Berner AHC10-1048, AHC10-1042, AHC10-2048, AHC10-2060, AHC10-2072 Important Instructions Manual

...Page 1

IMPORTANT INSTRUCTIONS

Saving energy and creating healthy, comfortable environments

READ AND SAVE

THESE INSTRUCTIONS

No. II-260

Date May, 2014

ARCHITECTURAL

High Performance 10

AIR CURTAIN SERIES AHC10

Installation & Maintenance Instructions

TABLE OF CONTENTS

I. UNCRATING............................................................................................................................................................ ...................................... 2

II. WALL MOUNTING - INDOOR INSTALLATION ........................................................................................................................................ 2

III. WALL PREPARATION ....................................................................................................................................... .........................................3

IV. ATTACHING THE AIR CURTAIN TO THE MOUNTING PLATE.......................... ...................................................................................... 3

V. TOP MOUNTING - INDOOR INSTALLATION............................................................................................................................................4

VI. ELECTRICAL CONNECTIONS ..................................................................................................................................................................4

VII. ELECTRICALLY HEATED MODELS .................................... ....................................................................................................................4

VIII. STEAM OR HOT WATER HEATED MODELS .........................................................................................................................................5

IX. OPERATING INSTRUCTIONS ...................................................................................................................................................................5

X MAINTENANCE AND CLEANING...............................................................................................................................................................6

XI. SERVICE ............................................................................................................................................................... ......................................4

XII.WARRANTY ................................................................................................................................................ ...............................................8

TROUBLESHOOTING ................................................................................................................................................ .....................................7

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Read all instructions before installing or using this air curtain.

B. Use this unit only in the manner intended by the manufacturer and described in this manual. Any other use not recommended by the

manufacturer may cause re, electric shock, or injury to persons. If you have any questions, contact the manufacturer.

C. Before servicing or cleaning unit, switch power o at service panel and lock the service disconnecting means to prevent power from

being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

D. Installation work and electrical wiring must be done by qualied person(s) in accordance with all applicable national and local codes

having jurisdiction, including re-rated construction. See page 4, ELECTRICAL CONNECTIONS (NEC Code ANSI/NFPA No. 70).

E. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

F. To reduce the risk of re, do not store or use gasoline or other ammable vapors and liquids in the vicinity of the air curtain.

G. This air curtain is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. Keep combustible materials, such as furniture,

pillows, bedding, papers, clothes, etc. and curtains at least 1 inch from the top, back, front, sides and at least 6 feet from the discharge

of the air curtain.

H. Extreme caution is necessary when any air curtain is used by or near children or invalids, and whenever the heater is left operating

unattended.

I. Do not operate any air curtain after it malfunctions. Disconnect power at the service panel and have the air curtain inspected by a

reputable electrician before reusing.

J. To disconnect the air curtain, turn controls to "o", and turn o power to the air curtain circuit at main disconnect panel.

K. Do not insert or allow foreign objects to enter any ventilation or discharge opening as this may cause an electric shock or re, or

damage the air curtain.

L. To prevent a possible re, do not block the air intake or discharge of the air curtain in any manner.

M. The air curtain has hot and arcing or sparking parts inside. Do not use it in areas where gasoline, paint, or ammable vapors or liquids

are used or stored.

N. This heater may include an audible or visual alarm to warn that parts of the heater are getting excessively hot. If the alarm sounds

(or illuminates), immediately turn the heater o and inspect for any objects on or adjacent to the heater that may have blocked the airow

or otherwise caused high temperatures to have occurred. DO NOT OPERATE THE HEATER WITH THE ALARM SOUNDING (OR ILLUMINATING).

