Page 1

INSTALLATION INSTRUCTIONS

CPD SERIES

Suitable for use in damp locations when installed in a GFCI protected branch

circuit. Intended for outdoor covered patio or lanai area.

!

INTENDED FOR DOMESTIC COOKING ONLY

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

HOMEOWNER: USE AND CARE INFORMATION ON PAGES 12 to 13.

BEST®; Hartford, Wisconsin www.BestRangeHoods.com 800-637-1453

BEST®; Drummondville, QC, Canada www.BestRangeHoods.com 866-737-7770

REGISTER YOUR PRODUCT ON LINE AT: www.BestRangeHoods.com/register

For additional information - visit www.BestRangeHoods.com

!

Page 2

WARNING WARNING

!

!

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address or telephone number

listed in the warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be done

by qualified personnel in accordance with all applicable

codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer’s guidelines and

safety standards such as those published by the

National Fire Protection Association (NFPA) and the

American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE) and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any solid-state speed control

device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit is not designed for use with a charcoal grille.

10. This unit must be grounded and protected by a GFCI

(Ground Fault Circuit Interrupter).

11. When applicable local regulations comprise more

restrictive installation and/or certification

requirements, the aforementioned requirements

prevail on those of this document and the installer

agrees to conform to these at his own expenses.

12. Suitable for use in damp locations only when installed

in a GFCI protected branch circuit.

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

a) Never leave surface units unattended at high

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low or

medium settings.

b) Always turn power pack ON when cooking at high

heat or when flambeing food (i.e.: Crêpes Suzette,

Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not

be allowed to accumulate on fan, filters or in exhaust

ducts.

d) Use proper pan size. Always use cookware

appropriate for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN

THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie

sheet or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. IF THE FLAMES

DO NOT GO OUT IMMEDIATELY, EVACUATE AND

CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or

towels — This could cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and you know

how to operate it.

B. The fire is small and contained in the area where

it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray, construction

dust, etc. off power unit.

3. Your insert motor has a thermal overload which will

automatically shut off the motor if it becomes

overheated. The motor will restart when it cools down.

If the motor continues to shut off and restart, have the

power pack serviced.

4. The minimum power pack distance above cooktop must

not be less than 36”.

5. Two installers are recommended because of the large

size and weight of this unit.

6. To reduce the risk of fire and to properly exhaust air,

be sure to duct air outside — Do not exhaust air into

spaces within walls or ceiling or into attics, crawl

space or garage.

7. This product is equipped with a thermostat which may

start blower automatically. To reduce the risk of injury

and to prevent power from being switched on

accidentally, switch power off at service panel and lock or

tag service panel.

8. Because of the high exhausting capacity of this unit,

you should make sure enough air is entering the

house to replace exhausted air by opening a window

close to or in the kitchen.

9. To reduce the risk of fire and electrical shock, the Best

models CPD Series should only be installed with built-in

blowers. Other blowers cannot be substituted.

10. Please read specification label on product for further

information and requirements.

- 2 -

Page 3

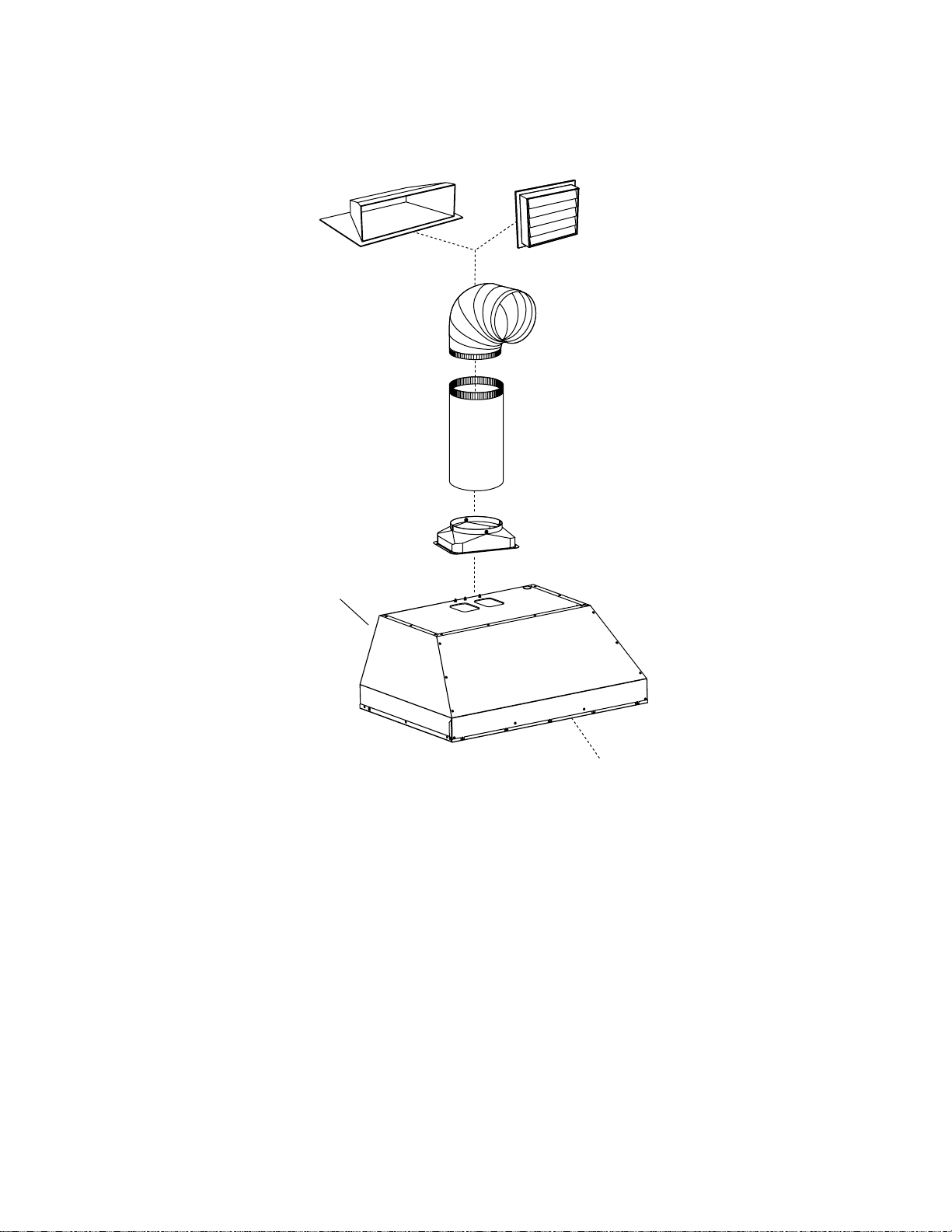

- CPD HOOD LINER SYSTEM -

MODEL 437

(HIGH CAPACITY ROOF CAP)

CPD HOOD LINER

MODEL 441

(10’’ ROUND WALL CAP)

M

ODEL 418

(10” ROUND

ADJUSTABLE ELBOW)

M

ODEL 410

(10” ROUND DUCT

— 2 FT. SECTIONS)

10” R

OUND ADAPTER

(SUPPLIED WITH HOOD LINER)

- 3 -

UAL BLOWER (1200 CFM)

D

(INCLUDED)

Page 4

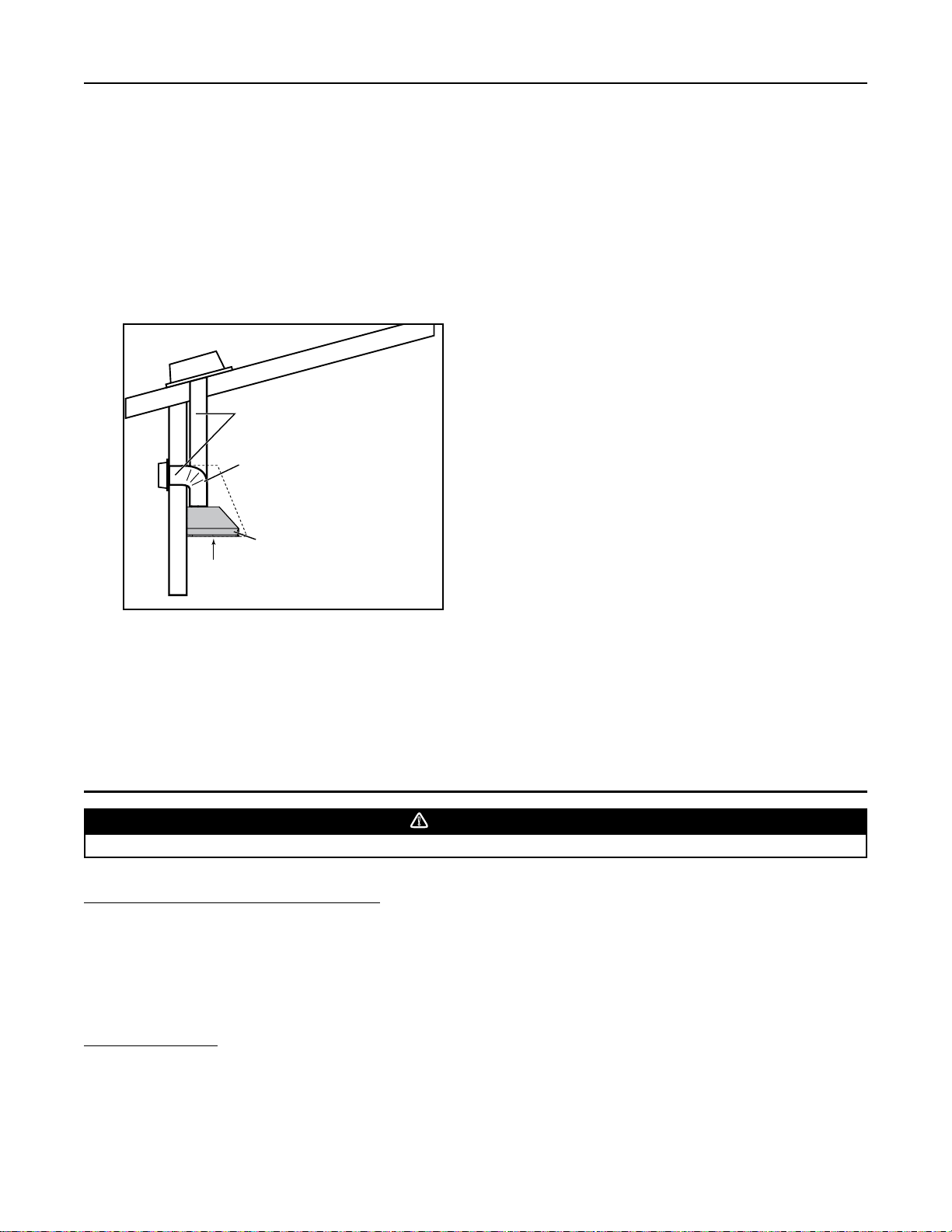

1. INSTALL DUCTWORK AND ELECTRICAL WIRING

INSTALLATION

Install proper-sized ductwork, elbows and roof or wall cap for the type of blower you are installing. Use 10” round ductwork.

Use metal foil duct tape to seal duct joints.

The minimum hood liner distance above cooktop must not be less than 36’’.

Distances over 36” are at the installer and users discretion.

Run 3-wire power supply cable to installation location. Its length should extend at least 4 feet below the bottom of the

custom hood.

10” ROUND DUCT

10” ROUND ELBOW

HOOD LINER

36” MIN.

ABOVE

COOKING SURFACE

CPD (DUAL INTERNAL BLOWER)

TYPICAL DUCTWORK

2. PREPARE THE INSTALLATION

!

WARNING

When performing installation, servicing or cleaning the unit, it is recommended to wear safety glasses and gloves.

NOTE: Before proceeding to the installation, check the contents of the box. If items are missing or damaged, contact the manufacturer.

Make sure that the following items are included:

- Hood Liner

- Accessories: • Bafflefilters(2for36’’width,3for48”and60”widths)

• Shieldedhalogenlamps(120V,50W,MR16withGU10baseor PAR16withGU10base)(2forCPDI362,

4 for all other models)

• 10”roundadapter

• Bagofpartsincluding:12-#8x½”flatheadscrews(16-forCPDI602),4-M4x6panheadscrews,

1 - suction cup tool, 3 - wire nuts

Parts sold separately:

- Ducts, elbows, wall and roof caps. Refer to pages 3 and 4 for a complete list of venting options and model numbers.

NOTE: During installation, protect countertop and/or cooktop.

