Page 1

Model CC34IQ63SB

CC34IQT63SB

ENGLISH........................................3

FRANÇAIS...................................23

ESPAÑOL.....................................45

In USA - BEST Hartford, Wisconsin

In CANADA - BEST Drummondville, QC, Canada

REGISTER YOUR PRODUCT ONLINE AT : www.BestRangeHoods.com/register

For additional Information visit www.BestRangeHoods.com

Page 2

- 2 -

Page 3

READ AND SAVE THESE INSTRUCTIONS

!

! INTENDED FOR DOMESTIC COOKING ONLY

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact

the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power o at service panel and lock service panel to

prevent power from being switched on accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning device, such as a tag, to the service

panel.

3. Installation work and electrical wiring must be done by a quali ed person(s) in accordance with

all applicable codes and standards, including re-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment

manufacturer’s guidelines and safety standards such as those published by the National Fire

Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden

utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of re, use only steel ductwork.

9. This unit must be grounded.

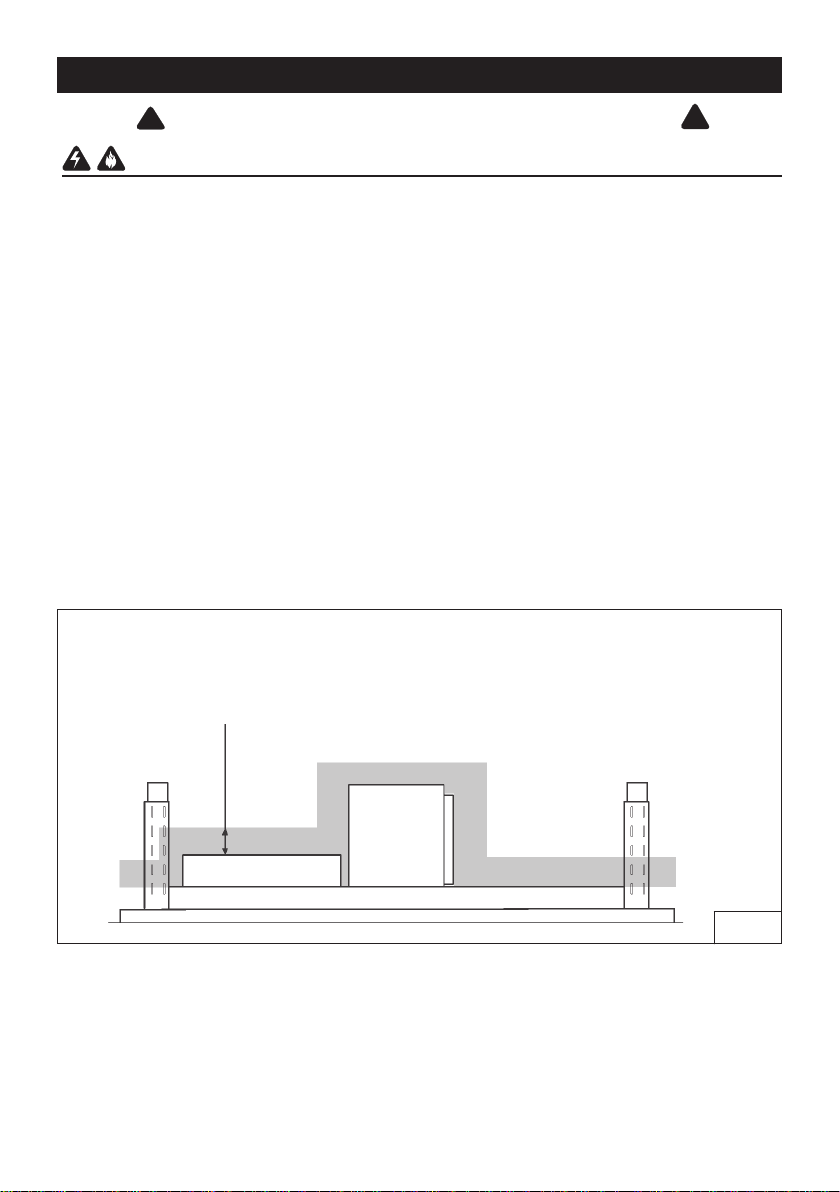

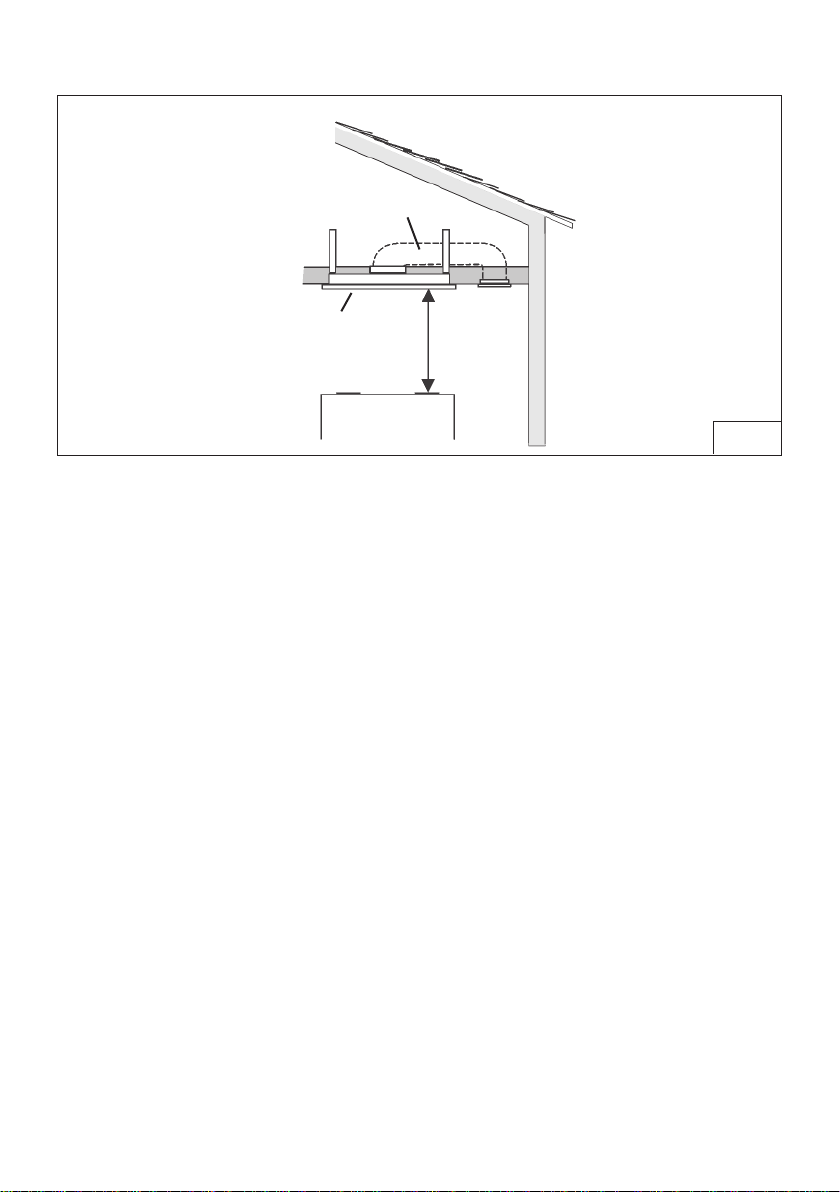

10. Type Non-IC Installation: Thermal insulation shall not cover top of range hood housing and

must be spaced 3-inches (76mm) from all sides. (Fig. 1)

NO INSULATION WITHIN THIS SHADED

3-INCH MINIMUM.

AREA OF COMPONENTS.

FIG. 1

- 3 -

Page 4

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

!

A. Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers

that may ignite. Heat oils slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when ambeing food (i.e. Crepes Suzette,

Cherries Jubilee, Peppercorn Beef Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or lter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close- tting lid, cookie sheet, or metal tray, then turn o the burner. BE

CAREFUL TO PREVENT BURNS. If the ames do not go out immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam explosion will re-

sult.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know how to operate it.

B. The re is small and contained in the area where it started.

C. The re department is being called.

D. You can ght the re with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For indoor use only.

2. To reduce risk of re and to properly exhaust air, be sure to duct air outside. Do not vent exhaust

air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

3. Take care when using cleaning agents or detergents.

4. Avoid using food products that produce ames under the Range Hood.

5. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and

vapors.

6. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray,

construction dust, etc. o power unit.

7. Your hood motor has a thermal overload which will automatically shut o the motor if it becomes

overheated. The motor will restart when it cools down. If the motor continues to shut o and

restart, have the hood serviced.

8. For best capture of cooking impurities, the bottom of the hood should be a minimum of 48” and a maxi-

mum of 72” above the cooking surface. See “Install Mounting Bracket” section for mounting restrictions.

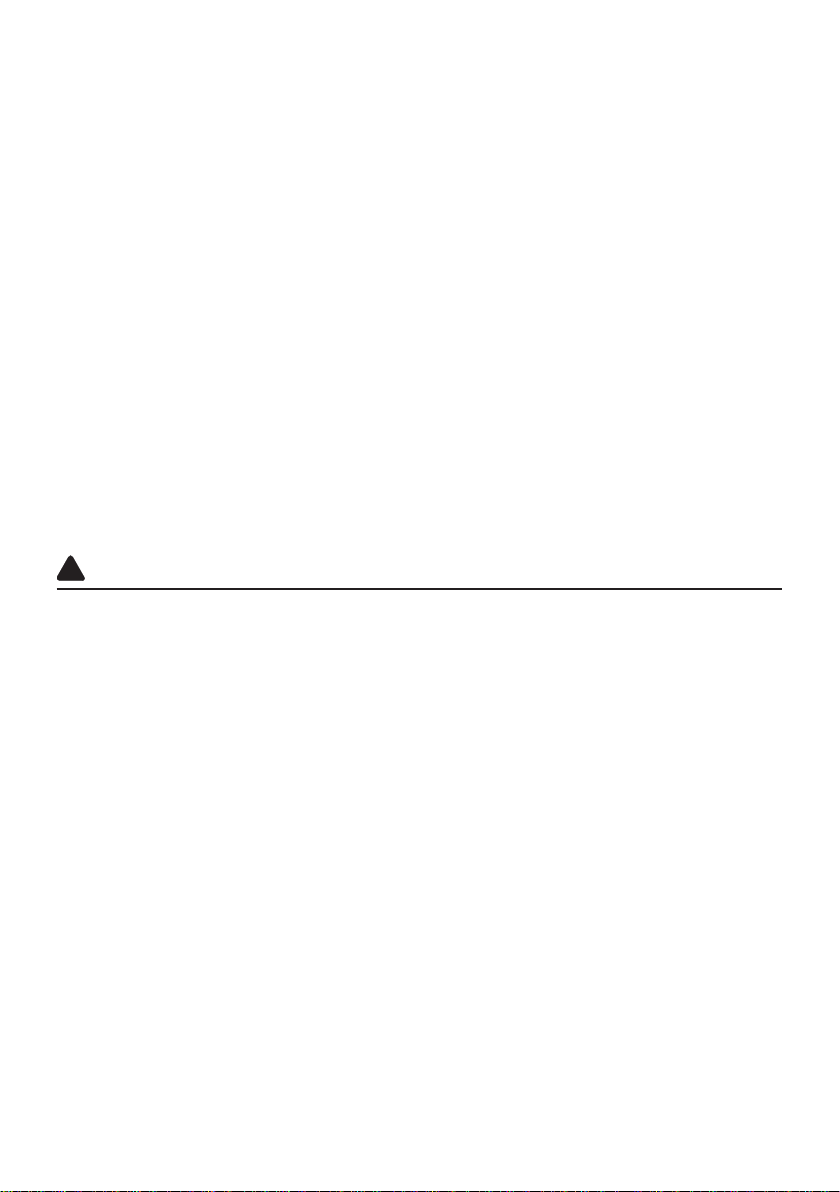

9. Multiple installers are recommended because of the large size and weight of this hood.

10. Please read speci cation label on product for further information and requirements.

11. This power pack is equipped with a RF receiver (optional remote control sold separately). Changes

or modi cations not expressly approved by the party responsible for compliance could void the

user’s authority to operate this product. The remote control has been tested and found to comply

with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules and the Canadian

ICES-003. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. The remote control generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment o and on, the user is encouraged to try to correct the

interference by one or more of the fol-lowing measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

- 4 -

Page 5

!

!

• Connect the equipment into an outlet on a circuit di erent from that to which the receiver is

connected.

- 5 -

Page 6

OPERATION

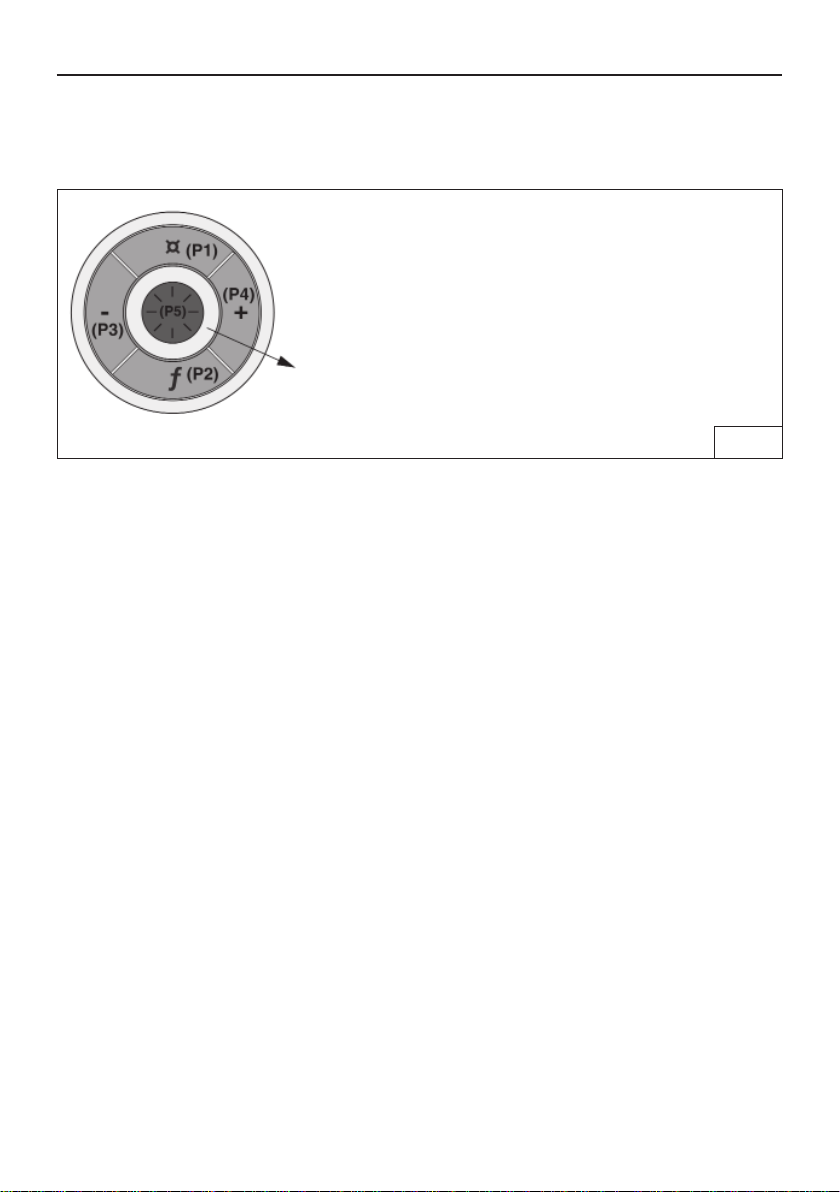

Controls (Fig.2)

The hood is operated using the (5) push buttons located on the hood and the remote control.

