BERTHOLD TECHNOLOGIES LB4710-050, LB4710-060, LB4710-160, LB4710-080, LB4710-090 User Manual

...

Process Control

Limit Switch

Mini-Switch LB 471

Hardware Manual

ID No. 39505 BA2

Rev. No.: 03 17. Nov. 2015

Soft. Version: 1.12 or higher

detect and identify

User’s Guide

The units supplied should not be repaired by anyone other than Berthold Service engineers or technicians by Berthold.

In case of operation trouble, please address to our central service department.

The complete user’s guide consists of two manuals, the hardware description and the software description.

The hardware manual comprises:

mechanical components

assembly

electrical installation

radiation protection guidelines

technical data

electrical and mechanical drawings

The software manual comprises:

operation of the evaluation unit

parameter description

basic setting

calibration

error messages

The present manual is the hardware description.

Subject to change in the course of further technical development.

Table of Contents

5

Table of Contents

Page

Chapter 1. General Information 9

1.1 Use and Function 9

1.2 Target Group 9

1.3 Radiation Protection Courses 10

1.4 Definitions 10

1.5 Safekeeping of the User’s Guide 12

Chapter 2. Safety 13

2.1 Safety Concept 13

2.2 Symbols and Pictograms 13

2.3 Radiological Safety Officer 14

2.4 Duty of Notification 14

2.5 Radiation Protection Areas 15

2.5.1 Exclusion Areas 15

2.5.2 Controlled Areas 15

2.5.3 Monitoring Areas 16

2.6 Safety Installations 17

2.6.1 Source Shieldings 17

2.7 General Safety Instructions 19

2.8 Emergency Instructions 19

2.8.1 Theft Protection 20

Chapter 3. Functional Safety 21

3.1 Use and Function 21

3.2 Safety Function 22

3.3 Safety Requirement 22

3.4 Project Planning 22

3.5 Getting Started 24

3.6 Behavior during Operation and Malfunctions 28

3.7 Recurrent Performance Test 29

3.8 Safety-Technical Data 29

Chapter 4. Instrument Description 36

4.1 Function 36

4.2 Mini Switch LB 471 Versions 37

4.2.1 Type Code 39

4.3 Detectors 40

4.3.1 GM Detector 40

4.3.2 NaI Detector 41

4.3.3 Super-Sens Detector 43

Chapter 5. Installation 45

5.1 Transport to the Installation Site 45

5.1.1 Transporting Detector and Evaluation Unit 45

5.1.2 Transport Shielding with Source 45

Mini-Switch LB 471

Table of Contents

6

5.1.3 Temporary Storage of Sources 46

5.1.4 Installation Site 46

5.1.5 Unpacking and Cleaning System Parts 46

5.2 Installing the Detector 47

5.2.1 Fastening Clamps for GM Detectors and NaI Counters 48

5.2.2 Stainless Steel Detector Holder (Alternative) 48

5.2.3 Installation of the GM Detector 49

5.2.4 Installation of the GM Detector 51

5.2.5 Installation of Super-Sens with Axial Irradiation 54

5.2.6 Installation of Super-Sens with Radial Irradiation 56

Chapter 6. Water Cooling 59

6.1 Subsequent Installation of Water Cooling (Option) 61

6.1.1 Water Cooling for NaI Detector with Collimator 62

6.1.2 Water Cooling for NaI Detector with Collimator 64

6.1.3 Water Cooling for GM Detector 65

6.2 Amount of Cooling Water Required 66

Chapter 7. Shielding Installation 67

7.1 General Installation Instructions 67

7.2 Installation Proposal for Shielding 68

7.3 Pneumatic Shielding Shutter (Option) 70

Chapter 8. Electrical Installation 71

8.1 Connecting Evaluation Unit and Detector 72

8.1.1 Pin Assignment of Terminal Block 73

8.1.2 Installing NaI Detector or Super-Sens 74

8.1.3 Installing the GM Detector 75

8.2 Digital In-/Outputs 77

8.2.1 Relays 77

8.2.2 Digital Input 77

8.3 Connecting the Evaluation Unit to Power 78

Chapter 9. Maintenance 79

9.1 Malfunctions 79

9.2 Replacing Fuses 79

9.3 Replacing the Evaluation Unit 80

9.4 Repairing the Detector 80

9.4.1 Dismantling the NaI Detector 81

9.4.2 Checking the Crystal-Multiplier Combination 84

9.4.3 Assembly of Crystal-Multiplier Combination 85

9.4.4 Plateau Measurement 86

9.4.5 Dismantling the GM Detector 87

9.5 Replacing the Source 88

9.5.1 Replacing the Source 90

9.6 Customer’s Service 92

9.6.1 Sending in the Electronics 93

9.6.2 Sending in Source and Shielding 94

Mini-Switch LB 471

Table of Contents

7

Chapter 10. Servicing the Shielding 95

10.1 Checking Shielding and Source 95

10.1.1 Testing the Locking Mechanism 95

10.2 Leak Test 96

10.2.1 Leak Test Documentation 96

10.2.2 Performing a Wipe Test 97

Chapter 11. Radiation Protection 99

11.1 Basics and Directives 99

11.2 Radiation Dose Calculations 101

11.3 Calculation with a given Dose Rate 101

11.4 Activity-based Calculation 102

Chapter 12. Disposal 103

Chapter 13. Technical Data 105

13.1 Evaluation Unit 105

13.2 Detectors 106

13.3 Shieldings 108

13.4 Pneumatic Locking Drive 108

Chapter 14. Certificates 109

14.1 ATEX Certificate for Evaluation Unit LB 4710-XXX 109

14.2 ATEX Certificate NaI Detector 113

14.3 ATEX Certificate GM Detector 117

14.4 EC Declaration of Conformity 119

Chapter 15. Technical Drawings 121

15.1 NaI Detector 121

15.2 GM Detector 122

15.2.1 Fastening Clamps 123

15.2.2 Detector Holder for GM Detector and NaI Counter 124

15.3 Super-Sens Detectors 125

15.4 Point Source Shielding LB 744X 131

15.5 Dimensions of the Evaluation Unit 134

15.5.1 19" Rack 134

15.5.2 Wall Housing 135

15.5.3 Cassette 136

15.6 Connection Diagrams 137

15.6.1 19" Rack 137

15.6.2 Wall Housing 138

15.6.3 Cassette 139

15.6.4 Connection Diagram for Power Supply Unit in 19" Rack 140

Mini-Switch LB 471

Chapter 1 General Information

9

Qualification

Training

Chapter 1. General Information

1.1 Use and Function

The limit switch system LB 471 Mini Switch has been designed for

monitoring and detection of levels in containers and pipelines.

Licensed as an “overflow protection device for containers storing

liquids that are hazardous to waters” in accordance with the Water

Resources Act, the system may also be used as overflow protection device.

Beyond this scope, each application is considered as not being in

compliance with the law and may result in severe personal injury

or property damage.

BERTHOLD TECHNOLOGIES does not assume any liability for this kind

of injuries or damage.

1.2 Target Group

This user’s guide has been written for operating, assembly and

service personnel.

The system may only be assembled, serviced and maintained by

authorized and trained persons. Any modification of the settings

may only be carried out by persons who are familiar with the function of the system. Persons working with ionizing radiation must be

familiar with the rules of radiation protection and adequate work

techniques.

Personnel have to be specially trained and informed about possible

hazards. Detailed knowledge of this user’s guide and careful observation of the instructions contained therein is an essential prerequisite.

Each staff member has to know the major rule of the “ALARA principle” (as low as reasonably achievable).

BERTHOLD TECHNOLOGIES is offering appropriate training courses.

Depending on the participant’s professional qualifications, two

kinds of training can be chosen:

Mini-Switch LB 471

Chapter 1 General Information

10

Automatic

Some parameters can either be set to the automatic or manual

mode. In the automatic mode the value is calculated using a

formula. Enter -1 to enable the automatic mode. The inverted C

in the top row indicates whether a parameter has been set to

automatic.

EVU

Evaluation Unit

Edit

Change value

Edit mode

In this mode, a value can be changed. Not every parameter can

be changed since some parameters are only used as display

values. Editable Parameters can be set to the edit mode with

the “Enter” button. In the edit mode the cursor positioned over

a digit is flashing.

GM detector

Detector with Geiger-Müller counter tube

NaI detector

NaI = sodium iodine crystal = scintillator

Scintillation detectors are very sensitive to Gamma radiation.

See pages 40 and 121.

Super-Sens detector

Detector which is highly sensitive to Gamma radiation with

large-volume plastic scintillator 150x150mm

See pages 43 and 125.

Limit value

Count rate or percentage value upon reaching the measurement level

1.3 Radiation Protection Courses

Special course in radiation protection

(Duration: 2 days)

This course is needed if the participant has not yet received any

radiation protection training. A successfully completed course

has a validity of 5 years.

