Bertazzoni AM64C61BX, AM64C71BX, TU64C61BX, TU64C71BX Installation, Maintenance And Use Instructions

Page 1

INSTALLATION, MAINTENANCE AND USE

INSTRUCTIONS FOR

FREE-STANDING COOKERS

60x60 cm (type M6V)

AM64C61BX

AM64C71BX

TU64C61BX

TU64C71BX

READ THE INSTRUCTION BOOKLET BEFORE INSTALLING AND USING

THE APPLIANCE.

The manufacturer will not be responsible for any damage to property or to persons

caused by incorrect installation or improper use of the appliance.

The manufacturer is not responsible for any inaccuracies, due to printing or transcription

errors, contained in this booklet. In addition, the appearance of the figures reported is also

purely indicative.

The manufacturer reserves the right to make changes to its products when considered

necessary and useful, without affecting the essential safety and operating characteristics.

Page 2

2

CONTENTS:

INSTALLER TECHNICAL MANUAL ............................................................................................................... pg. 2

Installing the cooker - Installation information ................................................................................................. pg. 2

Ventilation and aeration of rooms .................................................................................................................... pg. 3

Height-adjustable feet ..................................................................................................................................... pg. 3

Intalling the toekick panel ................................................................................................................................ pg. 3

Intalling the riser .............................................................................................................................................. pg. 3

Intalling the hob rail and oven handle .............................................................................................................. pg. 3

Gas connection ............................................................................................................................................... pg. 3

Anti-tilting chain / Hose restraining chain ........................................................................................................ pg. 4

Adaptation to different types of Gas and burner adjustments.......................................................................... pg. 4-5

Electric connection .......................................................................................................................................... pg. 6

APPLIANCE MAINTENANCE - Replacing parts ............................................................................................. pg. 6

USE AND MAINTENANCE MANUAL ............................................................................................................. pg. 7

Description of control panel and control types ................................................................................................. pg. 8

Using burners .................................................................................................................................................. pg. 8

Using the gas oven ........................................................................................................................................ pg. 9

Using the 2+0 change-over switch .................................................................................................................. pg. 10

Using the electric thermostat ........................................................................................................................... pg. 10

Using the 9+0 switch ....................................................................................................................................... pg. 10

Using the natural conventional electric oven .................................................................................................. pg. 11

Using the ventilated electric oven .................................................................................................................... pg. 12

Using the electric grill - ventilated electric grill ................................................................................................. pg. 13

Using the thermometer .................................................................................................................................... pg. 13

3 Keys electronic programmer

............................................................................................................... pg. 13

3 Keys electronic clock

............................................................................................................................. pg. 15

Using the self-cleaning oven ........................................................................................................................... pg. 16

Cleaning the appliance .................................................................................................................................... pg. 16

After-sales technical service & spare parts ..................................................................................................... pg. 26

Overall Dimensions ......................................................................................................................................... pg. 26-27

THIS APPLIANCE HAS BEEN DESIGNED FOR NON-PROFESSIONAL DOMESTIC USE.

INSTALLER TECHNICAL MANUAL

By ensuring this product is disposed of correctly, you will help prevent potential

negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product.

The symbol on the product indicates that this product may not be treated as

household waste. Instead it shall be handed over to the applicable collection point

for the recycling of electrical and electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please

contact your local city council office.

INSTALLER INFORMATION

The installation, all adjustments, transformations and maintenance listed in this part of the manual must be

carried out only by skilled personnel.

Improper installation may cause damage to persons, animals or property, for which the manufacture will not be

held responsible.

The appliance safety or automatic adjustment devices may be changed during the service life of th e system only

by the manufacturer or by the duly authorised supplier.

INSTALLING THE COOKER

After having removed the various loose parts from the internal and external packing, make sure that the cooker is n ot

damaged. In case of doubt, do not use the appliance and contact skilled personnel.

Keep all the dangerous packing parts (polystyrene foam, bags, cardboard, staples, etc.) away from children.

The appliance can be installed as a freestanding un it, next to a wall or inserted between two walls (Fig.1). A single

sidewall that exceeds the height of the work surface is possible. This must be at a minimum distance of 70 mm from th e

edge of the cooker (Fig.1)

Page 3

3

Any walls of the adjacent furniture pieces and the wall behi nd the cook er must be made with heat-resistant material that

can withstand a minimum overtemperature of 65 K.

WARNING: the connection to the gas network must only use metal flexib le pipes that conf orm with the nation al

standards in force.

IMPORTANT INFORMATION FOR INSTALLING THE APPLIANCE

The cooker can be installed separately, as a freestanding unit, on a plinth (Only for models with all electric

ovens/grills), or between kitchen units or between a kitchen unit and the wall.

If installing the appliance as a freestanding cooker, screw the height adjustable telescopic legs supplied to the

base of the appliance. If installing the appliance on a plinth, screw the levelling feet supplied to the base of the

appliance.

This appliance is not connected to devices which exhaust combustion products.

Special attention must be focused on the prescriptions described below regarding room aeration and

ventilation. Any hanging cabinets installed above the work surface m ust be located at a d istance o f no less tha n

700 mm.

This appliance is not intended to be operated by means of an external timer or separate remote-control system.

NOT FOR USE IN MARINE CRAFT, CARAVANS OR MOBILE HOMES UNLESS EACH BURNER IS FITTED WITH

FLAME SAFEGUARD.

WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT OR IN CARAVANS, IT SHALL NOT BE USED AS A

SPACE HEATER.

WARNING: SERVICING SHOULD BE CARRIED OUT ONLY BY AUTHORISED PERSONNEL.

DO NOT MODIFY THIS APPLIANCE.

ROOM VENTILATION

To ensure that the appliance operate correctly, the room where it is installed must be co ntinuously ventilated. The room

volume should not be less than 25 m³ and the quantit y of air needed shall be based on the regular combustion of gas

and on the ventilation of the room. Natural air will flow through permanent openings in the walls of the room to be

ventilated: these openings will be connected with the outside environment and shall have a minimum cross-section

defined by the current national standards regarding room ventilation (see Fig. 2).

These openings shall be built so that they cannot be clogged.

Indirect ventilation is also permitted by taking air from the rooms adjacent to the one to be ventilated.

LOCATION AND AERATION

The gas cooking appliances must always evacuate the co mbustion products by means of hoo ds connected to chimn eys,

flues or directly outside (see Fig. 3). If a hood cannot be installed, it is possible to use a fan installed on a window or

directly facing outdoors, to be operated together with the appliance (see Fig. 4), provided that there is strict complian ce

with the ventilation regulations.

HEIGHT-ADJUSTABLE FEET (figure.5)

The feet are packed in the top box.

The feet should be installed with the cooker close to its final i nstallatio n position; the feet are not safe to move the cooker

long distances.

After unpacking the cooker, lift it with your foot, to fit the cooker feet in the bases at the bottom. Slowly lower the cooker

so its weight is resting on the feet and on the assembly fixings. We recom mend using a lifting device or pallet instead of

tilting the cooker.

INSTALLING THE TOEKICK PANEL (only available for some models)

After installing the feet, install the cooker skirt as shown in the pictures in Figure 6

INSTALLING THE RISER

Remove the 2 screws securing the hob at the rear, as shown in (figure 7)

Put the upstand in place and secure at the bottom with the two screws, as shown in (figure 7)

Secure the middle of the upstand using the screws provided with the upstand (figure 7)

INSTALLING THE HOB RAIL AND OVEN HANDLE

The handle is packed with the upstand.

Assemble oven handle as shown in the figures (8-9)

Page 4

4

APPLIANCE GAS CONNECTION

Before connecting the appliance to the gas network, make sure that the data on the label attached to the food

warmer drawer or on the back of the cooker are compatible with what is indicated for the gas distribution

network.

A label attached to the last page of this handbook and in the food warmer drawer (or on the back) of the

appliance indicates the appliance adjustment conditions: type of gas and operating pressure.

IMPORTANT: This appliance must be installed in compliance with current national standards in force and used

only in a well-ventilated room.

This appliance shall be installed only by authorised persons and in accordance with the manufacturer's

installation instructions, local gas fitting regulations, municipal building codes, electrical wiring regulations,

local water supply regulations, AS/NZS 5601.1-2010-Gas Installations–General installations and any other

statutory regulations.

WARNING: It should be recalled that the appliance utilises a threaded 1/2" gas cylindrical male fitting according

to UNI-ISO 228-1.

For ease of service, the cooker should be connected with a Flexible Hos e, which complies with AS/NZS 1869 (AGA

Approved), 10mm ID, class B or D, between 1 - 1.2m long and in accordance with AS5601 for a high level connection.

WARNING: Ensure that the hose is not subjected to abrasion, kinking or permanent deformation and should be able to

be inspected along its entire length. Unions compatible with the hose fittings must be used and con nections tested for

gas leaks. The fixed consumer piping outlet should be at appro ximately the sam e height as the co oker connection point,

pointing downwards and approximately 200mm - 300mm in from the left han d side of the cooker. The hose should be

clear of the floor when the cooker is in the installed position. A hose restraint chain should be anchor ed to the wall to

prevent strain on the hose connections when the cooker is pulled forward.

