Page 1

DOWNDRAFT

!

VENTILATOR

Models D49M30SB • D49M36SB • D49M48SB

Page 1

For use with these blowers

(purchase blowers separately):

Model PF6 - Flex Blower - Interior

Models EB6, EB9, EB12, or EB15 - Exterior

Register your product online at: www.BestRangeHoods.com

Models ILB3, ILB6, ILB9 or ILB11 - In-Line

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. To reduce the risk of fire, use only metal ductwork.

8. Do not install this product with the activating switch directly

behind a burner or element. Minimum distance between the

switch and the edge of the burner should be 4 inches.

9. Loose-fitting or hanging clothing should never be worn when

operating this appliance. They may be ignited by burners/

elements on cooktop.

10. Children should not be left alone or unattended in the area

where this appliance is in use.

11. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

cooking flaming foods.

c) Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate

for the size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immedi-

ately, EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - a

violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher, and you

B. The fire is small and contained in the area where it

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

a

Based on “Kitchen Firesafety Tips” published by NFPA.

a

:

already know how to operate it.

started.

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

4. Clean filters and grease-laden surfaces frequently.

5. Do not repair or replace any part of this appliance unless

specifically recommended in this manual. All other servicing

should be done by a qualified technician.

6. Please read specification label on product for further information and requirements.

7. To reduce the risk of fire and electric shock, install this downdraft

only with blower models shown below. Other blower models

cannot be substituted. (Blowers sold separately).

Flex Blower Model PF6

Exterior Blower Models EB6, EB9, EB12, or EB15

In-Line Blower Models ILB3, ILB6, ILB9 or ILB11

INSTALLER:

Save this manual for Electrical

Inspector and Homeowner to use.

Page 2

Models D49M30SB • D49M36SB • D49M48SB

Page 2

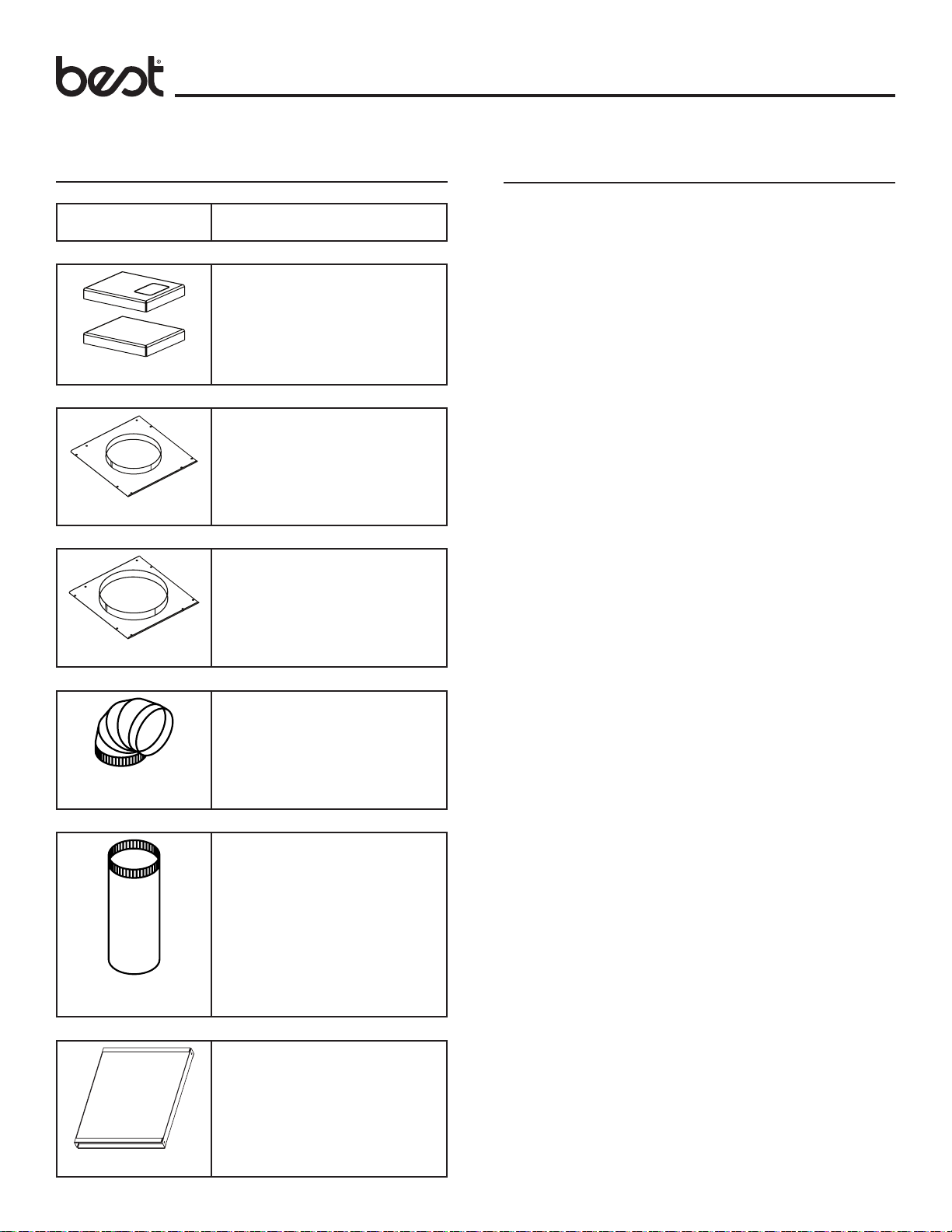

CONTENTS

These parts are included with your downdraft housing:

1 - Parts Bag containing:

2 - 2-in. Support Legs

2 - 4-in. Support Legs

2 - Screws, 1/4-20 x .50 Hex Head

2 - Screws, #8-18 x .375 Phillips

8 - Wood Screws, #10 x .50 Phillips Round Head

1 - Trim Door Kit

1 - Electrical Panel

2 - Support Brackets

1 - Countertop Cut-out Template

PLANNING

Due to its flexible design, this downdraft system can be used to

exhaust airborne contaminants when cooking with a variety of gas

or electric cooking appliances - including cooktops, rangetops,

slide-in ranges and free-standing ranges.

It can be mounted in island, peninsula, or conventional wall

locations. The blower (purchase separately) and electrical panel

can be mounted to the downdraft unit, inside the cabinet, or in a

convenient remote location.

This unit can be easily installed following these basic steps:

• Cut out the countertop opening.

• Mount the unit in the cabinet.

• Install the blower and electrical panel.

• Connect the ductwork and electrical.

• Install the trim.

• Install the cooking appliance.

Note: the high level of air flow of this appliance may effect the

gas flame on some types of gas cooktops. This is NORMAL and

will cause no harm, but can be corrected by lowering the speed

of the blower.

A cooktop sealing kit is recommended for use with all gas

cooktops. The kit creates a seal between the cooktop and

the lower cabinet. Includes trim bracket and trim seal. See

"OPTIONAL ACCESSORIES".

ELECTRICAL SPECIFICATIONS

Model PF6 - Internal Flex:

120 VAC • 60 Hz • 3.0 A

Models EB6, EB9, EB12, or EB15 - Exterior

Models ILB3, ILB6, ILB9 or ILB11 - In-Line

120 VAC • 60 Hz • 6.0 A (max.)

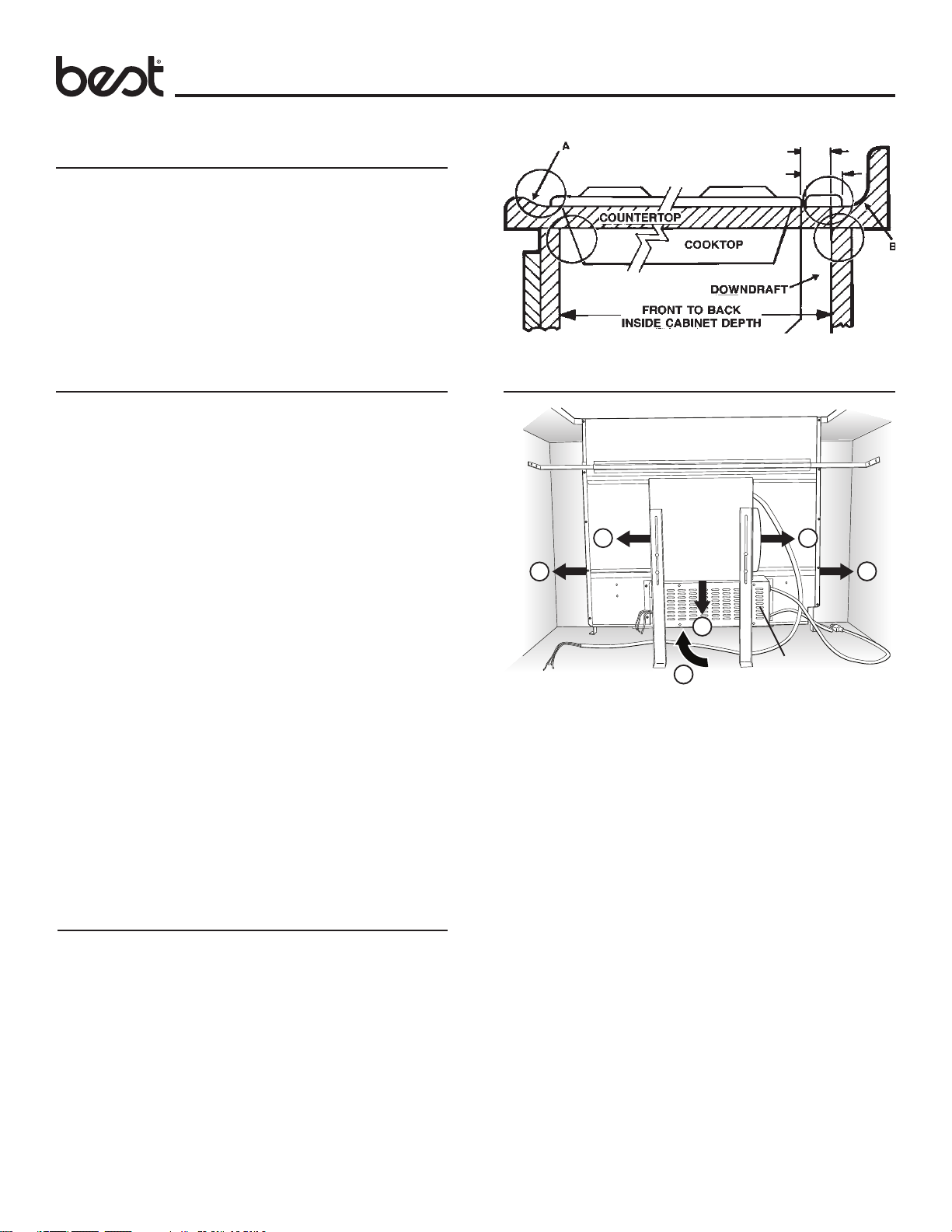

TAKE MEASUREMENTS

1. Refer to the cooktop installation instructions for dimensions

of cooktop, countertop cut-out, and cabinet requirements.

However, it is recommended that oversized cabinets be used

for easier installation. Custom island designs need to account

for deeper cabinets - especially when installed with a range

in front of the downdraft or when mounting the blower behind

the downdraft. You must also plan for an access door.

2. Cooktop depth can vary greatly from one to another. This may

cause the fit of these two appliances to be rather tight.

Pay special attention to the areas of potential interference high-

lighted above. A countertop with (A) a raised lip and/or (B) a

backsplash may not allow enough flat countertop for a proper

installation. Note that 2-3/4" of flat countertop is required behind

cooktop and that 2-1/2" is necessary between the back edge of

the cooktop and the inside of cabinet back.

2-1/2"

2-3/4"

PLAN THE DUCTWORK

HOUSING

FLEX

A

D

Remote blowers use 8" or 10" round remote discharge plate

*

instead of flex blower.

1. The downdraft blower system is designed for use with 8"

round ductwork using a flex blower or 10" Round ductwork

using a remote blower. (Purchase blowers separately.) Six

(6) different discharge connections are available:

A = 8" Round, Left Discharge out of Flex Blower

B = 8" Round, Right Discharge out of Flex Blower

C = 8" Round, Down Discharge out of Flex Blower

(Electrical Panel to be mounted remotely)

D = 1-7/8" x 19", Left Discharge out of Housing to

Remote Blower or Flex Blower in remote location.

Use 1-7/8" x 19" to 8" round transition, 1-7/8" x 19" to

10" round transition, or 1-7/8" x 19" ductwork

as appropriate.

E = 1-7/8" x 19", Right Discharge out of Housing to

Remote Blower or Flex Blower in remote location.

Use 1-7/8" x 19" to 8" round transition, 1-7/8" x 19" to

10" round transition, or 1-7/8" x 19" ductwork

as appropriate.

F = 1-7/8" x 19", Rear Discharge out of Housing to

Remote Blower or Flex Blower in remote location.

Use 1-7/8" x 19" to 8" round transition, 1-7/8" x 19" to

10" round transition, or 1-7/8" x 19" ductwork

as appropriate.

2. For best performance: Choose the ducting option which allows

the shortest length of ductwork and a minimum number of

elbows and transitions. Check location of floor joists, wall

studs, electrical wiring or plumbing for possible interference.

BLOWER

F

*

B

E

C

ELECTRICAL

PANEL

Page 3

Models D49M30SB • D49M36SB • D49M48SB

!

Page 3

PLAN CABINET CUTOUTS

CAUTION: BEFORE CUTTING HOLE IN CABINET

FOR DUCTWORK, check for interference with floor

joists, wall studs, electrical wiring, or plumbing.

REAR CORNER OF

COOKTOP CUT-OUT

7

/

5 ”

8

2”

21”

centered

4”

INSIDE

CABINET FLOOR

Dimension A Dimension B

Using Flex Blower (Model

PF6 & 8" round duct straight

down through cabinet floor.)

