Page 1

INSTALLATION INSTRUCTIONS

HB0312

CC6 SERIES

! !

INTENDED FOR DOMESTIC COOKING ONLY

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

HOMEOWNER: USE AND CARE INFORMATION ON PAGES 12 AND 13.

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800-558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.ca 866-737-7770

23862 rev. 02

Page 2

d

!

WARNING

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by

qualified personnel in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment

to prevent backdrafting. Follow the heating equipment

manufacturer’s guidelines and safety standards such as

those published by the National Fire Protection Association

(NFPA) and the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vente

7. To reduce the risk of fire or electric shock, do not use this unit

with any additional solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

10. When applicable local regulations comprise more

restrictive installation and/or certification requirements,

the aforementioned requirements prevail on those of this

document and the installer agrees to conform to these at his

own expenses.

d outdoors.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

flambeing food (i.e.: Crêpes Suzette, Cherries Jubilee,

Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed

to accumulate on fan, filters or in exhaust ducts.

d) Use proper pan size. Always use cookware appropriate for the

size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE

THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet or

metal tray, then turn off the burner. BE CAREFUL TO PREVENT

BURNS. IF THE FLAMES DO NOT GO OUT IMMEDIATELY,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be burned.

3. DO NOT USE WATER, including wet dishcloths or

towels — This could cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and you know how to

operate it.

B. The fire is small and contained in the area where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

4. Your power pack motor(s) has a thermal overload which will

automatically shut off the motor(s) if it overheats. The motor(s)

will restart when cooled down. If the motor(s) continues to shut

off and restart, have the power pack serviced.

5. The minimum hood distance above cooktop must not be

less than 24". A maximum of 30" above cooktop is highly

recommended for best capture of cooking impurities. For a

gas range, the bottom of the hood MUST NOT BE LESS

than 30” above cooktop.

6. Two installers are recommended because of the large size and

weight of this unit.

7. To reduce the risk of fire and to properly exhaust air, be sure to

duct air outside — Do not exhaust air into spaces within walls

or ceiling or into attics, crawl space or garage.

8. Because of the high exhausting capacity of this unit, you

should make sure enough air is entering the house to replace

exhausted air by opening a window close to or in the kitchen.

9. To reduce the risk of fire and electrical shock, the Best CC6

Series models must be installed only with their own built-in

blower(s). Other blowers cannot be substituted.

10. Please read specification label on product for further

information and requirements.

2

Page 3

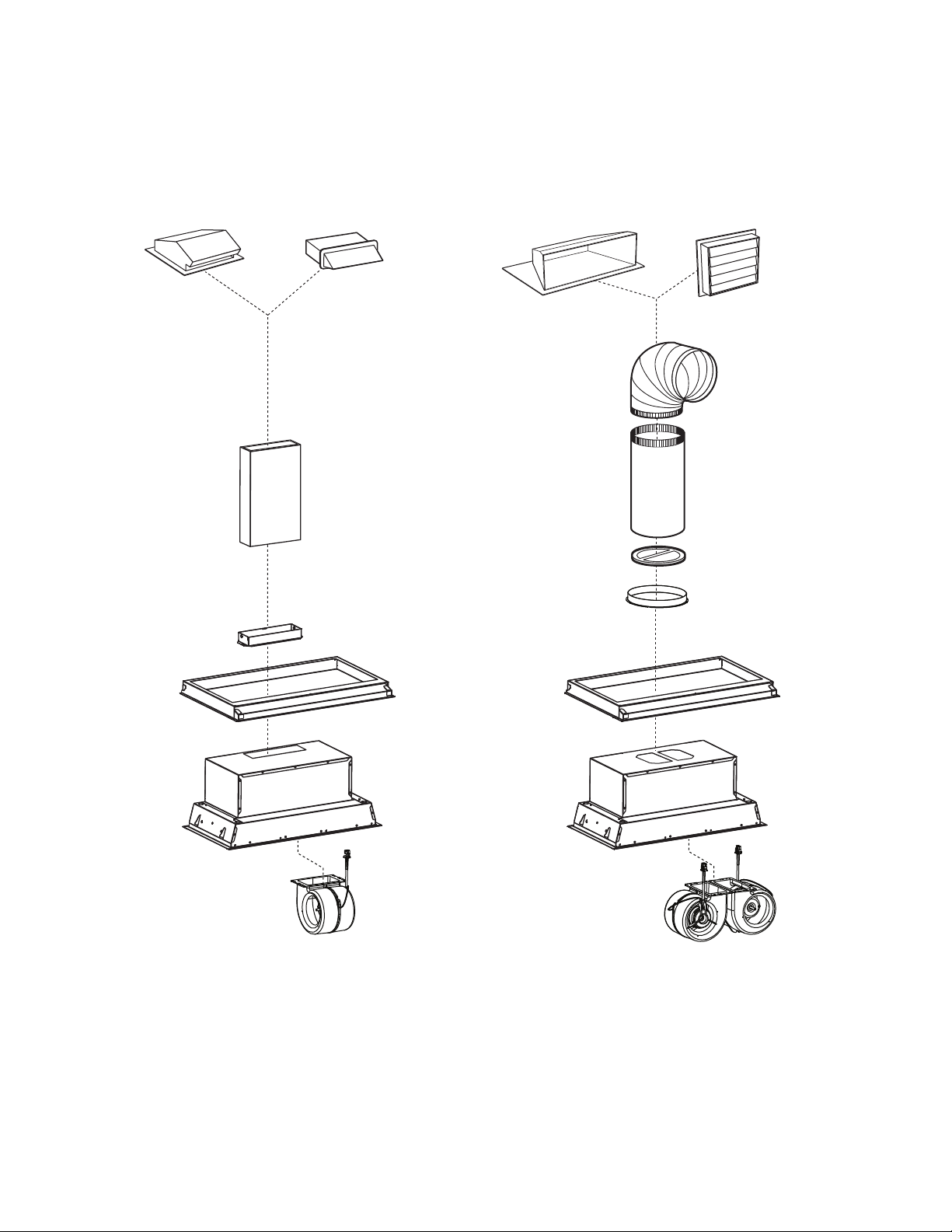

- CC6 SERIES POWER PACK SYSTEM -

STANDARD

3¼” X 10” ROOF CAP

(NOT INCLUDED)

TANDARD

S

3¼” X 10” DUCT

(NOT INCLUDED)

3¼” X 10” ADAPTER/

DAMPER

(SUPPLIED WITH SINGLE

BLOWER POWER PAC K)

TANDARD

S

3¼” X 10” WALL CAP

(NOT INCLUDED)

ODEL 437

M

HIGH CAPACITY ROOF CAP

(NOT INCLUDED)

10" ROUND ADAPTER

(SUPPLIED WITH

1000 CFM DUAL BLOWER

POWER PAC K )

ODEL 441

M

10" ROUND WALL CAP

(NOT INCLUDED)

ODEL 418

M

10" ROUND

ADJUSTABLE ELBOW

(NOT INCLUDED)

MODEL 410

10" ROUND DUCT

— 2 FT. SECTIONS

(NOT INCLUDED)

10" ROUND VERTICAL

IN-LINE DAMPER

(SUPPLIED WITH 1000 CFM

DUAL BLOWER POWER PAC K )

ALCC630SB,

ALCC636SB

OR ALCC642SB

CUSTOM HOOD LINER (OPTIONAL)

CC65I28SB

POWER PACK

HL0126

S

INGLE BLOWER

(600 CFM, SUPPLIED WITH POWER PAC K )

ALCC630SB,

ALCC636SB OR ALCC642SB

CUSTOM HOOD LINER (OPTIONAL)

CC67I28SB

POWER PACK

D

UAL BLOWER

(1000 CFM, SUPPLIED WITH POWER PAC K )

3

Page 4

1. PREPARE THE INSTALLATION

!

WARNING

When performing installation, servicing or cleaning the unit, it is recommended to wear safety glasses and gloves.

NOTE: Before proceeding to the installation, check the contents of the box. If items are missing or damaged, contact the manufacturer.

Make sure that the following items are included:

- Power Pack

- Accessories: • 2 Filters

• 2 Filter knobs with screws, taped inside power pack

• 3¼” x 10” adapter/damper (supplied with 600 CFM single blower power pack)

• 10” round in-line vertical damper (supplied with 1000 CFM dual blower power pack)

• 10” round adapter (supplied with 1000 CFM dual blower power pack)

• Bag of parts including: 1 wire clamp, 2 wire connectors, 4 no. 8 x 3/8” screws, 9 no. 8 x 1/2” chrome plated screws,

10 no. 8-32 x 1/4” screws. If need be, discard extra hardware.

Parts sold separately:

- Custom hood liner model ALCC630SB, ALCC636SB or ALCC642SB (optional)

- Ducts, elbows, wall and roof caps. Refer to page 3 for a complete list of venting options and model numbers.

NOTE: During installation, protect countertop and/or cooktop.

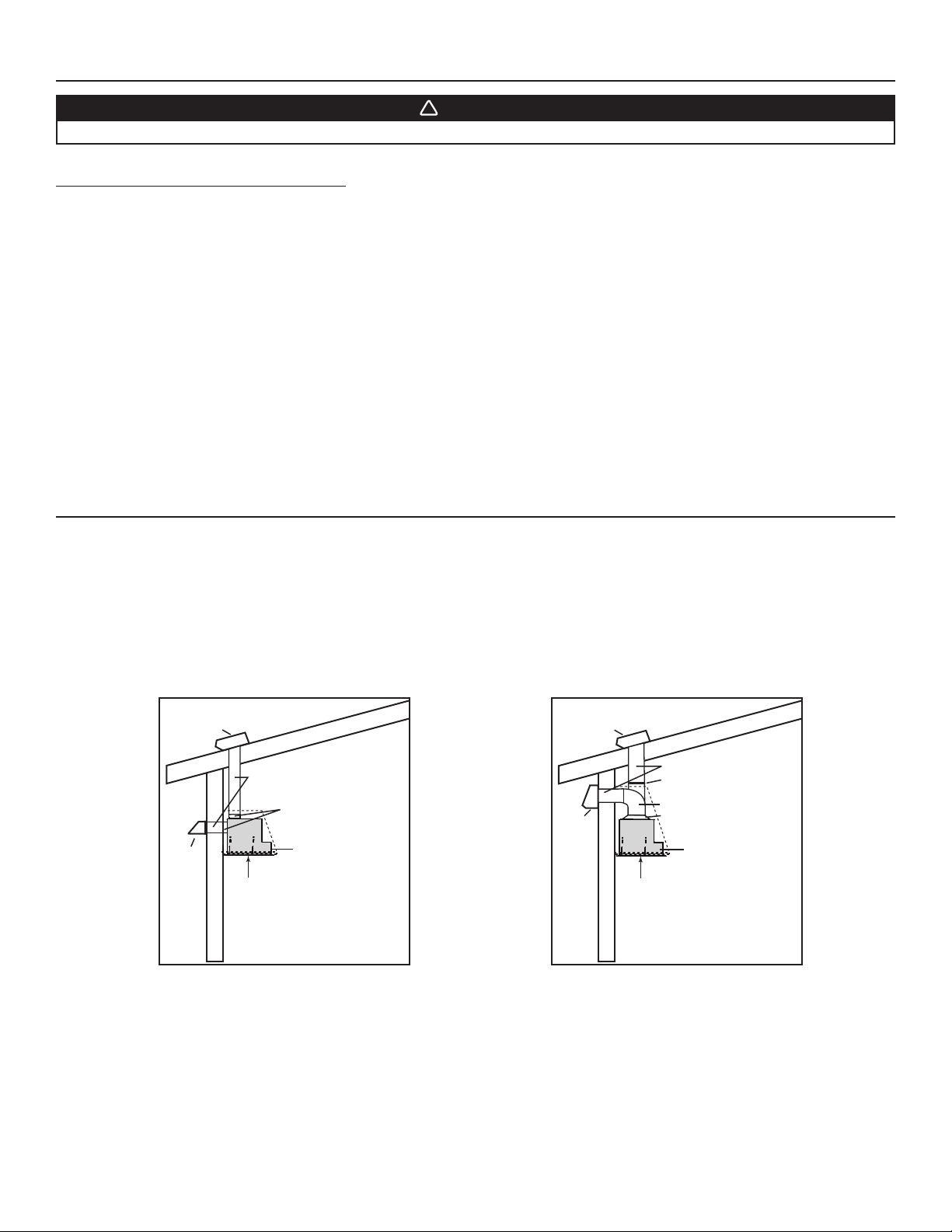

2. INSTALL DUCTWORK AND ELECTRICAL WIRING

Plan where and how the ductwork will be installed. Access to the top of the power pack is preferred for connection of ductwork.

Install proper-sized ductwork, elbows and roof or wall cap for the type of power pack you are installing. If installing CC65I28SB single

blower power pack, use 3¼” x 10” ductwork. If installing CC67I28SB double blower power pack, use 10” round ductwork. Use 2” metal foil

duct tape to seal duct joints.

We recommend to install the power pack at a minimum distance of 24” from an electric range and 30” from a gas range.

Distances over 30” are at the installer and users discretion.

Run 3-wire power supply cable to installation location. Its length should extend at least 4 feet below the bottom of the custom hood.

Roof cap

3¼” x 10” duct

3¼” x 10”

adapter & damper

Wall

cap

HH0116A

24” minimum above

cooking surface

(30” for gas range)

M

ODEL CC65I28SB

Power pack

(SINGLE BLOWER) TYPICAL DUCTWORK

Roof cap

10” round duct

10” in-line

vertical damper

10” round elbow

Wall

cap

HH0117A

10” round adapter

Power pack

24” minimum above

cooking surface

(30” for gas range)

MODEL CC67I28SB

(DUAL BLOWER) TYPICAL DUCTWORK

NOTE: Although the horizontal discharge installation is feasible with CC65I28SB power pack model, this installation type

should be performed in specific situation only since it requires particular knowledge and technical skills from the installers.

