Beretta POWER MAX 50 P DEP, POWER MAX 50 P, POWER MAX 100, POWER MAX 130, POWER MAX 110 Installation And Operation Manual

...Page 1

Installation and Operation Manual

Condensation | Heating module

POWER MAX

Installation and Operation Manual

EN

Page 2

2

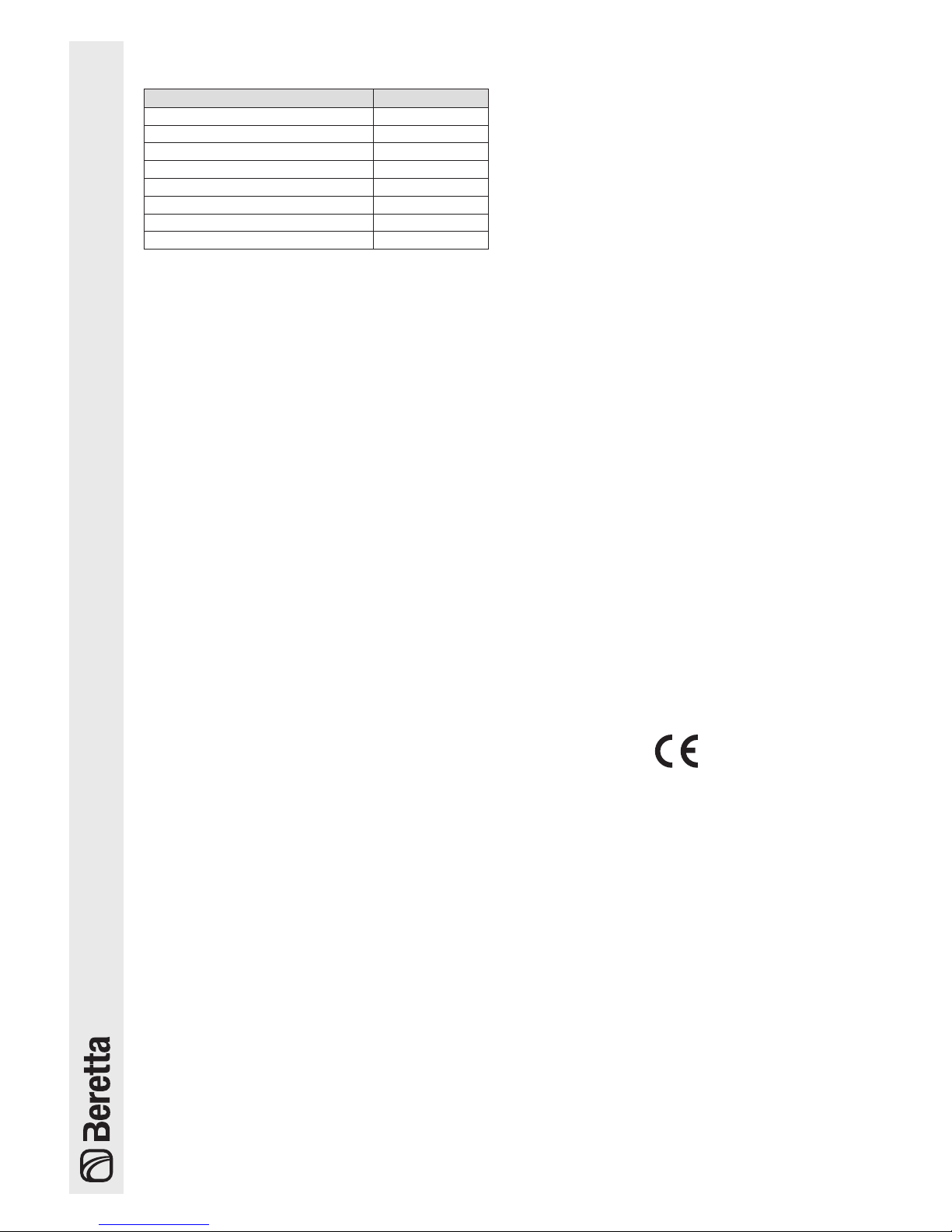

RANGE

MODEL CODE

POWER MAX 50 P DEP 20128429

POWER MAX 50 P 20128430

POWER MAX 65 P 20128431

POWER MAX 80 P 20128432

POWER MAX 100 20128433

POWER MAX 110 20128434

POWER MAX 130 20128435

POWER MAX 150 20128436

ACCESSORIES

For a complete list of accessories and details of their compatibility, refer to the Catalogue.