Fit the supplied gas connectors as shown in Fig. 10 for your installation gas type. The gas inlet has a 1/2" BSP male

thread. When making the connection, take care not to apply excessive stress by counterbalancing tightening force.

Ensure that the available gas supply is the same as the gas type label affixed near the gas connection point. If not,

contact Bertazzoni Service Center for a Gas Conversion Kit.

Natural Gas

The natural gas regulator supplied must be fitted for natural gas. Ensure t he arrow on the regulator points towards the

direction of the gas flow. Commissioning Procedure - The test point pr essure must be adjusted to 1.00 kPa with the Wok

and Rapid Burners operating on maximum flame.

Universal LPG (U-LPG)

Fit the LPG test point assembly (supplied in the gas conversion kit). An AGA Approved gas regulator suitable for a

supply pressure of 2.75kPa should be part of the gas tank supply.

ANTI-TILTING CHAIN/HOSE RESTRAINING CHAIN

A chain should be fitted by the installer within 50mm of the hose connection point to prev ent strain on the hose when the

cooker is pulled forward. The chain should restrict the appliance movement to no more than 80% of the hose length.

After the chain is installed, check that there is no strain on the hose or gas connections when the c ooker is pulled as fa r

forward as the chain allows.

The cooker is also supplied with two chain s which are connected to the rear left and right of the appliance. The chains

should be connected to the wall directly behind the chains as low as possible to prevent the appliance from tilting

forward. If the appliance is installed between two cupboards, drill a hole on each side o f the cupboards, pass the chains

through the holes and anchor the chains within each cupboard. Ensure the chain connections are strong enough to

support the weight of the appliance and taught to prevent it from tilting forward.

WARNING: In order to prevent accidental tipping of the app lianc e, for e xample a c hild cli mbing o nto the op en oven d oor,

the stabilising means must be installed. Ensure the chains are correctly anchored to prevent the app liance from tilting

forward and to prevent strain on the hose when the cooker is pulled forward.

MAKE SURE THE ANTI-TILTING CHAINS ARE TAUGHT WHEN ANCHORED TO PREVENT THE APPLIANCE

TILTING.

ADAPTATION TO DIFFERENT TYPES OF GAS FOR COOKER TYPE M6V

Before performing any maintenance operation, disconnect the appliance from the gas supply and electricity

network.

REPLACING THE NOZZLES TO OPERATE WITH ANOTHER TYPE OF GAS FOR COOKER TYPE M6V:

Follow the instructions below to change the burner nozzles on the work surface:

1) Pull out the plug from the electric outlet to avoid any type of electric contact.

Page 5

5

2) Remove the grids from the work surface (Fig. 11).

3) Remove the burners (Fig. 11).

4) Unscrew the nozzles using a 7 mm spanner, and replace them (F ig.12) with those needed for the new type of gas

according to what is indicated in Table 1.

Follow the instructions below to change the oven burner nozzle:

1) Remove the oven floor (Fig. 13).

2) Loosen the screw V and pull out the burner from the support being careful not to damage the ignition plug and the

thermocouple (Fig. 14).

3) Unscrew the nozzle R (Fig. 14) using a 10 mm spanner and replace it with the nozzle need ed for the ne w type of gas

according to what is indicated in Table 1.

Follow the instructions below to change the grill burner nozzle:

1) Loosen the screw A and pull out the burner from the support being c areful not to damage the ignition plug and the

thermocouple (Fig. 15).

2) Unscrew the nozzle C (Fig. 15) using a 7 mm spanner and replace it with the nozzle needed for the ne w type of gas

according to what is indicated in Table 1.

WARNING: After completing the above-mentioned replacements, the technician must adjust the burners, as

described in the paragraph below, seal any adjustment and pre-adjustmen t devices and apply the label on the

appliance, to replace the existing one, corresponding to the new gas adjustment. This label is contained in the

spare nozzle bag.

