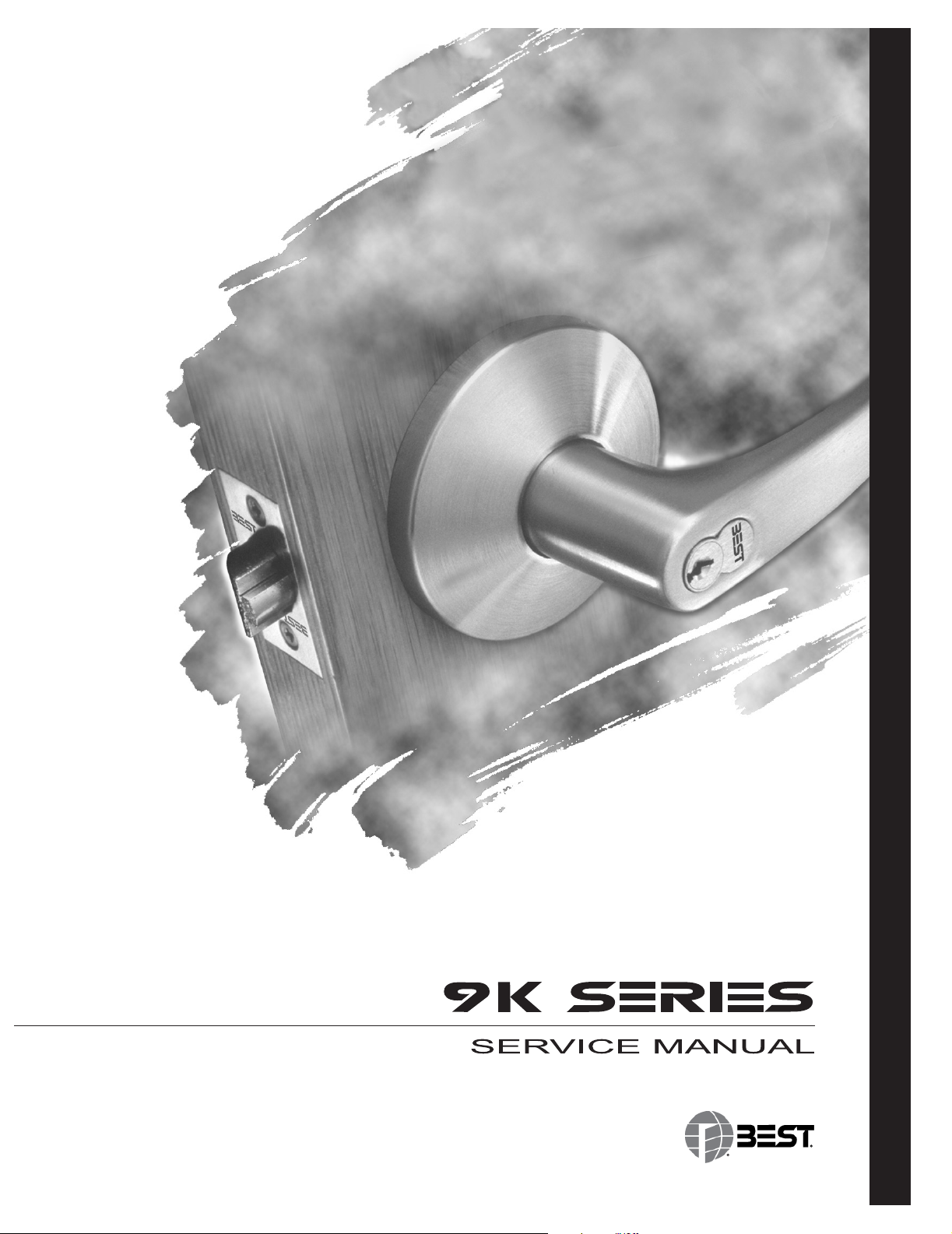

Best 9K Service Manual

SERVICE MANUAL

CREDITS/COPYRIGHT

Copyright

the United States of America.

Information in this document is subject to change without notice and does not

represent a commitment on the part of BEST Access Solutions, Inc. The software

described in this document is furnished under a license agreement or nondisclosure

agreement.

This publication is intended to be an accurate description and set of instructions

pertaining to its subject matter. However, as with any publication of this complexity,

errors or omissions are possible. Please call your BEST distributor or BEST Access

Solutions, Inc. (317) 849-2250, if you see any errors or have any questions. No part of

this manual and/or databases may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying, recording, or information

storage and retrieval systems, for any purpose, without the express written permission

of BEST Access Solutions, Inc.

This document is distributed as is, without warranty of any kind, either express or

implied, respecting the contents of this book, including but not limited to implied

warranties for the publication’s quality, performance, merchantability, or fitness for

any particular purpose. Neither BEST Access Solutions, Inc., nor its dealers or

distributors shall be liable to the user or any other person or entity with respect to

any liability, loss, or damage caused or alleged to be caused directly or indirectly by

this publication.

The Life Safety Code is a registered trademark of the National Fire Protection

Association.

Written and designed by BEST Access Solutions, Inc. and Avalon Group, Inc.,

Indianapolis, Indiana.