4

Page 5

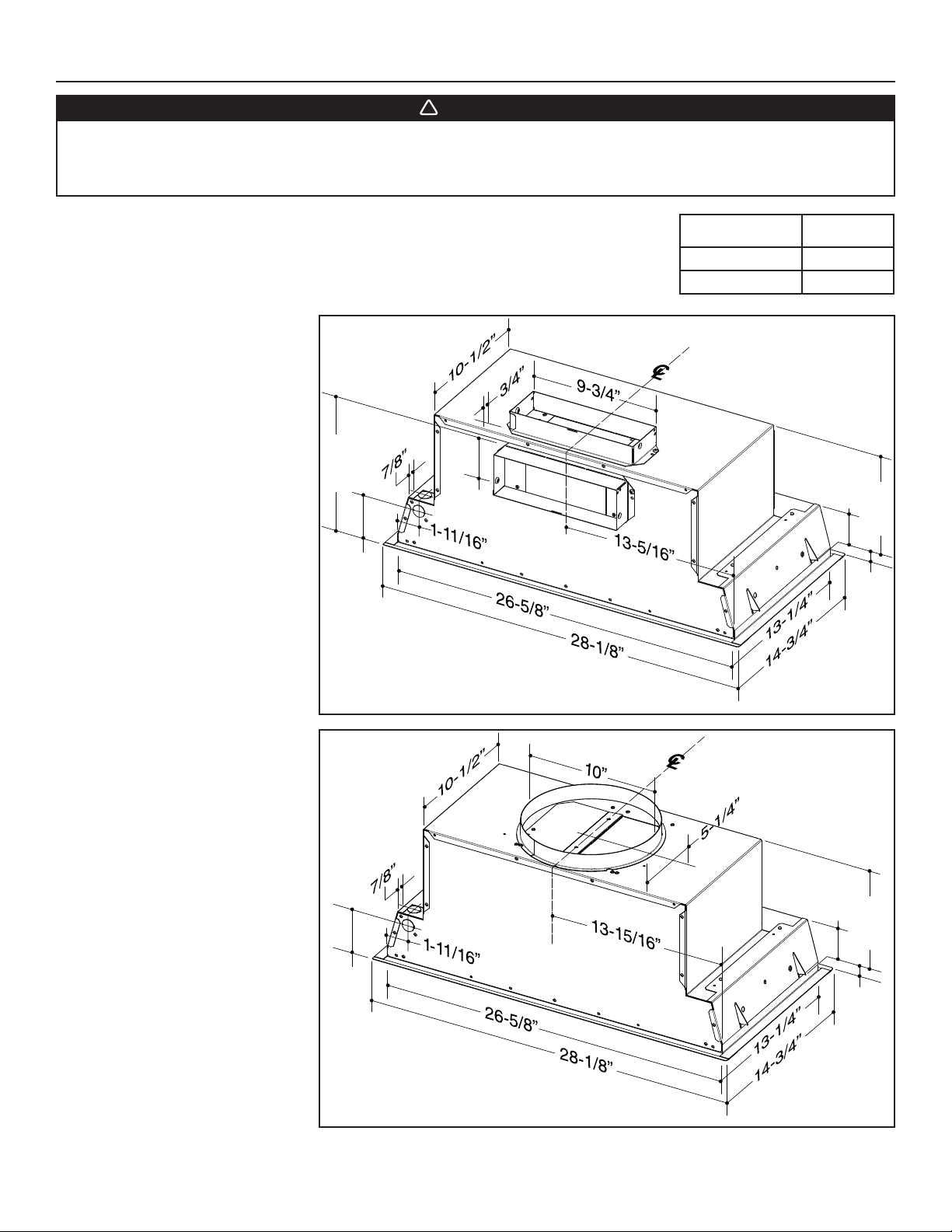

3. PREPARE CUSTOM HOOD

!

WARNING

When building a custom hood, always follow all applicable construction codes and standards. The custom hood

must be positively secured to wall studs or other wooden framework behind the drywall. Make sure it is capable of

supporting its own weight and the weight of the power pack. Failure to do so may cause personal injury or damage

to countertop or cooktop.

The custom hood must be constructed to fit the shape and total weight of the CC6 series power pack

model. The recommended minimum thickness for the custom hood base is 5/8”. If an optional custom

hood liner will be installed, we recommend the sides and front of the custom hood to be 3/4” thick. If

the optional custom hood liner will not be installed, the custom hood sides and front thickness are at

the installer’s discretion. See chart and illustration for details.

CC65I28SB

SINGLE BLOWER POWER PACK

10-1/8”

3-1/4”

2-15/16”

POWER PAC K MODEL TOTAL WEIGHT

CC65I28SB 33 LB.

CC67I28SB 45

LB.

2-3/4”

9-7/8”

1-1/16”

CC67I28SB

DUAL BLOWER POWER PACK

NOTE: The dual blower model has the

same dimensions as the single

blower model, but does not have a

horizontal discharge.

HK0292A

HK0291A

2-15/16”

2-3/4”

9-7/8”

1-1/16”

5

Page 6

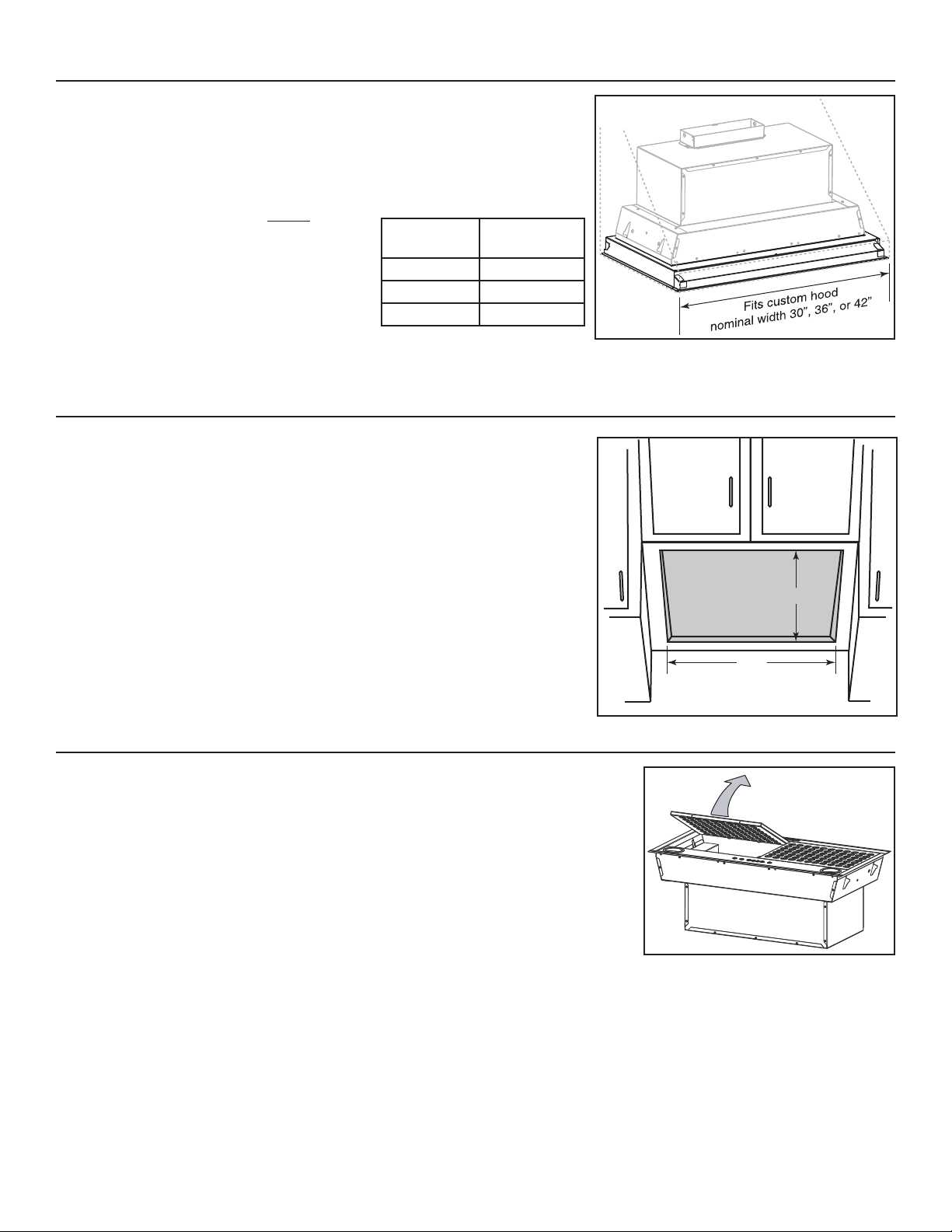

4. INSTALL CUSTOM HOOD LINER (OPTIONAL)

The liners are especially designed to protect the exterior base of the custom hood.

Refer to the table below to find the right liner model number according to the width of

the custom hood nominal width. To view specific model information, including depths

for each liner model, visit www.BestRangeHoods.com, www.BestRangeHoods.ca, or

contact Technical Support (phone number listed on front cover).

To install, see instruction packed with custom hood liner.

NOTE: The liner must be installed before the insert.

LINER MODEL

ALCC630SB 30”

ALCC636SB 36”

ALCC642SB 42”

CUSTOM HOOD

NORMINAL WIDTH

5. CUT THE HOLE IN CUSTOM HOOD BASE

HA0067A

If it is not done yet, cut a hole in the bottom of the custom hood, using the dimensions

shown at right.

NOTE: Keep in mind that the unit exterior flange is 3/4’’.

HD0340A

6. REMOVE FILTER

Rest the power pack on a table. Remove tapes on filters. Lift filters from power pack by pushing

them towards the back and rotate, then set filters aside.

13³/8”

26¾”

HD0366

6

Page 7

7. UNPLUG THE BLOWER(S)

Unplug the blower(s) (one or two, depending on model) from the front panel.

8. REMOVE WIRING COVER AND FRONT PANEL

Using a Robertson or a Phillips no. 2 screwdri ver, remove both wiring cover retaining screws (A).

Detach it from the power pack and set aside with its screws. Then, remove both sides screws (B)

retaining the front panel to the power pack. Carefully detach the front panel from the power

pack and set aside with its screws.

HD1098

HE0105

B

A

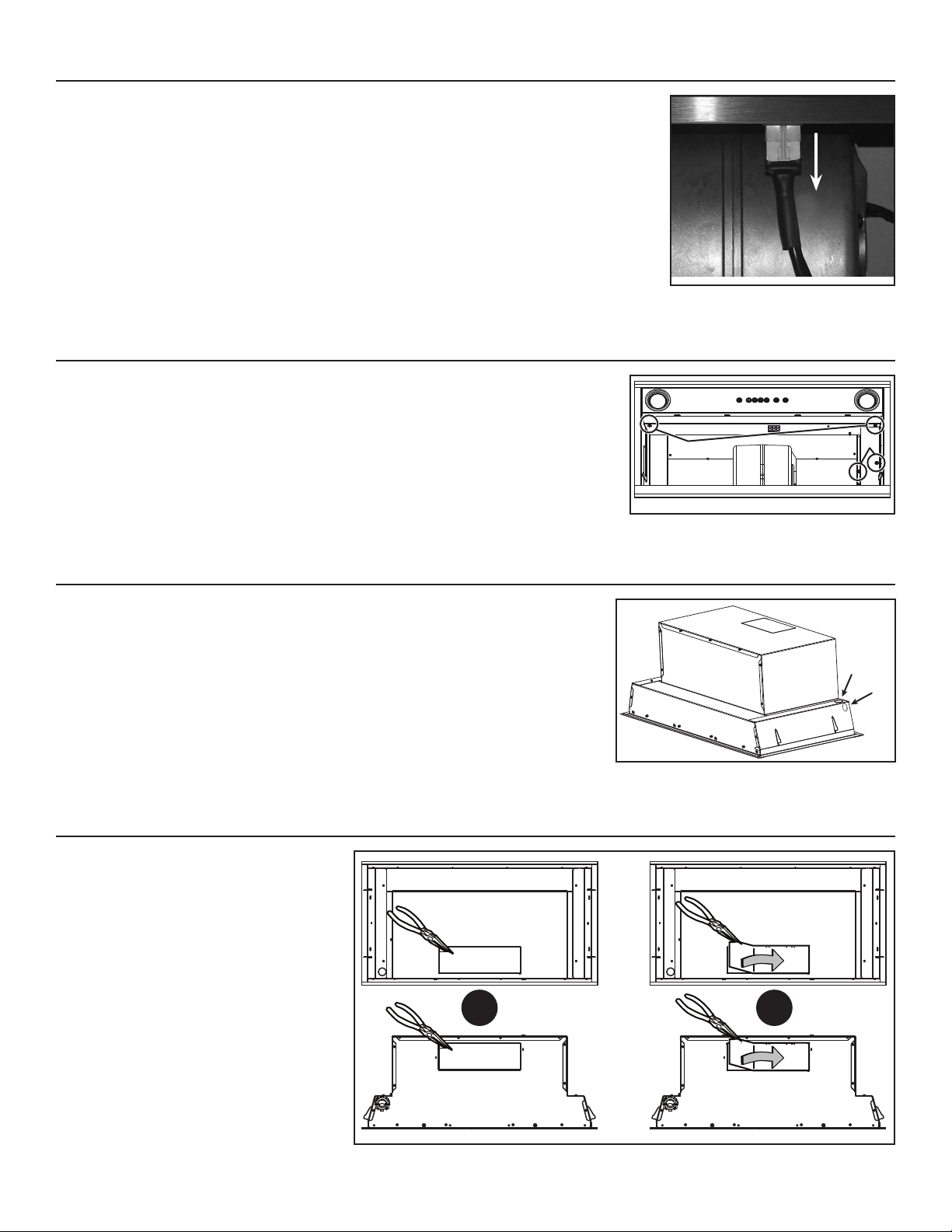

9. REMOVE THE ELECTRICAL KNOCKOUT

From inside the power pack, punch out the electrical knockout hole on top right side (C) OR

on back right side (D). Install the wire clamp (included in parts bag).

HR0030

10. REMOVE THE KNOCKOUT OPENING (SINGLE BLOWER MODEL ONLY)

Remove the knockout opening on top (vertical

discharge installation) or on back (horizontal

discharge installation) of the power pack.

1

C

D

2

HR0037

7

Page 8

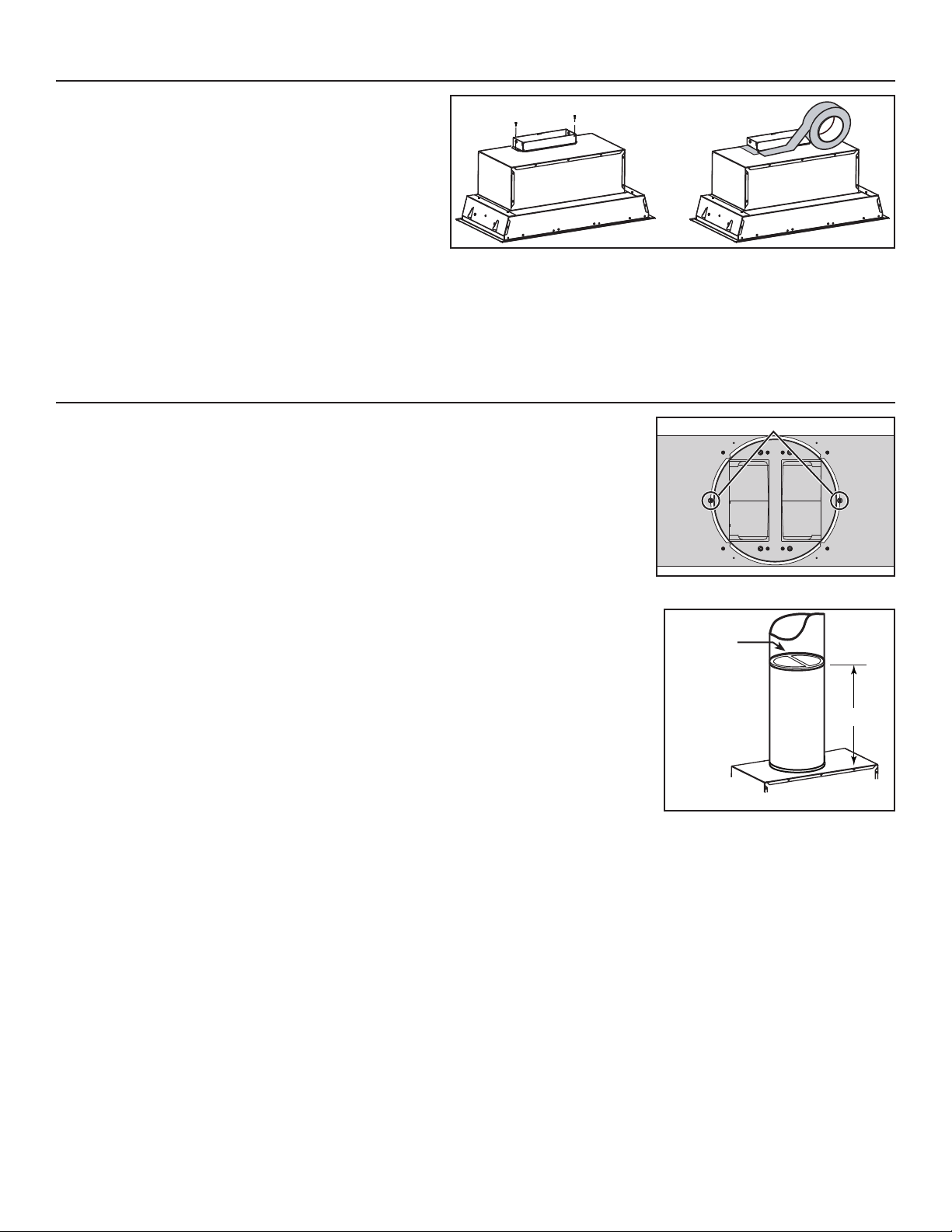

11. INSTALL THE ADAPTER/DAMPER (SINGLE BLOWER MODEL ONLY)

VERTICAL DISCHARGE INSTALLATION

Using 2 no. 8 x 3/8’’ screws provided in parts bag, secure the

adapter/damper to the top of the power pack. Remove tape from

damper flap. Seal the adapter to the power pack using metal foil

duct tape.