Refreshing course in radiation protection

(Duration: 1 day)

All persons who have already successfully completed the special course may refresh their special knowledge with this course

(Radiation Protection Ordinance of August 1, 2001).

A successfully refreshing course has a validity of 5 years.

1.4 Definitions

Mini-Switch LB 471

Chapter 1 General Information

11

HV

Detector high voltage

Cassette

Case (7 TE) into which the evaluation unit LB 4710 is installed,

so it can be used in any 19" rack

Empty

Level below limit value.

Empty count rate

Count rate with empty container

Manual

Some parameters can either be set to the automatic or manual

mode. For the manual mode you have to enter a fixed value in

the respective parameters.

Nuclide / Isotope

Type of radiation source: Cobalt-60 (Co-60) or Cesium-137

(Cs-137) for level measurements.

Zero count rate

Count rate caused by natural environmental radiation.

Parameters

A value stored under a certain code.

Timeout

Time after which an automatic reset is performed.

Full

Level below limit value.

Full count rate

Count rate with full container.

Count rate

Value of counts relative to one second.

cps

Count rate unit: Counts per second.

Read in count rate

A process that is started by the user in order to determine the

average value of the count rate at the respective level. This

count rate is needed to calibrate the measurement. The count

rate is averaged over a certain time (standard 60 s) to exclude

statistical and process-immanent fluctuations.

Factory setting

All parameters have been preset by the manufacturer using

standard values. In most cases this simplifies calibration of the

instrument significantly. Despite factory setting, calibration al-

ways has to be performed.

mSv

Dose rate unit

Millisievert

Mini-Switch LB 471

Chapter 1 General Information

12

MBq

Mega-Becquerel

This unit indicates the source activity. Each Bq corresponds to

one decay per second..

1 MBq = one million decays

mCi

Milli-Curie

This unit is also used for the activity of a source. However, this

unit has been replaced by the unit MBq (1mCi = 37 MBq)

Note!

This user’s guide always has to be available at a fixed place. The

personnel have to be informed about this place. Any time the device is used by another operator and whenever there is a change

in ownership of the device, the user’s guide has to be given to the

new operator or owner.

1.5 Safekeeping of the User’s Guide

Mini-Switch LB 471

Chapter 2 Safety

13

Danger!

Possible danger for life and health hazard

Caution!

Possible hazard

Minor personal injuries

Warning!

Possible hazard

Property damages

Note!

Tips for application and useful information

Chapter 2. Safety

2.1 Safety Concept

The state-of-the-art system is designed in accordance with accepted safety rules to ensure the greatest possible on-the-job safety.

To rule out health hazards when handling radioactive substances,

limit values stating the highest acceptable radiation exposure of

the operating personnel have been defined on an international level. These limits have to be observed when designing shieldings and

planning the configuration of the measuring system at the measurement point.

2.2 Symbols and Pictograms

The following symbols identify safety instructions in this user’s

guide:

The safety instructions are supplemented by explanatory pictograms, for example:

Mini-Switch LB 471

Chapter 2 Safety

14

Caution!

Radioactivity!

In case of suspected damage to the shielding, the radiological

safety officer has to be informed immediately. Further steps can

be taken in consultation with BERTHOLD TECHNOLOGIES.

2.3 Radiological Safety Officer

To ensure proper handling and the observance of the statutory

requirements the operating company has to appoint a radiological

safety officer who is in charge of all radiation protection issues in

connection with the measuring system.

The radiological safety officer has to:

monitor working with the radiometric measuring system

draw up a plan for the organization of radiation protection

monitor compliance with the regulations of the Radiation Pro-

tection Ordinance

issue directives and carry out training and instruction of the

employees

get on-site information on the situation and takes appropriate

actions immediately if operation problems have occurred

cooperates with the work’s council or the personnel office and

qualified personnel for on-the-job safety, advises and informs

them on important radiation protection issues.

2.4 Duty of Notification

Mini-Switch LB 471

Chapter 2 Safety

15

Caution!

Radioactivity!

The radiation protection directives have to be observed.

Exclusion areas have to be protected such that nobody has unchecked access to these areas – not even with single body parts.

This has to be ensured through constructive measures, for example by protective covers.

2.5 Radiation Protection Areas

Radiation protection areas define the boundaries around a radiation source. The maximum dose rate defines the limit. We distinguish three radiation protection areas:

2.5.1 Exclusion Areas

Exclusion areas are areas in which the local dose rate may be exceed 3 Millisievert (mSv) per hour. These areas have to be protected such that nobody has unchecked access to these areas –

not even with single body parts. Actually, these areas can occur

only in the active beam in the direct vicinity of the shielding.

2.5.2 Controlled Areas

Controlled areas are areas in which persons in one calendar year

may receive an effective dose of more than 6 mSv if they stay in

this area 40 hours a week and 50 weeks per calendar year. Based

on this, the calculated maximum dose rate is 3 µSv/h. These areas

should be planned such that accessibility is virtually not possible or

that the required safety fences can be installed easily. If con-

trolled areas are accessible they have to be secured. Moreover, they have to be identified clearly and permanently by a radiation danger sign and the comment “Controlled Area”. Persons may

access controlled areas only to carry out maintenance work for the

operations going on inside this area (§ 37). Body doses have to be

calculated or personal doses have to be measured. The authorities

may permit exceptions from the demarcation and identification

duty, provided individuals or the general population are not endangered. Higher limit values are admissible if reliable in-

formation is provided that the person affected stays within

the controlled area for a shorter period of time.

Mini-Switch LB 471

Chapter 2 Safety

16

Caution!

Radioactivity!

The radiation protection directives have to be observed.

Controlled areas outside the shielding have to be identified and

secured if they are accessible.

2.5.3 Monitoring Areas

Monitoring areas are operation areas which do not belong to the

controlled area. In these areas, a person may receive an effective

dose of more than 1 mSv in one calendar year.

The monitoring area starts at the controlled area. It is an area in

which persons staying permanently in this area may be exposed to

a radiation level of more than 1 mSv in one calendar year. For a

stay of 40 hours per week and 50 weeks per year the area is between the dose rate limit values of 3 µSv/h and 0.5 µSv/h. It has

to be ensured that persons are not exposed to a dose exceeding

1 mSv per year, taking into account the actual time they stay in

this area. This means that no permanent work place may be set up

in this area.

Mini-Switch LB 471

Chapter 2 Safety

17

Caution!

Radioactivity!

The shielding with the source installed may be taken into operation by specially licensed persons who have been trained on handling radioactive materials only after consultation and coordination

with the radiological safety officer.

The radiation exit channel must only be opened by authorized persons after consultation with the radiological safety officer.

Modification of or tampering with the shielding construction are

prohibited.

