Page 1

Installation Manual

CONDENSING

Power Plus Box 1001 INT-EXT

Installation Manual

EN

Page 2

This manual, Code 20073959 - Rev. 4 (12/15) comprises 40 pages.

2

RANGE

MODEL CODE

Power Plus Box 1001 INT 20067835

Power Plus Box 1001 EXT 20067836

CERTIFIED COMPANY

UNI EN ISO 9001:2008

UNI EN ISO 14001:2004

This manual, Code

- Rev.

comprises

pages.

ENGLISH

Contents

CONTENTS

The following symbols are used in this manual:

b

CAUTION! =

Identifies actions that require caution

and adequate preparation.

a

STOP! =

Identifies actions that you MUST NOT do.

1 GENERAL INFORMATION ................3

2 WARNINGS............................3

3 TECHNICAL FEATURES .................4

3.1 Main features ............................ 4

3.2 Advantages.............................. 5

3.3 Safety devices............................ 5

3.4 Components ............................. 6

4 INSTALLATION.........................9

4.1 Product packaging and identification.......... 9

4.2 Installation premises ....................... 9

4.3 System cleaning and water treatment ........ 10

4.4 General instructions ...................... 10

4.5 New heating systems ..................... 10

4.6 Upgrading existing systems ................ 10

4.7 Corrosion............................... 10

4.8 Positioning and preparation for installation..... 11

4.9 Condensate outlet........................ 11

4.10 Water circuit ............................ 12

4.11 Exhaust flue............................. 12

5 INSTALLATION DIAGRAMS .............12

6 ELECTRICAL SYSTEM .................14

6.1 Power supply ........................... 14

6.2 Electrical connections..................... 14

6.2.1 Connection to mains ...................... 14

6.2.2 Connection to thermoregulators .............15

6.2.3 Connection to pumps ..................... 15

6.2.4 Connection to room thermostats (on/off) ...... 15

6.2.5 Connection to weather temperature probe..... 15

6.2.6 Frost protection .......................... 16

6.2.7 Connection to 0-10v external thermoregulator ..17

6.2.8 Connection to alarm device ................ 17

6.3 Emergency mode ........................ 17

7 GAS VALVE CALIBRATION ..............18

8 USE AND ADJUSTMENT ................19

8.1 Control panel: description.................. 19

8.2 Display mode ........................... 20

8.3 Display mode ........................... 20

8.4 Changing the user parameters .............. 21

8.5 Monitor mode ........................... 21

8.6 Installer programming mode................ 22

8.7 Test mode .............................. 23

8.8 Error mode ............................. 23

8.9 Permanent block ......................... 23

9 SETTING FUNCTIONING PARAMETERS ...24

9.1 Setting the heating parameters.............. 24

9.2 Setting the DHW parameters ............... 25

9.3 Heat control setting....................... 26

10 LIST OF PARAMETERS .................31

11 ERROR LIST ..........................33

11.1 Master board errors ...................... 33

11.2 Slave board errors ....................... 33

12 WIRING DIAGRAMS....................35

13 TECHNICAL SPECIFICATIONS ...........37

Page 3

3

1 GENERAL INFORMATION

Dear Customer,

congratulations on your choice and thank you for placing

your confidence in our products. With

Power Plus Box 1001

you have chosen technology that is the very essence of

energy saving and functionality.

Moreover, all B products conform to the strictest

directives and European standards in force.

This product was produced, amongst others, in conformity

to the following directives and standards:

- Directive 2009/142/EC - Gas Appliances

- Directive 92/42/EEC on efficiency requirements

and Annex E and Pres. Republic Decree n. 412, 26

August 1993 (****)

- Electromagnetic Compatibility Directive 2004/108/EC

- Low Voltage Directive 2006/95/EC

- Ecodesign Directive 2009/125/CE for energy-related

products

- Delegated Regulation (EU) N. 813/2013

- EN 15417 Gas-fired central heating boilers - Specific

requirements for condensing boilers with a nominal

heat input greater than 70 kW but not exceeding

1000 kW

- EN 13836 Gas fired central heating boilers - Type B

boilers of nominal heat input exceeding 300 kW, but

not exceeding 1000 kW.

The

Power Plus Box 1001

condensing modular systems

moreover conform to the regulatory provisions pursuant to

the INAIL “R” File, section R.3.B.

B has been certified with UNI EN ISO 9001/2000 since

22.07.2004.

Power Plus Box 1001

is furthermore a product having to its

credit:

- European Conformity Mark (based on Directive

92/42/CEE) issued by the authorized German

certification organization ;

- Maximum energy efficiency class (according to

Directive 92/42/EEC) identified by the symbol ****;

- Classified in the strictest class for nitrogen oxiderelated pollution (fifth grade according to UNI EN

297)

- Patented heat exchanger.

2 WARNINGS

b

The heating unit must be used for the purpose for

which it was specifically designed and produced. Any

whatsoever contractual or extra-contractual liabilities

for damages caused to persons, animals or objects

due to errors in installation, adjustment, maintenance

and improper usage are to be excluded.

b

Installation must fully comply with provisions of

the law in force and instructions provided by the

manufacturer to ensure safety and correct functioning,

always calling upon professionally qualified technical

personnel who will issue the declaration of conformity

for the installation accomplished with good

workmanship, in compliance to regulatory provisions

in force and guidelines given in this handbook. The

appliance must be installed in appropriate premises

and together with the specific systems installed

according to the law.

b

Commissioning will be carried out by personnel from

the authorized Technical Assistance Centre only and

within 8 days from when the appliance was installed.

After initial ignition the Technical Assistance Centre

will fill in the warranty certificate, leaving the user their

part to be kept, marking the beginning of the period

of guarantee at the terms and conditions specified

on the relative slip.

The appliance in its original packing

may be exposed to temperatures between 4°C and 40°C.

Do not expose the appliance to bad weather conditions

after it has been unpacked, anyhow to temperatures

below 4°C or above 40°C until it has been connected

up to the water, gas and electricity mains so as to be

able to activate the frost protection systems described in

paragraph 6.2.6.

b

Check that the product is complete, undamaged

and as ordered as soon as you receive it. Report any

discrepancies or damage to the B dealer who sold it.

b

In case of leaks, disconnect the heating unit from the

mains, close the water from the mains and promptly

contact the Technical Assistance Centre.

b

Regularly check that the condensate drain is free from

obstruction.

b

Regularly check that the working pressure of the water

circulation system, when cold, is below the maximum limit

specified for the appliance. If not, contact the Technical

Assistance Centre.

b

Maintenance jobs on the heating unit must be carried out

by personnel from the authorized Technical Assistance

Centre. Maintenance must be performed at least once a

year. Correct maintenance is essential for safety as well

as for the efficiency and long working life of the product.

Proper maintenance keeps consumption and emissions

down, and ensures that the product continues to operate

reliably over time. Analyse the combustion fumes before

commencing maintenance. The results of fume analysis

can give a clear idea of what servicing or repairs are

needed.

b

We recommend cleaning inside the exchanger once

a year, extracting jet and burner and removing any

installation debris by suction. This operation will be done

by personnel from the Technical Assistance Centre only.

b

The warranty slip endorsed during the course of

commissioning will have to be produced for any servicing

required during the guarantee period. The manufacturer

shall not be held liable for any damages caused by

mishandling, improper use or errors in installation, use

and maintenance work on the appliance. In the event

of breakdown or malfunction switch off the appliance,

avoiding to make any attempt to repair it and contact the

Technical Assistance Centre.

b

This manual must be read carefully for the boiler to be

used rationally and safely, and must be kept with care

so as to be on hand where required by the technician or

installer, to facilitate the appropriate installation, running

and maintenance of the boiler. B will not be held

liable for any translations possibly giving rise to wrong

interpretation. This manual is an integral part of the

heating unit and must consequently be kept with care

and must ALWAYS accompany the boiler even when

passed on to another owner or user or transferred to

another installation. Ask the Technical Assistance Centre

for another copy if it should be lost or damaged.

Page 4

4

a

Children and people with disabilities or without

experience and specific knowledge are forbidden to use

the heating unit unless they are assisted by a qualified

person responsible for their safety.

It is forbidden to use

electrical devices or equipment, such as switches,

appliances, etc. if there is a smell of gas or un-burnt

products. If so:

- ventilate the room, opening doors and windows;

- close the gas valve at the mains;

- immediately call in the Technical Assistance Centre

or professionally qualified personnel.

a

It is forbidden to touch the heating unit with bare feet

or parts of the body wet.

a

It is forbidden to start on any technical or cleaning

jobs before disconnecting the heating unit from the

power mains.

a

It is forbidden to alter the safety and adjustment

devices without permission and instructions from the

heating unit manufacturer.

a

It is forbidden to obstruct the condensate drain.

a

It is forbidden to pull, detach, twist the wiring coming

out of the heating unit, even if unplugged from the

power supply.

a

It is forbidden to obstruct or reduce the size of air

vents.

a

It is forbidden to expose the boiler to atmospheric

agents (if it is not a specific unit for outdoors).

a

It is forbidden to leave containers or flammable

substances in the premises where the boiler is

installed.

a

Do not dispose of packaging material into the

environment, or leave it within the reach of children,

since it can become a potential hazard. Dispose of

packaging material in compliance with applicable

legislation.

a

The user is forbidden to open the cupboard containing

the heating unit. Any jobs on the inside of the latter

must be done by the Technical Assistance Centre or

by qualified personnel.

a

It is forbidden to discard the product as household

waste. At the end of its service life, it can be

consigned to specific selected waste centres

provided by the local authorities or else to dealers

providing this service. Disposing of a domestic

appliance separately will prevent possible harmful

consequences for environment and health derived

from inappropriate disposal, likewise making it

possible to recuperate the materials it is made of with

substantial savings in energy and resources.