HO0137

HORIZONTAL DISCHARGE INSTALLATION

The adapter/damper will be installed on the back of the power pack once the power pack is mounted in the custom hood. Refer to step 15.

12. INSTALL THE ADAPTER AND THE DAMPER (DUAL BLOWER MODEL ONLY)

MOUNTING SCREW LOCATIONS

Using 2 no. 8 x 3/8’’ screws from parts bag, assemble the adapter on the top of the power pack.

Seal all joints with metal foil duct tape to eliminate air leaks.

Install 10” damper inside the VERTICAL ductwork that will be attached to power pack. Do not install

in a horizontal ductwork or it will not open and close properly. Remove shipping tape if present.

To optimize airflow and reduce noise, position the damper at least 17” above the top of the double

blower power pack; or as far as the duct run will allow. Also, ensure the damper hinge will be parallel

to power pack sides (see figure at right). Secure the damper to the duct with 3 no. 8 sheet metal

screws (not provided). Ensure damper opens and closes freely. Seal all joints with metal foil duct

tape to eliminate air leaks.

HJ0035

DAMPER HINGE

PARALLEL TO

POWER PACK

SIDES

17” min.

HJ0036A

8

Page 9

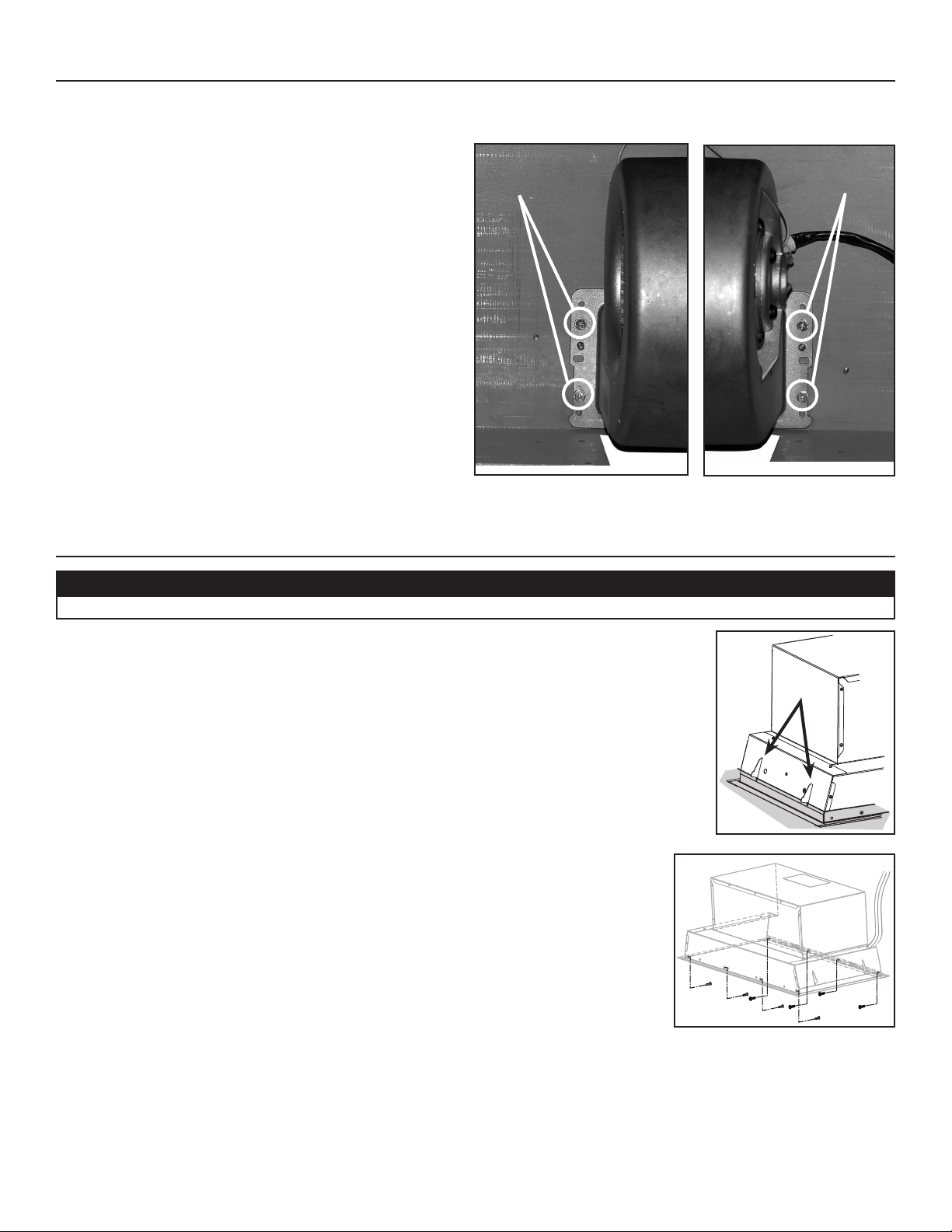

13. REMOVE THE BLOWER (SINGLE BLOWER MODEL, HORIZONTAL DISCHARGE ONLY)

In order to ease the power pack alignment with horizontal ductwork, disassemble the blower from the power pack before installing it in the

custom hood.

LEFT SIDE MOUNTING

SCREW LOCATIONS

Using a 5/16” socket, or a Phillips no. 2 or a Robertson no. 2

screwdriver, remove all blower mounting screws from the inner top

of the power pack. Set blower and screws aside.

HD0368

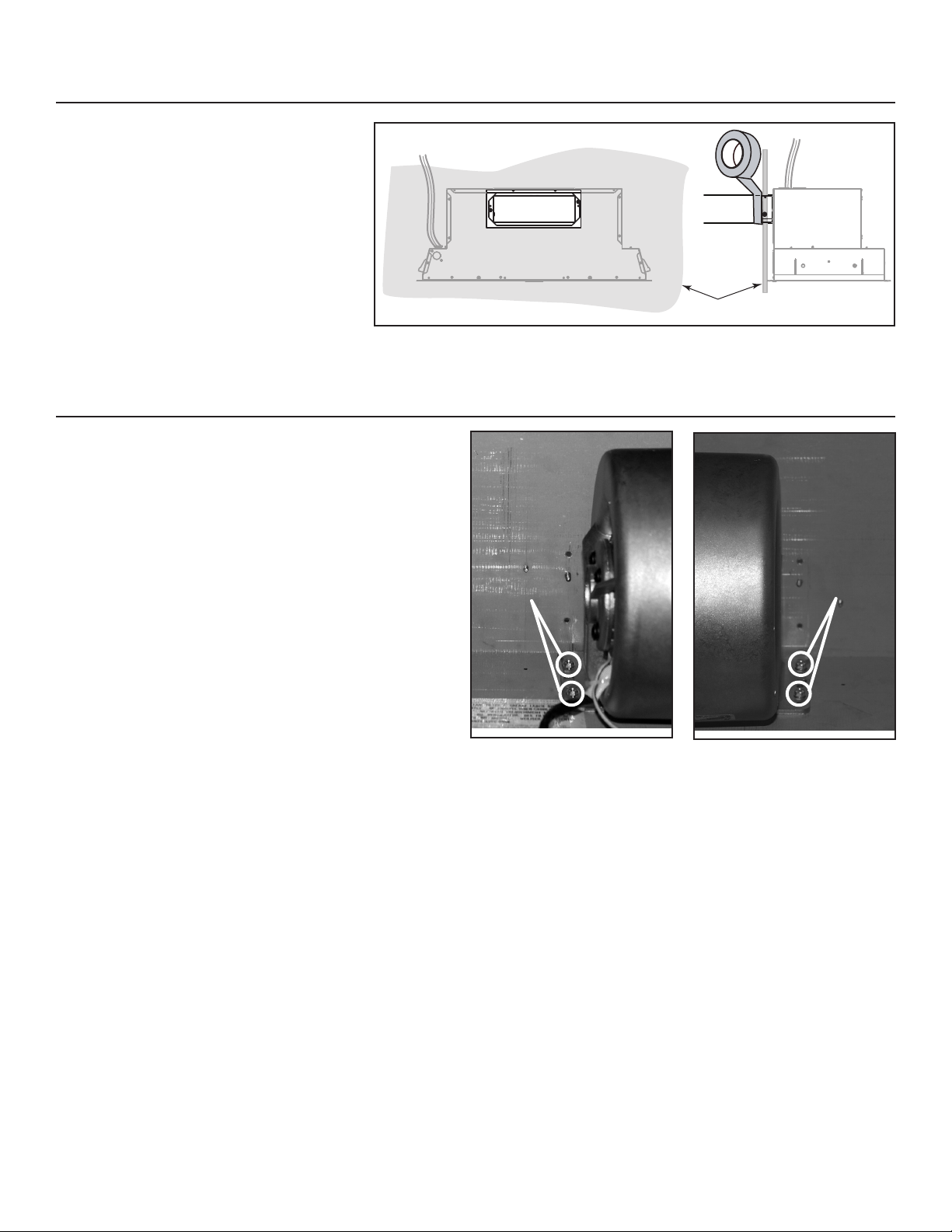

14. INSTALL THE POWER PACK

CAUTION

Take care not to kink ducting or pinch electrical cable when installing the power pack.

RIGHT SIDE MOUNTING

SCREW LOCATIONS

HD0369

Insert the power pack in the custom hood until the bottom of the clasping springs (2 per side) rests on the

top of the custom hood base (grey zone in illustration at right).

From inside the power pack, using provided no. 8-10 x 1/2” screws, mount the power pack to the

custom hood base. To do so, raise the front until its flange rests on the outer side of the custom hood

base and use 2 screws to secure in place. Do the same for the back, then complete the installation

with 2 additional screws on the front and back. See figure at right for mounting screws locations.

VERTICAL EXHAUST INSTALLATION ONLY

Ensure the adapter/damper enters the ducting and the damper opens freely. Wherever it is possible,

seal connections with metal foil duct tape.

HH0126

CLASPING

SPRINGS

HD0370

9

Page 10

15. INSTALL THE ADAPTER/DAMPER ON BACK OF POWER PACK

(SINGLE BLOWER MODEL, HORIZONTAL DISCHARGE ONLY)

From the outside of the wall, using two no. 8 x 3/8’’

screws provided in parts bag, secure the adapter/

damper to the back of the power pack. Remove

tape from damper flap. Connect ducting to the

adapter/damper and seal the joint using metal foil

duct tape.

HH0127A

BACK VIEW SIDE VIEW

WALL

16. REINSTALL THE BLOWER (SINGLE BLOWER MODEL, HORIZONTAL DISCHARGE ONLY)

The single blower power pack is factory shipped for a vertical

discharge installation. For a horizontal discharge installation,

the blower must be flipped. Using a 5/16” socket, or a Phillips or

Robertson no. 2 screwdriver, secure the blower to the inner back

of the power pack with all blower mounting screws (previously

removed in step 13).

LEFT SIDE MOUNTING

SCREW LOCATIONS

HD0371

HD0372

RIGHT SIDE MOUNTING

SCREW LOCATIONS

10

Page 11

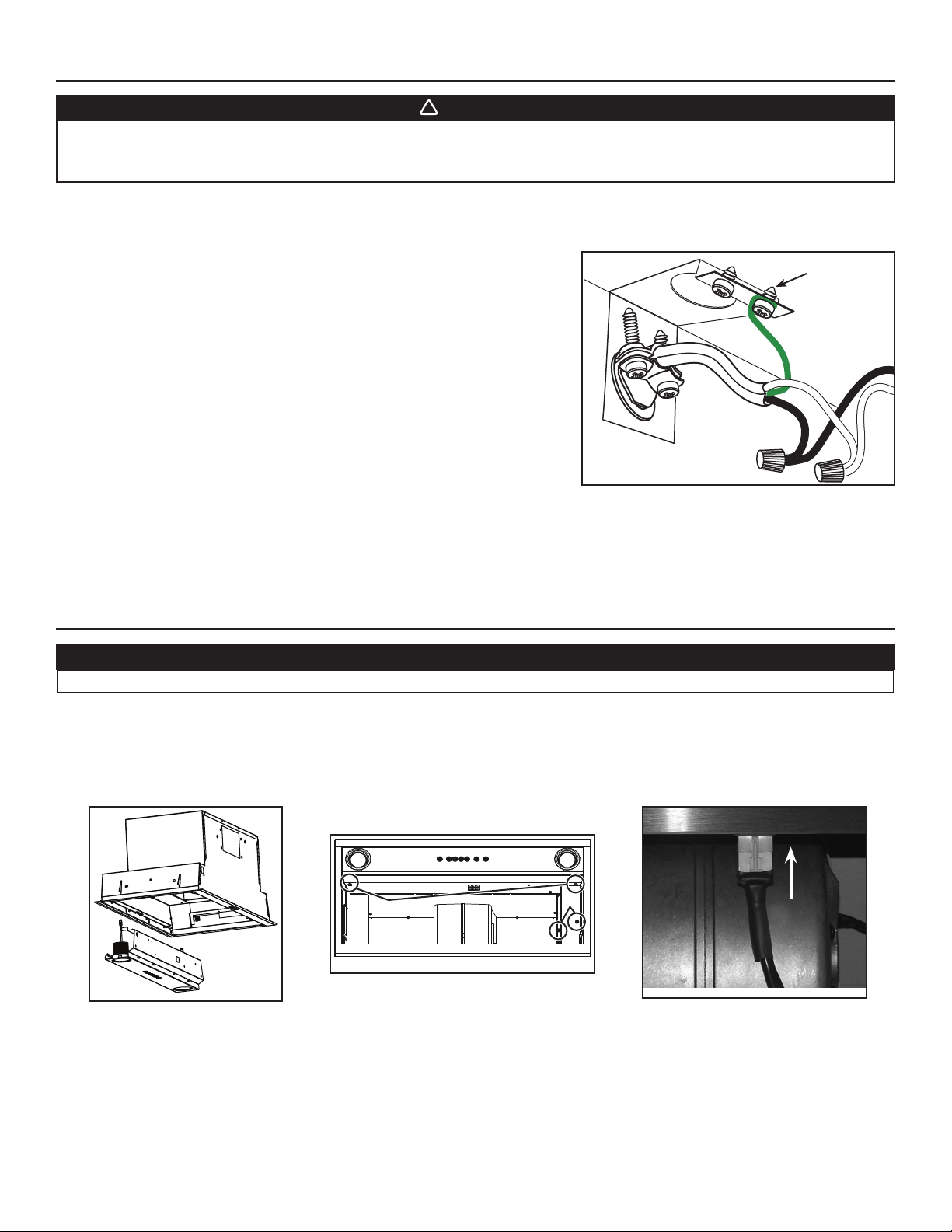

17. CONNECT WIRING (ALL MODELS)

!

