Page 1

IMPORTANT INSTRUCTIONS

READ AND SAVE

THESE INSTRUCTIONS

Saving energy and creating healthy, comfortable environments

No. II-470

Date July, 2015

ARCHITECTURAL

Low Prole 8

FDA

RECOMMENDED

USDA

COMPLIANCE

AIR CURTAIN SERIES ALC08

Installation & Maintenance Instructions

TABLE OF CONTENTS

I. UNCRATING.......................................................................................................................................................................................................... 2

II. GENERAL MOUNTING INSTRUCTIONS ...........................................................................................................................................................2

III. WALL MOUNTING .............................................................................................................................................................................................2

IV. SUSPENDED MOUNTING ................................................................................................................................................................................ 3

V. ELECTRICAL CONNECTIONS ........................................................................................................................................................................ ....4

VI. FIELD CONNECTIONS ......................................................................................................................................................................................6

VII. OPERATION INSTRUCTIONS ......................................................................................................................................................................... 6

VIII. MAINTENANCE AND CLEANING ................................................................................................................................................................. 7

IX. SERVICE ............................................................................................................................................................................................................ 7

INTELLISWITCH®...................................................................................................................................................................................................10

QUICK START OPERATION.......................................................................................................................................................................... .10

FAQ’s (FREQUENTLY ASKED QUESTIONS)................................................................................................................................................ 12

THE INTELLISWITCH® PROGRAMMING)....................................................................................................................................................14

X. TROUBLESHOOTING........................................................................................................................................................................................19

XI. WARRANTY ......................................................................................................................................................................................................20

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Read all instructions before installing or using this air curtain.

B. Use this unit only in the manner intended by the manufacturer and described in this manual. Any other use not recommended by the

manufacturer may cause re, electric shock, or injury to persons. If you have any questions, contact the manufacturer.

C. Before servicing or cleaning unit, switch power o at service panel and lock the service disconnecting means to prevent power from

being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

D. Installation work and electrical wiring must be done by qualied person(s) in accordance with all applicable national and local codes

having jurisdiction, including re-rated construction. See page 4, ELECTRICAL CONNECTIONS (NEC Code ANSI/NFPA No. 70).

E. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

F. To reduce the risk of re, do not store or use gasoline or other ammable vapors and liquids in the vicinity of the air curtain.

G. This air curtain is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. Keep combustible materials, such as furniture,

pillows, bedding, papers, clothes, etc. and curtains at least 1 inch from the top, back, front, sides and at least 6 feet from the discharge of

the air curtain.

H. Extreme caution is necessary when any air curtain is used by or near children or invalids, and whenever the heater is left operating

unattended.

I. Do not operate any air curtain after it malfunctions. Disconnect power at the service panel and have the air curtain inspected by a

reputable electrician before reusing.

J. To disconnect the air curtain, turn controls to "o", and turn o power to the air curtain circuit at main disconnect panel.

K. Do not insert or allow foreign objects to enter any ventilation or discharge opening as this may cause an electric shock or re, or damage

the air curtain.

L. To prevent a possible re, do not block the air intake or discharge of the air curtain in any manner.

M. The air curtain has hot and arcing or sparking parts inside. Do not use it in areas where gasoline, paint, or ammable vapors or liquids are

used or stored.

N. This heater may include an audible or visual alarm to warn that parts of the heater are getting excessively hot. If the alarm sounds (or

illuminates), immediately turn the heater o and inspect for any objects on or adjacent to the heater that may have blocked the airow or

otherwise caused high temperatures to have occurred. DO NOT OPERATE THE HEATER WITH THE ALARM SOUNDING (OR ILLUMINATING).

www.intelli-how2.com 800-245-4455 www.berner.com

Page 2

I. UNCRATING

6’ minimum*

8’ maximum

20°

1" minimum

AIR

Discharge

Nozzle

1" minimum

side clearance

from combustible

material*

A

I

R

A

I

R

*Electrically Heated Units Only

INTERIOR

EXTERIOR

Carefully examine the carton(s) for damage. If the carton is

damaged, immediately notify the shipping company. Do not

delay in ling claim. If the air curtain(s) were shipped on

wooden skids, remove protective wood and banding straps securing the carton(s) to the skid. Open the carton(s) and remove

all protective packaging. Immediately verify that the electrical

rating nameplate located on the cover matches electrical power

supply available. Retain the shipping carton(s) until the air

curtain(s) are installed and properly operating.

ACCESSORIES: If the air curtain(s) were ordered with optional

electrical accessories, the accessories will be found in the carton

containing the air curtain or in a separate carton(s) accompanying the air curtain(s). Check all of the cartons/skids for accessories before discarding.

II. MOUNTING INSTRUCTIONS

(General)

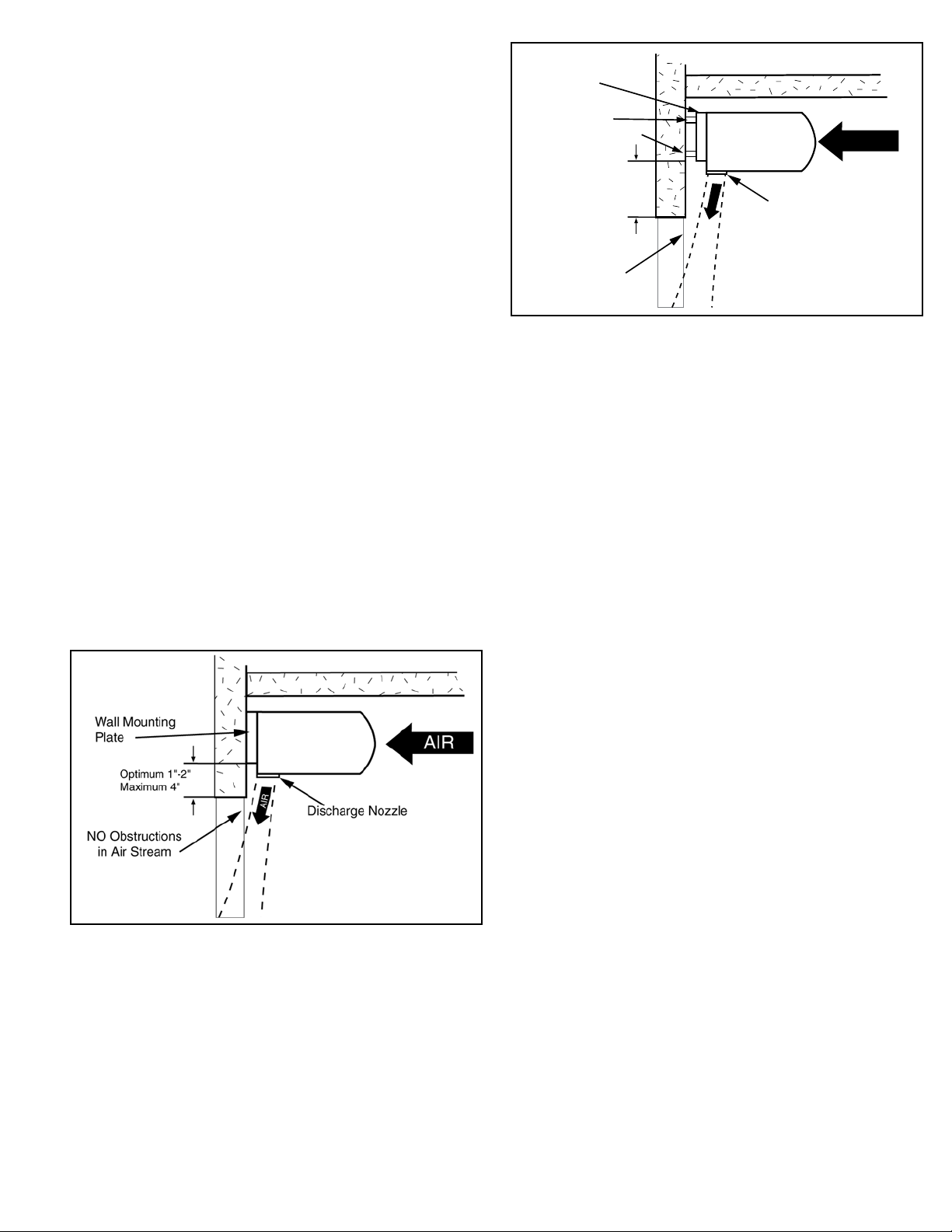

INDOOR MOUNTING ONLY - Environmental/Insect/Dust Control

The Architectural Low Prole 8 Air curtain is designed to be an eective barrier against cold drafts in the winter and hot air in the summer.

To achieve optimum protection, the air curtain should be mounted on

the inside of the building, ush to the wall and as close to the top of

the door opening as possible. To ensure peak performance, keep the

air stream free of obstructions.

The air curtain will not perform properly if negative air pressure

exists in the building. Under these conditions, a means for makeup

air to the building must be provided so that the air pressure on

both sides of the opening is in balance.

Before mounting the air curtain, check the supporting structure to verify that it has sucient load-carrying capacity to support the weight of

the air curtain(s). The mounting hardware (supplied by others) should

be capable of supporting a minimum of three (3) times the weight of

the air curtain.

See Table 1.

If the air stream strikes any obstruction (the top edge

of the doorway, a door opening device, etc.), the

eectiveness of the air curtain will be greatly reduced.

See Figure 1.

B. For optimum performance, the bottom of the air curtain

(discharge nozzle) should be no more than 1” above

the top of the door opening with the air curtain(s)

mounted ush to the wall. If the air curtain must be

mounted higher, it must be spaced out from the

wall ³/₈” for every inch the air curtain is above the door

opening. See Figure 3. For optimum protection, any void

between the air curtain and the wall should be sealed

along the full length of the air curtain.