3 TECHNICAL FEATURES

3.1 Main features

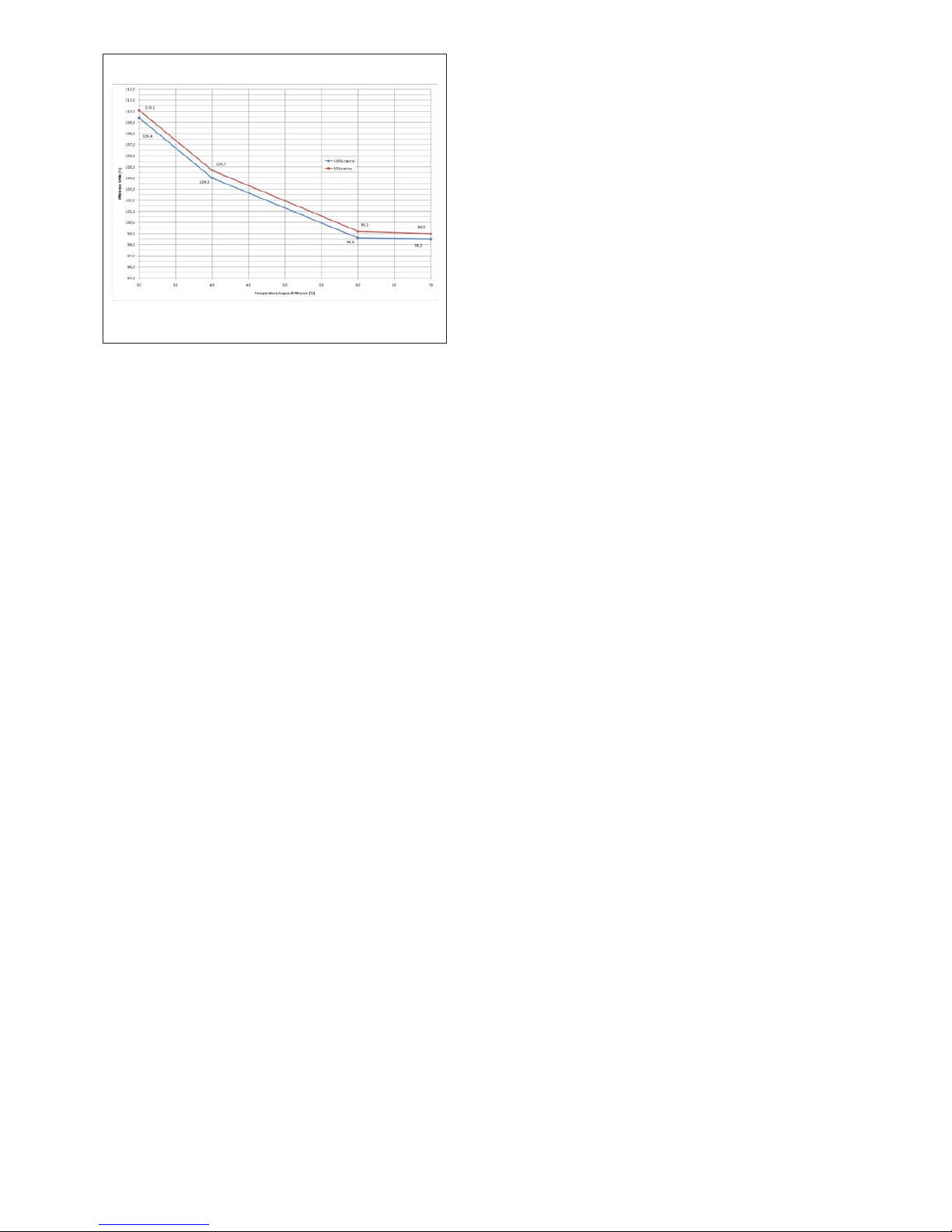

Power Plus Box 1001

is a modular condensing, premixed,

jet heating unit, comprising a modular unit at 26 to 128 kW

equipped with weather adjustment device.

The efficiency of the generators reaches 109% based

on the lower heat potential of natural gas (Hi) making it

possible to use a flue manifold entirely made of plastic

(PP). The system also enables continual modulation of the

gas and combustion air flow.

The

Power Plus Box 1001

heating unit is the optimum as far

as operating costs (up to 109% efficiency per Hi, see Figure

1), reliability and flexibility is concerned. Rapid connection

to any type of heating and domestic hot water system

with accumulation is in fact possible owing to a special

more powerful heat exchanger, new electronic control,

modulating electronic circulator and high efficiency.

Furthermore, the “master” board, supplied with each

heating unit, ensures the latter a simple conFiguretion and

enables it to be adapted to any type of system, optimizing

its performance in terms of creating comfort and cutting

down on consumption.

All the safety devices provided in the INAIL “R” File for

this particular application, have been installed on the flow

manifold, downstream from the last combustion unit.

A special water compensator is housed inside the hood

with attachments for simple connection to the systems

directly controlled by the master board which is supplied

with the heating unit:

- Direct system (high temperature)

- Mixed system (low temperature)

- Hot water system.

Distribution units are available as an accessory for each of

the above mentioned systems.

The heating unit thus becomes a complete, versatile

functional “system” to install in a variety of plant typologies.

All the systems and relevant functional components

(circulators, mixer valve and temperature probe) are

entirely controlled by the master board and are connected

up to the latter, without the help of additional boards.

Room thermostats in the unit’s system-related areas can

also be connected up to said board.

The system can also be extended to numerous additional

zones by a board called “zone master”, which is not

included in this manual.

Page 5

5

Figure 1

3.2 Advantages

- Totally pre-mixed micro-flame jet burner;

- condensing stainless steel exchanger, with efficiency

up to 109% (see Figure 1);

- maximum exhaust flue exit temperature 80°C;

- PPS plastic exhaust flue manifold, self-extinguishing

(see paragraph 4.11);

- modulating electronic primary circulator at low

consumption;

- weather temperature adjustment device supplied;

- hot water and systems control at different

temperatures, with or without function priority;

- automatic summer/winter switch-over;

- minimum flow capacity of thermal carrier fluid

controlled by a differen-tial pressure switch;

- compensator with inner partition for connection to

three systems;

- INAIL safety organs mounted in factory;

- appliance complete and ready to be connected up to

the installation.

3.3 Safety devices

All the heating unit functions are electrically controlled and

any fault will cause arrest of the heating unit and the gas

valve to automatically close.

The water circulation system includes:

- automatic resetting safety thermostat;

- differential water pressure switch acting as a

flowmeter;

- temperature probe on flow and return controlled

by a certified electronic device to carry out safety

functions with dual-processor technology. The

flow temperature is continually controlled by these

devices as well as the Δt between flow and return by

acting on the primary circulator modulation;

- modular flow temperature adjustment.

The combustion system includes:

- gas solenoid valve in B+C class with pneumatically

compensated gas flow dependent on air intake flow

capacity (air/gas ratio 1:1);

- ionization electrode for continual flame control;

- exhaust flue duct temperature control.

Protective actions and therefore closure of gas valves on

each heating unit are activated in the following cases:

- flame burnt out;

- over-temperature in exchanger system;

- high temperature of exhaust fumes;

- reduced air flow.

a

The appliance must not be started up, even

temporarily, where the safety devices have been

mishandled or excluded.

b

Safety devices must be replaced by the authorized

Technical Assistance Centre only, exclusively using

original parts.

Page 6

6

3.4 Components

Power Plus Box 1001

comprises a metal cupboard

containing the condensing combustion unit connected to

a separator, also acting as a distribution organ to three

distinct systems (high T, low T and hot water), see diagram

in Figure 2.

