Page 1

Models: D49M30SB, D49M30BLS, D49M36SB, D49M36BLS, D49M48SB

Downdraft Ventilator

For use with these blowers

(purchase blowers separately):

Model PF6* - Flex Blower - Interior

Models EB6, EB9*, EB12*, or EB15* - Exterior

Models ILB6, ILB9 or ILB11* - In-Line

* Recommended models

READ AND SAVE THESE INSTRUCTIONS

In U.S.A., register your product online at: www.BestRangeHoods.com

In Canada, register your product online at: www.BestRangeHoods.ca

Français p. 38

Español p. 75

Page 2

Table of Contents

Safety Information .................................................................................................................................................................................. 3

Contents .................................................................................................................................................................................................. 4

Electrical Specifi cations ......................................................................................................................................................................... 4

Tools Needed ........................................................................................................................................................................................... 4

Planning

Before You Begin ............................................................................................................................................................................... 5

Taking Measurements........................................................................................................................................................................ 5

Ducting Confi gurations ...................................................................................................................................................................... 5

Cabinet Cutouts .................................................................................................................................................................................11

Electrical Outlet Location ...................................................................................................................................................................13

Preparing the Downdraft

Downdraft Preparation ....................................................................................................................................................................... 14

Side, Below or Rear Rectangular Ducting ........................................................................................................................................... 14

Side, Below or Rear Round Ducting .................................................................................................................................................... 14

Front Ducting .....................................................................................................................................................................................15

Electrical Panel in Remote Location ...................................................................................................................................................16

Final Assembly ................................................................................................................................................................................... 16

Installation

Cutting Countertop Opening ............................................................................................................................................................... 17

Install Housing into Cabinet ................................................................................................................................................................ 18

Installing Finish Trim ..........................................................................................................................................................................19

Installing Ductwork ............................................................................................................................................................................19

Electrical Wiring Installation

Flex Blower Only ................................................................................................................................................................................20

Exterior or In-Line Blower Only ..........................................................................................................................................................11

Appliance Installation/Operation ........................................................................................................................................................... 22

Use and Care ........................................................................................................................................................................................... 23

Optional Accessories .............................................................................................................................................................................. 24

Appendices A-I ....................................................................................................................................................................................... 26

Warranty .................................................................................................................................................................................................35

Service Parts ...........................................................................................................................................................................................36

2

Page 3

Safety Information

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number on the back page.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service

panel.

3. Installation work and electrical wiring must be done by a

qualifi ed person(s) in accordance with all applicable codes and

standards, including fi re-rated construction codes and

standards.

4. Suffi cient air is needed for proper combustion and exhausting

of gases through the fl ue (chimney) of fuel burning equipment

to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. To reduce the risk of fi re, use only metal ductwork.

8. Do not install this product with the activating switch directly

behind a burner or element. Minimum distance between the

switch and the edge of the burner should be 4 inches.

9. Loose-fi tting or hanging clothing should never be worn when

operating this appliance. They may be ignited by burners/

elements on cooktop.

10. Children should not be left alone or unattended in the area

where this appliance is in use.

11. This unit must be grounded.

12. When applicable local regulations comprise more restrictive

installation and/or certifi cation requirements, the aforementioned

requirements prevail on those of this document and the installer

agrees to conform to these at his own expense.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boil

overs cause smoking and greasy spillovers that may ignite.

Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

cooking fl aming foods.

c) Clean ventilating fans frequently. Grease should not be allowed

to accumulate on fan or fi lter.

d) Use proper pan size. Always use cookware appropriate for the

size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:

1. SMOTHER FLAMES with a close-fi tting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO PREVENT

BURNS. If the fl ames do not go out immediately, EVACUATE AND

CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels a violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher, and you

already know how to operate it.

B. The fi re is small and contained in the area where it started.

C. The fi re department is being called.

D. You can fi ght the fi re with your back to an exit. Based on

“Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off

power unit.

4. Clean fi lters and grease-laden surfaces frequently.

5. Do not repair or replace any part of this appliance unless

specifi cally recommended in this manual. All other servicing

should be done by a qualifi ed technician.

6. Please read specifi cation label on product for further

information and requirements.

7. When installing, servicing or cleaning the unit, it is

recommended to wear safety glasses and gloves.

8. To reduce the risk of fi re and electric shock, install this

downdraft only with blower models shown below. Other blower

models cannot be substituted. (Blowers sold separately).

Flex Blower Model PF6, Exterior Blower Models EB6, EB9,

EB12, or EB15 In-Line Blower Models ILB6, ILB9, or ILB11.

INSTALLER: Save this manual for Electrical Inspector

and Homeowner to use.

3

Page 4

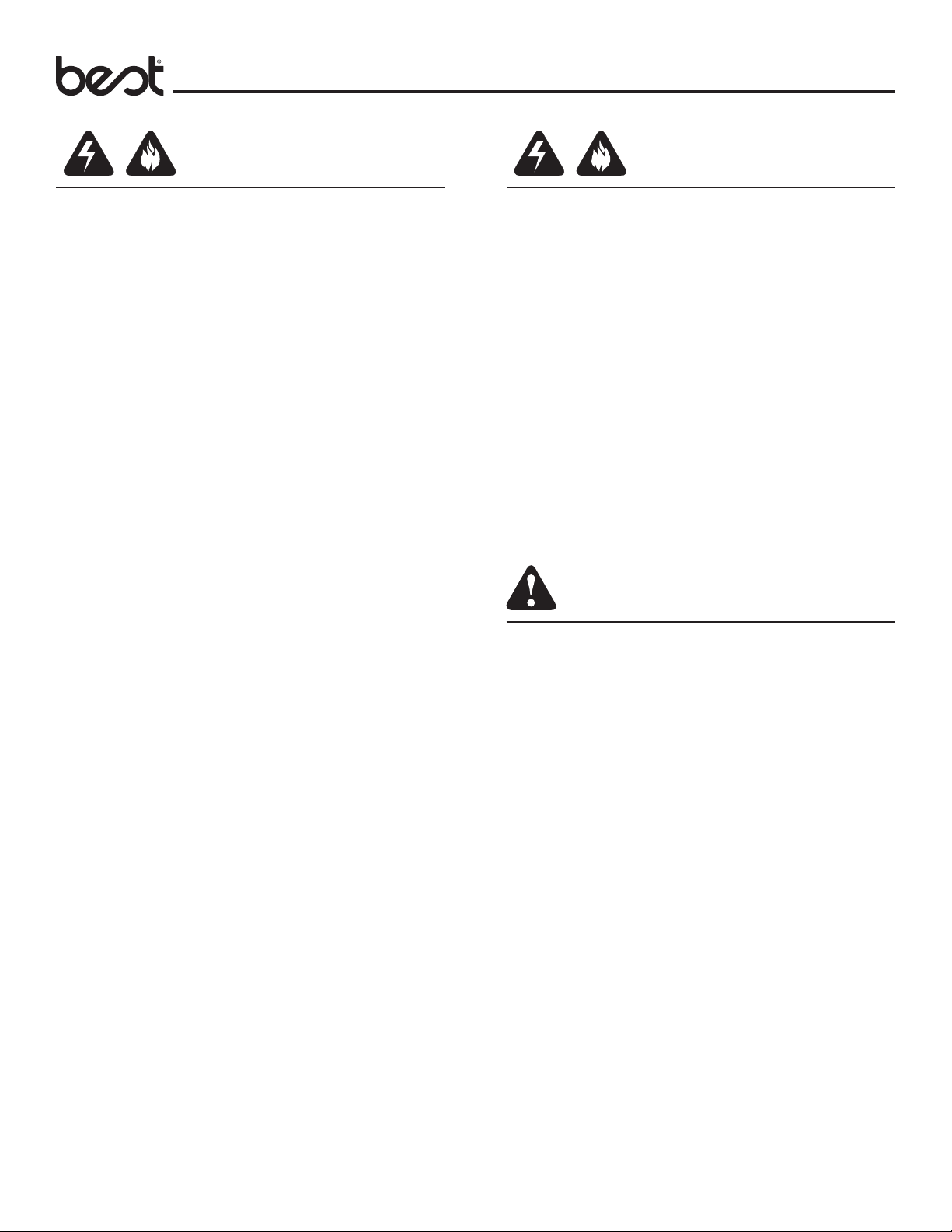

Contents

C

x8

D

AA

A

x4

F

x2

E

G

H

ELECTRICAL

SPECIFICATIONS

Model PF6 - Internal Flex:

120 VAC • 60 Hz • 3.0 A

Models EB6, EB9, EB12, or EB15 - Exterior

Models ILB6, ILB9 or ILB11 - In-Line

120 VAC • 60 Hz • 6.0 A (max.)

B

x2

BB

J

I

Part Description Quantity

A Upper support bracket (left) 1

B Downdraft ventilator housing 1

C End cap trim (left) 1

D End cap trim–up button (right) 1

E Support leg 2

F Discharge cover 4

Part Description Quantity

G Front panel cover 1

H Electrical panel 1

I Upper support bracket (right) 1

J Flip door 1

AA #10 x .50 Phillips round head screw 8

BB #8-18 x .375 Phillips screw 2

Tools Needed

Measuring tape, pencil, Phillips screwdriver #2, nut drivers (11/32", 3/8", 7/16"), saw, spirit-level, tin snips, work gloves, and aluminum tape.

(DO NOT use insulating tape.)