- 4 -

Page 5

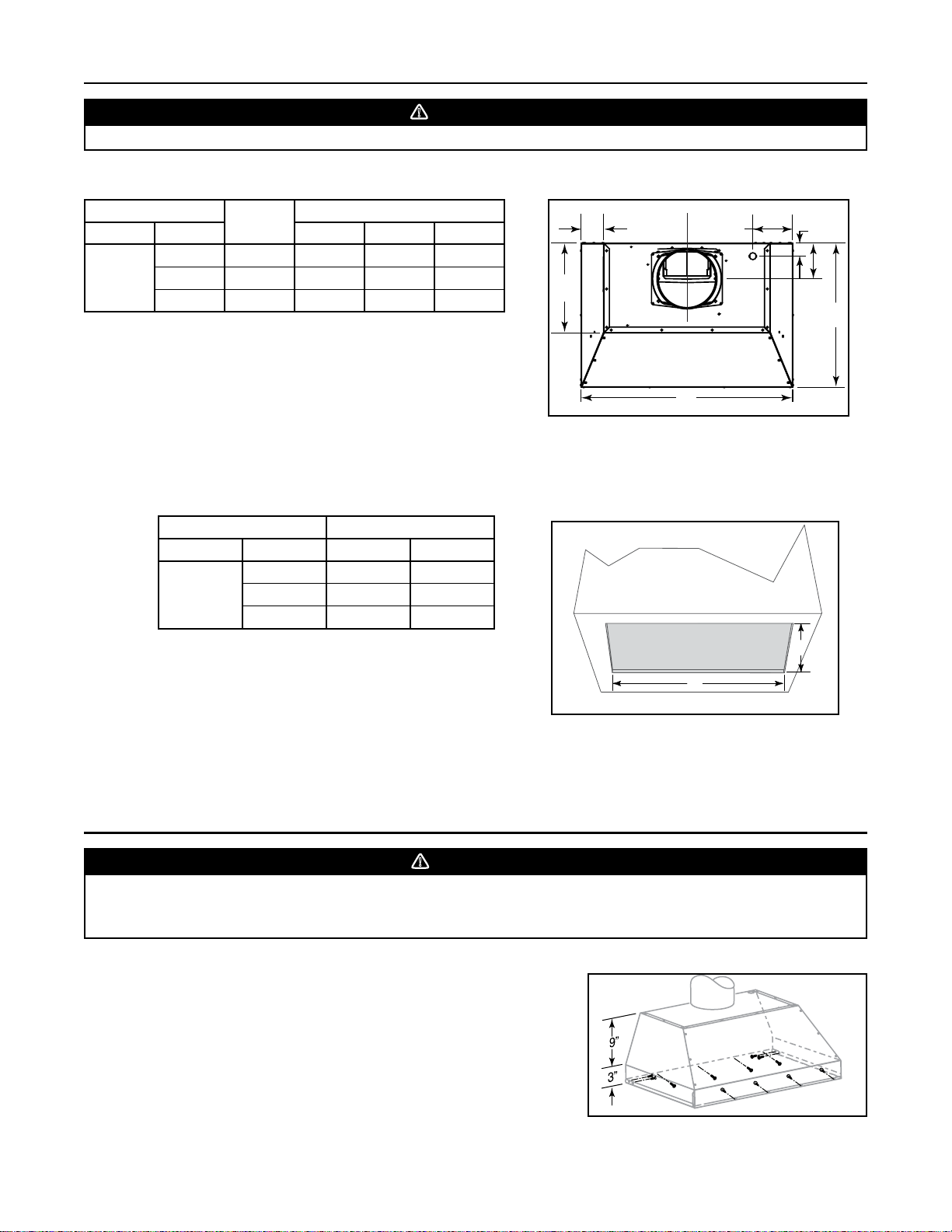

3. CUSTOM HOOD PREPARATION

!

WARNING

When building a custom hood, always follow all applicable construction codes and standards.

The custom hood must be constructed to fit the size and shape of the CPD hood liner.

See chart and illustration for details.

HOOD LINER TOTAL

SERIES MODEL *A *B C

CPDI362 73

CPD

CPDI482 88

CPDI602 102

WEIGHT

LB 22

LB 22

LB 22

* Dimensions A and B include rivets head.

RANGE HOOD DIMENSIONS

1

⁄2” 343⁄8” 57⁄8”

1

⁄2” 463⁄8” 57⁄8”

1

⁄2” 587⁄8” 57⁄8”

12”

3”

REAR

B

C

L

1

5

/8”

FRONT

2”

C

A

To minimize the gap around the hood liner, take actual width and depth measurements of hood liner and add 1/16” to get D and

E measurements. Cut the hole in the bottom of the cabinet according to dimensions. See chart and illustration for details.

HOOD LINER CUTOUT DIMENSIONS

SERIES MODEL D E

9

⁄16” 347⁄16”

9

⁄16” 467⁄16”

9

⁄16” 5815⁄16”

D

CPD

CPDI362 22

CPDI482 22

CPDI602 22

E

HD0367

4. MOUNT CUSTOM HOOD INTERNAL FRAMEWORK

WARNING

!

The wood hood must be positively secured to wall studs or other wooden framework behind the drywall.

Make sure it is capable of supporting its own weight and the weight of the CPD. Failure to do so may

cause personal injury or damage to countertop or cooktop.

The CPD hood liner is supported by the custom hood internal framework with (12)#8 x ½” flat-head screws (16 screwsfor

CPDI602) provided in parts bag.

Since the CPD hood liner mounting holes are located in front and rear sides (see

illustration at right), plan to install wood frame at front and sides for support.

- 5 -

Page 6

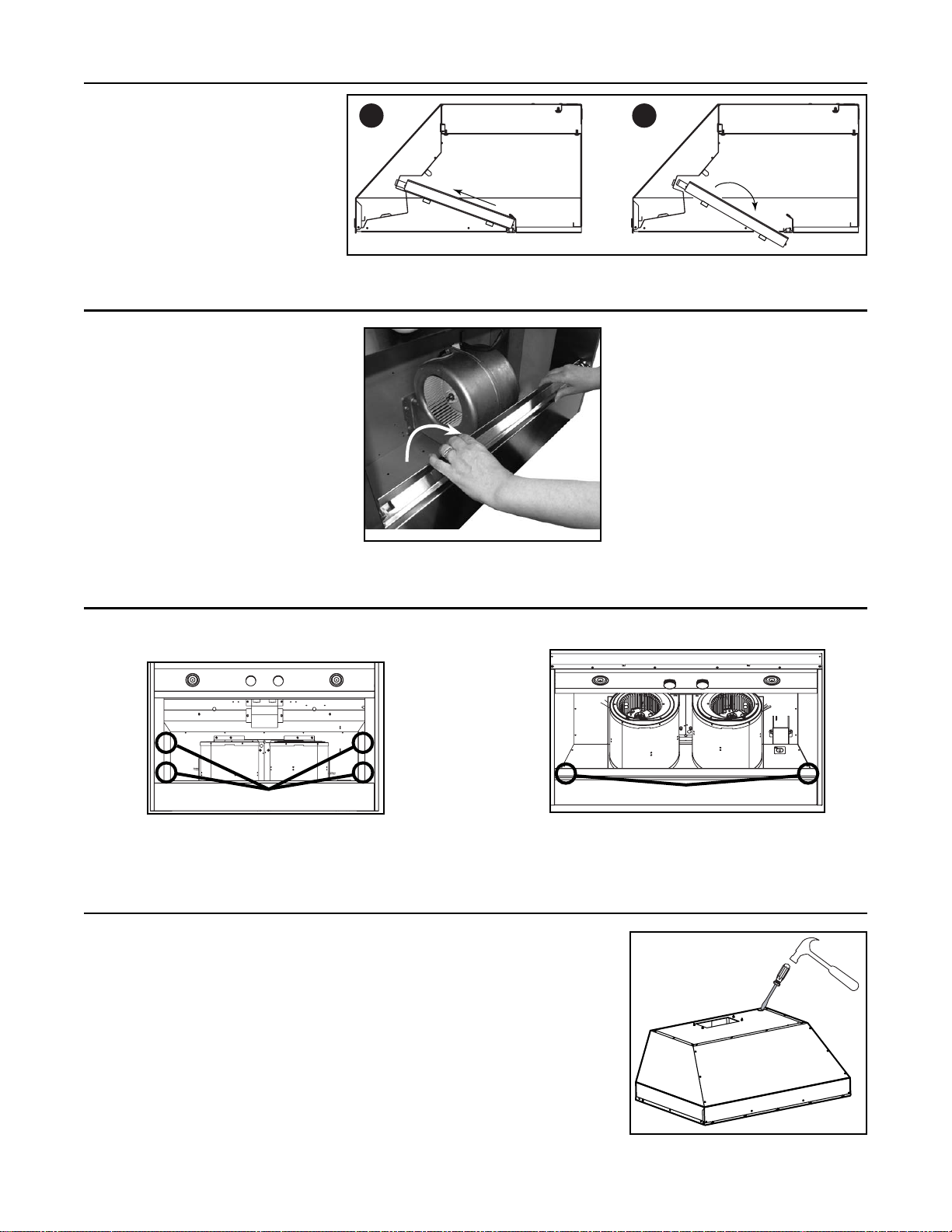

5. REMOVE BAFFLE FILTERS

Remove tape on filters. Remove filters

from power pack and set aside. It is

recommended to start with the center

filters.

1 2

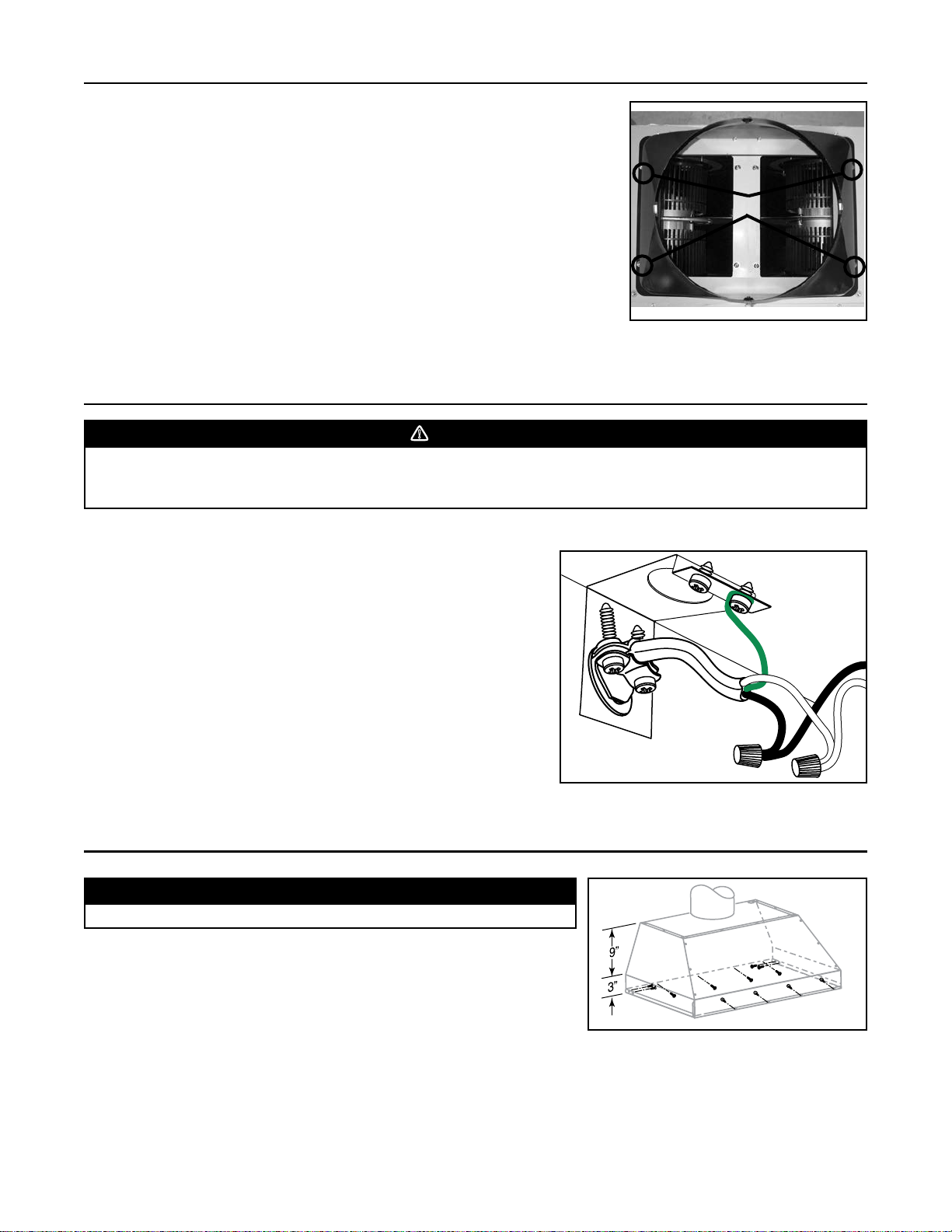

6. REMOVE GREASE DRIP RAIL

A. Lift grease drip rail to disengage it

from the bottom panel.

(Blower shown is for reference only

and does not represent actual

blower in this product.)