Figure 2

1

Heat exchanger

2

Burner

3

Jet

4

Venturi tubes

5

Gas valve

6

Vent valve

7

Safety thermostat

8

Min. and differential pressure

9

Flow temperature control

10

Return temperature control

11

Flue temperature control

12

Return pipe

13

Flow pipe

14

Gas pipe

15

Air inlet

16

Exhaust flue duct

17

Condensate outlet

18

Condensate manifold

19

Two-way gas valve

20

Fuel check valve

21

Separator

22

Separator drain cock

23

Separator vent valve

24

Modulating circulator

25

VIC probe pit

26

Safety valve

27

Max. INAIL pressure gauge

28

INAIL gauge

29

INAIL thermometer

30

Expansion tank opening

Page 7

7

DIMENSIONS AND CONNECTION POSITIONS

Power Plus Box 1001 INT

Figure 3

Power Plus Box 1001 EXT

Figure 4

1

Flow low temperature

2

Return low temperature

3

Flow high temperature

4

Return high temperature

5

Return high temperature

6

Return hot water

7

Flow low temperature*

8

Return low temperature*

9

Return high temperature*

10

Return hot water*

11

Condensate outlet

12

Exhaust flue duct

13

Gas inlet

Page 8

8

SYSTEM COMPONENTS

Figure 5

1

Hydraulic separator

2

Flow pipe

3

Return pipe

4

Gas pipe

5

Vent valve

6

Cock

7

Drain cock

8

Temperature gauge

9

Gauge fitting with cock

10

Damper device for gauge

11

Pressure gauge

12

Thermometer pit

13

Maximum pressure switch

14

Fuel check valve

15

5.4 bar safety valve

16

Expansion tank/filling fitting

17

Flow probe pit

18

Exchanger

19

Burner

20

Fan

21

Venturi tubes

22

Air inlet pipe

23

Gas valve

24

Exhaust flue duct

25

Condensate drainpipe

26

Vent valve

27

Ignition detection electrode

28

Safety thermostat

29

Gas cock

30

Diff. Pressure switch

31

Condensate drain manifold

32

Return probe

33

Exhaust flue probe

34

Master board

35

Slave board

36

Pump control board

37

Flow hot water system connection

38

Return hot water system connection

39

Flow high temperature connection

40

Return high temperature connection

41

Flow low temperature connection

42

Return low temperature connection

43

Modulating circulator

Page 9

9

4 INSTALLATION

b

Power Plus Box 1001

heating units must be installed

in conformity to the latest provisions of the law

and standards in force concerning heating units,

condensing boilers and/or other applicable regulatory

provisions.

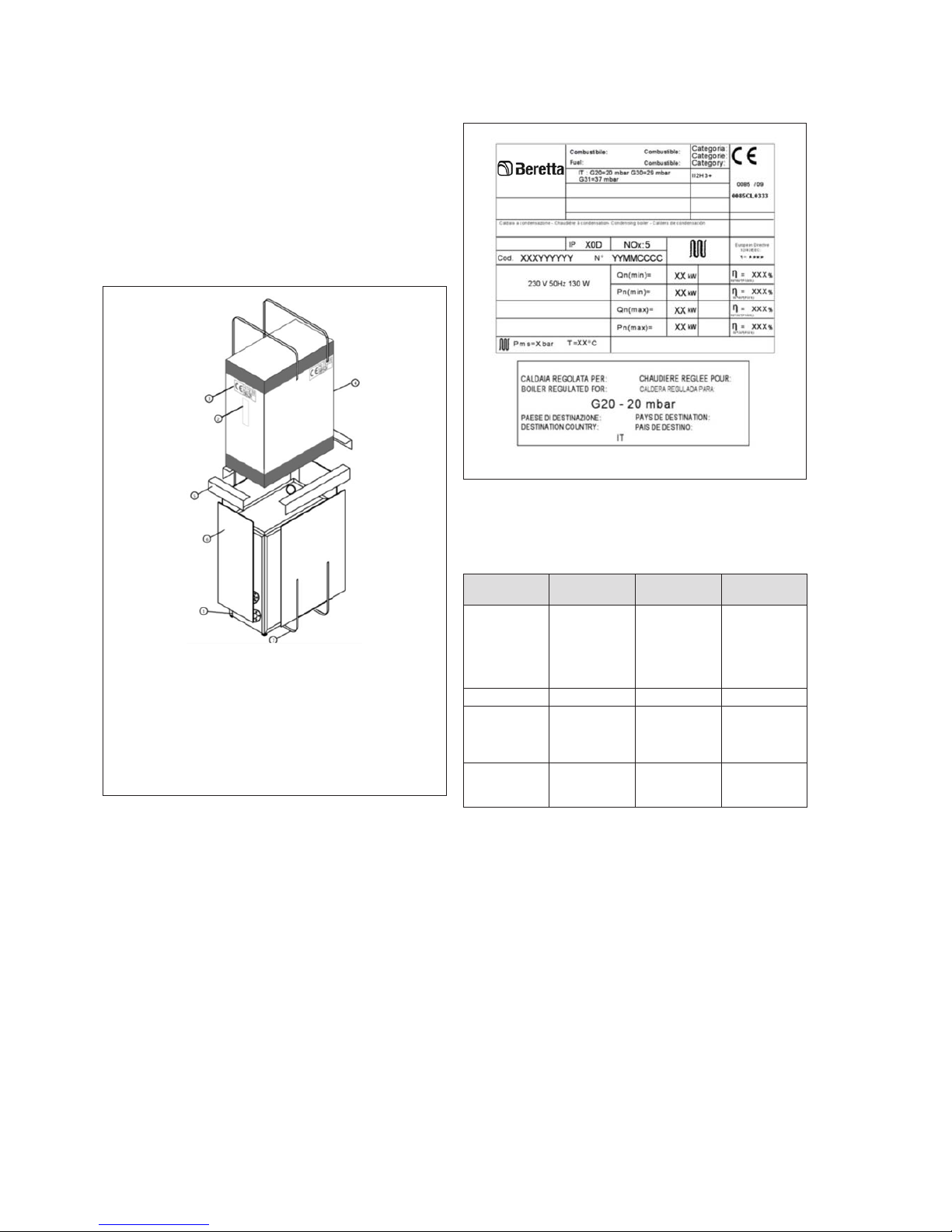

4.1 Product packaging and

identication

The

Power Plus Box 1001

heating unit is supplied, packed

and protected by a strapped carton.

Figure 6

1

Boiler

2

Control panel

3

EC marking/Symbol cartouche

4

Packaging

5

Polyester corners

6

Polyester protection panel

7

Strap

Details of the product are written on the outside: model,

power, version and type of fuel. Contact your local dealer

in case of any differences with the order.

Ensure the goods are intact and complete after unpacking

them.

b

Do not leave the packaging within the reach of

children as it could be a potential source of danger.

The tag on the front side of the boiler’s electrical board,

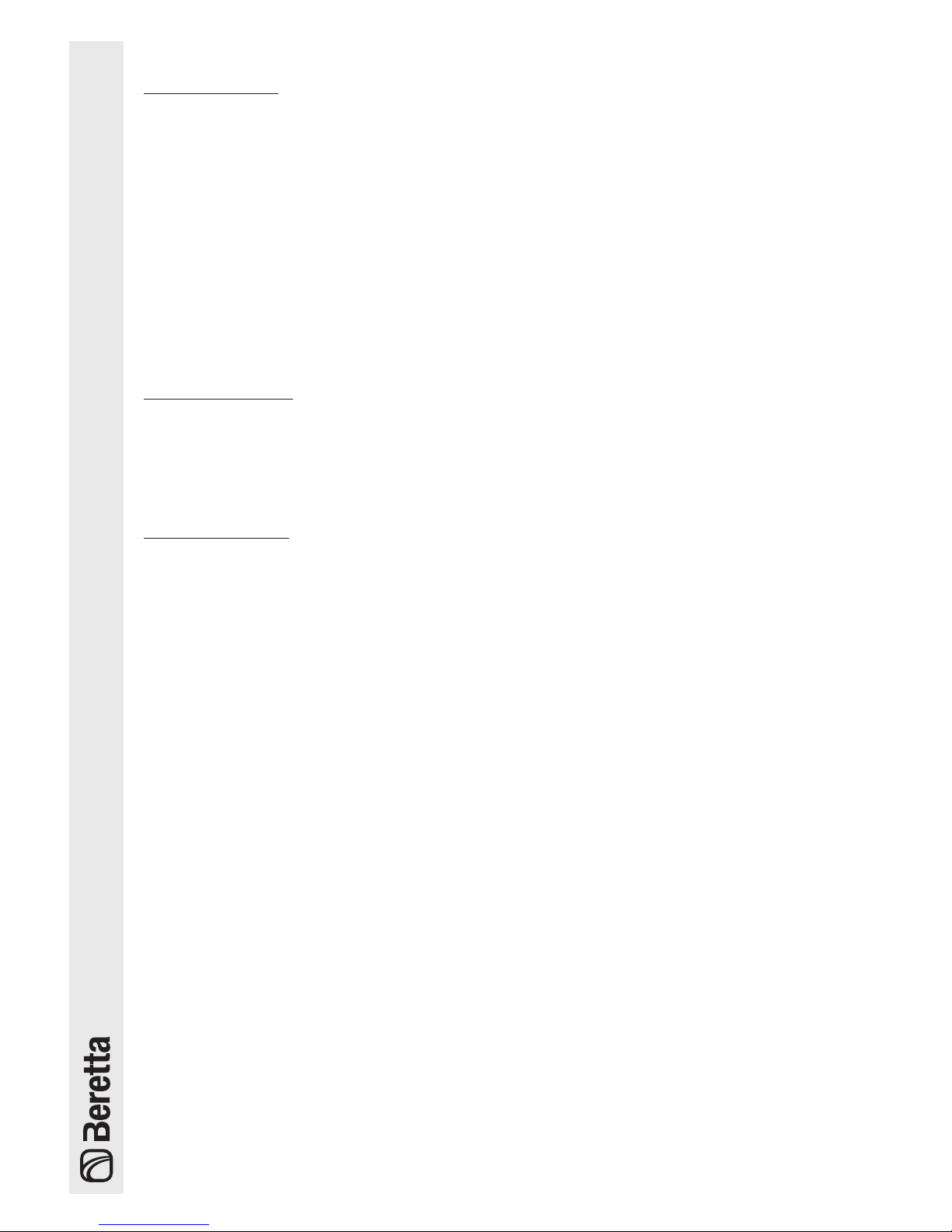

contains the following information:

- Product name

- Serial number

- Product identification code

- CE certification number

- Gas type and pressures from mains

- Power type from mains

- Rated heat capacity (Qn)

- Rated working power (Pn)

- Efficiency according to 92/42/EEC Directive (η)

- Max pressure and temperature (Pms)

- Primary system (T)

- NOx class (NOx)

Figure 7

a

It is forbidden to remove or mishandle the identification

plates, markings and any other making it difficult to

safely identify the product.