ENGLISH

Dear heating engineer,

congratulations on having chosen a thermal module B,

a quality product that is designed to give dependable, efcient and safe service and to provide comfort in the home

for many years to come.

This manual provides information that is essential to the installation of the appliance. Used in conjunction with your

own knowledge and expertise it will enable you to install the

appliance quickly, easily, and correctly.

Please accept our thanks and our congratulations on your

choice of product.

Beretta

CONFORMITY

thermal modules

POWER MAX

comply with:

- Gas Appliances Directive 2009/142/EC (until 20 April

2018) and Regulation (EU) 2016/426 (from 21 April

2018)

- Directive 92/42/EEC on efciency requirements and

Annex E and Pres. Republic Decree n. 412, 26 August 1993 (****)

- Electromagnetic Compatibility Directive 2014/30/EU

- Low Voltage Directive 2014/35/EU

- Ecodesign Directive 2009/125/CE for energy-related

products

- Energy Labelling Directive 2010/30/EU

- Delegated Regulation (EU) N. 811/2013

- Delegated Regulation (EU) N. 813/2013

- Standard for gas-red heating boilers - General requirements and tests - EN 15502-1

- Specic standard for type C appliances and type B2,

B3 and B5 appliances of nominal heat input not exceeding 1000 kW - EN 15502-2/1

- SSIGA Gas Appliance Directive G1

- AICAA Fire prevention requirements

- CFST LPG Directive Part 2

- VARIOUS cantonal and communal provisions on air

quality and energy saving.

Page 3

This manual, Code 20133145 - Rev. 3 (06/18) comprises 60 pages.

3

CONTENTS

The following symbols are used in this manual:

b

CAUTION! =

Identies actions that require caution

and adequate preparation.

a

STOP! =

Identies actions that you MUST NOT do.

This manual, Code

- Rev.

comprises

pages.

1 GENERAL INFORMATION . . . . . . . . . . . . . . .4

1.1 General Safety Information . . . . . . . . . . . . . . . . . 4

1.2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Description of the appliance . . . . . . . . . . . . . . . . 5

1.4 Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 System layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.7 Technical specications . . . . . . . . . . . . . . . . . . 10

1.8 Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.9 Water circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.10 Positioning the temperature sensors . . . . . . . . . 12

