Page 1

BST-MG08/09 Multi-gas Detecting Alarm

Manual Instruction

1. Application: This product is designed to ensure sa fety for users who work in dangerous

places. It’s used for detecting CO, O2, H2S, CH4 simultaneously and alarm users by light,

sound and vibration. This device is portable, anti-explosion and intrinsically safe.

2.

Features:

1. Measured gases: Combustible Gas(LEL/CH4), Oxygen(O2), Carbon Monoxide(CO), and

Hydrogen Sulfide(H2S). Contact manufacturer f

or other gas combinations.

2. It will alarm users by sound, vibration, and light with different intensity if actual

concentration is higher or lower than preset alarm points.

3.

Operation:

1. 4 buttons included.

On/Off button; OK button; ▲Up button; ▼Down button

2. Long press

On/Off button to activate the device. It will show below information in

turn:

A. Product brand

B. Low Alarm [L]

C. High Alarm [H]

D. STEL Alarm [S]

E. TWA Alarm [T]

F. Preset Calibration Value

G. Product number and next calibrate date, 30 seconds countdown

H. Auto Zero option

3. In auto zero option, after seeing “Adjust Zero?”, long press “OK” button to zero all

sensors, short press “

” button to exit. When the device is zeroed in unfresh air, the

system will zero itself when the device is back to fresh air, n o need to worry about the

accuracy.

4. In main interface, it shows 4 alarm icons on top area: [L], [H], [S], [T], if there is any alarm,

the corresponding icon will turn red. Short press “▲” to switch among STEL, TWA, PEAK,

and MIN. No operation for 30 seconds will bring it back to main interface.

