Page 1

INSTALLATION INSTRUCTIONS

HB0132

CP55IQ, CP57IQT AND CP57E SERIES

! !

INTENDED FOR DOMESTIC COOKING ONLY

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

HOMEOWNER: USE AND CARE INFORMATION ON PAGES 13 AND 14.

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800-558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.com 866-737-7770

To register your product online or for additional information visit www.BestRangeHoods.com

SV21422 rev. 06

Page 2

!

WARNING

CAUTION

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If

you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel

and lock service disconnecting means to prevent power from

being switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by qualified

personnel in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to

prevent backdrafting. Follow the heating equipment manufacturer’s

guidelines and safety standards such as those published by the

National Fire Protection Association (NFPA) and the American

Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE) and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

10. When applicable local regulations comprise more restrictive

installation and/or certification requirements, the aforementioned

requirements prevail on those of this document and the installer

agrees to conform to these at his own expenses.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

b) Always turn power pack ON when cooking at high heat or when

flambeing food (i.e.: Crêpes Suzette, Cherries Jubilee, Peppercorn

Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan, filters or in exhaust ducts.

d) Use proper pan size. Always use cookware appropriate for the

size of the surface element.

!

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE

THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

IF THE FLAMES DO NOT GO OUT IMMEDIATELY, EVACUATE

AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels — This

could cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and you know how to

operate it.

B. The fire is small and contained in the area where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust hazardous

or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

4. Your power pack motor has a thermal overload which will

automatically shut off the motor if it becomes overheated. The

motor will restart when it cools down. If the motor continues to

shut off and restart, have the power pack serviced.

5. The minimum hood distance above cooktop must not be less than

24”. A maximum of 30” above cooktop is recommended for best

capture of cooking impurities.

6. Two installers are recommended because of the large size and

weight of this unit.

7. To reduce the risk of fire and to properly exhaust air, be sure to

duct air outside — Do not exhaust air into spaces within walls or

ceiling or into attics, crawl space or garage.

8. This product is equipped with a thermostat which may start blower

automatically. To reduce the risk of injury and to prevent power

from being switched on accidentally, switch power off at service

panel and lock or tag service panel.

9. Because of the high exhausting capacity of this unit, you should

make sure enough air is entering the house to replace exhausted

air by opening a window close to or in the kitchen.

10. To reduce the risk of fire and electrical shock, the Best CP55IQ

& CP57IQT Series models should only be installed with their own

built-in blowers, and the Best CP57E Series models must only

be installed with Best exterior blower models EB6, EB9, EB12

or EB15; or Best in-line blowers models ILB3, ILB6, ILB9, ILB11.

Other blowers cannot be substituted.

11. Please read specification label on product for further information

and requirements.

12. This power pack is equipped with a RF receiver (optional remote

control sold separately). Changes or modifications not expressly

approved by the party responsible for compliance could void the

user’s authority to operate this product. The remote control has

been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules and the Canadian

ICES-003. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

The remote control generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected

2

Page 3

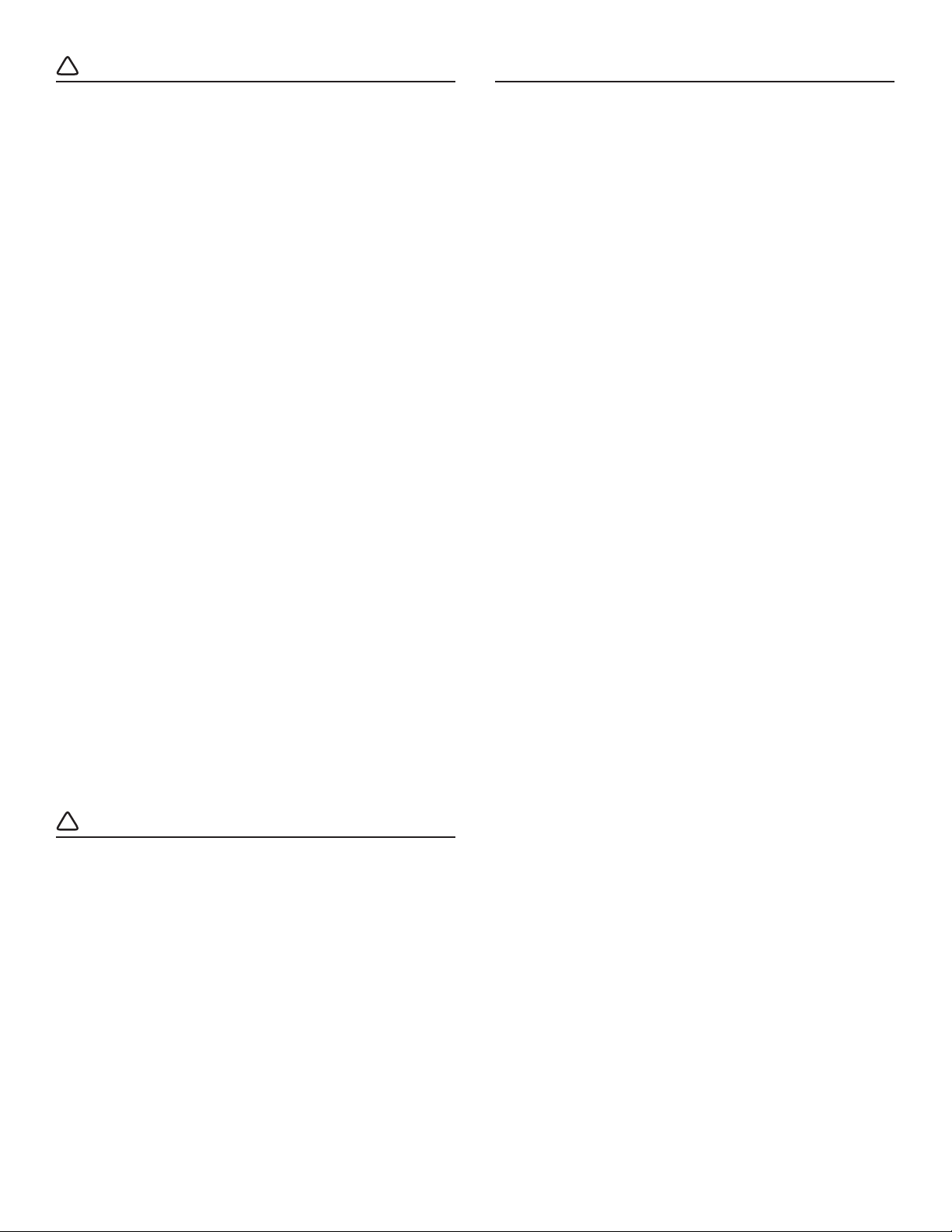

- CP55IQ AND CP57IQT POWER PACK SYSTEMS -

MODEL 634 OR 644

ADJUSTABLE ELBOW

STANDARD

ADAPTER/DAMPER

8” ROUND (SUPPLIED WITH

SINGLE

BLOWER POWER PAC K)

(ROOF CAP)

8” ROUND

OUND

8” R

DUCT

MODEL 643

(8” ROUND WALL CAP)

CP55IQ

POWER PACK

(HIGH CAPACITY ROOF CAP)

ADJUSTABLE ELBOW)

(10” ROUND DUCT

— 2 FT. SECTIONS)

CP57IQT

POWER PACK

MODEL 437

MODEL 418

(10” ROUND

ODEL 410

M

MODEL 441

(10’’ ROUND WALL CAP )

10” R

OUND VERTICAL

IN-LINE DAMPER (SUPPLIED WITH

DUAL BLOWER POWER PA CK )

10” ROUND ADAPTER

(SUPPLIED WITH DUAL BLOWER

POWER PAC K )

HL0207

ACR SERIES

+

-

REMOTE CONTROL KIT

¤

(SOLD SEPARATELY)

S

INGLE INTERIOR BLOWER DUAL INTERIOR BLOWER

3

Page 4

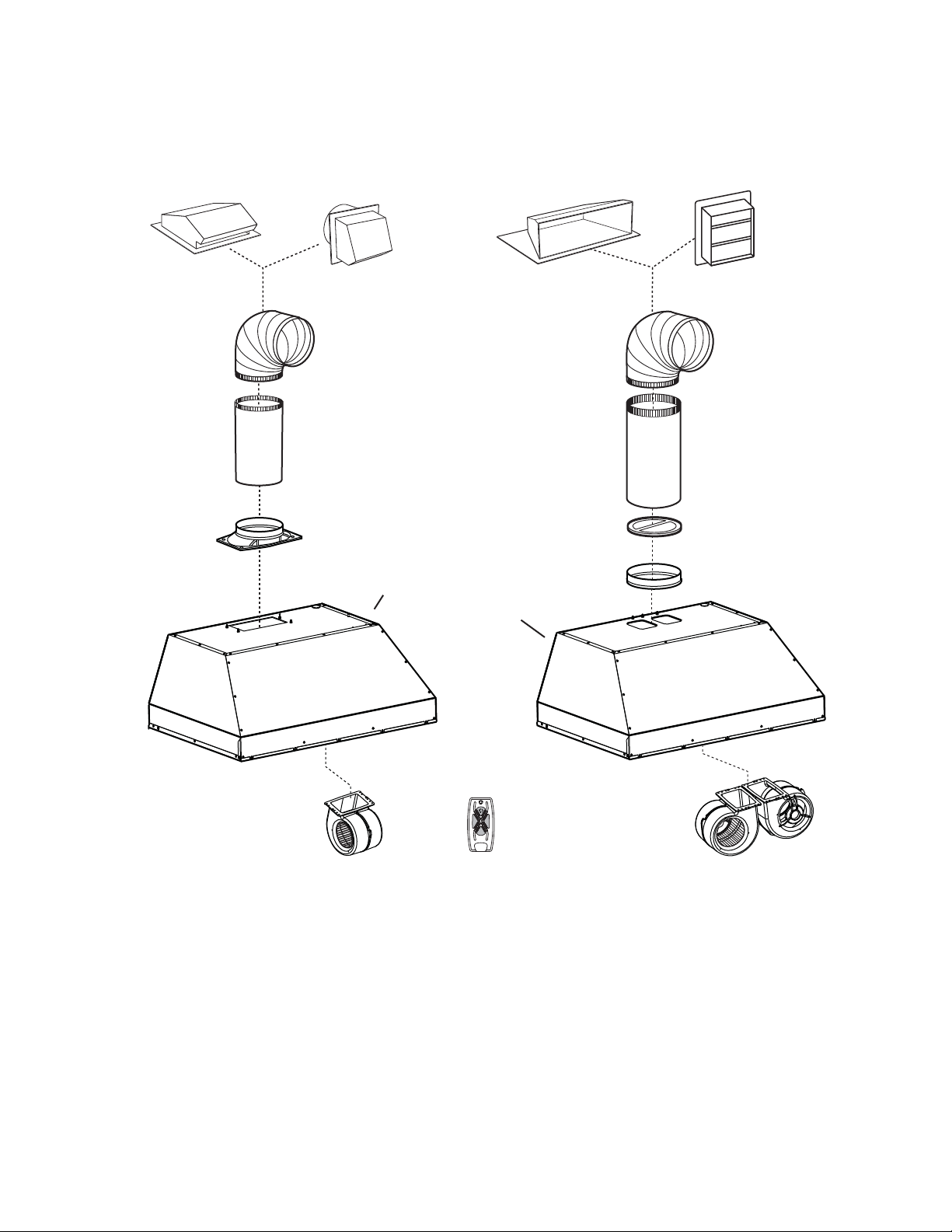

MODEL 643

(8” ROUND

WALL

CAP)

- CP57E POWER PACK SYSTEM -

MODEL 437

(HIGH CAPACITY ROOF CAP)

MODEL 441

(10” ROUND

WALL

MODEL ILB6 (600 CFM)

IN-LINE BLOWER

(INCLUDES TWO 4½” X 18½”

TO 10’’ ROUND TRANSITIONS)

CAP)

ODEL ILB9 (800 CFM)

M

OR ILB11 (1100 CFM)

IN-LINE BLOWER

(INCLUDES TWO 8” X 12” TO

10’’ ROUND TRANSITIONS)

M

ODEL 418

(10” ROUND

ADJUSTABLE ELBOW)—

OPTIONAL

MODEL EB6 (600 CFM)

OR EB9 (900 CFM)

EXTERIOR BLOWER

MODEL EB12 (1200 CFM)

OR EB15 (1500 CFM)

EXTERIOR BLOWER

MODEL ILB3 (280 CFM)

IN-LINE BLOWER

(INCLUDES ONE 8” TO 10”

ROUND TRANSITION)

ACR SERIES

+

-

REMOTE CONTROL KIT

¤

(SOLD SEPARATELY)

HL0208

MODEL 410

(10” ROUND DUCT

—2FT. SECTIONS)

CP57E

POWER PACK

IN-LINE AND EXTERIOR BLOWER ROUGH-IN KIT

(INCLUDED WITH EB6, EB9, EB12, EB15,

ILB3, ILB6, ILB9 AND ILB11 BLOWERS.)

4

Page 5

1. INSTALL DUCTWORK AND ELECTRICAL WIRING

1.1 NON-DUCTED INSTALLATION (CP55IQ SERIES POWER PACKS ONLY)

CP55IQ Series power packs may be non-ducted. ANKCP55 non-duct kit must be installed (sold separately).

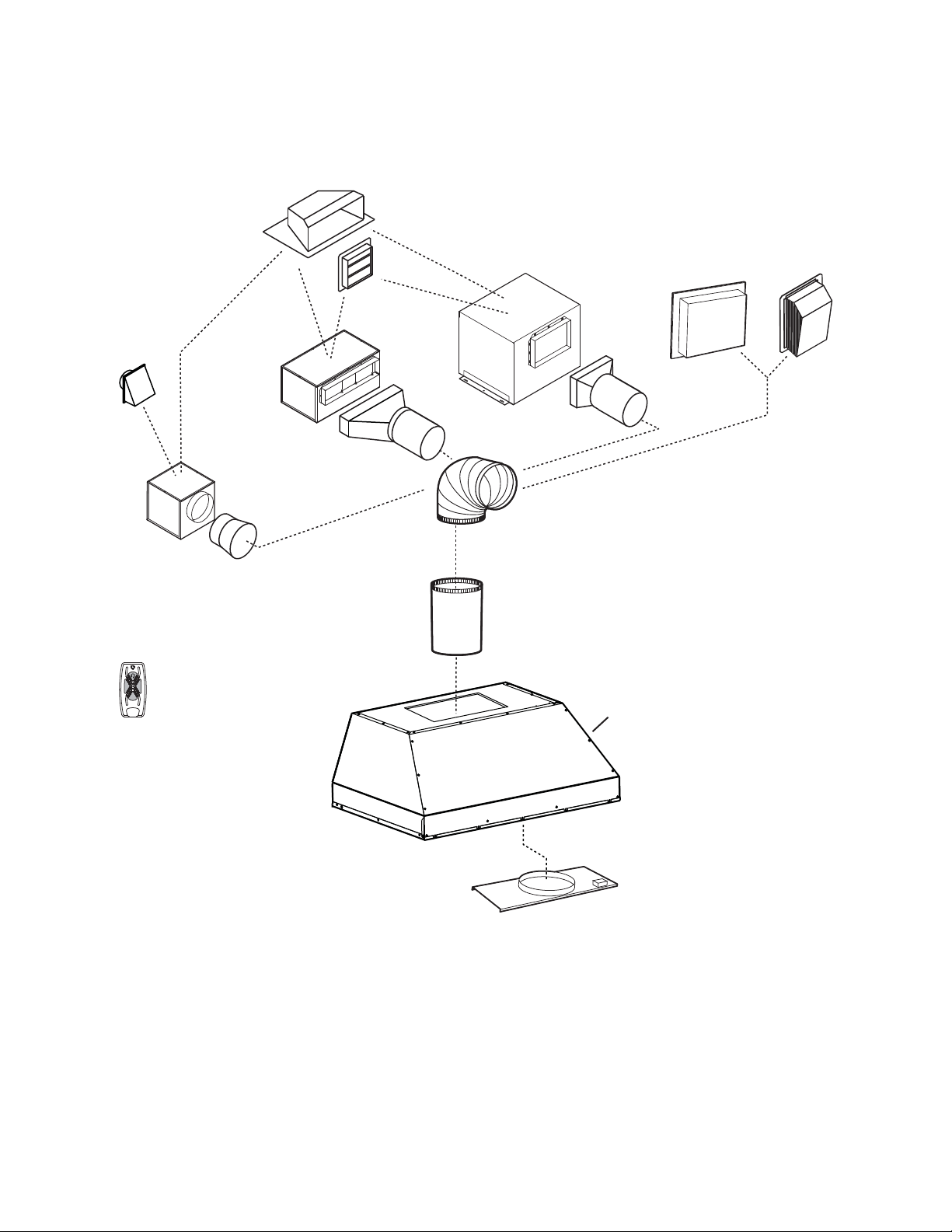

1.2 DUCTED INSTALLATION (ALL POWER PACKS)

For a CP57E Series power pack, either an exterior blower or in-line blower must be used. The CP57E Series power pack must be

installed with blower models ILB3, ILB6, ILB9, ILB11, EB6, EB9, EB12 or EB15 only. Other blowers cannot be substituted (blowers

sold separately.) Plan where and how the ductwork will be installed.