(1½" left of installation center line)

5-5/8 inches

INSTALLATION

CENTER LINE

HOLE

FOR

7

1 ” X 19”

/

8

DUCT &

TRANSITIONS

21”

1½”

Hole in Cabinet Floor

24¾”

7-5/8 inches

(Model 432

INSIDE

CABINET BACK

4”

B

A

Using Exterior or In-Line

Blower & 90

(on installation center line)

- 8" round

elbow)

0

Duct Elbow

8-5/8 inches

(Model 418

- 10" round

elbow)

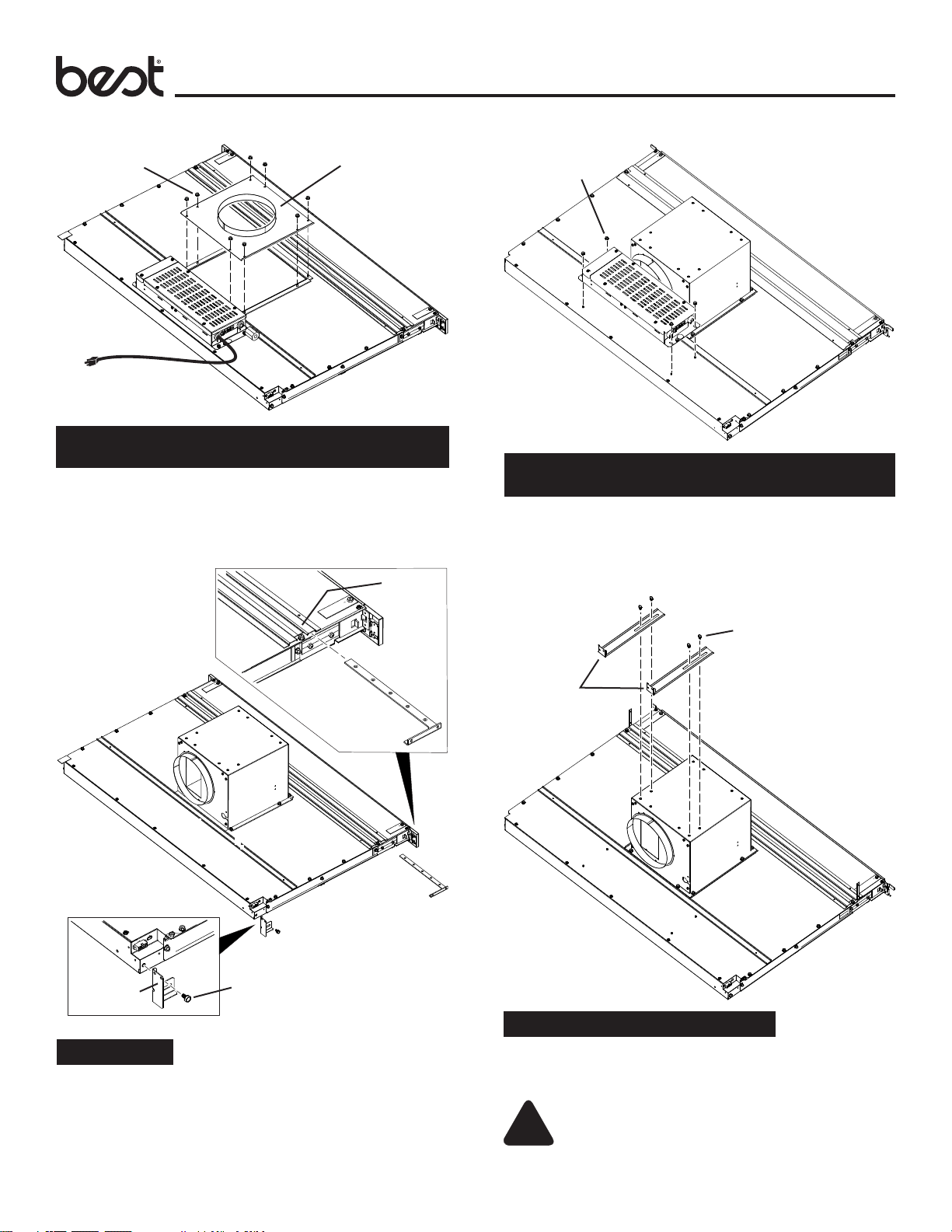

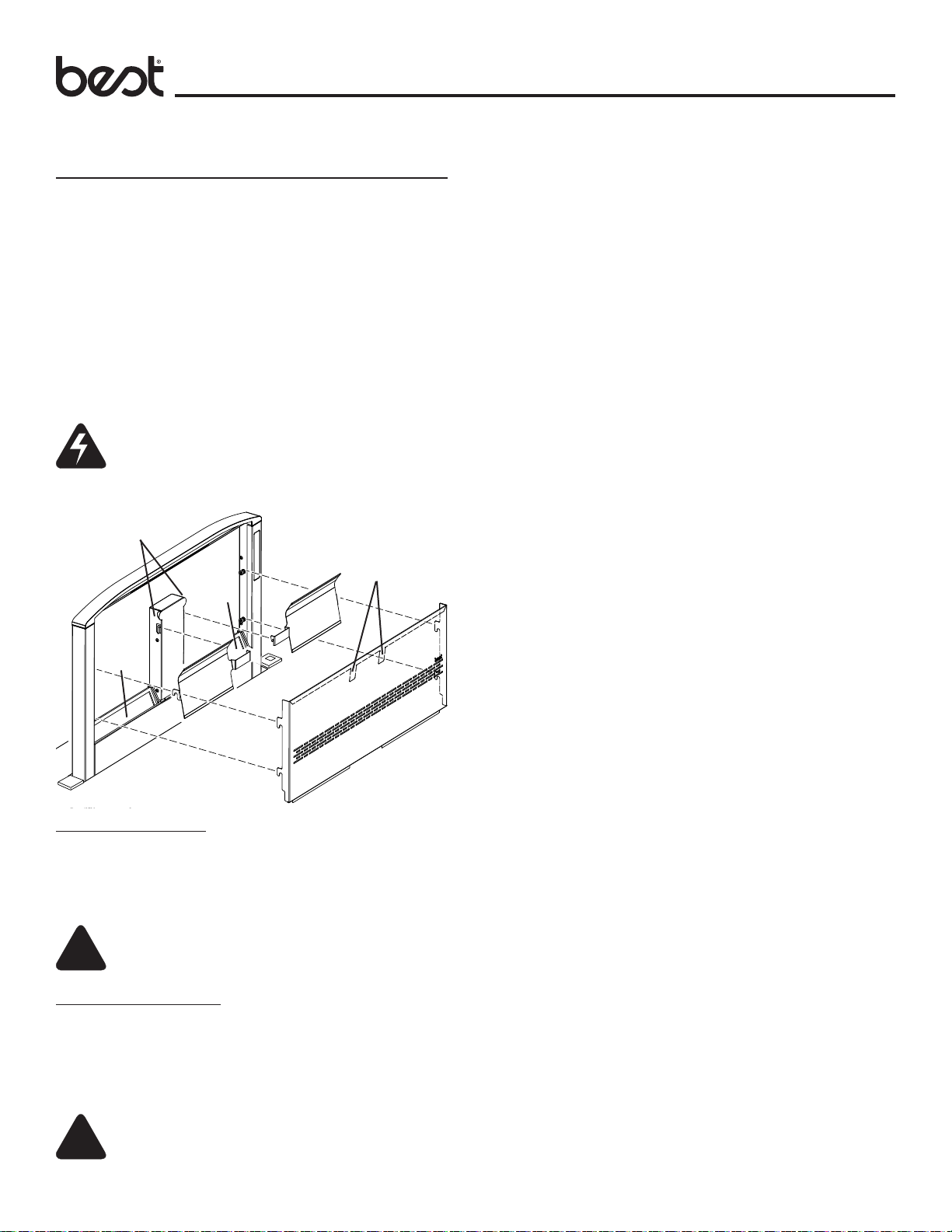

PREPARE THE DOWNDRAFT

FRONT PANEL COVER

(8)

#10-24 HEX

NUTS

Electrical panel

can be mounted

remotely.

Installations ducting through front panel opening only:

1. Place the downdraft on its back on a table or flat work surface.

2. Remove the HEX NUTS to remove the FRONT PANEL COVER.

FLEX

BLOWER

(8)

#10-24 HEX

NUTS

Use the dimensions in the above illustration to help plan how and

where to provide duct access through your cabinet. Generally, 1-7/8"

x 19" rectangular duct will be used through left, right, and back of

cabinet - while 8" round duct will be used through cabinet floor.

For left, right, or rear exhaust:

Allow at least 18" for transition and elbow or blower.

For left / right exhaust:

A 30" deep cabinet is recommended to align properly with flex

blower. Flex blower can be mounted to rear cabinet wall or to a

platform / frame (not provided) on the base of the cabinet floor.

(See flex blower instructions).

Cabinet depths of 24" to 30" are required - depending on the

type of cooking appliance.

PLAN THE WIRING

1. This downdraft blower using the Flex Blower (purchase

separately) draws 3.0 Amps and requires a 120 VAC, 60 Hz

circuit. If using a remote blower (purchase separately), the

system draws 6.0 Amps (max.) and requires a 120 VAC, 60

Hz circuit.

2. The unit has a 30 in. long power cord with a 3-pronged plug.

Plan to provide a grounded outlet in a location which will allow

the unit’s power cord to reach.

3. Install electrical box according to local codes.

FRONT

PANEL

If blower discharge is

down, electrical panel

must be relocated.

See Step 6.

Installations using FLEX BLOWER only:

(Purchase Model PF6 Flex Blower separately.)

3. Determine whether FLEX BLOWER will discharge to the left,

right, or down.

Tighten the hex nuts to secure blower in place.

Page 4

Models D49M30SB • D49M36SB • D49M48SB

!

Page 4

(8) #10-24

HEX NUTS

Installations using FLEX BLOWER (in remote location)

or REMOTE BLOWER only:

4. Use the REMOTE DISCHARGE PLATE.

Tighten the hex nuts to secure the REMOTE DISCHARGE

PLATE in place.

8" OR 10" ROUND

REMOTE

DISCHARGE

PLATE

(Purchase

separatly)

FRONT

PANEL

SLIDE

CHANNEL

#8-32 HEX

NUTS

Installations where ELECTRICAL PANEL needs to be

mounted in a remote location only:

6. Remove (4) #8-32 HEX NUTS and ELECTRICAL PANEL. 5-ft.

extension cables (Model AEWD5 - purchase separately) may

be needed to mount electrical panel in a remote location. Do

not use more than 2 extension cables.

UPPER

Flex Blower

shown

installed.

SUPPORT

LEGS

All Installations:

5. Slide UPPER SUPPORT BRACKETS into SLIDE CHANNEL

at top left and right of unit.

Attach LONG OR SHORT SUPPORT LEGS (depending upon

cabinet height) to bottom sides of unit with HEX SCREWS

provided. Do not tighten hex screws completely at this time.

HEX SCREW

1/4-20 X .500

SUPPORT

BRACKET

(4) SCREWS

BLOWER

SUPPORT

LEGS

Installations using FLEX BLOWER only:

7. Attach BLOWER SUPPORT LEGS with (4) SCREWS

provided.

CAUTION: If flex blower will be mounted

remotely: Do not use legs alone for support. It

may be necessary to add extra support for the

flex blower. Use mounting brackets supplied with

the blower.

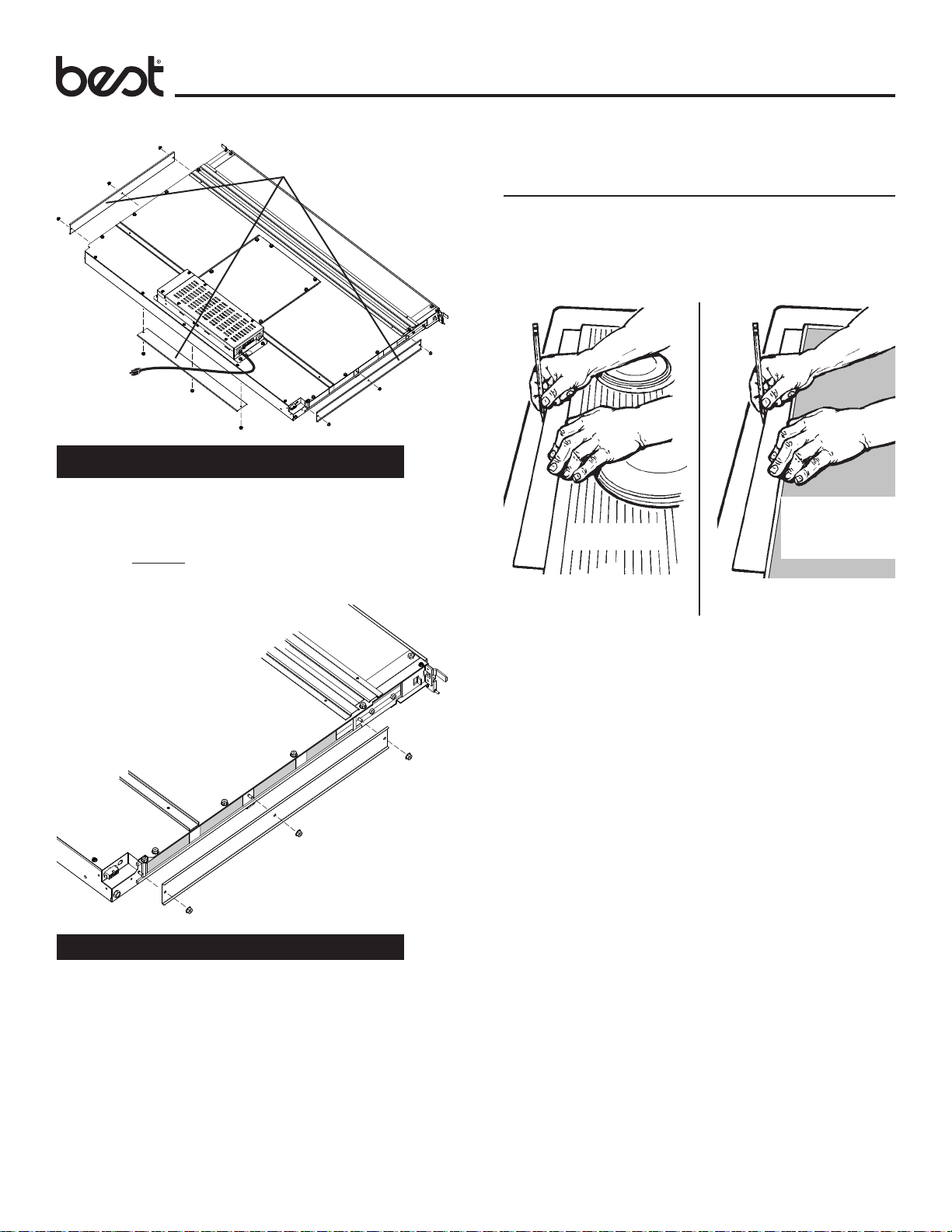

Page 5

RECTANGULAR

DISCHARGE COVERS

This

Front Panel

remains

in place.

Installations ducting through left, right or rear only:

Models D49M30SB • D49M36SB • D49M48SB

Page 5

CUT COUNTERTOP OPENING

1. Lay out and cut the cooktop cut-out far enough FORWARD so

downdraft will fit behind it.

2. Set cooktop in place and slide it as far forward as possible

without exposing any gaps. Center and square it with edges

of countertop.

(Requires purchase of 1-7/8" x 19" to 8" or 10" round transition.

1-7/8" x 19" rectangular duct and connection adapters are

also available.)

8. Remove only one RECTANGULAR DISCHARGE COVER.

Ducting out right side of housing shown.

COUNTERTOP

COOKTOP

Template against back

edge of cooktop.

3. Place the plastic template against the back flange of the cooktop or back edge of slide-in range countertop opening. Center

the template. Trace around template to mark the downdraft

opening.

4. Remove cooktop from countertop.

5. Cut downdraft opening. Be careful not to chip edges of countertop.

Template against back

edge of countertop opening.

