BERNSTEIN CA User Manual

298

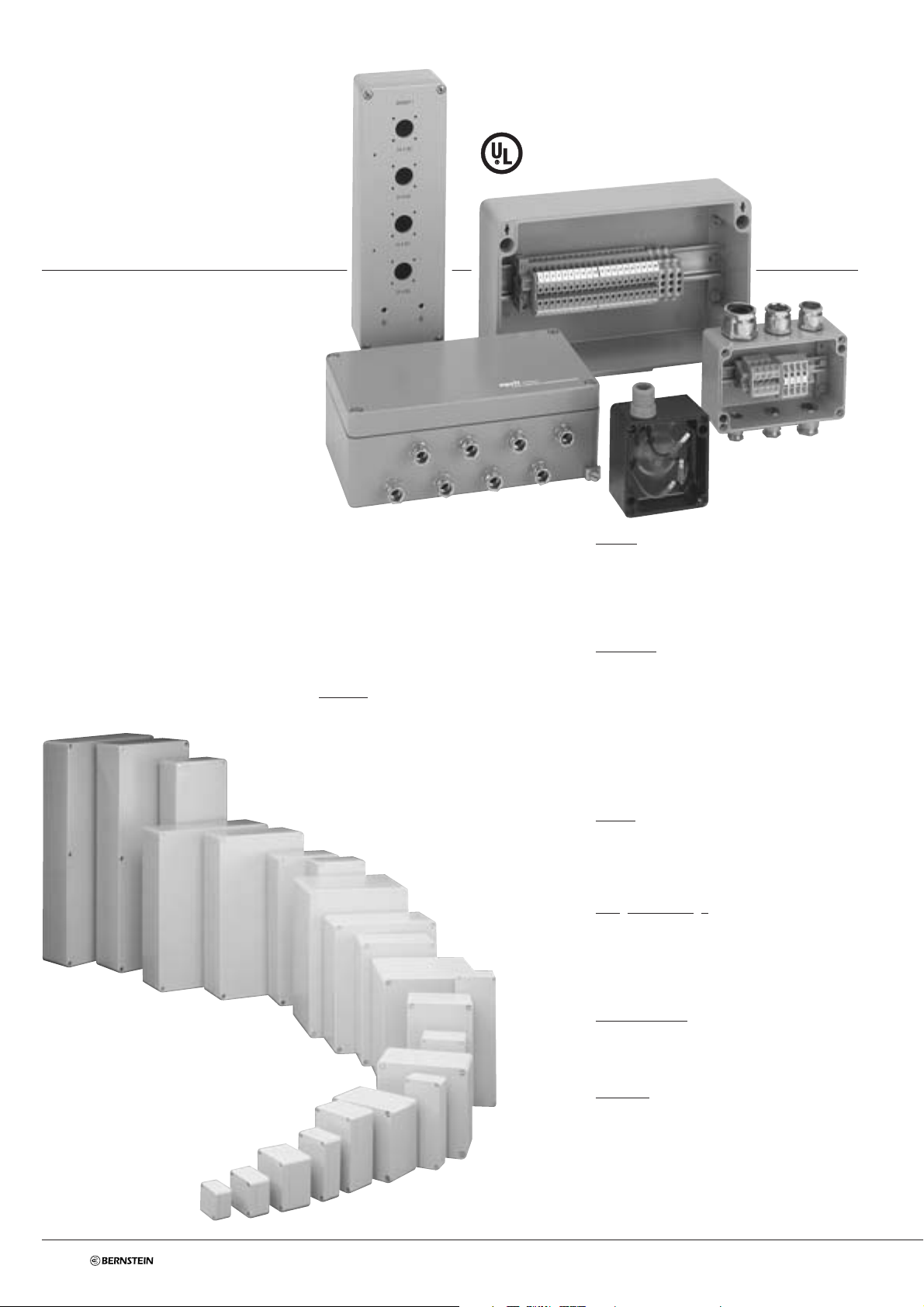

Aluminium enclosures

CA series

BERNSTEIN aluminium enclosures are

ideally suited to housing electrical,

electronic or pneumatic components.

Their high mechanical strength ensures

excellent protection against impact and all

sizes are sealed to IP 65, according to

IEC 529.