LED colors are displyed on hood control only.

P1: Activate/deactivate delay-o (10 minute)

P2: Filter change indication timer reset

P3: Decreases fan motor speed until turned o (4>3>2>1>OFF)

P4: Turns fan motor on and increased speed (ON>1>2>3>4)

P5: Lights o /low/medium/high

L1: LED Indicator Ring Signalling crown:

- Hood in standby: lights up green. 30 seconds after

the last key has been pressed the crown turns o

- Motor on: L1 lights up blue fl ashing. The fl ashing

L1

LED

RING

(P1) Delay- Off Switch

• Your hood includes a 10 minute blower delay o switch. Press this switch once to activate

the timer and the LED Ring (L1) ashes blue. The blower will continue to operate for

10minutes. After 10 minutes, the blower turns o automatically.

• To cancel the 10-minute delay, press the delay switch once again.

(P2) Filter Alarm Switch

• After 30 hours of blower operation, the lter alarm is activated and the LED ring (L1) turns

red/ ashes. It indicates that the grease lters need to be cleaned.

• After cleaning the grease lters, reset the hour counter by pressing the Filter Alarm/Timer

Reset button (P2) during display of the alarm.

frequency is proportional to the speed setting.

- 10’ TIMER function : L1 lights up and ashes blue.

- Filter alarm active: L1 lights up red

FIG. 2

(P3) Blower Speed Decrease and Off Switch

• Press to decrease blower speed, high to low. The LED ring (L1) ashes blue at a speed

proportionate to the blower setting (i.e.: four ashes is high speed, one ash is low

speed, etc.)

• Continue pressing this switch to turn the blower o .

(P4) Blower Speed Increase and On Switch

• Press this switch to turn the blower on to low speed.

• Press again to increase blower speed, low to high. The LED ring (L1) ashes blue at a

speed proportionate to the blower setting (i.e.: four ashes is high speed, one ash is low

speed, etc.)

(P5) Light Switch

Lights o /low/medium/high.

- 6 -

Page 7

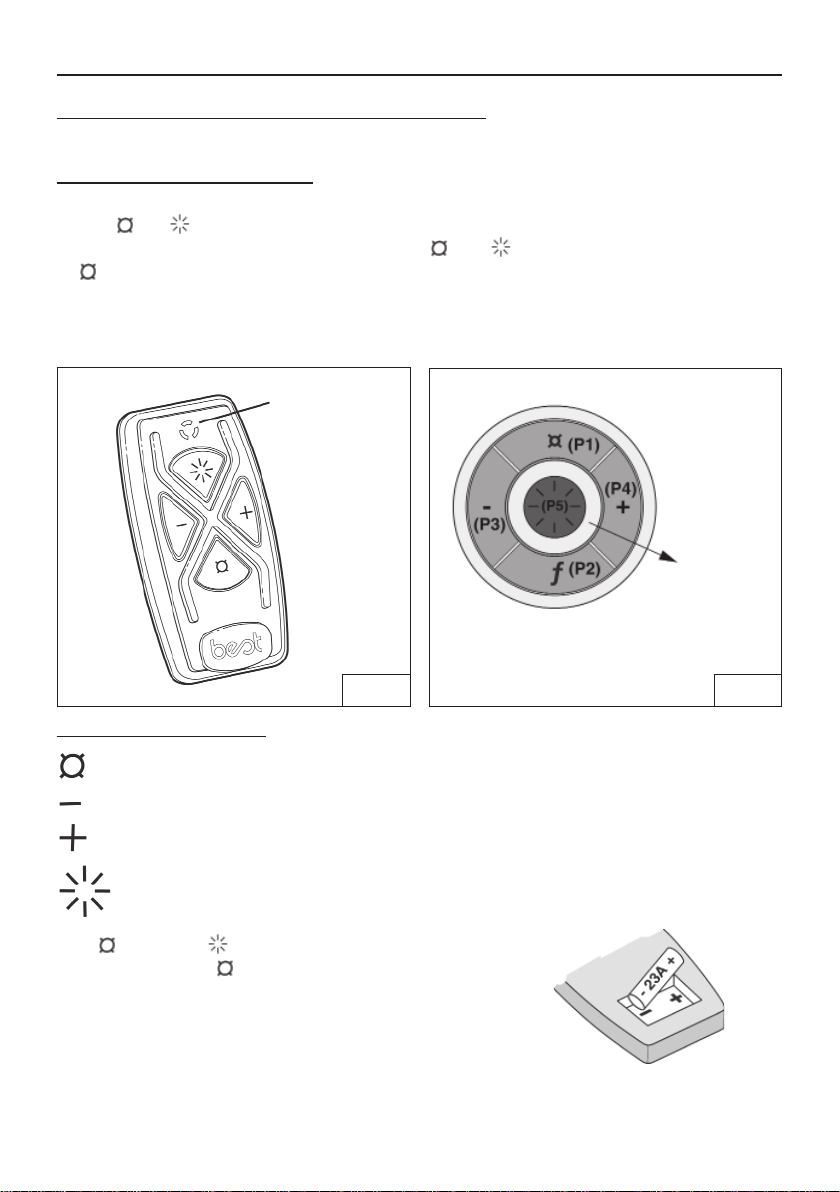

REMOTE CONTROL

The remote control is linked to the hood at the factory.

If, for some reason, the link is lost - follow the directions below:

To Link Remote Control to Hood

1. Turn o hood motor and hood lights.

2. Press

3. Within 3 seconds - press ƒ (P2) on the hood control (Fig. 4). The LED ring will light up for ap-

and buttons on the remote simultaneaously for 5 seconds, until the remote

control Indicator Light turns on (Fig.3). Release

and buttons. Press and release

button to con rm the linking. At this point the remote control Indicator Light starts

ashing to con rm the link is active.

proximately 10 seconds to con m that the linking process was successful.

INDICATOR

LIGHT

HOOD CONTROL

L1

LED

RING

FIG. 3 FIG. 4

Remote Control Functions (Fig.3)

Delay - O

Blower Speed Decrease and O

Blower Speed Increase and On

Light

Press (Delay) and (Light) together to Reset Filter Alarm.

IMPORTANT: holding

(Delay) for more than 3 seconds

will cause the link between the remote and hood to be lost.

CAUTION RISK OF EXPLOSION IF BATTERY IS REPLACED

BY AN INCORRECT TYPE. DISPOSE OF USED BATTERY TO

THE INSTRUCTION.

Battery disposal

When the batteries need to be replaced, dispose of them only and exclusively in the numerous readily

available special waste bins, especially in shops selling electronic consumer goods. Observance of the

regulations on di erentiated waste collection, in particular, proper disposal of used batteries, contributes to

preventing possible negative e ects on the environment and health.

See “Controls” section on previous page for

more information on each function.

- 7 -

Page 8

CLEANING AND MAINTENANCE

Proper maintenance of the Range Hood will assure proper performance of the unit.

Motor

The motor is permanently lubricated and never needs oiling. If the motor bearings make

excessive or unusual noise, replace the motor with the exact service motor. The impeller

should also be replaced.

Grease Filter

The grease lters should be cleaned frequently. Use a warm detergent solution. Grease

lter are dishwasher safe.

Clean all-metal lters in the dishwasher using a non-phosphate detergent. Discoloration of

the lter may occur if using phosphate detergents, or as a result of local water conditions but this will not a ect lter performance. This discoloration is not covered by the warranty.

See “INSTALL FILTERS” section for removal and installation instructions.

Stainless Steel Cleaning

DO:

• Regularly wash with clean cloth or rag

soaked with warm water and mild soap or

liquid dish detergent.

• Always clean in the direction of original

polish lines.

• Always rinse well with clear water (2 or 3

times) after cleaning. Wipe dry completely.

Avoid: When choosing a detergent

• Any cleaners that contain bleach will attack stainless steel

• Any products containing: chloride, uoride, iodide, bromide will deteriorate surfaces

rapidly.

• Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc.,

are highly explosive and should never be used close to a range.

DON’T:

• Use any steel or stainless steel wool or

any other scrapers to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction

residues reach the hood. During construction/renovation, cover the range hood to

make sure no dust sticks to the stainless

steel surface.

- 8 -

Page 9

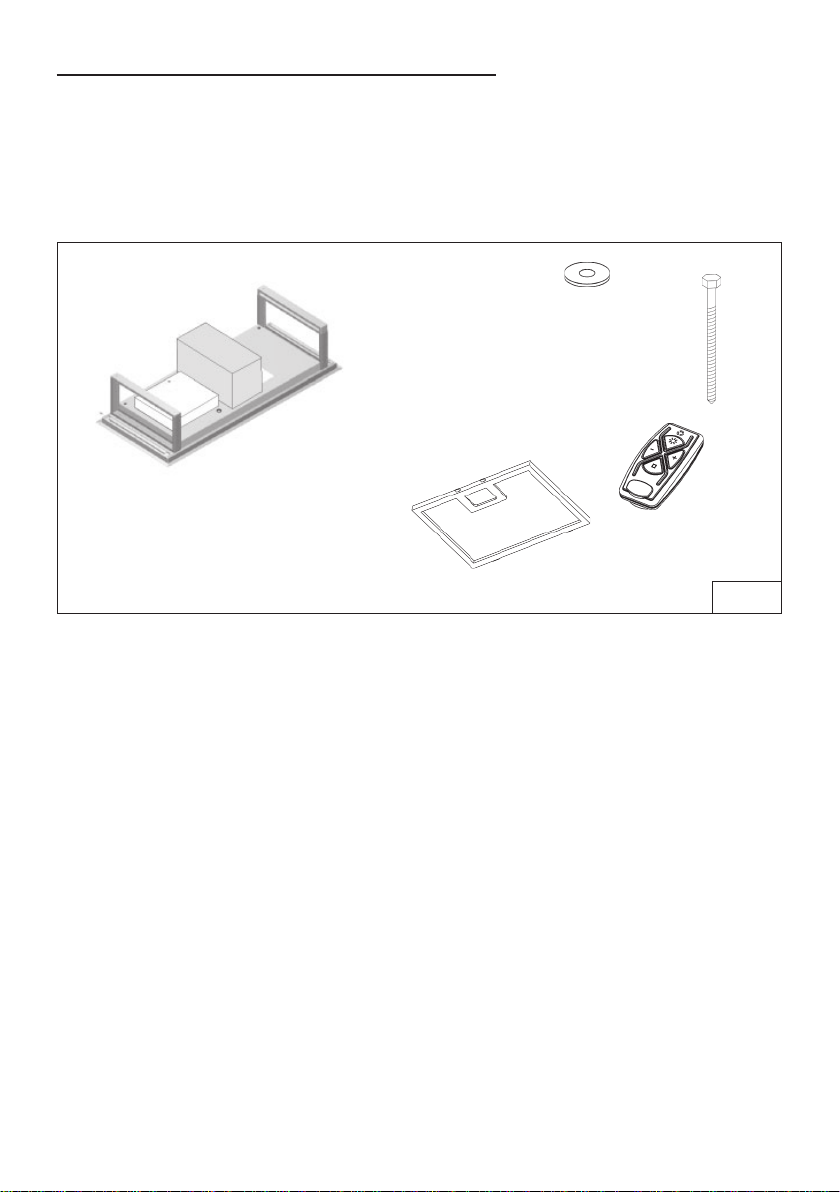

PREPARE THE HOOD

Unpack hood and check contents.

You should receive:

1 - Range Hood

1 - Remote Control

4 - Grease Filters

6 - Lag Bolts, 6 x 60 mm for wood

6 - Washer

6 WASHER

6 LAG BOLTS

(6 x 60 mm)

for wood

RANGE HOOD BODY

WITH DAMPER

4 GREASE

FILTERS

The installer is responsible for selecting fasteners that are suitable for the building construction.

REMOTE

CONTROL

FIG. 5

- 9 -

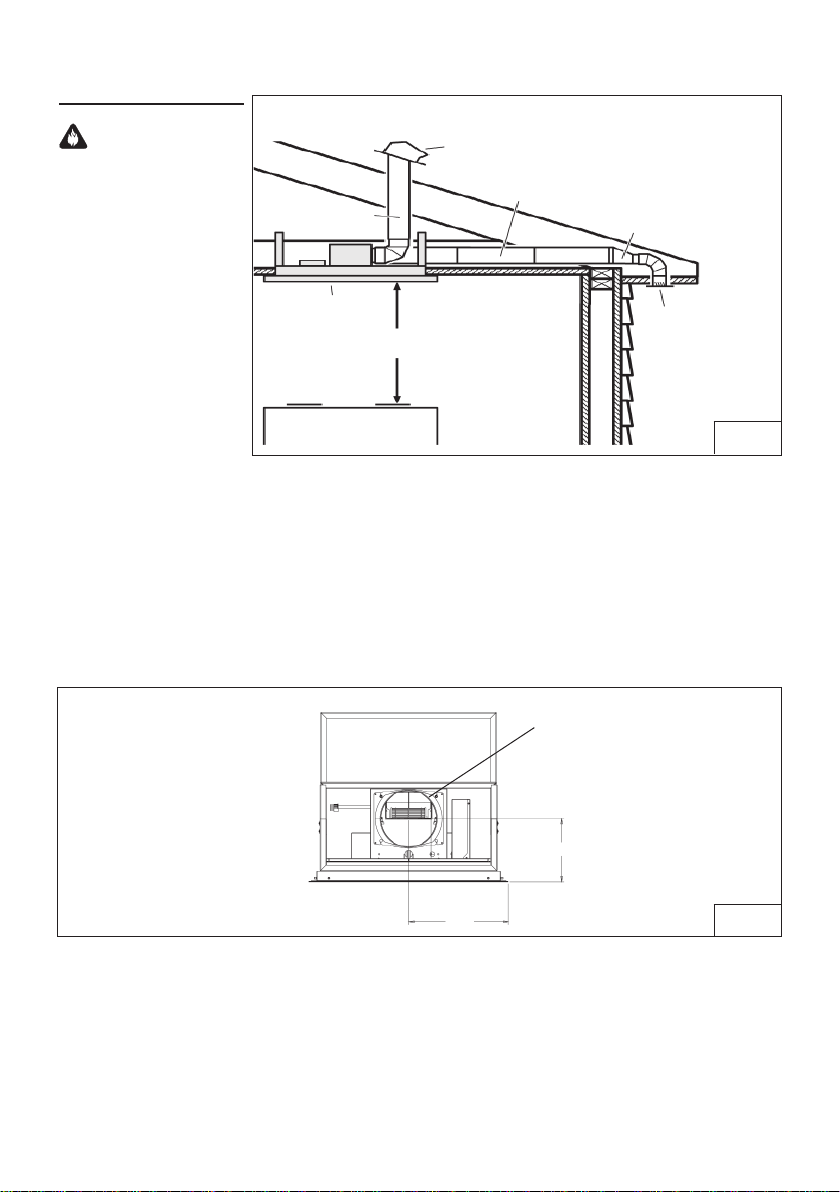

Page 10

INSTALL THE

DUCTWORK

WARNING: To

ROOF CAP

reduce the risk of

fire, use only metal

ductwork.