C. Electric heated air curtain(s) shall:

1. Have a minimum clearance of at least 1”

between the sides and top of the air curtain and

any combustible material.

2. Have a minimum clearance of at least 6’

between the bottom of the air curtain and the oor.

3. Be installed Indoors Only.

D. Proceed to either Section III - WALL MOUNTING

or Section IV - SUSPENDED MOUNTING

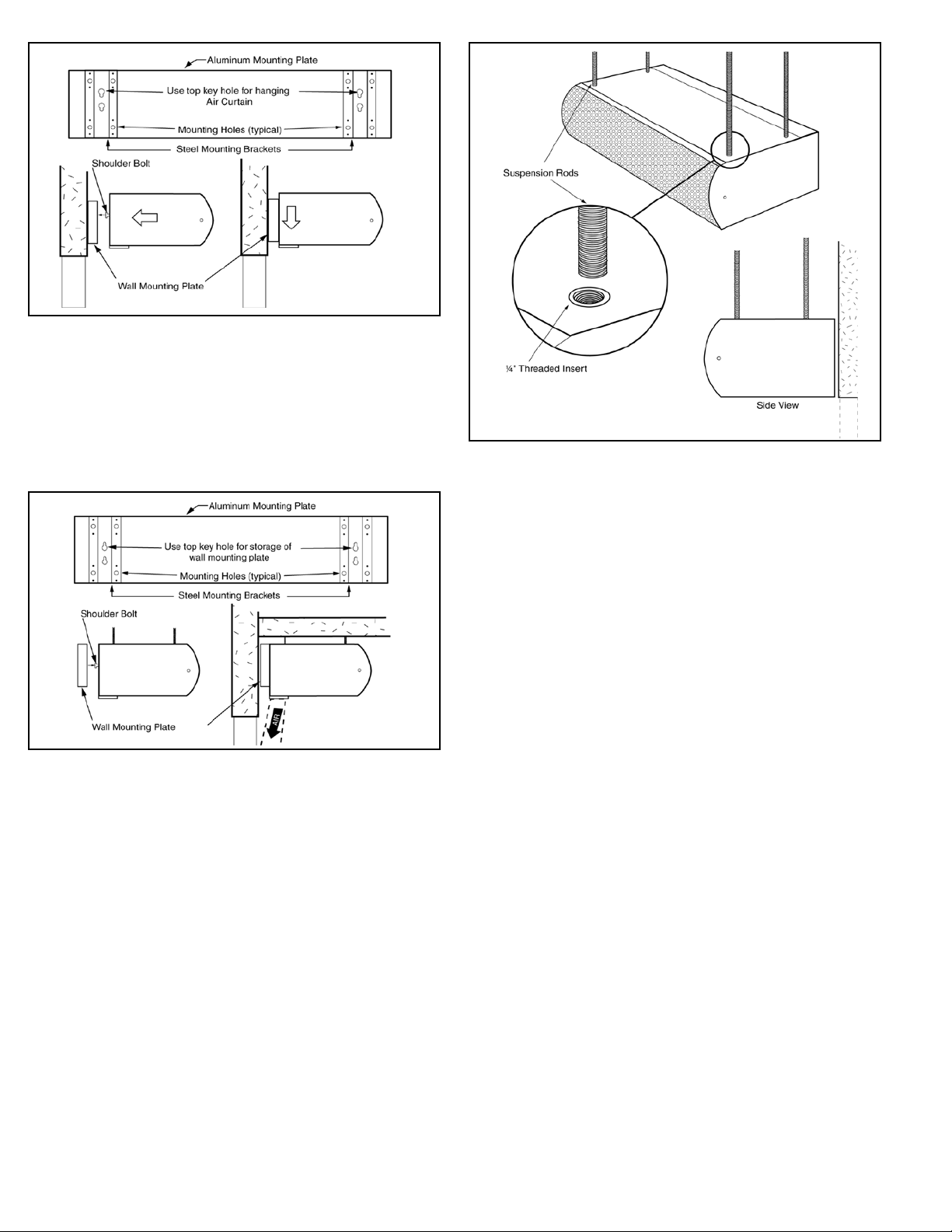

III. WALL MOUNTING

A. The Architectural Low Prole 8 Air curtain is equipped with

two ¼” threaded inserts on the back of each air curtain (two

per module on air curtains 84” and over). Insert and

tighten the shoulder bolts (provided in bag taped to the

wall plate) into these threaded inserts. A minimum of two

shoulder bolts are required; on air curtains comprised of

modules, use the outer threaded inserts and a minimum of

one of the inner threaded inserts.

IMPORTANT: A minimum of 1” is required above the top of the

air curtain for the installation and removal of the cover housing.

A. When determining the mounting location for the

air curtain(s), make sure that nothing interferes with the

curtain of air developed when the discharge vanes

are directed from 0º to 20º toward the door opening.

Net Weight

MODEL

Ambient (lbs)

Net Weight

Electric (lbs)

ALC08-1030 33 39 56

ALC08-1036 38 44 64

ALC08-1042 43 49 72

ALC08-1048 48 54 80

ALC08-1060 57 63 95

ALC08-1072 64 70 107

ALC08-2084 86 98 134

ALC08-2096 96 108 150

ALC08-2120 114 126 178

TABLE 1 - Unit Weight

Net Weight

Steam/Hot

Water (lbs)

FIGURE 1 - Mounting Location

2

Page 3

B. Determine the exact mounting location of the air curtain.

3

/8" Spacers

(for each inch over 4")

Wall Mounting

Plate

Discharge Nozzle

AIR

AIR

NO Obstructions

in Air Stream

Clearance Height

NOTE: A minimum of 1” is required above

the wall mounting plate to provide clearance

for installation and removal of the air curtain.

C. Remove the wall mounting plate from the unit to install.

The wall mounting plate (included) is designed to t ush

with the top of the Architectural Low Prole 8 Air curtain.

Therefore the location of the wall mounting plate will

determine the nal location of the top of the air curtain.

D. For Standard Flush Wall Mounting, position the center of

the wall mounting plate over the center of the door open

ing with the larger opening of the key hole slots facing up.

The wall mounting plate thickness provides a natural ¾”

space which allows for mounting it up to 4” above the

opening. For optimum performance, the bottom of the

mounting plate should be no more than 2” or less than

1” above the top of the door opening.

See Figure 2.

High Wall Mounting must be used if the wall mounting

plate must be mounted higher than 4” above the

door opening: the mounting plate must be spaced out

from the wall ³/₈ ” for every additional inch (over 4”)

that the air curtain is above the door opening (clearance

height). See Figure 3. For optimum protection, do not

exceed the recommended maximum mounting height of

8’ above the nished oor. Any void between the mount

ing plate and the wall should be sealed along the full

length of the mounting plate.

E. Determine which of the four holes provided in each of

the steel brackets of the wall mounting plate are located

where suitable support is available for the air curtain.

A minimum of one inside hole and one outside hole from

FIGURE 3 - High Wall Mounting

that are comprised of modules, remove the wiring tray

cover that is located closest to the electrical rating

nameplate. Remove the required knockouts and

attach the necessary electrical hardware. Save the wiring

diagram found inside of the wiring tray. See Figure 7.

I. There are two sets of keyhole slots on the wall mounting

plate. In low overhead installations, the air curtain may be

staged in the lower keyholes to provide clearance for

electrical wiring and then moved to the higher key holes

after completion. Raise the air curtain with the discharge

opening facing down toward the oor. While

holding the air curtain level, slide the heads of the

shoulder bolts into the larger hole of the keyhole

slots of the mounting plate. Lower the air curtain

into place, keeping both ends level, allowing it to rest ush

with the mounting plate. See Figure 4.

J. After attaching the air curtain to the mounting plate,

ensure that the air curtain is seated and ush with the

mounting plate on all four sides.

K. Proceed to Section V - Electrical Connections.

FIGURE 2 - Standard Flush Wall Mounting

each bracket must be used for proper support.

Drill out the aluminum backing of the holes chosen

with a ¼” drill bit. If the provided holes on the

mounting plate are not located where suitable support

is available, drill new holes in the space provided on

the steel mounting brackets.

F. Mark the wall in the centers of the ¼” holes drilled on the

mounting plate.

G. Attach the mounting plate to the wall (hardware by others).

H. The top of the air curtain is provided with two knockouts

on each side allowing for a left or right hand power

connection. Remove the wiring tray cover; on air curtains

IV. SUSPENDED MOUNTING

(Ceiling Suspension)

A. When the air curtain is top mounted, the wall mounting

plate is designed to store on the back of the air curtain for

future use. See Figure 5.

B. Four (4) factory installed ¼” threaded inserts are located

on the top of the air curtain for top suspension mounting;

on air curtains comprised of modules use the

outer threaded inserts.

To eliminate the slight deection of longer air curtains, the

inner threaded inserts may also be used. See Figure 6.

C. Determine the exact mounting location of the air curtain.

D. The top of the air curtain is provided with two knock outs on each side allowing for a left or right hand

power connection. Remove the wiring tray cover;

on air curtains that are comprised of modules, remove

the wiring tray cover that is located closest to the

electrical rating nameplate. Remove the required

knockouts and attach the necessary electrical hardware.

Save the wiring diagram found inside of the wiring tray.

See Figure 7.

E. Attach ¼” threaded rods or other suitable hardware to the

top mounted threaded inserts.

3

Page 4

FIGURE 4 - Installing Air Door on Wall Mounting Plate

F. Proceed to Section V - Electrical Connections.

V. ELECTRICAL CONNECTIONS

All electrical wiring and connections MUST be performed by

qualied personnel in accordance with the National Electrical Code ANSI/NFPA No. 70 (latest edition) or, in Canada, the

Canadian Electrical Code, Part 1-C.S.A. Standard C22.1 and local

codes and regulations.