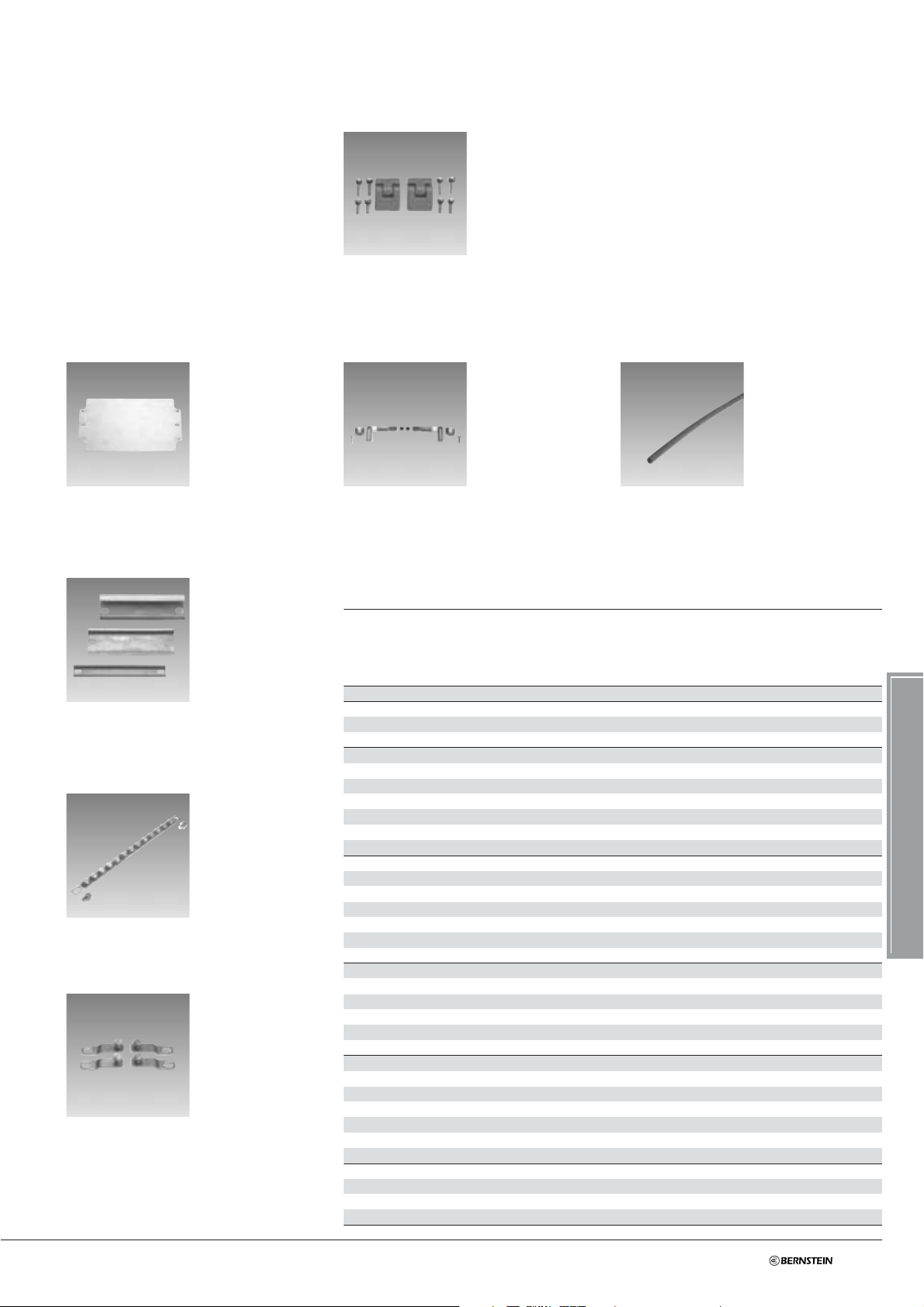

BERNSTEIN aluminium enclosures are fitted

with copper earthing screws (M4 or M6) in

both the base and lid, the surface below

the screws is unpainted allowing a good

earth connection to be made. The captive

lid screws are made of stainless steel and

are held in place by a lock integrated in the

lid. A gasket (for standard enclosures) is

factory-fitted, and ensures conformance

with the protection class. BERNSTEIN

aluminium enclosures are surface-coated in

RAL 7001 (silver-grey), as standard.

BERNSTEIN aluminium enclosures are either

die-cast or chill-cast. The dimension table

shows the production method used for

each respective enclosure.