1. Decide where the

ductwork will run

8” or 10”

ROUND

DUCT

8” or 10”

ROUND

DUCT

10” ROUND TO

3¼ X 14” REDU-

CER

between the hood

and the outside.

Fig. 6.

2. A straight, short duct

run will allow the

hood to perform

most efficiently. For

HOOD

48” TO 72” ABOVE

COOKING SURFACE

3¼ X 14”

UNDER

EAVE VENT

THIS INSTALLATION

NOT RECOMMENDED

FOR CC34IQT63SB

optimal performance,

it is recommended

to have 18 - 24” of

FIG. 6

straight duct before

using an elbow.

3. Long duct runs, elbows, and transitions will reduce the performance of the hood. Use as few of

them as possible. Larger ducting may be required for best performance with longer duct runs.

4. Install a roof cap, wall cap, or under-eave vent. Connect round metal ductwork to cap/vent

and work back towards hood location. Use duct tape to seal the joints between ductwork

sections.

5. The blower on model CC34IQ63SB can be rotated according to the air outlet location. See Fig.

7 for air outlet dimensions.

CC34IQ63SB: DUCT 8”

CC34IQT63SB: DUCT 10”

- 10 -

6-7/8”

9-1/8”

FIG. 7

Page 11

For Recirculation Mode, purchase KIT ANKCC3463 separately (Optional for CC34IQ63SB only). Fig.8

8” ROUND

DUCT

HOOD

48” TO 72” ABOVE

COOKING SURFACE

FIG. 8

- 11 -

Page 12

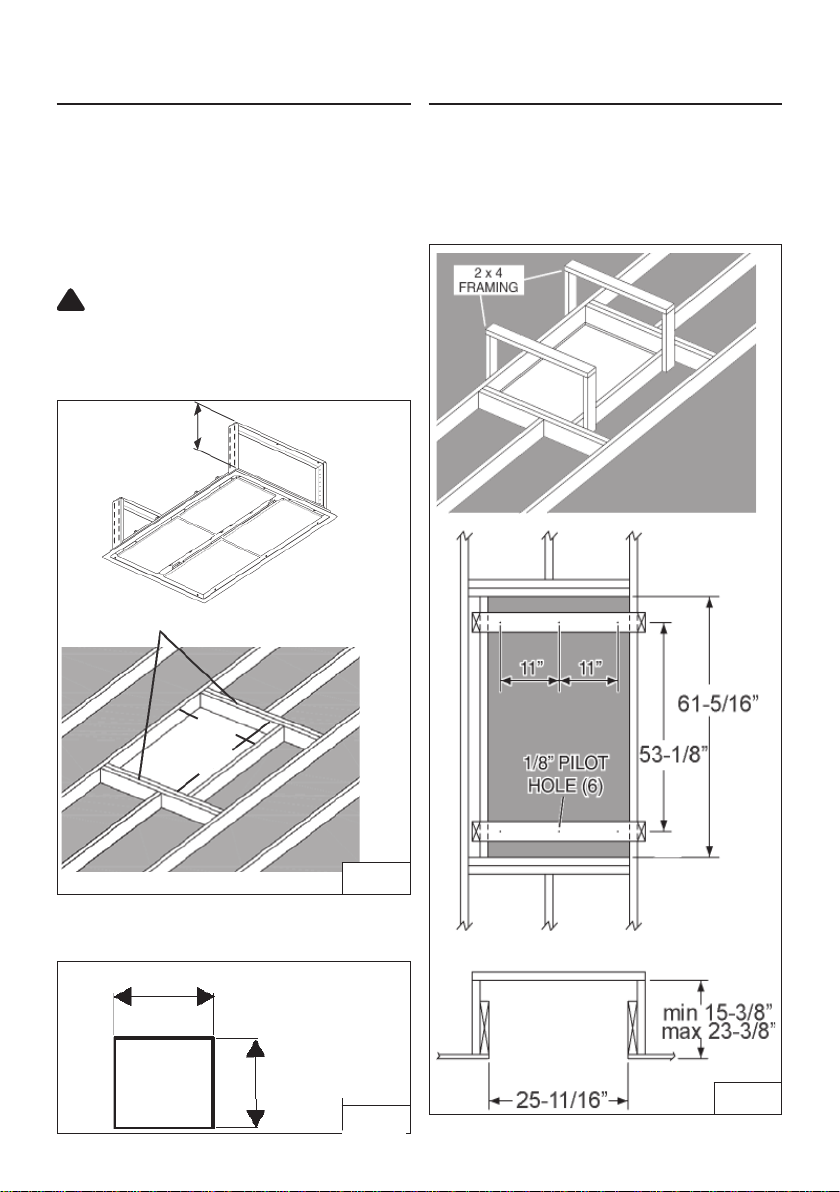

PREPARE THE CEILING

!

OPENING

PREPARE THE HOOD

SUPPORT

The hood should always be centered over the

cooktop. Make sure there is adequate space

in the ceiling structure to install the hood and

ductwork. The hood should be mounted 48”

to 72” above the cook top for best removal of

cooking impurities. Fig 6.

Use joist size lumber to frame in around the range

hood opening. Fig 9.

The ceiling structure must be able to

support the weight of the hood.

CC34IQ63SB Model: 105 pounds weight.

CC34IQT63SB Model: 121 pounds weight.

min. 15-3/8”

max. 23-3/8”

DOUBLE HEADERS

25-11/16”

1. Construct a wood framing system as shown

in Fig. 11.

2. The structure must be capable of supporting its own weight, plus the weight of the

hood.

61-5/16”

For Non-Ducted version:

Make a cut-out in the ceiling for the air return

vent. See Fig. 10 below and Fig. 24.

9-13/16”

9-13/16”

FIG. 9

FIG.11

FIG. 10

- 12 -

Page 13

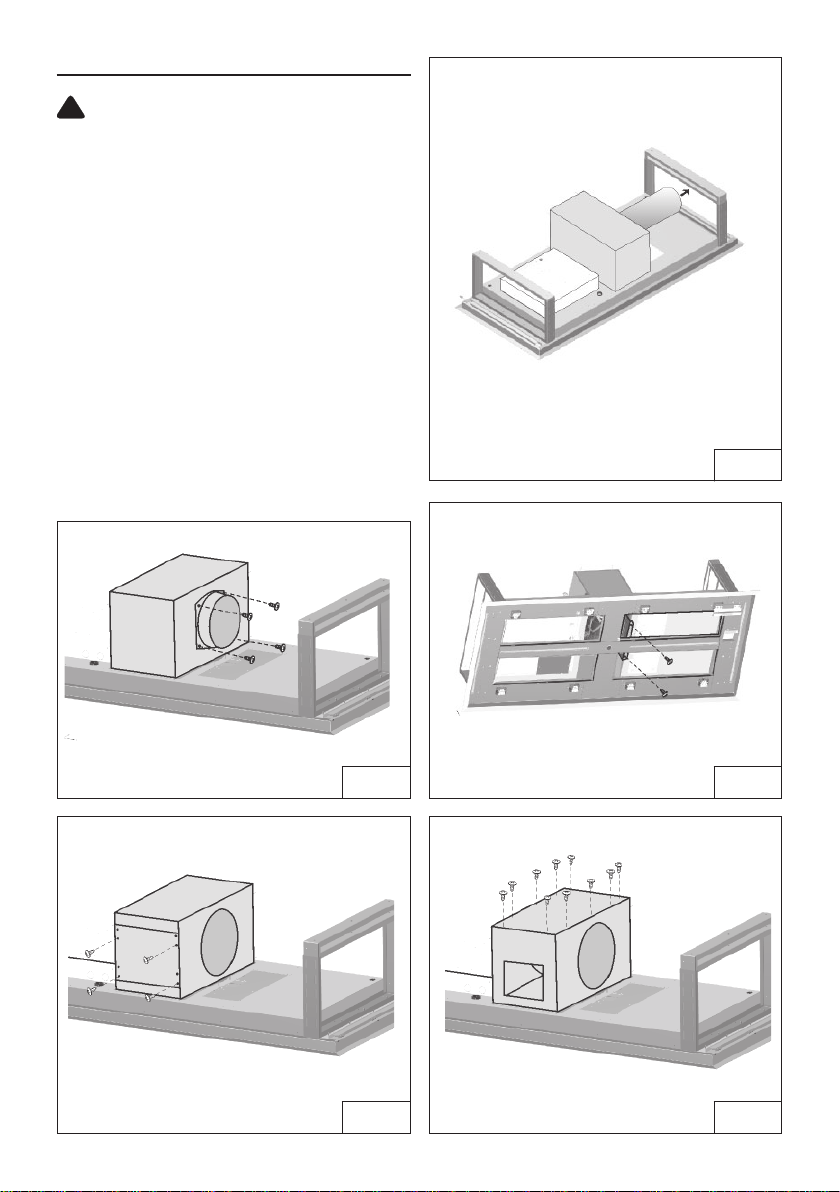

INSTALL THE HOOD

!

CAUTION: Multiple installers are

recommended because of the large size and

weight of this range hood.

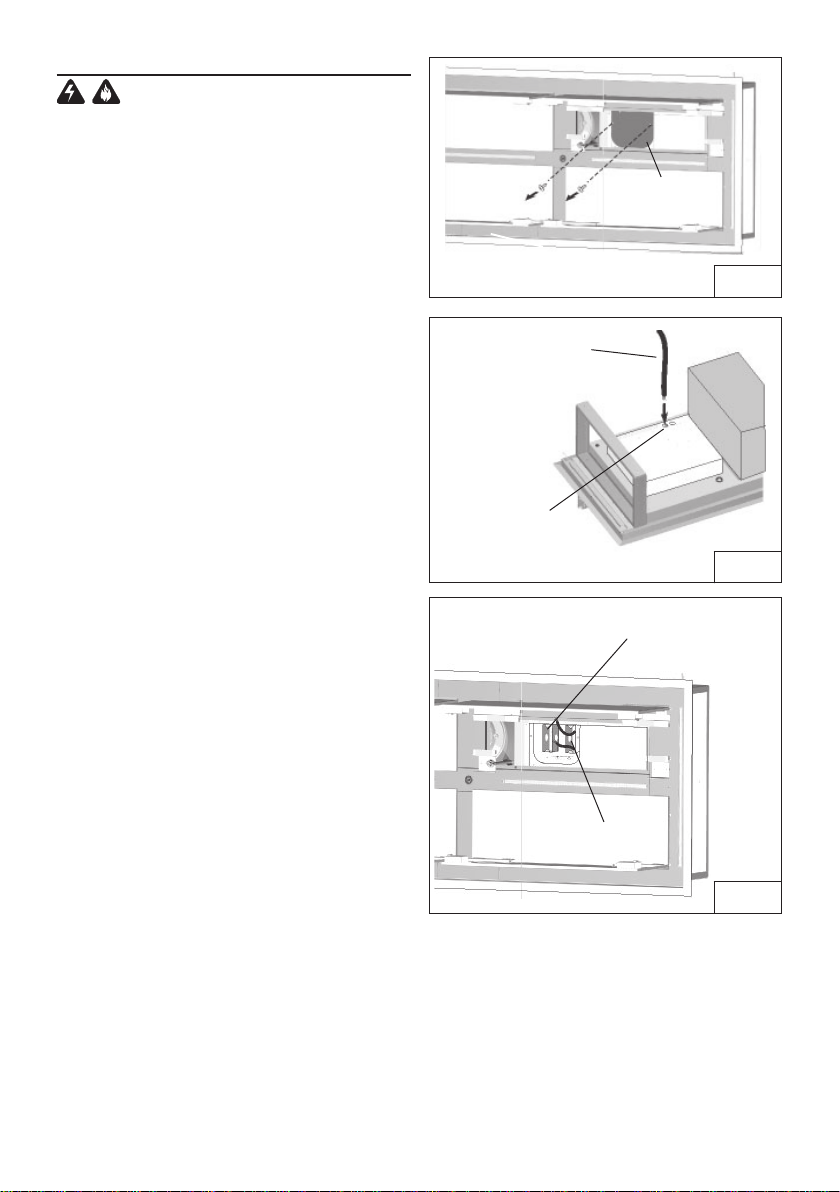

1. Hood is shipped in the horizontal duct

discharge position and is ready to be installed

(Fig.12).

Only CC34IQ63SB model (1 motor):

To change direction of the duct without using elbows.

• Remove (4) screws of the damper collar

(Fig.13).

• Remove (2) screws from inside of blower box

(Fig.14).

• Remove (4) screws from sides of blower box

(Fig.15).

• Remove (10) screws on the top of blower box

(Fig.16).