WARNING

Risk of electric shock. Electrical wiring must be done by qualified personnel in accordance with all applicable

codes and standards. Before connecting wires, switch power off at service panel and lock service disconnecting

means to prevent power from being switched on accidentally.

Insert the house wiring cable through the wire clamp previously installed in step 9. Tighten the wire clamp to secure the cable.

A

Connect cable using provided wire connectors.

Connect wires as follows: BLACK to BLACK, WHITE to WHITE and GREEN or BARE

wire under ground screw. DO NOT FORGET TO CONNECT THE GROUND.

HE0059

18. REINSTALL FRONT PANEL AND WIRING COVER

CAUTION

Take care not to pinch wiring when reinstalling the front panel and the wiring cover.

Carefully reassemble the front panel to the power pack by aligning the tabs with their corresponding slot. Using a Robertson or a Phillips

no. 2 screwdriver, secure the front panel to the power pack using its both retaining screws (A) previously removed in step 8. Reassemble

the wiring cover using its both retaining screws (B) previously removed in step 8. Plug the motor(s) (one or two, depending on model) to

the front panel.

B

HD1098

HO0260

A

HE0105

11

Page 12

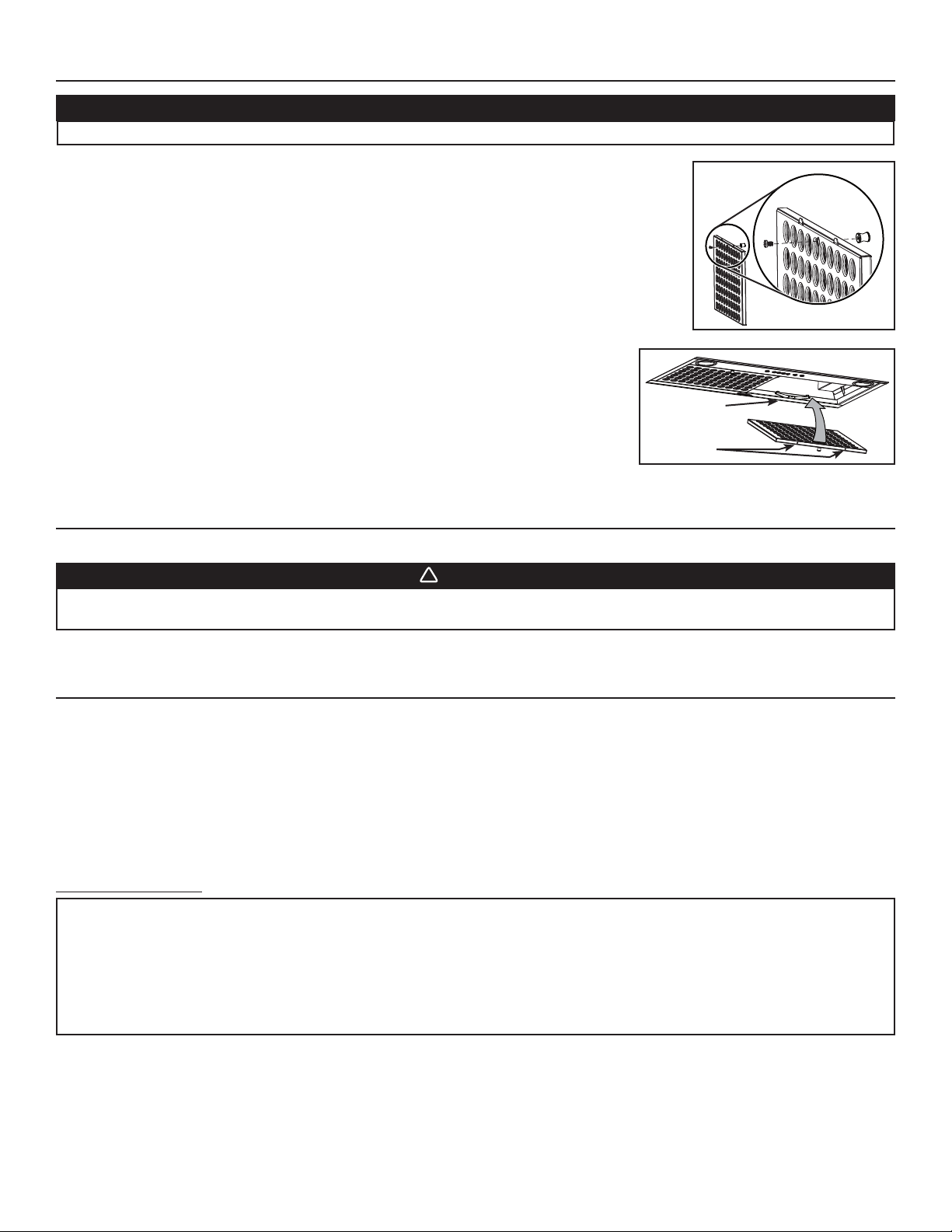

19. REINSTALL FILTERS

!

CAUTION

Remove protective plastic film covering filters before installing them.

1. Using a Phillips no. 2 screwdriver, assemble the knob to each filter.

NOTE: The screw MUST BE on filter tabs side. See illustration at right.

2. Rest rear filters edge on filter springs (A) in the power pack.

3. Using knob, tilt up the filters into position. Make sure filter tabs (B) are securely engaged in

power pack front edge after installation.

20. LED LIGHTING

HD0373

HO0139

A

B

The lighting of this unit is produced by two LED modules (included).

WARNING

Do not touch lamps during or soon after operation. Burns may occur. Cannot be replaced by any other type of light

bulb or LED module.

21. USE AND CARE

Filters

The filters should be cleaned frequently. Use a warm detergent solution. Wash more often if your cooking style generates more grease —

like frying foods or wok cooking.

Remove filter by pushing it towards the back of power pack and rotating filter downward. Filters are dishwasher safe. Allow filters to dry

completely before reinstalling them in the power pack.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of the filters may occur if using phosphate detergent or as a result of local water conditions — but this will not affect filter performance. This discoloration is not covered by the warranty.

Power Pack Cleaning

Stainless steel cleaning:

Do:

• Regularly wash with clean cloth or rag soaked with warm water

and mild soap or liquid dish detergent.

• Always clean in the direction of original polish lines.

• Always rinse well with clear water (2 or 3 times) after cleaning.

Wipe dry completely.

• You may also use a specialized household stainless steel

cleaner.

Avoid when choosing a detergent:

Don’t:

• Use any steel or stainless steel wool or any other scrapers to

remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues reach the

power pack. During construction or renovation, cover the power

pack to make sure no dust adheres to stainless steel surface.

- Any cleaners that contain bleach will attack stainless steel.

- Any products containing: chloride, fluoride, iodide, bromide will deteriorate surfaces rapidly.

- Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc., are highly explosive and should never be

used close to a range.

12

Page 13

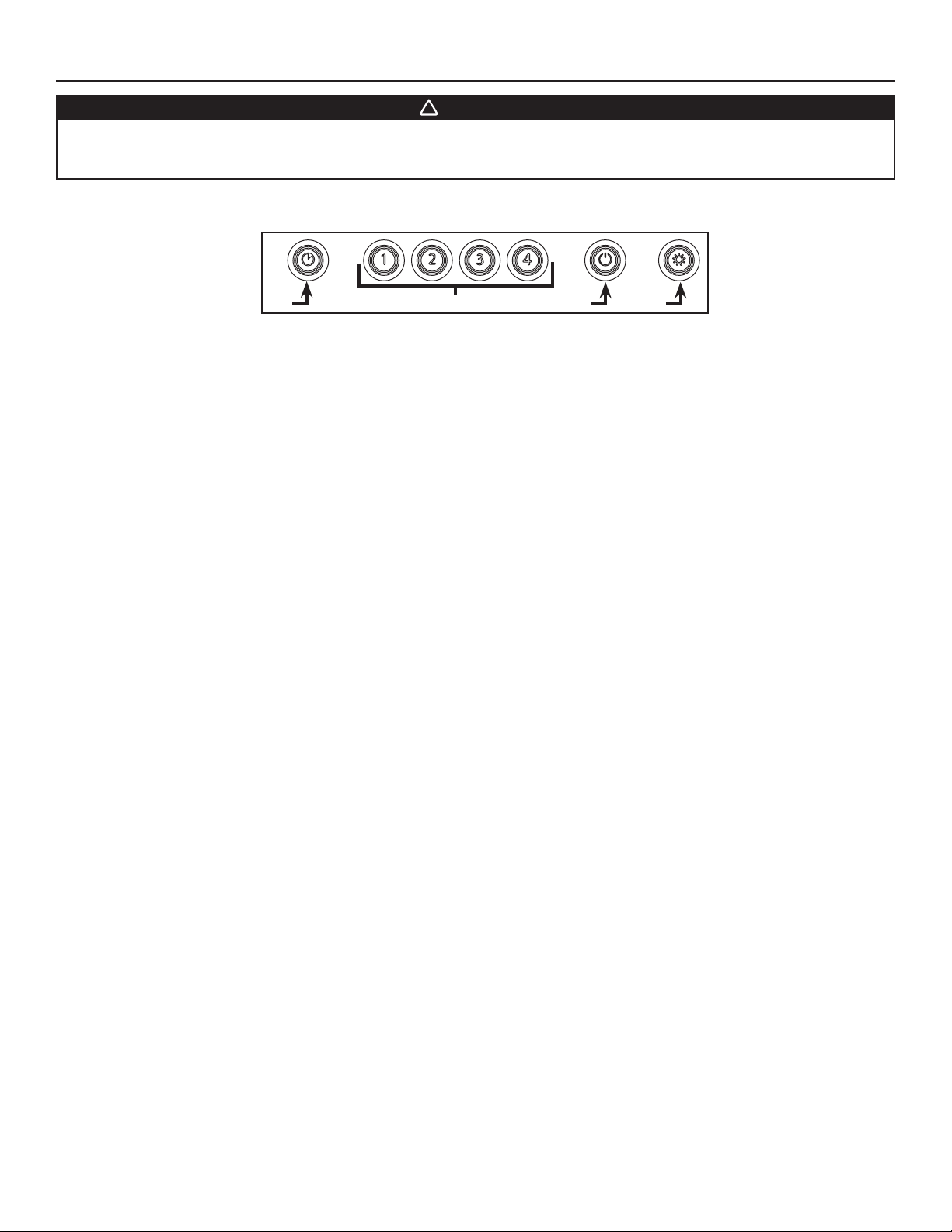

22. OPERATION

!

WARNING

When using a gas stove, always turn the power pack blower(s) on prior to begin cooking. In addition, the blower(s)

must be at least in third speed if three burners or more are turned on simultaneously. Failure to do so may lead the

surface of the power pack to become very hot.

Always turn your power pack on before you begin cooking to establish an air flow in the kitchen. Let the blower run for a few minutes to

clear the air after you turn off the range. This will help keep the whole kitchen cleaner and brighter.

HC0023

ABCD

A. DELAY SWITCH:

When a blower speed is selected, press this switch to activate the delay function. The corresponding blower speed switch will flash

to indicate this function is activated. The blower will continue to operate for 5 minutes and will stop automatically.

To cancel the delay function, press the delay switch once again.

B. STAR T/STOP/SPEED SELECTION SWITCHES:

Press the switch corresponding to the desired blower speed (from 1 for low speed to 4 for high speed). The chosen switch will light.

To turn off the blower, press once more on the corresponding blower speed switch; the switch light will shut off.

NOTE: When blower is off, pressing on blower speed 1 switch will cause the blower to start on high speed for a very short lapse of time,

and then resume on speed 1.

C. MASTER OFF/FILTER MAINTENANCE/HEAT SENTRY™ (TRIPLE FUNCTION SWITCH):

i. To turn off the blower(s) and the light simultaneously, press this switch once.

ii. After 25 hours of operation, this switch will light to indicate the filters and the blower wheel(s) need to be cleaned in order to maintain

efficient operation of the unit. The switch light will stay on until the function is reset by pressing this switch for 3 seconds.

iii. The light indicator is used for the Heat Sentry function as well.

HEAT SENTRY: The power pack is equipped with a protective device that activates when excessive heat is detected inside the power pack

and when it is set on speed 4. This device takes control of the blower and deactivates speed 4 for a 10-minute period and

sets it on speed 3. During the Heat Sentry activation, only speed 3 can be used; the Heat Sentry button (C) will flash while

the speed 3 button will light. The power pack can also be turned OFF.

D. LIGHT SWITCH:

This switch allows two different lighting levels according to your needs. Press once for full intensity, twice for nightlight.

To shut off the lights without turning off the blower, press once more.