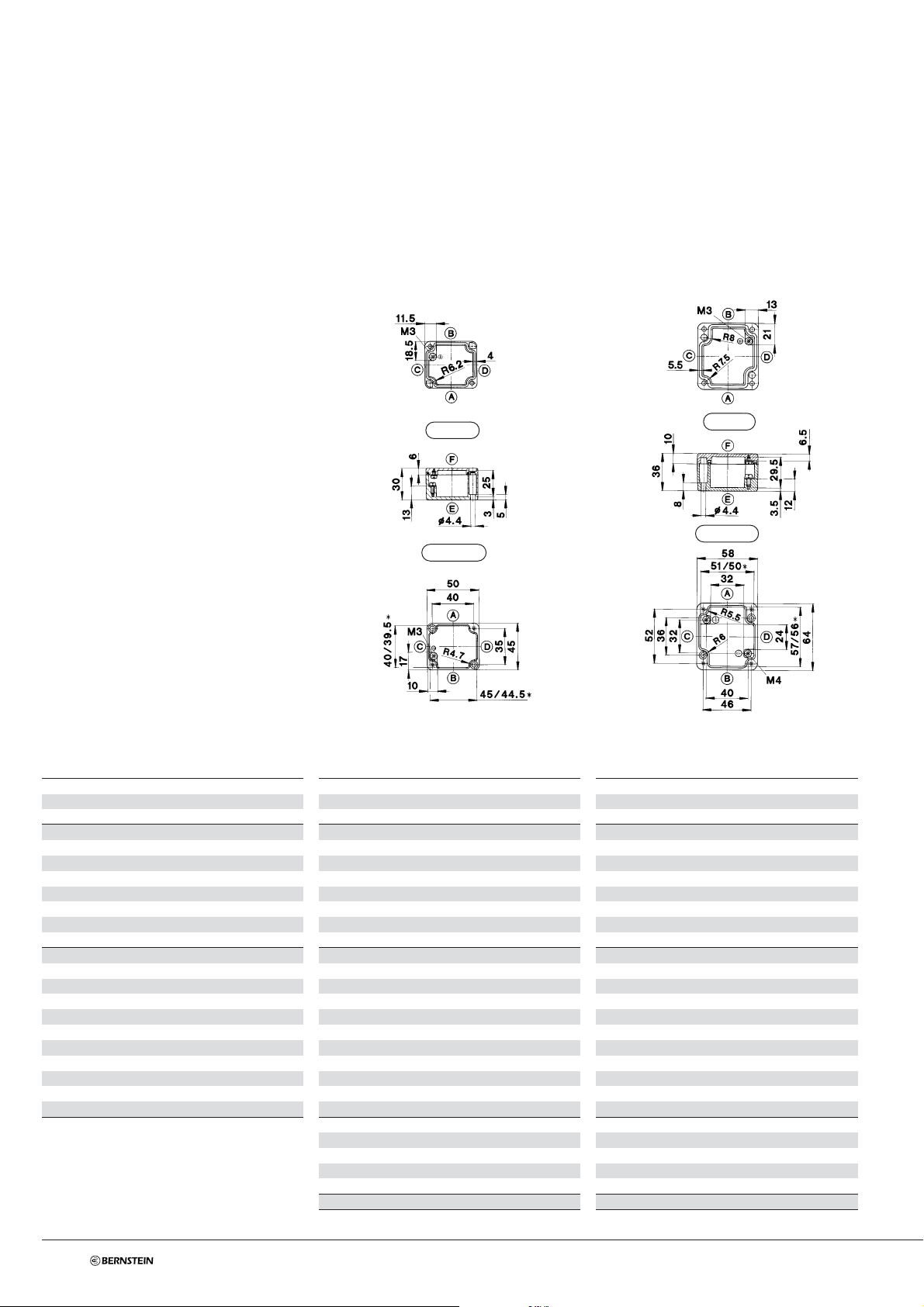

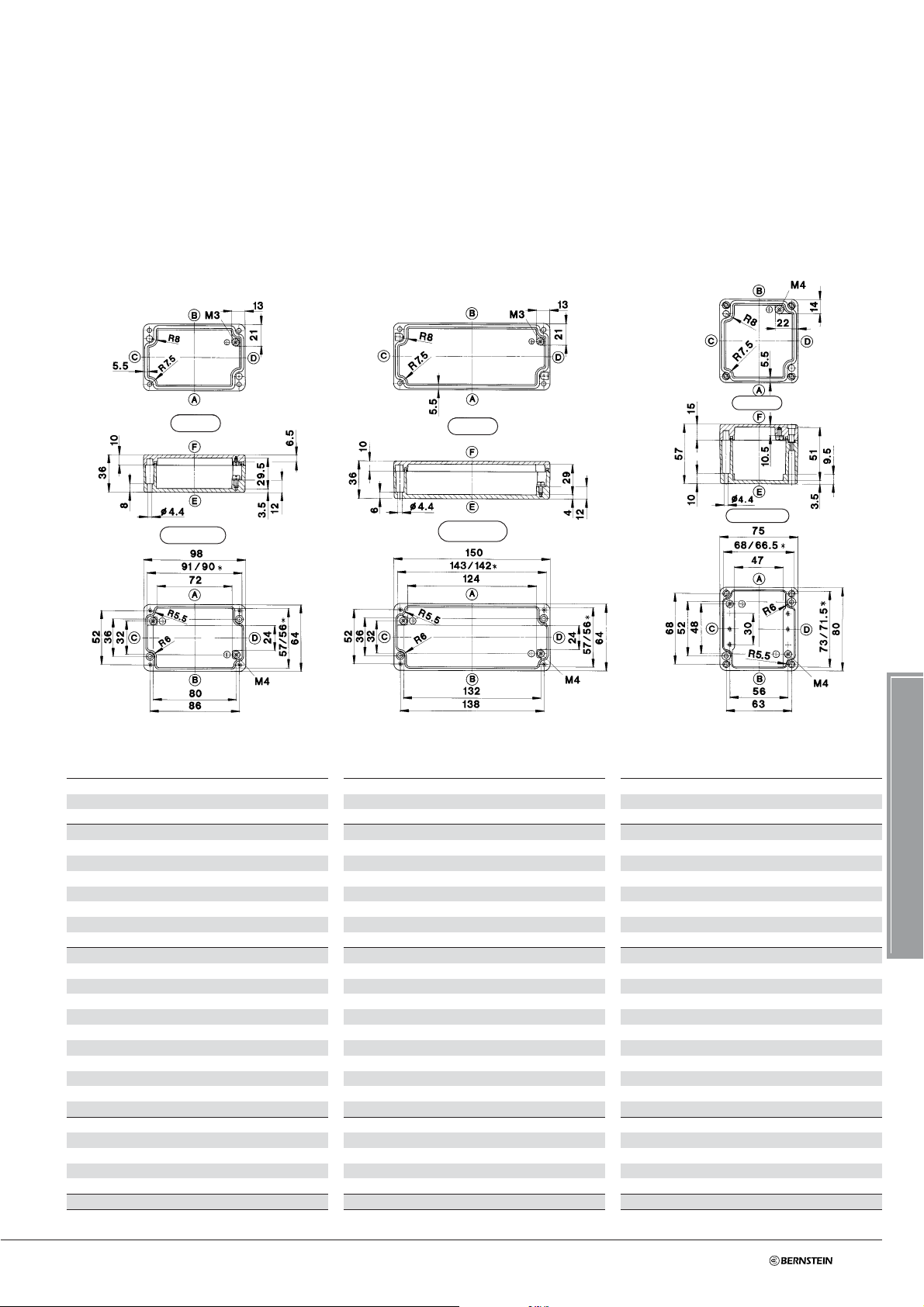

Attachment points inside the enclosure can

be used to hold equipment in place

(mounting rail, mounting plate, printed

circuit board etc.). Alternatively, the

earthing points may be used. These inner

attachment points are situated at different

heights and positions. (Refer to the

illustrations for detailed positions.)

Technical data

Material

Die-cast aluminium or AlSi 12 (Cu) chillcast

Gasket

Neoprene round seal (siliconised)

alternative:

Neoprene round seal

(silicone-free)

Silicone round seal

Lid scr

ews

Stainless steel, captive, multi-purpose cross

head

alternative:

– Stainless steel quarter turn quick release

(die-cast types only)

– Stainless steel hexagonal

socket head screws

– Lead-sealed steel lid screws

(9 S 20 K), slotted head

Coatin

g

RAL 7001 (silver-grey)

alternative:

– Special RAL colours

– Special coatings

T

emperature range

-40 °C to +80 °C (neoprene gasket)

alternative:

-50 °C to +130 °C (silicone gasket)

or -30 °C to +100 °C

(explosion-hazardous area)

Pr

otection class

IP 65

alternative:

higher protection class by request

Appr

oval

German Lloyd: No. 91 187 - 84HH

UL: File E 168772 (N)