CONNECTION

DIMENSION

CONNECTION

TYPE

REMARKS

Water

distribution

2” Threaded

Flow/return

connections

for hot water,

high/low

temperature

systems

Gas fitting 1” Threaded

Exhaust flue

duct

Ø110 Socked

Piping in

plastic

material

allowed

Condensate

outlet

50 mm Socked

See

paragraph

4.1.8

4.2 Installation premises

The heating unit must be installed in premises used

exclusively for the latter conforming to standards and

legislation in force and where combustion exhaust

products and combustion air intake is conveyed out of said

premises. Where combustion air is instead taken from the

installation premises then the latter must be equipped with

suitably sized vents conforming to standards.

Page 10

10

b

The space required to reach the safety and

adjustment devices and to carry out maintenance

must be considered. We recommend leaving a space

of at least 500 mm at the back of the appliance.

b

Ensure that the degree of the heating unit’s electrical

protection is compatible with the characteristics of

the installation premises.

b

Electrical parts must be placed at a height of no less

than 500 mm from the ground where heating units are

supplied with fuel gas with specific weight exceeding

that of air.

b

Heating units may not be installed out in the open

(unless they are not specific outdoor units).

b

The heating unit is equipped with a frost protection

function, useful for installations where the temperature

of the environment could be below 0°C. Gas and

electricity must be supplied for this system to work,

apart from a correctly pressurized water circulation

system and the system must not be in shutdown due

to any type of error.

4.3 System cleaning and water

treatment

It is ABSOLUTELY NECESSARY to treat the water system

for the heating unit to work properly and to guarantee its

service life together with all its components.

This not only applies to jobs carried out on existing

installations but also on new installations.

Sludge, lime-scale and pollutants present in the water can

cause permanent damage to the heating unit, also within

a short time and regardless of the quality standards of the

materials used.

Contact the Technical Assistance Centre for any further

information on type and use of additives.

Chemical-physical characteristics of the water must

conform to the European CSN EN 14868 standard and to

the table given here below:

Initial

filling

water

Regular

service

water (*)

ph 6-8 7,5-9,5

Hardness < 10° < 10° °fH

Electrical

conductivity

< 150

μs/cm

Chlorides < 20 mg/l

Sulphides < 20 mg/l

Nitrides < 20 mg/l

Iron < 0,5 mg/l

(*)

Value of water in circulation system after functioning for

8 weeks.

b

Where softened water is used it is compulsory

to re-check conformity to tolerances for water in

regular service after 8 weeks from topping up and in

particular the electrical conductivity.

b

No controls are required when using de-mineralized

water.

4.4 General instructions

b

An automatic filling system may not be used for

topping up, which must be done manually and

recorded in the unit handbook.

b

If there are more than one boiler, they must all be

put into service either contemporarily or with a very

low rotation time during the initial period of service,

so as to evenly distribute the limited quantity of initial

lime-scale.

b

A flushing cycle must be programmed after the plant

has been installed to flush out any installation debris.

b

Water used for filling or for eventually topping up the

system must always be filtered (synthetic or metal

mesh filters with filtering capacity of no less than

50 micron) to avoid deposits possibly triggering off

under-deposit corrosion.

b

The heating system must be flushed out and cleaned

with good workmanship before filling up the existing

systems. The boiler may not be filled until after the

heating system has been flushed out.

4.5 New heating systems

b

The system must be filled up slowly the first time;

once it is filled and the air expelled it should never

need to be topped up again.

b

The system must be turned to maximum service

temperature during the initial ignition to facilitate

deaeration (a too low temperature prevents the gas

from coming out).

4.6 Upgrading existing systems

Where the boiler has to be replaced it is not recommended

to fill up again if the quality of the water in the existing

systems conforms to specifications. If the quality of water

fails to conform to specifications, we recommend either

re-treating it or separating the systems (the water quality

requirements must be respected in the boiler system).

4.7 Corrosion

Under-deposit corrosion

Under-deposit corrosion is an electrochemical process,

due to the presence of sand, rust, etc., inside the mass

of water. These solid substances generally deposit on the

bottom of the boiler (sludge), on tube and pipe heads or in

the gaps between pipes and tubes.

Micro-corrosion phenomena may be triggered off owing

to the difference in electrochemical potential coming to be

created between the material in contact with the impurity

and the surrounding one.

Corrosion from stray currents

Corrosion from stray currents can occur due to the differing

electrical potentials between water in the boiler and the

metallic mass of the boiler or piping. This process leaves

unmistakeable traces i.e. small regular conical holes.

Page 11

11

b

It is advisable to connect up the various metal parts

to a good earthing system.

b

The systems must always be separated if oxygen is

either continuously or occasionally introduced into

the installations (e.g. floor heating without pipes in

synthetic material resistant to diffusion, open vessel

systems, frequent topping up).

From what we have seen it is therefore important to avoid two

factors possibly leading to the above mentioned processes

i.e. contact between air and water in the installation and

regular topping up with fresh water.

To eliminate contact between air and water (and to prevent

the latter from becoming oxidized), it is necessary:

- for the expansion system to be a closed vessel type,

correctly scaled and with the correct pre-loading

pressure (to be regularly checked);

- for the installation to always be at a higher pressure

than that of the atmosphere at any point (comprising

the pump suction side) and under all running

conditions (all the water sealing and couplings in the

installation are designed to resist pressure towards

outside, but not for depression);

- that the installation will not be made with materials

permeable to gas (e.g. plastic pipes for floor systems

without anti-oxygen barrier).

a

Please contact the B Technical Assistance Centre

for flushing out the water circuit inside the exchanger.

Do not use incompatible liquid detergents, including

acids (e.g. hydrochloric acid and similar acids) at

any whatsoever concentration.

b

Lastly we would remind you that the warranty does

not cover breakdowns incurred by the boiler due to

deposits and corrosion.

4.8 Positioning and preparation for

installation

When positioning the appliance in the heating system,

account for the fact that water, gas and condensate

drainage connections must be made on the right-hand

side of the cupboard; adequate room must therefore be

left at the sides of the appliance for the space taken up by

parts of the external systems and for mounting the latter, as

shown in Figure 8.

Figure 8

4.9 Condensate outlet

The condensate water produced by

Power Plus Box 1001

a normal running conditions is evacuated into a special

manifold.

Drainage must be done at atmospheric pressure, i.e. by

dripping into a connected drain-trap, as follows:

- install a drip at the condensate drainage manifold;

- connect the drip to the sewerage mains by a draintrap;

- be ready to use a neutralizer where required (see

project cig E.01.08.929.0; ATV A 115).

There is generally no need to take any special precautions

for draining condensate.

We advise using plastic (PP) piping for building the

condensate drainage.

a

DO NOT for any reason use pipes in copper or in any

other material not specifically used for this particular

scope, as the condensing action could cause rapid

degradation.

Condensate collector

(*) Fill the siphons with water.

(*)

(*)

(at atmospheric pressure)

i > 3%

Civil drain

i

i ≥ 3°

minimum

distance

300 mm

minimum

distance

10 mm

Fig. 9

Furthermore, should the vertical part of the flue exhaust

duct have to be prolonged by more than 4 metres the

condensate drain-trap will have to be placed at the foot of

the piping. The working height of the drain-trap must be at

least 30 cm. The drain-trap outlet must then be connected

up to the sewerage mains.

b

The condensate drain must be connected to the

sewerage mains in such way as to prevent it from

being frozen under any circumstances.

b

Always install a condensate drain in the exhaust flue

duct at no more than 1 m from the boiler

Page 12

12

4.10 Water circuit

WORKING PRESSURE

The maximum working pressure of the boiler is 6 bar (600

kPa) whilst the minimum is 0.5 bar (50 kPa).

b

It is compulsory to install devices along the topping

up/supply line as well as the water circulation system

to protect the installation from pressures exceeding

550 kPa, in conformity to prescriptions given in the

EN 60335-2-102.

b

Do not expose the exchanger to cyclic changes

in pressure as fatigue stress does a lot of harm to

the system components. Should the water system

suddenly start generating changes in pressure it is

compulsory to use the protection devices to make the

boiler work at a regular pressure.

b

Installation pressure control must be done under cold

conditions.