FIGURE 5 - Wall Mounting Plate Storage

A. Check the rating nameplate on the top of the air curtain for

supply voltage and current requirements. See Figure 7.

A separate line voltage supply with a suitable branch circuit

protection device should be run directly from the main

electrical panel to the air curtain. A disconnect switch for

each branch circuit is a required part of this installation.

B. All eld wiring must be copper with a minimum insulation

of 60° C within approved conduit. If any of the wire

supplied with the air curtain must be replaced, it must be

replaced with copper wiring with a minimum insulation of

90° C.

C. Remove the wiring tray cover; on air curtains that are

comprised of modules, remove the wiring tray cover that is

located closest to the electrical rating nameplate (if it has

not already been done).

D. Electric, steam and hot water heated air curtains are factory

equipped with a air curtain mounted solid state

temperature sensor cable (for the Intelliswitch thermostat)

located in the wiring tray. Depending where the tempera

ture is to be measured, the sensor may be left in the wiring

FIGURE 6 - Suspended Mounting

tray or it may be located outside of the air curtain. If the air

curtain is unheated, or the sensor will be left in the wiring

tray, skip to step E, otherwise continue.

1. Remove the ½” bushing taped to the back of the

wiring tray cover and set aside.

2. Determine mounting location of the temperature

sensor (do not mount at this time).

3. Choose end of the wiring tray that the sensor will exit

the air curtain based on the mounting location from

Step 2.

4. Locate the /” hole on the wiring tray next to

the electrical knockout on the side determined in

Step 3.

5. Drill out the /” hole to ½”.

CAUTION: DO NOT DAMAGE EXISTING WIRES IN

THE WIRING TRAY WHEN DRILLING.

6. Maneuver the tip of the temperature sensor from

the inside of the wiring tray out through ½” hole.

7. Thread the tip through ½” bushing from Step 1 and

snap the bushing into the wiring tray.

8. Mount the temperature sensor. Do not put any clamps

on the rubber coated tip.

E. The top of the air curtain has two knockouts on each side

of the air curtain, allowing for a left hand or right hand

power connection. Remove the required knockout if it has

not already been done and connect the power supply to

the air curtain. Connect all supply and control circuit wires

according to the wiring diagram provided.

NOTE: For Electric heated air curtains provided with the

optional remote thermostat, mount and wire the

thermostat according to instructions and wiring

diagram.

F. Master/Slave connection, if two or more units are to be

linked together for master/Slave operation continue, otherwise skip to step G.

4

Page 5

Electrical Knockouts

Wiring Tray Cover

Electrical Rating

Nameplate

Wiring Diagram and

Temperature Sensor

Inside

FIGURE 7 - Electrical Connections

NOTE: One Intelliswitch serial cable assembly (part #

505SC***INT485-A) is required for every unit that is to

be used as a master/slave. “***” denotes length of cable

in feet- “008” = 8 feet long.

For Master/Slave operation, a serial cable connection must

be made between the INTELLISWITCH GEN2 control boards

of each unit to be linked.

1. Disconnect power to all the units.

2. Access the wiring tray on top of each unit by removing

the screws that hold the cover in place.

3. Find the (RS485) phone jack couplers in the wiring

trays. There will be two short cables in the wiring

tray of each air curtain, each with a double ended

female phone jack coupler attached to the cable.

4. The serial cable ordered for each unit will be coiled up

in the wiring tray of the unit and connected to one of

the couplers.

Note: There may be one less serial cable than the

number of units ordered. e.g. Two units together will

need only one cable; three units together will need two

cables, etc. Any extra cables can be kept as spares.

5. Use one of the extra electrical knockouts to route serial

cable from one unit to the next. Be sure to protect the

edge of the knockout properly.

6. Plug (RS485) male phone jack on the end of the serial

cable into the empty coupler on the next unit.

7. Continue process for all units that are to be connected

serially.

8. Serial cable connections are capable of two way com

munication. It does not matter which coupler the

cables are connected to.

9. The rst and last air curtains in the group will each

have an empty coupler after all connections are made.

So if there are only two air curtains connected, each

will have an empty cable coupler.

Note: If a longer cable is required than was supplied,

it can be ordered from the factory or made by using

standard at telephone cable, phone jack connectors

and the proper crimping tool.

G. Remote mounted Display Faceplate - if operation of the

Intelliswitch is desired through a remote mounted display

face plate continue, otherwise skip to step H.

NOTE: Maximum mounting distance between the Dis-

play Faceplate and the unit is 20’.

The unit MUST be factory ordered with the remote

mounted faceplate option.

1. When the remote faceplate option is ordered

from the factory the air curtain comes equipped with

the blank faceplate and 12’ ribbon attached. The

Diplay Faceplate is shipped loose ready for eld

installation.

2. Locate the male end of the 14-conductor ribbon cable

in the wiring tray and run to the remote display loca

tion. The cable is minimum CL2 rated and should not

need to be in conduit.

3. Connect the ribbon cable to the 14-pin socket with red

stripe positioned on the top left when facing the front

of the display board.

4. Mount remote faceplate to the wall.

H. Reinstall the wiring tray cover.

I. For Electric, Steam and Hot Water air curtains proceed to

Section VI - Field Connections otherwise proceed to

Section VII - Operation and Controls.

VI. FIELD CONNECTIONS

A. ELECTRICALLY HEATED MODELS

The heater circuit may be controlled by a remote

thermostat or manually through the Intelliswitch located

on the discharge side of the air curtain. Overheating

protection is provided by auto reset thermal

cutouts built into the heater coil assembly

(see the wiring diagram).

B. STEAM OR HOT WATER HEATED MODELS

Piping should be done in accordance with local

codes, regulations and standard practices.

Connect the building system supply and return to

the ¾” MPT nipples on the heating coil. See Figure 8.

FIGURE 8 - Steam/Hot Water Connections

5

Page 6

VII. OPERATING INSTRUCTIONS

A. GENERAL OPERATION

Air curtain operation may be divided into four areas:

control package, fan activation, fan speed selection,

and heat activation. The air curtain must be properly

installed before it is used.

1. Control packages control the unit’s sequence of operation.

Unit modes/control packages are built into the unit and may

not be changed in the eld.. Refer to your wiring diagram

for specics about activation connections and sequence of

operation.

a. Basic Control Package – The unit is activated by a door

switch. The door switch may be line voltage or low

voltage (24V).

b. Deluxe Control Package – The unit is activated by a door

switch, but has a factory installed time delay allowing

the unit to keep running for a period of time after the

door closes.

c. Comfort Plus Control Package – Available only on heated

units, the unit is activated by the door switch OR by the

thermostat to provide supplemental heating.

2. Unheated units will have the fans activated by a door switch

or sensor. The unit speed can be selected from the

Intelliswitch display.

FIGURE 9 - Airow Adjustment

3. Heated units will have fans activated by a door switch or

sensor, but may also be activated by the thermostat in

Comfort Plus Mode. The unit speed can be selected from the

Intelliswitch display.

4. Heat activation is controlled by either a unit or remote

mounted thermostat, and a unit or remote mounted switch.

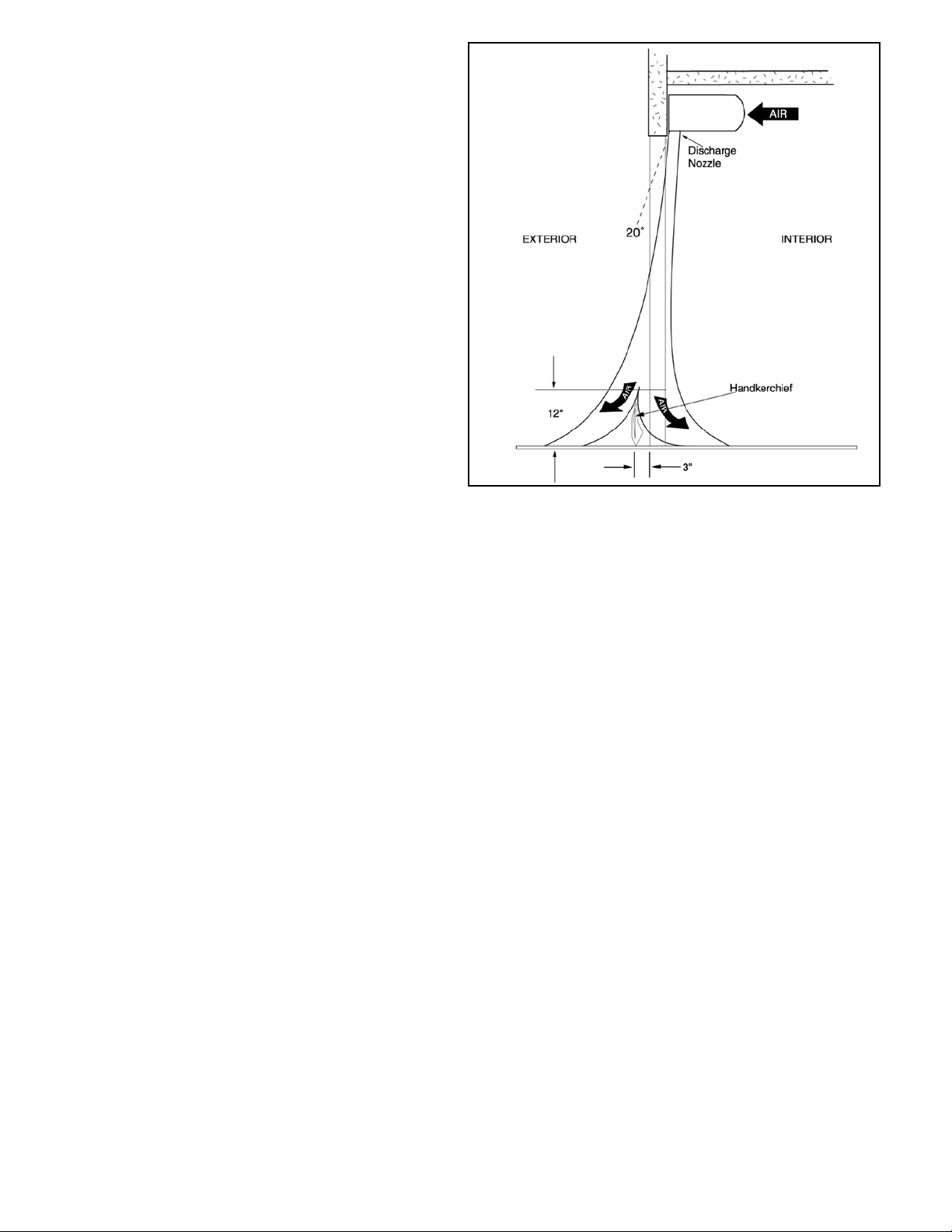

B. AIR STREAM ADJUSTMENT

1. With the air curtain operating and the door in its full open

position, check to see that nothing is obstructing the airow

at the discharge nozzle vanes.