OPENING FOR

SLIDE-IN RANGE

Installations ducting through left, right or rear only:

(Requires purchase of 1-7/8" x 19" to 8" or 10" round transition.

1-7/8" x 19" rectangular duct and connection adapters are

also available.)

9. Use nuts to connect 1-7/8" x 19" rectangular ductwork

connection adapter or 1-7/8" x 19" to 8" or 10" round transition

to housing when installing ductwork.

Page 6

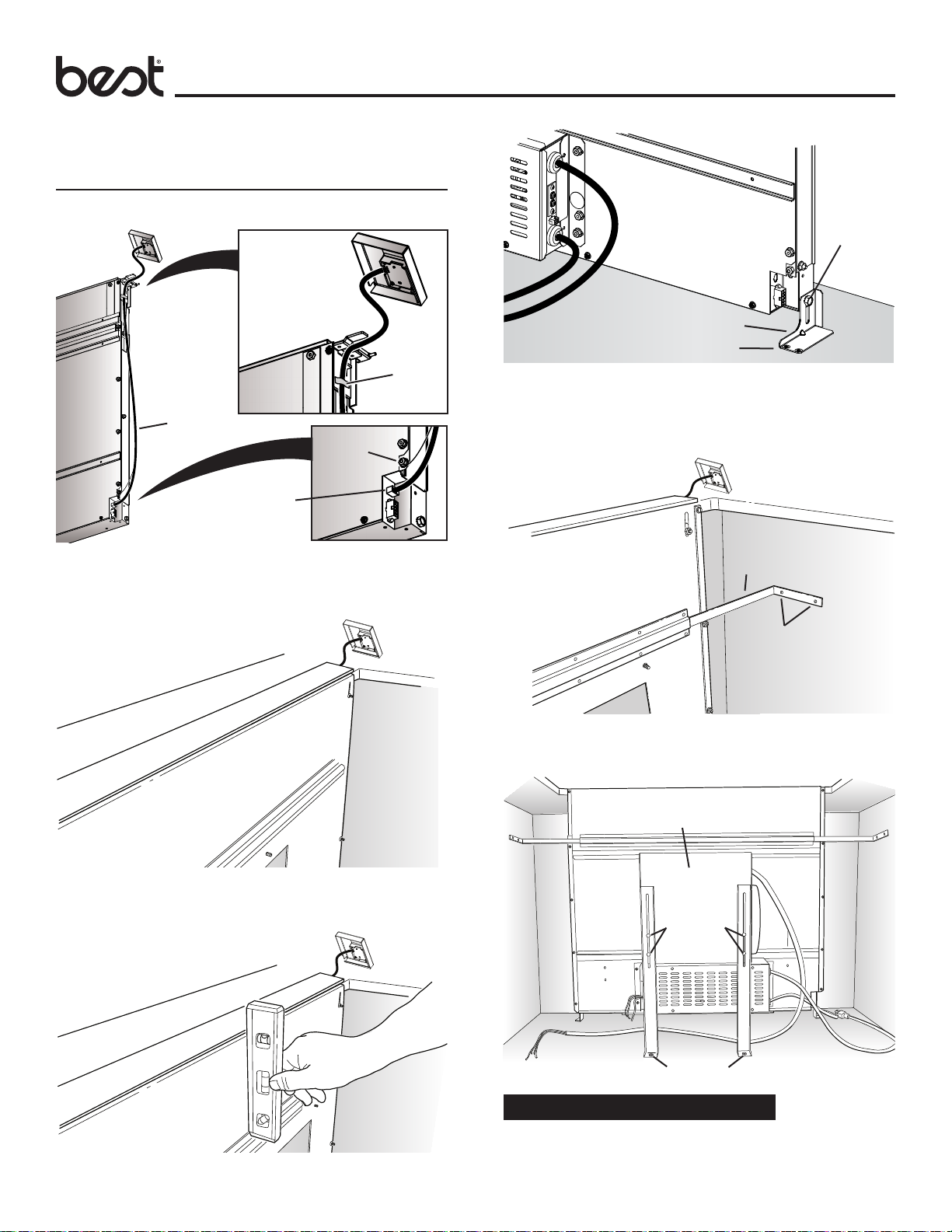

INSTALL HOUSING INTO

CABINET

Models D49M30SB • D49M36SB • D49M48SB

Page 6

1. Remove cooktop.

TAPE

UP

BUTTON

CABLE

UPPER

RECEPTACLE

2. Plug UP BUTTON CABLE from right trim into UPPER

RECEPTACLE at bottom right side of downdraft housing and

connect ground wire to GROUND NUT. Run cable up along side

of housing and TAPE in place near top.

GROUND

NUT

HEX

SCREW

SUPPORT LEG

(2) #10 X .500 WOOD SCREWS

5. Extend SUPPORT LEGS and attach to bottom of cabinet with

(2) SCREWS through each leg. Tighten HEX SCREWS.

If cabinet bottom is removed:

Use blocks as spacers between floor and support legs.

UPPER

SUPPORT

BRACKET

(2)

#10 X .500

WOOD

SCREWS

3. Set housing into cabinet / countertop opening as far back as

possible. Make sure up button cable threads through opening

as shown and is not pinched.

4. Make sure housing is level.

6. Extend UPPER SUPPORT BRACKETS and attached to sides

of cabinet with (2) SCREWS through each bracket.

FLEX

BLOWER

(4) 1/4-20

X .500

SCREWS

SCREWS

Installations using FLEX BLOWER only:

7. Loosen (4) SCREWS attaching BLOWER SUPPORT LEGS

to FLEX BLOWER. Extend legs and secure them to bottom of

cabinet with a SCREW through each bracket.

Page 7

Models D49M30SB • D49M36SB • D49M48SB

!

Page 7

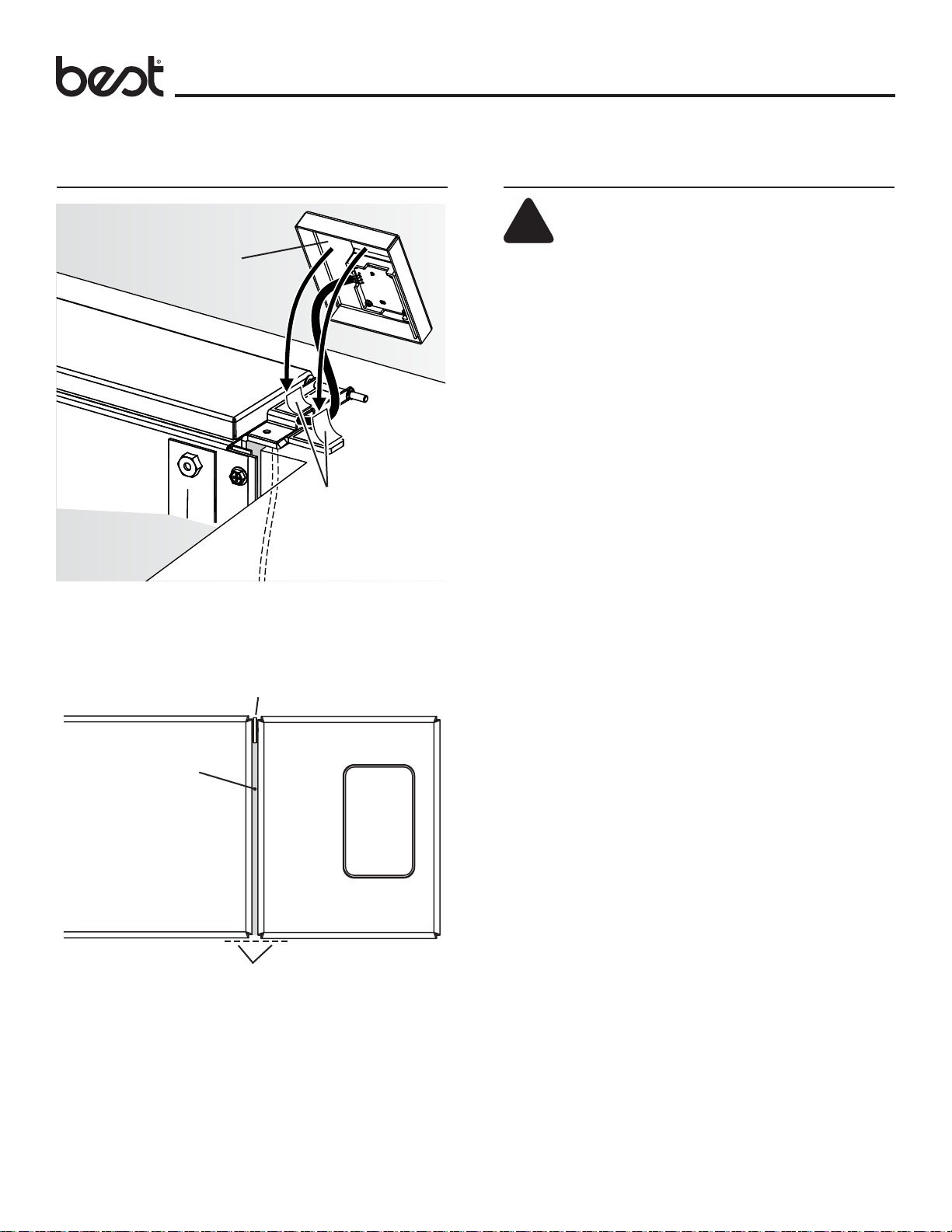

INSTALL FINISH TRIM

WIPE

SURFACES

CLEAN

TOP

DOOR

TAPE

BACKING

1. Remove TAPE BACKING.

2. WIPE SURFACES CLEAN on underside of right trim - so tape

adhesive will stick tightly.

INSTALL DUCTWORK

CAUTION: BEFORE CUTTING HOLE IN CABINET

FOR DUCTWORK, check for interference with floor

joists, wall studs, electrical wiring, or plumbing.

1. Cut hole in cabinet as well as holes in wall or floor as necessary.

2. Mount the roof or wall cap and work back towards the cabinet,

attaching all ductwork, elbows and transitions as previously

planned. Tape all ductwork connections to make them secure

and air tight.

3. Connect ductwork (and transition, if required) to downdraft.

WASHER

1/16" GAP

TOP

DOOR

RIGHT

TRIM

TOP VIEW

FLUSH

3. Press RIGHT TRIM in place.

Make sure trim:

• sits flat on countertop surface.

• is flush with TOP DOOR.

• has 1/16" GAP between trim and top door.

• wiring is not pinched.

4. Repeat Steps 1, 2 & 3 to install left trim.

Page 8

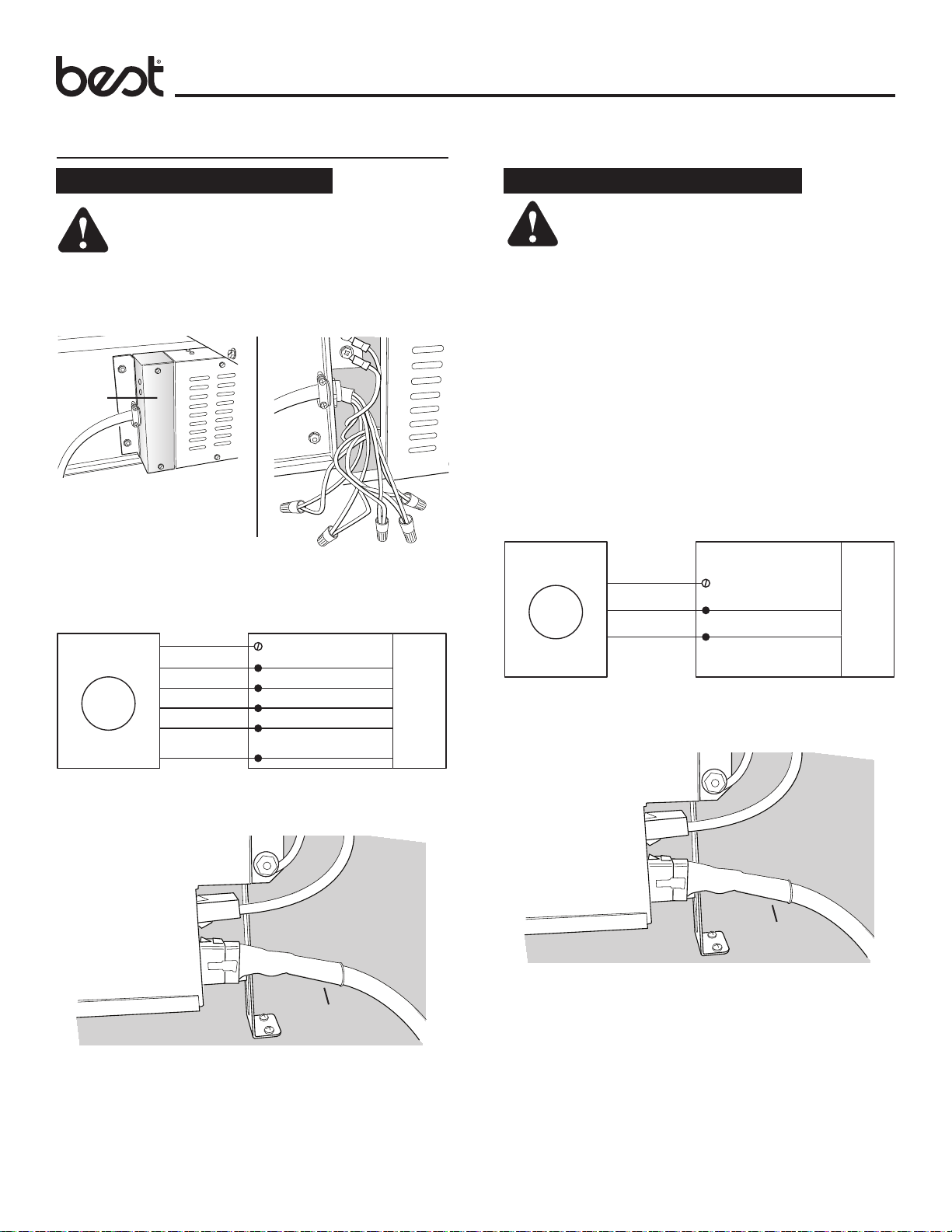

BLOWER

BOX

INSTALL ELECTRICAL WIRING

Models D49M30SB • D49M36SB • D49M48SB

Page 8

Installations using FLEX BLOWER only:

CAUTION: All electrical wiring should be done

by a qualified person(s) in accordance with all

applicable codes and standards.

1. Mount a standard wiring box, with 3-pronged receptacle, within

reach of the downdraft's power cord.

2. Run appropriate power cable and connect it to receptacle.

WIRING

BOX

COVER

3. Remove WIRING BOX COVER and connect blower wires to

wires in wiring box. Black to black, white to white, blue to blue,

orange to orange, gray to red, and green to ground screw.

ELECTRICAL PANEL

GROUND SCREW

WHITE (NEUTRAL)

BLUE (LOW 1)

GRAY (MED 2)

ORANGE (MED-HIGH)

BLACK (HIGH 4)

M

GREEN

WHITE

BLUE

RED

ORANGE

BLACK

Installations using REMOTE BLOWER only:

CAUTION: All electrical wiring should be done

by a qualified person(s) in accordance with all

applicable codes and standards.