-1-

Page 2

I. UNCRATING

Carefully examine the carton(s) for damage before opening. If

the carton is damaged, immediately notify the shipping company. Open the carton and remove all protective packing. Remove the unit by lifting vertically. Place the unit upside down

on end supports to avoid damage to the electrical junction

box. If the unit will be wall mounted, remove and save the two

(2) locking screws from the back corners and detach the wall

mounting plate. See Figure 1

Mounting

Screws

Mounting

Plate

FLUSH WALL

MOUNT

Spacer

EXTENDED

WALL MOUNT

Seal

ACCESSORIES: If the unit(s) were ordered with optional electrical accessories (door switch, control panel, etc.), the accessories may be found in

the carton containing the unit or in a separate carton(s) accompanying

the unit(s). Check all of the cartons/skids for accessories before discarding.

Locking Screws

Bottom of Unit

Packaging

Figure 1

Wall

Mounting

Plate

The ARCHITECTURAL HIGH PERFORMANCE 10 Air curtain is

designed to be an eective barrier against cold drafts in the

winter and hot air in the summer, ying insects and airborne

contaminants. To achieve optimum protection, the unit should

be mounted on the inside of the building, ush to the wall and as

close to the top of the door opening as possible. To ensure peak

performance keep air stream free of obstructions. See Figure 2.

Mounting

Screws

1"

Spacer

2"

3/8"