T56082 Rev D 1798144 ER-7991-6 March 2018

©

2000-2018 BEST Access Solutions, Inc. All rights reserved. Printed in

CONTENTS

FIGURES VII

GETTING STARTED 1–1

Introduction 1–1

Certifications and standards 1–2

9K Series Locks 1–2

Electrified Locks 1–2

Accessories 1–2

Documentation package 1–3

Technical support 1–4

Support services 1–4

Telephone technical support 1–4

Training seminars 1–4

FUNCTIONS AND PARTS LISTS 2–1

Function descriptions 2–2

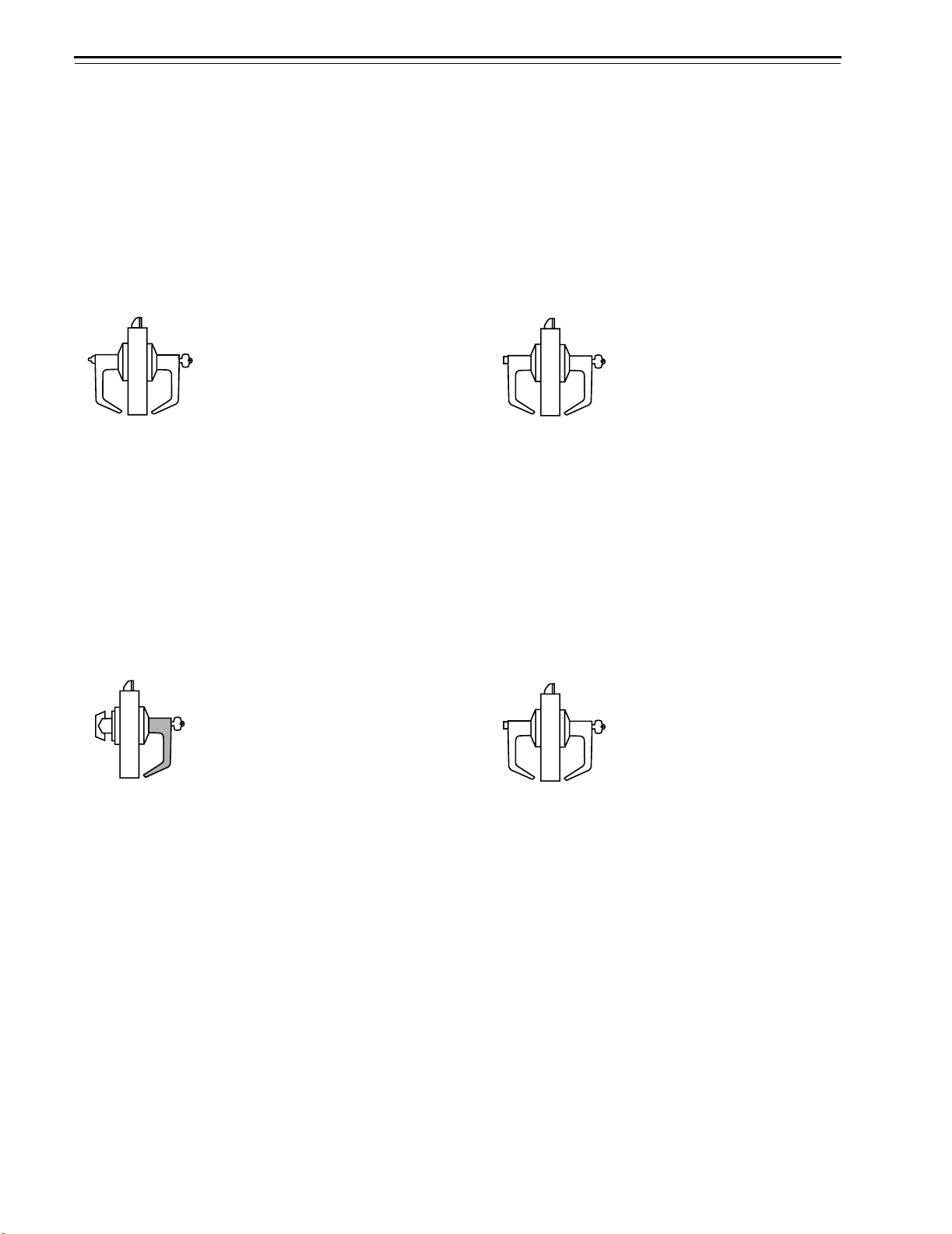

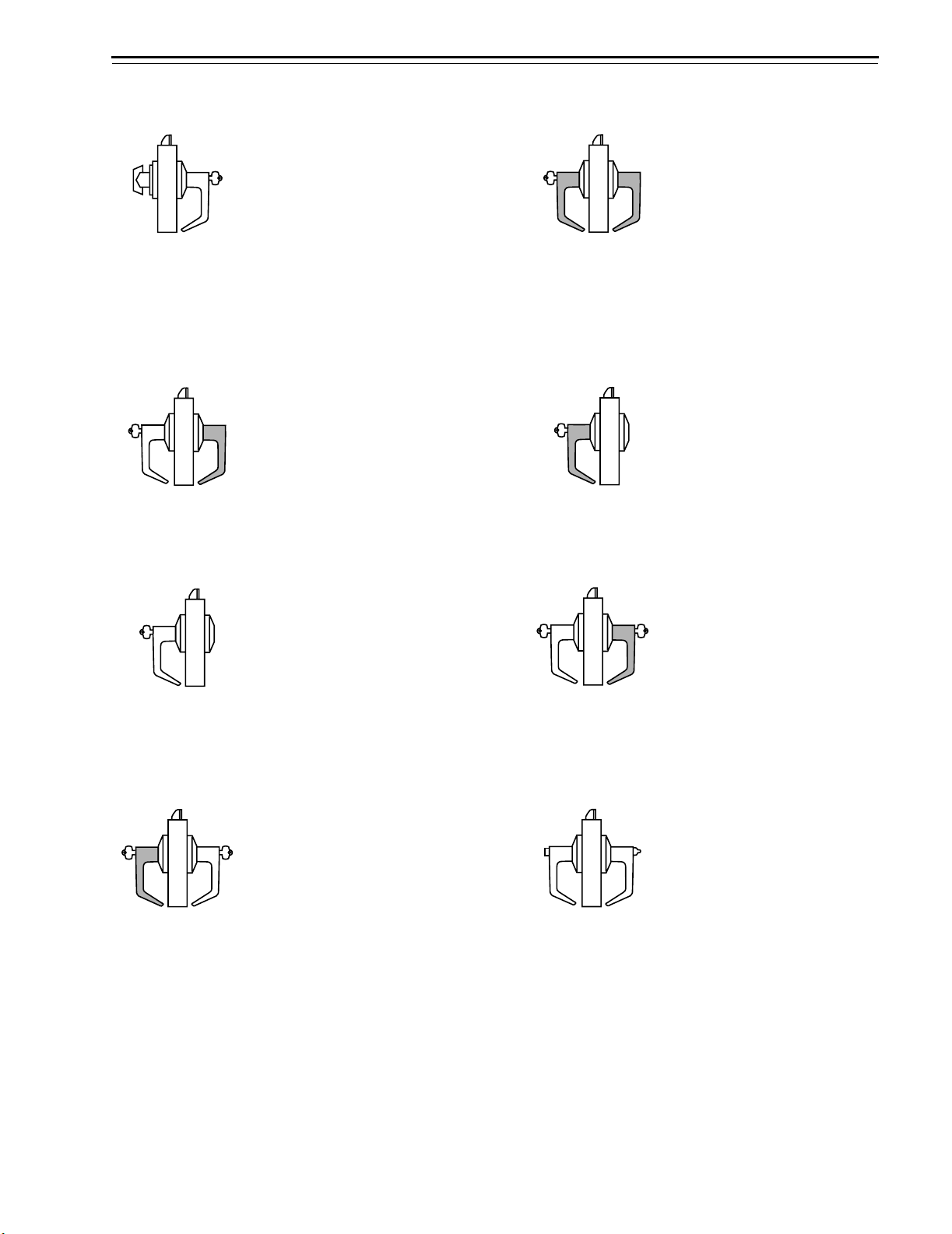

Single-keyed functions 2–3

Double-keyed functions 2–5

Non-keyed functions 2–7

Special functions 2–8

Electrified cylindrical functions 2–11

Functions by ANSI designation 2–11

Standard functions 2–12

AB function chassis—entrance lock (ANSI F109) 2–12

C function chassis—corridor lock (ANSI F88) 2–13

D function chassis—storeroom lock (ANSI F86) 2–14

E function chassis—service station lock (ANSI F92) 2–15

G function chassis—storeroom lock (ANSI F91) 2–16

9K Series Service Manual iii

Contents

H function chassis—hotel guest room lock with indicator

F93) 2–17

(ANSI

HJ function chassis—hotel guest room lock without indicator 2–17

L function chassis—privacy lock (ANSI F76) 2–18

N function chassis—passage lock (ANSI F75) 2–19

NX function chassis—exit lock (ANSI F89) 2–20

P function chassis—patio lock (ANSI F77) 2–21

R function chassis—classroom lock (ANSI F84) 2–22

S function chassis—communicating lock (ANSI F80) 2–23

T function chassis—dormitory lock (ANSI F90) 2–24

W function chassis—utility or institutional lock (ANSI F87) 2–25

Y function chassis—exit lock 2–26

Non-standard functions 2–27

A function chassis—entrance lock (ANSI F81) 2–27

B function chassis—office lock (ANSI F82) 2–28

DR function chassis—special lock 2–29

DZ function chassis—closet or storeroom lock 2–30

EA function chassis—entrance or office lock 2–31

IN function chassis—intruder lock 2–32

LL function chassis—hospital privacy lock 2–33

M function chassis—communicating lock (ANSI F78) 2–34

Q function chassis—exit lock (ANSI F83) 2–35

RD function chassis—special lock 2–36

RZ function chassis—closet or storeroom lock 2–37

XD function chassis—special lock 2–38

XR function chassis—special lock 2–39

YD function chassis—exit lock 2–40

YR function chassis—special lock 2–41

Z function chassis—closet lock 2–42

Electrified functions 2–43

DEL function chassis—electrically locked fail safe 2–43

DEU function chassis—electrically unlocked fail safe 2–45

Function conversion 2–47

Trim parts 2–50

Standard strikes and strike boxes 2–50

Non-standard strikes 2–50

Lead-lined parts 2–51

Roses, rose liners, and rose spacers 2–52

Standard levers and components 2–54

Dummy trim 2–57

Latches 2–58

Installation tools 2–59

iv 9K Series Service Manual

SERVICE AND MAINTENANCE 3–1

Maintenance tools 3–2

Replacing Parts 3–3

Replacing the lever 3–3

Replacing the inside rose and rose liner 3–4

Replacing the outside rose and liner assembly 3–6

Replacing the RQE rose liner for electrified locks 3–7

Replacing the button assembly 3–8

Replacing the lever keeper spring 3–10

Replacing the lever return spring 3–11

Replacing the key release cam assembly 3–15

Replacing the spring drive plate 3–16

Replacing the sleeve assembly 3–17

Replacing the solenoid for electified locks 3–19

Adding the RQE switch to electrified locks 3–19

Reversing the solenoid when changing the function 3–20

Lubricating the cores 3–20

Aligning the chassis and trim 3–21

Contents

Cam positioning instructions 3–22

Positioning the cam for C function locks 3–22

Positioning the cam for G and IN function locks 3–23

Emergency key instructions for H and HJ function locks 3–24

Troubleshooting 3–25

INSTALLATION INSTRUCTIONS A–1

NDEX B–1

I

9K Series Service Manual v

Contents

vi 9K Series Service Manual

FIGURES

FUNCTIONS AND PARTS LISTS

Understanding function drawings 2–2

Standard strikes and strike boxes 2–50

Understanding strike lip measurement 2–50

Cross-section of 9K locks showing lead-lined parts 2–51

Standard lever components 2–55

Lever components with interchangeable cores 2–55

Lever components for use with non-interchangeable cores 2–56

Dummy trim parts 2–57

Latches 2–58

Installation tools 2–59

SERVICE AND MAINTENANCE

Maintenance tools 3–2

Removing the keyed lever 3–3

Removing the plain lever or button lever 3–3

Replacing the lever (keyed lever shown) 3–4

Removing the inside rose with the spanner wrench 3–4

Removing the two through-bolts 3–5

Replacing the inside rose and rose liner 3–5

Removing the outside rose and liner assembly

Replacing the outside rose and liner assembly 3–7

Removing the button assembly 3–8

Inserting the button assembly into the sleeve 3–9

Bending the button assembly tab 3–9

9K Series Service Manual vii

3–6

Figures

Removing the lever keeper spring 3–

Positioning the lever keeper spring 3–10

Lever keeper spring in position 3–11

Separating the hub and sleeve assembly from the chassis 3–12

Removing the thrust plate 3–12

Removing the lever return spring 3–12

Positioning the lever return spring 3–13

Inserting the lever return spring 3–13

Installing the thrust plate 3–14

Positioning the retractor assembly 3–14

Installing the retractor assembly 3–15

Removing the key release cam assembly 3–15

Installing the key release cam assembly 3–16

Removing the spring drive plate 3–16

Positioning the sleeve 3–17

Installing the spring drive plate 3–17

Removing the sleeve assembly from the hub 3–18

10

Replacing the sleeve assembly 3–18

Positioning the sleeve 3–19

Engaging the retractor in the latch 3–21

Correct position of the C function inside locking cam 3–22

Correct position of the G and IN function locking cam 3–23

Intermediate position of the G and IN function locking cam 3–23

Inserting the emergency key 3–24

viii 9K Series Service Manual

1

GETTING STARTED

INTRODUCTION

The 9K Series Service Manual contains essential

information to help you maintain your 9K Series

Lock. This manual addresses standard and electrified

9K Series Locks. Throughout this manual, the term

electrified is used to refer to 93KW–95KW DEL, DEU

function locks.

9K Series Service Manual 1–1

Getting Started

CERTIFICATIONS AND STANDARDS

9K Series Locks ■ The locks comply with ANSI A156.2, Series 4000 Grade 1 standards.

■ The locks are listed by Underwriter’s Laboratories for use on 3 Hr., A

label single swinging doors (4´ x 10´), or pairs of doors 8´ wide and

10´ high.

■ When used with the 3/4″ throw latch, the locks comply with

Miami-Dade County standards with a design pressure rating of ±90

PSF for single doors and ±50 PSF for double door openings.

■ The AB, C, D, EA, G, IN, NX, Q, R, and YD function locks comply

with ANSI A250.13 Windstorm standards with a design load rating of

1750 pounds.

■ The chassis conforms to ANSI A115.2.

■ The 8KS3 strike fits the standard door frame cutout as specified in

ANSI A115.2.

■ The #14 and #15 lever handles conform to California Administrative

Code Title 19 and Title 24.

■ The #14, #15, and #16 lever handles conform to the Illinois

Accessibility Standard.

Electrified

Locks

■ The 9KW Locks are UL listed for GYQS electrically controlled single

point locks or latches.

■ The 9KW Locks are approved by the California State Fire Marshal

(CSFM) pursuant to section 13144.1 of the California Health and

Safety Code.

■ The 9KW Locks are approved by the city of New York Board of

Standards and Appeals under calendar number 730-89-SA. See CSFM

listing number 4136-1175:103.

Accessories ■ The 8W599 transformer is UL listed.

■ The 8WCON AC to DC converter full wave bridge rectifier is

UL recognized.

1–2 9K Series Service Manual

DOCUMENTATION PACKAGE

The following documentation is available to help you with the

installation, start-up, and maintenance of your 9K Series Lock.

The installation and assembly instructions also can be ordered

separately:

Document Title Doc. No.

Installation Instructions for 9K Cylindrical Locks

Single and Double Dummy Trim Assembly

Instructions for 9K1DT/2DT

Wiring Instructions for 8K and 9K Series

Electrified Cylindrical Locks with RQE

Door Wiring Instructions for Electrically-Operated

Locks

a. These installation instructions are included in this manual. See

Installation Instructions on page A–1.

Getting Started

a

T56075

T56076

T56090

a

T61926

The templates required for lock installations also can be ordered

separately:

Document Title Doc. No.

K08 Template for Door and Frame Preparation

for 63, 73, 83, 93K Locks

K09 Template for Door and Frame Preparation

for 63, 73, 83, 93K Locks

K10 Template for Door and Frame Preparation

for 64, 84, 94K Locks

K11 Template for Door and Frame Preparation

for 64, 84, 94K

K12 Template for Door Frame Preparation

for 65, 85, 95K

K13 Template for Door Frame Preparation

for 65, 85, 95K

K18 Template for 8K/9K Dummy Trim T56059

K21 Template for Strike Specification for

Cylindrical Locks

W14 Template; Installation Specifications for

83KW/93KW–85KW/95KW IDH Max Cylindrical

Locks

W16 Template; Installation Template for

83KW/93KW–85KW/95KW IDH Max Cylindrical

Locks

T56052

T56053

T56054

T56055

T56056

T56057

T56060

T60777

T60773

9K Series Service Manual 1–3

Getting Started

TECHNICAL SUPPORT

Support

services

Telephone

technical

support

Training

seminars

When you have a question about the 9K Series Lock, your first resource

for help is the 9K Series Service Manual. If you cannot find a

satisfactory answer, contact your local BEST Representative.

A factory-trained Certified Product Specialist (CPS) is available in your

area whenever you need help. Before you call, however, please make

sure you are where the 9K Series Lock is, and that you are prepared to

give the following information:

■ what happened and what you were doing when the question arose

■ what you have done so far to answer the question.

BEST Access Solutions, Inc. Representatives provide telephone

technical support for all 9K Series products. You may locate the

representative nearest you by calling (317) 849-2250 Monday through

Friday, between 7:00 a.m. and 4:00 p.m. eastern standard time; or visit

the web page, www.BestAccess.com.

