Page 1

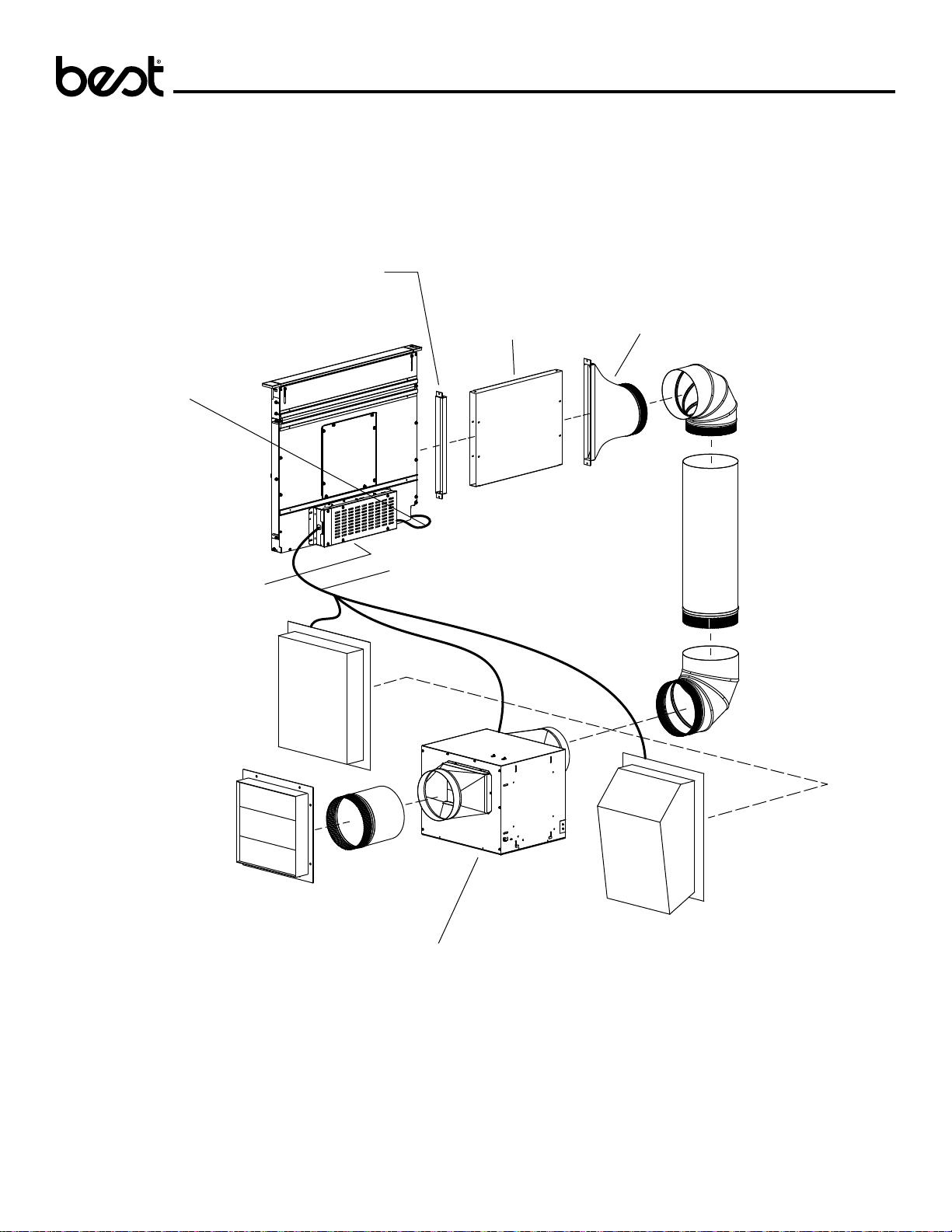

Models: D49M30SB, D49M36SB, D49M48SB

Downdraft Ventilator

For use with these blowers

(purchase blowers separately):

Model PF6* - Flex Blower - Interior

Models EB6, EB9*, EB12*, or EB15* - Exterior

Models ILB6, ILB9 or ILB11* - In-Line

* Recommended models

READ AND SAVE THESE INSTRUCTIONS

Register your product online at: www.BestRangeHoods.com

Français p. 33

Español p. 65

Page 2

Table of Contents

Safety Information .................................................................................................................................................................................. 3

Contents .................................................................................................................................................................................................. 4

Specifications ......................................................................................................................................................................................... 4

Tools Needed ........................................................................................................................................................................................... 4

Planning

Before You Begin ............................................................................................................................................................................... 5

Taking Measurements........................................................................................................................................................................ 5

Ducting Configurations ...................................................................................................................................................................... 5

Cabinet Cutouts ................................................................................................................................................................................. 10

Preparing the Downdraft

Side or Rear Ducting .......................................................................................................................................................................... 12

Front Ducting ..................................................................................................................................................................................... 12

Electrical Panel in Remote Location ................................................................................................................................................... 13

Final Assembly ................................................................................................................................................................................... 13

Installation

Cutting Countertop Opening ............................................................................................................................................................... 14

Install Housing into Cabinet ................................................................................................................................................................ 15

Install Finishing Trim .......................................................................................................................................................................... 16

Installing Ductwork ............................................................................................................................................................................ 16

Electrical Wiring Installation

Flex Blower Only ................................................................................................................................................................................ 17

Exterior or In-Line Blower Only .......................................................................................................................................................... 18

Appliance Installation/Operation ........................................................................................................................................................... 19

Use and Care ........................................................................................................................................................................................... 20

Optional Accessories .............................................................................................................................................................................. 21

Appendices A-G ...................................................................................................................................................................................... 23

Warranty .................................................................................................................................................................................................30

Service Parts ...........................................................................................................................................................................................31

2

Page 3

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number on the back page.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service

panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment

to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. To reduce the risk of fire, use only metal ductwork.

8. Do not install this product with the activating switch directly

behind a burner or element. Minimum distance between the

switch and the edge of the burner should be 4 inches.

9. Loose-fitting or hanging clothing should never be worn when

operating this appliance. They may be ignited by burners/

elements on cooktop.

10. Children should not be left alone or unattended in the area

where this appliance is in use.

11. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boil

overs cause smoking and greasy spillovers that may ignite.

Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

cooking flaming foods.

c) Clean ventilating fans frequently. Grease should not be allowed

to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate for the

size of the surface element.

Safety Information

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO PREVENT

BURNS. If the flames do not go out immediately, EVACUATE AND

CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher, and you

already know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit. Based on

“Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off

power unit.

4. Clean filters and grease-laden surfaces frequently.

5. Do not repair or replace any part of this appliance unless

specifically recommended in this manual. All other servicing

should be done by a qualified technician.

6. Please read specification label on product for further

information and requirements.

7. To reduce the risk of fire and electric shock, install this

downdraft only with blower models shown below. Other blower

models cannot be substituted. (Blowers sold separately).

Flex Blower Model PF6, Exterior Blower Models EB6, EB9,

EB12, or EB15 In-Line Blower Models ILB6, ILB9, or ILB11.

INSTALLER: Save this manual for Electrical Inspector

and Homeowner to use.

3

Page 4

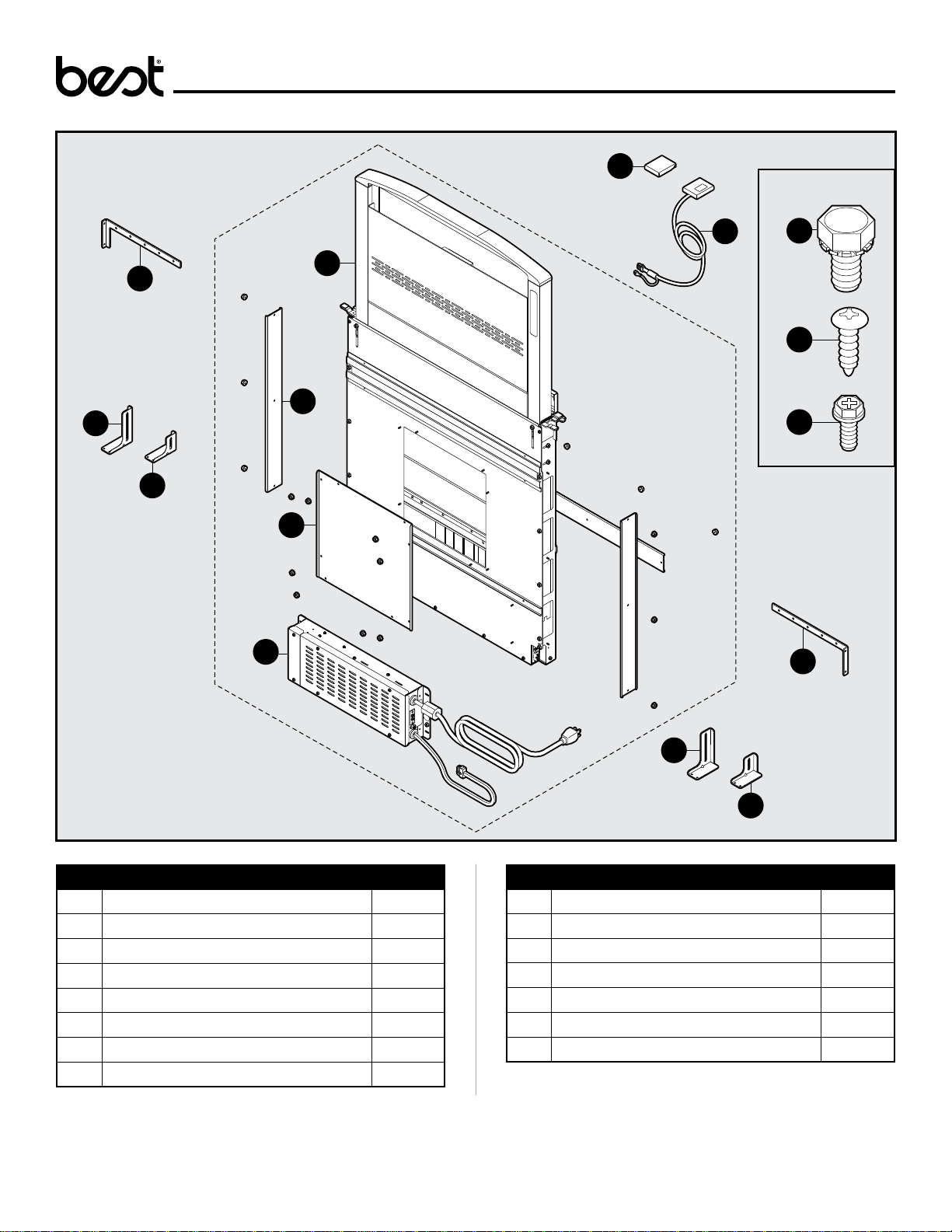

Contents

C

D

AA

x2

B

A

x8

BB

x3

G

x2

E

CC

F

H

I

J

ELECTRICAL

SPECIFICATIONS

Model PF6 - Internal Flex:

120 VAC • 60 Hz • 3.0 A

Models EB6, EB9, EB12, or EB15 - Exterior

Models ILB6, ILB9 or ILB11 - In-Line

120 VAC • 60 Hz • 6.0 A (max.)

Part Description Quantity

A

Upper support bracket (left) 1

B

Downdraft ventilator housing 1

C

End cap trim (left) 1

D

End cap trim–up button (right) 1

E

4" support leg (left) 1

F

2" support leg (left) 1

G

Discharge cover 3

H

Front panel cover 1

Part Description Quantity

I

Electrical panel 1

J

Upper support bracket (right) 1

K

4” support leg (right) 1

L

2” support leg (right) 1

AA

1/4-20 x .50 Hex Head screw 2

BB

#10 x .50 Phillips round head screw 8

CC

#8-18 x .375 Phillips screw 2

K

L

Tools Needed

Measuring tape, pencil, Phillips screwdriver #2, nut drivers (11/32", 3/8", 7/16"), box-end wrench, saw, spirit-level, tin snips, work gloves,

and aluminum tape. (DO NOT use insulating tape.)

4

Page 5

Before You Begin

Planning

Due to its flexible design, this downdraft system can be used to

exhaust airborne contaminants when cooking with a variety of gas

or electric cooking appliances - including cooktops, rangetops,

slide-in ranges and free-standing ranges.

It can be mounted in island, peninsula, or conventional wall

locations. The blower (purchase separately) and electrical panel

can be mounted to the downdraft unit, inside the cabinet, or in a

convenient remote location.

This unit can be easily installed following these basic steps:

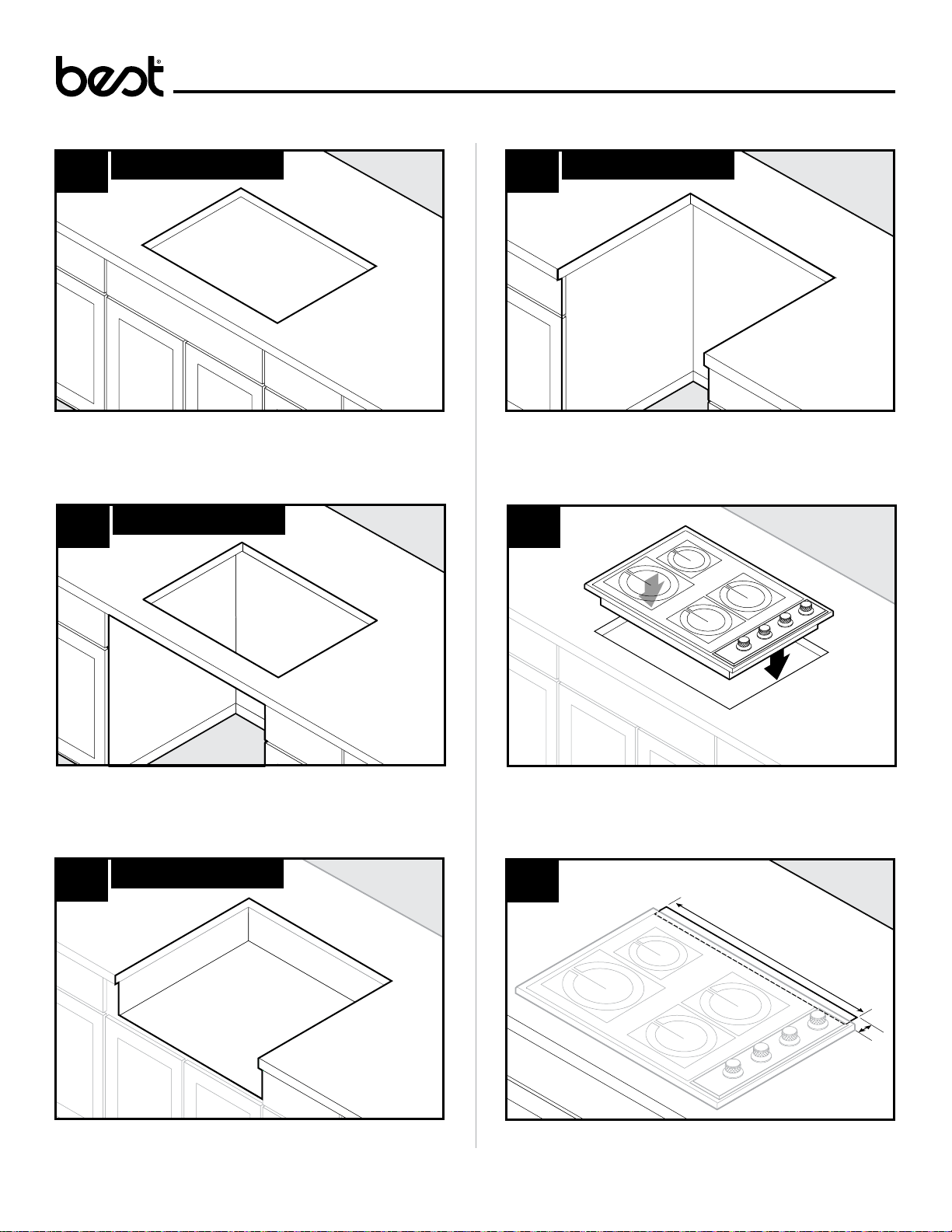

• Cut out the countertop opening.

• Mount the unit in the cabinet.

• Install the blower and electrical panel.

• Connect the ductwork and electrical.

• Install the trim.

• Install the cooking appliance.

Note: the high level of air flow of this appliance may affect the

gas flame on some types of gas cooktops. This is NORMAL and

will cause no harm, but can be corrected by lowering the speed

of the blower.

Gas Cooktop Seal Kit is recommended for use with all gas

cooktops. The kit creates a seal between the cooktop and the

lower cabinet. Includes trim bracket and trim seal. See Optional

Accessories section.

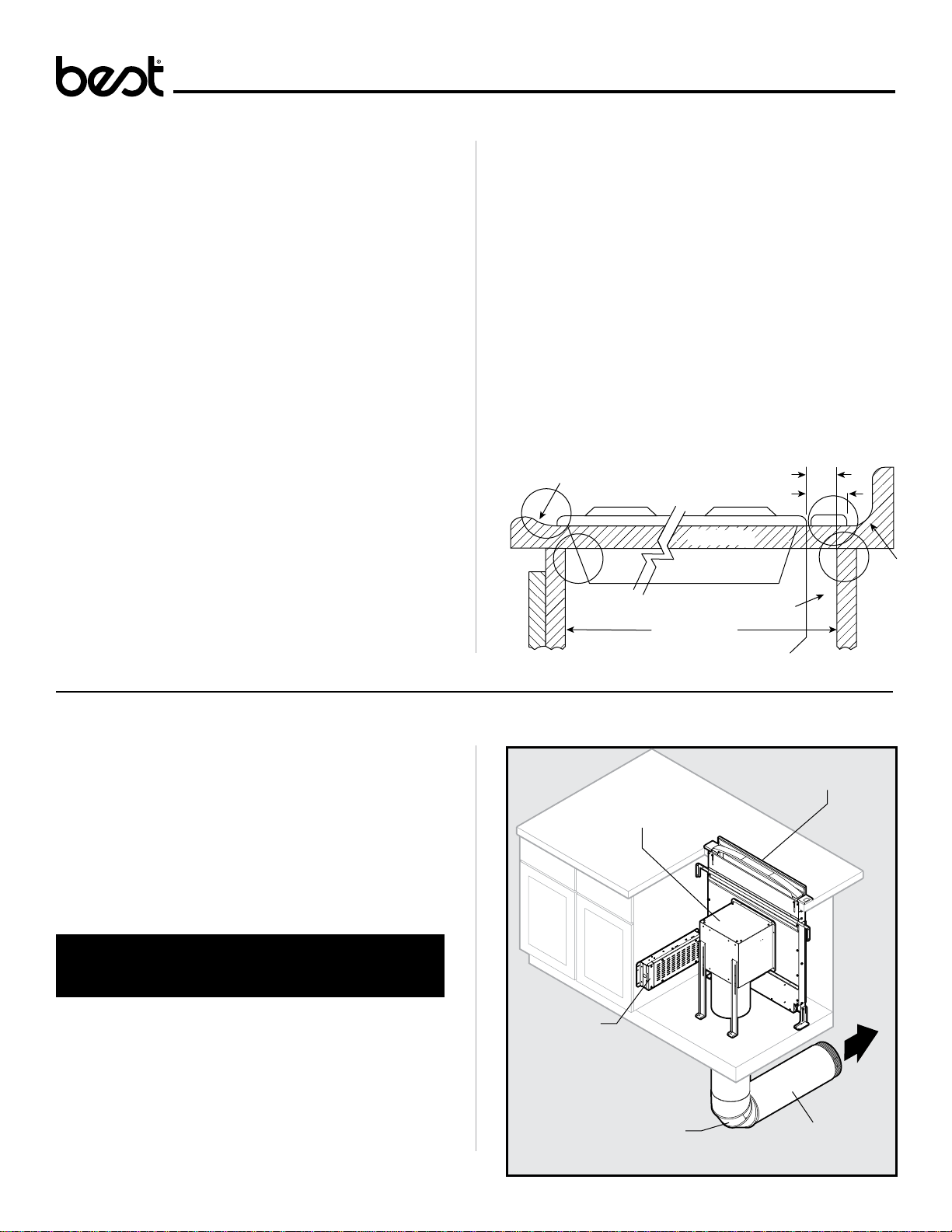

Taking Measurements

• Refer to the cooktop installation instructions for dimensions

of cooktop, countertop cut-out, and cabinet requirements.