5. Long press “OK” button to enter function interface.

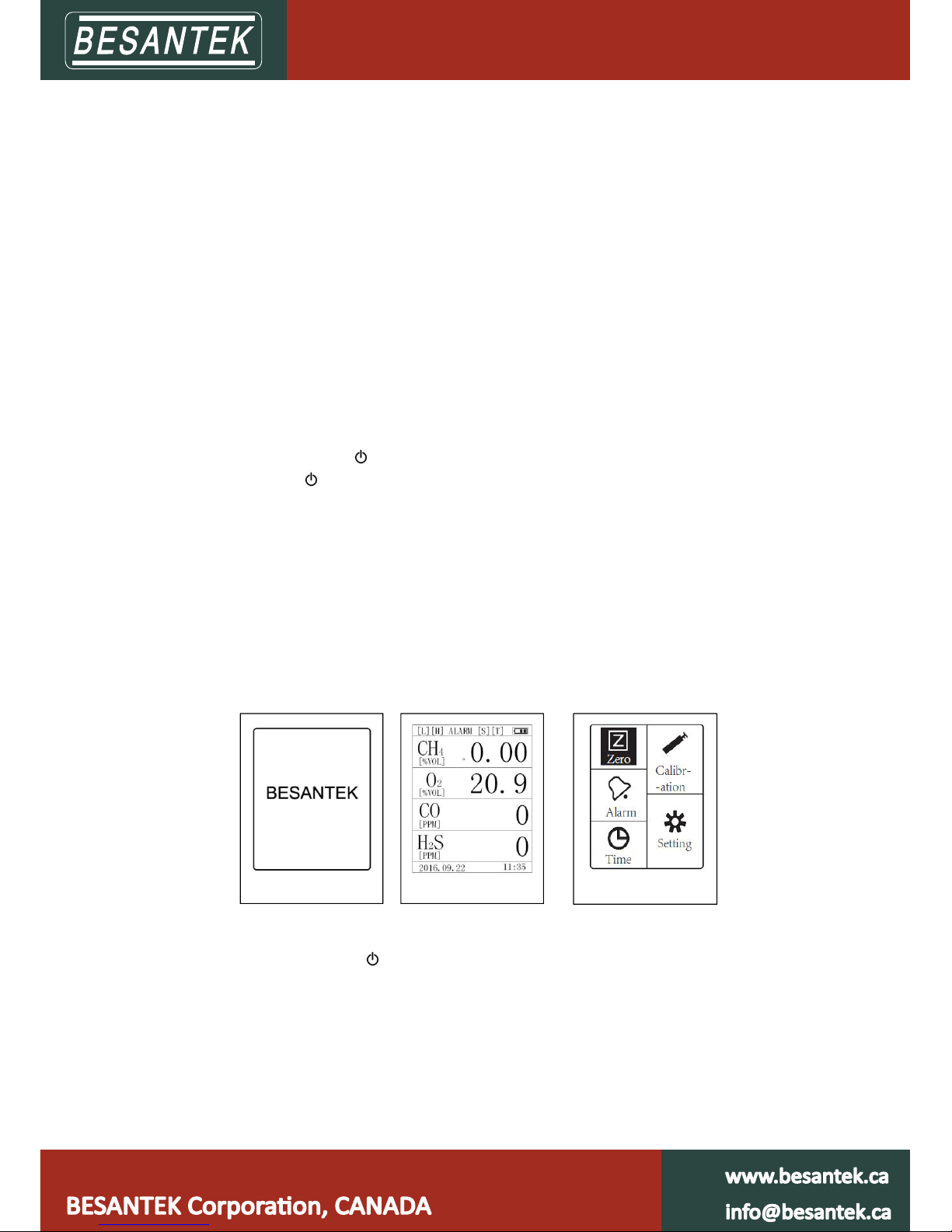

LOGO

Main Interface

Function interface

Page 2

6. In f unction interface, short press “▲ ” or “▼” to select function, then short press “OK”

button to enter corresponding function.

7. In zero interface, short press “ ▲ ” or “ ▼ ” to select gas, long press “OK” button, the

background of selected gas will turn red, long press “OK” button again to c o mplete the

operation with display “set OK”. If there is no “set OK” showed, it means operation is

failed. Short press “

” to exit.

Notice: Use 100%vol nitrogen gas to zero oxygen sensor, for other sensors, it can be done in

fresh air.

8. In alarm interface, short press “▲” or “ ▼” to select among “Set Low Alarm”, “Set High

Alarm”, “Set STEL Alarm”, and “Set TWA Alarm”. Short press “OK” bu tton to enter each

setting “Alarm[L]”, “Alarm[H]”, “STEL[S]”, “TWA[T]”, short press “▲ ” or “▼ ” to set the

value, long press “OK” button to complete the operation with displ ay “set OK”. Short

press “

” to exit.

9. In time setting interface, short press “OK” button to select “Year”, “Month”, “Day”,

“Hour”, “Min”, then press “▲ ” or “▼ ” to adjust the value. Long press “OK” button to

complete this operation with display of “Set OK”. Short press “

” to exit.

10. In calibration setting interface, short press “▲” or “▼” to select between“Set Value”

and “Common Calibration”

A. “Set Value”: user should input available calibration gas concentration here, short

press “OK” button to select among gases and short press “▲ ” or “▼ ” to adjust gas

values, long press “OK” button to complete this setting with display of “Set OK”.