2. Find the air stream split location. Hold a handkerchief by

its corners, approximately 12” above the oor. Gently move

the handkerchief back and forth in the doorway. Make sure

the air is being directed to both the inside and the outside.

See Figure 9. The split location is indicated where the

handkerchief is vertical with minimal or no uttering.

3. The split location should be approximately 3” outside the

doorway. If necessary adjust the discharge nozzle vanes by

de-energizing the unit, loosening the nozzle vane locking

screws and adjusting vanes.

6

Page 7

VIII. MAINTENANCE AND CLEANING

CAUTION: ELECTRIC SHOCK HAZARD Disconnect power

whenever servicing unit. More than one disconnect may

be required to de-energize unit.

Keep your air door operating at peak eciency by cleaning

the blower wheels, motor(s) and intake grille. Buildup of dust

on the blower wheels can cause vibration, noise and excessive

wear on the motor bearings. The frequency of cleaning will

depend on the environment where the unit is operating.

Dirty, dusty or greasy environments could require a

cleaning schedule of once every two months. If the envi-

ronment is not that dirty, the unit(s) should be scheduled

for cleaning a minimum of once every (6) months.

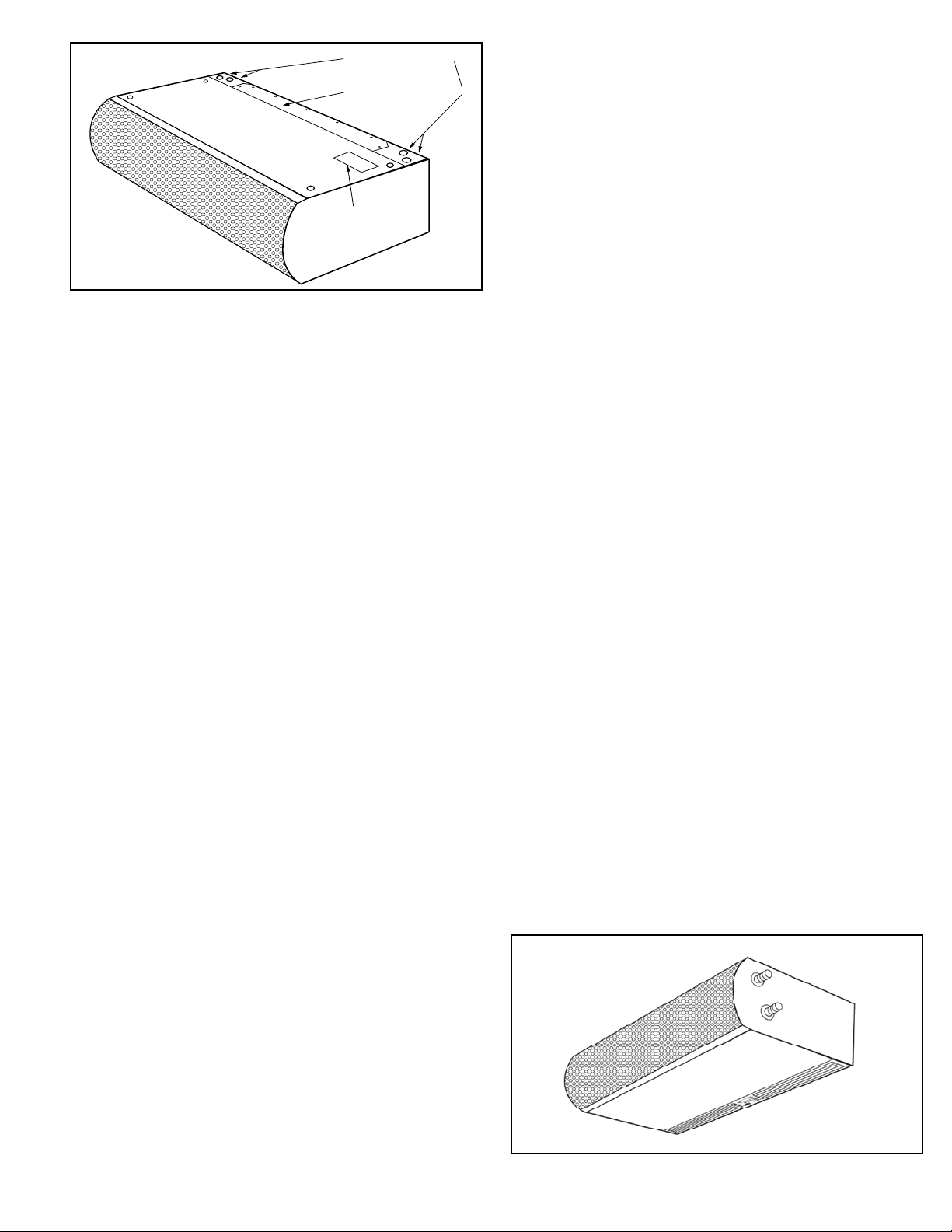

To access the interior of the unit:

A. Disconnect the power to the unit; remove the intake grille by

removing the locking screws on each end of the unit. Lift the

intake grille up and then towards you. See Figure 10.

B. Remove the bottom access panel by removing the phillips

head screws on the bottom of the unit.

C. Vacuum and scrape (if necessary) to remove the buildup of

dirt and debris. The motor(s) are permanently lubricated and

require no additional lubrication. Reinstall the cover and intake

grille.

D. Switch the power on after cleaning, reinstalling the cover and

intake grille.

CAUTION: STAND CLEAR OF THE UNIT OR WEAR SAFETY

GOGGLES AS LOOSE DEBRIS MAY BE PRESENT AND MAY

EXIT THE NOZZLE.

IX. SERVICE

CAUTION: ELECTRIC SHOCK HAZARD Disconnect power

whenever servicing unit. More than one disconnect may

be required to de-energize unit.

Any service performed on the Architectural Low Prole 8 air door

MUST be done by qualied personnel.

Berner air doors require very little servicing. All parts are eas-

ily accessible for periodic inspection and maintenance. Units

should be cleaned at least twice a year. Your particular application (the amount of dirt and dust in the air) and location of

the unit(s) will determine how often your unit(s) will need to

be cleaned and serviced. All motors have permanently lubricated, sealed, sleeve bearings and require no maintenance.

See Figure 11

FIGURE 11 - Unit Components

FIGURE 10- Intake Grill Removal

7

Page 8

A. INTELLISWITCH DISPLAY BOARD REMOVAL

OR REPLACEMENT

CAUTION: Do not expose the bare board to static electricity,

water, extreme heat or extreme moisture.

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit.

3. Remove the two Phillips head screws from the

Intelliswitch display faceplate.

4. Remove the faceplate from the unit by gently pulling it

away from the unit and unplugging the ribbon

cable from the back.

5. Flip the faceplate over and place it on a clean soft

surface.

6. Remove the two nuts, aluminum shield and at

washers holding the display board to the faceplate.

7. Lift display board o of the studs while leaving the

stand o spacers in place.

8. Install new display board onto faceplate studs, reinstall

washers with aluminum shield and attach with existing

nuts.

9. Reinstall display faceplate by attaching the ribbon

cable (with red stripe positioned on the top left) to the

back of display board. Place the face plate against the

mounting bracket, insert and tighten the two Phillips

head screws.

B. INTELLISWITCH CONTROL BOARD REMOVAL OR REPLACE-

MENT

CAUTION: Do not expose the bare board to static electric-

ity, water, extreme heat or extreme moisture.

NOTE: The Intelliswitch Control Board may be removed

without removing the bottom access cover or transverse.

However removal of the bottom access cover and transverse will simplify the process.

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit.

3. Remove the two Phillips head screws from the

Intelliswitch display faceplate.

4. Remove the faceplate from the unit by gently pulling it

away from the unit and unplugging the ribbon

cable from the back.

5. Mark and remove all wires connected to the control

board.

6. Remove the two plastic push-rivets that attach the

control board to the unit frame by gently prying

a screw driver under the metal bracket attached to the

control board.

7. Carefully maneuver the control board partially out of

the unit by sliding straight down. Avoid contact

between board components and the motor mount.

8. Remove the Phillips head screw that attaches the

control board to the mounting bracket and ground

wire and completely remove the control board from

the unit.

9. Attach mounting bracket to the new control board

with existing screw only on the side that does not

contain the ground wire.