If installing exterior or in-line blower, refer to instructions packed with blower and follow steps 1 up to 7, 11, 13 and up of

this manual.

Install proper-sized ductwork, elbows and roof or wall cap for the type of blower you are installing. If installing CP55IQ Series power

pack, use 8” round ductwork and if installing CP57IQT or CP57E Series power pack, use 10” round ductwork. Use metal foil duct

tape to seal duct joints.

NOTE: It is recommended that there be a minimum of 6" of straight duct from the hood to an elbow for 8" duct and 12" for 10" duct.

1.3 ALL INSTALLATIONS

The minimum power pack distance above cooktop must not be less than 24’’. A maximum of 30” above cooktop is

recommended for best capture of cooking impurities.

Distances over 30” are at the installer and users discretion.

Run 3-wire power supply cable to installation location. Its length should extend at least 4 feet below the bottom of the custom hood.

ROOF CAP

8” ROUND DUCT FOR CP55IQ OR

10” ROUND DUCT FOR CP57IQT

8” ROUND ELBOW FOR CP55IQ OR

10” ROUND ELBOW FOR CP57IQT

10” IN LINE

VERTICAL DAMPER FOR CP57IQT

8” ROUND ADAPTER & DAMPER

WALL

CAP

HH0201A

24” TO 30”

ABOVE COOKING SURFACE

FOR CP55IQ OR

10” ROUND ADAPTER FOR CP57IQT

POWER PACK

CP55IQ (SINGLE INTERNAL BLOWER)

OR CP57IQT (DUAL INTERNAL BLOWER)

TYPICAL DUCTWORK

ROOF CAP

10” ROUND DUCT

(except ILB3, 8’’ ROUND DUCT)

IN-LINE BLOWER

WALL

CAP

POWER PACK

24” TO 30” ABOVE

COOKING SURFACE

HH0114A

CP57E WITH MODEL ILB3, ILB6, ILB9

OR ILB11 IN-LINE BLOWER TYPICAL DUCTWORK

(BLOWER LOCATION IS SHOWN FOR REFERENCE ONLY)

EXTERIOR BLOWER

10” ROUND DUCT

10” ROUND ELBOW

EXTERIOR

BLOWER

POWER PACK

24” TO 30”

ABOVE

HH0115A

COOKING SURFACE

CP57E EXTERIOR BLOWER T YPICAL DUCTWORK

5

Page 6

2. PREPARE INSTALLATION

!

!

”

WARNING

When performing installation, servicing or cleaning the unit, it is recommended to wear safety glasses and gloves.

NOTE: Before proceeding to the installation, check the contents of the box. If items are missing or damaged, contact the manufacturer.

Make sure that the following items are included:

- Power Pack

- Accessories • Hybrid baffle filters with handles (3 for 36’’ width power pack, 4 for 42’’ width power pack and 5 for 48” to 66” width power

• 8” round adapter and damper (included with CP55IQ power pack series)

• 10” round in-line vertical damper (included with CP57IQT power pack series)

• 10” round adapter (included with CP57IQT power pack series)

• Bag of parts including: 1 wire clamp, 2 wire connectors, 4 no. 8 x 3/8” screws, 9 no. 8 x 1/2” chrome plated screws,

Parts sold separately:

• ACR Series remote control kit

• In-line blower assembly model ILB3, ILB6, ILB9 or ILB11.

• Exterior blower assembly model EB6, EB9, EB12 or EB15.

• Ducts, elbows, wall and roof caps. Refer to page 3 and 4 for a complete list of venting options and model numbers.

• Non-duct kit ANKCP55 Series, mandatory for non-ducted installation.

NOTE: During installation, protect countertop and/or cooktop.

packs)

10 no. 8-32 x 1/4” screws (not used with this product, please discard).

3. CUSTOM HOOD PREPARATION

WARNING

When building a custom hood, always follow all applicable construction codes and standards.

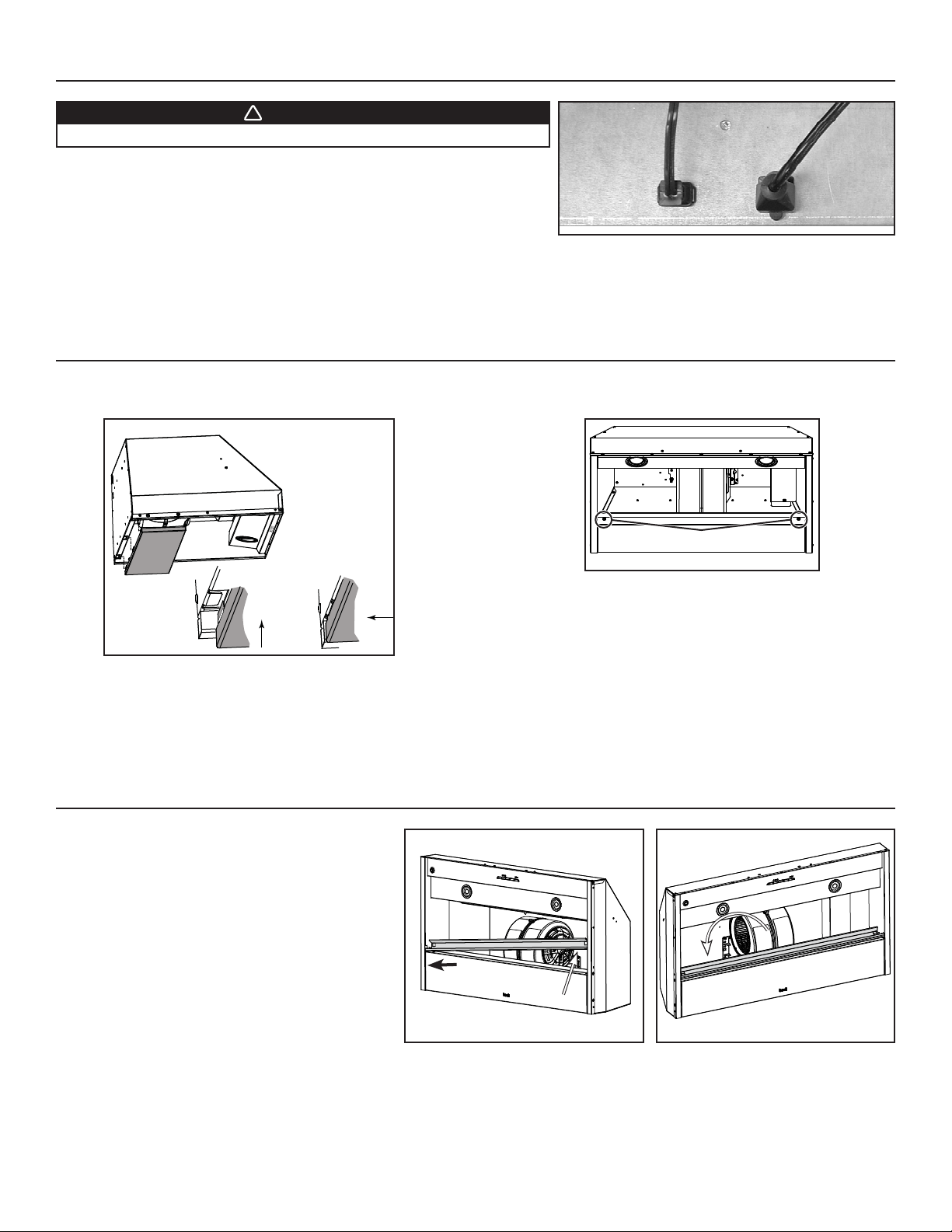

The custom hood must be constructed to fit the size and shape of the CP55IQ, CP57IQT or the CP57E power pack.

See chart and illustration for details.

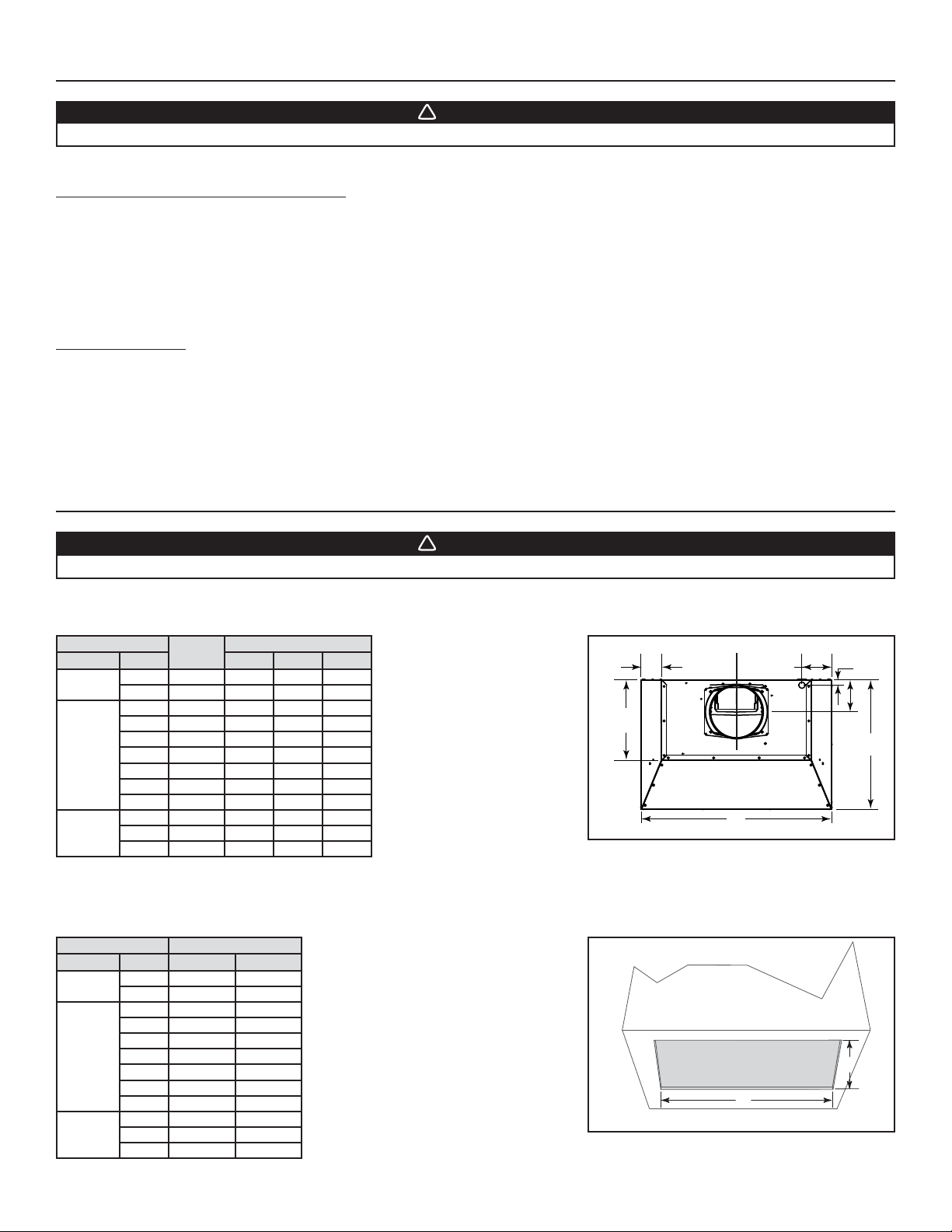

POWER PAC K TOTAL

MODEL WIDTH A* B* C

CP55IQ

CP57IQT

CP57E

WEIGHT

36” 52 LB.195⁄16”347⁄16” 4¼”

42” 62 LB.195⁄16”407⁄16”43⁄8”

36” 62 LB.195⁄16”347⁄16”53⁄8”

36” 62 LB.229⁄16”347⁄16”53⁄8”

48” 72 LB.195⁄16”467⁄16”53⁄8”

48” 72 LB.229⁄16”467⁄16”53⁄8”

54” 82 LB.229⁄16”527⁄16”53⁄8”

60” 85 LB.229⁄16”587⁄16”53⁄8”

66” 88 LB.229⁄16”647⁄16”53⁄8”

36” 40

48” 53 LB.229⁄16”467⁄16”6”

60” 66

POWER PAC K DIMENSIONS

LB.22

LB.22

9

⁄16”347⁄16”6”

9

⁄16”587⁄16”6”

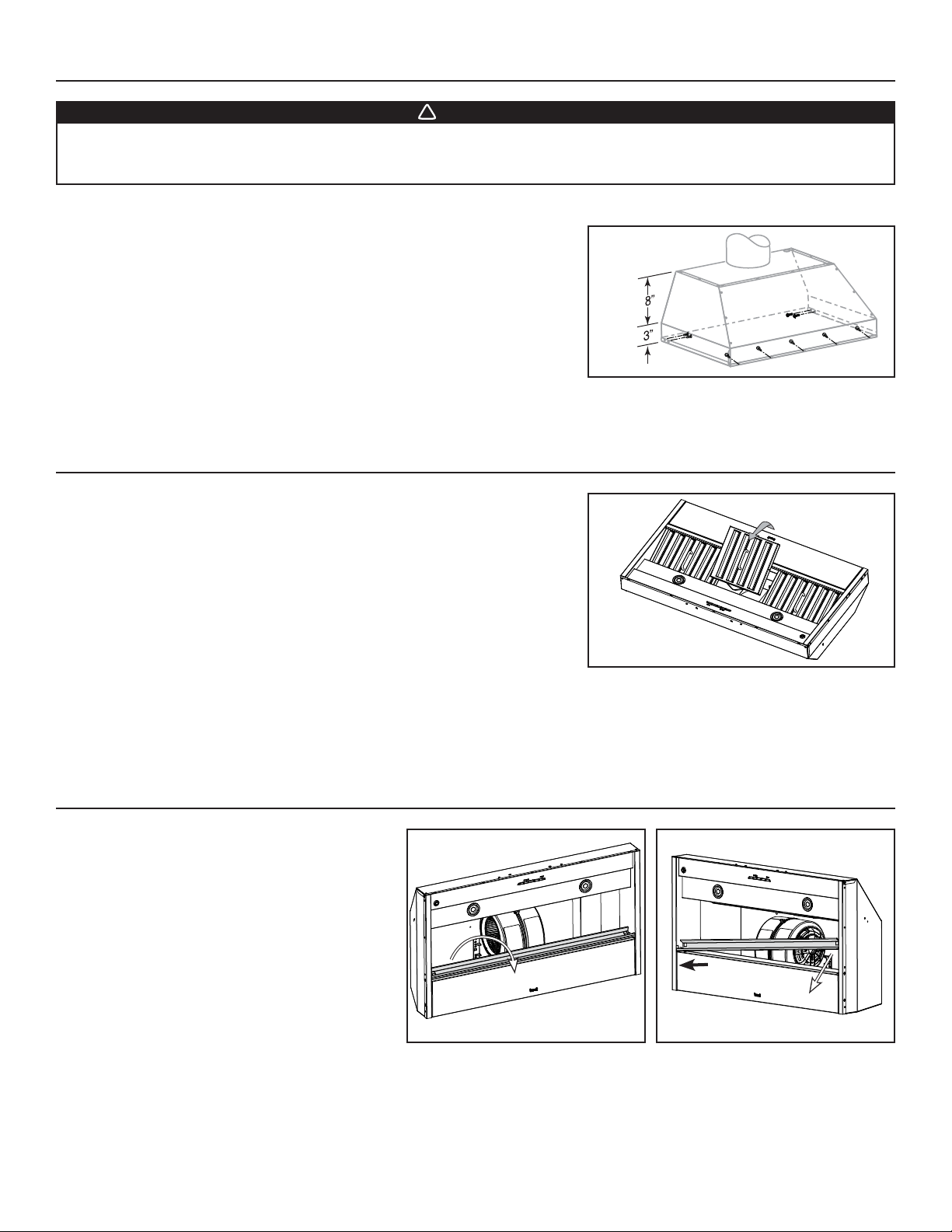

3”

12”

HD0296A

* Dimensions A and B include rivets head.