1. Mount a standard wiring box, with 3-pronged receptacle, within

reach of the downdraft's power cord.

2. Run appropriate power cable into cabinet and connect it to

electrical box and receptacle.

3. These exterior or in-line blower can be used:

Models EB6, EB9, EB12, or EB15 - Exterior

Models ILB3, ILB6, ILB9, or ILB11 - In-Line

120 VAC • 60 Hz • 6.0 A (max.)

4. Run 2-wire plus ground power cable from the exterior or in-line

blower to wiring box on adaptor plate. Remove WIRING BOX

COVER.

5. Connect blower wires to power cable from exterior or in-line

blower. Black to black, white to white, and green to ground

screw.

ELECTRICAL PANEL

GROUND SCREW

M

REMOTE

BLOWER

WHITE (NEUTRAL)

BLACK

WIRING

BOX

6. Replace wiring box cover.

FLEXIBLE

WIRING

4. Replace wiring box cover.

LOWER

RECEPTACLE

ELECTRICAL

CABINET BOTTOM

PANEL CABLE

5 Plug ELECTRICAL PANEL CABLE into LOWER RECEPTACLE

as shown.

6. Plug the downdraft's power cord into the outlet. Make sure that

the power cord is routed away from the heat generated by the

cooktop.

LOWER

RECEPTACLE

ELECTRICAL

CABINET BOTTOM

PANEL CABLE

7. Plug ELECTRICAL PANEL CABLE into LOWER RECEPTACLE

as shown.

8. Plug the downdraft's power cord into the outlet. Make sure that

the power cord is routed away from the heat generated by the

cooktop.

Page 9

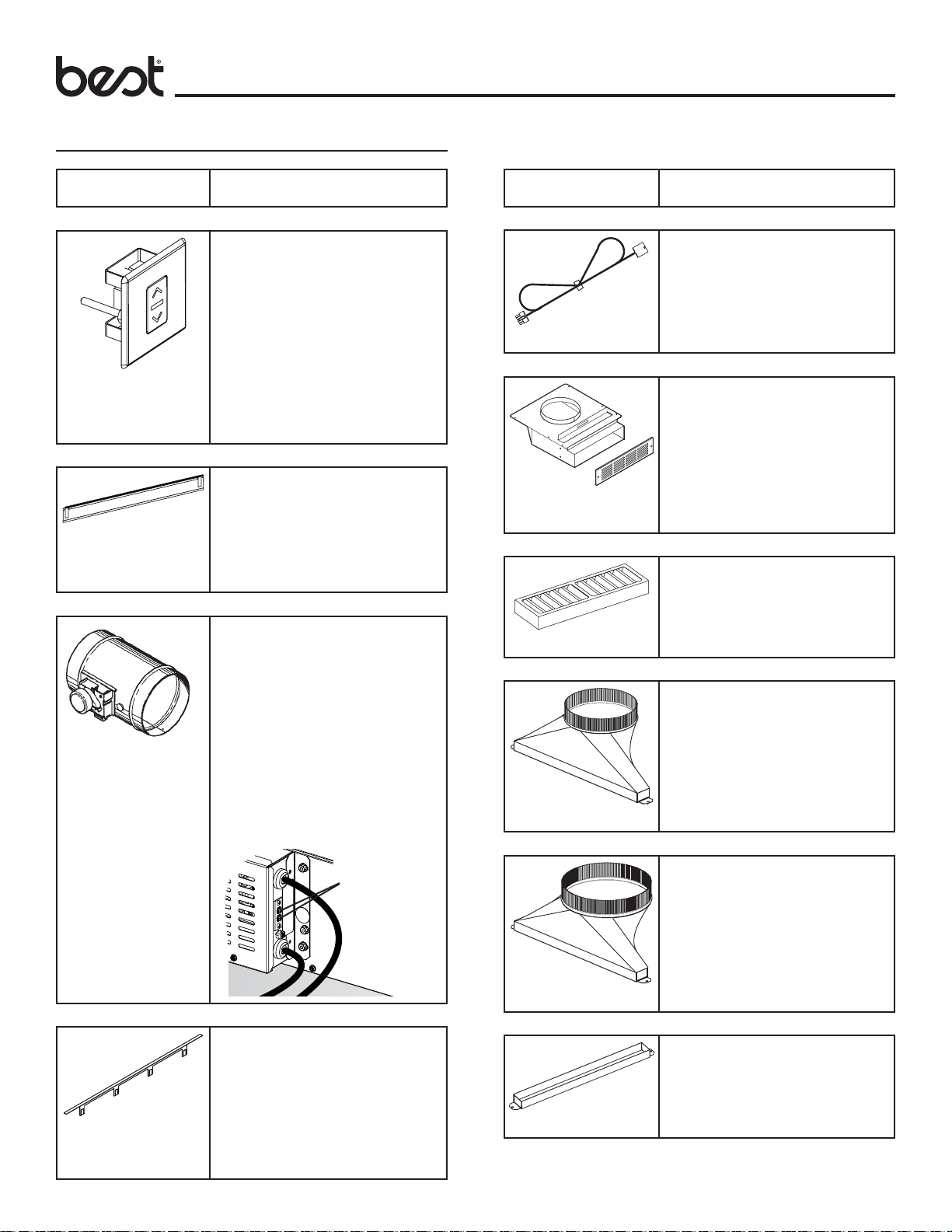

OPTIONAL ACCESSORIES

Models D49M30SB • D49M36SB • D49M48SB

Page 9

OPTIONAL

ACCESSORY

MODEL ACRD

MODELS

ATSKD30

ATSKD36

ATSKD48

MODELS

MD6T

MD8T

MD10T

DESCRIPTION /

APPLICATION

REMOTEUP/DOWN CONTROL

Use when you cannot reach the UP/

DOWN Button on the downdraft chimney.

Can be located on counter top, face of

cabinetry or on the side cabinet of an

island. Cut-out size: 2¼" H x 2" W.

Cannot be used where remote control

will interfere with cooking, where hot

pans could be set, or where hot liquids

could be spilled on the control.

Remote wiring connects with 6-pin connector on control box.

GAS COOKTOP SEAL KIT

Recommended for use with all gas

cooktops. Includes trim bracket and

trim seal.

30", 36" & 48" widths.

MAKE-UP AIR DAMPER

Use to provide make-up air when called

for to keep the home comfortable by

allowing the downdraft to operate at

optimum levels.

Directwire design works with select

®

downdrafts to balance indoor

BEST

air pressure by providing interlocked

make-up air; damper opens automatically when the range hood is activated

8" round & 10" round diameters.

Connects to 2 CONTACTS on

ELECTRICAL PANEL.

OPTIONAL

ACCESSORY

MODEL AEWD5

MODEL ANKD

MODEL AFCD

MODEL AVDKD8

DESCRIPTION /

APPLICATION

EXTENSION CABLE - 5-FT.

Use where electrical panel is remotely

mounted. Extends electrical panel cable an additional 5-feet.

NON-DUCT

RECIRCULATING KIT

Use where ducting is not feasible or

available. Mount to toe kick or base of

a cabinet and attach directly to Model

PF6 Flex Blower using 8" round duct.

Kit can be rotated so that the exhaust

is not directly at your feet. Includes

recirculation filter and decorative cover

plate.

RECIRCULATION FILTER

REPLACEMENT

Replacement filter for ANKD Non-Duct

Recirculating Kit. Use to effectively

capture cooking contaminants.

1-7/8" X 19" TO 8" ROUND

TRANSITION

Rectangular to 8" round transition for

left, right, or rear exhaust - using Model

PF6 Flex Blower. Can be attached

to downdraft unit or rectangular duct

(AEDD2). Includes S-clips for easy,

secure attachment.

MODELS

ATKD30SB

ATKD36SB

ATKD48SB

MAKE-UP

AIR DAMPER

CONTACTS

RANGE TRIM KIT

Use with free-standing range - where a

gap is present between back of range

and downdraft.

30", 36" & 48" widths.

1-7/8" X 19" TO 10" ROUND

TRANSITION

Rectangular to 10" round transition for

left, right, or rear exhaust - using Model

PF6 Flex Blower. Can be attached

to downdraft unit or rectangular duct

(AEDD2). Includes S-clips for easy,

secure attachment.

MODEL AVDKD10

RECTANGULAR ADAPTOR

FOR 1-7/8" X 19"

Use to connect 1-7/8" x 19" rectangular

duct directly to downdraft when using

side or rear exhaust.

MODEL AVDKD219

Page 10

OPTIONAL ACCESSORIES

(CONTINUED)

OPTIONAL

ACCESSORY

END CAP TRIM EXTENSION

+1" WIDTH - LH & RH

Use left and right to increase the

overall trim width by 1" - to 31", 37"

and 49".

MODEL ATTD1

FRONT PANEL ROUGH-IN PLATE 8" ROUND

Use where 8" round duct or elbow

attaches to front of airbox (Model PF6

remote blower installation).

MODEL ACVPD8

DESCRIPTION /

APPLICATION

Models D49M30SB • D49M36SB • D49M48SB

Page 10

INSTALL COOKING APPLIANCE

1. Align the cooking appliance with downdraft and fasten appliance in place following appliance instructions.

Note: Accurate alignment of cooking appliance and downdraft is

necessary to ensure that there is no interference when air vent

is raised and lowered. There should be a gap of 1/32" - 1/16" between the back of the cooktop and the front of the downdraft cover.

MODEL ACVPD10

MODEL 432 - 8" RD.

MODEL 418 - 10" RD.

MODEL 408 - 8" RD.

MODEL 410 - 10" RD.

FRONT PANEL ROUGH-IN PLATE 10" ROUND

Use where 10" round duct or elbow

attaches to front of airbox (exterior or

in-line blower installation).

0

90

DUCTWORK ELBOW

Adjustable from straight to 90

Galvanized steel construction.

STRAIGHT ROUND DUCT - 2-FT.

Galvanized steel construction.

0

.

MODEL AEDD2

RECTANGULAR DUCT - 2-FT.

SECTIONS (1-7/8" X 19")

Galvanized steel construction.

Page 11

USE AND CARE

!

!

Models D49M30SB • D49M36SB • D49M48SB

Page 11

Cooking

Always turn the downdraft blower on before you begin cooking

to establish an air flow in the kitchen. Let the blower run for a few

minutes to clean the air after you turn the cooktop off. This will

keep the whole kitchen cleaner and brighter.

It is recommended to use the rear burners when cooking with tall

pots or when the cooking method will generate high amounts of

smoke or steam. The combination of using the rear burners and

operating the unit at high speed will increase the likelihood that

all the smoke and steam will be removed by the downdraft.

WARNING: Always disconnect electric power

supply before cleaning and/or servicing unit.

Cleaning

EARS

TABS

FILTER

BAFFLE

Servicing

It may be necessary to remove the downdraft blower system from

the cabinet in order to service components such as the blower

motor or air vent mechanism.

Disconnect power to the cooktop and remove it first. Reverse the

steps under “INSTALL HOUSING INTO CABINET” to remove the

downdraft from the cabinet.

FILTER

BAFFLE

FRONT

PANEL

To clean grease filters:

Lift FRONT PANEL and BAFFLES up and out and take out the

GREASE FILTERS. Wash filters in a mild detergent solution or

a dishwasher. Replace filters, baffles and front panel and before

using downdraft. Be sure to engage TABS on front panel behind

EARS as shown.

CAUTION: Failure to engage tabs properly may cause

chimney to jam and fail to raise up.

To clean inside chimney:

Lift FRONT PANEL and BAFFLES up and out and take out

the GREASE FILTERS. Use a mild detergent. DO NOT USE

ABRASIVE CLOTH, STEEL WOOL PADS, OR SCOURING

POWDERS. Replace filters, baffles and front panel and before

using downdraft. Be sure to engage TABS on front panel behind

EARS as shown.

CAUTION: Failure to engage tabs properly may cause

chimney to jam and fail to raise up.

Page 12

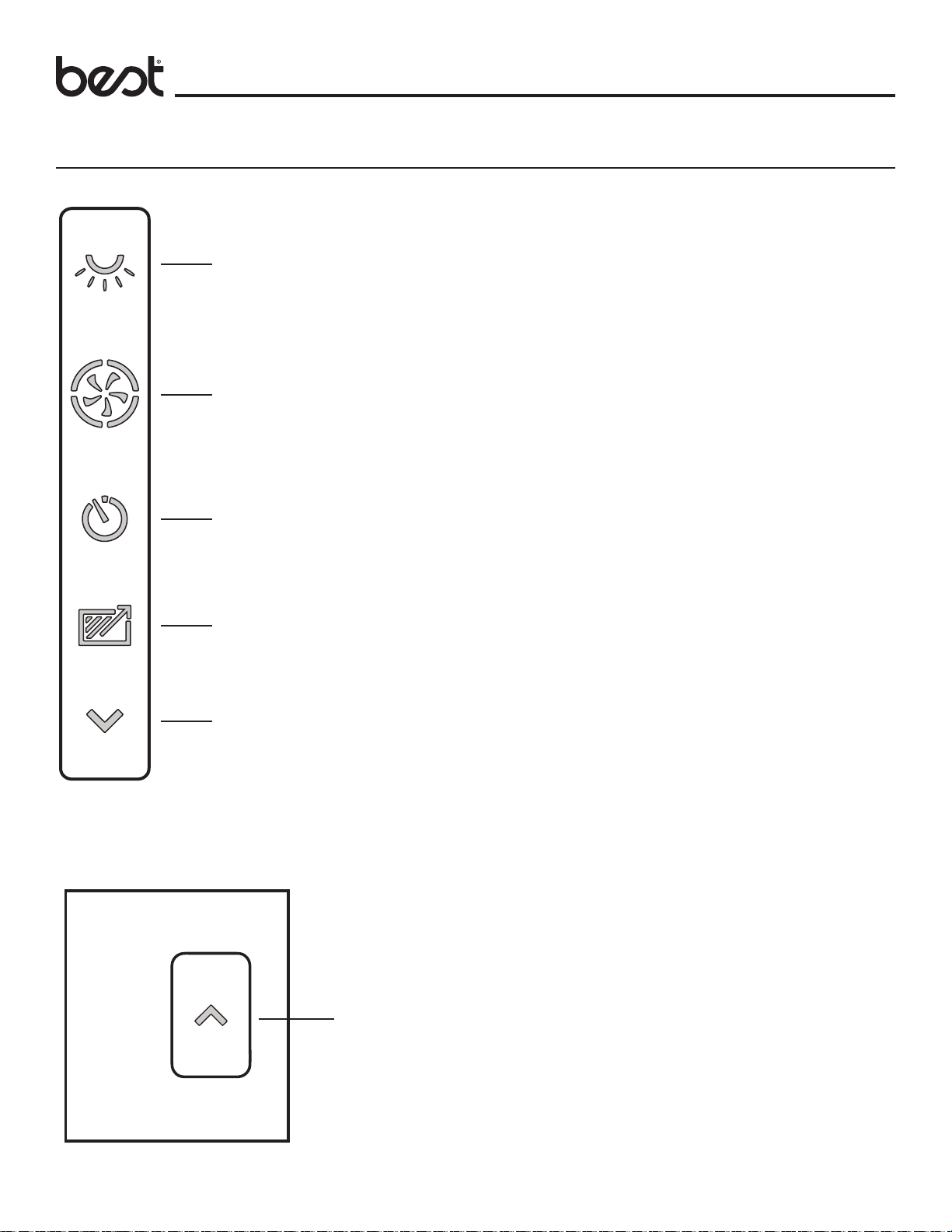

OPERATION

2-Level Task Light

4-Speed Fan Speed Control

Models D49M30SB • D49M36SB • D49M48SB

Page 12

2-Level Task Light

Press once for LOW setting. Top of icon will illuminate.

