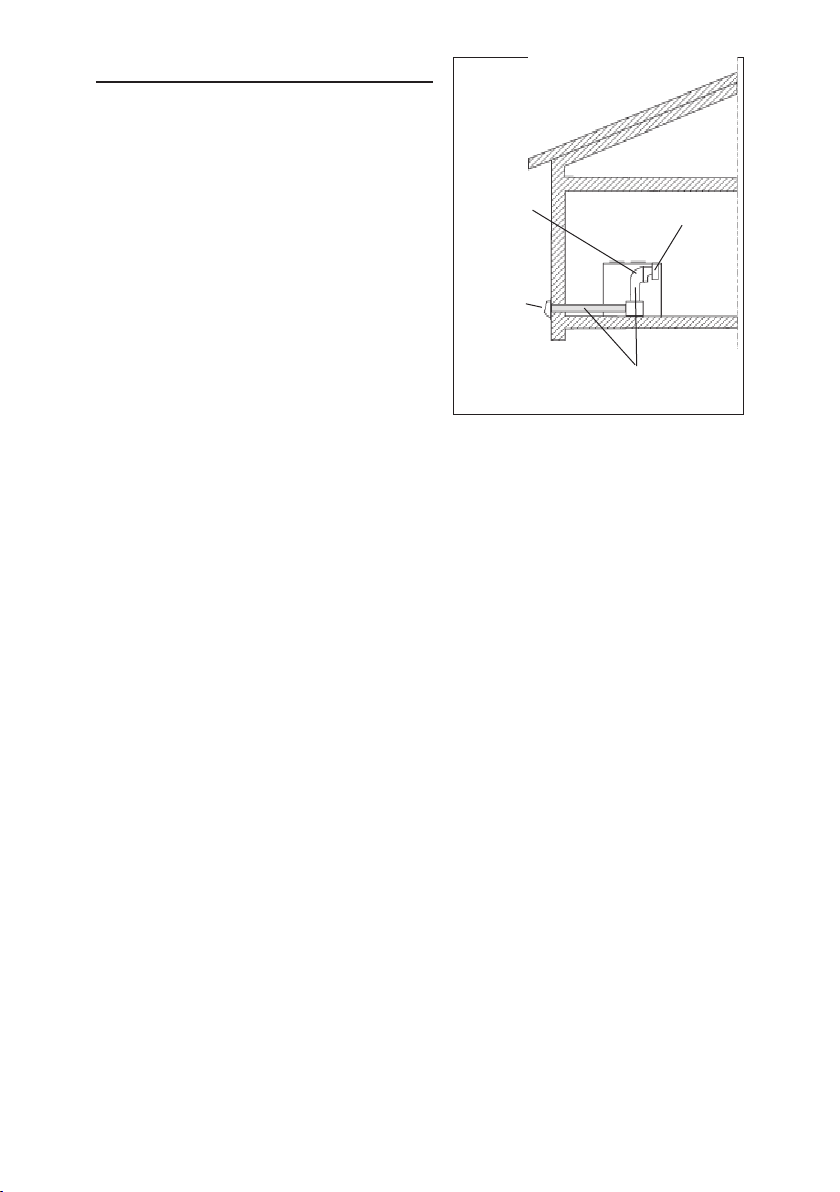

Note: This downdraft can only be used

with electric cooktops. Refer to Figure 2 for

examples of typical installations.

For installations using one electric cooktop, the

maximum total element wattage is 9400 watts.

For installations using two electric cooktops, the

maximum total element wattage is 3400 watts.

Follow cooktop manufacturer’s instructions to

prepare cabinet and countertop for cooktop

installation.

Determine the location of the downdraft(s) and

cut a 4-13/16” x 19-5/16” opening in countertop.

Please note: an electrical outlet will need to be

installed in the cabinet to supply the downdraft

control box with power. Refer to the section

titled “Wiring” for more information.

FIGURE 2

DOWN

DRAFT

DUCT

WORK

Examples of installation

COOKTOP

FIGURE 1

DOWN

DRAFTS

COOKTOP

BLOWER

ELECTRICAL BOX

BLOWERS

ELECTRICAL

BOXES

- 6 -

Page 7

INSTALL THE DUCTWORK

NOTE: To reduce the risk of fi re, use only

metal ductwork.

1. Decide where the ductwork will run

between the downdraft and the outside.

2. A straight, short duct run will allow the downdraft to perform most effi ciently.

3. Long duct runs, elbows, and transitions will

reduce the performance of the downdraft. Use

as few of them as possible. Larger ducting

may be required for best performance with

longer duct runs.

4. Install a roof or wall cap. Connect round

metal ductwork to cap and work back

towards downdraft location. Use duct tape to

seal the joints between ductwork sections.

FIGURE 3

ROUND

ELBOW

WALL

CAP

DOWNDRAFT

8”

ROUND DUCT

- 7 -

Page 8

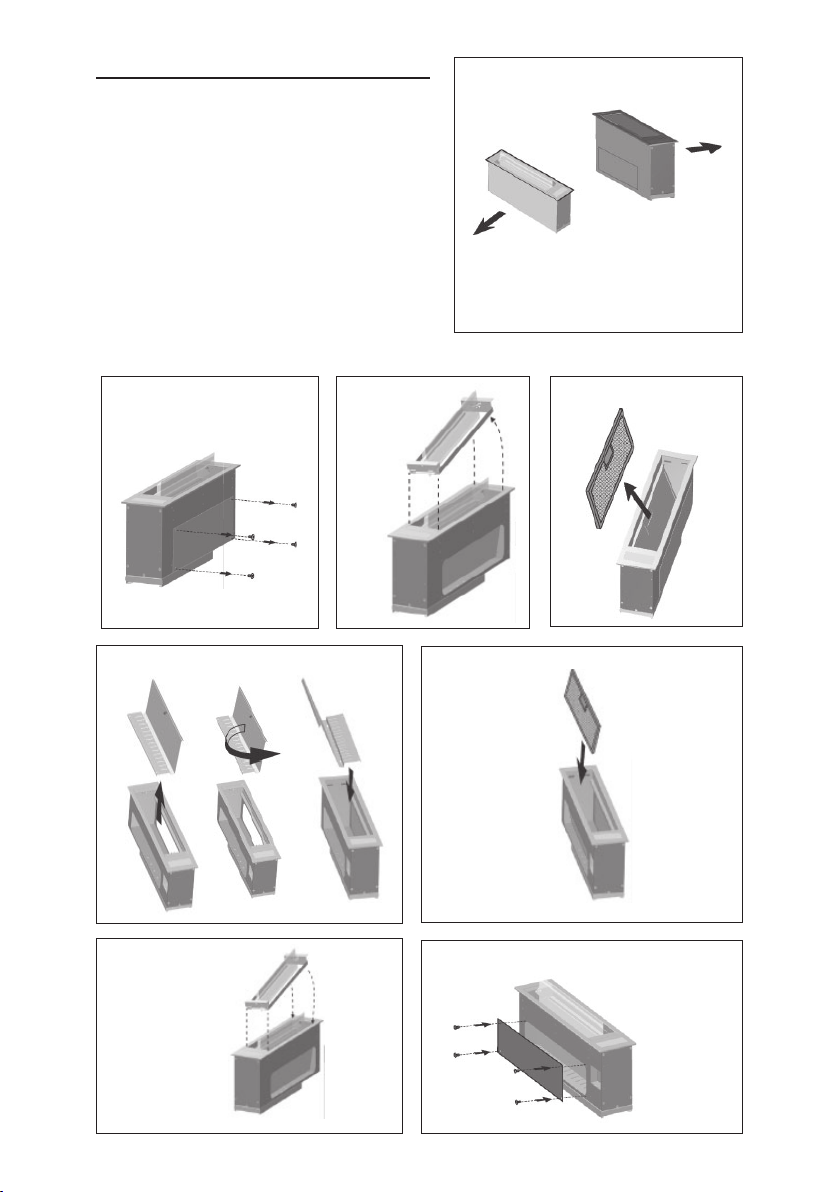

PREPARATION

Refer Figure 4. If you use the right air outlet,

please use the following steps:

1. Remove (1) side cover (Fig.5).

2. Remove the cover assembly (Fig.6).

3. Remove grease fi lter (Fig.7).

4. Remove grease fi lter support, rotate

and reinsert (Fig.8).

5. Reinsert the grease fi lter (Fig. 9) and

the cover assembly (Fig. 10).

6. Attach the side cover on the other

side (Fig.11).

FIGURE 4

RIGHT OUT-

LET AIR

LEFT OUTLET

AIR

FIGURE 5

FIGURE 8

FIGURE 10

FIGURE 6

FIGURE 7

FIGURE 9

FIGURE 11

- 8 -

Page 9

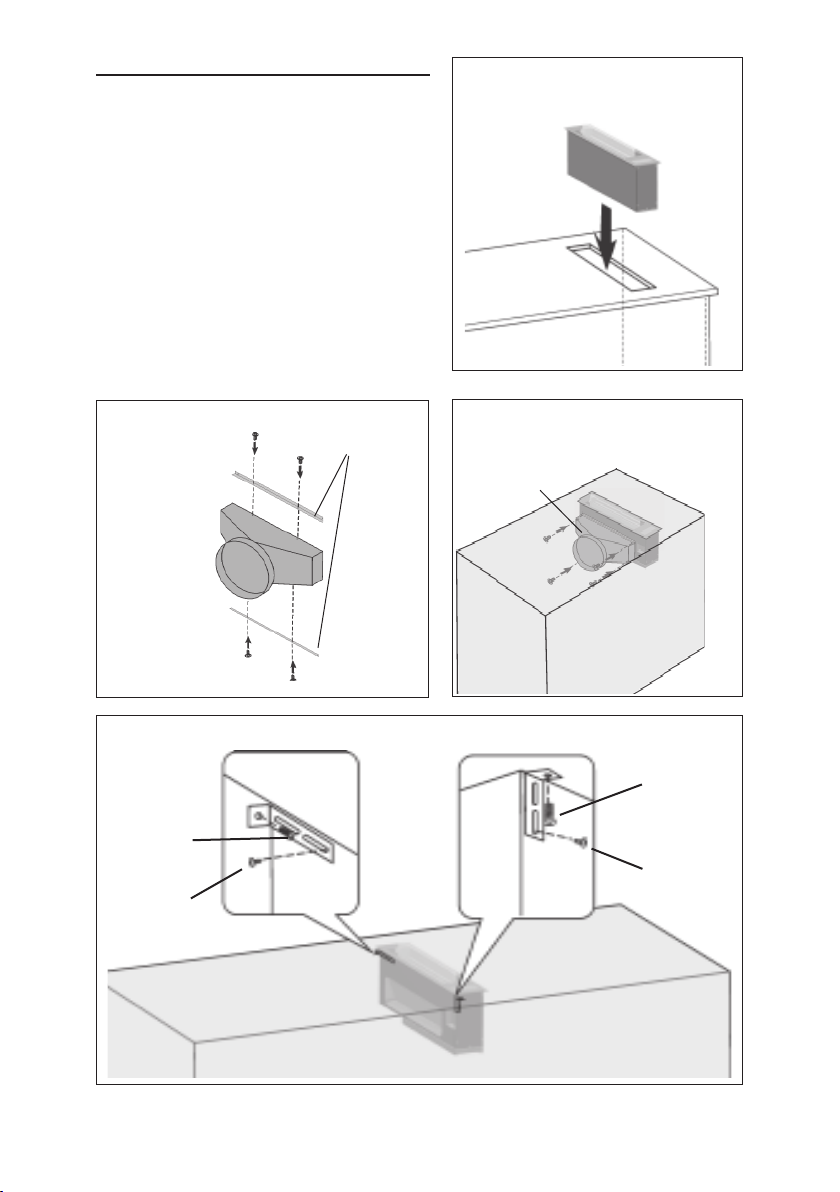

INSTALLATION

ATTENTION: The downdraft should be

installed by a qualifi ed installer.