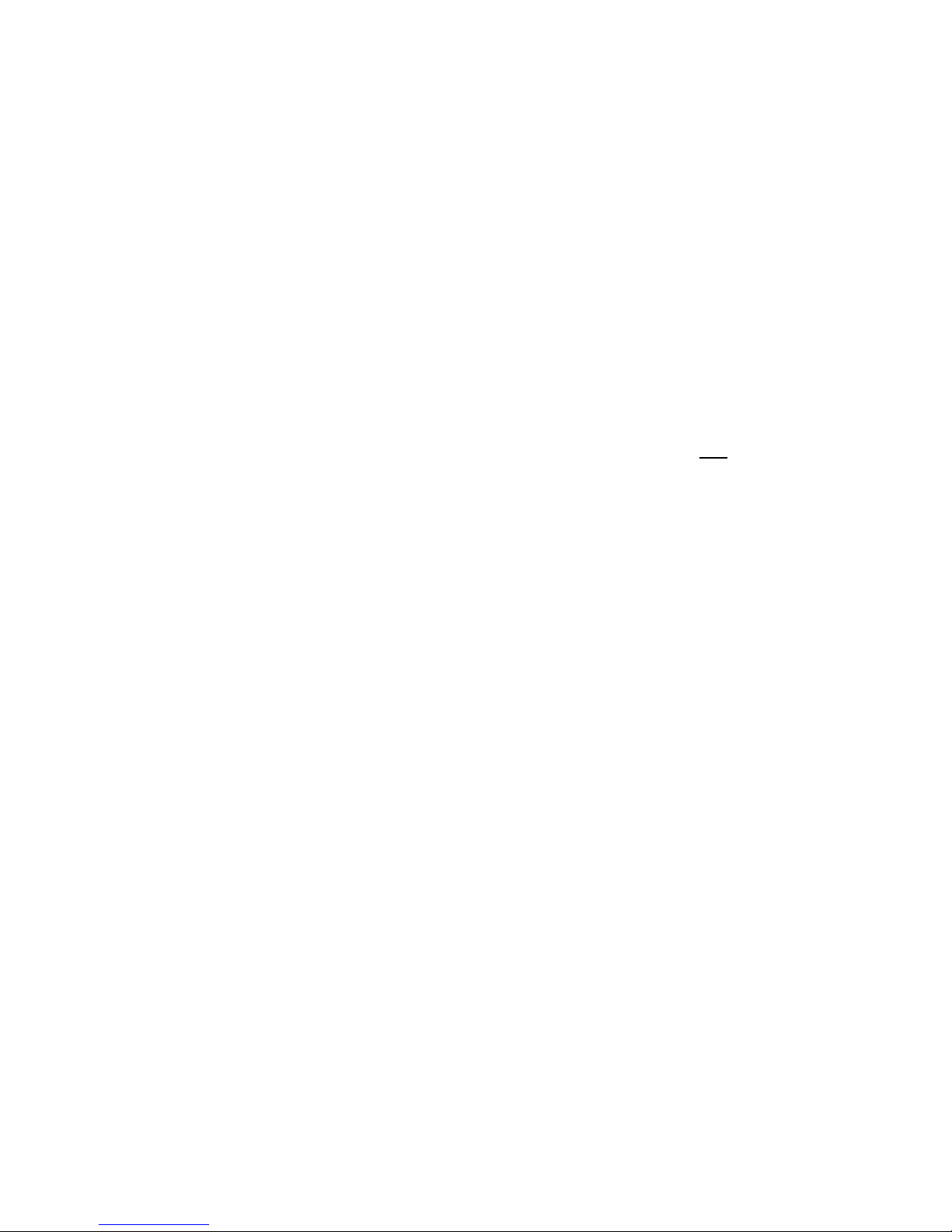

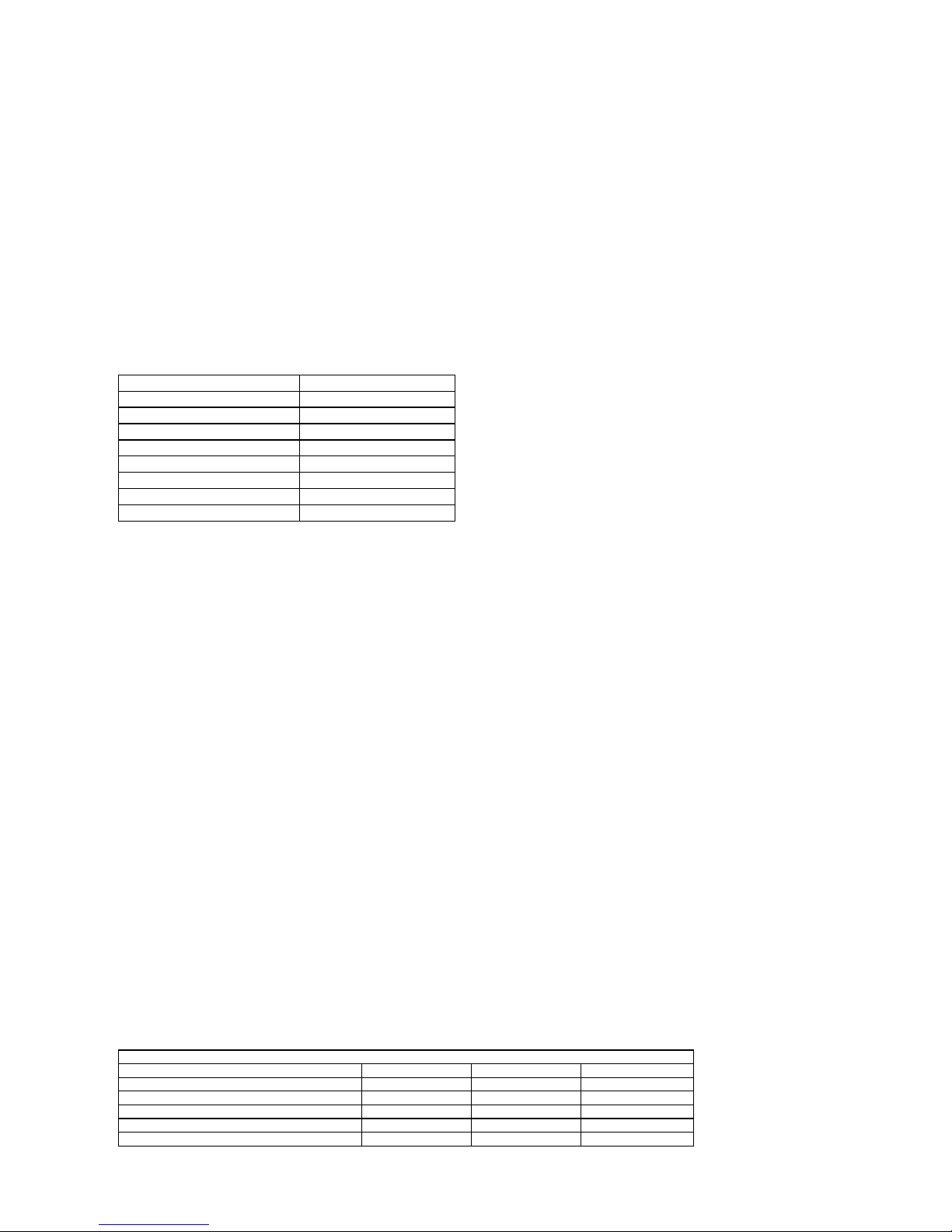

Adaption to various types of gas Table No. 1

Burners Gas type Pressure (kPa) Injector (mm) Mj/hr

Small Natural

1.00

0.90 3.85

Small U-LPG 2.75 0.54 3.75

Medium Natural 1.00 1.18 7.12

Medium U-LPG 2.75 0.70 6.20

Large Natural 1.00 1.55 12.0

Large U-LPG 2.75 0.92 11.25

Wok Natural 1.00 1.55 12.5

Wok U-LPG 2.75 0.95 13.1

Oven Natural 1.00 1.50

10.8

Oven U-LPG 2.75 0.85

9.4

BURNER ADJUSTMENT

1)Primary air adjustment:

Oven burner adjustment: follow the instructions below to adjust the primary air for the over burner:

1) Remove the oven bottom.

2) Loosen the screw P and adjust the position X of the Venturi cone (Fig. 16) according to the measurements indicated in

table 2.

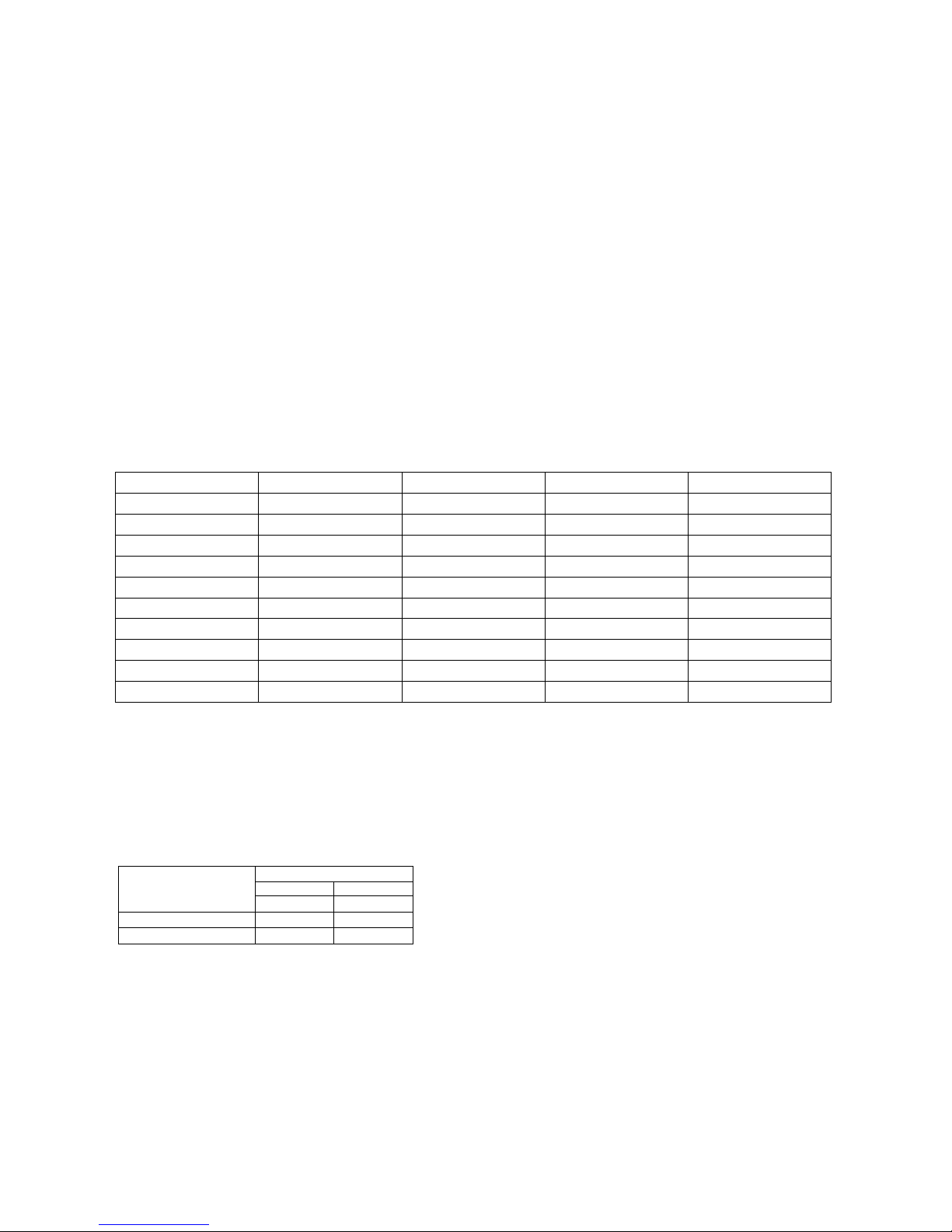

TABLE N°2: Burner primary air regulation (indicative)

BURNER

Type of gas Oven (mm)

M6

Natural fully open

Universal LPG fully open

2) Burner "MINIMUM" adjustment:

Work surface burner adjustment: follow the instructions below to adjust the work surface burner minimum:

1) Light the burner and set the knob to the MINIMUM position (small flame).

2) Remove the knob of the valve that is press fit on the rod of that valve.

3) If the cooker is not equipped with safety valves on the surface burners, insert a sm all slotted scre wdriver into the hole

on the valve rod (Fig. 18) and turn the choke screw to the right or left u ntil t he burner flam e is a djusted to minimum. If th e

cooker is equipped with safety valves, the choke valve is not located in the rod hole, but on the valve body (see fig. 19).

4) Make sure that the flame does not go out when switching quickly from the MAXIMUM to the MINIMUM position.

Oven burner adjustment: follow the instructions below to adjust the minimum:

1) Light the burner setting the knob to the MAXIMUM position.

2) Close the oven door and operate the oven for at least 10 minutes.

3) Set the knob to the MINIMUM position (corresponding to 120°) and then remove it.

Page 6

6

4) With a slotted screwdriver turn the choking screw (see figure 20) and, while observing the flame at the same time

through the cooker porthole, evaluate the consistency of the flame so it remains on when switching quickl y from the

MINIMUM to the MAXIMUM position.

WARNING: The above-mentioned adjustment should be made only with Natural gas burners, while for those

operating with Universal LPG the screw must be locked at the end in a clockwise direction

APPLIANCE ELECTRIC CONNECTION:

The electric connection must comply with the current legal standards an d regulations.

Before making the connection, check that:

- The system electrical rating and the current outlets are adequate for the maximum power output of the appliance (se e

the label applied to the bottom of the casing).

- The outlet or the system is equipped with an efficient gr ound c onnection in accorda nce with the curren t legal standards

and regulations. The company will not be responsible for the non-compliance with these instructions.

When the connection to the power supply network is made using an outlet:

- If the power cord is supplied without a plug, ap ply a standard plug that is suitable for the load indicated on the label.