However, it is recommended that oversized cabinets be used

for easier installation. Custom island designs need to account

for deeper cabinets - especially when installed with a range in

front of the downdraft or when mounting the blower behind the

downdraft. You must also plan for an access door.

• Cooktop depth can vary greatly from one to another. This

may cause the fit of these two appliances to be rather tight.

Pay special attention to the areas of potential interference

highlighted above. A countertop with (A) a raised lip and/or (B)

a backsplash may not allow enough flat countertop for a proper

installation. Note that 2-3/4" of flat countertop is required

behind cooktop and that 2-1/2" is necessary between the back

edge of the cooktop and the inside of cabinet back.

A

CountertopCountertop

Cooktop

Front to Back

Inside Cabinet Depth

2-1/2"

2-3/4"

Downdraft

B

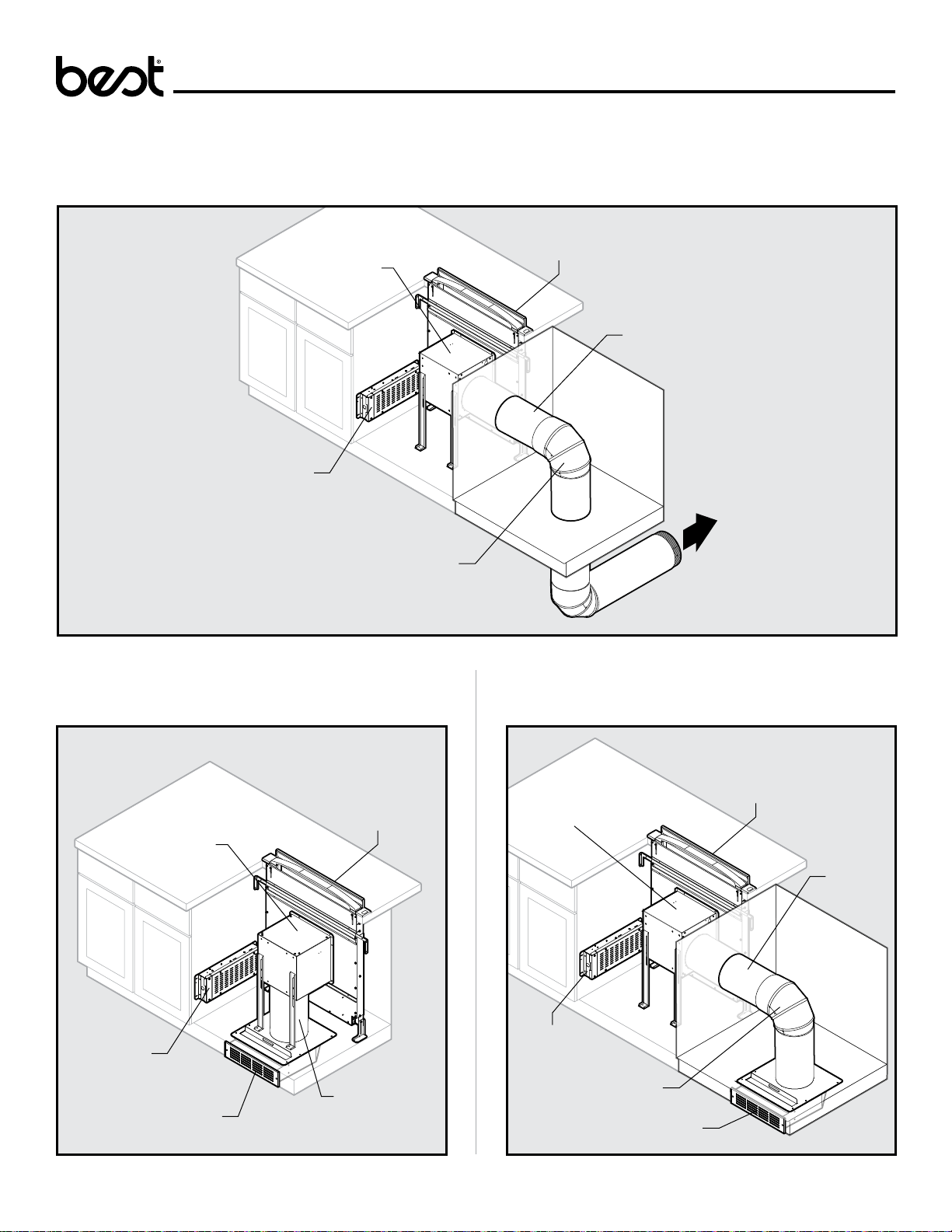

Ducting Configurations

• The downdraft blower system is designed for use with 8"

round ductwork using a flex blower or 10” round ductwork

using a remote blower. (Purchase blowers separately.)

• For best performance: Choose the ducting option which allows

the shortest length of ductwork and a minimum number of

elbows and transitions. Check location of floor joists, wall

studs, electrical wiring or plumbing for possible interference.

For more detailed ducting information see appendices A-G

at the end of document.

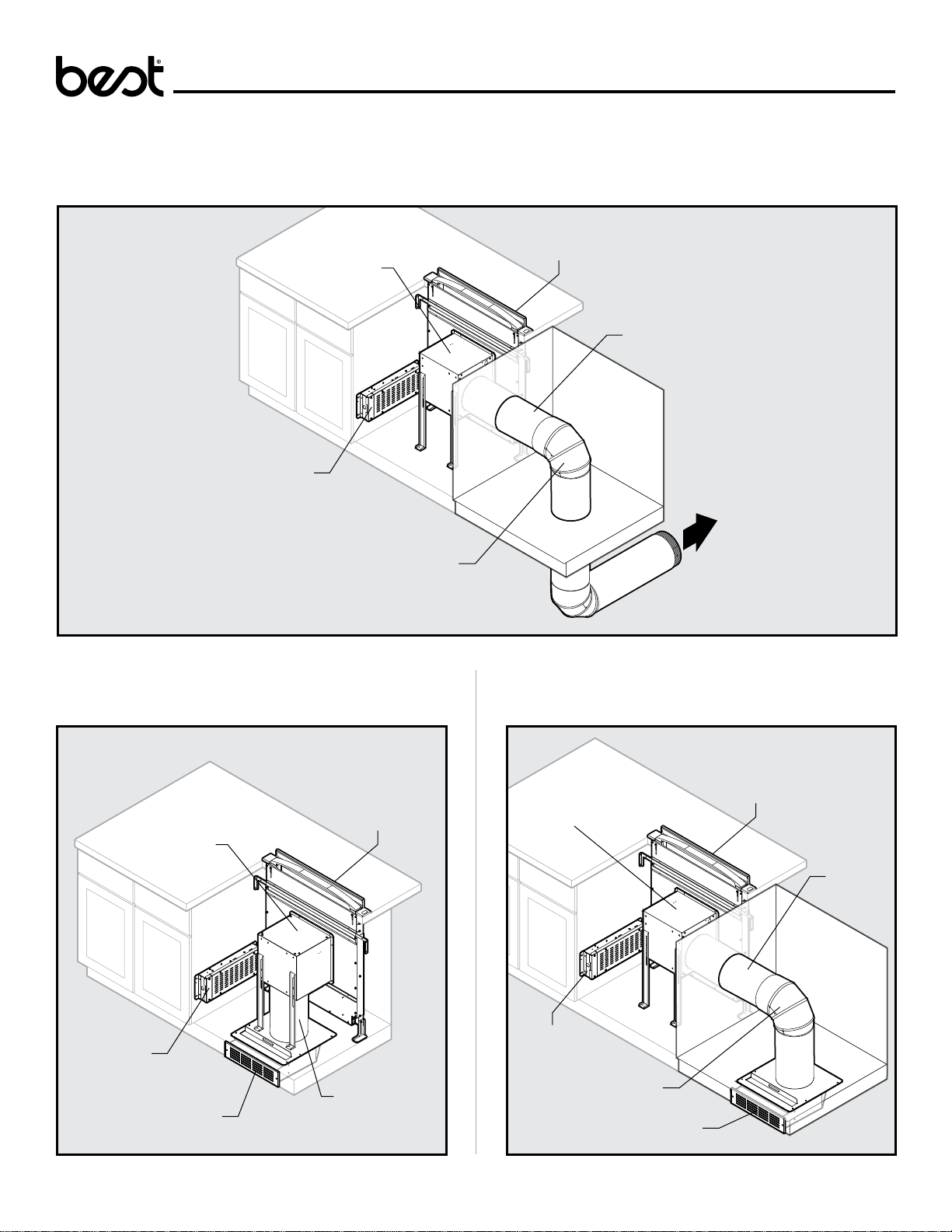

Front Exhaust with Flex Blower

PF6 (Flex Blower)

Wiring Box

8" Round Elbow

*To Model 643 (8" Round Wall Cap)

Downdraft

*

8" Straight Duct

5

Page 6

Ducting Configurations (continued)

Front Exhaust with Flex Blower (through cabinet)

PF6 (Flex Blower)

Wiring Box

Planning

Downdraft

8" Straight Duct

Front Exhaust with Flex Blower and

Recirculating Kit

Downdraft

PF6 (Flex Blower)

*

8" Round Elbow

*To Model 643 (8" Round Wall Cap)

Front Exhaust with Flex Blower (through

cabinet) and Recirculating Kit

Downdraft

PF6 (Flex Blower)

8" Straight

Duct

Wiring Box

ANKD (Recirculation Kit)

8" Straight Duct

Wiring Box

8" Round Elbow

ANKD (Recirculation Kit)

6

Page 7

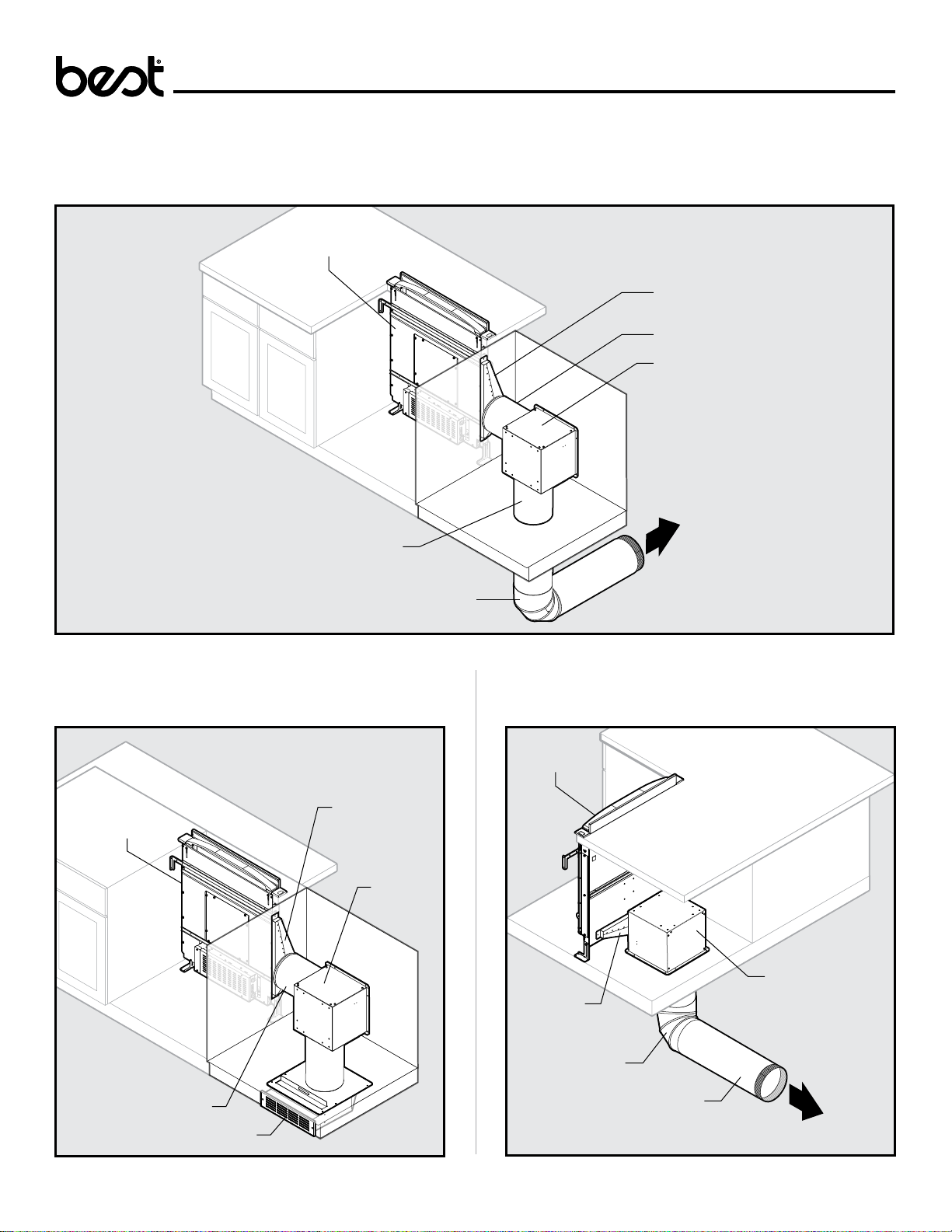

Ducting Configurations (continued)

Side Exhaust with Flex Blower

Downdraft

Planning

1-7/8" to 8"

Round Transition

8" Straight Duct

PF6 (Flex Blower)

8" Straight Duct

8" Round Elbow

*

*To Model 643 (8" Round Wall Cap)

Side Exhaust with Flex Blower and

Recirculating Kit Rear Exhaust with Flex Blower

Downdraft

1-7/8" to 8"

Downdraft

Round Transition

Flex Blower

PF6 (Flex Blower)

8" Straight Duct

Recirculation Kit

1-7/8" to 8"

Round Transition

8" Round Elbow

8" Straight Duct

*

*To Model 643 (8" Round Wall Cap)

7

Page 8

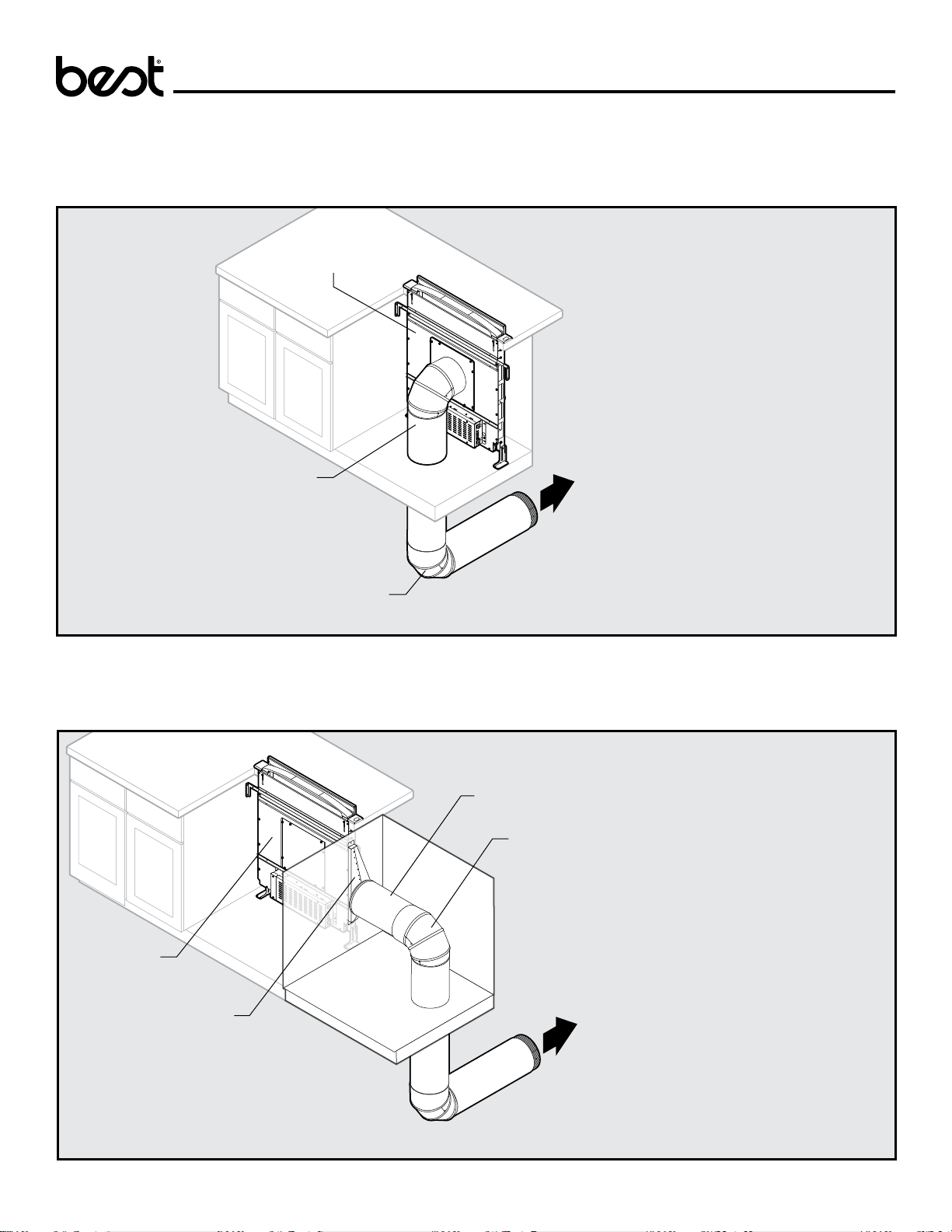

Ducting Configurations (continued)

Front Exhaust with Remote Blower

Downdraft

8

" or 10"

Straight Duct

8" or 10" Round Elbow

Note: Flex blowers require 8" ducting. External or in-line blowers require 10" ducting.