To minimize the gap around the power pack, take actual width and depth measurements of power pack and add 1/16” to get D and E

measurements. Cut the hole in the bottom of the cabinet according to dimensions. See chart and illustration for details.

POWER PAC K CUTOUT DIMENSIONS

MODEL WIDTH DE

CP55IQ

CP57IQT

CP57E

36” 193⁄8” 34½”

42” 193⁄8” 40½”

36” 19

36” 22

48” 193⁄8”” 46½”

48” 225⁄8” 46½”

54” 225⁄8” 52½”

60” 225⁄8” 58½”

66” 225⁄8” 64½”

36” 22

48” 22

60” 225⁄8” 58½”

3

⁄8” 34½”

5

⁄8” 34½”

5

⁄8” 34½”

5

⁄8” 46½”

HD0367

REAR

C

L

B

FRONT

E

4½”

7/8

C

A

D

6

Page 7

4. MOUNT CUSTOM HOOD INTERNAL FRAMEWORK

!

WARNING

The wood hood must be positively secured to wall studs or other wooden framework behind the drywall. Make

sure it is capable of supporting its own weight and the weight of the CP55IQ, CP57IQT or CP57E. Failure to do so

may cause personal injury or damage to countertop or cooktop.

The CP55IQ, CP57IQT and CP57E power pack is supported by the custom hood internal framework with screws provided in parts bag.

Since the CP55IQ, CP57IQT and CP57E power pack mounting holes are located in

front and rear sides (see illustration at right), plan to install wood frame at front and

sides for support.

HH0102A

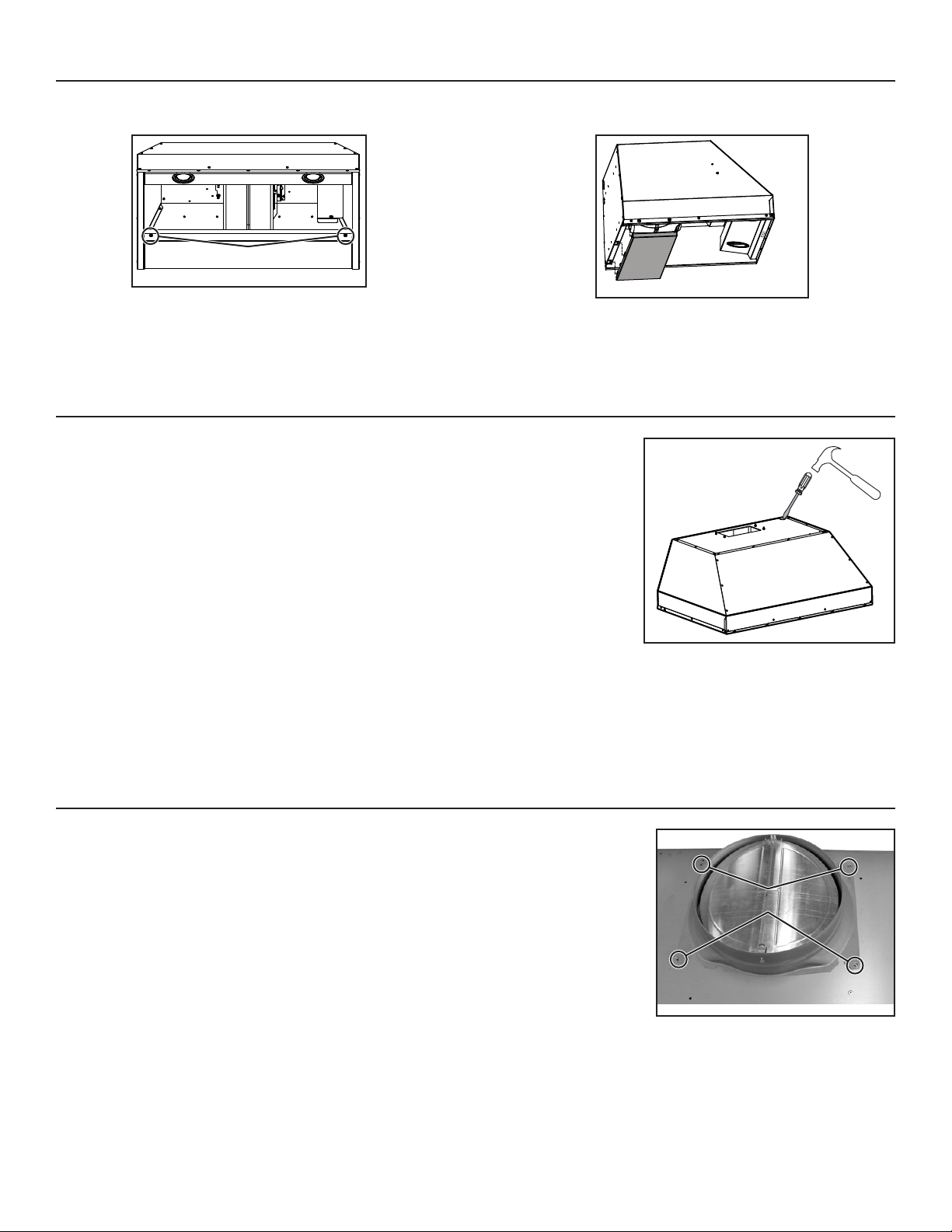

5. REMOVE HYBRID BAFFLE FILTERS

Remove tape on filters. Remove filters from power pack and set aside.

It is recommended to start with the center one(s).

6. REMOVE GREASE DRIP RAIL

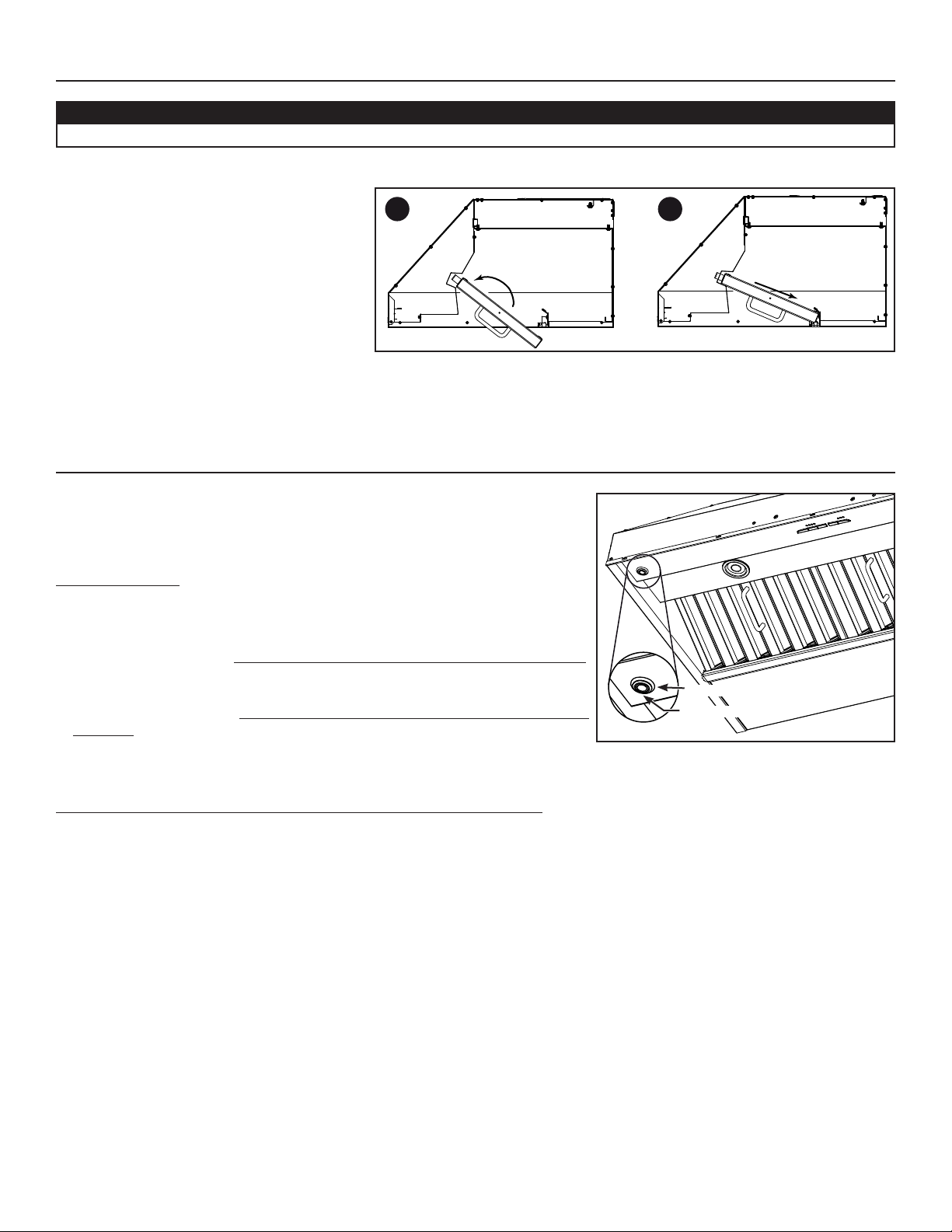

A. Lift grease drip rail to disengage it from the bottom

panel.

B. Slide grease rail all the way to the left or right () and

lift the opposite end to disengage the other end from

the bottom panel (). Remove it from the power pack

and set aside for later use.

HD0524

A

HD0521

B

HD0525

7

Page 8

7. REMOVE BOTTOM PANEL

Using a Phillips screwdriver, remove both bottom panel retaining

screws and set aside.

RETAINING SCREW LOCATIONS

HO0224

Disassemble bottom panel from power pack and set aside.

SIDE VIEW

HO0120

8. REMOVE KNOCK-OUT OPENING (CP55IQ AND CP57IQT SERIES ONLY)

From inside the power pack, remove the wiring box cover by removing 2 retaining screws and

set aside. Punch out the electrical knockout hole on top of the power pack. Install the wire clamp

(included in parts bag).

HR0027

9. INSTALL THE 8” ADAPTER/DAMPER (CP55IQ SERIES ONLY)

Using 4 no. 8 x 3/8” screws from parts bag, assemble the adapter/damper on the top of the power pack. To ensure proper opening of the

dampers, remove shipping tape if present. Seal all joints with metal foil duct tape to eliminate air leaks.

MOUNTING SCREW LOCATIONS

HJ0016

8

Page 9

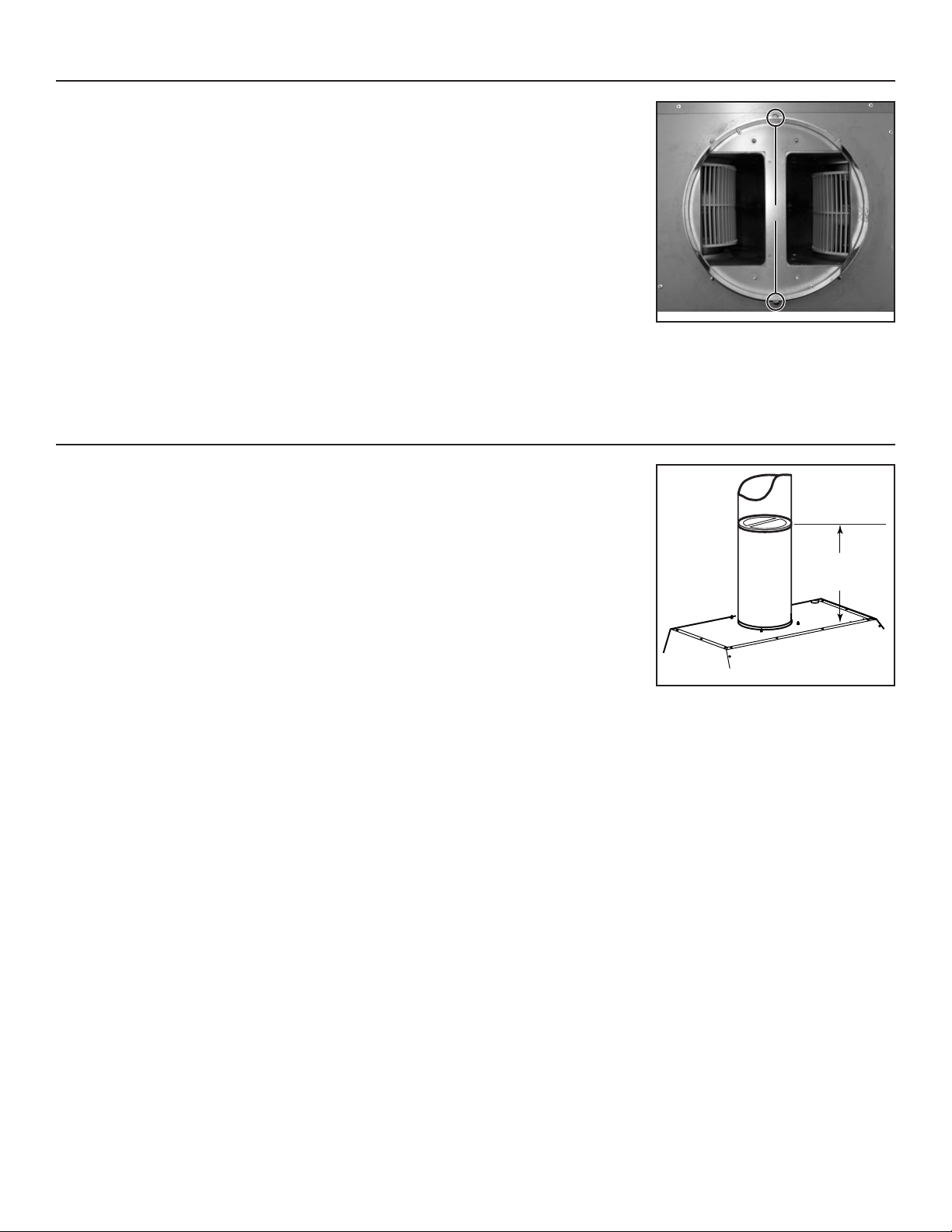

10. INSTALL THE 10” ADAPTER (CP57IQT SERIES ONLY)

Using 2 no. 8 x 3/8” screws from parts bag, assemble the adapter on the top of the power pack.

Seal all joints with metal foil duct tape to eliminate air leaks.

11. INSTALL THE 10” IN-LINE DAMPER

(CP57IQT AND CP57E SERIES, DUCTED INSTALLATION ONLY)

NOTE: For a non-ducted installation, do not install the 10” in-line damper.

Install 10” in-line damper inside the vertical ductwork that will be attached to power pack. Do not

install in a horizontal ductwork or it will not open and close properly. Remove shipping tape if

present. Secure the damper to the duct with 3 no. 8 sheet metal screws (not provided). Ensure

damper opens and closes freely. Seal all joints with metal foil duct tape to eliminate air leaks.

MOUNTING SCREW LOCATIONS

HJ0026

10" min.

recommended

HJ0073A

9

Page 10

!

12. INSTALL THE ROUGH-IN PLATE FOR EXTERNAL BLOWER

(CP57E SERIES ONLY)

Refer to the instructions included with the selected blower/rough-in kit (sold

separately) for details on installing the rough-in plate. Install the rough-in plate so

that the wiring box is located on the right side when facing the hood, as specified

on the blower housing label.

HD0522

WIRING BOX

COVER

LOCK NUTS

13. CONNECT WIRING (ALL BLOWERS)

WARNING

Risk of electric shock. Electrical wiring must be done by qualified personnel in accordance with all applicable

codes and standards. Before connecting wires, switch power off at service panel and lock service disconnecting

means to prevent power from being switched on accidentally.

Position the power pack below the installed custom hood.