The transition (model 459) must be purchased separately.

1. Insert the downdraft in the counter top

(Fig.12).

2. Attach (2) transition brackets to

transition with 3.9x6mm mounting

screws (Fig.13).

3. Attach the transition (Best model 459

sold separately) on the downdraft with

(4) 3.9x6mm mounting screws (Fig.14).

4. Attach the brackets with mounting

screws (Fig.15).

FIGURE 12

FIGURE 13

FIGURE 15

MOUNTING

SCREWS

(4.2 x 15 mm)

MOUNTING

SCREWS

(3.9 x 6 mm)

TRANSITION

BRACKETS

FIGURE 14

TRANSITION

MOUNTING

SCREWS

(3.9 x 6 mm)

OPTIONAL

MOUNTING

SCREWS

(4.2 x 15 mm)

MOUNTING

SCREWS

(3.9 x 6 mm)

- 9 -

Page 10

5. Place the blower housing inside cabinet

and secure in place (Fig.16) using

mounting hardware supplied with blower.

FIGURE 16

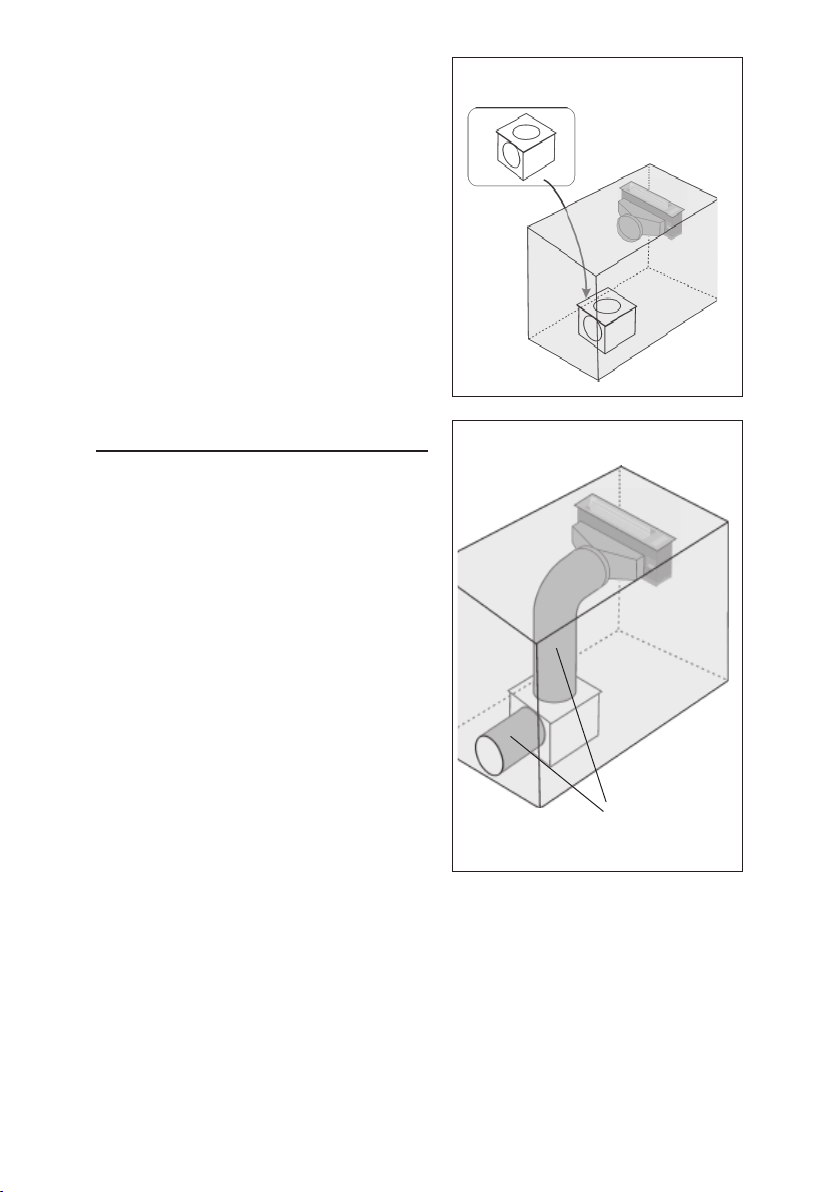

CONNECT DUCTWORK

1. Use 8” round metal duct to connect the

transition on the downdraft to the ductwork. Refer Figure 17.

2. Use duct tape to make all joints secure

and air tight.

FIGURE 17

Ø 8”

ROUND METAL

DUCT

- 10 -

Page 11

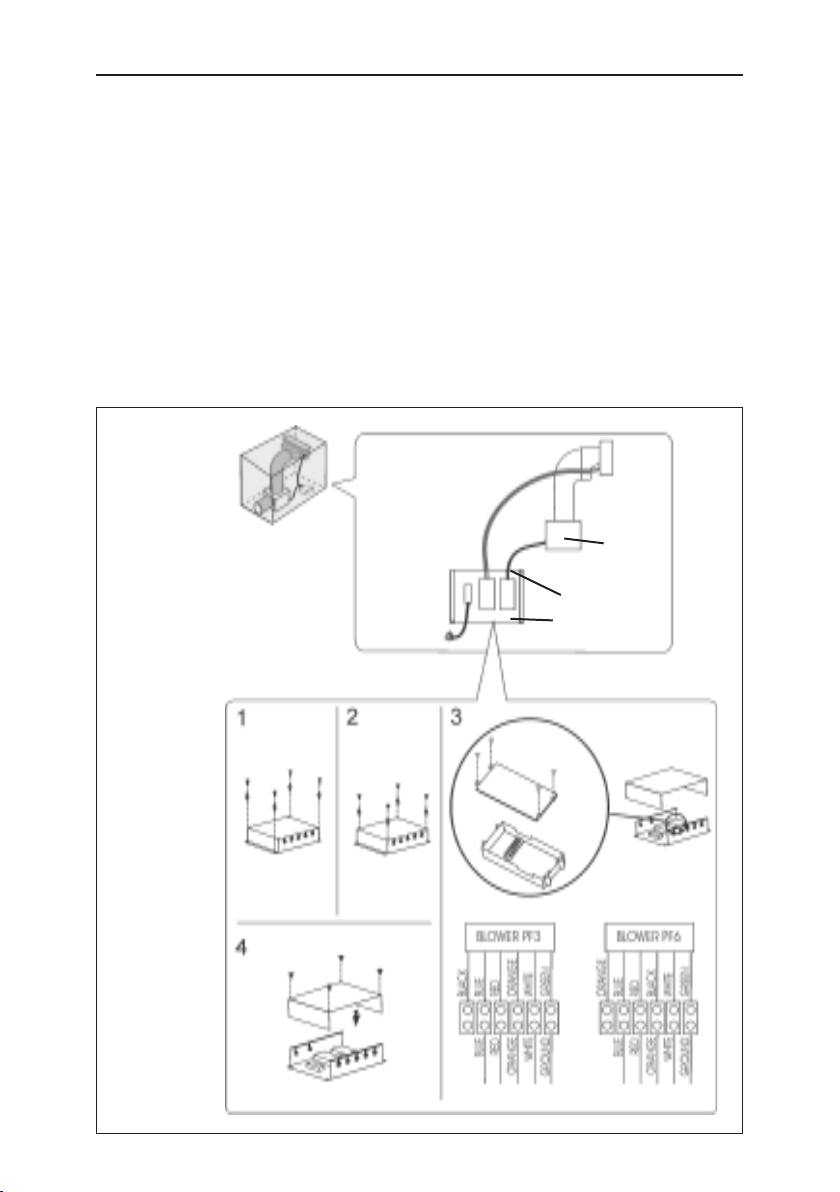

WIRING

Note: This Downdraft must be properly grounded. The unit should be installed

by a qualifi ed electrician in accordance with all applicable national and local

electrical codes.

1. Secure the electrical box to cabinet with (4) 4.2x15mm mounting screws (see

Fig.1).

2. Open the electrical box by unscrewing (4) screws (see Fig. 2).

3. Open the wiring box by unscrewing (4) screws (see Fig. 3).

4. Remove a knockout from the electrical box and insert a strain relief clamp.

5. Make electrical connections. Connect wires from blower to control:

Blower PF6: blue to blue, red to red, black to orange, white to white, green/yellow

to ground.

Blower PF3: blue to blue, red to red, orange to orange, white to white, green/

yellow to ground.

6. Reseal the wiring box and electrical box with screws. Make sure that wires are

not pinched between cover and box.

FIGURE 18

BLOWER

STRAIN RELIEF

CLAMP

ELECTRICAL BOX

MOUNTING

SCREWS

(4.2 x 15 mm)

- 11 -

WIRING

BOX

Page 12

MAINTENANCE

Proper maintenance of the Downdraft will

assure proper performance of the unit.

BEFORE SERVICING OR CLEANING

UNIT, SWITCH POWER OFF AT SERVICE PANEL AND LOCK SERVICE

DISCO-NNECTING MEANS TO PREVENT

POWER FROM BEING SWITCHED ON

ACCIDENTALLY.

WHEN THE SERVICE DISCONNECTING

MEANS CANNOT BE LOCKED, SECURELY FASTEN A PROMINENT WARNING

DEVICE, SUCH AS A TAG, TO THE SERVICE PANEL.

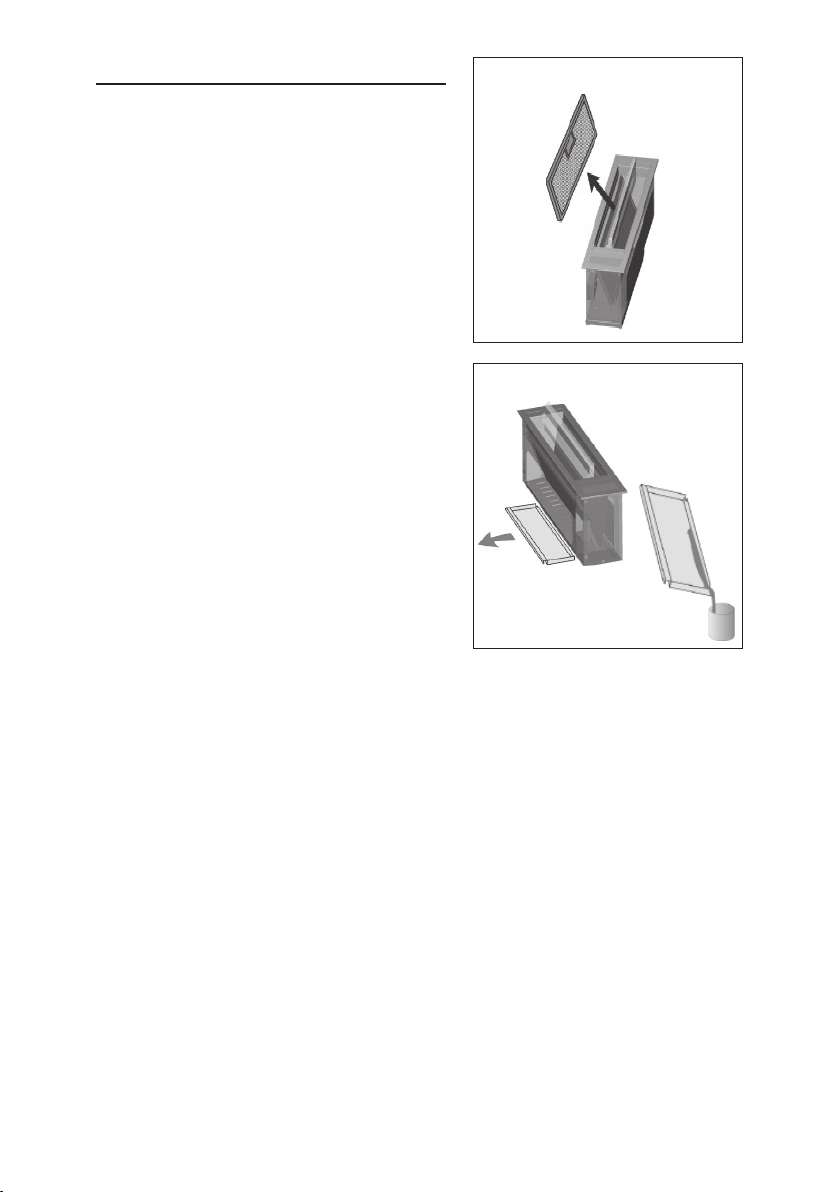

Grease fi lters

The grease fi lters should be cleaned perio-

dically depending upon use (approximately

every (1) month).