FILLING UP THE BOILER

The boiler must be filled up by connecting the water from to

the mains to any part of the installation.

b

It is compulsory to use a standard filling device

(EN61770 type) for coupling up to the mains

specifically preventing the back-flow of liquid from

installation to water mains.

EMPTYING THE BOILER

The boiler is emptied through special emptying cocks

installed on the exchanger and water separator.

4.11 Exhaust ue

The exhaust flue duct and fitting to the flue duct must be

made in conformity to standards, legislation in force and to

local rules and regulations.

It is compulsory for ducts to be stiff, resistant to temperature,

condensate, mechanical stress and be sealed.

The flue duct must be as straight as possible, sealed and

insulated.

It must not have any occlusions or narrowing.

Maximum length of the exhaust flue duct (with a diameter of

Ø110 mm) is 55 metres.

Keep in mind that a 90° elbow equals 4 metres of straight

pipe and a 45° elbow one metre of straight pipe.

b

The boiler’s total potential exceeds 35 kW and can

therefore only be installed in premises with air vents

opening towards the outside and made in conformity

to provisions of the law in force (Ministerial Decree

D.M. 12.04.1996).

a

DO NOT for any reason use piping not specifically

designed for this specific scope as the condensing

action could cause rapid degradation.

a

In the event of installation with air intake from the

premises (both in the heating unit and externally)

avoid obstructing the passage of air under the metal

cupboard.

5 INSTALLATION DIAGRAMS

An installation diagram must generally be adapted to the

manufacturing characteristics of the relevant heating unit,

with the purpose of exploiting the boiler potentials to the

full and maintain the entire installation efficient for as long

as possible.

The electronic modulating circulator placed inside the

appliance is only for the primary system and works to keep

the ΔT constant with changes in power modulation. The ΔT

value is set at 20° in the factory and may be altered by

specialized personnel only.

The installation circulators must be scaled to the project

flow capacity and load-loss of said installation only. If the

distribution kits, provided as an accessory, are installed it

will be necessary to check that the technical features of the

low. system circulators and mixer valve are compatible with

the installation.

The Figure 10 shows the water diagram of the unit and

a typical system connectable to the latter, with the three

high, low temperature and hot water systems. Everything

in the large box with dotted lines is in the interior of the

unit. The circulation part in the shaded area is available

as an accessory distribution kit; otherwise it will have to be

installed on the outside of the system.

The Figure 11 shows the accessory distribution kits

installable inside the cupboard.

b

Distribution kits are equipped with shut-off valves.

These must be installed in appropriate places on the

installation.

Page 13

13

Figure 10

Figure 11

1

Heating module

2

High temperature system users

3

Low temperature system users

4

Remote controlled water tank

5

Check valve

6

Pressure reducer

7

Filter

8

Expansion tank

EAF

Water from mains

A

High temperature kit

B

Low temperature kit

C

Water tank kit

R

Non-return valve

Technical data - circulator in distribution kit

Figure 12

Page 14

14

6 ELECTRICAL SYSTEM

6.1 Power supply

A detailed wiring diagram of the heating unit is shown in

caption 11, at the diagram and technical data section.

Installation of the heating unit requires connection to a

230V - 50Hz grid system and must be done with good

workmanship in conformity to the electrical regulatory

provisions in force.

It is best to install a differential circuit-breaker switch along

the line supplying power to the boiler.

b

Adapters, multiple sockets, extensions to feed the

appliance are not allowed.

b

Always check the effectiveness of the electricity

earthing system, compulsory for the appliance and

used for connecting up to the heating unit. The

electronics could in fact put the entire heating unit into

safety shutdown should the latter not be compatible.

b

Make sure that the water and heating pipes have not

been used as earths for the electrical installation.

They are absolutely unsuited for this usage.

Wiring at a voltage of 230 V must be separated from those

at a voltage of 24V, using raceways or separate PVC tubes.

Make sure that the electrical features (volt, absorption,

starting current, etc.) of the external electrical components

(thermoregulators, solenoid valves, weather probes, etc.)

are compatible with the inlets and outlets available before

connecting them up.

Relays and/or ancillary contactors are to be used to

connect up the external electrical components, which must

be installed on a special electrical board externally.

This solution also enables circulators, valves, etc. to

function in emergency mode, i.e. should the boiler master

board not be serviceable.

a

Do not touch the electrical apparatus with parts of the

body wet or damp or with bare feet.

a

Do not leave the appliance exposed to atmospheric

agents (rain, sun, wind, etc.) unless it is the special

model for out of doors.

a

It is forbidden to pull, detach, twist the wiring coming

out of the heating unit, even if unplugged from the

power supply.

a

Do not allow people without experience to use the

appliance and switch off the heating unit if the power

cable should break; call in qualified personnel to

replace it.

Always refer to the data given in the diagrams in this

handbook for operations of an electrical nature.

Remember that B is not to be held liable for any

damages caused by ignoring the information given in the

wiring diagrams of this manual.

a

Never turn off the boiler while it is functioning

normally (with burner ignited) suddenly cutting off the

power supply with the on-off switch. This could cause

abnormal overheating in the primary exchanger. Use

a room thermostat or remote control to turn off (whilst

heating system is on).

6.2 Electrical connections

b

Qualified personnel only may work on the electrical

system and in compliance to provisions of the law,

with particular attention to rules on safety.

a

Lock the cables in their cable clamp designed to

ensure the latter are always in the correct position

inside the appliance.

6.2.1 Connection to mains

Connection must be made in compliance to regulatory

provisions in force on matters of electrical safety, with a

H05-VV-F-3GI multi-polar sheathed cable and minimum

conductor section of 1.5 mm

2

, appropriately protected

against humidity, abrasion and accidental contact.

The power cable must be connected to the terminal board

mounted on the DIN guide located on the right hand side

in the slave holder panel, located on the front of the boiler

under the control panel (see Figure 13).

Fix the cable by its cable clamp and supplied anchorages

to ensure it is correctly in place inside the appliance and

to prevent it from coming into contact with parts at high

temperatures (burner, etc.).

b

The earth conductor must be longer than the other

conductors (Phase, Neutral) so that the conductor

cables would the first to feel the strain should the

power cable become unplugged.

b

The rubber cable guides placed on the body of the

appliance must not be removed as their purpose is

to protect the cables from the wear generated by

direct contact between cable and appliance body.

It is sufficient to perforate the cable guide to pass

through a cable.

Figure 13

Page 15

15

6.2.2 Connection to thermoregulators

Power Plus Box 1001

heating units are equipped with an

extremely versatile control and operating system, able to

operate three independent systems functioning at different

temperatures. The procedure for connecting up the output

signal to the specific points on the terminal board will be

illustrated in the following pages (see Figure 15).

H05-VV-F type cables with minimum external diameter of

5mm and adequate conductor section may be used for

thermoregulation and low voltage systems, being careful to

fix the latter to their cable guides.

6.2.3 Connection to pumps

The

Power Plus Box 1001

adjustment system operates three

circulators at the same time for distribution to the high and

low temperature and hot water systems.

This operation is done by a Technical Assistance Centre

authorized by

B during commissioning the system, by

setting an appropriate parameter (specifically n. 34 in the

list of parameters).

b

Pumps or other external parts will be installed by using

a special relay/change-over switch as demonstrated

in Figure 14.

Use a H05-VV-F type cable with minimum external diameter

of 6 mm and adequate conductor section to connect the

terminal board to the relay (to be housed in a special

external board), being careful to fix the latter to its cable

guide.

For example, by connecting the low temperature circulator

to a timer and/or external room thermostat the electrical

installation will be the one shown in Figure 14.

This device will enable the circulators (external devices)

to be powered directly from the mains, without the relative

electrical load passing through the fuse on the board.

Furthermore, in cases of emergency mode, circulator

functioning can be controlled by the 0, 1, AUTO manual

device independently from the one on the board. It must

be strictly used for the above reasons.

Use a bi-polar cable of the power cable sort (unless

otherwise recommended by the component’s manufacturer.

6.2.4 Connection to room thermostats (on/

off)

Connect up the high temperature system room thermostat

to terminals 9. and 10 (Figure 15).

The thermostat for the low temperature system must instead

be connected to terminals n. 11 and 12 (6585977f-8ecf4eeb-8acd-1be6cdc82fb2).

6.2.5 Connection to weather temperature

probe

If you want to use a weather thermoregulator, the external

probe (optional) must be connected up to terminals n.7

and 8 (Figure 15). The external probe must be placed on

an outer wall facing north to north-east at a height of at least

2.5 metres and at a distance from windows, doors and air

vents.

Protect the probe from direct exposure to the sun. Contact

the Technical Assistance Centre authorized by B if the

curve has to be adjusted or the weather function excluded.

Figure 14

Page 16

16

Figure 15

Initials Jumper N. Description

S1 J11 (1-2)

Flow temp. probe

(HT)

SB J11 (3-4)

Water tank temp.