Lower Lip

Figure 3

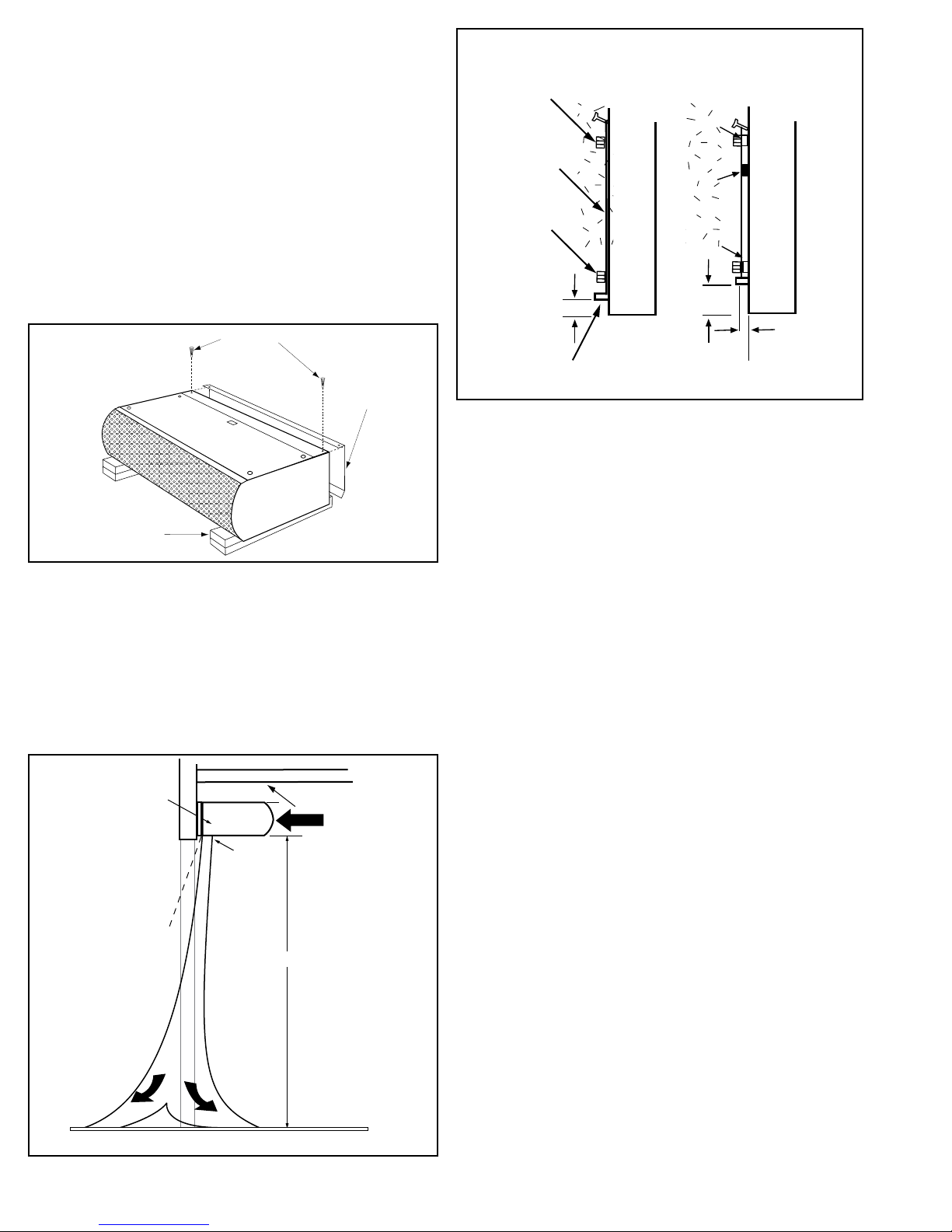

II. WALL MOUNTING INDOOR INSTALLATION

Unit should be mounted no higher than 10’ above

the oor. For maximum eciency, the unit should be

mounted no higher than 8’.

1. Install the ARCHITECTURAL HIGH PERFORMANCE 10 Air

curtain so that nothing interferes with the curtain of air

when it is deected 20° to either side. If the air stream

strikes any obstruction, i.e. the top edge of the doorway, a

structural beam, a door opening device, etc., its eciency

will be greatly reduced. See Figure 2.

4" minimum

side clearance

from combustible

material*

Discharge

Nozzle

20˚

EXTERIOR

A

R

I

I

R

A

*Electrically Heated Units Only

Figure 2

8" minimum

AIR

6' minimum

INTERIOR

2. The lower lip of the mounting plate should be no more

than 1” above the door opening when the unit is mounted

ush to the wall. If the Air curtain must be mounted

higher, it must be spaced out from the wall 3/8” for every

inch the unit is above the door opening. For the best performance, any void between the Air curtain and the wall

must be sealed (use foam, plastics or a similar packing).

See Figure 3.

3. Do not block the air ow to or from the unit since this

could cause overheating. On electrically heated units

there should be:

a. A minimum clearance of at least 4” between the side of

the unit and any combustible material if the unit is

enclosed in the ceiling or a decorative cover.

b. A minimum clearance of 8” between the top of the unit

and the ceiling in order to service the junction box(es).

c. Do not install less than six feet (or 1.8 meters) from the

oor to the unit. See Figure 2.

-2-

Page 3

Recommended Mounting

Plate Holes

Doorway Opening

Figure 4

45º Lip and Rubber

Vibration Gasket

1"

45˚ Lip and Rubber

Vibration Gasket

Discharge

Nozzle

Mounting

Plate

2 Locking Screws

(One In Each Corner)