Use a warm detergent solution. Grease fi lters

are dishwasher safe.

the dishwasher or sink using a non-phosphate

detergent. Discoloration of the fi lter may occur

if using phosphate detergent or as a result of

local water conditions — but this will not affect

fi lter performance. This discoloration is not

covered by the warranty.

To remove the grease fi lter, push the retainer

near the handle inwards and pull the fi lter

upwards (Fig. 19).

Cleaning liquid waste pan

The appliance is equipped with a removable

oil pan that will collect oil, grease and con-

densation from cooking. Remove the pan (Fig.20), keeping it in horizontal position,

and clean it with a neutral cleaning agent. This should be cleaned regularly, as

needed, every month.

Hood Cleaning

Stainless steel is one of the easiest materials to keep clean. Occasional care will

help preserve its fi ne appearance.

Cleaning tips:

• Hot water with soap or detergent is all that is usually needed.

• Follow all cleaning by rinsing with clear water. Wipe dry with a clean, soft cloth

to avoid water marks.

• For discolorations or deposits that persist, use a non-scratching household

cleanser or stainless steel polishing powder with a little water and a soft cloth.

• For stubborn cases, use a plastic scouring pad or soft bristle brush together with

cleanser and water. Rub lightly in direction of polishing lines or “grain” of the

stainless fi nish. Avoid using too much pressure which may mar the surface.

• DO NOT allow deposits to remain for long periods of time.

• DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere

to the surface causing rust.

• DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to

contact stainless steel. Many of these compounds contain chemicals which may

be harmful. Rinse with water after exposure and wipe dry with a clean cloth.

• DO NOT use bleach ever!

• Surfaces should be cleaned with warm water and mild detergent only.

Clean all-metal fi lters in

FIGURE 19

FIGURE 20

- 12 -

Page 13

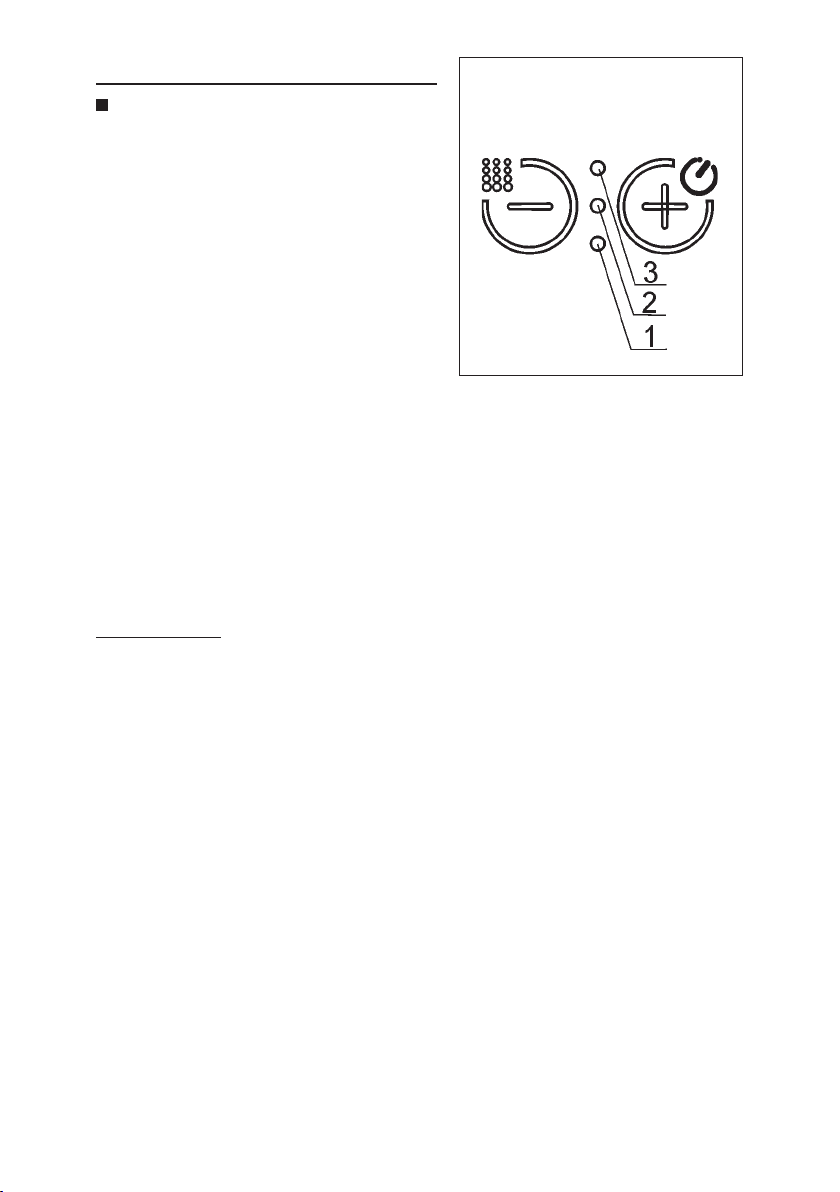

OPERATION

Note: Avoid using food products

that produce fl ames near downdraft.

Controls (Fig.21)

Button “—” : Pressing this button for more than 2

seconds turns the blower off.

Pressing the button quickly while the blower is on

will decrease the blower speed.

Button “+”: Pressing this button for more than 2

seconds turns the blower on.

Pressing the button quickly while the blower is on

will decrease the blower speed.

LED 1, 2 and 3 display the speeds.

Function Timer 10 Minute

After pressing the button “+” for more than 2

seconds, the 10 minute timer will be activated.

The LED of the current speed begins to blink, to

show this function. After 10 minutes the blower

will be turned off. Changing the speed while the

Timer is on, will NOT deactivate this function. To

deactivate this function, press button “+”for more

than 2 seconds.

Filter alarm

Filter ALARM 30H: after 30 hours of operation, the

alarm for cleaning the grease fi lter, will turn on.

Once activated, the fi lter alarm will be displayed

for 30 seconds each time the downdraft is turned

off. This alarm is displayed by the #2 LED and will

blink or remain on.

To reset the alarm, press and hold the “-” button

for 2 seconds. The #2 LED will blink twuice, verifyng the downdraft has been reset.

FIGURE 21

Auto-Off Timer

After 10 hours on continuous blower operation

without user interaction, the downdraft will automatically turn the blower off.

- 13 -

Page 14

Limited Warranty

Warranty Period and Exclusions: Broan-NuTone, LLC(the “Company”) warrants to the consumer purchaser of its product (“you”) that

the product (the “Product”) will be free from material defects in the materials or its workmanship for a period of fi ve (5) years from the date

of original purchase (or such longer period as may be required by applicable law) or a period of two (2) years from the date of service for

any labor provided on the Product.

The limited warranty period for any replacement parts provided by the Company and for any Products repaired or replaced under this limited

warranty shall be the remainder of the original warranty period (or such longer period as may be required by applicable law).

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES AND BULBS, FUSES, FILTERS, DUCTS, ROOF

CAPS, WALL CAPS AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a) normal maintenance and service, (b)

normal wear and tear, (c) any Products or parts which have been subject to misuse, abuse, abnormal usage, negligence, accident, improper

or insuffi cient maintenance, storage or repair (other than repair by the Company), (d) damage caused by faulty installation, or installation

or use contrary to recommendations or instructions, (f) damage caused by exposure to salt air, (g) damage in transit, (h) natural wear of

fi nish, (i) Products in commercial or nonresidential use, (j) damage caused by fi re, fl ood or other act of God, or (k) Products with altered,

defaced or removed serial numbers. This warranty covers only Products sold to consumers in North America.

This warranty supersedes all prior warranties and, subject to applicable law, is not transferable from the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s sole obligation and your sole remedy for defective Products. The

foregoing warranties are exclusive and in lieu of any other warranties and conditions, express or implied. TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, THE COMPANY DISCLAIMS AND EXCLUDES ALL OTHER EXPRESS WARRANTIES AND

CONDITIONS, AND DISCLAIMS AND EXCLUDES ALL WARRANTIES AND CONDITIONS IMPLIED BY LAW, INCLUDING WITHOUT

LIMITATION THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the extent that applicable law prohibits

the exclusion of implied warranties or conditions, the duration of any applicable implied warranty or condition is limited to the period specifi ed

for the express warranty above. Some jurisdictions (which may include the Province of Quebec or specifi c US states) do not allow limitations

on how long an implied warranty lasts, so the above limitation may not apply to you. Any oral or written description of the Product is for the

sole purpose of identifying it and shall not be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted in such manner as to be effective and valid under applicable

law, but if any provision is held to be prohibited or invalid, such provision shall be ineffective only to the extent of such prohibition or invalidity,

without invalidating the remainder of such provision or the other remaining provisions of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its option, provide replacement parts for, or repair or replace,

without charge, any Product or part thereof, to the extent the Company fi nds it to be covered by and in breach of this limited warranty

under normal use and service. The Company will ship the repaired or replaced Product or replacement parts to you at no charge. You are

responsible for all costs for removal, reinstallation and shipping, insurance or other freight charges incurred in the shipment of the Product

or part to the Company. If you must send the Product or part to the Company, as instructed by the Company, you must properly pack the

Product or part—the Company is not responsible for damage in transit. The Company reserves the right to utilize reconditioned, refurbished,

repaired or remanufactured Products or parts in the warranty repair or replacement process. Such Products and parts will be comparable

in function and performance to an original Product or part and warranted for the remainder of the original warranty period (or such longer

period as may be required by applicable law).

Company reserves the right, in its sole discretion, to refund the money actually paid by you for the Product. If the Product or component

is no longer available, replacement may be made with a similar product of equal or greater value, at Company’s sole discretion. This is

your sole and exclusive remedy for breach of this limited warranty.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE REPLACEMENT PARTS, OR REPAIR OR REPLACE, AT THE

COMPANY’S OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY AND THE COMPANY’S

SOLE AND EXCLUSIVE OBLIGATION. THE COMPANY SHALL NOT BE LIABLE FOR INCIDENTAL, INDIRECT, CONSEQUENTIAL OR

SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE PRODUCT, ITS USE OR PERFORMANCE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This warranty gives you specifi c legal rights, and you may also have other rights, which vary from jurisdiction to jurisdic-

tion. The disclaimers, exclusions, and limitations of liability under this warranty will not apply to the extent prohibited by applicable law.

This warranty covers only replacement or repair of defective Products or parts thereof at the Company’s main facility and does not include

the cost of fi eld service travel and living expenses.

Any assistance the Company provides to or procures for you outside the terms, limitations or exclusions of this limited warranty will not

constitute a waiver of such terms, limitations or exclusions, nor will such assistance extend or revive the warranty.

The Company will not reimburse you for any expenses incurred by you in repairing or replacing any defective Product, except for those

incurred with the Company’s prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a) notify the Company at the address or telephone number

stated below within seven (7) days of discovering the covered defect, (b) give the model number and part identifi cation and (c) describe the

nature of any defect in the Product or part. At the time of requesting warranty service, you must present evidence of the original purchase

date. If you cannot provide a copy of the original written limited warranty, then the terms of the Company’s most current written limited

warranty for your particular product will control.