Enclosures

299

Aluminium enclosures – product line

Dimensions/mm Aluminium enclosures Cast type

dc = die casting

Lx W x H Part number Type cc = chilled casting

50 x 45 x 30 102.0.0000.00 CA-020 dc

58 x 64 x 36 106.0.0000.00 CA-060 dc

98 x 64 x 36 108.0.0000.00 CA-080 dc

150 x 64 x 36 110.0.0000.00 CA-100 dc

75 x 80 x 57 113.0.0000.00 CA-130 dc

75 x 80 x 57 114.0.0000.00 CA-140 dc

125 x 80 x 57 115.0.0000.00 CA-150 dc

125 x 80 x 57 116.0.0000.00 CA-160 dc

175 x 80 x 57 117.0.0000.00 CA-170 dc

175 x 80 x 57 118.0.0000.00 CA-180 dc

250 x 80 x 57 119.0.0000.00 CA-190 dc

122 x 122 x 80 121.0.0000.00 CA-210 dc

122 x 122 x 90 121.0.0000.50 CA-215 dc

122 x 122 x 80 122.0.0000.00 CA-220 dc

220 x 122 x 80 123.0.0000.00 CA-230 dc

220 x 122 x 90 123.0.0000.50 CA-235 dc

220 x 122 x 80 124.0.0000.00 CA-240 dc

360 x 122 x 80 125.0.0000.00 CA-250 dc

160 x 160 x 90 127.0.0000.00 CA-270 dc

160 x 160 x 90 128.0.0000.00 CA-280 dc

260 x 160 x 90 129.0.0000.00 CA-290 dc

260 x 160 x 90 130.0.0000.00 CA-300 dc

360 x 160 x 90 131.0.0000.00 CA-310 dc

560 x 160 x 90 133.0.0000.00 CA-330 cc

200 x 230 x 110 135.0.0000.00 CA-350 dc

200 x 230 x 180 136.0.0000.00 CA-360 cc

280 x 230 x 110 137.0.0000.00 CA-370 dc

330 x 230 x 110 138.0.0000.00 CA-380 dc

330 x 230 x 180 139.0.0000.00 CA-390 cc

401 x 230 x 110 140.0.0000.00 CA-400 dc

600 x 230 x 110 142.0.0000.00 CA-420 cc

402 x 310 x 110 145.0.0000.00 CA-450 dc

402 x 310 x 180 146.0.0000.00 CA-460 cc

600 x 310 x 110 147.0.0000.00 CA-470 cc

600 x 310 x 180 148.0.0000.00 CA-480 cc

Accessories for

aluminium enclosures

Mounting plates

Galvanised sheet steel (thickness:

CA-060 to CA-310, CA-350 to CA-400:

1.5 mm; CA-330, CA-420 to CA-480: 2.5 mm) allows

mounting of additional equipment.

Mounting rails

Standard rails TS-15, TS-32 or TS-35 (steel),

yellow-passivated for attachment of terminal blocks.

Earthing rails

Galvanised steel for connecting and

routing of protective earth connection.

External attachment brackets

Stainless steel for mounting enclosures without opening

the lid.

Can be mounted in 90° steps at the base of the

enclosure.

External hinges

For hinged attachment of the enclosure lid. Swivelling

angle of lid approx. 155°. Aluminium casting,

RAL 7001 coating. Machining required to fit.

Drill template is supplied.

Internal hinges

For hinged attachment of the enclosure lid. Swivelling

angle of lid approx. 95°. Made of stainless steel.

Machining required to fit.

Silicone lid gasket

Improved temperature range (-50 °C to +130 °C).

Standard type made of silicone foam.

300

Model

Terminal width (mm):

Single core mm

2

Stranded mm

2

Nominal voltage V

Loading capacityt A

Terminal bridging

Mounting rail TS 15

TS 32

TS 35

Part number

Type

CA-020

CA-060

CA-080

CA-100

CA-130

CA-140

CA-150

CA-160

CA-170

CA-180

CA-190

CA-210/215/220

CA-230/235/240

CA-250

CA-270/280

CA-290/300

CA-310

CA-330

CA-350

CA-350*)

CA-360

CA-360*)

CA-370

CA-370*)

CA-380

CA-380*)

CA-390

CA-390*)

CA-400

CA-400*)

CA-420

CA-420*)

CA-450

CA-450*)

CA-450**)

CA-460

CA-460*)

CA-460**)

CA-470

CA-470*)

CA-470**)

CA-480

CA-480*)

CA-480**)

Component overview

for aluminium enclosures

CA series

**) Assembled on 2 mounting rails

**) Assembled on 3 mounting rails

The number of terminals is reduced

when partitions are used.