HD0291

A

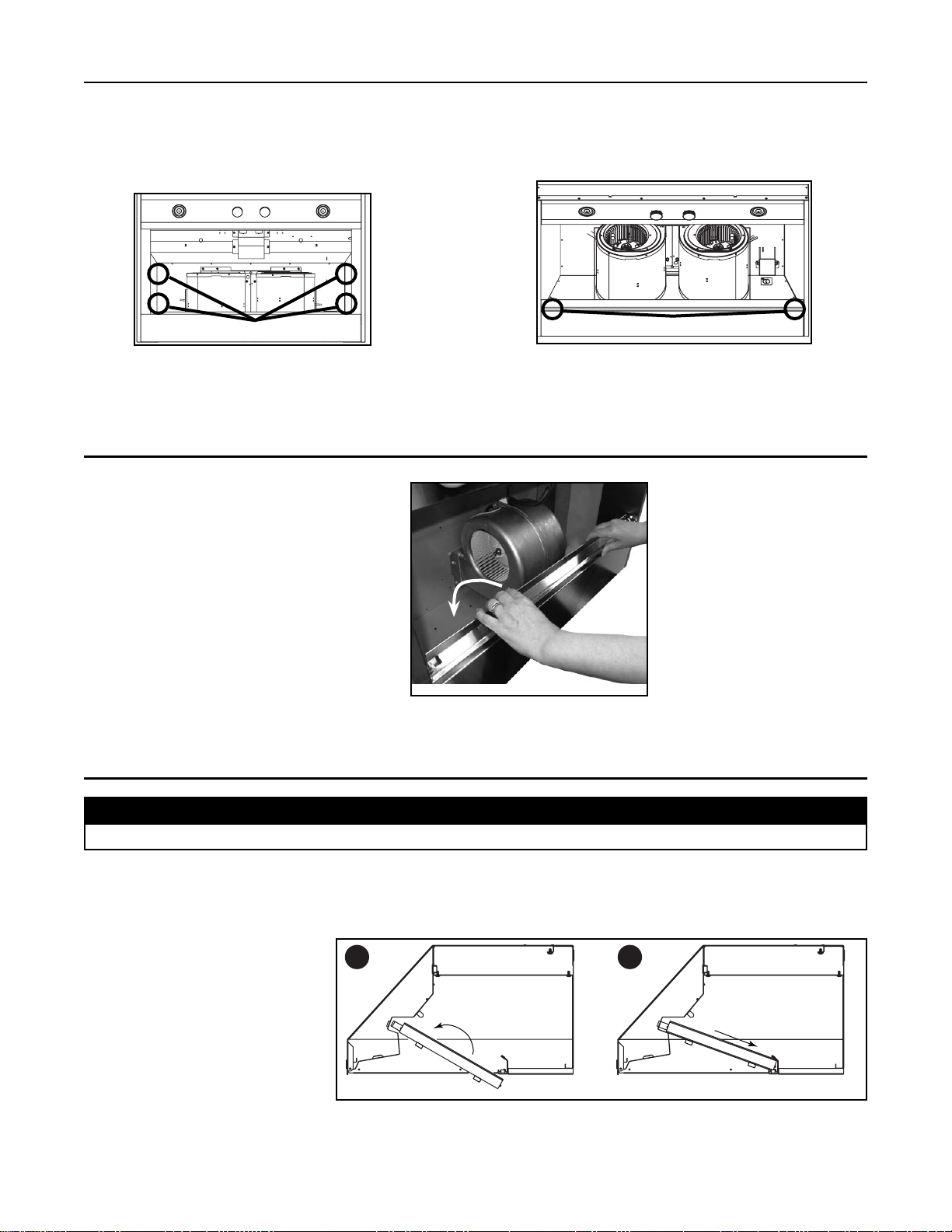

7. REMOVE THE BOTTOM PANEL

Using a Phillips screwdriver, remove both bottom filter filler

panels.

RETAINING SCREW LOCATIONS

BOTTOM VIEW

Disassemble bottom panel, lift up and out, and set aside.

RETAINING SCREW LOCATIONS

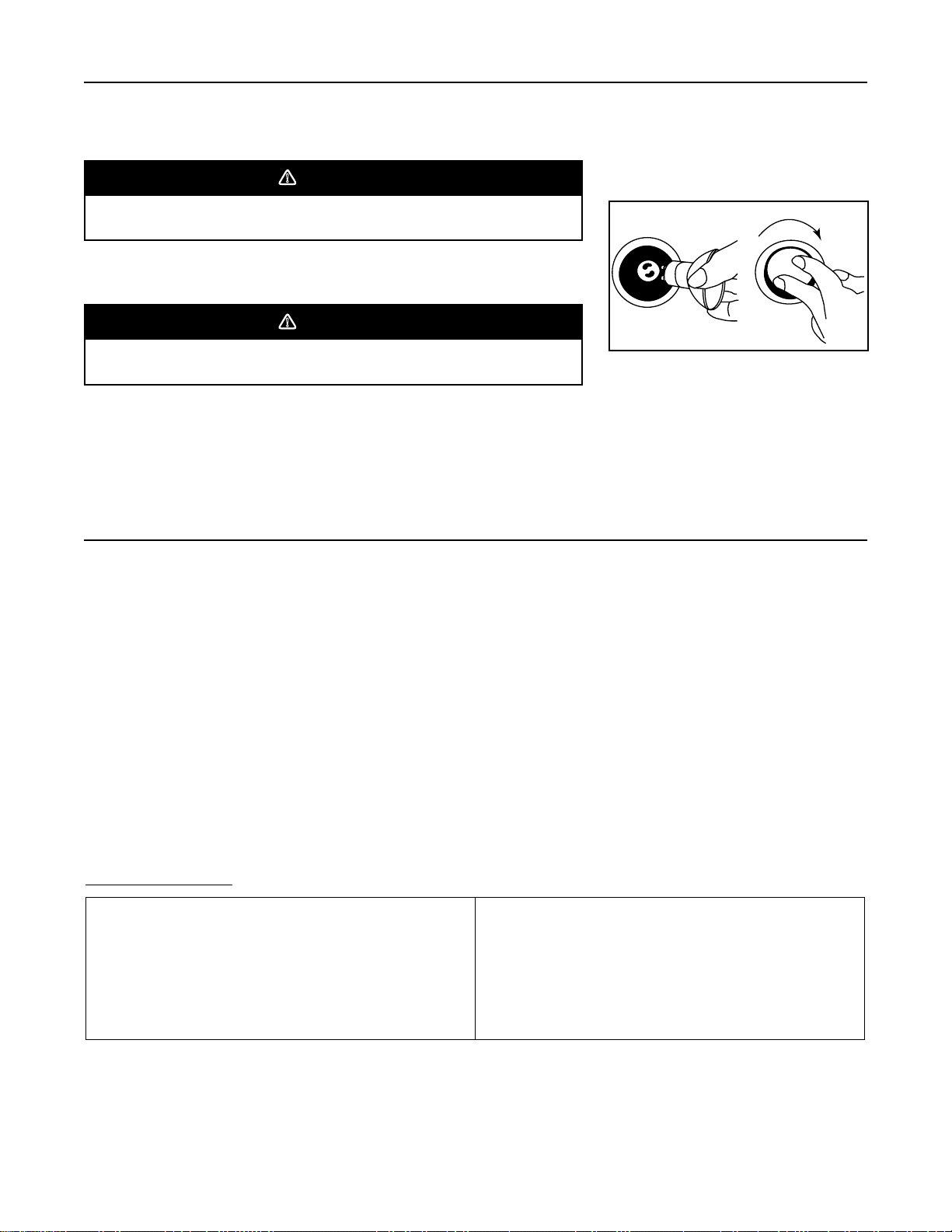

8. REMOVE THE KNOCK-OUT OPENING

From inside the hood liner, remove the wiring cover and set aside. Punch out the

electrical knockout hole on top of the hood. Install the wire clamp (included in parts bag).

BOTTOM VIEW

- 6 -

HR0027

Page 7

9. INSTALL THE 10” ADAPTER

Using (4) no. M4 x 6 screws from parts bag, assemble the adapter on the top of the

hood liner. Seal all joints with metal foil duct tape to eliminate air leaks.

MOUNTING SCREW LOCATION

HJ0026

10. CONNECT THE WIRING

!

WARNING

Risk of electric shock. Electrical wiring must be done by qualified personnel in accordance with all

applicable codes and standards. Before connecting wires, switch power off at service panel and lock

service disconnecting means to prevent power from being switched on accidentally.

Position the hood liner below the installed custom hood.

INTERNAL BLOWERS: Insert the house wiring cable through the wire

clamp previously installed in step 8. Tighten the

wire clamp to secure the cable. Connect cable into

wiring box using wire connectors. Connect BLACK

to BLACK, WHITE to WHITE and GREEN or bare

wire under GREEN ground screw. DO NOT

FORGET TO CONNECT THE GROUND. Reinstall

wiring cover.

HE0059

11. INSTALL THE POWER PACK

CAUTION

Take care not to kink ducting when installing the power pack.

Using provided screws, install the hood liner inside the custom hood. Start with 2

screws on front corners, then use 4 screws for sides and use the remaining

screws to finalize securing the front hood liner. (See figure at right for mounting

screw specific locations.)

Make sure the adapter/damper (or the adapter) enters the ducting. When there is

access to the top of the hood liner, seal connections with metal foil duct tape.

- 7 -

Page 8

12. REINSTALL BOTTOM PANEL

Lift the bottom panel and engage the hood liner metal tabs in

bottom panel slots.

Secure the bottom panel to the hood liner using its screws.

RETAINING SCREW LOCATIONS

BOTTOM VIEW

13. REINSTALL GREASE DRIP RAIL

A. Center the grease drip rail over the bottom

panel edge and drop it in place.

Re-install filter filler panels as shown.

RETAINING SCREW LOCATIONS

BOTTOM VIEW

A

(Blower shown is for reference only

and does not represent actual

blower in this product.)

HD0291

14. REINSTALL BAFFLE FILTERS

CAUTION

Remove protective plastic film covering baffle filters before installing them.

NOTE: It is recommended to install side filters first and finish with center filter(s).

1. Insert one end of baffle filter into

the front channel of the hood.

2. Raise the other end toward the

inside of hood liner and insert in

the grease drip rail of the hood

liner.

1 2

Replacement filters are available

from your dealer. See label

inside hood liner for size and

part number.

- 8 -

Page 9

15. LIGHT BULBS

12

This power pack must use shielded halogen lamps (120 V, 50 W PAR16 with GU10 base, 2 for CPDI362 and 4 for the

CPDI482 & CPDI602), included.

NOTE: Before using lamps, remove shipping tape on them (if present).

!

WARNING

In order to prevent the risk of personal injury, do not install a lamp

not suitable for use in enclosed fixtures.

1. Install the lamps by placing the bulb leads into their grooves in the socket.

2. Gently push upwards and turn clockwise until secure.

!

WARNING

In order to prevent the risk of personal injury, do not install a lamp

not suitable for use in enclosed fixtures.

To remove lamps, gently push upwards and turn counterclockwise to disengage bulb leads from their grooves.

NOTE: If need be, use a rubber dishwashing glove to add grip when removing the bulb; or use suction cup tool available from

®

BEST

to ease removal of the bulbs. Contact BEST® Technical Support at 1-800-637-1453 to order suction cup tool,

part number 99526707.

HO0090

16. USE AND CARE

Baffle Filters

The baffle filters should be cleaned frequently. Use a warm detergent solution. Wash more often if your cooking style generates

greater grease — like frying foods or wok cooking.

Remove baffle filters by pushing them towards the front of hood liner and rotating filters downward. Baffle filters are dishwasher

safe. Allow filters to dry completely before reinstalling them.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of the filter may occur if using

phosphate detergent or as a result of local water conditions — but this will not affect filter performance. This discoloration is not

covered by the warranty.

Grease Drip Rail

The grease drip rail should be cleaned frequently. Remove it from the hood liner (see step 6 on page 6) and use a warm detergent

solution. As with the baffle filters, wash more often if your cooking style generates greater grease — like frying foods or wok

cooking. Allow grease drip rail to dry completely before reinstalling it.

Interior Blowers Cleaning

Remove the filters in order to access the blowers. Vacuum blowers to clean. Do not immerse in water.

Hood Liner Cleaning

Stainless steel cleaning:

Do:

• Regularly wash with clean cloth or rag soaked with warm

water and mild soap or liquid dish detergent.

• Always clean in the direction of original polish lines.

• Always rinse well with clear water (2 or 3 times) after

cleaning. Wipe dry completely.

• You may also use a specialized household stainless steel

cleaner

Don’t:

• Use any steel or stainless steel wool or any other scrapers

to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues reach

the hood. During construction/renovation, cover the power

pack to make sure no dust sticks to stainless steel surface.

Avoid when choosing a detergent:

- Any cleaners that contain bleach will attack stainless steel.

- Any products containing: chloride, fluoride, iodide, bromide will deteriorate surfaces rapidly.

- Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc., are highly explosive and should

never be used close to a range.

- 9 -

Page 10

17. OPERATION

Always turn your hood liner on before you begin cooking to establish an air flow in the kitchen. Let the blower run for a few

minutes to clear the air after you turn off the range. This will help keep the whole kitchen cleaner and brighter.

COOKTOP LIGHTING (HALOGEN)

The halogen lighting is controlled by the dial.

• POSITION 1: OFF

• POSITION 2: LOW

• POSITION 3: HIGH

• POSITION 4: OFF

• Use 120 V, 50 W, MR16 with GU10 base or PAR16 with GU10 base, shielded halogen lamps (included).

BLOWER

The blower is controlled by the dial.

• POSITION 1: OFF

• POSITION 2: LOW

• POSITION 3: MEDIUM

• POSITION 4: HIGH

• HEAT SENTRY™

This hood liner is equipped with a Heat Sentry™ thermostat. This thermostat is a device that will start or speed up the

blower if it senses excessive heat above the cooking surface.

1) If blower is OFF - it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting – it turns the blower up to HIGH speed.

When the temperature level drops to normal, the blower will return to its original setting.

!

WARNING

The HEAT SENTRY can start the blower during a range top fire or other excessive heat situations even if

the hood is turned off. In this case, it is impossible to turn the blower OFF with blower switch. If you must

stop the blower, do it from the main electrical panel.