10. Partially insert the board into the unit and attach the

second Phillips head screw and ground wire.

NOTE: GROUND RING TERMINAL MUST BE SITUATED OR

BEND SUCH THAT IT DOES NOT TOUCH ANY TRACES ON

THE CONTROL BOARD

11. Continue installing the new control board into the unit

by carefully sliding the two tabs at the top of the

control board into the two corresponding slots in the

unit frame. Attach with new plastic push-rivets

provided. Note: when the tabs of the board hit the unit

frame tip the board up and angle the tabs into the slots.

12. Reconnect all wires to the control board.

13. Reinstall display faceplate by attaching the ribbon

cable (with red stripe positioned on the top left) to

the back of display board. Place the face plate against

the mounting bracket, insert and tighten the two

Phillips head screws.

C. INTELLISWITCH SPEED SENSOR REPLACEMENT

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit

3. Remove the intake grille by removing the locking

screws on each end of the unit. Lift the intake grille up

and then away from the unit.

4. Remove the bottom access panel by removing the

Phillips head screws on the bottom of the unit.

5. Remove the two Phillips head screws from the

Intelliswitch display faceplate.

6. Remove the faceplate from the unit by gently pulling it

away from the unit and unplugging the ribbon

cable from the back.

7. Disconnect the speed sensor from the control board by

locating the pin connection marked J5 and

labeled PROXIMITY. Grasp the socket and carefully pull

away from the control board.

8. Remove the 13 mm hex nut and washer closest to the

fan from the sensor.

9. Remove the sensor.

10. Connect the new sensor to the control board; secure all

loose wires from rotating parts.

11. Install new sensor into mounting bracket. Use the

13 mm nuts to position the tip of the sensor a

maximum of 1/16” (2 mm) away from the rotating

trigger located on the motor shaft. When the unit is

energized, the LED on the back of the sensor will illumi

nate when the trigger passes if the correct distance has

been set.

CAUTION: Do not mount the speed sensor too close to

the trigger, the sensor will be ruined if it is struck by the

trigger.

12. Reinstall display faceplate by attaching the ribbon

cable (with red stripe positioned on the top left) to the

back of display board. Place the face plate against the

mounting bracket, insert and tighten the two Phillips

head screws.

13. Reinstall remaining components in reverse order of

removal.

D. INTELLISWITCH SPEED SENSOR ADJUSTMENT

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit

3. Remove the intake grille by removing the

locking screws on each end of the unit. Lift the intake

8

Page 9

grille up and then away from the unit.

4. Remove the bottom access panel by removing the

Phillips head screws on the bottom of the unit.

5. The speed sensor is held in with two 13 mm hex nuts

and a star washer.

6. Use the 13 mm nuts to position the tip of the sensor a

maximum of 1/16” (2 mm) away from the rotating

trigger located on the motor shaft. When the unit is

energized, the LED on the back of the sensor will

illuminate when the trigger passes if the correct

distance has been set.

CAUTION: Do not mount the speed sensor too close to

the trigger, the sensor will be ruined if it is struck by the

trigger.

7. Reinstall remaining components in reverse order of

removal.

E. INTELLISWITCH TEMPERATURE SENSOR REPLACEMENT

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit.

3. Remove the wiring tray cover.

4. Cut necessary cable ties that may be holding the

brown temperature sensor lead.

5. Disconnect the temperature sensor from the socket.

6. Install new temperature sensor and all necessary

cable ties.

7. Reinstall remaining components in reverse order.

14. Install the trigger bar on the replacement motor so

that it is not closer than 0.030” to the motor bearing

cap (including shaft movement).

15. Ensure the trigger does not contact the speed sensor.

Maximum gap distance between trigger and sensor is

1/16” (2mm).

16. Reinstall in reverse order of removal.

G. REPLACEMENT OF ELECTRIC HEATER ELEMENT

1. Disconnect power to the unit.

2. Remove the intake grille by removing the locking

screws on each end of the unit.

3. Lift the intake grille up and away from the unit.

4. Remove the bottom access panel by removing the

Phillips head screws on the bottom of the unit.

5. Remove and mark all wires from damaged element.

6. To remove damaged element from unit, drill out rivets

and remove screws.

7. Install new element and connect all wires.

8. Reinstall cover and intake grille.

F. FAN AND MOTOR REMOVAL

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit.

3. Remove the intake grille by removing the

locking screws on each end of the unit. Lift the intake

grille up and then away from the unit.

4. Remove the bottom access panel by removing the

Phillips head screws on the bottom of the unit.

5. Free the fan bearing retainer bracket(s) by loosening

the Phillips head screw lock located on the inside unit

end plate(s). Rotate them out of the way to allow the

fans to be removed.

6. Remove the transverse by removing the four (4) 5/16”

hex washer head bolts.

7. Rotate the speed sensor bracket away from the motor

by removing the Phillips screw farthest from the

motor and loosening the second Phillips screw. Do not

remove the speed sensor from the bracket.

8. Unplug motor harness from motor and remove

necessary wiring.

9. Using a 1/8” Allen wrench, loosen each set screw

attaching fan(s) to motor.

10. While holding the motor in place, loosen and remove

the motor clips.

11. Slide the fans toward the motor so that the ball bear

ings on the outer fan shaft are exposed.

12. Slowly roll the motor out of the motor mount cradle

forward and down. The hubs of the fans are exible

enough to allow the motor to move before the

fans’ outer ball bearings pull out of the unit.

13. If the unit equipped with an Intelliswitch, remove the

trigger bar from the motor shaft with a 5/64” Allen

wrench.

9

Page 10

QUICK START INSTRUCTIONS

For your Berner Air Curtain with Intelliswitch™

www.intelli-how2.com

Mode/Fan Speed:

Mode: Select your mode of operation (see steps on page 2)

Fan Speed: Sets the speed of the fan

Delay Time: Amount of time the air curtain is to run after the door closes

Temp Set: Amount of heat and time the air curtain is to run after the door closes

Start Time: Programmable time of day air curtain becomes active

Stop Time: Programmable time of day air curtain stops running

T-Stat Mode: Set only heat or heat & fan

Set Time/Day: Programmable clock

Locked: Unit will run as programmed but settings cannot be changed

IMPORTANT NOTE!

If you air curtain unit is in “Locked” mode when you receive it:

Press and hold the left and right arrows simultaneously for 5 seconds to unlock.

www.berner.com Berner International Corporation 800.245.4455

10

Page 11

STEP ONE

To Start: Press the Down Arrow button once.

NOTE: To change from “Mode” to “Fan Speed” press the down arrow twice.

STEP TWO

Use the Left and Right Arrows to scroll through the 8 available modes of operations

5 Standard Mode of Operation Options:

Door opens: The air curtain is o

OFF

ON

AUTO

Door shuts: The air curtain is o

Door opens: The air curtain activates

Door shuts: The air curtain continues to run

Door opens: The air curtain activates

Door shuts: The air curtain turns o

Door opens: The air curtain activates

delu

PLUS

For heated units only

Door shuts: The air curtain continues to run for a minimum of 60 seconds

Door opens: The air curtain and heater activate and run at set speed

Door shuts: The air curtain continues to run for a minimum of 60 seconds. If thermostat

is not satised, air curtain and heater continue to run until thermostat is satised. If

thermostat drops below set temperature, the heater and air curtain will run until

thermostat is satised.

3 Customizable Mode of Operation Options:

(See Installation Instructions for programming directions)

PRO1

For unheated units only

PRO2

For heated units only For heated units only

PRO3

STEP THREE

www.berner.com Berner International Corporation 800.245.4455

Once the Mode of Operation is selected, press the“OK” button

11

Page 12

INTELLISWITCH™ FAQ’s (Frequently Asked Questions)

www.intelli-how2.com

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

Before servicing or cleaning unit, switch power o at service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag, to the service panel.

Even though every Architectural Low Prole 8 unit is individually tested at the factory before shipment,

on occasion improper functionality may be experienced. Here is a list of common questions:

Q. Why can’t I change my settings?

A. The Intelliswitch™ may be locked. If the Lock light is illuminated, the control is locked. To unlock, press and hold the left &

right arrows simultaneously for 5 seconds. The Lock mode can

also be protected with a PASScode. If the PASScode option is

on, an attempt to unlock the control will display PASS and then

a 0000 prompt. A four-digit code (available in the installation

instruction book Appendix) must then be entered to unlock

the control. Use the up and down arrows to select a number

and the left and right arrows to select the digit to edit. Press OK

when done. Note: If the AutoLock setting is on, the control will

re-lock if there is no activity after 5 minutes.

Q. Why won’t my heat work, even though fans are running?

A. The thermostat(s) or speed sensor may need adjusted or

replaced.

1.) Make sure that the thermostat probe and/or remote thermostat are in the “On” position and set above ambient (room)

temperature.

2.) Check internal and external thermostat status in the Diagnostics Menu for a faulty thermostat. To do this, hold the right

arrow for ve seconds until DIAG appears, then arrow down to

the ts setting, if it displays “1” then the thermostat(s) is working

(there is a call for heat).

3.) If no external thermostat is used, check to see if the internal

probe is attached to the control board. Disconnect power to

the unit, remove the display board and check that the beige

sheathed cable is attached at both ends. If the thermostat(s)

and settings are correct and you are still not getting heat, then

check to see the fan speed. to do this, press the down arrow to

reach the Mode/Fan speed setting. Use the right and left arrow

to change the fan speed.

4.) Check to see if you can adjust the fan speed. If the speed

sensor is bad there will be no speed control and the Intelliswitch will not let the heat come on. If it is too dicult to determine a change in speed, the speed sensor can be checked by

entering the DIAG menu and checking the rst error code. If ER

10 displays, the speed sensor is recognized by the Intelliswitch.

