EXPRESS DUAL 4000DX

Please read this manual carefully before using the Express Dual 4000DX.

This manual should be kept in a safe place so that it can be used for future reference.

Touch Screen Model

User’s Guide &

Instruction Manual

EXPRESS DUAL 4000DX

EXPRESS DUAL 4000DX

© Bernhard and Company Limited

NOTES

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

EXPRESS DUAL 4000DX

© Bernhard and Company Limited

EXPRESS DUAL

BERNHARD & CO. LIMI TED

Bilton Road • Rugby • England • CV22 7DT

Tel +44 1788 811600 • Fax +44 1788 812640

Email: i n fo@bernhard.co.uk

USA Toll Free 1-888 GRIND IT

(

1-888 474 6348

)

ED4000DX Precison Reel/Cylinder Grinder

Welcome to the Bernhard Express Dual 4000DX. If cared for and operated

correctly this machine will give you years of good service.

This manual will enable you to obtain the best results from your Express Dual so

please read it thoroughly before using your machine.

If you have any service or operational issues please contact your distributor or

phone our technical support hotline

Technical Helpline (USA only) 1-888 474 6348

Rest of World: UK Head Ofce, England (+44) 1788 811600

Email: support@bernhard.co.uk

Technical FAQs can be found on our web site: www.b

ernhard.co.uk

When ordering spare parts please quote the machine type and serial number.

THE MANUFACTURERS ACCEPT NO RESPONSIBILITY FOR ANY SITUATION ARISING FROM THE

FITTING AND/OR USE OF NON-ORIGINAL SPARE PARTS.

Contents

Identication of Pictograms 3

Safety 5

Installation 6

Identication of Tools and Equipment 8

Understanding the Machine 9

In Frame Grinding 11

Electrical Fault Finding 21

Maintenance 23

Part Lists and Exploded Diagrams 29

Lift Table Instructions 48

Quick Start Guide 58

ED400 0DX Touchscreen – 1003 .4/ENG/2017RB

Please quote this serial number on all

correspondence:

Serial #:

© Bernhard and Company Limited

4

EXPRESS DUAL 4000DX

BEWARE! HIGH VOLTAGE

1. Identication of Pictograms

MAXIMUM LIFT PLATFORM

LOAD - 250 KG (550 LBS)

BEWARE!

TRAPPING FEET OR OTHER OBJECTS

WHEN LOWERING LIFT PLATFORM

MAXIMUM GRINDSTONE

DIAMETER 150mm

MAXIMUM SPEED 4000 Rev/Min

RUNS AT 2200 Rev/Min

BEWARE!

MOVING GRINDSTONE AND SHAFT

REEL ROTATING AT BETWEEN

147 AND 255 Rev/Min

TOTAL WEIGHT OF MACHINE (KG)

© Bernhard and Company Limited

5

EXPRESS DUAL 4000DX

WEAR EYE, EAR AND BREATHING

PROTECTION

1. Identication of Pictograms

(Continued)

POINTS FOR ATTACHING

LIFTING EYES

BEWARE!

MOVING COMPONENTS KEEP HANDS

AND OTHER OBJECTS CLEAR

GRINDSTONE START CONTROL

REEL START CONTROL

STOP CONTROL

TRAVERSE START CONTROL

ENGAGE / DISENGAGE (INCREASE /

REDUCE) GRINDSTONE FEED

© Bernhard and Company Limited

6

EXPRESS DUAL 4000DX

2.1 This machine is designed and manufactured ONLY for grinding lawn mower reels, rollers,

groomers and verticut units, and MUST NOT be used for any other purpose.

2.2 This machine should be installed, operated and maintained by competent personnel who

have received adequate training.

2.3 Before carrying out any work on the machine, other than grinding, ALWAYS SWITCH OFF

the main electrical supply, or remove the power lead from its socket.

2.4 ALWAYS operate the machine with the guards in position.

2.5 NOISE - Owing to the widely varying conditions of use, noise emissions may vary

considerably. There may be occasions when the safe noise level may be exceeded (see

note on noise emission). In this case adequate ear protection MUST be worn.

2.6 NEVER t or use a grinding wheel (or other spares) other than those supplied specically

for use on the EXPRESS DUAL (Warranty will be invalidated).

2.7 NEVER t or use a grinding wheel which has been dropped or subjected to any other form

of abuse.

NOTE: Grinding wheels should be tted O N LY by competent, trained personnel.

2.8 NEVER leave rags or tools on the machine or wear any loose clothing or other articles

which could be caught in moving components.

2.9 NEVER allow any combustible materials to be placed on or around the machine.

2.10 ALWAYS ensure that all parts of the cutting unit being ground are securely xed.

2.11 ALWAYS ensure that all electrical connections are sound and all cables are safely routed.

2.12 ALWAYS carry out cleaning and maintenance of the machine as instructed in this manual

(Refer to safety note 2.3).

2.13 STAY ALERT. Watch what you are doing. NEVER operate the machine when tired, or

under the inuence of drugs or alcohol.

If a lift table is tted NEVER attempt to lift in excess of the rated capacity, and always

ensure that the area is clear before lowering the load.

2. Safety

© Bernhard and Company Limited

7

EXPRESS DUAL 4000DX

3. Set Up and Installation

Fig: 3.2

3.1 Handling

If the machine is crated, it can be moved by a suitable fork lift truck or pallet truck under

the pallet (skid). Once the lid and sides of the crate are removed, a fork lift truck may be

used under the lifting members of the machine chassis.

The machine can be lifted off the pallet using suitable lifting tackle through 4 lifting eyes

(provided) tted at the points indicated on the top corners of the machine.

The total weight of the machine is indicated on the machine plate and also at the front of

this manual.

3.2 Location

The machine should be located in a well lit environment with adequate headroom. For

ideal operation, the machine should be accessible from the front, rear and at least one

side, with clearance around it as indicated in the sketch (Fig. 3.2).

3.3 Leveling

The machines should, ideally, be placed on a solid level oor, and this should be checked

by placing a spirit level on the table. Check the level in both directions. Steel shims should

be placed under the feet as necessary to ensure that the machine is rm and level. Bolt

holes are provided in the feet which can be used for xing down if required.

NOTE Ensure that the packing under the feet is correct before tightening the bolts, otherwise

twisting of the frame may occur.

1.5m (5 ft)

1.5m (5 ft)

ENSURE ADEQUATE SPACE FOR

LOADING UNITS AND FOR A LIFT

TABLE (IF FITTED)

FRONT OF MACHINE

© Bernhard and Company Limited

8

EXPRESS DUAL 4000DX

3.4 Electrical Supply

USE A QUALIFIED ELECTRICIAN

The EXPRESS DUAL is supplied with a .75 kW (1 HP) single phase main (grind) motor

plus 2 fractional HP motors, for spin and traverse.

Power connection to the machine is via plug and socket termination of the lead supplied.

Connection is at the rear of the main electrical control box on the right hand end of the

machine.

Ensure that any cable or conduit run to the machine does not constitute a hazard to the

operator or other personnel.

Machine should be connected to the supply via a 20A breaker.

The top of the reel and the top of the grinding wheel should both move away from the

front of the machine (i.e. both rotate clockwise when viewed from right hand end of the

machine). In this way, the reel and grinding wheel are moving in OPPOSITE DIRECTIONS

at the point of contact.

3.5 Preparation

If the machine has been

received in a crate, the handles

on the control wheels should be

removed from the underneath of

the control wheels and retted to

the top (see Fig. 3.5).

It is important that the protective

lm on the main shaft is

removed prior to using the

machine. This can be done

using a WD40® or similar

product (not gas/petrol) and then

drying the shaft with a clean, dry

cloth so that the grinding wheel

assembly moves freely along the

whole length of the shaft.

A spray lubricant, such as WD40®, should be applied to all bare metal surfaces and

moving parts; this includes the reversing bar and the shafts (along which the fork assembly

traverse, but NOT THE MAINSHAFT).

The mainshaft should be washed down as instructed in the maintenance section of this

manual. The feed control screws are normally coated with Molycote®, and may be washed

down with WD40® if required and recoated with Molycote® (or similar anti friction coating)

when dry.