Figure 5

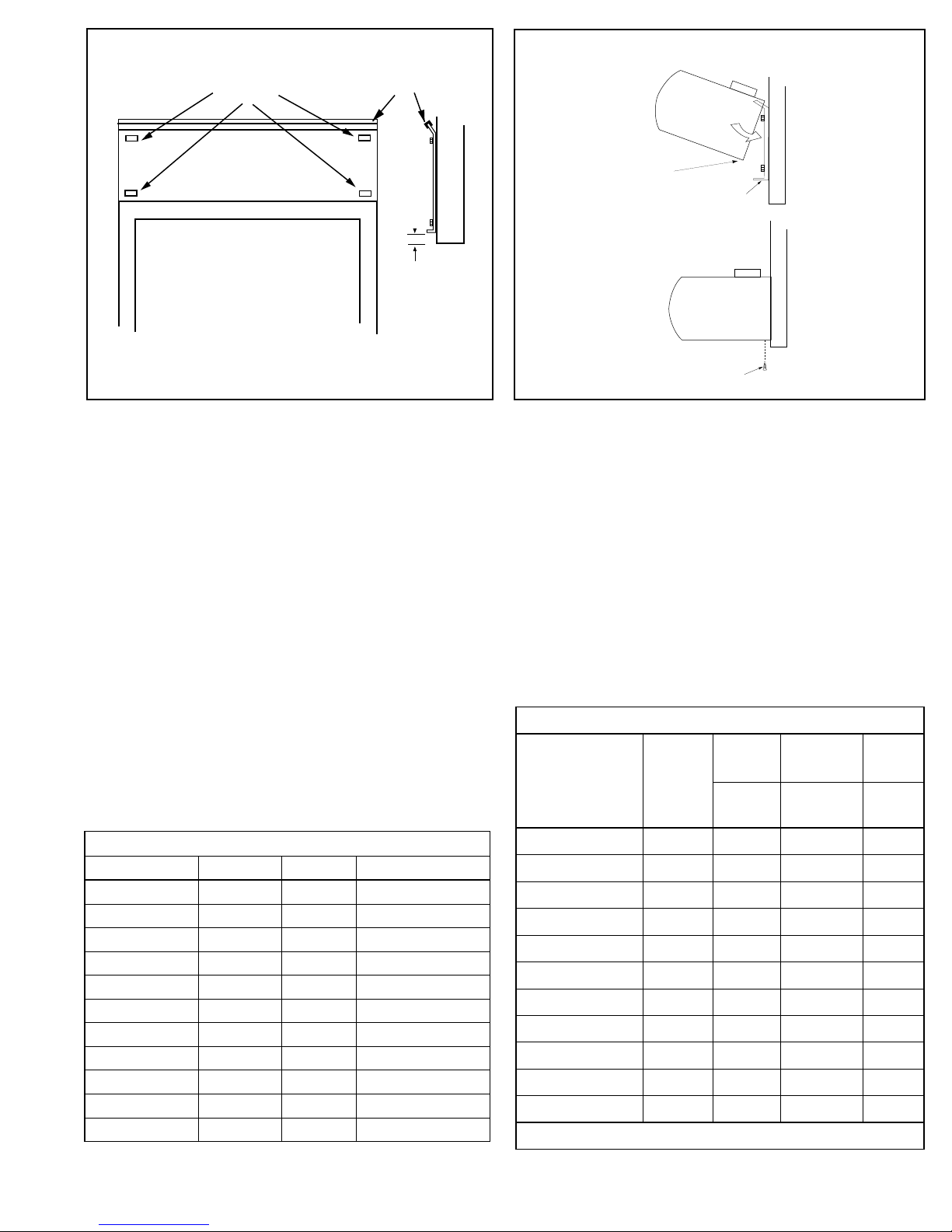

III. WALL PREPARATION

1. Position and center the mounting plate over the door

opening. The mounting plate must be positioned with the

45° lip and the rubber vibration gasket on top. Drill mounting holes on the mounting plate. See Figure 4.

2. Mark the wall in the center of each mounting plate hole.

The wall must provide sucient support for the Air curtain.

The mounting hardware (supplied by others) must be

capable of supporting a minimum of three times the net

weight of the Air curtain. See Weight Chart, Table 1. If

the location of the marks on the wall do not provide suitable support, mark and drill additional holes.

3. Drill the four holes as marked on the wall and attach the

mounting plate with anchors (if used) and the four mounting screws (provided by others).

WEIGHT IN POUNDS

Model Unheated Electric Steam/Hot Water

AHC10-1036 65 71 98

AHC10-1042 68 74 104

AHC10-1048 70 76 109

AHC10-2048 95 107 134

AHC10-2060 125 137 171

AHC10-2072 130 142 181

AHC10-2084 140 152 197

AHC10-2096 145 157 208

AHC10-3096 165 183 228

AHC10-3108 170 188 240

AHC10-3120 175 193 248

TABLE 1 - Weight Chart

IV. ATTACHING THE AIR CURTAIN TO THE

MOUNTING PLATE

1. Raise the unit over the door (air discharge nozzle facing

down) and on to the mounting plate. First, tilt the unit upward matching the top recessed edge of the unit to the top

45° angled lip on the mounting plate. See Figure 5.

2. Lower the unit into place, allowing it to rest on the lower lip

of the mounting plate.