Press 2x for HIGH setting. Top and bottom of icon will illuminate.

Press 3x to turn task light OFF.

4-Speed Fan Speed Control

Press once for LOW setting. Top-right quadrant of icon will illuminate.

Press 2x for MEDIUM LOW setting. Top-right and bottom-right

quadrants of icon will illuminate.

Press 3x for MEDIUM HIGH setting. Top-right, bottom-right, and

bottom-left quadrants of icon will illuminate.

Press 4x for HIGH setting. All quadrants of icon will illuminate.

Press 5x to turn fan OFF.

10-Minute Delay Off

30-Hour Filter Clean Reminder

Down / Retract Chimney

10-Minute Delay Off

When fan is ON at any speed setting, press delay-off icon to start

10-minute timer. Fan and icon will shut off after 10 minutes.

To reset or de-activate delay-off, press icon again.

30-Hour Filter Clean Reminder

After 30 hours of blower "ON" time, filter clean icon will blink

continuously.

To reset, touch and hold icon for 2 or more seconds. Indicator

will turn off.

Down / Retract Chimney

To retract chimney, touch down button. Any feature that is active

will shut off.

Up Button

Touch up button on right trim to raise chimney. All functions will

return to their previous settings.

Up Button

Heat Sentry

When the operating temperature is too high, the fan speed will

increase to its highest setting to protect sensitive components.

The fan icon will blink and cannot be overridden until the temperature reaches an acceptable level. The fan speed will return

to the previous setting and the icon will stop blinking.

Page 13

Models D49M30SB • D49M36SB • D49M48SB

Page 13

SERVICE PARTSWARRANTY

Warranty Period and Exclusions: Broan-NuTone LLC (the “Company”) warrants to the

original consumer purchaser of its BEST

“Product”) will be free from material defects in the Product or its workmanship for a period

of one (1) year from the date of original purchase.

The limited warranty period for any replacement parts provided by the Company and for

any Products repaired or replaced under this limited warranty shall be the remainder of the

original warranty period.

This warranty does not cover fluorescent lamp starters, tubes, halogen and incandescent

bulbs, fuses, filters, ducts, roof caps, wall caps and other accessories for ducting that

may be purchased separately and installed with the Product. This warranty also does not

cover (a)normal maintenance and service, (b)normal wear and tear, (c)any Products

or parts which have been subject to misuse, abuse, abnormal usage, negligence,

accident, improper or insufficient maintenance, storage or repair (other than repair by

the Company), (d)damage caused by faulty installation, or installation or use contrary to

recommendations or instructions, (e)any Product that has been moved from its original

point of installation, (f)damage caused by environmental or natural elements, (g)damage

in transit, (h)natural wear of finish, (i)Products in commercial or nonresidential use, or

(j)damage caused by fire, flood or other act of God. This warranty covers only Products

sold to original consumers in the United States by the Company or U.S. distributors

authorized by the Company.

This warranty supersedes all prior warranties and is not transferable from the original

consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s sole obligation

and your sole remedy for defective products. The foregoing warranties are exclusive

and in lieu of any other warranties, express or implied. THE COMPANY DISCLAIMS AND

EXCLUDES ALL OTHER EXPRESS WARRANTIES, AND DISCLAIMS AND EXCLUDES

ALL WARRANTIES IMPLIED BY LAW, INCLUDING WITHOUT LIMITATION THOSE OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the extent that

applicable law prohibits the exclusion of implied warranties, the duration of any applicable

implied warranty is limited to the period specified for the express warranty above. Some

states do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you. Any oral or written description of the Product is for the

sole purpose of identifying it and shall not be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted in such

manner as to be effective and valid under applicable law, but if any provision is held to

be prohibited or invalid, such provision shall be ineffective only to the extent of such

prohibition or invalidity, without invalidating the remainder of such provision or the other

remaining provisions of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its option,

provide replacement parts for, or repair or replace, without charge, any Product or part

thereof, to the extent the Company finds it to be covered by and in breach of this limited

warranty under normal use and service. The Company will ship the repaired or replaced

Product or replacement parts to you at no charge. You are responsible for all costs for

removal, reinstallation and shipping, insurance or other freight charges incurred in the

shipment of the Product or part to the Company. If you must send the Product or part

to the Company, as instructed by the Company, you must properly pack the Product or

part—the Company is not responsible for damage in transit. The Company reserves the

right to utilize reconditioned, refurbished, repaired or remanufactured Products or parts in

the warranty repair or replacement process. Such Products and parts will be comparable

in function and performance to an original Product or part and warranted for the remainder

of the original warranty period.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE REPLACEMENT

PARTS, OR REPAIR OR REPLACE, AT THE COMPANY’S OPTION, SHALL BE YOUR SOLE

AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY AND THE COMPANY’S

SOLE AND EXCLUSIVE OBLIGATION. THE COMPANY SHALL NOT BE LIABLE FOR

INCIDENTAL, INDIRECT, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR

IN CONNECTION WITH THE PRODUCT, ITS USE OR PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights, which vary from state to state.

This warranty covers only replacement or repair of defective Products or parts thereof at

the Company’s main facility and does not include the cost of field service travel and living

expenses.

Any assistance the Company provides to or procures for you outside the terms, limitations

or exclusions of this limited warranty will not constitute a waiver of such terms, limitations

or exclusions, nor will such assistance extend or revive the warranty.

The Company will not reimburse you for any expenses incurred by you in repairing or

replacing any defective Product, except for those incurred with the Company’s prior written

permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a)notify

the Company at the address or telephone number stated below within seven (7)days

of discovering the covered defect, (b)give the model number and part identification and

(c)describe the nature of any defect in the Product or part. At the time of requesting

warranty service, you must present evidence of the original purchase date. If you cannot

provide a copy of the original written limited warranty, then the terms of the Company’s

most current written limited warranty for your particular product will control. The

most current limited written warranties for the Company’s products can be found at

www.BestRangeHoods.com.

In USA: BEST

In Canada: BEST

www.BestRangeHoods.com

ONE YEAR LIMITED WARRANTY FOR BEST® PRODUCTS

®

product (“you”) that the BEST® product (the

®

, 926 West State Street, Hartford, Wisconsin 53027 800-558-1711

®

, 550 Bd Lemire, Drummondville, QC J2C 7W9 866-737-7770

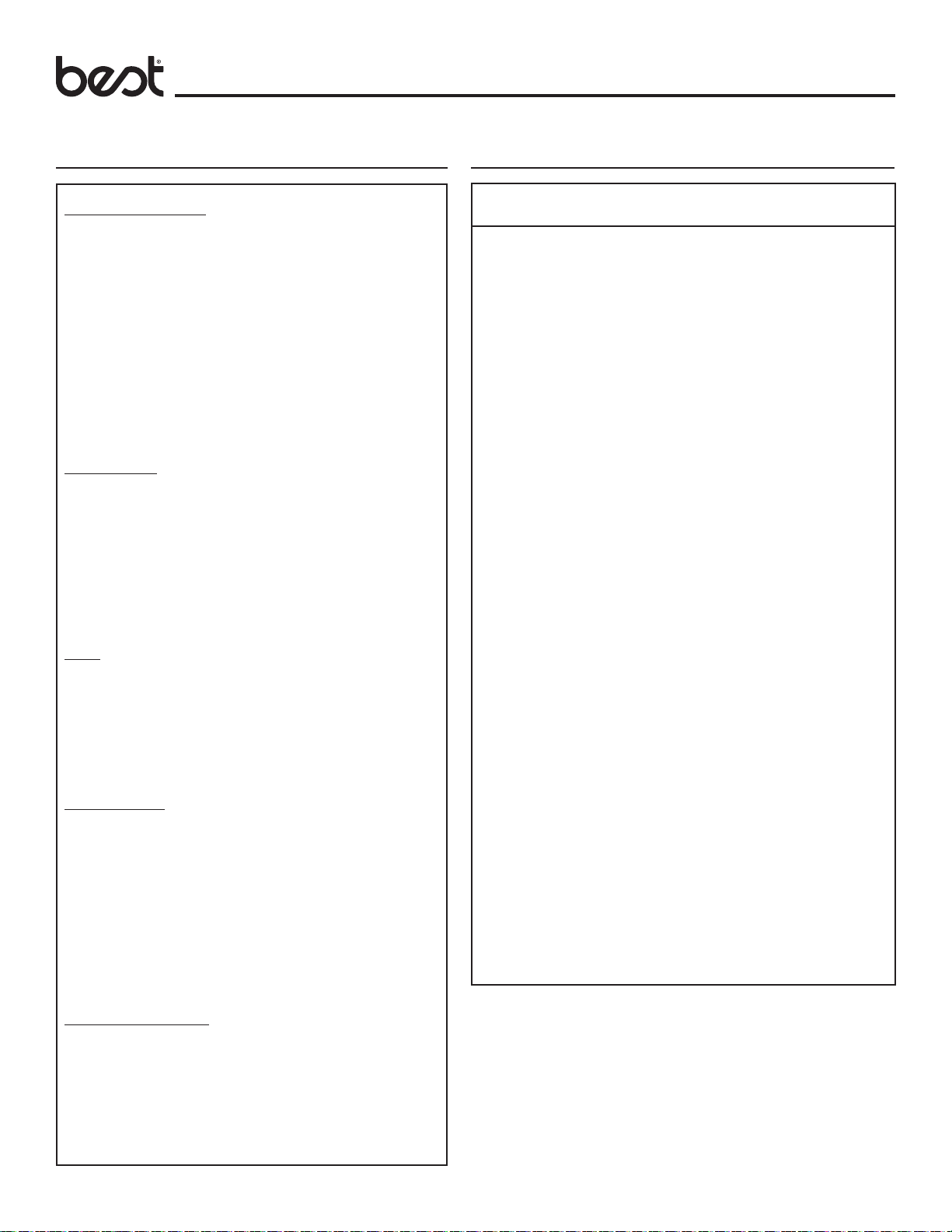

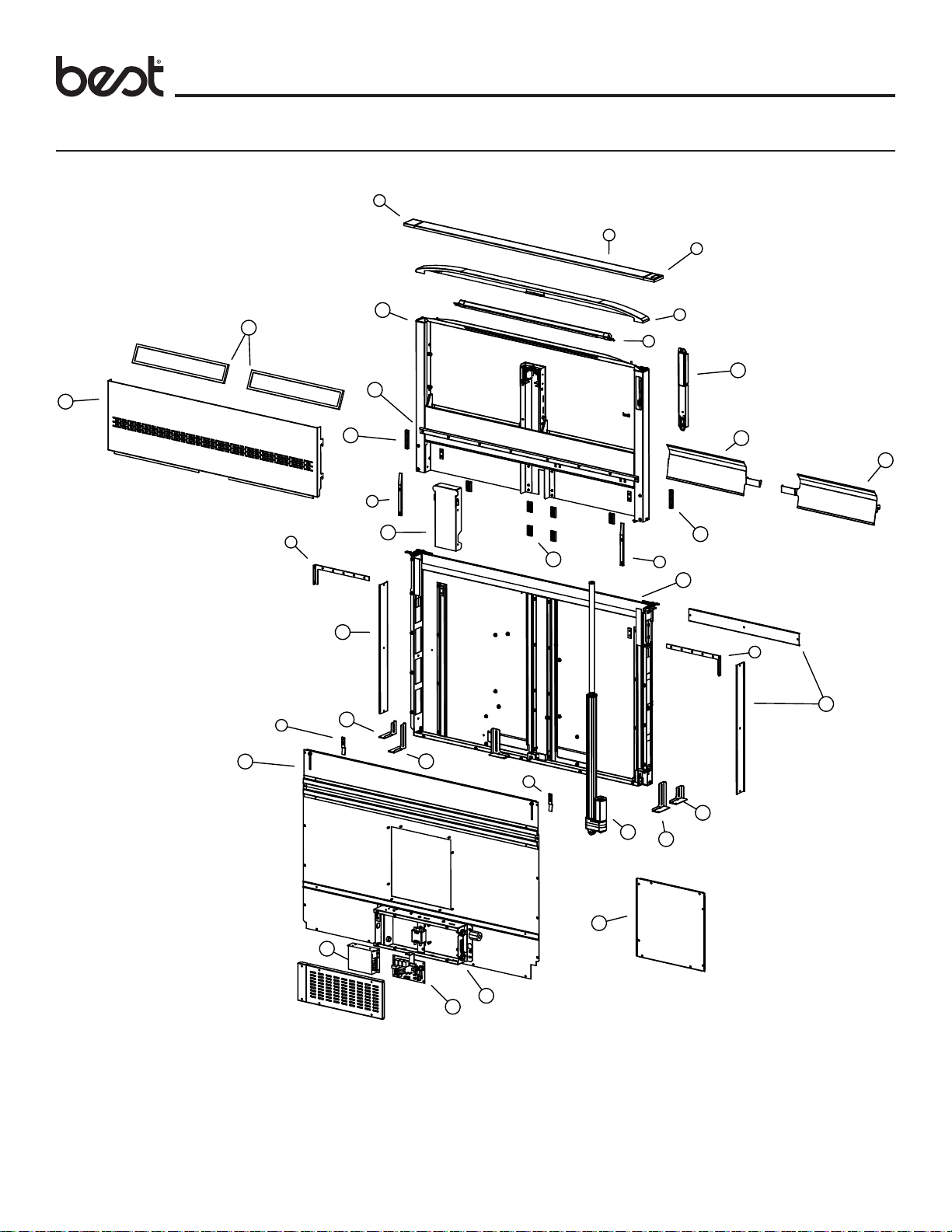

KEY 30N 36N 48N

NO. WIDTH WIDTH WIDTH DESCRIPTION

1 97019624 97019625 97019626 TOP CAP ASSY

2 99271515 99271516 99271517 LED LIGHT BAR

3 98011506 98011506 98011506 ANGLE BRACKET RH

4 98011507 98011507 98011507 ANGLE BRACKET LH

5 97019636 97019637 97019638 DOOR ASSY.