Fig: 3.5

3. Installation (Continued)

© Bernhard and Company Limited

9

EXPRESS DUAL 4000DX

4. Indentication of Tools and Equipment

The items below may not necessarily be included since the tools and equipment

supplied will vary according to the machine specication.

4.1 Express Dual 4000 and 4000DX (see illustrated parts list).

A9502 Adjustable Mounting Bracket Set (Fitted) ........................1

A6505 Grind Stone (Fitted) ..................................................................1

A6737 Diamond Dresser (In Spin Drive Support) .......................1

A2719 Grinding Wheel Wrench ..........................................................1

A6342 Pressure Plate ............................................................................1

A4095 Plain Drive Rod Short ..............................................................1

A4134 Square Drive Rod Short (Fitted To Cable Drive) ...........1

A4066 Long Ball Handled Allen Key .................................................1

A2720 Large Hex Key ............................................................................1

A2706 3/16 T Handled Allen Key .......................................................1

A4097 Plain Shaft Driver ......................................................................1

A4063 Large Two Pin Sprocket Driver .............................................1

A4133 Drive Kit - Female Splines......................................................1

A9535 Adj. Sprocket Driver Complete .............................................1

A9534 Eccentric Pin For Adj Sprocket Driver ...............................3

A2722 Molycote Paste ...........................................................................1

A6847 Molycote Brush...........................................................................1

A4087 Multix Channels .......................................................................1

A2712 8mm Allen Key ...........................................................................1

A8786 Pack of Spare Fuses ................................................................1

A2708 3mm Allen Key ...........................................................................1

A3306 22mm 1/2 Drive Socket ...........................................................1

A6603 Guarantee Certicate ..............................................................1

A6615 Operating Instructions .............................................................1

© Bernhard and Company Limited

10

EXPRESS DUAL 4000DX

5. Understanding the Machine

5.1 General Principles

The EXPRESS DUAL is designed to grind reels completely assembled, or as a separate

“loose” reel. A Loose Reel Kit (Available as an optional extra, at additional cost) is required

for this operation.

The basic principle of the EXPRESS DUAL is to grind mowers in exactly the same

conditions that they mow in. The grinding wheel takes the place of the grass, striking the

reel in relatively close proximity to that found in the mowing position.

5.2 Basic Requirements

It is important that grinding the cutting unit, when it remains completely assembled, takes

place under the following conditions:

5.2.1 The reel bearings MUST be in good condition, adjusted correctly and if the roller is to be

located on the roller mounting brackets or the multix brackets, the roller bearings MUST

also be in good condition.

5.2.2 The bedknife must be ground separately on a machine, such as the ANGLEMASTER

bedknife grinder which can guarantee that the blade will be perfectly STRAIGHT and at

whilst mounted on the bedbar.

During the reel grinding process, it is advisable that the bedknife/bedbar assembly is

replaced in the unit after having been ground. On many units the bedknife/bedbar is an

integral part of the frame and contributes to its strength and rigidity.

5.2.3 The reel or bedknife must be adjusted away from one another to allow free rotation (There

should be no reel to bedknife contact!).

5.2.4 It is essential that all work to be carried out on the mowing unit (all mower repairs

– bearings, seals, roller work, etc.) has been completed prior to grinding the reel. The last

operation of all, apart from nal setting reel to bedknife, is the actual grinding of the reel

in-frame.

It is essential that the unit is held totally rm during the grinding process. When in frame

grinding, the front of the unit must be held rmly in the multix brackets or on the front

roller brackets.

5.2.5 It is essential that the unit is held totally rm during the grinding process. When in frame

grinding, the front of the unit must be held rmly in the multix brackets or on the front

roller brackets.

The rear of the unit will be held by the radiused pressure bar at the rear of the grinder.

© Bernhard and Company Limited

11

EXPRESS DUAL 4000DX

5. Understanding the Machine (Continued)

5.3 Machine Functions

The EXPRESS DUAL has separate motors driving the different functions of the machine,

all are turned on and off from the control panel in ‘manual’ mode or by the machine

program in ‘auto’ mode. These functions are as follows:

5.3.1 Traverse

This motor and the accompanying drive mechanism controls the automatic movement of

the grinding wheel along the mainshaft.

5.3.2 Reel/Spin drive

This motor drives the reel through a exible shaft driving from a drive mechanism under

the table. It is a three phase motor controlled by an inverter for varying output speed.

5.3.3 Grinding Wheel

A motor situated under the table, drives the mainshaft and grinding wheel at around 2200

rpm.

5.3.4 Stop

Pressing the stop button shuts off all motors and locks into the “off” position. None of the

start buttons will operate until the stop button has been unlocked by twisting the knob

counter-clockwise to release it (and the m/c control error warning has been reset).

NOTE The machine must NOT be stopped when there is contact between the reel and grinding

wheel, except in cases of emergency.

5.3.5 Reset Button (see also Electrical Fault Finding section)

If the main motor is subject to a voltage drop or overloading, the current being drawn

will rise and a safety device will automatically shut the grinder off. The overload trip

device (thermal overload contactor) is attached to the main motor contactor in the main

electrical control box which is located within the safety guard on the right hand side of the

machine.(looking from the front). The (red) reset button is on this overload.

The trip setting will vary with the electrical specication of each machine and is normally

set to the full load current of the motor. If the overload trip has shut off the grinder it can be

reset by pushing the reset button after a few minutes delay. This will allow the grinder to be

re started.

NOTE The overload is variable and should be adjusted, if required, as indicated in the appropriate

service bulletin.

Other motor, VSD inverter (reel spin speed control), and other electrical devices are

protected by individual fuses located on the electrical control panel accessible via key

entry to the enclosure on the right hand side of the guard.

© Bernhard and Company Limited

12

EXPRESS DUAL 4000DX

6.1.1 Mower Preparation

Units of up to 36” long can be ground

in frame, this includes most machines

including Greens mowers and Fairway

units. In order to spin / drive the reel,

one end of the reel shaft drive must be

exposed. This will require the removal

of the hydraulic motor, the chain / belt

or cover depending on which type

of unit is being ground. This should

be done before the mower is on the

grinder (see example Fig. 6.1).

Ensure that the mower is clean and

that both reel and roller bearings are

in good condition. Also ensure that

the bedknife has been sharpened, if

necessary, and replaced with a small

amount of clearance between it and the reel.

FOLLOW THE ILLUSTRATED INSTRUCTIONS IN THE QUICK START

GUIDE AT THE END OF THIS MANUAL

6.1. 2 FOLLOW THE SCREEN PROMPTS

Press Auto icon button to progress from the welcome screen to automatic mode

– display advances to next screen

Screen prompts to:

Ensure traverse is not engaged

To mount mower

To engage clamp

6.1.3 Unscrew the traverse engagement screw until it is released from the traverse chain so that

fork/grindstone can be traversed manually along the mainshaft.

6. In-frame Grinding

Fi g: 6 .1

© Bernhard and Company Limited

13

EXPRESS DUAL 4000DX

6. In-frame Grinding (Continued)

6.2. Mounting Mower

The mainshaft / Grinding stone should be wound down to its lowest position and the unit

placed on the table. The unit should then be carefully moved towards the multix brackets

or front roller brackets, which can be adjusted in any direction to allow the unit to be xed

in such a position that the grinding wheel can be raised towards the reel without coming

into contact with either the bedknife or the front roller/groomer.

6.3. Clamping

With the mower correctly positioned the radiused pressure bar) is moved forward to rest

on the rear of the mower and locked in position by pressing the key on the operator display

panel on the operator control panel downwards. The operator should release the key as

the pressure bar engages the cutting unit thus retaining pressure on the mower until the

grinding operation is completed. A backing up plate is supplied to protect the rear of the

units and to evenly disperse the force of the pressure bar across the width of the mower

(see Fig. 6.3.1.).