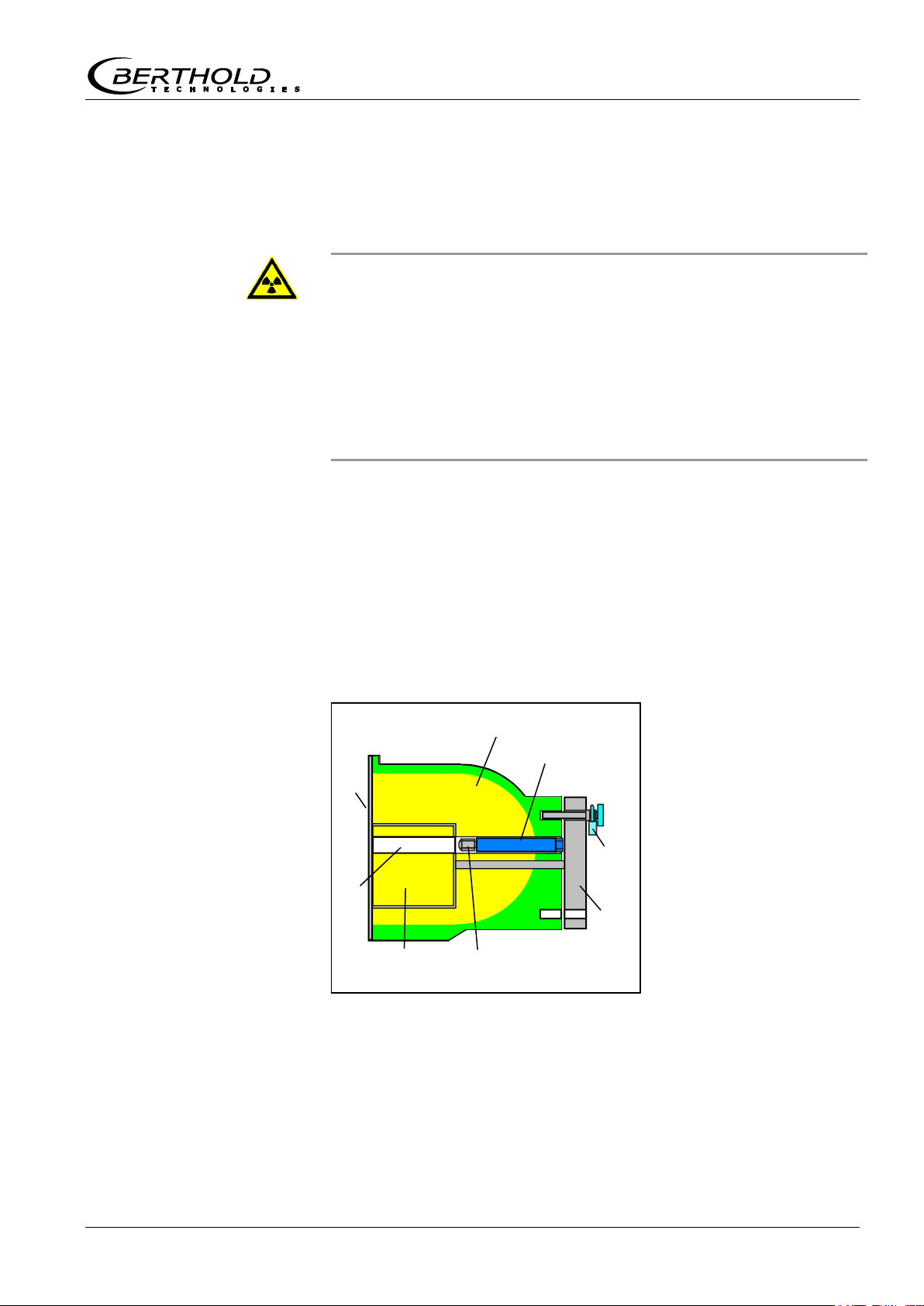

Shielding

Locking core

Radiation channel

Point sources

Source holder

Lever

Padlock

Cover plate front

Source

Shielding

Figure 1:

Point source shielding

radiation channel open

Sectional drawing

2.6 Safety Installations

2.6.1 Source Shieldings

Co-60 or Cs-137 point sources are used for the system. They

are tightly welded into a sturdy stainless steel capsule, so that the

radioactive substance cannot escape and contamination is prevented. The capsule with the source is fixed on a holder and

installed into the shielding.

The shielding consists of a lead cylinder with radiation exit channel

, surrounded by a steel jacket. The locking core is fixed to a

lever . The padlock secures the open / closed position and

protects the source against unauthorized removal.

When turning the lever , the locking core is rotated as well and

the radiation exit channel is opened towards the detector. The arrow on the lever is pointing towards “OPEN”.

Mini-Switch LB 471

Chapter 2 Safety

18

Lever with arrow

Padlock

Cover plate rear

Source number

Activity

Isotope

Source manufacturing

date

Dose rate in

1m distance

Effective shielding

thickness

Shielding material

Type of shielding

Shielding manufacturer

Figure 2:

Shielding

- view of lock

Type label

Figure 3:

Type label

on shielding

Strahler-Nr.:

1234 - 11- 9 4

MBq

Co-60

400

Abschirmung

mm

Datum

12. 11.94

Pb

98

Dosisleistung in 1m Abstand

5

Sv/h

MODEL LB 7440

Bad Wildbad D-75323

The radiation exit channel has to be closed during transport, assembly and while carrying out work on the container.

The arrow on the lever is then pointing to “CLOSED”.

The lever or the locking core is secured by a padlock in the

“OPEN” and in the “CLOSED” position.

Shielding, radiation type, isotope and activity have to be selected

for each measuring configuration such that the internationally

permissible dose rate limits will not be exceeded.

The source and shielding version is documented in the supplied

technical source documentation and on the type label on the

shielding.

Mini-Switch LB 471

Chapter 2 Safety

19

Caution!

The safety instructions in this user’s guide have to be observed

without fail.

All laws, directives, accident prevention regulations and generally

accepted safety regulations have to be complied with!

The system may be used only in technically good order and only

for contractual use!

Only persons may work with the system who have been authorized to do this and who have the proper qualification and have

received the necessary instructions!

Installations and modifications on the system which may affect the

operational safety are prohibited!

Danger!

Hazard due to radiation damages.

Never touch the source with your hands!

2.7 General Safety Instructions

2.8 Emergency Instructions

The following basic principles are indispensable for health and

safety: Time, distance and shielding. In an emergency, the following provisions have to be taken:

Restrict access to this area, identify radiation protection areas.

Check the function of the shielding and measure the dose rate.

Localize the source.

Document the event and, if possible, estimate the potential

radiation exposure of the persons involved.

Report event to BERTHOLD TECHNOLOGIES.

In case of loss of radiation sources, the regulatory agency has

to be notified immediately.

In case of suspected damage to the source capsule the follow-

ing issues have to be taken into consideration:

Grasp source with a tool (e.g. a pair of pliers or tweezers) and

put both (source and tool) into a plastic bag.

Place plastic bag behind an auxiliary shielding (concrete wall,

steel or lead plate).

Check if environment is free of contamination.

If a source has any leaks or if you suspect that the permissible

dose has been exceeded, the regulatory agency has to be notified immediately.

Mini-Switch LB 471

Chapter 2 Safety

20

2.8.1 Theft Protection

Radioactive substances or facilities containing radioactive substances have to be secured such that they are protected against

access by unauthorized persons. If you discover that radioactive

substances are missing, you have to notify the radiological safety

officer and the regulatory agency. In case of theft, the police have

to be informed.

Please see Chapter 11 for more information on radiation protection.

Mini-Switch LB 471

Chapter 3 Functional Safety

21

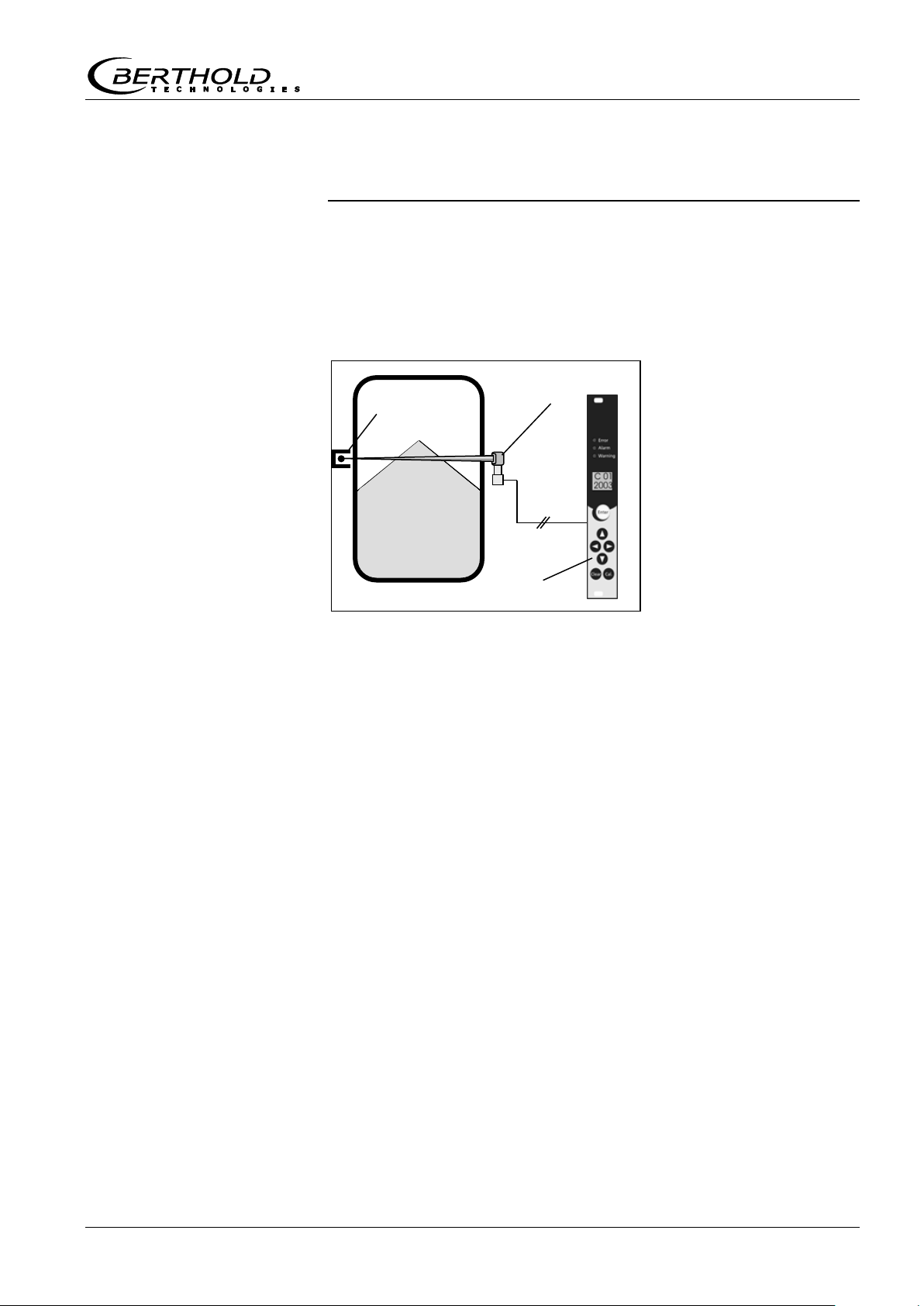

Source

Detector

Evaluation unit

Figure 4:

Measuring system

2 wires

Chapter 3. Functional Safety

3.1 Use and Function

The LB 471 Mini Switch is employed for monitoring and detection

of the limit levels of liquids and bulk material in containers and

pipelines.

