F

Common Features of Electromechanical Switches

F

Switching systems

Switching elements lie at the heart of

all electromechanical switching devices

and must correspond to the respective

application. Essentially there are two basic

types of switching system that differ in terms

of their mechanical design and consequently

their scope of application:

l Slow-action contacts

l Snap-action contacts

Slow-action contacts

l On actuation, the normally-closed

and normally-open contact functions

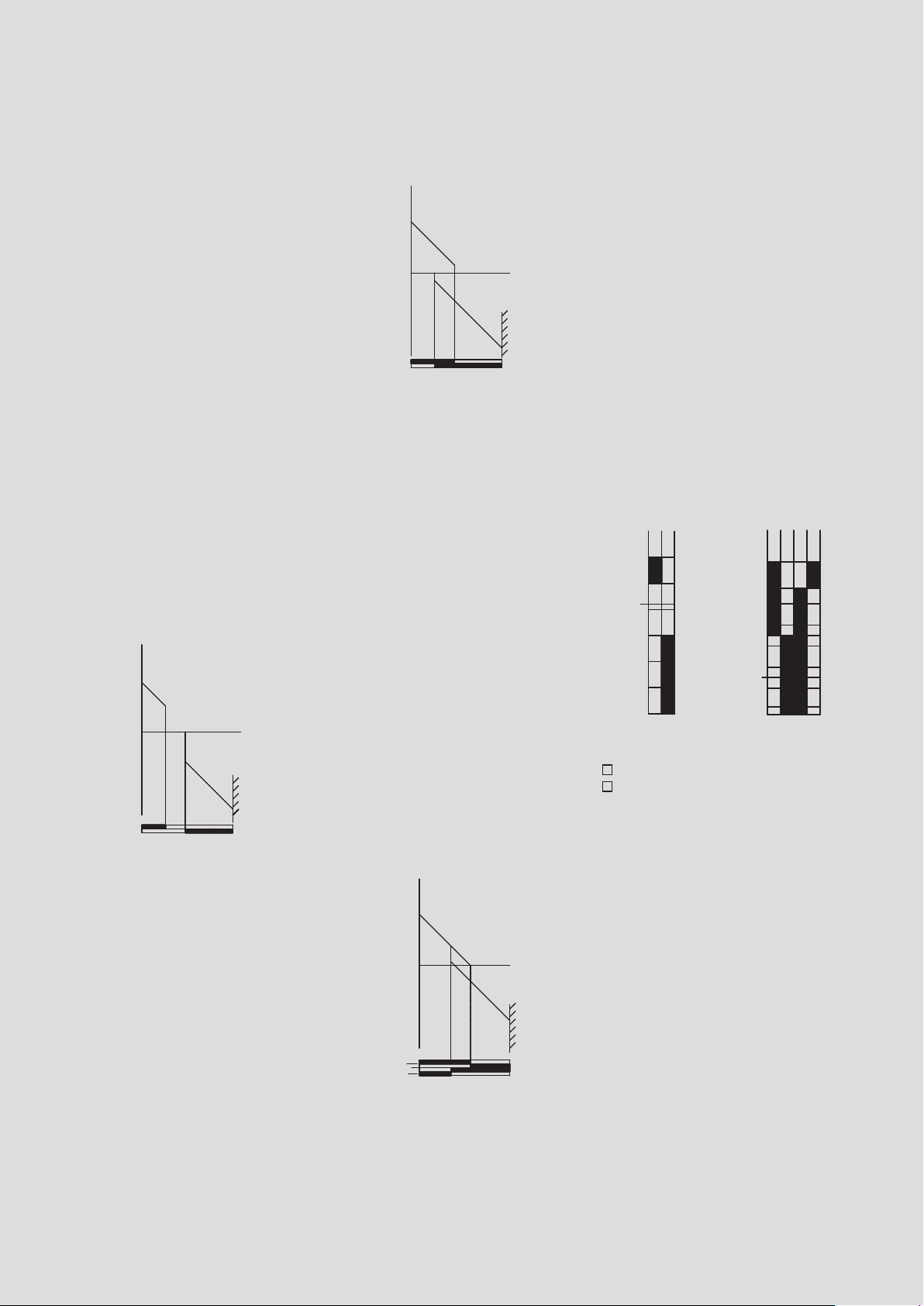

Fig. 2 shows the contact force during the

switching cycle of a slow-action contact

with overlap.

correspond to the movement of the

impact pin

l The approach speed controls the contact

opening (closing) time

l Large distance / actuating travel

between normally-closed and normallyopen contact function

l The switching points are identical in

forward and reverse travel

F

Lag between NC and NO

contact function

Snap-action contact

l On actuation, the normally-closed

contact function is immediately followed

by the normally-open contact function

l In this configuration there is no overlap

of the NC/NO contacts. The switch

provides a distinct OR-function.

l The changeover accuracy is not

dependent on the approach speed

l Consistently effective suppression

of DC arc

l Reliable contact-making also for

extremely slow approach speeds

S

l The snap mechanism triggers the

full opening width of the contact on

reaching the changeover point

l Due to the force reversal in the

mechanical system, a different switching

point occurs in forward and reverse

travel. The lag is referred to as hysteresis.