13

Page 14

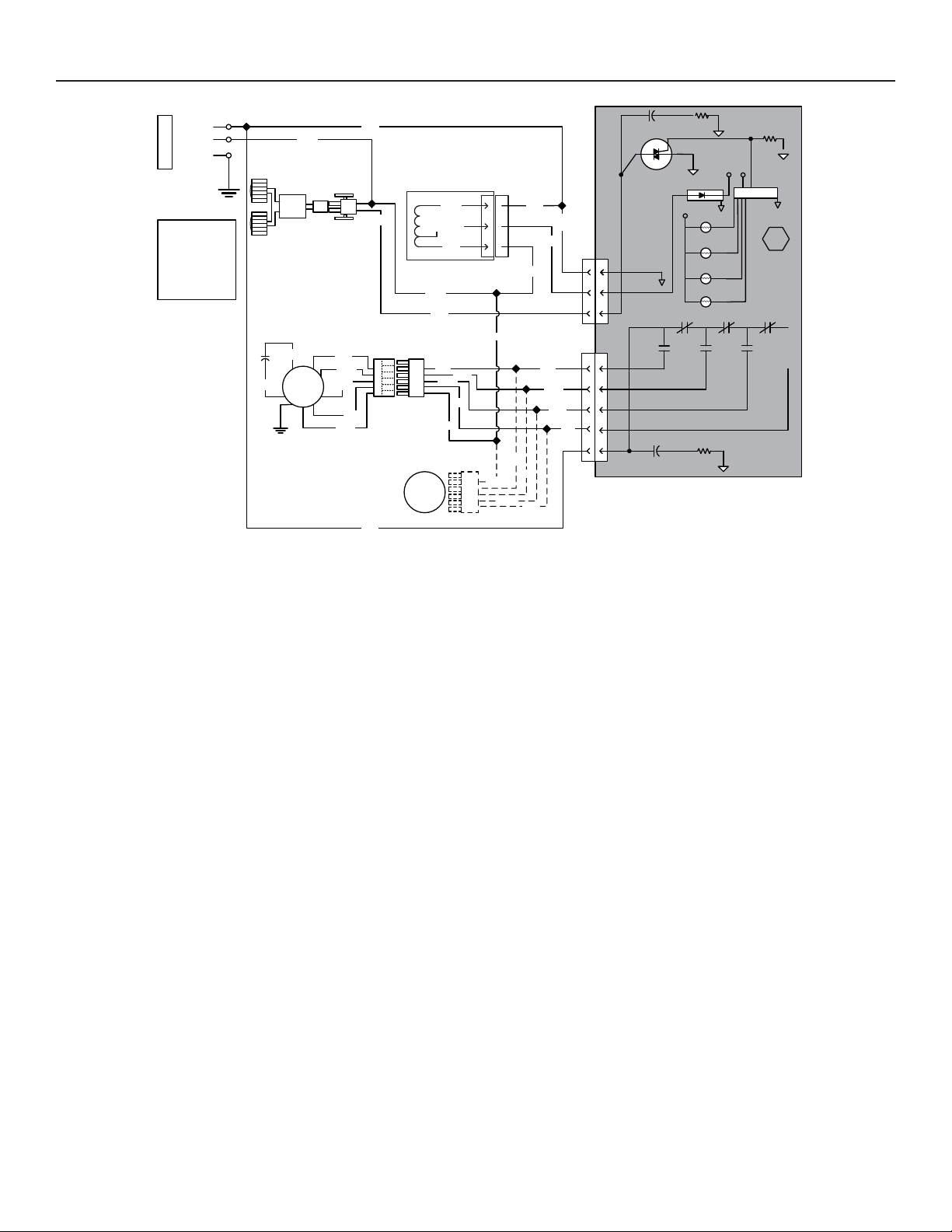

23. WIRING DIAGRAM

LINE

NEUTRAL

GROUND

120 VAC

COLOR CODE

BLK BLACK

BLU BLUE

BRN BROWN

GRY GREY

ORG ORANGE

RED RED

WHT WHITE

YEL YELLOW

HE0162A

LED

LED

BRN

WHT

LED

B

DRIVER

BLOWER MOTOR

GRY

BLU

WHT

ORG

M

RED

OPTIONAL SECOND

BLOWER MOTOR

BLK

BLK

BLK

YEL

TRANSFORMER

WHT

RED 9.5 V

BLK

WHT

YEL

BLU

WHT

ORG

BLK

WHT

M

WHT

WHT

ORG

BLU

WHT

WHT

BLK

BLK

BLU

YEL

WHT

ORG

BLK

BLK

Q1

LOGIC

K1

K1

J1

1

2

3

J2

1

2

3

4

5

INE

120 V L

REF

10 VAC

K1 NO K2 NO K3 NO K4 NO

K2

K3

K4

K1 NC K2 NC K3 NC

A1

ELECTRONIC

ASSEMBLY

14

Page 15

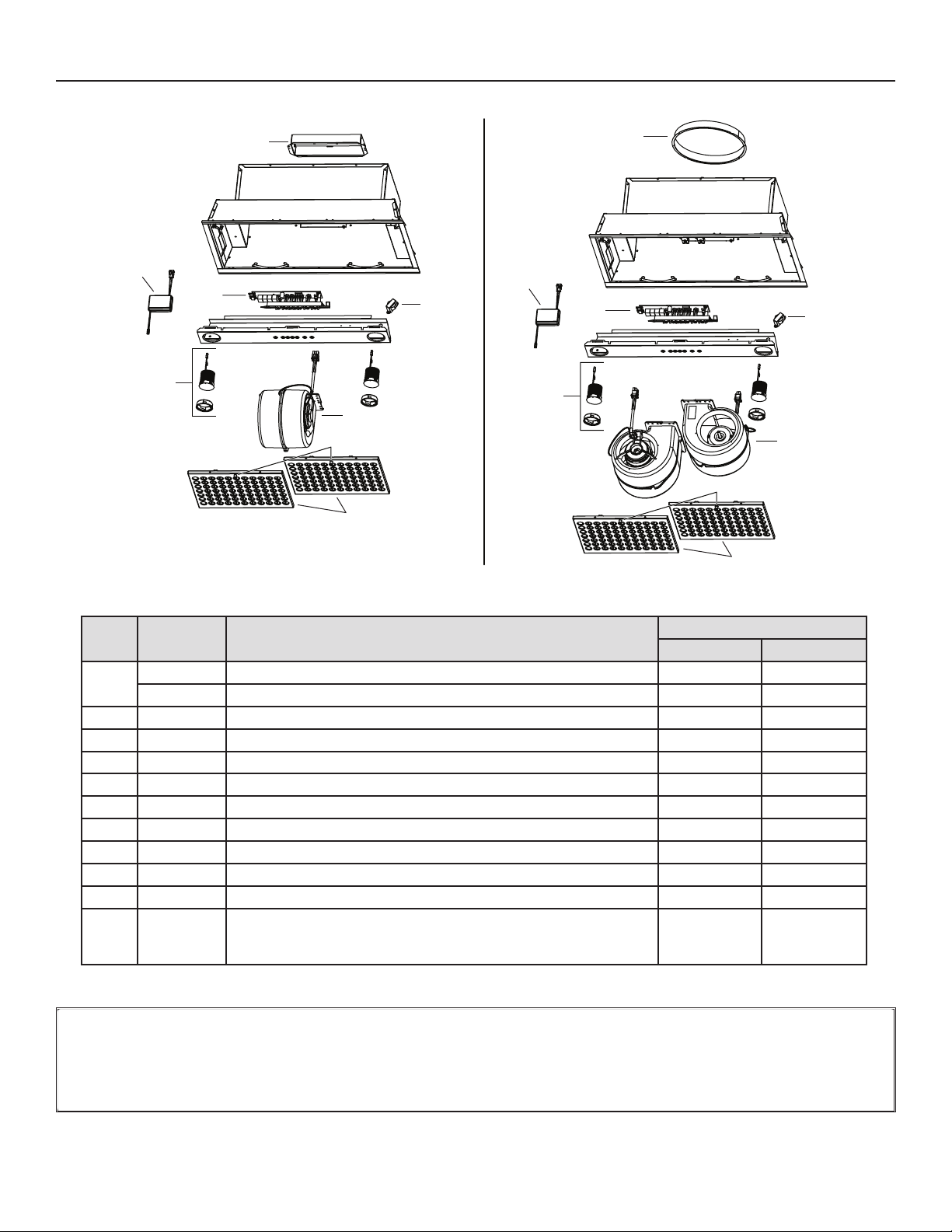

24. SERVICE PARTS

CC65I28SB

2

CC67I28SB

1

2

3

8

4

4

7

6

5

1

3

8

7

6

HL0447

KEY

NO.

1

PART NO.DESCRIPTION

SV13296 A

SV08541 A

2 62248 LED D

3 SV21244 E

4 62612 LED

5 SV18428 T

6 SV08967 F

7 SV08582 I

8 SV09022 T

* SV05869 B

* SV23862 I

* SV08545

*Not shown

5

QTY. (POWER PACK MODEL)

CC65I28SB CC67I28SB

DAPTER/DAMPER 3¼” X 10” 1 -

DAPTER 10” ROUND -1

RIVER AND CONNECTION HARNESS 11

LECTRONIC CONTROL WITH CHROMED BUTTONS AND BLUE LEDS 11

MODULE (1) 2 2

HIN BAFFLE FILTER 22

ILTER KNOBS (INCLUDING SCREWS) (SET OF 2) 1 1

NTERNAL BLOWER 12

RANSFORMER 11

EST LOGO 11

NSTALLATION MANUAL 11

ARTS BAG: 2 WIRE CONNECTOR, 1 WIRE CLAMP,

P

4 S

CREWS NO. 8 X 3/8”, 9 CHROMED PLATED SCREWS NO. 8-10 X 1/2”,

ECHANICAL SCREWS NO. 8-32 X 1/4”

10 M

11

R

EPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good working condition, you must use Broan-NuTone genuine replacement parts only.

Broan-NuTone genuine replacement parts are specially designed for each unit and are manufactured to comply with all the applicable

certification standards and maintain a high standard of safety. Any third party replacement part used may cause serious damage and

drastically reduce the performance level of your unit, which will result in premature failing. Broan-NuTone recommends to contact a

certified service depot for all replacement parts and repairs.

15

Page 16

25. WARRANTY

FIVE-YEAR LIMITED WARRANTY FOR BEST® PRODUCTS

Warranty Period and Exclusions: Broan-NuTone, LLC (the “Company”) warrants to the consumer purchaser of its product (“you”) that the product (the

“Product”) will be free from material defects in the materials or its workmanship for a period of five (5) years from the date of original purchase (or such

longer period as may be required by applicable law) or a period of two (2) years from the date of service for any labor provided on the Product.

The limited warranty period for any replacement parts provided by the Company and for any Products repaired or replaced under this limited warranty shall

be the remainder of the original warranty period (or such longer period as may be required by applicable law).

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES AND BULBS, FUSES, FILTERS, DUCTS, ROOF CAPS, WALL CAPS

AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a) normal maintenance and service, (b) normal wear and tear, (c) any Products or

parts which have been subject to misuse, abuse, abnormal usage, negligence, accident, improper or insufficient maintenance, storage or repair (other than

repair by the Company), (d) damage caused by faulty installation, or installation or use contrary to recommendations or instructions, (f) damage caused by

exposure to salt air, (g) damage in transit, (h) natural wear of finish, (i) Products in commercial or nonresidential use, (j) damage caused by fire, flood or

other act of God, or (k) Products with altered, defaced or removed serial numbers. This warranty covers only Products sold to consumers in North America.

This warranty supersedes all prior warranties and, subject to applicable law, is not transferable from the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s sole obligation and your sole remedy for defective Products. The foregoing warranties

are exclusive and in lieu of any other warranties and conditions, express or implied. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THE

COMPANY DISCLAIMS AND EXCLUDES ALL OTHER EXPRESS WARRANTIES AND CONDITIONS, AND DISCLAIMS AND EXCLUDES ALL WARRANTIES

AND CONDITIONS IMPLIED BY LAW, INCLUDING WITHOUT LIMITATION THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

To the extent that applicable law prohibits the exclusion of implied warranties or conditions, the duration of any applicable implied warranty or condition

is limited to the period specified for the express warranty above. Some jurisdictions (which may include the Province of Quebec or specific US states) do

not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. Any oral or written description of the Product is

for the sole purpose of identifying it and shall not be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted in such manner as to be effective and valid under applicable law, but if any

provision is held to be prohibited or invalid, such provision shall be ineffective only to the extent of such prohibition or invalidity, without invalidating the

remainder of such provision or the other remaining provisions of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its option, provide replacement parts for, or repair or replace, without charge,

any Product or part thereof, to the extent the Company finds it to be covered by and in breach of this limited warranty under normal use and service. The

Company will ship the repaired or replaced Product or replacement parts to you at no charge. You are responsible for all costs for removal, reinstallation

and shipping, insurance or other freight charges incurred in the shipment of the Product or part to the Company. If you must send the Product or part

to the Company, as instructed by the Company, you must properly pack the Product or part—the Company is not responsible for damage in transit. The

Company reserves the right to utilize reconditioned, refurbished, repaired or remanufactured Products or parts in the warranty repair or replacement

process. Such Products and parts will be comparable in function and performance to an original Product or part and warranted for the remainder of the

original warranty period (or such longer period as may be required by applicable law).

Company reserves the right, in its sole discretion, to refund the money actually paid by you for the Product. If the Product or component is no longer

available, replacement may be made with a similar product of equal or greater value, at Company’s sole discretion. This is your sole and exclusive remedy

for breach of this limited warranty.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE REPLACEMENT PARTS, OR REPAIR OR REPLACE, AT THE COMPANY’S OPTION,

SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY AND THE COMPANY’S SOLE AND EXCLUSIVE OBLIGATION. THE

COMPANY SHALL NOT BE LIABLE FOR INCIDENTAL, INDIRECT, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH

THE PRODUCT, ITS USE OR PERFORMANCE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from jurisdiction to jurisdiction. The disclaimers,

exclusions, and limitations of liability under this warranty will not apply to the extent prohibited by applicable law.

This warranty covers only replacement or repair of defective Products or parts thereof at the Company’s main facility and does not include the cost of field

service travel and living expenses.

Any assistance the Company provides to or procures for you outside the terms, limitations or exclusions of this limited warranty will not constitute a waiver

of such terms, limitations or exclusions, nor will such assistance extend or revive the warranty. The Company will not reimburse you for any expenses

incurred by you in repairing or replacing any defective Product, except for those incurred with the Company’s prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a) notify the Company at the address or telephone number stated below within

seven (7) days of discovering the covered defect, (b) give the model number and part identification and (c) describe the nature of any defect in the Product

or part. At the time of requesting warranty service, you must present evidence of the original purchase date. If you cannot provide a copy of the original

written limited warranty, then the terms of the Company’s most current written limited warranty for your particular product will control.

PRODUCT SPECIFICATIONS

All illustrations and specifications in this catalog are based on the latest product information available at time of production. Broan-NuTone, LLC and

BEST® reserves the right to make changes at any time, without notice, in prices, colors, materials, equipment, specifications and models, place of

manufacture and to discontinue models or equipment.

Best

Broan-NuTone, LLC- 926 W. State Street, Hartford, WI 53207 1-800-637-1453

Best®, 550 Lemire Blvd., Drummondville, QC, Canada (1-866-737-7770) www.bestrangehoods.com

16

Page 17

GUIDE D'INSTALLATION

HB0312

SÉRIE CC6

! !

CONÇUE UNIQUEMENT POUR LA CUISSON DOMESTIQUE

LIRE ET CONSERVER CES DIRECTIVES

INSTALLATEUR : LAISSER CE GUIDE AU PROPRIÉTAIRE.

PROPRIÉTAIRE : DIRECTIVES D’UTILISATION ET D’ENTRETIEN

EN PAGES 12 ET 13.

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800 558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.ca 866 737-7770

23862 rév. 02

Page 18

!

AVERTISSEMENT

!