The measuring system can be employed for the detection and indication of maximum levels (overflow protection) and minimum levels (protection against dry running) and fulfills the requirements

regarding:

Explosion protection (depending on version and category),

Water Resources Act (overflow protection device for containers

storing liquids that are hazardous to waters),

Electromagnetic compatibility according to EN 61326 and Na-

mur NE 21.

If the device is employed in safety-relevant systems (functional

safety according to IEC 61508/61511), all information in this

User's Manual has to be observed. In particular, the safetytechnical data in section 3.8 apply only to the application of the

system in the operating mode with low demand mode and taking

into account the information in this manual.

Beyond this scope, each application is considered as not being in

compliance with the law and may result in severe personal injury

or property damage.

BERTHOLD TECHNOLOGIES does not assume any liability for this kind

of injuries or damage.

Mini-Switch LB 471

Chapter 3 Functional Safety

22

Safety integrity

level

Operating mode with

low demand rate

Operating mode with high

or continuous demand rate

SIL

PFD

avg

PFH

4

≥10-5 to <10-4

≥10-9 to <10-8

3

≥10-4 to <10-3

≥10-8 to <10-7

2

≥10-3 to <10-2

≥10-7 to <10-6

1

≥10-2 to <10-1

≥10-6 to <10-5

Safe failure fraction

Hardware fault tolerance

SFF

HFT = 0

HFT = 1

HFT = 2

none: <60%

not allowed

SIL 1

SIL 2

low: 60% to <90%

SIL 1

SIL 2

SIL 3

medium: 90% to <99%

SIL 2

SIL 3

high: ≥99%

SIL 3

General instructions and

restrictions

3.2 Safety Function

The safety function of the measuring system comprises the detection and indication of changes in the count rate of the detectors

caused by the presence of product being measured in the measuring path between radiation source and measuring system.

The safe status is dependent on the mode of operation:

Maximum level (overflow protection): Product between radia-

tion source and detector -> low count rate

Minimum level (protection against running dry): No product

between radiation source and detector -> high count rate

3.3 Safety Requirement

3.4 Project Planning

Please make sure that the measuring system will be used in

accordance with its designated function.

The application-specific limits have to be observed and the

specifications must not be exceeded. See also the technical data and ambient conditions in the User’s Manual.

The fault tolerance time of the overall system must be greater

than the reaction time of the measuring system.

The relay contacts have to be protected by a 1A fuse.

The digital inputs 1 and 2 must not be closed in case of a safe-

ty-related application.

Mini-Switch LB 471

Chapter 3 Functional Safety

23

Assumptions

Safe state and fault

description

Interfering radiation, e.g. due to welding seam tests, is largely

identified and signaled by the measurement. However, in some

situations it is conceivable that the intensity of the interfering

radiation will increase the radiation level at the detector only

slightly, so that no alarm is triggered or not in due time. Therefore, the facility always has to be informed as soon as a welding seam test is carried out in the environment of the facility in

which the measurement is employed. In this case, suitable

safety precautions have to be taken.

Interfering radiation from adjacent measuring points has to be

avoided.

The FMEDA (Failure Mode Effects and Diagnostics Analysis) is

based on the following assumptions:

The failure rates are constant over the service life of the de-

vice.

The following is not taken into consideration:

external power supply failure rates

multiple errors

operating mode as minimum level switch

The mean ambient temperature during the operating time is

40°C.

The environmental conditions correspond to those of an aver-

age industrial environment.

The working life of the components is between 8 and 12 years.

The time to repair (replacement of the measuring system) after

a fault protected from interference is eight hours (MTTR = 8h).

If the demand rate is not more than once a year, the measuring

system may be operated as a safety-relevant sub-system in the

operating mode with low demand rate (IEC 61508-4, 3.5.12).

Numerical values see section “Safety-Technical Data”.

The fail-safe state is reached when the current output indicates the

following values.

A safe failure is defined as a failure that causes the measuring system to go to the defined fail-safe state without a demand from the

process.

A dangerous undetected failure is present if the measuring system,

following a demand from the process, does not go to the defined

fail-safe state.

Mini-Switch LB 471

Chapter 3 Functional Safety

24

3.5 Getting Started

The conditions at the facility affect the safety of the measuring

system. Therefore, the mounting and installation instructions in

the User’s Manual have to be observed. In particular, the correct

setting of the parameters has to be ensured. For more information

on the parameters and on getting started, please refer to the User’s Manual LB 471 ID No. 39505BA2.

The device may be operated as safety-relevant only in the professional mode.

Reset

1

Keep Clear button pushed and turn the power supply on.

The device is reset to factory setting.

Basic parameter setting

Set parameters according to the following parameter list.

The order in which the parameters have to be set is shown

in the last column.

Fields that are not numbered in this column are display

parameters or parameters that remain on factory setting.

If the Value column includes data, then you have to enter

this data exactly.

If no data has been entered in the Value column but a

number has been entered in the last column, then the

value of the parameter has to be adapted to the given

measurement situation. However, the value has to be

adapted only if this is required by the measurement situation.

Mini-Switch LB 471

Chapter 3 Functional Safety

25

Code

no.

Designation

Value range

Factory

setting

Value

Order

00

Password

0000 - 9999

01

Year

1970 - 2099

Current

year

1

02

Month / Day

01.01-12.31

Current

date

2

03

Hour / Minute

00.00-23.59

Current

time

4 04

Operation mode

Standard/Professional

0 - 1

0

1

3

05

Detector code

0 - 99

99

5

06

Nuclide

0=Co60, 1=Cs-137

0 - 1

0

6

07

Automatic password

protection

0 - 9999

0

08

Warning relay as

second alarm relay

0 – 1

10 – 100

0

09

Alarm relay follows

the error relay

0 - 1

0

1

7

10

Reading (%)

-999 - 9999

Display

11

Average count rate

0 - 999.9

Display

12

Time constant (s)

0,1 – 999,9

-1

13

Live count rate

0 - 999.9

Display

14

Maximum time constant (s)

0 - 999

999

8

15

Standard reading

10 - 11

10

16

Max. or min. limit

value switch

0=Max, 1=Min

0 - 1

0

17

Switching threshold (%)

0 - 100

-1

18

Switching threshold in (cps)

0 - 999.9

-1

19

Hysteresis (%)

0 - 999

-1

20

Empty count rate (no input)

0 - 999.9

Display

21

Full count rate (no input)

0 - 999.9

Display

22

Zero count rate (no input)

0 - 9.999

Display

30

Empty count rate

0 - 999.9

20 GMZ

300 FSK

31

Full count rate

0 - 999.9

-1

32

Zero count rate

0 - 9.999

Depending

on detector

code

33

Measuring path (in mm)

0 - 9999

0

9

34

Gas density (kg/m³)

0 - 9999

0

10

35

Bulk density (kg/m³)

0 - 9999

0

11

36

Compute

35.01–35.08

Display

37

Counting time for

calibration (s)

5 - 600

60

12

38

Bulk cone diameter (mm)

0 - 9999

0

Table 1:

Code table

for professional mode

Mini-Switch LB 471

Chapter 3 Functional Safety

26

Code

no.

Designation

Value range

Factory

setting

Value

Order

39

Half-value layers

1 - 9

2

13

40

Interference radiation

detection

0 - 1

0

1

14

41

Waiting time after

interference radiation

0 - 999

20

15

42

Signaling interference

radiation

0 - 2

0

1

16

43

Signaling unlocked

0 - 2

0

1

17

44

Signaling minor errors

0 - 2

0

1

18

45

Signaling excess temp.

Detector (only FSK detector)

0 - 2

0

0

46

Temperature threshold

detector (only FSK)

0 - 99

40

47

Signaling excess temp.