4

Page 5

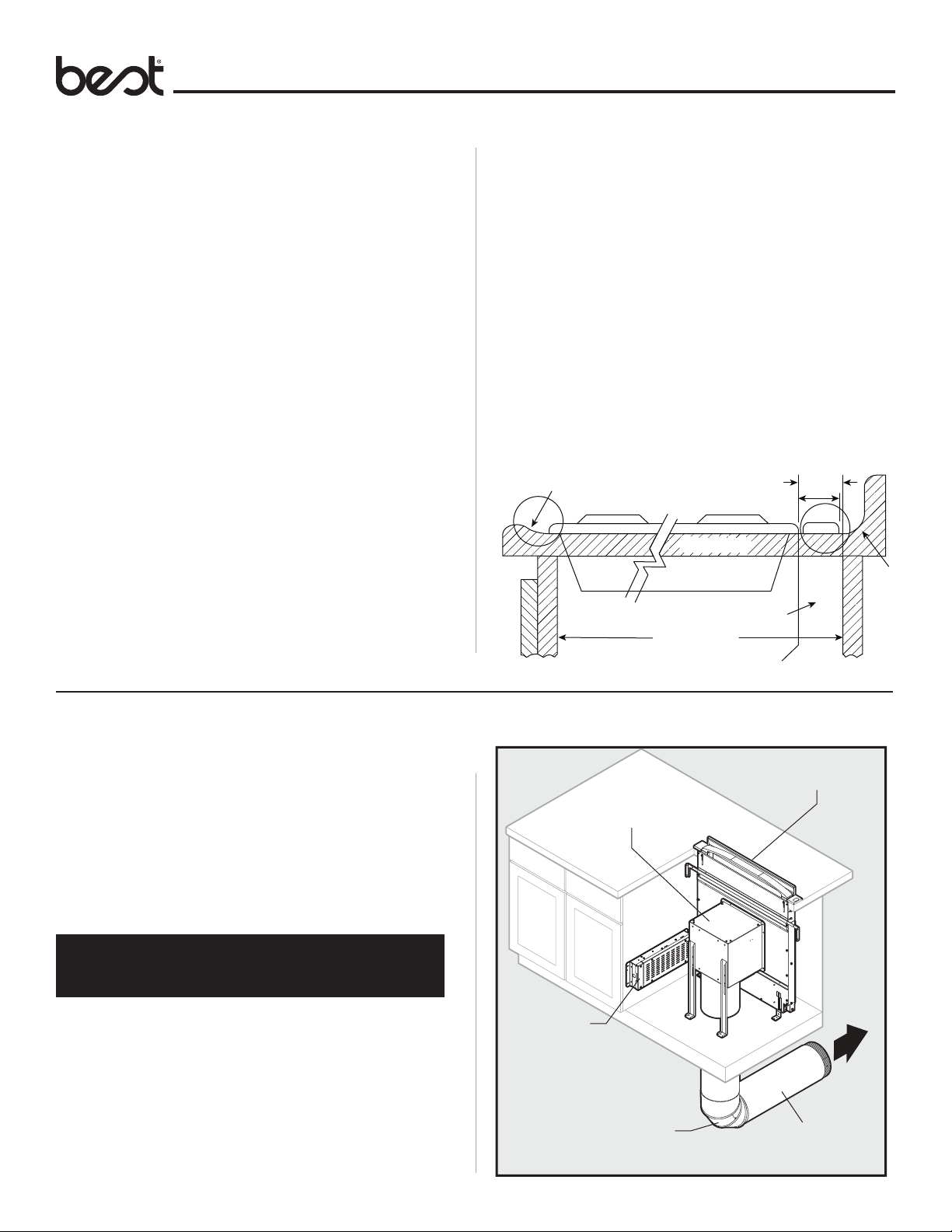

Before You Begin

Planning

Due to its fl exible design, this downdraft system can be used to

exhaust airborne contaminants when cooking with a variety of gas

or electric cooking appliances - including cooktops, rangetops,

slide-in ranges and free-standing ranges.

It can be mounted in island, peninsula, or conventional wall

locations. The blower (purchase separately) and electrical panel

can be mounted to the downdraft unit, inside the cabinet, or in a

convenient remote location.

This unit can be easily installed following these basic steps:

• Cut out the countertop opening.

• Mount the unit in the cabinet.

• Install the blower and electrical panel.

• Connect the ductwork and electrical.

• Install the trim.

• Install the cooking appliance.

Note: the high level of air ow of this appliance may affect the

gas ame on some types of gas cooktops. This is NORMAL and

will cause no harm, but can be corrected by lowering the speed

of the blower.

Gas Cooktop Seal Kit is recommended for use with all gas

cooktops. The kit creates a seal between the cooktop and the

lower cabinet. Includes trim bracket and trim seal. See Optional

Accessories section.

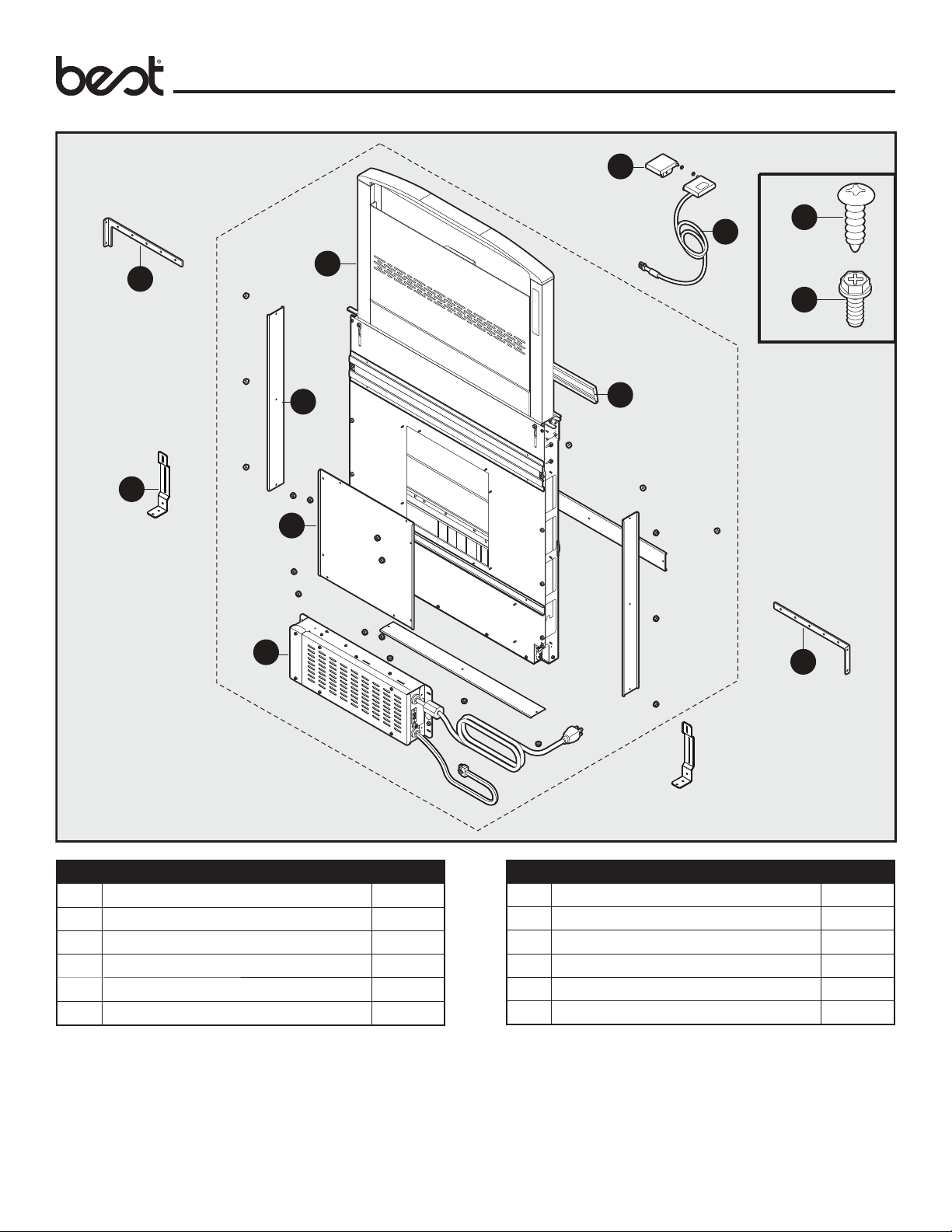

Taking Measurements

• Refer to the cooktop installation instructions for dimensions

of cooktop, countertop cut-out, and cabinet requirements.

However, it is recommended that oversized cabinets be used

for easier installation. Custom island designs need to account

for deeper cabinets - especially when installed with a range in

front of the downdraft or when mounting the blower behind the

downdraft. You must also plan for an access door.

• Cooktop depth can vary greatly from one to another. This

may cause the fi t of these two appliances to be rather tight.

Pay special attention to the areas of potential interference

highlighted below. A countertop with (A) a raised lip and/or (B)

a backsplash may not allow enough fl at countertop for a proper

installation. Note that 2-3/4" of fl at countertop is required

behind cooktop and that 2-7/8" is necessary between the back

edge of the cooktop and the inside of cabinet back.

A

CountertopCountertop

Cooktop

Front to Back

Inside Cabinet Depth

2-7/8"

2-3/4"

Downdraft

B

Ducting Confi gurations

• The downdraft blower system is designed for use with 8"

round ductwork using a fl ex blower or 10" round ductwork

using a remote blower. (Purchase blowers separately.)

• For best performance: Choose the ducting option which allows

the shortest length of ductwork and a minimum number of

elbows and transitions. Check location of fl oor joists, wall

studs, electrical wiring or plumbing for possible interference.

For more detailed ducting information see appendices A-G

at the end of document.

Front Exhaust with Flex Blower

PF6 (Flex Blower)

Wiring Box

8" Round Elbow

*To Model 643 (8" Round Wall Cap)

Downdraft

*

8" Straight Duct

5

Page 6

Ducting Confi gurations (continued)

Front Exhaust with Flex Blower (through cabinet)

PF6 (Flex Blower)

Wiring Box

Planning

Downdraft

8" Straight Duct

Front Exhaust with Flex Blower and

Recirculating Kit

Downdraft

PF6 (Flex Blower)

*

8" Round Elbow

*To Model 643 (8" Round Wall Cap)

Front Exhaust with Flex Blower (through

cabinet) and Recirculating Kit

Downdraft

PF6 (Flex Blower)

8" Straight

Duct

Wiring Box

ANKD (Recirculation Kit)

8" Straight Duct

Wiring Box

8" Round Elbow

ANKD (Recirculation Kit)