Connect the wires according to the diagram shown in FIG.21 and check that:

letter L (phase) = brown wire;

letter N (neutral) = blue wire;

ground symbol = green-yellow wire;

- The power cord must be positioned so that an overtemperature of 75 K will not be reached at any point.

- Do not use reductions, adapters or splitters since they might cause false contacts and lead to dangerous overheating.

When the connection is made directly to the electric network:

- Use a device that ensures disconnection from the mains in which the contacts are o pened to a distance that permits

complete disconnection according to the conditions for over-voltage category III.

- Remember that the ground wire must not be interrupted by the circuit-breaker.

- As an alternative, the electric connection can also be protected by a high-sensitivity residual current circ uit-breaker.

- It is highly recommended to attach the special green-yellow ground wire to an efficient g round system.

WARNING: If the power cord is replaced, the ground wire (yellow-green) connected to the terminal, should be

longer than the other wires by about 2 cm.

WARNING: If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard.

For New Zealand - This cooking range must be connected to the supply by a supply cord fitted with an appropriately

rated plug that is compatible with the socket-outlet fitted to the final sub-circuit in the fixed wiring that is intended to

supply this cooking range.

TABLE N°3 : TYPES OF POWER CORDS

Work surface operation Oven operation Cross section 230V ~

Only gas burner Gas oven / Electric grill 3x1mm²

Ventilated Electric Oven 3x1,5mm²

BEFORE LEAVING

When the installation is complete, always check for gas leaks using a soapy solution. Never use a flame to make this

check.

Ignite all burners on high flame to ensure correct operation of gas valves, burners and ignition. Turn gas taps to low

flame position and observe each burner to ensure they ignite completely at all ports and that the flame is stable. Conduct

these checks for each burner individually and concurrently.

When satisfied with the appliance, please instruct the user on the correct method of operation. In case the appliance fails

to operate correctly after all checks have been carried out, please call the Bertazzoni Service Center.

APPLIANCE MAINTENANCE

ATTENTION: IMPORTANT WARNINGS

For cookers resting on a base

ATTENTION: If the cooker rests on a base, take the measures necessary to prevent the cooker from sliding along the

support base.

For cookers with glass covers

ATTENTION: Before opening the appliance’s glass cover, carefully remove all liquid residues from the top of it.

ATTENTION: Before closing the appliance’s glass cover, make sure that the work surface has cooled.

For cookers with electric ovens

During use, the appliance becomes hot. Care should be taken to avoid touching heating elements inside the oven.

For cookers with electric ovens

WARNING: Accessible parts may become hot during use. To avoid burns, young children should b e kept away.

For the food warmer compartment (or drop leaf in our case)

ATTENTION: The internal parts of the food warmer can become hot during use.

Page 7

7

For glass doors

Do not use harsh abrasive cleaners or sharp metal scrapers to clean the oven door gla ss since they can scratch the

surface, which may result in shattering of the glass.

Do not use steam cleaners to clean the appliance.

NOTE: various parts of the cooker heat up reaching temperatures which seem very high but which are actually fully

within safety limits. According to these limits:

1) With the oven on at 200°C for 1 hour, front accessible parts which cannot be grasped, can reach the following

temperatures:

- Control panel: Tmax = Room Temperature +60°C

- Glass of the oven door: Tmax = Room temperature+60°C

- Metal part of the oven door: Tmax = Room temperature+45°C

2) With the oven on at 230°C for 1 hour, the parts which can be grasped, can reach the following temperatures:

- Plastic knobs: Tmax = Room temperature+60°C

- Metal oven door handle: Tmax = Room temperature+35°C

where the room temperature is the temperature in °C of the place where the appliance is installed.

REPLACING PARTS

Before performing any maintenance operation, disconnect the appliance from the gas supply and electricity

network.

To replace parts such as knobs and burners, just remove them from the seats without disassembling any part of the

cooker.

To replace parts such as nozzle supports, valves and electric component s follow the procedure described in the burner

adjustment paragraph. To replace the valve or the gas thermostat, it is also necessary to disassem ble the two rear gas

train brackets, loosening the 4 screws (2 per bracket) that attach it to the rest of the cooker and, unscre w the nuts that

attach the front burner valves to the control support, after removing all the knobs. To replace the gas or electric

thermostat, also disassemble the rear cooker guard, loosening the relative scre ws, to be able to pull out and reposition

the thermostat bulb.

To replace the oven bulb, just unscrew the protection cap that projects out inside the oven. (Fig.22)

WARNING: Ensure the appliance is switched off before replacing the lamp to avoid the possibility of electric

shock.

WARNING: The power cord supplied with the appliance is con nected to that appliance with a type Y connection (in

compliance with standards EN 60335-1, EN 60335- 2-6 and subsequent amendments) for which it must be replaced by

the manufacturer or its service agent or a similarly qualified person in order to avoid a hazard.

If the power cord becomes worn or damaged, replace it based on the information reported in table 3 .

WARNING: If the power cord is replaced, the installer shall ensure that the ground cable is longer than the

phase cables and also shall comply with the warnings regarding the electric connection.

To replace the power cable, lift the terminal board’s cover and replace the cable.

USE AND MAINTENANCE MANUAL

WARNING: This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

WARNING: Children should be supervised to ensure that they do not play with the appliance.

DO NOT USE OR STORE FLAMMABLE MATERIALS IN THE APPLIANCE STORAGE DRAWER OR NEAR THIS

APPLIANCE.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

DO NOT STORE OR USE FLAMMABLE LIQUIDS OR ITEMS IN THE VICINITY OF THIS APPLIANCE.

WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT OR IN CARAVANS, IT SHALL NOT

BE USED AS A

SPACE HEATER.

WARNING: SERVICING SHOULD BE CARRIED OUT ONLY BY AUTHORISED PERSONNEL.

DO NOT MODIFY THIS APPLIANCE.

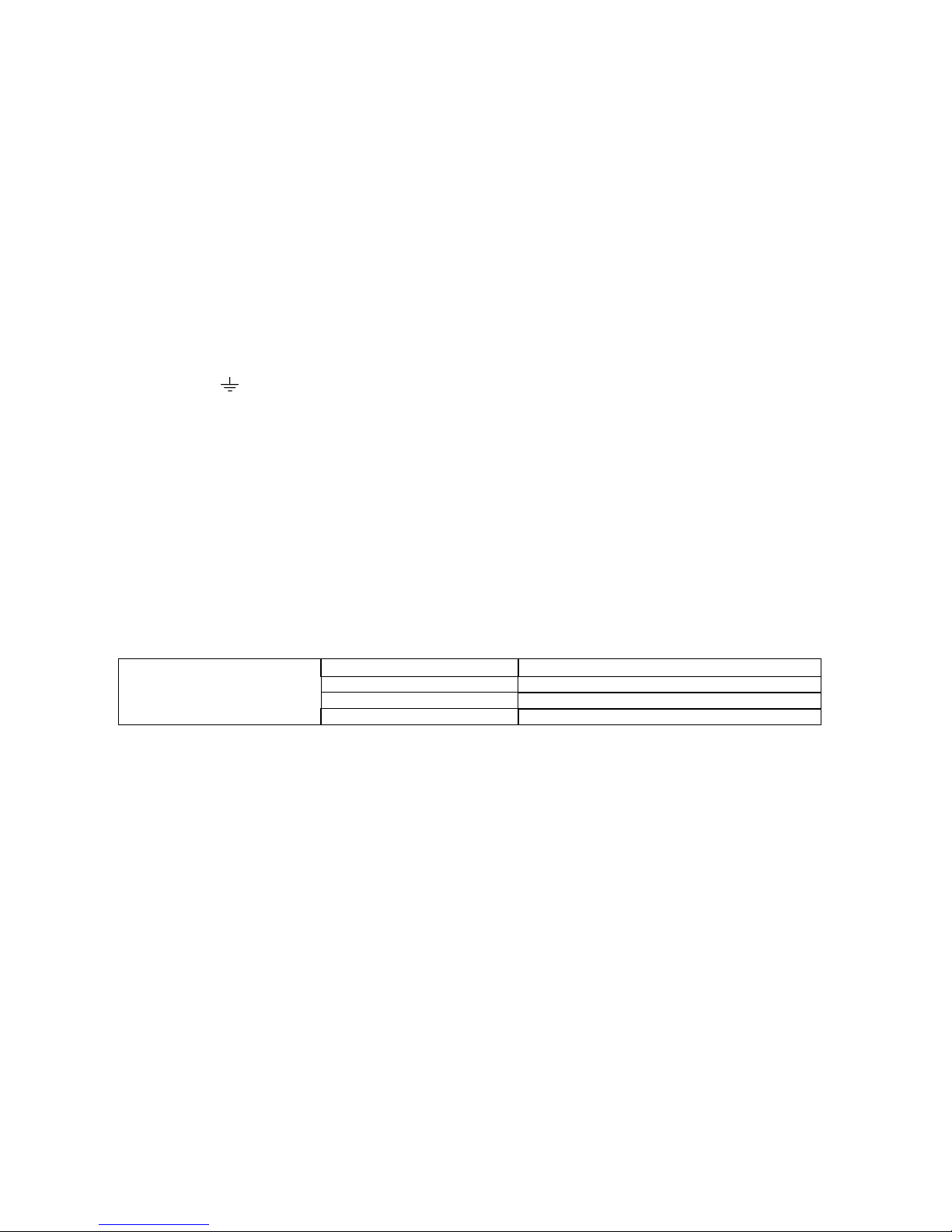

TABLE 4 GAS BURNER DIMENSION

Burner Dimension (mm)