- 10 -

Page 11

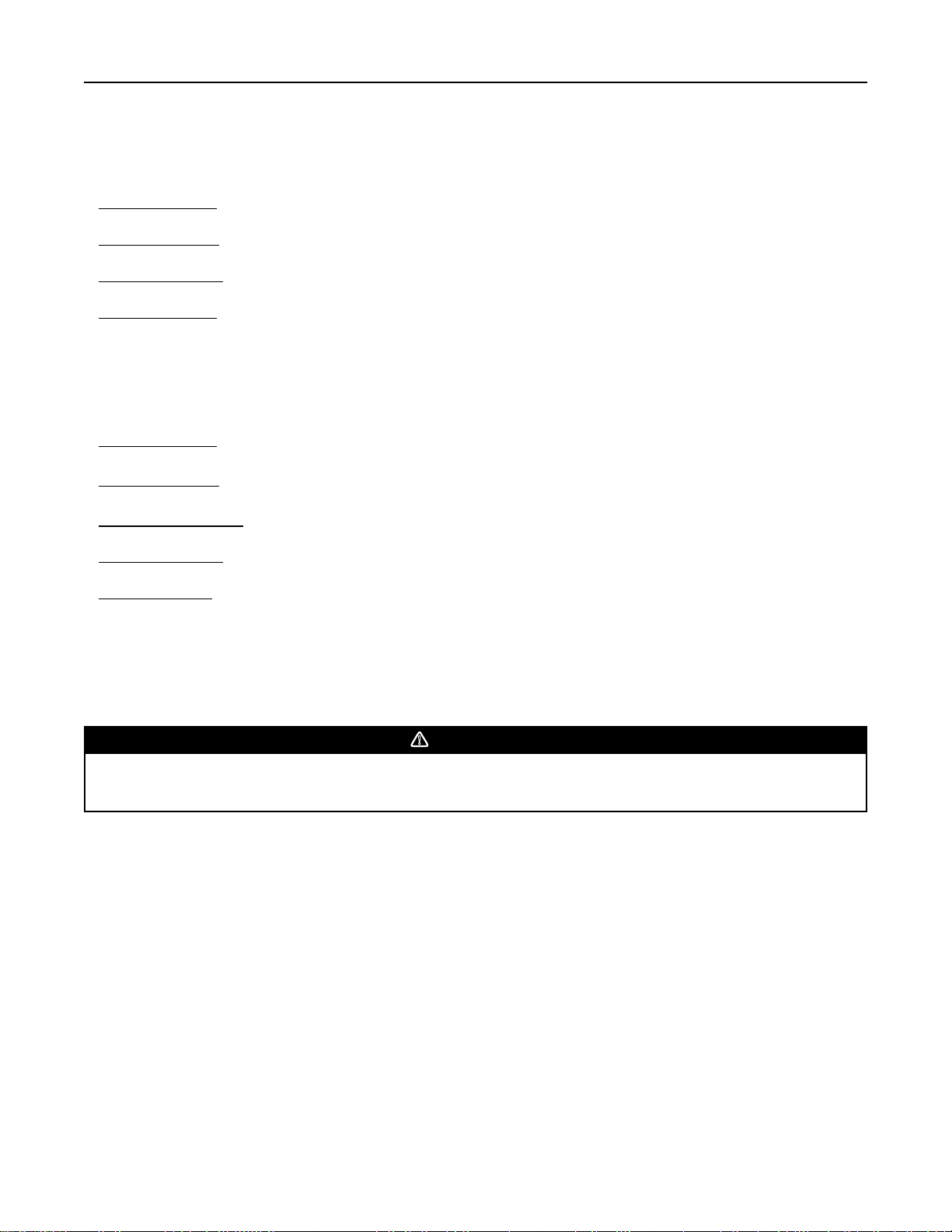

18. WIRING DIAGRAM

MODEL CPDI362SB MODELS CPDI482SB & CPDI602SB

19. WARRANTY

WARRANTY

ONE-YEAR LIMITED WARRANTY

Broan-NuTone LLC (“Broan-NuTone”) warrants to the original consumer purchaser of its products that such products will be

free from defects in materials or workmanship for a period of one year from the date of original purchase. THERE ARE NO

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is

found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES AND BULBS, FUSES, FILTERS,

DUCTS, ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a) normal

maintenance and service or (b) any products or parts which have been subject to misuse, negligence, accident, improper

maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation

instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states or

provinces do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAI R OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE

PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WA RRANTY. BROAN-NUTONE SHALL NOT BE LIABLE

FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT

USE OR PERFORMANCE. Some states or provinces do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state or province to

another. Any modification performed on this product without the authorization of Broan-NuTone will void this warranty. This

warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number stated below, (b) give

the model number and part identification and (c) describe the nature of any defect in the product or part. At the time of

requesting warranty service, you must present evidence of the original purchase date.

BEST®, 926 W. State Street, Hartford, WI 53027 (1-800-637-1453)

BEST®, 550 Lemire Blvd., Drummondville, QC, Canada (1-866-737-7770)

www.BestRangeHoods.com

- 11 -

Page 12

20. SERVICE PARTS

Best CPD Series

7, 8

1

2

3

4

13

12

6

5

10

9

KEY

NO.

P

ART NO. DESCRIPTION

1 97018874 A

2 98010930

98010931

3 97018875 I

4 99271454 C

5 99271455 C

6 V05921 S

7 98010933 F

8 98010936 F

9 97018876 B

10 98010934 F

11 99840023 B

12 97018879 L

13 99271456 R

* 97018878 P

* 99526707 S

* NOT SHOWN.

11

QTY. (POWER PACK WIDTH)

36” 48” 60”

DAPTER 10” ROUND 1 1 1

REASE RAIL 36”

G

G

REASE RAIL 48" & 60”

NTERNAL BLOWER (2 REQUIRED) 2 2 2

APACITOR 2 2 2

ONTROL BOARD W/ HEAT SENTRY 1 1 1

HIELDED HALOGEN LAMPS (120 V, 50 W, GU-10) 2 4 4

ILTER FILLER (PAIR) (FOR 36") 1 - -

ILTER FILLER (PAIR) (FOR 60") - - 1

AFFLE FILTER (INCLUDES ITEM 11) 2 3 3

ILTER SPRING (SET OF 6) 1 1 1

AFFLE FILTER KNOB WITH SCREWS (PAIR) 2 3 3

AMP SHELL ASSEMBLY 2 4 4

OTARY SWITCH 2 2 2

ARTS BAG 1 1 1

UCTION CUP BULB REMOVAL TOOL 1 1 1

1

-

-

1

-

1

- 12 -

99044954B

Page 13

DIRECTIVES D'INSTALLATION

SÉRIE CPD

Peut être installé dans des endroits humides si branché sur un circuit à

disjoncteur de fuite à la terre (GFCI). S’utilise à l’extérieur sur les terrasses

couvertes ou vérandas.

!

POUR USAGE DOMESTIQUE SEULEMENT

LIRE CES DIRECTIVES ET LES CONSERVER

INSTALLATEUR : VEUILLEZ REMETTRE CE MANUEL AU PROPRIÉTAIRE.

PROPRIÉTAIRE : VOIR LE MODE D'UTILISATION ET D'ENTRETIEN AUX

PAGES 12 ET 13.

BEST®; Hartford, Wisconsin www.BestRangeHoods.com 800-637-1453

®

BEST

; Drummondville, QC, Canada www.BestRangeHoods.com 866-737-7770

ENREGISTREZ VOTRE PRODUIT EN LIGNE À : www.BestRangeHoods.com/register

Pour de plus amples informations - visitez www.BestRangeHoods.com

!

Page 14

AVERTISSEMENT AVERTISSEMENT

!

!

AFIN DE RÉDUIRE LES RISQUES D'INCENDIE,

DE CHOC ÉLECTRIQUE OU DE BLESSURES

CORPORELLES, VEUILLEZ OBSERVEZ LES

DIRECTIVES SUIVANTES :

1. N'utilisez cet appareil que de la manière prévue

par le fabricant. Si vous avez des questions,

communiquez avec le fabricant à l'adresse ou au

numéro de téléphone indiqués dans la garantie.

2. Avant de procéder à la réparation ou à l'entretien

de l'appareil, coupez l'alimentation du panneau

électrique et verrouillez le dispositif de sectionnement

de manière à empêcher que le courant ne soit

accidentellement rétabli. S'il est impossible de

verrouiller l'interrupteur principal, fixez solidement un

message d'avertissement, par exemple une étiquette,

sur le panneau électrique.

3. L'installation et les branchements électriques

doivent êtreeffectués par un personnel compétent,

conformément aux normes et aux codes en vigueur,

y compris les normes et les codes du bâtiment relatifs

à la résistance au feu.

4. Pour éviter les refoulements, l'apport d'air doit être

suffisant pour brûler les gaz produits par les appareils à

combustion et les évacuer dans le conduit de fumée

(cheminée). Respectez les directives du fabricant de

l'appareil de chauffage et les normes de sécurité,

notamment celles publiées par la National Fire Protection

Association (NFPA), l'American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE)

et les codes des autorités locales.

5. Veillez à ne pas endommager le câblage électrique

ou d'autres équipements non apparents lors de la

découpe ou du perçage du mur ou du plafond.

6. Les ventilateurs canalisés doivent toujours rejeter l'air

à l'extérieur.

7. N'utilisez pas de commande de régime à semi-

conducteurs conjointement avec cet appareil.

8. Pour réduire les risques d'incendie, utilisez seulement

des conduits en métal.

9. Cet appareil n’est pas conçu pour être utilisé avec un

gril au charbon de bois.

10. Cet appareil doit comporter une mise à la terre et être

protégé par un circuit à disjoncteur de fuite à la

terre(GFCI).

11. Lorsque les législations fédérales, provinciales ou

d'état comportent des exigences plus sévères quant à

l'installation et/ou l'homologation, celles-ci auront

préséance sur celles de ce document et l'installateur

s'engage à s'y conformer à ses frais.

12. Peut être installé dans des endroits humides si

branché sur un circuit à disjoncteur de fuite à la

terre(GFCI).

POUR RÉDUIRE LES RISQUES D'INCENDIE

CAUSÉS PAR DE LA GRAISSE SUR LE PLAN

DECUISSON :

a) Ne laissez jamais les éléments de surface allumés à

haute température. Les débordements peuvent

causer de la fumée et occasionner des écoulements

de graisse inflammables. L'huile doit être chauffée

graduellement à basse ou à moyenne température.

b) Mettez toujours la hotte en MARCHE lors de la cuisson

à feu vif ou lors de la cuisson d'aliments à flamber

(crêpes Suzette, cerises jubilé, bœuf au poivre flambé).

c) Nettoyez souvent la hotte. Ne laissez pas la graisse

s'accumuler sur le ventilateur, les filtres ou les

conduits d’évacuation.

d) Utilisez des casseroles de dimension appropriée.

Utilisez toujours une batterie de cuisine adaptée à la

dimension de la surface chauffante.

OBSERVEZ LES CONSIGNES SUIVANTES AFIN DE

RÉDUIRE LES RISQUES DE BLESSURES

ORPORELLES EN CAS D'INCENDIE CAUSÉ PA R

DE LA GRAISSE SUR LE PLAN DE CUISSON* :

1. ÉTOUFFEZ LES FLAMMES à l'aide d'un couvercle

étanche, d'une tôle à biscuits ou d'un plateau en métal

puis éteignez le brûleur. FAITES ATTENTION DE NE

PAS VOUS BRÛLER. SI LES FLAMMES NE

S'ÉTEIGNENT PAS IMMÉDIATEMENT, QUITTEZ LES

LIEUX ET APPELEZ LE SERVICE DES INCENDIES.

2. NE SOULEVEZ JAMAIS UNE CASSEROLE EN

FLAMMES – vous pourriez vous brûler.

3. N'UTILISEZ PAS D'EAU, ni de linges ou de serviettes

mouillés – une violente explosion de vapeur

pourraitsurvenir.

4. Utilisez un extincteur SEULEMENT si :

A. Vous savez qu'il est de classe ABC et vous

connaissez déjà son mode de fonctionnement.

B. L'incendie n'est pas très important et ne se

propage pas.

C. Vous avez déjà téléphoné au service des incendies.

D. Vous pouvez combattre l'incendie en faisant dos à

une sortie.

* Conseils tirés de la publication de la NFPA « Kitchen Fire

Safety Tips ».

ATTENTION

1. Pour ventilation générale uniquement. N'utilisez pas

cet appareil pour évacuer des matières ou des

vapeurs dangereuses ou explosives.

2. Pour éviter d'endommager les roulements de moteur,

de déséquilibrer les pales ou de les rendre bruyantes,

débarrassez l'appareil de la poussière de plâtre,

deconstruction, etc.

3. Le moteur du ventilateur est muni d'un dispositif

de protection de surcharge électrique qui coupe

automatiquement le moteur en cas de surchauffe.

Il seremet en marche lorsqu'il a refroidi. Faitesréparer

la hotte si le moteur continue à fonctionner

parintermittence.

4. La distance minimale de la hotte au-dessus de la

surface de cuisson ne doit pas être inférieure à 91 cm

(36 po).

5. Il est recommandé que les installateurs soient deux,

compte tenu de la taille et du poids de cette hotte.

6. Pour réduire les risques d'incendie et obtenir une

évacuation adéquate de l'air, acheminez les conduits

jusqu'à l'extérieur – n'évacuez pas l'air dans des

interstices entre les murs ou le plafond, ni dans

ungrenier, un vide sanitaire ou un garage.

7. Ce produit est doté d'un thermostat qui peut faire

démarrer automatiquement le ventilateur. Pour réduire

les risques de blessures, coupez l'alimentation sur le

panneau électrique et verrouillez-le ou accrochez-y

une étiquette de manière à éviter que le courant ne

soit rétabli par accident.

8. En raison de la grande capacité d’évacuation de cette

hotte, vous devez vous assurer qu’il y a suffisamment

d’air qui pénètre dans la maison pour remplacer l’air

évacué en ouvrant une fenêtre à proximité ou dans

lacuisine.

9. Pour réduire les risques d’incendie et de choc électrique,

les modèles Best de la Série CPD ne doivent être

installés qu’avec leurs ventilateurs intégrés. Aucun autre

ventilateur ne peut être substitué.

10. Veuillez lire l'étiquette de spécifications du produit

pour obtenir plus de renseignements, notamment sur

les exigences.