Probe

S2 J11 (5-6)

Flow temp. probe

(LT)

SE J11 (7-8) External temp. Probe

T2 J12 (9-10)

Room thermostat

(HT)

T2 J12 (11-12)

Room thermostat

(LT)

AI J12 (13-14)

0-10V analogic

device

CR J12 (15-17) Remote control

AL J8 (18-19) Alarm signal

VM J9 (20-22) Mixer valve

P4 J10 (23-24) LT system circulator

P1 J10 (25-26) HT system circulator

P2 J10 (27-28) Hot water circulator

Correspondence table for all sensors

Measured temperatures (°C) - Resistive values of the sensors (Ω).

T (°C)

R (°Ω)

T (°C)

R (°Ω)

T (°C)

R (°Ω)

T (°C)

R (°Ω)

T (°C)

R (°Ω)

T (°C)

R (°Ω)

T (°C)

R (°Ω)

- 20 67739 - 1 28481 18 13062 37 6470 56 3426 75 1925 94 1137

- 19 64571 0 27279 19 12565 38 6247 57 3319 76 1870 95 1108

- 18 61568 1 26135 20 12090 39 6033 58 3216 77 1817 96 1079

- 17 58719 2 25044 21 11634 40 5828 59 3116 78 1766 97 1051

- 16 56016 3 24004 22 11199 41 5630 60 3021 79 1717 98 1024

- 15 53452 4 23014 23 10781 42 5440 61 2928 80 1669 99 998

- 14 51018 5 22069 24 10382 43 5258 62 2839 81 1622 100 973

- 13 48707 6 21168 25 9999 44 5082 63 2753 82 1577 101 948

- 12 46513 7 20309 26 9633 45 4913 64 2669 83 1534 102 925

- 11 44429 8 19489 27 9281 46 4751 65 2589 84 1491 103 901

- 10 42449 9 18706 28 8945 47 4595 66 2512 85 1451 104 879

- 9 40568 10 17959 29 8622 48 4444 67 2437 86 1411 105 857

- 8 38780 11 17245 30 8313 49 4300 68 2365 87 1373 106 836

- 7 37079 12 16563 31 8016 50 4161 69 2296 88 1336 107 815

- 6 35463 13 15912 32 7731 51 4026 70 2229 89 1300 108 796

- 5 33925 14 15289 33 7458 52 3897 71 2164 90 1266 109 776

- 4 32461 15 14694 34 7196 53 3773 72 2101 91 1232 110 757

- 3 31069 16 14126 35 6944 54 3653 73 2040 92 1199

- 2 29743 17 13582 36 6702 55 3538 74 1982 93 1168

6.2.6 Frost protection

The heating unit electronic control includes a frost

protection function. When the flow temperature sinks

to below a minimum value, the burners start working at

minimum power according to the procedure used to set

the functional parameters.

The frost protection mode is activated even if the external

probe (supplied with the appliance) is not connected to the

boiler: parameters 14 (related to the Ch1 high temperature

system) and 22 (Ch2 low temperature system) are in fact in

default and set in weather function.

Should one not want to connect the probe, the boiler must

be made to work at a fixed point to avoid problems. The

parameter 14 and 22 settings may only be altered by a

Technical Assistance Centre authorized by

B.

b

Power and fuel gas supply must be activated and

the water system at a correct pressure for the frost

protection system to function.

Glycol can be used as an additive for the system (up to a

maximum of 50%) there where considered necessary by

the person responsible for the project, keeping in mind that

this substantially reduces efficiency as it alters the specific

heat of the fluid.

Furthermore several parts of the system could be damaged

by altering the pH.

Page 17

17

6.2.7 Connection to 0-10v external

thermoregulator

An external thermoregulator connection using a 0 – 10 v

signal could be used by connecting the output signal to

terminals n.13 and 14 (Figure 15).

b

The positive pole of the signal output must be

connected to terminal 13 for the device to work

correctly.

6.2.8 Connection to alarm device

A beeping or visual alarm device, to signal any technical

faults, may be connected outside by a special output with

clean contact on the boiler terminal board.

The alarm device must be connected to terminals n.18 and

19 (Figure 15).

6.3 Emergency mode

The

Power Plus Box 1001

electronic control system includes

a functional mode called “Emergency”, which can be

activated in case of a Master board malfunction.

The master board can in fact be excluded so as to enable

the system to work with a flow temperature preset in default

by the manufacturer, guaranteeing the heating unit with

continual service.

b

Qualified personnel only may work on the electrical

system and in compliance to provisions of the law,

with particular attention to rules on safety.

The following procedure must be adopted to enable the

“Emergency” function:

- Disconnect the 4-pole J14 connector from the master

board (see Figure 16);

- Set all four J17 switches on the heating unit slave

board to OFF (Figure 17);

- Supply power to all the circulators in the system

directly from the mains using the specific relays/

change-over switches;

- Connect terminal X1 or terminal X2 (which are part

of the J14 connector wiring disconnected during the

first step of this procedure) to a 24 V ac power supply

(see Figure 18).

Figure 16

Figure 17

Figure 18

Page 18

18

7 GAS VALVE CALIBRATION

Procedure

b

Gas valve calibration jobs must be done by the

Technical Assistance Centre authorized by B

only.

The procedure for calibrating the gas valve is given here

below:

- place the exhaust flue probe of the combustion

analyzer into the socket on the clapet;

- make sure there is demand from the two room

thermostats. In case of problems with starting up

the burner after the ignition cycle, turn the adjusting

screws anti-clockwise by about 1 turn at a time;

- take the burner to maximum power from the control

panel by pressing key

”SET/ESC”

and together for

5 secs. This will make it possible to select max. speed

with the (par. nr.15). All the fans in the system will

work at the set speed; this will be displayed on the

first digit to the left. H = maximum speed. The other 2

digits will show the flow temperature (e.g.: T1=80°C);

- Adjust combustion by the screws shown in Figure

19 until reaching the rated CO2 value, (see table),

turning the screws clockwise to reduce the value;

-

N.B.

Turn anti-clockwise to increase the gas flow

capacity and clockwise to reduce it;

- leave the boiler to run regularly at maximum power,

then adjust calibration if necessary;

- take the burner to minimum power, pressing key ;

- the letter “L” (Low=, the boiler will go to minimum

power) will appear to the left on the display; use the

gas valve offset adjusting screws (see Figure 20) to

reach the ideal values given in the following table.

GAS MAX CAPACITY MIN CAPACITY

Natural gas CO2 = 8.9 - 9.1 CO2 = 8.9 - 9.1

Figure 19

Figure 20

Page 19

19

8 USE AND ADJUSTMENT

8.1 Control panel: description

The

Power Plus Box 1001

panel is located inside the

Master board and is reached by opening the front panel.

The various buttons on the panel cover a large range of

functions going from simply monitoring the principal system

parameters to configuring the heating unit dependant on

the type of system found downstream from the latter.

The control panel was designed to enable the user to enter

the various user modes; each one of these has a set of

corresponding functions, activated by pressing a button or

combination of two buttons pressed together. Furthermore,

each button has a specific function depending on the

selected user mode.

Figure 21

BUTTON KEY DESCRIPTION

S1 Reset button Serves to release the electric board after a permanent arrest

S2 Set/esc button

Press to enter parameter mode and monitor mode for individual

units

S3 System selection button Press to visualize functional status of the various master systems

S4 Increase button Press to increase a specific value

S5 Reduce button Press to reduce a specific value

S6 Confirmation button Press to memorize new values

U2 Illuminated display Displays information on boiler status

U3 Illuminated display Displays information on boiler status

D4 Green led If on, it indicates the system is live

D5 Red led If on, it indicates a possible fault

Page 20

20

8.2 Display mode

The red (error) LED turns on in the case of faults that involve the permanent block of a heating element (normal operation

can be reset by pressing the Master or Slave reset button).

The green (on) LED indicates the presence of the electric power supply.

The 3 digits with seven segments display the system statuses:

SYSTEM STATUS DISPLAY

No demand for heating or hot water.

The two right hand digits display flow temperature T1. E.g. T1 = 30°C

Demand for 1st system or 1st and 2nd system simultaneously.

The two right hand digits display flow temperature T1. E.g. T1 = 80°C

Demand for hot water or simultaneous functioning.

The two right hand digits display flow temperature T1. E.g. T1 = 80°C

The point after the first digit flashes.

Demand for 2nd system.

The two right hand digits display flow temperature T1. E.g. T1 = 80°C

Antifreeze function

8.3 Display mode

Temperature values and operating status of the various circuits

Press the button to scroll forward and view the values set for the individual circuits.

The values listed below will be displayed in succession by pressing the button.

POS. VISUALIZED VALUES DISPLAY

1

Manifold delivery temperature T1

(e.g. T1 = 80°C)

2

Hot water T3

(e.g. water tank temp. = 50°C)

3

Outside temperature T4

(e.g. T4 = 7°C)

4 Flow temperature 2nd system or low T6 system

5

1st system room thermostat off or on

(e.g. OFF = contact open; ON = contact closed)

6

2nd system room thermostat off or on

(e.g. OFF = contact open; ON = contact closed)

7

0-10V analogue input

(e.g. 5.5V ; 10V respectively)

8

Mixer valve function status

(e.g. closing, opening, pause)

9

Principal circulator function status.

(e.g. circulator OFF; circulator ON respectively)

10

Function status hot water system circulator.