Auxiliary Ø 50

Semi-rapid Ø 70

Rapid Ø 95

Ultra-rapid Ø 130

Page 8

8

CONTROL PANEL DESCRIPTION

On the control panel, small symbols show the function of each knob or ke y. Here as follows are t he several controls that

a cooker can have:

the symbol o shows the disposition of burners on the worktop, the full dot identifies the burner in

object (in this case the front left burner).

the symbol or shows the running of any oven (gas oven with electric grill, static oven,

9 positions switch)

the symbol or shows the electric thermostat for electric fan oven

USING BURNERS

A diagram is etched on the control panel above each knob which indicates which burner corresponds to that knob. The

burners can be ignited in different ways depending on the type of appliance and its specific characteristics:

- Manual lighting (it is always possible even when the power is cut off): Turn the knob anticlockwise that

corresponds to the burner selected, setting it to the MAXIMUM position at the etched star (large flame Fig.23-24) and

place a lit match up to the burner.

- Electric ignition: Turn the knob counterclockwise that corresponds to the burner sele cted, setting it to the MAXIMUM

position (large flame Fig. 23-24) and keep on pressing the knob in correspondence of the ignition s ymbol marked with a

star (for cookers equipped with ignition trough knob) or press the ignition button marked with a star and release it as

soon as the burner has ignited.

- Burner ignition equipped with safety device (thermocouple)(fig.25): Turn the knob anticlockwise that corresponds

to the burner selected, setting it to the MAXIMUM position at t he etche d s tar (large fl ame F ig. 23-24), pr ess the kn ob a nd

activate one of the above-mentioned ignition devices. Once ignited, keep pressing the knob for about 10 seconds to

allow the flame to heat the thermocouple. If the burner goes out after releasing the knob, repeat the entire operation.

Note: It is recommended not to try to ignite a burner if the relative flame cap is not in the correct position.

If the flame does not light after the first attempt, wait 5 minutes for the gas to dissipate before attempting to re-light the

burner.

Tips for using burners correctly:

- Use suitable pots for each burner (see tab. 5 and Fig. 27).

- When the liquid is boiling, turn the knob to the MINIMUM position (small flame Fig. 23-24).

- Always use pots with a cover.

TABLE N°5

BURNER PAN DIAMETER recommended (cm)

Auxiliary 12-14

Semi-rapid 14-26

Rapid 18-26

Double ring 22-26

NOTE: use flat-bottomed pans

NOTE: after cleaning the burners, make sure the caps “A” an d flame spreader heads “B” are positioned properly

as shown in figure 26A and are not positioned as shown in figure 26B.

WARNING: If the power is cut off, the burners can be lit with matches. When cooking foods with oil and fat,

which are very flammable, the user should not leave the appliance unattended. If the appliance is equipped with

a glass cover, such a cover may break when h eated. Turn off all burners before lowering th e cover. Do not use

sprays near the appliance when it is being used. When using the burners, make sure that the handles of the pots

are correctly positioned. Keep children away from the appliance. If equipped with a cover, before being closed,

any food deposits should be cleaned off the built-in surface.

NOTE: The use of a gas cooking appliance produces heat and humidity in the room where it is installed.

Therefore, proper aeration in the room is needed while ensuring that natural ventilation openings remain

unobstructed (Fig.2) and activating the mechanical aeration device/exhaust hood or electric fan (Fig. 3 and Fig.

4). Intensive and continuous use of the appliance m ay require additional aeration, for example by opening a

window, or more efficient aeration by increasing the power of the mechanical exhauster, if installed.

ATTENTION:Usepotswithaflat

bottom

Page 9

9

USING THE GAS OVEN

All the gas oven cookers are equipped with a thermostat a nd safety device to ad just the cooking temperature. T he oven

temperature is set by turning the knob counterclockwise to match the indicator with the temperature selected. The gas

oven can be combined with a gas grill or an electric grill. See the specific pages for use information.

Operating the fan of the oven by means of the appropriate switch situated on the control panel, the circulation of warm air

guarantees a uniform heat distribution. The preheating of the oven can be avoide d. However for delicate baking, it is

preferable to warm the oven before introducing the baking- pan. The baking system with the fan convection changes in

part the various traditional baking notions. When roasting meat it is not necessary to turn the meat an y more and for a

roast on the spit, it is not indispensable to use the spit-roaster,

but is sufficient to put the meat directly on the grate.

With the use of the fan gas oven, the baking temperatures a re slightly lower of ab out 10-15°C compared to those in use

with the traditional gas oven. The oven can also b e used in a traditional way, for foods requiring h eat from the bottom,

e.g. pizza.

WARNING: If the burner flames are extinguished accidentally, turn off the control knob and do not try to relight

the oven until after at least 1 minute.

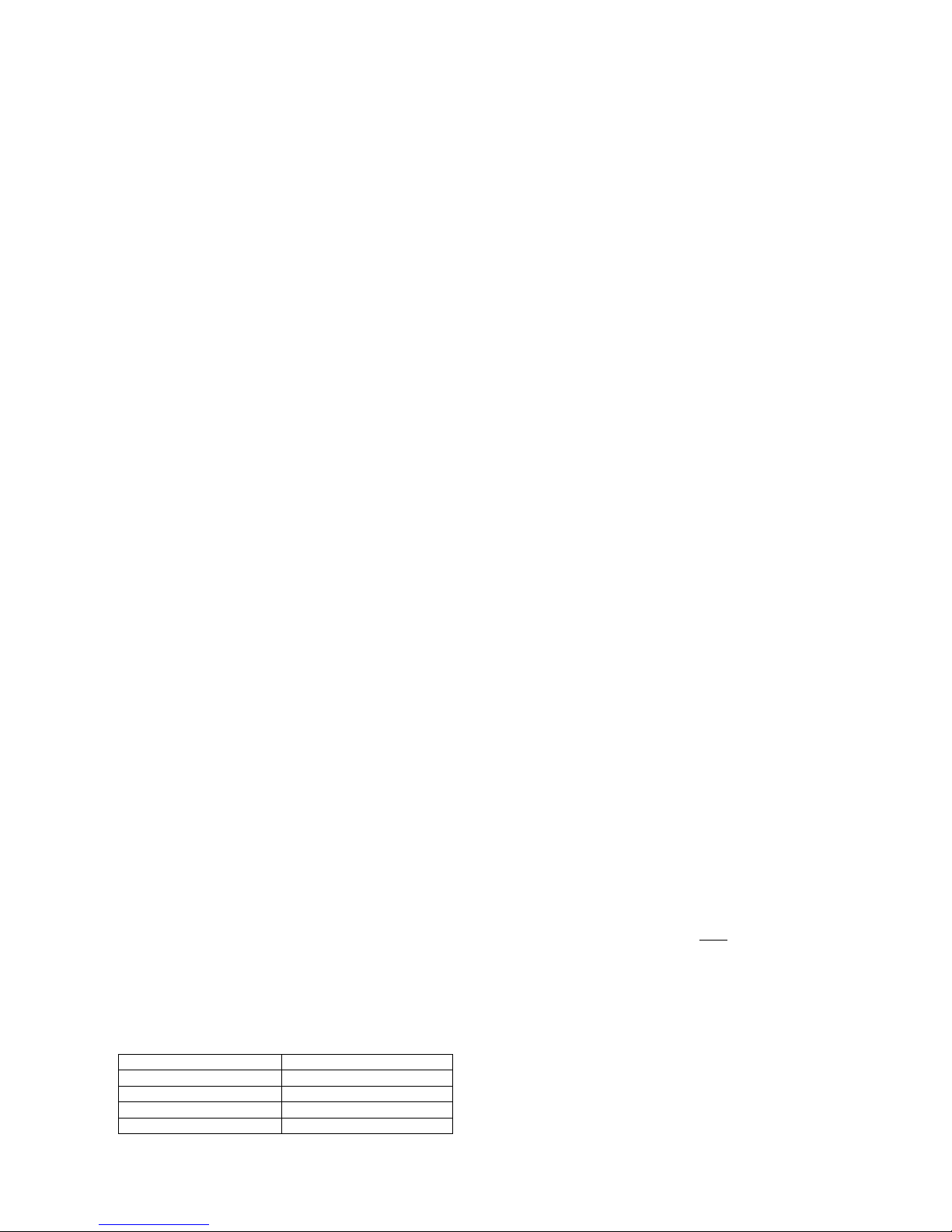

ABLE N°6

THERMOSTAT SETTING TEMPERATURE °C

1 120

2 140

3 160

4 175

5 190

6 210

7 235

8 250

The oven burner can be ignited in different ways:

- Manual lighting (it is always possible even when the power is cut off):

To light the oven, open the oven door and t urn the knob so the no. 8 on the scale matches the i ndicator (fig.28-29). At

the same time put a lit match next to the ignition tube that is visible on th e oven level (fig. 30). Then press the therm ostat

knob (this makes the gas start to flow) and keep it pressed, after the burner h as been completely lit, for 10 seconds.