Planning

* To one of the following:

*

• Model PF6 (Flex Blower)

Model 643 (8" Round Wall cap)

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

Side Exhaust with Remote Blower

8" or 10"

Straight Duct

Downdraft

1-7/8" to 8" or

10" Round Transition

Note: Flex blowers require 8" ducting. External or in-line blowers require 10" ducting.

8" or 10"

Round Elbow

*

* To one of the following:

• Model PF6 (Flex Blower)

Model 643 (8" Round Wall cap)

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

8

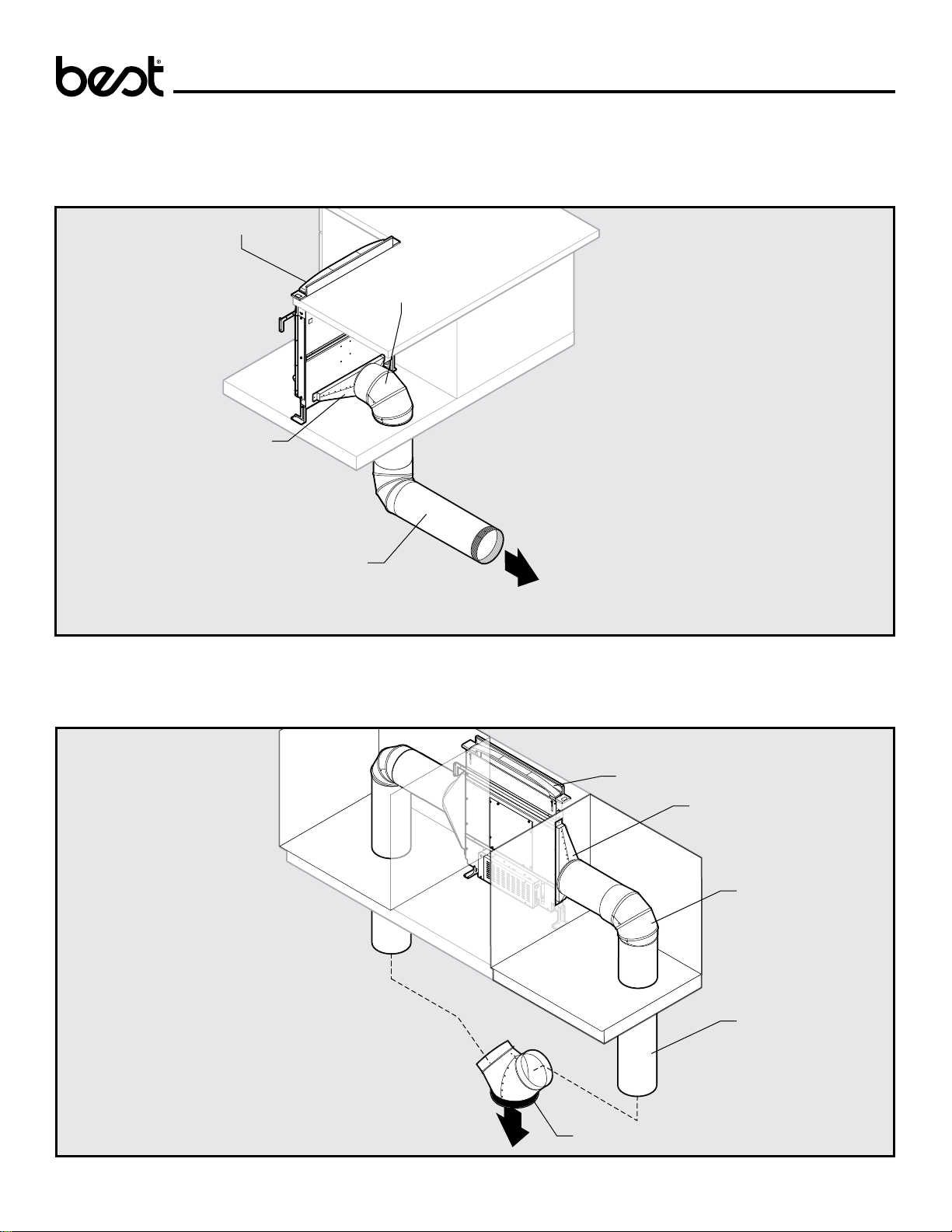

Page 9

Ducting Configurations (continued)

Rear Exhaust with Remote Blower

Downdraft

8" or 10" Round Elbow

1-7/8" to 8" or 10"

Round Transition

8" or

10"

Straight Duct

Note: Flex blowers require 8" ducting. External or in-line blowers require 10" ducting.

Planning

* To one of the following:

• Model PF6 (Flex Blower)

Model 643 (8" Round Wall cap)

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

*

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

Dual Duct Side Exhaust with Remote Blower

* To one of the following:

• Model EB9 (900 cfm 10" Exterior Blower)

• Model ILB11 (10" Round In-Line Blower)

Model 441 (10" Round Wall Cap)

• Model EB12 (1200 cfm 10" Round Exterior Blower)

• Model EB15 (1500 cfm 10" Round Exterior Blower)

Downdraft

1-7/8" to 8"

Round Transition

8" Round Elbow

8" Straight Duct

*

Dual 8" Round to 10" Round Transition

9

Page 10

Cabinet Cutouts

CAUTION

BEFORE CUTTING HOLE IN CABINET FOR DUCTWORK,

check for interference with floor joists, wall studs,

electrical wiring, or plumbing.

Use the dimensions in illustrations to help plan how and where to

provide duct access through your cabinet. Generally, 1-7/8" x 19"

rectangular duct will be used through left, right, and back of

cabinet - while 8" round duct will be used through cabinet floor.

For left, right, or rear exhaust: Allow at least 18" for transition and

elbow or blower.

For left / right exhaust: a 30" deep cabinet is recommended to

align properly with flex blower. Flex blower can be mounted to rear

cabinet wall or to a platform / frame (not provided) on the base of

the cabinet floor. (See flex blower instructions).

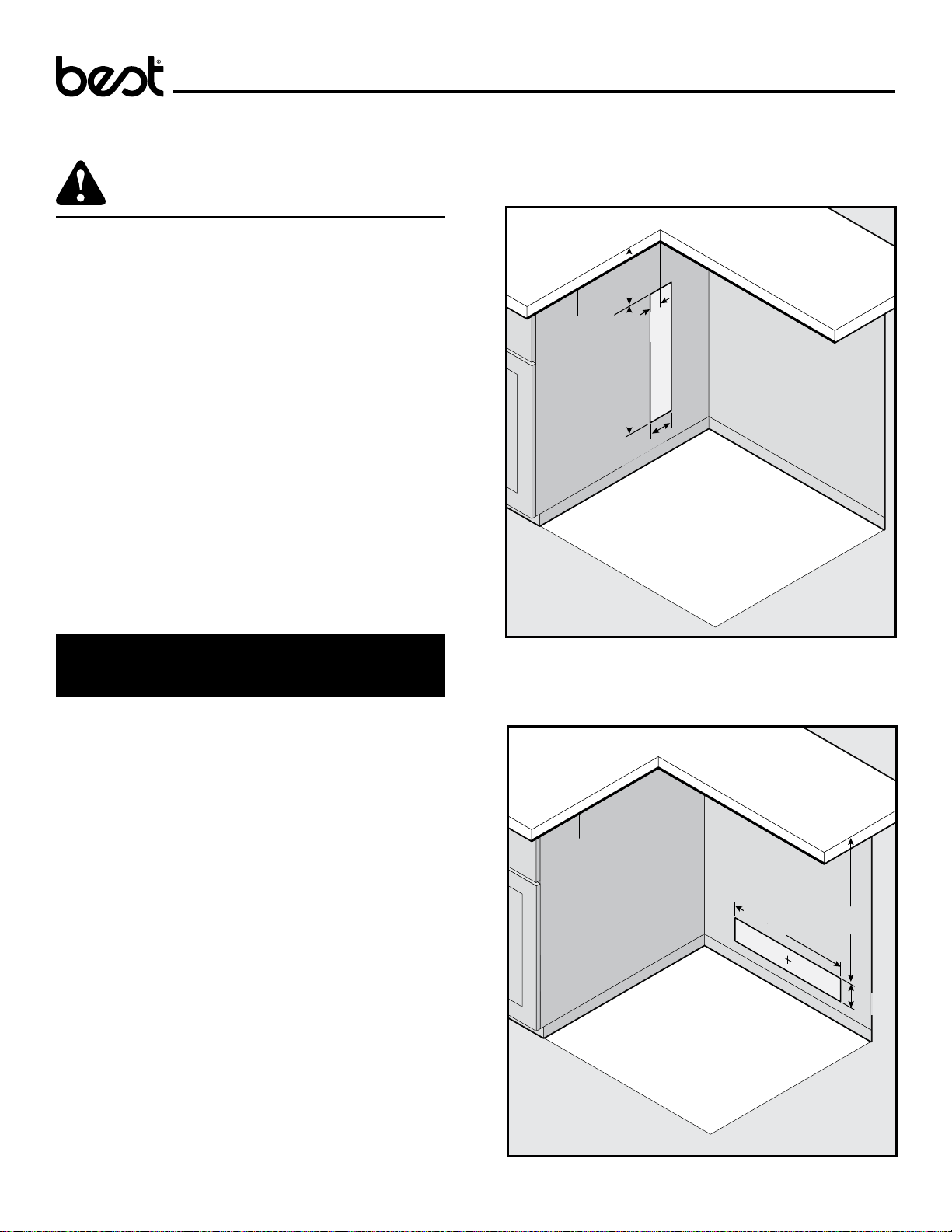

Side Ducting Cutout

5-7/8"

5-7/8"

(14.9 cm)

(14.9 cm)

(5.1 cm)

21"

21"

(53.3 cm)

(53.3 cm)

(10.2 cm)

2"

4"

Appliance

Cutout

Planning

Note: Flex blower can only attach to the front of the downdraft.

Cabinet depths of 24" to 30" are required - depending on the

type of cooking appliance.

If using a Recirculating Kit, see “Plan the installation”

section of the installation instructions packaged with the kit.

Rear Ducting Cutout

Appliance

Cutout

21"

21"

(53.3 cm)

(53.3 cm)

24-3/4"

24-3/4"

(62.9 cm)

(62.9 cm)

(10.2 cm)

4"

10

Page 11

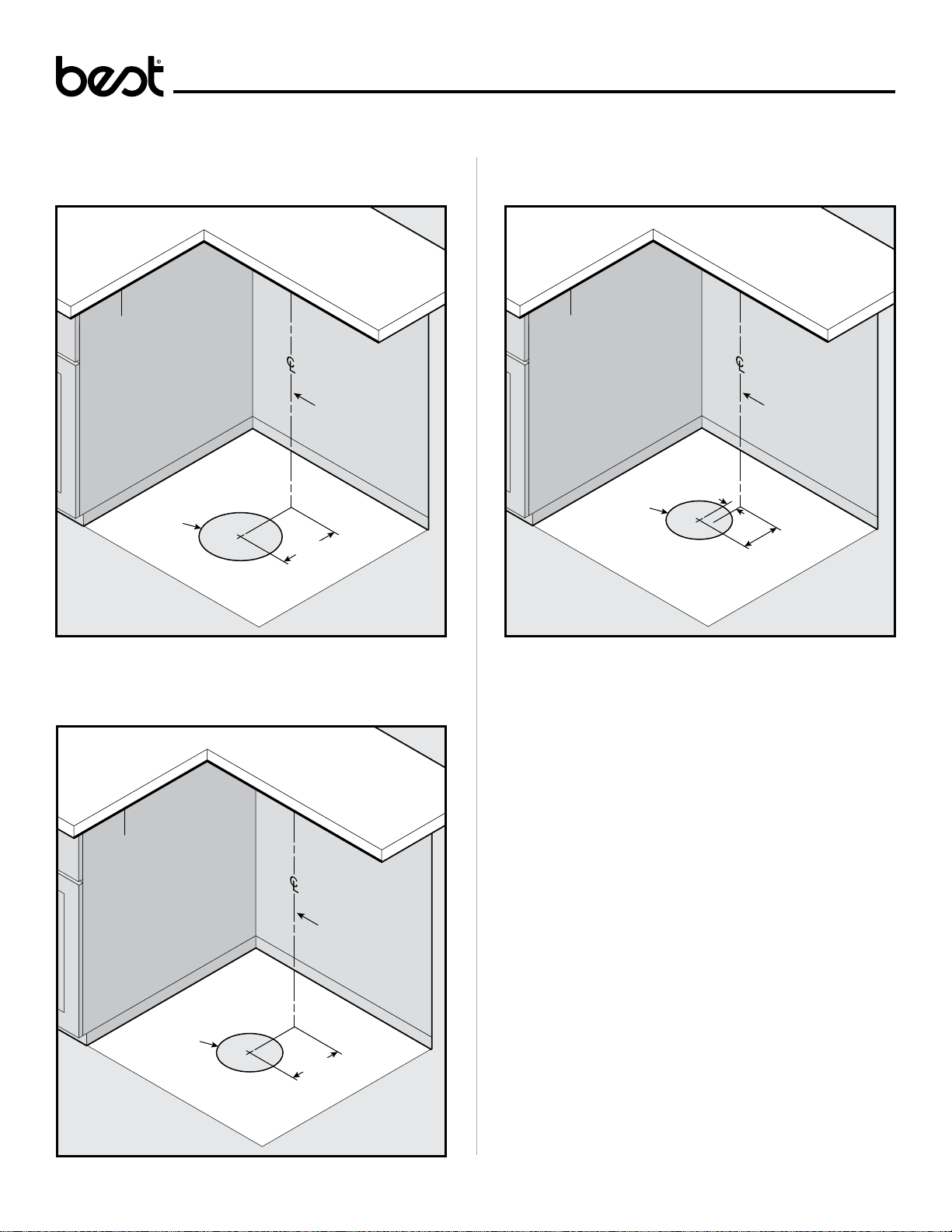

Cabinet Cutouts (continued)

Planning

Flex Blower Ducting Cutout10" Exterior or In-line Blower Ducting Cutout

Appliance

Cutout

Center line of downdraft

Ø10"

(25.4 cm)

8-5/8"

8-5/8"

(14.3 cm)

(14.3 cm)

Dimensions based off of Model 418 - 10" round elbow

Flex Blower Ducting – Remote Location Cutout

Appliance

Cutout

Ø8"

(20.3 cm)

1-1/2"

(3.8 cm)

Center line of downdraft

5-5/8"

5-5/8"

(14.3 cm)

(14.3 cm)

Appliance

Cutout

Center line of downdraft

Ø8"

(25.4 cm)

7-5/8"

7-5/8"

(14.3 cm)

(14.3 cm)