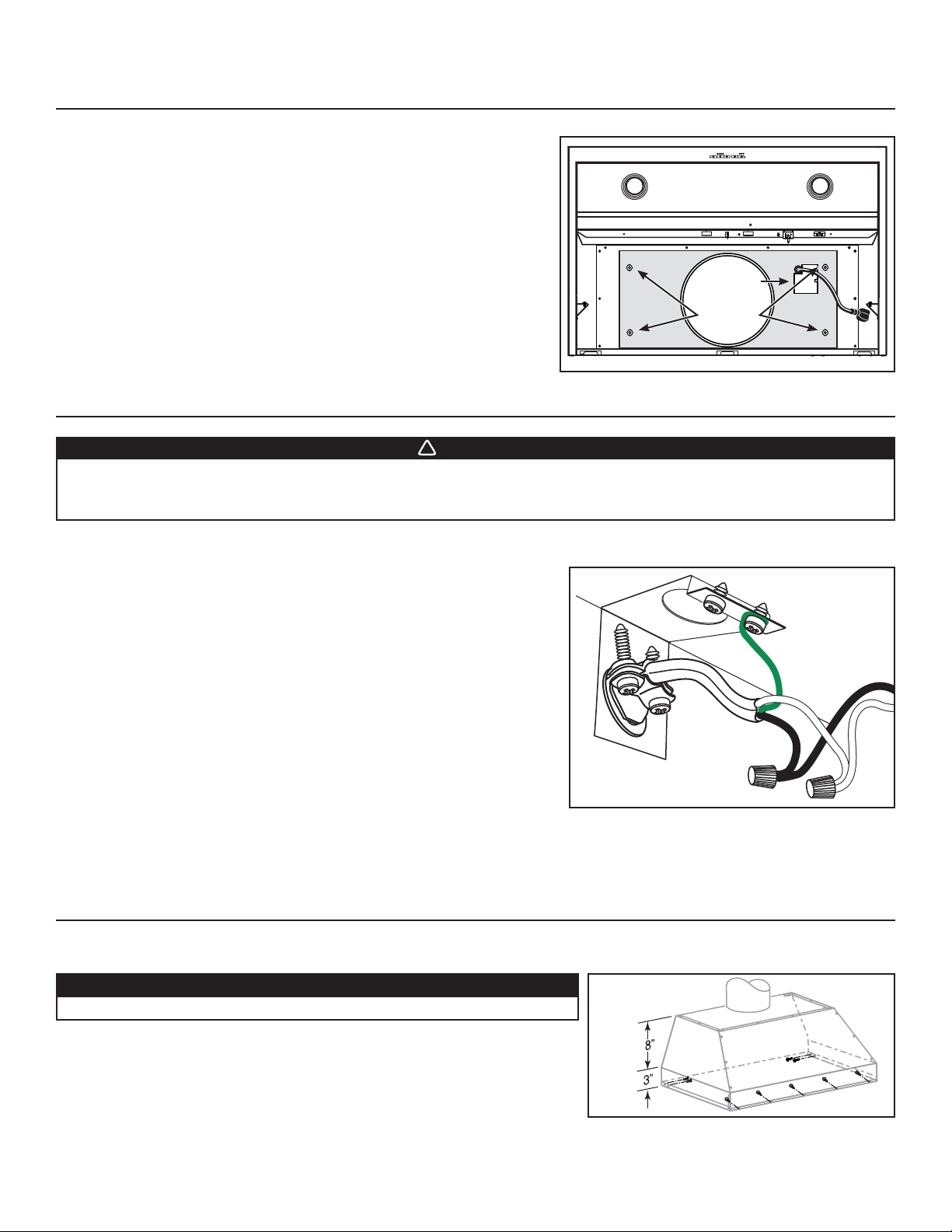

INTERNAL BLOWERS: Insert the house wiring cable through the wire clamp

previously installed in step 8. Tighten the wire clamp to

secure the cable. Connect cable into wiring box using

wire connectors. Connect BLACK to BLACK, WHITE to

WHITE and GREEN or bare wire under GREEN ground

screw. DO NOT FORGET TO CONNECT THE GROUND.

Reinstall wiring box cover.

IN-LINE OR EXTERIOR BLOWERS: See instructions included with blower.

HE0059

14. INSTALL POWER PACK

MODEL CP55IQ ONLY: If the model CP55IQ is to be installed with a non-duct kit, install a 8” to 7” reducer (included in non-duct kit) prior

to install the power pack in its custom hood.

CAUTION

Take care not to kink ducting when installing the power pack.

Using provided no. 8 x 1/2” chrome plated screws, install the power pack inside the

custom hood. Start with 2 screws on front corners, then use 4 screws for sides and use

the remaining screws to finalize securing the front power pack. (See figure at right for

mounting screw specific locations.)

Make sure the adapter/damper (or the adapter) enters the ducting. When there is

access to the top of the power pack, seal connections with metal foil duct tape.

HH0102A

10

Page 11

15. PERFORM THE EXTERNAL BLOWER CONNECTIONS (CP57E SERIES ONLY)

!

WARNING

Do not plug the two cords together.

To install the blower see instructions included with the blower.

Plug the 3-prong plug cord from rough-in plate to the 3-prong male connector

inside the power pack (A) and the 2-prong male connector cord from rough-in

plate to the 2-prong plug inside the power pack (B).

HE0078

AB

16. REINSTALL BOTTOM PANEL

Lift the bottom panel and engage the power pack metal tabs in

bottom panel slots, as shown in details A and B below.

SIDE VIEW

AB

HO0121

17. REINSTALL GREASE DRIP RAIL

Secure the bottom panel to the power pack using its screws

previously removed in step 7.

RETAINING SCREW LOCATIONS

HO0224

A. Insert one end of grease rail in power pack side ()

while lifting the other end over the bottom panel

edge ().

B. Center the grease drip rail over the bottom panel

edge and flip it to snap in place.

HD0525

A

HD0524

B

11

Page 12

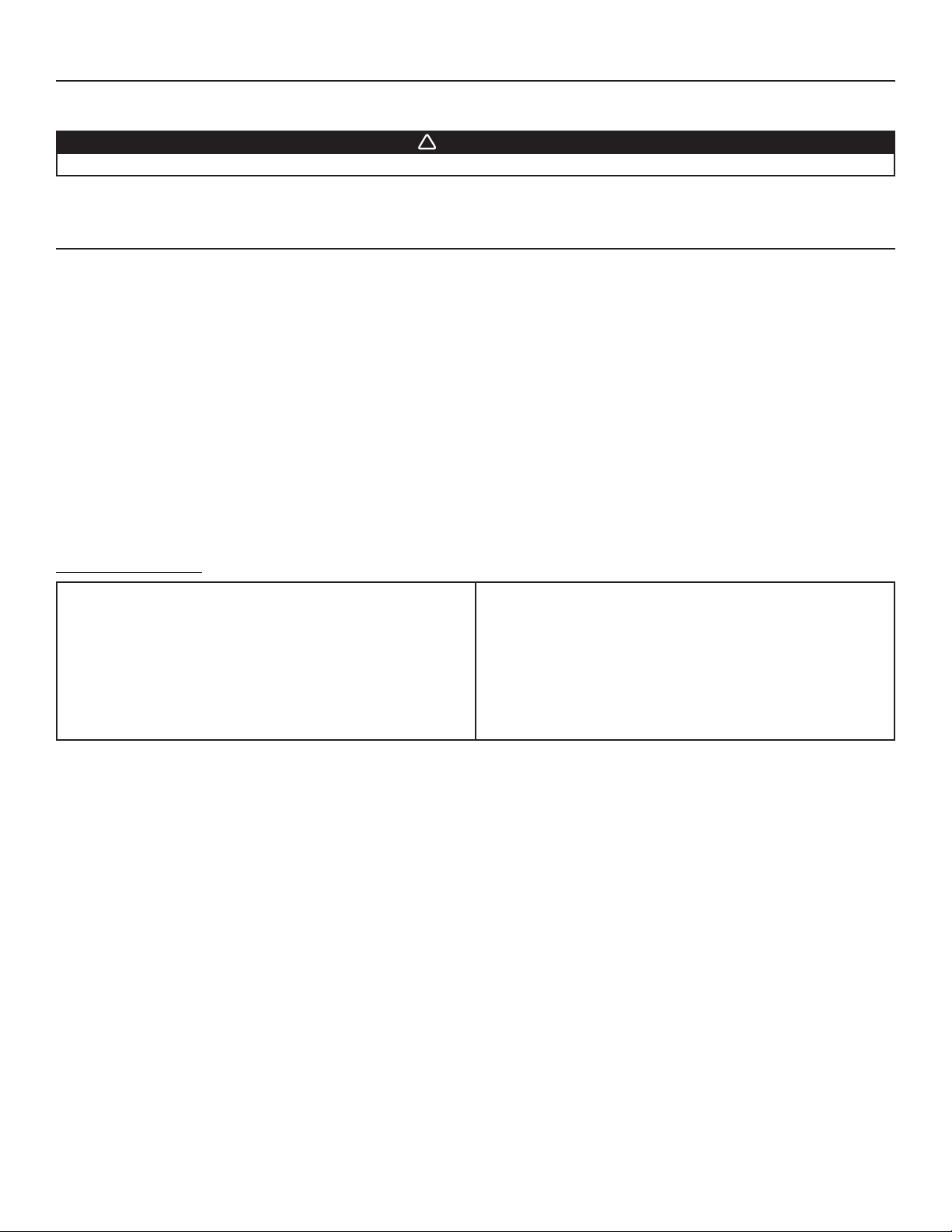

18. REINSTALL HYBRID BAFFLE FILTERS

CAUTION

Remove protective plastic film covering hybrid baffle filters before installing them.

It is recommended to install side filters first and finish with center one(s).

1

1. Insert one end of hybrid baffle filter into the front

channel of the power pack.

2. Raise the other end toward the inside of power

pack and insert in the grease drip rail of the

power pack.

HD0526

2

19. CALIBRATE IQ BLOWER SYSTEM™ (CP55IQ & CP57IQT SERIES ONLY)

NOTE: Calibration is for ducted installations only. Do not calibrate non-ducted installations.

After the power pack is installed and wired, engage the calibration process (our

Guaranteed Performance System Technology to ensure full-rated airflow is being

delivered). Prior to calibration, ensure that all filters and duct system are installed.

CALIBRATION PROCESS

Hold the calibration button for 3 seconds; calibration button will light up and stay on

for up to 13 minutes. The blower will start and begin the calibration process. When

calibration is complete, one of two things will occur:

A. The blower turns off and calibration button light stays on = Successful calibration.

Press the button to turn off the LED.

NOTE: The LED will also turn off if you select any blower speed on the control.

B. The blower turns off and calibration button light blinks continuously = Too much

restriction in the ductwork is preventing the IQ Blower System™ from achieving the

rated airflow. The blower is automatically set to maximum intensity.

NOTE: Common items that cause restrictions: restricted damper flap (backdraft damper, wall cap, roof cap), too many elbows, duct

size less than 80% of hood outlet, poor transition, use of flex ducting and/or crushed ducting.

Three options are available if your power pack system has too much restriction:

1. Accept airflow as is. Press the calibration button to accept airflow as is. The IQ Blower System™ is now configured to its highest possible

performance. The blinking calibration light goes out.

NOTE: The LED will also turn off if you select any blower speed on the control.

2. Correct duct restriction, clear the original calibration data, and repeat the calibration process.

a. Correct the duct restriction.

b. Clear the original calibration data by holding calibration button for 10 seconds. The light will blink 3 times to confirm and the blower

configuration will go back to default settings.

c. Repeat calibration process from the beginning.

3. Clear calibration data to reset power pack to default factory settings and achieve standard high pressure blower performance by holding

calibration button for 10 seconds. The light will blink 3 times to confirm and the blower configuration will go back to default settings.

HC0071

CALIBRATION BUTTON

CALIBRATION LIGHT

12

Page 13

20. LIGHTING

!

This power pack is equipped with LED lamps which require no maintenance.

WARNING

Do not touch lamps during or soon after operation. Burns may occur.

21. USE AND CARE

Hybrid Baffle Filters

The hybrid baffle filters should be cleaned frequently. Use a warm detergent solution. Wash more often if your cooking style generates

greater grease — like frying foods or wok cooking.

Remove hybrid baffle filters by pushing them towards the back of power pack and rotating filters downward. Baffle filters are dishwasher

safe. Allow filters to dry completely before reinstalling them in the power pack.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of the filter may occur if using phosphate detergent

or as a result of local water conditions — but this will not affect filter performance. This discoloration is not covered by the warranty.

Grease Drip Rail

The grease drip rail should be cleaned frequently. Remove it from the power pack (see step 6 on page 7) and use a warm detergent

solution. As with the baffle filters, wash more often if your cooking style generates greater grease — like frying foods or wok cooking. Allow

grease drip rail to dry completely before reinstalling it in the power pack.

Interior Blower(s) Cleaning

Remove the filters in order to access the blower(s). Vacuum blower(s) to clean. Do not immerse in water.

Power pack cleaning

Stainless steel cleaning:

Do:

• Regularly wash with clean cloth or rag soaked with warm water

and mild soap or liquid dish detergent.

• Always clean in the direction of original polish lines.

• Always rinse well with clear water (2 or 3 times) after cleaning.

Wipe dry completely.

• You may also use a specialized household stainless steel

cleaner.

Avoid when choosing a detergent:

- Any cleaners that contain bleach will attack stainless steel.

- Any products containing: chloride, fluoride, iodide, bromide will deteriorate surfaces rapidly.

- Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc., are highly explosive and should never be

used close to a range.

Don’t:

• Use any steel or stainless steel wool or any other scrapers to

remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues reach the

power pack. During construction/renovation, cover the power

pack to make sure no dust sticks to stainless steel surface.

13

Page 14

22. OPERATION

!

Always turn your blower on before you begin cooking to establish an airflow in the kitchen. Let the blower run for a few minutes to clear

the air after you turn off the range.

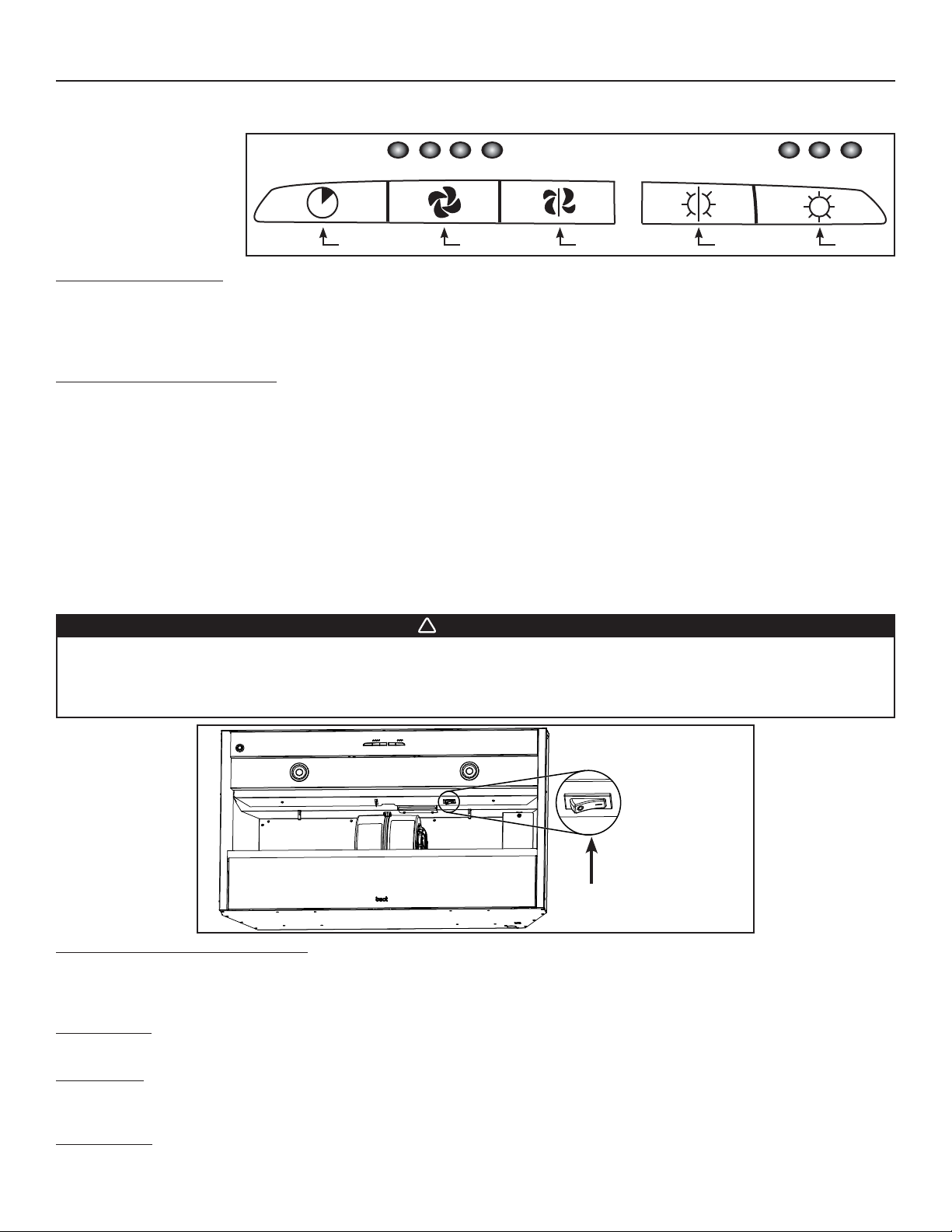

A) Blower delay-off button

B) ON blower/Speed control button

C) OFF blower/

Filter maintenance button

D) OFF lighting

E) ON lighting

HC0016

SPEED 1 2 3 4

BA C D E

A. BLOWER DELAY-OFF BUTTON:

When blower is on, press the delay-off button to activate the delay-off function. The corresponding speed indicator LED will start flashing to

indicate this function is activated. The fan will continue to operate for 10 minutes and will stop automatically. To cancel the delay-off function,

press the blower delay-off button once again; the blower will then work in normal mode.