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE,

D’ÉLECTROCUTION OU DE BLESSURES CORPORELLES,

SUIVEZ LES DIRECTIVES SUIVANTES :

1. N’utilisez cet appareil que de la façon prévue par le

manufacturier. Si vous avez des questions, contactez le

manufacturier à l’adresse et au numéro de téléphone indiqués

dans la garantie.

2. Avant de réparer ou de nettoyer l’appareil, couper l’alimentation

électrique en verrouillant le panneau de distribution afin

d’éviter sa remise en marche accidentelle. Si le panneau de

distribution ne peut être verrouillé, y fixer un avertissement en

évidence, telle qu’une étiquette de couleur vive.

3. Les travaux d’installation et de raccordement électrique doivent

être effectués par une personne qualifiée, conformément aux

codes et standards de construction, incluant ceux concernant

la protection contre les incendies.

4. Une quantité d’air adéquate est requise afin d’assurer une

bonne combustion et l’évacuation des gaz par la cheminée

dans le cas des appareils alimentés au gaz, afin de prévenir

les retours de cheminée. Conformez-vous aux instructions et

aux standards de sécurité des manufacturiers d’équipement

de chauffage, tel que publiés par la National Fire Protection

Association (NFPA), et l’American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), ainsi

que les responsables des codes locaux.

5. Lorsque vous coupez ou perforez un mur ou un plafond,

prenez garde de ne pas endommager les fils électriques ou

autre installation qui pourraient y être dissimulés.

6. L’évacuation des ventilateurs avec conduits doit toujours se

faire à l’extérieur.

7. Afin de réduire le risque d’incendie ou d’électrocution, ne

pas utiliser cet appareil avec une commande de vitesse à

semi-conducteur additionnelle.

8. Afin de réduire le risque d’incendie, n’utilisez que des conduits

en métal.

9. Cet appareil doit être relié à une mise à la terre.

10. Lorsqu’une réglementation est en vigueur localement et qu’elle

comporte des exigences d’installation et/ou de certification

plus restrictives, lesdites exigences prévalent sur celles de ce

document et l’installateur entend s’y conformer à ses frais.

AFIN DE RÉDUIRE LES RISQUES DE FEU DE CUISINIÈRE :

a) Ne jamais laisser les appareils de cuisson sans surveillance

lorsqu’ils sont réglés à feu vif. Les débordements engendrent de

la fumée et des déversements graisseux pouvant s’enflammer.

Chauffez l’huile lentement, à feu doux ou moyen.

b) Toujours mettre la hotte en marche lorsque vous cuisinez à

feu vif ou que vous cuisinez des mets flambés (par exemple :

crêpes Suzette, cerises jubilée, steaks au poivre flambés).

c) Nettoyez régulièrement la (les) roue(s) du ventilateur. Ne

laissez pas la graisse s’accumuler sur le ventilateur, les filtres

ou les conduits d’évacuation.

d) Utilisez le bon format de casserole. Servez-vous toujours de

casseroles et d’ustensiles appropriés à la dimension de la

surface chauffante.

AFIN D’ÉVITER TOUT RISQUE DE BLESSURES LORS D’UN

FEU DE CUISINIÈRE, SUIVEZ CES DIRECTIVES* :

1. Étouffez les flammes avec un couvercle hermétique, une

tôle à biscuits ou un plateau métallique et ensuite, éteindre

le brûleur. PRENEZ SOIN D’ÉVITER LES BRÛLURES. SI

LES FLAMMES NE S’ÉTEIGNENT PAS IMMÉDIATEMENT,

ÉVACUEZ LES LIEUX ET APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS UNE CASSEROLE EN FLAMMES

DANS VOS MAINS – Vous pourriez subir des brûlures.

3. N’UTILISEZ PAS D’EAU, incluant linge à vaisselle ou serviette

mouillés – ceci pourrait occasionner une violente explosion.

4. N’utilisez un extincteur QUE DANS LE CAS OÙ :

A. Vous savez qu’il s’agit d’un extincteur de classe ABC et

que vous en connaissez le fonctionnement.

B. Le feu est petit et limité à l’endroit où il a débuté.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en ayant accès à une

sortie de secours.

*Tirées du Kitchen Fire Safety Tips publié par la NFPA.

ATTENTION

1. Pour une utilisation à l’intérieur seulement.

2. Pour usage domestique seulement. Ne pas utiliser pour évacuer

des vapeurs ou des matières dangereuses ou explosives.

3. Afin d’éviter tout dommage au moteur et de débalancer ou de

rendre bruyante la roue du moteur, garder votre appareil à l’abri

des poussières de placoplâtre et de construction/rénovation, etc.

4. Le moteur de votre hotte encastrable possède une protection

thermique qui arrêtera automatiquement le fonctionnement du

moteur s’il surchauffe. Le moteur redémarrera automatiquement

une fois refroidi. Si le moteur continue de s’arrêter et de

redémarrer, faites-le vérifier.

5. La distance minimale entre le bas de votre hotte encastrable

et le plan de cuisson ne doit pas être inférieure à 24 po.

Un maximum de 30 po au-dessus du plan de cuisson est

fortement recommandé pour une meilleure évacuation des

odeurs de cuisine. Pour une cuisinière au gaz, le bas de votre

hotte encastrable NE DOIT PAS ÊTRE INFÉRIEUR à 30 po

au-dessus de la surface de cuisson.

6. Deux installateurs sont recommandés lors de l’installation en

raison de la grande dimension et le poids de cet appareil.

7. Afin de réduire les risques d’incendie, assurez-vous d’évacuer

l’air à l’extérieur – Ne pas évacuer l’air dans des espaces

restreints comme l’intérieur des murs ou plafond ou dans le

grenier, faux plafond ou garage.

8. En raison de la grande capacité d’évacuation de cet appareil,

il est recommandé d’ouvrir une fenêtre dans ou près de la

cuisine afin de remplacer l’air évacué.

9. Afin de réduire les risques d’incendie et d’électrocution, les

modèles Best de la série CC6 doivent être installés uniquement

avec leur propre ventilateur intérieur. Aucun autre ventilateur

ne doit être utilisé.

10. Veuillez consulter l’autocollant apposé à l’intérieur du produit

pour plus d’information ou autres exigences.

2

Page 19

- SÉRIE CC6 SYSTÈME DE HOTTE ENCASTRABLE-

ODÈLE 437

CAPUCHON DE TOIT

STANDARD

DE

3¼ PO X 10 PO

NON INCLUS)

(

C

ONDUIT STANDARD

3¼ PO X 10 PO

DE

(NON INCLUS)

CAPUCHON DE MUR

STANDARD

DE

3¼ PO X 10 PO

NON INCLUS)

(

M

CAPUCHON DE TOIT

À HAUT RENDEMENT

(NON INCLUS)

MODÈLE 441

CAPUCHON DE MUR POUR

DE 10 PO ROND

CONDUIT

(NON INCLUS)

MODÈLE 418

COUDE AJUSTABLE

DE 10 PO ROND

(NON INCLUS)

M

ODÈLE 410

CONDUIT ROND DE

10 PO EN SECTIONS DE

2 PI (NON INCLUS)

ADAPTATEUR/VOLET

DE 3¼ PO X 10 PO

(INCLUS AVEC LA HOTTE

ENCASTRABLE À VENTILATEUR

SIMPLE)

ALCC630SB,

ALCC636SB

OU ALCC642SB

REVÊTEMENT D'ARMOIRE

(OPTIONNEL)

HOTTE ENCASTRATBLE

CC65I28SB

HL0126

ENTILATEUR SIMPLE

V

(600 PI³/MIN INCLUS AVEC LA

HOTTE ENCASTRABLE)

DAPTATEUR DE 10 PO ROND

A

(INCLUS AVEC LA HOTTE ENCASTRABLE À

VENTILATEUR DOUBLE DE 1000 PI³/MIN)

ALCC630SB,

ALCC636SB

OU ALCC642SB

REVÊTEMENT D'ARMOIRE

(OPTIONNEL)

HOTTE ENCASTRABLE

CC67I28SB

OLET VERTICAL EN LIGNE DE

V

10 PO ROND (INCLUS AVEC LA

HOTTE ENCASTRABLE À

VENTILATEUR DOUBLE DE

1000 PI³/MIN)

ENTILATEUR DOUBLE

V

(1000 PI³/MIN, INCLUS AVEC LA

HOTTE ENCASTRABLE)

3

Page 20

1. PRÉPARER L'INSTALLATION

!

AVERTISSEMENT

Il est recommandé de porter des lunettes et des gants de sécurité lors de l’installation, de l’entretien ou de la

réparation de cet appareil.

NOTE: Avant de commencer l'installation, vérifier le contenu de la boîte. Si des pièces sont manquantes ou endommagées, contacter le

manufacturier.

S’assurer que les articles suivants sont inclus :

- Hotte encastrable

- Accessoires : • 2 filtres

• 2 boutons de filtre avec vis, collés à l’intérieur de la hotte

• 1 adaptateur/volet de 3¼ po x 10 po (inclus avec la hotte encastrable à ventilateur simple de 600 pi³/min)

• 1 volet vertical en ligne de 10 po rond (inclus avec la hotte encastrable à ventilateur double de 1000 pi³/min)

• 1 adaptateur de 10 po rond (inclus avec la hotte encastrable à ventilateur double de 1000 pi³/min)

• Sac de pièces incluant : 1 serre-fils, 2 capuchons de connexion, 4 vis n° 8 x 3/8 po, 9 vis plaquées chrome n° 8 x 1/2po,

10 vis n° 8-32 x 1/4 po. Jeter la quincaillerie excédentaire s’il y a lieu.

Pièces vendues séparément :

- Revêtement d’armoire modèle ALCC630SB, ALCC636SB ou ALCC642SB (optionnel)

- Conduits, coudes, capuchons de mur ou de toit. Consulter la page 3 pour la liste complète des accessoires de ventilation et les numéros

de modèle.

NOTE : Lors de l’installation, protéger le plan de cuisson et le comptoir de cuisine.

2. INSTALLER LES CONDUITS ET LE CÂBLAGE ÉLECTRIQUE

Déterminer à quel endroit et comment les conduits seront installés. Un accès au-dessus de la hotte est préférable pour le raccordement

des conduits.

Installer les conduits, les coudes et un capuchon de mur ou de toit de format approprié selon le type d’installation et de hotte encastrable.

Utiliser des conduits de 3¼ po x 10 po pour installer la hotte encastrable à ventilateur simple CC65I28SB. Pour la hotte encastrable à

ventilateur double de modèle CC67I28SB, se servir de conduits ronds de 10 po. Utiliser du ruban adhésif de métal de 2 po pour assurer

l’étanchéité des joints.

Il est recommandé d’installer la hotte à une distance minimale de 24 po au-dessus d’une cuisinière électrique et de 30 po

au-dessus d’une cuisinière au gaz.

Une distance de plus de 30 po demeure à la discrétion de l’installateur et de l’utilisateur.

Acheminer le câble d’alimentation électrique à 3 conducteurs jusqu’à l’emplacement de la hotte. Le câble devrait excéder d’au moins 4pi

le dessous de l’armoire.

Capuchon de toit

Conduit

de 3¼ po x 10 po

Adaptateur/volet

de 3¼ po x 10 po

Capuchon

de mur

24 po minimum

au-dessus de la

surface de cuisson

(30 po pour une

cuisinière au gaz)

HH0116F

M

ODÈLE CC65I28SB

VENTILATEUR SIMPLE) INSTALLATION TYPE

(

Hotte encastrable

Capuchon de toit

Conduit rond

de 10”

Volet vertical de 10 po

Coude rond

Capuchon

de mur

HH0117F

de 10 po

Adaptateur de 10 po rond

Hotte encastrable

24 po minimum

au-dessus de la

surface de cuisson

(30 po pour une

cuisinière au gaz)

MODÈLE CC67I28SB

VENTILATEUR DOUBLE) INSTALLATION TYPE

(

NOTE : Bien qu’une installation à évacuation horizontale soit possible avec le modèle de hotte encastrable CC65I28SB, ce type

d’installation ne doit être réalisé que dans certains cas seulement, puisqu’il requiert un savoir-faire et des habiletés techniques

particulières de la part des installateurs.

4

Page 21

3. PRÉPARER L'ARMOIRE

!

AVERTISSEMENT

Toujours suivre les codes et standards en vigueur lors de la contruction de l’armoire pour hotte. La charpente doit

être fixée solidement aux montants ou autre structure derrière la cloison. S’assurer qu’elle puisse supporter son

propre poids en plus de celui de la hotte encastrable. Ne pas suivre cette directive peut entraîner des blessures

corporelles ou des dommages à la surface de cuisson ou au comptoir de cuisine.

Construire l’armoire en fonction de la forme et du poids total de la hotte encastrable de la

série CC6. L’épaisseur minimale recommandée pour la base de l’armoire est de 5/8 po. Si l’installation

d’un revêtement d’armoire optionnel est prévue, nous recommandons que les côtés et l’avant de

l’armoire aient 3/4 po d’épaisseur. Si le revêtement d’armoire optionnel n’est pas installé, l’épaisseur

des côtés et de l’avant de l’armoire est à la discrétion de l’installateur. Consulter le tableau et les

illustrations pour plus de détails.

CC65I28SB

HOTTE ENCASTRABLE

VENTILATEUR SIMPLE

À

3-1/4”

10-1/8 po

2-15/16 po

MODÈLE DE HOTTE

ENCASTRABLE

CC65I28SB 33 LB

CC67I28SB 45 LB

POIDS TOTAL

2-3/4 po

9-7/8po

1-1/16 po

CC67I28SB

HOTTE ENCASTRABLE

VENTILATEUR DOUBLE

À

NOTE : Le modèle à ventilateur double

possède les mêmes dimensions

que celui à ventilateur simple, sauf

qu’il ne possède pas d’ouverture

pour l’évacuation latérale

HK0292F

HK0291F

2-15/16 po

2-3/4 po

9-7/8 po

1-1/16 po

5

Page 22

4. INSTALLER LE REVÊTEMENT D'ARMOIRE (OPTIONNEL)

Les revêtements d’armoire sont spécialement conçus pour protéger l’extérieur de la base

de l’armoire. Consulter le tableau ci-dessous afin de trouver le modèle de revêtement

correspondant à la largeur nominale de l’armoire.

Visiter le site www.BestRangeHoods.com, www.BestRangeHoods.ca, ou contacter le

service technique (voir le numéro de téléphone en page couverture) afin de connaître

leurs caractéristiques, incluant la profondeur de chacun des modèles.

Pour l’installation, voir les directives incluses avec le revêtement d’armoire.

NOTE : Le revêtement d’armoire s’installe avant

la hotte encastrable.

MODÈLE DE

REVÊTEMENT

ALCC630SB 30 po

ALCC636SB 36 po

ALCC642SB 42 po

LARGEUR NOMINALE

DE L'ARMOIRE

HA0067F

5. DÉCOUPER L'OUVERTURE DANS LA BASE DE L'ARMOIRE

Si ce n’est déjà fait, découper l'ouverture dans la base de l’armoire, aux dimensions

indiquées ci-contre.

