Page 1

Installation Instructions

for 48H & 49H Mortise Locks

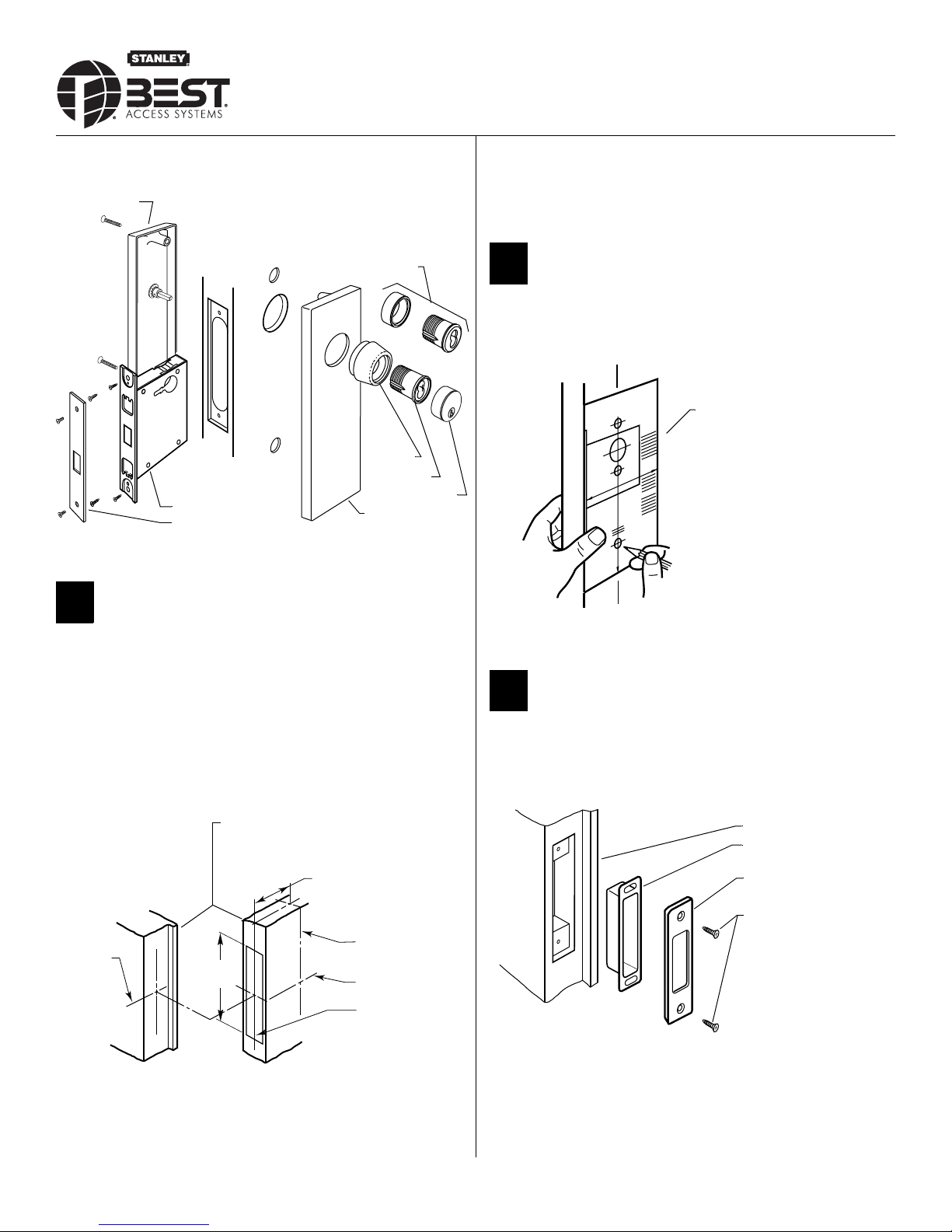

Overview

49H inside trim

Mortise lock

Faceplate

Figure 1 48H and 49H Mortise Lock overview diagram

48H Trim

49H Ring

49H Cylinder

49H Cylinder face

49H Outside

escutcheon

2 Mark the vertical centerline of the lock on the door edge.

3 Mark the vertical centerline of the lock on both sides of the door as

measured from the vertical centerline on the door’s edge.