Release the knob and make sure that the burner remains on, otherwise repeat the operation.

- Electric ignition (only for the models equipped with this device):

In this case, first open the oven door, then turn the knob to the maximum temperature setting (number 8). Then press the

thermostat knob (models with ignition trough knob). Wait about 10 seconds after the burner h as been completely lit and

then release the knob. Make sure that the burner remains on, otherwise repeat the operation. As for cookers without

ignition trough knob, press the thermostat knob and the key with the spark symbol, wait about 10 seconds after the

burner has been completely lit and then release the knob. Make sure that the burner remains on, other wise repeat the

operation.

The ignition device should not be used for more than 15 seconds. If after that period the burner still has not

been lit, do not use the device and open the door of the room or wait at least 60 seconds before trying to light

the oven again.

WARNING: when trying to light the oven, the door must always be open. When using the oven, leave the cooker

cover open to prevent it from overheating.

NOTICE: when using the oven for the first time it should be operated for 15-30 minutes at a temperature of

about 250° without cooking anything inside in order to eliminate any moisture and odours from the internal

insulation.

During normal oven use, after lighting the burner and setting the desir ed temperature, wait about 15 minutes before

putting in any food to preheat the oven.

The oven is equipped with 5 guides at different heights level (fig.31a) which can be use d to insert shelve s or the tray. To

keep the oven as clean as possible it is recommended to cook meat on the tray or on the shelf that has been inserted

inside the tray. The table below lists the general cooking times an d the position of the tray for different types of foods.

Personal experience will help to determine any variations in the values reported in the table. In any case, it is

recommended to follow the instructions of the specific recipe being used.

Temperatures between brackets are referred to the use of oven with fan assisted gas.

TABLE N°7

GAS OVEN COOKING TABLE

TEMP °C HEIGHT MINUTES

MEAT

PORK ROAST 220 (210) 4 60-70

BEEF ROAST (YOUNG STEER) 250 (240) 4 50 -60

BEEF ROAST 240 (230) 4 60-70

VEAL ROAST 220 (210) 4 60-70

Page 10

10

LAMB ROAST 220 (210) 4 45-55

ROAST BEEF 230 (230) 4 55-65

ROAST HARE 235 (225) 4 40-50

ROAST RABBIT 220 (210) 4 50-60

ROAST TURKEY 235 (225) 4 50-60

ROAST GOOSE 225 (215) 4 60-70

ROAST DUCK 235 (225) 4 45-60

ROAST CHICKEN 235 (225) 4 40-45

FISH

200-225 (190-215) 3 15-25

PASTRY

FRUIT PIE 200 (210) 3 35-40

TEA CAKE 190 (180) 3 50-55

BRIOCHES 175 (165) 3 25-30

SPONGE CAKE 235 (225) 3 20

RING CAKE 190 (180) 3 30-40

SWEET PUFF PASTRIES 220 (210) 3 20

RAISIN LOAF 220 (210) 3 15-20

STRUDEL 180 (170) 3 15-20

SAVOIA COOKIES 190 (180) 3 15

APPLE FRITTERS 220 (210) 3 20

SAZOIARDI SANDWICH 220 (210) 3 20-30

TOAST SANDWICH 250 (240) 4 5

BREAD 220 (210) 3 30

PIZZA 220 (210) 3 20

USING THE 2+0 CHANGE-OVER SWITCH (figure 35-36)

(only for gas ovens)

The 2+0 change-over switch used for gas oven models.

the symbol or is for oven fan and light operation, to use the gas oven or grill with fan.

the symbol or is for turning on the oven light

USING THE ELECTRIC THERMOSTAT FOR MULTI-FUNCTION COOKERS

The thermostat provided in every model keeps the temperature inside the ov en constant at a temperature range from

50°C to 250°C .

Turn the knob clockwise (Figure 34-35),to align the selected temper ature on the metal ring with the indicator pr inted on

the front panel. An orange light shows the thermostat is working and goes off when the oven temperature has exceede d

the selected temperature by 10°C and comes on when the selected temperatures dro ps below 10°C. The thermostat

can operate the oven heating elements only if the switch is in one of the heating el ement operating m odes. If the switch

is set to 0, the thermostat will not operate the heating elements.

USING THE 9-SETTING MULTI-FUNCTION OVEN SELECTOR

The 9+0 setting change-over switch for multi-function ovens is used to control, along with the thermostat, the fan motor

and heating elements. To turn on the elements, both the knob on the 9+0 switch and thermostat nee d to be turned; if

only one knob is turned, the oven will not work and onl y the light or fan motor will come on. The electric oven has 4

heating elements: a bottom element, two top elements and a round element; turn the change-over switch knob (Figur e

36-37) to enable the heating element matching the symbol on the metal ring. However to operate this element, you nee d

to turn the thermostat knob until the orange light shows the element has come on. If you position the change-over switch

to any one of the nine operating modes, the relative he ating element is enabled as well as the oven light. After the

temperature and heating elements to operate have been selected, the oven heating elements are operated by the

thermostat, so it is normal for the orange light to come on and off during operation.

To turn off the electric oven, set the change-over switch knob to 0 to prevent the thermostat operating the heating

elements. The heating elements will be disa bled, but the fan motor and oven light can be turned on from the ch angeover switch.

The switch has 9 settings, for 9 different types of oven operation:

- the symbol

or indicates that only the oven light is on;

Page 11

11

- the symbol or indicates that the 1300W bottom heating element and external 900W top heating

element are on;

- the symbol

or indicates that only the external 900 W top heating element is on;

- the symbol

or indicates that only the 1300W bottom heating element is on;

- the symbol

or indicates that only the 2000 grill heating element is on (see specific section);

- the symbol or indicates that the external 900W top he ating element and 2000W grill heating element

are on (see specific section);

- the symbol

or indicates that the e xternal 900W top heating element, the 2000W grill heating element

and fan motor are on (see specific section);

- the symbol

or indicates that the 2400W round heating element and fan motor are on;

- the symbol

or indicates that only the fan motor is on.

When the knob is turned to one of these nine positions, the oven light is always on, to indicate tension inside the oven.

USING THE ELECTRIC OVEN WITH NATURAL CONVECTION

When using the oven for the first time, leave it on for maximu m 30 minutes at a temperature of 250°, t o eliminate smell

from the internal seals.

During normal use, select the cooking temperature using the thermostat knob, then wait for the orange lig ht to go off

before putting foods in.

The oven has 5 grooves at different heights (Figure 31a) for fitting racks or trays. To prevent getting the oven to o dirty,

meat should be cooked on a tray or rack placed in the tray.

TABLE 8 COOKING TIMES FOR ELECTRIC OVENS WITH NATURAL CONVECTION

TEMP °C HEIGHT MINUTES

MEAT

ROAST PORK 225 3/4 60-80

ROAST STEER 225 3/4 60-80

ROAST OX 250 3/4 50-60

ROAST VEAL 225 3/4 60-80

ROAST LAMB 225 3 40-50

ROAST BEEF 230 3/4 50-60

ROAST HARE 250 3/4 40-50

ROAST RABBIT 250 3 60-80

ROAST TURKEY 250 3 50-60

ROAST GOOSE 225 3 60-70

ROAST DUCK 250 3/4 45-60

ROAST CHICKEN 250 3/4 40-45

FISH

200-225 2 15-25

CAKES AND PASTRIES

FRUIT CAKE 225 2 35-40

SANDWICH CAKE 175-200 2 50-55

BRIOCHES 175-200 2 25-30

SPONGE CAKE 220-250 2 20-30

DOUGHNUTS 180-200 2 30-40

PUFF PASTRY 200-220 2 15-20

GRAPE TART 250 2 25-35

STRUDEL 180 2 20-30

SAVOYARD BISCUITS 180-20 0 2 40-50

APPLE FRITTERS 200-220 2 15-20

PUDDING WITH SAVOYARD

BISCUITS 200-220 2 20-30

TOASTED SANDWICH 250 3 5

BREAD 220 3 30

PIZZA 220 2 20

Page 12

12

USING THE ELECTRIC OVEN WITH FAN

When using the oven for the first time, leave it on for maximu m 30 minutes at a temperature of 250°, t o eliminate smell

from the internal seals.

Before cooking foods, make sure the oven reaches the selected temperature and the orange light is off. This type of

oven has a round heating element inside, where the fan for forced air circulation in a horizontal direction is positioned.

Based on this operating principle, a fan oven can be used for different kinds of cooking at the same time, without

changing the taste of the food. A few models are fitted at the r ear with a r emovable metal filt er that retains grease when

cooking roasts. This filter should be cleaned regularly with soapy water to remove the gr ease and ri nsed thor oughly. T o

remove the metal filter, apply gentle pressure upwards on the tab, indicated by the arrow. The circulation of hot air

ensures that heat is evenly distributed. It is not necessary to preheat the oven, however in the case of delicate baking,

the oven should be preheated before putting in baking trays. The convectio n fan cooki ng system chang es to some exten t

concepts about traditional cooking. Meat does not have to be turned during cooking an d a spit does not have to be used

for rotisserie roasting. The meat can be simply put on the rack.