BEST holds training sessions for its customers. The seminars are

specifically designed for BEST end-users who have a registered BEST

masterkeyed system and registered BEST security equipment. If you are

interested, you may contact your local BEST representative for details.

1–4 9K Series Service Manual

2

FUNCTIONS AND PARTS LISTS

The following pages contain function descriptions

for all 9K Series Locks. This chapter also includes

exploded diagrams that show all field serviceable

mechanical parts, diagrams of trim and other

miscellaneous parts, and function conversion

information.

9K Series Service Manual 2–1

Functions and Parts Lists

FUNCTION DESCRIPTIONS

This section includes function descriptions grouped by the following

function types:

■ single-keyed (page 2–3)

■ double-keyed (page 2–5)

■ non-keyed (page 2–7)

■ special (page 2–8)

■ electrified (page 2–11).

For a list of the BEST designation for each ANSI-defined function, see

page 2–11.

Note: If the function is ANSI defined, the ANSI designation appears by

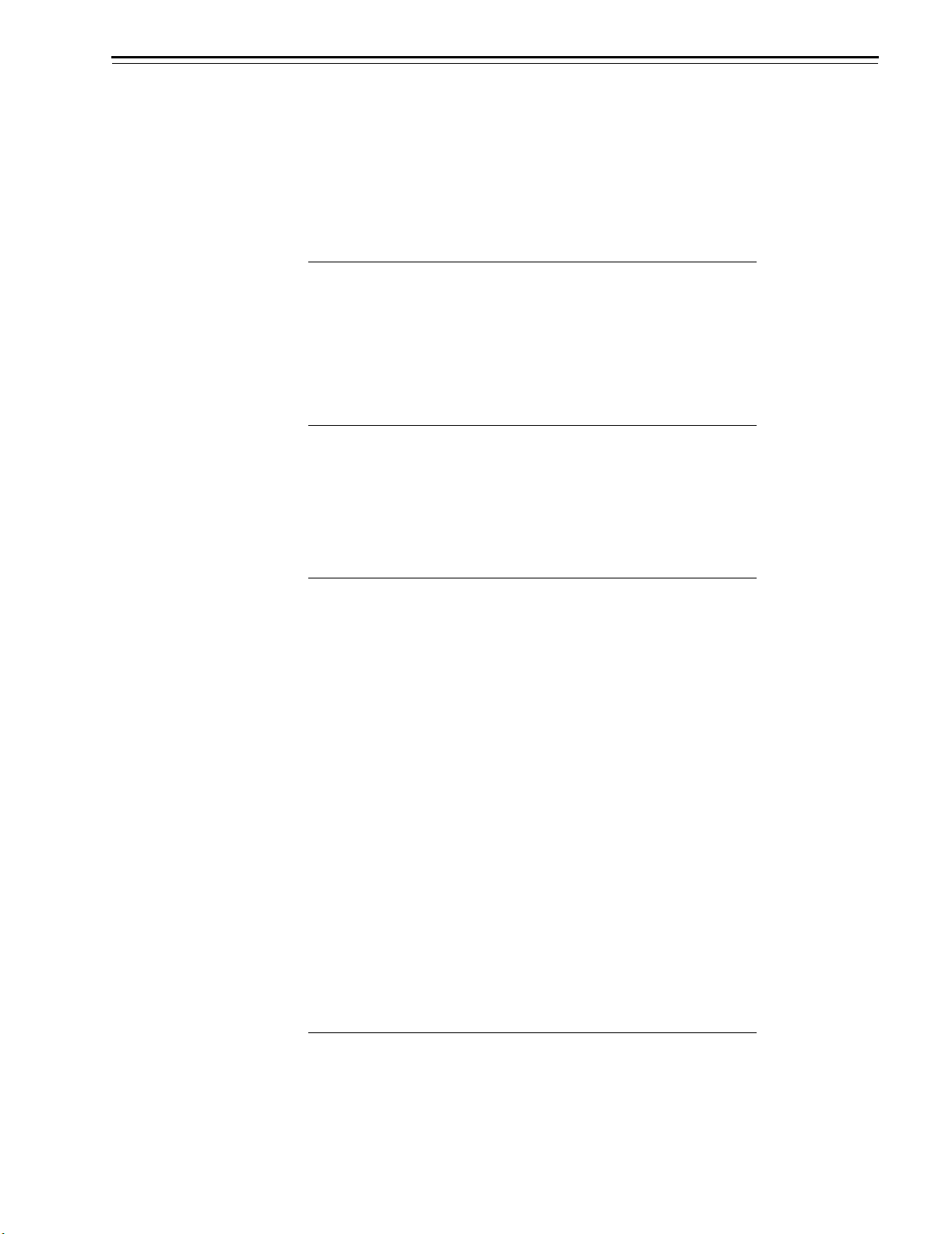

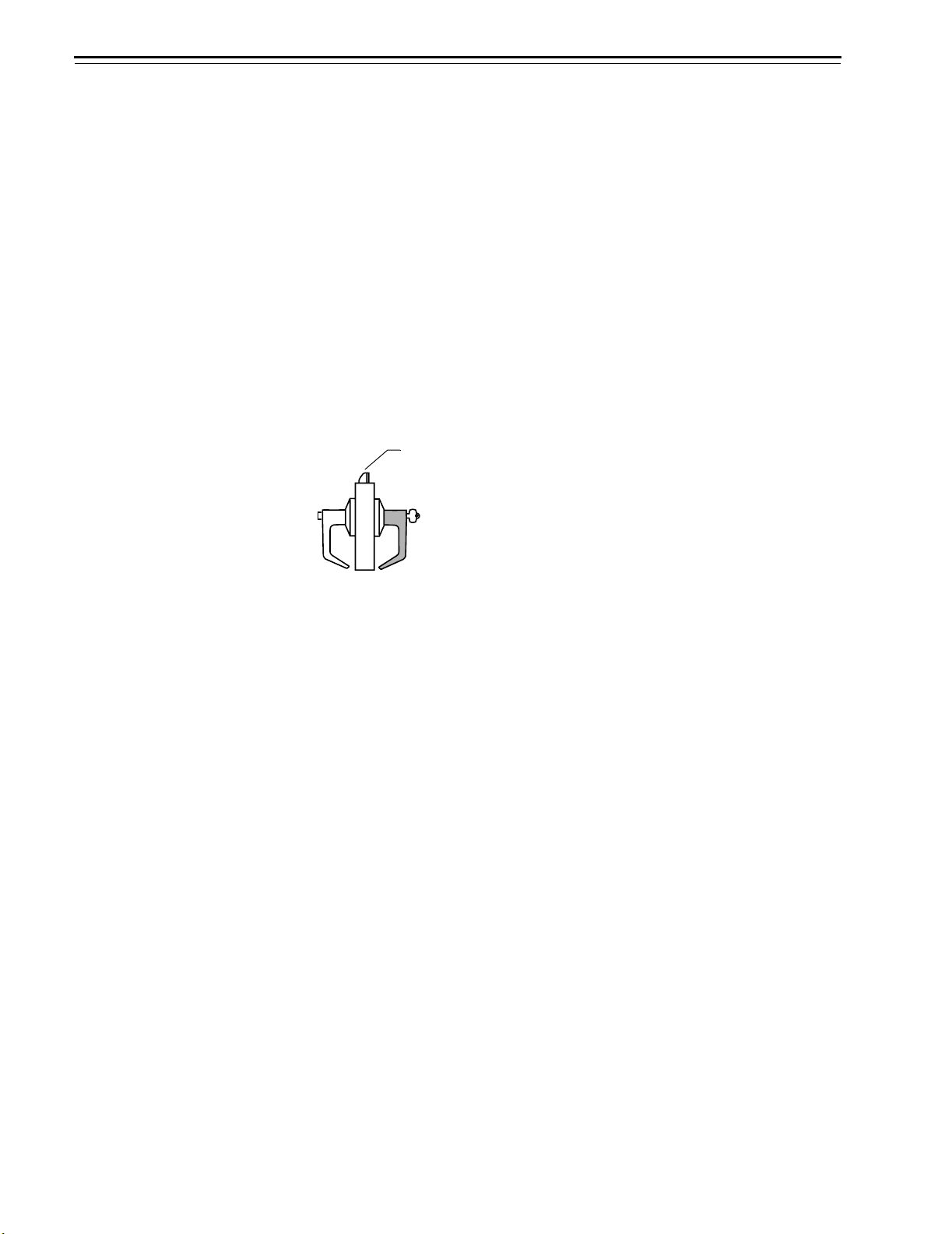

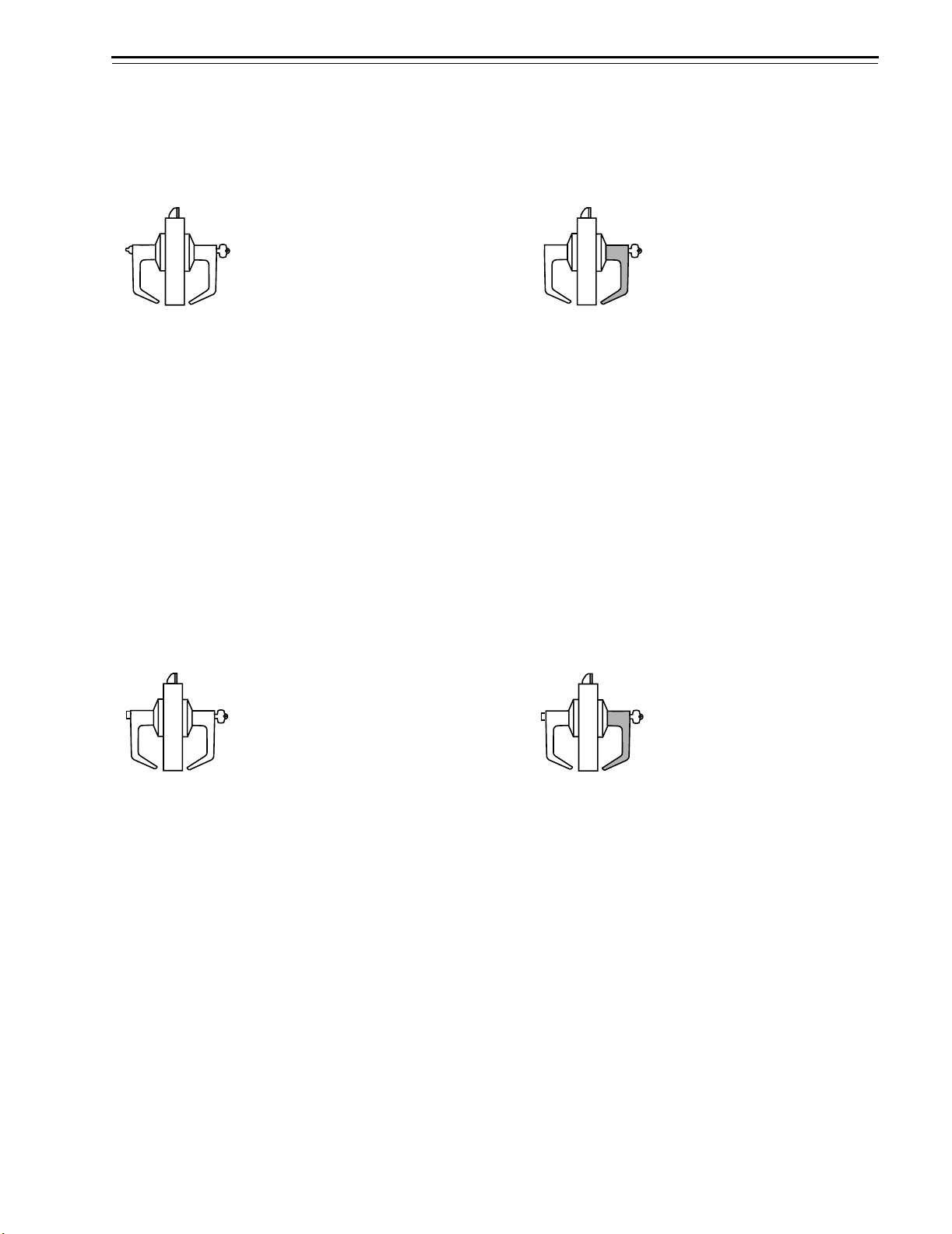

the function name.