Fi g: 6 .3.1

© Bernhard and Company Limited

14

EXPRESS DUAL 4000DX

To ensure that the correct position for the mower unit has been achieved, both control

wheels (right hand and left hand) should be wound in a clockwise direction so that the

grinding wheel may be placed to contact each end of the reel evenly. If the grinding wheel

touches the bedknife or any part other than the reel, the whole unit must be moved by

adjusting the position of the multix brackets or roller brackets. The exact position required

will be easily seen by looking along the mainshaft from one end of the machine as the

stone is raised to check that the point of contact is in a suitable position (see Figure 6.3.2.)

Rotate hand wheels anti-clockwise to move grinding wheel away from reel. It is important

that the grinding wheel should clear the highest blade along the full length of the reel

before proceeding.

NOTE If the cutting unit has no front roller tted so that the multix brackets are used then, once

the correct position for any particular unit has been nalised a “set up guide” should be

completed and led for future reference so that the identical multix brackets positions can

be used for all subsequent applications on the same type of unit.

6. In-frame Grinding (Continued)

Fig: 6.3.2

Reel

blades

Front Roller position

is adjustable

Grind stone has to contact

reel blades for sharpening

without touching anything else

Adjustable Front

Roller support

Position of

bedknife is

adjustable

© Bernhard and Company Limited

15

EXPRESS DUAL 4000DX

6.4 Linking Up The Reel Drive Unit to the Reel

Machines are supplied with the reel drive motor under the table and a exible drive which

can be attached to either end of the machine do not have to be prepared before the mower

unit is placed on the table, as the complete drive unit can be moved to either side of the

table with a mower unit in place.

6.4.1 Select the attachment with which to drive the reel. If the reel sprocket, gear or pulley

is secured with a nut it may be easier to use a standard socket together with a 1/2”

square end driver. Ensure the nut is tight as the direction of rotation may tend to unscrew

it. Ensure that the drive shaft is through the exible coupling/driver before setting the

machine on the table and that the whole unit is at the correct end of the table.

Alternatively it may be easier to drive directly onto the sprocket using one of the pin or

adjustable type sprocket drivers tted to the plain drive rod.

6.4.2. When the cutting unit is in place and rmly xed into the multix brackets, or front roller

brackets, and the rear clamped with the radiused pressure bar, adjust the drive unit left or

right so that the appropriate drive rod will reach the end of the reel shaft. Tighten unit in

place.

Adjust the height and position, forwards and backwards and up and down, of the cable

drive support so that the shaft is square with the driven end of the reel, and tighten clamps

to hold it in place.

The black lobed hand screw allows the drive head to be moved along the square support

shaft to adjust the height of the drive, while the 5/8” hex headed socket screw allows the

support shaft to be clamped at any desired angle, and also allows the whole assembly to

be moved left or right along the machine bed to engage in the drive mechanism on the

reel.

The drive head of the shaft can also be slid through it’s support for further adjustment or

nal connection/ disconnection of drive.

6.4.3 Tighten the drive rod via the allen screw in the exible coupling onto the at of the drive

shaft.

6. In-frame Grinding (Continued)

© Bernhard and Company Limited

16

EXPRESS DUAL 4000DX

6. In-frame Grinding (Continued)

6.4.4 Moving the exible Shaft

There is a lay shaft socket at both ends of the

machine into which the exible drive can be

engaged as required. The other end of the

exible shaft can be disconnected if required

but this would not generally be necessary as the

bracket and shaft would normally be moved as

an assembly

The exible drive shaft can be detached

from its socket on the end of the machine by

pulling sharply on the shaft, to release it from

a spring loaded ball detent. (Earlier units by

rst removing the spring retainer (R-pin)),

and withdrawing the complete shaft (see Fig.

6.4.2.2.) When replacing the shaft, ensure that

it is properly engaged in the lay shaft socket.

By loosening the socket screw and allowing

the clamp nut, under the table, to twist through

approximately 90 degrees, the whole assembly

can be lifted clear of the table, and moved to the

other side of the mower unit if required.

Press “next” icon on operator display – display advances to next screen.

Fig. 6.4.4.2

© Bernhard and Company Limited

17

EXPRESS DUAL 4000DX

6.5 Actual Grinding

Screen requests size of mower.

6.5.1 Press the relevant icon to select size of mower:

n Smaller units (or Greens)

n n Medium sized units (or Tees / Light

Fairway)

n n n Large units (or Fairway)

Display advances to the next screen.

Screen requests type of grind required.

6.5.2 Press the relevant icon to select type of grind required:

n “touch up” (mower needs little

sharpening, probably part of a regular

sharpening regime)

n n “maintain” (blades need just a little more

material removing to get a good edge) or

n n n “rectify” (damaged blades, or a unit rarely

ground or heavily back-lapped)

Display advances to the next screen.

6.5.3 Screen shows selected answers (grind cycle)

CLOSE GUARD FIRST

Press tick (“accept”) icon if OK. (Grind, Traverse and Reel drive motors start – display

advances to the next screen).

or

Press cross (“reject”) icon if you wish to make an alternative selection (display returns to

size of mower question).

6. In-frame Grinding (Continued)

© Bernhard and Company Limited

18

EXPRESS DUAL 4000DX

6. In-frame Grinding (Continued)

6.5.4 Set up of Traverse

With motors running, the screen prompts: “set grind stone to reel” and

“set traverse limit stops”

Traverse the grinding wheel by hand, using the Traverse Engagement Screw until it is at

the extreme point of desired travel. Ensure that the traverse reversing bar is also moved in

that direction and slide the reversing stop up to the grinding wheel traverse assembly and

tighten. Move the grinding wheel to the opposite end of the desired travel and repeat the

operation ensuring that the reversing bar has also been moved in the opposite direction.

This is critical where the grinding wheel cannot pass beyond the end plates if they protrude

below the maximum diameter of the reel.

NOTE On the EXPRESS DUAL it is not necessary for the whole width of the grinding wheel to

pass the end of the reel and it SHOULD NOT DO SO EVEN IF SPACE PERMITS (see

Fig. 6.5.4).

Ensure that the leading edge

of grinding stone passes the

end of the reel – but clearance

must be maintained between

stone and end frame of unit.

NOTE: The reversing bar will move approximately ½” (13mm) before the direction of travel is

reversed and will allow the grinding wheel to move with it. It is therefore ESSENTIAL that

this is taken into account when setting the maximum point of travel.

Fig: 6.5.4

© Bernhard and Company Limited

19

EXPRESS DUAL 4000DX

6.6.1 With the stone positioned at the left hand end of the reel, place the left hand on the left

hand control wheel and the right hand on the traverse knob, moving the grinding wheel

along the reel by hand using the traverse engagement screw, wind up the left hand control

wheel clockwise until the grinding wheel strikes and sparks gently against the reel.

6.6.2 Unwind a complete turn to move the stone away from the reel.

6.6.3 Move the grinding wheel to the right hand end of the reel and, using the right hand on the

right control wheel, raise the shaft until the reel again can be gently rotates against the top

of the grinding wheel.

6.6.4 Unwind half a turn.

6.6.5 Go back to the left hand end and repeat the process but this time, after contact has been

made, unwind only sufciently to release the contact.

6.6.6 Go back to the right hand end and repeat the process and again release the contact only

slightly.

6.6.7 Repeat this process on the right hand side of the reel, raising the shaft with your right hand

and moving the grinding wheel along with your left hand. Repeat this process until the

contact all along the reel is light, even and parallel.

6.6.8 Screw in traverse knob to engage power traverse.

NOTE: Check auto traverse is changing direction at correct point at each end of its

movement.

6.6.9 Press “next” icon to start grinding cycle

Screen reads “GRINDING”. Pictures on display animate.

Both handwheels will automatically rotate clockwise to apply a parallel cut to the reel.

After a pre-determined number of traverse passes of the stone along the reel a further in

feed will be applied.

According to the program selected a certain number of in feeds / traverse passes will

follow until the cycle is completed. Both handwheels will then rotate counter-clockwise, to

back the stone away from the reel, and all motors will stop.