If the code ER 11 is displayed, the Intelliswitch does not recognize the sensor, and it may be faulty or need adjusted closer to

the trigger bar. Turn o the power to the unit and remove the

screen to check the distance between the sensor and the trigger located on the left side of the motor (use the bottom access

cover for steam/hot water heated units). The sensor should be

less than 1/16” from the trigger face. Check distance at both

ends of trigger. Adjust if necessary.

5.) If there is still no heat or speed control, you may need a new

speed sensor: consult factory.

Q. Why won’t the Intelliswitch light up?

A. There may not be power to the control.

1.) Check to see if the main power is turned on to the unit. Your

air curtain may have multiple disconnects, be sure all are turned

on.

2.) Verify that there is power to the board. NOTE: ONLY QUAIL-

IFED PERSONS SHALL CHECK POWER IN THE UNIT WITH THE

POWER ON. The power terminals are located directly behind

the display. Remove two Phillips screws from the Intelliswitch

display to expose the power terminals and check the line voltage at spade terminals L2 and 120, 208 or 240 (depending on

the voltage supplied to the unit).

3.) Check the ribbon cable connections to the display board for

a loose connector or improperly connected cable (see Installation Instructions for correct cable connection).

4.) If display still doesn’t light, unplug the speed sensor and

thermostat probe (if a heated unit) from the control board. If

the display lights, plug one component back in at a time to see

which one may be shorted. The faulty component will make

the display go blank again.

5.) If there is line voltage power at the board terminals, the

ribbon cable is correctly connected, the speed sensor and the

thermostat are working, and it is still not working, you may

need a new circuit board: consult factory.

Q. Why won’t my fans shut o?

A. The Intelliswitch may be in the wrong mode or mis-wired.

1.) Check to see if the control is in the “ON” mode, if it is, then

change the Mode to another setting.

2.) The T-Stat Mode may be set to the “both” setting and the

thermostat is calling for both Fan and Heat, change the T-Stat

Mode to “HEAT”.

3.) If there is a door switch and the unit is in a mode that is activated by it, there could be a short, mis-wiring or mixup in components. Close the door and check the door switch status in the

Diagnostics menu. Hold the right arrow for ve seconds until

DIAG appears, then arrow down to the ds setting, if it displays

“1” then the door switch signal is closed (there is a call for fan). If

the door is closed, the signal should be “0” or open.

4.) There could be a short in the eld connections to the door

switch or the door switch leads could be mis-wired. To test,

disconnect the door switch connection at the unit. Opening the

wiring tray on top of the unit and be cautious of high voltage

connections. Disconnect the blue wires labeled 9 & 10 from the

eld wiring to the door switch or make sure they are not tied

together. There is no danger of getting shocked because the

signal is 5 volt dc. Be sure not to touch the blue wires to anything metal (or grounded). The unit should shut o when it is in

12

Page 13

INTELLISWITCH™ FAQ’s Continued (Frequently Asked Questions)

www.intelli-how2.com

any mode that is activated by the door switch.

5.) If the air curtain is heated, make sure that the thermostat

isn’t wired to the door switch leads. Door switch leads are blue

and labeled 9 & 10.

Q. How can I check the door switch to be sure it’s working?

A. The Intelliswitch may be in the wrong mode, be mis-wired or

have a faulty door switch.

1.) Test the wiring and controller function at the same time rst.

Locate the door switch and open its wiring compartment by removing the two screws holding on the back cover. There should

be two wires connected to screws inside the switch. There is no

danger of getting shocked because the signal is 5 volt dc. Be

sure not to touch the wires to anything metal (or grounded).

Either disconnect both wires from the screws (noting which

screws the wires are under) and touch them together (with air

curtain in “Auto” mode) or make a short jumper wire and touch

the jumper to both screws at the same time to see if air curtain

comes on. If it does, the controller and wiring work.

2.) If the wiring and unit pass the function test, the problem

could be either misalignment or a faulty door switch. On a

magnetic reed switch check for magnet alignment, for plunger/

roller type switch, check contact engagement with door.

3.) If you have access to an electrical test meter, the door switch

contacts can be tested for continuity when the door switch

wires are disconnected from the unit.

Q. Why won’t my heat shut o?

A. The Intelliswitch may need adjusted, have been mis-wired or

have a faulty thermostat.

1.) Heat is activated by one of two thermostat connections.

To test the internal thermostat set the external thermostat to

OFF. The settings of the unit mounted thermostat probe are

accessed through the display. Press the down arrow until the

Temp Set indicator lights up; check if the temperature setting

and unit of measure are correct. Test to see if it shuts o by setting the thermostat temperature to OFF or lower than the room

temperature.

2.) If an external thermostat is connected to the unit, there

could be a short in the eld connections or the thermostat

leads may be mis-wired. To test the external thermostat set the

internal thermostat to OFF. Disconnect the external thermostat

connections at the unit. Open the wiring tray on top of the unit

and be cautious of high voltage connections. Disconnect the

orange wires labeled 6 & 7 from the eld wiring to the thermostat or make sure they are not tied together. There is no danger

of getting shocked because the signal is 5 volt dc. Be sure not

to touch the orange wires to anything metal (or grounded). The

heat should shut o when the wires are separated.

For more complex troubleshooting of either thermal cutouts or

heater contactors, please consult a qualied electrician or the

factory.

Q. Why didn’t the Intelliswitch save the changes I made to a

program?

A. If a program is active (a dot is illuminated by one of the

clock digits), changes can be made to any settings on the User

Menu. These changes however will only remain in eect until

the program changes to the next time zone. To make changes

permanent, settings must be changed in the program from the

Program Menu. Access the Program Menu by holding down the

left arrow for 5 seconds until “PRO” is displayed. Arrow down

to select programming and arrow left to select the program to

edit. Use the down arrow to step through the options and make

changes as desired. Continue to press the down arrow until Stor

is displayed. Press OK or down to keep or store the changes.

Q. How do I undo a change that I made to a program in the

Program Menu?

A. Changes to programs cannot be undone. The programs can

however be reset to the factory default settings. This must be

done on the Factory Menu. Access to the Factory Menu is attained through the Diagnostics Menu. Press and hold the right

arrow for 5 seconds until “DIAG” is displayed. From the “DIAG”

display press and hold the up and down simultaneously for 10

seconds until “FACT” is displayed. Use the down arrow to select

“DEFn” on the display then use the right arrow to select “DEFP”.

Press “OK” to reset. The control display will go blank then blink

as conrmation.

Q. My air curtain won’t turn on?

A. Check the AM/PM setting on the Start and Stop times or the

clock (considering the AM indicator light whensetting values).

Note: set the start time and stop time to the exact time for the

unit to be active full time. Check to see if a program is active

that may have dierent start/stop times than those expected.

Q. My building has a Building Management System, can the

Intelliswitch work with a BMS?

A. The Intelliswitch can be controlled by a Building Manage-

ment System (BMS) but currently does not have the ability to

communicate with them. Dry contacts on the BMS may be used

to control the unit activation through the door switch connections (blue wires 9 & 10) and the heat activation thought the

remote thermostat connections (orange wires 6 & 7). Consult

factory.

13

Page 14

A. PROGRAMMING THE INTELLISWITCH™

To reduce the risk of injury and ensure proper operation all

Notes and instructions shall be read!

Note: The STOP button is available at all times and immediately stops the unit for an emergency situation. The

Intelliswitch® will display STBY for Stand By when selected.

To release the control from STBY press STOP again. When

the control is released from STOP it will be in the OFF Mode.

Press the left or right arrows to select new Mode or OK to

return to the clock.

STOP

2.2. Multi-level Options

Multi-level options require additional actions to access an options setting. The right or left arrow is required to enter into an

option.

If the multi-level option has one value to edit it may be

changed directly with the up and down arrows.

If the multi-level menu option has two values (such as a time

value) the rst option value ashes upon selection. Use the left

or right arrow to select which value to change and then use the

up and down arrows to change the option value. See the Menu

Options section for the option increment i.e. hours/minutes,

minutes/seconds.

To leave a multi-level option, use the left or right arrow to cycle

through the option value until it stops ashing. The up or down

arrow may now be used to navigate to the other options.

3. Menu Structure

The Intelliswitch™ has four menus:

• User Menu (Section 4)

• Program Menu (Section 5)

• Diagnostic Menu (Section 6)

• Factory Menu (Section 7)

Note: When changing options, if there is no activity for 15

seconds, the control will save changes and default back to

the User Menu display clock.

Note: The OK button always saves the current entered

value and returns you to the User Menu display clock.

Section 1: Quick Start Reference

Section 2: Arrow Navigation

Section 3: Menu Structure

Section 4: User Menu

Section 5: Program Menu

Section 6: Diagnostic Menu

Section 7: Factory Menu

Section 8: External Connections

1. Quick Start Reference

1.1. Press the Menu button (down Arrow).

1.2. Using the left and right arrows, select the operating

Mode: O, On, Auto, Deluxe, Comfort Plus or Program

Number 1, 2 or 3.

1.3. Press OK.

2. Arrow Navigation

The up and down arrows select the menu options.

The left and right arrows change values for single-

level menu options (Mode, Speed, Temp Degree, Temp Set,

T-stat Mode and Day) or are used to enter into multi-level

menu options (Delay Time, Temp Set, Start Time, Stop Time

and Set Time).

Arrow sequence and available settings are illustrated under

each option.

2.1. Single Level Options

Single level options can change values directly with the left and

right arrows. No additional actions are necessary to access these

option settings.