6

Page 7

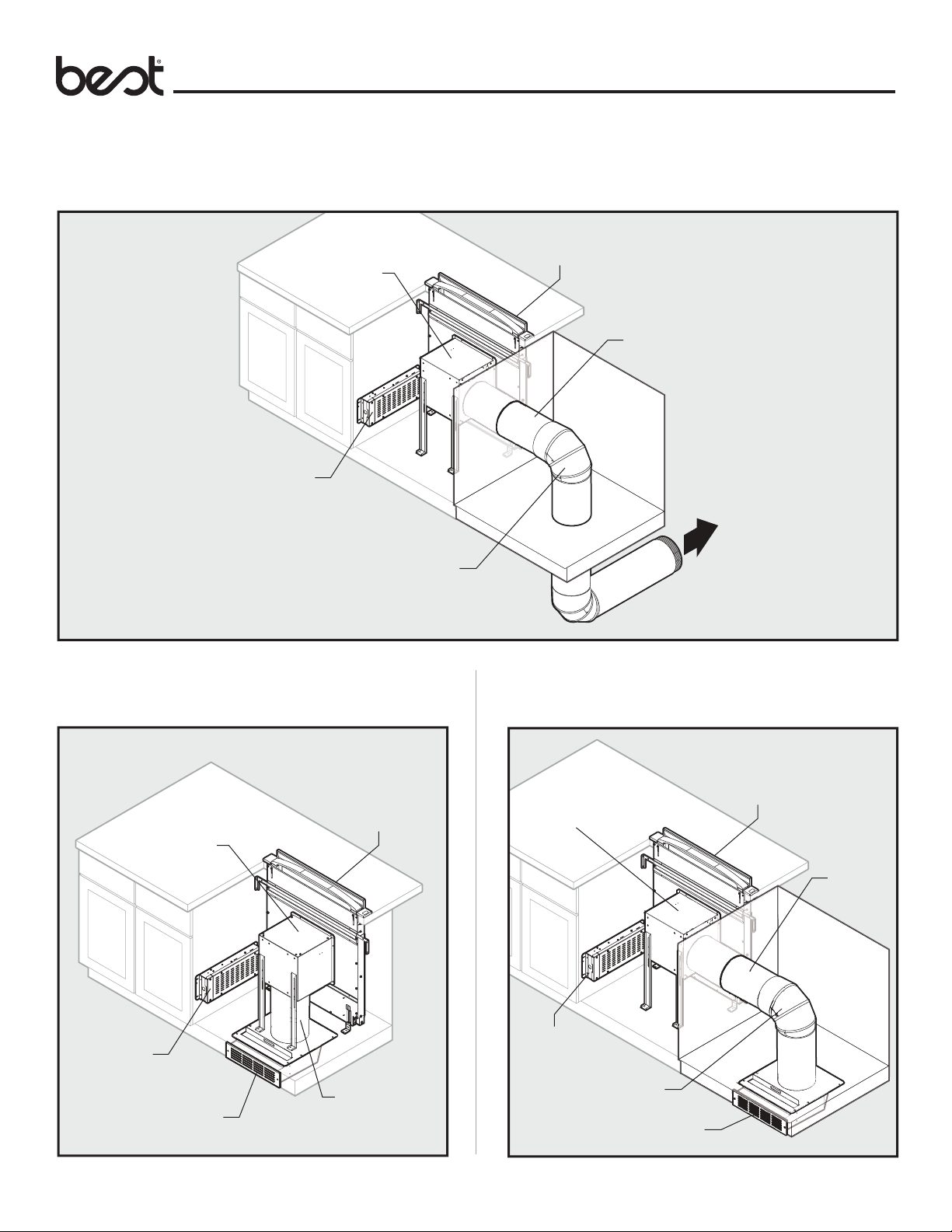

Ducting Confi gurations (continued)

Side Exhaust with Flex Blower

Downdraft

Planning

1-7/8" to 8"

Round Transition

8" Straight Duct

PF6 (Flex Blower)

8" Straight Duct

8" Round Elbow

*

*To Model 643 (8" Round Wall Cap)

Side Exhaust with Flex Blower and

Recirculating Kit Rear Exhaust with Flex Blower

Downdraft

1-7/8" to 8"

Downdraft

Round Transition

PF6

(Flex Blower)

1-7/8" to 8"

Round Transition

PF6 (Flex Blower)

8" Straight Duct

ANKD (Recirculation Kit)

8" Round Elbow

8" Straight Duct

*

*To Model 643 (8" Round Wall Cap)

7

Page 8

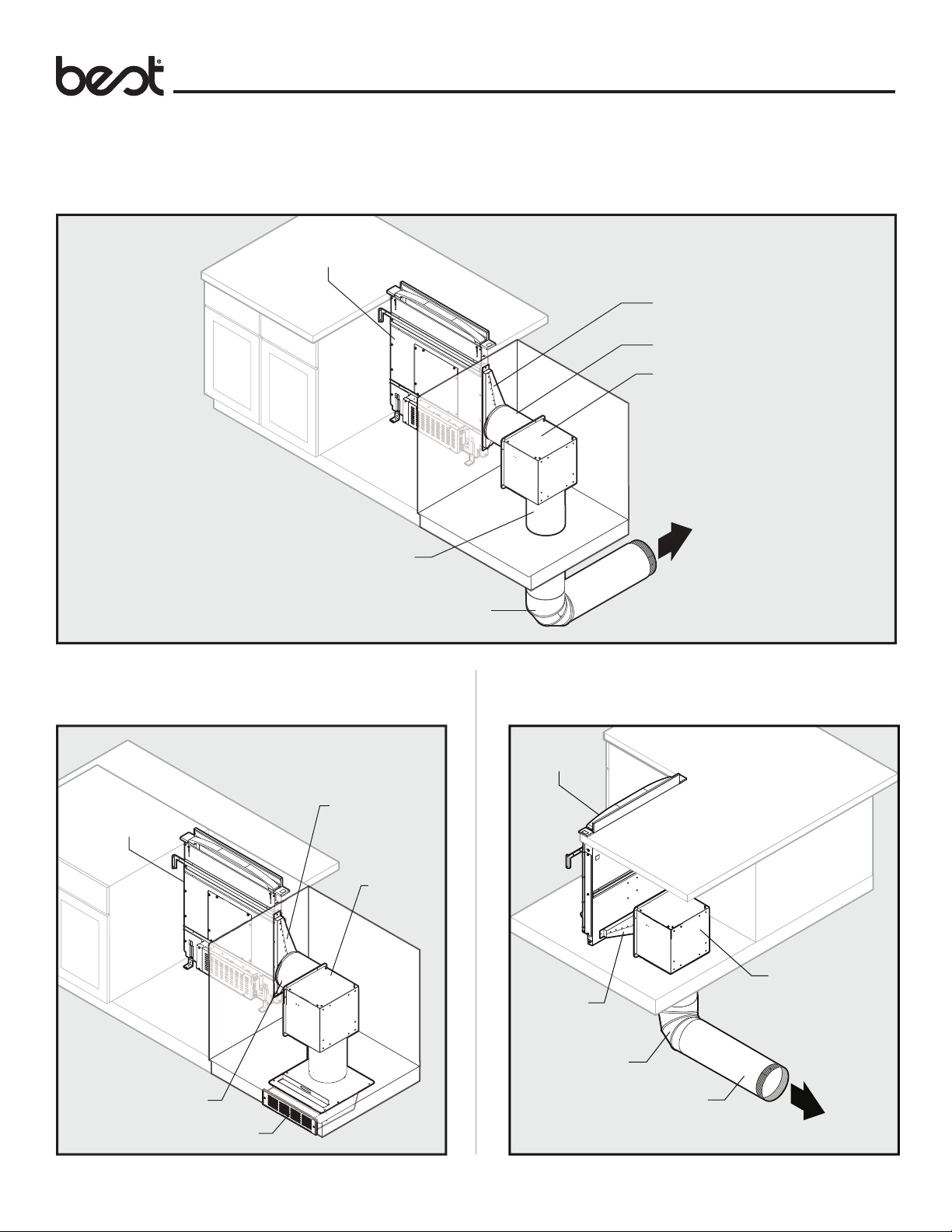

Ducting Confi gurations (continued)

Front Exhaust with Remote Blower

Downdraft

8

" or 10"

Straight Duct

8" or 10" Round Elbow

Note: Flex blowers require 8" ducting. External or in-line blowers require 10" ducting.

Planning

* To one of the following:

*

• Model PF6 (Flex Blower)

Model 643 (8" Round Wall cap)

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

Side Exhaust with Remote Blower

8

" or 10"

Downdraft

1-7/8" to 8" or

10" Round Transition

Note: Flex blowers require 8" ducting. External or in-line blowers require 10" ducting.

Straight Duct

8" or 10" Round Elbow

* To one of the following:

• Model PF6 (Flex Blower)

*

Model 643 (8" Round Wall cap)

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

8

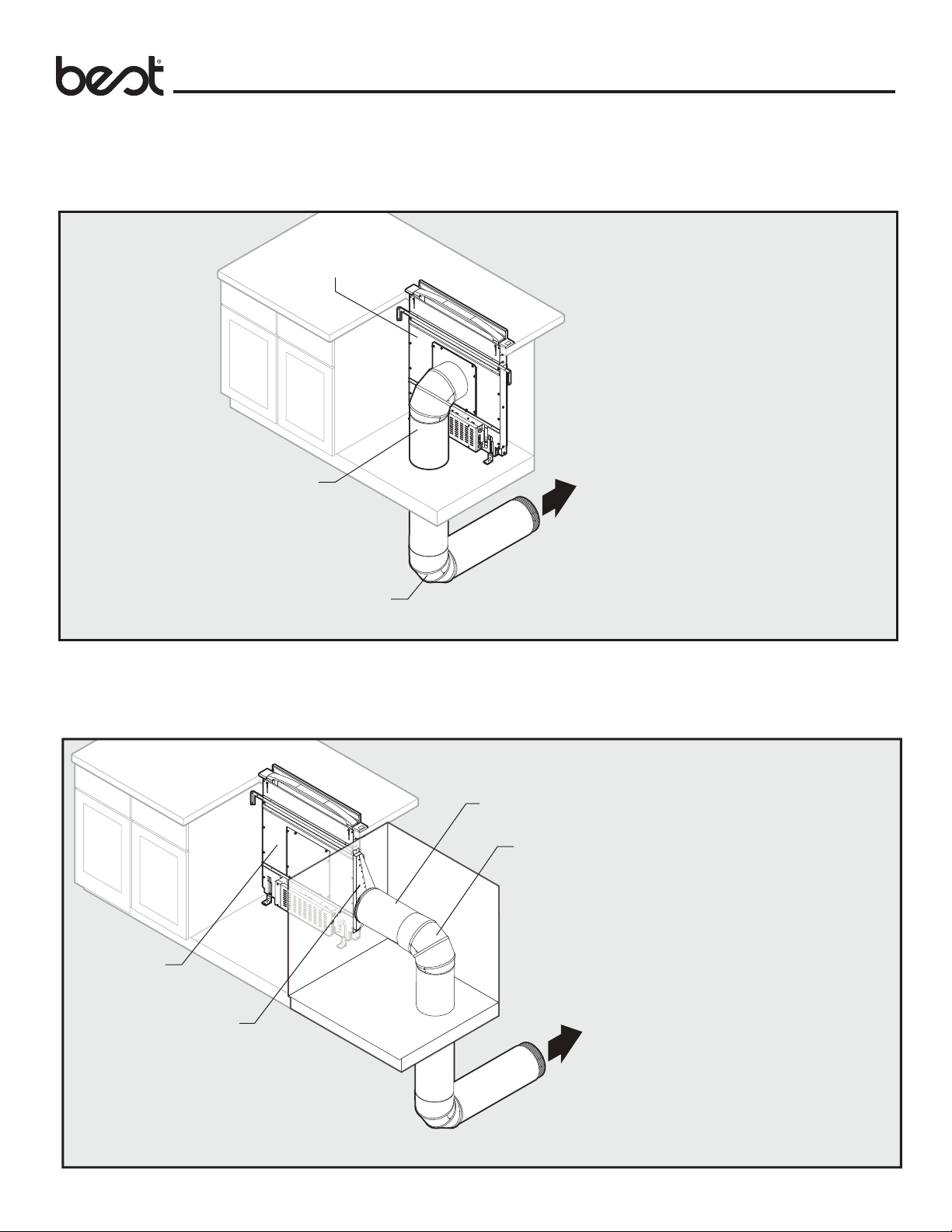

Page 9

Ducting Confi gurations (continued)

Below Exhaust with Remote Blower

Downdraft

1-7/8" to 8" or

10" Round Transition

8

" or 10"

Straight Duct

8" or 10" Round Elbow

Note: Flex blowers require 8" ducting. External or in-line blowers require 10" ducting.