PRODUCT SPECIFICATIONS

All illustrations and specifi cations in this catalog are based on the latest product information available at time of production. Broan-NuTone,

LLC and BEST® reserves the right to make changes at any time, without notice, in prices, colors, materials, equipment, specifi cations and

models, place of manufacture and to discontinue models or equipment.

Best

Broan-NuTone, LLC- 926 W. State Street, Hartford, WI 53207

1-800-637-1453

Best®, 550 Lemire Blvd., Drummondville, QC, Canada (1-866-737-7770) www.bestrangehoods.com

- 14 -

Page 15

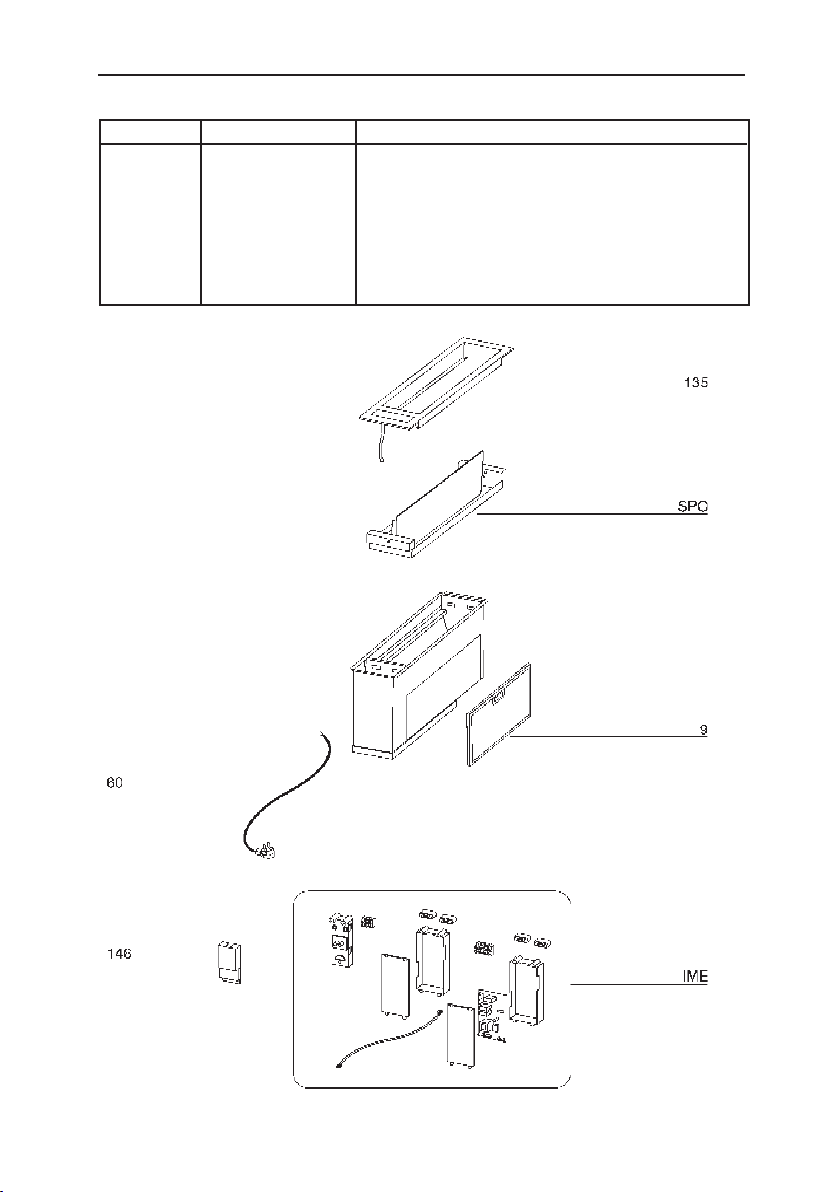

SERVICE PARTS

DC54MSB

KEY NO. PART NO. DESCRIPTION

135 B08094361

SPO B08094130 Cover assembly

9 B08087761 Grease fi lter

IME B06142998 Electrical System Assembly

60 B02300248 Feeder Cable

146 B032920180 Power Box Cover

998 B080811046 Hardware Package

Controls Frame Assembly

- 15 -

Page 16

- 16 -

Page 17

Modèle DC54MSB

ENGLISH............................................3

FRANÇAIS.......................................17

ESPAÑOL.........................................33

Aux États-Unis - BEST Hartford, Wisconsin

Au CANADA - BEST Drummondville, QC, Canada

ENREGISTREZ VOTRE PRODUIT EN LIGNE À : www.BestRangeHoods.com/register

Pour de plus amples informations, visitez www.BestRangeHoods.com

- 17 -

Page 18

LISEZ ET CONSERVEZ CES INSTRUCTIONS

POUR USAGE DOMESTIQUE SEULEMENT

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE, D’ÉLECTROCUTION OU DE BLESSURES

CORPORELLES, OBSERVEZ LES INSTRUCTIONS SUIVANTES :

1. N’utilisez cet appareil que de la façon prévue par le manufacturier. Si vous avez des

questions, contactez le manufacturier à l’une des adresses ou numéros de téléphone

indiqués dans la garantie.

2. Avant de nettoyer ou de réparer l’appareil, coupez le courant au panneau d’alimentation

et verrouillez-en l’accès afi n d’éviter sa remise en marche accidentelle. Si le panneau

d’alimentation ne peut être verrouillé, apposez un avertissement bien en évidence, par

exemple une étiquette de couleur vive.

3. Les travaux d’installation et de raccordement électrique doivent être effectués par du personnel qualifi é en respectant les normes et règlements en vigueur, y compris les normes

et codes de bâtiment en matière de prévention d’incendie.

4. Une circulation d’air effi cace est requise afi n d’assurer la combustion et l’évacuation

complète des gaz par la cheminée des appareils à combustion pour prévenir les retours

de cheminée. Conformez-vous aux instructions et aux standards de sécurité des manufacturiers d’appareils de chauffage, tels qu’ils sont publiés par la National Fire Protection

Association (NFPA) et l’American Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE) ainsi que les responsables des codes locaux.

5. Lorsque vous coupez ou perforez un mur ou un plafond, prenez garde de ne pas endommager les fi ls électriques ou autre installation qui pourraient y être dissimulés.

6. Les ventilateurs avec conduits doivent toujours évacuer l’air à l’extérieur.

7. N’utilisez pas cet appareil avec une commande de vitesse à semi-conducteur additionnelle.

8. Afi n de réduire le risque d’incendie, n’utilisez que des conduits en métal.

9. Cet appareil doit être relié à une mise à la terre.

10. Lorsqu’une réglementation est en vigueur localement et qu’elle comporte des exigences

d’installation et/ou de certifi cation plus restrictives, lesdites exigences prévalent sur celles

de ce document et l’installateur entend s’y conformer à ses frais.

AFIN DE RÉDUIRE LE RISQUE DE FEU DE CUISINIÈRE :

A. Ne laissez jamais les appareils de cuisson sans surveillance lorsqu’ils sont réglés à feu

vif. Les débordements engendrent de la fumée et des déversements graisseux pouvant

s’enfl ammer. Chauffez l’huile lentement, à feu doux ou moyen.

B. Mettez toujours l’appareil en marche lorsque vous cuisinez à feu vif ou que vous cuisinez

des mets fl ambés (par ex. : Crêpes Suzette, Cerises Jubilé, Steak au Poivre Flambé).

C. Nettoyez régulièrement la (les) roue(s) du moteur de ventilateur. Ne laissez pas la graisse

s’accumuler sur le ventilateur ou les fi ltres.

D. Utilisez le bon format de casserole. Servez-vous toujours de casseroles et d’ustensiles

appropriés à la dimension de la surface chauffante.

E. Utilisez seulement avec des table de cuisson électrique ou à induction. Pas de gaz.

AVERTISSEMENT

AFIN D’ÉVITER TOUT RISQUE DE BLESSURES LORS D’UN FEU DE CUISINIÈRE, OBSERVEZ LES INSTRUCTIONS SUIVANTES* :

1. ÉTOUFFEZ LES FLAMMES à l’aide d’un couvercle hermétique, une plaque à

biscuits ou un plateau en métal, puis éteignez le brûleur. ATTENTION DE NE PAS VOUS

BRÛLER. SI LES FLAMMES NE S’ÉTEIGNENT PAS IMMÉDIATEMENT, PRENEZ SOIN

D’ÉVITER LES BRÛLURES, SORTEZ ET APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS EN MAIN UNE POÊLE OU UNE CASSEROLE QUI A PRIS FEU;

vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni de linge à vaisselle ou de serviettes mouillés; cela pourrait

occasionner une violente explosion de vapeur.

4. Utilisez un extincteur SEULEMENT LORSQUE :

A. Vous savez qu’il s’agit d’un extincteur de classe ABC et que vous en connaissez le

fonctionnement.

B. L’incendie est petit et limité à l’endroit où il a débuté.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en ayant accès à une sortie de secours.

*Tirées du “Kitchen Fire Safety Tips” publié par la NFPA.

- 18 -

Page 19

ATTENTION

1. Pour usage intérieur seulement.

2. Pour réduire tout risque d’incendie et évacuer correctement l’air, assurez-vous

d’évacuez l’air à l’extérieur. N’évacuez pas l’air dans des espaces clos comme

l’intérieur des murs ou un plafond, dans le grenier, faux-plafond ou garage.

3. Faites très attention lors de l’utilisation de produits de nettoyage ou de détergents.

4. Évitez d’utiliser des produits alimentaires pouvant s’enfl ammer sous la hotte de

cuisinière.

5. N’utilisez cet appareil que pour une ventilation générale. Ne l’utilisez pas pour évacuer

des vapeurs ou des matières dangereuses ou explosives.

6. Afi n d’éviter tout dommage au moteur et de débalancer ou de rendre bruyante

la roue du moteur, gardez votre appareil à l’abri des poussières de gypse et de

construction/rénovation, etc.

7. Nous vous recommandons de lire l’étiquette indiquant les caractéristiques de votre

hotte pour de plus amples renseignements et exigences.

8. Appareil avec fonctionnement automatique. Pour réduire les risques de blessures,

débrancher avant l’entretien.

9. Remarque: cet appareil n’a pas été conçu pour réchaud à gaz.

10.

Le cordon d’alimentation doit être acheminé sous l’appareil et loin de la chaleur

générée par la table de cuisson.

MISE EN GARDE: Pour réduire les risques d’incendie et de choc électrique,

11.

installez cet appareil uniquement avec un ventilateur intégré fabriqué par Best,

modèle (s) PF6 ou PF3. Les autres ventilateurs ne peuvent pas être remplacés.

(ventilateur expédié séparément).

CONSIGNES DE MISE À LA TERRE

Cet appareil doit être mis à la terre. En cas de court-circuit, le fi l de mise à la terre

limite le risque de choc électrique parce qu’il assure le retour du courant à la terre.

L’appareil est livré avec un cordon muni d’un fi l de terre et d’une fi che de mise à la

terre, qui doit être branchée sur une prise mise à la terre correctement installée.

AVERTISSEMENT — Une mise à la terre incorrecte peut entraîner des risques

de choc électrique. Consulter un électricien compétent en cas de doute sur ces

consignes de mise à la terre ou en cas d’incertitude concernant la mise à la terre

correcte du circuit sur lequel l’appareil est branché.

Ne pas utiliser de cordon de rallonge. Si le cordon d’alimentation est trop court, faire

installer une prise par un électricien compétent à proximité de l’appareil.

- 19 -

Page 20

PRÉPARATION DE LA HOTTE

Retirer la hotte de l’emballage, puis vérifi er le contenu.

Vous devez avoir:

1 - Hotte

1 - Sachet de pièces (B080811046) comprenant:

10 - Vis de montage (3.9 x 6 mm tête fraisée)

6 - Vis de montage (4.2 x 15 mm)

2 - Etrieres de montage

2 - Etrieres du transition

1 - Instructions pour l’installation

2 ÉTRIÈRES

DUTRANSITION

10 VIS DE MONTAGE (3.9 x 6 mm)

2 ÉTRIÈRES

DE MONTAGE

6 VIS DE MONTAGE (4.2 x 15 mm)

- 20 -

Page 21

AVANT DE COMMENCER

Cet appareil peut être installée en procédant

comme suit:

- Découpez l’ouverture du comptoir.