EVU

0 - 2

0

1

19

48

Temperature threshold EVU

0 - 99

85

≤50

20

50

Limit switch software

1.00 - 9.99

Version

51

Detector software

(only FSK)

1.00 - 9.99

Display

52

Detector temperature °C

(only FSK detector)

-40 - 80

Display

53

Detector high voltage

(only FSK)

500 - 1300

-1

54

detector HV start value

(only FSK)

500 - 1300

HV default

55

Source replacement

00.00- 99.12

-1

56

Evaluation unit electronics

temperature

-100 - 200

Display

60

Test pulse generator

0 - 999.9

0

61

Test error relay

0 - 2

0

62

Test alarm relay

0 - 2

0

63

Test warning relay

0 - 2

0

64

Test display

65

Test keyboard

66

Status digital in

00.00 - 01.01

Display

67

HV max for plateau

measurement

500 - 1300

1000

68

Detector plateau

measurement

(only FSK)

0 - 5

0

70

Error log

0 - 1

0

71

Revision log

0 - 1

0

72

Save & Load / Reset

0 - 99

0

Mini-Switch LB 471

Chapter 3 Functional Safety

27

Empty calibration

The level must be at least 50 mm below the limit level. The

radiation channel of the shielding is open.

Push the “Cal” button for 3 seconds

The empty count rate is read in.

At the end of the measuring time, code 30 is displayed and

the read-in empty count rate.

Full calibration

The level must be at least 50 mm above the limit level.

If this is not possible, you may also close the source shielding. If only the source shielding is closed to carry out the

full calibration, then you have to keep in mind:

- Make sure that the absorption of the closed shielding

nearly corresponds to the absorption of the product. If in

doubt, please contact BERTHOLD TECHNOLOGIES or your local

representative.

- Typically, you will lose some dynamics in the measurement, which results in a higher time constant.

Select code 31.

Push the Enter button

Push the Cal button.

The full count rate is read in.

At the end of the measuring time, code 31 is displayed and

the read-in full count rate.

Calibration

Select code 36.

Push the Cal button.

A checkmark and the digits 0000 confirms that the calibra-

tion was successful.

If an error message is display, the error has to be removed

as described in the User's Manual and in the error list; then

the calibration has to be carried out once more.

Test

Write down the empty and full count rate in code 30 and

code 31.

Select code 60.

Enter the full count rate in code 60.

The measurement must show 0% in code 10.

If not, check the calibration.

Select code 60.

Enter the full count rate in code 60.

The measurement must show 100% in code 10.

If not, check the calibration.

Mini-Switch LB 471

Chapter 3 Functional Safety

28

Function check

Level is at least 50mm below the limit level when the radia-

tion channel of the shielding is open.

The measured value in code 10 has to fluctuate around 0%.

The alarm output must not trigger an alarm.

Increase the level above the limit level or close the shield-

ing.

The measured value in code 10 has to fluctuate around

100%. The alarm output must indicate an alarm and must

not switch back anymore.

Password

Enter a password in code 00.

This rules out data manipulation by unauthorized persons.

The error relay switches to normal only when the password

has been entered and no error message is output.

The calibration is now finished and the measurement has been

taken into operation.

3.6 Behavior during Operation and

Malfunctions

The following parameter are automatically adjusted in the

course of operation relative to the decay compensation; therefore, their values may change: code 12 and code 18 – 31

If the operation is changed, please observe the safety func-

tions.

Malfunctions that may occur are described in the User’s Manu-

al.

If failures have been detected or malfunctions are reported,

you have to take the entire measuring system out of service

and keep the process in a safe state through other measures.

Replacement of the measuring system is rather simple; it is

described in the User’s Manual.

If parts are replaced as a result of a detected failure, please

inform BERTHOLD TECHNOLOGIES (including failure description).

If modifications in the product, the gas pressure, or the con-

struction of the tank in the area of the radiation path are carried out, the measurement has to be calibrated again.

Mini-Switch LB 471

Chapter 3 Functional Safety

29

λsd

230 Fit

safe detected failure (1 FIT = failure/109h)

λsu

536 Fit

safe undetected failure

λdd

210 Fit

dangerous detected failure

λdu

83 Fit

dangerous undetected failure

SFF

>92%

Safe Failure Fraction

T

Reaction

Failure reaction time

1.5 sec

max. service life of the measuring system for the

safety function.

7 years

General data

3.7 Recurrent Performance Test

The recurrent performance test is used to check the safety function to uncover possibly undetected dangerous failure. The operational capability of the measuring system has to be checked in adequate intervals.

It is in the responsibility of the operator to select the type of test

and the proof test interval. The intervals are dependent on the

PFD

Technical Data” (see also FMEDA Report).

The test has to be carried out such that the proper safety function

will be proven through interaction of all components.

This is the case when the level is controlled within the scope of a

filling. If a filling is not feasible, the measuring system has to be

triggered to respond by suitable simulation of the level or of the

physical measurement effect.

The methods and procedures used in the tests have to be named

and their degree of suitability has to be specified. The tests have

to be documented.

If the function check is negative, you have to take the entire

measuring system out of service and keep the process in a safe

state through other measures.

value defined in the table and chart in the section “Safety-

avg

3.8 Safety-Technical Data

Failure rates of the electronics were determined through FMEDA

according to IEC 61508. Calculations are based on the component

failure rates according to SN 29500. All numerical values refer to

an average ambient temperature of +40°C (104°F) during the operating period. Calculations are further based on the information

provided in chapter 3.4 Project Planning.

Mini-Switch LB 471

Chapter 3 Functional Safety

30

PFD

avg

T

Proof

= 1 year

T

Proof

= 2 years

T

Proof

= 5 years

T

Proof

= 10 years

<0.036 x 10

-2

<0.073 x 10

-2

<0.180 x 10

-2

<0.360 x 10-2

PFD

avg

T

Proof

= 1 year

T

Proof

= 2 years

T

Proof

= 5 years

T

Proof

= 10 years

<1.8 x 10

-5

<3.7 x 10

-5

<9.5 x 10

-5

<20 x 10-5

PFD

avg

T

Proof

= 1 year

T

Proof

= 2 years

T

Proof

= 5 years

T

Proof

= 10 years

<3.7 x 10

-5

<7.3 x 10

-5

<19 x 10

-5

<38 x 10-5

Detector

Evaluation units

Container

Shielding with

source

Detectors

Evaluation units

Container

Shielding with

source

Single channel architecture

HFT = 0 (Hardware Fault Tolerance)

Two-channel architecture

HFT = 1 (Hardware Fault Tolerance)

1) for Common cause ß=5%

2) for Common cause ß=10%

Mini-Switch LB 471

Chapter 3 Functional Safety

31

Time-dependent

trend of PFD

avg

PFD

avg

T

Proof

1 5 10 1 2

3

4

The time trend of PVD

is nearly linear to the operating time in

avg

the period up to 10 years. The above mentioned values apply only

to the T

interval, according to which a recurrent performance

Proof

check has to be carried out.

Time-dependent trend of PFD

avg

Mini-Switch LB 471

Chapter 3 Functional Safety

33

Mini-Switch LB 471

Chapter 3 Functional Safety

34

Mini-Switch LB 471

Chapter 3 Functional Safety

35

Mini-Switch LB 471

Chapter 4 Instrument Description

36

Figure 5:

Measuring system

2 wires

Chapter 4. Instrument Description

4.1 Function

The limit switch system Mini Switch LB 471 is working on the basis

of non-contact Gamma absorption measurement. The system can

also be employed with heavy process conditions and aggressive

media.

In order to obtain an optimum measurement effect at minimum

source activity the best measurement geometry is calculated for

the respective measuring point and the source is designed on the

basis of this calculation.

The system comprises three major components:

shielding with radiation source

Detector

evaluation unit .

The shielded radiation source is installed outside the container

on the level to be measured. A detector is installed on the opposite side of the container. The evaluation unit is connected to

the detector by a 2-wire line.

If the level of the medium inside the container comes up to the

level of the detector or the source, the radiation is absorbed and

the evaluation unit sends a corresponding signal.

The following radiation sources are used:

Mini-Switch LB 471

Chapter 4 Instrument Description

37

Caution!

Observe explosion protection!

Intrinsically safe and not intrinsically safe systems must not be

mixed, neither in a 19" rack nor in a wall housing.

In a 19" rack

Co-60 has a relatively high energy of 1.17 or 1.33 MeV and is

used on very thick pipeline or container walls. Its half-life time

is 5.27 years.

In most cases, Cs-137 with an energy of 0.660 MeV is ade-

quate to irradiate common pipeline or container walls. Its halflife time of Cs-137 is around 30 years.

Due to the lower energy, operating expenses for shielding a

Cs-137 source are lower than for Co-60.