TABLE 9

COOKING TIMES FOR ELECTRIC FAN OVENS

TEMP °C HEIGHT MINUTES

MEAT

ROAST PORK 160-170 2 70-100

ROAST STEER 170-180 2 65-90

ROAST OX 170-190 2 40-60

ROAST VEAL 160-180 2 65-90

ROAST LAMB 140-160 2 100-130

ROAST BEEF 180-190 2 40-45

ROAST HARE 170-180 2 30-50

ROAST RABBIT 160-170 3 80-100

ROAST TURKEY 160-170 3 160-240

ROAST GOOSE 160-180 3 120-160

ROAST DUCK 170-180 2 100-160

ROAST CHICKEN 180 2 70-90

FISH

160-180 2-3

CAKES AND PASTRIES

FRUIT CAKE 180-200 2 40-50

SANDWICH CAKE 200-220 2 40-45

BRIOCHES 170-180 2 40-60

SPONGE CAKE 200-230 2 25-35

DOUGHNUTS 160-180 2 35-45

PUFF PASTRY 180-200 2 20-30

GRAPE TART 230-250 2 30-40

STRUDEL 160 2 25-35

SAVOYARD BISCUITS 150-18 0 2 50-60

APPLE FRITTERS 180-200 2 18-25

PUDDING WITH SAVOYARD

BISCUITS 170-180 2 30-40

TOASTED SANDWICH 230-250 3 7

BREAD 200-220 3 40

PIZZA 200-220 2 20

POSITIONING THE OVEN TRAYS & SHELVES

The Grill Tray or Oven Shelf can be located in any of the four height positions in the oven (See Fig. 31a).

Refer to the ‘Oven Cooking Tables’ for the recommended shelf position. When fitting the trays or shelves, ensure they

are fitted between the two wires that are closest together (See Fig. 31b).

Oven Shelves have a stop so that they are not fully withdrawn by accident. To fully remove the Oven Shelves, lift the

front of the shelf slightly and withdraw fully from the oven. (See Fig. 31d) Note that the Grill Tray does not have a stop

position and can be fully withdrawn without interruption, so be careful not to accidentally fully withdraw the tray.

To remove the Oven Shelf Support, remove the top and bottom screws shown in Fig 31c and then pull the support from

the holes in the rear oven wall. Repeat for opposite side. Replace in reverse procedure.

Page 13

13

USING THE STATIC ELECTRIC GRILL

The electric grill can be combined with the gas or electric oven.

With a gas oven + electric grill combination, the grill is operated from the oven thermostat knob.

The electric grill for gas oven cookers has a 2500W rating.

IMPORTANT: When using the electric grill in electric oven cookers, do not turn the thermostat knob to more

than 150°C to prevent overheating the oven front; the oven has been designed for closed-door grilling.

Grilling on the rack: In this case, the rack should be put at level 1 or 2, placing foods on top of the rack and a drip tra y

below. Turn on the grill heating element, setting the thermostat to the relative position.

IMPORTANT NOTE: the oven door must be kept closed when grilling using the static electric grill.

WARNING: during use the appliance gets very hot. Do not touch the heating elements inside the oven.

WARNING: Accessible parts may become hot when the grill is in use. Children should be kept away.

USING THE ELECTRIC GRILL WITH FAN

The electric grill with fan is a special function for optimal grilli ng, with the oven rack at an intermediate position and the

drip tray below.

With gas oven cookers with electric grills, set the thermostat to the grill symbol and the 2+0 change-over switch to the

position to turn on the 1500W grill heating element and fan motor.

With cookers with a 9-setting change-over switch, set the 9+ 0 switch to the relative position and the electric thermostat to

the temperature required, to turn on the grill heating element and fan motor.

IMPORTANT: When using the electric grill with fan, do not turn the thermostat knob to not more than 175°C

(between 150° and 200°C) to prevent overheating the oven front; the oven has been designed for closed-door fan

grilling.

USING THE THERMOMETER Figure 40

The cooker is fitted with a device to measure the temperature in the middle of the oven.

This lets you check the temperature inside the oven and adjust food cooking temperatures more accurately.

ELECTRIC OVEN

When you turn on the oven, the orange light comes on to indicate that the heating elements are working: The

thermometer dial will start to move towards the set temperature.

The orange light will keeping coming on and off, indicating that the heating elements are working to maintain the

temperature inside the oven.

The light may go off for a few minutes before the thermometer has reached the temperature required. This is normal,

because operation of the heating elements is regulated so that heat is distributed properly inside the oven.

Heat is optimally distributed inside the oven when the thermometer dial has stopped.

If the oven temperature drops or goes up, the thermometer dial will follow these variations in the same way.

When the oven is turned off, the temperature on the thermometer will slowly drop until it reaches room temperature.

NOTE: The temperatures on the knob are indicative. Follow the thermometer temperature for cooking.

GAS OVEN

When the oven is turned on, the burner will start working at the maximum and the thermometer dial will start to move

towards the set temperature.

The flame may die down before the thermometer has reac hed the temperature required. T his is because burner power

is reduced so that heat can be evenly distributed inside the oven.

Heat is optimally distributed inside the oven when the thermometer dial has stopped.

When the oven is turned off, the temperature on the thermometer will slowly drop until it reaches room temperature.

NOTE: The Thermostat Position and Oven Temperature correspondence in table no. 6 is indicative and depends on

various factors such as the type of gas and supply pressure.

Follow the thermometer temperature for cooking.

NOTE: it is normal to record different temperatures from those indicated on the panel thermometer, when you measur e

the temperature in the middle of the oven using a different thermometer.

The temperature indicated by the thermometer is the mean temperature inside the oven and does not indicate the

temperature of any single point.

3 KEYS ELECTRONIC PROGRAMMER (fig.43)

The first start up

The numbers and the A letter on the display are blinking w hen the oven is switched on for the first time, or

after a power cut:

the appliance cannot be operated in this condition.

To set the hour and/or to enable the appliance to operate press the M key for at least 2 seconds: the A letter

turns off and the numbers now are steady on the display.

The dot (3) starts blinking: press the - or

+

key to set the hour.

The hour is accepted by the programm er just few se co nd after havin g releas ed th e ke y.

N.B. the appliance can be c or rect l y us e d f or coking only when you will see on t h e dis pl ay t he symbol (2).

Page 14

14

The symbols on the display:

1

A

*

Automatic programme is working.

(* in some models there is the writinq 'Auto' instead of A).

2

The appliance is ready for manual use (not automatic).

3

•

When blinking, the programmer is in setting hour mode.

4

Timer set.

5 -

Decreasing numbers when setting the timer.

Also for choose your desired sound level ( 3 levels available).

6

M

"Mode" kev to access the programming option s of the pro gram m e.

7

+

Increasing numbers when setting the timer.

Timer

The purpose of the timer is just of a sound signal, which can be set for a max time of 23h59min. once elapsed

the set time, the (4) symbol turns off and a sound signal is heard; this sound set off automatically in 7min, or

you can stop it by pressing any key of the program mer. To set the timer press the M key for 2 seconds, or

anyway just to see the (4) symbol blinking. Set the timer by using the

+

or - keys. Release the + or - key when

you have matched your desired time. In a few seconds the current time appears on the display together with

the ) symbol. The countd ow n starts immediately from now on.

Semi-automatic cooking

Cooking time: Once having selected a coking function and set the desired temperature, press the M key for a 2

seconds time to access the programming mode. The (4) symbol appears. Release and press again the M key.

On the display, the A symbol starts blinking and the " dur " writing appears on the display, then it changes to O'

00. Set the cooking time with the - or

+

keys. (max available tim e: 10h). The selected time is automatically

processed by the programmer in a few seconds, or you can also touch the M key many times just to see again

the current time.

The A and (2) symbols will be on the display. Once the set cooking time is finished, a sound will be heard and

the oven automatically switches off. Please see the following paragraphs about how to disable the sound alarm

and restarting the oven.

End of cooking

once having selected a cooking function and set the desired temperature, touch the M key to access the

programming mode for at least 2 sec. the ) sy m b ol switches on. Release and touch again the M key.

On the display the A symbol starts blinking and the writing "dur" appears. Touch again the M key. On the

display the writing "End" appears. The last one changes few seconds after with the symbol 0· 00.

Set the end of cooking time with the keys - or

+.

(maximum available time: 10hOOm).

The selected time is automatically processed by the programmer in a few seconds, or you can also touch the

M key many times just to see again the current time.

The cooking immediately starts, while on the program mer display the current time is shown again in a few

seconds. The A and (2) symbols will be on the display.

Once the set end of cooking time is finished, a sound will be heard and the oven automatically switches off.

Please see the following paragraphs about how to disable the sound alarm and restarting the oven.