Appendix -14

The User Menu is the top level menu where values for each op-

tion is entered based on the Mode selected. Each option is identied by a green light when selected. The clock display is the

default home position for the User Menu when OK is selected or

there is no activity for 15 seconds.

Note: Access to all Secondary Menus must originate from

the User Menu. Secondary Menus are identied by the

menu title upon successful entry, e.g. PRO, DIAG and FACT.

The Program Menu is used to edit all program option param-

eters.

The Diagnostic Menu is used to diagnose and troubleshoot

errors with the Intelliswitch™.

The Factory Menu is only to be used when directed to reset or

change factory default settings.

4. User Menu

To enter into the User Menu press the down arrow (menu) or up

arrow. Use the down or up arrow to step through each option.

Each option is identied by a green light when selected.

Options available from the User Menu are:

• Mode

• Fan Speed

• Delay Time

• Thermostat degree type

• Thermostat Set Point

• Start Time

• Stop Time

• Thermostat Control Mode

• Time Set

• Day Set

• Lock/PASScode

4.1. Mode: single-level

NOFF-ON-AUTO-DELU-PLUS-PRO1-PRO2-PRO3O

Use left or right arrows to select the desired Mode of Operation.

Press “OK to accept selection.

• OFF – air door o.

• ON – air door will run when start/stop time is satised.

Page 15

• AUTO – air door will run when terminals 9 & 10 are

connected through a switch (i.e. doorswitch) and the

start/stop time is satised, ALL menu options available.

• DELU – air door will run when terminals 9 & 10 are

connected through a switch (i.e. doorswitch) and the

start/stop time is satised, MUST set time delay from

1-10 minutes, T-Stat Mode NOT available.

• PLUS - air door will run when terminals 9 & 10 are

connected through a switch (i.e. doorswitch) and

the start/stop time is satised, when door is closed and

temperature drops below the set point the air door

will run on low speed with heat (low speed set on the

Program Menu), air door will run at higher user level

set speed when the door opens.

• PRO1 – Runs Program #1; see Program Menu Section,

1st digit indicator light when active.

• PRO2 – Runs Program #2; see Program Menu Section,

2nd digit indicator light when active.

• PRO3 – Runs Program #3 see Program Menu Section,

3rd digit indicator light when active.

NOTE: When Program Modes are selected changes can only

be made to the Mode, Time Delay, Temperature, Time and

Day settings. Changes will only remain in aect until the

program changes between active time zones.

NOTE: AutoLock, Comfort + Low Speed and PASSCode are

global options and their settings are the same for any Mode

selected. They will not change when the Mode or Program

changes.

4.2. Fan Speed: single-level

SP N 1-2-3-4-5-6-7-8-9-10 O

Use left & right arrows to select fan speed from 1 to 10. (1=low,

10 = high)

4.3. Delay Time: multi-level – min/sec

N OFF – 00:01 thru 10:00 O

Select option with right arrow, use up & down arrows to set the

amount of time that the air door will delay shutting o after

terminals 9 & 10 or doorswitch are opened.

4.4. Temp Set (air doors): single level

N °F – °CO

Use left & right arrows to select the temperature degree type,

Fahrenheit or Celsius, for thermostat set point.

Note: This option is only available for heated units with a

built-in thermostat.

4.5. Temp Set : single level

N OFF – 34°F thru 90°F O

or

N OFF – 1°C thru 32°C O

Use left & right arrows to select the temperature set point when

the heat is to be activated.

Note: This option is only available for heated air doors with

built-in thermostat.

4.6. Start Time: multi-level – hours/min

Select this option with right arrow, use up & down arrows to set

the time that the unit is to turn on in the ON Mode or become

active for AUTO, DELU and PLUS Modes

Note: To turn o this feature the Start Time must be set

equal to Stop Time (including am/pm).

4.7. Stop Time: multi-level – hours/min

Select this option with right arrow, use up & down arrows to set

the time that the unit is to turn o in the ON Mode or become

Appendix - 15

active for AUTO, DELU and PLUS Mode.

Note: to turn o this feature the Start Time must be set

equal to Stop Time (including am/pm).

4.8. Thermostat Mode: single level

N HEAT-BOTH O

Select the control mode for the built-in and remote thermostats. The HEAT mode only cycles the heater on call for heat

from either internal or external thermostats when the fan is running. BOTH mode cycles both the fan and the heater on a call

for heat from either internal or external thermostats.

Note: This option is only available for electric heated air

doors with built-in thermostat or air doors with external

remote mount thermostat connected between terminals 6

& 7.

4.9. Set Time: multi-level – hours/min

Select option with right arrow, use up & down arrows to set the

clock. Note: time does not adjust for daylight savings time.

4.10. Set Day: single level

N DAY1-DAY2-DAY3-DAY4-DAY5-DAY6-DAY7 O

Use left & right arrows to select day of the week, where Sunday

= DAY1, Monday = DAY2, etc. Used as a reference by programs.

4.11. Lock/Unlock

The Intelliswitch™ can be locked to prevent unauthorized

tampering of the settings.

When locked, only the options on the User Level may be

viewed. Only the Mode can be changed between OFF and the

Mode that was active when it was locked, all other options may

NOT be changed.

To lock or unlock, press and hold the left and right arrows simultaneously for 5 seconds, the Locked light will illuminate.

If the PASScode option is ON, an attempt to unlock the control

will display PASS and then a 0000 prompt to enter a four digit

unlock code. Use the up & down arrows to change the numbers

and the left & right arrows to move between positions.

Note: When the AutoLock option is set to ON in the Program Menu, the Intelliswitch™ will automatically lock after

5 minutes without any activity. Default setting – OFF. See

Section 5.2

Note: When the PASScode option is set to ON in the Factory

Menu, the Intelliswitch™ will require a code be entered to

unlock the control. Default setting – OFF. See Section 7.4.

5. Program Menu

To enter into the Program Menu hold down the left arrow for 5

seconds. PRO will display when the Program Menu is available.

Use the Program Menu to set the following options:

• Program 1, 2 & 3 settings

• AutoLock setting

• Comfort Plus low speed setting

• Master/Slave Stand By setting

NPRO-AULC-PLUS-STBY O

Program Menu – single level

Use left & right arrows to select the option to change.

5.1. Program

The Intelliswitch™ can store up to three Dual-Tine Zone programs. Use the Program option to select and save User Menu

settings to be recalled at anytime.

A time zone is the period of operation dened by the use for

the unit to be active. Both zones may operate one after the

other or have gaps between them.

Page 16

Note: If a longer cable is required than was supplied,

The Program menu allows parameters for the following options

it can be ordered from the factory or made by using

to be set:

• Number of Zones: 1 or 2

standard at telephone cable, phone jack connectors

• Days of the week to operate per zone

and the proper crimping tool.

• Mode (O-On-Auto-Deluxe-Plus)

• Speed

G. Remote mounted Display Faceplate - if operation of the

• Time Delay

Intelliswitch is desired through a remote mounted display

• Thermostat Set Point

face plate continue, otherwise skip to step H.

• Start Time

NOTE: Maximum mounting distance between the Dis-

• Stop Time

play Faceplate and the unit is 20’.

• Thermostat Mode

The unit MUST be factory ordered with the remote

mounted faceplate option.

To enter into the Program menu press the down arrow (menu

1. When the remote faceplate option is ordered

button) at the PRO display. Use the left & right arrows to select

the program to be edited.

from the factory the air curtain comes equipped with

N PRO1-PRO2-PRO3 O

the blank faceplate and 12’ ribbon attached. The

Note: After setting the number of zones and active days all

Diplay Faceplate is shipped loose ready for eld

parameters are set the same as the User Menu. Use the Up

installation.

and Down arrows to accept changes and OK to return to

2. Locate the male end of the 14-conductor ribbon cable

User Menu.

in the wiring tray and run to the remote display loca

tion. The cable is minimum CL2 rated and should not

5.1.1. Zone: single level

need to be in conduit.

N Zn 01-Zn 02 O

3. Connect the ribbon cable to the 14-pin socket with red

stripe positioned on the top left when facing the front

Select the number of Zones for the program. If one zone is

of the display board.

selected a prompt will ask to save settings after the last option.

If two zones are selected, Zone1 parameters will be set rst and

4. Mount remote faceplate to the wall.

then parameters for Zone2 will be set. A prompt will ask to save

H. Reinstall the wiring tray cover.

settings after the last option of Zone2.

I. For Electric, Steam and Hot Water air curtains proceed to

Section VI - Field Connections otherwise proceed to

5.1.2. Day: multi-level

Section VII - Operation and Controls.

Nday-day1-day2-day3-day4-day5-day6-day7 O

VI. FIELD CONNECTIONS

Select the days of the week that the program is to operate for

A. ELECTRICALLY HEATED MODELS

each zone.

The heater circuit may be controlled by a remote

When day is displayed, press the right arrow to enter into the

thermostat or manually through the Intelliswitch located

day parameters.

on the discharge side of the air curtain. Overheating

Once in the day parameters each day is identied by the day

number, use the right or left arrows to select yes to active a day

protection is provided by auto reset thermal

or no to deactivate a day.

cutouts built into the heater coil assembly

N dy 1n-dy 1yO

(see the wiring diagram).

i

B. STEAM OR HOT WATER HEATED MODELS

N dy 2n-dy 2y O

Piping should be done in accordance with local

i

codes, regulations and standard practices.

N dy 3n-dy 3y O

Connect the building system supply and return to

the ¾” MPT nipples on the heating coil. See Figure 8.

Use the up and down arrows to move to the next day or skip

days until day is displayed.

From this point enter right to re-enter day settings or down to

continue.

Note: The top seven LED’s will light from the top down representing days 1 thru 7 that have been activated.