1.11 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . .14

2.1 Unpacking the product . . . . . . . . . . . . . . . . . . . 14

2.1.1 Positioning of labels. . . . . . . . . . . . . . . . . . . . . . 14

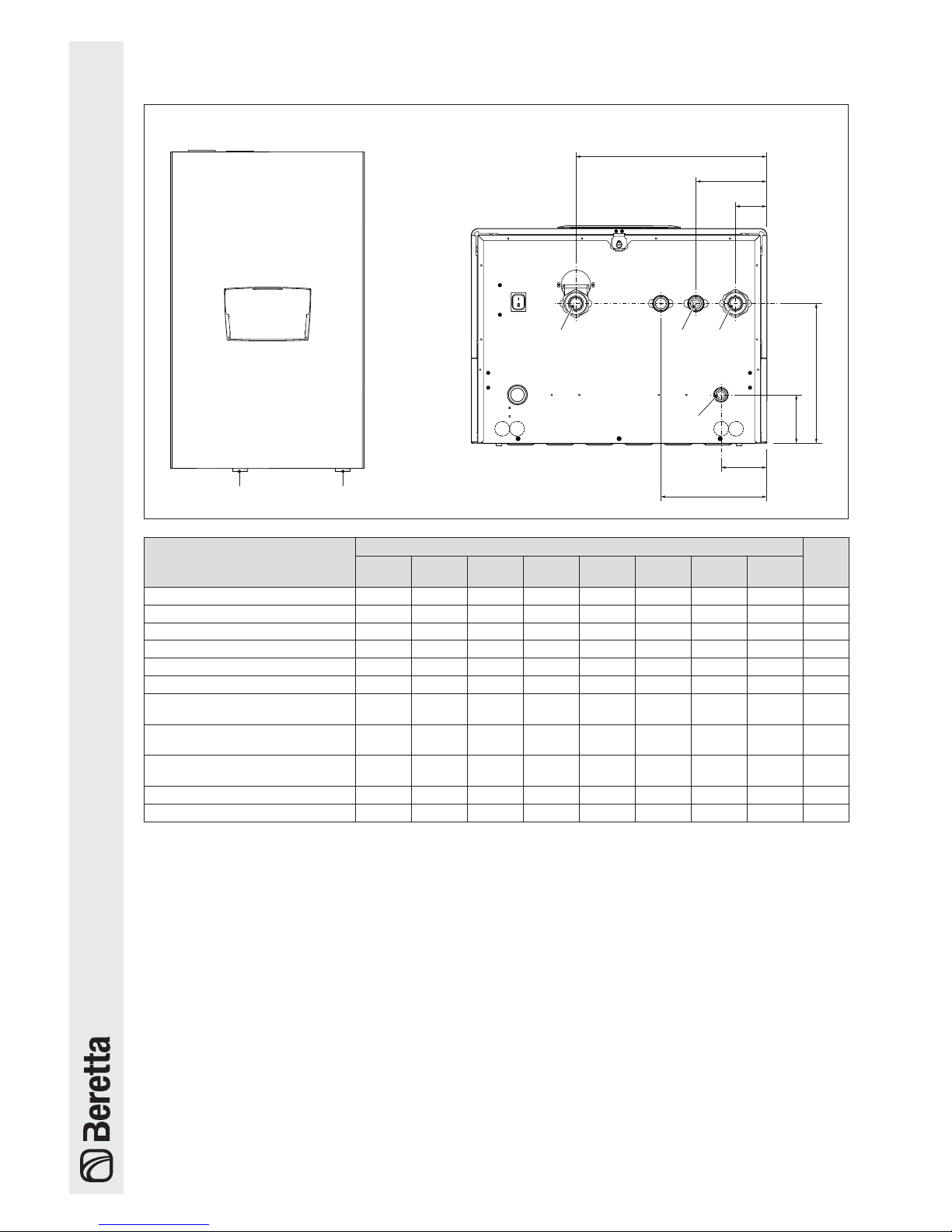

2.2 Overall dimensions and weights . . . . . . . . . . . . 14

2.3 Installation premises . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 Recommended minimum distances . . . . . . . . . 15

2.4 Installation in older systems and systems

requiring modernisation. . . . . . . . . . . . . . . . . . . 15

2.5 Moving and removing the packing . . . . . . . . . . 16

2.6 Thermal module assembly. . . . . . . . . . . . . . . . . 16

2.7 Water connections . . . . . . . . . . . . . . . . . . . . . . . 18

2.8 Typical water system schematics . . . . . . . . . . . 19

2.9 Gas connections . . . . . . . . . . . . . . . . . . . . . . . . 22

2.10 Discharge of combustion products . . . . . . . . . . 22

2.10.1 Preparation for the condensate drain . . . . . . . . 24

2.11 Neutralising the condensate . . . . . . . . . . . . . . . 24

2.11.1 Water quality requirements . . . . . . . . . . . . . . . . 24

2.12 System lling and emptying. . . . . . . . . . . . . . . . 25

2.12.1 Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.12.2 Emptying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.13 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.14 Electrical connections . . . . . . . . . . . . . . . . . . . . 29

2.14.1 USER navigation MENU. . . . . . . . . . . . . . . . . . . 32

2.15 Navigation Menu INSTALLER /

MANUFACTURER . . . . . . . . . . . . . . . . . . . . . . . 34

3 COMMISSIONING AND MAINTENANCE . . . 39

3.1 Preparing for initial startup. . . . . . . . . . . . . . . . . 39

3.2 Initial startup . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2.1 Switching the appliance on and off . . . . . . . . . . 39

3.2.2 Password access. . . . . . . . . . . . . . . . . . . . . . . . 39

3.2.3 Setting the heating parameters . . . . . . . . . . . . . 40

3.2.4 Setting the domestic hot water parameters. . . . 42

3.3 Checks during and after initial start-up . . . . . . . 43

3.4 Error List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.1 Permanent Errors . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.2 Temporary Errors . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.3 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.5 Transformation from one gas type to another . . 45

3.6 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.7 Temporary or short-term shut-down . . . . . . . . . 48

3.8 Preparing for extended periods of disuse . . . . . 48

3.9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.10 Cleaning and removing internal components . . 49

3.11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 SYSTEM MANAGER . . . . . . . . . . . . . . . . . . .54

4.1 Putting into service . . . . . . . . . . . . . . . . . . . . . . 54

4.2 Temporary or short-term shut-down . . . . . . . . . 55

4.3 Preparing for extended periods of disuse . . . . . 55

4.4 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6 Useful information . . . . . . . . . . . . . . . . . . . . . . . 56

5 RECYCLING AND DISPOSAL. . . . . . . . . . . . 57

Page 4

4

1 GENERAL INFORMATION

1.1 General Safety Information

b

After removing the packaging, check the condition

and completeness of the supply. If there are any

problems, contact the company

B that sold the

equipment.