6 97020244 97020244 97020244 DOOR ASSY. COVER

WITH BUTTON RH

7 97019640 97019640 97019640 DOOR ASSY. COVER LH

8 99111677 99111677 99111677 CHIMNEY PLASTIC SLIDES

9 97019910 97019910 97019910 AIRBOX RAMP ASSEMBLY

10 99010405 99010406 99010407 FILTERS

11 99710032 99710032 99710032 SPACERS

* 99271510 99271510 99271510 WIRE HARNESS AIRBOX*

13 99271514 99271514 99271514 USER INTERFACE

14 99271524 99271524 99271524 LINEAR ACTUATOR

* 97019665 97019665 97019665 HEAT SENTRY ASSY*

16 97020255 97020226 97020227 AIRBOX FRONT

17 98011158 98011159 98011160 CHIMNEY FRONT GRILL

18 97020235 97020236 97020237 AIRBOX ASSY.

19 97019630 97019631 97019632 CHIMNEY ASSY.

20 98011401 98011401 98011401 LIFT GUIDE COVER

21 97019874 97019875 97019877 CHIMNEY SEAL

22 98011503 98011503 98011503 AIRBOX ADJUSTMENT LEG

RH (SHORT)

23 98011505 98011505 98011505 AIRBOX ADJUSTMENT LEG

RH (LONG)

24 98011502 98011502 98011502 AIRBOX ADJUSTMENT LEG

LH (SHORT)

25 98011504 98011504 98011504 AIRBOX ADJUSTMENT LEG

LH (LONG)

26 98011668 98011668 98011668 AIRBOX HOLE COVER

27 97019676 97019676 97019676 LIFT GUIDE PUCKS

(INCLUDES TOOL)

28 98011659 98011659 98011659 VENT COVERS

29 99271565 99271565 99271565 MAIN PCB

30 99271512 99271512 99271512 POWER SUPPLY

31 97019584 97019584 97019584 ELECTRICAL BOX ASSY.

32 98011688 98011687 98011686 RH BAFFLE

33 98011695 98011694 98011693 LH BAFFLE

* 97019570 97019570 97019570 PARTS BAG*

* Not Shown

Page 14

SERVICE PARTS

Models D49M30SB • D49M36SB • D49M48SB

Page 14

7

5

19

10

17

4

21

11

8

20

27

28

2

6

1

13

33

32

11

8

18

3

9

16

24

25

9

22

14

23

26

30

31

29

28

99045242E

Page 15

VENTILATEUR

!

ENCASTRÉ

Modèles D49M30SB • D49M36SB • D49M48SB

Page 15

À utiliser avec les ventilateurs suivants

(ventilateursvendus séparément) :

Modèle PF6 - Ventilateur Flex - intérieur

Modèles EB6, EB9, EB12 ou EB15 - extérieurs

Enregistrez votre produit en ligne à : www.BestRangeHoods.com

Modèles ILB3, ILB6, ILB9 ou ILB11 - intermédiaires

LIRE CES DIRECTIVES ET LES CONSERVER

AVERTISSEMENT

AFIN DE DIMINUER LES RISQUES D’INCENDIE, D’ÉLECTROCUTION

OU DE BLESSURES, SUIVEZ CES DIRECTIVES :

1. N’utilisez cet appareil que de la manière prévue par le fabricant. Si vous

avez des questions, communiquez avec le fabricant à l’adresse ou au

numéro de téléphone indiqués dans la garantie.

2. Avant de procéder à l’entretien ou au nettoyage de l’appareil, coupez

l’alimentation du panneau électrique et verrouillez l’interrupteur principal

afin d’empêcher que le courant ne soit accidentellement rétabli. S’il

est impossible de verrouiller l’interrupteur principal, fixez solidement

un message d’avertissement, par exemple une étiquette, sur le

panneauélectrique.

3. La pose de l’appareil et les travaux d’électricité doivent être effectués par

des personnes qualifiées conformément à la réglementation en vigueur,

notamment les normes de la construction ayant trait à la protection contre

les incendies.

4. Pour éviter les refoulements, l’apport d’air doit être suffisant pour brûler les

gaz produits par les appareils à combustion et les évacuer dans le conduit

de fumée (cheminée). Respectez les directives du fabricant de l’appareil

de chauffage et les normes de sécurité, notamment celles publiées par

la National Fire Protection Association (NFPA), l’American Society for

Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) et les

codes des autorités locales.

5. Veillez à ne pas endommager le câblage électrique ou d’autres

équipements non apparents lors de la découpe ou du perçage du mur

ou du plafond.

6. Les ventilateurs canalisés doivent toujours rejeter l’air à l’extérieur.

7. Pour réduire les risques d’incendie, utilisez seulement des conduits

enmétal.

8. N’installez pas ce produit en plaçant son interrupteur directement derrière

un brûleur ou un élément. La distance minimale entre l’interrupteur et le

bord du brûleur est de 10,2 cm (4 pouces).

9. Ne portez jamais de vêtements ou accessoires amples lors de l’utilisation

de cet appareil. Ils peuvent s’enflammer en raison des brûleurs ou des

éléments de la surface de cuisson.

10. Ne laissez jamais un enfant seul ou sans surveillance aux environs de

cet appareil lors de son utilisation.

11. Cet appareil doit être relié à une mise à la terre.

POUR RÉDUIRE LES RISQUES D’INCENDIE CAUSÉS PAR DE LA

GRAISSE SUR LE PLAN DE CUISSON :

a) Ne laissez jamais les éléments de surface allumés à haute température.

Les débordements peuvent causer de la fumée et occasionner des

écoulements de graisse inflammables. L’huile doit être chauffée

graduellement à basse ou à moyenne température.

b) Mettez toujours la hotte en marche lors de la cuisson à haute température

ou lors de la cuisson d’aliments à flamber.

c) Nettoyez souvent la hotte. Ne laissez pas la graisse s’accumuler sur le

ventilateur ou les filtres.

d) Utilisez des casseroles de dimension appropriée. Utilisez toujours une

batterie de cuisine adaptée à la dimension de la surface chauffante.

AVERTISSEMENT

OBSERVEZ LES CONSIGNES SUIVANTES DE MANIÈRE À RÉDUIRE

LES RISQUES DE BLESSURES CORPORELLES EN CAS D’INCENDIE

CAUSÉ PAR DE LA GRAISSE SUR LE PLAN DE CUISSON :

1. ÉTOUFFEZ LES FLAMMES à l’aide d’un couvercle étanche, d’une

tôle à biscuits ou d’un plateau en métal puis éteignez le brûleur.

FAITES ATTENTION DE NE PAS VOUS BRÛLER. SI LES FLAMMES

NE S’ÉTEIGNENT PAS IMMÉDIATEMENT, QUITTEZ LES LIEUX

ETAPPELEZ LE SERVICE DES INCENDIES.

2. NE SOULEVEZ JAMAIS UNE CASSEROLE EN FLAMMES – vous

pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni de serviettes ou de linges mouillés – une

violente explosion de vapeur pourrait survenir.

4. Utilisez un extincteur SEULEMENT si :

A. Vous savez qu’il est de classe ABC et vous connaissez déjà son

mode de fonctionnement.

B. L’incendie n’est pas très important et ne se propage pas.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en faisant dos à une sortie.

a

Conseils tirés de la publication de la NFPA « Kitchen Fire Safety Tips ».

a

ATTENTION

1. Pour usage intérieur seulement.

2. Pour ventilation générale uniquement. N’utilisez pas cet appareil pour

évacuer des matières ou des vapeurs dangereuses ou explosives.

3. Pour éviter d’endommager les roulements du moteur, de déséquilibrer

les pales ou de les rendre bruyantes, débarrassez l’appareil de la

poussière de plâtre, de construction, etc.

4. Nettoyez fréquemment les filtres et les surfaces graisseuses.

5. Ne réparez ou ne remplacez aucune pièce de cet appareil à moins

que ce manuel le recommande précisément. Tout autre travail de

réparation doit être confié à un technicien qualifié.

6. Veuillez lire l’étiquette de spécifications du produit pour obtenir plus

de renseignements, notamment sur les exigences.

7. Pour réduire les risques d’incendie et de choc électrique, n’installez

cette hotte encastrée qu’avec les modèles de ventilateur indiqués

ci-dessous. D’autres ventilateurs ne peuvent pas leur être substitués.

(Ventilateurs vendus séparément.)

Ventilateur Flex de modèle PF6

Ventilateurs extérieurs de modèles EB6, EB9, EB12 ou EB15

Ventilateurs intermédiaires de modèles ILB3, ILB6, ILB9 ou ILB11

INSTALLATEUR :

Conservez ce manuel pour l’inspection

électrique et le propriétaire.

Page 16

Modèles D49M30SB • D49M36SB • D49M48SB

CONTENU

Ces pièces sont incluses avec le boîtier de hotte encastrée :

1 - Sac de pièces contenant :

2 - Pieds de support de 5 cm (2 po)

2 - Pieds de support de 10 cm (4 po)

2 - Vis à tête hexagonale, 1/4-20 x 0,50

2 - Vis cruciformes, n° 8-18 x 0,375

8 - Vis à bois à tête ronde cruciforme, n° 10 x 0,50

1 - Ensemble de bordures de porte

1 - Panneau électrique

2 - Supports

1 - Gabarit de découpe du comptoir

PLANIFICATION

En raison de sa polyvalence, ce système de hotte encastrée peut servir à

évacuer les contaminants aériens lorsque vous cuisinez avec une variété

d’appareils de cuisson au gaz ou à l’électricité - dont les surfaces de

cuisson, cuisinières, cuisinières encastrables et cuisinières autonomes.

Elle peut être installée dans un îlot, une péninsule ou un mur ordinaire. Le

ventilateur (vendu séparément) et le panneau électrique peuvent être fixés

à la hotte encastrée, ou installés à l’intérieur d’une armoire ou à distance

dans un endroit pratique.

Cette unité s’installe facilement en suivant ces étapes de base :

• Découpez l’ouverture dans le comptoir.

• Installez l’unité dans l’armoire.

• Installez le ventilateur et le panneau électrique.

• Raccordez les conduits et le câblage électrique.

• Installez la bordure.

• Installez l’appareil de cuisson.

Remarque : le débit d’air élevé de cet appareil peut affecter la flamme de

certains types de surface de cuisson au gaz. Ce phénomène est NORMAL

et ne causera aucun dommage mais il peut être corrigé en diminuant le

régime du ventilateur.

Il est conseillé d’utiliser un jeu de joints d’étanchéité avec toute surface de

cuisson au gaz. Ce jeu assure l’étanchéité entre la surface de cuisson et

l’armoire située en dessous. Il comprend un joint de bordure et les attaches

requises. Voir « ACCESSOIRES EN OPTION ».

SPÉCIFICATIONS ÉLECTRIQUES

Modèle PF6 - Flex interne :

120 VCA • 60 Hz • 3,0 A

Modèles EB6, EB9, EB12 ou EB15 - extérieurs

Modèles ILB3, ILB6, ILB9 ou ILB11 - Intermédiaires

120 VCA • 60 Hz • 6,0 A (max.)

PRISE DES MESURES

1. Consultez les directives d’installation de la surface de cuisson pour les

dimensions de l’ouverture à découper dans le comptoir et les dimensions

de l’armoire. Toutefois, il est recommandé que l’armoire soit plus grande

que nécessaire pour faciliter l’installation. Les îlots conçus sur mesure

doivent comporter des armoires plus profondes - particulièrement

lorsque la cuisinière est installée devant la hotte encastrée ou quand le

ventilateur est placé derrière la hotte. Vous devez également prévoir une

porte d’accès.

2. La profondeur de la surface de cuisson peut varier grandement d’un

produit à un autre. Il se peut que la pose de ces deux appareils soit

relativement serrée.

Faites particulièrement attention aux nuisances possibles indiquées cidessous. Un comptoir avec (A) une lèvre soulevée à l’avant ou (B) un

dosseret risque de laisser une surface plane insuffisante pour l’installation.

Veuillez noter que le comptoir doit comporter une partie plane de 7 cm

(2-3/4 po) derrière le plan de cuisson et qu’une distance de 6,4 cm

(2-1/2po) est nécessaire entre la bord arrière du plan de cuisson et la

paroi arrière intérieure de l’armoire.

Page 16

6,4 CM (2-1/2 PO)

7 CM (2-3/4 PO)

PLANIFICATION DE LA POSE

DES CONDUITS

BOÎTIER

VENTILATEUR

FLEX*

A

D

C

F

Les ventilateurs installés à distance utilisent une plaque de sortie pour

*

conduits ronds de 20,3 cm (8 po) ou de 25,4 cm (10 po) au lieu d’un

ventilateur Flex.

1. Le système de hotte encastrée est conçu pour utiliser des conduits

ronds de 20,3 cm (8 po) avec un ventilateur Flex ou des conduits ronds

de 25,4 cm (10 po) avec un ventilateur installé à distance. (Ventilateur

vendu séparément.) Six (6) différents raccords de sortie sont possibles :

A = 20,3 cm (8 po) rond, sortie à gauche, ventilateur Flex

B = 20,3 cm (8 po) rond, sortie à droite, ventilateur Flex

C = 20,3 cm (8 po), sortie vers le bas, ventilateur Flex

(panneauélectrique à monter à distance)

D = 4,8 cm x 48,3 cm (1-7/8 po x 19 po), sortie à gauche du boîtier

vers le ventilateur à distance ou le ventilateur Flex situé à distance.

Utiliser une transition de 4,8 cm x 48,3 cm (1-7/8 po x 19 po) à

20,3cm (8 po) rond, une transition de 4,8 cm x 48,3 cm (1-7/8 po

x19 po) à 25,4 cm (10 po) rond, ou un conduit de 4,8 cm x 48,3 cm

(1-7/8 po x 19 po) comme il convient.

E = 4,8 cm x 48,3 cm (1-7/8 po x 19 po), sortie à droite du boîtier vers le

ventilateur à distance ou le ventilateur Flex situé à distance. Utiliser

une transition de 4,8 cm x 48,3 cm (1-7/8 po x 19 po) à 20,3 cm

(8po) rond, une transition de 4,8 cm x 48,3 cm (1-7/8 po x 19 po) à

25,4 cm (10 po) rond, ou un conduit de 4,8 cm x 48,3 cm (1-7/8 po

x19 po) comme il convient.

F = 4,8 cm x 48,3 cm (1-7/8 po x 19 po), sortie à l’arrière du boîtier

vers le ventilateur à distance ou le ventilateur Flex situé à distance.

Utiliser une transition de 4,8 cm x 48,3 cm (1-7/8 po x 19 po) à

20,3cm (8 po) rond, une transition de 4,8 cm x 48,3 cm (1-7/8 po

x19 po) à 25,4 cm (10 po) rond, ou un conduit de 4,8 cm x 48,3 cm

(1-7/8 po x 19 po) comme il convient.

2. Pour la meilleure performance : Choisissez l’option qui permet l’utilisation

des conduits les plus courts possible et un nombre minimum de coudes

et de transitions. Vérifiez l’emplacement des solives du plancher, des

montants des murs, des fils électriques et de la plomberie pour éviter les

nuisances éventuelles.