Weidmüller Phoenix Wieland

Block terminal Block terminal Block terminal

4 4 4 2.5 4 4 4 2.5 2.5 2.5 2.5

4 4 4 2.5 4 4 4 2.5 2.5 2.5 2.5

380 380 380 380 500 500 500 500 500 500 500

36 36 36 25 36 36 36 25 25 25 25

–––––––––––

–––––––––––

m ––––––––––

m ––––––––––

––– 1–––––––

1––– 1––––––

– 1–––1– 11––

–– 1––– 1–– 11

11–– 11– 1–––

11–– 11– 1–––

–11––111–––

–11––111–––

–– 1–––––– 1–

–– 1––– 1–– 1–

–– 2––– 2– 2––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

–––––––––––

Entrelec

Terminal block

5.2 6.2 5.2 6.2 8.2 10.2 12.2

2.5 4 4 4 10 16 25

1.5 4 2.5 4 6 10 16

250 380 750 750 750 750 750

20 35 26 35 46 63 85

– mmmmmm

mm– m –––

––mmmmm

––mmmmm

––– 1–––

4––––––

10––––––

20––––––

64–––––

64–––––

1613–––––

1613–––––

2621–––––

2621–––––

3933–––––

– – 12 10 8 6 5

– – 31 26 19 15 13

– – 58 49 37 29 24

– – 19 16 12 9 8

– – 38 32 24 19 16

– – 57 48 36 29 24

– – 96 80 61 48 40

– – 27 22 17 13 11

– – 54 44 34 26 –

– – 27 22 17 13 11

– – 54 44 34 26 –

– – 42 35 27 21 18

– – 84 70 54 42 –

– – 52 43 33 26 22

– – 104 86 66 52 –

– – 52 43 33 26 22

– – 104 86 66 52 –

– – 66 55 41 33 27

– – 132 110 82 66 –

– – 104 87 65 53 44

– – 208 174 130 106 –

– – 65 55 41 33 28

– – 130 110 82 66 56

– – 195 165 123 99 –

– – 65 55 41 33 28

– – 130 110 82 66 56

– – 195 165 123 99 –

– – 104 87 65 53 44

– – 208 174 130 106 88

– – 312 261 195 159 –

– – 104 87 65 53 44

– – 208 174 130 106 88

– – 312 261 195 159 –

Phoenix

Terminal block

5.2 6.2 7.5 5.2 6.2 8.2 10.2

2.5 410 4 41016

1.5 4 6 2.5 4 6 10

500 500 500 750 750 750 750

27 36 65 36 36 65 87

– m – mmmm

mmm––––

–––mmmm

–––mmmm

––– 1–––

4––––––

12––––––

20––––––

64–––––

644––––

1613–––––

161310––––

2621–––––

262117––––

393327––––

– – – 12 10 8 6

– – – 31 26 19 15

– – – 58 49 37 29

– – – 19 16 12 9

– – – 38 32 24 19

– – – 57 48 36 29

– – – 96 80 61 48

– – – 27 22 17 13

– – – 54 44 34 26

– – – 27 22 17 13

– – – 54 44 34 –

– – – 42 35 27 21

– – – 84 70 54 42

– – – 52 43 33 26

– – – 104 86 66 52

– – – 52 43 33 26

– – – 104 86 66 52

– – – 66 55 41 33

– – – 132 110 82 66

– – – 104 87 65 53

– – – 208 174 130 106

– – – 65 55 41 33

– – – 130 110 82 66

– – – 195 165 123 99

– – – 65 55 41 33

– – – 130 110 82 66

– – – 195 165 123 99

– – – 104 87 65 53

– – – 208 174 130 106

– – – 312 261 195 159

– – – 104 87 65 53

– – – 208 174 130 106

– – – 312 261 195 159

BK 4 9.40.1.0100.00

BK 6 9.40.1.0090.00

BK 12 9.40.1.0130.00

MK 3/4 9.40.1.0010.00

G 5/4 9.40.1.0020.00

G 5/6 9.40.1.0030.00

G 5/12 9.40.1.0040.00

KL-16/8 9.40.1.0050.00

KL-16/12 9.40.1.0060.00

KL-16/16 9.40.1.0070.00

KL-16/20 9.40.1.0080.00

DR 1.5/5 9.40.2.1270.00

DR 4/6 9.40.2.0940.00

MA 2.5/5 9.40.2.1090.00

M 4/6 9.40.2.1030.00

M 6/8 9.40.2.1040.00

M 10/10 9.40.2.1050.00

M 16/12 9.40.2.1060.00

MBK 9.40.2.0010.00

MBK 5/E 9.40.2.0020.00

MBK 10 9.40.2.0030.00

UK 3 N 9.40.2.0050.00

UK 5 N 9.40.2.0070.00

UK 10 9.40.2.0090.00

UK 16 9.40.2.0110.00

301

Enclosures

Siemens

Terminal block Terminal block

Screw terminals

Caged tension spring

4 4 10 25 4 4 10

2.5 4 6 16 2.5 4 6

750 750 750 750 750 750 750

26 35 46 85 36 36 65

mmmmmmm

– m –––––

–––––––

mmmmmmm

–––––––

–––––––

–––––––

–––––––

–––––––

–––––––

–––––––

–––––––

–––––––

–––––––

–––––––

10 10 8 6 12 10 8

27 25 20 16 31 26 20

50 46 37 30 58 49 37

16 15 12 9 19 16 12

32 30 24 19 38 32 24

49 45 37 29 57 48 36

83 76 62 49 96 80 60

22 21 17 13 26 22 17

44 42 34 26 52 44 34

22 20 17 13 26 22 10

44 40 34 26 52 49 32