b

This product must be installed by a legally qualied

heating engineer. On completion of the installation,

the installer must issue the owner with a declaration

of conformity conrming that the installation has been

completed to the highest standards in compliance

with the instructions provided by B in this instruction manual, and that it conforms to all applicable

laws and standards.

b

This product must only be used for the purpose

for which it is designed and made, as specied by

B. B declines all responsibility, contractual or

other, for damage to property or injury to persons or

animals caused by improper installation, adjustment,

maintenance or use.

b

In the event of a water leak, disconnect the thermal

module from the main power supply, shut off the water

supply and promptly notify the Technical Assistance

Centre B or professionally qualied personnel.

b

Periodically check that operating pressure in the water circuit is over 1 bar but below the maximum limit

specied for the boiler. If this is not the case, contact

Technical Assistance Centre B or a professional-

ly qualied heating engineer.

b

The following operations shall be necessary if the

thermal module is not used for a long period of time:

- Switch the boiler OFF at the control panel

- Turn the main system switch "off"

- Close the fuel cock and heating circuit water cock

- Drain the central heating circuit if there is any risk of

freezing.

b

Maintenance must be performed on the thermal module at least once a year.

b

This manual is an integral part of the appliance and

must therefore be kept with care and must ALWAYS

accompany the thermal module, even when it is

passed on to another owner or user or transferred to

another installation. If it is lost or damaged, please

contact your local Technical Assistance Centre B

for a new copy.

b

This manual must be read carefully so as to ensure

the correct and safe installation, operation and maintenance of the appliance. The Owner must be adequately informed and trained on how to operate the

appliance. Make sure that he/she is familiar with all

the information required for safe system operation.

b

The thermal module, before being connected to the

hydraulic system, the gas network, and the electrical

system, may be exposed to temperatures ranging

from 4°C to 40°C. After it can activate the Frost Protection function, it can be exposed to temperatures

ranging from -20°C to 40° C

b

Regularly check that the condensate drain is free

from obstruction.

b

We recommend cleaning inside the exchanger once

a year, extracting jet and burner and removing any

installation debris by suction. This operation will be

done by personnel from the Technical Assistance

Centre only.

1.2 Precautions

The operation of any appliance that uses fuel, electrical

power and water demands that a number of fundamental

safety precautions be respected:

a

Do not allow children or inrm persons to operate the

system unsupervised.

a

It is forbidden to use electrical devices or equipment,

such as switches, appliances, etc. if there is a smell

of gas or un-burnt products. If so:

- Ventilate the room, opening doors and windows

- Close the fuel shut-off cock

- Report the fault immediately to the B's Technical

Assistance Centre or a professionally qualied heating engineer.

a

Do not touch the boiler while barefoot or wet.

a

Any technical or cleaning activity is forbidden before

disconnecting the appliance from the main power

supply by switching the system's master switch and

the appliance's main switch to the "OFF" position.

a

Do not tamper with or adjust the safety or control devices without prior authorisation and instructions from

the manufacturer.

a

Do not plug or block the condensate drain outlet.

a

Never pull, disconnect, or twist the electrical cables

coming from the appliance even if it is disconnected

from the mains electricity supply.

a

Do not obstruct or restrict the vents in the room where

the boiler is installed. Adequate ventilation is essential for correct combustion.

a

Do not expose the appliance to weather elements

(without using the dedicated accessory). It has been

designed for indoor use.

a

Do not switch off the appliance if the outdoor temperature may drop to below ZERO (frost hazard).

a

Do not leave ammable containers and substances

in the room where the device is installed.

a

Do not dispose of packaging material into the environment, or leave it within the reach of children, since

it can become a potential hazard. Dispose of packaging material in compliance with applicable legislation.

a

Do not activate the thermal module without water.

a

Individuals without specic qualications and skills

are not allowed not remove the thermal module's

casing.

Page 5

5

1.3 Description of the appliance

POWER MAX

it is a condensing, pre-mixed thermal module

consisting in a modulating thermal element.

It is available in various models, ranging from 35kW to

131kW.

Optimal combustion management supports high yields

(over 109%, calculated over NVC, in condensation regime) and low polluting emissions (Class 6 pursuant to EN

15502).

The thermal module is designed for open chamber operation, but can be converted to sealed chamber operation by

tting a dedicated accessory.

The appliance in standard conguration is envisaged for

indoor installation to guarantee an IPX4D protection level.

b

Appliances may be cascaded

POWER MAX

to reach

a maximum power of 1.12 MW.