5.1.3. Mode: single level

Select operating mode for Zone. Only O, On, Auto or Plus are

available.

5.1.4. Fan Speed: single level

Select the fan speed for the time zone being programmed.

5.1.5. Time Delay: multi-level

Set the time delay for the time zone being programmed.

5.1.6. Temperature Set: single level

Appendix -16

Set the temperature set point for internal thermostat for Zone

being programmed. Degree type is based on degrees selected

on the User Menu.

5.1.7. Start Time: multi-level

Set start time for zone program to activate including am/pm.

Note: Zone 1 has priority over Zone 2 and if conicting

times are entered Zone 1 will always activate and take precedence over Zone 2.

5.1.8. Stop Time: multi-level

Set stop time for zone program to activate including am/pm.

Note: Zone 1 has priority over Zone 2 and if conicting

times are entered Zone 1 will always activate and take precedence over Zone 2.

5.1.9. Thermostat Mode: single level

Set thermostat mode for Zone.

5.1.10. Store: single level

N str y-str n O

Use the right or left arrows to select yes to save program or no

to abandon changes.

A single zone program will prompt to save all options after the

rst set of parameters; a dual zone program will prompt to save

after the second set of parameters.

Note: upon saving, the LED on the digit light corresponding

to the program number will blink.

5.2. AutoLock: multi-level

N ON-YES O

To enter into the AutoLock menu press the down arrow (menu

button) at the AULC display. Use the left or right arrows to select ON to have control automatically lock if there is no activity

for 5 minutes or OFF to deactivate.

5.3. Comfort Plus (fan speed): multi-level

SP N1-2-3-4-5-6-7-8-9-10 O see Note*

To enter into the Comfort Plus low speed setting, press the

down arrow (menu button) at the PLUS display. Use the left or

right arrows to select the fan speed for the PLUS mode, when

the door is closed and the thermostat set point is reached.

*Note: The speed range is limited to be equal to of less than

that of the User Menu speed setting.

5.4. Master/Slave Stand By: multi-level

N ind-ALL n O

To enter into the Master/Slave stand by setting press the down

arrow at the STBY display. Use the left or right arrows to select

the STOP button behavior when units are connected together

in a Master/Slave conguration. Select “ind” or independent to

stop only the unit where STOP is pressed. Select “ALL” to stop all

connected units.

6. Diagnostic Menu

To enter into the Diagnostic Menu hold down the right arrow

for 5 seconds. DIAG will display when the Diagnostic Menu is

available.

The Diagnostic Menu is used to diagnose and troubleshoot Intelliswitch™ errors. Only “live” parameter settings are displayed,

there are no options to change.

Page 17

The Diagnostic Menu displays the following parameters:

• Software version release

• Speed Range Setting

• Internal Thermostat reading – Celsius

• Internal Thermostat reading – Fahrenheit

• Motor rpm reading

• Supply Voltage Frequency

• Door Switch status

• External Thermostat status

• Heater Relay status

• Error Code 1 – Speed Sensor

• Error Code 2 – Line Frequency

• Error Code 3 – Power Issue

• Error Code 4 – Motor O Fault

6.1. Software Release Version – Format: rX.XX

6.2. Fan Speed Range – rn XX (see Section 7.1)

6.3. Thermostat Probe – Pr XX (see Section 7.2)

6.4. Internal Thermostat – ºC (np = no probe)

6.5. Internal Thermostat – ºF (np = no probe)

6.6. Motor RPM – measured speed in rpm

6.7. Supply Voltage – measured frequency in Hz

6.8. Door Switch Status – 0=open, 1=closed

6.9. External T-stat Status – 0=open, 1=closed

6.10. Heater Relay Status – 0=open, 1=closed

6.11. Error Codes

The Intelliswitch has six error codes, 1 through 6, to help

troubleshooting. The status of 1-4 can be observed from the

Diagnostic Menu. The format for displaying the error code is the

“Er” descriptor and a two digit code. The rst digit is the error

number and the second digit is the status using international

convention. 0 = inactive, 1 = on or active.

6.11.1. Error Code 1 – Speed Sensor

Er 10 – Prox Sensor or Speed feedback exists

Er 11 – NO Prox Sensor or Speed feedback

Solution – check to see if the proximity sensor (located next

to the motor) is connected to the control board and check

distance between tip and trigger bar is approximately 1/16 of

an inch.

6.11.2. Error Code 2 – Line Frequency

Er 20 – power supply line frequency exists

Er 21 – undetermined supply line frequency

Solution – The Intelliswitch automatically senses line frequency. In the event that it can not determine the proper line

frequency, it will run at full speed and ash error. Manually set

the line frequency in the FACT menu. See Section 7.5.

6.11.3. Error Code 3 – Zero Cross/Power Issues

Er 30 – clean power exists

Er 31 – poor power exists, electrical noise

Solution – When the control encounters “noise” in the electrical

power supply it will run at full speed and ash error code. There

are no internal changes available. Have the electrical system

checked for problems.

6.11.4. Error Code 4 – Speed Feedback

Er 40 – proper motor and sensor operation

Er 41 – Motor o but receiving prox/speed sensor feedback

Solution – this is usually the result of a failing motor control

component on board that cannot be serviced. A replacement

board is required.

6.11.5. Error Code 5 – Corrupted Memory Setting

Appendix - 17

Er 51 – Status of this error is not available. It only appears when

there has been an event that has corrupted the settings in

memory. When corrupted settings are identied the control

will reset all settings (except for Speed Range) back to Factory

default values. Because some speed ranges are not compatible with all motors, the proper value cannot be automatically

set and therefore requires user input. This is prompted by the

scrolling “Set FACt SPEEd” on the display.

Solution – press the “OK” button. This will open the range setting identied by “rn”. Select the correct speed range (see Section 7.1) based on the Series/Model. Press “OK” button.

6.11.6. Error Code 6 – Incompatible Speed Range for Master/Slave Operation

Er 61 – Status of this error is not available. It only appears when

unit are connected in a Master/Slave conguration that do not

have identical Speed Range settings.

If two units are connected without equivalent speed ranges,

every time a button is pressed on the Master unit (the unit used

to make setting selections) the Slave unit will display an “Er 61”

and the Slave will ignore the command to protect the control

from damaging the motor.

Solution – Enter the Factory Menu to select the proper Speed

Range (See Sections 7 and 7.1)

Note: This error does not monitor if the correct speed range

has been selected for a Series/Model. Only that two or more

units have been connected that do not have equivalent

speed ranges.

Note: Once the correct speed ranges are selected and the

controls accept commands from one another, the controls

should be synchronized by simply cycling through all of the

settings on the User Menu using the up or down arrows.

None of the settings need to be changed.

7. Factory Menu – Service Personnel Only

The Factory Menu must be entered from the DIAG header. To

enter into the Factory Menu hold down the right arrow for 5

seconds. DIAG will display when the Diagnostic Menu is available. From the DIAG display, press and hold the up and down

arrows simultaneously for 10 seconds. FACT will display when

the Factory Menu is available.

Note: When the Factory Menu is accessed it automatically

shut the unit o by changing the Mode to OFF.

The Factory Menu is used to change or reset core settings to

change base functions or resolve Intelliswitch™ errors.

The Factory Menu allows parameters for the following options

to be set:

• Speed Range Setting

• Restore Factory Default Settings

• Reboot Software

• PASScode

• Supply Voltage Frequency

To enter into the Factory Menu from the header press the down

arrow. Use the left & right arrows to change setting values. Use

the OK button select action and return to the User Menu.

7.1. Speed Range: single level

rn N 0 – 1 – 2 – 3 – 4 – 5 – 6 – 7 – 8 – 9 – 10 -11 – 99 O

Select the fan speed range from 0 to 11 using the left or right

arrows. The speed range for each unit is located on the unit wiring diagram called out in a box in the Intelliswitch® schematic

by “SPEED rn __”.

Page 18

Note: Selecting the incorrect speed range can damage the

motor(s) beyond repair and potentially create abnormally

high temperatures.

Speed ranges are dependent upon the air curtain Series, motor

type and heat option.

ALC08(1/5 hp) – all voltages use ranges 0-2

Available ranges are:

0 = ambient – variable 10-speed, 600 rpm to full

1 = ambient – variable 10-speed, 1050 rpm to full

2 = heated – variable 10-speed, 1250 rpm to full

3 = ambient – full on, no adjustment

4 = heated – full on, no adjustment (monitored)

5 = heated – full on, no adjustment (not monitored)

6 = ambient – multiple 3-speed, ITC relay control

7 = heated – multiple 3-speed, ITC relay control

8 = ambient – variable 3-speed, 1250 rpm to full

9 = heated – variable 3-speed, 1250 rpm to full

10 = ambient – multiple 2-speed, ITC relay control

11 = heated – multiple 2-speed, ITC relay control

99 = lock out – scrolling request for user input

7.2. Thermostat Probe Mode: single level

In “St” (Standard) mode the lowest operating point for the

thermostat probe is 34°F (1°C). Below this temperature there

will be no call for heat and “nP” (no Probe) will display on the

diagnostics menu.

In “Cd” (Cold) mode the thermostat will operate below 34°F

(1°C) but disables the “nP” (no Probe) feature and will call for

heat on a probe failure or if it is disconnected.

St - Standard mode, locks out below 34°F (1°C). Cd - Cold

mode, works below 34°F (1°C).

7.3. Restore Factory Default: single level

DEF N n – U – P – A – tO

If it is necessary to restore any of the controls settings back to

the factory defaults, select DEF using the down arrow. Select

the factory setting restore type using the left or right arrows.

This will reset the option settings back to the factory default

settings. Available selections are:

DEFn – no changes