Fig. 1 shows the contact force during the

switching cycle of a slow-action contact.

Overlap

l The switching principle of snap-action

contacts makes overlapping of the NC /

NO contact function possible. The term

overlap refers to the area, in which both

the normally-closed contact as well as

the normally-open contact are closed in

connection with a changeover switch

with delay.

Fig. 3 shows the contact force during the

switching cycle of a snap-action contact.

1)

Changeover point in forward travel

2)

Changeover point in reverse travel

Lag between NC and NO

contact function

S

Lag

(hysteresis)

S

2) 1)

Switching diagram

The switching diagram describes the

function of the switching device in detail.

It combines the mechanical input

variables that act on the contact system

via the actuator with the electrical output

variables. The user can deduct the following

information from the switching diagram:

l Mechanical input variables

(force, travel, torque, angle)

l Electrical contact-making in forward

and reverse travel

l Terminal designation

l Point at which positive opening

is achieved

l Type of contact system

23-24

11-12

2N

0

1

1.8

3

12,5N

6

0

10

35

55

75

21-22

13-14

13-14

21-22

6.5Ncm

6Ncm

Slow-action contact Snap-action contact

Contact closed

■

Contact open

■

Contact designation

In accordance with DIN 50013 and DIN 50005

the terminal designations of the contact

elements are always make up of two digits.

The contact rows are numbered

consecutively with the allocating digit

(1st digit) in actuation direction. Contacts

of a switching element that belong

together have the same allocating digit.

The second digit is the function digit that

denotes the type of contact element.

1–2 Normally-closed contact

3–4 Normally-open contact

5–6 Normally-closed contact with

delayed opening

7–8 Normally-open contact with

delayed closing

12

Protection class

Enclosures

Safety switches

The protection class of an enclosed

device denotes the degree of protection.

The degree of protection includes the

protection of persons against contactwith

parts under voltage and the protection of

equipment against the infiltration of foreign

bodies and water. BERNSTEIN standard

enclosures mainly correspond to protection

classes IP65 and IP67. Higher protection

ratings are also available for individual

customer solutions. In accordance with DIN

EN 60521 (IEC 529), the numerals used in

the protection rating denote the following:

1st digit Degree of protection against

contact and infiltration of foreign bodies

2nd digit Degree of protection against

infiltration of water

Example IP65:

6 =

l

Complete protection against contact

with components under voltage or

with internal moving parts

l

Protection against dust infiltration

5 =

l

A water jet directed from all directions

at the device must not have damaging

effects

l

Protection against hose water

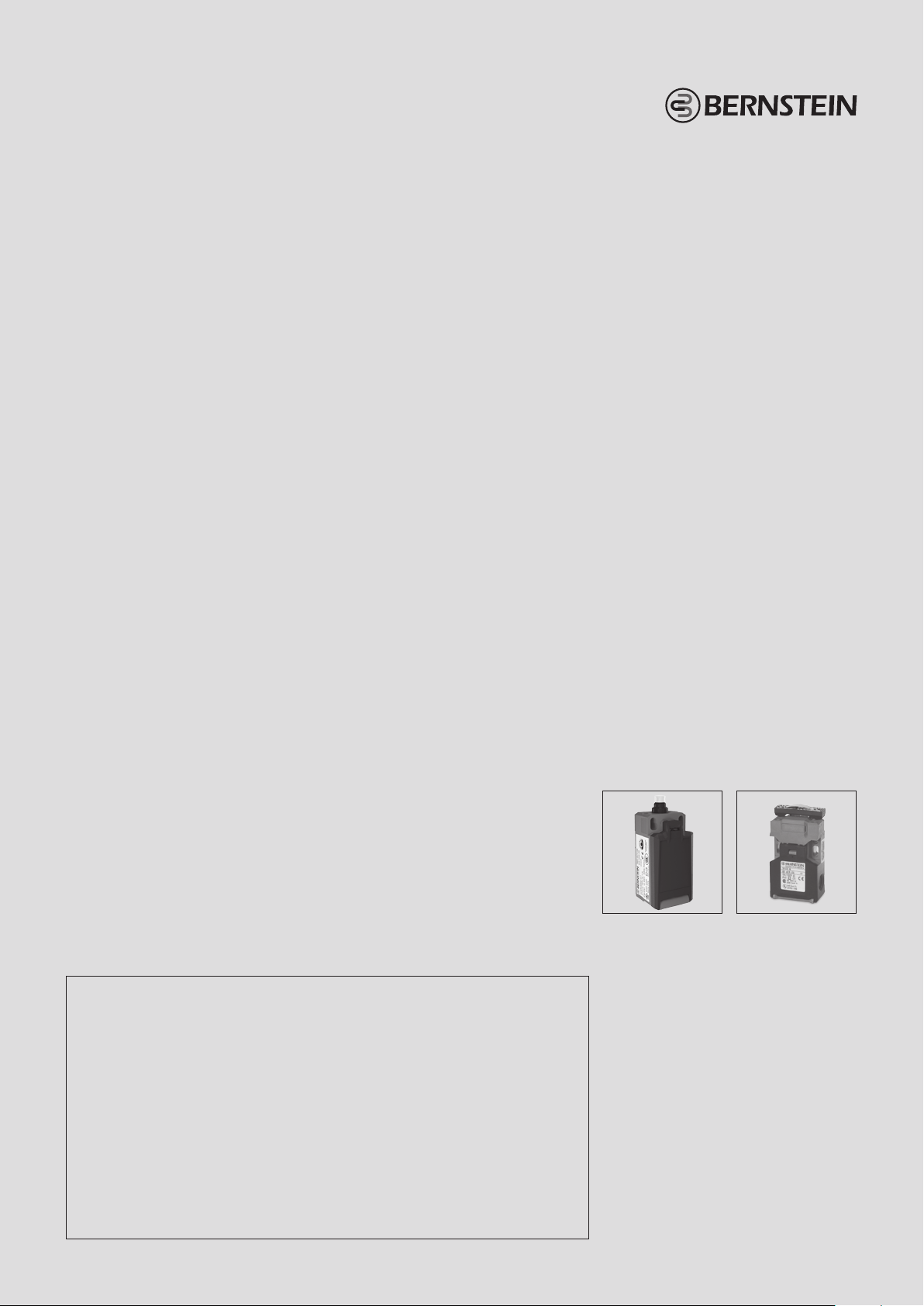

Limit switches are supplied either in a

plastic enclosure or a metal enclosure.

Which material is to be selected for a

specific application depends on the

ambient conditions, the location as well

as several other factors.

Plastic limit switches provide protective

insulation and are resistant to many

aggressive chemicals and liquids.

The formation of condensation water

in moist environments with extreme

temperature fluctuations is

significantly

reduced on plastic enclosures.

In insulation-enclosed switches the

switching elements are integrated directly

in the plastic enclosure and are therefore

not replaceable (complete switching

devices).

Metal-enclosed limit switches are able to

withstand high mechanical loads, they

can also be used wherever hot metal chips

and sparks occur and are resistant to many

solvents and detergents. The switching

elements in metal-enclosed switches are

often integrated in the metal enclosure as

modular built-in switches. The enclosure

has a VDE-compliant connection for the

PE conductor.

The scope of application for limit switches

has changed over time. Whereas limit

switches were previously used for the

purpose of detecting end positions, today

they are increasingly assuming functions

designed

machine,

to protect persons and products in

equipment and plant construction.

The BERNSTEIN range of safety switches

offers the right solution for the most diverse

applications in many branches of industry.

Particularly when it comes to safety, users

appreciate the fact that they are able to

procure all required safety switches and

receive professional advice from one source.

The decisive factors governing the selection

of safety equipment include the ambient

conditions, installation situation and risk

analysis.

A switching device that can be used

for safety functions is identified by the

standardised symbol conforming to

EN 60947-5-1 Addendum K. The switches

can, of course, also be used for pure

position monitoring purposes.

Safety switches are divided into two

categories, Type 1 and Type 2. The difference

is in the actuating elements which are

com

pletely integrated in the enclosure in

Type 1

and separated from the switching

element in Type 2.

Designation

The designation of BERNSTEIN switching devices depends on:

l The enclosure designation of the switching device

l The switching function

l The type of actuator

Type code of position and safety switches

IN65

Switch group

l C2

l Ti2

l I49

l IN62, IN65, I81

l Bi2

l ENK

l GC

A2Z

Switching system

l U1

l SU1

l A2

l SA2

l E2

l SE2

l UV1

2)

AH

Actuator

See Pages

68 – 69

1)

l SN2

l ENM2

l D

M12

Special features

l M12 connection

l Actuator turned

90°, 180°, 270°

l Special switching

forces

l Special temperature

ranges

l Other special

features on request

Type 1 Type 2

1)

The letter Z suffix to the designation

of the switching function denotes the

mechanical positive opening action of

the normally-closed contacts. In technical

data sheets, the positive opening point is

identified by the international symbol �.

2)

Please refer to the following pages in the

catalogue to establish which switching

system can be used in the switch groups.

13

Loading...

Loading...