4 Mark the horizontal centerline of the strike on the door jamb in line

with the centerline of the lock.

2 Mark drill points

1 Cut the H18 template along the dotted line and align the horizontal

and vertical arrows to the marked centerlines on the door.

H18 template

1 Mark centerlines

Caution: If you use hollow metal doors, decide whether the

doors are reinforced enough to support the lock. If the door

reinforcement is not adequate, consult the door manufacturer

about proper reinforcement.

Note: Prepare the door according to ANSI A115.1 before using these

instructions.

1 Mark the horizontal centerline of the lock on both sides of the door

and on the door’s edge.

Door to jamb gap: 1/16” to 3/16”

2 3/4” backset

Vertical center-

Centerline

of strike

line of lock

Horizontal centerof lock

Vertical centerline of door’s edge

Figure 3 Marking the drill points with the template

2 Tape the template onto the door.

3 Install strike

1 Using the H18 template, mortise the jamb and install the strike and

strike box. See Installation Specifications, Template H17 for dimen

sions.

Jamb

Strike box

Strike plate

#8–32 combination

screws

Figure 4 Installing the strike box and strike

-

Figure 2 Marking the centerlines on the door

Note: BEST suggests a 38" height as measured from floor to lock centerline.

T81175/Rev – ER-7991-19 Nov 2005

BEST ACCESS SYSTEMS

a Division of Stanley Security Solutions, Inc

1

Page 2

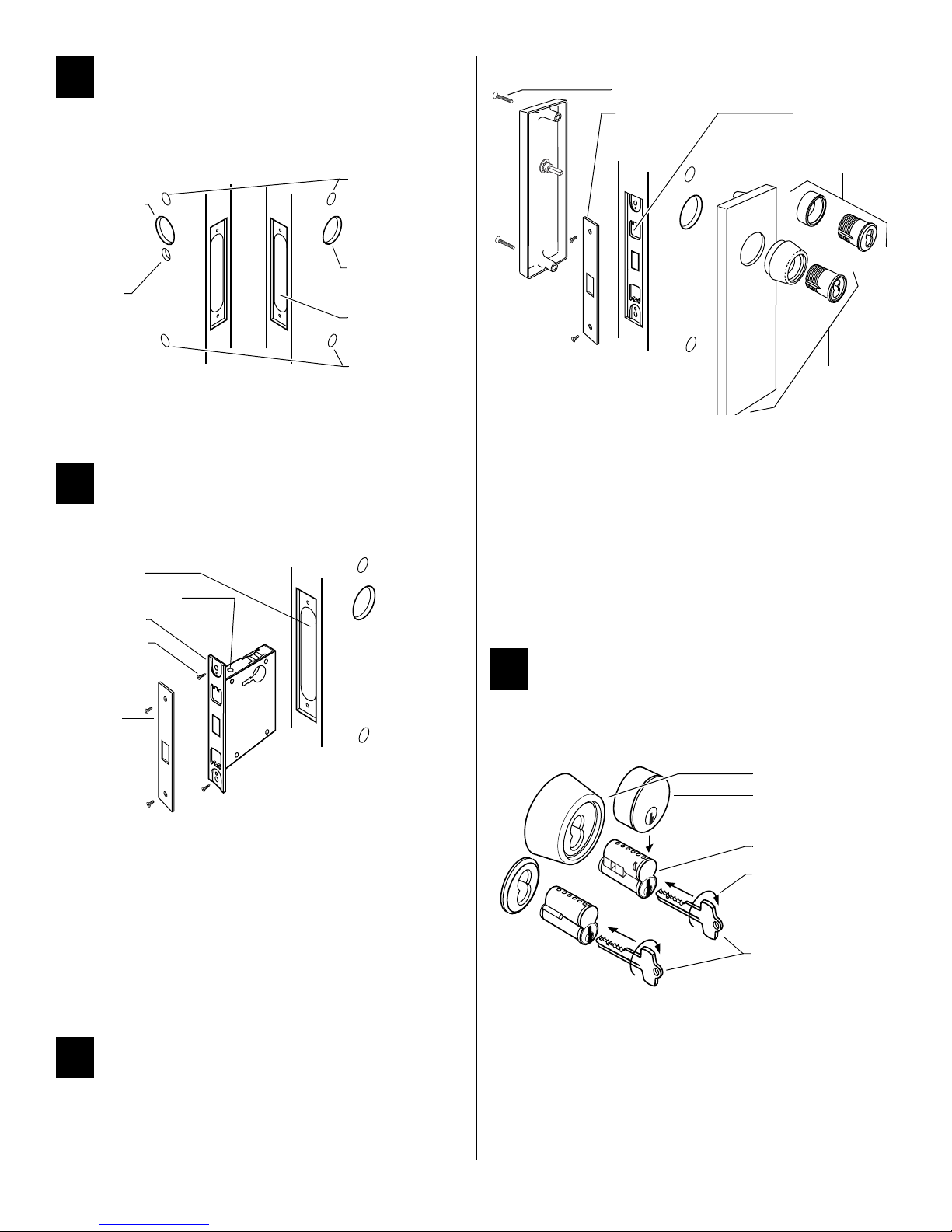

4 Mortise and drill holes

1 Mortise the door for the lock case and faceplate.

Note: Check the lock for function before drilling.

Inside cylinder

hole

‘K’ function

turn knob hole

Escutcheon

hole

Outside cylinder

hole

Mortise for lock

case & faceplate

3 Reinstall the faceplate.

Through-bolts

Faceplate

Cylinder clamp

screw (inside)

Standard cylinder

& ring (48H)

Inside Outside

Escutcheon

hole

Figure 5 Mortising and drilling holes

2 Drill only those holes required for the lock function and trim. See