Dimensions based off of Model 432 - 8" round elbow

11

Page 12

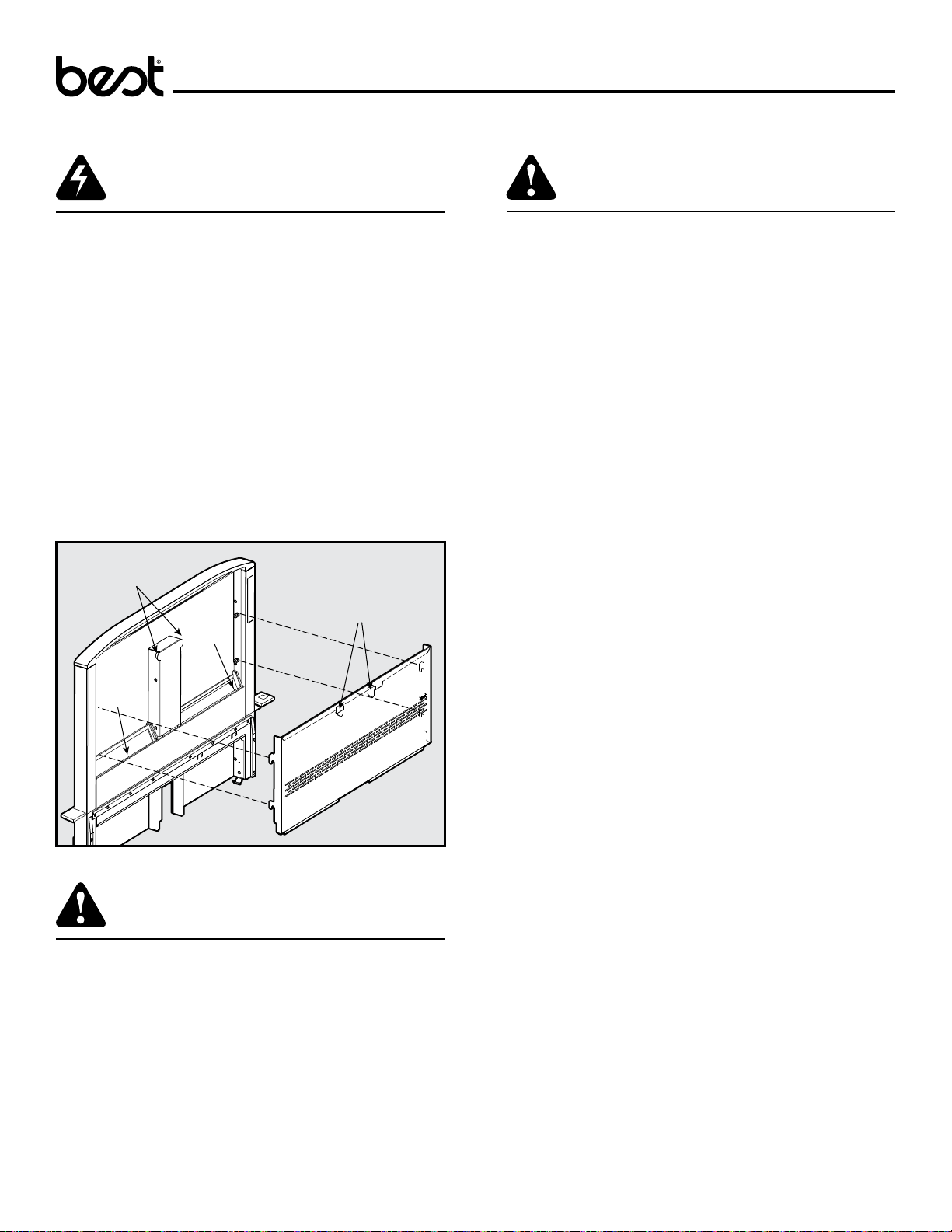

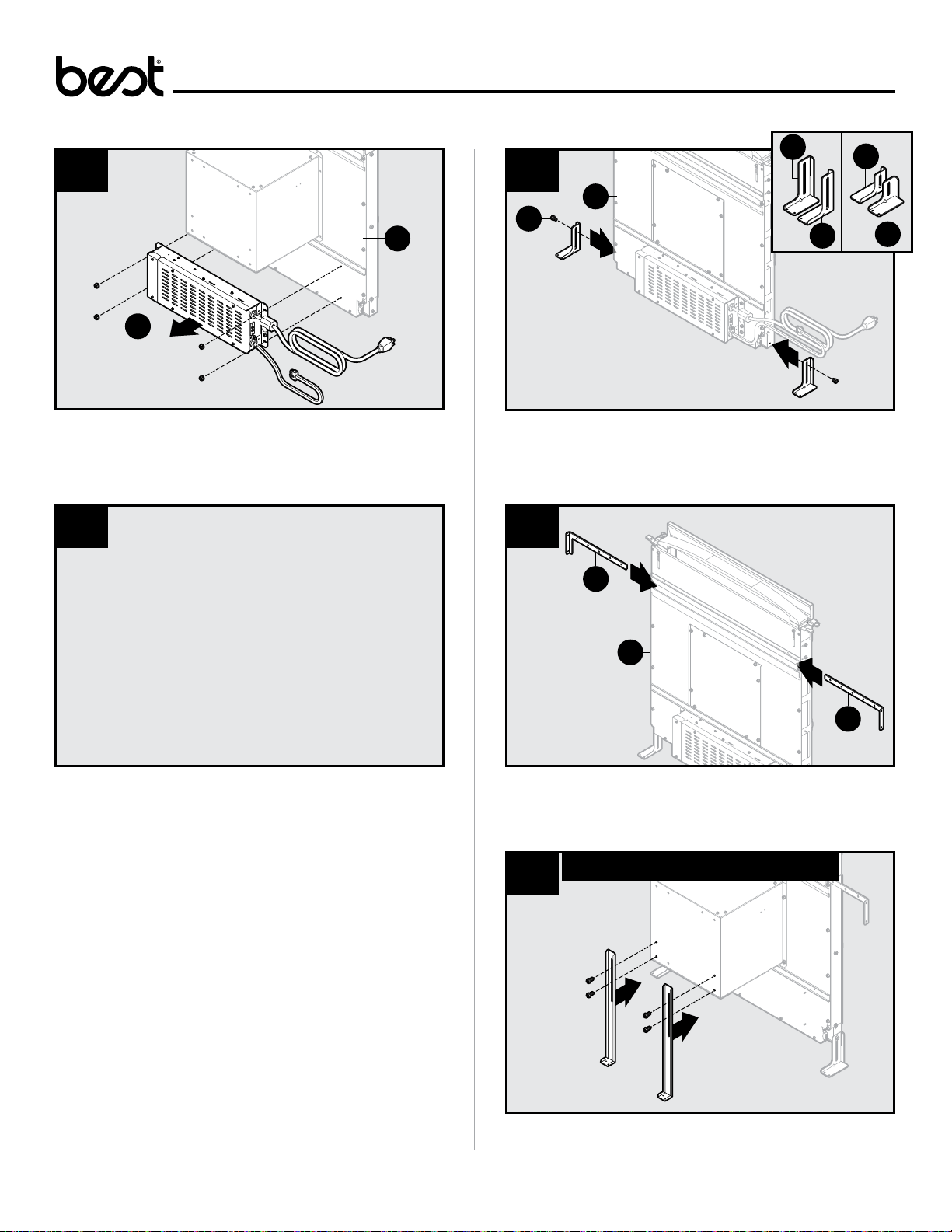

Preparing the Downdraft

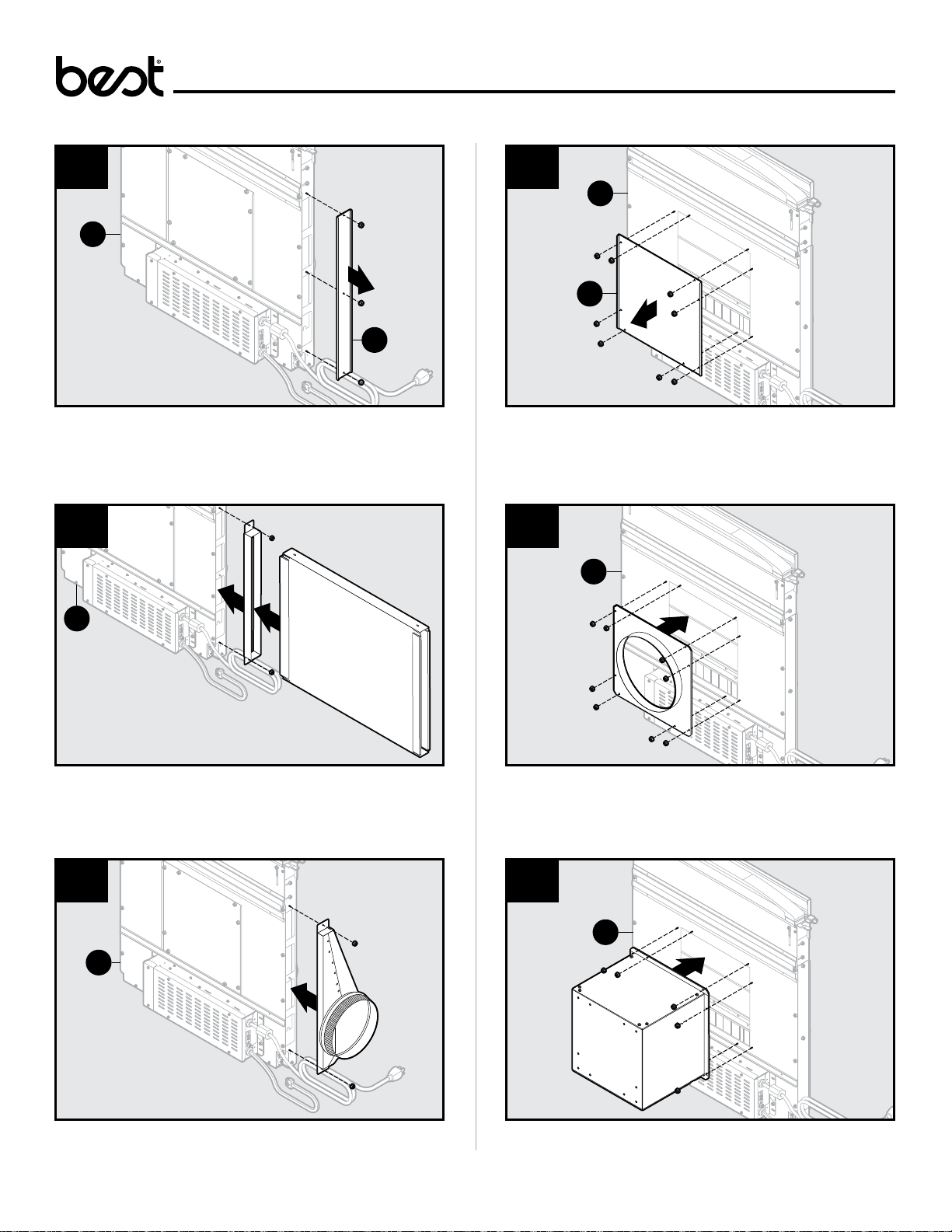

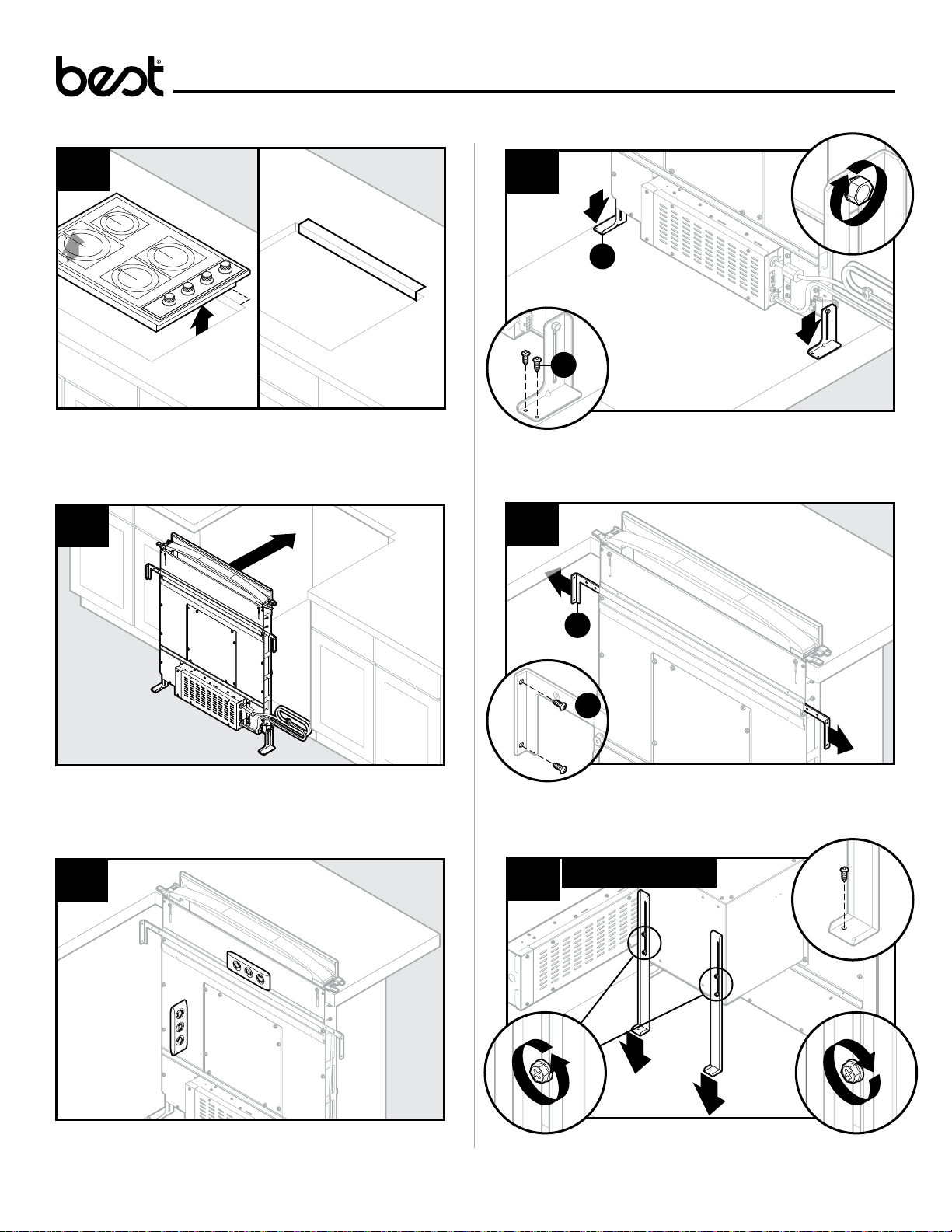

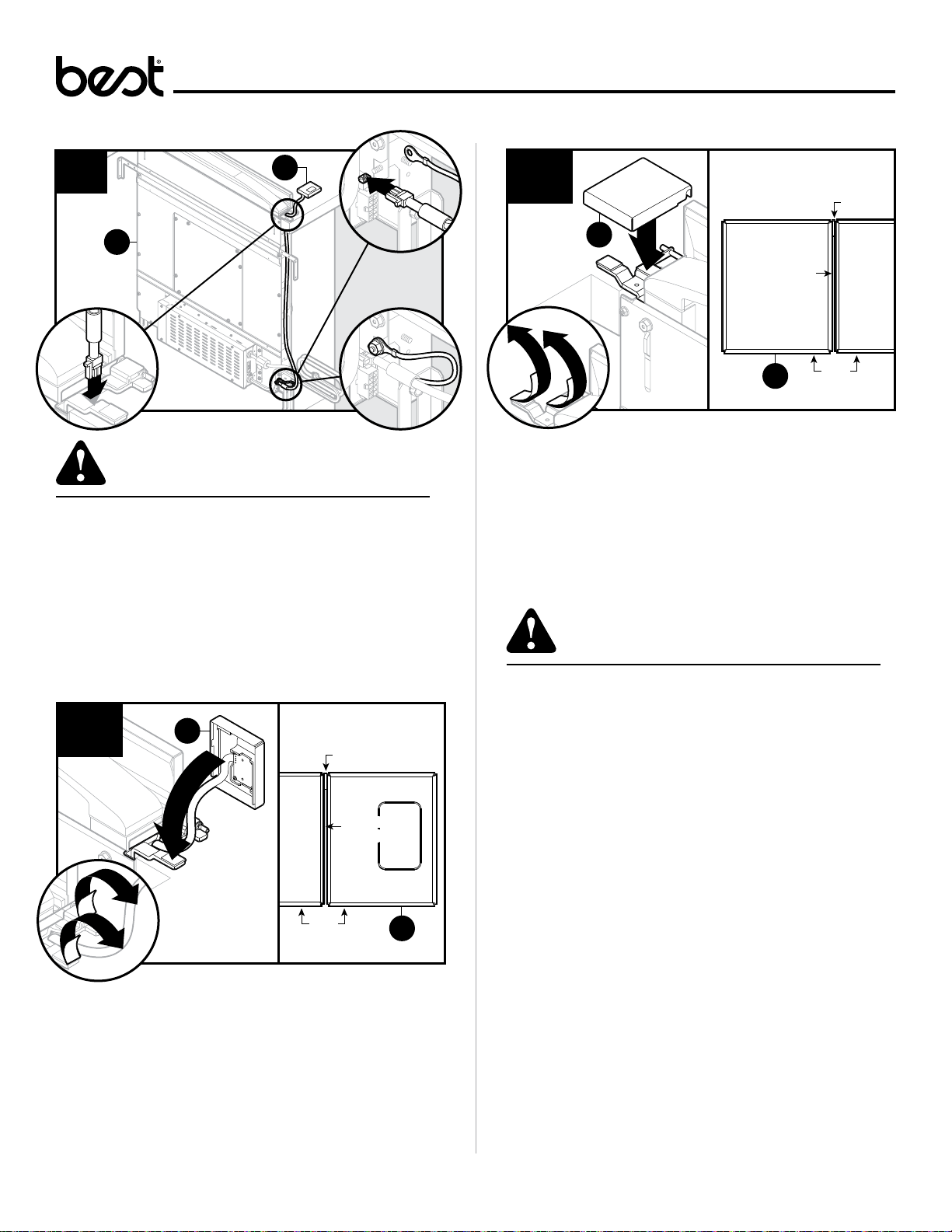

Side or Rear Ducting

1

B

G

Remove a discharge cover (G) from sides or rear of downdraft (B).

Note: Only remove one cover.

2a

1

B

2

Front Ducting

1

B

H

Remove front panel cover (H) from downdraft (B).

2a

B

Install a transition and rectangular ductwork to downdraft (B).

2b

B

1

Install 1-7/8" to 8" or 10" round transition to downdraft (B).

Install 8" or 10" remote discharge plate to downdraft (B).

2b

B

Install the flex blower to downdraft (B).

Note: Flex blower can be installed with duct to left, right or downward.

12

Page 13

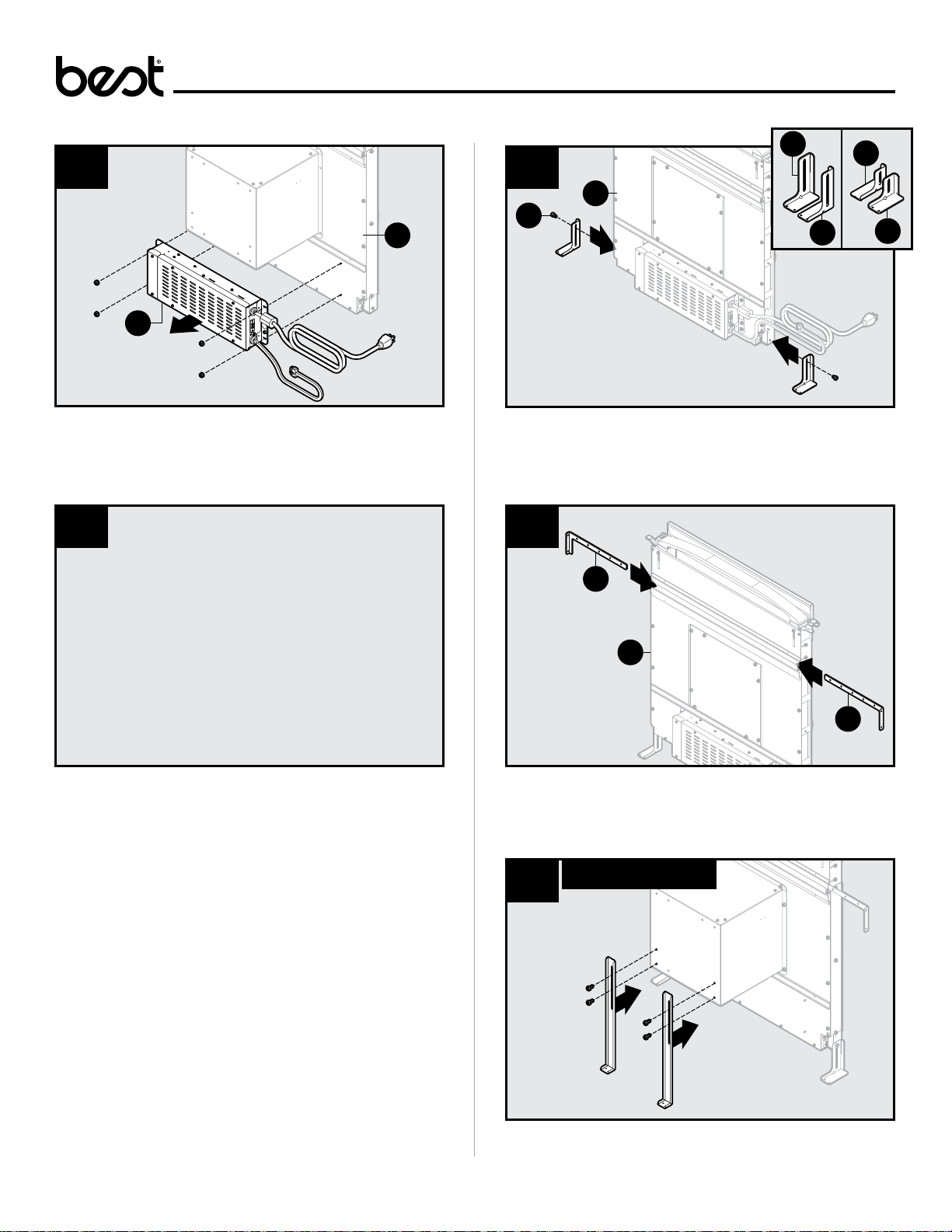

Preparing the Downdraft

Electrical Panel in Remote Location

1

B

I

Remove electrical panel (I) from downdraft (B). Note: Option for most

installations. Required for flex blower installations when discharge is down.