B

E

PANNEAU

ÉLECTRIQUE

Page 17

Modèles D49M30SB • D49M36SB • D49M48SB

!

PLANIFICATION DE LA

DÉCOUPE DU COMPTOIR

ATTENTION : AVANT DE DÉCOUPER L’OUVERTURE DES

CONDUITS DANS L’ARMOIRE, vérifiez que les solives du

plancher, les montants des murs, les fils électriques et la

plomberie ne présentent aucune nuisance.

COIN ARRIÈRE DE

LA DÉCOUPE

14,9 CM

(5 ⅞ PO)

53,3 CM

(21 PO)

DU COMPTOIR

(2 PO)

(21 PO) CENTRÉ

10 CM

(4 PO)

INTÉRIEUR DE

L’ARMOIRE - BAS

5 CM

53,3 CM

LIGNE DE CENTRE DE

L’INSTALLATION

OUVERTURE POUR

CONDUIT DE

4,8 CM X 48,3 CM

(1- ⅞ PO

X 19 PO) ET

TRANSITION

3,8 CM

(1 ½ PO)

L’ARMOIRE - ARRIÈRE

62,9 CM

(24 ¾ PO)

INTÉRIEUR DE

10 CM

(4 PO)

B

A

Ouverture dans le bas de l’armoire

Dimension A Dimension B

Ventilateur Flex (Modèle PF6 et conduit

rond de 20,3 cm (8 po) à la verticale

à travers le plancher de l’armoire.)

(à3,8cm (1 ½ po) à gauche de la

ligne de centre del’installation)

14,3 cm (5-5/8 po)

Ventilateur extérieur ou

intermédiaire avec coude de

90° (sur la ligne de centre

del’installation)

19,4 cm

(7-5/8po)

[Modèle 432 -

coude rond de

20,3 cm (8 po)]

21,9 cm

(8-5/8 po)

[Modèle 418-

coude rond

de 25,4 cm

(10 po)]

Utilisez les dimensions indiquées dans l’illustration ci-dessus pour planifier

l’accès des conduits dans l’armoire. En règle générale, un conduit rectangulaire

de 4,8 cm x 48,3 cm (1-7/8 po x 19 po) est utilisé pour une sortie à gauche, à

droite ou à l’arrière de l’armoire - alors qu’un conduit rond de 20,3 cm (8po)

est utilisé pour une sortie vers le bas au travers du plancher de l’armoire.

Pour une sortie à gauche, à droite ou à l’arrière :

Prévoir au moins 46 cm (18 po) pour la transition et le coude ou le ventilateur.

Pour une sortie à gauche ou à droite :

Une armoire de 76 cm (30 po) de profondeur est recommandée pour un

alignement adéquat avec le ventilateur Flex. Le ventilateur Flex peut être

fixé à la paroi arrière de l’armoire ou à une plateforme ou un cadre (non

fourni) appuyé sur la base de l’armoire. (Consulter les instructions du

ventilateurFlex).

Une armoire de 61 à 76 cm (24 à 30 po) de profondeur est nécessaire selon

le type d’appareil de cuisson.

PLANIFICATION DU CÂBLAGE

1. Cette hotte encastrée utilisant un ventilateur Flex (vendu séparément)

consomme 3,0 A et exige un circuit de 120 VCA, 60 Hz. Si un ventilateur

est installé à distance (vendu séparément), le système consomme

6,0 A et exige un circuit de 120 VCA, 60 Hz.

2. L’unité comporte un cordon électrique de 76 cm (30 po) de longueur

muni d’une fiche à trois broches. Prévoyez l’installation d’une prise

de courant permettant de brancher le cordon de l’appareil.

3. Installez la boîte électrique conformément aux codes locaux.

Page 17

PRÉPARATION DE LA HOTTE

ENCASTRÉE

COUVERCLE DU

PANNEAU AVANT

(8)

ÉCROUS

HEXAGONAUX

10-24

Le panneau

électrique doit être

posé à distance.

Conduit installé à travers l’ouverture du panneau avantseulement :

1. Placez la hotte encastrée sur le dos sur une table ou une surface

de travail plane.

2. Enlevez les ÉCROUS HEXAGONAUX pour retirer le COUVERCLE

DU PANNEAU AVANT.

VENTILATEUR

FLEX

(8)

ÉCROUS

HEXAGONAUX

10-24

PANNEAU

AVANT

Si la sortie du ventilateur

est en bas, placer le

panneau électrique

ailleurs. Voir l’étape 6.

Installations avec VENTILATEUR FLEX seulement :

(Acheter un ventilateur Flex modèle PF6 séparément.)

3. Déterminez si le VENTILATEUR FLEX sortira à gauche, à droite ou

vers le bas.

Serrez les écrous hexagonaux pour fixer le ventilateur en place.

Page 18

Modèles D49M30SB • D49M36SB • D49M48SB

!

(8)

ÉCROUS

HEXAGONAUX

10-24

Installations avec VENTILATEUR FLEX (à distance) ou

VENTILATEUR À DISTANCE seulement :

4. Utilisez la PLAQUE DE SORTIE À DISTANCE.

Serrez les écrous hexagonaux pour fixer la PLAQUE DE SORTIE

ÀDISTANCE.

PLAQUE DE SORTIE À

DISTANCE DE 20,3CM

(8 PO) OU 25,4 CM

(10 PO) (vendue

séparément)

PANNEAU

AVANT

COULISSE

Page 18

ÉCROUS

HEXAGONAUX

8-32

Installations dans lesquelles le PANNEAU ÉLECTRIQUE doit être

monté à distance seulement :

6. Enlevez les quatre (4) ÉCROUS HEXAGONAUX 8-32 et le PANNEAU

ÉLECTRIQUE. Des câbles de rallonge de 1,5 m (5 pi) (vendus

séparément) peuvent être nécessaires pour monter le panneau

électrique à distance. N’utilisez pas plus de deux câbles de rallonge.

SUPPORT

Ventilateur

Flex installé.

PIEDS DE

SUPPORT

Toutes les installations :

5. Glissez les SUPPORTS SUPÉRIEURS dans la COULISSE en haut

à gauche et à droite de l’unité.

Fixez les PIEDS DE SUPPORT COURTS OU LONGS (selon la

hauteur de l’armoire) au bas de l’unité sur les côtés à l’aide des VIS

HEXAGONALES fournies. Ne serrez pas complètement ces vis à

cette étape-ci.

VIS À TÊTE

HEXAGONALE

1/4-20 X 0,500

SUPÉRIEUR

(4) VIS

PIEDS DE

SUPPORT DU

VENTILATEUR

Installations avec VENTILATEUR FLEX seulement :

7. Fixez les PIEDS DE SUPPORT DU VENTILATEUR à l’aide des

quatre (4) VIS fournies.

ATTENTION : Si le ventilateur Flex doit être monté à

distance : N’utilisez pas seulement les pieds comme

supports. Il peut être nécessaire d’ajouter d’autres

supports au ventilateur. Utilisez les profilés de montage

fournis avec le ventilateur.

Page 19

Modèles D49M30SB • D49M36SB • D49M48SB

Page 19

COUVERCLES

RECTANGULAIRES

DESORTIE

Le panneau

avantdemeure

enplace.

Installations avec conduit à gauche, à droite ou à l’arrièreseulement :

(Exige l’achat d’une transition de 4,8 cm x 48,3 cm (1-7/8 po x 19po)

à 20,3 cm (8 po) ou 25,4 cm (10 po) rond. Des adaptateurs pour

conduits rectangulaires de 4,8 cm x 48,3 cm (1-7/8 po x 19 po) sont

aussi disponibles.)

8. Enlevez un seul COUVERCLE RECTANGULAIRE DESORTIE.

DÉCOUPER L’OUVERTURE

DU COMPTOIR

1. Tracez et découpez l’ouverture de la surface de cuisson suffisamment

vers l’AVANT de sorte que la hotte puisse s’encastrer derrière.

2. Disposez la surface de cuisson en place et glissez-la le plus possible

vers l’avant sans qu’aucun écart ne soit visible. Centrez-la et vérifiez

son équerre avec les bords du comptoir.

OUVERTURE

DU COMPTOIR

SURFACE DE

CUISSON

Gabarit contre le bord

arrièreducomptoir.

Gabarit contre le bord arrière

del’ouverture du comptoir.

POUR CUISINIÈRE

ENCASTRABLE

Conduit sortant du côté droit du boîtier illustré.

Installations avec conduit à gauche, à droite ou à l’arrièreseulement :

(Exige l’achat d’une transition de 4,8 cm x 48,3 cm (1-7/8 po x 19po)

à 20,3 cm (8 po) ou 25,4 cm (10 po) rond. Des adaptateurs pour

conduits rectangulaires de 4,8 cm x 48,3 cm (1-7/8 po x 19 po) sont

aussi disponibles.)

9. Utilisez des écrous pour raccorder l’adaptateur de conduit

rectangulaire de 4,8 cm x 48,3 cm (1-7/8 po x 19 po) ou la transition

de 4,8 cm x48,3cm (1-7/8 po x 19 po) à 20,3 cm (8 po) ou 25,4 cm

(10 po) rond lors de la pose du conduit.

3. Placez le gabarit en plastique contre la bordure arrière de la surface

de cuisson ou contre le bord arrière de l’ouverture de la cuisinière

encastrable. Centrez le gabarit. Tracez le pourtour du gabarit pour

marquer l’ouverture de la hotte encastrée.

4. Retirez la surface de cuisson du comptoir.

5. Découpez l’ouverture de la hotte. Prenez garde de ne pas ébarber les

bords du comptoir.

Page 20

INSTALLER LE BOÎTIER

DANS L’ARMOIRE

Modèles D49M30SB • D49M36SB • D49M48SB

Page 20

1. Enlevez la surface de cuisson.

RUBAN

CÂBLE DU

BOUTON

HAUT

PRISE DU HAUT

2. Branchez le CÂBLE DU BOUTON HAUT de la bordure de droite

dans la PRISE DU HAUT située en bas à droite du boîtier de la hotte

et raccordez le fil de terre sur l’ÉCROU DE MISE À LA TERRE.

Acheminez le câble le long du boîtier et maintenez-le en place avec

du RUBAN ADHÉSIF près du haut.

ÉCROU DE

MISE À

LA TERRE

VIS

HEXAGONALE

PIED DE SUPPORT

(2) VIS À BOIS 10 X 0,500

5. Allongez les PIEDS DE SUPPORT et fixez-les au fond de l’armoire

avec deux (2) VIS dans chaque pied. Serrez les VIS HEXAGONALES.

Si le fond de l’armoire est enlevé :

Utilisez des blocs ou des cales d’espacement entre le plancher et

les pieds de support.

SUPPORT

SUPÉRIEUR

(2) VIS À BOIS

10 X 0,500

3. Insérez le boîtier dans l’ouverture du comptoir et l’armoire en le

poussant le plus possible vers l’arrière. Assurez-vous que le câble

du bouton HAUT est enfilé dans l’ouverture tel qu’illustré et qu’il n’est

paspincé.

4. Assurez-vous que le boîtier est de niveau.

6. Allongez les SUPPORTS SUPÉRIEURS et fixez-les sur les côtés de

l’armoire avec deux (2) VIS dans chaque support.

VENTILATEUR FLEX

(4) VIS

1/4-20 X0,500

VIS

Installations avec VENTILATEUR FLEX seulement :

7. Desserrez les quatre (4) VIS retenant les PIEDS DE SUPPORT DU

VENTILATEUR sur le VENTILATEUR FLEX. Allongez les pieds et

fixez-les au bas de l’armoire avec une VIS dans chacun.

Page 21

!

INSTALLATION DE LA

Modèles D49M30SB • D49M36SB • D49M48SB

Page 21

BORDURE DE FINITION

NETTOYEZ

LESSURFACES

CAPOT

PELLICULE

DURUBAN

1. Enlevez la PELLICULE DU RUBAN.

2. NETTOYEZ LES SURFACES sous la bordure de droite - afin que le

ruban adhésif colle solidement.

POSE DES CONDUITS

ATTENTION : AVANT DE DÉCOUPER L’OUVERTURE

DES CONDUITS DANS L’ARMOIRE, vérifiez que les

solives du plancher, les montants des murs, les fils

électriques et la plomberie ne présentent aucune

nuisance.

1. Découpez les ouvertures dans l’armoire ainsi que dans les murs ou le

plancher, selon le cas.

2. Installez le capuchon de toit et, tout en revenant vers l’armoire, posez

tous les conduits, coudes et transitions prévus. Étanchez tous les

joints avec du ruban adhésif.

3. Raccordez le conduit (et la transition, s’il y a lieu) à la hotte encastrée.

RONDELLE

JEU DE 1,6 MM

(1/16 PO)

CAPOT

BORDURE

DEDROITE

VUE DU DESSUS

ÉGAL

3. Pressez la BORDURE DE DROITE en place.

Assurez-vous que la bordure :

• s’appuie à plat sur la surface du comptoir

• est à égalité avec le CAPOT

• a un JEU DE 1,6 MM (1/16 PO) avec le capot

• et que le câble n’est pas pincé.

4. Répétez les étapes 1, 2 et 3 pour installer la bordure de gauche.

Page 22

FLEXIBLE

CÂBLAGE

CÂBLAGE

DISTANCE

Modèles D49M30SB • D49M36SB • D49M48SB

Page 22

Installations avec VENTILATEUR FLEX seulement :

ATTENTION : Les travaux d’électricité doivent être

effectués par des personnes qualifiées en respectant

les codes et les normes en vigueur.

1. Posez une boîte électrique standard, avec une prise pour fiches à

trois lames accessible pour le cordon de la hotte.

2. Acheminez le fil d’alimentation électrique approprié et connectez-le

à la prise de courant.

COUVERCLE

DU BOÎTIER

DECÂBLAGE

3. Enlevez le COUVERCLE DU BOÎTIER DE CÂBLAGE et raccordez

les fils du ventilateur aux fils situés dans le boîtier de câblage.

Connectez le fil noir avec le noir, le blanc avec le blanc, le bleu avec

le bleu, l’orange avec l’orange, le gris avec le rouge et le vert avec la

vis de mise à la terre.

PANNEAU ÉLECTRIQUE

VIS DE MISE À LA TERRE

BLANC (NEUTRE)

BLEU (BAS RÉGIME 1)

GRIS (MOYEN 2)

ORANGE (MOYEN-HAUT)

M

VERT

BLANC

BLEU

ROUGE

ORANGE

Installations avec VENTILATEUR À DISTANCE seulement :

ATTENTION : Les travaux d'électricité doivent être

effectués par des personnes qualifiées en respectant

les codes et les normes en vigueur.

1. Posez une boîte électrique standard, avec une prise pour fiches à

trois lames accessible pour le cordon de la hotte.

2. Acheminez le fil d’alimentation électrique approprié dans l’armoire et

connectez-le à la boîte électrique et à la prise de courant.