Automatic cooking

Set a cooking time following the instructions on the cooking time paragraph, then set the end of cooking time

following the instructions on the previous paragraph. (Max available end of cooking time 24h). The oven

automatically switches on at a determined time which is the difference between the end of cooking time and

the cooking time.

During the waiting time before cooking, which goes from the oven start to the heating, on the display appears

the A symbol to show that an automatic program is on and the current time. The oven on is marked by the (2)

symbol. Once the set end of cooking time is finished, a sound will be heard and the oven automatically

switches off.

Please see the following paragraphs about how to disable the alarm and restarting the oven.

How to disable the sound alarm:

To disable the sound just touch one of the keys.

Operating again the

oven

Once a semi-automatic or automatic cooking has expired, on the display appear the current time and the

blinking A symbol. In this condition, the heating elements and the light bulb of the oven are disabled. To enable

again the oven, just touch and keep the M key up to see the sy mbol (2) on the display and the A symbol

disappears.

OTHER FUNCTIONS

How to delete a cooking time

(semi-automatic or Automatic)

Page 15

15

To delete a semi-automatic or automatic cooking program, with the A symbol on, touch together the - and

+

keys for at least 2 seconds or anyway up to see the (2) and the disabling of A symbol.

How to delete the countdown timer

To delete the counting of the timer, which symbol is ) t touch the M key for at least 2 seconds or anyway up to

see the ) symbol blinking. Touch together the - and

+

keys.

Checking the function settings

The set or remaining time of every cooking function of the programmer can be recalled to the display by

entering in program mode with the M key. Touch and keep the M key for almost 2 seconds or anyway up to

see the (4) symbol. The remaining time appears on the display, or a series of zero numbers if the timer is

disabled. Touch again the M key. On the display appears the "dur" writing, then alternately the remaining time

or a series of zero number (disable timer).

By touching again the M key, the end of cooking time appears together with the "End" writing.

How to change the current time or the sound level

With the programmer in standard mode, the (2) symbol is on, touch together the - and + keys for at least 2

seconds or anyway up to see the dot (3) blinking.

To update the hour on the display:

touch the + or - keys.

To change the sound level:

touch the M key. On the display appears the writing: Ton.. followed by a number.

Select with the - key your favourite sound level.

Note: number 1 is referred to the highest sound level. The available levels are 3.

Attention:

Power cut causes the loss of any program, even the clock; that means the programmer will have to

be set again

.

3 KEYS ELECTRONIC CLOCK (FIG. 43)

Mains frequency detection

At power on mains frequency is determined. When the timer is connected to 60Hz, the Celsius symbol is

flashing during start-up.

Power On

At power on, the relay contact is opened. The display and AUTO symbol flashes and time of day starts

from 0:00. Power on state with flashing daytime remains until time of day is set.

Setting Time of Day

Press PLUS and MINUS button simultaneously. At Power On, also MODE button is possible.

Time of day can be set with PLUS or MINUS, while the colon between hours and minutes is flashing.

Quick setting mode starts when PLUS or MINUS is held for more than 1 second. If daytime setting mode

is selected while an automatic program is active, the automatic program is cancelled.

The Buzzer

The buzzer interval alarm signal sounds if minute minder has reached the end time. The signal can be

switched off by pressing any key or by passing the signal duration limit.

Changing the Buzzer frequency

First press Plus and Minus simultaneously (menu far editing the time) and then Mode for selecting the

menu far changing the buzzer frequency. While the text tonX is visible the buzzer signal frequency can

be changed by touching Minus repetitively.

Note: If the touch pad is inactive, a visual alarm will only be reset when a valid key combination is

pressed far more than 2 seconds.

Clearing Programs and Manual function

The duration of the minute minder can be cleared by

a) "clear Function": First select minute minder program, then press PLUS and MINUS button

simultaneously.

after this clear the display returns from adjustment mode to time of day immediately.

b) Back counting of duration to zero. The timer remains in adjustment mode.

Minute Minder

While minute minder mode is selected, the Bell symbol flashes and the display reads the remaining time

in hours and minutes, only if the last minute is counting down the remaining seconds are displayed.

An active minute minder program is indicated by the statically illuminated Bell symbol. If alarm time has

finished, an acoustic interval signal sounds and the Bell symbol flashes.

Page 16

16

The minute minder program runs independently of other programs.

Key Lock

After power on reset or when no key is pressed for

7

seconds, the key look function is activated. Pressing a

valid key or key combination for 2 seconds or more will deactivate the key lock.

USING THE SELF-CLEANING OVEN

On models which have this device, the self-cleaning oven differs from normal ovens because the inner surfaces are

coated with a special micro-porous enamel that absorbs and eliminates grease residues during cooking. If liquid gr ease

is released, self-cleaning is not sufficient, so wipe the grease stains with a damp sponge and then heat the oven to the

maximum temperature, wait for it to cool down and wipe again with a damp sponge.

ABNORMAL OPERATION

Any of the following are considered to be abnormal operation and may require servicing:

• Yellow tipping of the burner flame. • Burners failing to remain alight.

• Sooting up of cooking utensils. • Burners extinguished by cupboard doors.

• Burners not igniting properly. • Gas valves, which are difficult to turn.

In case the appliance fails to operate correctly, contact Bertazzoni Service Center.

CLEANING THE APPLIANCE

Before any cleaning, unplug the appliance and turn off the gas tap.

Do not use steam cleaners to clean the appliance

Cleaning the hob:

Clean the burner heads, enamelled steel pan supports, enamell ed caps and flame spreaders regularly using warm soapy

water. Rinse and dry well.

Use a cloth to wipe away any liquids spilt from pans.

If the gas tap does not open or close easily, do not force it, but seek technical assistance immediately.

Cleaning enamelled parts:

Clean enamelled parts frequently with soapy water, to keep their char acteristics unaltered . Never use abrasive powders.

Do not leave acid or alkaline substances (vinegar, lemon juice, salt, tomato juice, etc.) on enamelled parts, and clean the

parts when still warm.

Cleaning stainless steel parts:

Clean with soapy water then dry with a soft cloth. Use special stainless steel cleaning products re gularly to maintain the

shine. Never use abrasive powders.

Cleaning the flame spreaders:

As the flame spreaders rest on the hob surface, to clean them, remove and wash with soapy water. Dry well and make

sure the holes are not obstructed, before putting them back in position.

Cleaning the oven glass panel:

The oven glass panel can be removed. After o pening the doors and blocking the hinges (figure 41) remove the glass

panel (figure 42) and clean. Clean the panel when the oven is cold, using a damp cloth. Do not use a brasive products.

Put the glass panel back, making sure the smooth part is on the outside and the pri nted part inside t he oven door. Then

release the hinges.

Note: do not release the hinges if the glass panel is not fitted on the door.

Cleaning inside the oven:

To make heavy-duty cleaning easier, the door can be removed as follows. After opening the door and blocking the

hinges (figure 41), put the door in a semi-open position a nd pull towards yourselves until it is rele ased. To reassemble,

proceed as above in reverse. The side racks can also be removed, by removing the nuts securing them to the oven.

Cast iron or aluminium strip racks:

Soft aluminium-bottomed pans are not recommended, to prevent leaving permanent marks on the rack surface which

cannot be removed with normal washing.

Page 17

17

Fig. 1

Fig. 2 Fig. 3 Fig. 4

Fig. 5

Page 18

18

Fig. 6

Page 19

19

Fig. 7

Page 20

20

Fig. 8

Page 21

21

Fig. 9

Page 22

22

Fig.10 fig.11 fig.12 fig13

fig14 fig15 Fig. 16

Fig. 17 Fig. 18 Fig.19

T

Fig.20 fig.21 Fig.22

Page 23

23

Fig.23 Fig.24 fig.25

fig.26 fig.27

fig.28 fig.29 fig.30

Page 24

24

fig.31a

Fig.31b

Fig.31c Fig.31d

Fig. 32 Fig. 33

Page 25

25

Fig. 34 Fig. 35 Fig. 36

Fig. 37 Fig. 38 Fig. 39

Fig. 40 Fig. 41 Fig.42

Fig. 43

Page 26

26

AFTER-SALES TECHNICAL SERVICE AND SPARE PARTS

Before leaving the factory, this appliance was tested a nd adjusted by specialist skilled staff to give the best operating

results. Any subsequent necessary repairs or adjustments must be carried out with the greatest care and attention by

authorised personnel. For this reason, we strongly adv ise you contact the Bertazzoni Service Center, specifying the

nature of the problem, the model of the equipment and the serial number. This data is provided o n the data label adhered

to the base of the appliance and on the duplicate data label. Always use original Bertazzoni spare parts.

OVERALL DIMENSIONS

AM64C61BX

Page 27

27

TU64C61BX

BERTAZZONI GROUP ABN 38 069 686 326

650 Bridge Road, Richmond, Victoria 3121

Service & Spare Parts: 1300 748 308

Bertazzoni After Sales Service - P.O. Box 543 SOMERTON VIC 3061

Email: customercare@bertazzonigroup.com.au

Page 28

28

Cod. 310793

Loading...

Loading...