4.2 Mini Switch LB 471 Versions

The Mini Switch LB 471 can either be delivered in a 19" rack, in a

wall housing or in a cassette.

The 19" rack can be mixed with limit switches for GM detectors

and fitted for NaI detectors. The 19" rack includes a back plane.

A filter module is used (for max. 19 limit switch modules) for

24V AC/DC supply. It includes:

one mains switch

on mains On LED

two fuses (see Technical Data on page 105)

additional filter section

A 85W transformer module is used (for max. 18 limit switch

modules) for 115/230V supply. In addition to the filter module, the

transformer module has:

a transformer with voltage selector switch 115V/230V

Mini-Switch LB 471

Chapter 4 Instrument Description

38

for any 19" rack

In a wall housing

As cassette

Front view Side view

The wall housing can be mixed with limit switches for GM detectors

and fitted for NaI detectors. The wall housing includes a back

plane.

A filter module is used for 24 V AC/DC supply. It includes:

one mains switch

on mains On LED

two fuses (see Technical Data on page 105)

additional filter section

For 115/230V a 17W transformer module is installed. In addition

to the filter module, the transformer module has:

a transformer with voltage selector switch 115V/230V

The evaluation unit is installed in a cassette with 7TE. Thus, it can

be used in any 19" rack without back plane. A 32-pole terminal

block is available to connect the wires.

Mini-Switch LB 471

Chapter 4 Instrument Description

39

Type

Detector

Det. connection

Version

LB4710-050

GM detector

II (2) G [EEx ib] IIC

and I M2 [EEx ib] I

19" rack / wall

housing

LB4710-060

II (2) G [EEx ib] IIC

and I M2 [EEx ib] I

Cassette

LB4710-080

not Ex

19" rack / wall

housing

LB4710-090

not Ex

Cassette

LB4710-150

NaI detector

or

Super-Sens

II (2) G [EEx ib] IIC

and I M2 [EEx ib] I

19" rack / wall

housing

LB4710-160

II (2) G [EEx ib] IIC

and I M2 [EEx ib] I

Cassette

LB4710-180

not Ex

19" rack / wall

housing

LB4710-190

not Ex

Cassette

Detector

LB 471

Limit switch module

GM detector

LB 4710-0XX

NaI detector or Super-Sens

LB 4710-1XX

Type code

evaluation unit

4.2.1 Type Code

The following table shows the type code for the different versions

of the evaluation unit LB 471.

Depending on the detector type you have to combine the following

limit switch modules:

Mini-Switch LB 471

Chapter 4 Instrument Description

40

Type

Number of

counter tubes

Ex-protection

SZ5 GHS 3171-1Gd

1

pressure-proof casing

SZ5 GHS 3171-2Gd

2

pressure-proof casing

SZ5 GHS 3171-1Gi

1

intrinsically safe

SZ5 GHS 3171-2Gi

2

intrinsically safe

GHS 3172-1

1

no

GHS 3172-2

2

no

GM detector types

4.3 Detectors

The detector converts the Gamma quanta emitted by the source

into electrical pulses and passed them on to the evaluation unit.

All components are installed together with the high voltage generation in a sturdy cylindrical stainless steel case with integrated

connection box.

Different versions are available which are selected in accordance

with physical, radiation protection or economical considerations in

the project planning phase.

4.3.1 GM Detector

Depending on the operation conditions, the GM detector is

equipped with one halogen counter tube for standard applications

or with two halogen counter tubes for special applications for short

switching times or to reduce a high source activity.

GM detectors are installed with the respective electronics including

high voltage generation and pulse amplification in a stainless steel

case.

The protection type is IP 65.

The connection is made in the integrated connection room with

two wires. The maximum cable length is 1000 m at a cable crosssection ≥1.0 mm2.

Mini-Switch LB 471

Chapter 4 Instrument Description

41

LB 4700

0 standard temperature range

1 enhanced temperature range

11 50/50 NaI point detector

12 50/50 NaI point detector + water cooling

1A 50/60 polymer

1B 50/60 polymer + water cooling

2A 500 mm

2B 500 mm

2E 1000 mm

2F 1000 mm

2I 1500 mm

2J 1500 mm

2K 2000 mm

2L 2000 mm

0 without

a axial

r sidewise

00 without Ex approval

1A ATEX/IECEx; Ex-d/e/t

IA ATEX/IECEx; Ex-d/i/t

47 Ex

57 non Ex

4.3.2 NaI Detector

The detector material is an artificially manufactured and specially

dotted NaI crystal. Different crystal sizes are available, depending

on the required sensitivity.

Installed in a sturdy stainless steel case, the detector is protected

from normal environmental strain which may occur in industrial

applications.

Mini-Switch LB 471

Chapter 4 Instrument Description

42

LB 44xx

E Europe / ATEX

U USA / FM

C CANADA / CSA

J JAPAN / TIIS

Z FM / CSA

K Korea

Terminal Compartment

x without certificate

d Ex-e (exception USA/FM

and CSA = flame proofed)

i Ex-i

Protection Type

G Gas-Ex

S Dust-Ex

M Mining-Ex

Irradiation

x without collimator

a axial

r side irradiation 66°

s side irradiation 90°

Cable Entry

0 sidewise

1 axial

Point Detector

Rod Detector

1 25/25 1 500 mm

2 40/35 2 750 mm

3 50/50 3 1000 mm

4 150/150 Plastic 4 1250 mm

5 40/5 5 1500 mm

6 44/5 6 2000 mm

Water Cooling

0 without

1 with

0 point-detector

1 point-detector

2 point-detector

3 point-detector

5 rod-detector

4 Ex

5 Non Ex

Mini-Switch LB 471

Chapter 4 Instrument Description

43

Standard Gas Ex: EEx de

LB 4430-04-0a-Gd-E

axial irradiation

LB 4430-14-0a-Gd-E

with WC, axial irradiation

LB 4431-04-0s-Gd-E

lateral irradiation. 90°

LB 4431-04-0r-Gd- E

lateral irradiation. 66°

LB 4431-14-0s-Gd-E

with WC, lateral irradiation 90°

LB 4431-14-0r-Gd-E

with WC, lateral irradiation 66°

Intrinsically safe, Gas Ex: EEx ib

LB 4430-04-0a-Gi-E

axial irradiation.

LB 4430-14-0a-Gi-E

with WC, axial irradiation

LB 4431-04-0s-Gi-E

lateral irradiation 90°

LB 4431-04-0r-Gi-E

lateral irradiation 66°

LB 4431-14-0s-Gi-E

with WC, lateral irradiation 90°

LB 4431-14-0r-Gi-E

with WC, lateral irradiation 66°

Firedamp protection

LB 4430-04-1a-Md-E

axial irradiation

LB 4431-04-1s-Md-E

lateral irradiation 90°

Firedamp protection: intrinsically safe

LB 4430-04-1a-Mi-E

axial irradiation

LB 4431-04-1s-Mi-E

lateral irradiation 90°

not Ex

LB 5430

axial irradiation

LB 5431

lateral irradiation 66°

Super-Sens

detector types

4.3.3 Super-Sens Detector

The Super-Sens detector is extremely sensitive to Gamma radiation. The high sensitivity is achieved by using a 150x150 mm large

plastic scintillator. It is provided with a lead shielding to reduce the

zero count rate and to reduce interferences. Working with the Super-Sens detector allows you to reduce the required source activity

significantly.

WC = water cooling

Mini-Switch LB 471

Chapter 5 Installation

45

Danger!

Risk of injury!

When unloading heavy system parts, never step under floating

loads!

Only use tested separate lifting accessories matching the transport

weights.

Observe adequate safety margin.

Wear hard hat and protective gloves.

Warning!

Risk of damage!

System parts may get damaged during transport.

Transport detector and evaluation unit in their original packing.

Protect parts against vibrations.

Caution!

Radioactivity!

The radiation protection directives have to be observed.

Radioactive substances may be transported on public traffic routes

only by persons in possession of the proper transport license!

A source may be transported only in the shielding.

Chapter 5. Installation

5.1 Transport to the Installation Site

5.1.1 Transporting Detector and Evaluation Unit

Use the eyebolts for transporting the Super-Sens detectors.

5.1.2 Transport Shielding with Source

The shielding with the source inside can be lifted onto a palette by

a fork-lift and transported to its destination. The shielding includes

eyebolts for transportation by a crane.

Mini-Switch LB 471

Chapter 5 Installation

46

Danger!

Risk of injury and damage!

Heavy system parts may fall down if not installed properly.

The carrying capacity of the container walls or the holders must be

adequate to install the source with shielding and the detector.

5.1.3 Temporary Storage of Sources

The operator has to take suitable provisions for intermediate storage of sources at the place of installation between the period from

source delivery to the start of the installation work. A source may

be stored only in a lockable room which is identified accordingly.