Latch

Shading indicates

that the lever is fixed.

OutsideInside

View looking down

at the top of the door

Figure 2.1 Understanding function drawings

2–2 9K Series Service Manual

Functions and Parts Lists

Single-keyed

functions

The following lists describe how the latchbolt, outside lever, and inside

lever operate for each single-keyed 9K function.

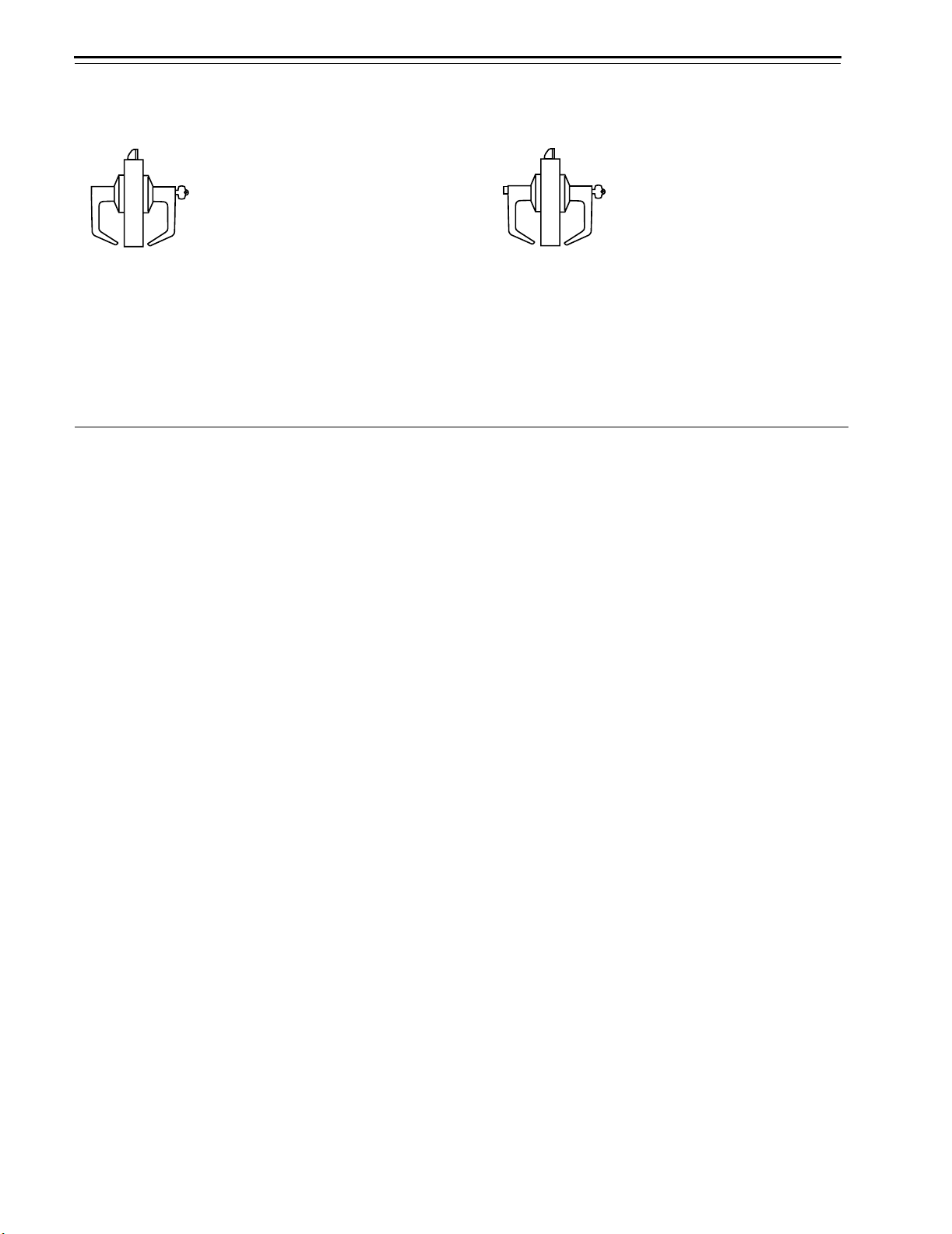

AB–Entrance (ANSI F109) D–Storeroom (ANSI F86)

Latchbolt operated by:

■ inside lever

■ outside key

■ outside lever when the inside

bu

tton is in the unlock

positi

on

ed

Outside lever locked by:

■ inside button when pushed in

■ inside button when pushed in

an

d rotated clockwise

Outside lever unlocked by:

■ inside lever when the inside

button is pushed in but not

rotated

■ outside key when the inside

button is pushed in but not

rotated

■ closing the door when the

inside button is pushed in but

not rota

ted

Inside lever is always

unlocked

Latchbolt operated by:

■ inside lever

■ outside key

Outside lever is always fixed

Inside lever is alwa

unlocked

ys

E–Service station (ANSI F92) H and HJ–Hotel guest room (ANSI F93 for H only)

Latchbolt operated by:

■ inside lever

■ outside key

■ outside lever when the inside

bu

tton is in the unlock

positi

on

ed

Outside lever locked by:

■ inside slotted button

■ inside slotted button when

pus

hed in and rota

ted

clockwise

Outside

■ inside lever

■ inside slotted button when

■ outside key

■ closing the door when the

lever unlocked by:

rot

ated counterclockwise

inside button is pushed in but

not rota

ted

Inside lever is always

unlocked

Note: For the H fu

projects an “Occupied” indicator in the outside lever

and blocks all operating keys. For the HJ function,

pushing the inside button blocks all operating keys.

Latchbolt operated by:

■ inside lever

■ outside key when the inside

button is in th

e unlock

ed

position

■ special emergency key after

the core is

removed with th

control key

O

utside lever is always fixed

Key block feature released

by:

■ inside lever

■ closing the door

Inside lever is alwa

ys

unlocked

nction, pushing the inside button

e

9K Series Service Manual 2–3

Functions and Parts Lists

R–Classroom (ANSI F84) T–Dormitory (ANSI F90)

Latchbolt operated by:

■ inside lever

■ outside key

■ outside lever when not locked

Outside lever locked by:

■ outside key

Outside lever unlocked by:

■ outside key

Inside lever is always

unlocked

Latchbolt operated by:

■ inside lever

■ outside lever when not locked

Outside lever locked by:

■ inside button

■ outside key

Outside lever unlocked by:

■ inside lever when the inside

■ outside key

■ closing the door when the

Inside lever is always

unlocked

button is pushed in

inside button is pushed in

2–4 9K Series Service Manual

Functions and Parts Lists

Double-keyed

functions

The following lists describe how the latchbolt, outside lever, and inside

lever operate for each double-keyed 9K function.

Warning:

Locks that secure both sides of the door are controlled by

®

building codes and the Life Safety Code

. In an emergency exit

situation, failure to quickly unlock the door could be hazardous,

or even fatal.

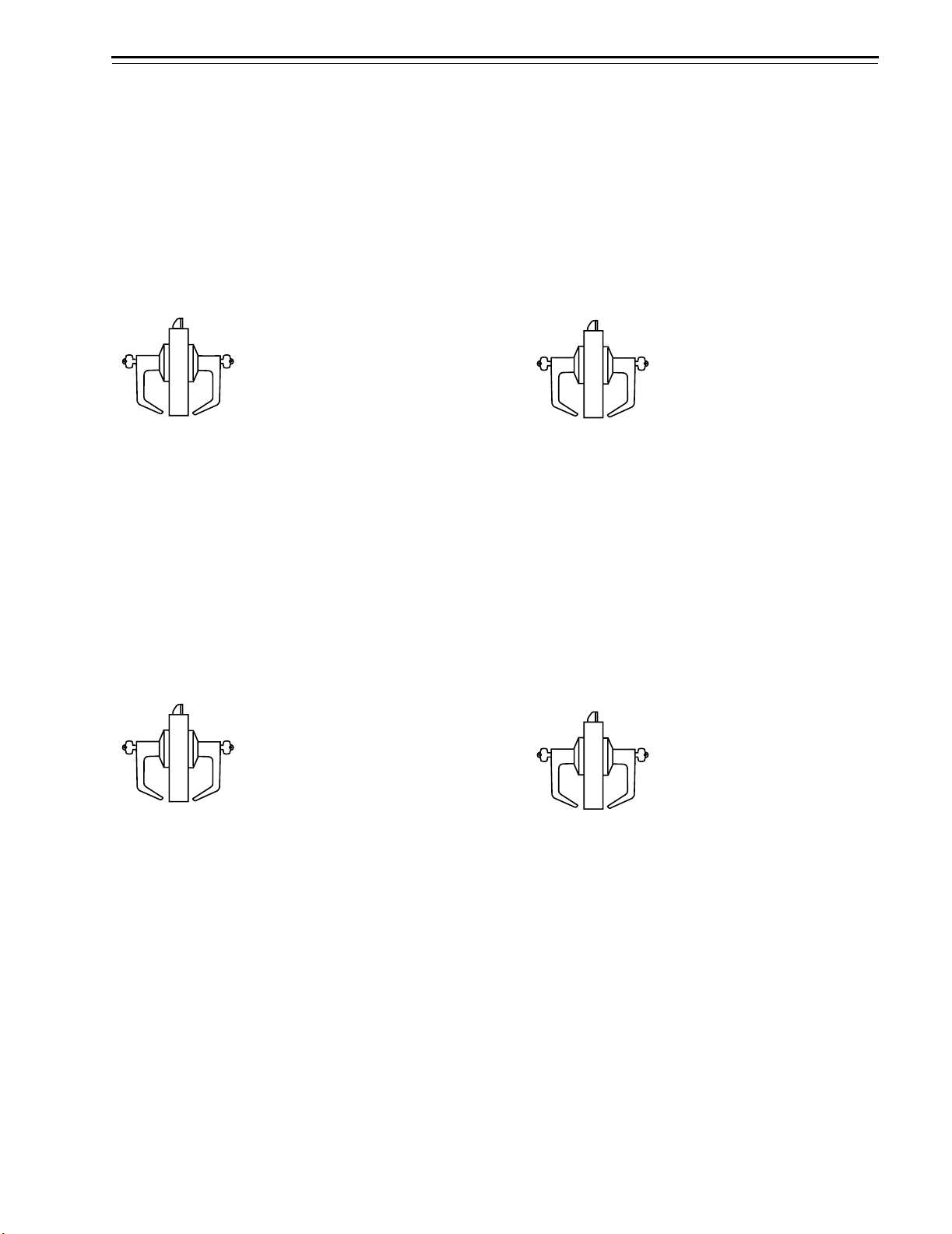

C–Corridor (ANSI F88) G–Storeroom (ANSI F91)

Latchbolt operated by:

■ inside lever

■ outside key

■ outside lever when not locked

Outside lever locked by:

■ inside key

Outside lever unlocked by:

■ inside key

Inside lever is always

unlocked

Note: Turning the key in either the inside or outside

lever locks or unlocks both sides.