(e.g. circulator OFF; circulator ON respectively)

11

Second circulator function status

(e.g. circulator OFF; circulator ON respectively)

To exit the value display, press the

"OK"

button.

If no operation is performed within 5 minutes, the card will automatically return to display mode.

Page 21

21

8.4 Changing the user parameters

Pressing displays the following values in succession:

- manifold delivery temperature T1

- DHW temperature T3

- low temperature circuit delivery temperature T6.

To change the relative setpoints:

- press the

"Set/esc"

button: the relative value will appear, the two digits on the right will flash

- if the value should not be changed, press

”Set/esc”

again to return to display mode

- if the value should be changed, press and until the required value appears on the display. Press

"OK"

to save

the new value. The displayed value stops flashing and the display returns to the display mode

For example’s sake here below is a table showing the procedure for changing the setpoint value of the low temp. heating

system from 50 to 40°C.

POS. PROCEDURE DISPLAY

1 E.g. value read on display for high system 80° C

2

Press button

to enter display mode, press again and go to the first of 6 digits to

visualize the set value (e.g. 50° C)

3 Press button

”Set/esc”

4

Press

to take the setpoint to the desired value (e.g. 40° C)

5 Press

”OK”

to memorize the new value

6 After 3 secs. the display will return to the display mode with the new setpoint

If there is no change after pressing

”Set/esc”

for 10 secs. (the desired value corresponding to the set one) the display

returns to display mode function.

If there is no operation after pressing buttons and , after one minute the display will return to display mode. The

new selected value is not memorized.

8.5 Monitor mode

Press “Set/esc” for 5 seconds to access "Monitor" mode. This mode is used to check the operating values for every

system unit (addresses from 1 to 60).

POS. OPERATIONS DISPLAY

1 From current T1 position at 80° C

2

Press

”Set/esc”

for 5 secs. The displays shows it is possible to read the values or

functional status of unit 1

3

Press

or to scroll and read the values of the desired unit (e.g. fig., unit 19)

4

Pressing

the first value of the selected unit will appear. Afterwards by pressing the

same

button the next values will be visualized.

(e.g. fig., 1st value – flow temperature NTC 70° C).

5

Press

”Set/esc”

to exit monitor mode. The display will return to display mode function if it

is not pressed within 5 minutes or if no operation has been done.

Page 22

22

The following values for each single unit can be visualized with :

POS. DIMENSIONS DISPLAY

1 Flow temperature (e.g. 70° C)

2 Return temperature (e.g. 50° C)

3 Exhaust flue temperature (e.g. 60° C)

4

Ionization current (index from 0 to 99).

E.g. fig. Ionization current index 44.

5

Fan PWM signal (%).

If PWM = 100%, it corresponds to 99 on the display. E.g. fig. with

66%.

6

Flowmeter contact open and closed (e.g. fig. contact open then

contact closed)

7

Circulator or motor-driven valve individual unit on/off.

(e.g. fig. circulator on then circulator off)

8

Maximum ionization current (range from 0 to 99) at first attempt.

E.g. fig. Maximum ionization current value on display 80.

9

Hours worked by unit (from 0 to 9999 hours)

E.g. fig. 8050 hours: first thousands and hundreds then tens and

units will appear in succession and coupled on the display

8.6 Installer programming mode

The installer parameters can be changed by entering the password (22).

The installer level password makes it possible to view and change the user and installer parameters.

Procedure for accessing the programming mode:

POS. PROCEDURE DISPLAY

1

Manifold delivery temperature T1

(e.g. T1 = 80°C)

2 Press

“Set/esc”

and

“OK”

. After 5s, the second and third digits will flash

3

Use

and to enter the second number of the password (the right digit).

E.g: password = X2

4 Press

“OK”

to save the second number of the password

5

Use

and to enter the first number of the password (the central digit).

E.g: password = 22

6

Press

“OK”

to confirm the password, if the password is incorrect, the card returns to the

Display mode. If it is correct, the first parameter P06 is displayed

7

Press

and to scroll the parameters enabled by the password.

Press

“Set/esc”

to start to modify the parameters.

Now P-XX and the respective value will be shown alternatively on the display.

8

Press

and to change the parameter value.

Each time a button is pressed, the alternating display of the parameter and the respective

value stops for 5 seconds and only the value is displayed.

9 Press

“OK”

to save the new parameter value.

To exit the installer programming mode, press the

“Set/esc”

button.

See the chapter "Parameter list" for a complete list of the parameters.

Page 23

23

8.7 Test mode

In test mode it is possible to generate a high temperature heating demand at maximum power and at minimum power.

All system fans must be activated. If the installer turns off the switch for some Slaves, the others, connected to the Master,

must continue to operate.

Proceed as follows to enter Test mode from Display mode:

POS. VISUALIZED VALUES DISPLAY

1

Press

“Set/esc”

and at the same time for 5 s.

After 5 s select the maximum speed or the minimum speed with the

and buttons.

All system fans will operate at the selected speed.

The first digit indicates the selected speed (H = maximum speed; L = minimum speed).

The other two digits display the delivery temperature. E.g: T1 = 80°C.

2 Press

“OK”

to exit Test mode and return to Display mode.

8.8 Error mode

The display starts to flash in case of a fault originating from any heating element.

Follow the procedure indicated for identifying the errors.

POS. PROCEDURE DISPLAY

1 The display starts to flash to indicate one or more errors.

1.b

Press

: the address of the first unit will appear on the display, alternating with the first

error code.

Press

again to display the rest of the errors for this unit.

The errors of the subsequent units that are not functioning will be displayed in succession,

pressing the

button. By pressing the button, the errors will be displayed in reverse

order (E.g. unit 2 error code E05). If the errors originate from the Master card, they are

displayed as unit 00 errors (U 00 + error code).

2 Press

“Set/esc”

to exit Error mode and return to Display mode.

See the chapter "Fault list" for a complete list of the errors.

8.9 Permanent block

In the case of burners with a permanent block, the

“Reset”

button must be pressed to reset their operation.

If the

“Reset”

button is pressed while in Display mode, all the Slave heating elements will be reset.

If the

“Reset”

button is pressed while displaying the error that caused the permanent block, only the heating element

related to the block will be reset.

Page 24

24

9 SETTING FUNCTIONING PARAMETERS

The heating functions can be set for the high temperature, low temperature and DHW circuits based on the system

requirements by setting the functional parameters.

The first three parameters can be accessed on the user level. The next three require a password (“22”, see the "INSTALLER

PROGRAMMING mode" chapter in the "User interface" chapter.

To access the user parameters, press the button, and the following values will be displayed in order:

- manifold delivery temperature T1

- DHW temperature T3

- low temperature circuit delivery temperature T6.

To change the relative setpoints:

- press the

"Set/esc"

button: the relative value will appear, the two digits on the right will flash

- press and until obtaining the required value. Press

"OK"

to save the new value. The displayed value will stop

flashing after 3 sec and will be operative.

A detailed description of all the parameters and the factory preset values can be found in the "Parameter list" chapter.

9.1 Setting the heating parameters

The following heating parameters can be set:

1

Setpoint_T_CH_High

High temperature circuit setpoint (parameter 1)

If the "fixed point" operating mode is set (par. 14=CH_type_high=0), it is the target temperature.

If the "climatic control" operating mode is set (par. 14=1) , it is the maximum target temperature with minimum outdoor

temperature (T_out_min=par. 37, preset to 0°C).

parameter 18 (T_ch_high_foot, preset to 50°C) defines the minimum setpoint at maximum outdoor temperature (T_out_

max=par. 38, preset to 18°C).

Preset to 70°C and upper value limited by par. 17 (T_ch_high_limit, preset to 80°C).

T_out_max

External temperature (°C)

Delivery temperature (°C)

100

90

80

70

60

50

40

30

20

10

0

25 20 15 10 50-5 -10 -15

-20

CLIMATIC CURVE

HIGH TEMPERATURE circuit

T_CH_High

Max heat

requirement

T_CH_High_foot

T_out_min

Fig. 22

Page 25

25

2

Setpoint_T_CH_Low

Low temperature circuit setpoint (parameter 3)

If the "fixed point" operating mode is set (par. 22=CH_type_low=0), it is the target temperature.

If the "climatic control" operating mode is set (par. 22=1) , it is the maximum target temperature with minimum outdoor

temperature (T_out_min=par. 37, preset to 0°C).

parameter 24 (T_ch_low_foot, preset to 25°C) defines the minimum setpoint at maximum outdoor temperature (T_out_

max=par. 38, preset to 18°C).

Preset to 40°C and upper value limited by par. 23 (T_ch_low_limit, preset to 50°C).

T_out_max

External temperature (°C)

Delivery temperature (°C)

100

90

80

70

60

50

40

30

20

10

0

25 20 15 10 50-5 -10 -15

-20

CLIMATIC CURVE

LOW TEMPERATURE circuit

T_CH_Low

Max heat

requirement

T_CH_Low_foot

T_out_min

Fig. 23

Therefore, it is possible to work with a fixed point or set a climatic curve on every circuit.

3

CH_Priority

Heating priority (parameter 16)

If set to 0, the system will work without heating priority with the high temperature and low temperature circuits served in

parallel.