FIG.12

FIG.13

FIG.14

FIG.16FIG.15

- 13 -

Page 14

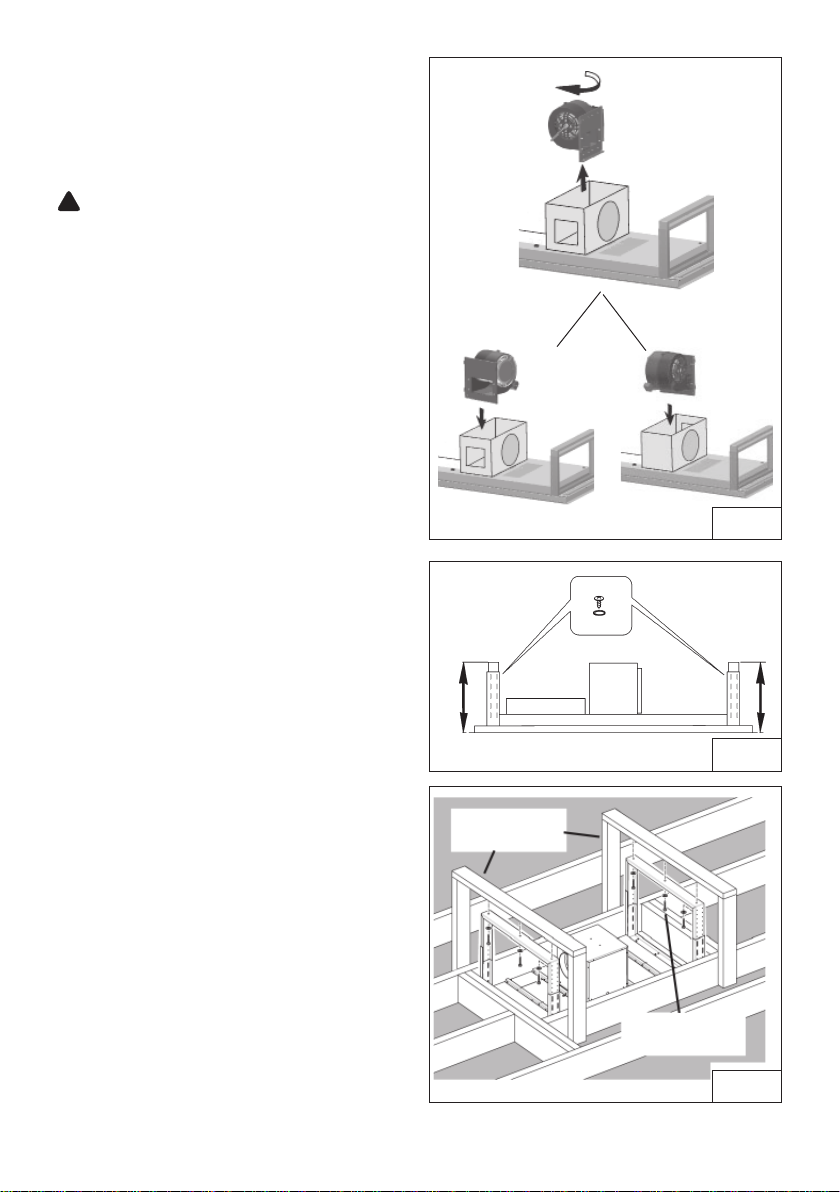

• Rotate blower 90 degrees and reinstall (2)

!

screws (Fig.17). Reinstall blower box covers,

damper and screws.

2. Adjust height of the telescoping support

frame and secure with screws and washers.

Fig.18.

CAUTION: Adjust the height before

installation.

3. Lift range hood into the ceiling opening.

4. Secure each support frame to the wooden

hood support frame using (6) 6 x 60 mm lag

bolts and washers provided. Fig. 19.

5. Install exterior or in-line blower by following

instructions provided with blower.

6. Install ductwork and duct tape all joints to

ensure an air tight seal.

FIG.17

FIG.18

2x4 WOOD

FRAME

(6) WASHERS

& LAG BOLTS

FIG.19

- 14 -

Page 15

CONNECT THE WIRING

ELEC TRIC AL

COMPARTMENT

COVE R

WARNING: All electrical wiring

should be done by a qualifi ed person (s) in

accordance with all applicable codes and

standards. This range hood must be properly

grounded.

1. Remove electrical compartment cover by

removing (2) screws (Fig.20).

2. Run 2-wire plus ground, 120 VAC electrical

power cable to the ¾” knockout located on

the back of the hood. Fig. 21.

3. Remove ¾” electrical knockout from the

back of the hood.

4. From the electrical box marked “120 VAC Inlet”,

remove (2) screws that secure the cover to the

metal wiring box. Fig. 22.

5. Pull 120VAC electrical power cable into the box

and secure with an appropriate cable clamp.

6. Make electrical connections inside the box.

Connect white-to-white, black-to-black and

green-to-ground.

7. Replace the wiring box cover and the screws.

Reinstall electrical compartment cover and

screws. Make sure wires are not pinched

between the cover and box.

2-WIRE PLUS GROUND

120 VAC LINE IN

KNOCKOUTS

CONNECT

WHITE-TO-WHITE

BLACK-TO-BLACK

GREEN-TO-GROUND

ELECTRICAL

COMPARTMENT

COVER

120VAC 60Hz

LINE-IN

FIG. 20

FIG. 21

- 15 -

BOX MARKED

“120VAC INPUT”

FIG. 22

Page 16

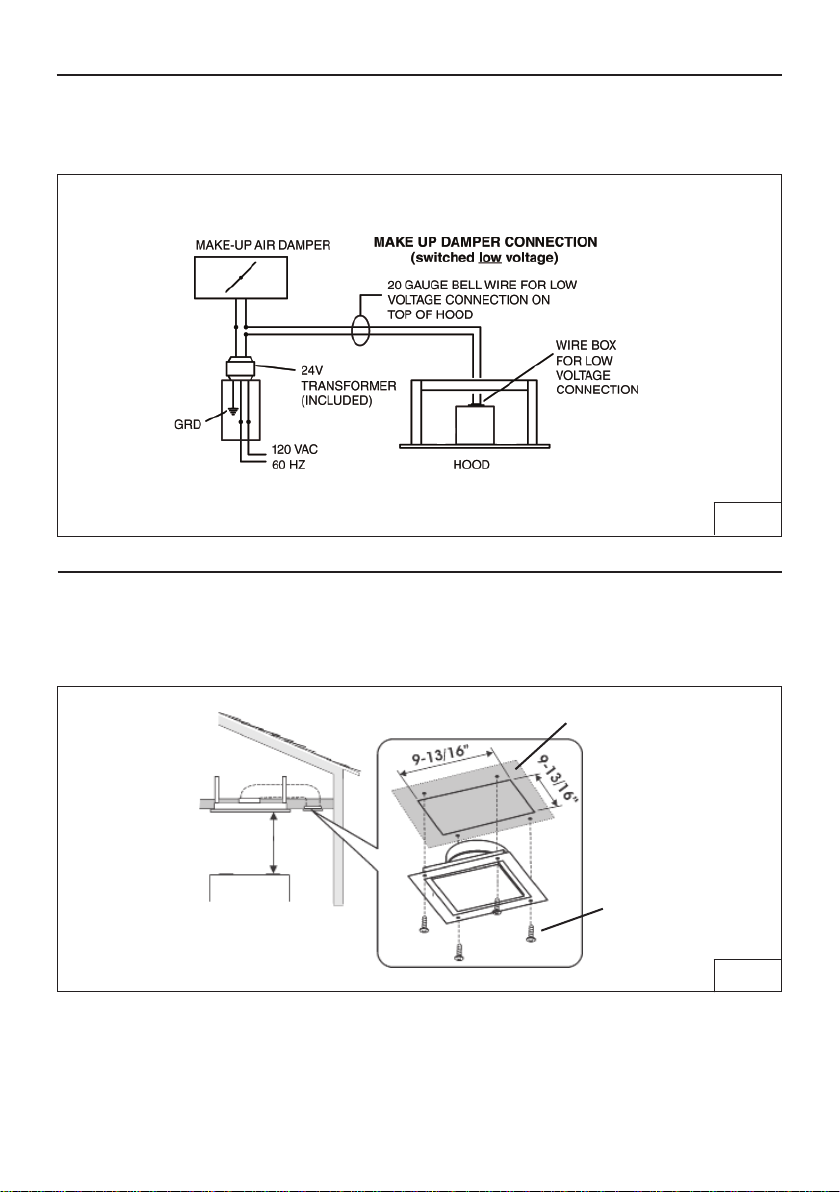

MAKE-UP AIR DAMPER

CAUTION: The hood is compatible only with Broan Make-Up Air Damper Model MD8T

(recommended for CC34IQ63SB)or MD10T (recommended for CC34IQT63SB). Purchase separately.

Make the connection to the Make-Up Air Damper with low voltage wiring, as shown. See Make-Up

Air Damper instructions for additional information (Fig.23)

FIG.23

INSTALL THE AIR RETURN VENT NONDUCTED VERSION

Purchase the optional ANKCC3463 recirculating kit, sold separately (Optional for CC34IQ63SB

only). The kit includes the air return vent and the charcoal lters.

Fix the air return vent to the ceiling, by means (4) 4,2x15 mm screws. See Fig.24.

- 16 -

CEILING

(4) MOUNTING SCREWS

4,2x15mm

FIG.24

Page 17

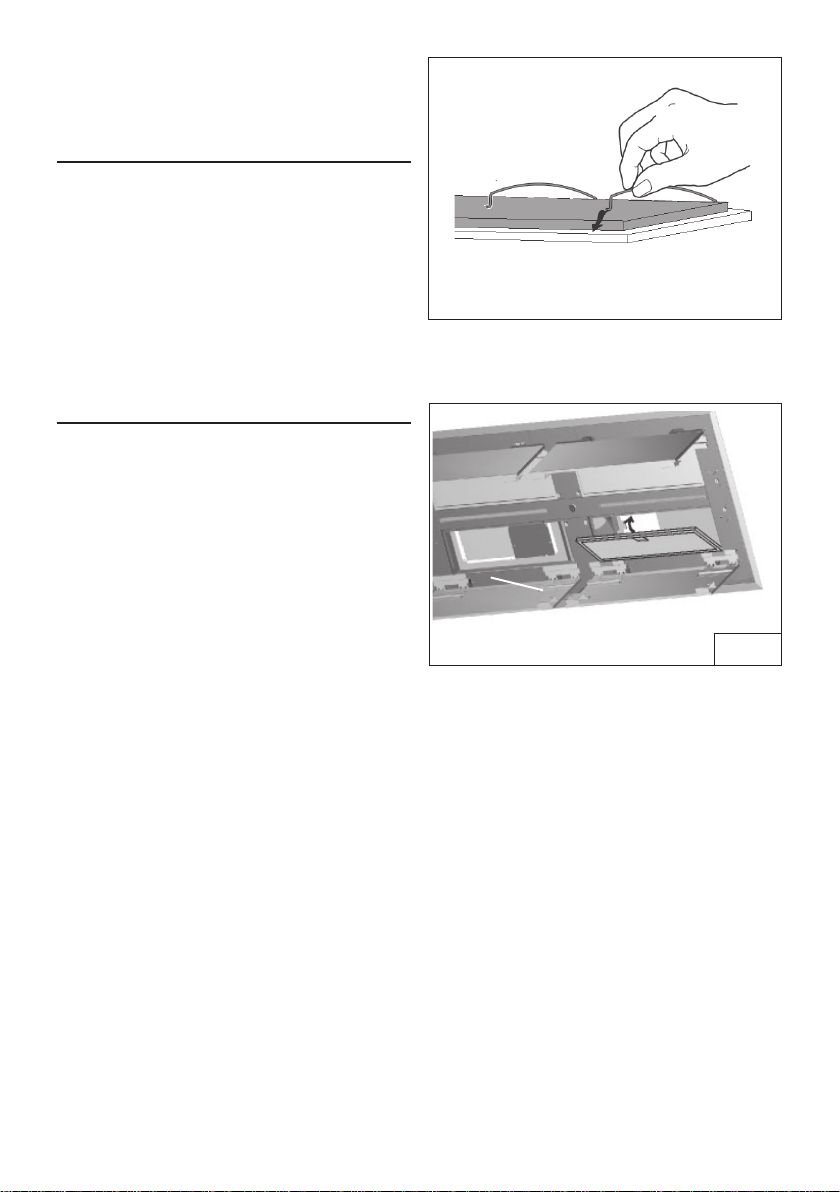

NON-DUCTED

RECIRCULATION FILTERS

INSTALLATION (NONDUCTED HOODS ONLY)

Non-ducted recirculation lters are included

with kit ANKCC3463. Replacement nonducted recirculation lters can be purchased

separately (AFCCC3463).

Kit and non-ducted recirculation filter are

optional for CC34IQ63SB only.

Position the non-ducted recirculation lter

over the grease lter and secure it by means

(4) wire retainers. Refer Figure 25.

INSTALL THE FILTERS

1. To install the grease lters, align rear lter tabs

with slots in the hood. Push latch tab in, push

lter into position and release. Make sure lter

is securely engaged after installation. Fig. 26.

2. To remove the lters for cleaning, push latch

tab in to disengage lter from hood. Tilt the

lter downward and remove.

FIG. 25

NOTE: Remove protective lm from lters and

steel surfaces before using cooking under

range hood.

FIG. 26

- 17 -

Page 18

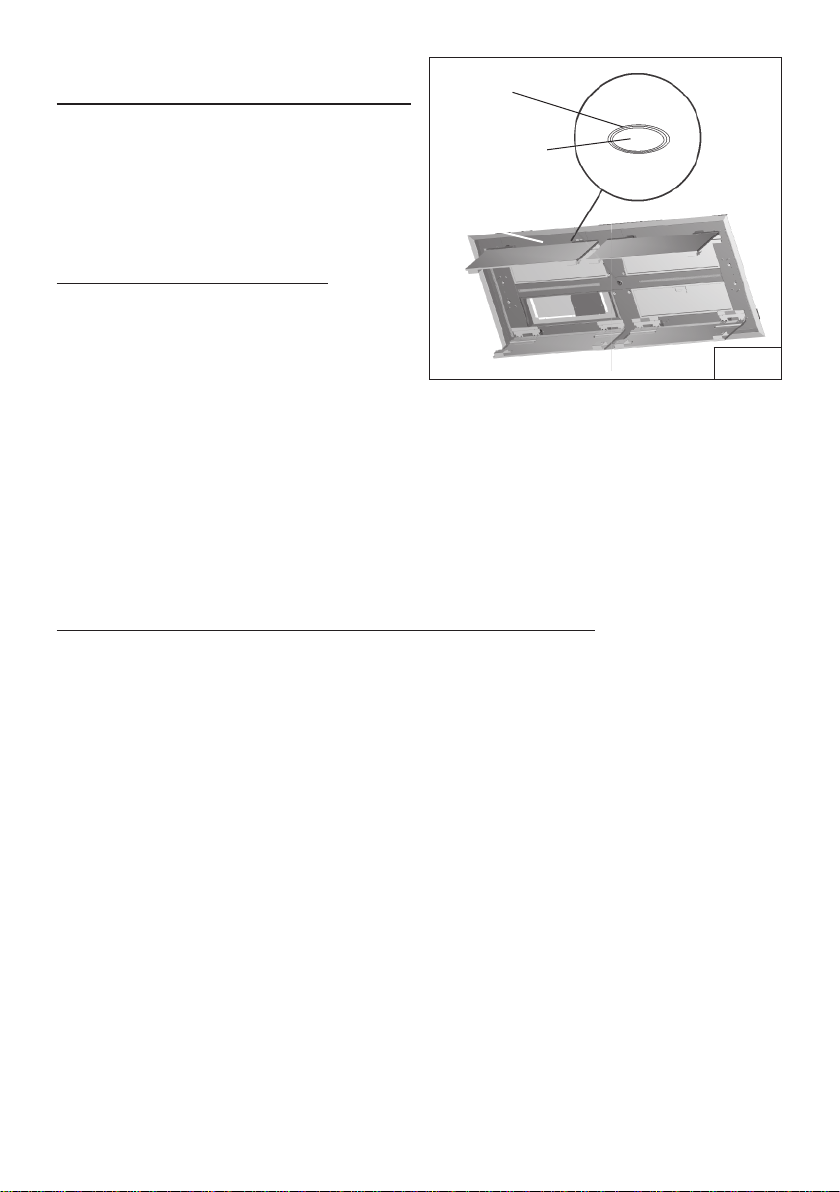

CALIBRATE IQ BLOWER

SYSTEM

TM

CALIBRATION

LIGHT

After the hood is installed and wired,

engage the calibration process (our

CALIBRATION

BUTTON

Guaranteed Performance System

Technology to ensure full-rated air ow is

being delivered). Prior to calibration, ensure

that all lters, light bulbs and duct system

are installed.