NOTE : Tenir compte que l’appareil possède un rebord extérieur de 3/4 po.

HD0340F

6. RETIRER LES FILTRES

Poser la hotte encastrable à plat sur une table. Retirer les rubans adhésifs des filtres.

Soulever les filtres en les poussant vers l’arrière et en les dégageant de la hotte encastrable,

puis les mettre de côté.

13³/8 po

26¾ po

HD0366

6

Page 23

7. DÉBRANCHER LE(S) VENTILATEUR(S)

Débrancher le(s) ventilateur(s) du panneau avant (un ou deux, selon le modèle).

HE0105

8. RETIRER LE COUVERCLE DU COMPARTIMENT ÉLECTRIQUE ET LE PANNEAU AVANT

À l’aide d’un tournevis Robertson ou Phillips n° 2, dévisser les deux vis (A) retenant le

couvercle du compartiment électrique. Le retirer de la hotte encastrable et le mettre de côté

avec ses vis. Dévisser ensuite les deux vis latérales (B) retenant le panneau avant à la hotte

encastrable. Retirer soigneusement le panneau avant et le mettre de côté avec ses vis.

HD1098

B

A

9. DÉFONCER L’OUVERTURE PRÉAMORCÉE POUR L’ALIMENTATION ÉLECTRIQUE

Par l’intérieur de la hotte encastrable, défoncer l’ouverture préamorcée située sur le

dessus (C), à droite OU à l’arrière (D), à droite. Installer le serre-fils (inclus dans le sac de

pièces).

HR0030

10. RETIRER L'OUVERTURE PRÉAMORCÉE (VENTILATEUR SIMPLE SEULEMENT)

Retirer l’ouverture préamorcée sur le dessus

(installation à évacuation verticale) ou à l’arrière

(installation à évacuation horizontale) de la

hotte encastrable.

1

2

C

D

HR0037

7

Page 24

11. INSTALLER L'ADAPTATEUR/VOLET (VENTILATEUR SIMPLE SEULEMENT)

INSTALLATION À ÉVACUATION VERTICALE

À l’aide de 2 vis n° 8 x 3/8 po (incluses dans le sac de pièces),

assembler l’adaptateur/volet sur le dessus de la hotte encastrable.

Enlever le ruban adhésif sur le volet. Sceller l’adaptateur à la

hotte encastrable à l’aide de ruban adhésif de métal.

HO0137

INSTALLATION À ÉVACUATION HORIZONTALE

L’adaptateur/volet sera installé à l’arrière de la hotte encastrable une fois que celle-ci sera installée dans son armoire. Voir l’étape 15.

12. INSTALLER L'ADAPTATEUR ET LE VOLET (VENTILATEUR DOUBLE SEULEMENT)

EMPLACEMENT DES VIS

À l’aide de 2 vis n° 8 x 3/8 po provenant du sac de pièces, assembler l’adaptateur sur le dessus

de la hotte encastrable. Sceller tous les joints avec du ruban adhésif de métal afin d’éliminer les

fuites d’air.

Installer le volet de 10 po à l’intérieur du conduit VERTICAL lequel sera rattaché à la hotte

encastrable. Ne pas l’installer dans un conduit horizontal car l’ouverture et la fermeture

ne pourraient se faire adéquatement. Retirer le ruban adhésif s’il y a lieu. Pour optimiser le

débit d’air et réduire le bruit, placer le volet à au moins 17 po du dessus de la hotte encastrable à

ventilateur double, ou le plus éloigné possible selon la longueur du conduit. De plus, s’assurer que

la penture du volet est parallèle aux côtés de la hotte encastrable (voir l’illustration ci-contre). Fixer

le volet au conduit à l’aide de 3 vis à métaux n° 8 (non incluses). S’assurer que le volet s’ouvre et

se ferme librement. Sceller les joints avec du ruban adhésif de métal pour éliminer les fuites d’air.

HJ0035

PENTURE DU VOLET

PARALLÈLE

CÔTÉS DE LA

AUX

HOTTE ENCASTRABLE

HJ0036F

17 po min.

8

Page 25

13. RETIRER LE VENTILATEUR (VENTILATEUR SIMPLE, ÉVACUATION HORIZONTALE SEULEMENT)

Afin de faciliter l’alignement de la hotte encastrable avec le conduit horizontal, désassembler le ventilateur de la hotte encastrable avant

d’installer celle-ci dans l’armoire.

EMPLACEMENT DES VIS

CÔTÉ GAUCHE

EMPLACEMENT DES VIS,

CÔTÉ DROIT

À l’aide d’une douille 5/16 po, ou d’un tournevis Phillips ou

Robertson n° 2, enlever toutes les vis retenant le ventilateur

au dessus intérieur de la hotte encastrable. Mettre de côté le

ventilateur et ses vis.

HD0368

HD0369

14. INSTALLER LA HOTTE ENCASTRABLE

ATTENTION

Prendre soin de ne pas plier les conduits ou coincer le câble d’alimentation en installant la hotte encastrable.

Soulever la hotte encastrable dans son armoire jusqu’à ce que la base des ressorts d’accrochage

(2 par côté) s’appuie contre le dessus de la base de l’armoire (zone grise dans l’illustration ci-contre).

Par l’intérieur de la hotte encastrable, à l’aide des vis n° 8-10 x 1/2 po, fixer la hotte encastrable à

la base de l’armoire. Pour ce faire, soulever l’avant jusqu’à ce que son rebord s’appuie sur la face

externe de la base de l’armoire et visser en place à l’aide de deux vis. Faire de même pour l’arrière,

puis finaliser l’installation en vissant deux autres vis à l’avant et à l’arrière. Voir l’illustration ci-contre

pour l’emplacement des vis.

INSTALLATION À ÉVACUATION VERTICALE SEULEMENT

S’assurer que l’adaptateur/volet entre dans le conduit et que son volet ouvre librement. Dans la

mesure du possible, sceller les joints avec du ruban adhésif de métal.

RESSORTS

D'ACCROCHAGE

HD0370

HH0126

9

Page 26

15. INSTALLER L’ADAPTATEUR/VOLET À L’ARRIÈRE DE LA HOTTE ENCASTRABLE

(VENTILATEUR SIMPLE, ÉVACUATION HORIZONTALE SEULEMENT)

Par l’extérieur du mur, à l’aide de deux

vis n° 8 x 3/8 po (incluses dans le sac de pièces),

fixer l’adaptateur/volet à l’arrière de la hotte

encastrable. Enlever le ruban adhésif sur le volet.

Raccorder le conduit à l’adaptateur/volet et sceller

le joint à l’aide de ruban adhésif de métal.

HH0127F

VUE ARRIÈRE VUE LATÉRALE

16. RÉINSTALLER LE VENTILATEUR

(VENTILATEUR SIMPLE, ÉVACUATION HORIZONTALE SEULEMENT)

La hotte encastrable à ventilateur simple est configurée en usine

pour une installation à évacuation verticale. Pour une installation

à évacuation horizontale, retourner le ventilateur. À l’aide d’une

douille 5/16 po, ou d’un tournevis Phillips ou Robertson n° 2 et des

vis retirées précédemment à l’étape 13, assembler le ventilateur au

dos interne de la hotte encastrable.

EMPLACEMENT DES VIS,

CÔTÉ GAUCHE

MUR

EMPLACEMENT DES VIS,

CÔTÉ DROIT

HD0371

10

HD0372

Page 27

17. BRANCHEMENT ÉLECTRIQUE (TOUS LES MODÈLES)

!

AVERTISSEMENT

Risque d’électrocution. Le raccordement électrique doit être effectué par du personnel qualifié conformément aux

codes et standards. Avant d’effectuer le branchement, coupez l’alimentation électrique au panneau de distribution

et verrouillez-le pour éviter une mise en marche accidentelle.

Insérer le câble d’alimentation dans la hotte à travers le serre-fils installé précédemment à l’étape 9. Serrer le serre-fils pour maintenir en

place le câble d’alimentation.

A

Connecter les fils à l’aide des capuchons de connexion inclus.

Connecter le fil NOIR au NOIR, le BLANC au BLANC et le VERT ou le fil dénudé

à la vis de mise à la terre (A). NE PAS OUBLIER DE CONNECTER LA MISE À LA

TERRE.

HE0059

18. RÉINSTALLER LE PANNEAU AVANT ET LE COUVERCLE DU COMPARTIMENT

ÉLECTRIQUE

ATTENTION

Prendre soin de ne pas coincer les fils lors de la remise en place du panneau avant et du couvercle du compartiment

électrique.

Réassembler soigneusement le panneau avant à la hotte encastrable en alignant les pattes dans les fentes correspondantes. À l’aide

d’un tournevis Robertson ou Phillips n° 2 et des deux vis (A) précédemment retirées à l’étape 8, fixer le panneau avant à la hotte

encastrable. Réinstaller le couvercle du compartiment électrique à l’aide des deux vis (B) précédemment retirées à l’étape 8. Brancher

le(s) ventilateur(s) (un ou deux, selon le modèle) au panneau avant.

B

HD1098

HO0260

A

HE0105

11

Page 28

!

19. REMETTRE LES FILTRES EN PLACE

ATTENTION

Retirer la pellicule protectrice de plastique des filtres avant de les installer.

1. À l’aide d’un tournevis Phillips n° 2, assembler chaque bouton à son filtre.

NOTE : La vis DOIT ÊTRE sur le côté des languettes du filtre. Voir l’illustration ci-contre.

2. Appuyer le rebord arrière des filtres sur les ressorts de filtre (A) à l’intérieur de la hotte

encastrable.

3. À l’aide du bouton, incliner chaque filtre vers le haut jusqu’à ce que les languettes (B) soient

bien engagées dans le rebord avant de la hotte encastrable. S’assurer que les filtres soient

bien en place après l’installation.

20. ÉCLAIRAGE À DEL

HD0373

HO0139

A

B

L'éclairage de cette hotte est produit par deux modules à DEL (inclus).

AVERTISSEMENT

Ne pas toucher aux modules à DEL durant ou peu après leur utilisation. Peuvent causer des brûlures. Ne peuvent

être remplacés par aucun autre type d'ampoule ou de module à DEL.

21. ENTRETIEN

Filtres

Les filtres doivent être nettoyés fréquemment. Utiliser une solution d’eau chaude et de détergent. Nettoyer les filtres souvent si vos

habitudes de cuisson génèrent beaucoup de graisse, comme la friture ou les aliments sautés au wok. Retirer les filtres en les poussant

vers l’arrière de la hotte encastrable et en les abaissant. Les filtres sont lavables au lave-vaisselle. Laisser les filtres sécher complètement

avant de les réinstaller dans la hotte encastrable.

Nettoyer les filtres fabriqués entièrement de métal au lave-vaisselle à l’aide d’un détergent sans phosphate. L’utilisation d’un détergent

avec phosphate ainsi que les conditions locales de l’eau peuvent entraîner une décoloration du filtre, sans toutefois altérer sa

performance. Cette décoloration n’est pas couverte par la garantie.

Nettoyage de la hotte encastrable

Acier inoxydable :

À faire :

• Laver régulièrement les surfaces à l’aide d’un chiffon ou linge

propre imbibé d’eau tiède et de savon doux ou détergent liquide

à vaisselle.

• Toujours nettoyer dans le sens du polissage.

• Toujours bien rincer avec de l’eau claire (2 à 3 fois) et essuyer

complètement.

• Un nettoyant domestique conçu spécialement pour l’acier

inoxydable peut aussi être utilisé.

À éviter lors du choix d’un détergent :

- Tous produits nettoyants contenant des agents de blanchiment; ils attaqueront l’acier inoxydable.

- Tous produits contenant du chlorure, du fluorure, de l’iode ou du bromure; ils détérioreront rapidement les surfaces.

- Tous produits combustibles utilisés pour le nettoyage : acétone, alcool, éther, benzène, etc.; ils sont grandement explosifs et ne

devraient jamais être utilisés près d’une cuisinière.

À éviter :

• Utiliser de la laine d’acier ou d’acier inoxydable ou tout autre

grattoir pour enlever la saleté tenace.

• Utiliser une poudre nettoyante abrasive ou rugueuse.

• Laisser la saleté s’accumuler.

• Laisser la poussière de plâtre ou tout autre résidu de construction

atteindre la hotte encastrable. Couvrir la hotte encastrable pour

la durée des travaux afin de s’assurer qu’aucune poussière ne

l’atteint.

12

Page 29

22. FONCTIONNEMENT

!

AVERTISSEMENT

Lors de l’utilisation d’une cuisinière au gaz, toujours faire fonctionner le(s) ventilateur(s) de la hotte avant de

commencer la cuisson. De plus, le ou les ventilateurs doivent être réglés au moins en troisième vitesse si trois

brûleurs ou plus sont en fonction simultanément. La surface de la hotte pourrait devenir très chaude si cet

avertissement n’était pas suivi.

Toujours mettre en marche le ventilateur avant de commencer la cuisson afin d’établir une circulation d’air dans la cuisine. Laisser

également le ventilateur fonctionner quelques minutes après l’arrêt de la cuisinière afin de nettoyer l’air. Ceci aidera à garder la cuisine

plus propre et plus claire.

HC0023

ABCD

A. BOUTON D'ARRÊT DIFFÉRÉ :

Lorsque le ventilateur est en marche, appuyer sur ce bouton pour activer la fonction d’arrêt différé. Le bouton correspondant à la vitesse

en vigueur clignotera pour indiquer que la fonction est activée. Le ventilateur continuera de fonctionner pendant 5 minutes et s’arrêtera

automatiquement. Pour annuler la fonction d’arrêt différé, appuyer une autre fois sur ce bouton.

B. BOUTONS DE MARCHE/ARRÊT/SÉLECTION DE VITESSE :

Appuyer sur le bouton correspondant à la vitesse de ventilateur désirée. Le bouton de la vitesse choisie s’allumera pour indiquer quelle

vitesse est activée (de 1 pour la basse vitesse à 4 pour la haute vitesse). Pour arrêter le ventilateur, appuyer une fois de plus sur le

bouton correspondant à la vitesse actuelle.

NOTE : Appuyer sur le bouton 1 lorsque le ventilateur est arrêté résulte en un départ en haute vitesse pour un très court laps de temps

suivi d'un retour à la basse vitesse.

C. BOUTON D'ARRÊT PRINCIPAL/ENTRETIEN DES FILTRES/HEAT SENTRYMC (INTERRUPTEUR DE TRIPLE FONCTION) :

i. Pour désactiver simultanément le(s) ventilateur(s) et l’éclairage, appuyer une fois sur ce bouton.

ii. Après 25 heures de fonctionnement, le bouton d’entretien des filtres s’allumera. Cela indique que les filtres et le(s) ventilateur(s)

doivent être nettoyés afin de maintenir leur haut niveau d’efficacité. Ce bouton restera allumé jusqu’à sa remise à zéro, qui s'effectue

en appuyant sur celui-ci pendant 3 secondes.

iii. Le bouton s’allume aussi pour indiquer la fonction Heat Sentry.