Planning

*

* To one of the following:

• Model PF6 (Flex Blower)

Model 643 (8" Round Wall cap)

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

Rear Exhaust with Remote Blower

Downdraft

8" or 10" Round Elbow

1-7/8" to 8" or

10" Round Transition

8

" or 10"

Straight Duct

Note: Flex blowers require 8" ducting. External or in-line blowers require 10" ducting.

* To one of the following:

• Model PF6 (Flex Blower)

Model 643 (8" Round Wall cap)

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

*

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

9

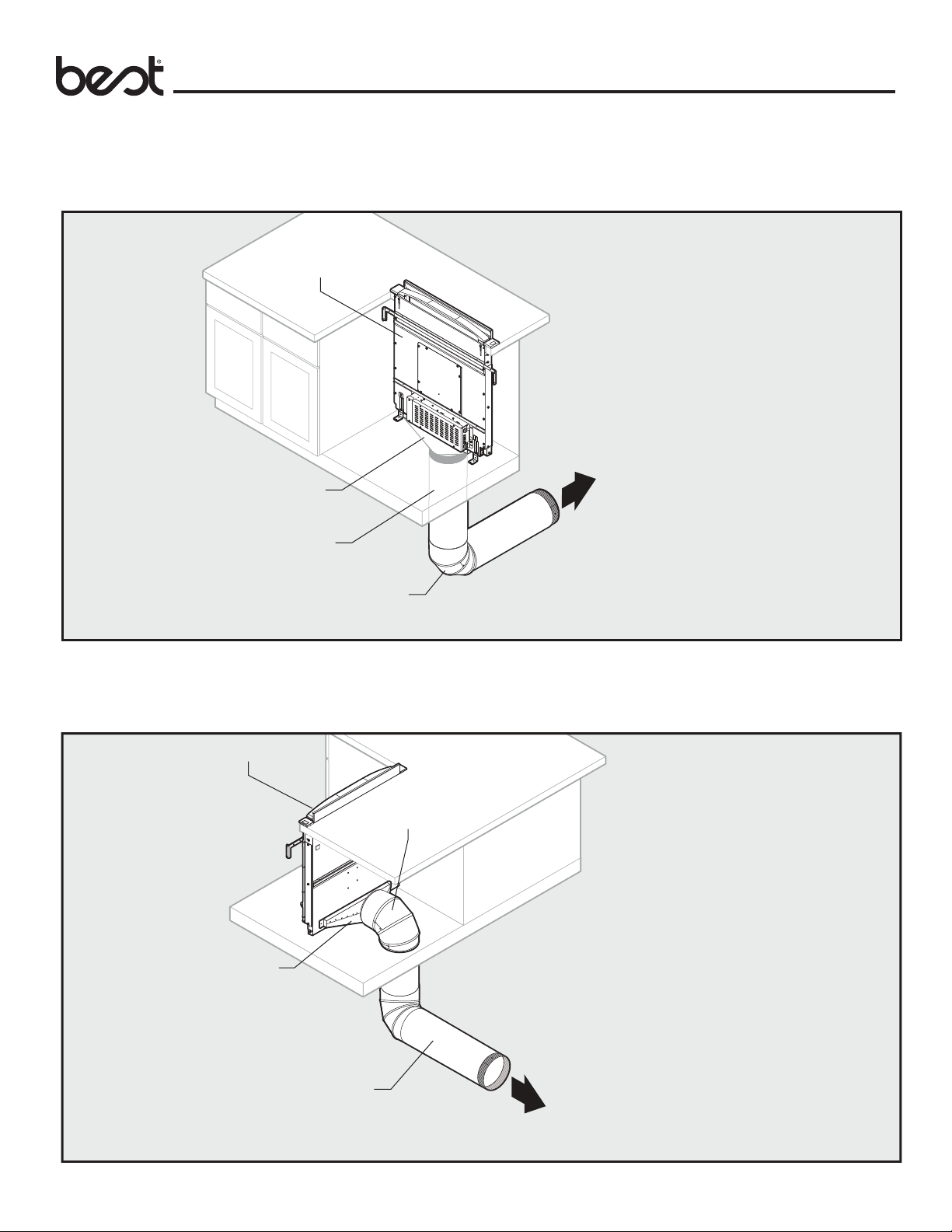

Page 10

Ducting Confi gurations (continued)

Dual Duct Side Exhaust with Remote Blower

Planning

Downdraft

1-7/8" to 8"

Round Transition

8" Round Elbow

8" Straight Duct

* To one of the following:

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

*

Dual 8" Round to 10" Round Transition

10

Page 11

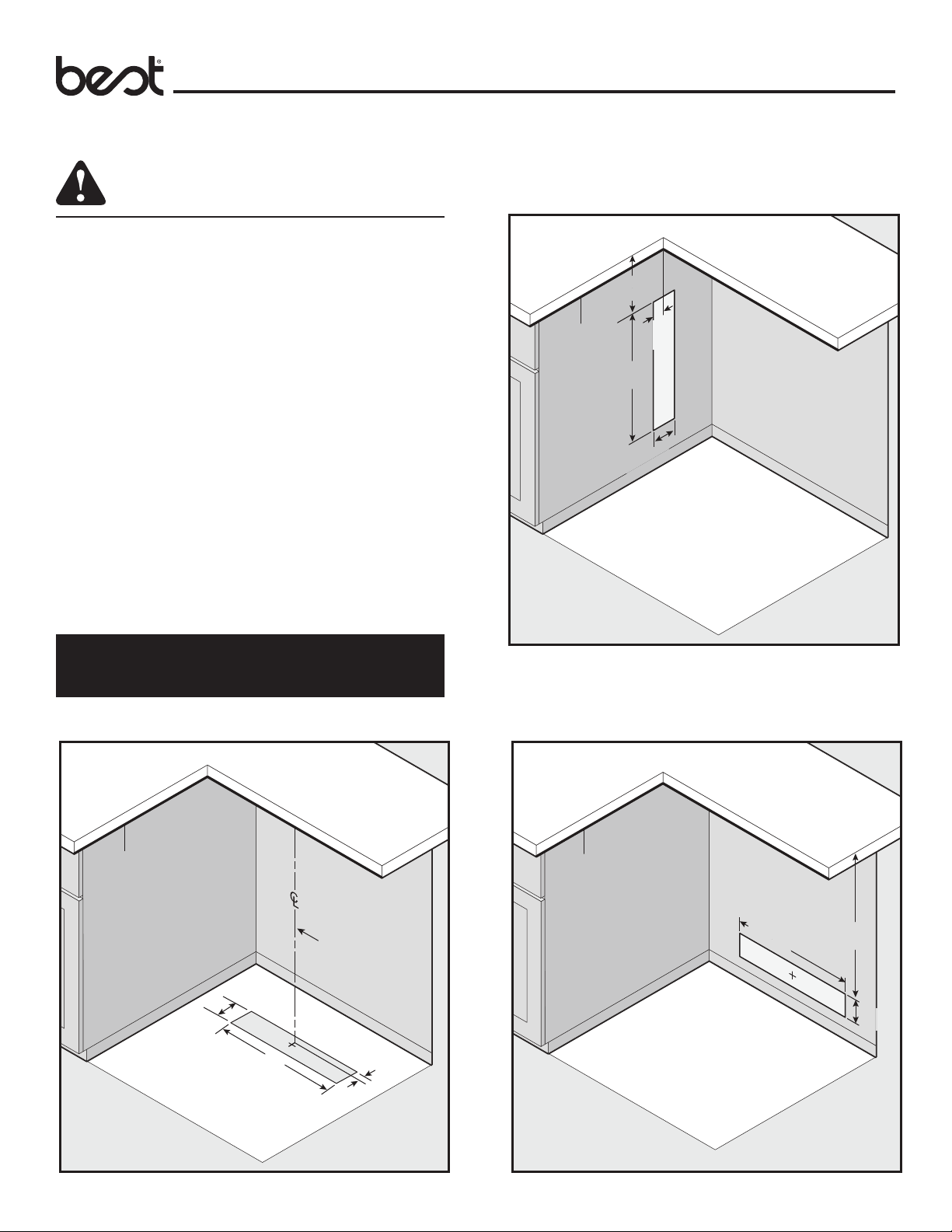

Cabinet Cutouts

CAUTION

BEFORE CUTTING HOLE IN CABINET FOR DUCTWORK,

check for interference with fl oor joists, wall studs,

electrical wiring, or plumbing.

Use the dimensions in illustrations to help plan how and where to

provide duct access through your cabinet. A 1-7/8" x 19" rectangular

duct can be used through left, right, fl oor and back of cabinet. Also,

8" round or 10” round can also be used through cabinet fl oor.

For left, right, or rear exhaust: Allow at least 18" for transition and

elbow or blower.

For left / right exhaust: a 30" deep cabinet is recommended to

align properly with fl ex blower. Flex blower can be mounted to rear

cabinet wall or to a platform / frame (not provided) on the base of

the cabinet fl oor. (See fl ex blower instructions).

Side Ducting Cutout

5-7/8"

5-7/8"

(14.9 cm)

(14.9 cm)

(5.1 cm)

"

21"

21

(53.3 cm)

(53.3 cm)

(10.2 cm)

2"

4"

Appliance

Cutout

Planning

Note: Flex blower can only attach to the front of the downdraft.

Cabinet depths of 24" to 30" are required - depending on the

type of cooking appliance.

If using a Recirculating Kit, see “Plan the installation”

section of the installation instructions packaged with the kit.

Below Ducting Cutout

Appliance

Cutout

Center line of downdraft

(10.2 cm)

(10.2 cm)

4"

4"

Rear Ducting Cutout

Appliance

Cutout

21"

21"

(53.3 cm)

(53.3 cm)

24-3/4"

24-3/4"

(62.9 cm)

(62.9 cm)

(53.3 cm)

(53.3 cm)

21"

21"

1-1/8"

1-1/8"

(2.9 cm)

(2.9 cm)

4"

(10.2 cm)