CALIBRATION PROCESS Fig. 27

Hold the calibration button for 3 seconds;

calibration button will light up and stay on

for up to 13 minutes. The blower will start

and begin the calibration process. When

FIG. 27

calibration is complete, one of two things

will occur:

1.The blower turns o and calibration button light stays on = Successful calibration. Press

the button to turn o the LED. Note: The LED will also turn o if you select any blower

speed on the control.

2.The blower turns o and calibration button light blinks continuously = Too much

restriction in the ductwork is preventing the IQ Blower System™ from achieving the rated

air ow. The blower is automatically set to maximum intensity. NOTE: Common items that

cause restrictions: restricted damper ap(backdraft damper, wall cap, roof cap), too many

elbows, duct size less than 80% of hood outlet, poor transition, use of ex ducting and/or

crushed ducting.

Three options are available if your hood system has too much restriction:

1. Accept air ow as is.

a. Press the calibration button to accept air ow as is. The IQ Blower System™ is now

con gured to the highest possible performance. The blinking calibration light goes out.

Note: The LED will also turn o if you select any blower speed on the control.

2. Correct duct restriction, clear the original calibration data, and repeat the calibration

process.

a. Correct the duct restriction.

b. Clear the original calibration data by holding calibration button for 10 seconds. The light

will blink 3 times to con rm and the blower con guration will go back to default settings.

c. Repeat calibration process from the beginning.

3. Clear calibration data to reset hood to default factory setting and achieve standard high

pressure blower performance.

a. Clear calibration data and reset hood to factory default setting by holding calibration

button for 10 seconds. The light will blink 3 times to con rm and the blower con guration

will go back to default settings.

- 18 -

Page 19

Limited Warranty

Warranty Period and Exclusions: Broan-NuTone, LLC(the “Company”) warrants to the consumer purchaser of its product (“you”) that

the product (the “Product”) will be free from material defects in the materials or its workmanship for a period of fi ve (5) years from the date

of original purchase (or such longer period as may be required by applicable law) or a period of two (2) years from the date of service for

any labor provided on the Product.

The limited warranty period for any replacement parts provided by the Company and for any Products repaired or replaced under this limited

warranty shall be the remainder of the original warranty period (or such longer period as may be required by applicable law).

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES AND BULBS, FUSES, FILTERS, DUCTS, ROOF

CAPS, WALL CAPS AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover (a) normal maintenance and service, (b)

normal wear and tear, (c) any Products or parts which have been subject to misuse, abuse, abnormal usage, negligence, accident, improper

or insuffi cient maintenance, storage or repair (other than repair by the Company), (d) damage caused by faulty installation, or installation

or use contrary to recommendations or instructions, (f) damage caused by exposure to salt air, (g) damage in transit, (h) natural wear of

fi nish, (i) Products in commercial or nonresidential use, (j) damage caused by fi re, fl ood or other act of God, or (k) Products with altered,

defaced or removed serial numbers. This warranty covers only Products sold to consumers in North America.

This warranty supersedes all prior warranties and, subject to applicable law, is not transferable from the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s sole obligation and your sole remedy for defective Products. The

foregoing warranties are exclusive and in lieu of any other warranties and conditions, express or implied. TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, THE COMPANY DISCLAIMS AND EXCLUDES ALL OTHER EXPRESS WARRANTIES AND

CONDITIONS, AND DISCLAIMS AND EXCLUDES ALL WARRANTIES AND CONDITIONS IMPLIED BY LAW, INCLUDING WITHOUT

LIMITATION THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the extent that applicable law prohibits

the exclusion of implied warranties or conditions, the duration of any applicable implied warranty or condition is limited to the period specifi ed

for the express warranty above. Some jurisdictions (which may include the Province of Quebec or specifi c US states) do not allow limitations

on how long an implied warranty lasts, so the above limitation may not apply to you. Any oral or written description of the Product is for the

sole purpose of identifying it and shall not be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted in such manner as to be eff ective and valid under applicable

law, but if any provision is held to be prohibited or invalid, such provision shall be ineff ective only to the extent of such prohibition or invalidity,

without invalidating the remainder of such provision or the other remaining provisions of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its option, provide replacement parts for, or repair or replace,

without charge, any Product or part thereof, to the extent the Company fi nds it to be covered by and in breach of this limited warranty

under normal use and service. The Company will ship the repaired or replaced Product or replacement parts to you at no charge. You are

responsible for all costs for removal, reinstallation and shipping, insurance or other freight charges incurred in the shipment of the Product

or part to the Company. If you must send the Product or part to the Company, as instructed by the Company, you must properly pack the

Product or part—the Company is not responsible for damage in transit. The Company reserves the right to utilize reconditioned, refurbished,

repaired or remanufactured Products or parts in the warranty repair or replacement process. Such Products and parts will be comparable

in function and performance to an original Product or part and warranted for the remainder of the original warranty period (or such longer

period as may be required by applicable law).

Company reserves the right, in its sole discretion, to refund the money actually paid by you for the Product. If the Produc

is no longer available, replacement may be made with a similar product of equal or greater value, at Company’s sole discretion. This is

your sole and exclusive remedy for breach of this limited warranty.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE REPLACEMENT PARTS, OR REPAIR OR REPLACE, AT THE

COMPANY’S OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY AND THE COMPANY’S

SOLE AND EXCLUSIVE OBLIGATION. THE COMPANY SHALL NOT BE LIABLE FOR INCIDENTAL, INDIRECT, CONSEQUENTIAL OR

SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE PRODUCT, ITS USE OR PERFORMANCE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This warranty gives you specifi c legal rights, and you may also have other rights, which vary from jurisdiction to jurisdiction. The disclaimers, exclusions, and limitations of liability under this warranty will not apply to the extent prohibited by applicable law.

This warranty covers only replacement or repair of defective Products or parts thereof at the Company’s main facility and does not include

the cost of fi eld service travel and living expenses.

Any assistance the Company provides to or procures for you outside the terms, limitations or exclusions of this limited warranty will not

constitute a waiver of such terms, limitations or exclusions, nor will such assistance extend or revive the warranty.

The Company will not reimburse you for any expenses incurred by you in repairing or replacing any defective Product, except for those

incurred with the Company’s prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a) notify the Company at the address or telephone number

stated below within seven (7) days of discovering the covered defect, (b) give the model number and part identifi cation and (c) describe the

nature of any defect in the Product or part. At the time of requesting warranty service, you must present evidence of the original purchase

date. If you cannot provide a copy of the original written limited warranty, then the terms of the Company’s most current written limited

warranty for your particular product will control.

PRODUCT SPECIFICATIONS

All illustrations and specifi cations in this catalog are based on the latest product information available at time of production. Broan-NuTone,

LLC and BEST® reserves the right to make changes at any time, without notice, in prices, colors, materials, equipment, specifi cations and

models, place of manufacture and to discontinue models or equipment.

Best

Broan-NuTone, LLC- 926 W. State Street, Hartford, WI 53207

1-800-637-1453

Best®, 550 Lemire Blvd., Drummondville, QC, Canada (1-866-737-7770) www.bestrangehoods.com

t or component

- 19 -

Page 20

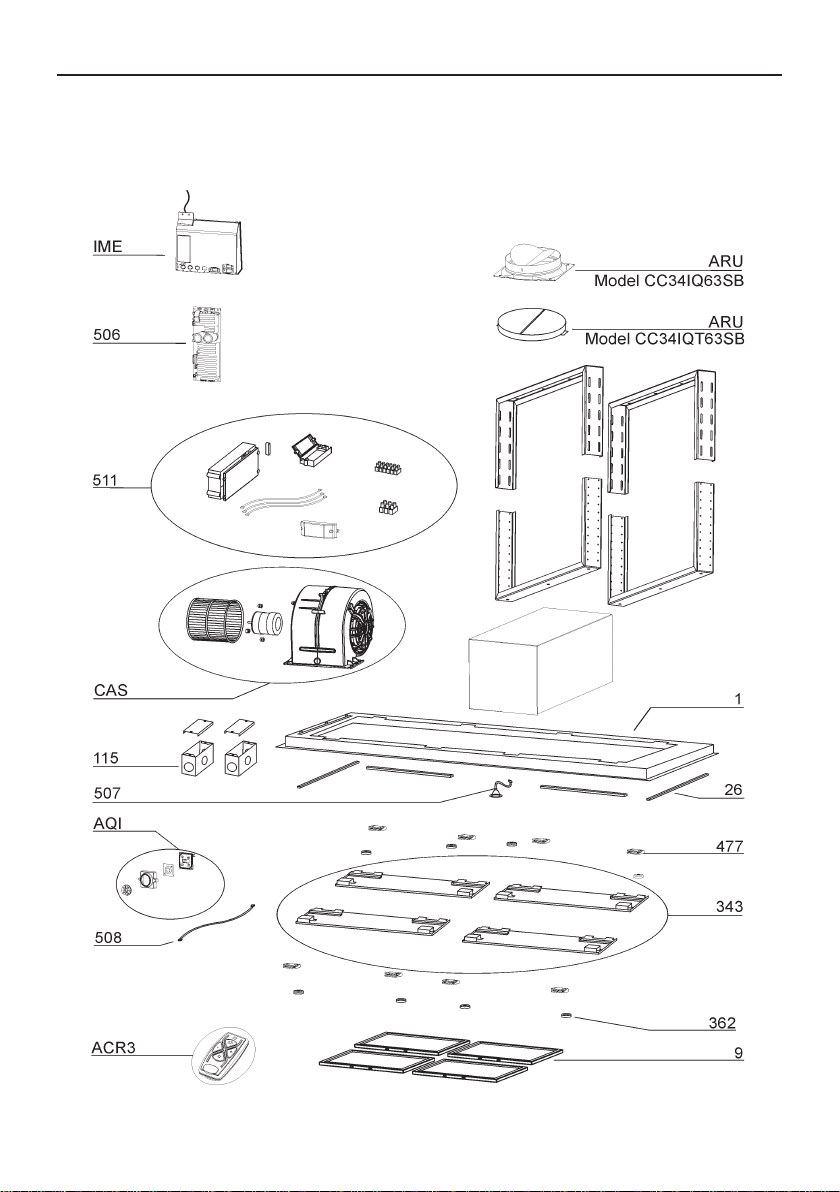

SERVICE PARTS

MODEL

CC34IQ63SB

KEY NO. PART NO. DESCRIPTION

1 B003103711 FRAME

9 B08087836 GREASE FILTER

26 B023004301 LIGHT BAR

115 BE3350233 ELECTRICAL BOX

343 B08094449 ELECTRICAL COMPARTMENT COVER

362 B02011422 MAGNET

477 B02011376 HINGE

506 B08080878 BLDC DRIVER

507 B06102584 CALIBRATION BUTTON

508 B02301083 CONTROL CABLE

511 B06102814 DRIVER ASSEMBLY

998 B080810962 HARDWARE

999 B080814337 INSTALLATION INSTRUCTIONS

CAS B06002259 BLOWER ASSEMBLY

IME B06102805 ELECTRICAL INSTALLATION ASSEMBLY

AQI B06102812 SWITCH ASSEMBLY

ARU B08092501 DAMPER ASSEMBLY

ACR3 B08999186 REMOTE CONTROL

- B902980139 NONDUCTED RECIRCULATION FILTERS

CC34IQT63SB

KEY NO. PART NO. DESCRIPTION

1 B003103711 FRAME

9 B08087836 GREASE FILTER

26 B023004301 LED

115 BE3350233 ELECTRICAL BOX

343 B08094449 ELECTRICAL COMPARTMENT COVER

362 B02011422 MAGNET

477 B02011376 HINGE

506 B08080879 BLDC DRIVER

507 B06102584 CALIBRATION BUTTON

508 B02301083 CONTROL CABLE

511 B06102806 DRIVER ASSEMBLY

998 B080810962 HARDWARE

999 B080814337 INSTALLATION INSTRUCTIONS

CAS B06002259 BLOWER ASSEMBLY

IME B06102805 ELECTRICAL INSTALLATION ASSEMBLY

AQI B06102812 SWITCH ASSEMBLY

ARU B02011533 DAMPER ASSEMBLY

ACR3 B08999186 REMOTE CONTROL

- 20 -

Page 21

SERVICE PARTS

MODEL

CC34IQ63SB

CC34IQT63SB

- 21 -

Page 22

- 22 -

Page 23

Modèle CC34IQ63SB

CC34IQT63SB

ENGLISH........................................3

FRANÇAIS...................................23

ESPAÑOL.....................................45

Aux États-Unis - BEST Hartford, Wisconsin

Au CANADA - BEST Drummondville, QC, Canada

ENREGISTREZ VOTRE PRODUIT EN LIGNE À : www.BestRangeHoods.com/register

Pour de plus amples informations, visitez www.BestRangeHoods.com

- 23 -

Page 24

LIRE CES DIRECTIVES ET LES CONSERVER

!

!

POUR USAGE DOMESTIQUE SEULEMENT

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE, D’ÉLECTROCUTION OU DE BLESSURES PHYSIQUES, RESPECTEZ LES INSTRUCTIONS CI-DESSOUS:

1. Utilisez cet appareil uniquement de la manière prévue par le fabricant. Si vous avez des

ques- tions, contactez le fabricant à l’adresse ou au numéro de téléphone indiqués dans la

garantie.

2. Avant d’e ectuer l’entretien ou le nettoyage de l’appareil, coupez le courant au panneau

d’alimentation et verrouillez ce dernier pour éviter que l’appareil soit mis sous tension par inadvertance. S’il n’est pas possible de verrouiller le dispositif de déconnexion, apposez un avertissement

bien visible (par exemple une étiquette) sur le panneau d’alimentation.

3. L’installation et le raccordement électrique doivent être e ectués par du personnel quali é con-

formément à toutes les réglementations et normes en vigueur, y compris les normes et codes de

bâtiment en matière de prévention d’incendie.

4. A n d’éviter les retours de cheminée lors de l’utilisation d’appareils à combustion, une circulation

d’air su sante est nécessaire pour assurer une combustion et une évacuation adéquates des gaz

à travers le conduit (la cheminée). Conformez-vous aux instructions et aux standards de sécurité

des manufacturiers d’appareils de chau age, tels qu’ils sont publiés par la National Fire Protection

Association (NFPA) et l’American Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), ainsi que les réglementations locales.

5. Quand vous e ectuez une découpe ou une perforation dans un mur ou un plafond, veillez à ne pas

endommager des ls électriques ou d’autres équipements non visibles.