3. After the unit is securely attached to the mounting plate, reinstall the two (2) locking screws at the bottom corners.

See Figure 5.

Model

AHC10-1036 1@½ 7.2 4.0 1.3

AHC10-1042 1@½ 7.2 4.0 1.3

AHC10-1048 1@½ 7.2 4.0 1.3

AHC10-2048 2@½ 14.4 8.0 2.6

AHC10-2060 2@½ 14.4 8.0 2.6

AHC10-2072 2@½ 14.4 8.0 2.6

AHC10-2084 2@½ 14.4 8.0 2.6

AHC10-2096 2@½ 14.4 8.0 2.6

AHC10-3096 3@½ 21.6 12.0 3.9

AHC10-3108 3@½ 21.6 12.0 3.9

AHC10-3120 3@½ 21.6 12.0 3.9

*Special 1/3 hp Two Speed Motor

-3-

#Motors

MOTOR DATA

120 V 1ø208/240 V 1ø460 V*

@HP

Motor

Amps

Table 2

Motor

Amps

Motor

Amps

1 ø

Page 4

V. TOP MOUNTING INDOOR INSTALLATION

(CEILING SUSPENSION)

For top mounting suspension rods, four (4) factory installed

5

/16” threaded inserts are located on the top of the unit.

See Figure 6.

1. Install the ARCHITECTURAL HIGH PERFORMANCE 10

Air curtain so that nothing interferes with the curtain of air

when it is deected 20° to either side. If the air stream strikes

any obstruction, i.e. the top edge of the doorway, a structural

beam, a door opening device, etc., its eciency will be greatly

reduced. See Figure 2.

2. Follow instructions 2 and 3 under INDOOR INSTALLATION:

WALL MOUNTING (on page 1) checking to assure the minimum

clearances are met.

3. Attach 5/16” threaded rods, or other suitable hardware to the

top mounted threaded inserts.

VI. ELECTRICAL CONNECTIONS

All electrical wiring and connections MUST be performed by

qualied personnel in accordance with the latest edition of the

National Electrical Code ANSI/NFPA No. 70 or, in Canada, the

Canadian Electrical Code, Part 1-C.S.A. Standard C22.1 and local

codes and regulations. MAKE SURE THE CORRECT VOLTAGE AS

MARKED ON THE UNIT IS USED.

The ARCHITECTURAL HIGH PERFORMANCE 10 Air curtain is

internally wired to the junction box(es) on top of the of the unit.

1. Run the proper size cable from the source to the junction box

and connect the leads.

2. Wiring diagrams are located inside the junction box. For amp

rating, See Tables 2 or 3 and the name plate on the unit.

Suspension Rods

5/16" Recessed Insert

Side View

Figure 6

VII. ELECTRICALLY HEATED MODELS

The heater circuit may be controlled by a remote thermostat, a

built-in thermostat or a manual on/o heater switch located on

the discharge side of the unit. See Figure 7.

1. If a thermostat is used, connect the proper leads located in

the junction box to the leads of the thermostat. (See wiring

diagram located in the junction box)

2. If a manual heat on/o switch is used, factory wiring is supplied

from the heating coil to the unit mounted heat on/o switch.

Overheat protection is provided by thermal cutouts built

into the heater coil assembly. (See the wiring diagram

located in the junction box.)

ELECTRIC HEATER DATA* Add total motor amp draw from Table #2 to circuit #1 for unit total amp draw