- Montez l’appareil dans l’armoire.

- Installez le ventilateur et le panneau électri-

que.

- Connectez les conduits et l’électricité.

- Installez l’appareil de cuisson.

PRÉPARATION

Préparation de l’armoire:

Remarque: cet appareil ne peut être utilisé qu’avec des cuisinières électriques. Reportez-vous à

la fi gure 2 pour des exemples d’installations types.

Pour les installations utilisant une seule cuisinière

électrique, la puissance maximale totale des

éléments est de 9400 watts. Pour les installations

utilisant deux cuisinières électriques, la puissance

maximale totale des éléments est de 3 400 watts.

Suivez les instructions du fabricant de la cuisinière

électrique pour préparer l’armoire et le comptoir

en vue de l’installation de la cusinière électrique.

Déterminez l’emplacement de l’appareil et

découpez une ouverture de 4-13 / 16po x 19-5

/ 16po dans le comptoir. Remarque: une prise

électrique devra être installée dans l’armoire pour

alimenter le boîtier de commande. Reportezvous à la section intitulée “Câblage” pour plus

d’informations.

FIGURE 2

APPAREIL

CONDUIT

Exemples d’installation

FIGURE 1

APPAREIL

CUISINIÈRE

ÉLECTRIQUE

APPAREIL

MOTEUR

BOÎTIER DE COM-

MANDE

MOTEURS

BOÎTIERS DE COMMANDE

- 21 -

Page 22

INSTALLATION DU

SYSTÈME DE CONDUITS

NOTE : Pour réduire le risque d’incendie,

n’utilisez que des conduits en métal.

1. Déterminer par où passera le conduit, entre vo-

tre hotte à aspiration descendante et l’extérieur.

2. Un conduit droit et court permettra à votre

appareil de fonctionner plus effi cacement.

3. Un conduit long avec des coudes et des tran-

sitions réduira la performance de votre hotte

à aspiration descendante. En utiliser le moins

possible. Pour une grande distance, il faut un

conduit d’évacuation d’air au diamètre plus

grand.

4. Installer un capuchon de toit ou de mur. Relier

le conduit circulaire en métal au capuchon, puis

acheminer le conduit jusqu’à l’emplacement

de votre appareil. Sceller hermétiquement les

raccords à l’aide de ruban à conduits.

FIGURE 3

COUDE

ROND

CAPUCHON

DE MUR

CONDUIT

ROND DE 8”

HOTTE À

ASPIRATION

DESCENDANTE

- 22 -

Page 23

PRÉPARATION

Reportez-vous à la Figure 4. Si vous

utilisez la sortie d’air à droite, veuillez

suivre les étapes suivantes:

1. Enlever le couvercle latéral (Fig.5).

2. Retirez le couvercle assemblé (Fig.6).

3. Retirez le fi ltre à graisse (Fig.7).

4. Retirer le support du fi ltre à graisse, le

tourner et le réinsérer (Fig.8).

5. Réinsérez le fi ltre à graisse (Fig. 9) et

le couvercle assemblé (Fig. 10).

6. Fixez le couvercle latéral de l’autre

côté (Fig.11).

FIGURE 4

SORTIE D’AIR

À GAUCHE

SORTIE D’AIR

À DROITE

FIGURE 5

FIGURE 8

FIGURE 10

FIGURE 6 FIGURE 7

FIGURE 9

FIGURE 11

- 23 -

Page 24

INSTALLATION

ATTENTION: L’appareil doit être installé

par un installateur qualifi é.

La transition (modèle 459, doit être

achetée séparément).

1. Insérer l’appareil dans le comptoir

(Fig.12).

2. Fixer (2) étrières à la transition avec des

vis de montage 3.9x6 mm (Fig. 13).

3. Fixer la transition (modèle Best 459

achetée séparément) sur l’appareil avec

(4) vis de montage 3.9x6 mm (Fig.14).

4. Fixer les étrières avec des vis de mon-

tage (Fig.15).

FIGURE 12

FIGURE 13

FIGURE 15

VIS DE

MONTAGE

(4.2 x 15 mm)

VIS DE

MONTAGE

(3.9 x 6 mm)

ÉTRIÈRES DE

LA TRANSI-

TION

FIGURE 14

TRANSITION

VIS DE MONTAGE

(3.9 x 6 mm)

VIS DE

MONTAGE OP-

TIONNELLE

(4.2 x 15 mm)

VIS DE

MONTAGE

(3.9 x 6 mm)

- 24 -

Page 25

5. Placer le moteur à l’intérieur de l’armoire

et le fi xer en place (Fig.16), en utilisant le

matériel de montage fourni avec le moteur.

FIGURE 16

RACCORDEMENT

DES CONDUITS

1. Utiliser un conduit circulaire en métal de

8 po pour relier la transition de la hotte

à aspiration descendante au conduit

menant à l’extérieur. Voir la Figure 17.

2. Sceller hermétiquement les joints du

conduit à l’aide de ruban à conduits.

FIGURE 17

CONDUIT

CIRCULAIRE EN

MÉTAL DE 8PO

- 25 -

Page 26

BRANCHEMENT ÉLECTRIQUE

AVERTISSEMENT : Cet appareil doit être correctement reliée à une mise à la

terre. L’installation doit être effectuée par du personnel qualifi é en vertu des

codes électriques nationaux et locaux en vigueur.

1. Fixez le boîtier de commande dans l’armoire à l’aide de (4) vis de montage de

4,2 x 15 mm (voir Fig.1).

2. Ouvrez le boîtier de commande en dévissant les vis (4) (voir Fig. 2).

3. Ouvrez le boîtier de câblage en dévissant les vis (4) (voir Fig. 3).

4. Dégagez une ouverture préamorcée du boîtier de commande et insérez un

serre-fi ls.

5. Effectuez les connexions électriques. Connectez les fi ls du ventilateur au com-

mandes:

Moteur PF6: bleu à bleu, rouge à rouge, noir à orange, blanc à blanc, vert / jaune

à la terre.

Moteur PF3: bleu à bleu, rouge à rouge, orange à orange, blanc à blanc, vert /

jaune à la terre.

6. Refermez le boîtier de câblage et le boîtier de commande à l’aide de vis. Assurez-

vous que les fi ls ne sont pas pincés entre le couvercle et le boîtier.

FIGURE 18

MOTEUR

SERRE-FILS

BOÎTIER DE

COMMANDE

VIS DE MONTAGE

(4.2 x 15 mm)

- 26 -

BOÎTIER DE

CÂBLAGE

Page 27

ENTRETIEN

Un entretien adéquat de votre appareil garantira

une excellente performance.

AVANT DE NETTOYER OU DE RÉPARER

L’APPAREIL, COUPEZ LE COURANT AU PANNEAU D’ALIMENTATION ET VERROUILLEZEN L’ACCÈS AFIN D’ÉVITER SA REMISE EN

MARCHE ACCIDENTELLE. SI LE PANNEAU

D’ALIMENTATION NE PEUT ÊTRE VERROUILLÉ, APPOSEZ UN AVERTISSEMENT BIEN EN

ÉVIDENCE, PAR EXEMPLE UNE ÉTIQUETTE

DE COULEUR VIVE.

Filtre à graisses

Le fi ltre à graisses doit être nettoyé périodique-

ment en fonction de l’usage (approximativement

chaque mois).

Utiliser de l’eau chaude additionnée de détergent.

Le fi ltre à graisses est lavable au lave-vaisselle.

Nettoyer tous les fi ltres fabriqués entièrement en

métal dans le lave-vaisselle avec un détergent

avec phosphates. Si vous utilisez un détergent

phosphaté ou selon le type d’eau, il est possible

que le fi ltre se décolore, mais cela n’affectera au-

cunement ses performances. Cette décoloration

n’est pas couverte par la garantie.

Pour retirer le fi ltre à graisses, appuyer sur le

taquet de la poignée et tirer le fi ltre vers le bas

(Fig.19).

Nettoyage du récipient pour résidus

L’appareil est muni d’un récipient amovible pour récupérer les huiles, les graisses et la

condensation de la cuisine. Sortir le récipient (Fig.20) en le maintenant position horizontale et le nettoyer avec un savon douxe. Le nettoyage doit être réalisé périodiquement

en fonction de l’usage (approximativement chaque mois).

Nettoyage de votre hotte

L’acier inoxydable est un matériau facile à nettoyer. Un entretien régulier permettra de

conserver sa belle apparence.

Conseils de nettoyage :

• De l’eau chaude et du savon ou un détergent est tout ce qui est normalement requis.

• Après le nettoyage, rincer toujours à l’eau claire. Essuyer la surface avec un chiffon

propre et doux pour éviter les stries.

• Pour les ternissures ou les dépôts tenaces, utiliser un nettoyant domestique non

abrasif ou une poudre à polir l’acier inoxydable avec un peu d’eau et un chiffon doux.

• Pour la saleté rebelle, utiliser un tampon à récurer en plastique ou une brosse à poils

doux avec un nettoyant et de l’eau. Frotter doucement dans le sens des lignes de

polissage ou du « grain » de l’acier. Éviter de trop appuyer au risque de gâcher la surface.

• NE PAS LAISSER les dépôts s’accumuler trop longtemps.

• NE PAS UTILISER une laine d’acier ordinaire ou une brosse d’acier. De petites

particules d’acier risqueraient d’adhérer à la surface et de la faire rouiller.

• NE PAS LAISSER en contact avec l’acier inoxydable une solution saline, un désinfec-

tant, de l’eau de Javel ou tout autre produit détachant. Bon nombre de ces nettoyants

contiennent des produits chimiques pouvant en altérer la surface. Après l’utilisation

du nettoyant, rincer la surface à l’eau, puis l’essuyer avec un chiffon propre.

• NE PAS UTILISER d’eau de Javel.

• Nettoyer les surfaces peintes uniquement à l’eau tiède avec un détergent doux.

FIGURE 19

FIGURE 20

- 27 -

Page 28

FONCTIONNEMENT

Note: Éviter l’utilisation de

substances/d’aliments produisant

des fl ammes à proximité de l’appareil.

Commandes (Fig.21)

Bouton”—”: Appuyer longue (environ 2

secondes) pour éteindre le moteur. Appuyer

brièvement lorsque le moteur est en marche

pour réduire la vitesse du moteur.

Bouton “+”: Appuyer (environ 2 secondes)

pour mettre le moteur en marche. Appuyer

brièvement lorsque le moteur est en marche,

pour augmenter la vitesse du moteur.

DEL 1, 2 et 3 activée, indique la vitesse.

La minuterie 10 minutes

Après avoir appuyé sur le bouton “+”

pendant deux secondes, la fonction de

minuterie 10 minutes est activée. La DEL

de la vitesse en cours clignote pour indiquer

cette fonctionnalité. Après 10 minutes de

fonctionnement, le moteur s’éteint. S’il y a un

changement de vitesse alors que la minuterie

est activée, la fonction minuterie ne sera pas

désactivée.

Pour désactiver la fonction, appuyez sur le

bouton “+” pendant deux secondes.

FIGURE 21

Alarme nettoyage du fi ltre

Alarme fi ltre 30H: après 30 heures de

fonctionnement, une alarme pour nettoyer le

fi ltre à graisse est activée. Quand l’alarme

fi ltre est active, elle s’affi che pendant 30

secondes chaque fois que le moteur s’éteint.

La DEL 2 reste allumée ou clignote. Il est

possible, au cours de cette période, de

réinitialiser l’alarme en appuyant longuement

sur le touche “—” (la DEL 2 clignote 2 fois

pour indiquer la réinitialisation s’est produite).