11

Page 12

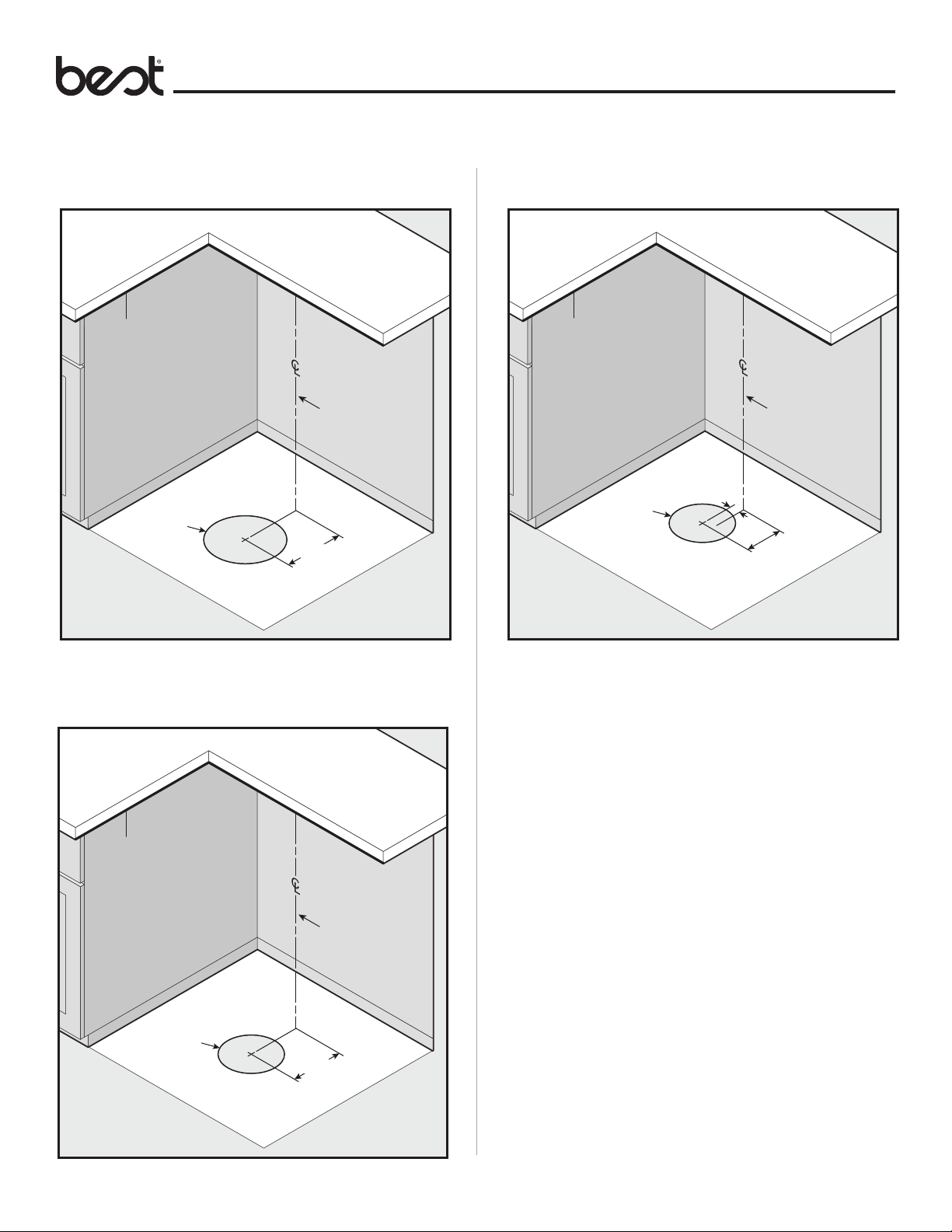

Cabinet Cutouts (continued)

Planning

Flex Blower Ducting Cutout10" Exterior or In-line Blower Ducting Cutout

Appliance

Cutout

Center line of downdraft

Ø10"

(25.4 cm)

8-5/8

8-5/8

(21.9 cm)

(21.9 cm)

"

"

Dimensions based off of Model 418 - 10" round elbow

Flex Blower Ducting – Remote Location Cutout

Appliance

Cutout

Ø8"

(20.3 cm)

1-1/2"

(3.8 cm)

Center line of downdraft

5-5/8"

5-5/8"

(14.3 cm)

(14.3 cm)

Appliance

Cutout

Center line of downdraft

Ø8"

(20.3 cm)

7-5/8"

7-5/8"

(19.4 cm)

(19.4 cm)

Dimensions based off of Model 432 - 8" round elbow

12

Page 13

Electrical Outlet Location

Planning

Flex Blower only

CAUTION

All electrical wiring should be done by a qualifi ed

person(s) in accordance with all applicable codes

and standards.

• This downdraft blower using the Flex Blower (purchase

separately) draws 3.0 Amps and requires a

120 VAC, 60 Hz circuit.

• The unit has a 30 in. long power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will

allow the unit’s power cord to reach.

• Install electrical box according to local codes.

Note: The unit electrical panel can be installed in remote

location (as show below) to help reach the outlet (see page 16).

Exterior or In-Line Blower only

CAUTION

All electrical wiring should be done by a qualifi ed

person(s) in accordance with all applicable codes

and standards.

• If using a remote blower (purchase separately), the

system draws 6.0 Amps (max.) and requires a 120 VAC,

60 Hz circuit.

• The unit has a 30 in. long power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will allow

the unit’s power cord to reach.

• Install electrical box according to local codes.

Note: The unit electrical panel can be installed in remote

location (as shown below) to help reach the outlet (see page 16).

Mount a standard wiring box, with 3-pronged receptacle, within reach

of downdraft’s power cord. Run appropriate power cable and connect it

to receptacle.

Mount a standard wiring box, with 3-pronged receptacle, within reach

of downdraft’s power cord. Run appropriate power cable and connect it

to receptacle.

13

Page 14

Preparing the Downdraft

Downdraft Preparation

1

B

E

E

JA

Detach the upper support brackets (A, J) from the downdraft (B) by cutting

off the tie wraps. Remove and set aside both support legs (E) from sides of

the downdraft (one leg per side).

Note: Discard the retaining screws, but KEEP THE NUTS.

2

Side, Below or Rear Rectangular Ducting

1

B

Install an adapter and a rectangular ductwork to downdraft (B).

2

Side, Below or Rear Round Ducting

B

F

Remove the bundle of 3 dischage covers (F) from the bottom of the

donwdraft (B).

3

B

B

1

Install 1-7/8" x 19” to 8" or 10" round transition to downdraft (B).

F

F

Cover the discharge openings that won’t be used for ducting.

Note: Use the nuts removed in step 1 for side discharge covers.

14

Page 15

Front Ducting

1

B

G

Remove front panel cover (G) from downdraft (B).

Preparing the Downdraft

2a

B

Install 8" or 10" remote discharge plate to downdraft (B).

2b

B

Install the fl ex blower to downdraft (B).

Note: Flex blower can be installed with duct to left, right or downward.

15

Page 16

Preparing the Downdraft

Electrical Panel in Remote Location

1

B

H

Remove electrical panel (H) from downdraft (B).

Note: Option for most installations. Required for ex blower installations when

discharge is down.

2

Final Assembly

3

B

E

E

Attach previously removed lower support legs (E) to downdraft (B) using one

nut for each leg.

4

Install electrical panel

in remote location.

A

B

I

Slide upper support brackets (A, I) into side channels of downdraft (B).

Flex Blower Only

5

If using fl ex blower, attach blower support legs with supplied screws.

16

Page 17

Cutting Countertop Opening

Installation

6a

6b

Cooktop

Cooktop with Oven

6d

7

Range

6c

Rangetop

Place appliance.

Note: Cook top shown.

Center line

8

Center template against the back fl ange of cooktop and mark downdraft

opening.

17

of back flange

Page 18

Installation

Cutting Counter Top Opening (continued)

9

Remove cook top/appliance and cut opening.

Install Housing into Cabinet

10

Install Housing into Cabinet

12

1

E

1

AA

2

Attach support legs (E) to bottom of cabinet with two screws (AA) per

leg. Tighten hex screws. Note: If cabinet bottom is removed, use wood

blocks as spacers between oor and support legs.

13

Set housing into cabinet.

11

A

J

AA

2

Extend upper support brackets (A and J) and attached to sides of cabinet

with two screws (AA) per bracket.

Flex Blower Only

14

1

1

2

3

4

Level housing.

Note: Steps 11-15, right cabinet not shown for clarity.

2

Loosen four screws attaching blower support legs to fl ex blower. Extend

legs and secure to bottom of cabinet with one screw through each

18

bracket. Re-tighten four blower screws.

Page 19

Installation

1

1

C

Installing Finish Trim

15

B

1

D

2

CAUTION

Only connect or disconnect UP BUTTON CABLE

with main power off for at least 60 seconds.

Insert wiring harness from right upper button (D) into opening in side of

downdraft (B). Insert upper button (D) wiring harness into receptacle at

lower right side of downdraft (B).

Installing Finish Trim (continued)

17

C

2

2

Retaining

Retaining

Washer

Washer

Place retaining washer on left trim cap (C). Insert hinge pin into slot of the

fl ip door. Position left trim cap and fl ip door. Align trim caps and complete

assembly by hand tightening trim cap screws.

Note: Make sure trim sits at on countertop surface, is ush with top door,

and has 1/16” GAP between trim and top door.

3

TOP VIEW

1/16" Gap1/16" Gap

C

Washer

DoorTrim

Flush

Installing Ductwork

CAUTION

16

TOP VIEW

Washer

D

Retaining

Retaining

Washer

Washer

4

2

Door Trim

3

Flush

1/16" Gap1/16" Gap

D

D

Position right trim cap (D) and start screw. Do not fully tighten screw.

Place retaining washer on right trim cap. Insert hinge pin into slot of the

fl ip door.

Note: Make sure trim: sits at on countertop surface, is ush with top door,

has 1/16” GAP between trim and top door, and wiring is not pinched.

BEFORE CUTTING HOLE IN CABINET FOR

DUCTWORK, check for interference with fl oor

joists, wall studs, electrical wiring, or plumbing.

• Refer to Ductwork Confi gurations in the Planning section of this

document.

• Cut hole in cabinet as well as holes in wall or fl oor as necessary.

• Mount the roof or wall cap and work back towards the cabinet,

attaching all ductwork, elbows and transitions as previously

planned. Tape all ductwork connections to make them secure and

air tight.

• Connect ductwork (and transition, if required) to downdraft.

19

Page 20

Flex Blower only

CAUTION

All electrical wiring should be done by a qualifi ed

person(s) in accordance with all applicable codes

and standards.

18a

Electrical Wiring Installation

20a

Plug electrical panel cable into lower receptacle on side of downdraft.

H

Remove electrical panel (H) cover and route blower wire into wiring box.

19a

Connect blower wires to wires in electrical panel: White to White, Blue to

Blue, Red to Gray, Orange to Orange and Black to Black. Connect Green

wire to ground screw. Replace electrical panel cover.

Green (ground)Green (ground)

White White (neutral)

White White (neutral)

Blue Blue (low 1)

Blue Blue (low 1)

Red Gray (med 2)

Red Gray (med 2)

Orange Orange (med- high)

Orange Orange (med- high)

Black Black (high 4)

Black Black (high 4)

21a

Plug downdraft’s power cord into outlet.

Note: Make sure that power cord is routed away from the heat

generated by the cooktop.

20

Page 21

Exterior or In-Line Blower only

CAUTION

All electrical wiring should be done by a qualifi ed

person(s) in accordance with all applicable codes

and standards.

18b

From Exterior or

From Exterior or

In-Line Blower

In-Line Blower

Electrical Wiring Installation

20b

Plug electrical panel cable into lower receptacle as shown.

21b

H

Remove wiring box (H) cover and route blower wire into wiring box.

19b

Connect blower wires to wires in wiring box: White to White, Black to Black

and Green wire to ground screw. Replace wiring box cover.

Note: Ensure that Blue, Gray and Orange wires are capped off but not connected.

Green (ground)Green (ground)

White White (neutral)

White White (neutral)

Blue

Blue

Gray

Gray

Orange

Orange

Black Black (high 4)

Black Black (high 4)

Plug downdraft’s power cord into outlet.