(Programme will NOT let a reel “spark-out” with factory set programme parameters)

6. In-frame Grinding (Continued)

© Bernhard and Company Limited

20

EXPRESS DUAL 4000DX

6.6.10 Screen reads “PROGRAM COMPLETE

Press “nished” icon if reel is satisfactory

or

Press “re-do” icon if it needs more grinding, to repeat the whole cycle

or

Press “touch-up” icon if reel is almost there but could do with a “touch up” to nish it off.

6.6.11 Press “nished” icon to advance display to the next screen “Grinding completed”-

remove mower from machine”

6.6.12 Press “unlock” icon to undo clamp and remove mower

6.6.13 Press “next” icon to return to the starting screen

6.7 ALTERNATIVES

6.7.1 If “re-do” or “touch up are selected, (close the guard before selection).

After a pause the motors will re-start and the handwheels will return the grindstone to the

position where the grind cycle nished. Further feeds/traverses will follow until the cycle is

completed once more,

6.7.2 At this time the guard can be opened and the condition of the reel checked.

6.7.3 If the blades are sharp enough Press the “nished” icon.

6.7.4 The display will change to “Grinding completed – remove mower from machine”

screen.

6.7.5 If the blades still need some grinding, the “resume” icon can be pressed, after closing

the guard. After a pause the motors will re-start and the handwheels will return the

grindstone to the position where the grind cycle was paused. The cycle will continue to it’s

conclusion.

6. In-frame Grinding (Continued)

© Bernhard and Company Limited

21

EXPRESS DUAL 4000DX

6.8 MANUAL MODE GRINDING

If at welcome screen “Manual Mode” is selected, the Express Dual can be used as with

any other machine in the ED series.

The operator display shows the three motor buttons as:

– Grind

– Spin

– Traverse

In manual mode, pressing one of these icons once will start a motor (icon colour changes

to red). Pressing it a second time will then stop the motor.

Also displayed are two digital, numerical counters, one for each handwheel.

Pressing the Reset key will set these counters to zero.

The clamp is still operated by the “lock” and “unlock” and the vacuum can be “toggled”

on and off using its icon.

For other screen information see QUICK START GUIDE at the back of this manual.

6. In-frame Grinding (Continued)

© Bernhard and Company Limited

22

EXPRESS DUAL 4000DX

USE A QUALIFIED ELECTRICIAN

In the event of any motor not starting, the following procedure should be adopted:

7.1. Check that the EMERGENCY STOP BUTTON on the control panel, immediately below the

HMI screen, is not locked down in STOP position (twist counter-clockwise to release).

7.2 Check fuses – main fuses feeding machine (alongside isolator switch by power connection

to machine) and small fuses on electrical panel (in the enclosure on the right hand side of

the safety guard).

7.3. Check voltage in isolator/junction box (right hand side of machine) coming out of the

isolator switch.

7.4. Check that safety contactor on the main electrical panel is engaged (centre pulled in).

7.5. Check for open circuit on overload, terminals 95 and 96, to determine whether or not main

motor is faulty. If open circuit press red resetting button on overload and re-test.

7.6. To determine that all motor contactors are OK test each one by relative icon button on the

HMI screen (in ‘manual’ mode), they should noticeably pull in. This can be checked by

someone looking in the junction box while the start icons are pressed.

7.7. Trav erse

Check the traverse and reversing contactor function (press screen icon and operate the

reversing bar so that traverse microswitch is activated) If only the traverse contactor is

functioning properly check the microswitch. If this is found to be OK check capacitor if

possible. If neither of these is faulty, then the motor is probably at fault.

7.8. Reel Drive

If the contactor is functioning properly, check the Inverter:

Check the red LED display on the front of the unit. This should be lit and display a value

that reects the reel speed (as a frequency). If it is out, or shows a fault/error code, the

start button, there is an inverter fault.

Disconnect the power to the machine, wait 2 minutes, then re-connect and try again (to

re-set the inverter).

If neither are faulty then the motor is probably at fault.

7.9. Main Motor

If the contactor is functioning correctly, check the load current with an ammeter across

terminals T2 and T3 on thermal overload. If this exceeds full load current indicated on

the motor identication plate then a new motor is needed. If the reading is below full load

current then possibly the overload is set too low.

NOTE Before assuming that there is an electrical fault in any of the systems ensure that the

mechanical drive assemblies attached to a particular motor are moving freely, and have

not got increased resistance due to damage, or the build up of dirt. This can best be done

by detaching the motor drive and ensuring that the mechanism is moving freely.

7. Electrical Fault Finding

© Bernhard and Company Limited

23

EXPRESS DUAL 4000DX

NEW FUSEHOLDERS (ED4000DX)

TO ACCESS FUSE

USE A SCREWDRIVER

TO UNCLIP & PIVOT

THE HOLDER

UPWARDS

NEW

FUSEHOLDERS

Led ILLUMINATES

ONLY WHEN FUSE

USE

SCREWDRIVER TO

OPEN COVER &

ACCESS FUSE

TAKE CARE WHEN

REMOVING FUSE

NOT TO DISPLACE

METAL CONTACTS

© Bernhard and Company Limited

24

EXPRESS DUAL 4000DX

8. Maintenance

8.1 Grinding Wheel Replacement

NOTE Grinding wheels should always be tted by competent, trained personnel.

8.1.1 The grinding wheel (stone) is held on the carrier by a nut which should be loosened, using

the “C” Spanner provided, before the assembly is removed from the mainshaft.

8.1.2 Slide the grinding wheel to the left hand side of the machine (viewed from the operator

position).

8.1.3 Release the 2 allen screws in the bearing ange ring on the left hand end of the main

shaft.

8.1.4 Raise the mainshaft to its maximum height, maintaining the shaft as horizontal as possible

until the right hand side comes up against the stop in the feed column and the left hand

side is at its maximum height. At this point the fork will drop away from the grinding wheel

assembly.

8.1.5 Place a wooden block under the mainshaft to the right hand side of the grinding wheel

assembly, bridging the front bed and front channel to take the weight of the mainshaft

when the side arm is removed (see Fig. 8.1.5).

Fi g: 8 .1. 5

© Bernhard and Company Limited

25

EXPRESS DUAL 4000DX

8. Maintenance (Continued)

8.1.6 USING THE “C” SPANNER PROVIDED, loosen the retaining nut. (If not a worn, to be

discarded, stone can be held in a vice whilst the nut is loosened. NEVER hold the sleeve

and nut in a vice)

8.1.7 Remove the circlip retaining the left hand side arm to the rear shaft. The side arm can now

be removed from the machine.

8.1.8 The grinding wheel and sleeve can now be withdrawn. (Note into which keyway of the

mainshaft the assembly was tted.) Remove the retaining nut and the old wheel. Clean

sleeve and nut thoroughly.

8.1.9 Fit the new grinding wheel and replace the collar, ensuring that all mating services are

clean and undamaged.

8.1.10 Ensure that the mainshaft and sleeve are perfectly clean and dry. Reassemble in the

reverse order ensuring that when you replace the grinding wheel assembly onto the

mainshaft, the nut is on the LEFT HAND side when viewed from the operator’s position

(Tighten nut whilst assembly is on the mainshaft). Use the opposite keyway from

which the assembly was removed.

NOTE Be careful to guide the assembly into the fork when lowering the mainshaft. Make sure that

the left hand side arm is centered in the channel.

8.1.12 Loosen the small allen key in the reel drive support block, pull the diamond dresser out a

short way and re tighten the screw.

8.1.13 With the stone NOT running, bring the mainshaft (and grindstone) up horizontally.

Manually traverse the ‘stone past the diamond, making a light scratch, to conrm that the

shaft is horizontal.

8.1.14 Move the stone just clear of the dresser then start the grind motor.

8.1.15 Bring up the shaft equally on each side and manually traverse the ‘stone across the

dresser.

8.1.16 Switch on and engage the auto traverse with the stops set so that the stone completely

passes the dresser back and forth.

8.1.17 Apply more feed as necessary to true the stone.

NOTE Dressing in this way should be carried out periodically to keep the grindstone clean and

true BUT remove only the minimum material off the stone to keep long service.