6. Les ventilateurs avec conduits doivent toujours évacuer l’air vers l’extérieur.

7. N’utilisez pas cet appareil avec une commande de vitesse à semi-conducteur additionnelle.

8. Pour réduire les risques d’incendie, utilisez uniquement des conduits en métal.

9. Cet appareil doit être mis à la terre.

10. Type d’installation non-IC : L’isolant thermique de la maison ne doit pas couvrir le haut de la

hotte et doit être à au moins 76 mm (3 po) du boîtier de tout côté. (Fig. 1)

MINIMUM 76 MM (3 PO). PAS D’ISOLANT DANS

LA ZONE OMBRÉE.

AFIN DE RÉDUIRE LE RISQUE DE FEU DE CUISINIÈRE

A. Ne laissez jamais les appareils de cuisson sans surveillance lorsqu’ils sont réglés à feu vif. Les débor-

dements peuvent causer de la fumée et occasionner des écoulements de graisse in ammables.

L’huile doit être chau ée lentement, à feu doux ou moyen.

- 24 -

FIG. 1

Page 25

B. Mettez toujours la hotte en MARCHE lors de la cuisson à feu vif ou lors de la cuisson d’aliments à

!

amber (par ex., crêpes Suzette, cerises jubilé, steak au poivre ambé).

C. Nettoyez souvent les ventilateurs. Ne laissez pas la graisse s’accumuler sur le ventilateur ou les ltres.

D. Utilisez des casseroles de dimension appropriée. Utilisez toujours des casseroles et des ustensiles

adaptés à la dimension de la surface de cuisson.

OBSERVEZ LES CONSIGNES SUIVANTES DE MANIÈRE À RÉDUIRE LES RISQUES DE

BLESSURES CORPORELLES EN CAS D’UN FEU DE CUISINIÈRE CAUSÉ PAR DE LA

GRAISSE SUR LA SURFACE DE CUISSON* :

1. ÉTOUFFEZ LES FLAMMES à l’aide d’un couvercle hermétique, d’une tôle à biscuits ou d’un plateau

en métal puis éteignez le brûleur. FAITES ATTENTION DE NE PAS VOUS BRÛLER. Si les ammes ne

s’éteignent pas immédiatement, QUITTEZ LES LIEUX ET APPELEZ LE SERVICE DES INCENDIES.

2. NE SOULEVEZ JAMAIS UNE CASSEROLE EN FLAMMES - vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni de serviettes ou de linges mouillés – une violente explosion de

vapeur pourrait survenir.

4. Utilisez un extincteur SEULEMENT si :

A. Vous savez qu’il est de classe ABC et vous connaissez déjà son mode de fonctionnement.

B. Le feu n’est pas très important et ne se propage pas.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre le feu en faisant dos à une sortie.* Conseils tirés de la publication de la

NFPA « Kitchen Fire Safety Tips ».

ATTENTION

1. Pour usage intérieur seulement.

2. Pour réduire les risques d’incendie et évacuer l’air correctement, assurez-vous d’évacuer l’air à

l’extérieur. N’évacuez pas l’air dans des espaces clos comme l’intérieur des murs ou un plafond, dans

le grenier, un faux-plafond ou un garage.

3. Faites attention lorsque vous utilisez des agents nettoyants ou des détergents.

4. Évitez d’utiliser des produits alimentaires pouvant produire des ammes sous la hotte.

5. Pour ventilation générale uniquement. N’utilisez pas cet appareil pour évacuer des matières

ou des vapeurs dangereuses ou explosives.

6. A n d’éviter tout dommage au moteur et de débalancer ou de rendre bruyante la roue du moteur,

garder l’appareil à l’abri de la poussière de plâtre, de construction, etc.

7. Le moteur de la hotte est muni d’un dispositif de protection thermique qui coupe automatique-

ment le moteur en cas de surchau e. Il se remet en marche lorsqu’il a refroidi. Faites réparer

la hotte si le moteur continue à fonctionner par intermittence.

8. Pour mieux capter les vapeurs de cuisson, le bas de la hotte doit être au minimum à 121,9 cm (48

po) et au maximum à 183 cm (72 po) de la surface de cuisson. Pour les restrictions s’appliquant au

montage, voir la section « Installation de la bride de montage ».

9. Il est recommandé d’avoir plusieurs d’installateurs, compte tenu de la taille et du poids de cette

hotte.

10. Veuillez lire l’étiquette de spéci cations du produit pour obtenir plus de renseignements, notam-

ment sur les exigences.

11. Cette hotte encastrable est munie d’un récepteur radio. Tous les changements ou modi cations qui

ne sont pas approuvés par la partie responsable de la conformité pourraient annuler la possibilité

d’utiliser l’équipement. La télécommande a été testée et est en accord avec les limites de la Classe

B appareil numérique et est conforme au chapitre 15 du règlement de la FCC et de celui du ICES-

003 canadiens. Ces limites sont développées a n de fournir une protection raisonnable contre des

interférences dommageables dans une installation résidentielle. La télécommande génère, utilise

et peut émettre des ux de fréquences radio qui peuvent causer des interférences aux communi-

cations radio, si elle n’est pas installée selon les instructions. Cependant, il n’y a aucune garantie

que ces interférences ne se produiront pas dans une installation particulière. Si cet équipement

cause des interférences à un récepteur radio ou un téléviseur, cela peut être con rmé en éteignant

et rallumant l’appareil, l’usager est encouragé à corriger cette situation en essayant les solutions

suivantes :

• Réorienter ou relocaliser l’antenne réceptrice

• Augmenter la distance entre l’équipement et le récepteur

• Connecter l’équipement à une autre prise électrique ou un autre disjoncteur di érent de

celui du récepteur

- 25 -

Page 26

- 26 -

!

!

Page 27

FONCTIONNEMENT

Commandes (Fig.2)

La hotte fonctionne à l’aide de cinq (5) boutons-poussoirs situés sur la hotte et avec la télécommande. Couleurs de DEL sont a chées sur le contrôle de la hotte uniquement.

P1 : Activer/désactiver l’arrêt diff éré (10 minutes)

P2 : Remise à zéro de l’indicateur de changement de fi ltre

P3 : Réduit la vitesse du ventilateur jusqu’à son arrêt

(4>3>2>1>ARRÊT)

P4 : Actionne le ventilateur et augmente sa vitesse

(MARCHE>1>2>3>4)

P5 : Éclairage arrêt/bas/moyen/haut.

L1 : Anneau indicateur DEL :

- Hotte en veilleuse : s’allume de couleur verte. S’éteint

30 secondes après que l’on ait appuyé sur une touche

- Moteur en marche : L1 clignote en bleu. La rapidité du

clignotement est fonction du réglage de la vitesse.

ANNEAU

DEL L1

(P1) Interrupteur d’arrêt diff éré

• Votre hotte comprend un interrupteur pour l’arrêt di éré de 10 minutes. Appuyez une fois

pour activer la minuterie d’arrêt di éré et l’anneau DEL (L1) se met à clignoter en bleu. Le

ventilateur continuera de fonctionner pendant 10 minutes. Après 10 minutes, le ventilateur

s’arrête automatiquement.

• Pour annuler l’arrêt di éré, appuyez de nouveau sur l’interrupteur.

(P2) Interrupteur d’alarme de fi ltre

• Après 30 heures de fonctionnement du ventilateur, l’alarme de ltre s’active et l’anneau

DEL (L1) se met à clignoter en rouge. Cela indique que les ltres à graisses doivent être

nettoyés.

• Une fois ceux-ci nettoyés, appuyez sur le bouton de remise à zéro de l’indicateur de

changement de ltre (P2) pendant l’a chage de l’alarme.

- Délai diff éré de 10 minutes : L1 s’allume et clignote en

bleu - Alarme de fi ltre activée : L1 s’allume en rouge

FIG. 2

(P3) Bouton de réduction de la vitesse du ventilateur et d’arrêt

• Appuyez pour réduire la vitesse du ventilateur. La vitesse de clignotement de l’anneau

DEL (L1) en bleu est fonction du réglage choisi (par ex. : quatre clignotements correspondent au régime maximal, un clignotement au régime lent, etc.)

• Pour arrêter le ventilateur, continuez d’appuyer sur l’interrupteur.

(P4) Bouton de mise en marche et d’augmentation de la vitesse du ventilateur

• Appuyez une fois pour mettre le ventilateur en marche au régime le plus lent.

• Appuyez de nouveau pour augmenter le régime du ventilateur. La vitesse de clignotement de l’anneau DEL (L1) en bleu est fonction du réglage choisi (par ex. : quatre clignotements correspondent au régime maximal, un clignotement au régime lent, etc.)

(P5) Interrupteur d’éclairage

Éclairage arrêt/bas/moyen/haut.

- 27 -

Page 28

TÉLÉCOMMANDE

La télécommande est jumelée à la hotte dès sa sortie de l’usine.

Si pour une raison quelconque cette liaison est perdue – veuillez suivre les directives ci-dessous :

Liaison de la télécommande à la hotte

1. Arrêtez le moteur de la hotte et éteignez l’éclairage.

2.Appuyez simultanément sur les boutons

et sur la télécommande pendant 5 secondes

jusqu’à ce que le voyant de la télécommande s’allume (Fig.3). Relâchez les boutons et

puis appuyez et relâchez le bouton pour con rmer la liaison. À ce stade, le voyant de la

télécommande commence à clignoter pour con rmer que la liaison est active.

3. Dans les 3 secondes, appuyez sur P2 sur le panneau de commande de la hotte (Fig.4). Le signal

sonore con rme que le processus de liaison a réussi.

PANNEAU DE COMMANDE DE LA HOTTE

TÉMOIN LUMI-

NEUX

ANNEAU

DEL L1

FIG. 3 FIG. 4

Fonctions de la télécommande (Fig.3)

Arrêt di éré

Bouton de réduction de la vitesse du

ventilateur et d’arrêt.

Bouton de mise en marche et d’augmentation de la vitesse du ventilateur

Éclairage

Appuyez sur (Arrêt di éré) et (Éclairage)

ensemble pour réinitialiser l’alarme de ltre.

ATTENTION IL Y A RISQUE D’EXPLOSION SI LA PILE EST

REMPLACÉE PAR LE MAUVAIS TYPE DE PILES. METTRE LES

PILES USÉES AU REBUT CONFORMÉMENT À LA RÉGLEMENTATION.

Mise au rebut des piles

Lorsque les piles doivent être remplacées, prenez soin de les déposer dans l’un des nombreux bacs de recyclage répartis au pays, particulièrement dans les magasins d’électronique. Le respect des normes en matière de

collecte sélective, particulièrement pour la mise au rebut des piles usées, contribue à éviter de possibles e ets

négatifs sur l’environnement et la santé.

IMPORTANT: Maintenez (Arrêt di éré)

pour plus de 3 secondes pour annuler la liaison

entre la hotte et la télécommande.

Pour de plus amples information sur chaque fonction, consultez la section “Commandes” à la page

précédente.

- 28 -

Page 29

NETTOYAGE ET ENTRETIEN

Un entretien approprié de votre appareil garantira une performance adéquate.

Moteur

Le moteur est lubri é à vie et aucun graissage n’est nécessaire. Si les roulements du moteur font

un bruit excessif ou inhabituel, remplacez le moteur par une pièce de rechange identique. Remplacez aussi la roue de ventilateur.

Filtres à graisses

Les ltres à graisses doivent être nettoyés souvent. Vous pouvez utiliser une solution détergente

chaude ou le mettre dans le lave-vaisselle.

Nettoyez tous les ltres métalliques dans le lave-vaisselle avec un détergent sans phosphate.

Si vous utilisez un détergent phosphaté ou selon le type d’eau, il est possible que le ltre

se décolore, mais cela n’a ectera aucunement ses performances. Cette décoloration n’est

pas couverte par la garantie. Consultez la section «INSTALLATION DES FILTRES» pour

connaître les instructions de retrait et d’installation.

Nettoyage de l’acier inoxydable

À FAIRE :

• nettoyez régulièrement l’acier inoxydable

avec un chi on ou un torchon enduit d’eau

tiède et de savon doux ou de liquide à vaisselle.

• nettoyez toujours dans le sens des lignes

de polissage d’origine.

• rincez toujours à l’eau claire (2 ou 3fois)

après le nettoyage. Essuyez complètement.

À éviter quand vous choisissez un détergent :

• tous les produits de nettoyage contenant de l’eau de Javel attaquent l’acier inoxydable.

• tous les produits contenant du chlore, du uorure, de l’iode ou du bromure provoquent une dété-

rioration rapide des surfaces.

• tous les produits combustibles utilisés pour le nettoyage, tels que l’acétone, l’alcool, l’éther, le

benzène sont extrêmement explosifs et ne doivent jamais être employés à proximité d’une surface

de cuisson.

À NE PAS FAIRE :

• n’utilisez pas de laine d’acier inoxydable

ou d’autres racloirs pour éliminer la saleté

di cile à éliminer.

• n’utilisez pas de poudre nettoyante abrasive

ou rugueuse.

• ne laissez pas la saleté s’accumuler.

• maintenez la hotte à l’abri de la poussière

de plâtre ou d’autres résidus de construction. Pendant la construction/les

rénovations, couvrez la hotte a n d’éviter

qu’aucune poussière n’adhère aux surfaces

en acier inoxydable.

- 29 -

Page 30

PRÉPARATION DE LA HOTTE

Déballez la hotte et véri ez le contenu de l’emballage.

Il doit comprendre :

1 - Hotte

1 - Télécommande

4 - Filtres à graisses

6 - Tire-fonds, 6 x 60 mm pour bois

6 - Rondelles

6 RONDELLES

6 TIRE-FONDS

(6 x 60 mm)

pour bois

BOÎTIER DE LA

HOTTE AVEC VOLET

TÉLÉCOMMANDE

4 FILTRES À

GRAISSES

L’installateur est responsable de la sélection des xations adaptées à la construction.

FIG. 5

- 30 -

Page 31

INSTALLER

LES

CONDUITS

CAPU-

REMARQUE:

CHON DE

pour réduire les

risques d’incendie,

utilisez uniquement

des conduits de métal.

CONDUIT ROND DE

25,4 CM (10 PO) ou

20CM (8po)

1. Décidez de

l’emplacement des

conduits entre la

hotte et l’extérieur.

Fig. 6.

2. Un tracé droit et

court permet à la

hotte d’être plus ef-

HOTTE

121,9 CM (48 PO) À 183 CM (72

PO) AU-DESSUS DE LA SURFACE

DE CUISSON

cace. Pour des performances optimales,

il est recommandé

d’avoir un conduit

droit de 18 à 24 po

avant d’utiliser un

coude.

3. Des conduits longs, des coudes et des transitions réduisent son e cacité. En utiliser le moins possible. Pour plus d’e cacité, des conduits plus gros peuvent être nécessaires si le tracé est trop long.

4. Installez un capuchon mural ou de toit, ou un évent d’avant-toit. Connectez le conduit de métal

au capuchon ou évent en progressant vers la hotte. Scellez les joints avec du ruban à conduit à

chaque section.

5. L’orientation du ventilateur sur le modèle CC34IQ63SB peut être changée selon l’emplacement

de la sortie. Voir Fig. 7 pour les dimensions de la sortie d’air.