NOTE: The blower speed can be increased—or decreased—during delay-off mode without starting another 10-minute cycle.

BLOWER/SPEED CONTROL BUTTON:

B. ON

Press this button to turn on the blower at the last selected speed. To change the blower speed, press the button again until the desired

speed is obtained. Press and hold this button for 2 seconds to decrease the speed level down by one increment. Possible decreases are

then: 4 to 3; 3 to 2; 2 to 1 and 1 to OFF.

NOTES: 1. Each time you press the speed control button, the speed changes by increments of 1 (e.g.: speed 1 to speed 2, to speed 3,

and then speed 4). From the fourth speed, the speed goes down to level 1.

2. The last speed used is kept in memory so that when the unit is turned on, it will return to the last setting except the fourth, the

next time the blower will be turned on, it will return to speed 3. The memorized speed level is also synced with the optional

remote control.

HEAT SENTRY™

The power pack is equipped with a protective device that activates when excessive heat is detected inside the power pack. During the Heat

Sentry activation, this device takes control of the blower and set it on speed 4; the speed 4 button LED will flash. The blower will remain

on speed 4 until the heat is back to normal, it then returns to the speed previously selected.

WARNING

The HEAT SENTRY can start the blower during a range top fire or other excessive heat situations even if the power

pack is turned off. In this case, it is impossible to turn the blower OFF with blower button. If you must stop the blower

on CP55IQ/CP57IQT series models: set the main power switch located behind the baffle filters in OFF position, if

it is possible to do safely (see illustration below). For CP57E series models: do it from the main electrical panel.

CP55IQ AND

CP57IQT

SERIES ONLY

MAIN

POWER

SWITCH

C. OFF

HD0527

BLOWER/FILTER MAINTENANCE BUTTON:

Press this button to turn off the blower. Pressing this button also cancels the delay-off function (if activated).

NOTE: After 30 hours of operation, the 4 blower speed lights will flash 30 seconds to indicate the filters need to be cleaned in order to

maintain efficient power pack operation. Pressing this button will reset the code to indicate that maintenance has been completed.

D. OFF

LIGHTING:

Press this button to turn the lamps off.

LIGHTING:

E. ON

Press this button to turn the lamps on; all 3 control LED will light on.

NOTE: There is only one light setting.

EMOTE CONTROL:

R

An optional ACR Series remote control (purchase separately) can be used to operate the power pack.

14

Page 15

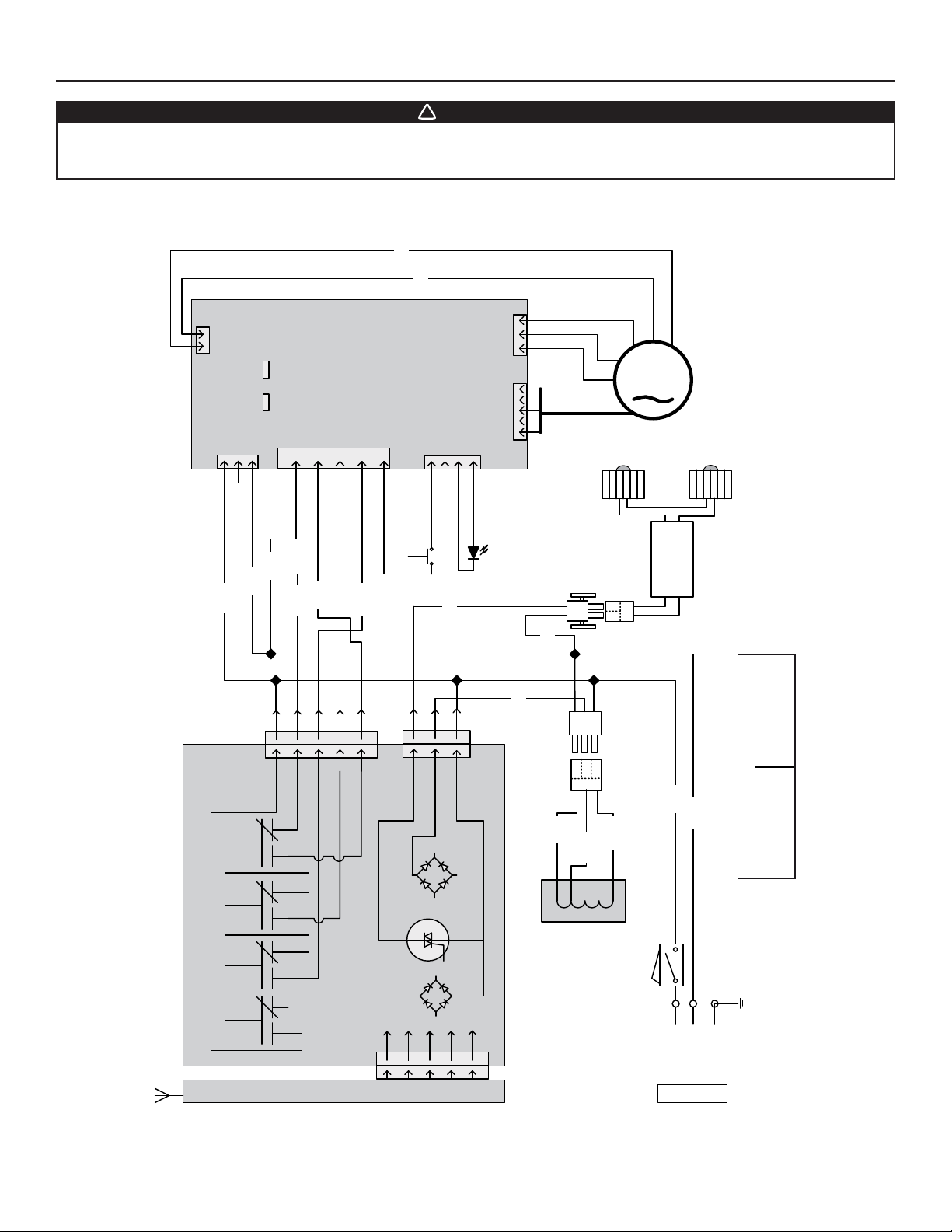

23. WIRING DIAGRAMS

!

WARNING

Risk of electrical shock. Electrical wiring must be done by qualified personnel in accordance with all applicable

codes and standards. Before connecting wires, switch power off at service panel and lock service disconnecting

means to prevent power from being switched on accidentally.

Best CP55IQ Series (single blower)

WHT

WHT

3

2

BLDCHALL

THERMAL

PROTECTION

TRA1PRA1

POWER CALIBRATIONRELAY INTERFACE

L

N

PE

453

2

1

432

1

M

1

LED

LED

BLK

WHT

WHT

MOTOR

NEUTRAL

SPEED 1

BLK

453

HIGH

MED HIGH

BLU

2

SPEED 2

WHT

MED LOW

SPEED 3

1

LOW

SPEED 4

ORG

J1

3

LAMP

AL. SWITCH

C

~

2

LOW VAC

Q1

LED DRIVER

INPUT OUTPUT

YEL

WHT

RED

1

RED RED

WHT WHITE

J7

EF

R

BLK

YEL YELLOW

COLOR CODE

WHT

BLK

+

~

-

RED

WHT

T1

BLU BLUE

BLK BLACK

ORG ORANGE

+

~

K1 K2 K3 K4

~

-

453

2

1

J6

RF RECEIVER

MAIN SWITCH

LINE

GROUND

NEUTRAL

120 V AC

HE0168A

15

Page 16

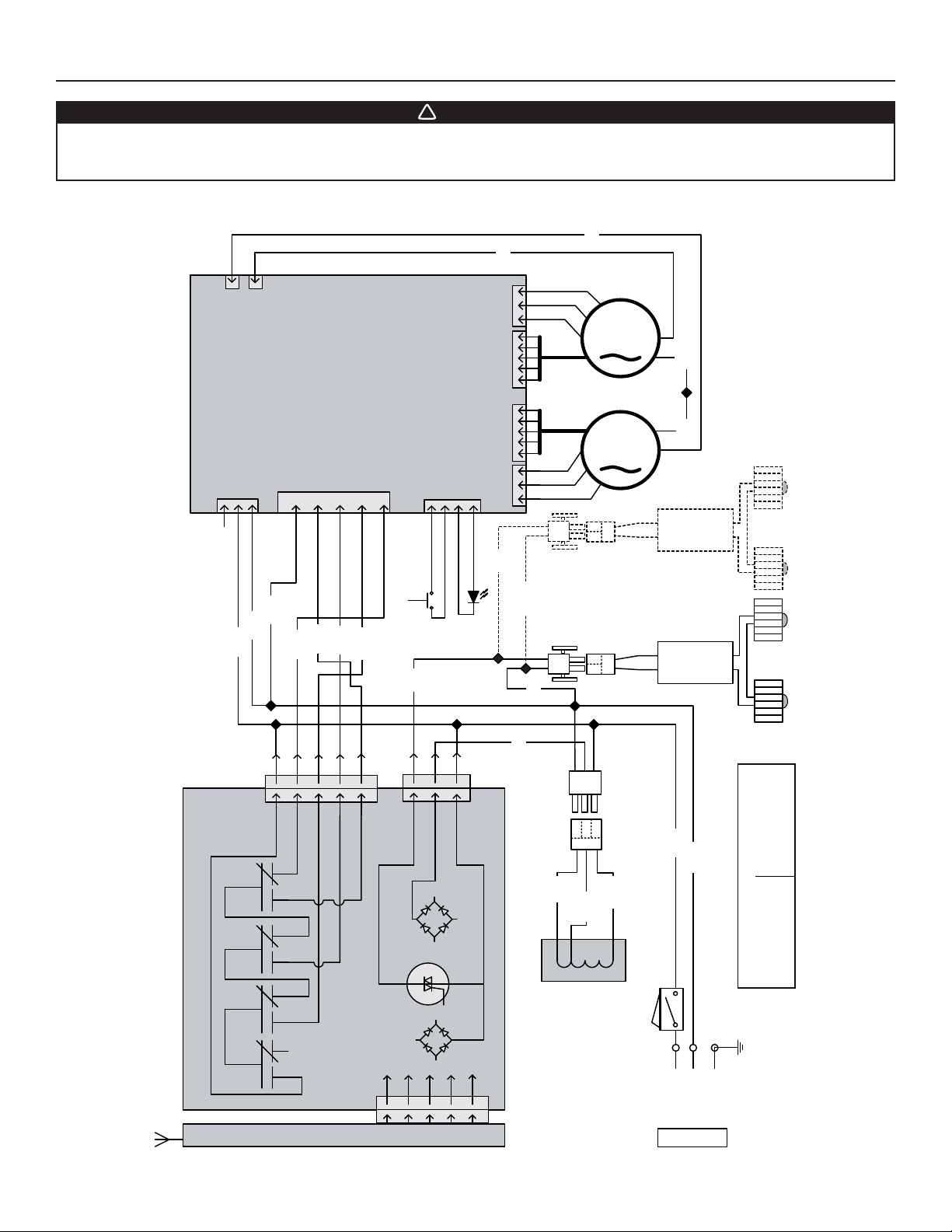

23. WIRING DIAGRAMS (CONT'D)

!

WARNING

Risk of electrical shock. Electrical wiring must be done by qualified personnel in accordance with all applicable

codes and standards. Before connecting wires, switch power off at service panel and lock service disconnecting

means to prevent power from being switched on accidentally.

Best CP57IQT Series (dual blower)

WHT

WHT

2

3

C

HM1

HM2

MT_T

MT_T

POWER CALIBRATIONRELAY INTERFACE

L

E

N

WHT

WHT

BLK

1

EUTRAL

N

SPEED

BLK

453

PEED 2SPEED 3SPEED 4

S

BLU

WHT

2

ORG

1

SWITCH

AL.

C

3

4

YEL

D

2

L

B1

1

_2

ALL

_1 H

ALL

C

3

D

2

L

BH

2

1

1

YEL

WHT

WHT

M

M

BLK BLK

LED DRIVER

INPUT OUTPUT

LED DRIVER

INPUT OUTPUT

LED

LED

LED

K1 K2 K3 K4

LED

RED

2

453

IGH

H

MOTOR

HIGH

MED

1

LOW

MED LOW

J1

3

LAMP

2

1

J7

EF

R

LOVAC

+

~

~

-

Q1

BLK

WHT

RED

BLK

WHT

RED RED

WHT WHITE

COLOR CODE

BLK BLACK

BLU BLUE

YEL YELLOW

ORG ORANGE

T1

+

~

~

-

453

2

1

J6

RF RECEIVER

MAIN SWITCH

LINE

ROUND

G

NEUTRAL

120 V AC

HE0172A

16

Page 17

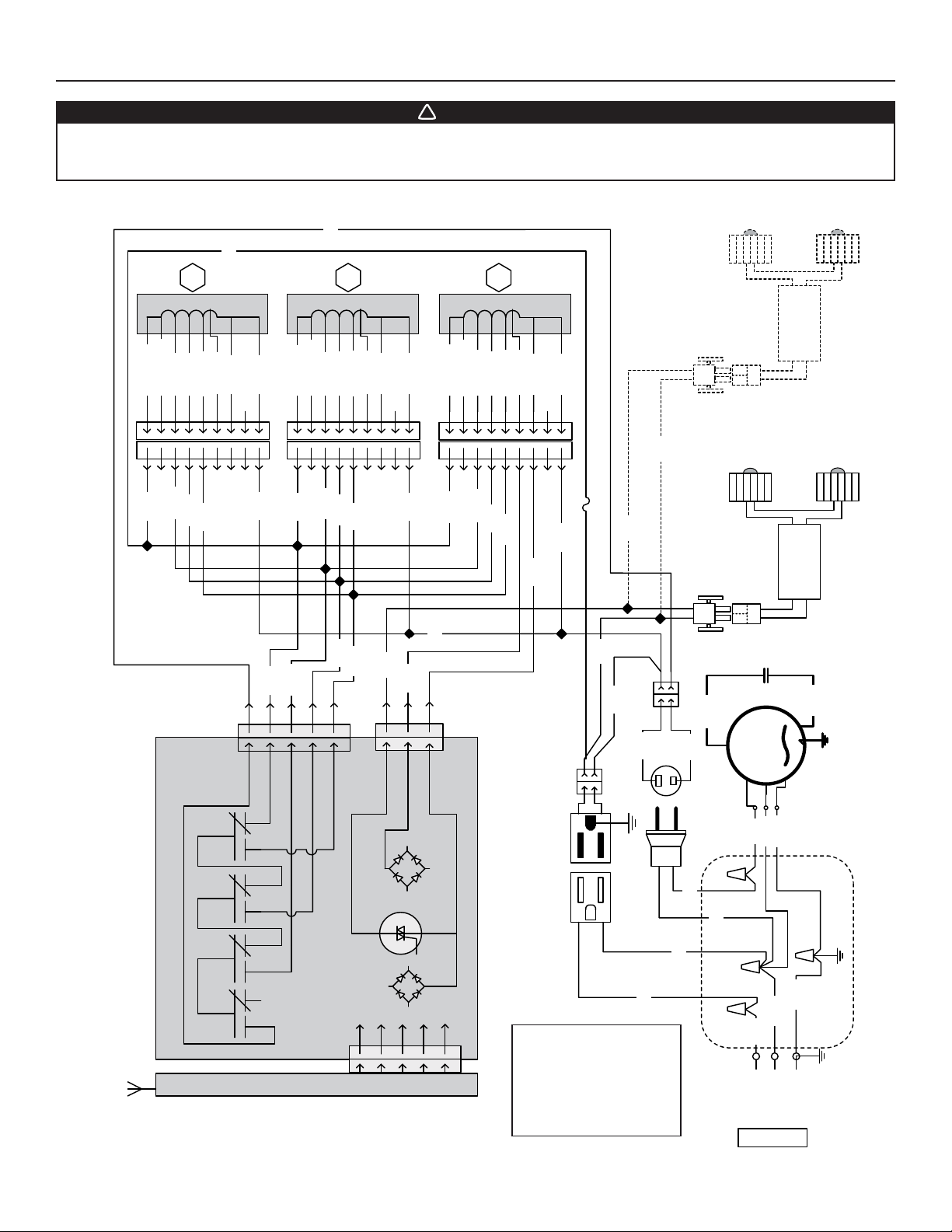

23. WIRING DIAGRAMS (CONT'D)

!