© Bernhard and Company Limited

26

EXPRESS DUAL 4000DX

8. Maintenance (Continued)

NOTE When tting a new sleeve and nut, it may appear that the assembly is too tight to t onto

the mainshaft of the Express Dual.

This is because all replacement sleeve and nut assemblies are shipped with the drive key

left very slightly oversize to allow for varying degrees of wear in the mainshaft keyway.

(The key is ‘glued’ into the sleeve NOT welded).

The key needs to be “tted” to the mainshaft. This may entail ling a small amount of

material from both the depth of the key and the sides. Remove only a very small amount of

material at a time, then check the t, until the sleeve and nut assembly slides freely along

the length of the mainshaft without any play between key and keyway.

REMEMBER

The mainshaft keyway will be less worn at the ends of the shaft than where the normal

traverse of the grindstone occurs, do not remove too much metal from the key.

NEVER grip the sleeve and nut assembly in a vice. Fully tighten the nut when the

assembly is tted to the mainshaft.

Sleeve

Key

Mainshaft

2nd Key

Remove minimal material from

sides and bottom of key

© Bernhard and Company Limited

27

EXPRESS DUAL 4000DX

8. Maintenance (Continued)

8.2 Cleaning and Lubrication

NOTE: IF THESE CLEANING AND MAINTENANCE PROCEDURES ARE NOT

FOLLOWED THE MACHINE WARRANTY WILL BE INVALIDATED.

8.2.1 Daily

Before use:

Mainshaft –after thoroughly cleaning, dry and ensure that no oil remains at all.

It is essential that the grinding wheel sleeve and nut can be moved freely along the entire

length of the mainshaft at all times.

After use:

Wipe off any deposits of grinding dust with a dry cloth or brush ensuring the keyways

are kept clean. Using a ne spray oil, such as WD40® or Bernhard ‘Fine clean/lube’,

spray the whole shaft. Use an excess of uid sprayed in one place and slide the grinding

wheel assembly backwards and forwards over that area in order to wash out thoroughly

the inside of the sleeve. This will remove any build up of material and ensure the free

movement of the assembly along the shaft.

Leave a ne lm of WD40® / ‘Fine clean/lube’ spray in place overnight but ensure that

Shaft is wiped DRY before any grinding is carried out.

Over a weekend, or longer periods where machine may not be used, spray main and other

nearing shafts with Bernhard ‘Protective oil lm’ but clean with WD40® / ‘Fine clean/lube’

and dry before any grinding is carried out.

Occasionally lubricate the contact areas of the fork driver (with the sleeve and nut)

with “MOLYCOTE”® (Molybdenum Disulphide), this will impregnate the surface. Excess

lubricant / propellant should be wiped off again after a short time.

NOTE Never leave any oil or grease on the mainshaft.

8.2.2 Weekly

Spray WD40® / ‘Fine clean/lube’ or equivalent onto all moving parts (the mainshaft must

be completely dried before any grinding is carried out). This includes the threads under the

feed column handwheels, the reversing bar and the shafts on which the fork and pickup

assembly run. The majority of bearings are either oil impregnated or are ball races and,

apart from those mounted in special sealed housings or tted with grease nipples, require

the occasional drop of oil.

Check the vacuum collector beneath the grindstone and the container and lter of the

vacuum unit beneath the machine (accessible by removing the panel on the back of the lift

table). Clean/empty as necessary.

Examine belts for wear and tension. DO NOT OVER-TIGHTEN. Examine fork assembly

for wear – some slight discolouration may occur, this is not a problem.

© Bernhard and Company Limited

28

EXPRESS DUAL 4000DX

8. Maintenance (Continued)

8.2.3 6 Monthly

Chain and idler sprocket require cleaning and oiling.

8.2.4 Yearl y

Mainshaft bearings are pre-packed with grease. IF grease nipples are tted ONLY 1

SMALL SHOT of grease should be applied annualy.

These bearings run warm/hot, that is OK. Extra grease will not reduce the temperature,

more likely the reverse, the seals and subsequently the bearings may fail prematurely.

Replace the vacuum lter (if not already done following routine examination).

© Bernhard and Company Limited

29

EXPRESS DUAL 4000DX

9. Parts List

Page

MAIN FRAME 9.1

FEED ADJUSTMENT 9.2

MAINSHAFT MOUNTING AND MAIN MOTOR DRIVE 9.3

TRAVERSE ASSEMBLY 9.4

REEL DRIVE 9.5

CLAMP ASSEMBLY 9.6

MULTI-FIX BRACKET ASSEMBLY 9.7

GUARD 9.8

CONTROL BOX 9.9

ELECTRICAL CABINET 9.10

LIFT TABLE 9.11

© Bernhard and Company Limited

30

EXPRESS DUAL 4000DX

9.1 MAIN FRAME

__________________________________________________________

1 Frame ...................................................................................... 1 A4050

2 Top Plate .................................................................................1 A4142

3 Upper Front Skir t ..................................................................... 1 A6352

4 Rear Skirt ................................................................................1 A6397

(not required if Lift Table tted)

5 Front Skirt ................................................................................ 1 A6328

6 Drawer ..................................................................................... 2 A6321

7 Drawer Handle ........................................................................2 A6110

8 Dust Tray .................................................................................1 A6323

9 Dust Tray Handle ..................................................................... 2 A6111

10 Drawer Runner (Pad) ..............................................................4 A6 742

11 Drawer Runner (Drawer) ......................................................... 4 A6741

12 M5 x 10 Button Socket Screw ................................................. 8 A5129

9. Parts List (Continued)

Ref # Name of Part Qty. Part #

© Bernhard and Company Limited

31

EXPRESS DUAL 4000DX

7

6

5

4

3

2

1

8

9

10

11

12

MAIN FRAME

9. Parts List (Continued)

© Bernhard and Company Limited

32

EXPRESS DUAL 4000DX

9. Parts List (Continued)

9.2 FEED ADJUSTMENT _____________________________________

1 Feed Channel L.H. c/w top and bottom cap ........................... 1 A4 041

Feed Channel R.H. c/w top and bottom cap ........................... 1 A40 42

2 Feedscrew Cap c/w Bush ....................................................... 4 A4044

3 Feedscrew ............................................................................... 2 A90 41

4 Locknut .................................................................................... 4 A5502

5 Handwheel 150mm dia ...........................................................2 A 6113

6 Die Spring ................................................................................ 2 A6278

5/8” Double Coil Spring Washer (older machines) ..........................2 A5303

7 5/8” whit x 5/8” Socket Screw ................................................. 2 A5110

8 5/8” Washer ............................................................................. 4 A5305

9 Bush (included with item 2) ..................................................... 4

10 Feed Nut .................................................................................. 2 A4043

11 Enco d er ................................................................................... 2 A 80 74

12 Encoder Layshaft Coupling .....................................................2

13 Encoder Support Stud ............................................................. 4

14 Cross Helical Gearbox 1:3 ...................................................... 2 A6007

15 Feed Layshaft ..........................................................................2 A9069

16 Electromagnetic Clutch 24v .................................................... 2 A8057

17 Feed Motor 24v ....................................................................... 2 A6018

Ref # Name of Part Qty. Part #

© Bernhard and Company Limited

33

EXPRESS DUAL 4000DX

1

2

3

4

9

5

6

8

10

7

16

17

18

19

15

12

11

12

20

14

13

21

17A

FEED ADJUSTMENT

9. Parts List (Continued)

© Bernhard and Company Limited

34

EXPRESS DUAL 4000DX

Ref # Name of Part Qty. Part #

9.3 MAINSHAFT MOUNTING AND MAIN MOTOR DRIVE

______________

1 Side Arm L.H. .......................................................................... 1 A 412 2

2 Side Arm R.H. .........................................................................1 A 4123

3 Rear Shaft c/w circlips ............................................................ 1 A9108

4 Circlip.......................................................................................2 A5601

5 Main Motor 220/240v 50/60Hz ................................................ 1 A6040

6 Drive Pulley 50Hz .................................................................... 1 A7203

7 Taperlock Bush 1108 x 19 .......................................................1 A7301

8 Driven Pulley ........................................................................... 1 A7201

9 Taperlock Bush 1610 x 1 ¼” .................................................... 1 A7303

10 SPZ Drive Belt 50Hz ............................................................... 1 A7102

11 Drive Belt Guard ...................................................................... 1 A6334

12 Mainshaft .................................................................................1 A9068

13 Grinding Stone ........................................................................1 A6505

14 Sleeve ...................................................................................... 1 A9116

15 Nut ........................................................................................... 1 A9095

Sleeve & Nut assembly ...........................................................1 A9506