TOIT

CONDUIT

ROND DE

25,4 CM (10

PO) ou 20

CM (8po)

RÉDUCTEUR

25,4 CM (10 PO)

ROND À 8,3 X

35,6 CM (3¼ X

14 PO)

ÉVENT D’AVANT-

TOIT 8,3 X 35,6 CM

(3¼ X 14 PO)

CETTE INSTALLATION

N’EST PAS

RECOMMANDÉE POUR

CC34IQT63SB

FIG. 6

6-7/8””

(17,5 cm

- 31 -

CC34IQ63SB: CONDUIT 8”

CC34IQT63SB: CONDUIT 10”

9-1/8” (23,2 cm)

FIG. 7

Page 32

Pour le mode recirculation, acheter le KIT ANKCC3463 séparément (En option seulement pour le

modèle CC34IQ63SB). Fig.8

CONDUIT ROND DE

20CM (8po)

HOTTE

121,9 CM (48 PO) À 183 CM (72

PO) AU-DESSUS DE LA SURFACE

DE CUISSON

FIG. 8

- 32 -

Page 33

PRÉPARATION DE

!

L’OUVERTURE AU PLAFOND

La hotte doit être centrée au-dessus de la surface

de cuisson. Assurez-vous d’un espace adéquat

dans la structure du plafond pour l’installation de

la hotte et des conduits. Pour mieux capter les

vapeurs de cuisson, la hotte doit être installée de

122 cm (48 po) à 183 cm (72 po) au-dessus de la

cuisinière. (Fig. 6).

Utilisez du bois de la taille des solives pour fabriquer une charpente autour de l’ouverture de la

hotte. Fig.9

La structure du plafond doit être capable de

supporter le poids de la hotte.

Modèle CC34IQ63SB: 105 livres (48Kg).

Modèle CC34IQT63SB: 121 livres (55Kg).

min. 39 cm (15-3/8 po)

max. 59.3 cm (23-3/8 po)

CHEVÊTRES DOUBLES

PRÉPARATION DU SUPPORT

DE LA HOTTE

1. Construisez une charpente, tel qu’illustré à la

Fig. 11.

2. La structure doit être capable de supporter son

propre poids et celui de la hotte.

65,2 cm

(25-11/16 po)

156.7 cm

(61-516 po)

Pour la version en recirculation:

Faire un’ouverture sur le plafond pour la partie

de retour d’air. Voir Fig. 10 et Fig.24.

9-13/16” (25cm)

9-13/16” (25cm)

FIG. 9

FIG. 10

- 33 -

AVANT TROU DE

3 mm (1/8 po) (6)

FIG.11

Page 34

INSTALLATION DE LA HOTTE

!

ATTENTION : Il est recommandé d’avoir

plusieurs d’installateurs, compte tenu de la

taille et du poids de cette hotte.

1. La hotte est livrée de manière à recevoir un

conduit de sortie en position horizontale et

est prête à installer (Fig.12).

Seulement pour le modèle CC34IQ63SB (1

moteur):

Pour modi er la direction du conduit sans

utiliser de coudes:

• Enlevez (4) vis du collet d’évacuation (Fig.13).

• Enlevez (2) vis à l’intérieur du boîtier du ventilateur (Fig.14).

• Enlevez (4) vis des côtés du boîtier du ventilateur (Fig.15).

• Enlevez (10) vis sur le boîtier du ventilateur

(Fig. 16).

FIG.12

FIG.13

FIG.14

FIG.16FIG.15

- 34 -

Page 35

• Tournez le ventilateur de 90 degrés et réin-

!

stallez (2) vis (Fig.17). Réinstallez les couvercle

du boîtier, le clapet et les vis.

2. Ajustez la hauteur des cadres de soutien téle-

scopiques et serrures a les vis et rondelles

(Fig. 18).

Attention: Ajustez la hauteur avant

l’installation.

3. Soulevez la hotte dans l’ouverture du

plafond.

4. Fixez chaque cadre de soutien de la hotte à

la charpente de bois à l’aide des (6) tire-fonds

de 6 x 60 mm et rondelles fournis. Fig. 19.

5. Installez le conduit et scellez les joints avec

du ruban à conduit.

FIG.17

FIG.18

CADRE DE 2X4

EN BOIS

(6) TIRE-FONDS

ET RONDELLES

FIG.19

- 35 -

Page 36

RACCORD DU CÂBLAGE

AVERTISSEMENT : Les travaux

d’électricité doivent être effectués par des

personnes qualifi ées en respectant les codes et

les normes en vigueur. Cette hotte de cuisine doit

être correctement mise à la terre.

1. Enlevez les (2) vis du couvercle du compartiment

électrique Fig. 20.

2. Amener un câble électrique 120 VCA à deux ls

plus un l de mise à la terre près de l’ouverture

préamorcée de 3/4 po située à l’arrière de la

hotte. Fig. 21.

3. Enlevez l’ouverture préamorcée de 19 mm

(3/4 po) à l’arrière de la hotte.

4. Dans le boîtier électrique où il est écrit

«ENTRÉE 120 VCA », enlevez les deux (2) vis qui

retiennent le couvercle à la boîte métallique

de câblage. Fig. 22.

5. Passer le câble 120 VCA dans le boîtier et le xer

à l’aide d’un serre-câble approprié.

6. Effectuez les connexions électriques à

l’intérieur du boîtier. Branchez les ls blancs

ensemble, les ls noirs ensemble et le l vert

avec le l de terre.

7. Replacez le couvercle du boîtier de câblage et

les vis. Replacez le couvercle du compartiment

électrique et les vis. Assurez-vous qu’aucun

des câbles n’est coincé entre le couvercle et

le boîtier.

CÂBLE 120 VCA

À DEUX FILS ET

FIL DE TERRE

OUVERTURES

PRÉAMORCÉES

CONNEXION

BLANC AVEC BLANC

NOIR AVEC NOIR

VERT AVEC FIL DE TERRE

COUVERCLE DU

COMPARTIMENT

ÉLECTRIQUE

ENTRÉE 120

VCA 60 Hz

FIG. 20

FIG. 21

- 36 -

BOÎTIER OÙ IL EST

ÉCRIT «ENTRÉE 120

VCA»

FIG. 22

Page 37

CLAPET D’AIR DE COMPENSATION

ATTENTION: La hotte est compatible seulement avec le Clapet d’air de compensation Broan

modèle MD8T (pour CC34IQ63SB) ou MD10T (pour CC34IQT63SB), vendu séparément.

Connectez le clapet d’air de compensation avec des ls de basse tension, tel qu’illustré. Pour de plus

amples renseignements, consultez les directives du clapet d’air de compensation. Fig. 23

FIG.23

INSTALLER LA SECTION POUR LE RETOUR D’AIR VERSION EN

RECIRCULATION

Acheter le kit de recirculation ANKCC3463, vendu séparément (en option seulement pour le modèle

CC34IQ63SB). Le kit comprend la section pour le retour d’air et les ltres à charbon.

Fixer la partie pour le retour d’air sur le plafond en utilisant (4) vis de montage 4,2x15mm. Voir Fig. 24

PLAFOND

(4) VIS DE MONTAGE

4,2x15mm

FIG.24

- 37 -

Page 38

INSTALLATION DE FILTRES

À RECIRCULATION

(SEULEMENT POUR HOTTE

EN RECIRCULATION)

Les ltres à recirculation sont inclus dans

le kit ANKCC3463. Achetez des filtres de

recirculation (AFCCC3463) séparément.

Placer le ltre de recirculation à l’extérieur

du ltre à graisses et le bloquer à l’aide de (4)

dispositifs de retenue. Voir g.25.

Le Kit et le ltre de recirculation sont en option

seulement pour le modèle CC34IQ63SB.

INSTALLATION DES FILTRES

1. Pour installer les ltres à graisses, alignez les

languettes arrière des ltres dans les fentes

de la hotte. Enfoncez la languette métallique, poussez le ltre en place et relâchez la

languette. Véri ez si le ltre est bien xé une

fois replacé. Fig.26.

2. Pour enlever les ltres pour le nettoyage,

enfoncez la languette métallique a n de

dégager les ltres de la hotte. Inclinez le ltre

vers le bas et enlevez-le.

NOTE: Retirez le lm protecteur des ltres à

graisse et de toutes les pièces en acier avant

de cuire sous la hotte.

FIG. 25

FIG. 26

- 38 -

Page 39

CALIBRER LE VENTILATEUR

MC

MC

MC

IQ

Une fois la hotte installée et connectée,

enclenchez le processus de calibrage (notre

Technologie de performance garantie s’assure

que le débit d’air optimal sera émis). Avant le

calibrage, assurez-vous que les ltres, les ampoules d’éclairage et les conduits sont installés.

CALIBRAGE Fig. 27

Maintenez le bouton de calibrage pendant

3 secondes; le bouton s’allumera jusqu’à 13

minutes. Le ventilateur se met en marche et

le calibrage commence. Une fois le calibrage

terminé, il y a deux possibilités :

1.Le ventilateur s’arrête et la lumière du bouton

de calibrage reste allumée = Calibrage réussi. Appuyez sur le bouton pour éteindre la DEL.

Remarque : La DEL s’éteindra aussi si vous sélectionnez n’importe quelle vitesse de ventilateur à

l’aide de la commande.

2.Le ventilateur s’arrête et la lumière du bouton de calibrage clignote continuellement =Trop de

restriction dans le conduit empêchant le ventilateur IQ

ventilateur se règle automatiquement à l’intensité maximale.

REMARQUE : Les causes les plus courantes de restriction sont : un clapet coincé (clapet antirefoulement, capuchon mural, capuchon de toit), un trop grand nombre de coudes, un conduit

dont la dimension est 80 % inférieure à la sortie de la hotte, une mauvaise transition, l’utilisation

de conduit exible et/ou un conduit écrasé.

Trois options s’o rent à vous si le débit de votre hotte est soumis à une restriction trop

importante :

1. Accepter le débit tel quel.

a. Appuyez sur le bouton de calibrage pour accepter le débit d’air tel quel. Le ventilateur IQ

est maintenant con guré au meilleur rendement possible. Le témoin de calibrage clignotant

s’éteint. Remarque : La DEL s’éteindra aussi si vous sélectionnez n’importe quelle vitesse de

ventilateur à l’aide de la commande.

2. Corriger la restriction, e acer les données du calibrage original et recommencer le

calibrage.

a. Corrigez la restriction dans le conduit.

b. E acez les données du calibrage original en maintenant le bouton de calibrage pen-

dant 10 secondes. Le témoin clignotera 3 fois pour con rmer et le ventilateur retournera

aux paramètres par défaut.

c. Recommencez le calibrage depuis le début.

3. E acer les données de calibrage pour rétablir les paramètres par défaut de la hotte et

obtenir le rendement standard à haute pression du ventilateur.

a. E acez les données de calibrage pour rétablir les paramètres par défaut de la hotte

en maintenant le bouton de calibrage pendant 10 secondes. Le témoin clignotera 3 fois

pour con rmer et le ventilateur retournera aux paramètres par défaut.

TEMOIN DE

CALIBRAGE

BOUTON DE

CALIBRAGE

MC

d’atteindre le débit d’air nominal. Le

FIG. 27

MC

- 39 -

Page 40

Garantie limitée

Période de garantie et exclusions : Broan-NuTone LLC (l’« entreprise ») garantit au consommateur qui achète son produit (« vous »)

que le produit (le « produit ») restera exempt de défauts importants dans ses composants ou sa fabrication pendant une période de cinq

(5) ans à compter de la date de l’achat initial (ou pour une période plus longue si la loi en vigueur l’exige) ou une période de deux (2) ans

à compter de la date de la prestation d’un service sur le produit.

La garantie limitéedes pièces de rechange fournies par l’entreprise et de tout produit réparé ou remplacé en vertu de cette garantie est

valide pour la durée non écoulée de la période de garantie initiale (ou d’une période plus longue si la loi en vigueur l’exige).

LA PRÉSENTE GARANTIE NE S’APPLIQUE PAS AUX DÉMARREURS DE LAMPE FLUORESCENTE, NI AUXTUBES, AMPOULES,

FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE TOIT, CAPUCHONS MURAUX ET AUX AUTRES ACCESSOIRES POUR CONDUITS.Cette garantie exclut : a) l’entretien normal, b) l’usure normale, c) les produits et les pièces ayant fait l’objet d’une utilisation mauvaise,

abusive ou anormale, d’une négligence, d’un accident, d’un entretien ou d’un entreposage, d’une réparation ou d’un entretien inadéquats

ou insuffi sants (sauf s’il s’agit d’une réparation eff ectuée par l’entreprise), d) les dommages attribuables à une installation incorrecte ou à

une installation ou utilisation contraires aux recommandations ou aux instructions, e) les dommages attribuables au contact de l’air salin, f)

les dommages survenus durant le transport, g) l’usure normale de la fi nition, h) les produits d’utilisation commerciale ou non résidentielle, i)

les dommages causés par le feu, une inondation ou une autre catastrophe naturelle, ou j) les produits dont le numéro de série a été altéré

ou eff acé. Cette garantie ne s’applique qu’aux produits vendus aux consommateurs en Amérique du Nord.

La présente garantie remplace les garanties précédentes et, sous réserve de la loi applicable, n’est pas transférable par l’acheteur initial.

Aucune autre garantie : La présente garantie limitée énonce l’unique obligation de l’entreprise et votre seul recours pour les produits

défectueux. Les garanties qui précèdent sont exclusives et l’emportent sur les autres garanties et modalités, expresses ou implicites.

DANS TOUTE LA MESURE PERMISE PAR LA LOI EN VIGUEUR, L’ENTREPRISE SE DÉGAGE DES AUTRES GARANTIES ET MODALITÉS EXPRESSES ET DES GARANTIES ETMODALITÉS IMPLICITES EN VERTU DE LA LOI, Y COMPRIS, SANS S’Y LIMITER,

LES GARANTIES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN USAGE PARTICULIER. Dans la mesure où la loi applicable

interdit l’exclusion des garanties ou modalités implicites, la durée d’une garantie ou modalité implicite applicableest restreinte à la période

indiquée pour la garantie expresse ci-dessus. Certains territoires de compétence (ce qui peut inclure la province de Québec ou certains

États des États-Unis) interdisent les limites à la durée des garanties implicites; la restriction susmentionnée pourrait donc ne pas s’appliquer

à vous. Les descriptions orales ou écrites du produit ont pour seul objet d’indiquer les produits et ne sauraient être interprétées dans le

sens d’une garantie expresse.

Autant que possible, chaque disposition de cette garantie limitée est interprétée de sorte qu’elle soit valide sous le régime de la loi applicable,

mais si l’une de ses dispositions est déclarée interdite ou nulle, cette disposition n’est nulle que dans la mesure de cette interdiction ou

nullité, et les autres éléments de cette disposition ainsi que les autres dispositions de la garantie limitée restent valides.