2

Final Assembly

K

F

3

B

AA

E

Attach lower support legs to downdraft (B) using one screw (AA) for each leg.

Note: Use either short (F,L) or long (E,K) legs depending on cabinet height.

L

4

Install electrical panel

in remote location.

DO NOT mount the electrical box with the vent holes facing down.

A

B

J

Slide upper support brackets (A,J) into side channels of downdraft (B).

Flex Blower Only

5

If using flex blower, attach blower support legs with supplied screws.

13

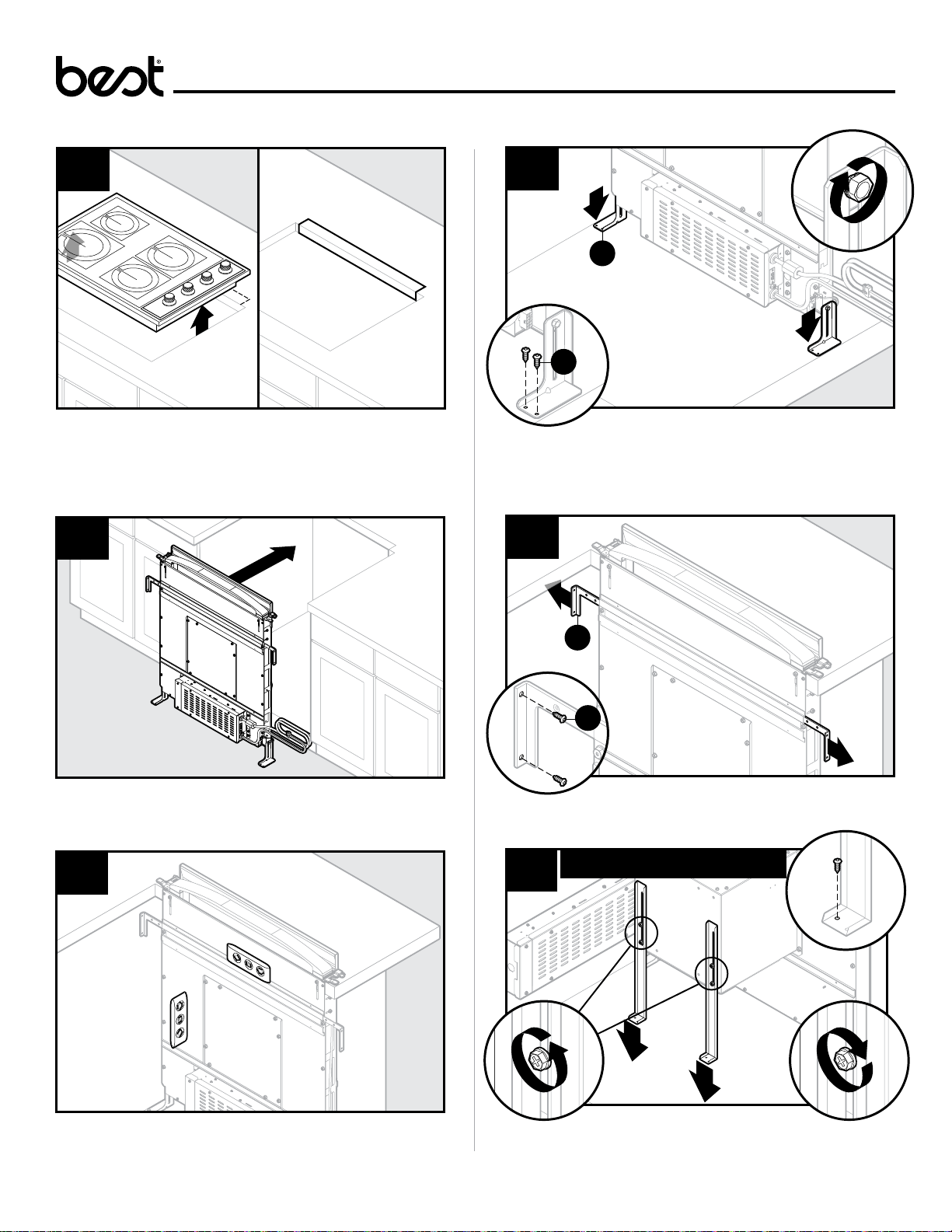

Page 14

Cutting Counter Top Opening

Installation

6a

6b

Cooktop

Cooktop with Oven

6d

7

Range

6c

Rangetop

Place appliance.

Note: Cook top shown.

8

B

Center template against the back flange and mark downdraft opening.

A = 1.865" B = 27.070" D49M30SB, 33.070" D49M36SB,

45.070" D49M48SB

14

A

Page 15

Installation

Cutting Counter Top Opening (continued)

9

Remove cook top/appliance and cut opening.

Install Housing into Cabinet

10

Install Housing into Cabinet

12

1

(continued)

3

E

1

2

BB

Extend support legs (E/F) and attach to bottom of cabinet with two

screws (BB) per leg. Tighten hex screws. Note: If cabinet bottom is

removed, use blocks as spacers between floor and support legs.

13

Set housing into cabinet.

11

1

A

BB

2

Extend upper support brackets (A) and attached to sides of cabinet with

two screws (BB) per bracket.

14

Flex Blower Only

1

1

3

Level housing.

Note: Steps 11-15, right cabinet not shown for clarity.

1

Loosen four screws attaching blower support legs to flex blower. Extend

legs and secure to bottom of cabinet with one screw through each

bracket. Re-tighten four blower screws.

15

2

2

4

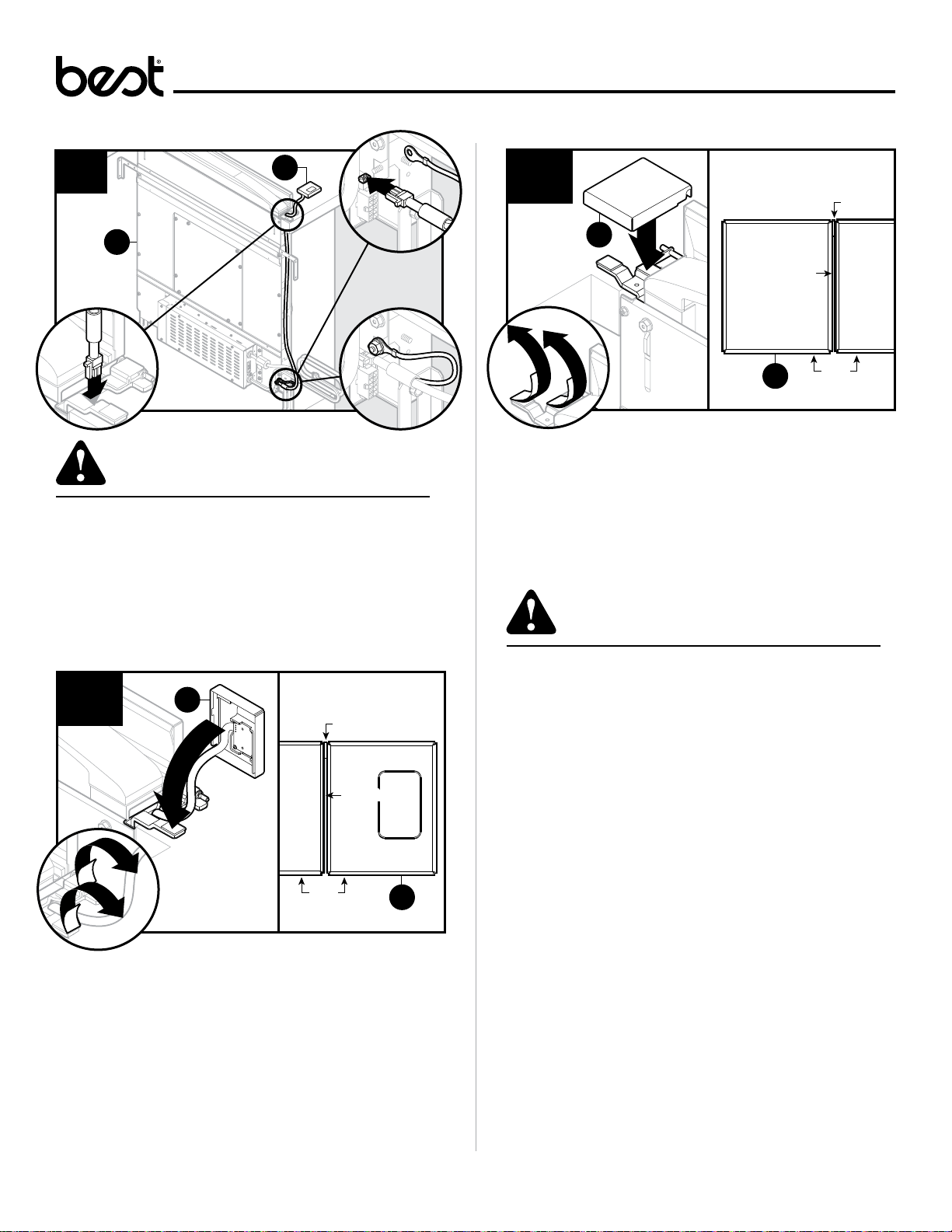

Page 16

Installation

Installing Finish Trim

15

B

1

D

2

3

CAUTION

Only connect or disconnect UP BUTTON CABLE

with main power off for at least 60 seconds.

Insert wiring harness with wire from right upper button (D) into opening

in side of downdraft (B). Insert upper button (D) wiring harness into

receptacle at lower right side of downdraft (B). Connect ground wire to

ground nut on lower right of downdraft.

Installing Finish Trim (continued)

TOP VIEW

17

Washer

C

1

1

Remove tape backing. Wipe underside surface of left trim (C) so that tape

adhesive will stick tightly. Press left trim in place.

Note: Make sure trim sits flat on countertop surface, is flush with top door,

and has 1/16 " GAP between trim and top door.

Installing Ductwork

CAUTION

2

1/16" Gap1/16" Gap

DoorTrim

C

Flush

16

1

1

Remove tape backing. Wipe surfaces clean on underside of right trim (D)

so that tape adhesive will stick tightly. Press right trim in place.

Note: Make sure trim: sits flat on countertop surface, is flush with top

door, has 1/16" GAP between trim and top door, and wiring is not pinched.

D

2

TOP VIEW

Washer

1/16" Gap1/16" Gap

Door Trim

Flush

D

BEFORE CUTTING HOLE IN CABINET FOR

DUCTWORK, check for interference with floor

joists, wall studs, electrical wiring, or plumbing.

• Refer to Ductwork Configurations in the Planning section of this

document.

• Cut hole in cabinet as well as holes in wall or floor as necessary.

• Mount the roof or wall cap and work back towards the cabinet,

attaching all ductwork, elbows and transitions as previously

planned. Tape all ductwork connections to make them secure and

air tight.

• Connect ductwork (and transition, if required) to downdraft.

16

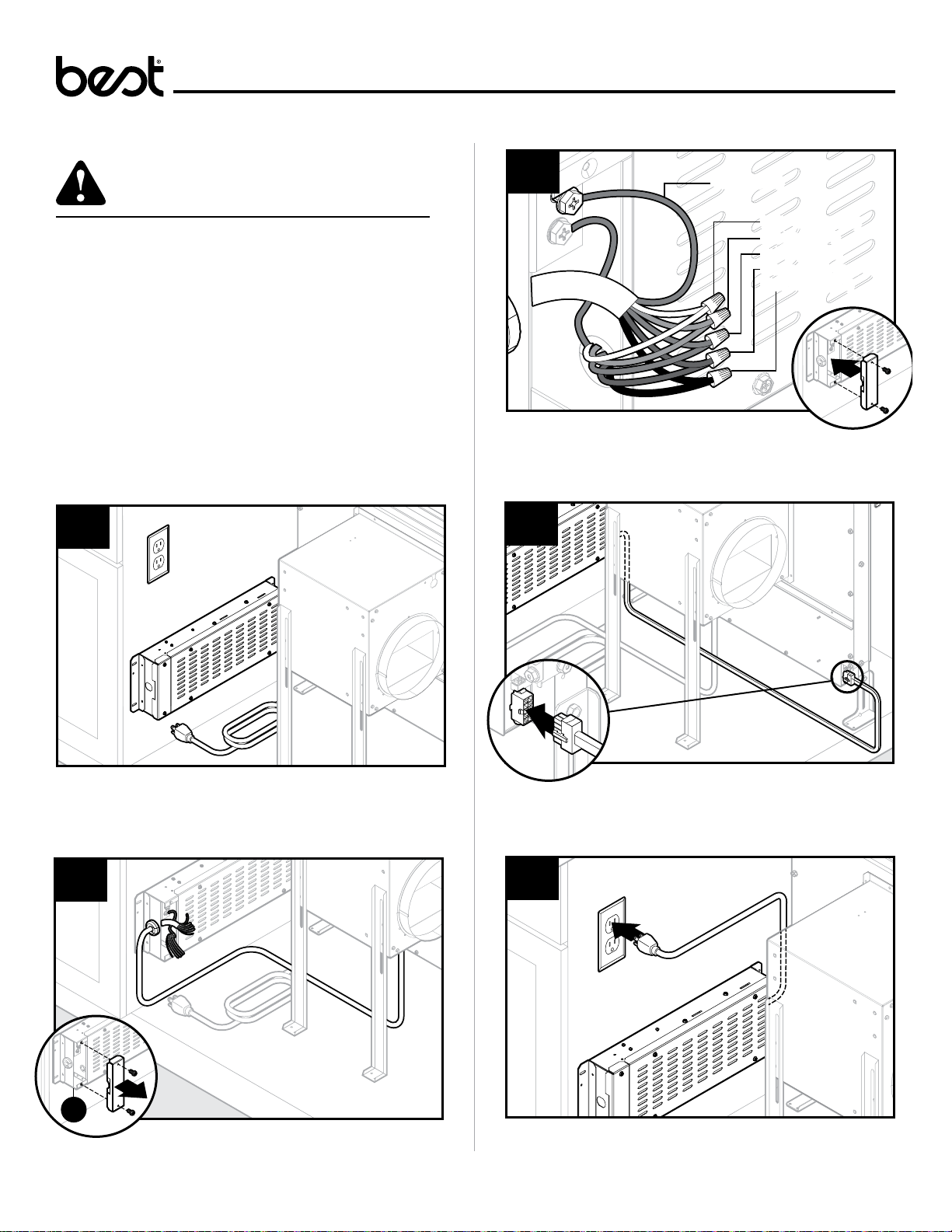

Page 17

Flex Blower only

Electrical Wiring Installation

CAUTION

All electrical wiring should be done by a qualified

person(s) in accordance with all applicable codes

and standards.

• This downdraft blower using the Flex Blower (purchase

separately) draws 3.0 Amps and requires a

120 VAC, 60 Hz circuit.

• The unit has a 30 in. long power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will

allow the unit’s power cord to reach.

• Install electrical box according to local codes.

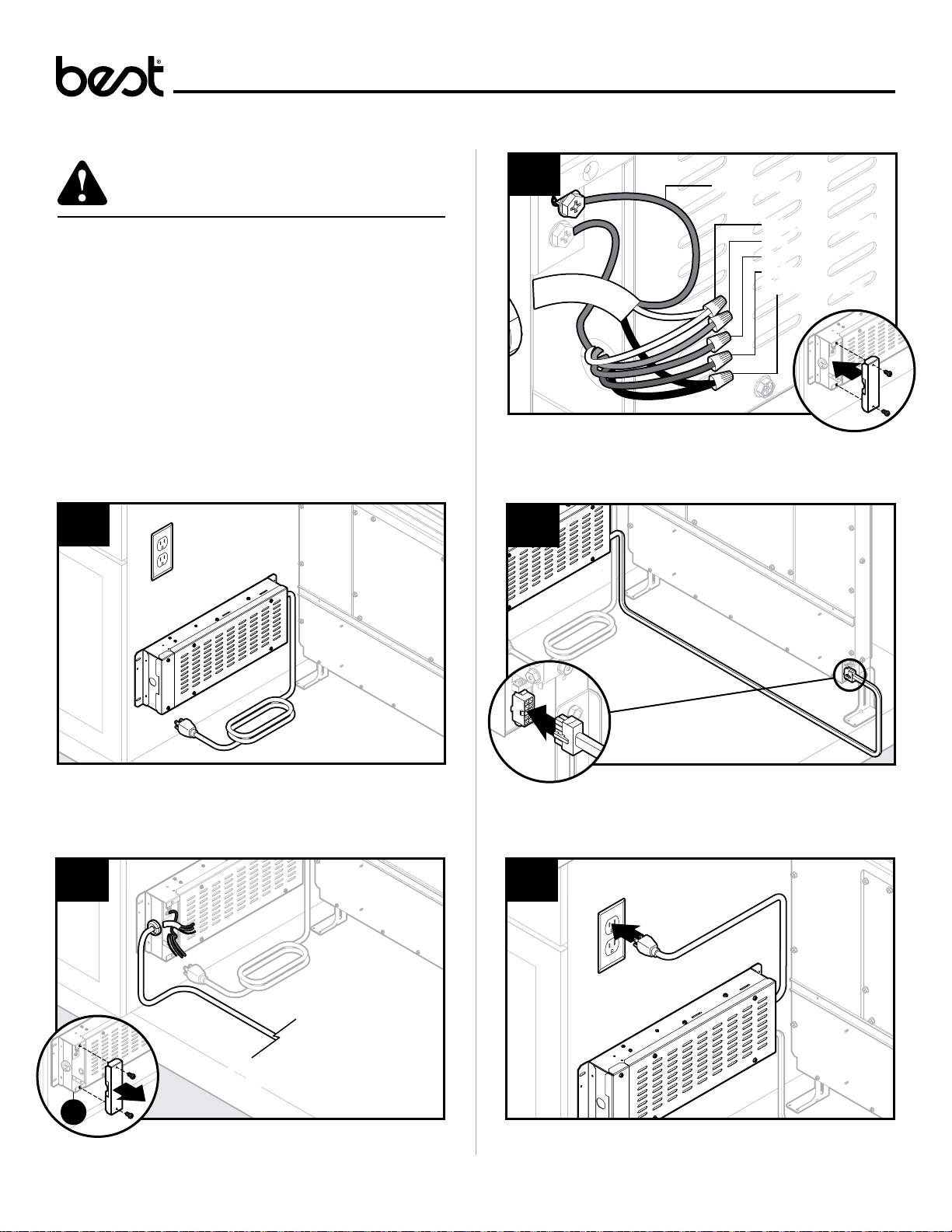

18a

20a

Connect blower wires to wires in electrical panel. Replace electrical

panel cover.