16 Mainshaft Bearing ................................................................... 1 A7721

17 Oilite Bush 1 ¼” bore ...............................................................2 A7701

18 Plastic Washer ........................................................................2 A6759

19 Hex.Nut M12 ............................................................................ 4 A5506

20 Washer M12 ............................................................................8 A5315

21 Hex. Head Bolt M12 x 45 ......................................................... 4 A5714

22 Hex. Head Bolt M8 x 25 ..........................................................4 A5216

23 Washer M8 .............................................................................. 4 A5321

24 Motor Bolt Retaining Plate ...................................................... 2 A4078

25 Hex. Set Screw M10 x 70 ........................................................ 2 A5 711

26 Locknut M10 ............................................................................ 2 A5503

27 Button Head Socket Screw M5 x 10 ....................................... 2 A512 9

28 Limit Switch ............................................................................. 2 A8842

9. Parts List (Continued)

© Bernhard and Company Limited

35

EXPRESS DUAL 4000DX

14

13

1

2

4

11

6

7

3

5

9

8

16

17

18

19

20

21

22

10

12

15

23

24

25

26

27

28

9. Parts List (Continued)

MAINSHAFT MOUNTING

AND MAIN MOTOR DRIVE

© Bernhard and Company Limited

36

EXPRESS DUAL 4000DX

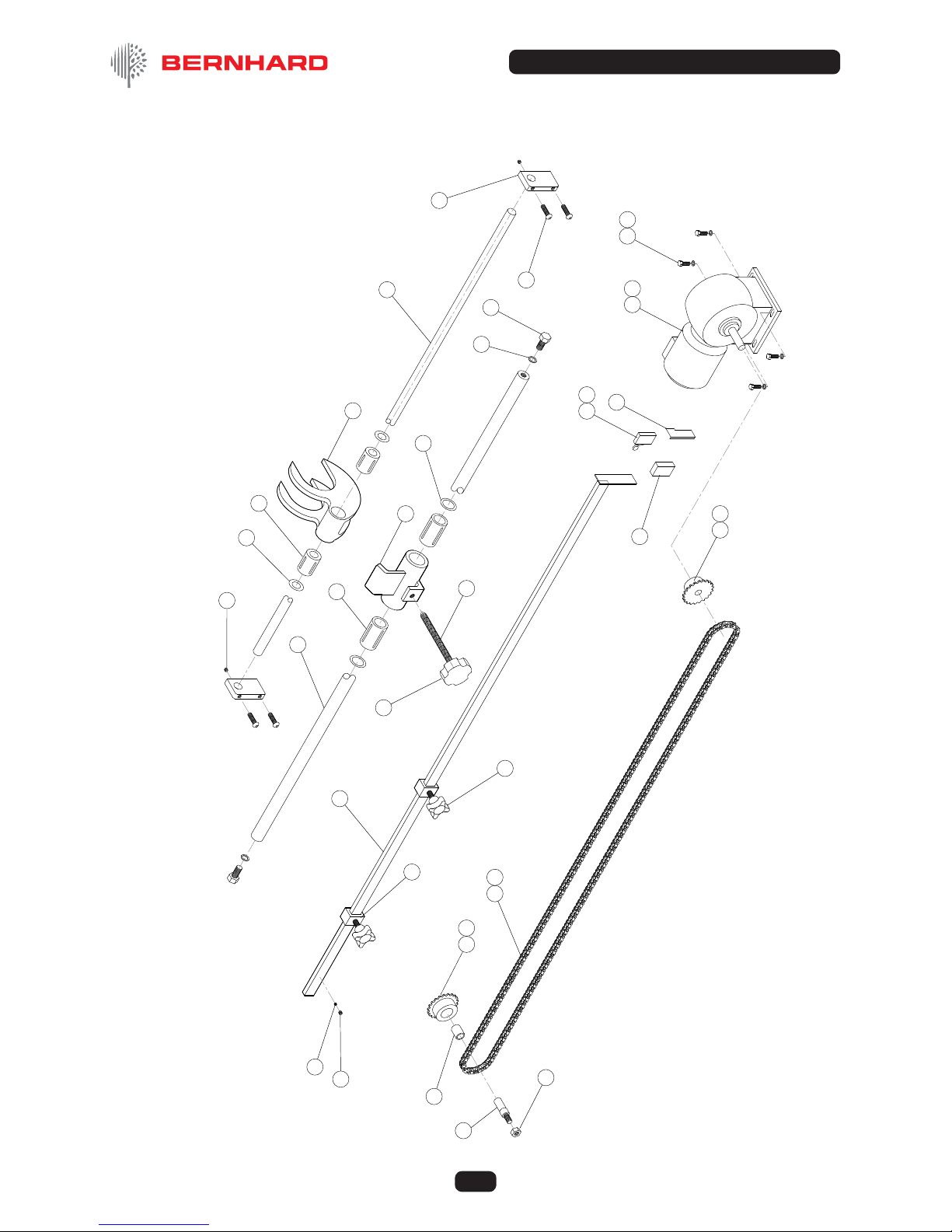

9.4 TRAVERSE ASSEMBLY

______________________________________________

1 Forkdriver (only) ...................................................................... 1 A9512

Forkdriver c/w bushings and seals ..........................................1 A9505

2 Shaft for Forkdriver .................................................................1 A9050

3 Brackets for Forkdriver Shaft .................................................. 2 A4049

4 Ball Bushing for Forkdriver ...................................................... 2 A7706

5 Dust Seals for Forkdriver ........................................................2 A7707

6 Button Head Screw M8 x 30 ................................................... 4 A5164

7 Socket Screw M6 x 6 ...............................................................2 A5156

8 Shaft for Pick up ...................................................................... 1 A9183

9 Traverse Pick Up ..................................................................... 1 A9 518

10 Ball Bushing for Trav. Pick Up ................................................. 2 A7702

11 Dust Seal for Trav. Pick Up ..................................................... 2 A7703

12 Hex. Head Screw M12 x 25 ..................................................... 2 A5712

13 Washer M12 ............................................................................2 A5315

14 Engagement Screw ................................................................. 1 A 6112

15 Lobed Knob M12 ..................................................................... 1 A6102

16 Reversing Bar .......................................................................... 1 A4111

17 Reversing Bar Stop .................................................................2 A 4113

18 Cross Knob M8 x 15 ................................................................ 2 A6131

19 Microswitch..............................................................................1 A8111

20 Housing for Microswitch ......................................................... 1 A8113

21 Guard for Microswitch ............................................................. 1 A6382

22 Screw 2BA x 1 ¾” ....................................................................2 A5404

23 Traverse Motor 60Hz ............................................................... 1 A6024

Traverse Motor 50Hz ............................................................... 1 A6022