Recours : Durant la période de la garantie limitée applicable, l’entreprise fournira, à son choix, des pièces de rechange ou des services

de réparation ou de remplacement sans frais pour tout produit ou toute pièce de produit, dans la mesure où l’entreprise constate que la

présente garantie limitée s’applique à ce produit ou à cette pièce dans le contexte d’une utilisation et d’un entretien normaux.L’entreprise

vous expédiera le produit réparé, son remplacement ou les pièces de rechange sans frais. Vous assumez la totalité des coûts de mise

hors service, de réinstallation, d’expédition etd’assurance et les autres frais de transport associés à la livraison du produit ou de la pièce à

l’entreprise. Si vous devez envoyer le produit ou la pièce à l’entreprise, conformément à ses instructions, vous devez emballer adéquatement le produit ou la pièce; l’entreprise n’est pas responsable des dommages survenus durant le transport. L’entreprise se réserve le droit

d’utiliser des produits ou pièces remis à neuf, réparés ou remanufacturés aux fi ns de réparation ou de remplacement dans le cadre de la

garantie. Ces produits et ces pièces seront comparablesquant à la fonction et aux performancesavec les produits ou pièces d’origine, et

protégés par une garantie pour la durée restante de la période de garantie initiale (ou d’une période plus longue si la loi en vigueur l’exige).

L’entreprise se réserve le droit, à son entière discrétion, de rembourser le montant que vous avez eff ectivement payé pour le produit. Si le

produit ou la pièce n’est plus disponible, elle peut le ou la remplacer par un produit similaire de valeur égale ou supérieure, à son entière

discrétion. Ceci constitue votre seul recours advenant un non-respect de la présente garantie limitée.

Exclusion des dommages :L’OBLIGATION DE L’ENTREPRISE DE FOURNIR DES PIÈCES DE RECHANGE, OU DE RÉPARER OU

REMPLACER LE PRODUIT, À SON CHOIX, EST VOTRE SEUL RECOURS EN VERTU DE LA PRÉSENTE GARANTIE LIMITÉE ET

L’UNIQUE OBLIGATION DE L’ENTREPRISE. CETTE DERNIÈRE N’EST PAS RESPONSABLE DES DOMMAGES INDIRECTS OU

SPÉCIAUX DÉCOULANT DIRECTEMENT OU INDIRECTEMENT DU PRODUIT, DE SON UTILISATION OU DE SES PERFORMANCES.

Certains territoires de compétence interdisent l’exclusion ou la restriction des dommages indirects; la restriction qui précède pourrait donc

ne pas s’appliquer à vous. Cette garantie vous donne des droits spécifi ques, et vous pourriez aussi avoir d’autres droits, qui varient selon

le territoire de compétence. Les renonciations, exclusions et restrictions de responsabilité aux termes de cette garantie ne s’appliquent

pas dans la mesure où la loi en vigueurinterdit une telle application.

La présente garantie ne s’applique qu’au remplacement ou à la réparation de produits ou pièces de produit défectueux eff ectué au principal

lieu d’aff aires de l’entreprise, et exclut les frais de déplacement et de subsistance liés aux services fournis sur le terrain.

Tout soutien que l’entreprise vous fournit ou vous procure et qui n’est pas visé par les dispositions, limites ou exclusions de la présente

garantie limitée ne constitue pas une renonciation à ces dispositions, limites ou exclusions, et la fourniture de ce soutien ne prolonge ni

ne rétablit la garantie.

L’entreprise ne vous remboursera pas vos dépenses faites pour la réparation ou le remplacement d’un produit défectueux, sauf celles pour

lesquelles vous avez obtenu le consentement écrit de l’entreprise.

Comment obtenir le service de garantie : Pour avoir droit au service de garantie, vous devez : a) aviser l’entreprise à l’adresse ou au

numéro de téléphone indiqué ci-dessous dans les sept (7) jours qui suivent la date où vous avez eu connaissance de la défectuosité couverte, b) indiquer le numéro de modèle et les données d’identifi cation de la pièce, et c) décrire la nature de toute défectuosité du produit ou

de la pièce. Au moment où vous demandez le service de garantie, vous devez présenter une preuve de la date de l’achat initial. Si vous ne

pouvez pas produire de copie de l’original de la garantie limitée, alors ce seront les modalités de la dernière version de la garantie limitée

de votre produit de l’entreprise qui s’appliqueront.

- 40 -

Page 41

SPÉCIFICATIONS DU PRODUIT

Toutes les illustrations et les spécifi cations des produits contenues dans ce catalogue sont établies d’après les plus récentes donnéesdisponibles en date de la production. Broan-NuTone LLC et BESTᴹᴰ se réservent le droitde modifi erles prix, les couleurs, les composants,

les produits, les spécifi cations et les modèles, de déplacer le lieu de fabrication et de cesser la production d’un modèle ou d’un produit, et

ce, en tout temps et sans préavis.

Best

Broan-NuTone LLC : 926 W. State Street, Hartford (WI) 53207

1 800 637-1453

Bestᴹᴰ, 550, boul. Lemire, Drummondville (Québec), Canada (1 866 737-7770) fr.bestrangehoods.ca

- 41 -

Page 42

PIÈCES DE RECHANGE

Modèle CC34IQ63SB

REPÈRE N° DE PIÈCE DESCRIPTION

1 B003103711 CADRE

9 B08087836 FILTRE À GRAISSES

26 B023004301 DEL

115 BE3350233 BOÎ TIER DE CONNEXION DU CÂBLE D’ALIMENTATION

343 B08094449 COUVERCLE DU COMPARTIMENT ELECTRIQUE

362 B02011422 AIMANT

477 B02011376 CHARNIERE

506 B08080878 CARTE BLDC

507 B06102584 BOUTON DE CALIBRAGE

508 B02301083 CÂBLE COMMANDES

511 B06102814 ENSEMBLE COMMANDES

998 B080810962 ENSEMBLE DE FIXATION

999 B080814337 ENSEMBLE DE DIRECTIVES D’INSTALLATION

CAS B06002259 ENSEMBLE MOTEUR

IME B06102805 ENSEMBLE D’INSTALLATION ÉLECTRIQUE

AQI B06102812 ENSEMBLE DE BOÎTIER COMMANDES

ARU B08092501 ENSEMBLE RACCORD

ACR3 B08999186 TÉLÉCOMMANDE

- B902980139 FILTRES À RECIRCULATION

Modèle CC34IQT63SB

REPÈRE N° DE PIÈCE DESCRIPTION

1 B003103711 CADRE

9 B08087836 FILTRE À GRAISSES

26 B023004301 DEL

115 BE3350233 BOÎ TIER DE CONNEXION DU CÂBLE D’ALIMENTATION

343 B08094449 COUVERCLE DU COMPARTIMENT ELECTRIQUE

362 B02011422 AIMANT

477 B02011376 CHARNIERE

506 B08080879 CARTE BLDC

507 B06102584 BOUTON DE CALIBRAGE

508 B02301083 CÂBLE COMMANDES

511 B06102806 ENSEMBLE COMMANDES

998 B080810962 ENSEMBLE DE FIXATION

999 B080814337 ENSEMBLE DE DIRECTIVES D’INSTALLATION

CAS B06002259 ENSEMBLE MOTEUR

IME B06102805 ENSEMBLE D’INSTALLATION ÉLECTRIQUE

AQI B06102812 ENSEMBLE DE BOÎTIER COMMANDES

ARU B02011533 ENSEMBLE RACCORD

ACR3 B08999186 TÉLÉCOMMANDE

- 42 -

Page 43

PIÈCES DE RECHANGE

Modèle

CC34IQ63SB

CC34IQT63SB

- 43 -

Page 44

- 44 -

Page 45

Modelo CC34IQ63SB

CC34IQT63SB

ENGLISH........................................3

FRANÇAIS...................................23

ESPAÑOL.....................................45

En EE.UU.: BEST Hartford, Wisconsin

En CANADÁ - BEST Drummondville, QC, Canada

REGISTRE SU PRODUCTO EN LÍNEA EN: www.BestRangeHoods.com/register

Para obtener información adicional visite www.BestRangeHoods.com

- 45 -

Page 46

LEA Y CONSERVE ESTAS INSTRUCCIONES

!

!

PARA COCINAS DOMÉSTICAS SOLAMENTE

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS ELÉCTRICAS O LESIONES

PERSONALES, RESPETE LO SIGUIENTE:

1. Utilice esta unidad sólo de la manera prevista por el fabricante. Si tiene preguntas, comu-

níquese con el fabricante a la dirección o el número de teléfono que aparecen en la garantía.

2. Antes de realizar el mantenimiento de la unidad o de limpiarla, desconecte la energía en el

panel de servicio y bloquéelo para evitar conectar la energía accidentalmente. Cuando no se

pueda bloquear el mecanismo de desconexión, je rmemente un dispositivo de advertencia

que se destaque, como una etiqueta, en el panel de servicio.

3. Una persona capacitada debe realizar el trabajo de instalación y el cableado eléctrico con-

forme a los códigos y estándares correspondientes, incluidos los códigos y estándares de

construcción de resistencia al fuego.

4. Es necesario que haya su ciente aire para que se produzca una combustión adecuada y los

gases de los equipos que consumen combustible se puedan evacuar a través del conducto

de humo (chimenea) para evitar el contratiraje. Siga las directrices y las normas de seguridad del fabricante del equipo de calefacción como las publicadas por la Asociación Nacional

de Protec-ción contra Incendios (National Fire Protection Association, NFPA) y la Sociedad

Americana de Ingenieros en Calefacción, Refrigeración y Aire Acondicionado (American Society for Heating, Refrigeration and Air Conditioning Engineers, ASHRAE) y las autoridades

de códigos locales.

5. Cuando realice cortes o perforaciones en paredes o techos, no dañe el cableado eléctrico ni

otros servicios públicos ocultos.

6. Los ventiladores entubados siempre deben ventilarse hacia el exterior.

7. No utilice esta unidad con un dispositivo de control de velocidad de estado sólido independi-

ente.

8. Para reducir el riesgo de incendios, sólo utilice entubados de metal.

9. Este artefacto se debe conectar a tierra.

10. Instalación del tipo que no es IC: El aislamiento térmico no debe cubrir la cubierta superior

de la campana y debe estar separado 3 pulgadas (76 mm) de todos los lados. (Fig. 1)

MÍNIMO DE 3 PULG. (76 MM).

SIN AISLAMIENTO DENTRO DE ESTA ZONA

SOMBREADA DE COMPONENTES

FIG. 1

- 46 -

Page 47

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO POR GRASA PRESENTE EN LA

!

ESTUFA:

A. Nunca deje desatendidas las unidades de la super cie cuando estén en ajustes altos de calor.

Los alimentos en ebullición provocan derrames grasosos y con humo que se pueden incendiar.

Caliente el aceite lentamente en ajustes de calor bajo o medio.

B. Siempre ENCIENDA la campana cuando esté cocinando a altas temperaturas o amee alimentos

(por ejemplo crepas Suzette, cerezas Jubilee, bistec con pimienta ameado).

C. Limpie frecuentemente los ventiladores. No permita la acumulación de grasa en el ventilador

ni en el ltro.

D. Use una cacerola del tamaño adecuado. Siempre use utensilios de cocina que sean apropiados

para el tamaño del elemento de la super cie.

PARA REDUCIR EL RIESGO DE LESIONES A LAS PERSONAS EN CASO DE UN INCENDIO

PRODUCIDO POR GRASA EN UNA ESTUFA, OBSERVE LO SIGUIENTE*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una charola para galletas o una bandeja

de metal, y después apague el quemador. PROCEDA CON CUIDADO PARA EVITAR QUEMADURAS. Si las llamas no se apagan inmediatamente, EVACUE EL ÁREA Y LLAME A

LOS BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA porque podría ocasionarse quemaduras.

3. NO TRATE DE APAGAR EL FUEGO CON AGUA ni con trapos o toallas de cocina mojados,

pues ocasionará una explosión violenta de vapor.

4. Use un extintor SOLO si:

A. El extintor es de Clase ABC y usted sabe cómo hacerlo funcionar.

B. El incendio es pequeño y está con nado al área en la que se inició.

C. Se está llamando al Departamento de Bomberos.

D. Puede combatir el incendio teniendo la espalda orientada hacia una salida.

* Basado en “Kitchen Fire Safety Tips” (Sugerencias para la seguridad contra incendios en la

cocina).

PRECAUCIÓN

1. Solo debe usarse bajo techo.

2. Para reducir el riesgo de incendio y para descargar adecuadamente el aire, asegúrese de dirigir

el aire hacia el exterior. No descargue el aire en espacios contenidos entre paredes o cielos

rasos, ni en áticos, sótanos bajos ni en la cochera.

3. Tenga cuidado cuando use agentes de limpieza o detergentes.

4. Evite usar bajo la campana de la estufa productos alimenticios que produzcan llamas.

5. Solo para usarse como medio de ventilación general. No debe usarse para la extracción de

materiales o vapores peligrosos o explosivos.

6. Para evitar daños a los cojinetes del motor y rotores ruidosos o desbalanceados, mantenga la

unidad de potencia protegida contra rociados de yeso, polvos de construcción, etc.

7. Este motor de campana tiene una protección contra sobrecargas térmicas que automáticamente

apagará el motor en caso de sobrecalentamiento. El motor reanudará su funcionamiento

cuando se enfríe. Si el motor continúa apagándose y encendiéndose, solicite servicio para

la campana.

8. Para capturar mejor las impurezas producidas al cocinar, la parte inferior de la campana debe estar a

una altura mínima de 48 pulg. (121,9 cm) y máxima de 72 pulg. (183 cm) sobre la super cie de cocinado. Consulte el apartado “Instalación del soporte de montaje” para ver las restricciones de montaje.

9. Se recomienda que mas personas hagan la instalación debido al gran tamaño y peso de esta campana.

10. Lea la etiqueta de especi caciones del producto para ver información y requisitos adicionales.

11. Este grupo de alimentación está equipado con un receptor de RF (control remoto opcional se vende

por separado). Los cambios o modi caciones no aprobadas expresamente por la parte responsable

del cumplimiento podrían anular la autoridad del usuario para operar el equipo. Este control remoto

ha sido probado y cumple con los límites establecidos para un dispositivo digital de clase B, acorde a

la parte 15 del Reglamento de la FCC e ICES-003 canadiense. Estos límites están diseñados para proporcionar una protección razonable contra interferencias perjudiciales en una instalación residencial.

Este control remoto genera, utiliza y puede irradiar energía de radiofrecuencia y, si no se instala y

utiliza de acuerdo con las instrucciones, puede causar interferencias perjudiciales a las comunicaciones

por radio. Sin embargo, no hay garantía de que no se produzcan interferencias en una instalación

particular. Si este equipo causa interferencias perjudiciales para la recepción de radio o televisión, lo

cual puede determinarse apagando y encendiendo el equipo, se recomienda al usuario que intente

corregir la interferencia por una o varias de las siguientes medidas:

• Reoriente o cambie la localización de la antena receptora

- 47 -

Page 48

• Aumentar la distancia entre el equipo y el receptor

!

!

• Conecte el equipo en un tomacorriente localizado en un circuito diferente al que está conectado

el receptor.

- 48 -

Page 49

FUNCIONAMIENTO