MODEL KW

AHC10-1036 9.5 45.7 - 39.6 - 26.4 - - 22.9 - 11.4 9.5

AHC10-1042 9.5 45.7 - 39.6 - 26.4 - - 22.9 - 11.4 9.5

AHC10-1048 9.5 45.7 - 39.6 - 26.4 - - 22.9 - 11.4 9.5

AHC10-2048 12.5 20.0 40.1 17.4 34.7 34.7 - - 30.1 - 15.0 12.6

AHC10-2060 16.0 - - - - 44.4 - - 38.5 - 19.2 16.1

AHC10-2072 19.0 - - - - 26.4 26.4 - 22.9 22.9 22.9 19.1

AHC10-2084 19.0 - - - - 26.4 26.4 - 22.9 22.9 22.9 19.1

AHC10-2096 19.0 - - - - 26.4 26.4 - 22.9 22.9 22.9 19.1

AHC10-3096 25.0 - - - - 34.7 34.7 - 30.1 30.1 30.1 25.1

AHC10-3108 28.5 - - - - 26.4 26.4 26.4 22.9 45.7 34.3 28.6

AHC10-3120 28.5 - - - - 26.4 26.4 26.4 22.9 45.7 34.3 28.6

*Optional kW available. Check wiring diagram supplied with unit for kW and AMP draw if not listed above.

208V 1Ø 240V 1Ø 208V 3Ø Amp Draw

Circuit 1 Circuit 2 Circuit 1 Circuit 2 Circuit 1

** Separate 120V, 208V or 240V single phase circuit required to operate motors.

Circuit 2 Circuit 3

Table 3

240V 3Ø

Amp Draw

Circuit 1 Circuit 2

460V 3Ø**

Amp Draw

Circuit 1 Circuit 1

-4-

600V 3Ø**

Amp Draw

Page 5

VIII. STEAM OR HOT WATER HEATED

MODELS

Piping should be done in accordance with local codes, regulations

and standard practice.

1. Connect the supply & return to the 1” MPT nipples on the

heating coil. See Figure 8.

2. Temperature controls to be supplied by others.

AIR

Discharge

Nozzle

IX. OPERATING INSTRUCTIONS

A. GENERAL OPERATION

Air curtain operation may be divided into four areas: control

package, fan activation, fan speed selection, and heat

activation. Depending on the type of controls ordered one

or more of the following may be applicable. The air curtain

must be properly installed before it is used.

1. Control packages control the unit’s sequence of operation.

Unit modes/control packages are built into the unit and

may not be changed in the eld. Refer to your wiring

diagram for specics about activation connections and

sequence of operation.

a. Basic Control Package – The unit is activated by a door

or selector switch. Either switch may be line voltage or

low voltage (24V).

b. Deluxe Control Package – The unit is activated by a

door or selector switch, but has a factory installed time

delay allowing the unit to keep running for a period of

time after the door closes.

c. Comfort Plus Control Package – Available only on

heated units, the unit is activated by a door

or selector switch AND a thermostat to provide

supplemental heating.

20˚

EXTERIOR

12"

R

I

A

INTERIOR

A

I

R

Handkerchief

3"

Figure 9

2. Unheated units will have the fans activated by a door or

selector switch or sensor. The unit may be single speed and

require no fan speed selector (On/O), or

may have multiple fan speeds which require either a unit or

remote mounted switch (O, High, Med, Low).

Figure 7

Figure 8

3. Heated units will have fans activated by a door or selector

switch or sensor, but may also be activated by the thermo

stat in Comfort Plus Mode. The unit may be single speed

and controlled by either a unit or remote mounted switch

(Fan, O, Heat), or may have multiple fan speeds which can

be set by either a unit or remote mounted switch (Low,

Med, High, O, Low heat, Med Heat, High Heat).

4. Heat activation is controlled by either a unit or remote

mounted thermostat, and a unit or remote mounted switch.

B. AIR STREAM ADJUSTMENT

1. With the air curtain operating and the door in its full open

position, check to see that nothing is obstructing the airow

at the discharge nozzle vanes.

2. Find the air stream split location. Hold a handkerchief by

its corners, approximately 12” above the oor. Gently move

the handkerchief back and forth in the doorway. Make sure

the air is being directed to both the inside and the outside.

See Figure 9. The split location is indicated where the

handkerchief is vertical with minimal or no uttering.

3. The split location should be approximately 3” outside the

doorway. If necessary adjust the discharge nozzle vanes by

de-energizing the unit, loosening the nozzle vane locking

screws and adjusting vanes.