24 Idler Sprocket ..........................................................................1 A7609

25 Oilite Bush for Sprocket .......................................................... 1 A7704

26 Spindle for Idler Sprocket ........................................................ 1 A9057

27 Drive Sprocket ......................................................................... 1 A7603

28 Traverse Chain ........................................................................ 1 A74 06

29 Link for Traverse Chain ........................................................... 1 A7502

30 Circlip ½” ................................................................................. 1 A5602

31 Hex. Nut M10 ........................................................................... 1 A5503

32 Socket Screw ..........................................................................1

33 Hex Head Screw M6 x 18 ........................................................ 4 A5719

34 Washer M6 .............................................................................. 4 A5320

35 Capacitor 3uf for Traverse Motor ........................................... 1 A814 8

36 Friction Spring for Reversing Bar ............................................1 A6 746

37 Socket Screw ¼”Whit x ¼” ...................................................... 1 A510 1

9. Parts List (Continued)

Ref # Name of Part Qty. Part #

© Bernhard and Company Limited

37

EXPRESS DUAL 4000DX

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

21

22

23

24

13

25

26

27

28 29

30

31

32

33 34

36

37

35

TRAVERSE ASSEMBLY

9. Parts List (Continued)

© Bernhard and Company Limited

38

EXPRESS DUAL 4000DX

9.5 REEL DRIVE

___________________________________________________________

1 Reel Drive Motor ...................................................................... 1 A6011

2 Layshaft (Long) .......................................................................1 A9059

3 Layshaft (Short) ....................................................................... 1 A9060

4 Layshaft Bearing ..................................................................... 2 A7722

5 Socket for Flexible Drive ......................................................... 2 A9121

6 Flexible Drive Shaft .................................................................1 A74 04

7 Flexible Drive Bracket Base .................................................... 1 A4046

8 Retaining Nut ........................................................................... 1 A4110

9 ‘L’ Post Drive Hd Support Bar .................................................1 A4001

10 Flexible Drive Bracket ............................................................. 1 A4045

11 Cylinder Drive Motor Bracket ..................................................1 A 4031

12 Cross Knob M8 x 15 ................................................................ 2 A6131

13 Ball Spring Plunger ................................................................. 2 A5460

14 Cap Hd Screw 5/8”Whit x 5 1/2” .............................................1 A5109

15 Socket Screw M6 x 12 .............................................................1 A5146

16 Diamond Dresser ....................................................................1 A6737

17 Locknut M10 ............................................................................ 1 A5503

18 Flexible Coupling .....................................................................1 A6744

19 Grub Screw 3/8” Whit x 3/8”....................................................2 A5106

20 Short Square Drive Shaft ........................................................ 1 A 413 4

Ref # Name of Part Qty. Part #

9. Parts List (Continued)

© Bernhard and Company Limited

39

EXPRESS DUAL 4000DX

18

19

20

5

4

2

8

6

7

9

1

5

4

3

10

11

12

14

15

16

13 17

REEL DRIVE

9. Parts List (Continued)

© Bernhard and Company Limited

40

EXPRESS DUAL 4000DX

Ref # Name of Part Qty. Part #

9.6 CLAMP ASSEMBLY

____________________________________________________

1 Radius Pressure Arm Bracket ................................................. 1 A 410 1

2 Radius Pressure Arm .............................................................. 1 A 410 0

3 Pressure Bar Rubber...............................................................2 A6761

4 Linear Actuator ........................................................................ 1 A6 013

5 Plug 4 Pin ................................................................................ 1 A8121

6 Hex Head Bolt M16 x 170 ........................................................1 A5 749

7 Nyloc Nut M16 ......................................................................... 1 A5524

8 C’s’k Socket Screw M10 x 30 .................................................. 4 A 5117

9 Nut M10 ...................................................................................4 A5503

10 Hex Head Bolt M10 x 45 ..........................................................2 A5706

11 Nyloc Nut M10 ......................................................................... 2 A5505

12 Washer M10 ............................................................................6 A5310

13 Pressure Plate (not shown) ....................................................1 A6342

9. Parts List (Continued)

© Bernhard and Company Limited

41

EXPRESS DUAL 4000DX

1

2

3

4

5

6 7

8

9

10

11

12

CLAMP ASSEMBLY

9. Parts List (Continued)

© Bernhard and Company Limited

42

EXPRESS DUAL 4000DX

9.7 MULTI-FIX BRACKET ASSEMBLY

_________________________________

1 Adjustable Mtg Brkt Base L.H. ................................................ 1 A4 012

2 Adjustable Mtg Brkt ‘V’ Base ..................................................2 A 4 011

3 Adjustable Mtg Brkt Base R.H. ...............................................1 A4014

4 ‘L’ Upright Mounting Brkt R.H. ................................................. 1 A4010

5 ‘L’ Upright Mounting Brkt L.H. ................................................. 1 A4009

6 Adjustable Mtg Brkt Horizontal ...............................................2 A4016

7 Mounting Brkt ‘C’ Clamp L.H. .................................................1 A4006

8 Mounting Brkt ‘C’ Clamp R.H. ................................................. 1 A4007

9 ‘C’ Clamp Screw ......................................................................2 A4008

10 ‘V’ Bracket Clamp Finger ........................................................ 2 A4003

11 Kip Lever M10 x 20 .................................................................. 4 A6118

12 ‘V’ Bracket Stud M16 ............................................................... 2 A5401