Accessible controlled areas have to be identified and, if necessary,

secured.

5.1.4 Installation Site

Free space must be foreseen at the installation site for:

Freedom of motion for delivery of shielding, detector and eval-

uation unit

Servicing and repair work, to install and dismantle parts.

The source with shielding and the detector are horizontally installed on the designated limit level on the outside of the container

and outside a possibly installed heat insulation. Any special features at the measuring point have to be taken into account.

5.1.5 Unpacking and Cleaning System Parts

After unpacking, compare all parts with the packing list and check

if the shipment is complete and shows any sign of damage. If necessary, you may have to clean parts.

If you detect any damage, notify the forwarder and the manufacturer immediately.

Mini-Switch LB 471

Chapter 5 Installation

47

Warning!

Risk of damage!

The detector may be damaged by heavy mechanical strain, vibrations and high temperatures.

The detector has to be mounted free from vibrations. During installation and operation, the detector must not be exposed to mechanical strain.

The ambient temperature must not exceed the values stated in

the technical data section (see chapter 13.2). If the ambient temperature is higher, the detector has to be cooled. Appropriate water cooling jackets are available as extras. See also Chapter 6

Water Cooling and the technical drawings on pages 121 to 130.

Direct exposure to sunlight is not permitted as this may lead to an

unacceptable increase of the surface temperature. In these cases,

you have to install a canopy top (see Figure 6).

Figure 6:

Detector with canopy top

canopy top

detector

5.2 Installing the Detector

Mark the level to be monitored at the container. Position the detector there in a

horizontal line with the

source. At the same time, the

horizontal line is the limit level where the device is switching. Make sure that the radiation window of the detector is

not covered by the holder.

The distance to the surface of

the container or the heat insulation should be approx 20

mm.

Mini-Switch LB 471

Chapter 5 Installation

48

Clamps for detector without

water cooling

Clamps for detector with water

cooling

ID-NO 31346

(1 set= 2 clamps)

ID-NO 31347

(1 set = 2 clamps)

Holder for detector complete

ID-NO 39246

Figure 7:

Clamp for GM detectors

and NaI detectors

Figure 8:

Detector holder

5.2.1 Fastening Clamps for GM Detectors and NaI

Counters

Stainless steel clamps are available to install the detector. The

dimensions of the clamps are shown in the technical drawings in

the Appendix. The technical drawing with dimensions is shown on

page 123.

5.2.2 Stainless Steel Detector Holder

(Alternative)

A sturdy stainless steel holder may be used instead of clamps. The

holder comprises an angle on which two clamps have already been

installed. You can fix the holder on a bracket either with screws

or through welding. Due to the plastic rings, the same holder

may be used for detectors with or without water cooling. All metal

parts of this holder are made of stainless steel. The technical

drawing with dimensions is shown on page 124.

Mini-Switch LB 471

Chapter 5 Installation

49

Red marking strip for

counter tube position

Connection room

Figure 9:

Installation on container

GM detector

Figure 10:

Alternative installations

Radiation

path

Bracket

provided by

customer

A B C

5.2.3 Installation of the GM Detector

Align the detector horizontally exactly on the level of the source.

The red marking strip on the case shows the position of the counter tube in the detector. The counter tube must not be covered by

the holder or by clamps, as this would adversely affect the sensitivity of the measurement.

Mini-Switch LB 471

If the bracket cannot be installed on the container, then it has to

be mounted on the girder located in the vicinity. Figure 10 shows

three alternative proposals for installing the detector (A, B, C).

Chapter 5 Installation

50

Figure 11:

GM detector

mounted on bracket

Figure 12:

Examples of

installed detectors

View from above

Red marking strips for

counter tube position

Bracket

Radiation path

Installation with clamps

Make a suitable bracket for the container.

1

Using the drawing below, drill 4 holes (d=11 mm) into the

2

bracket for the clamps.

Install the bracket either directly on the container or on a

3

sturdy girder.

Install the detector on the bracket using clamps.

4

Mini-Switch LB 471

Chapter 5 Installation

51

Radiation window

Collimator

Connection room

Screwed cable gland

Figure 13:

NaI detector

Figure 14:

NaI detector mounted on a

container

Figure 15:

Alternative installations

Bracket

provided by

customer

Radiation path

70

A B C

5.2.4 Installation of the GM Detector

The lateral opening (radiation window) in the collimator covers the

sensitive area of the detector; it has to face the source.

If the bracket cannot be installed on the container, then it has to

be mounted on the girder located in the vicinity. Figure 15 shows

three alternative proposals for installing the detector (A, B, C).

Mini-Switch LB 471

Chapter 5 Installation

52

Figure 16:

NaI detector

mounted on bracket

View from above

Radiation path

Radiation path

Bracket

Slot is required only

when a water cooling is used.

Bracket

Installation with clamps

Make a suitable bracket for the container.

1

Using the drawing below, drill 4 holes (d=11 mm) into the

2

bracket for the clamps.

Install the bracket either directly on the container or on a stur-

3

dy girder.

Install the detector on the bracket using clamps.

4

Mini-Switch LB 471

Chapter 5 Installation

53

Figure 17:

Installation proposal

with detector holder

Figure 18:

Bracket with drilled holes

for detector holder

Installation with detector holder (chapter 5.2.2)

Make a suitable bracket for the container.

1

If the holder is not welded onto the bracket, drill 2 holes

2

(d=17 mm) for the holder in the bracket, using the drawing below.

Install the bracket either directly on the container or on a stur-

3

dy girder.

Install the holder with the detector on the bracket.

4

Mini-Switch LB 471

Chapter 5 Installation

54

Figure 19:

Installation with

Super-Sens detector

Figure 20:

Super-Sens mounted

on a container

Square hole distance: 198 mm

Diameter: >160 mm

Length of angle iron

depending on thickness

of insulation

Bracket

provided by

customer

Radiation path

5.2.5 Installation of Super-Sens

with Axial Irradiation

The axial radiation window, located in the center of the flange,

covers the sensitive area of the detector. The radiation window

must face the source.

Mini-Switch LB 471

Chapter 5 Installation

55

Warning!

Risk of damage!

Heat conduction above the bracket or heat radiation from the container may destroy the detector.

Heat conduction has to be reduced using a heat-resistant sealing

between bracket and flange of the Super-Sens detector.

Figure 21:

Super-Sens mounted

on a container

View from above

Rad. path

Radiation path

Bracket

Installation

Make a suitable bracket for the container.

1

Using the drawing below, drill 4 holes (d=18 mm) into the

2

bracket for the flange.

Install the bracket either directly on the container or on a stur-

3

dy girder.

Install the detector on the bracket using the flange.

4

Mini-Switch LB 471

Chapter 5 Installation

56

Figure 22:

Install Super-Sens

with lateral irradiation on

container

Bracket

provided by

customer

Radiation path

5.2.6 Installation of Super-Sens

with Radial Irradiation

The radial radiation window, located on the side, covers the sensitive area of the detector. The radiation window must face the

source.

Mini-Switch LB 471

Chapter 5 Installation

57

Installation

Make a suitable bracket for the container.

1

Using the technical drawings on pages 127 to 130, drill 4 holes

2

(d=18 mm) into the bracket for the flange.

Install the bracket either directly on the container or on a

3

sturdy girder.

Install the detector on the bracket.

4

Mini-Switch LB 471

Chapter 6 Water Cooling

59

If the detector is installed horizontally, then the bottom connection piece

is to be used as water inlet.

Connecting the

water cooling device

If the detector is mounted vertically,

then the connection box has to face

up so that the fittings are located on

the top end of the water cooling.

Inlet

Outlet

Inlet

Outlet

bottom

top

Connection box

Chapter 6. Water Cooling

A water cooling device is needed if the ambient temperature may

rise above the max. permitted value. The maximum operating

temperature for the respective detector is listed in the technical

data section on page Chapter 13.

If a water cooling device is installed on the detector, the connection piece has to be aligned such that the water feed pipes can be

connected easily. Make sure that the water pipes do not lead past

the radiation window.

Keep the following in mind to prevent that an air cushion builds up

in the water cooling device:

Horizontal installation:

Vertical installation:

This rule applies to all detector types.

Mini-Switch LB 471

Chapter 6 Water Cooling

60

Water inlet

Water outlet

Connection between

both cooling jackets

Warning!

Risk of damage!

The cooling water flow must not be turned off if the maximum

ambient temperature of the detector (see technical data in chapter

13.2) will be exceeded even if the facility is not in operation.

In case of danger of frost the water cooling has to be emptied.

Dirty cooling water may block up the water cooling so that the

detector may get overheated and destroyed. Make sure to use

clean cooling water!

Super-Sens with

water cooling

In a Super-Sens with water cooling, the water cooling device is

integrated in the case. The water cooling comprises two cooling

jackets which have to be connected with each other during installation.