36 33 27 21 42 35 26

72 66 54 42 84 70 52

44 51 33 26 51 43 32

88 82 66 52 102 86 64

44 40 33 26 51 43 32

88 80 66 52 102 86 64

56 52 42 33 65 54 41

112 104 84 66 130 108 82

89 82 67 53 103 86 65

178 164 134 106 206 172 130

56 52 42 34 65 55 41

112 104 84 68 130 110 82

163 156 126 102 195 165 123

56 52 42 33 65 54 41

112 104 84 66 130 108 82

163 156 126 99 195 162 123

89 82 67 53 103 68 65

178 164 134 106 206 172 130

267 246 201 159 309 258 195

89 82 67 53 103 86 65

178 164 134 106 206 172 130

267 246 201 159 309 258 195

9.40.2.4000.00

9.40.2.4010.00

9.40.2.4020.00

9.40.2.4030.00

9.40.2.4040.00

9.40.2.4050.00

9.40.2.4060.00

264-701 9.40.2.3020.00

264-721 9.40.2.3030.00

264-711 9.40.2.3210.00

264-731 9.40.2.3220.00

279-621 9.40.2.3230.00

280-601 9.40.2.0930.00

280-901 9.40.2.3240.00

281-601 9.40.2.3250.00

281-901 9.40.2.3260.00

282-601 9.40.2.3270.00

284-601 9.40.2.3280.00

283-601 9.40.2.3290.00

AKZ 2.5 PA 9.40.2.0500.00

AKZ 4 PA 9.40.2.0130.00

SAK 2.5 PA 9.40.2.0140.00

SAK 4 PA 9.40.2.0150.00

SAK 6 NPA 9.40.2.0160.00

SAK 10 PA 9.40.2.0470.00

SAK 16 PA 9.40.2.0170.00

WDU 2.5 9.40.2.1460.00

WDU 4 9.40.2.1470.00

WAGO

Terminal block

6.2 10.2 6.2 10.2 4.2 5.2 5.2 6.2 6.2 8.2 10.2 12.2

2.5 2.5 2.5 2.5 1.5 2.5 2.5 4 4 6 10 16

2.5 2.5 2.5 2.5 1.5 2.5 2.5 4 4 6 10 16

800 800 800 800 800 800 800 800 800 800 800 800

26 26 26 26 18 26 26 34 34 44 61 82

mmmmmmmmmmmm

mm––––––––––

––––––––––––

––mmmmmmmmmm

––––––––––––

––––––––––––

––––––––––––

––––––––––––

53––––––––––

53––––––––––

138––––––––––

138––––––––––

2113––––––––––

2113––––––––––

3420––––––––––

––12718–––––––

––281743–––––––

––513143–––––––

– – 10 17 25 20 20 17 17 12 10 8

– – 33 20 50 40 40 33 33 25 20 16

– – 50 30 76 60 60 50 50 37 30 28

– – 83 50 125 100 100 83 83 62 50 41

– – 23 14 35 28 28 23 23 17 14 11

– – 46 28 70 56 56 46 46 34 28 –

– – 23 14 35 28 28 23 23 17 14 11

– – 46 28 70 56 56 46 46 34 28 –

– – 36 22 55 44 44 37 37 27 22 18

– – 72 44 110 88 88 74 74 54 44 –

– – 45 27 68 54 54 45 45 33 27 22

– – 90 54 136 108 108 90 90 66 54 –

– – 45 27 68 54 54 45 45 33 27 22

– – 90 54 136 108 108 90 90 66 54 –

– – 57 34 86 68 68 57 57 42 34 28

– – 114 68 172 136 136 114 114 84 68 –

– – 90 54 135 108 108 90 90 67 54 45

– – 180 108 270 216 216 180 180 134 108 –

– – 57 34 86 69 69 57 57 43 34 28

– – 114 68 172 138 138 114 114 86 68 56

– – 171 102 258 207 207 171 171 129 102 –

– – 57 34 86 68 68 57 57 42 34 28

– – 114 68 172 136 136 114 114 84 68 56

– – 171 102 258 204 204 171 171 126 102 –

– – 90 54 135 108 108 90 90 67 54 45

– – 180 108 270 216 216 180 180 134 108 90

– – 270 162 405 324 324 270 270 201 162 –

– – 90 54 135 108 108 90 90 67 54 45

– – 180 108 270 216 216 180 180 134 108 90

– – 270 162 405 324 324 270 270 201 162 –

Weidmüller

Terminal block

5.2 6.2 6.2 6.5 8.2 10.2 12.2 5.2 6.2

2.5 4 4 6 10 16 25 4 6

1.5 4 2.5 4 6 10 15 2.5 4

250 380 750 750 750 750 750 750 750

27 36 27 36 47 65 87 26 34

mmmmmmmmm

mmm––––––

–––mmmm––

–––––––mm

–––––––––

–––––––––

–––––––––

–––––––––

64–––––––

64–––––––

1612–––––––

1612–––––––

2620–––––––

2620–––––––

4133–––––––

––1097651210

– – 26 24 20 15 12 31 26

– – 48 45 37 29 24 58 48

– – 16 15 12 9 8 19 16

– – 33 30 25 19 16 38 32

– – 48 45 36 29 24 57 48

– – 86 74 61 48 40 96 80

– – 22 20 17 13 11 26 22

– – 44 40 34 26 – 52 44

– – 22 20 17 13 11 26 22

– – 44 40 34 26 – 52 44

– – 35 32 26 21 18 42 35

– – 70 64 52 42 – 84 70

– – 43 40 32 26 22 51 43

– – 86 86 64 52 – 102 86