13 Kip Lever M12 x 30 .................................................................. 4 A6121

14 Slide Nut M10 .......................................................................... 2 A 4180

15 Nut M16 ..................................................................................2 A5508

16 Wing Nut M16 .......................................................................... 2 A5509

17 Cap Head Skt Screw M10 x 25 ..............................................4 A 5116

18 Washer M12 ............................................................................4 A5315

19 Washer M10 ............................................................................4 A5310

20 Base Scale ..............................................................................2 A6601

21 Button Head Skt Screw M4 x 8 ............................................... 4 A5125

22 Multix Channel (not shown) ................................................... 2 A4087

Ref # Name of Part Qty. Part #

9. Parts List (Continued)

© Bernhard and Company Limited

43

EXPRESS DUAL 4000DX

1

2

3

4

5

6

7

8

9

10

11

11

12

13

14

15

16

17

18

19

20

21

MULTI-FIX BRACKET

ASSE M B LY

9. Parts List (Continued)

© Bernhard and Company Limited

44

EXPRESS DUAL 4000DX

9.8 GUARD

_________________________________________________________________

1 Guard Roof Fabrication ........................................................... 1 A03553

2 Guard RH End Fabrication (Electrical Enclosure) .................. 1 A03554

3 Guard LH End Fabrication (Storage) ...................................... 1 A03555

4 Guard Front Fabrication .......................................................... 1 A03556

5 Polycarbonate Retainer Assembly ..........................................1 A03557

6 Guard Linkage Assembly ........................................................ 1 A03546

7 Guard Rear Flap Fabrication................................................... 8 A03565

8 Guard LH Rear Inll Fabrication ............................................. 2 A03559

9 Guard LH Rear Inll Fabrication ............................................. 1 A03558

10 Guard Light Bracket Fabrication .............................................1 A03564

11 Guard LH Door End Fabrication ............................................. 1 A03567

12 Guard RH Door End Fabrication .............................................4 A03566

13 Guard Polycarbonate .............................................................. 2 A03560

14 Electrical Panel Chassis Plate Fabrication ............................. 1 A03618

Ref # Name of Part Qty. Part #

9. Parts List (Continued)

© Bernhard and Company Limited

45

EXPRESS DUAL 4000DX

12

1

7

8

9

10

11

3

6

5

4

13

14

2

GUARD

9. Parts List (Continued)

© Bernhard and Company Limited

46

EXPRESS DUAL 4000DX

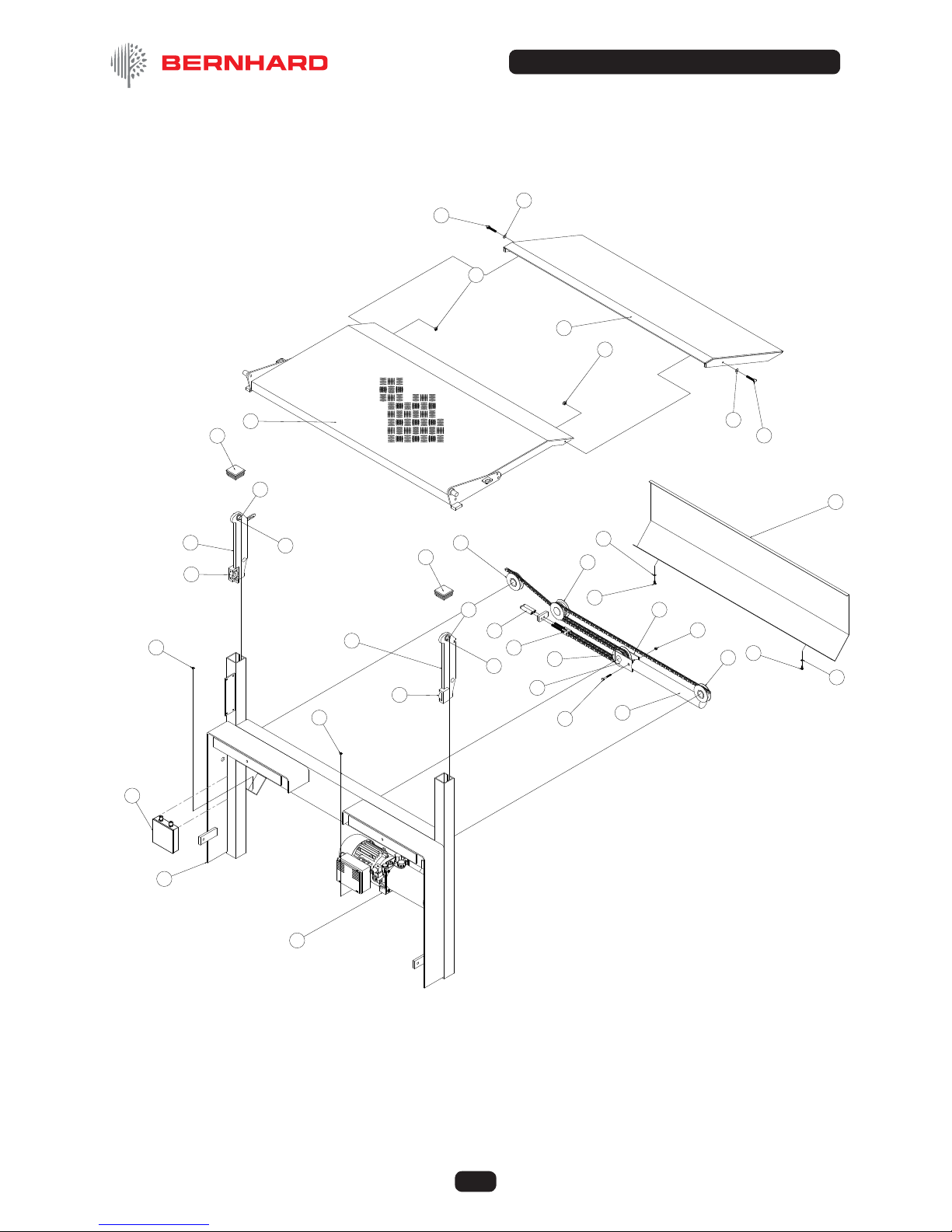

9.11 LIFT TABLE

__________________________________________________________

1 Frame ...................................................................................... 1 A413 8

2 Power Pack 220v .................................................................... 1 A8954

Power Pack 24v ....................................................................... 1 A8023

Power Pack 12v ....................................................................... 1 A8770

3 L.H. Slider Plate ......................................................................1 A4127

4 R.H.Slider Plate ....................................................................... 1 A4128

5 Bearing .................................................................................... 2 A7 744

6 Bearing .................................................................................... 2 A7 744

7 Slider Plate Pin ........................................................................ 2 A4127

8 Plastic End Cap 60 x 60 ......................................................... 2 A619 4

9 Taillift Platform .........................................................................1 A4139

10 Single Pulley ............................................................................2 A7209

11 Double Pulley ..........................................................................2 A7204

12 Hydraulic Cylinder complete ...................................................1 A6923

13 Chain Screw Tensioner ........................................................... 2 A4119

14 Chain Bottle Tensioner ............................................................ 2 A4022

15 L.H. Pulley Mounting Plate ...................................................... 2 A4098

16 Hex Head Bolt M6 x 45 ........................................................... 1 A5722

17 Nyloc Nut M6 ........................................................................... 1 A 5517

18 R.H.Pulley Mounting Plate ...................................................... 1 A4099

19 Cover Plate .............................................................................. 1 A6319

20 Washer M6 .............................................................................. 2 A5320

21 Hex Head Screw M6 x 12 ........................................................2 A5718

22 Nut M6 ..................................................................................... 2 A5 516

23 Lift Platform Extension ............................................................ 1 A413 7

24 Washer M8 .............................................................................. 2 A5321

25 Hex Head Set Screw M8 x 45 ................................................. 2 A5725

26 Nyloc Nut M8 ........................................................................... 2 A5220

27 Lift Table Lowering Solenoid 220v ..........................................1 A8943

Lift Table Lowering Solenoid 24v ............................................ 1 A8392

Lift Table Lowering Solenoid 12v ............................................ 1 A8391

28 Control Pendant 24v (not shown) ............................................1 A8018

Mains Control Pendant (not shown) ........................................ 1 A8890

29 Label for Tail Lift Pendant (not shown) .................................... 1 A6552

30 Mains Tail Lift Controller (not shown) ...................................... 1 A8904

Ref # Name of Part Qty. Part #

9. Parts List (Continued)

© Bernhard and Company Limited

47

EXPRESS DUAL 4000DX

1

5

4

7

6

8

9

10

8

11

11

10

12

2

5

3

6

7

13

14

15

16

17

20

18

19

21

21

20

23

24

25

25

24

22

22

26

26

30

LIFT TABLE

9. Parts List (Continued)

© Bernhard and Company Limited

48

EXPRESS DUAL 4000DX

9.9 CONTROL BOX (OMRON NS5)

_____________________________________

1 Control Box and Lid ................................................................. 1 A6973

2 Control Box Arm ...................................................................... 1 A4028

3 On –Off Switch (Control System) ............................................ 1 A8155

4 Comm’s Lead, HMI - PLC ........................................................ 1 A3586

5 1k Potentiometer ..................................................................... 1 A8014

6 Emergency Stop Button ..........................................................1 A8073

7 B4T02 Contact Block (for the above) ...................................... 1 A8358

8 Omron Graphical Operator Panel (HMI) touch screen .......... 1 A8500

9 Label ....................................................................................... 1 A6549

Ref # Name of Part Qty. Part #

9. Parts List (Continued)

2

3

5

VIEW WITH HINGED LID OPEN

9

6

3

5

7

8

4

1

10

CONTROL BOX

OMRON NS5

© Bernhard and Company Limited

49

EXPRESS DUAL 4000DX

ELECTRICAL PANEL

9. Parts List (Continued)

9.10 ELECTRICAL JUNCTION BOX

Main

(grind)

PLC (Cpu-

includes

encoder

input &

comms)

PLC

Input

module

Transformer

24V (AC)

output

Safety

Vac’ Trav’

left

Contactors

Overload

Relay

Feed motor

up

Rectifier

(

DC out

)

Relay

Feed motor

down

Relay

Clamp

up (on)

Relay

Clamp

Down (off)

Fuses

PLC

Output

module

Trav’

ri

g

ht

PLC

(psu

Regulated

PSU

24V dc

output

Inverter

Reel speed

control

Traverse

capacitor

ISOLATOR SWITCH

ENCODER

CONNECTIONS

SIDE ARM LIMIT

SWITCH WIRES

TO OPERATOR

PANEL

TO MAIN

ELECTRICAL PANEL

SUPPLY FUSES

F1,F2, 16A (x2)

A8084

MAINS INLET

SUPPLY FUSE

HOLDER (x2)

A8081

A08373

© Bernhard and Company Limited

50

EXPRESS DUAL 4000DX

ELECTRICAL PANEL

____________________________________________________

1 PLC Power Supply Unit ........................................................... 1 A3537

2 PLC CPU (includes High Speed Encoder Count Module) ...... 1 A3536

3 PLC Input Module .................................................................... 1 A3538

4 PLC Output Module ................................................................. 2 A3539

5 Contactor 24v DC ....................................................................5 A6973

6 Thermal Overload Contactor ..................................................1 A8368

7 Relay 24v DC...........................................................................4 A8380

8 Relay Base .............................................................................. 1 A8381

9 Rectier ...................................................................................1 A8350