Latchbolt operated by:

■ inside lever when not locked

■ outside lever when not locked

Outside lever locked by:

■ inside key

■ outside key

Outside lever unlocked by:

■ inside key

■ outside key

Inside lever locked by:

■ inside key

■ outside key

Inside lever unlocked by:

■ inside key

■ outside key

IN–Intruder S–Communicating (ANSI F80)

Latchbolt operated by:

■ inside lever

■ outside lever when not locked

Outside lever locked by:

■ inside key

■ outside key

Outside lever unlocked by:

■ inside key

■ outside key

Inside lever is always

unlocked

Note: Turning the key in either lever locks or

unlocks that lever independently.

Latchbolt operated by:

■ inside key

■ inside lever when not locked

■ outside key

■ outside lever when not locked

Outside lever locked by:

■ outside key

Outside lever unlocked by:

■ outside key

Inside lever locked by:

■ inside key

Inside lever unlocked by:

■ inside key

9K Series Service Manual 2–5

Functions and Parts Lists

W–Institutional (ANSI F87)

Latchbolt operated by:

■ inside key

■ outside key

Outside

Inside lever is always fixed

lever is always fixed

2–6 9K Series Service Manual

Functions and Parts Lists

Non-keyed

functions

The following lists describe how the latchbolt, outside lever, and inside

lever operate for each non-keyed 9K function.

L–Privacy (ANSI F76) N–Passage (ANSI F75)

Latchbolt operated by:

■ inside lever

■ outside lever when the inside

bu

tton is in the unlock

positi

on

ed

Outside lever locked by:

■ inside button

Outside lever unlocked by:

■ inside lever

■ outside slotted button when

pus

hed in and rota

coun

terclockwise

■ closing the door

ted

Inside lever is always

unlocked

Latchbolt operated by:

■ inside lever

■ outside lever

O

unlocked

Inside lever is

unlocked

NX–Exit (ANSI F89) P–Patio (ANSI F77)

Latchbolt operated by:

■ inside lever

Outside lever is always fixed

Inside lever is always

unlocked

Latchbolt operated by:

■ inside lever

■ outside lever when the inside

O

■ inside button

Outside lever unlocked by:

■ inside lever

■ closing the door

Inside lever is alwa

unlocked

utside lever is al

alwa

ways

ys

button is in the unlock

position

utside lever locked by:

ys

ed

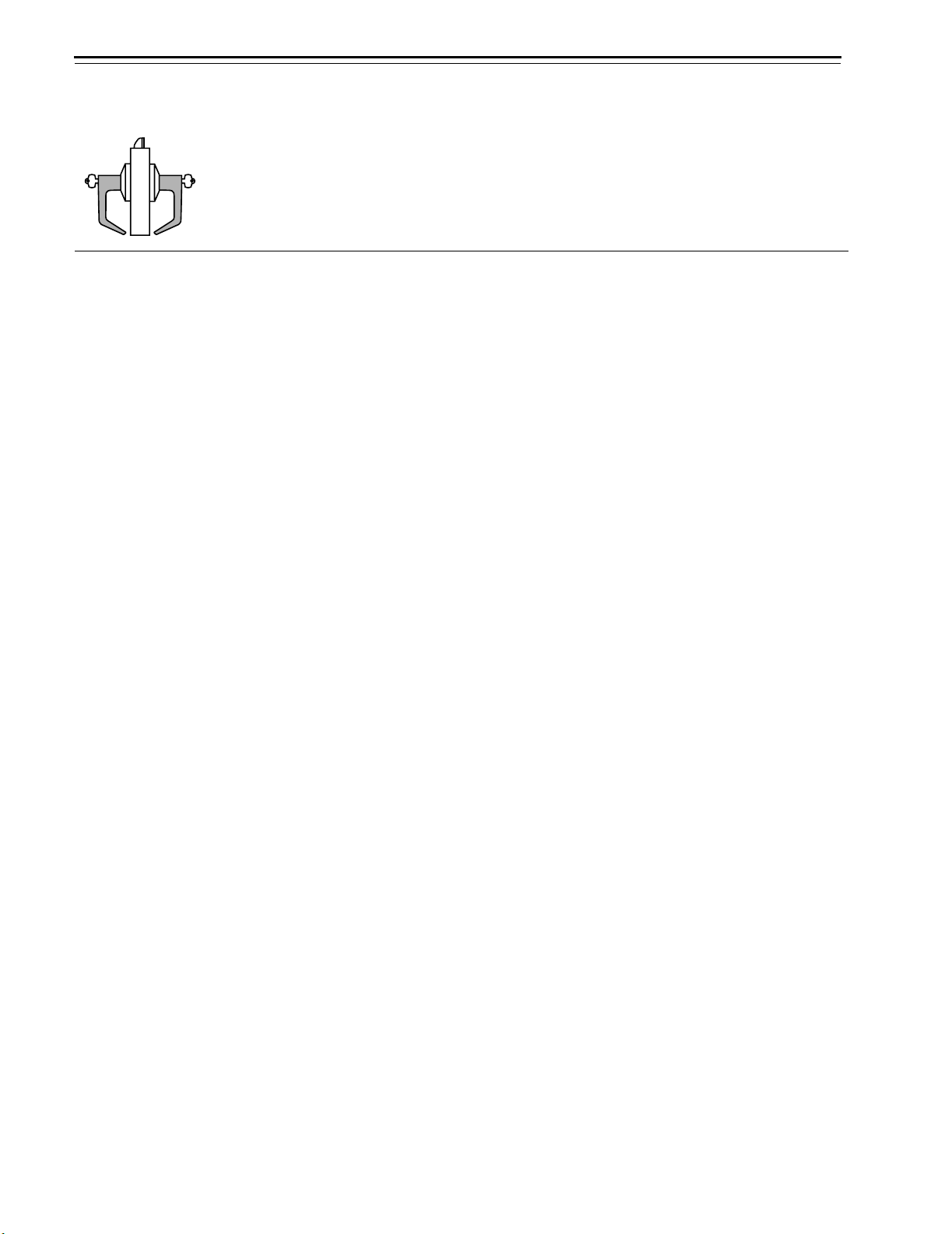

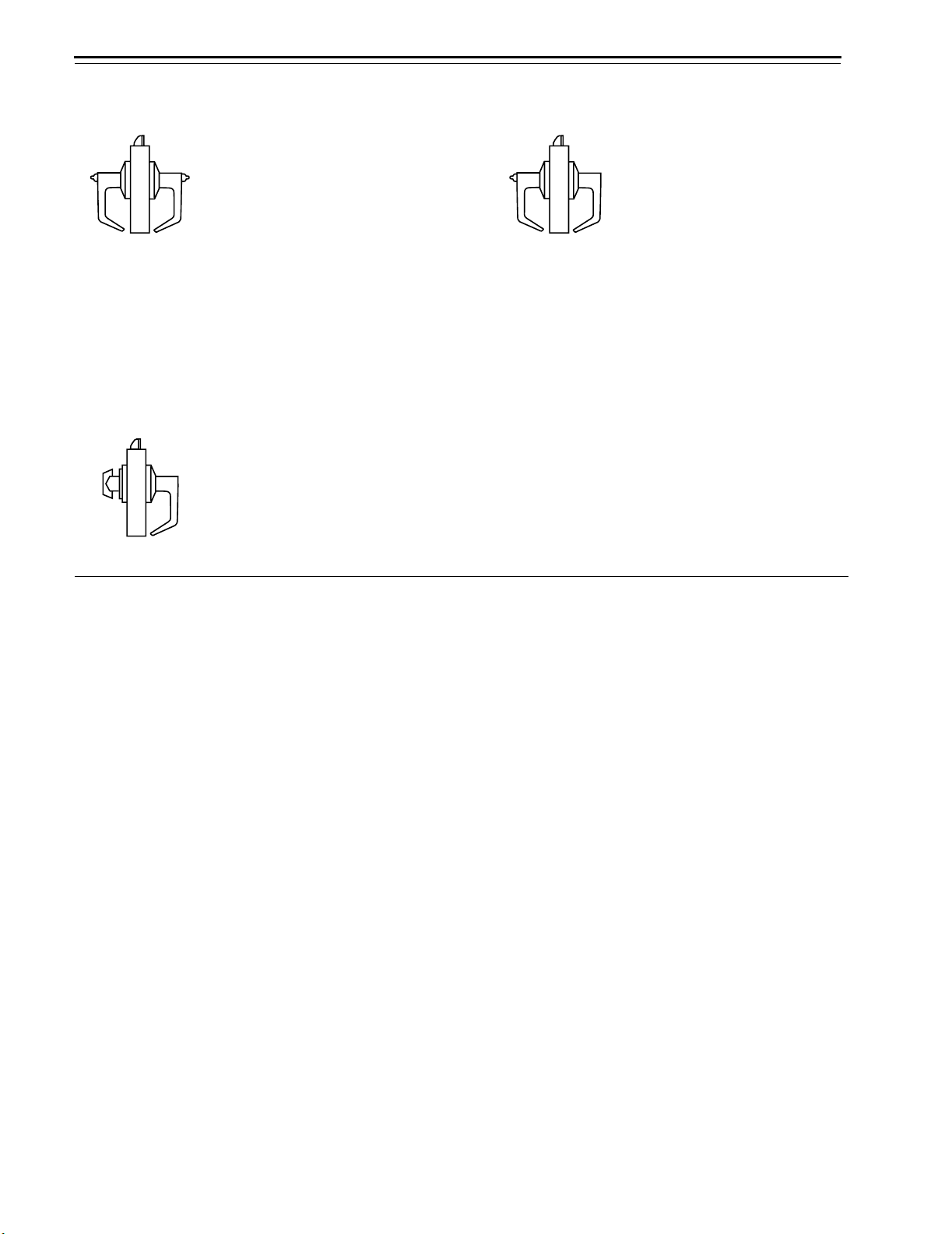

Y–Exit 1DT–Single dummy trim

Latchbolt operated by:

■ inside lever

Inside lever is always

unlocked

This lock is a single, surface

mounted lever for an inactive

door or a non-latching door.

2DT–Double dummy trim

This lock is a through-bolt

mounted pair of matching levers

for an inactive door or a

non-latching door.

9K Series Service Manual 2–7

Functions and Parts Lists

Special

functions

The following lists describe how the latchbolt, outside lever, and inside

lever operate for each special 9K function.

Warning:

Locks that secure both sides of the door are controlled by

building codes and the Life Safety Code

®

situation, failure to quickly unlock the door could be hazardous,

or even fatal.