– – 43 40 32 26 22 51 43

– – 86 86 64 52 – 102 86

– – 54 50 41 33 27 65 54

– – 108 100 – 66 – 130 108

– – 87 80 65 52 44 103 86

– – 174 160 – 104 – 206 172

– – 54 50 41 33 27 65 54

– – 108 100 82 66 54 130 108

– – 162 150 – 99 – 195 162

– – 54 50 41 33 27 65 54

– – 108 100 82 66 54 130 108

– – 162 150 – 99 – 195 162

– – 87 80 65 52 44 103 86

– – 174 160 130 104 88 206 172

– – 261 240 – 156 – 309 258

– – 87 80 65 52 44 103 86

– – 174 160 130 104 88 206 172

– – 261 240 – 156 – 309 258

8WA1011-

1DF11

8WA1011-

1DG11

8WA1011-

1DH11

8WA1204

8WA2011-

1DF20

8WA2011-

1DG20

8WA2011-

1DH20

302

50 x 45 x 30 mm

CA-020

Aluminium enclosure

UNTERTEIL

DECKEL

Type

Weight (g)

External dimensions (mm)

Complete enclosures

Coated, with gasket and lid screws

Coated, with gasket and hex. socket head screws

Coated, with silicone gasket and lid screws

Coated, with HF gasket and lid screws

Saltwater-proof coating, with gasket and lid screws

Saltwater-proof coating, passivated, lid screws with gasket

Unwashed, unpainted, no accessories

Accessories (separate or as a mounting set)

Mounting plate

TS 15 mounting rail

TS 32 mounting rail

TS 35 mounting rail

Grounding rail

External attachment brackets

External hinges side

Internal hinges with lid guiding**

Silicone gasket for wider temperature range (piece goods)

Max. Pg threads

58 x 64 x 36 mm

CA-060

Aluminium enclosure

* minimum dimensions at level of mounting plate support * minimum dimensions at level of mounting plate support

CA-020

70

50 x 45 x 30

Part number

102.0.0000.00 l

–

–

–

102.0.0100.00

102.0.0060.00

102.0.0340.00

–

–

–

–

–

–

–

–

–

ISO M 12 16 20 25 32 40 50 63

Side A/B 10000000

Side C/D 10000000

** mechanical enclosure machining required

l = kept in stock

CA-060

160

58 x 64 x 36

Part number

106.0.0000.00 l

–

106.0.0940.00

106.0.0080.00

106.0.0100.00

106.0.0060.00

106.0.0380.00

951.1.0010.00 l

982.0.0000.00 l

–

–

–

–

–

–

923.1.0050.00 l

ISO M 12 16 20 25 32 40 50 63

Side A/B 21000000

Side C/D 10000000

** mechanical enclosure machining required

l = kept in stock

LID

BASE

LID

BASE

303

98 x 64 x 36 mm

CA-080

Aluminium enclosure

150 x 64 x 36 mm

CA-100

Aluminium enclosure

75 x 80 x 57 mm

CA-130

Aluminium enclosure

* minimum dimensions at level of mounting plate support * minimum dimensions at level of mounting plate support * minimum dimensions at level of mounting plate support

CA-080

220

98 x 64 x 36

Part number

108.0.0000.00 l

–

108.0.0090.00

108.0.0080.00

108.0.0100.00

108.0.0060.00

108.0.0420.00

951.1.0020.00 l

982.0.0050.00 l

–

–

–

–

–

–

923.1.0050.00 l

ISO M 12 16 20 25 32 40 50 63

Side A/B 43000000

Side C/D 10000000

** mechanical enclosure machining required

l = kept in stock

CA-100

330

150 x 64 x 36

Part number

110.0.0000.00 l

–

110.0.0760.00

110.0.0080.00

110.0.0100.00

110.0.0060.00

110.0.0530.00

951.1.0030.00 l

982.0.0110.00 l

–

–

–

–

–

–

923.1.0050.00 l

ISO M 12 16 20 25 32 40 50 63

Side A/B 64000000

Side C/D 10000000

** mechanical enclosure machining required

l = kept in stock

CA-130

280

75 x 80 x 57

Part number

113.0.0000.00 l

–

113.0.0820.00

113.0.0080.00

113.0.0100.00

113.0.0060.00

113.0.0570.00

982.3.0150.00 l

982.0.0020.00 l

–

–

–

–

980.1.0440.00 l

–

923.1.0050.00 l

ISO M 12 16 20 25 32 40 50 63

Side A/B 52100000

Side C/D 32100000

** mechanical enclosure machining required

l = kept in stock

Enclosures

LID

BASE

LID

BASE

LID

BASE

Loading...

Loading...