WARNING

Risk of electrical shock. Electrical wiring must be done by qualified personnel in accordance with all applicable

codes and standards. Before connecting wires, switch power off at service panel and lock service disconnecting

means to prevent power from being switched on accidentally.

Best CP57E Series

BLK

BLK

T3

BLK 120

ORG 120

123456789

PPL 60

BLU 88

YEL 10

WHT 0

PNK 45

BLK 120

WHT 0

ORG 120

123456789

T2

PPL 60

BLU 88

PNK 45

YEL 10

WHT 0

WHT 0

T1

BLK 120

ORG 120

123456789

PPL 60

BLU 88

YEL 10

WHT 0

PNK 45

LED

WHT 0

LED

LED DRIVER

INPUT OUTPUT

123456789

BLK

ORG

WHT

BLU

MOTOR

123456789

BLK

WHT

BLK

ORG

453

2

HIGH

MED LOW

MED HIGH

ORG

WHT

WHT

1

LOW

BLU

BLU

J1

3

LAMP

YEL

~

2

LOVAC

+

-

Q1

WHT

RED

EF

R

123456789

BLK

ORG

WHT

WHT

1

J7

~

BLU

WHT

WHT

FUSE 8 A

BLK

YEL

WHT

WHT

BLK

BLK

BLK

BRN

WHT

LED

M

BLK

WHT

GRN

LED

LED DRIVER

INPUT OUTPUT

GRY

K1 K2 K3 K4

+

~

~

-

BLK

WHT

ROUGH-IN PLATE

GRN

WHT

453

2

1

J6

BLK

RF RECEIVER

LINE

GROUND

COLOR CODE

BLK BLACK

BLU BLUE

BRN BROWN

GRY GREY

GRN GREEN

ORG ORANGE

PNK PINK

PPL PURPLE

RED RED

WHT WHITE

YEL YELLOW

NEUTRAL

120 V AC

HE0169A

17

Page 18

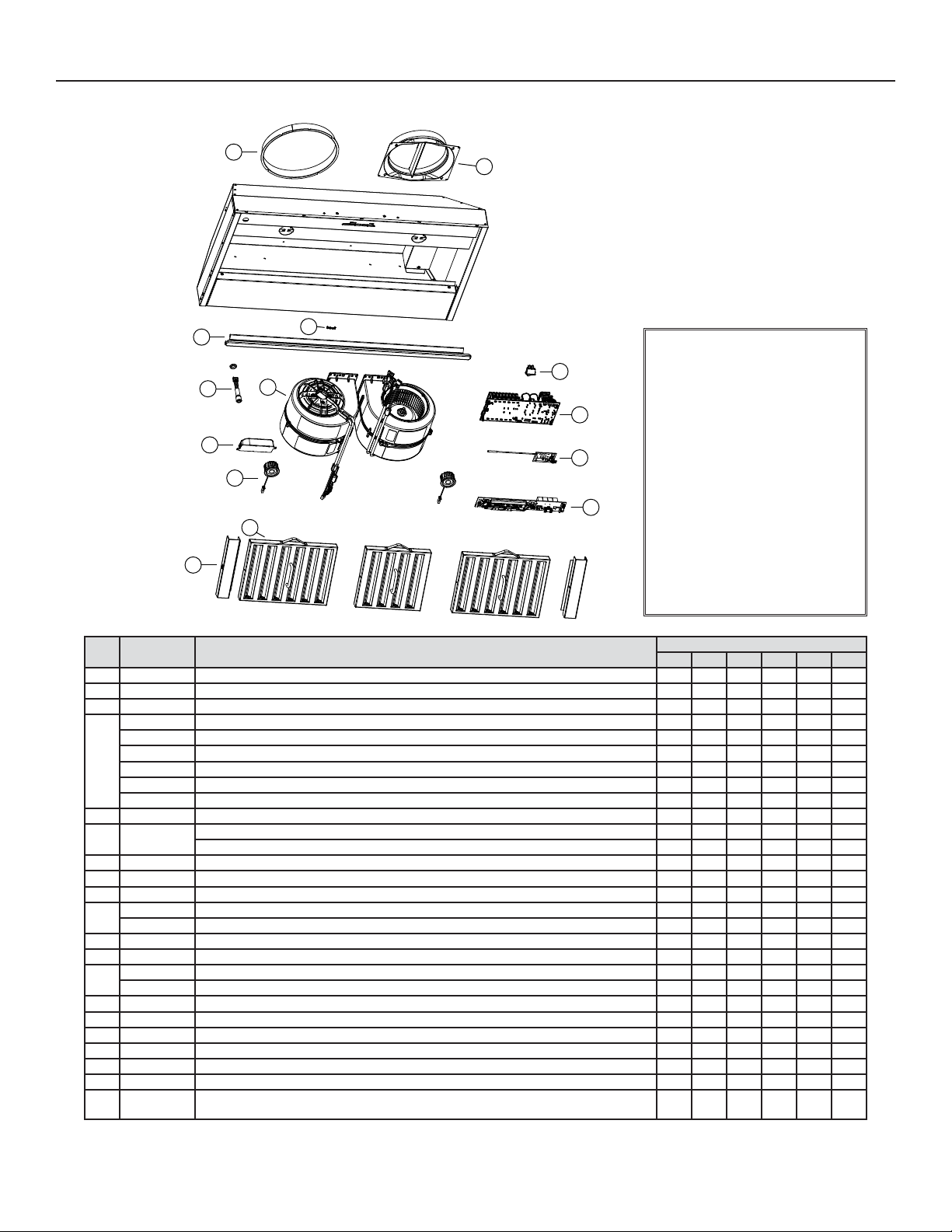

24. SERVICE PARTS

Best CP55IQ & CP57IQT Series

4

9

HL0211

1

3

2

REPLACEMENT PARTS AND REPAIRS

14

5

7

6

13

12

8

11

10

In order to ensure your unit remains in

good working condition, you must use

Broan-NuTone genuine replacement

parts only. Broan-NuTone genuine

replacement parts are specially

designed for each unit and are

manufactured to comply with all the

applicable certification standards and

maintain a high standard of safety.

Any third party replacement part

used may cause serious damage and

drastically reduce the performance

level of your unit, which will result

in premature failing. Broan-NuTone

recommends to contact a certified

service depot for all replacement

parts and repairs.

KEY

PART NO.DESCRIPTION

NO.

QTY. (POWER PAC K WIDTH)

36" 42" 48" 54" 60" 66"

1 SV08541 ADAPTER 10” ROUND (FOR CP57IQT SERIES) 1-1111

2 SV08543 ADAPTER/DAMPER 8” ROUND (FOR CP55IQ SERIES) 11---3 SV05869 B

EST LOGO 111111

SV17871 GREASE RAIL 36” 1----SV17872 GREASE RAIL 42” -1---SV17873 GREASE RAIL 48” - - 1 - - -

4

SV17874 GREASE RAIL 54” - - - 1 - -

SV17875 GREASE RAIL 60” - - - - 1 -

SV17876 GREASE RAIL 66” -----1

5 SV20817 CALIBRATION BUTTON 111111

6 S97018985

7 SV21414 LED D

BLDC BLOWER (FOR CP55IQ SERIES) 11---BLDC BLOWER (FOR CP57IQT SERIES) 2-2222

RIVER AND LED LIGHT HARNESS EXTENSION 111222

8 SV21413 LED MODULE 222444

9 SV61691 F

SV61639 H

10

SV61640 HYBRID BAFFLE FILTER WITH MICROMESH + HANDLE 11.84” X 8.61” X 1” 2 - - 2 4 5

ILTER FILLER (PAIR) -1---1

YBRID BAFFLE FILTER WITH MICROMESH + HANDLE 8.84” X 8.61” X 1” 14531-

11 SV21411 CONTROL INTERFACE PCB FOR INTERNAL BLOWER 111111

12 SV20816 REMOTE CONTROL PCB 111111

SV21416 ELECTRONIC DRIVE (FOR CP55IQ SERIES) 11----

13

SV20818 ELECTRONIC DRIVE (FOR CP57IQT SERIES) 1-1111

14 SV08548 B

LACK ROCKER SWITCH 111111

* SV21418 ELECTRICAL HARNESS (FOR CP55IQ SERIES) 11---* SV20824 ELECTRICAL HARNESS (FOR CP57IQT SERIES) 1-1111

* SV09022 TRANSFORMER 120 VAC, 9 VOLTS DC 111111

* SV08542 10” ROUND VERTICAL IN-LINE DAMPER (FOR CP57IQT SERIES) 1-1111

* SV21422 INSTALLATION GUIDE 111111

ARTS BAG: 2 WIRE CONNECTORS, 1 WIRE CLAMP, 4 SCREWS NO. 8 X 3/8”,

* SV08545

* NOT SHOWN.

P

9 CHROME PLATED SCREWS NO. 8 X 1/2”, 10 MECHANICAL SCREWS NO. 8-32 X 1/4”

111111

18

Page 19

24. SERVICE PARTS (CONT'D)

Best CP57E Series

2

4

5

6

1

3

10

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in

good working condition, you must use

Broan-NuTone genuine replacement

parts only. Broan-NuTone genuine

replacement parts are specially

designed for each unit and are

manufactured to comply with all the

applicable certification standards and

9

8

maintain a high standard of safety.

Any third party replacement part

used may cause serious damage and

drastically reduce the performance

level of your unit, which will result

in premature failing. Broan-NuTone

recommends to contact a certified

7

service depot for all replacement

parts and repairs.

HL0212

KEY

PART NO.DESCRIPTION

NO.

QTY. (POWER PAC K WIDTH)

36" 48" 60"

1 SV05869 BEST LOGO 111

SV17871 GREASE RAIL 36” 1 - -

2

SV17873 G

REASE RAIL 48” -1-

SV17875 GREASE RAIL 60” --1

3 SV61659 AUTOTRANSFORMER AND FUSE KIT (INCLUDING METAL SUPPORT) 111

4 SV21414 LED DRIVER AND LED LIGHT HARNESS EXTENSION 112

5 SV21413 LED MODULE 224

SV61639 HYBRID BAFFLE FILTER WITH MICROMESH + HANDLE 8.84” X 8.61” X 1” 1 5 1

6

SV61640 HYBRID BAFFLE FILTER WITH MICROMESH + HANDLE 11.84” X 8.61” X 1” 2 - 4

7 SV21412 CONTROL INTERFACE PCB FOR EXTERNAL BLOWER 111

8 SV20816 REMOTE CONTROL PCB 1 1 1

9 SV13923 F

10 SV13924 M

EMALE CONNECTOR 111

ALE CONNECTOR 111

* SV20825 ELECTRICAL HARNESS (FOR CP57E SERIES) 111

* SV21422 I

* SV08545

* NOT SHOWN.

NSTALLATION GUIDE 111

PARTS BAG: 2 WIRE CONNECTORS, 1 WIRE CLAMP, 4 SCREWS NO. 8 X 3/8”,

9 CHROME PLATED SCREWS NO. 8 X 1/2”, 10 MECHANICAL SCREWS NO. 8-32 X 1/4”

111

19

Page 20

25. WARRANTY

ONE-YEAR LIMITED WARRANTY

Broan-NuTone LLC (“Broan-NuTone”) warrants to the original consumer purchaser of its products that such products will be free

from defects in materials or workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is found to be

defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES AND BULBS, FUSES, FILTERS, DUCTS,

ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a) normal maintenance and

service or (b) any products or parts which have been subject to misuse, negligence, accident, improper maintenance or repair (other

than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states or provinces

do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE PURCHASER’S

SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE.

Some states or provinces do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state or province to another.

Any modification performed on this product without the authorization of Broan-NuTone will void this warranty. This warranty supersedes

all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number stated below, (b) give the model

number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty service,

you must present evidence of the original purchase date.

®

Best

, 926 W. State Street, Hartford, WI 53027 (1-800-637-1453)

®

Best

, 550 Lemire Blvd., Drummondville, QC, Canada (1-866-737-7770)

www.bestrangehoods.com

20

Page 21

GUIDE D’INSTALLATION

HB0132

SÉRIES CP55IQ, CP57IQT ET CP57E

! !

CONÇUES POUR USAGE DOMESTIQUE SEULEMENT

LIRE ET CONSERVER CES DIRECTIVES

INSTALLATEUR : LAISSER CE GUIDE AU PROPRIÉTAIRE.

PROPRIÉTAIRE : DIRECTIVES D’UTILISATION ET D’ENTRETIEN

EN PAGES 33 ET 34.

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800 558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.com 866 737-7770

Pour enregistrer votre produit en ligne ou pour obtenir plus d’information, veuillez consulter le www.BestRangeHoods.com

SV21422 rév. 06

Page 22

!

AVERTISSEMENT

ATTENTION

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE,

D’ÉLECTROCUTION OU DE BLESSURES CORPORELLES,

SUIVEZ LES DIRECTIVES SUIVANTES :

1. N’utilisez cet appareil que de la façon prévue par le manufacturier. Si

vous avez des questions, contactez le manufacturier à l’adresse ou au

numéro de téléphone indiqués dans la garantie.

2. Avant de réparer ou de nettoyer l’appareil, couper l’alimentation

électrique en verrouillant le panneau de distribution afin d’éviter sa

remise en marche accidentelle. Si le panneau de distribution ne peut

être verrouillé, y fixer un avertissement en évidence, telle qu’une

étiquette de couleur vive.

3. Les travaux d’installation et de raccordement électrique doivent être

effectués par une personne qualifiée, conformément aux codes et

aux standards de construction, incluant ceux concernant la protection

contre les incendies.

4. Une quantité d’air adéquate est requise afin d’assurer une bonne

combustion et l’évacuation des gaz par la cheminée dans le cas

des équipements alimentés au gaz afin de prévenir les retours de

cheminée. Conformez-vous aux instructions et aux standards de

sécurité des manufacturiers d’équipement de chauffage, tel qu’ils

sont publiés par la National Fire Protection Association (NFPA) et

l’American Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE) ainsi que les responsables des codes locaux.

5. Veillez à ne pas endommager le câblage électrique ou d’autres

équipements non apparents lors de la découpe ou du perçage du mur

ou du plafond.

6. Les ventilateurs avec conduits doivent toujours évacuer l’air

à l’extérieur.

7. Ne pas utiliser cet appareil avec une commande de vitesse à

semi-conducteur.

8. Afin de réduire les risques d’incendie, n’utilisez que des conduits

de métal.

9. Cet appareil doit être mis à la terre.

10. Lorsqu’une réglementation est en vigueur et qu’elle comporte des

exigences d’installation et/ou de certification plus restrictives, lesdites

exigences prévalent sur celles de ce document et l’installateur entend

s’y conformer à ses frais.

AFIN DE RÉDUIRE LES RISQUES DE FEU DE CUISINIÈRE :

a) Ne jamais laisser les appareils de cuisson sans surveillance lorsqu’ils

sont réglés à feu vif. Les débordements engendrent de la fumée et

des déversements graisseux pouvant s’enflammer. Chauffez l’huile

lentement, à feu doux ou moyen.

b) Mettez toujours la hotte encastrable en marche lorsque vous cuisinez

à feu vif ou que vous cuisinez des mets flambés (par ex. : crêpes

Suzette, cerises jubilé, steaks au poivre flambés).

c) Nettoyez régulièrement la (les) roue(s) du ventilateur. Ne laissez pas

la graisse s’accumuler sur le ventilateur, les filtres ou les conduits

d’évacuation.

d) Utilisez le bon format de casserole. Servez-vous toujours de casseroles

et d’ustensiles appropriés à la dimension de la surface chauffante.

AFIN D’ÉVITER TOUT RISQUE DE BLESSURES LORS D’UN

FEU DE CUISINIÈRE, SUIVEZ CES DIRECTIVES* :

1. Étouffez les flammes avec un couvercle hermétique, une tôle à biscuits

ou un plateau métallique et ensuite, éteindre le brûleur. PRENEZ

SOIN D’ÉVITER les brûlures. SI LES FLAMMES NE S’ÉTEIGNENT

PAS IMMÉDIATEMENT, ÉVACUEZ LES LIEUX ET APPELEZ

LES POMPIERS.

2. NE PRENEZ JAMAIS UNE CASSEROLE EN FLAMMES DANS VOS

MAINS. Vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, incluant un linge à vaisselle ou une serviette

mouillée, cela pourrait occasionner une violente explosion de vapeur.

4. N’utilisez un extincteur QUE DANS LE CAS OÙ :

A. Vous savez qu’il s’agit d’un extincteur de classe ABC et que vous

en connaissez le fonctionnement.