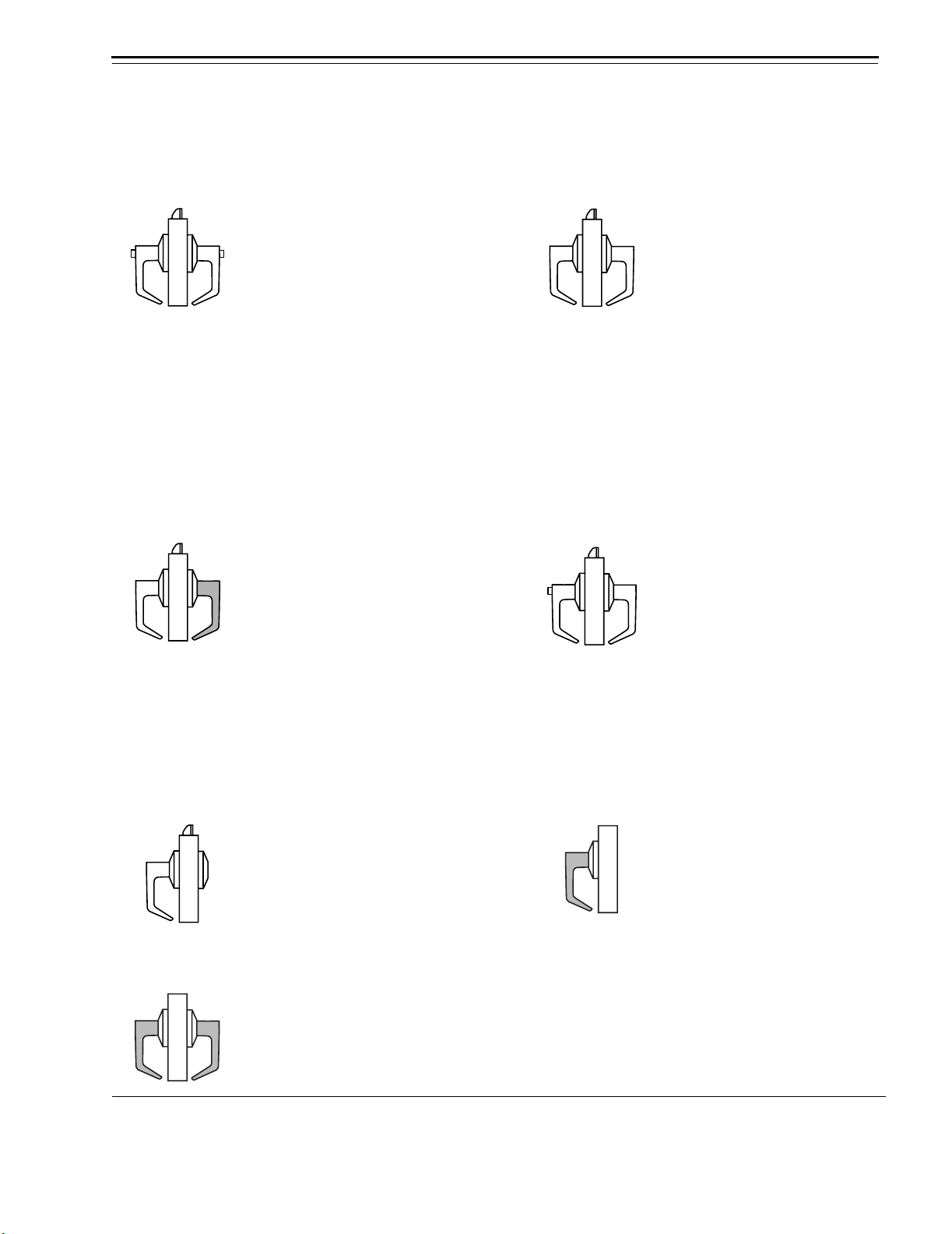

A–Dormitory or storeroom lock (ANSI F81) B–Office (ANSI F82)

Latchbolt operated by:

■ inside lever

■ outside key

■ outside lever when the inside

bu

tton is in the unlock

positi

on

Outside lever locked by:

■ inside button

Outside lever unlocked by:

■ inside button

Inside lever is always

unlocked

e: Inside button must be rotated

Not

counterclockwise to unlock the outside lever.

ed

Note: Inside button is released by turning the key in

the outside lever or rotating the inside lever. Closing

the door does not release the inside button.

. In an emergency exit

Latchbolt operated by:

■ inside lever

■ outside key

■ outside lever when the inside

button is in the unlock

position

O

utside lever locked by:

■ inside button

Outside lever unlocked by:

■ inside lever

■ outside key

Inside lever is alwa

unlocked

ed

ys

DZ–Closet or storeroom EA–Entrance or Office

Latchbolt operated by:

■ inside turn knob

■ outside key

Outside lever is always fixed

Inside turn knob

is always

unlocked

e: Turning the slotted button keeps the outside

Not

lever locked until the button is turned back.

Latch

■ inside lever

■ outside key

■ outside lever when the inside

O

■ inside button

■ inside button when pushed in

Outside lever unlocked by:

■ inside lever

■ inside button when rotated

■ outside key

Inside lever is alwa

unlocked

bolt operated by:

button is in the unlock

position

utside lever locked by:

a

nd rotated clockwise

counterclockwise

ys

ed

2–8 9K Series Service Manual

RZ–Closet or storeroom XD–Special

Latchbolt operated by:

■ inside turn knob

■ outside key

■ outside lever when not locked

Outside lever locked by:

■ outside key

Outside lever unlocked by:

■ outside key

Inside turn knob

is always

unlocked

XR–Special YD–Exit

Latchbolt operated by:

■ inside key

■ inside lever when not locked

Outside lever is always fixed

Inside lever locked by:

■ inside key

Inside lever unlocked by:

■ inside key

Functions and Parts Lists

Lat

chbolt operated by:

■ inside key

Outside lever is always fixed

Inside lever is always fixed

Latchbolt operated by:

■ inside key

Inside lever is always fixed

YR–Special DR–Special

Latchbolt operated by:

■ inside key

■ inside lever when not locked

Inside lever locked by:

■ inside key

Inside lever unlocked by:

■ inside key

RD–Special LL–Hospital privacy

Latchbolt operated by:

■ inside key

■ outside key

■ outside lever when not locked

Outside lever locked by:

■ outside key

Outside lever unlocked by:

■ outside key

Inside lever is always fixed

Latchbolt operated by:

■ inside key

■ inside lever when not locked

■ outside key

Outside lever is always fixed

Inside lever locked by:

■ inside key

Inside lever unlocked by:

■ inside key

Latchbolt operated by:

■ inside lever

■ outside lever when not locked

Outside lever locked by:

■ inside button when pushed in

Outside lever unlocked by:

■ inside lever

■ outside button when pushed

in and rota

ted

counterclockwise

■ closing the door

Inside lever is alwa

ys

unlocked

9K Series Service Manual 2–9

Functions and Parts Lists

M–Communicating (ANSI F78) Q–Exit (ANSI F83)

Latchbolt operated by:

■ inside lever when not locked

■ outside lever when not locked

Outside lever locked by:

■ inside button

Outside lever unlocked by:

■ inside button

Inside lever locked by:

■ outside button

Inside lever unlocked by:

■ outside button

e: Do not use this function for rooms that have

Not

no other entrance.

Z–Closet latch

Latchbolt operated by:

■ inside turn knob

■ outside lever

Outside lever is alwa

unlocked

Inside tu

rn knob

unlocked

ys

is always

Latchbolt operated by:

■ inside lever

■ outside lever when not locked

Outside lever locked by:

■ inside button

Outside lever unlocked by:

■ inside button

Inside lever is alwa

ys

unlocked

2–10 9K Series Service Manual

Functions and Parts Lists

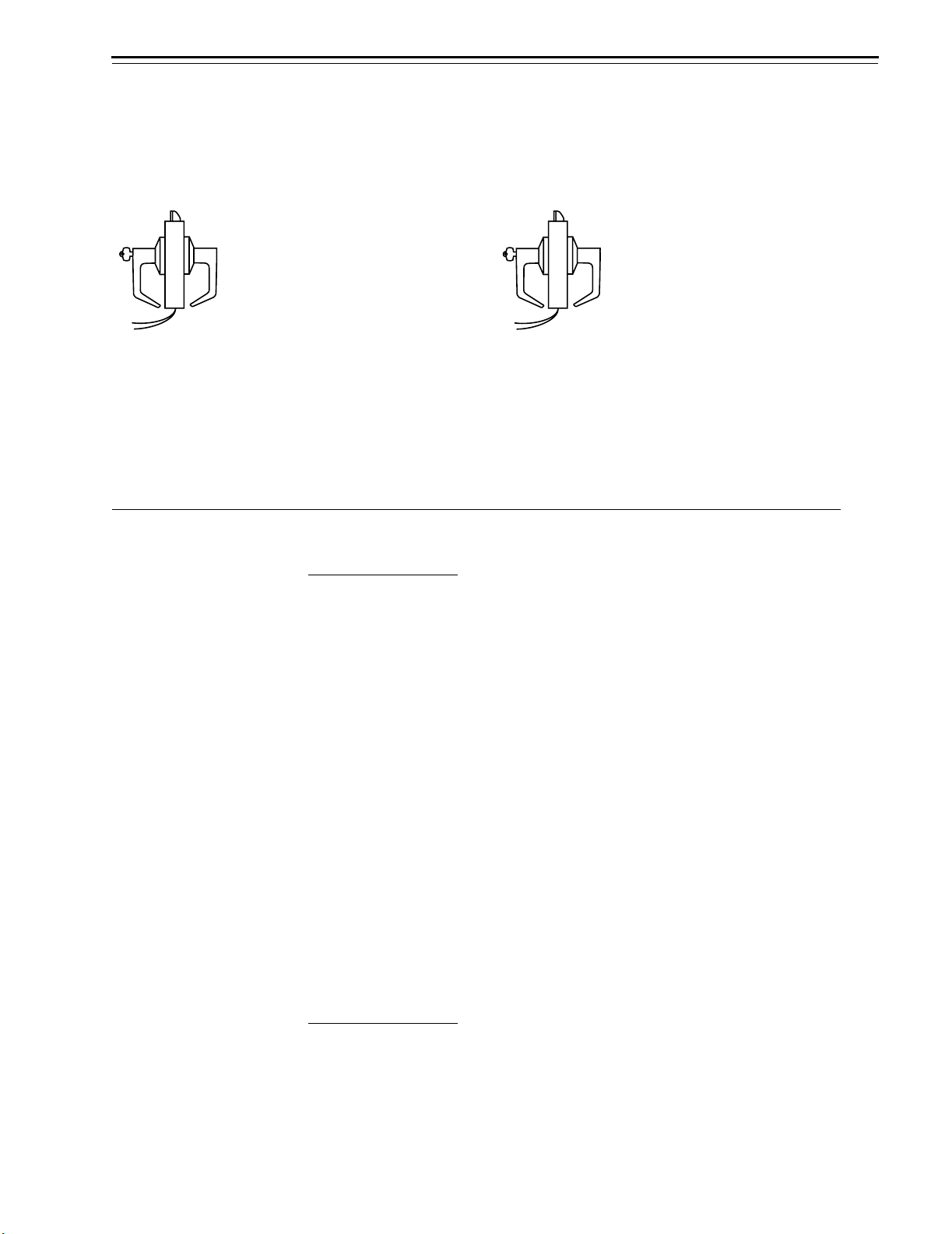

Electrified

cylindrical

The following lists describe how the latchbolt, outside lever, and inside

lever operate for each electrified 9K function.

functions

DEL–Electrically Locked–Fail Safe DEU–Electrically Unlocked–Fail Secure

Latchbolt operated by:

■ inside lever

■ outside lever when electric

enoid

is remo

ved from the

power

sol

■ outside key

Outside lever locked by:

■ applying 24 VDC to the

solenoid; remains locked only

whil

e power continues to

pplied

a

Outside lever unlocked by:

■ removing 24 VDC from the

enoid

sol

Inside lever is always

unlocked

be

Latchbolt operated by:

■ inside lever

■ outside lever when electric

power is applied to the

sol

enoid

■ outside key

Outside lever locked by:

■ removing 24 VDC from the

sol

enoid

Outside lever unlocked by:

■ applying 24 VDC to the

solenoid; remains unlocked

only whil

to be

e power continue

applied

Inside lever is always

unlocked

Functions

by ANSI

designation

ANSI no. Function

F75 N

F76 L

F77 P

F78 M

F80 S

F81 A

F82 B

F83 Q

F84 R

F86 D

F87 W

F88 C

F89 NX

F90 T

F91 G

F92 E

F93 H

F109 AB

s

9K Series Service Manual 2–11

2–12 9K Series Service Manual

STANDARD FUNCTIONS

AB FUNCTION CHASSIS—ENTRANCE LOCK (ANSI F109)

Functions and Parts Lists

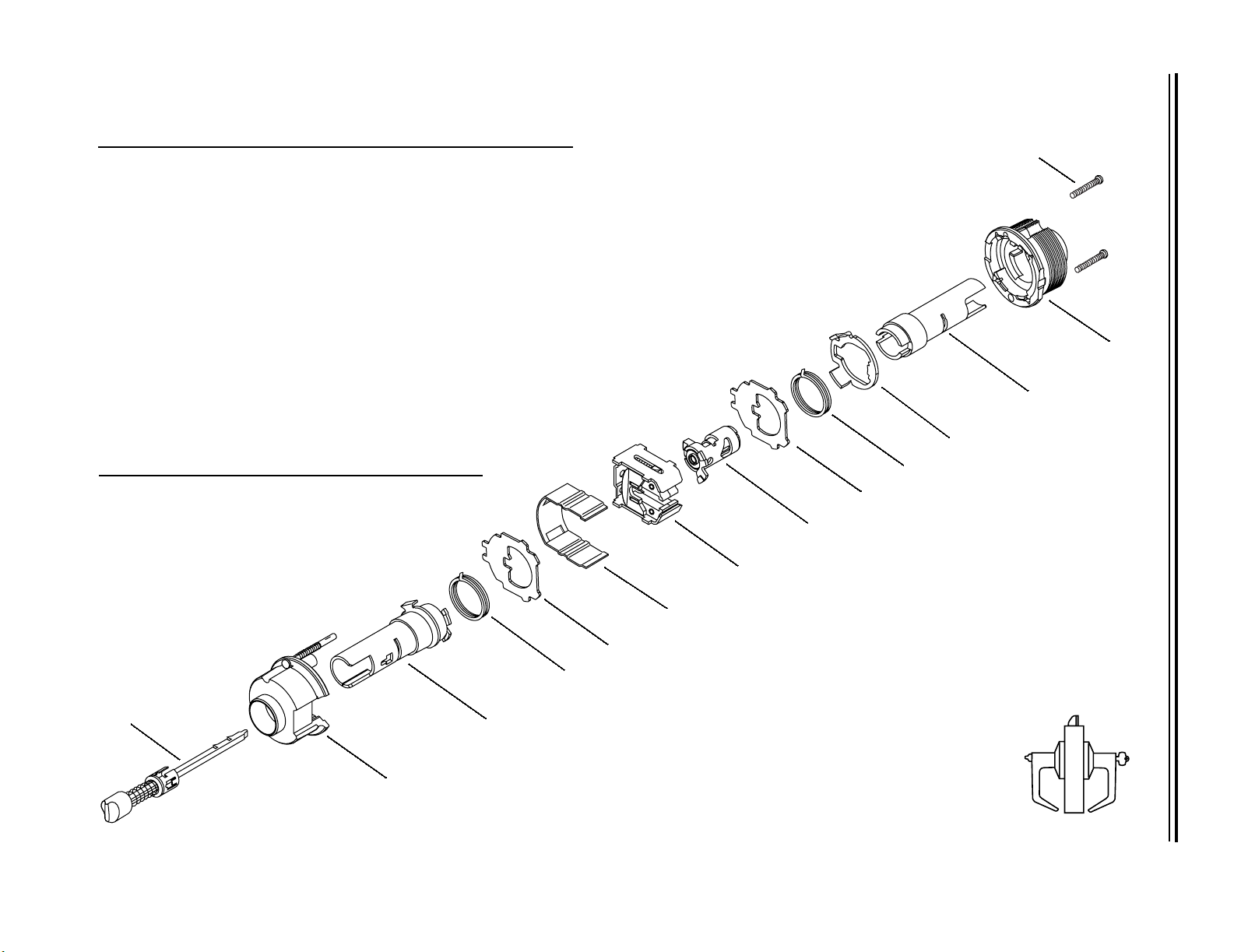

Item Part No. Qty. Description

1 B55692 1 Turn button assembly

2 A55685 1 Inside hub and locking pin assembly

3 B55610 1 Non-keyed sleeve and driver assembly

4 B55518 2 Lever return spring

5 B55504 2 Thrust plate

6 B54172 1 Chassis cover

7 B54886 1

8 A55673 1

9 C55515 1

10

not shown

not shown

11

not shown

12 A55505 2 Chassis screw

a. Specify finish.

b. For use with non-interchangeable cores.

c. For use with large format interchangeable cores.

A55687

A55725

A88631

D55571

D5600311

Retractor assembly with long catchplate

Key release cam assembly

Spring drive plate

1

Keyed sleeve assembly or

Keyed sleeve assembly

1

1

Keyed sleeve assembly

Outside hub or

Outside hub, lost motion

a

b

c

12

11

10

9

4

5

8

7

Outside

1

2

Inside

Figure 2.2 AB function exploded diagram

6

5

4

3

AB

9K Series Service Manual 2–13

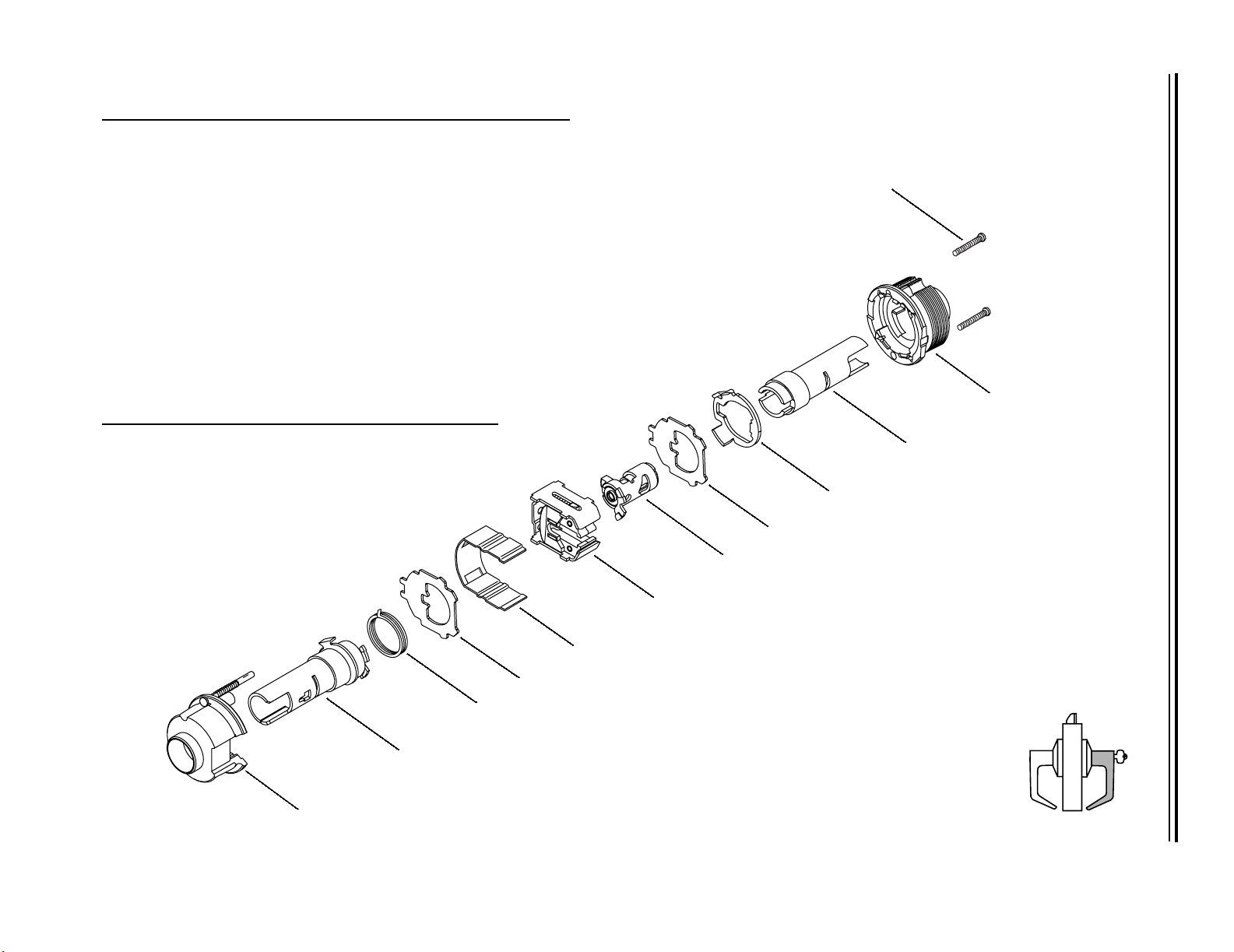

C FUNCTION CHASSIS—CORRIDOR LOCK (ANSI F88)

Item Part No. Qty. Description

1

not shown

2

not shown

not shown

3 C55515 2 Spring drive plate

4 B55518 2 Lever return spring

5 B55504 2 Thrust plate

6 B54172 1 Chassis cover

7 A54190 1 Locking bar

8 B54888 1

9 A55673 1

10

not shown

not shown

11

not shown

12 A55505 2 Chassis screw

a. For use with non-interchangeable cores.

b. For use with large format interchangeable cores.