Green (ground)Green (ground)

White White (neutral)

White White (neutral)

Blue Blue (low 1)

Blue Blue (low 1)

Red Gray (med 2)

Red Gray (med 2)

Orange Orange (med- high)

Orange Orange (med- high)

Black Black (high 4)

Black Black (high 4)

21a

Mount a standard wiring box, with 3-pronged receptacle, within reach

of downdraft’s power cord. (Run appropriate power cable and connect it

to receptacle.)

19a

I

Remove electrical panel (I) cover and route blower wire into wiring box.

Plug electrical panel cable into lower receptacle on side of downdraft.

22a

Plug downdraft’s power cord into outlet.

Note: Make sure that power cord is routed away from the heat

generated by the cooktop.

17

Page 18

Exterior or In-Line Blower only

Electrical Wiring Installation

CAUTION

All electrical wiring should be done by a qualified

person(s) in accordance with all applicable codes

and standards.

• If using a remote blower (purchase separately), the

system draws 6.0 Amps (max.) and requires a 120 VAC,

60 Hz circuit.

• The unit has a 30 in. long power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will allow

the unit’s power cord to reach.

• Install electrical box according to local codes.

18b

20b

Connect blower wires to wires in wiring box. Replace wiring box cover.

Note: Blue, gray and orange wires are capped off but not connected.

Green (ground)Green (ground)

White White (neutral)

White White (neutral)

Blue

Blue

Gray

Gray

Orange

Orange

Black Black (high 4)

Black Black (high 4)

21b

Mount a standard wiring box, with 3-pronged receptacle, within

reach of downdraft’s power cord. Run appropriate power cable and

connect it to receptacle.

19b

From Exterior or

From Exterior or

In-Line Blower

In-Line Blower

I

Remove wiring box cover and route blower wire into wiring box.

Plug electrical panel cover into lower receptacle as shown.

22b

Plug downdraft’s power cord into outlet.

Note: Make sure that power cord is routed away from the heat

generated by the cooktop.

18

Page 19

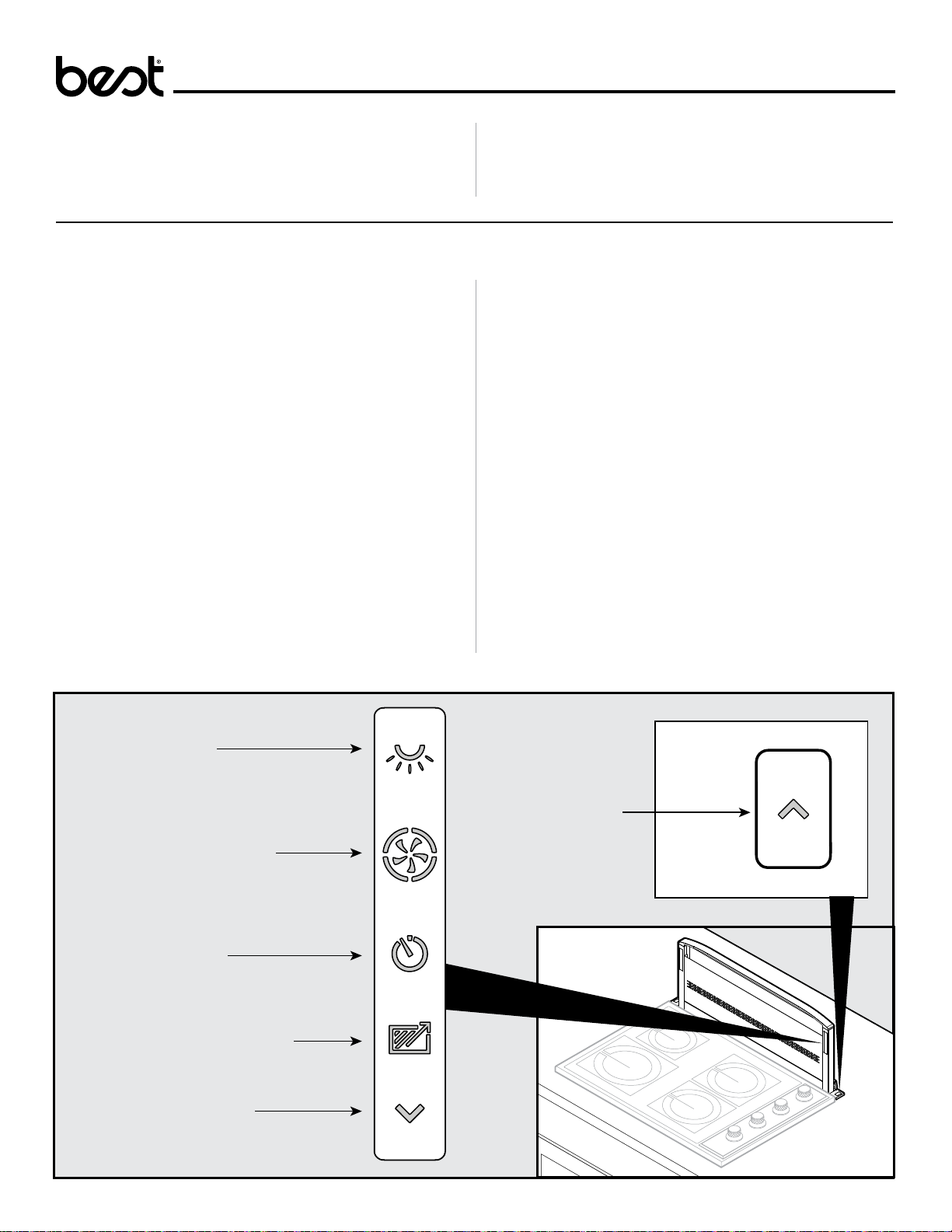

Appliance Installation/Operation

Install Cooking Appliance

1. Align the cooking appliance with downdraft and fasten appliance

in place following appliance instructions.

Control Panel and Up Button

2-Level Task Light

• Press once for LOW setting. Top of icon will illuminate.

• Press 2x for HIGH setting. Top and bottom of icon will

illuminate.

• Press 3x to turn task light OFF.

4-Speed Fan Speed Control

• Press once for LOW setting. Top-right quadrant of icon will

illuminate.

• Press 2x for MEDIUM LOW setting. Top-right and bottom-right

quadrants of icon will illuminate.

• Press 3x for MEDIUM HIGH setting. Top-right, bottom-right, and

bottom-left quadrants of icon will illuminate.

• Press 4x for HIGH setting. All quadrants of icon will illuminate.

• Press 5x to turn fan OFF.

10-Minute Delay Off

When fan is ON at any speed setting, press delay-off icon to start

10-minute timer. Fan and icon will shut off after 10 minutes.

To reset or deactivate delay-off, press icon again.

Note: Accurate alignment of cooking appliance and downdraft is

necessary to ensure that there is no interference when air vent

is raised and lowered. There should be a gap of 1/32" - 1/16 "

between the back of the cooktop and the front of the downdraft

cover.

30-Hour Filter Clean Reminder

• After 30 hours of blower “ON” time, filter clean icon will blink

continuously.

• To reset, touch and hold icon for 2 or more seconds. Indicator

will turn off.

Down / Retract Chimney

• To retract chimney, touch down button. Any feature that is

active will shut off.

Up Button

• Touch up button on right trim to raise chimney. All functions will

return to their previous settings.

Heat Sentry

• When the operating temperature is too high, the fan speed will

increase to its highest setting to protect sensitive components.

The fan icon will blink and cannot be overridden until the

temperature reaches an acceptable level. The fan speed will

return to the previous setting and the icon will stop blinking.

2-Level Task Light

4-Speed Fan Speed Control

10-Minute Delay Off

30-Hour Filter Clean Reminder

Down / Retract Chimney

Up Button

19

Page 20

Use and Care

Cooking

WARNING

Always disconnect electric power

supply before cleaning and/or servicing unit.

Always turn the downdraft blower on before you begin cooking

to establish an air flow in the kitchen. Let the blower run for a few

minutes to clean the air after you turn the cooktop off. This will

keep the whole kitchen cleaner and brighter.

It is recommended to use the rear burners when cooking with tall

pots or when the cooking method will generate high amounts of

smoke or steam. The combination of using the rear burners and

operating the unit at high speed will increase the likelihood that

all the smoke and steam will be removed by the downdraft.

Cleaning

Ears

Tabs

Filter

CAUTION

Failure to engage tabs properly may cause chimney

to jam and fail to raise up.

To clean inside chimney:

Lift FRONT PANEL up and out and take out the GREASE FILTERS.

Use a mild detergent. DO NOT USE ABRASIVE CLOTH, STEEL WOOL

PADS, OR SCOURING POWDERS. Replace filters and front panel

before using downdraft.

Be sure to engage TABS on front panel behind EARS as shown.

Servicing

It may be necessary to remove the downdraft blower system from

the cabinet in order to service components such as the blower

motor or air vent mechanism.

Disconnect power to the cooktop and remove it first. Reverse the

steps under “INSTALL HOUSING INTO CABINET” to remove the

downdraft from the cabinet.

Filter

Front Panel

CAUTION

Failure to engage tabs properly may cause chimney

to jam and fail to raise up.

To Clean grease filters:

Lift FRONT PANEL up and out and take out the GREASE FILTERS.

Wash filters in a mild detergent solution or a dishwasher. Replace

filters and front panel before using downdraft.

Be sure to engage TABS on front panel behind EARS as shown.

20

Page 21

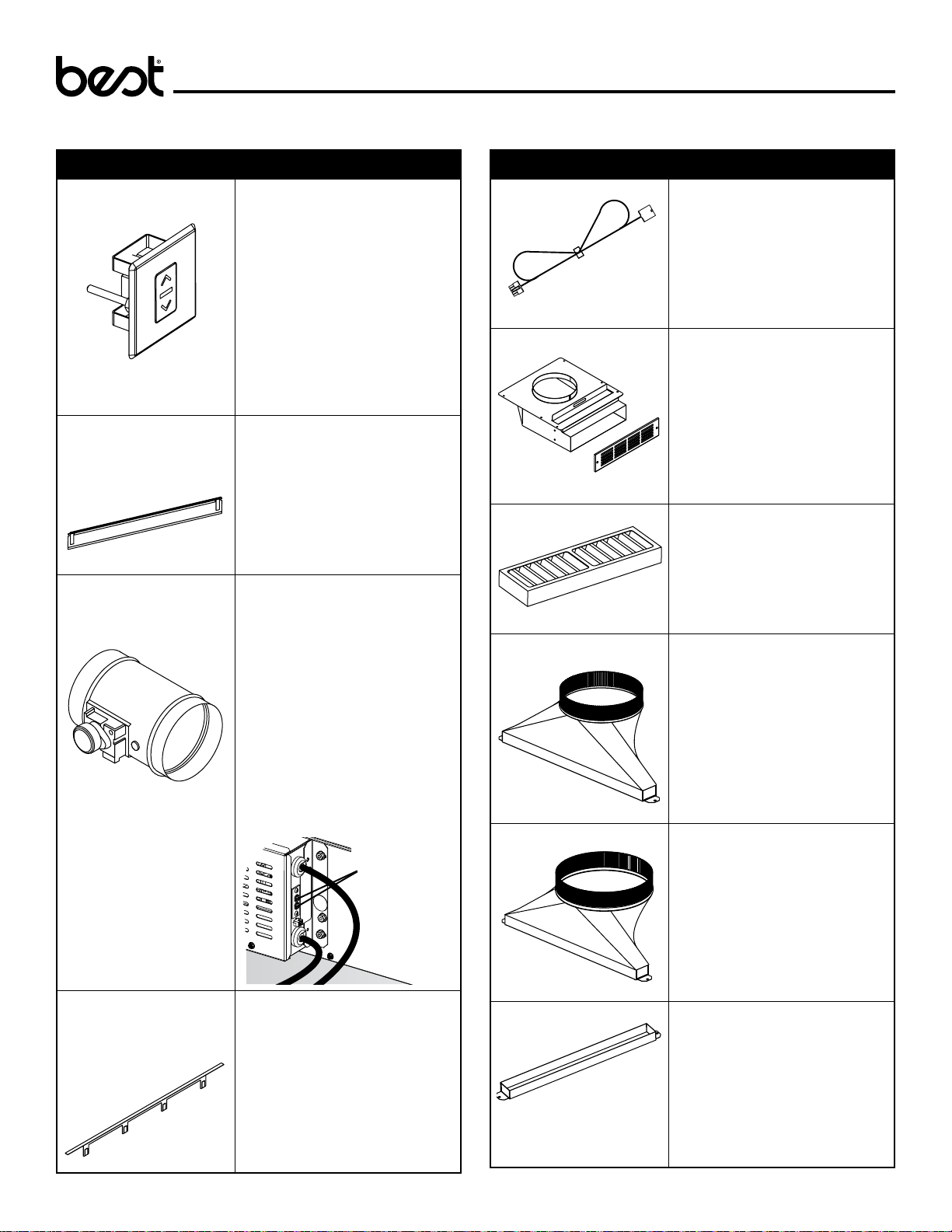

Optional Accessories

Optional Accessories

Accessory Description

Model ACRD

MODELS

ATSKD30

ATSKD36

ATSKD48

MODELS

MD6T

MD8T

MD10T

REMOTE UP/DOWN CONTROL

Use when you cannot reach the UP/

DOWN Button on the downdraft chimney.

Can be located on counter top, face of

cabinetry or on the side cabinet of an

island. Cut-out size: 2 1/4" H x 2" W

Cannot be used where remote control

will interfere with cooking, where hot

pans could be set, or where hot liquids

could be spilled on the control.

(Remote wiring connects with 6-pin

connection)

GAS COOKTOP SEAL KIT

Recommended for use with all gas

cooktops. Includes trim bracket and trim

seal.

30", 36" & 48" widths.

MAKE-UP AIR DAMPER

Use to provide make-up air (when called

for) to keep the home comfortable by

allowing the downdraft to operate at

optimum levels.

Directwire design works with select

BEST® downdrafts to balance indoor air

pressure by providing interlocked makeup air; damper opens automatically

when the range hood is activated.

8" & 10" round diameters.

Connects to 2 CONTACTS on

ELECTRICAL PANEL.

MAKE-UP

AIR DAMPER

CONTACTS

Accessory Description

MODEL AEWD5 EXTENSION CABLE - 5-FT.

Use where electrical panel is remotely

mounted. Extends electrical panel cable

an additional 5-feet.

MODEL ANKD

MODEL AFCD

MODEL AVDKD8

MODEL AVDKD10

NON-DUCT RECIRCULATING KIT

Use where ducting is not feasible or

available. Mount to toe kick or base of

a cabinet and attach directly to Model

PF6 Flex Blower using 8" round duct. Kit

can be rotated so that the exhaust is not

directly at your feet. Includes

recirculation filter and decorative

cover plate.

RECIRCULATION FILTER REPLACEMENT

Replacement filter for ANKD Non-Duct

Recirculating Kit. Use to effectively

capture cooking contaminants.

1-7/8" X 19” TO 8" ROUND

TRANSITION

Rectangular to 8" round transition for

left, right, or rear exhaust - using Model

PF6 Flex Blower. Can be attached to

downdraft unit or rectangular duct

(AEDD2). Includes S-clips for easy,

secure attachment.

1-7/8" X 19" TO 10" ROUND

TRANSITION

Rectangular to 10" round transition for

left, right, or rear exhaust - using

external blower. Can be attached to

downdraft unit or rectangular duct

(AEDD2).

MODELS

ATKD30SB

ATKD36SB

ATKD48SB

RANGE TRIM KIT

Use with free-standing range - where a

gap is present between back of range

and downdraft.

30", 36" & 48" widths.

MODEL AVDKD219 RECTANGULAR ADAPTOR FOR

1-7/8" X 19"

Use to connect 1-7/8" x 19" rectangular

duct directly to downdraft when using

side or rear exhaust.

21

Page 22

Optional Accessories (continued)

Optional Accessories

Accessory Description

MODEL ATTD1

MODEL ACVPD8

MODEL ACVPD10 FRONT PANEL ROUGH-IN PLATE -

END CAP TRIM EXTENSION +1"

WIDTH - LH & RH

Use left and right to increase the overall

trim width by 1".

FRONT PANEL ROUGH-IN PLATE -

8" ROUND

Use where 8" round duct or elbow

attaches to front of airbox (Model PF6

remote blower installation).

10" ROUND

Use where 10" round duct or elbow

attaches to front of airbox (exterior or

in-line blower installation).

Accessory Description

MODEL 408 - 8" RD.

MODEL 410 - 10" RD.

MODEL AEDD2

STRAIGHT ROUND DUCT - 2-FT.

Galvanized steel construction.

RECTANGULAR DUCT - 2-FT.

SECTIONS (1-7/8" X 19")

Galvanized steel construction.

MODEL 432 - 8" RD.

MODEL 418 - 10" RD.

90˚ DUCTWORK ELBOW

Adjustable from straight to 90˚.

Galvanized steel construction.

MODEL AVDKD8810

TRANSITION “Y” (2) - 8" ROUND TO

(1) - 10" ROUND

Galvanized steel construction.