HEAT SENTRY : La hotte est munie d’un dispositif de protection qui s’active lorsqu’une chaleur excessive est détectée à l’intérieur de la

hotte et que celle-ci est réglée en vitesse 4. Ce dispositif prend le contrôle du ventilateur et désactive la vitesse 4 pour une période de

10 minutes et passe en vitesse 3. Durant l’activation du Heat Sentry, seule la vitesse 3 peut être utilisée; le bouton du Heat Sentry (C)

clignotera, tandis que celui de la vitesse 3 s’allumera. Le fonctionnement de la hotte peut également être arrêté.

D. BOUTON D'ÉCLAIRAGE :

Cet interrupteur offre 2 différents niveaux d’éclairage, selon vos besoins. Appuyer une fois pour la haute intensité, deux fois pour un

éclairage de basse intensité. Appuyer une autre fois pour éteindre les lumières sans arrêter le fonctionnement du (des) ventilateur(s).

13

Page 30

23. SCHÉMA ÉLECTRIQUE

LIGNE

NEUTRE

MISE À

120 V C.A.

LA TERRE

CODE DE COULEUR

B BLANC

BL BLEU

BR BRUN

G GRIS

J JAUNE

N NOIR

O ORANGE

R ROUGE

HE0162F

B

M

ODULE

DEL

D’

ALIMENTATION

DEL

DEL

B

MOTEUR DU VENTILATEUR

G

BL

B

BR

DEUXIÈME MOTEUR DU

VENTILATEUR (OPTIONNEL)

O

M

R

N

TRANSFORMATEUR

N

N

J

B

B

BL

B

B

O

N

J1

1

2

3

J2

BL

1

B

2

O

3

N

4

5

R 9,5 V

B

J

BL

B

N

B

O

N

B

J

N

M

N

Q1

LOGIQUE

K1

K1

K2

L

IGNE 120 V

REF

10 V

C.A.

K1 NO K2 NO K3 NO K4 NO

K3

K4

K1 NC K2 NC K3 NC

A1

CARTE

ÉLECTRONIQUE

14

Page 31

24. PIÈCES DE REMPLACEMENT

CC65I28SB

2

CC67I28SB

1

2

3

8

4

4

7

6

5

1

3

8

7

6

HL0447

NO DE

RÉF.

*Non illustré

PIÈCES DE REMPLACEMENT ET SERVICE

Pour assurer le bon fonctionnement de votre appareil, vous devez toujours utiliser des pièces d'origine provenant de Broan-NuTone. Les

pièces d'origine de Broan-NuTone sont spécialement conçues pour satisfaire toutes les normes de certification de sécurité applicables.

Leur remplacement par des pièces ne provenant pas de Broan-NuTone pourrait ne pas assurer la sécurité de l'appareil, entraîner une

réduction sévère des performances ainsi qu'un risque de défaillance prématurée. Broan-NuTone recommande également de toujours

vous référer à une entreprise de services compétente et reconnue par Broan-NuTone pour vos pièces de remplacement et appels de

service.

NO DE PIÈCE DESCRIPTION

1

2 62248 M

3 SV21244 C

4 62612 M

5 SV18428 F

6 SV08967 B

7 SV08582 V

8 SV09022 T

* SV05869 L

* SV23862 G

* SV08545

SV13296 A

SV08541 A

DAPTATEUR/VOLET 3¼ PO X 10 PO 1-

DAPTATEUR 10 PO ROND -1

ODULE D'ALIMENTATION DEL ET FAISCEAU DE CONNECTION 11

OMMANDE ÉLECTRONIQUE AVEC BOUTONS CHROMÉS ET DEL BLEUES 11

ODULE À DEL (1) 2 2

ILTRES À CHICANE MINCES 22

OUTONS DE FILTRE (VIS INCLUSES) (JEU DE 2) 1 1

ENTILATEUR 12

RANSFORMATEUR 11

OGO BEST 11

UIDE D'INSTALLATION 11

AC DE PIÈCES : 2 CAPUCHONS DE CONNEXION, 4 VIS N° 8 X 3/8 PO,

S

9 VIS PLAQUÉES CHROME N° 8-10 X 1/2 PO, 1 SERRE-FILS,

10 VIS À MÉTAUX N° 8-32 X 1/4 PO

QTÉ (MODÈLE DE HOTTE ENCASTRABLE)

CC65I28SB CC67I28SB

5

11

15

Page 32

25. GARANTIE

GARANTIE LIMITÉE DE 5 ANS SUR LES PRODUITS BEST

Période de garantie et exclusions : Broan-NuTone LLC (l’« entreprise ») garantit au consommateur qui achète son produit (« vous ») que le produit (le « produit ») restera

exempt de défauts importants dans ses composants ou sa fabrication pendant une période de cinq (5) ans à compter de la date de l’achat initial (ou pour une période plus

longue si la loi en vigueur l’exige) ou une période de deux (2) ans à compter de la date de la prestation d’un service sur le produit.

La garantie limitée des pièces de rechange fournies par l’entreprise et de tout produit réparé ou remplacé en vertu de cette garantie est valide pour la durée non écoulée de la

période de garantie initiale (ou d’une période plus longue si la loi en vigueur l’exige).

LA PRÉSENTE GARANTIE NE S’APPLIQUE PAS AUX DÉMARREURS DE LAMPE FLUORESCENTE, NI AUX TUBES, AMPOULES, FUSIBLES, FILTRES, CONDUITS,

CAPUCHONS DE TOIT, CAPUCHONS MURAUX ET AUX AUTRES ACCESSOIRES POUR CONDUITS. Cette garantie exclut : a) l’entretien normal, b) l’usure normale, c) les

produits et les pièces ayant fait l’objet d’une utilisation mauvaise, abusive ou anormale, d’une négligence, d’un accident, d’un entretien ou d’un entreposage, d’une réparation

ou d’un entretien inadéquats ou insuffisants (sauf s’il s’agit d’une réparation effectuée par l’entreprise), d) les dommages attribuables à une installation incorrecte ou à une

installation ou utilisation contraires aux recommandations ou aux instructions, e) les dommages attribuables au contact de l’air salin, f) les dommages survenus durant le

transport, g) l’usure normale de la finition, h) les produits d’utilisation commerciale ou non résidentielle, i) les dommages causés par le feu, une inondation ou une autre

catastrophe naturelle, ou j) les produits dont le numéro de série a été altéré ou effacé. Cette garantie ne s’applique qu’aux produits vendus aux consommateurs en Amérique

du Nord. La présente garantie remplace les garanties précédentes et, sous réserve de la loi applicable, n’est pas transférable par l’acheteur initial.

Aucune autre garantie : La présente garantie limitée énonce l’unique obligation de l’entreprise et votre seul recours pour les produits défectueux. Les garanties qui précèdent sont

exclusives et l’emportent sur les autres garanties et modalités, expresses ou implicites. DANS TOUTE LA MESURE PERMISE PAR LA LOI EN VIGUEUR, L’ENTREPRISE SE

DÉGAGE DES AUTRES GARANTIES ET MODALITÉS EXPRESSES ET DES GARANTIES ET MODALITÉS IMPLICITES EN VERTU DE LA LOI, Y COMPRIS, SANS S’Y LIMITER, LES

GARANTIES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN USAGE PARTICULIER. Dans la mesure où la loi applicable interdit l’exclusion des garanties ou modalités

implicites, la durée d’une garantie ou modalité implicite applicable est restreinte à la période indiquée pour la garantie expresse ci-dessus. Certains territoires de compétence (ce

qui peut inclure la province de Québec ou certains États des États-Unis) interdisent les limites à la durée des garanties implicites; la restriction susmentionnée pourrait donc ne

pas s’appliquer à vous. Les descriptions orales ou écrites du produit ont pour seul objet d’indiquer les produits et ne sauraient être interprétées dans le sens d’une garantie expresse.

Autant que possible, chaque disposition de cette garantie limitée est interprétée de sorte qu’elle soit valide sous le régime de la loi applicable, mais si l’une de ses dispositions

est déclarée interdite ou nulle, cette disposition n’est nulle que dans la mesure de cette interdiction ou nullité, et les autres éléments de cette disposition ainsi que les autres

dispositions de la garantie limitée restent valides.

Recours : Durant la période de la garantie limitée applicable, l’entreprise fournira, à son choix, des pièces de rechange ou des services de réparation ou de remplacement

sans frais pour tout produit ou toute pièce de produit, dans la mesure où l’entreprise constate que la présente garantie limitée s’applique à ce produit ou à cette pièce dans le

contexte d’une utilisation et d’un entretien normaux. L’entreprise vous expédiera le produit réparé, son remplacement ou les pièces de rechange sans frais. Vous assumez la

totalité des coûts de mise hors service, de réinstallation, d’expédition et d’assurance et les autres frais de transport associés à la livraison du produit ou de la pièce à l’entreprise.

Si vous devez envoyer le produit ou la pièce à l’entreprise, conformément à ses instructions, vous devez emballer adéquatement le produit ou la pièce; l’entreprise n’est

pas responsable des dommages survenus durant le transport. L’entreprise se réserve le droit d’utiliser des produits ou pièces remis à neuf, réparés ou remanufacturés aux fins

de réparation ou de remplacement dans le cadre de la garantie. Ces produits et ces pièces seront comparables quant à la fonction et aux performances avec les produits ou pièces

d’origine, et protégés par une garantie pour la durée restante de la période de garantie initiale (ou d’une période plus longue si la loi en vigueur l’exige). L’entreprise se réserve le

droit, à son entière discrétion, de rembourser le montant que vous avez effectivement payé pour le produit. Si le produit ou la pièce n’est plus disponible, elle peut le ou la remplacer

par un produit similaire de valeur égale ou supérieure, à son entière discrétion. Ceci constitue votre seul recours advenant un non-respect de la présente garantie limitée.

Exclusion des dommages : L’OBLIGATION DE L’ENTREPRISE DE FOURNIR DES PIÈCES DE RECHANGE, OU DE RÉPARER OU REMPLACER LE PRODUIT, À SON CHOIX, EST

VOTRE SEUL RECOURS EN VERTU DE LA PRÉSENTE GARANTIE LIMITÉE ET L’UNIQUE OBLIGATION DE L’ENTREPRISE. CETTE DERNIÈRE N’EST PAS RESPONSABLE DES

DOMMAGES INDIRECTS OU SPÉCIAUX DÉCOULANT DIRECTEMENT OU INDIRECTEMENT DU PRODUIT, DE SON UTILISATION OU DE SES PERFORMANCES.

Certains territoires de compétence interdisent l’exclusion ou la restriction des dommages indirects; la restriction qui précède pourrait donc ne pas s’appliquer à vous. Cette

garantie vous donne des droits spécifiques, et vous pourriez aussi avoir d’autres droits, qui varient selon le territoire de compétence. Les renonciations, exclusions et

restrictions de responsabilité aux termes de cette garantie ne s’appliquent pas dans la mesure où la loi en vigueur interdit une telle application.

La présente garantie ne s’applique qu’au remplacement ou à la réparation de produits ou pièces de produit défectueux effectué au principal lieu d’affaires de l’entreprise, et

exclut les frais de déplacement et de subsistance liés aux services fournis sur le terrain.

Tout soutien que l’entreprise vous fournit ou vous procure et qui n’est pas visé par les dispositions, limites ou exclusions de la présente garantie limitée ne constitue pas une

renonciation à ces dispositions, limites ou exclusions, et la fourniture de ce soutien ne prolonge ni ne rétablit la garantie.

L’entreprise ne vous remboursera pas vos dépenses faites pour la réparation ou le remplacement d’un produit défectueux, sauf celles pour lesquelles vous avez obtenu le

consentement écrit de l’entreprise.

Comment obtenir le service de garantie : Pour avoir droit au service de garantie, vous devez : a) aviser l’entreprise à l’adresse ou au numéro de téléphone indiqué

ci-dessous dans les sept (7) jours qui suivent la date où vous avez eu connaissance de la défectuosité couverte, b) indiquer le numéro de modèle et les données d’identification

de la pièce, et c) décrire la nature de toute défectuosité du produit ou de la pièce. Au moment où vous demandez le service de garantie, vous devez présenter une preuve de

la date de l’achat initial. Si vous ne pouvez pas produire de copie de l’original de la garantie limitée, alors ce seront les modalités de la dernière version de la garantie limitée

de votre produit de l’entreprise qui s’appliqueront.

SPÉCIFICATIONS DU PRODUIT

Toutes les illustrations et les spécifications des produits contenues dans ce catalogue sont établies d’après les plus récentes données disponibles en date de la production.

Broan-NuTone LLC et BESTMD se réservent le droit de modifier les prix, les couleurs, les composants, les produits, les spécifications et les modèles, de déplacer le lieu de

fabrication et de cesser la production d’un modèle ou d’un produit, et ce, en tout temps et sans préavis.

Best

Broan-NuTone LLC : 926 W. State Street, Hartford (WI) 53207 1 800 637-1453

BestMD, 550, boul. Lemire, Drummondville (Québec), Canada (1 866 737-7770) fr.bestrangehoods.ca

MD

16

Page 33

INSTRUCCIONES DE INSTALACIÓN

HB0312

SERIE CC6

! !

DESTINADA ÚNICAMENTE PARA COCINAS DOMÉSTICAS

LEA Y GUARDE ESTAS INSTRUCCIONES

INSTALADOR: DEJE ESTE MANUAL AL PROPIETARIO.

PROPIETARIO: INFORMACIÓN SOBRE USO Y CUIDADO EN LAS

PÁGINAS 12 Y 13.

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800-558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.ca 866-737-7770

23862 rev. 02

Page 34

!

ADVERTENCIA

!

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, CHOQUE

ELÉCTRICO O HERIDAS CORPORALES, SIGA LAS

INDICACIONES SIGUIENTES:

1. Utilice este aparato sólo en la forma prevista por el fabricante.

Si tiene preguntas, póngase en contacto con el fabricante en la

dirección o número de teléfono indicados en la garantía.

2. Antes del mantenimiento o de la limpieza del aparato, apague

la alimentación en el tablero de servicio y bloquee los medios

de desconexión para evitar que se conecte la corriente

accidentalmente. Cuando no se puedan bloquear los medios de

desconexión de servicio, coloque firmemente un dispositivo de

aviso visible, como una etiqueta, en el tablero de servicio.

3. Los trabajos de instalación y el cableado eléctrico han de ser

realizados por personal cualificado, de conformidad con todos

los códigos y normas aplicables, incluyendo los códigos y

normas de construcción contra incendios.

4. Se necesita aire suficiente para una combustión adecuada y

para sacar los gases por la chimenea del equipo que quema el

combustible para evitar la contracorriente. Siga las directrices del

fabricante del equipo de calefacción y las normas de seguridad,

tales como las que publica la Asociación Nacional de Protección

Contra Incendios (NFPA) y la Sociedad Americana de Ingenieros

de Calefacción, Refrigeración y Aire Acondicionado (ASHRAE)

y las de las autoridades responsables del código local.

5. Al cortar o taladrar en la pared o en el techo, procure no dañar

el cableado eléctrico ni otras instalaciones ocultas.

6. Los ventiladores con conductos deben tener siempre salida al

exterior.

7. No use el aparato con cualquier dispositivo de control de

velocidad de semiconductores.