Minuterie d’arrêt automatique

Après 10 heures de fonctionnement sans

intervention humaine, l’appareil s’arrête

automatiquement.

- 28 -

Page 29

Garantie limitée

Période de garantie et exclusions : Broan-NuTone LLC (l’« entreprise ») garantit au consommateur qui achète son produit (« vous »)

que le produit (le « produit ») restera exempt de défauts importants dans ses composants ou sa fabrication pendant une période de cinq

(5) ans à compter de la date de l’achat initial (ou pour une période plus longue si la loi en vigueur l’exige) ou une période de deux (2) ans

à compter de la date de la prestation d’un service sur le produit.

La garantie limitéedes pièces de rechange fournies par l’entreprise et de tout produit réparé ou remplacé en vertu de cette garantie est

valide pour la durée non écoulée de la période de garantie initiale (ou d’une période plus longue si la loi en vigueur l’exige).

LA PRÉSENTE GARANTIE NE S’APPLIQUE PAS AUX DÉMARREURS DE LAMPE FLUORESCENTE, NI AUXTUBES, AMPOULES,

FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE TOIT, CAPUCHONS MURAUX ET AUX AUTRES ACCESSOIRES POUR CONDUITS.Cette garantie exclut : a) l’entretien normal, b) l’usure normale, c) les produits et les pièces ayant fait l’objet d’une utilisation mauvaise,

abusive ou anormale, d’une négligence, d’un accident, d’un entretien ou d’un entreposage, d’une réparation ou d’un entretien inadéquats

ou insuffi sants (sauf s’il s’agit d’une réparation effectuée par l’entreprise), d) les dommages attribuables à une installation incorrecte ou à

une installation ou utilisation contraires aux recommandations ou aux instructions, e) les dommages attribuables au contact de l’air salin, f)

les dommages survenus durant le transport, g) l’usure normale de la fi nition, h) les produits d’utilisation commerciale ou non résidentielle, i)

les dommages causés par le feu, une inondation ou une autre catastrophe naturelle, ou j) les produits dont le numéro de série a été altéré

ou effacé. Cette garantie ne s’applique qu’aux produits vendus aux consommateurs en Amérique du Nord.

La présente garantie remplace les garanties précédentes et, sous réserve de la loi applicable, n’est pas transférable par l’acheteur initial.

Aucune autre garantie : La présente garantie limitée énonce l’unique obligation de l’entreprise et votre seul recours pour les produits

défectueux. Les garanties qui précèdent sont exclusives et l’emportent sur les autres garanties et modalités, expresses ou implicites.

DANS TOUTE LA MESURE PERMISE PAR LA LOI EN VIGUEUR, L’ENTREPRISE SE DÉGAGE DES AUTRES GARANTIES ET MODALITÉS EXPRESSES ET DES GARANTIES ETMODALITÉS IMPLICITES EN VERTU DE LA LOI, Y COMPRIS, SANS S’Y LIMITER,

LES GARANTIES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN USAGE PARTICULIER. Dans la mesure où la loi applicable

interdit l’exclusion des garanties ou modalités implicites, la durée d’une garantie ou modalité implicite applicableest restreinte à la période

indiquée pour la garantie expresse ci-dessus. Certains territoires de compétence (ce qui peut inclure la province de Québec ou certains

États des États-Unis) interdisent les limites à la durée des garanties implicites; la restriction susmentionnée pourrait donc ne pas s’appliquer

à vous. Les descriptions orales ou écrites du produit ont pour seul objet d’indiquer les produits et ne sauraient être interprétées dans le

sens d’une garantie expresse.

Autant que possible, chaque disposition de cette garantie limitée est interprétée de sorte qu’elle soit valide sous le régime de la loi applicable,

mais si l’une de ses dispositions est déclarée interdite ou nulle, cette disposition n’est nulle que dans la mesure de cette interdiction ou

nullité, et les autres éléments de cette disposition ainsi que les autres dispositions de la garantie limitée restent valides.

Recours : Durant la période de la garantie limitée applicable, l’entreprise fournira, à son choix, des pièces de rechange ou des services

de réparation ou de remplacement sans frais pour tout produit ou toute pièce de produit, dans la mesure où l’entreprise constate que la

présente garantie limitée s’applique à ce produit ou à cette pièce dans le contexte d’une utilisation et d’un entretien normaux.L’entreprise

vous expédiera le produit réparé, son remplacement ou les pièces de rechange sans frais. Vous assumez la totalité des coûts de mise

hors service, de réinstallation, d’expédition etd’assurance et les autres frais de transport associés à la livraison du produit ou de la pièce à

l’entreprise. Si vous devez envoyer le produit ou la pièce à l’entreprise, conformément à ses instructions, vous devez emballer adéquatement le produit ou la pièce; l’entreprise n’est pas responsable des dommages survenus durant le transport. L’entreprise se réserve le droit

d’utiliser des produits ou pièces remis à neuf, réparés ou remanufacturés aux fi ns de réparation ou de remplacement dans le cadre de la

garantie. Ces produits et ces pièces seront comparablesquant à la fonction et aux performancesavec les produits ou pièces d’origine, et

protégés par une garantie pour la durée restante de la période de garantie initiale (ou d’une période plus longue si la loi en vigueur l’exige).

L’entreprise se réserve le droit, à son entière discrétion, de rembourser le montant que vous avez effectivement payé pour le produit. Si le

produit ou la pièce n’est plus disponible, elle peut le ou la remplacer par un produit similaire de valeur égale ou supérieure, à son entière

discrétion. Ceci constitue votre seul recours advenant un non-respect de la présente garantie limitée.

Exclusion des dommages :L’OBLIGATION DE L’ENTREPRISE DE FOURNIR DES PIÈCES DE RECHANGE, OU DE RÉPARER OU

REMPLACER LE PRODUIT, À SON CHOIX, EST VOTRE SEUL RECOURS EN VERTU DE LA PRÉSENTE GARANTIE LIMITÉE ET

L’UNIQUE OBLIGATION DE L’ENTREPRISE. CETTE DERNIÈRE N’EST PAS RESPONSABLE DES DOMMAGES INDIRECTS OU

SPÉCIAUX DÉCOULANT DIRECTEMENT OU INDIRECTEMENT DU PRODUIT, DE SON UTILISATION OU DE SES PERFORMANCES.

Certains territoires de compétence interdisent l’exclusion ou la restriction des dommages indirects; la restriction qui précède pourrait donc

ne pas s’appliquer à vous. Cette garantie vous donne des droits spécifi ques, et vous pourriez aussi avoir d’autres droits, qui varient selon

le territoire de compétence. Les renonciations, exclusions et restrictions de responsabilité aux termes de cette garantie ne s’appliquent

pas dans la mesure où la loi en vigueurinterdit une telle application.

La présente garantie ne s’applique qu’au remplacement ou à la réparation de produits ou pièces de produit défectueux effectué au principal

lieu d’affaires de l’entreprise, et exclut les frais de déplacement et de subsistance liés aux services fournis sur le terrain.

Tout soutien que l’entreprise vous fournit ou vous procure et qui n’est pas visé par les dispositions, limites ou exclusions de la présente

garantie limitée ne constitue pas une renonciation à ces dispositions, limites ou exclusions, et la fourniture de ce soutien ne prolonge ni

ne rétablit la garantie.

L’entreprise ne vous remboursera pas vos dépenses faites pour la réparation ou le remplacement d’un produit défectueux, sauf celles pour

lesquelles vous avez obtenu le consentement écrit de l’entreprise.

Comment obtenir le service de garantie : Pour avoir droit au service de garantie, vous devez : a) aviser l’entreprise à l’adresse ou au

numéro de téléphone indiqué ci-dessous dans les sept (7) jours qui suivent la date où vous avez eu connaissance de la défectuos

verte, b) indiquer le numéro de modèle et les données d’identifi cation de la pièce, et c) décrire la nature de toute défectuosité du produit ou

de la pièce. Au moment où vous demandez le service de garantie, vous devez présenter une preuve de la date de l’achat initial. Si vous ne

pouvez pas produire de copie de l’original de la garantie limitée, alors ce seront les modalités de la dernière version de la garantie limitée

de votre produit de l’entreprise qui s’appliqueront.

ité cou-

- 29 -

Page 30

SPÉCIFICATIONS DU PRODUIT

Toutes les illustrations et les spécifi cations des produits contenues dans ce catalogue sont établies d’après les plus récentes donnéesdi-

sponibles en date de la production. Broan-NuTone LLC et BESTᴹᴰ se réservent le droitde modifi erles prix, les couleurs, les composants,

les produits, les spécifi cations et les modèles, de déplacer le lieu de fabrication et de cesser la production d’un modèle ou d’un produit,

et ce, en tout temps et sans préavis.

Best

Broan-NuTone LLC : 926 W. State Street, Hartford (WI) 53207

1 800 637-1453

Bestᴹᴰ, 550, boul. Lemire, Drummondville (Québec), Canada (1 866 737-7770) fr.bestrangehoods.ca

- 30 -

Page 31

PIÈCES DE RECHANGE

DC54MSB

N° N° PIÈCE DESCRIPTION

135 B08094361

SPO B08094130 Couvercle assemblé

9 B08087761 Filtre à graisses

IME B06142998

60 B02300248 Cordon d’alimentation

146 B032920180 Boîtier de câblage

998 B080811046 Sachet de pièces

Cadre avec commandes

Ensemble système électrique

- 31 -

Page 32

- 32 -

Page 33

Modelo DC54MSB

ENGLISH............................................3

FRANÇAIS.......................................17

ESPAÑOL.........................................33

En EE.UU.: BEST Hartford, Wisconsin

En CANADÁ - BEST Drummondville, QC, Canada

REGISTRE SU PRODUCTO EN LÍNEA EN: www.BestRangeHoods.com/register

Para obtener información adicional visite www.BestRangeHoods.com

- 33 -

Page 34

LEA Y CONSERVE ESTAS INSTRUCCIONES

INDICADO PARA EL USO EN COCINAS DOMESTICAS

ADVERTENCIA

PARA EVITAR EL RIESGO DE INCENDIO, CORTOCIRCUITO O DAÑO PARA LAS PERSONAS, OBSERVE ATENTAMENTE LAS SIGUIENTES NORMAS:

1. Use esta unidad solamente de la manera indicada por el fabricante; si tiene dudas, póngase

en contacto con éste a la dirección o teléfono indicados en la garantía.

2. Antes de hacer una revisión o de limpiar la unidad, desconéctela de la red para evitar que

se encienda de manera accidental. En el caso de que éste no pueda ser desacti-vado, se

indicará nel panel de servicio.

3. El montaje y la instalación eléctrica debe hacerlos un técnico especializado siguiendo las

normas estándar e incluyendo aquellas de construcción anti incendio.

4. Necesita aire sufi ciente para una apropiada combustión y escape de gases a través del

tubo del depósito de quema de combustible. Para evitar que el humo aspirado vuelva a la

cocina, siga las directivas del fabricante y las normas estándar de siguridad así como las

normas publicadas por la Asociación de prevención de incendios (NFPA) y la Socie-dad

americana de especialistas en cale-facción, refrigeración y aire acondicionado y además

las normas de las autoridades locales.

5. Hacer un corte o un taladro en la pared o en el techo no debe dañar la instalación eléctrica

u otras instalaciones ocultas en la pared.

6. Los conductos ventiladores deben siempre desalojar al exterior.

7. No use esta unidad con dispositivo de control de la velocidad a estado sólido.

8. Para evitar el riesgo de incendio, use solamente conductos de metal.

9. Esta unidad tiene que ser conectada a tierra.

10. Cuando las regulaciones locales comprenden la instalación y los requisitos más restrictivos

/ o certifi cación, los requisitos anteriores prevalecen sobre las del presente documento y

el instalador se compromete a cumplir con estas exigencias a sus propios gastos.

PARA EVITAR EL RIESGO DE FUEGO POR ALTO NIVEL DE GRASA:

A. Nunca abandone los quemadores con el fuego alto. La cocción causa humo y restos

de grasa que pueden arder. Caliente el aceite a fuego medio o bajo.