22

Page 23

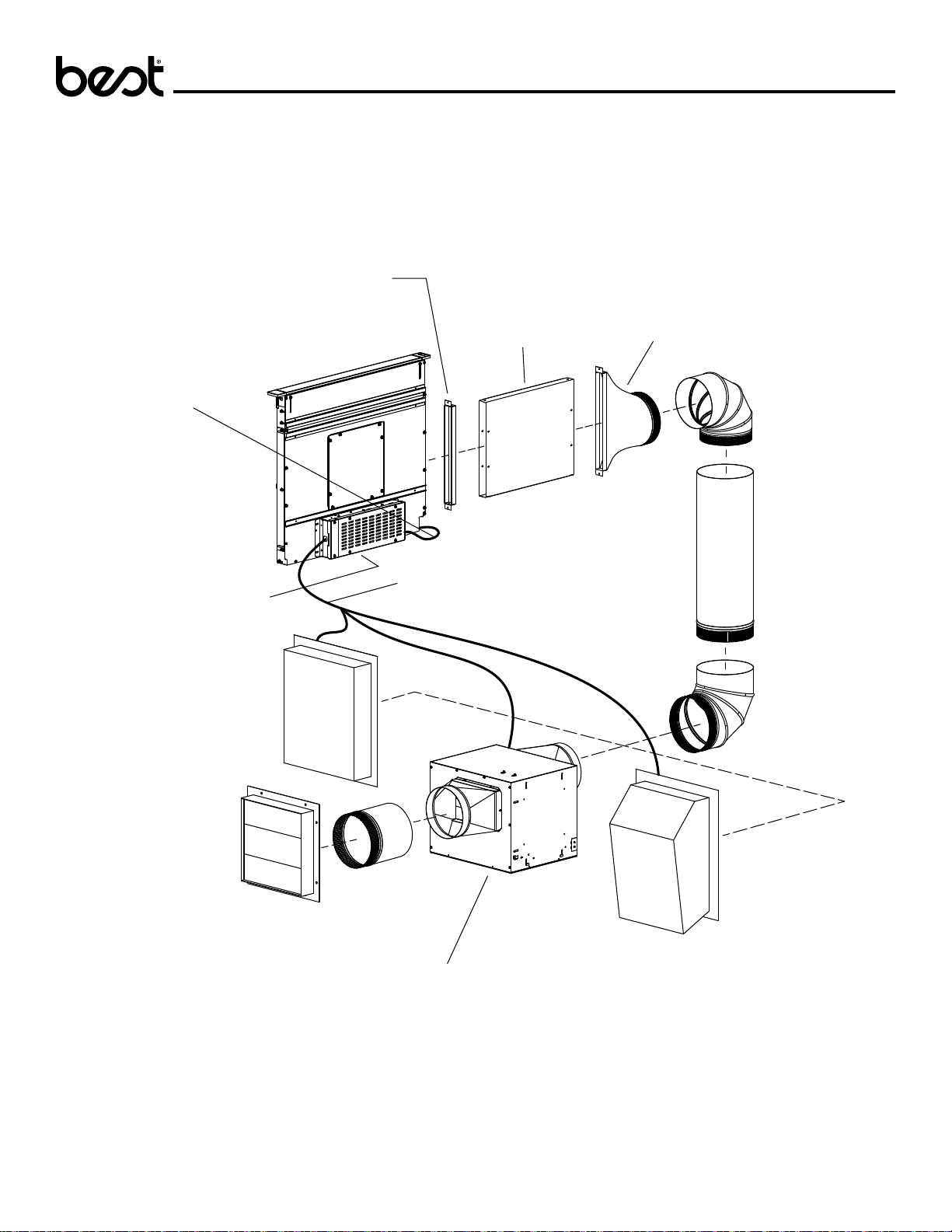

Internal Blower (Pf6) – Front Mounted to Downdraft

MODEL PF6

Flex Blower (sold separately)

(“Down” discharge shown. Blower can

also be rotated for “Left” or “Right”

discharge.)

MODEL 408 *

8-inch Round

Straight Duct

Electrical Panel

(Mount in remote location)

MODEL 432 *

8-inch Round Elbow

Appendix A

MODEL 643 *

8-inch Round

Wall Cap

MODEL AEWD5

5-foot Extension

Cable (sold separately)

(Only required if electrical panel

is more than 2-feet away from

downdraft. Use up to 2 extension

cables connected together.)

MODEL ANKD

Non-Duct Recirculation Kit with

Kickspace Grille (sold separately)

(Only required for non-duct

applications. “Front” discharge

shown. Kit can also be rotated for

“Left” , “Right” or “Rear” discharge.)

MODEL 408 *

8-inch Round

Straight Duct

* As required - sold separately.

23

Page 24

Internal Blower (Pf6) – Remote Mounted – Front Outlet

MODEL ACVPD8

8-inch Round Front

Rough-in Plate

(sold separately)

MODEL 432 *

8-inch Round Elbow

Electrical Panel

(Can be mounted

in remote location)

MODEL 408 *

8-inch Round

Straight Duct

Appendix B

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if electrical panel

is mounted in a remote location more than 2-feet away from

downdraft. Use up to 2 extension

cables connected together.)

* As required - sold separately

MODEL PF6

Flex Blower (sold separately)

MODEL 408 *

8-inch Round

Straight Duct

MODEL 643 *

8-inch Round

Wall Cap

24

Page 25

Internal Blower (Pf6) – Remote Mounted – Side or Rear Outlet

MODEL AVDKD219 *

1-7/8-inch x 19-inch

Rectangular Transition

(sold separately)

(Only required to

extend duct along

back of cabinet.)

Electrical Panel

(Can be mounted in

remote location.)

MODEL AEDD2 *

1-7/8-inch x 19-inch

Rectangular Duct

(sold separately)

(Only required to

extend duct along

back of cabinet.)

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if

electrical panel is mounted

in a remote location - more

than 2-feet away from downdraft.

Use up to 2 extension cables

connected together.)

MODEL AVDKD8

1-7/8-inch to 8-inch

Round Transition

(sold separately)

MODEL 432 *

8-inch Round

Elbow

MODEL 408 *

8-inch Round

Straight Duct

Appendix C

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

adjacent cabinet)

MODEL ANKD

Non-Duct Recirculation Kit

with Kickspace Grille

(sold separately)

(Only required for non-duct

applications. “Front” discharge

shown. Kit can also be rotated

for “Left” , “Right” or “Rear” discharge.)

MODEL 643 *

8-inch Round

Wall Cap

MODEL 408 *

8-inch Round

Straight Duct

25

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

adjacent cabinet)

* As required - sold separately.

Page 26

Internal Blower (Pf6) – Remote Mounted – Rear Outlet

MODEL AEDD2 *

1-7/8-inch x 19-inch

Rectangular Duct

(sold separately)

MODEL AVDKD219 *

1-7/8-inch x 19-inch

Rectangular Transition

(sold separately)

Appendix D

MODEL AVDKD8

1-7/8-inch to 8-inch

Round Transition

(sold separately)

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

adjacent cabinet)

MODEL 643 *

8-inch Round

Wall Cap

MODEL 408 *

8-inch Round

Straight Duct

MODEL 432 *

8-inch Round

Elbow

MODEL 408 *

8-inch Round

Straight Duct

MODEL PF6

Flex Blower

(sold separately)

(Mounted in

remote location)

MODEL ANKD

Non-Duct Recirculation Kit

with kickspace grille

(sold separately)

(Only required for non-duct

applications. “Front” discharge

shown. Kit can also be rotated

for “Left” , “Right” or “Rear” discharge.)

* As required - sold separately.

26

Page 27

Exterior or In-Line Blower – Front Outlet

Appendix E

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if

Electrical Panel is mounted

in a remote location - more

than 2-feet away from downdraft.

Use up to 2 Extension Cables

connected together.)

(Standard 120 VAC

wiring rated for 6A

minimum - sold separately.)

MODEL EB9 **

900 cfm

10-inch Round

Exterior Blower

MODEL

10-inch Round

Front Rough-in Plate

(sold separately)

Electrical Panel

(Can be mounted in

remote location.)

ACVPD10

MODEL 418 *

10-inch Round Elbow

MODEL 410 *

10-inch Round Straight Duct

MODEL 418 *

10-inch Round Elbow

MODEL 441 *

10-inch Round

Wall Cap

MODEL 410 *

10-inch Round

Straight Duct

MODEL ILB11 **

1100 cfm

10-inch Round

In-Line Blower

MODEL EB12 **

1200 cfm

10-inch Round

Exterior Blower

27

-- OR --

* As required - sold separately.

** Choose 1 exterior or in-line

blower - sold separately.

MODEL EB15 **

1500 cfm

10-inch Round

Exterior Blower

Page 28

Exterior or In-Line Blower – Side or Rear Outlet

MODEL AVDKD219 *

1-7/8-inch x 19-inch

Rectangular Transition

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if

Electrical Panel is mounted

in a remote location - more

than 2-feet away from downdraft.

Use up to 2 extension cables

connected together.)

Electrical Panel

(Can be mounted in

remote location)

(sold separately)

(Only required to extend

duct along back of cabinet)

(Standard 120 VAC

wiring rated for 6A

minimum - sold separately)

MODEL AEDD2 *

1-7/8-inch x 19-inch

Rectangular Duct

(sold separately)

(Only required to

extend duct along

back of cabinet.)

Appendix F

MODEL AVDKD10

1-7/8-inch to 10-inch

Round Transition

(sold separately)

MODEL 418 *

10-inch Round Elbow

MODEL 410 *

10-inch Round Straight Duct

MODEL EB9 **

900 cfm

10-inch Round

Exterior Blower

MODEL 441 *

10-inch Round

Wall Cap

MODEL 410 *

10-inch Round

Straight Duct

MODEL ILB11 **

1100 cfm

10-inch Round

In-Line Blower

MODEL EB12 **

1200 cfm

10-inch Round

Exterior Blower

-- OR --

MODEL 418 *

10-inch Round Elbow

* As required - sold separately

** Choose 1 exterior or in-line

blower - sold separately.

MODEL EB15 **

1500 cfm

10-inch Round

Exterior Blower

28

Page 29

Exterior or In-Line Blower – Dual Duct – Side Outlets

Appendix G

MODEL AEWD5

5-foot Extension Cable

(sold separately)

(Only required if electrical

panel is mounted in a remote

location - more than 2-feet

away from downdraft. Use

up to 2 extension cables

connected together.)

(Standard 120 VAC wiring rated

for 6A minimum - sold separately)

MODEL AVDKD219 *

1-7/8-inch x 19-inch

Rectangular Transition

(sold separately)

(Only required to extend

duct along back of cabinet)

Electrical Panel

(Can be mounted in

remote location)

MODEL AEDD2 *

1-7/8-inch x 19-inch

Rectangular Duct

(sold separately)

(Only required to

extend duct along

back of cabinet)

MODEL AVDKD8

1-7/8-inch to 8-inch

Round Transition

(sold separately)

MODEL 423 *

8-inch Round Elbow

MODEL 408 *

8-inch Round Straight Duct

MODEL EB9 **

900 cfm

10-inch Round

Exterior Blower

MODEL 441 *

10-inch Round

Wall Cap

MODEL 410 *

10-inch Round

Straight Duct

MODEL ILB11 **

1100 cfm

10-inch Round

In-Line Blower

MODEL EB12 **

1200 cfm

10-inch Round

Exterior Blower

-- OR --

MODEL ATKD8810

Dual 8-inch Round to 10-inch

Round Transition (sold separately)

MODEL 408 *

10-inch Round Elbow

* As required - sold separately.

** Choose 1 exterior or in-line

blower - sold separately

MODEL EB15 **

1500 cfm

10-inch Round

Exterior Blower

29

Page 30

ONE YEAR LIMITED WARRANTY FOR BEST® PRODUCTS

Warranty

Warranty Period and Exclusions: Broan-NuTone LLC (the “Company”)

warrants to the original consumer purchaser of its BEST® product (“you”)

that the BEST® product (the “Product”) will be free from material defects

in the Product or its workmanship for a period of one (1) year from the date

of original purchase.

The limited warranty period for any replacement parts provided by the

Company and for any Products repaired or replaced under this limited

warranty shall be the remainder of the original warranty period.

This warranty does not cover fluorescent lamp starters, tubes, halogen and

incandescent bulbs, fuses, filters, ducts, roof caps, wall caps and other

accessories for ducting that may be purchased separately and installed

with the Product. This warranty also does not cover (a)normal maintenance

and service, (b)normal wear and tear, (c)any Products or parts which have

been subject to misuse, abuse, abnormal usage, negligence, accident,

improper or insufficient maintenance, storage or repair (other than repair

by the Company), (d)damage caused by faulty installation, or installation

or use contrary to recommendations or instructions, (e)any Product that

has been moved from its original point of installation, (f)damage caused by

environmental or natural elements, (g)damage in transit, (h)natural wear of

finish, (i)Products in commercial or nonresidential use, or (j)damage caused

by fire, flood or other act of God. This warranty covers only Products sold

to original consumers in the United States and Canada by the Company or

U.S. and Canadian distributors authorized by the Company.

This warranty supersedes all prior warranties and is not transferable from

the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s

sole obligation and your sole remedy for defective products. The

foregoing warranties are exclusive and in lieu of any other warranties,

express or implied. THE COMPANY DISCLAIMS AND EXCLUDES ALL

OTHER EXPRESS WARRANTIES, AND DISCLAIMS AND EXCLUDES ALL

WARRANTIES IMPLIED BY LAW, INCLUDING WITHOUT LIMITATION

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. To the extent that applicable law prohibits the exclusion of

implied warranties, the duration of any applicable implied warranty is

limited to the period specified for the express warranty above. Some states

do not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to you. Any oral or written description of the

Product is for the sole purpose of identifying it and shall not be construed

as an express warranty. Whenever possible, each provision of this Limited

Warranty shall be interpreted in such manner as to be effective and valid

under applicable law, but if any provision is held to be prohibited or invalid,

such provision shall be ineffective only to the extent of such prohibition or

invalidity, without invalidating the remainder of such provision or the other

remaining provisions of the Limited Warranty.

replacement parts to you at no charge. You are responsible for all costs

for removal, reinstallation and shipping, insurance or other freight charges

incurred in the shipment of the Product or part to the Company. If you must

send the Product or part to the Company, as instructed by the Company,

you must properly pack the Product or part—the Company is not

responsible for damage in transit. The Company reserves the right to utilize

reconditioned, refurbished, repaired or remanufactured Products or parts in

the warranty repair or replacement process. Such Products and parts will

be comparable in function and performance to an original Product or part

and warranted for the remainder of the original warranty period.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE

REPLACEMENT PARTS, OR REPAIR OR REPLACE, AT THE COMPANY’S

OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY AND THE COMPANY’S SOLE AND EXCLUSIVE

OBLIGATION. THE COMPANY SHALL NOT BE LIABLE FOR INCIDENTAL,

INDIRECT, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR

IN CONNECTION WITH THE PRODUCT, ITS USE OR PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not

apply to you. This warranty gives you specific legal rights, and you may

also have other rights, which vary from state to state. This warranty covers

only replacement or repair of defective Products or parts thereof at the

Company’s main facility and does not include the cost of field service

travel and living expenses.

Any assistance the Company provides to or procures for you outside the

terms, limitations or exclusions of this limited warranty will not constitute

a waiver of such terms, limitations or exclusions, nor will such assistance

extend or revive the warranty. The Company will not reimburse you for any

expenses incurred by you in repairing or replacing any defective Product,

except for those incurred with the Company’s prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you

must (a) notify the Company within seven (7) days of discovering the

covered defect, (b) give the model number and part identification and

(c) describe the nature of any defect in the Product or part. At the time of

requesting warranty service, you must present evidence of the original

purchase date. If you cannot provide a copy of the original written limited

warranty, then the terms of the Company’s most current written limited

warranty for your particular product will control. The most current limited

written warranties for the Company’s products can be found at

www.BestRangeHoods.com.

Remedy: During the applicable limited warranty period, the Company will,

at its option, provide replacement parts for, or repair or replace, without

charge, any Product or part thereof, to the extent the Company finds it to

be covered by and in breach of this limited warranty under normal use

and service. The Company will ship the repaired or replaced Product or

30

Page 31

Parts

Service Parts

6

4

5

15

1

9

2

11

17

10

14

3

7

16

15

20

21

10

7

3

21

8

13

18

8

23

22

Key 30" 36" 48"

No. Width Width Width Description

1 S97019624 S97019625 S97019626 Top Cap

2 S99271515 S99271516 S99271517 Led Light Bar

3 S97020361 S97020361 S97020361 Angle Brackets

(Right & Left)

4 S97019636 S97019637 S97019638 Door Assembly

(Includes Door Assembly

Hardware Kit)

* S97020366 S97020366 S97020366 Door Assembly

Hardware Kit

5 S97020982 S97020982 S97020982 Door Assembly Cover

(Right) With Up Button

6 S97019640 S97019640 S97019640 Door Assembly Cover

(Left)

7 S99111677 S99111677 S99111677 Chimney Plastic Slides

(Set Of 2)

8 S97019910 S97019910 S97019910 Airbox Wedge Assembly

(Set Of 2)

9 S99010438 S99010439 S99010440 Filters (Set Of 2)

10 S97020380 S97020380 S97020380 Spacers (Set Of 2)

11 S99271514 S99271514 S99271514 User Interface

12 S99271616 S99271616 S99271616 Actuator

13 S97020225 S97020226 S97020227 Airbox Front

12

18

19

24

Key 30" 36" 48"

No. Width Width Width Description

14 S98011888 S98011889 S98011890 Chimney Grille

15 S97020367 S97020367 S97020367 Felt

16 S98011892 S98011892 S98011892 Lift Guide Cover

17 S97019874 S97019875 S97019877 Chimney Seal

18 S97020362 S97020362 S97020362 Airbox Adjustment Legs

(4 Pcs. Right - Long

& Short, Left - Long &

19 S98011668 S98011668 S98011668 Airbox Hole Cover

20 S97019676 S97019676 S97019676 Lift Guide Pucks

(Set Of 4 - Includes Tool)

21 S98011659 S98011659 S98011659 Vent Covers (Set Of 3)

22 S99271573 S99271573 S99271573 Main Pcb

* S97020368 S97020368 S97020368 Fuse (From Key No. 22)

23 S99271512 S99271512 S99271512 Power Supply

24 S97019584 S97019584 S97019584 Electrical Box Assembly

(Includes Key Nos.