3. Vous pouvez utiliser les ventilateurs intermédiaires suivants :

Modèles EB6, EB9, EB12 ou EB15 - extérieurs

Modèles ILB3, ILB6, ILB9 ou ILB11 - intermédiaires

120 VCA • 60 Hz • 6,0 A (max.)

4. Acheminez un câble électrique à deux fils plus un fil de terre du

ventilateur extérieur ou intermédiaire jusqu’au boîtier de câblage

sur la plaque d’adaptateur. Retirez le COUVERCLE DU BOÎTIER

DECÂBLAGE.

5. Raccordez les fils du ventilateur aux fils de l’alimentation du

ventilateurextérieur ou intermédiaire. Connectez le fil noir avec le

noir, le blanc avec le blanc et le vert avec la vis de mise à la terre.

PANNEAU ÉLECTRIQUE

VIS DE MISE À LA TERRE

M

VENTILATEUR À

BLANC (NEUTRE)

NOIR

BOÎTIER

DE CÂBLAGE

6. Replacez le couvercle du boîtier de câblage.

NOIR

VENTILATEUR

NOIR (HAUT 4)

BOÎTIER DE

4. Replacez le couvercle du boîtier de câblage.

PRISE DU BAS

CÂBLE DU

BAS DE L’ARMOIRE

PANNEAU

ÉLECTRIQUE

5 Branchez le CÂBLE DU PANNEAU ÉLECTRIQUE dans la PRISE

DU BAS tel qu’illustré.

6. Branchez le cordon électrique de la hotte dans la prise. Assurezvous que le cordon électrique passe loin de la chaleur produite par

la surfacede cuisson.

PRISE DU BAS

CÂBLE DU

BAS DE L’ARMOIRE

PANNEAU

ÉLECTRIQUE

7. Branchez le CÂBLE DU PANNEAU ÉLECTRIQUE dans la PRISE

DU BAS, tel qu’illustré.

8. Branchez le cordon électrique de la hotte dans la prise. Assurezvous que le cordon électrique passe loin de la chaleur produite par

la surfacede cuisson.

Page 23

ACESSOIRES EN OPTION

Modèles D49M30SB • D49M36SB • D49M48SB

Page 23

ACESSOIRE

ENOPTION

MODÈLE ACRD

MODÈLES

ATSKD30

ATSKD36

ATSKD48

MODÈLES

MD6T

MD8T

MD10T

DESCRIPTION /

APPLICATION

TÉLÉCOMMANDE HAUT/BAS

Utilisez-la quand vous n’avez pas accès

au bouton HAUT/BAS de la cheminée

d’évacuation.

Elle peut être placée sur le dessus du

comptoir, sur la face de l’armoire ou sur le

côté d’un îlot. Taille de la découpe : 5,7cm

(2¼ po) H x 5 cm (2 po) L.

Ne placez pas la télécommande à un

endroit où elle pourrait gêner les travaux

culinaires, là où vous déposez des

chaudrons chauds ou à un endroit où des

liquides chauds risquent de l’éclabousser.

Le câble de la télécommande se branche

au moyen du connecteur à 6 broches sur

le boîtier de commande.

JEU DE JOINTS D’ÉTANCHÉITÉ POUR

SURFACE DE CUISSON AUGAZ

Recommandé pour toutes les surfaces

de cuissons au gaz. Comprend bordure

d’étanchéité et attaches

Largeurs de 76 cm, 91 cm et 121 cm (30po,

36 po et 48 po)

CLAPET D’AIR DE COMPENSATION

L’utiliser pour fournir de l’air de compensation

à la demande afin de garder la maison

confortable tout en permettant à la hotte

d’offrir un rendement optimal.

La conception Directwire convient aux

hottes encastrées BEST

pour équilibrer la pression d’air intérieure

en fournissant de l’air de compensation; le

clapet s’ouvre automatiquement lorsque la

hotte est mise en marche

Conduits ronds de 20,3 cm (8 po)

et 25,4 cm (10 po) de diamètre.

Seconnecte à 2 CONTACTS sur le

PANNEAU ÉLECTRIQUE.

®

sélectionnées

CONTACTS

DU CLAPET

D’AIR DE

COMPENSATION

ACESSOIRE

ENOPTION

MODÈLE AEWD5

MODÈLE ANKD

MODÈLE AFCD

MODÈLE AVDKD8

MODÈLE AVDKD10

DESCRIPTION /

APPLICATION

CÂBLE DE RALLONGE - 1,5 M (5 PI)

S’utilise lorsque le panneau électrique

est installé à distance. Rallonge le câble

du panneau électrique de 1,5 m (5 pi).

ENSEMBLE DE RECIRCULATION

SANS CONDUIT

S’utilise lorsqu’il est impossible de poser

des conduits. Se monte dans le coup de

pied ou la base de l’armoire et se fixe

directement au ventilateur Flex modèle

PF6 à l’aide d’un conduit rond de 20,3 cm

(8 po). L’ensemble peut être tourné afin

de ne pas rejeter l’air directement à vos

pieds. Comprend un filtre de recirculation

et une plaque décorative.

FILTRE DE RECIRCULATION DE

REMPLACEMENT

Filtre de remplacement pour le filtre de

recirculation sans conduit ANKD. S’utilise

pour capter efficacement les impuretés

provenant de la cuisson.

TRANSITION DE 4,8 CM X 48,3CM

(1-7/8 PO X 19 PO) À 20,3 CM

(8PO)ROND

Transition rectangulaire à 20,3 cm (8 po)

rond pour sortie à gauche, à droite ou

vers l’arrière - avec le ventilateur Flex

modèle PF6. Peut être raccordé à la hotte

encastrée ou à un conduit rectangulaire

(AEDD2). Attaches en S comprises pour

une fixation solide.

TRANSITION DE 4,8 CM X 48,3CM

(1-7/8 PO X 19 PO) À 25,4 CM

(10PO)ROND

Transition rectangulaire à 25,4 cm (10po)

rond pour sortie à gauche, à droite ou

vers l’arrière - avec le ventilateur Flex

modèle PF6. Peut être raccordé à la hotte

encastrée ou à un conduit rectangulaire

(AEDD2). Attaches en S comprises pour

une fixation solide.

MODÈLES

ATKD30SB

ATKD36SB

ATKD48SB

JEU DE BORDURE POUR CUISINIÈRE

S’utilise avec une cuisinière autonome

lorsqu’un écart sépare l’arrière de la

cuisinière et la hotte encastrée.

Largeurs de 76 cm, 91 cm et 121 cm (30po,

36 po et 48 po).

MODÈLE AVDKD219

ADAPTATEUR RECTANGULAIRE

POUR CONDUIT DE 4,8 CM X 48,3

CM (1-7/8 PO X 19 PO)

S’utilise pour raccorder un conduit

rectangulaire de 4,8 cm x 48,3 cm

(1-7/8 po x 19 po) directement à la hotte

encastrée lors de l’utilisation d’une sortie

latérale ou arrière.

Page 24

ACESSOIRES EN OPTION

(SUITE)

Modèles D49M30SB • D49M36SB • D49M48SB

Page 24

INSTALLATION DE L’APPAREIL

ACCESSOIRE

ENOPTION

MODÈLE ATTD1

MODÈLE ACVPD8

MODÈLE ACVPD10

DESCRIPTION /

APPLICATION

CAPOT D’EXTRÉMITÉ ÉLARGI

DE +1PO - GAUCHE ET DROITE

Allonge de 2,5 cm (1 po) à gauche ou à

droite la bordure pour donner 78,7cm,

93,9 cm et 124,5 cm (31 po, 37 po

et49po).

PLAQUE DE RACCORDEMENT

POUR PANNEAU AVANT - RONDE

20,3CM(8 PO)

S’utilise à l’endroit ou un conduit rond de

20,3 cm (8 po) ou un coude se raccorde

à l’avant du boîtier d’air (installation d’un

ventilateur à distance, modèle PF6).

PLAQUE DE RACCORDEMENT

POUR PANNEAU AVANT - RONDE

25,4CM(10 PO)

S’utilise à l’endroit ou un conduit rond de

25,4 cm (10 po) ou un coude se raccorde

à l’avant du boîtier d’air (installation d’un

ventilateur extérieur ou intermédiaire).

COUDE DE CONDUIT À 90°

S’ajuste de 0° à 90°.

Fait de tôle galvanisée.

DE CUISSON

1. Alignez l’appareil de cuisson sur la hotte encastrée et fixez-le conformément aux instructions qui l’accompagnent.

Remarque : L’alignement adéquat de l’appareil de cuisson et de la hotte

encastrée est nécessaire pour garantir que rien ne nuit à l’ouverture et à la

fermeture de la cheminée d’évacuation. Il doit y avoir un écart de 0,8mm

à 1,6 mm (1/32 po à 1/16 po) entre l’arrière de la surface de cuisson et

l’avant du capot de la hotte encastrée.

MODÈLE 432 - 20,3 CM

(8 PO) ROND

MODÈLE 418 - 25,4 CM

(10 PO) ROND

MODÈLE 408 - 20,3 CM

(8 PO) ROND

MODÈLE 410 - 25,4 CM

(10 PO) ROND

MODÈLE AEDD2

LONGUEUR DE CONDUIT

ROND - 61 CM (2 PI)

Fait de tôle galvanisée.

CONDUIT RECTANGULAIRE SECTIONS DE 61 CM (2 PI) [4,8 CM

X48,3 CM (1-7/8 PO X 19 PO)]

Fait de tôle galvanisée.

Page 25

Modèles D49M30SB • D49M36SB • D49M48SB

!

!

UTILISATION ET ENTRETIEN

Page 25

Cuisson

Mettez toujours la hotte en marche avant de commencer à cuisiner

afin d’établir une circulation d’air dans la cuisine. Laissez le ventilateur

fonctionner quelques minutes après l’arrêt de la cuisinière afin de nettoyer

l’air. Ceci contribuera à maintenir la propreté de toute la cuisine.

Il est recommandé d’utiliser les brûleurs arrière pour cuisiner avec des

ustensiles hauts ou lorsque la méthode de cuisson produit beaucoup

de fumée ou de vapeur. L’utilisation combinée des brûleurs arrière et

du ventilateur à haut régime facilitera l’évacuation de la fumée et de la

vapeur par la hotte encastrée.

AVERTISSEMENT : Débranchez toujours l'alimentation

électrique avant de nettoyer ou de réparer l'appareil.

Nettoyage

OREILLES

ERGOTS

FILTRE

DÉFLECTEUR

FILTRE

DÉFLECTEUR

Réparation

Il peut être nécessaire d’enlever le système de hotte encastrée de l’armoire

afin de réparer ou remplacer des pièces comme le moteur du ventilateur

ou le mécanisme de prise d’air.

Débranchez l’alimentation électrique de la plaque de cuisson et enlevez

d’abord celle-ci. Suivez les étapes inverses de l’« INSTALLATION DU

BOÎTIER DANS L’ARMOIRE » pour en sortir la hotte encastrée.

PANNEAU

AVANT

Pour nettoyer les filtres à graisses :

Soulevez le PANNEAU AVANT et les DÉFLECTEURS et retirez-les pour

enlever les FILTRES À GRAISSE. Lavez les filtres dans une solution de

détergent doux ou au lave-vaisselle. Replacez les filtres, les déflecteurs

et le panneau avant afin d’utiliser de nouveau la hotte encastrée. Prenez

soin d’engager les ERGOTS du panneau avant derrière les OREILLES,

tel qu’illustré.

ATTENTION : Négliger d’engager correctement les ergots

peut entraîner le coincement de la cheminée d’évacuation

et l’empêcher de monter.

Pour nettoyer l’intérieur de la cheminée d’évacuation :

Soulevez le PANNEAU AVANT et les DÉFLECTEURS et retirez-les pour

enlever les FILTRES À GRAISSE. Utilisez une solution de détergent doux.

N’UTILISEZ PAS DE CHIFFONS ABRASIFS, DE LAINE D’ACIER NI DE

POUDRE À RÉCURER. Replacez les filtres, les déflecteurs et le panneau

avant afin d’utiliser de nouveau la hotte encastrée. Prenez soin d’engager

les ERGOTS du panneau avant derrière les OREILLES, tel qu’illustré.

ATTENTION : Négliger d’engager correctement les ergots

peut entraîner le coincement de la cheminée d’évacuation

et l’empêcher de monter.

Page 26

FONCTIONNEMENT

Éclairage à 2 niveaux

Commande de ventilateur à

4 vitesses

Arrêt différé de 10 minutes

Modèles D49M30SB • D49M36SB • D49M48SB

Page 26

Éclairage à 2 niveaux

Appuyez une fois pour l’éclairage à FAIBLE intensité. L’icône du

hauts’illumine.

Appuyez 2x pour l’éclairage à HAUTE intensité. L’icône du haut et du

bas s’illuminent.

Appuyez 3x pour éteindre l’éclairage.

Commande de ventilateur à 4 vitesses

Appuyez une fois pour actionner le ventilateur à BAS régime. L’icône du

quadrant supérieur droit s’illumine.

Appuyez 2x pour actionner le ventilateur à MOYEN-BAS régime. Les

icônes des quadrants supérieur droit et inférieur droit s’illuminent.

Appuyez 3x pour actionner le ventilateur à MOYEN-HAUT régime.

Les icônes des quadrants supérieur droit, inférieur droit et inférieur

gauches’illuminent.

Appuyez 4x pour actionner le ventilateur à HAUT régime. Les icônes de

tous les quadrants s’illuminent.

Appuyez 5x pour arrêter le ventilateur.

Rappel de nettoyage des

filtres après 30 heures

Abaisser la cheminée

d’évacuation

Bouton HAUT

Arrêt différé de 10 minutes

Lorsque le ventilateur est en marche, quelle que soit sa vitesse, appuyez

sur l’arrêt différé pour enclencher la minuterie de 10 minutes. Le ventilateur

s’arrêtera après 10 minutes et l’icône s’éteindra.

Pour remettre à zéro ou désactiver la minuterie, appuyez de nouveau

sur l’icône.

Rappel de nettoyage des filtres après 30 heures

Après 30 heures d’utilisation du ventilateur, l’icône de rappel de nettoyage

des filtres s’allumera.

Pour remettre le compte à zéro, touchez l’icône et maintenez-la pendant

au moins 2 secondes. Le voyant s’éteindra alors.

Abaisser la cheminée d’évacuation

Pour abaisser la cheminée d’évacuation, touchez le bouton Abaisser.

Toutes les fonctions actives s’arrêteront.

Bouton HAUT

Appuyez sur le bouton HAUT sur la bordure droite de la cheminée. Toutes

les fonctions reprendront leurs réglages précédents.

Thermostat Heat Sentry

Lorsque la température de fonctionnement est trop élevée, la vitesse du

ventilateur augmente au niveau maximal pour protéger les composantes

sensibles. L’icône du ventilateur clignote et celui-ci ne peut pas être arrêté tant que la température ne revient pas à un niveau acceptable. Le

ventilateur reviendra à la vitesse choisie et l’icône arrêtera de clignoter.

Page 27

Modèles D49M30SB • D49M36SB • D49M48SB

Page 27

PIÈCES DE RECHANGEGARANTIE