- 14 -

Page 15

- SYSTÈME DE HOTTE CPD À DOUBLE PAROI -

ODÈLE 441

MODÈLE 437

(CAPUCHON DE TOIT

À GRANDE CAPACITÉ)

M

(CAPUCHON MURAL ROND

DE 25 CM [10 PO])

M

ODÈLE 418

(COUDE ROND AJUSTABLE

DE 25 CM [10 PO])

ODÈLE 410

M

(CONDUIT ROND DE 25 CM [10 PO]

– SECTIONS DE 61 CM [2 PI])

A

DAPTATEUR ROND DE 25 CM (10 PO)

(FOURNI AVEC LA PAROI DE LA HOTTE)

PAROI DE HOTTE CPD

ENTILATEUR DOUBLE

V

3,4 CM3/MIN (1200 PI3/MIN)

(INCLUS)

- 15 -

Page 16

1. INSTALLATION DES CONDUITS ET DU CÂBLAGE ÉLECTRIQUE

INSTALLATION

Installez des conduits, coudes et capuchon de toit ou mural de la taille appropriée pour le type de ventilateur que

vousinstallez. Utilisez du conduit rond de 25 cm (10 po). Scellez tous les joints avec du ruban pour conduit.

La distance minimale de la paroi de hotte au-dessus de la surface de cuisson ne doit pas être inférieure

à 91cm(36 po).

Une distance de plus de 91 cm (36 po) est laissée à la discrétion de l'installateur et des utilisateurs.

Acheminez un câble à trois fils jusqu’au lieu d’installation. Sa longueur doit dépasser d’au moins 122 cm (4 pi) en dessous

la hotte.

CONDUIT ROND DE 25 CM (10 PO)

COUDE ROND DE 25 CM (10 PO)

PAROI DE HOTTE

MINIMUM 91 CM

(36 PO) AU-DESSUS

DE LA SURFACE DE CUISSON

CANALISATION TYPE D’UNE HOTTE CPD

(À DOUBLE VENTILATEUR INTERNE)

2. PRÉPARATION DE L'INSTALLATION

AVERTISSEMENT

Il est conseillé de porter des lunettes de sécurité et des gants lors de l'installation, de l'entretien ou du nettoyage

de l'appareil.

REMARQUE : Avant d’entreprendre l’installation, vérifiez le contenu de la boîte. Si des éléments sont manquants ou endommagés,

contactez le fabriquant.

Vérifiez que l'emballage contient les pièces suivantes :

- Paroi de hotte

- Accessoires: • Filtresdedéflecteurs(2pourunelargeur de91cm[36 po],3pourune largeurde122 cm [48po]oude

152cm[60po])

• Ampoules halogènes à écran (120 V, 50 W, MR16 à culot GU10 ou PAR16 à culot GU10) (2 pour le

modèleCPDI362, 4 pour les autres modèles)

• Adaptateurrondde25cm(10po)

• Sachetdepiècesincluant:12 -visàtêteplaten°8x ½po(16 -pourle modèleCPDI602),4-visàtête

cylindrique M4 x 6, 1 - outil à ventouse, 3 - serre-fils

Pièces vendues séparément :

- Conduits, coudes, capuchon de toit. Consultez les pages 3 et 4 pour la liste complète des options de ventilation et les numéros

de modèle.

!

REMARQUE : Au cours de l’installation, protégez le comptoir et la surface de cuisson.

- 16 -

Page 17

3. PRÉPARATION D’UNE HOTTE SUR MESURE

!

!

AVERTISSEMENT

Lors de la fabrication d’une hotte sur mesure, suivez les codes du bâtiment et les normes en vigueur.

La hotte sur mesure doit être fabriquée de manière à convenir à la taille et à la forme de la paroi de hotte CPD.

Voir le tableau et l’illustration pour plus de détails.

3”

ARRIÈRE

1

C

5

/8”

L

2”

C

PAROI DE HOTTE POIDS TOTAL DIMENSIONS DE LA HOTTE

SÉRIE MODÈLE *A *B C

CPDI362 33 kg

CPDI482 40 kg (88

CPD

CPDI602 46 kg (102

(73

LB)

57,2 cm (22

LB)

57,2 cm (22

LB)

57,2 cm (22

1

⁄2 po) 87,3 cm (34 3⁄8 po) 14,9 cm (5 7⁄8 po)

1

⁄2 po) 117,8 cm (46 3⁄8 po) 14,9 cm (5 7⁄8 po)

1

⁄2 po) 149,5 cm (58 7⁄8 po) 14,9 cm (5 7⁄8 po)

12”

A

* Les dimensions A et B comprennent les têtes de rivets.

B

AVANT

Pour minimiser l’écart autour de la paroi de la hotte, prenez les mesures réelles de la largeur et de la profondeur de la paroi

dela hotte et ajoutez 1,6 mm (1/16 po) aux mesures D et E. Découpez l’ouverture au bas de l’armoire selon ces dimensions.

Voir le tableau et l’illustration pour plus de détails.

PAROI DE HOTTE DIMENSIONS DE L’OUVERTURE

SÉRIE MODÈLE D E

9

⁄16 po) 87,5 cm (34 7⁄16 po)

9

⁄16 po) 118,0 cm (46 7⁄16 po)

9

⁄16 po) 149,7 cm (58 15⁄16 po)

D

CPD

CPDI362

CPDI482

CPDI602

57,3 cm (22

57,3 cm (22

57,3 cm (22

E

HD0367

4. ASSEMBLAGE DU CADRE INTERNE DE LA HOTTE SUR MESURE

AVERTISSEMENT

La hotte en bois doit être solidement fixée aux montants du mur ou à d’autres pièces de charpente

derrière la cloison sèche. Assurez-vous qu’elle est capable de supporter son propre poids plus celui de

la hotte CPD. Toute négligence à cet égard peut entraîner des blessures personnelles ou endommager le

comptoir ou la surface de cuisson.

LaparoidelahotteCPDestsupportéeparlecadreinternedelahottesurmesureavecdouze(12)visàtêteplaten°8x½po

(16 vis pour CPDI602) fournies dans le sachet de pièces.

Puisque les trous de fixation de la paroi de la hotte sont situés à l’avant et à

l’arrière (voir l’illustration à droite), prévoyez d’installer un cadrage de bois à

l’avant et à l’arrière pour la supporter.

- 17 -

Page 18

5. ENLEVER LES FILTRES DE DÉFLECTEURS

Enlevez le ruban adhésif des filtres.

Enlevez les filtres de la hotte et mettezles de côté. Il est conseillé de commencer par les filtres du centre.

1 2

6. ENLEVER LA GOUTTIÈRE À GRAISSES

A. Soulevez la gouttière pour la dégager du

panneau du fond.

(Le ventilateur, montré, est pour

référence seulement et ne représente

pas le véritable soufflerie dans ce

produit.)

HD0291

A

7. ENLEVER LE PANNEAU INFÉRIEUR

À l’aide d’un tournevis cruciforme, enlevez les filtres

inférieurs et les panneaux de filtre.

EMPLACEMENT DES VIS

VUE DE DESSOUS

Démontez le panneau inférieur, soulevez-le et mettez-le de côté.

8. ENLEVER L’OUVERTURE PRÉAMORCÉE

De l’intérieur de la paroi de la hotte, enlevez le couvercle de câblage. Mettez-les de côté.

Dégagez l’ouverture préamorcée sur le dessus de la hotte. Installez le connecteur de fil

(inclus dans le sac de pièces).

EMPLACEMENT DES VIS

VUE DE DESSOUS

- 18 -

HR0027

Page 19

9. INSTALLER L’ADAPTATEUR DE 25 CM (10 PO)

!

À l’aide des quatre (4) vis M4 x 6 du sachet de pièces, assemblez l’adaptateur sur le

dessus dela paroi de la hotte. Scellez tous les joints avec du ruban à conduit pour éviter

les fuitesd’air.

EMPLACEMENT DES VIS DE MONTAGE

HJ0026

10. RACCORD DU CÂBLAGE

AVERTISSEMENT

Risque de choc électrique. Les branchements électriques doivent être effectués par un personnel compétent,

conformément aux normes et aux codes en vigueur. Avant d'effectuer les branchements, coupez l'alimentation

du panneau électrique et verrouillez l'interrupteur principal afin d'empêcher que le courant ne soit rétabli

accidentellement.

Positionnez la paroi de la hotte sous la hotte sur mesure installée.

VENTILATEURS INTERNES : Insérez le câble d’alimentation dans le

connecteur installé à l’étape 8. Serrez le

connecteur pour fixer le câble. Connectez le

câble dans le boîtier de câblage à l'aide des

serre-fils. Connectez le NOIR avec le NOIR, le

BLANC avec le BLANC, et le VERT ou fil nu sur

la vis VERTE de mise à la terre. N’OUBLIEZ

PAS DE CONNECTER LE FIL DE TERRE.

Refermez le couvercle de connexion.

HE0059

11. INSTALLATION DE LA PAROI DE LA HOTTE

ATTENTION

Prenez garde de ne pas plier les conduits lors de l’installation de

la paroi.

À l’aide des vis fournies, installez la paroi de la hotte à l’intérieur de la hotte sur

mesure. Commencez par les deux vis des coins avant, puis utilisez quatre vis sur

les côtés et les vis restantes pour terminer la fixation de l’avant. (Voir la position

des vis dans la figure de droite.)

Assurez-vous que l’adaptateur / clapet (ou l’adaptateur) s'insère à l'intérieur

du conduit. Si vous pouvez accéder sur le dessus de la paroi de la hotte,

scelleztous les raccords avec du ruban pour conduits.

- 19 -

Page 20

12. REPOSER LE PANNEAU INFÉRIEUR

Soulevez le panneau inférieur et engagez les languettes

métalliques de la paroi de la hotte dans les fentes

dupanneau.

Fixez le panneau inférieur à la paroi de la hotte à l’aide de

ses vis.

EMPLACEMENT DES VIS

VUE DE DESSOUS

13. REPOSER LA GOUTTIÈRE À GRAISSES

A. Centrez la gouttière à graisses au-dessus

du rebord du panneau inférieur et

déposez-le en place.

Reposez les panneaux de filtre tel qu'illustré.

EMPLACEMENT DES VIS

VUE DE DESSOUS

A

(Le ventilateur, montré, est pour

référence seulement et ne représente

pas le véritable soufflerie dans ce

produit.)

HD0291

14. REPOSER LES FILTRES DE DÉFLECTEURS

ATTENTION

Enlevez la pellicule protectrice de plastique des filtres avant de les installer.

REMARQUE : Il est conseillé d’installer d’abord les filtres des côtés puis de terminer avec le ou les filtres du centre.

1. Insérez une extrémité du filtre de

déflecteur dans la rainure avant.

2. Soulevez l’autre extrémité vers

l’intérieur de la hotte et insérez-la

dans la gouttière à graisses.

1 2

Des filtres de rechange sont

offerts chez votre détaillant.

Consultez l’étiquette à l’intérieure

de la hotte pour la taille et le

numéro de pièce.

- 20 -

Page 21

15. AMPOULES

12

Cette hotte utilise des ampoules halogènes à écran (120 V, 50 W, PAR16 à culot GU10, deux pour le modèle CPDI362 et quatre

pour les modèles CPDI482 et CPDI602) (incluses).

REMARQUE : Avant d’utiliser les ampoules, enlevez le ruban adhésif d’emballage (s’il y a lieu).

!

AVERTISSEMENT

Pour éviter les risques de blessure personnelle, n’utilisez pas

d’ampoules qui ne conviennent pas aux luminaires fermés.

1. Posez les ampoules en insérant leurs bornes dans les encoches de la douille.

2. Appuyez légèrement sur l’ampoule et tournez-la vers la droite pour la fixer.

!

AVERTISSEMENT

Pour éviter les risques de blessure personnelle, n’utilisez pas

d’ampoules qui ne conviennent pas aux luminaires fermés.

Pour enlever les ampoules, appuyez délicatement vers le haut et tournez vers la gauche pour dégager les bornes de l’ampoule

des encoches.

REMARQUE : Si nécessaire, utilisez un gant à vaisselle pour avoir plus d’adhérence ou utilisez la ventouse BEST

l’enlèvement des ampoules. Pour commander cette ventouse, pièce n° 99526707, communiquez avec

l’assistance technique de BEST

®

au 1-800-637-1453.

HO0090

®

pourfaciliter

16. UTILISATION ET ENTRETIEN

Filtres de déflecteur

Les filtres de déflecteur doivent être nettoyés fréquemment. Utilisez une solution tiède de détergent. Lavez-les plus souvent si le

type de cuisine produit plus de graisses, telle que la friture et la cuisson au wok.

Enlevez les filtres de déflecteur en les poussant vers l’avant de la hotte puis en les faisant pivoter vers le bas Les filtres dedéflecteur

sont lavables au lave-vaisselle. Laissez les filtres sécher complètement avant de les réinstaller.

Nettoyez les filtres entièrement métalliques au lave-vaisselle avec un détergent sans phosphate. Une décoloration du filtre peut

seproduire si des détergents phosphatés sont utilisés et selon les conditions locales de l'eau, sans toutefois affecter lerendementdu

filtre. Cette décoloration n'est pas couverte par la garantie.

Gouttière à graisses

La gouttière à graisses doit être nettoyée fréquemment. Enlevez la gouttière de la hotte (étape 6, page 21) et lavez-la dans une

solution de détergent tiède. Tout comme les filtres, lavez la gouttière plus souvent si le type de cuisine produit plus de graisses,

telleque la friture et la cuisson au wok. Laissez la gouttière sécher complètement avant de la réinstaller.

Nettoyage des ventilateurs internes

Enlevez les filtres pour accéder aux ventilateurs. Nettoyez-les avec un aspirateur. Ne les plongez pas dans l'eau.

Nettoyage de la paroi de la hotte

Nettoyage de l'acier inoxydable :

À faire :

• Régulièrement, nettoyez toutes les surfaces avec un

chiffon propre imbibé d'eau tiède et de savon doux ou de

liquide à vaisselle.