Note: Make sure that power cord is routed away from the heat generated

by the cooktop.

21

Page 22

Appliance Installation/Operation

Install Cooking Appliance

1. Align the cooking appliance with downdraft and fasten appliance

in place following appliance instructions.

Control Panel and Up Button

2-Level Task Light

• Press once for LOW setting. Top of icon will illuminate.

• Press 2x for HIGH setting. Top and bottom of icon will

illuminate.

• Press 3x to turn task light OFF.

4-Speed Fan Speed Control

• Press once for LOW setting. Top-right quadrant of icon will

illuminate.

• Press 2x for MEDIUM LOW setting. Top-right and bottom-right

quadrants of icon will illuminate.

• Press 3x for MEDIUM HIGH setting. Top-right, bottom-right, and

bottom-left quadrants of icon will illuminate.

• Press 4x for HIGH setting. All quadrants of icon will illuminate.

• Press 5x to turn fan OFF.

10-Minute Delay Off

When fan is ON at any speed setting, press delay-off icon to start

10-minute timer. Fan and icon will shut off after 10 minutes.

To reset or deactivate delay-off, press icon again.

Note: Accurate alignment of cooking appliance and downdraft is

necessary to ensure that there is no interference when air vent is raised

and lowered. There should be a gap of 1/32" - 1/16 " between the back

of the cooktop and the front of the downdraft cover.

30-Hour Filter Clean Reminder

• After 30 hours of blower “ON” time, fi lter clean icon will blink

continuously.

• To reset, touch and hold icon for 2 or more seconds. Indicator

will turn off.

Down / Retract Chimney

• To retract chimney, touch down button. Any feature that is

active will shut off.

Up Button

• Touch up button on right trim to raise chimney. All functions will

return to their previous settings.

Heat Sentry

• When the operating temperature is too high, the fan speed will

increase to its highest setting to protect sensitive components.

The fan icon will blink and cannot be overridden until the

temperature reaches an acceptable level. The fan speed will

return to the previous setting and the icon will stop blinking.

2-Level Task Light

4-Speed Fan Speed Control

10-Minute Delay Off

30-Hour Filter Clean Reminder

Down / Retract Chimney

Up Button

22

Page 23

Cooking

WARNING

Use and Care

Always disconnect electric power

supply before cleaning and/or servicing unit.

Always turn the downdraft blower on before you begin cooking

to establish an air fl ow in the kitchen. Let the blower run for a few

minutes to clean the air after you turn the cooktop off. This will

keep the whole kitchen cleaner and brighter.

It is recommended to use the rear burners when cooking with tall

pots or when the cooking method will generate high amounts of

smoke or steam. The combination of using the rear burners and

operating the unit at high speed will increase the likelihood that

all the smoke and steam will be removed by the downdraft.

Cleaning

Ears

Tabs

Filter

Filter

CAUTION

Failure to engage tabs properly may cause chimney

to jam and fail to raise up.

To clean inside chimney:

Lift FRONT PANEL up and out and take out the GREASE FILTERS.

Use a mild detergent. DO NOT USE ABRASIVE CLOTH, STEEL WOOL

PADS, OR SCOURING POWDERS. Replace fi lters and front panel

before using downdraft.

Be sure to engage TABS on front panel behind EARS as shown.

Servicing

It may be necessary to remove the downdraft blower system from

the cabinet in order to service components such as the blower

motor or air vent mechanism.

Disconnect power to the cooktop and remove it fi rst. Reverse the

steps under “INSTALL HOUSING INTO CABINET” to remove the

downdraft from the cabinet.

Front Panel

CAUTION

Failure to engage tabs properly may cause chimney

to jam and fail to raise up.

To Clean grease fi lters:

Lift FRONT PANEL up and out and take out the GREASE FILTERS.

The grease fi lters should be cleaned frequently. Use a warm

dishwashing detergent solution. Grease fi lters are dishwasher safe.

Clean all-metal fi lters in the dishwasher using a non-phosphate

detergent. Discoloration of the fi lters may occur if using phosphate

detergents, or as a result of local water conditions - but this

will not affect fi lter performance. This discoloration is not covered

by the warranty. To minimize or prevent discoloration, hand wash

fi lters using a mild detergent. Replace fi lters and front panel before

using downdraft.

Be sure to engage TABS on front panel behind EARS as shown.

23

Page 24

Optional Accessories

Optional Accessories

Accessory Description

MODELS

ACRD

ACRDBLS

MODELS

ATSKD30

ATSKD36

ATSKD48

MODELS

MD6T

MD8T

MD10T

REMOTE UP/DOWN CONTROL

Use when you cannot reach the UP/

DOWN Button on the downdraft chimney.

Can be located on counter top, face of

cabinetry or on the side cabinet of an

island. Cut-out size: 2 1/4" H x 2" W.

Cannot be used where remote control

will interfere with cooking, where hot

pans could be set, or where hot liquids

could be spilled on the control.

(Remote wiring connects with 6-pin

connection)

GAS COOKTOP SEAL KIT

Recommended for use with all gas

cooktops. Includes trim bracket and trim

seal.

30", 36" & 48" widths.

MAKE-UP AIR DAMPER

Use to provide make-up air (when called

for) to keep the home comfortable by

allowing the downdraft to operate at

optimum levels.

Directwire design works with select

BEST® downdrafts to balance indoor air

pressure by providing interlocked makeup air; damper opens automatically

when the range hood is activated.

8" & 10" round diameters.

Connects to 2 CONTACTS on

ELECTRICAL PANEL.

MAKE-UP

AIR DAMPER

CONTACTS

Accessory Description

MODEL AEWD5 EXTENSION CABLE - 5-FT.

Use where electrical panel is remotely

mounted. Extends electrical panel cable

an additional 5 feet.

MODEL ANKD

MODEL AFCD RECIRCULATION FILTER REPLACEMENT

MODEL AVDKD8

MODEL AVDKD10

NON-DUCT RECIRCULATING KIT

Use where ducting is not feasible or

available. Mount to toe kick or base of

a cabinet and attach directly to Model

PF6 Flex Blower using 8" round duct. Kit

can be rotated so that the exhaust is not

directly at your feet. Includes

recirculation fi lter and decorative

cover plate.

Replacement fi lter for ANKD Non-Duct

Recirculating Kit. Use to effectively

capture cooking contaminants.

1-7/8" X 19” TO 8" ROUND

TRANSITION

Rectangular to 8" round transition for

left, right, or rear exhaust - using Model

PF6 Flex Blower. Can be attached to

downdraft unit or rectangular duct

(AEDD2). Includes S-clips for easy,

secure attachment.

1-7/8" X 19" TO 10" ROUND

TRANSITION

Rectangular to 10" round transition for

left, right, or rear exhaust - using

external blower. Can be attached to

downdraft unit or rectangular duct

(AEDD2).

MODELS

ATKD30SB

ATKD36SB

ATKD48SB

RANGE TRIM KIT

Use with free-standing range - where a

gap is present between back of range

and downdraft.

30", 36" & 48" widths.

MODEL AVDKD219

24

RECTANGULAR ADAPTER FOR

1-7/8" X 19"

Use to connect 1-7/8" x 19" rectangular

duct directly to downdraft when using

side, below or rear exhaust.

Page 25

Optional Accessories (continued)

Optional Accessories

Accessory Description

MODELS

ATTD1

ATTD1BLS

MODEL ACVPD8

MODEL ACVPD10 FRONT PANEL ROUGH-IN PLATE -

END CAP TRIM EXTENSION +1"

WIDTH - LH & RH

Use left and right to increase the overall

trim width by 1".

FRONT PANEL ROUGH-IN PLATE 8" ROUND

Use where 8" round duct or elbow

attaches to front of airbox (Model PF6

remote blower installation).

10" ROUND

Use where 10" round duct or elbow

attaches to front of airbox (exterior or

in-line blower installation).

Accessory Description

MODEL 408 - 8" RD.

MODEL 410 - 10" RD.

MODEL AEDD2

STRAIGHT ROUND DUCT - 2-FT.

Galvanized steel construction.

RECTANGULAR DUCT - 2-FT.

SECTIONS (1-7/8" X 19")

Galvanized steel construction.

MODEL 432 - 8" RD.

MODEL 418 - 10" RD.

90˚ DUCTWORK ELBOW

Adjustable from straight to 90˚.

Galvanized steel construction.

MODEL AVDKD8810

TRANSITION “Y” (2) - 8" ROUND TO

(1) - 10" ROUND

Galvanized steel construction.

25

Page 26

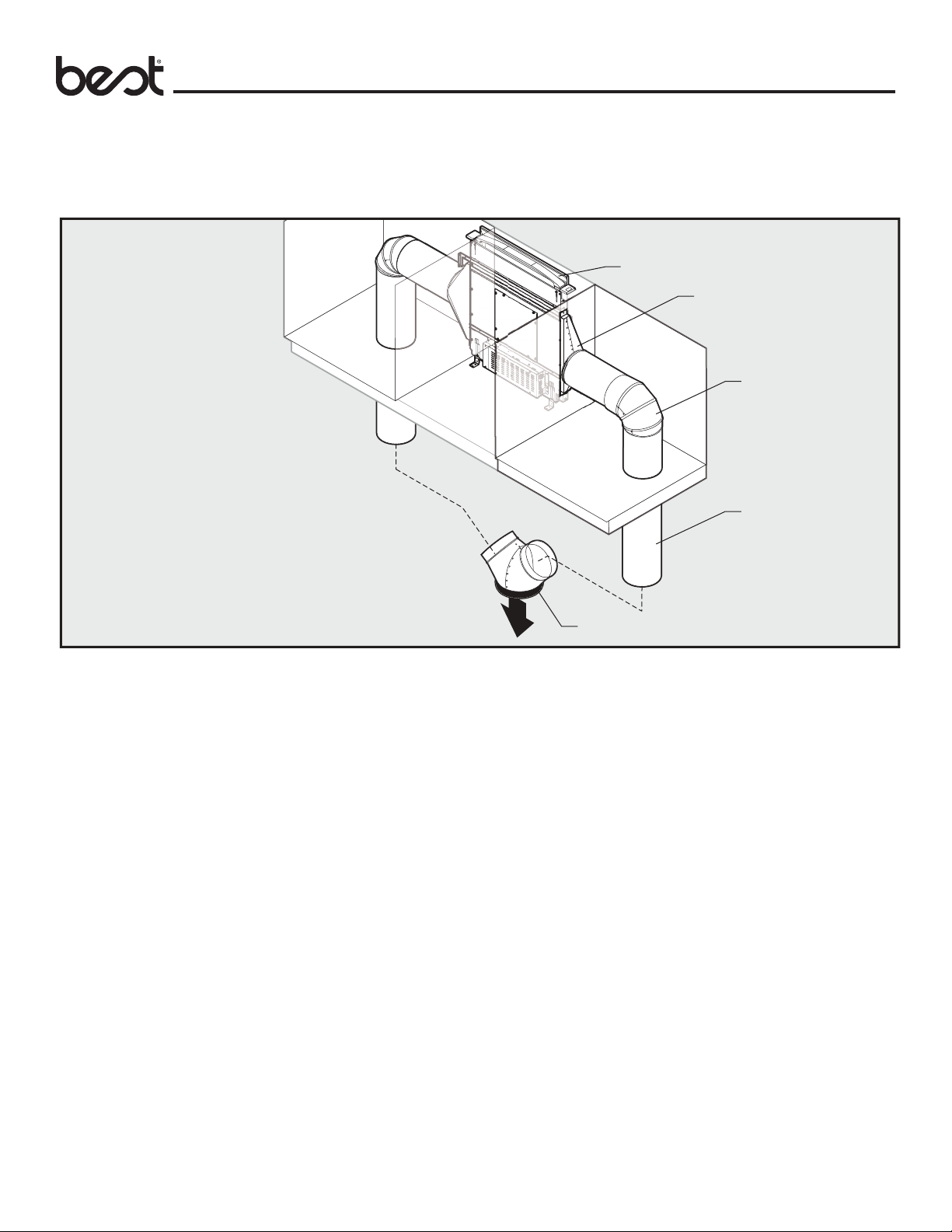

Internal Blower (PF6) – Front Mounted to Downdraft

MODEL PF6

Flex Blower (sold separately)

(“Down” discharge shown. Blower

can also be rotated for “Left” or

“Right” discharge.)