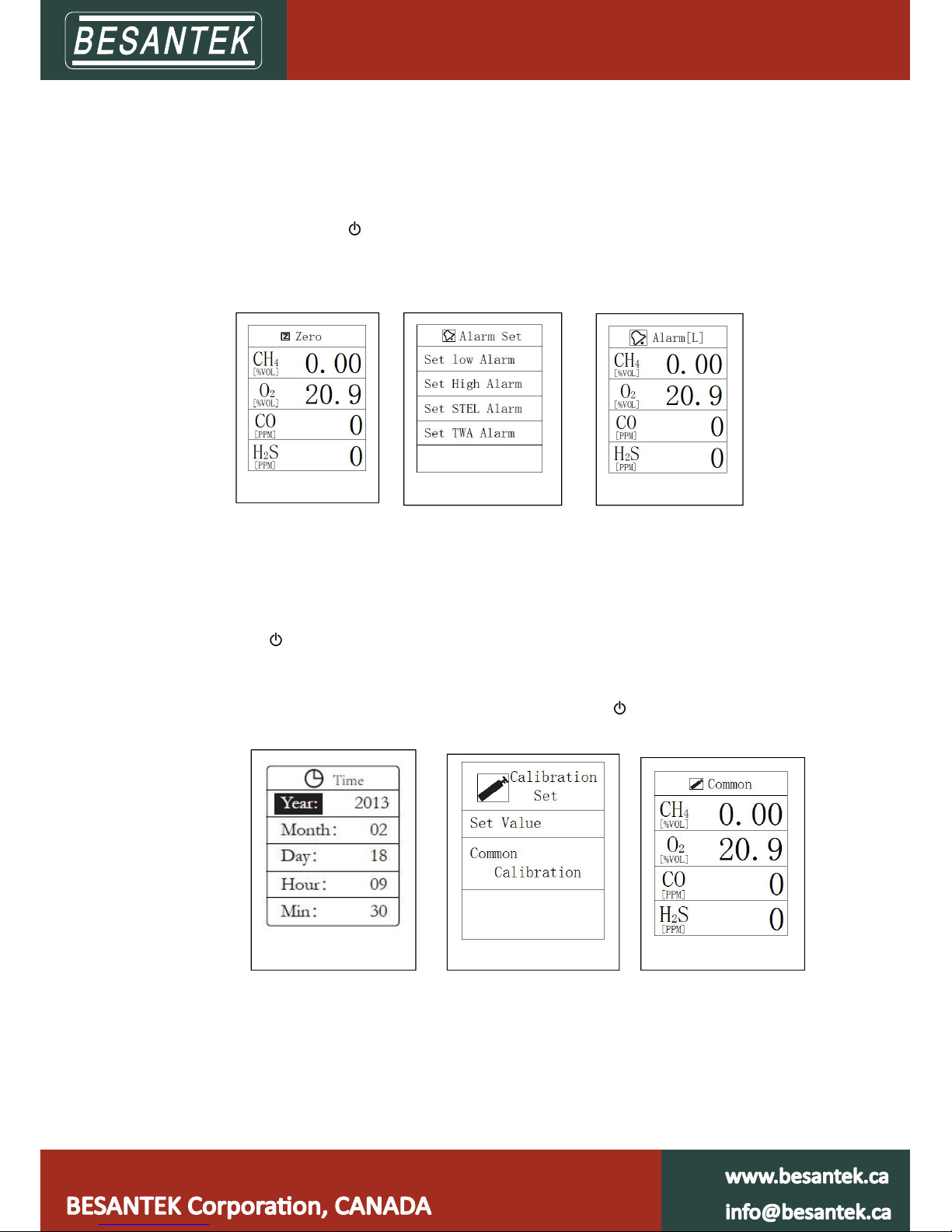

Zero Interface

Alarm Set

Low Alarm setting

Time Setting

Calibration Setting

Common Calibration

Page 3

Important: user should make this setting before following operations.

B. In “Co mmon Calibration” interface, short press “▲” or “▼” to select gas, long press

“OK” button, the background of selected gas will turn red, connect calibration gas

and after the value is stable, long press “OK” button to complete this operation with

display of “Set OK”. Short press “

” to exit.