-5-

Page 6

X. MAINTENANCE AND CLEANING

CAUTION: ELECTRIC SHOCK HAZARD Disconnect power

whenever servicing unit. More than one disconnect may

be required to de-energize unit.

Keep your air door operating at peak eciency by cleaning

the blower wheels, motor(s) and intake grille. Buildup of dust

on the blower wheels can cause vibration, noise and excessive

wear on the motor bearings. The frequency of cleaning will

depend on the environment where the unit is operating.

Dirty, dusty or greasy environments could require a cleaning

schedule of once every two months. If the environment is

not that dirty, the unit(s) should be scheduled for cleaning a

minimum of once every (6) months. To access the interior of

the unit:

1. Disconnect the power to the unit.

2. Remove the intake grille by removing the locking screw on

each end of the unit. Lift the intake grille up and then towards

you. See Figure 11.

3. Remove the bottom access panel. Remove Phillips head

screws on the bottom of the unit. Vacuum and scrape (if

necessary) to remove the build-up of dirt and debris. The

motor(s) are permanently lubricated and require no additional

lubrication. Re-install the cover and intake grille.

XI. SERVICE

CAUTION: ELECTRIC SHOCK HAZARD Disconnect power

whenever servicing unit. More than one disconnect may

be required to de-energize unit.

Any service performed on the ARCHITECTURAL HIGH PERFOR-

MANCE 10 Series air door MUST be done by qualied personnel.

Berner air doors require very little servicing. All parts are eas-

ily accessible for periodic inspection and maintenance. Units

should be cleaned at least twice a year. Your particular application (the amount of dirt and dust in the air) and location of the

unit(s) will determine how often your unit(s) will need to be

cleaned and serviced. All motors have permanently lubricated,

sealed, sleeve bearings and require no maintenance.

4. Switch the power on after cleaning. CAUTION: STAND CLEAR

OF THE UNIT OR WEAR SAFETY GOGGLES AS LOOSE DEBRIS

MAY BE PRESENT AND MAY EXIT THE NOZZLE.

Intake Grill

Grill Locking Screws

Figure 11

-6-

Page 7

TROUBLESHOOTING

SYMPTOMS REMEDY

NO AIR

MINIMUM AIR

AIR IS NOT HITTING

FLOOR

• Power supply line open (no power)

• Fuse blown/circuit breaker tripped

• Motor overload tripped

• Failed switch

MOTOR RUNNING/FANS ARE NOT ROTATING

• Brokenordamagedexiblehub

• Shaft rotating inside fan

ELECTRICAL CONTROLS NOT FUNCTIONING WHEN DOOR IS OPEN

• Selector switch is in off position

• Door limit switch not operating

• Air directional discharge vanes mis-adjusted

• Inadequate intake clearance

• Blower motor operates below speed

• Fan rubbing against housing

• Fan wheels clogged with dirt

• Fan in backwards

• Air stream too weak

• Air steam hits obstruction

• Negative pressure

CAUSE

• Check power source, check method of control in ON

position

• Replace fuse(s)/reset breaker

• Internally protected motor - should reset automatically

after cool-down, if not, replace motor.

• Replace switch

• Replace fan sleeve/reengage coupling

• Tighten set screws/tighten fan on shaft

• Turn switch to “ON” position

• Repair or replace limit switch

• Adjust vanes to proper position, see instructions

• Move air curtain or remove obstruction

• Provide adequate space for air curtain

• Improper voltage

• Free fan from housing

• Clean and vacuum fan wheels

• Check fans for blade curve toward discharge

• Adjust nozzle to proper position, adjust motor speed;

see installation instructions

• Remove obstruction or reposition air curtain (move out

3/8” for every 1” up from the door)

• Relieve negative pressure by providing makeup air

UNEVEN AIR

EXCESSIVE AIR

MOVEMENT AT DOORWAY

NO HEAT

MINIMAL HEAT

EXCESSIVE HEAT

• Shaft rotating inside fan

• One motor not operating

• Nozzle not angled out far enough

• Unit too powerful

• Air movement too cold

• Pushing air outside building

SEE AIR IS NOT HITTING FLOOR SYMPTOMS

ELECTRICALLY HEATED MODELS

• Switch turned to “ON” position

• Thermostat not set properly

• Coils burned out due to lack of air

• Automatic reset thermal cutout failed in open position

• Manual reset thermal cutout tripped (if supplied)