MODEL 408 *

8-inch Round

Straight Duct

Electrical Panel

(Mount in remote location)

Appendix A

MODEL 643 *

8-inch Round

Wall Cap

MODEL 432 *

8-inch Round Elbow

MODEL AEWD5

5-foot Extension

Cable (sold separately)

(Only required if electrical panel

is more than 2-feet away from

downdraft. Use up to 2 extension

cables connected together.)

MODEL ANKD

Non-Duct Recirculation Kit with

Kickspace Grille (sold separately)

(Only required for non-duct

applications. “Front” discharge

shown. Kit can also be rotated for

“Left” , “Right” or “Rear” discharge.)

MODEL 408 *

8-inch Round

Straight Duct

* As required - sold separately.

26

Page 27

Internal Blower (PF6) – Remote Mounted – Front Outlet

MODEL ACVPD8

8-inch Round Front

Rough-in Plate

(sold separately)

MODEL 432 *

8-inch Round Elbow

Electrical Panel

(Can be mounted

in remote location)

MODEL 408 *

8-inch Round

Straight Duct

Appendix B

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if electrical panel

is mounted in a remote location more than 2-feet away from

downdraft. Use up to 2 extension

cables connected together.)

* As required - sold separately

MODEL PF6

Flex Blower (sold separately)

MODEL 408 *

8-inch Round

Straight Duct

MODEL 643 *

8-inch Round

Wall Cap

27

Page 28

Internal Blower (Pf6) – Remote Mounted – Side Outlet

MODEL AVDKD219 *

1-7/8-inch x 19-inch

Rectangular Adapter

(sold separately)

(Only required to

extend duct along

back of cabinet.)

Electrical Panel

(Can be mounted in

remote location.)

MODEL AEDD2 *

1-7/8-inch x 19-inch

Rectangular Duct

(sold separately)

(Only required to

extend duct along

back of cabinet.)

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if

electrical panel is mounted

in a remote location - more

than 2-feet away from downdraft.

Use up to 2 extension cables

connected together.)

MODEL AVDKD8

1-7/8-inch x 19-inch

to 8-inch Round Transition

(sold separately)

MODEL 432 *

8-inch Round

Elbow

MODEL 408 *

8-inch Round

Straight Duct

Appendix C

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

adjacent cabinet)

MODEL 408 *

8-inch Round

Straight Duct

MODEL ANKD

Non-Duct Recirculation Kit

with Kickspace Grille

(sold separately)

(Only required for non-duct

applications. “Front” discharge

shown. Kit can also be rotated

for “Left” , “Right” or “Rear” discharge.)

MODEL 643 *

8-inch Round

Wall Cap

MODEL 408 *

8-inch Round

Straight Duct

28

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

adjacent cabinet)

* As required - sold separately.

Page 29

Internal Blower (Pf6) – Remote Mounted – Rear Outlet

MODEL AEDD2 *

1-7/8-inch x 19-inch

Rectangular Duct

(sold separately)

MODEL AVDKD219 *

1-7/8-inch x 19-inch

Rectangular Adapter

(sold separately)

Appendix D

MODEL AVDKD8

1-7/8-inch x 19-inch

to 8-inch Round Transition

(sold separately)

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

adjacent cabinet)

MODEL 643 *

8-inch Round

Wall Cap

MODEL 408 *

8-inch Round

Straight Duct

MODEL 432 *

8-inch Round

Elbow

MODEL 408 *

8-inch Round

Straight Duct

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

remote location)

MODEL 408 *

8-inch Round

Straight Duct

MODEL ANKD

Non-Duct Recirculation Kit

with kickspace grille

(sold separately)

(Only required for non-duct

applications. “Front” discharge

shown. Kit can also be rotated

for “Left” , “Right” or “Rear” discharge.)

* As required - sold separately.

29

Page 30

)

Internal Blower (Pf6) – Remote Mounted – Below Outlet

Electrical Panel

(Can be mounted in

remote location.)

MODEL AVDKD8

1-7/8-inch x 19-inch

to 8-inch Round Transition

(sold separately)

Appendix E

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if

electrical panel is mounted

in a remote location - more

than 2-feet away from downdraft.

Use up to 2 extension cables

connected together.)

MODEL 643 *

8-inch Round

Wall Cap

MODEL 408 *

8-inch Round

Straight Duct

MODEL PF6

Flex Blower

MODEL 408 *

8-inch Round

Straight Duct

* As required - sold separately.

(sold separately)

(Mounted in

adjacent cabinet)

MODEL 432 *

8-inch Round Elbow

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

adjacent cabinet)

MODEL 408 *

8-inch Round

Straight Duct

MODEL ANKD

Non-Duct Recirculation Kit

with Kickspace Grille

(sold separately)

(Only required for non-duct

applications. “Front” discharge

shown. Kit can also be rotated

for “Left” , “Right” or “Rear” discharge.

30

Page 31

Exterior or In-Line Blower – Front Outlet

Appendix F

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if

Electrical Panel is mounted

in a remote location - more

than 2-feet away from downdraft.

Use up to 2 Extension Cables

connected together.)

(Standard 120 VAC

wiring rated for 6 A

minimum - sold separately.)

MODEL EB9 **

900 cfm

10-inch Round

Exterior Blower

MODEL

10-inch Round

Front Rough-in Plate

(sold separately)

Electrical Panel

(Can be mounted in

remote location.)

ACVPD10

MODEL 418 *

10-inch Round Elbow

MODEL 410 *

10-inch Round Straight Duct

MODEL 418 *

10-inch Round Elbow

MODEL 441 *

10-inch Round

Wall Cap

MODEL 410 *

10-inch Round

Straight Duct

MODEL ILB11 **

1100 cfm

10-inch Round

In-Line Blower

MODEL EB12 **

1200 cfm

10-inch Round

Exterior Blower

31

-- OR --

* As required - sold separately.

** Choose 1 exterior or in-line

blower - sold separately.

MODEL EB15 **

1500 cfm

10-inch Round

Exterior Blower

Page 32

Exterior or In-Line Blower – Side or Rear Outlet

MODEL AVDKD219 *

1-7/8-inch x 19-inch

Rectangular Adapter

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if

Electrical Panel is mounted

in a remote location - more

than 2-feet away from downdraft.

Use up to 2 extension cables

connected together.)

(sold separately)

(Only required to extend

duct along back of cabinet)

MODEL AEDD2 *

1-7/8-inch x 19-inch

Rectangular Duct

(sold separately)

(Only required to

extend duct along

back of cabinet.)

Appendix G

MODEL AVDKD10

1-7/8-inch x 19-inch

to 10-inch Round Transition

(sold separately)

MODEL 418 *

10-inch Round Elbow

Electrical Panel

(Can be mounted in

remote location)

MODEL EB9 **

900 cfm

10-inch Round

Exterior Blower

MODEL 441 *

10-inch Round

Wall Cap

(Standard 120 VAC

wiring rated for 6A

minimum - sold separately)

MODEL 410 *

10-inch Round

Straight Duct

MODEL ILB11 **

1100 cfm

10-inch Round

In-Line Blower

MODEL EB12 **

1200 cfm

10-inch Round

Exterior Blower

-- OR --

MODEL 410 *

10-inch Round Straight Duct

MODEL 418 *

10-inch Round Elbow

* As required - sold separately

** Choose 1 exterior or in-line

blower - sold separately.

MODEL EB15 **

1500 cfm

10-inch Round

Exterior Blower

32

Page 33

Exterior or In-Line Blower – Below Outlet

Electrical Panel

(Can be mounted in

remote location.)

Appendix H

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if

electrical panel is mounted

in a remote location - more

than 2-feet away from downdraft.

Use up to 2 extension cables

connected together.)

MODEL AVDKD10

1-7/8-inch x 19-inch

to 10-inch Round Transition

(sold separately)

MODEL EB9 **

900 cfm

10-inch Round

Exterior Blower

MODEL 441 *

10-inch Round

Wall Cap

(Standard 120 VAC

wiring rated for 6 A

minimum - sold separately.)

MODEL 410 *

10-inch Round

Straight Duct

MODEL ILB11 **

1100 cfm

10-inch Round

In-Line Blower

MODEL EB12 **

1200 cfm

10-inch Round

Exterior Blower

-- OR --

MODEL 410 *

10-inch Round Straight Duct

MODEL 418 *

10-inch Round Elbow

* As required - sold separately.

** Choose 1 exterior or in-line

blower - sold separately.

MODEL EB15 **

1500 cfm

10-inch Round

Exterior Blower

33

Page 34

Exterior or In-Line Blower – Dual Duct – Side Outlets

Appendix I

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if electrical

panel is mounted in a remote

location - more than 2-feet

away from downdraft. Use

up to 2 extension cables

connected together.)

(Standard 120 VAC wiring rated

for 6A minimum - sold separately)

MODEL AVDKD219 *

1-7/8-inch x 19-inch

Rectangular Adapter

(sold separately)

(Only required to extend

duct along back of cabinet)

Electrical Panel

(Can be mounted in

remote location)

MODEL AEDD2 *

1-7/8-inch x 19-inch

Rectangular Duct

(sold separately)

(Only required to

extend duct along

back of cabinet)

MODEL AVDKD8

1-7/8-inch x 19-inch

to 8-inch Round Transition

(sold separately)

MODEL 423 *

8-inch Round Elbow

MODEL 408 *

8-inch Round Straight Duct

MODEL EB9 **

900 cfm

10-inch Round

Exterior Blower

MODEL 441 *

10-inch Round

Wall Cap

MODEL 410 *

10-inch Round

Straight Duct

MODEL ILB11 **

1100 cfm

10-inch Round

In-Line Blower

MODEL EB12 **

1200 cfm

10-inch Round

Exterior Blower

-- OR --

MODEL ATKD8810

Dual 8-inch Round to 10-inch

Round Transition (sold separately)

MODEL 418 *

10-inch Round Elbow

* As required - sold separately.