B. Encienda siempre el aparato cuando cocine a fuego alto o cuando cocine alimentos

fácilmente infl amables. (por ejemplo Crê

fl ambeada con granos de pimienta).

C. Limpie con frecuencia los ventiladores. No se debe acumular grasa en el ventilador o

en el fi ltro.

D. Usa el tamaño de cazuela apropiado. Use siempre utensilios de cocina de tamaño y

material adecuados.

E. Usa solo con cocinas eléctricas o de inducción. Sin Gas.

pes Suzette, Cerezas Jubilee, Ternera

ADVERTENCIA

PARA EVITAR EL RIESGO DE DAÑOS A PERSONAS EN CASO DE FUEGO POR ALTO

NÍVEL DE GRASA, TENGA EN CUENTA LO SIGUIENTE:*

1. SOFOQUE LA LLAMA con una tapadera apropiada, una bandeja metálica ó un utensilio de

cocína que pueda cubrirla, despues, apague el quemador. ACTÚE CON PRECAUCÍON

PARA EVITAR QUEMADURAS. SI LA LLAMA NO SE EXTINGUE INMEDIATAMENTE ,

SALGA Y LLAME A LOS BOMBEROS.

2. NUNCA COJA UNA SARTEN EN LLAMAS, porque corre el riesgo de quemarse.

3. NO USE AGUA ni paños o toallas húmidas porque puede provocarse una violenta hu-

mareda.

4. Use un extintor SOLAMENTE si:

A. Posee un extintor de clase ABC y sabe perfectamente cómo usarlo.

B. El fuego es pequeño y está controlado en el mismo sitio en que empezó.

C. Ha llamado con anterioridad a los bomberos.

D. Puede combatir el fuego retrocedíendo hacia la salida.

* Basado en “Seguridad antifuego en la cocína” publicado por NFPA.

- 34 -

Page 35

ADVERTENCIA

1. Para uso en interiores.

2. Para reducir el riesgo de incendios y para evacuar correctamente los humos, ase-

gurarse de haber realizado una conducción del aire hasta el exterior. No expulsar

los humos en espacios cerrados por paredes o techos, áticos, espacios angostos

o garajes.

3. Prestar la máxima atención al utilizar productos de limpieza o detergentes.

4. Evitar el uso de productos alimentarios que puedan infl amarse bajo la campana.

5. Sólo para ventilación total. No use gases de escape peligrosos o materiales y vapores

explosivos.

6. Para evitar daños en el funcionamiento del motor e impulsores ruidosos y/o desequi-

librados, mantenga alejados de la unidad de encendido pulverizadores en seco o

polvo.

7. Se recomienda leer la placa de caracteristicas del producto para ulterior infor-

mación.

8. Aparato con automatismo. Para evitar el riesgo de daños, colocar el interruptor del

panel de servicio en la posición OFF antes de mantenimiento.

9. Atención: este dispositivo no está diseñado para una cocina de gas.

El cable de la fuente de alimentación se debeen rutar por debajo del aparato y

10.

alejarse del calor generado por la estufa.

11.

PRECAUCIÓN: Para reducirelriesgo de incendio y descargaeléctrica, instale

este “Downdraft” solo con motor”Downdraft” integralfabricado por Best,

modelo (s) PF6 o PF3. Otrosmotores no pueden ser sustituidos. (Motorenviado

por separado)

INSTRUCCIONES DE CONEXIÓN A TIERRA

Este aparato debe estar conectado a tierra. En caso de cortocircuito, el cable de

conexión a tierra limita el riesgo de descarga eléctrica porque garantiza el retorno de

la corriente a tierra. La unidad se suministra con un cable con un cable a tierra y un

enchufe de conexión a tierra, que debe enchufarse en un tomacorriente con conexión

a tierra instalado correctamente.

ADVERTENCIA: una conexión a tierra inadecuada puede provocar un riesgo

de descarga eléctrica. Consulte a un electricista califi cado si no está seguro de

estas instrucciones de conexión a tierra o si no está seguro de la conexión a tierra

adecuada del circuito al que está conectada la unidad.

No utilice un cable de extensión. Si el cable de alimentación es demasiado corto,

tomada por un electricista competente cerca del aparato.

- 35 -

Page 36

PREPARE LA CAMPANA

Sacar la campana de l’embalaje y controlar el contenido.

Recivireis:

1 - Campana

1 - Bolsita (B080811046) con:

10 - Tornillos de montaje (3.9 x 6 mm cabeza plano)

6 - Tornillos de montaje (4.2 x 15 mm)

2 - Abrazaderas de montaje

2 - Abrazaderas de transicion

1 - Instrucciones para instalación

2 ABRAZADERAS

DE TRANSICCION

10 TORNILLOS DE MONTAJE (3.9 x 6

mm)

6 TORNILLOS DE MONTAJE (4.2 x 15 mm)

2 ABRAZADERAS

DE MONTAJE

- 36 -

Page 37

ANTES DE QUE EMPIECES

Esta unidad se puede instalar siguiendo estos

pasos básicos:

- Cortar la abertura de la encimera.

- Montar la corriente descendente en el armario.

- Instale el ventilador y el panel eléctrico.

- Conectar los conductos y eléctricos.

- Instale el aparato de cocción.

PREPARACION

Preparación del mueble:

Nota: este tiro descendente solo se puede utilizar

con placas eléctricas. Consulte la Figura 2 para

ver ejemplos de instalaciones típicas.

Para instalaciones que usan una placa eléctrica,

el vataje total máximo del elemento es de 9400

vatios. Para instalaciones que utilizan dos placas

de cocina eléctricas, el vataje total máximo del

elemento es de 3400 vatios. Siga las instrucciones del fabricante de la cubierta para preparar el

gabinete y la encimera para la

instalación de la cubierta.

Determine la ubicación de la (s) corriente (es)

descendente (s) y corte una abertura de 4-13 /

16 “x 19-5 / 16” en la encimera. Tenga en cuenta

que será necesario instalar un tomacorriente en

el gabinete para suministrar energía a la caja de

control de tiro descendente. Consulte la sección

titulada “Cableado” para obtener más información.

FIGURE 2

DOWN

DRAFT

Ejemplos de instalación

PLACA

ELECTRICA

FIGURE 1

DOWN

DRAFTS

PLACAS

ELECTRICAS

MOTOR

CONDUC-

TO

CAJA ELECTRICA

MOTORS

CAJAS ELECTRICAS

- 37 -

Page 38

INSTALACION DEL TUBO DE

EXTRACCION

NOTA: para evitar el riesgo de incendio, use

solamente material de metal.

1. Decida donde va a colocar el tubo de extrac-

ción entre el downdraft y la parte exterior.

2. Un recorrido de tubo corto y recto permitirá al

downdraft funcionar de manera más efi caz.

3. Los recorridos largos de tubo, codos y man-

guitos impiden el buen funcionamiento del

downdraft. Use el menor número de ellos

posible. Para usos prolongados es necesario

un tubo de evacuación del aire de mayor

diámetro.

4. Instale una cubierta ó una tapa. Una el tubo

de metal a la cubierta y retroceda hasta la

posición del downdraft. Use une cinta para

precintar las juntas entre las partes del entubado.

FIGURE 3

MAN-

GUITO

TAPA

PARED

DOWNDRAFT

TUBO RE-

DONDO DE 8”

- 38 -

Page 39

PREPARACION

Consulte la Figura 4. Si usa la salida de

aire derecha, siga los siguientes pasos:

1. Retire (1) la cubierta lateral (Fig.5).

2. Retire la cubierta ensamblada (Fig.6).

3. Retire el fi ltro de grasa (Fig.7).

4. Retire el soporte del fi ltro de grasa,

gírelo y vuelva a insertarlo (Fig.8).

5. Vuelva a insertar el fi ltro de grasa (Fig.

9) y la cubierta ensamblada (Fig.10).

6. Fije la cubierta lateral del otro lado

(Fig.11).

FIGURE 4

SALIDA DE

AIRE A LA

IZQUIERDA

SALIDA DE

AIRE A LA

DERECHA

FIGURE 5

FIGURE 8

FIGURE 10

FIGURE 6 FIGURE 7

FIGURE 9

FIGURE 11

- 39 -

Page 40

INSTALACION

ATENCION: el downdraft debe ser instalado

por un instalador califi cado.

La transición se debe comprar por

separado.

1. Inserte el downdraft en la encimera

(Fig.12).

2. Asegure (2) abrazaderas de transición

al transición con tornillos de montaje de

3.9x6 mm (Fig.13).

3. Asegure la transición (modelo Best 459

comprar por separado) al downdraft

con (4) tornillos de montaje de 3.9x6

mm (Fig.14).

4. Asegure los abrazaderas con los tornillos

de montaje (Fig.15).

FIGURE 12

FIGURE 13

FIGURE 15

TORNILLOS

DE MONTAJE

(4.2 x 15 mm)

TORNILLOS

DE MONTAJE

(3.9 x 6 mm)

ABRAZADERAS DE

TRANSICIÓN

FIGURE 14

TRANSICIÓN

TORNILLOS DE

MONTAJE

(3.9 x 6 mm)

TORNILLOS

DE MONTAJE

OPCIONAL

(4.2 x 15 mm)

TORNILLOS

DE MONTAJE

(3.9 x 6 mm)

- 40 -

Page 41

5. Coloque el motor dentro el mueble y

asegurelo en su lugar (Fig.16), usando la

bolsa de montaje provista con el motor.

FIGURE 16

CONEXION

DEL CONDUCTO

1. Utilice un conducto de metal redondo de

8” (150 mm) para conectar la transición

con el tubo de arriba. Fig. 17

2. El conducto tapa todas las juntas, ase-

gurándolas y volviéndolas herméticas.

FIGURE 17

TUBO REDON-

DO DE 8”

- 41 -

Page 42

INSTALACIÓN ELECTRICA

Nota: Este tipo de aparelho tiene que ser conectada a tierra cuidadosamente.

La unidad debe instalarla un técnico electricista siguiendo las normas nacionales y locales.

1. Asegure la caja eléctrica al gabinete con (4) tornillos de montaje de 4.2x15mm

(vea la Fig.1).

2. Abra la caja eléctrica desenroscando (4) tornillos (vea la Fig. 2).

3. Abra la caja de connección desenroscando (4) tornillos (vea la Fig. 3).

4. Retire un agujero ciego de la caja eléctrica e inserte una abrazadera de alivio

de tensión.

5. Haga conexiones eléctricas. Conecte los cables del motor al comando:

Motor PF6: azul a azul, rojo a rojo, negro a naranja, blanco a blanco, verde /

amarillo a tierra.

Motor PF3: azul a azul, rojo a rojo, naranja a naranja, blanco a blanco, verde /

amarillo a tierra.

6. Vuelva a sellar la caja de connección y la caja eléctrica con tornillos. Asegúrese

de que los cables no queden atrapados entre la cubierta y la caja.

FIGURE 18

MOTOR

ABRADAZERA

DE ALIVIO DE

TENSION

CAJA

ELECTRICA

VIS DE MONTAGE

(4.2 x 15 mm)

- 42 -

CAJA DE CO-

NECCION

Page 43

MANTENIMIENTO

Un mantenimiento adecuado do aparato asegura el funcionamiento correcto del aparato.

ANTES DE REALIZAR OPERACIONES DE

MANTENIMIENTO O LIMPIEZA DE LA UNIDAD, DESCONECTE LA ALIMENTACIÓN EN

EL PANEL DE SERVICIO Y CIERRE EL MISMO CON UN CANDADO. DESCONECTAR EL

SERVICIO SIGNIFICA EVITAR LA CONEXIÓN

ACCIDENTAL DE LA ALIMENTACIÓN.