A55685

A5600811

B55700

B56024

B89839

A55687

A55725

A88631

D55571

D5600311

Inside hub and locking pin assembly or

Inside hub assembly, lost motion

Sleeve & key release cam assembly or

1

Sleeve & key release cam assembly

1

Sleeve & key release cam assembly

1

Retractor assembly without catchplate

Key release cam assembly

Keyed sleeve assembly or

1

Keyed sleeve assembly

1

Keyed sleeve assembly

1

Outside hub or

Outside hub, lost motion

a

b

a

b

12

9

7

10

3

4

5

8

11

Outside

Inside

Figure 2.3 C function exploded diagram

6

5

4

3

2

1

C

Functions and Parts Lists

2–14 9K Series Service Manual

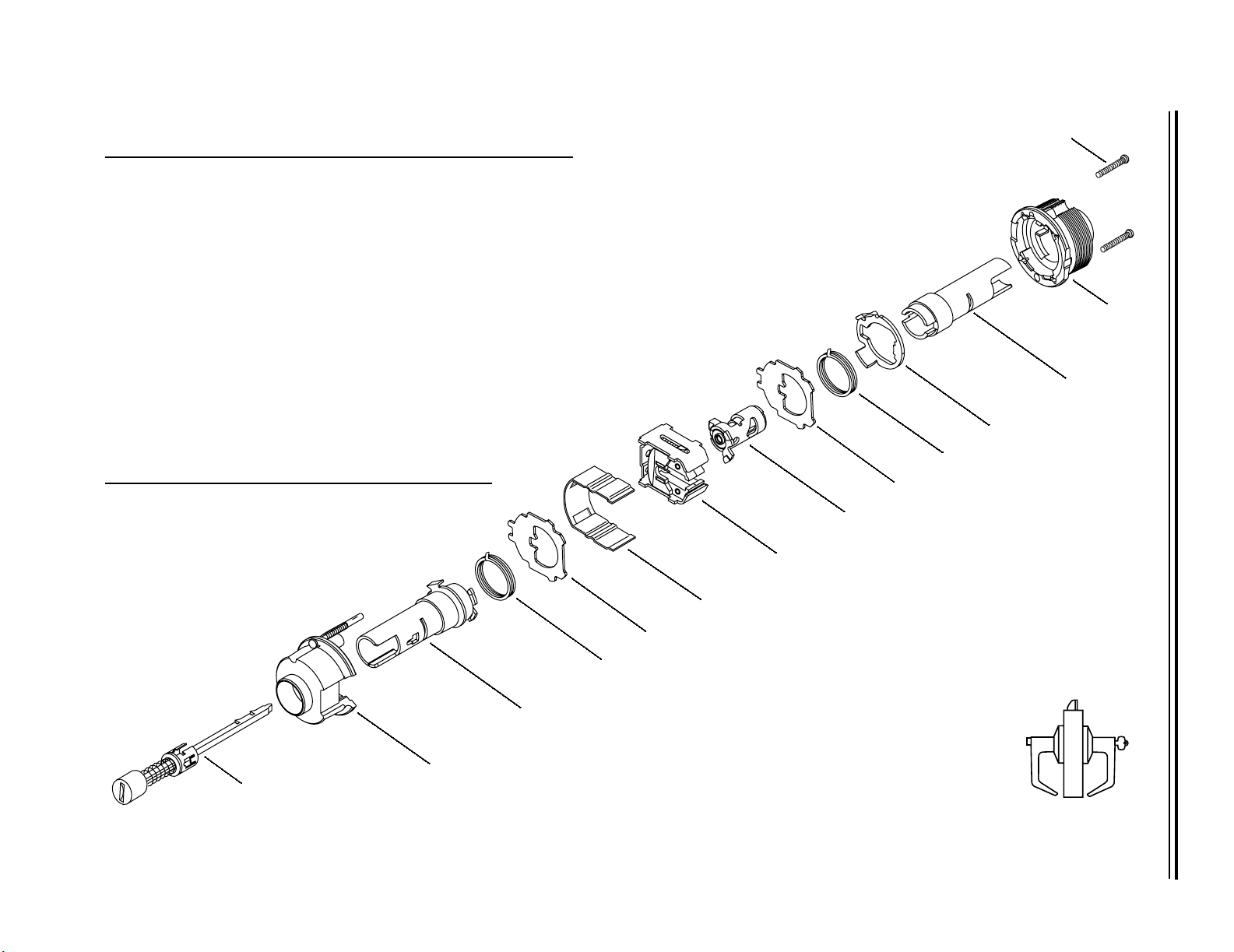

D FUNCTION CHASSIS—STOREROOM LOCK (ANSI F86)

Item Part No. Qty. Description

1 A55685 1 Inside hub and locking pin assembly

2 B55610 1 Non-keyed sleeve and driver assembly

3 B55518 1 Lever return spring

4 B55504 2 Thrust plate

5 B54172 1 Chassis cover

6 B54888 1 Retractor assembly without catchplate

7 A55675 1 Key release cam assembly

8 C55515 1

9

not shown

not shown

10

not shown

11 A55505 2 Chassis screw

A55687

A55725

A88631

D55571

D5600311

Spring drive plate

Keyed sleeve assembly or

1

1

Keyed sleeve assembly

1

Keyed sleeve assembly

Outside hub or

Outside hub, lost motion

Functions and Parts Lists

11

a

b

10

a. For use with non-interchangeable cores

b. For use with large format interchangeable cores.

Inside

1

Figure 2.4 D function exploded diagram

9

Outside

8

4

7

6

5

4

3

2

D

9K Series Service Manual 2–15

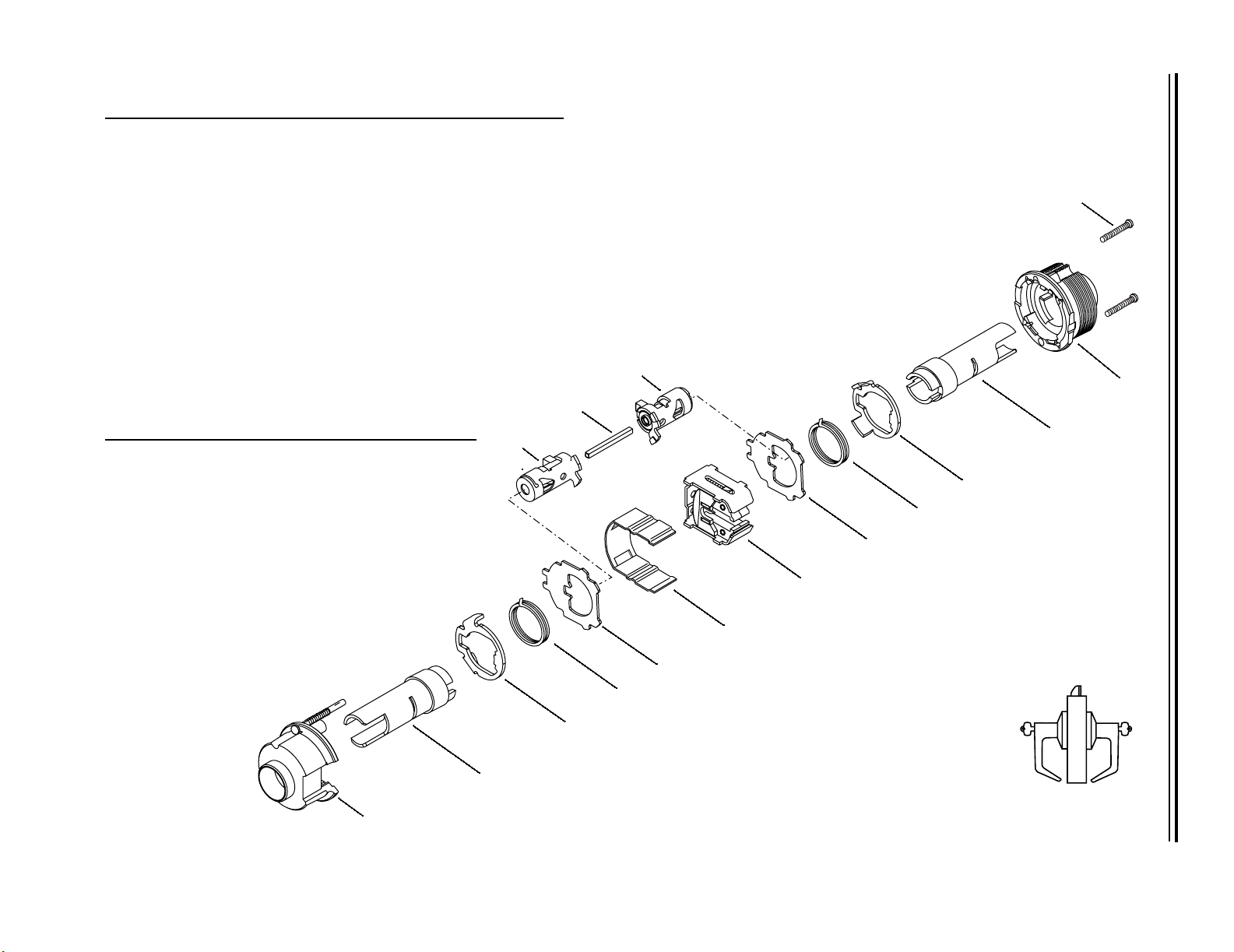

E FUNCTION CHASSIS—SERVICE STATION LOCK (ANSI F92)

Item Part No. Qty. Description

1 B55694 1 Slotted button assembly

2 A55685 1 Inside hub and locking pin assembly

3 B55610 1 Non-keyed sleeve and driver assembly

4 B55518 2 Lever return spring

5 B55504 2 Thrust plate

6 B54172 1 Chassis cover

7 B54886 1

8 A55673 1

9 C55515 1

10

not shown

not shown

11

not shown

12 A55505 2 Chassis screw

a. Specify finish.

b. For use with non-interchangeable cores.

c. For use with large format interchangeable cores.

A55687

A55725

A88631

D55571

D5600311

Retractor assembly with long catchplate

Key release cam assembly

Spring drive plate

Keyed sleeve assembly or

1

Keyed sleeve assembly

1

1

Keyed sleeve assembly

Outside hub or

Outside hub, lost motion

a

b

c

12

11

10

9

4

5

8

7

Outside

1

Inside

Figure 2.5 E function exploded diagram

6

5

4

Functions and Parts Lists

3

E

2

2–16 9K Series Service Manual

G FUNCTION CHASSIS—STOREROOM LOCK (ANSI F91)

Item Part No. Qty. Description

1

not shown

2

not shown

not shown

3 C55515 2 Spring drive plate

4 B55518 2 Lever return spring

5 B55504 2 Thrust plate

6 B54172 1 Chassis cover

7 A55676 2 Key release cam assembly

8 B54888 1 Retractor assembly without catchplate

9 A54195 1 Locking bar

10

not shown

11 A55505 2 Chassis screw

a. For use with non-interchangeable cores.

b. For use with large format interchangeable cores.

A55685

A5600811

A55687

A55725

A88631

D55571

D5600311

Inside hub and locking pin assembly or

Inside hub assembly, lost motion

Keyed sleeve assembly or

2

2

Keyed sleeve assembly

Keyed sleeve assembly

2

Outside hub or

Outside hub, lost motion

a

b

Functions and Parts Lists

11

7

9

2

7

3

4

Outside

10

Inside

1

Figure 2.6 G function exploded diagram

5

8

6

5

4

G

3

2

9K Series Service Manual 2–17

H FUNCTION CHASSIS—HOTEL GUEST ROOM LOCK WITH INDICATOR (ANSI F93)

HJ FUNCTION CHASSIS—HOTEL GUEST ROOM LOCK WITHOUT INDICATOR

a

Item

1 B55693 1 Push button assembly

2 A55685 1 Inside hub and locking pin assembly

3 B55610 1 Non-keyed sleeve and driver assembly

4 B55518 1 Lever return spring

5 B55504 2 Thrust plate

6 B54172 1 Chassis cover

7 B54886 1 Retractor assembly with long catchplate

8 A55677 1 Key release cam assembly

9 C55515 1 Spring drive plate

10 A55687 1 Keyed sleeve assembly

11

not shown

12 A55505 2 Chassis screw

a. These functions require a special throw member. See page 2–54.

b. Specify finish.

Part No. Qty. Description

D55571

D5600311

Outside hub or

Outside hub, lost motion

b

8

12

11

10

Outside

9

5

1

Inside

Figure 2.7 H/HJ function exploded diagram

7

6

5

4

3

H, HJ

2

Functions and Parts Lists

2–18 9K Series Service Manual

L FUNCTION CHASSIS—PRIVACY LOCK (ANSI F76)

Functions and Parts Lists

Item Part No. Qty. Description

1 B55693 1 Push button assembly

2 A55685 1 Inside hub and locking pin assembly

3 B55610 1 Non-keyed sleeve and driver assembly

4 B55518 2 Lever return spring

5 B55504 2 Thrust plate

6 B54172 1 Chassis cover

7 B54886 1 Retractor assembly with long catchplate

8 A55673 1 Key release cam assembly

9 C55515 1 Spring drive plate

10 A55701 1 Keyed sleeve assembly

11

not shown

12 A54745 1 Button release assembly

13 A55505 2 Chassis screw

a. Specify finish.

D55571

D5600311

Outside hub or

Outside hub, lost motion

a

12

9

4

5

8

7

13

11

10

Outside

1

Inside

Figure 2.8 L function exploded diagram

6

5

4

3

L

2

Loading...

Loading...