Installation Specifications for hole requirements in Template H17.

5 Install mortise case

1 Remove the faceplate from the lock.

Mortise cavity

Bevel adjusting screw

Armored front

Case mounting

screws

Faceplate

High-security

cylinder, ring, &

escutcheon (49H)

Figure 7 Installing 48H or 49H trim

4 Check the lock for proper operation.

To install 49H trim:

1 Position inside and outside escutcheons opposite each other and

screw them loosely in place.

2 Put the high security cylinder(s) and ring(s) into the cylinder hole(s).

Thread the cylinder(s) into the case until the cylinder head touches

the inside rim of the ring.

3 Secure the cylinder(s) with the cylinder clamp screw(s).

4 Tighten the through-bolts.

5 Reinstall the faceplate.

7 Install core

For 5C cores only:

■ Slide the cylinder face down over the 5C core.

High security cylinder

Cylinder face

Figure 6 Installing the mortise case

2 Loosen the bevel adjusting screws on the top and bottom of the lock

case and adjust the bevel of the armored front to match the door

bevel. Retighten the screws.

For ‘R’ function only:

■ Check the cylinder and lock for proper operation.

Caution: If the handing of the ‘R’ turn knob is incorrect, you can

be locked in.

3 Install the lock into the mortise cavity.

4 Secure the lock case with the case mounting screws.

6 Install trim

To install 48H trim:

1 Install cylinder(s) and ring(s) and fasten with cylinder clamp screw(s).

2 Install thumb turn if needed.

5C core

Turn 15 degrees

Control key

Figure 8 Installing the core

For all cores:

1 Put the control key into the core (or cylinder face) and turn the key

15 degrees clockwise.

2 Adjust the throw pins if needed, then put the core (and cylinder face)

into the cylinder with the control key.

3 Turn the key 15 degrees counterclockwise and remove the key.

Note: Follow these steps to remove the core also.

BEST ACCESS SYSTEMS

a Division of Stanley Security Solutions, Inc

Loading...

Loading...