• Nettoyeztoujoursdanslesensdeslignesdupolioriginal.

• Rinceztoujoursàl'eaupropre(2ou3fois)aprèslenettoyage.

Séchez complètement en essuyant.

• Vouspouvezégalementutiliserun nettoyantspécial pour

acier inoxydable.

À ne pas faire :

• N'utilisezpasde laine d'acier ordinairenidelained'acier

inoxydable ou tout genre de grattoir pour déloger la saleté.

• N'utilisezaucunnettoyantpuissantouabrasif.

• Nelaissezpaslasaletés'accumuler.

• Protégezlahottedela poussièredeplâtreoude toutautre

résidu de construction. Pendant des travaux de construction

ou de rénovation, couvrez la hotte pour empêcher la

poussière d’adhérer aux surfaces d'acier inoxydable.

Lors du choix d'un détergent :

- Tout nettoyant contenant de l'eau de javel attaquera l'acier inoxydable.

- Tout produit contenant : du chlore, du fluor, de l'iode ou du brome détériorera rapidement les surfaces.

- Tout produit combustible utilisé pour le nettoyage comme l'acétone, l'alcool, l'éther, le benzol, etc., est hautement explosif

et ne doit jamais être utilisé à proximité d'une hotte.

- 21 -

Page 22

17. FONCTIONNEMENT

Mettez toujours la hotte en marche avant de cuisiner afin d'établir une circulation d'air dans la cuisine. Laissez la hotte

fonctionner quelques minutes après l'arrêt de la cuisinière afin de nettoyer l'air. Ceci contribuera à la propreté de toute

votrecuisine.

ÉCLAIRAGE (HALOGÈNE)

L’éclairage halogène est commandé par un cadran.

• POSITION 1 : ÉTEINT

• POSITION 2 : FAIBLE INTENSITÉ

• POSITION 3 : HAUTE INTENSITÉ

• POSITION 4 : ÉTEINT

• Utilisez des ampoules halogènes à écran de 120 V, 50 W, MR16 à culot GU10 ou PAR16 à culot GU10 (incluses).

VENTILATEUR

Le ventilateur est commandé par un cadran.

• POSITION 1 : ARRÊT

• POSITION 2 : RÉGIME LENT

• POSITION 3 : RÉGIME MOYEN

• POSITION 4 : RÉGIME ÉLEVÉ

• THERMOSTAT HEAT SENTRY

Votre hotte est équipée d'un thermostat Heat SentryMC. Ce dispositif actionne le ventilateur ou en augmente le régime en cas

de chaleur excessive dégagée par les éléments de cuisson.

1) En position ARRÊT, le ventilateur est mis en MARCHE au régime ÉLEVÉ.

2) En position MARCHE à un régime plus lent, le ventilateur passe au régime ÉLEVÉ.

Le thermostat HEAT SENTRY peut faire démarrer le ventilateur s’il y a un feu sur la cuisinière ou dans

une situation de chaleur excessive, même si la hotte est arrêtée. Dans ce cas, il est impossible

d'ARRÊTERle ventilateur avec son interrupteur. Si vous devez arrêter le ventilateur, coupez le disjoncteur

du panneau d'alimentation électrique.

Une fois la température revenue à la normale, le ventilateur revient à son réglage d'origine.

MC

!

AVERTISSEMENT

- 22 -

Page 23

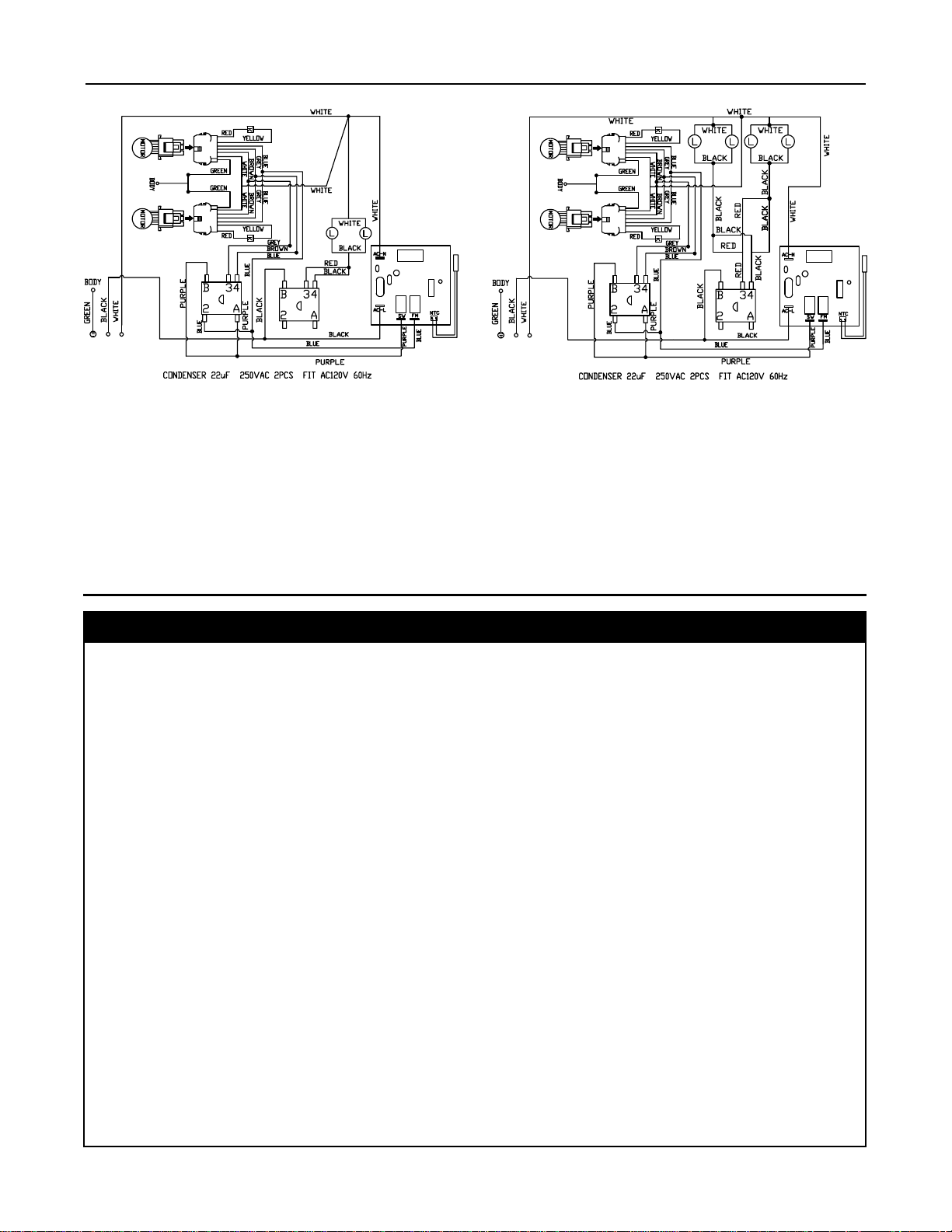

18. DIAGRAMME DE CÂBLAGE

BLANC

VIOLET

VERT

VERT

ROUGE

BLEU

ROUGE

VIOLET

JAUNE

BRUN

BLANC BLANC

BRUN

JAUNE

BLEU

GRIS

GRIS

BLEU BLEU

GRIS

BRUN

BLEU

NOIR

BLANC

ROUGE

BLEU

BLANC

NOIR

NOIR

NOIR

VIOLET

BOÎTIER

VERT

NOIR

MOTEUR

BOÎTIER

MOTEUR

BLANC

CONDENSATEUR 22 uF 250VCA 2 PIÈCES CONVIENT À 120VCA 60Hz

MODÈLE CPDI362SB

BLANC

VIOLET

BLEU

BOÎTIER

VERT

NOIR

BLANC

BRUN

BRUN

BLEU

GRIS

GRIS

GRIS

BRUN

BLEU

BLEU BLEU

BLANC

BLANC

NOIR

NOIR

VIOLET

VERT

VERT

ROUGE

BLEU

ROUGE

JAUNE

BLANC BLANC

JAUNE

VIOLET

MOTEUR

BOÎTIER

MOTEUR

BLANC

NOIR

NOIR

ROUGE

BLEU

ROUGE

ROUGE

NOIR

VIOLET

BLANC

BLANC

NOIR

NOIR

NOIR

NOIR

CONDENSATEUR 22 uF 250VCA 2 PIÈCES CONVIENT À 120VCA 60Hz

MODÈLES CPDI482SB et CPDI602SB

BLANC

VIOLET

BLANC

BLEU

19. GARANTIE

GARANTIE

GARANTIE LIMITÉE D’UN AN

Broan-NuTone LLC (« Broan-NuTone ») garantit à l'acheteur original que ses produits sont libres de tout vice de matériau ou

de fabrication pour une période d'un an à compter de la date d'achat originale. CETTE GARANTIE NE COMPORTE AUCUNE

AUTRE GARANTIE, EXPRESSE OU TACITE, Y COMPRIS, MAIS SANS S'Y LIMITER, LES GARANTIES TACITES DE

VALEUR MARCHANDE OU D'ADAPTATION À UN USAGE PARTICULIER.

Durant cette période d'un an, Broan-NuTone réparera ou remplacera gratuitement, à sa discrétion, tout produit ou toute pièce

jugés défectueux dans des conditions normales d'utilisation.

CETTE GARANTIE NE S'APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS, NI AUX AMPOULES,

FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE TOIT, CAPUCHONS MURAUX ET AUTRES ACCESSOIRES POUR

CONDUITS. Cette garantie ne couvre pas (a) les frais d'entretien ou de service normaux ni (b) tout produit ou toute pièce

soumis à un abus, une négligence, un accident, un entretien ou une réparation inadéquats (autres que ceux

effectués par Broan-NuTone), une mauvaise installation ou une installation contraire aux instructions recommandées.

La durée de toute garantie tacite est limitée à la période d'un an stipulée pour la garantie expresse. Certains territoires ou

provinces ne permettant pas la limitation de la durée d'une garantie implicite, la limitation ci-dessus peut ne pas s'appliquer à

votre situation.

L'OBLIGATION POUR BROAN-NUTONE DE RÉPARER OU DE REMPLACER LE PRODUIT, À SA DISCRÉTION,

CONSTITUE LE SEUL RECOURS DE L'ACHETEUR EN VERTU DE LA PRÉSENTE GARANTIE. BROAN-NUTONE

NE PEUT ÊTRE TENUE RESPONSABLE DES DOMMAGES INDIRECTS OU CONSÉCUTIFS NI DES DOMMAGES-INTÉRÊTS

PARTICULIERS DÉCOULANT DE L'UTILISATION OU DU RENDEMENT DU PRODUIT. Certains territoires ou provinces ne

permettant pas la limitation ou l'exclusion des dommages indirects ou consécutifs, la limitation ou l’exclusion ci-dessus

peut ne pas s'appliquer à votre situation.

La présente garantie vous confère des droits juridiques particuliers auxquels peuvent s’ajouter d’autres droits qui varient

d’un territoire ou d’une province à l’autre. Toute modification apportée à ce produit sans l’autorisation de Broan-NuTone annule

cette garantie. La présente garantie remplace toutes les autres garanties précédentes.

Pour vous prévaloir de cette garantie, vous devez (a) aviser Broan-NuTone à l'adresse ou au numéro de téléphone indiqués

ci-dessous, (b) donner le numéro de modèle du produit et le numéro d'identification de la pièce et (c) décrire la nature de

la défectuosité du produit ou de la pièce. Lors de votre demande de garantie, vous devez présenter une preuve de la date

d'achat originale.

BEST®, 926 W. State Street, Hartford, WI 53027 (1-800-637-1453)

BEST®, 550 Lemire Blvd., Drummondville, QC, Canada (1-866-737-7770)

www.BestRangeHoods.com

- 23 -

Page 24

20. PIÈCES DE RECHANGE

Série Best CPD

7, 8

1

2

3

4

13

12

6

5

10

9

11

REPÈRE

N° DE PIÈCE DESCRIPTION

1 97018874 ADAPTATEUR ROND DE 25 CM (10 PO) 1 1 1

2 98010930

98010931

3 97018875 V

4 99271454 C

5 99271455 T

6 V05921 A

7 98010933 P

8 98010936 P

9 97018876 F

10 98010934 R

11 99840023 B

12 97018879 E

13 99271456 C

* 97018878 C

* 99526707 V

* NON ILLUSTRÉ.

OUTTIÈRE À GRAISSES DE 91 CM (36 PO)

G

GOUTTIÈRE À GRAISSES DE 122 CM (48 PO) ET 152 CM (60 PO)

ENTILATEUR INTERNE (2 REQUIS) 2 2 2

ONDENSATEUR 2 2 2

ABLEAU DE COMMANDE AVEC HEAT SENTRY 1 1 1

MPOULES HALOGÈNES À ÉCRAN (120 V, 50 W, GU-10) 2 4 4

ANNEAU DE FILTRE (PAIRE) (POUR 91 CM / 36 PO) 1 - -

ANNEAU DE FILTRE (PAIRE) (POUR 152 CM / 60 PO) - - 1

ILTRE DE DÉFLECTEUR (COMPREND ARTICLE 11) 2 3 3

ESSORT DE FILTRE (JEU DE 6) 1 1 1

OUTON DE FILTRE DE DÉFLECTEUR (PAIRE) 2 3 3

NSEMBLE DE DOUILLE D’AMPOULE 2 4 4

OMMUTATEUR ROTATIF 2 2 2

OMMUTATEUR ROTATIF 1 1 1

ENTOUSE POUR AMPOULE 1 1 1

QTÉ (LARGEUR DE LA HOTTE)

91 CM

(36 PO)

122 CM

(48 PO)

1

-

-

1

152 CM

(60 PO)

-

1

- 24 -

99044954B

Page 25

INSTRUCCIONES DE INSTALACIÓN

SERIE CPD

Adecuado para usarse en sitios húmedos cuando se instala en un circuito de

derivación protegido GFCI. Diseñado para patio exterior cubierto o techado.