** Choose 1 exterior or in-line

blower - sold separately

MODEL EB15 **

1500 cfm

10-inch Round

Exterior Blower

34

Page 35

FIVE-YEAR LIMITED WARRANTY FOR BEST® PRODUCTS

Warranty

Limited Warranty

Warranty Period and Exclusions: Broan-NuTone, LLC (the “Company”)

warrants to the consumer purchaser of its product (“you”) that the product (the

“Product”) will be free from material defects in the materials or its workmanship

for a period of fi ve (5) years from the date of original purchase (or such longer

period as may be required by applicable law) or a period of two (2) years from

the date of service for any labor provided on the Product.

The limited warranty period for any replacement parts provided by the Company

and for any Products repaired or replaced under this limited warranty shall be

the remainder of the original warranty period (or such longer period as may be

required by applicable law).

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS,

TUBES AND BULBS, FUSES, FILTERS, DUCTS, ROOF CAPS, WALL CAPS

AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a)

normal maintenance and service, (b) normal wear and tear, (c) any Products or

parts which have been subject to misuse, abuse, abnormal usage, negligence,

accident, improper or insuffi cient maintenance, storage or repair (other than

repair by the Company), (d) damage caused by faulty installation, or installation

or use contrary to recommendations or instructions, (f) damage caused by

exposure to salt air, (g) damage in transit, (h) natural wear of fi nish, (i) Products

in commercial or nonresidential use, (j) damage caused by fi re, fl ood or other act

of God, or (k) Products with altered, defaced or removed serial numbers. This

warranty covers only Products sold to consumers in North America.

This warranty supersedes all prior warranties and, subject to applicable law, is

not transferable from the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s sole

obligation and your sole remedy for defective Products. The foregoing warranties

are exclusive and in lieu of any other warranties and conditions, express or

implied. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THE

COMPANY DISCLAIMS AND EXCLUDES ALL OTHER EXPRESS WARRANTIES

AND CONDITIONS, AND DISCLAIMS AND EXCLUDES ALL WARRANTIES AND

CONDITIONS IMPLIED BY LAW, INCLUDING WITHOUT LIMITATION THOSE OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the extent

that applicable law prohibits the exclusion of implied warranties or conditions,

the duration of any applicable implied warranty or condition is limited to the

period specifi ed for the express warranty above. Some jurisdictions (which may

include the Province of Quebec or specifi c US states) do not allow limitations on

how long an implied warranty lasts, so the above limitation may not apply to you.

Any oral or written description of the Product is for the sole purpose of identifying

it and shall not be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted

in such manner as to be effective and valid under applicable law, but if any

provision is held to be prohibited or invalid, such provision shall be ineffective only

to the extent of such prohibition or invalidity, without invalidating the remainder

of such provision or the other remaining provisions of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its

option, provide replacement parts for, or repair or replace, without charge, any

Product or part thereof, to the extent the Company fi nds it to be covered by and

in breach of this limited warranty under normal use and service. The Company

will ship the repaired or replaced Product or replacement parts to you at no

charge. You are responsible for all costs for removal, reinstallation and shipping,

insurance or other freight charges incurred in the shipment of the Product or

part to the Company. If you must send the Product or part to the Company, as

instructed by the Company, you must properly pack the Product or part—the

Company is not responsible for damage in transit. The Company reserves the

right to utilize reconditioned, refurbished, repaired or remanufactured Products

or parts in the warranty repair or replacement process. Such Products and parts

will be comparable in function and performance to an original Product or part

and warranted for the remainder of the original warranty period (or such longer

period as may be required by applicable law).

Company reserves the right, in its sole discretion, to refund the money actually

paid by you for the Product. If the Product or component is no longer available,

replacement may be made with a similar product of equal or greater value, at

Company’s sole discretion. This is your sole and exclusive remedy for breach of

this limited warranty.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE

REPLACEMENT PARTS, OR REPAIR OR REPLACE, AT THE COMPANY’S

OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY AND THE COMPANY’S SOLE AND EXCLUSIVE

OBLIGATION. THE COMPANY SHALL NOT BE LIABLE FOR INCIDENTAL,

INDIRECT, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN

CONNECTION WITH THE PRODUCT, ITS USE OR PERFORMANCE.

Some jurisdictions do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specifi c legal rights, and you may also have other rights, which

vary from jurisdiction to jurisdiction. The disclaimers, exclusions, and limitations of

liability under this warranty will not apply to the extent prohibited by applicable law.

This warranty covers only replacement or repair of defective Products or parts

thereof at the Company’s main facility and does not include the cost of fi eld

service travel and living expenses.

Any assistance the Company provides to or procures for you outside the terms,

limitations or exclusions of this limited warranty will not constitute a waiver of

such terms, limitations or exclusions, nor will such assistance extend or revive

the warranty.

The Company will not reimburse you for any expenses incurred by you in

repairing or replacing any defective Product, except for those incurred with the

Company’s prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a)

notify the Company at the address or telephone number stated below within

seven (7) days of discovering the covered defect, (b) give the model number

and part identifi cation and (c) describe the nature of any defect in the Product

or part. At the time of requesting warranty service, you must present evidence

of the original purchase date. If you cannot provide a copy of the original written

limited warranty, then the terms of the Company’s most current written limited

warranty for your particular product will control.

PRODUCT SPECIFICATIONS

All illustrations and specifi cations in this catalog are based on the latest product

information available at time of production. Broan-NuTone, LLC and BEST®

reserves the right to make changes at any time, without notice, in prices, colors,

materials, equipment, specifi cations and models, place of manufacture and to

discontinue models or equipment.

Best

Broan-NuTone, LLC- 926 W. State Street, Hartford, WI 53207

1-800-637-1453

Best®, 550 Lemire Blvd., Drummondville, QC, Canada (1-866-737-7770)

www.bestrangehoods.com

35

Page 36

Parts

Service Parts

Stainless Steel Models

J

F

H

G

I

E

C

D

B

U

T

S

J

R

K

K

L

K

Key 30" 36" 48"

No. Width Width Width Description

1 S97021277-001 S97021277-002 S97021277-004 Top Cap Ass’y

Best

2 S97020367 S97020367 S97020367 Felt

3 S97021274 S97021274 S97021274 Door Ass’y Cover

(Right) with

Up Button

4 S97019636 S97019637 S97019638 Door Ass’y

(Includes

Door Ass’y

Hardware Kit)

* S97021101 S97021101 S97021101 Door Assembly

Hardware Kit

5 S97021069 S97021069 S9702109 Door Ass’y

Cover (Left)

6 S99271515 S99271516 S99271517 LED Light Bar

7 S97019874 S97019875 S97019877 Chimney Seal

8 S98012028-B01 S98012028-B01 S98012028-B01 Lift Guide Cover

9 S97020361 S97020361 S97020361 Angle Brackets

(Left & Right)

10 S98011659 S98011659 S98011659 Vent Cover

(Set of 3)

N

M

Q

N

O

Key 30" 36" 48"

No. Width Width Width Description

11 S99271616 S99271616 S99271616 Actuator

12 S98011668 S98011668 S98011668 Airbox Hole Cover

13 S98012061 S98012061 S98012061 Legs (Set of 2)

14 S97019584 S97019584 S97019584 Electrical Box

Ass’y (Includes

Key Nos. 15 & 16)

15 S99271512 S99271512 S99271512 Power Supply

16 S99271573 S99271573 S99271573 Main PCB

* S97020368 S97020368 S97020368 Fuse (From Key

No. 16)

17 S97021257 S97021257 S97021257 Plastic Guides

with Felt

(Set of 2)

18 S98011888 S98011889 S98011890 Chimney Grille

19 S99010438 S99010439 S99010440 Filters (Set of 2)

20 S99271514 S99271514 S99271514 User Interface

* S99271664 S99271664 S99271664 Wire Harness

* S97019665 S97019665 S97019665 Heat Sentry

* S99111754 S99111755 S99111756 Install Template

* S97019570 S97019570 S97019570 Hardware/

Bag

P

Parts

36

Page 37

Service Parts

E

D

Black Stainless Steel Models

F

H

J

G

I

C

B

U

T

S

J

R

K

K

M

L

N

K

Key 30" 36"

No. Width Width Description

1 S97021277-K01 S97021277-K02 Top Cap Ass’y Best

2 S97020367 S97020367 Felt

3 S97021274-K01 S97021274-K01 Door Ass’y Cover (Right)

with Up Button

4 S97021106-K01 S97021107-K02 Door Ass’y (Includes

Door Ass’y

Hardware Kit)

* S97021101 S97021101 Door Assembly

Hardware Kit

5 S97021069K01 S97021069K01 Door Ass’y

Cover (Left)

6 S99271515 S99271516 LED Light Bar

7 S97019874 S97019875 Chimney Seal

8 S98012028-B01 S98012028-B01 Lift Guide Cover

9 S97020361 S97020361 Angle Brackets

(Left & Right)

10 S98011659 S98011659 Vent Cover (Set of 3)

N

Q

O

Key 30" 36"

No. Width Width Description

11 S99271616 S99271616 Actuator

12 S98011668 S98011668 Airbox Hole Cover

13 S98012061 S98012061 Legs (Set of 2)

14 S97019584 S97019584 Electrical Box

Ass’y (Includes

Key Nos. 15 & 16)

15 S99271512 S99271512 Power Supply

16 S99271573 S99271573 Main PCB

* S97020368 S97020368 Fuse (From Key No. 16)

17 S97021257 S97021257 Plastic Guides

with Felt (Set of 2)

18 S98011888-K01 S98011889-K01 Chimney Grille

19 S99010438 S99010439 Filters (Set of 2)

20 S99271514 S99271514 User Interface

* S99271664 S99271664 Wire Harness

* S97019665 S97019665 Heat Sentry

* S99111754 S99111755 Install Template

* S97019570 S97019570 Hardware/

P

Parts Bag

37

Page 38

In USA: BEST

®

926 West State Street, Hartford, Wisconsin 53027 800-558-1711

www.BestRangeHoods.com

®

In Canada: BEST

550 Lemire Blvd., Drummondville, QC J2C 7W9 866-737-7770

www.BestRangeHoods.ca

Aux États-Unis: BEST

®

926 West State Street, Hartford, Wisconsin 53027 800-558-1711

www.BestRangeHoods.com

®

Au Canada: BEST

550 boul. Lemire, Drummondville, QC J2C 7W9 866 737-7770

www.BestRangeHoods.ca

99045242S

En EE.UU.: BEST

®

926 West State Street, Hartford, Wisconsin 53027 800-558-1711

www.BestRangeHoods.com

®

En Canadá: BEST

550 boul. Lemire, Drummondville, QC J2C 7W9 866-737-7770

www.BestRangeHoods.ca

Loading...

Loading...