* S99271644 S99271644 S99271644 Wire Harness

* S97019665 S97019665 S97019665 Heat Sentry

* S99111728 S99111729 S99111730 Install Template

* S97019570 S97019570 S97019570 Hardware/Parts Bag

Short)

22 & 23)

31

Page 32

99045242N

In USA: BEST

®

926 West State Street, Hartford, Wisconsin 53027 800-558-1711

www.BestRangeHoods.com

®

In Canada: BEST

550 Bd Lemire, Drummondville, QC J2C 7W9 866-737-7770

www.BestRangeHoods.com

32

Page 33

Modelos: D49M30SB, D49M36SB, D49M48SB

Ventilador de tiro descendente

Para uso con estos ventiladores

(los ventiladores se compran por separado):

Modelo PF6* – Ventilador flexible – Interior

Modelos EB6, EB9*, EB12* o EB15* – Exterior

Modelos ILB6, ILB9 o ILB11* – En línea

* Modelos recomendados

LEA Y GUARDE ESTAS INSTRUCCIONES

Registre el producto en línea en: www.BestRangeHoods.com

65

65

Page 34

Índice

Información de seguridad ...................................................................................................................................................................... 67

Contenido ................................................................................................................................................................................................ 68

Especificaciones ..................................................................................................................................................................................... 68

Herramientas necesarias ....................................................................................................................................................................... 68

Planificación

Antes de comenzar ............................................................................................................................................................................ 69

Medidas que debe tomar ................................................................................................................................................................... 69

Configuraciones de los conductos ...................................................................................................................................................... 69

Recortes del gabinete ........................................................................................................................................................................ 74

Preparación de los conductos

laterales o traseros del tiro descendente ............................................................................................................................................ 76

Conducto delantero............................................................................................................................................................................76

Panel eléctrico en ubicación remota .................................................................................................................................................. 77

Montaje final ...................................................................................................................................................................................... 77

Instalación

Recorte de abertura del tope .............................................................................................................................................................. 78

Instale la carcasa en el gabinete ........................................................................................................................................................ 79

Instale la moldura de acabado ........................................................................................................................................................... 80

Instalación de los conductos .............................................................................................................................................................. 80

Instalación del cableado eléctrico

Solo para el ventilador flexible ........................................................................................................................................................... 81

Solo para el ventilador exterior o en línea ........................................................................................................................................... 82

Instalación/funcionamiento del aparato ............................................................................................................................................... 83

Uso y cuidado ......................................................................................................................................................................................... 84

Accesorios opcionales ........................................................................................................................................................................... 85

Apéndices A-G ........................................................................................................................................................................................ 87

Garantía...................................................................................................................................................................................................94

Piezas de servicio ................................................................................................................................................................................... 95

66

Page 35

Información de seguridad

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA

ELECTRICA O LESIONES, CUMPLA CON LOS

SIGUIENTES PUNTOS:

1. Use esta unidad únicamente de la manera indicada por el fabricante.

Sitiene preguntas, comuníquese con el fabricante mediante

ladirección o número telefónico incluidos en la página final.

2. Antes de dar mantenimiento a la unidad o limpiarla, corte laalimentación

al panel de servicio y bloquee los medios dedesconexión del servicio

para evitar que la alimentación seencienda accidentalmente. Cuando

los medios de desconexión del servicio nopuedan bloquearse, fije

firmemente un dispositivo de advertencia enun lugar visible, como

unaetiqueta, al panel de servicio.

3. Personal calificado debe hacer el trabajo de instalación ycableado

eléctrico de acuerdo con todos los códigos y normas correspondientes,

incluidos los códigos y normas de construcción específicos para incendios.

4. Se necesita suficiente aire para la combustión y extracción de gases

adecuadas a través de la chimenea del quemador de combustible

para evitar el contratiro. Siga la guía del fabricante del equipo

decalentamiento y las normas de seguridad, como las publicadas

por la Asociación nacional de protección contra incendios (National

Fire Protection Association , NFPA), y la Sociedad estadounidense

deingenieros de calentamiento, refrigeración y aire acondicionado

(American Society for Heating, Refrigeration y AirConditioning

Engineers, ASHRAE), y las autoridades de códigos locales.

5. Cuando corte o perfore la pared o el cielorraso, evite dañar

elcableado eléctrico y otros servicios ocultos.

6. Los ventiladores de conductos siempre deben expulsar hacia el exterior.

7. Para reducir el riesgo de incendios, use únicamente conductosmetálicos.

8. No instale este producto con el interruptor de activación directamente

detrás de un quemador o elemento calentador. La distancia mínima entre

el interruptor y el borde del quemador debe ser de 4 pulgadas (10,2cm).

9. Nunca debe usarse ropa holgada o suelta al operar este aparato.

Pueden encenderse con los quemadores o elementos calentadores

enla placa de cocción.

10. Los niños no deben dejarse solos ni sin atención en el área en laque

se use este aparato.

11. Esta unidad debe conectarse a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO POR PRESENCIA

DE GRASA EN LA ESTUFA:

a) Nunca deje las unidades de la superficie desatendidas en ajustes de

calor alto. Los derrames por ebullición provocan humo y salpicaduras

de grasa que pueden encenderse. Caliente lentamente los aceites

aajustes de calor bajo o medio.

b) Siempre encienda la campana cuando cocine a calor alto ocuando

cocine alimentos inflamables.

c) Limpie con frecuencia los ventiladores. No permita que la grasa

seacumule en el ventilador ni en el filtro.

d) Utilice una sartén de tamaño adecuado. Siempre utilice una olla

adecuada para el tamaño del elemento calentador de la superficie.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES EN CASO

DE INCENDIO POR PRESENCIA DE GRASA EN LA ESTUFA,

CUMPLA CON LO SIGUIENTE:

1. APAGUE LAS LLAMAS con una tapa, una bandeja de horno o una

bandeja de metal que cierre completamente, y después apague el

quemador. TENGA CUIDADO PARA EVITAR QUEMADURAS. Si las

llamas no se apagan inmediatamente, EVACUE EL ÁREA Y LLAME

ALDEPARTAMENTO DE BOMBEROS.

2. NUNCA LEVANTE UNA SARTÉN EN LLAMAS – puede quemarse.

3. NO USE AGUA, incluidos pañitos o toallas húmedos – puede

producirse una explosión violenta de vapor.

4. Utilice un extinguidor SOLO si:

A. Sabe que tiene un extinguidor de clase ABC, y ya sabe cómo

utilizarlo.

B. El incendio es pequeño y se restringe al área donde se inició.

C. Se llama al Departamento de bomberos.

D. Combate el incendio con la salida a su espalda. Basado en “Kitchen

Firesafety tips” (Consejos de seguridad contra incendios en la cocina)

publicado por la NFPA.

PRECAUCIÓN

1. Solo para uso en interiores.

2. Solo para usarse con fines de ventilación general. No debe utilizarse

para extraer materiales y vapores peligrosos o explosivos.

3. Para evitar daños a los cojinetes del motor o terminar con impulsores

desbalanceados o ruidosos, proteja la unidad de alimentación contra

pulverización de yeso, polvo de construcción, etc.

4. Limpie con frecuencia los filtros y superficies que contengan grasa.

5. No repare ni reemplace ninguna pieza de este aparato a menos que

se recomiende específicamente en este manual. Todas las demás

actividades de mantenimiento debe realizarlas un técnico calificado.

6. Lea la etiqueta de especificaciones del producto para obtener

másdetalles y requisitos.

7. Para reducir el riesgo de incendios y descargas eléctricas, instale

esteventilador de tiro descendente solo con los modelos de ventilador

que se muestran a continuación. No pueden utilizarse otros modelos

deventilador. (Los ventiladores se venden por separado).

Ventilador flexible modelo PF6, Ventilador exterior modelos EB6, EB9,

EB12 o EB15, Ventilador en línea modelos ILB6, ILB9 o ILB11.

INSTALADOR: Guarde este manual para que lo use

el inspector eléctrico y propietario.

67

Page 36

Contenido

C

D

AA

x2

B

A

x8

BB

x3

G

x2

E

CC

F

H

I

J

ESPECIFICACIONES

ELÉCTRICAS

Modelo PF6 - Flexible interno:

120 VCA • 60 Hz • 3,0 A

Modelos EB6, EB9, EB12 o EB15 - Exteriores

Modelos ILB6, ILB9 o ILB11 - En línea

120 VCA • 60 Hz • 6,0 A (máx.)

Soporte de apoyo superior (izquierdo) 1

A

Carcasa del ventilador de tiro descendente 1

B

Moldura final (izquierda) 1

C

Botón de ascenso de moldura final (derecha) 1

D

Pata de apoyo de 4 pulg. (izquierda) 1

E

Pata de apoyo de 2 pulg. (izquierda) 1

F

Cubierta de descarga 3

G

Cubierta de panel delantero 1

H

Panel eléctrico 1

I

Pieza Descripción Cantidad

Soporte de apoyo superior (derecho) 1

J

Pata de apoyo de 4 pulg. (derecha) 1

K

Pata de apoyo de 2 pulg. (derecha) 1

L

Tornillo de cabeza hexagonal 1/4-20 x 0,50 2

AA

Tornillo de cabeza redonda Phillips n.°10 x 0,50 8

BB

Tornillo Phillips n.°8-18 x 0,375 2

CC

K

L

Herramientas necesarias

Cinta métrica, lápiz, destornillador Phillips n.°2, destornillador de tuercas (11/32 pulg., 3/8 pulg., 7/16 pulg.), lave inglesa, sierra, nivel de burbuja, cortadores

dehojalata, guantes, cinta de aluminio, (NO UTILICE cinta aislante)

68

Page 37

Antes de comenzar

Planificación

Debido a su diseño flexible, este sistema de tiro descendente puede

utilizarse para extraer contaminantes contenidos en el aire cuando cocine

con diversos aparatos de cocina a gas o eléctricos– incluidas placas

de cocción, estufas, estufas empotradas e independientes.

Puede montarse en ubicaciones tipo isla, península o pared convencional.

El ventilador (se compra por separado) y panel eléctrico pueden montarse

alaunidad de tiro descendente, dentro del gabinete o en una ubicación

remotaconveniente.

Esta unidad puede instalarse fácilmente siguiendo estos pasos básicos:

• Recorte la apertura del tope.

• Monte la unidad en el gabinete.

• Instale el ventilador y el panel eléctrico.

• Conecte los conductos y el sistema eléctrico.

• Instale la moldura.

• Instale el aparato de cocción.

Nota: el nivel alto de flujo de aire de este aparato puede afectar la llama de

gas en algunos tipos de placas de gas. Esto es NORMAL y no causará daños,

pero puede corregirse reduciendo la velocidad del ventilador.

Se recomienda utilizar el kit de sellos de la placa de cocción de gas con

todas las placas de cocción de gas. El kit crea un sello entre laplaca

decocción y el gabinete inferior. Incluye el soporte y sello delamoldura.

Consulte la sección Accesorios opcionales.

Medidas que debe tomar

• Consulte las instrucciones de instalación de la placa de cocción para

obtener sus dimensiones, el recorte del tope, y los requisitos del gabinete.

Sin embargo, se recomienda utilizar gabinetes de mayor tamaño para

facilitar la instalación. Al utilizar diseños deisla personalizados deben

tomarse en cuenta gabinetes más profundos, en especial cuando

seinstalan con una estufa en frente del tiro descendente o cuando

semonta el ventilador detrás del tiro descendente. También debe

planificar una puerta de acceso.

• La profundidad de las placas de cocción puede variar considerablemente.

Esto puede causar que estos dos aparatos queden muy ajustados.

Preste especial atención a las áreas de posible interferencia resaltadas

anteriormente. Es posible que un tope con (A) un reborde levantado

o(B) un protector contra salpicaduras no permitan suficiente superficie

plana para una instalación adecuada. Tome en cuenta que se necesitan

2-3/4 pulg. (7cm) de tope plano detrás de la placa de cocción y que

se necesitan 2-1/2pulg. (6,4cm) entre el reborde trasero de la placa

decocción y el interior de la parte trasera del gabinete.

A

Placa de cocción

Desde la parte delantera a la trasera

Profundidad dentro del gabinete

2-1/2 pulg.

2-3/4 pulg.

TopeTope

Tiro descendente

B

Configuraciones de los conductos

• El sistema de ventiladores de tiro descendente se diseña para

conductos de sección circular de 8 pulg. con un ventilador flexible

o para conductos de sección circular de 10 pulg. con un ventilador

remoto. (Los ventiladores se compran por separado).

• Para obtener el mejor funcionamiento: Elija la opción de conductos

de longitud más corta con el menor número de codos y transiciones.

Revise que no haya posibles interferencias con las vigas del piso,

vigas de pared, cableado eléctrico o tuberías.

Para obtener más detalles sobre los conductos consulte los apéndices

A-G al final del documento.

Extracción delantera con ventilador flexible

Tiro descendente

PF6 (Ventilador flexible)

Caja de cableado

*

Codo de secc. circular de 8 pulg.

* Para el modelo 643 (Tapa de pared de secc. circ. de 8 pulg.)

Conducto recto de 8 pulg.

69

Page 38

Configuraciones de los conductos (continuación)

Extracción delantera con ventilador flexible (a través del gabinete)

Planificación

PF6 (Ventilador flexible)

Caja de cableado

Codo de secc. circular de 8 pulg.

Extracción delantera con ventilador flexible

y kit de recirculación

Tiro descendente

Conducto recto de 8 pulg.

*

* Para el modelo 643 (Tapa de pared

de secc. circ. de 8 pulg.)

Extracción delantera con ventilador flexible

(a través del gabinete) y kit de recirculación

PF6 (Ventilador flexible)

Caja de cableado

ANKD (Kit de recirculación)

Tiro descendente

Conducto recto

de 8 pulg.

Tiro descendente

PF6 (Ventilador flexible)

Conducto

recto

de 8 pulg.

Caja de cableado

Codo de secc.

circular de 8 pulg.

ANKD (Kit de recirculación)

70

Page 39

Configuraciones de los conductos (continuación)

Extracción lateral con ventilador flexible

Tiro descendente

Planificación

Transición de sección circular

1-7/8 pulg. a 8 pulg.

Conducto recto de 8 pulg.

PF6 (Ventilador flexible)

Conducto recto de 8 pulg.

Codo de secc. circular de 8 pulg.

*

* Para el modelo 643 (Tapa de pared

de secc. circ. de 8 pulg.)

Extracción lateral con ventilador flexible

y kit de recirculación Extracción trasera con ventilador flexible

Tiro descendente

Transición

de sección circular

Tiro descendente

1-7/8 pulg. a 8 pulg.

Ventilador

flexible

PF6 (Ventilador flexible)

Transición

de sección circular

1-7/8 pulg. a 8 pulg.

Conducto recto de 8 pulg.

Kit de recirculación

8" Round Elbow

Conducto recto de 8 pulg.

*

* Para el modelo 643 (Separación de secc. circ. de 8 pulg.)

71

Page 40

Configuraciones de los conductos (continuación)

Extracción delantera con ventilador remoto

Tiro descendente

Conducto recto

de 8 pulg. o 10 pulg.

Codo de secc. circ. de 8 pulg. o 10 pulg.

Nota: Los ventiladores flexibles requieren conductos de 8 pulg. Los ventiladores externos

o en línea requieren conductos de 10 pulg.

Planificación

* Para uno de los siguientes:

• Modelo PF6 (Ventilador flexible)

Modelo 643 (Tapa de pared de secc. circ. de 8 pulg.)

• Modelo EB9 (Ventilador exterior de secc. circ.

de 10 pulg., 900 piecúb./min.)

*

• Modelo ILB11 (Ventilador en línea de secc. circ.

de 10 pulg.)

Modelo 441 (Tapa de pared de secc. circ. de 10 pulg.)

• Modelo EB12 (Ventilador exterior de secc. circ.

de 10 pulg., 1200 piecúb./min.)

• Modelo EB15 (Ventilador exterior de secc. circ.

de 10 pulg., 1500 piecúb./min.)

Extracción lateral con ventilador remoto

Tiro descendente

Transición de sección

circular 1-7/8 pulg.

a 8 pulg. o 10 pulg.

Nota: Los ventiladores flexibles requieren conductos de 8 pulg.

Los ventiladores externos o en línea requieren conductos de 10 pulg.

8" or 10"

Straight Duct

8" or 10"

Round Elbow

* Para uno de los siguientes:

• Modelo PF6 (Ventilador flexible)

Modelo 643 (Tapa de pared de secc. circ. de 8 pulg.)

• Modelo EB9 (Ventilador exterior de secc. circ.

de 10 pulg., 900 piecúb./min.)

• Modelo ILB11 (Ventilador en línea de secc. circ.

*

de 10 pulg.)

Modelo 441 (Tapa de pared de secc. circ. de 10 pulg.)

• Modelo EB12 (Ventilador exterior de secc. circ.

de 10 pulg., 1200 piecúb./min.)

• Modelo EB15 (Ventilador exterior de secc. circ.

de 10 pulg., 1500 piecúb./min.)

72

Page 41

Configuraciones de los conductos (continuación)

Extracción trasera con ventilador remoto

Tiro descendente

Codo de secc. circ.

de 8 pulg. o 10 pulg.

Planificación

Transición de sección circular

1-7/8 pulg. a 8 pulg. o 10 pulg.

Conducto recto de 8 pulg. o 10 pulg.

*

Nota: Los ventiladores flexibles requieren conductos de 8 pulg.

Los ventiladores externos o en línea requieren conductos de 10 pulg.

Extracción lateral de doble conducto con ventilador remoto

* Para uno de los siguientes:

• Modelo PF6 (Ventilador flexible)

Modelo 643 (Tapa de pared de secc. circ. de 8 pulg.)

• Modelo EB9 (Ventilador exterior de secc. circ.

de 10 pulg., 900 piecúb./min.)

• Modelo ILB11 (Ventilador en línea de secc. circ.

de 10 pulg.)

Modelo 441 (Tapa de pared de secc. circ. de 10 pulg.)

• Modelo EB12 (Ventilador exterior de secc. circ.

de 10 pulg., 1200 piecúb./min.)

• Modelo EB15 (Ventilador exterior de secc. circ.

de 10 pulg., 1500 piecúb./min.)

Tiro descendente

Transición de sección

circular 1-7/8 pulg.

a 8 pulg. o 10 pulg.

* Para uno de los siguientes:

• Modelo EB9 (Ventilador exterior de secc. circ. de 10 pulg.,

900 piecúb./min.)

• Modelo ILB11 (Ventilador en línea de secc. circ. de 10 pulg.)

Modelo 441 (Tapa de pared de secc. circ. de 10 pulg.)

• Modelo EB12 (Ventilador exterior de secc. circ. de 10 pulg.,

1200 piecúb./min.)

• Modelo EB15 (Ventilador exterior de secc. circ. de 10 pulg.,

1500 piecúb./min.)

Codo de secc. circular

de 8 pulg.

Conducto recto de 8 pulg.

Transición doble de secc. circ. de 8 pulg.

*

73

a secc. circ. de 10 pulg.

Page 42

Recortes del gabinete

PRECAUCIÓN

ANTES DE CORTAR EL AGUJERO EN EL GABINETE PARA

LOS CONDUCTOS, compruebe si hay interferencias con

viguetas del piso, vigas de pared, cableado eléctrico

o tuberías.

Utilice las dimensiones de las ilustraciones para ayudar a planificar cómo

y dónde proporcionar acceso a los conductos a través del gabinete.

Generalmente, el conducto de sección rectangular de 1-7/8pulg.x19pulg.