SI NO ES POSIBLE CERRAR EL PANEL DE

SERVICIO CON UN CANDADO, COLOQUE

EN ÉL UN DISPOSITIVO DE SEÑALIZACIÓN

ADECUADO COMO, POR EJEMPLO, UN

LETRERO DE ADVERTENCIA.

Filtros antigrasa

Los fi ltros de grasa deben limpiarse periódica-

mente según el uso (aproximadamente cada

mes).

Utilice una solución limpiadora tibia. El fi ltro de

grasa es a prueba de lavavajillas. Limpie los

fi ltros que sean completamente de metal del

lavavajillas con un detergente sinfosfato. Es

posible que se produzca una decoloración del

fi ltro si se usan detergentes confosfato o como

resultado del estado del agua local, pero esto

no afectará el rendimientodel fi ltro. Esta decol-

oración no está cubierta por la garantía.

Para desmontar los fi ltros de grasa, empuje hacia

dentro el retén cerca de la manilla y tire del fi ltro

hacia abajo (Fig. 19).

Limpieza de la bandeja para líquidos

El equipo está provisto con bandeja para recoger partede aceite, grasa y condensación

de la cocina. Sáquese la bandeja (Fig. 20) manteniéndola en la posición horizontal y

límpiese con agente neutro de limpieza. La limpiezadebe efectuarse periódicamente

en función del gastopor término medio cada mes.

Limpieza de la campana

El acero inoxidable es uno de los meteriales más fáciles de limpiar, pero sería aconsejable un especial cuidado en su uso para mantenerla en buen estado. La campana se

puede limpiar de las siguientes maneras:

l Agua caliente con jabón o detergente es la mejor manera para limpiarla.

l Aclárela con agua corriente, séquela con un paño suave y limpio para evitar las

huellas que deja el agua.

l Para las manchas o restos de grasa que persistan, use un producto químico doméstico

que no raye ó un limpiador para acero inoxidable con poca agua y un paño suave.

l Si las manchas persisten, use un estropajo y un cepillo de cerdas suaves con un

producto limpiador y agua. Frote suavemente en el sentido del pulido o de las “vetas”

del remate del inoxidable. No apriete demasiado porque podría dañar la superfi cie.

• NO DEJE que las manchas se acumulen durante mucho tiempo.

• NO USE utensilios o cepillos de acero. Pequeñas particulas de acero pueden ad-

herirse y oxidarse.

• NO USE soluciones salinas, desinfectantes, lejías, o productos de limpieza en con-

tacto con el acero inoxidable. Muchos de estos productos contienen componentes

químicos que podrían resultar nocivos. Aclare con agua y seque con un paño limpio.

• NO USE nunca lejía!

• Las superfi cies lacadas deben limpiarse solamente con agua tibia y detergente no

muy fuerte.

FIGURE 19

FIGURE 20

- 43 -

Page 44

FUNCIONAMIENTO

Notas: Evite utilizar productos que-

produzcan llamas cerca do aparehlo.

Mandos (Fig.21)

El botón “—” : mantener pulsado (durante

aproximadamente 2 segundos) para desactivar

el motor. Una pulsación corta, con el motor en

marcha, reduce la velocidad del motor.

El botón “+”: mantener pulsado (durante

aproximadamente 2 segundos) para activar el

motor. Una pulsación corta, con el motor en

marcha, aumenta la velocidad del motor.

LED 1, 2 y 3 activadas, indica les velocidades.

La función del temporizador Timer 10

minutos

Después de pulsar el botón “+” durante dos

segundos,se activa la función del temporizador

Timer 10 minutos. LED de velocidad actual

empieza a parpadear para mostrar la función.

Después de 10 minutos de funcionamiento,

el motor se apaga. Después del cambio de

velocidad con el temporizador activado, la

funcción NO es desactivada. Para desactivar

la función pulse el botón “+” durante dos

segundos.

FIGURE 21

Alarma de fi ltros

ALARMA de fi ltros30H: después de 30 horas

de funcionamiento se activa una alarma con el

fi n de limpiar el fi ltro de grasa. La alarma del

fi ltro cuando se activa, se muestra durante 30

segundos cada vez que el motor se desactiva:

LED 2 permanece encendida o parpadea.

Durante este período, es posible restablecer la

alarma por una presión prolongada del botón

“—” (led 2 parpadea 2 dos veces para indicar

que se ha reseteado).

Tiempo límite de operación

Después de 10 horas de inactividad, el aparato

se detendrá automáticamente.

- 44 -

Page 45

Garantía limitada

Periodo de garantía y exclusiones: Broan-NuTone LLC (la «Compañía») garantiza al consumidor quien compra su producto(«Usted»)

que el producto (el «Producto») será libre de defectos importantes de fabricación y de materiales por una duración de cinco (5) años a

partir de la fecha de compra (o por una duración más larga si la ley aplicable lo exige) o un periodo de dos (2) años a partir de la fecha de

prestación de un servicio sobre el Producto.

El periodo de garantía limitadapara las piezas de repuesto proporcionadas por la Compañía y los Productos reparados o reemplazados

bajo esta garantía limitadaserá el resto del periodo de garantíaoriginal (o un periodo más largo si la ley aplicable lo exige).

ESTA GARANTÍA EXCLUYE LOS ARRANCADORES DE LÁMPARAS FLUORESCENTES, LOS TUBOS, LAS BOMBILLAS, LOS

FUSIBLES, LOS FILTROS, LOS CONDUCTOS, LAS TAPAS PARA TECHO, LAS TAPAS PARA PARED Y LOS OTROS ACCESORIOS

PARA CONDUCTOS. También excluye: a) el mantenimiento normal, b) el uso y desgaste normales, c) los productos y las piezas que han

sido objeto de un uso indebido, anormal o negligente, un maltrato, un accidente, un mantenimiento, almacenamiento o reparación inadecuados (excepto en caso de reparación por la Compañía), d) los daños causados por una instalación inadecuada, o por una instalación o

un uso contrario a las recomendaciones o instrucciones, e)los daños causados por el contacto con el aire salino, f) los daños que ocurran

durante el transporte, g) el desgaste normal del acabado, h) los Productos que son objeto de un uso comercial o no residencial, i) los daños

causados por el fuego, una inundación u otro desastre natural o j) los Productos a los cuales se les haya alterado, desfi gurado o removido

el número de serie. Esta garantíasolo cubre los Productos vendidos a consumidores de Norteamérica.

Esta garantía substituye todas las garantías anteriores y, sin perjuicio de la ley aplicable, no se puede transferir por el comprador original.

Ninguna otra garantía: Esta garantía limitadaenuncia la única obligación de la Compañía y el único recurso que tiene Usted en cuanto

a los Productos defectuosos. Las garantías enunciadas arriba son exclusivas y se anteponen a todas las otras garantías y condiciones,

ya sean expresas o implícitas. EN LA MEDIDA MÁXIMA EN QUE LO PERMITA LA LEY APLICABLE, LA COMPAÑÍARENUNCIA A TO-

DAS LAS OTRAS GARANTÍAS Y CONDICIONES EXPRESAS O IMPLÍCITAS POR LA LEY Y LAS EXCLUYE, INCLUYENDO, ENTRE

OTRAS, LAS GARANTÍAS DE COMERCIALIZACIÓN Y LAS DE IDONEIDAD PARA UN PROPÓSITO PARTICULAR. En la medida en

que la ley aplicable prohíba la exclusión de las garantías o condiciones implícitas, la duración de cualquier garantía o condición implícita

aplicable se limita al periodo indicado para la garantía expresa mencionada arriba. Ciertas jurisdicciones (incluyendo a veces la provincia

de Quebec o ciertos estados de los Estados Unidos) prohíben la restricción de la duración de las garantías implícitas, así que la restricción

mencionada arriba podría no aplicarse a Usted.Las descripciones orales o escritas del Productotienen como único propósito identifi car al

Producto y no se deben interpretar como una garantía expresa.

Cuando sea posible, cada disposición de esta garantía limitadase debe interpretar de manera que tenga plena validez y efectos legales

bajo la ley aplicable, pero en el caso de que se declare prohibida o nula una disposición, ésta será nula solo en la medida en que lo prevea

esta prohibición o nulidad, sin efecto para los otros elementos de esta disposición o las otras disposiciones de esta garantía limitada.

Recurso: Durante el periodo de garantía limitadaaplicable, la Compañía, según su criterio, proporcionará piezas de repuesto o servicios

de reparación o reemplazo sin cargo alguno para cualquier Producto o pieza de Producto, en la medida en que la Compañíaconstata

a) que esta garantía cubre este Producto o esta pieza bajo un uso y mantenimiento normales y b)que la garantía queda incumplida. La

Compañíale enviará el Producto reparado, el producto de reemplazo o las piezas de repuesto sin cargo alguno. Usted tendrá que pagar

todos los costos de desinstalación, reinstalación y envío así como los otros cargos de transporte relacionados con el envío del Producto o

la pieza a la Compañía. Si Usted debe enviar el Producto o la pieza a la Compañía, conforme a las instrucciones de la misma, Usted tendrá

que empaquetar el Producto o la pieza correctamente; la Compañíano es responsable de los daños que ocurran durante el transporte.

La Compañíase reserva el derecho de utilizar Productos o piezas reacondicionados, renovados, reparados o remanufacturados para la

reparación o el reemplazo bajo esta garantía. Estos Productos y piezas serán comparables en cuanto a la función y el rendimiento con

el Productoo la pieza original y serán garantizados por la duración restante del periodo de garantíaoriginal (o por una duración más larga

si la ley aplicable lo exige).

La Compañíase reserva el derecho, según su exclusivo criterio, de reembolsar el monto que Usted haya realmente pagado por el Producto.

Si el Producto o la pieza ya no está disponible, la Compañía puede, según su exclusivo criterio, reemplazarlo con un producto similar de

valor igual o superior. Esto constituye su único y exclusivo recurso en caso de incumplimiento de esta garantía limitada.

Exclusión de los daños: LA OBLIGACIÓN DE LA COMPAÑÍA DE PROPORCIONAR PIEZAS DE REPUESTOO DE REPARAR O

REEMPLAZAR EL PRODUCTO, SEGÚN SU CRITERIO, ES EL ÚNICO Y EXCLUSIVO RECURSO QUE TIENE USTED BAJO ESTA

GARANTÍA LIMITADAY LA ÚNICA OBLIGACIÓN DE LA COMPAÑÍA. ÉSTA NOSERÁ RESPONSABLE DE LOS DAÑOS INCIDENTALES, INDIRECTOS, CONSECUENTES O ESPECIALES CAUSADOSDIRECTAMENTE O INDIRECTAMENTE POR EL PRODUCTO,

SU USO O SU RENDIMIENTO.

Puesto que ciertas jurisdicciones prohíben la exclusión o restricción de los daños incidentales o consecuentes, la exclusión o restricción

mencionada arriba podría no aplicarse a Usted. Esta garantíale otorga derechos legales específi cos, y Usted también podría tener otros

derechos, los cuales pueden ser diferentes según la jurisdicción. Las renuncias, exclusiones y restricciones de responsabilidad bajo esta

garantíano se aplican en la medida en que lo prohíba la ley aplicable.

Esta garantíasolo cubre el reemplazo o la reparación de las piezas o los Productos defectuosos al sitio de negocio principal de la Compañía;

los gastos de viaje y estancia relacionados con los servicios de campo están excluidos.

Cualquier asistencia proporcionada u obtenida para Usted por la Compañíay que no está cubierta por las condiciones, restricciones

oexclusiones de esta garantía limitadano constituye una renuncia a estas condiciones, restricciones y exclusiones, y la prestación de dicha

asistencia no prolongará o restablecerá la garantía.

La Compañíano le reembolsará los gastos que Usted haya hecho por la reparación o el reemplazo de un Producto defectuoso, excepto

si Usted ha previamente recibido el permiso escrito de la Compañía por ellos.

Cómo obtener el servicio de garantía

número de teléfono escrito aquí abajo dentro de siete (7) días después de que haya descubierto el defecto cubierto, b) dar el número de