• Thermostat in wrong location - thermostat too

close to discharge

• Improper voltage

• Thermostat not set properly

• Incorrect speed range

• Thermostat in wrong location

• Thermostat not set properly

• Insufcientairovercoil

• Improper voltage

• Tighten set screws

• Repair or replace motor

• Adjust nozzle angle to outside

• Adjust motor speed

• Add auxiliary heat to overcome wind chill factor

• Adjust discharge angle back into building, adjust motor

speed

• Replace switch or check wiring

• Change thermostat setting

• Correctairowproblem;replacecoils

• Replace automatic thermal cutout

• Reset manual thermal cutout

• Move thermostat away from air stream

• Supply proper voltage

• Change temperature setting

• Set dip switch to electric heated speed range

• Move the thermostat closer to air stream

• Change temperature setting

• Remove restriction on intake

• Supply proper voltage

EXCESSIVE HEAT

MINIMAL HEAT

• Too high steam/hot water pressure

• Inadequateairow,nspluggedup,dirtycoils

• Insufcientremovalofcondensation(steam)

• Not enough steam pressure/water temperature too

• Intake air below design temperature

STEAM/HOT WATER HEATED UNITS

low

-7-

• Reducesteampressure/hotwaterow

• Clean intake and coils

• Increase trap size

• Raisepressureforsteam/increasewaterow

• Increasesteampressure/increasewaterow

Page 8

XII. WARRANTY

Berner International ("The Company") warrants all new equipment to be free of defects in workmanship and material for a period of

ve years (5 years) on unheated models and two years (2 years) on heated models from the original date of shipment, provided the

equipment has been properly cared for, installed and operated in accordance with the limits specied on the nameplate and The

Company’s instructions.

The Company will correct by repair or replacement, at its option and expense, any proven defects in said apparatus, subject to

the above conditions, provided that immediate written notice of such defects is given to The Company. The warranty does not

include any labor incurred for the removal or installation of defective part(s). The Company reserves the right to inspect, or have

inspected by a qualied representative, any apparatus at the place of installation before authorizing repair or replacement. Repair or

replacement will be made F.O.B. factory with any applicable transportation charges to be borne by the customer. Merchandise not of

The Company’s manufacture supplied in piece, or in component assemblies, is not covered by the above warranty, but The Company

will give the customer the benet of any adjustment as made with the Manufacturer.

This warranty is void if the apparatus has been tampered with in any way or shows evidence of misuse.

The Company will not assume any expense or liability for repairs made outside its factory without proper written consent from

its service manager, nor for any transportation charges on apparatus returned to the factory without written authorization by The

Company.

Nothing in the above warranty provisions, however, shall impose any liability or obligation of any type, nature or description upon

Berner International if Berner has not received payment in full for the apparatus in question.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HERE OF INCLUDING

THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF DAMAGES

Notwithstanding anything to the contrary above, customer’s exclusive remedy for any and all losses or damages resulting

from the sale of The Company’s equipment under this agreement, including but not limited to, any allegations of breach

of warranty, breach of contract, negligence or strict liability, shall be limited, at The Company’s option, to either the return

of the purchase price or the replacement of the particular equipment for which a claim is made and proved. In no event

shall The Company be liable for any special, consequential, incidental or indirect losses or damages from the sale of The

Company’s equipment under this agreement.

SERIAL NUMBER MODEL NUMBER DATE PURCHASED

BERNER INTERNATIONAL CORPORATION

724-658-3551 • 1-800-245-4455 • www.berner.com • airdoors@berner.com

Berner reserves the right to alter specifications without prior notice.

© Copyright 2014 Berner International Corporation MADE IN U.S.A.

New Castle, Pennsylvania

-8-

Loading...

Loading...