B. L’incendie est petit et limité à l’endroit où il a débuté.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en ayant accès à une sortie

de secours.

*Tirées du Kitchen Fire Safety Tips publié par la NFPA.

1. Pour une utilisation à l’intérieur seulement.

2. Pour usage domestique seulement. Ne pas utiliser pour évacuer des

vapeurs ou des matières dangereuses ou explosives.

3. Afin d’éviter tout dommage au moteur et de débalancer ou de

rendre bruyante la roue du moteur, garder votre appareil à l’abri des

poussières de gypse et de construction/rénovation, etc.

4. Le moteur de votre hotte encastrable possède une protection

thermique qui éteindra automatiquement le moteur s’il devient

surchauffé. Le moteur redémarrera automatiquement une fois refroidi.

Si le moteur continue à arrêter et à redémarrer, faites-le vérifier.

5. La distance minimale entre le bas de votre hotte et la surface de

cuisson ne doit pas être inférieure à 24 po. Un maximum de 30 po

au-dessus de la surface de cuisson est recommandé pour une

meilleure évacuation des odeurs de cuisson.

6. Deux installateurs sont recommandés lors de l’installation vu la grande

dimension et le poids de cet appareil.

7. Afin de réduire les risques d’incendie, assurez-vous d’évacuer l’air à

l’extérieur. Ne pas évacuer l’air dans des espaces restreints comme

l’intérieur des murs ou plafond ou dans le grenier, faux plafond

ou garage.

8. Cet appareil est équipé d’un thermostat pouvant faire démarrer le

ventilateur automatiquement. Afin de réduire le risque de blessure,

couper le courant à partir du panneau électrique et le verrouiller ou

apposer un avertissement sur le panneau afin de prévenir que la hotte

encastrable ne soit mise en marche accidentellement.

9. En raison de la grande capacité d’évacuation de cet appareil, il est

recommandé d’ouvrir une fenêtre dans ou près de la cuisine afin de

remplacer l’air évacué.

10. Afin de réduire les risques d’incendie et d’électrocution, les modèles

Best de la série CP55IQ et CP57IQT doivent être installés uniquement

avec leurs ventilateurs internes intégrés et les modèles Best de la série

CP57E avec les ventilateurs externes EB6, EB9, EB12 ou EB15 ou un

ventilateur en ligne ILB3, ILB6, ILB9, ILB11. Aucun autre ventilateur ne

doit être utilisé.

11. Veuillez consulter l’autocollant apposé à l’intérieur du produit pour

plus d’information ou autres exigences.

12. Cette hotte encastrable est munie d’un récepteur radio (télécommande

optionnelle vendue séparément). Tous changements ou modifications

qui ne sont pas approuvés par la partie responsable de la

conformité pourraient annuler la possibilité d’opérer l’équipement.

La télécommande a été testée et est en accord avec les limites

de la Classe B appareil numérique et est conforme au chapitre

15 des règlements FCC et ICES-003 canadiens. Ces limites sont

développées afin de fournir une protection raisonnable contre des

interférences dommagables dans une installation résidentielle. La

télécommande génère, utilise et peut émettre des flux de fréquences

radio qui peuvent causer des interférences aux communications

radio, si elle n’est pas installée selon les instructions. Cependant, il

n’y a aucune garantie que ces dites interférences ne se produiront

pas dans une installation particulière. Si cet équipement cause des

interférences à un récepteur radio ou un téléviseur, cela peut être

confirmé en éteignant et rallumant l’appareil, l’usager est encouragé à

corriger cette situation en essayant les solutions suivantes :

• Réorienter ou relocaliser l’antenne réceptrice

• Augmenter la distance entre l’équipement et le récepteur

• Connecter l’équipement à une autre prise électrique ou un autre

disjoncteur différent de celui du récepteur

22

Page 23

MODÈLE 634 OU 644

(CAPUCHON DE TOIT)

- SYSTÈMES DE HOTTES ENCASTRABLES SÉRIES CP55IQ ET CP57IQT

M

ODÈLE 437

(C

MODÈLE 643

(CAPUCHON MURAL 8 PO ROND)

APUCHON DE TOIT

À HAUT RENDEMENT)

ODÈLE 441

M

(C

APUCHON MURAL

10 PO ROND)

COUDE AJUSTABLE

DE 8 PO ROND

ONDUIT

C

STANDARD

DE

8 PO ROND

ADAPTATEUR/VOLET

8 PO ROND (FOURNI AVEC

LES HOTTES ENCASTRABLES

À VENTILATEUR SIMPLE)

HOTTE ENCASTRABLE

CP55IQ

MODÈLE 418

(COUDE AJUSTABLE

DE 10 PO ROND)

MODÈLE 410

(CONDUIT DE 10 PO ROND

— SECTIONS DE 2 PI)

HOTTE ENCASTRABLE

CP57IQT

VOLET VERTICAL EN LIGNE

DE 10 PO ROND (FOURNI AVEC

LA HOTTE ENCASTRABLE

À VENTILATEUR DOUBLE)

A

DAPTATEUR DE 10 PO ROND

(FOURNI AVEC LA HOTTE

ENCASTRABLE À VENTILATEUR DOUBLE)

HL0207

ENSEMBLE DE TÉLÉCOMMANDE

+

-

SÉRIE ACR (OPTIONNEL)

¤

23

V

ENTILATEUR DOUBLEVENTILATEUR SIMPLE

Page 24

ODÈLE 643

M

(CAPUCHON MURAL

8 PO ROND)

- SYSTÈME DE HOTTE ENCASTRABLE -

ODÈLE 437

M

(C

APUCHON DE TOIT

À HAUT RENDEMENT)

MODÈLE 441

(CAPUCHON MURAL

10 PO ROND)

V

ENTILATEUR EN LIGNE

MODÈLE ILB6 (600 PCM)

(INCLUANT DEUX TRANSITIONS DE

4½ PO X 18½ PO À 10 PO ROND)

SÉRIE CP57E

ENTILATEUR EN LIGNE

V

MODÈLE ILB9 (800 PCM)

OU ILB11 (1100 PCM)

(INCLUANT DEUX TRANSITIONS DE

8 PO X 12 PO À 10 PO ROND)

M

(COUDE AJUSTABLE

DE 10 PO ROND) —

OPTIONNEL

ODÈLE 418

VENTILATEUR EXTÉRIEUR

MODÈLE EB6 (600 PCM)

OU EB9 (900 PCM)

VENTILATEUR EXTÉRIEUR

MODÈLE EB12 (1200 PCM)

OU EB15 (1500 PCM)

VENTILATEUR EN LIGNE 10 PO

MODÈLE ILB3 (280 PCM)

(INCLUANT UNE TRANSITION

RONDE

DE 8 PO À 10 PO)

NSEMBLE DE TÉLÉCOMMANDE

E

+

-

SÉRIE ACR2 (OPTIONNEL)

¤

HL0208

MODÈLE 410

(CONDUIT DE 10 PO ROND

— SECTIONS DE 2 PI)

HOTTE ENCASTRABLE

CP57E

PLAQUE VENTILATEUR POUR VENTILATEURS

EXTÉRIEURS

LES

OU EN LIGNE (INCLUSE AVEC

VENTILATEURS EB6, EB9, EB12,

EB15, ILB3, ILB6, ILB9 ET ILB11).

24

Page 25

1. INSTALLER LES CONDUITS ET LE CÂBLAGE ÉLECTRIQUE

1.1 INSTALLATION EN RECIRCULATION (HOTTES ENCASTRABLES DE SÉRIE CP55IQ SEULEMENT)

Les hottes encastrables de série CP55IQ peuvent être installées en recirculation. Le kit de recirculation ANKCP55 doit être installé

(vendu séparément).

1.2 INSTALLATION AVEC CONDUITS (TOUTES LES HOTTES ENCASTRABLES)

Pour les hottes encastrables de la série CP57E, un ventilateur en ligne ou extérieur doit être utilisé. La hotte encastrable de la série

CP57E doit être installée avec les ventilateurs de modèle ILB3, ILB6, ILB9, ILB11, EB6, EB9, EB12 ou EB15 seulement. Aucun autre

ventilateur ne peut être utilisé (ventilateurs vendus séparément). Déterminer à quel endroit et de quelle façon les conduits seront installés.

Si un ventilateur en ligne est installé, se reporter aux directives incluses avec celui-ci et suivre les étapes 1 à 7, 11, 13 et

suivantes de ce guide.

Installer des conduits de dimensions appropriées, coude(s) et capuchon de mur ou de toit selon le type de ventilateur. Installer des

conduits ronds de 8 po avec la hotte encastrable de la série CP55IQ et des conduits ronds de 10 po avec la hotte encastrable de la

série CP57IQT ou CP57E. Se servir de ruban adhésif de métal pour assurer l’étanchéité des joints.

NOTE : Il est recommandé d'installer un conduit droit entre la hotte et un coude, d'une longueur minimale de 6 po pour un conduit

1.3 TOUTES LES INSTALLATIONS

La distance minimale entre le bas de votre hotte et la surface de cuisson ne doit pas être inférieure à 24 po. Un maximum de

30 po au-dessus de la surface de cuisson est fortement recommandé pour une meilleure évacuation des odeurs de cuisson.

Une distance de plus de 30 po demeure à la discrétion de l’installateur et de l’utilisateur. Acheminer le câble d’alimentation électrique

à 3 conducteurs jusqu’à l’emplacement de la hotte. Le câble devrait excéder de 4 pi le dessous de la hotte.

de 8 po et d'une longueur minimale de 12 po pour un conduit de 10 po.

CAPUCHON DE TOIT

CONDUITS RONDS DE

8 PO POUR CP55IQ

OU DE 10 PO POUR CP57IQT

COUDE ROND DE 8 PO POUR CP55IQ

OU DE 10 PO POUR CP57IQT

VOLET VERTICAL

10 PO ROND POUR CP57IQT

ADAPTATEUR ET VOLET

CAPUCHON

DE MUR

HH0201F

DE 24 PO À 30 PO

AU-DESSUS DE LA

SURFACE DE CUISSON

8 PO ROND POUR CP55IQ

OU ADAPTATEUR 10 PO ROND

POUR CP57IQT

HOTTE ENCASTRABLE

INSTALLATION TYPE

CP55IQ (VENTILATEUR INTERNE SIMPLE)

OU CP57IQT (VENTILATEUR INTERNE DOUBLE)

VENTILATEUR EXTÉRIEUR

CONDUIT ROND 10 PO

(sauf ILB3, CONDUIT ROND 8 PO)

VENTILATEUR EN LIGNE

HOTTE

ENCASTRABLE

DE 24 PO À 30 PO

AU-DESSUS DE LA

SURFACE DE CUISSON

HH0114F

INSTALLATION TYPE CP57E AVEC VENTILATEUR EN

LIGNE MODÈLE ILB3, ILB6, ILB9 OU ILB11

(L’EMPLACEMENT DU VENTILATEUR EST ILLUSTRÉ

À TITRE DE RÉFÉRENCE SEULEMENT)

CONDUITS RONDS

DE 10 PO

CAPUCHON

DE TOIT

CAPUCHON

DE MUR

COUDE ROND

DE 10 PO

VENTILATEUR

EXTÉRIEUR

HH0115F

DE 24 PO À 30 PO

AU-DESSUS DE LA

SURFACE DE CUISSON

HOTTE

ENCASTRABLE

INSTALLATION TYPE CP57E AVEC VENTILATEUR EXTÉRIEUR

25

Page 26

2. PRÉPARER L’INSTALLATION

!

!

AVERTISSEMENT

Il est recommandé de porter des lunettes et des gants de sécurité lors de l’installation, de l’entretien et de la

réparation de cet appareil.

NOTE : Avant de commencer l’installation, vérifier le contenu de la boîte. Si des pièces sont manquantes ou endommagées, contacter

le manufacturier.

S’assurer que les articles suivants sont inclus :

- Hotte encastrable

- Accessoires : • Filtres à chicane hybrides (3 pour le modèle de 36 po de largeur, 4 pour le modèle de 42 po de largeur et 5 pour les

modèles de 48 po à 66 po de largeur)

• Adaptateur/volet de 8 po rond (fourni avec les hottes encastrables de série CP55IQ)

• Volet vertical en ligne de 10 po rond (fourni avec les hottes encastrables de série CP57IQT)

• Adaptateur de 10 po rond (fourni avec la hotte encastrable série CP57IQT)

• Sac de pièces : 1 serre-fils, 2 capuchons de connexion, 4 vis n° 8 x 3/8 po, 9 vis plaquées chrome n° 8 x 1/2 po,

10 vis n° 8-32 x 1/4 po (ne pas utiliser avec ce produit, veuillez vous défaire des vis n° 8-32 x 1/4 po ).

Pièces vendues séparément :

• Ensemble de télécommande série ACR

• Ventilateur en ligne modèle ILB3, ILB6, ILB9 ou ILB11.

• Ventilateur externe modèle EB6, EB9, EB12 ou EB15.

• Conduits, coudes, capuchons de mur ou de toit. Consulter les pages 23 et 24 pour la liste complète des accessoires de ventilation et

les numéros de modèle.

• Kit de recirculation de série ANKCP55, essentiel pour une installation sans conduit.

NOTE : Lors de l’installation, protéger la surface de cuisson et le comptoir de cuisine.

3. PRÉPARATION DE L’ARMOIRE POUR HOTTE

AVERTISSEMENT

Toujours suivre les codes et standards en vigueur lors de la contruction de l’armoire pour hotte.

Construire l’armoire en fonction du format et du poids total de la hotte encastrable CP55IQ, CP57IQT ou CP57E.

Consulter le tableau et l’illustration pour plus de détails.

HOTTE ENCASTRABLE POIDS

MODÈLE LARGEUR A* B* C

CP55IQ

CP57IQT

CP57E

36 PO 52 LB 195⁄16 PO 347⁄16 PO 4¼ PO

42 PO 62 LB 195⁄16 PO 407⁄16 PO 43⁄8 PO

36

36 PO 62 LB 229⁄16 PO 347⁄16 PO 53⁄8 PO

48 PO 72 LB 195⁄16 PO 467⁄16 PO 53⁄8 PO

48 PO 72 LB 229⁄16 PO 467⁄16 PO 53⁄8 PO

54 PO 82 LB 229⁄16 PO 527⁄16 PO 53⁄8 PO

60 PO 85 LB 229⁄16 PO 587⁄16 PO 53⁄8 PO

66 PO 88 LB 229⁄16 PO 647⁄16 PO 53⁄8 PO

36 PO 40 LB 229⁄16 PO 347⁄16 PO 6 PO

48 PO 53 LB 229⁄16 PO 467⁄16 PO 6 PO

60 PO 66 LB 229⁄16 PO 587⁄16 PO 6 PO

TOTAL

PO 62 LB 19

* Les têtes de rivets sont incluses dans les dimensions A et B.

DIMENSIONS DE LA HOTTE ENCASTRABLE

5

⁄16 PO 347⁄16 PO 53⁄8 PO

12 po

HD0296F

3 po

ARRIÈRE

C

L

B

AVANT

4½ po

7/8 po

C

A

Afin de minimiser l’espace autour de la hotte encastrable, mesurer la longueur et profondeur de celle-ci et ajouter 1/16 po pour obtenir les

mesures de D et E. Découper le trou dans la base de l’armoire selon les dimensions obtenues. Consulter le tableau et l’illustration pour

plus de détails.

HOTTE ENCASTRABLE DIMENSIONS DE LA DÉCOUPE

MODÈLE LARGEUR DE

CP55IQ

CP57IQT

CP57E

36 PO 193⁄8 PO 34½ PO

42 PO 193⁄8 PO 40½ PO

36

PO 19

36 PO 225⁄8 PO 34½ PO

48 PO 193⁄8 PO 46½ PO

48 PO 225⁄8 PO 46½ PO

54 PO 225⁄8 PO 52½ PO

60 PO 225⁄8 PO 58½ PO

66 PO 225⁄8 PO 64½ PO

36

PO 22

48 PO 225⁄8 PO 46½ PO

60 PO 225⁄8 PO 58½ PO

3

⁄8 PO 34½ PO

5

⁄8 PO 34½ PO

D

E

HD0367

26

Page 27

4. ASSEMBLAGE DE LA CHARPENTE DE L’ARMOIRE

!

AVERTISSEMENT

La charpente de bois doit être fixée solidement aux montants ou autre structure derrière la cloison. S’assurer qu’elle

puisse supporter son propre poids en plus de celui de la CP55IQ, CP57IQT ou CP57E. Ne pas suivre cette directive

peut entraîner des blessures corporelles ou des dommages à la surface de cuisson ou au comptoir de cuisine.