Notice:

a. Before calibration, a ctivate this device for at least 6 minutes to allow it run stably

b. When the device is alarming for low power, stop calibration and charge it right away

c. Calibration gas must be standard gas used for calibration purpose

d. Zero sensors firstly before calibration

e. Make sure gas flow is stable before connecting calibration gas, calibration gas flow for CH4,

CO, O2 is 200ml/min, 300ml/min for H2S.

f. Suggested calibration gases are

as following:

CH4 1.00%vol, CO 500ppm, H2S 50ppm, oxygen can be calibrated in fresh air

11. In setting interface, short press “ ▲ ” or “ ▼ ” to select among “CH4”, “LEL”, “PPM”,

“MG/m³ ”, “Allow Calibration”, “√ ” means item is selected. Long press “OK” button to

select a nd confirm. Short press “

” to exit.

Important: User can’t enter calibration i nterface without choosing “Allow Calibration”

4.

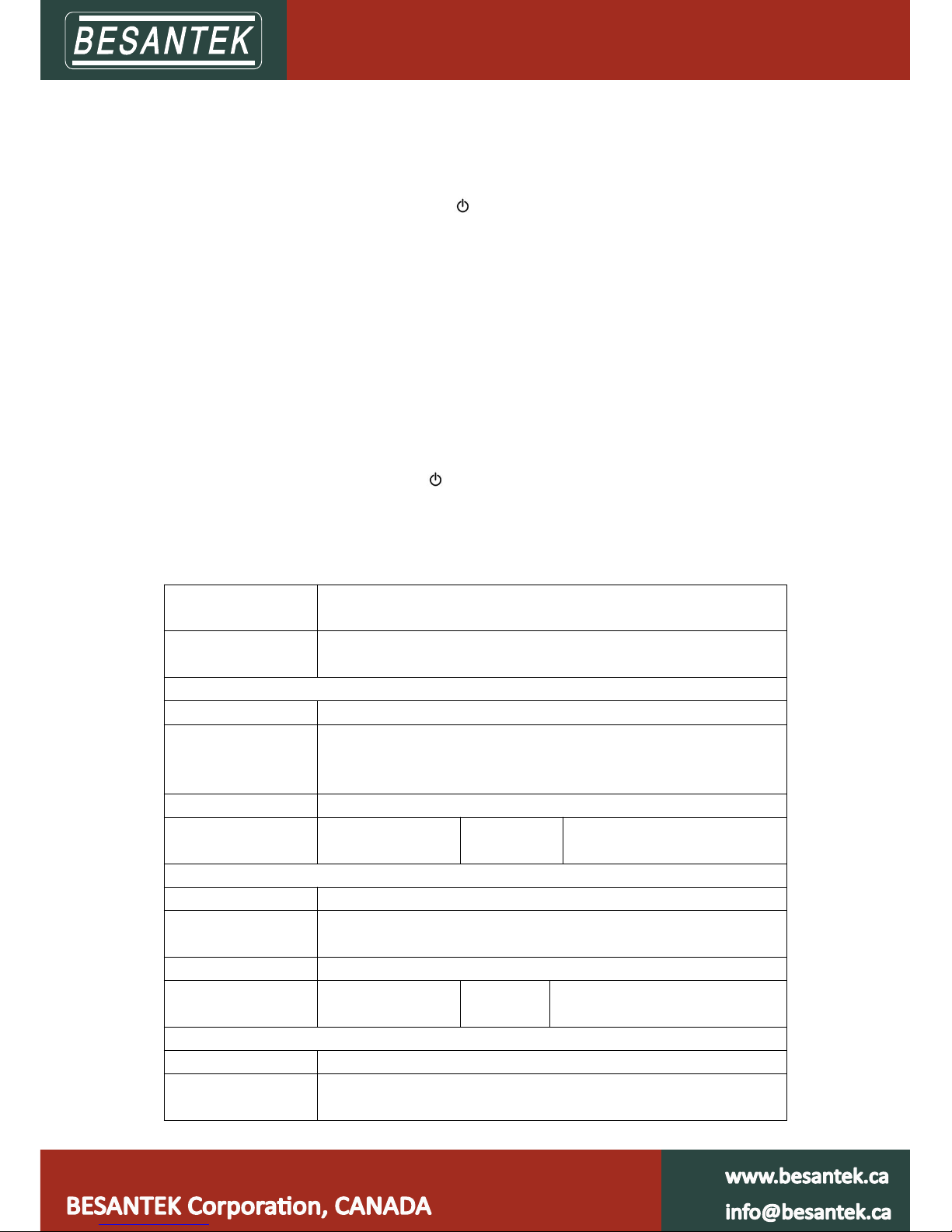

Technical Parameter:

Technical

Specification

Parameter

Measured gas Methane(CH4), Oxygen(O2),

Carbon Monoxide(CO), Hydrogen Sulfide(H2S)

Methane (CH4)

Measurement range (0.00~5.00)%vol

Measurement error

(0.00~1.00)%vol: ±0.10%CH4

(1.00~3.00)%vol: True value±10%

(3.00-5.00)%vol: ±0.30%CH4

Respond time

≤20s (T90)

Resolution

0.01%vol Alarm point

1.0

0%vol (Adjustable for full

range)

Oxygen (O2)

Measurement range (0.0~30.0)%vol

Measurement error

(0.0~5.0)%vol: O2:±0.5%vol

(>5.0~30.0)%vol: O2:0.9%vol

Respond time

≤35s (T90)

Resolution

0.1%vol Alarm point

18.0%vol(Adjustable for full range)

25.0%vol(Adjustable for full range)

Carbon Monoxide (CO)

Measurement range (0~1000)ppm

Measurement error

(0~20)ppm:±2ppm

(>20~100)ppm:±4ppm

Page 4

(>100~500)ppm: True Value±5%

(>500~1000)ppm:True value±6%

Respond time

≤

45s (T90)

Resolution 1p pm Alarm point 24%vol(Adjustable for full range)

Hydrogen Sulfide (H2S)

Measurement range (0~100)ppm

Measurement error

(0~50)ppm:±3ppm

(>50~100)ppm: ±10%

Respond time

≤45s (T90)

Resolution 1p pm Alarm point 10ppm(Adjustable for full range)

Sensor lifetime

CH4:≥1 year

CO,H2S,O2:≥2 years

Alarms

Audible--buzzer with ≥85dB @1m audible

Visible--flashing red LED, ≥

20m visible

Vibration

Charging time 4-5hours

Continuous operating

hours

13 hours

Battery model PL123450, 3.7V/1500mA

Protect Grade IP66

Working temperature

-25

℃

~

50

℃

Size(mm) 130*70*37

Data logging for

MG08 only

Continuously data logging

(100000 records with 1-10 minutes interval)

Enclosure

PC+ABS with resistance ≤10

-9

Ω

Display Color Screen LCD

≥

Safety Standard:

- CE: EN 50270:2006

MA/KA: GB3836-2010

EX: GB3836.1-2010 & 3836.4-2010

Page 5

External Sampling Pump

Manual Instruction

Product description:

This gas sampling pump can be used with any portable gas detectors, and detect target

gas as far as 30 meters. With 4 LED indicators, user can know power left easily.

Technical parameter:

Sampling Air Flow

Sampling Distance

Working Temperature

Working Humidity

Power Source

Output

Input

Charging Time

Weight

How to turn ON and OFF this pump:

Long press power switch to activate this pump and long press power switch again to

shut it off.

1600ml/min

30m

-20~50�

≤90%RH

3.7V rechargeable lithium battery

5W

DC5V 1A

8h

200g

Page 6

Gas Check User’s Guide

1. Gas Detector Data Collection Setting

1.1. Activate gas detector by long pressing button.

1.2. Long press OK button to function interface

1.3. Press up/down button and choose “Setting”, enter it by short pressing OK button

1.4. Press up/down button and choose “Data Store”,enter it by short pressing OK button

Use: The amount of data have been collected & stored

Total: Total amount of data can be collected & stored

Time: Configurable time interval between 1-600s for data collection

Stop: Stop data collection. Short press

button to confirm.