INDICADO SOLAMENTE PARA COCINAR EN CASA

!

LEA Y CONSERVE ESTAS INSTRUCCIONES

INSTALADOR: DEJE ESTE MANUAL CON EL PROPIETARIO

DE LA VIVIENDA.

PROPIETARIO DE LA VIVIENDA: INFORMACIÓN DE USO Y CUIDADO

EN LAS PÁGINAS 12 a 13.

BEST®; Hartford, Wisconsin www.BestRangeHoods.com 800-637-1453

®

BEST

; Drummondville, QC, Canada www.BestRangeHoods.com 866-737-7770

REGISTRE SU PRODUCTO EN LÍNEA EN: www.BestRangeHoods.com/register

Si desea información adicional, visite www.BestRangeHoods.com

!

Page 26

ADVERTENCIA ADVERTENCIA

!

!

PARA REDUCIR EL RIESGO DE INCENDIOS,

DESCARGAS ELÉCTRICAS O LESIONES

PERSONALES, SIGA LAS SIGUIENTES

PRECAUCIONES:

1. Use la unidad solo de la manera indicada por el

fabricante. Si tiene preguntas, comuníquese con el

fabricante a la dirección o al número telefónico que se

incluye en la garantía.

2. Antes de dar servicio o limpiar la unidad, interrumpa el

suministro eléctrico en el panel de servicio y bloquee

los medios de desconexión del servicio para evitar que

la electricidad sea reanudada accidentalmente.

Cuando no sea posible bloquear los medios de

desconexión del servicio, fije firmemente una señal de

advertencia (como una etiqueta) en un lugar visible del

panel de servicio.

3. Solo personal calificado debe realizar el trabajo de

instalación y el cableado eléctrico, de acuerdo con

todos los códigos y las normas correspondientes,

incluidos los códigos y las normas de construcción

específicos sobre protección contra incendios.

4. Es necesario suficiente aire para que se lleve a cabo

una combustión y una extracción adecuadas de

los gases a través del tubo de humos (chimenea)

del equipo quemador de combustible, con el fin de evitar

el contratiro. Siga las directrices y las normas de seguridad

del fabricante del equipo de calefacción, como las

publicadas por la Asociación Nacional de Protección

contra Incendios (National Fire Protection Association,

NFPA), y la Sociedad Americana de Ingenieros

en Calefacción, Refrigeración y Aire Acondicionado

(American Society for Heating, Refrigeration and Air

Conditioning Engineers, ASHRAE), y las autoridades de

los códigos locales.

5. Al cortar o perforar a través de la pared o del techo,

tenga cuidado de no dañar el cableado eléctrico ni

otros servicios ocultos.

6. Los ventiladores en conductos siempre deben

ventearse hacia el exterior.

7. No use esta unidad junto con ningún dispositivo de

control de velocidad de estado sólido.

8. Para reducir el riesgo de incendio, use solamente

conductos metálicos.

9. Esta unidad no está diseñada para usarse con una

parrilla de carbón.

10. Esta unidad debe estar conectada a tierra y protegida

por un GFCI (interruptor de circuito de falla a tierra).

11. Cuando la legislación local correspondiente incluya

requisitos de instalación y/o de certificación más

estrictos, los requisitos ya mencionados prevalecen

sobre los de este documento, y el instalador acepta

cumplir con ellos a sus propias expensas.

12. Adecuado para usarse solamente en sitios húmedos

cuando se instala en un circuito de derivación

protegido GFCI.

PARA REDUCIR EL RIESGO DE INCENDIO

PROVOCADO POR GRASA PRESENTE EN

LA ESTUFA:

a) Nunca deje desatendidas las unidades de la superficie

cuando estén en ajustes altos de calor. Los alimentos

en ebullición provocan derrames grasosos y con

humo que se pueden incendiar. Caliente el aceite

lentamente en ajustes de calor bajo o medio.

b) Siempre ENCIENDA el paquete de potencia cuando

esté cocinando a altas temperaturas o flamee alimentos

(por ejemplo crepas Suzette, cerezas Jubilee, bistec con

pimienta flameado).

c) Limpie frecuentemente los ventiladores. No permita la

acumulación de grasa en el ventilador ni en los filtros

ni en los conductos de escape.

d) Use una cacerola del tamaño adecuado. Siempre use

utensilios de cocina que sean apropiados para el

tamaño del elemento de la superficie.

PARA REDUCIR EL RIESGO DE LESIONES A

PERSONAS EN CASO DE UN INCENDIO

PRODUCIDO POR GRASA EN UNA ESTUFA,

OBSERVE LO SIGUIENTE*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto,

una charola para galletas o una bandeja de metal,

y después apague el quemador. PROCEDA CON

CUIDADO PARA EVITAR QUEMADURAS. SI LAS

LLAMAS NO SE APAGAN INMEDIATAMENTE,

EVACÚE EL ÁREA Y LLAME AL DEPARTAMENTO

DE BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA,

porque podría sufrir quemaduras.

3. NO USE AGUA ni toallas húmedas, ya que provocará

una violenta explosión de vapor.

4. Use un extintor SOLO si:

A. Tiene un extintor clase ABC y usted sabe cómo

usarlo.

B. El incendio es pequeño y está confinado al área

en la que se inició.

C. Se ha llamado al departamento de bomberos.

D. Puede combatir el incendio teniendo la espalda

orientada hacia una salida.

*Basado en “Kitchen Fire Safety Tips” (Sugerencias para

la seguridad contra incendios en la cocina) publicado

por NFPA.

PRECAUCIÓN

1. Solo para usarse como medio de ventilación general.

No debe usarse para la extracción de materiales o

vapores peligrosos o explosivos.

2. Para evitar daños a los cojinetes del motor y rotores

ruidosos o desbalanceados, mantenga la unidad de

potencia protegida contra rociados de yeso, polvos de

construcción, etc.

3. Este motor de inserción tiene una protección contra

sobrecargas térmicas que apagará el motor

automáticamente en caso de sobrecalentamiento.

El motor reanudará su funcionamiento cuando

se enfríe. Si el motor continúa apagándose y

encendiéndose, solicite servicio para el paquete

de potencia.

4. La distancia mínima del paquete de potencia sobre la

superficie de la estufa no debe ser menor de 36 pulg.

(91 cm).

5. Se recomienda que dos personas hagan la instalación

debido al gran tamaño y peso de esta unidad.

6. Para reducir el riesgo de incendio y para extraer

adecuadamente el aire, asegúrese de dirigir el aire

hacia el exterior. No extraiga el aire hacia espacios

contenidos entre paredes o cielos rasos, ni hacia

áticos, sótanos bajos ni la cochera.

7. Este producto está equipado con un termostato que

podría iniciar automáticamente el funcionamiento del

ventilador. Para reducir el riesgo de lesiones

personales y para evitar que la electricidad sea

reanudada accidentalmente, interrumpa el suministro

eléctrico en el panel de servicio y bloquee o rotule

este panel.

8. Debido a la alta capacidad de extracción de

esta unidad, debe asegurarse de que entre suficiente

aire a la casa para reemplazar el aire extraído

abriendo una ventana cercana o en la cocina.

9. Para reducir el riesgo de incendio y de descarga

eléctrica, solamente debe instalar modelos Best serie

CPD con ventiladores integrados. No se pueden

utilizar otros ventiladores.

10. Lea la etiqueta de especificaciones del producto para

ver información y requisitos adicionales.

- 26 -

Page 27

- SISTEMA DE RECUBRIMIENTO DE CAMPANA CPD -

MODELO 437

(TAPA DE TECHO

DE ALTA CAPACIDAD)

RECUBRIMIENTO

DE LA CAMPANA CPD

M

ODELO 441

(TAPA REDONDA DE PARED,

DE 10 PULG. (25 CM))

M

ODELO 418

(CODO REDONDO

AJUSTABLE DE 10 PULG.

(25 CM))

M

ODELO 410

(CONDUCTO REDONDO DE 10 PULG.

(25 CM) – SECCIONES DE 2 PIES (61 CM))

A

DAPTADOR REDONDO

DE 10 PULG. (25 CM)

(SE INCLUYE CON EL

RECUBRIMIENTO DE LA CAMPANA)

- 27 -

ENTILADOR DOBLE (1200 CFM)

V

(INCLUIDO)

Page 28

1. INSTALE LOS CONDUCTOS Y EL CABLEADO ELÉCTRICO

INSTALACIÓN

Instale conductos, codos y tapa para techo o muro de tamaño adecuado al tipo de ventilador que está instalando.

Utilice un conducto redondo de 10 pulg. (25 cm). Use cinta para conductos metálica para sellar las uniones de conductos.

La distancia mínima del recubrimiento de la campana sobre la superficie de la estufa no debe ser menor

de 36 pulg. (91 cm).

Las distancias mayores de 36 pulg. (91 cm) se deben manejar a discreción del usuario y de la persona encargada

de la instalación.

Coloque cable eléctrico de 3 alambres en el sitio de la instalación. Su longitud debe prolongarse por lo menos 4 pies

(122 cm) por debajo de la parte inferior de la campana a la medida.

CONDUCTO REDONDO

DE 10 PULG. (25 CM)

CODO REDONDO

DE 10 PULG. (25 CM)

RECUBRIMIENTO

DE LA CAMPANA

36 PULG. (91 CM)

SOBRE LA SUPERFICIE

PARA COCINAR

CONDUCTOS TÍPICOS DEL CPD

(VENTILADOR DOBLE INTERNO)

2. PREPARE LA INSTALACIÓN

ADVERTENCIA

Cuando realice la instalación, el servicio o la limpieza de la unidad, se recomienda que use gafas de seguridad

y guantes.

NOTA: Antes de continuar con la instalación, revise el contenido de la caja. Si faltan artículos o si están dañados, comuníquese con

el fabricante.

Asegúrese de que se han incluido los siguientes elementos:

- Recubrimiento de la campana

- Accesorios: •Filtrosdeflectores(2paraanchurasde36pulg.[91cm],3paraanchurasde48y60pulg.

[122y152cm])

•Lámparas de halógeno protegidas (120 V, 50 W, MR16 con base GU10 o PAR16 con base GU10)

(2 para CPDI362, 4 para todos los demás modelos)

•Adaptadorredondode10pulg.(25cm)

•Bolsadepiezasqueincluye:12–tornillosdecabezaplana8x½pulg.(16paraCPDI602),

4 – tornillos de cabeza troncocónica M4 x 6, 1 – herramienta de taza de succión, 3 – tuercas

de alambre

Piezas que se venden por separado:

- Conductos, codos, tapas para pared y techo. Consulte la lista completa de opciones de ventilación y números de modelos en

las páginas 3 y 4.

!

NOTA: Durante la instalación, proteja la cubierta y/o la superficie de la estufa.

- 28 -

Page 29

3. PREPARACIÓN DE LA CAMPANA A LA MEDIDA

!

ADVERTENCIA

Cuando arme una campana a la medida, siga siempre todos los códigos y normas de construcción

correspondientes.

La campana a la medida debe construirse para adecuarse en tamaño y forma al recubrimiento de la campana CPD.

Consulte los detalles en el cuadro y la ilustración.

3”

ATRÁS

1

C

5

/8”

L

2”

C

A

RECUBRIMIENTO

DE LA CAMPANA

SERIE MODELO *A *B C

CPDI362 73

CPDI482 88

CPD

CPDI602 102

PESO TOTAL DIMENSIONES DE LA CAMPANA

LB (33 kg)

LB (40 kg)

LB (46 kg)

1

⁄2” (57.2 cm) 34 3⁄8” (87.3 cm) 5 7⁄8” (14.9 cm)

22

1

⁄2” (57.2 cm) 46 3⁄8” (117.8 cm) 5 7⁄8” (14.9 cm)

22

1

⁄2” (57.2 cm)

22

7

58

⁄8” (149.5 cm)

7

5

⁄8” (14.9 cm)

12”

* Las dimensiones A y B incluyen las cabezas de los remaches.

B

FRENTE

Para reducir al mínimo la separación alrededor del recubrimiento de la campana, tome mediciones reales de ancho y de fondo

del recubrimiento de la campana y agregue 1/16 pulg. (1.6 mm) para obtener las mediciones D y E. Corte el orificio en la parte

inferior del gabinete de acuerdo con las dimensiones. Consulte los detalles en el cuadro y la ilustración.

RECUBRIMIENTO

DE LA CAMPANA

SERIE MODELO D E

CPD

CPDI362

CPDI482

CPDI602

22

22

22

DIMENSIONES DEL CORTE

9

⁄16 pulg. (57.3 cm) 34 7⁄16 pulg. (87.5 cm)

9

⁄16 pulg. (57.3 cm) 46 7⁄16 pulg.(118.0 cm)

9

⁄16 pulg. (57.3 cm) 58 15⁄16 pulg.(149.7 cm)

D

E

HD0367

4. MONTAJE DE LA ESTRUCTURA INTERNA DE LA CAMPANA A LA MEDIDA

ADVERTENCIA

La campana de madera debe estar bien fija a montantes de pared u otra estructura de madera detrás

de la placa de yeso. Asegúrese de que sea capaz de soportar su propio peso y el peso del CPD.

De no hacerlo, podría ocasionar lesiones personales o daños a la cubierta o a la estufa.