Les hottes encastrables séries CP55IQ, CP57IQT et CP57E sont fixées à la charpente de l’armoire à l’aide des vis fournies dans le sac

de pièces.

Puisque les trous d’assemblage des hottes encastrables de séries CP55IQ, CP57IQT

et CP57E sont situés à l’avant et sur les côtés arrière (voir l’illustration ci-contre),

prévoir d’installer un cadrage de bois à l’avant et de chaque côté pour supporter

la hotte encastrable.

HH0102F

5. ENLEVER LES FILTRES À CHICANE HYBRIDES

Enlever le ruban adhésif des filtres. Retirer les filtres de la hotte encastrable et les

mettre de côté.

Il est recommandé de commencer par le(s) filtre(s) du centre.

6. RETIRER LA GOUTTIÈRE

A

A. Soulever la gouttière pour la désengager du

panneau inférieur.

B. Glisser la gouttière complètement vers la gauche ou

la droite () et soulever l’extrémité opposée pour la

désengager du panneau inférieur (). La retirer de la

hotte encastrable et la mettre de côté.

HD0521

B

HD0524

HD0525

27

Page 28

7. RETIRER LE PANNEAU INFÉRIEUR

À l’aide d’un tournevis Phillips, enlever les deux vis de retenue

du panneau inférieur et les mettre de côté.

EMPLACEMENT DES VIS DE RETENUE

HO0224

Retirer le panneau inférieur de la hotte encastrable et le mettre

de côté.

8. DÉFONCER L’OUVERTURE PRÉAMORCÉE

(SÉRIES CP55IQ ET CP57IQT SEULEMENT)

HO0120

VUE LATÉRALE

Par l’intérieur de la hotte encastrable, retirer le couvercle de la boîte de jonction en dévissant les

2 vis de retenue et les mettre de côté. Défoncer l’ouverture préamorcée pour le fil d’alimentation

électrique située sur le dessus de la hotte encastrable. Installer le serre-fil (inclus dans le sac

de pièces).

HR0027

9. INSTALLER L’ADAPTATEUR/VOLET DE 8 PO (SÉRIE CP55IQ SEULEMENT)

À l’aide de 4 vis n° 8 x 3/8 po fournies dans le sac de pièces, assembler l’adaptateur/volet sur le

dessus de la hotte encastrable. Le cas échéant, retirer le ruban adhésif des volets pour assurer leur

bon fonctionnement. Sceller les joints avec du ruban adhésif de métal pour éliminer les fuites d’air.

EMPLACEMENT DES VIS D’ASSEMBLAGE

HJ0016

28

Page 29

10. INSTALLER L’ADAPTATEUR DE 10 PO (SÉRIE CP57IQT SEULEMENT)

À l’aide de 2 vis n° 8 x 3/8 po fournies dans le sac de pièces, assembler l’adaptateur sur le dessus

de la hotte encastrable. Sceller les joints avec du ruban adhésif de métal pour éliminer les fuites d’air.

11. INSTALLER LE VOLET EN LIGNE DE 10 PO

(SÉRIES CP57IQT ET CP57E SEULEMENT)

NOTE : Pour une installation sans conduit, ne pas installer le volet en ligne de 10 po.

Installer le volet en ligne de 10 po à l’intérieur du conduit vertical lequel sera rattaché à la hotte

encastrable. Ne pas l’installer dans un conduit horizontal car l’ouverture et la fermeture ne

pourraient se faire adéquatement. Fixer le volet au conduit à l’aide de 3 vis à métaux n° 8 (non

fournies). S’assurer que le volet s’ouvre et se ferme librement. Sceller les joints avec du ruban

adhésif de métal pour éliminer les fuites d’air.

EMPLACEMENT DES VIS D’ASSEMBLAGE

HJ0026

10 po min.

recommandé

HJ0073F

29

Page 30

!

12. INSTALLER LA PLAQUE VENTILATEUR POUR VENTILATEURS EXTERNES

(SÉRIE CP57E SEULEMENT)

Pour les détails concernant l’installation de la plaque ventilateur, voir les

instructions comprises avec l’ensemble ventilateur et la plaque du ventilateur

(vendu séparément). Installer la plaque ventilateur de façon à ce que la boîte de

jonction se trouve à droite lorsque vous faites face à la hotte, tel qu’il est spécifié

sur l’étiquette du ventilateur.

HD0522

COUVERCLE

DE LA BOÎTE

DE JONCTION

ÉCROUS

DENTELÉS

13. BRANCHEMENT ÉLECTRIQUE (TOUS LES VENTILATEURS)

AVERTISSEMENT

Risque d’électrocution. Le raccordement électrique doit être effectué par du personnel qualifié conformément

aux codes et aux standards. Avant d’effectuer le branchement, coupez l’alimentation électrique au panneau de

distribution et verrouillez-le pour éviter une mise en marche accidentelle.

Placer la hotte encastrable sous son armoire.

VENTILATEURS INTERNES : Passer le fil d’alimentation électrique à travers le

serre-fils précédemment installé à l’étape 8. Serrer

le serre-fils pour retenir le fil d’alimentation en place.

Connecter les fils dans la boîte de jonction en utilisant

les capuchons de connexion fournis. Connecter

le fil NOIR au NOIR, le fil BLANC au BLANC et le

fil VERT ou dénudé à la vis de mise à la terre. NE

PAS OUBLIER DE CONNECTER LA MISE À LA

TERRE. Remettre en place le couvercle de la boîte

de jonction.

VENTILATEURS EXTÉRIEURS OU EN LIGNE : Voir les directives incluses avec ce

type de ventilateur.

HE0059

14. INSTALLER LA HOTTE ENCASTRABLE

MODÈLE CP55IQ SEULEMENT : Si le modèle CP55IQ est installé avec un kit de recirculation, installer le réducteur de 8 po à 7 po (inclus

dans le kit de recirculation) avant d’installer la hotte encastrable dans son armoire.

ATTENTION

Prendre soin de ne pas gauchir les conduits en installant la hotte encastrable.

À l’aide des vis plaquées chrome n° 8 x 1/2 po, encastrer la hotte dans son armoire.

Commencer par les vis des coins avant gauche et droit, puis visser les 4 vis des côtés.

Utiliser les vis restantes pour fixer l’avant de la hotte encastrable. (Voir l’illustration

ci-contre pour l’emplacement spécifique des vis de montage.)

S’assurer que l’adaptateur/volet (ou l’adaptateur) entre dans le conduit. Si l’accès au

dessus de la hotte encastrable est ouvert, sceller le joint avec du ruban adhésif de métal.

HH0102F

30

Page 31

15. BRANCHER LE VENTILATEUR EXTERNE (SÉRIE CP57E SEULEMENT)

!

AVERTISSEMENT

Ne jamais brancher ensemble le fil du ventilateur au fil d’alimentation

de la hotte.

Pour installer le ventilateur, voir les instructions comprises avec celui-ci.

Brancher le fil du ventilateur à la prise à 2 alvéoles (B) et le fil d’alimentation

électrique de la hotte encastrable (A) à la fiche à 3 broches, à l’intérieur de la

hotte encastrable.

HE0078

AB

16. REMETTRE EN PLACE LE PANNEAU INFÉRIEUR

Soulever le panneau inférieur et engager les pattes de métal de

la hotte dans les fentes du panneau inférieur, tel qu’il est illustré

dans les détails A et B ci-dessous.

VUE LATÉRALE

Fixer le panneau inférieur à la hotte encastrable à l’aide de ses

vis retirées précédemment à l’étape 7.

AB

HO0121

17. REMETTRE LA GOUTTIÈRE EN PLACE

EMPLACEMENT DES VIS DE RETENUE

HO0224

A. Insérer une extrémité de la gouttière dans un côté

de la hotte encastrable () tout en soulevant

l’autre extrémité par dessus le rebord du panneau

inférieur ().

B. Centrer la gouttière au dessus du rebord du panneau

inférieur et la rabaisser pour l’enclencher en place.

HD0525

A

HD0524

B

31

Page 32

18. RÉINSTALLER LES FILTRES À CHICANE HYBRIDES

ATTENTION

Avant d’installer les filtres à chicane hybrides, retirer le plastique protecteur de ceux-ci.

Il est recommandé d’installer d’abord les filtres situés aux extrémités et de terminer par le(s) filtre(s) du centre.

1

1. Insérer une extrémité du filtre hybride dans le

rail avant de la hotte.

2. Lever l’autre bout du filtre à l’intérieur de la hotte

et l’insérer dans la gouttière.

HD0526

2

19. CALIBRER LE VENTILATEUR IQMC (SÉRIES CP55IQ & CP57IQT SEULEMENT)

NOTE : Le processus de calibrage est destiné aux installations avec conduit. Ne pas

calibrer les installations en recirculation.

Une fois la hotte encastrable installée et connectée, enclencher le processus de calibrage

(notre Technologie de performance garantie s’assure que le débit d’air optimal sera émis).

Avant le calibrage, s’assurer que les filtres, les ampoules et le conduit sont installés.

CALIBRAGE

Maintenir le bouton de calibrage enfoncé pendant 3 secondes; le bouton s’allume pour

une durée pouvant aller jusqu’à 13 minutes. Le ventilateur se met en marche et le

calibrage commence. Une fois le calibrage terminé, il y a deux possibilités :

A. Le ventilateur s’arrête et la lumière du bouton de calibrage s’allume = Calibrage

réussi. Appuyer sur le bouton pour éteindre la DEL.

NOTE : La DEL s’éteindra aussi si vous sélectionnez n’importe quelle vitesse de

ventilateur à l’aide de la commande.

B. Le ventilateur s’arrête et la lumière du bouton de calibrage clignote continuellement = Trop de restriction dans le conduit empêchant le

ventilateur IQMC d’atteindre le débit d’air nominal. Le ventilateur se règle automatiquement à l’intensité maximale.

NOTE : Les causes les plus courantes de restriction sont : un clapet coincé (clapet antirefoulement, capuchon mural, capuchon

de toit), un trop grand nombre de coudes, un conduit dont la dimension est inférieure à 80 % de la sortie de la hotte, une

mauvaise transition, l’utilisation de conduit flexible et/ou un conduit écrasé.

Trois options s’offrent à vous si le débit de votre hotte encastrable est soumis à une restriction trop importante :

1. Accepter le débit tel quel. Appuyer sur le bouton de calibrage pour accepter le débit d’air tel quel. Le ventilateur IQMC est maintenant

configuré au meilleur rendement possible. Le témoin de calibrage clignotant s’éteint.

NOTE : La DEL s’éteindra aussi si vous sélectionnez n’importe quelle vitesse de ventilateur à l’aide de la commande.

2. Corriger la restriction, effacer les données du calibrage original et recommencer le calibrage.

a. Corriger la restriction dans le conduit.

b. Effacer les données de calibrage original en maintenant le bouton de calibrage enfoncé pendant 10 secondes. Le témoin clignotera

alors 3 fois pour confirmer et le ventilateur retournera aux paramètres par défaut.

c. Recommencer le calibrage depuis le début.

3. Effacer les données de calibrage pour rétablir les paramètres par défaut de la hotte encastrable et obtenir le rendement standard à

haute pression du ventilateur en maintenant le bouton de calibrage enfoncé pendant 10 secondes. Le témoin clignotera 3 fois pour

confirmer et le ventilateur retournera aux paramètres par défaut.

HC0071

BOUTON DE CALIBRAGE

LUMIÈRE DE CALIBRAGE

32

Page 33

20. ÉCLAIRAGE

!

L’éclairage de cette hotte encastrable est produit par des ampoules à DEL ne nécessitant aucun entretien.

AVERTISSEMENT

Ne pas toucher aux ampoules durant ou peu après leur utilisation. Peuvent causer des brûlures.

21. ENTRETIEN

Filtres à chicane hybrides

Les filtres à chicane hybrides doivent être nettoyés fréquemment. Utiliser une solution d’eau chaude et de détergent. Nettoyer les filtres à

chicane plus souvent si vos habitudes de cuisson génèrent plus de graisse, comme par exemple la friture ou les aliments sautés au wok.

Les filtres à chicane sont lavables au lave-vaisselle.

Retirer les filtres à chicane en les poussant vers l’arrière de la hotte et en les retournant vers le bas. Laisser les filtres sécher complètement

avant de les réinstaller dans la hotte encastrable.

Nettoyer les filtres fabriqués entièrement de métal au lave-vaisselle à l’aide d’un détergent sans phosphate. L’utilisation d’un détergent

avec phosphate ainsi que les conditions locales de l’eau peuvent entraîner une décoloration des filtres, sans toutefois affecter leur

performance. Cette décoloration n’est pas couverte par la garantie.

Gouttière

La gouttière doit être nettoyée fréquemment. La retirer de la hotte encastrable (voir l’étape 6 en page 27) et se servir d’une solution d’eau

chaude et de détergent. Comme pour les filtres à chicane, la nettoyer plus souvent si vos habitudes de cuisson génèrent plus de graisse,

comme par exemple la friture ou les aliments sautés au wok. Essuyer complètement la gouttière avant de la remettre en place.

Nettoyage du (des) ventilateur(s) interne(s)

Retirer les filtres pour accéder au(x) ventilateur(s) et passer l’aspirateur. Ne pas le(s) plonger dans l’eau.

Nettoyage de la hotte encastrable

Acier inoxydable :

À faire :

• Laver régulièrement les surfaces à l’aide d’un chiffon ou linge

propre imbibé d’eau tiède et de savon doux ou de détergent

liquide à vaisselle.

• Toujours nettoyer dans le sens du polissage.

• Toujours bien rincer avec de l’eau claire (2 à 3 fois) et essuyer

complètement.

• Un nettoyant domestique conçu spécialement pour l’acier

inoxydable peut aussi être utilisé.

À ne pas faire :

• Ne pas utiliser de laine d’acier ou d’acier inoxydable ou tout

autre grattoir pour enlever la saleté tenace.

• Ne pas utiliser une poudre nettoyante abrasive ou rugueuse.

• Ne pas laisser la saleté s’accumuler.

• Ne pas laisser la poussière de plâtre ou tout autre résidu de

construction atteindre la hotte. Couvrir la hotte pour la durée

des travaux afin de s’assurer qu’aucune poussière n’atteigne

la hotte.

À éviter lors du choix d’un détergent :

- Tous produits nettoyants contenant des agents de blanchiment; ils attaqueront l’acier inoxydable.

- Tous produits contenant du chlorure, du fluorure, de l’iode ou du bromure; ils détérioreront rapidement les surfaces.

- Tous produits combustibles utilisés pour le nettoyage : acétone, alcool, éther, benzène, etc.; ils sont grandement explosifs et ne

devraient jamais être utilisés près d’une cuisinière.

33

Page 34

!

22. FONCTIONNEMENT

Toujours mettre en marche le ventilateur avant de commencer la cuisson afin d’établir une circulation d’air dans la cuisine. Aussi, laisser

le ventilateur fonctionner quelques minutes après l’arrêt de la cuisinière afin d’aérer.

A) Bouton d’arrêt différé

B) Bouton de mise en marche/

Vitesse du ventilateur

C) Bouton d’arrêt du ventilateur/

Entretien des filtres

D) Bouton d’arrêt d’éclairage

E) Bouton d'activation d'éclairage

HC0016

VITESSE 1 2 3 4

BA C D E

A. BOUTON D’ARRÊT DIFFÉRÉ :

Lorsque le ventilateur est en marche, appuyer sur ce bouton pour activer la fonction d’arrêt différé. L’indicateur lumineux de la vitesse

correspondante commencera à clignoter pour indiquer que la fonction est activée. Le ventilateur continuera à fonctionner pendant

10 minutes, puis s’arrêtera automatiquement. Pour annuler la fonction d’arrêt différé, appuyer de nouveau sur ce bouton, le ventilateur

fonctionnera alors en mode normal.

NOTE : Lorsque la fonction d’arrêt différé est activée, la vitesse du ventilateur peut être augmentée ou diminuée à l’intérieur du même

cycle de 10 minutes.

B. B

OUTON DE MISE EN MARCHE/VITESSE DU VENTILATEUR :

Appuyer sur ce bouton pour mettre en marche le ventilateur; il démarrera à la vitesse réglée avant son dernier arrêt. Pour modifier la

vitesse du ventilateur, appuyer de nouveau sur le bouton jusqu’à l’obtention de la vitesse désirée. Appuyer et maintenir ce bouton enfoncé

pendant 2 secondes afin de diminuer la vitesse par incrément de 1. Les diminutions possibles sont alors : 4 à 3; 3 à 2; 2 à 1 et 1 à ARRÊT.