Start: Start data collection. Short press OK button to switch between “Stop” and “Start”, long press OK

button to confirm.

OK button to switch between “Stop” and “Start”, long press OK

1.5. After well setted, user can find

storing data.

Notice: when gas detector is connected with Gascheck software for real-time data collection, gas detector

data collection will be out of work.

on top of detecting interface, which means device is collecting&

2. Gascheck Driver and Software Installation

2.1. Open CD-Rom Driver on your computer and put the offered CD into it

2.2. Read the CD and find

OS.

2.3. Double click “PreInstaller.exe” or “CP210xVCPInstaller.exe” and click “Install”, then you’ll see

window prompt with “Installation Successfully”.

2.4. To confirm this driver has been installed successfully: right click “My Computer”and choose “Device

manager “ and unfold “Port (COM and LPT)” you’ll find “silicon Labs CP210× USB toUART Bridge”.

2.5. Find “Gas Check Setup”, install this software by dou

for installation

Notice: Before connecting gas detector with Gascheck software, please install driver firstly, or gas

detector can’t be recognised by software.

Gas Check Driver programme, then choose right file according to your computer

ble clicking this setup, follow window prompt

3. Gascheck operation

3.1. Double click “Gas Check” icon on your desktop, and connect with activated gas detector using USB

cable.

3.2. Click “Connect”to connect gas detector with this software, after well connected, status wi

“Connected”and model number will come out.

ll become

Page 7

3.3. After connection, date and time on gas detector will synchronize automatically with computer.

“Real-time” is for collecting real-time data, these data will only store on computer, check&analyze these

data on “Data show” section “Real-time data”.

“History data” is for checking data collected by gas detector or data have been stored on computer

A. Real-time data collection and checking

1. Click “Modify” to set interval time from 1-10 min, click “Save”to confirm.

2. Switch “Real-time” ON, you’ll get real-time data and they will be shown on “Show Data” chart.

3. Stop real-time data collection by switching OFF.

B. Gas detector data collection and checking

1. Click “Get data” to get data collected by device, time needed is 1-6 minutes, device will show

“Loading” during this period.

2. Check&analyze these data on “Data show” section “History data”.

3. This software can get and store data from several gas detectors, when data acquisition finished for one

device, click “Disconnect” and connect with another one.

4. Click “Clear data

” to delete all data collected by gas detector

5. When collecting data by device, user has 2 operation methods

a. Set device following “Gas detector data collection setting”

b. Set “Device setting” on software

1)Set valid start and stop time, click “Modify” to set time interval from 1-10m, then click “Save” to

finish.

2)User will find

on top of detecting interface, which means device is collecting& storing data.

3)Accident power ON or OFF during start and stop time will not affect data collection, after restarting,

data collection will go on .

3.4. “Show data” section

Tick the colorful boxes to choose gases needed to be shown up on chart.

“Real-time data” is for real-time collected data.

Page 8

“History data” is for data collected by gas detector and data have been stored on computer.

“Select device” to see available history data of a certain gas detector.

“DEL” is to delete just model number of gas detectors which have been registered on this computer, this

function is for a better management of more than one gas detector you use. When you register it the

second time, you’ll find all history data.

r can also check data in a certain day by setting start-stop time, start and stop time need to be in same

Use

day; if not, you’ll get min, ave, max values for each gas and each day.

Place mouse pointer on any point of collected data curve, you’ll get exact time and concentration of this

data.

Press left mouse and drag from left to right to spread all detailed data points, and drag from right to left to

pull back, o

r click cross point of x and y axises to pull back.

On right side of the chart, you’ll find 3 gas analyzing circle diagrams with “Avg”

“Min””Max”, tick circles below to see analysis for each gas.

Click “Disconnect” to disconnect this gas detector with software, status will become:

Disconnected

Click “Export” to export data in excel format.

Loading...

Loading...