El recubrimiento de campana CPD está apoyado por la estructura interna de la campana con doce (12) tornillos de cabeza plana

8x½pulg.(16tornillosparaCPDI602),queseincluyenenlabolsadepiezas.

Dado que los orificios de montaje del recubrimiento de campana CPD se

encuentran en los lados delantero y trasero (vea la ilustración a la derecha),

planifique instalar el marco de madera al frente y a los lados para tener apoyo.

!

- 29 -

Page 30

5. RETIRE LOS FILTROS DEFLECTORES

Retire la cinta de los filtros. Saque los

filtros del paquete de potencia y deje a

un lado. Se recomienda comenzar con

los filtros centrales.

1 2

6. RETIRE EL RIEL PARA ESCURRIMIENTOS DE GRASA

A

A. Levante el riel para escurrimientos de

grasa para desmontarlo del panel

inferior.

(El soplador, que se muestra, es sólo

para referencia y no representa la

real soplador en este producto.)

HD0291

7. RETIRE EL PANEL INFERIOR

Con un destornillador Phillips, retire ambos paneles

de relleno del filtro inferior.

UBICACIONES DE LOS TORNILLOS DE RETENCIÓN

VISTA INFERIOR

Desmonte el panel inferior, levántelo, sáquelo y póngalo a un lado.

UBICACIONES DE LOS TORNILLOS DE RETENCIÓN

8. RETIRE LA ABERTURA DEL AGUJERO CIEGO

Desde el interior del recubrimiento de la campana, retire la cubierta del cableado y deje

a un lado. Marque el orificio del agujero ciego para la instalación eléctrica en la parte

superior de la campana. Instale la abrazadera para cables (se incluye en la bolsa de

piezas).

VISTA INFERIOR

- 30 -

HR0027

Page 31

9. INSTALE EL ADAPTADOR DE 10 PULG. (25 CM)

!

Utilizando cuatro (4) tornillos M4 x 6 de la bolsa de piezas, arme el adaptador en la parte

superior del recubrimiento de la campana. Selle todas las uniones con cinta para

conductos metálica para eliminar fugas de aire.

UBICACIÓN DE LOS TORNILLOS DE MONTAJE

HJ0026

10. CONECTE EL CABLEADO

ADVERTENCIA

Riesgo de descarga eléctrica. El personal calificado debe realizar el trabajo de cableado eléctrico, de acuerdo

con todos los códigos y normas correspondientes. Antes de conectar los cables, interrumpa el suministro

eléctrico en el panel de servicio y bloquee los medios de desconexión del servicio para evitar que la

electricidad sea reanudada accidentalmente.

Coloque el recubrimiento de la campana debajo de la campana a la medida instalada.

VENTILADORES INTERIORES: Inserte el cableado de la vivienda a través

de la abrazadera para cables que instaló en

el paso 8. Apriete la abrazadera para

asegurar el cable. Conecte el cable a la caja

de cableado con conectores para cables.

Conecte NEGRO con NEGRO, BLANCO

con BLANCO y VERDE o desnudo al

tornillo VERDE de puesta a tierra. NO SE

OLVIDE DE CONECTAR LA TIERRA.

Regrese a su lugar la cubierta del cableado.

HE0059

11. INSTALE EL PAQUETE DE POTENCIA

PRECAUCIÓN

Tenga cuidado de no doblar los conductos cuando instale el

paquete de potencia.

Con los tornillos suministrados, instale el recubrimiento de la campana dentro de

la campana a la medida. Comience con 2 tornillos en las esquinas delanteras,

luego use 4 tornillos para los lados, y use el resto de los tornillos para terminar

de asegurar el recubrimiento de la campana delantero. (Vea las ubicaciones

específicas de los tornillos de montaje en la figura a la derecha.)

Asegúrese de que el adaptador/deflector (o el adaptador) entre a los conductos.

Cuando tenga acceso a la parte superior del recubrimiento de campana, selle las

conexiones con cinta para conductos metálica.

- 31 -

Page 32

12. REINSTALE EL PANEL INFERIOR

Levante el panel inferior y acople las lengüetas metálicas del

recubrimiento de la campana en las ranuras del panel inferior.

Asegure el panel inferior al recubrimiento de la campana

utilizando sus tornillos.

UBICACIONES DE LOS TORNILLOS DE RETENCIÓN

VISTA INFERIOR

Reinstale los paneles de relleno del filtro tal como

se muestra.

UBICACIONES DE LOS TORNILLOS DE RETENCIÓN

VISTA INFERIOR

13. REINSTALE EL RIEL PARA ESCURRIMIENTOS DE GRASA

A

A. Centre el riel para escurrimientos de grasa

sobre la parte inferior del borde del panel y

colóquelo en su lugar.

(El soplador, que se muestra, es sólo

para referencia y no representa la

real soplador en este producto.)

HD0291

14. REINSTALE LOS FILTROS DEFLECTORES

PRECAUCIÓN

Retire la película plástica de protección que cubre los filtros antes de instalarlos.

NOTA: Se recomienda instalar primero los filtros laterales y terminar con los filtros centrales.

1. Inserte un extremo del filtro

deflector en el canal delantero de

la campana.

2. Levante el otro extremo hacia el

interior del recubrimiento de la

campana e inserte el riel para

escurrimientos de grasa del

recubrimiento de la campana.

1 2

Los filtros de repuesto se pueden

conseguir con el distribuidor. Vea

la etiqueta situada en el interior

del recubrimiento de la campana

para ver el tamaño y el número

de pieza.

- 32 -

Page 33

15. BOMBILLAS

12

Este paquete de potencia debe usar lámparas de halógeno protegidas (120 V, 50 W PAR16 con base GU10, 2 para el CPDI362

y 4 para los CPDI482 y CPDI602), que se incluyen.

NOTA: Antes de usar las lámparas, retire la cinta de envío colocada sobre ellas (si la hubiera).

!

ADVERTENCIA

Con el fin de prevenir el riesgo de lesiones personales, no instale

una lámpara que no sea adecuada para accesorios cerrados.

Para quitar las lámparas, empuje suavemente hacia arriba y gire hacia la

izquierda para desacoplar los contactos de la bombilla de sus ranuras.

!

ADVERTENCIA

Con el fin de prevenir el riesgo de lesiones personales, no instale

una lámpara que no sea adecuada para accesorios cerrados.

1. Instale las lámparas colocando los

contactos de la bombilla en las ranuras

del enchufe.

2. Empuje suavemente hacia arriba y gire

hacia la derecha hasta que esté bien fija.

NOTA: De ser necesario, use un guante de caucho para lavar platos para tener más sujeción al quitar la bombilla, o use una

herramienta con taza de succión disponible con BEST

mienta con taza de succión, número de pieza 99526707, llame al departamento de Apoyo técnico de BEST

®

para facilitar el proceso de quitar las bombillas. Para ordenar la herra-

®

al 1-800-637-1453.

16. USO Y CUIDADO

Filtros deflectores

Los filtros deflectores se deben limpiar con frecuencia. Use una solución tibia de detergente y agua. Lave con más frecuencia si

su estilo de cocinar genera más cantidad de grasa, como al freír alimentos o cocinar en sartén china (wok).

Retire los filtros deflectores empujando hacia el frente del recubrimiento de la cubierta y girando hacia abajo. Los filtros deflectores

se pueden lavar en lavaplatos. Permita que los filtros sequen totalmente antes de volverlos a instalar.

Limpie los filtros completamente metálicos en el lavaplatos con un detergente sin fosfatos. El filtro se puede decolorar si se utilizan

detergentes con fosfatos o como resultado de la condición del agua local, pero esto no afectará el rendimiento del filtro.

Estadecoloración no está cubierta por la garantía.

Riel para escurrimiento de grasa

El riel para escurrimiento de grasa se debe limpiar con frecuencia, Retírelo del recubrimiento de la campana (vea el paso 6 de la

página 36) y use una solución tibia de detergente y agua. Tal como los filtros deflectores, lave con más frecuencia si su estilo de

cocinar genera más cantidad de grasa, como al freír alimentos o cocinar en sartén china (wok). Permita que el riel seque totalmente

antes de volverlo a instalar.

Limpieza de los ventiladores interiores

Retire los filtros con el fin de acceder a los ventiladores. Limpie los ventiladores con aspiradora. No los sumerja en agua.

Limpieza del recubrimiento de la campana

Limpieza del acero inoxidable:

Cosas que puede hacer:

• Regularmente,lave conuna telao trapolimpio remojado

con agua tibia y jabón o detergente líquido para platos.

• Siempre limpie en la dirección de las líneas originales

de pulido.

• Siempre enjuague bien con agua limpia (2 o 3 veces)

después de la limpieza. Séquelo por completo.

• También puede usar un limpiador casero especializado

para acero inoxidable.

Cosas que no debe hacer:

• Usarlanadeacerooaceroinoxidablenialgúnotrotipode

raspador para quitar mugre difícil de sacar.

• Usarlimpiadoresfuertesniabrasivos.

• Dejarqueseacumulelamugre.

• Dejar que el polvo forme plastas ni que quede en la

campana algún otro residuo de la construcción. Durante la

construcción o la renovación, cubra el paquete de potencia

para estar seguro de que el polvo no se pegue a la

superficie de acero inoxidable.

Al elegir un detergente, evite lo siguiente:

- Todo limpiador que contenga blanqueador, pues atacará al acero inoxidable.

- Todo producto que contenga: cloruro, fluoruro, yoduro, bromuro, pues deteriorará las superficies rápidamente.

- Todo producto combustible utilizado para la limpieza, como acetona, alcohol, éter, benzol, etc., pues son altamente

explosivos y nunca se deben usar cerca de una estufa.

- 33 -

Page 34

17. FUNCIONAMIENTO

Encienda siempre el recubrimiento de la campana antes de comenzar a cocinar para establecer un flujo de aire en la cocina.

Deje el ventilador funcionando unos cuantos minutos para despejar el aire después de apagar la estufa. Esto ayudará a

mantener toda la cocina más limpia y brillante.

LUZ DE LA ESTUFA (HALÓGENO)

Las luces de halógeno se controlan con el indicador de carátula.

• POSICIÓN 1: APAGADO

• POSICIÓN 2: BAJO

• POSICIÓN 3: ALTO

• POSICIÓN 4: APAGADO

• Use lámparas de halógeno protegidas de 120 V, 50 W, MR16 con base GU10 o PAR16 con base GU10 (incluidas).

VENTILADOR

El ventilador se controla con el indicador de carátula.

• POSICIÓN 1: APAGADO

• POSICIÓN 2: BAJO

• POSICIÓN 3: MEDIO

• POSICIÓN 4: ALTO

• TERMOSTATO HEAT SENTRY™

Este recubrimiento de campana está equipado con un termostato Heat Sentry™ Este termostato es un dispositivo que

encenderá el ventilador o aumentará su velocidad si detecta un calor excesivo sobre la superficie de cocinado.

1) Si el ventilador está APAGADO: ENCIENDE el ventilador a ALTA velocidad.

2) Si el ventilador está ENCENDIDO a una velocidad menor: pone el ventilador a ALTA velocidad.

!

ADVERTENCIA

El termostato HEAT SENTRY puede encender el ventilador cuando exista un incendio en la estufa o en

otras situaciones de calor excesivo, aunque la campana esté apagada. En este caso, es imposible APAGAR

el ventilador con el interruptor. Si debe apagar el ventilador, hágalo desde el panel eléctrico principal.

Cuando la temperatura disminuye a valores normales, el ventilador regresa a su posición original.

- 34 -

Page 35

18. DIAGRAMA DE CABLEADO

BLANCO

BLANCO

AZUL AZUL

GRIS

GRIS

MARRÓN

NEGRO

GRIS

AZUL

BLANCO

BLANCO

ROJO

NEGRO

AZUL

BLANCO

NEGRO

NEGRO

VIOLETA

CAJA

VERDE

NEGRO

BLANCO

MOTOR

MOTOR

ROJO

AMARILLO

MARRÓN

CAJA

VIOLETA

VERDE

VERDE

ROJO

AZUL

BLANCO BLANCO

MARRÓN

AMARILLO

AZUL

VIOLETA

CONDENSATOR 22 uF 250VCA 2 PIEZAS ENCAJA 120VCA 60Hz

MODELO CPDI362SB

BLANCO

ROJO

VERDE

VERDE

ROJO

AZUL

AMARILLO

BLANCO BLANCO

AMARILLO

VIOLETA

MOTOR

CAJA

MOTOR

CAJA

BLANCO

NEGRO

VERDE

VIOLETA

AZUL

VIOLETA

MARRÓN MARRÓN

GRIS

GRIS

GRIS

MARRÓN

AZUL

AZUL

AZUL AZUL

BLANCO

NEGRO

NEGRO

BLANCO

NEGRO

NEGRO

ROJO

AZUL

ROUGE

ROJO

NEGRO

VIOLETA

BLANCO

NEGRO

NEGRO

NEGRO

NEGRO

BLANCO

VIOLETA

BLANCO

AZUL

CONDENSATOR 22 uF 250VCA 2 PIEZAS ENCAJA 120VCA 60Hz

MODELOS CPDI482SB y CPDI602SB

19. GARANTÍA

GARANTÍA

GARANTÍA LIMITADA DE UN AÑO

Broan-NuTone LLC (“Broan-NuTone”) garantiza al consumidor comprador original de sus productos que tales productos

estarán libres de defectos en materiales o mano de obra durante un período de un año a partir de la fecha de la compra

original. NO EXISTEN OTRAS GARANTÍAS, EXPLÍCITAS O IMPLÍCITAS, INCLUYENDO, ENTRE OTRAS, GARANTÍAS

IMPLÍCITAS DE COMERCIALIZACIÓN O APTITUD PARA UN PROPÓSITO PARTICULAR.