If set to 1, the demand from the low temperature circuit is ignored and the relative pump remains off. The low temperature

circuit demand is only accepted when the high temperature circuit demand is inactive. Vice versa, if set to 2, the low

temperature circuit has priority.

Preset to 0.

9.2 Setting the DHW parameters

The following DHW parameters can be set:

1

Setpoint_DHW

DHW setpoint (parameter 2)

This is the production temperature for DHW.

The maximum limit is indicated by par. 8 (T_DHW_limit,

preset to 60°C).

Preset to 50°C.

2

DHW_Type

Boiler type (parameter 6)

0 = No DHW service

1 = Quick exchanger with sensor

2 = Boiler with sensor

6 = Boiler with thermostat

In the case of a boiler with a thermostat, if the input is a

closed contact, the DHW demand is activated, if it is an

open contact the demand stops.

Preset to 0.

Page 26

26

3

DHW_Priority

DHW priority (parameter 9)

0 = Shifting priority A

The purpose of shifting priority function A is that the system

can also serve heating if the heating demand is low.

The system responds to the heating demand if:

(Setpoint_Ch - 50°C) < Temp_collettore < (Setpoint_Ch +

1°C)

Setpoint_Ch = Setpoint of the high or low temperature

circuit depending on demand.

1 = Shifting priority B

The purpose of shifting priority function B is that the system

never stops the heating service for too much time.

The system responds to the heating demand if:

(Setpoint_Dhw+T_Tank_extra) - 50°C < Temp_collettore <

(Setpoint_Dhw + T_tank_extra) + 1°C

T_tank_extra = Par. 10 = preset to 30°C.

2 = Absolute priority (only DHW service)

Preset to 0.

9.3 Heat control setting

1

Attenuation_High

HIGH TEMPERATURE circuit attenuation function

(parameter 21)

There are 2 cases:

- Fixed point operation Par. 14=0

- Operation with climatic control Par. 14=1.

FIXED POINT OPERATION, PAR. 14=0

With the high temperature circuit attenuation disabled,

Par21=0 when the high temperature circuit thermostat is

closed, the heating demand is activated. When opened,

the system turns off.

The Master control unit activates the high temperature

circuit pump PZ1 and the system pump PZ2 (if parameter

P34=0).

On the Master control unit it is possible to set the high

temperature circuit setpoint, Setpoint_T_CH_High = Par.

1, preset to 70°C and settable from 10°C to T_CH_high_

limit=Par 17, which is in turn preset to 80°C. The setpoint

used will be the one set with parameter 1.

The burner is on when:

Manifold temperature <=Setpoint – ignition hysteresis.

Ignition hysteresis can be set, CH_High_hyst_on = Par. 19,

preset to 7°C, can be set between 0 and 20°C.

The Master control unit converts the heat demand into

power demand for each slave control unit.

The burners are off when:

Manifold temperature >=Setpoint + shut-off hysteresis .

Shut-off hysteresis can be set (CH_High_Hyst_off=Par. 20,

preset to 3, can be set between 0 and 20°C).

With the high temperature circuit attenuation parameter,

Par. 21≠0, the high temperature thermostat contact

is ignored and a heat demand is present for the high

temperature circuit when:

Manifold temperature <=Setpoint – ignition hysteresis

The heat demand stops when:

Manifold temperature >=Setpoint + shut-off hysteresis .

The setpoint in this case coincides with the value set for

parameter 1 (Setpoint_t_ch_high) if the high temperature

thermostat contact is closed, whereas it is calculated as the

value set for parameter 1 less the attenuation (Setpoint_t_

ch_high-Attenuation_high) if the contact is open.

OPERATION WITH CLIMATIC CONTROL, PAR. 14=1

If the high temperature circuit attenuation is equal to 0 ,

Attenuation_high=Par. 21=0, its behaviour is the same as

the previous paragraph, with the exception that the setpoint

is calculated based on the outdoor temperature.

If the outdoor temperature = Tout_min=Par. 37, preset to

0°C, then setpoint =setpoint_T_Ch_high.

If the outdoor temperature = Tout_max=Par. 38, preset

to 18°C, then setpoint T_ch_high_ foot=Par. 18, preset to

50°C.

The setpoint is calculated linearly between the 2 outdoor

temperature values.

Preset to 0.

2

Attenuation_Low

LOW TEMPERATURE circuit attenuation function

(parameter 25)

This paragraph is similar to the previous paragraph for the

low temperature circuit.

There are 2 cases:

- Fixed point operation Par. 22=0

- Operation with climatic control Par. 22=1.

FIXED POINT OPERATION, PAR. 22=0

With low temperature circuit attenuation disabled, Par. 25=0

at the closure of the low temperature circuit thermostat,

heating demand is activated. When opened, the system

turns off.

The Master control unit activates the low temperature

circuit pump if the parameter for the third pump is set to

1 (P34=1).

On the Master control unit, it is possible to set the low

temperature circuit setpoint, Setpoint_T_CH_Low = Par.

3, preset to 40°C and can be set between 10°C and T_

CH_low_limit=Par. 23, which in turn is preset to 50°C. The

setpoint used will be the one set with parameter 3.

Page 27

27

The burner is on when:

Manifold temperature <=Setpoint – ignition hysteresis.

Ignition hysteresis can be set, CH_Low_hyst_on = Par. 26,

preset to 5°C, can be set between 0 and 20°C.

The Master control unit converts the heat demand into

power demand for each slave control unit.

The burners are off when:

Manifold temperature >=Setpoint + shut-off hysteresis .

Shut-off hysteresis can be set (CH_Low_Hyst_off=Par. 27,

preset to 3, can be set between 0 and 20°C).

With the low temperature circuit attenuation parameter, Par.

25≠0, the low temperature thermostat contact is ignored

and a heat demand is present for the low temperature

circuit when:

Manifold temperature <=Setpoint – ignition hysteresis

The heat demand stops when:

Manifold temperature >=Setpoint + shut-off hysteresis .

The setpoint in this case coincides with the value set for

parameter 3 (Setpoint_t_ch_low) if the low temperature

thermostat contact is closed, whereas it is calculated as the

value set for parameter 3 less the attenuation (Setpoint_t_

ch_low-Attenuation_low) if the contact is open.

OPERATION WITH CLIMATIC CONTROL, PAR. 22=1

If the low temperature circuit attenuation is equal to 0 ,

Attenuation_low=Par. 25=0, its behaviour is the same as

the previous paragraph, with the exception that the setpoint

is calculated based on the outdoor temperature.

If the outdoor temperature = Tout_min=Par. 37, preset to

0°C, then setpoint =setpoint_T_Ch_low.

If the outdoor temperature = Tout_max=Par. 38, preset

to 18°C, then setpoint T_ch_high_ foot=Par. 24, preset to

50°C.

The setpoint is calculated linearly between the 2 outdoor

temperature values.

Preset to 0.

3

T_out_correct

Outdoor temperature correction (parameter 39)

Normally, the displayed value is the value read by the

microcontroller plus or minus a correction value (T_

visualizzata = T read by the sensor +/- correction).

The read value of the outdoor temperature can be corrected

by varying the value of parameter 39, (the permitted limit

for the correction is +/- 30 °C). In this phase, it is suggested

to use a reference thermometer.

Preset to 0.

4

Summer Mode

Summer function (parameter 38.)

The Summer Mode function is used to deactivate requests

received by the High Temperature and Low Temperature

circuits and from the zones when the outside temperature,

T outside, is equal to or above the value set in parameter

38.

The Parameter 38. can be set with values between 0 and

30 [°C].

Preset to 0 (summer function disabled).

5

T4_frost_protection

Antifreeze protection (parameter 35)

The electronic control unit has active antifreeze protection

also in stand-by mode. The antifreeze protection has two

levels, the first that activates the pump and the second that

activates the pump and the burner.

If the manifold temperature ≤ 5°C, the high temperature

circuit pump and the system pump (third pump) are active

or, with CH_type=1 and outdoor sensor connected,

if the outdoor temperature ≤ 3°C (par. 35) the high

temperature pump and the system pump (third pump) are

active

If after 10’ the manifold temperature ≤ 5°C

a burner is on at maximum until the manifold temperature

≥ 20°C.

If after 10’ the manifold temperature ≥ 5°C but, with CH_

type=1 (Par. 14 or 22) and outdoor sensor connected, the

outdoor temperature ≤ 3°C (par. 35) the pump continues to

operate until the outdoor temperature ≥ 3°C. Parameter 35

can be set between -30°C and 15°C.

Preset to 3.

6

Power_control_mode

Cascading management (parameter 33)

To manage the power delivered by the system, two

cascading strategies are possible. In both cases, the

Master control unit can only add a new burner when

another is on.

If the Master control unit must increase the number of

ignited burners, first check that the next burner can be

ignited: no errors present and modular system temperature

below the maximum. Otherwise, check another burner. If

no burner is ready for ignition, the master will decrease the

number of burners to ignite.

Page 28

28

MODE: MINIMUM QUANTITY OF BURNERS IGNITED

(PAR. 33=0)

System power modulation is controlled by a PID regulator,

which controls the manifold temperature and the setpoint