Mini-Switch LB 471

Chapter 6 Water Cooling

61

6.1 Subsequent Installation of Water

Cooling (Option)

If you are working with the NaI detectors LB 4401, LB 5401 or GM

detectors, you may install a water cooling subsequently. See technical drawings on pages 121 and 122.

Preparation

You need clamps with a large diameter (90 mm) in order to fix the

detector later at its position again. These clamps have to be ordered separately in addition to the water cooling. If you are using

a detector holder instead of the clamps, you only have to remove

the plastic ring. See technical drawings on pages 123 and 124.

Depending on the type of detector, a different type of water cooling may be needed. The assembly instructions apply to the following detector types:

NaI detector with collimator

NaI detector without collimator

GM detector

Mini-Switch LB 471

Chapter 6 Water Cooling

62

Cooling nozzle

Drilled hole for screws

Screws

(~30mm long)

Collimator

Water cooling

Detector

Figure 23:

Water cooling for

NaI detector

Installing the

water cooling

Figure 24:

Fastening screws

for collimator

Figure 25:

NaI detector

with water cooling

6.1.1 Water Cooling for NaI Detector

with Collimator

Collimators only have detectors with 50/50 crystal such as:

LB 4401-03

LB 5401-03

Pull off collimator from detector. To do this, open the four

1

screws on the front side.

In order to install the collimator and the water cooling again to

the detector, you need four screws which are 5 mm longer than

the original screws.

Push the cooling jacket over the detector.

2

Mini-Switch LB 471

Chapter 6 Water Cooling

63

Screws

Plastic ring

Detector with water

cooling

Collimator

Figure 26:

Collimator for

NaI detector

Figure 27:

NaI detector with water

cooling and collimator

Positioning the pitch circle

Remove the plastic ring from the collimator by opening the

3

screws on the side of the collimator.

Push the collimator over the water cooling so that the radiation

4

window is facing the source. Position the collimator and water

cooling towards the pitch circle of the detector. Make sure that

the position of the cooling nozzle is such that you later have

unimpeded access to install the water feed pipes.

Mini-Switch LB 471

To install the collimator and the water cooling on the detector,

5

you have to use the 5 mm longer screws mentioned above.

Chapter 6 Water Cooling

64

Screws

Cover plate

Installing the

water cooling

Figure 28:

NaI detector

without collimator

6.1.2 Water Cooling for NaI Detector

with Collimator

Open the four frontal screws of the cover plate . Leave

1

the cover plate and the lead plate below it in their position.

In order to install the water cooling to the detector, you need

four screws which are 5 mm longer than the original screws

(not included in delivery).

Push the cooling jacket over the detector.

2

Position the water cooling on the pitch circle of the detector.

3

Make sure that the position of the cooling nozzle is such that

you later have unimpeded access to install the water feed

pipes.

Now fix the collimator with the four screws which are 5 mm

4

longer than the original screws.

Mini-Switch LB 471

Chapter 6 Water Cooling

65

Cooling nozzle

Water cooling

Locking screw

Water cooling

GM detector

Locking ring

Figure 29:

Water cooling for

GM detector

Installing the

water cooling

Figure 30:

Water cooling with

GM detector

Figure 31:

Water cooling

installed on

GM detector

6.1.3 Water Cooling for GM Detector

Push the cooling jacket over the detector.

1

Make sure that you position the cooling nozzle such that you

later have unimpeded access to install the water feed pipes.

Tighten the locking ring for the water cooling.

2

Mini-Switch LB 471

Chapter 6 Water Cooling

66

Warning!

Risk of damage!

The cooling water flow must not be turned off if the maximum

ambient temperature of the detector (see technical data in chapter

13.2) will be exceeded even if the facility is not in operation.

In case of danger of frost the water cooling has to be emptied.

Dirty cooling water may block up the water cooling so that the

detector may get overheated and destroyed. Make sure to use

clean cooling water!

Figure 32:

Characteristic curve for

cooling water requirement

Required cooling water for NaI point detector

0

50

100

150

200

250

50

60

70

80

90

100

110

120

130

140

150

160

170

180

Ambient temperature in °C

Water flow rate in l/h

40°C

Cooling water feed temperature

30°C

10°C

20°C

6.2 Amount of Cooling Water Required

The amount of cooling water required may be taken from the

graph below.

The X-axis shows the max. achievable ambient temperature.

The different characteristic curves are valid for the respective

feed temperature of the cooling water.

The Y-axis shows the min. required water flow.

Mini-Switch LB 471

Chapter 7 Shielding Installation

67

Caution!

Radioactivity!

Installation and start-up of radiometric measuring systems may

be carried out only by persons who have been instructed adequately by professional personnel!

Work is carried out under the guidance and supervision of the radiological safety officer. It has to be ensured that the lock of the

shielding is closed.

Damage on the shielding must be avoided.

The shielding should be positioned as closely as possible to the

container surface.

The radiation danger sign has to be installed very close by to the

shielding.

The controlled area, if there is one, has to be identified and, if

necessary, secured.

How to calculate the radiation exposure during installation of the

shielding is described on page 101.

The user has to be familiar with the radiation protection guidelines

in Chapter 11.

Note!

Especially for measuring points with Super-Sens detector, the

shielding should be installed only after the zero count rate has

been determined, since the residual radiation from the shielding

(even if the shielding is closed) may distort the measurement of

the zero count rate.

See also code 32 in the software description.

Chapter 7. Shielding Installation

7.1 General Installation Instructions

Mini-Switch LB 471

Chapter 7 Shielding Installation

68

Arrangement

Figure 33:

Installation on

a container

Installation sequence

Shielding

Monitoring level

Bracket provided

by customer

Source and center of the detector have to be installed on a horizontal line. At the same time, this horizontal line is the monitoring

level where the device switches.

The shielding is installed at the measuring point by means of

brackets.

Install suitable bracket which has to be provided by the cus-

1

tomer on the respective level. See installation proposal below.

Unpack source with shielding and mount it on the respective

2

bracket.

If you are working with a shielding with pneumatic shutter, a compressed air connection has to be available. Signals supplied by an

optional limit switch have to be connected via an electrical line

(see Shielding LB 744X with Pneumatic on page 132).

7.2 Installation Proposal for Shielding

The shielding container comprises a lead-filled sturdy cast iron

case. A revolving shutter is installed to close the radiation exit

channel. This shutter is operated from the rear side via a lever,

which can be locked by means of a padlock in its open or closed

position.

For installation, the shielding container includes a cast-on flange

and in addition a fastening foot with threaded holes.

The specifications for the required drilled holes are listed in the

Appendix on page 131.

Mini-Switch LB 471

Chapter 7 Shielding Installation

69

Figure 34:

Installation proposal

for shielding

Figure 35:

Example of

flange installation

Flange installation

Installation on pedestal

LB 7440

LB 7445

LB 7442

LB 7445

LB 7444

h

90

120

161

Mini-Switch LB 471

Chapter 7 Shielding Installation

70

7.3 Pneumatic Shielding Shutter (Option)

A pneumatically operated shutter is available as a special version.

When turning on the compressed air, the locking core moves to

the “OPEN” position. In case of failure of the compressed air, the

shutter is turned by to the “CLOSED” position by a flat spiral

spring. A switching contact indicates the shutter position.

For technical details and drawings see page 132 in the Appendix.

Mini-Switch LB 471

Chapter 8 Electrical Installation

71

Danger!

The special aspects of intrinsically safe installation have to be taken into consideration.

In Ex-areas the detector has to be connected with the equipotential busbar of the facility.

In Ex-areas and for measurements that are not intrinsically safe

the evaluation unit has to be disconnected from power during the

electrical installation.

If the intrinsically safe electric circuit is installed in areas engendered of dust explosion which are classified as area 20 or 21, it

has to be ensured that the devices which are connected to these

electric circuits fulfill the requirements of category 1D or 2D and

have been certified accordingly.

A length of thread1 of 50 mm has to be observed between intrinsically safe connections and connections that are not intrinsically

safe.

The maximum cable length between detector and evaluation unit

has to be observed. It is dependent on the capacity and inductivity

of the cable used and is limited by the max. permissible values

stated on the ATEX certificate on page 109. If you are using the

cable #32024 supplied by BERTHOLD TECHNOLOGIES, then the max.

cable length is 1000m.

The EU type verification documents are shown on page 109.

Warning!

Malfunction due to electromagnetic fields in the line between evaluation unit and detector.

Installation of the line in multi-wire cables is permitted, provided

the other parallel running wires are only signal lines, not power

lines.

If electromagnetic interference is likely to occur in the line, the

cable has to be installed separately in a shielded cable. The screen

may be put onto the detector only one-sided.

Strong electromagnetic fields in the line are not permitted. The