The appliance's key technical features are

- pre-mix burner with constant air-gas ratio;

- helicoidal heat exchanger with double coil with

smooth stainless steel pipe, to guarantee good corrosion resistance and the option of operating with high

∆ts (up to 40°C), reducing system set-up times;

- power from 35 to 131 kW;

- maximum ue gas output temperature 100°C;

- microprocessor management and control with self-diagnostics, shown by means of a display, and logging

of main errors;

- Anti-Frost function;

- pre-setting for room/heat demand thermostat for low

and high temperature ranges;

- option to manage a CH circuit and a DHW circuit with

storage tank;

- high-efciency and high residual discharge head circulator (for models up to 70kW; a circulator is available as an accessory upon request for other models);

- climate control function (available only when using

the outdoor temperature sensor accessory).

1.4 Safety devices

All appliance functions are electronically controlled by a

dual processor technology board approved for safety functions.

Any malfunction results in the appliance being shut down

and the automatic closure of the gas valve.

The following is installed on the water circuit:

-

Safety thermostat

.

-

Flow sensor

capable of monitoring the main circuit's

ow on an ongoing basis and of stopping the appliance in the event of insufcient ow.

-

Temperature probes

on delivery and return lines that

measure the temperature difference (∆t) between

input and output uid and enable activation of the

control.

-

Minimum pressure switch

.

The following is installed on the combustion circuit:

-

Gas solenoid

in class B+C , with pneumatic gas ow

compensation depending on the suction line's air

ow rate.

-

Ignition/detection electrode

.

-

Flue gases temperature probe

.

b

The triggering of safety devices indicates the malfunction of a potentially hazardous thermal module.

Therefore, contact Technical Assistance Centre immediately. After a brief pause, it is possible to try and

restart the appliance (see Paragraph "Initial startup").

b

Safety devices must be replaced by Technical Assistance Centre, using only original parts. Refer to the

spare parts catalogue supplied with the appliance.

After making the repair, check that the appliance is

working properly.

a

The appliance must not be put in service, even temporarily, when tampered safety devices are not in operation or have been tampered with.

Page 6

6

1.5 Identication

The products are identied by:

1 Technical data plate

It indicates the technical and performance data.

2 Gas label

.

Is located on the appliance's side and states the type of fuel used and the country of destination.

2

Paese di destinazione:

Tipo di apparecchio

Caldaia categoria::

B23

II2H3+

Pressioni di alimentazione gas:

Regolazione effettuata dal costruttore:

G20 - 20 mbar - 2H METANO

ATTENZIONE

Leggere attentamente il libretto istruzioni

prima di installare e mettere in servizio

l'apparecchio.

(Laterale DX)

Temperatura ambiente:

min. -10°C max. 50°C

Questo apparecchio puó essere installato e

funzionare all'aperto o solo in locali

permanentemente ventilati secondo norma

UNI7129.

068411_E0

G20 20 mbar

G30 28-30 mbar

G31 37 mbar

1

European Directive

92/42/EEC:

Gas type:

Category:

IT

Caldaia a condensazione - Chaudierè a condensation - Brennwertkessel - Condenserende verwamingsketel

G20 G25

Qn(max)=

Cod.

N°

Pn(max)=

Qn(min)=

Pn(min)=

-

P.min.G20= 20 mbar

IP

G20 - 20 mbar

NOx:

bar

T=

°C

kW

kW

kW

kW

kW

kW

kW

kW

T067692GE

-

-

-

17

CALDAIA REGOLATA PER:

CHAUDIERE REGLEE POUR:

KESSEL GEREGELT FUR:

VERWARMINGSKETEL INGESTELD OP:

KEDEL REGULERET TIL:

CENTRALA REGLATA PENTRU:

A KAZAN AZ ALABBI ADAKTORA LETT BEALLITVA:

PAESE DI DESTINAZIONE:

PAYS DE DESTINATION:

LAND VON BESTEMMING:

BESTIMMUNGSLAND:

LAND,HVOR KEDLEN SKAN INSTALLERES:

TARA DE DESTINATIE:

RENDELTETESI ORSZAG:

PMS=

Beretta Caldaie

Via Risorgimento, 13

23900 Lecco (LC)

Central heating section

Qn

Rated heat input

Pn

Rated useful heat output

IP

Electric degree of protection

PMS

Maximum operating pressure, CH circuit

T

Temperature

η

Efciency

NOx

NOx class

b

If these plates or any other means of clearly identifying the product are defaced, removed or lost, proper installation

and servicing may be rendered difcult.

Page 7

7

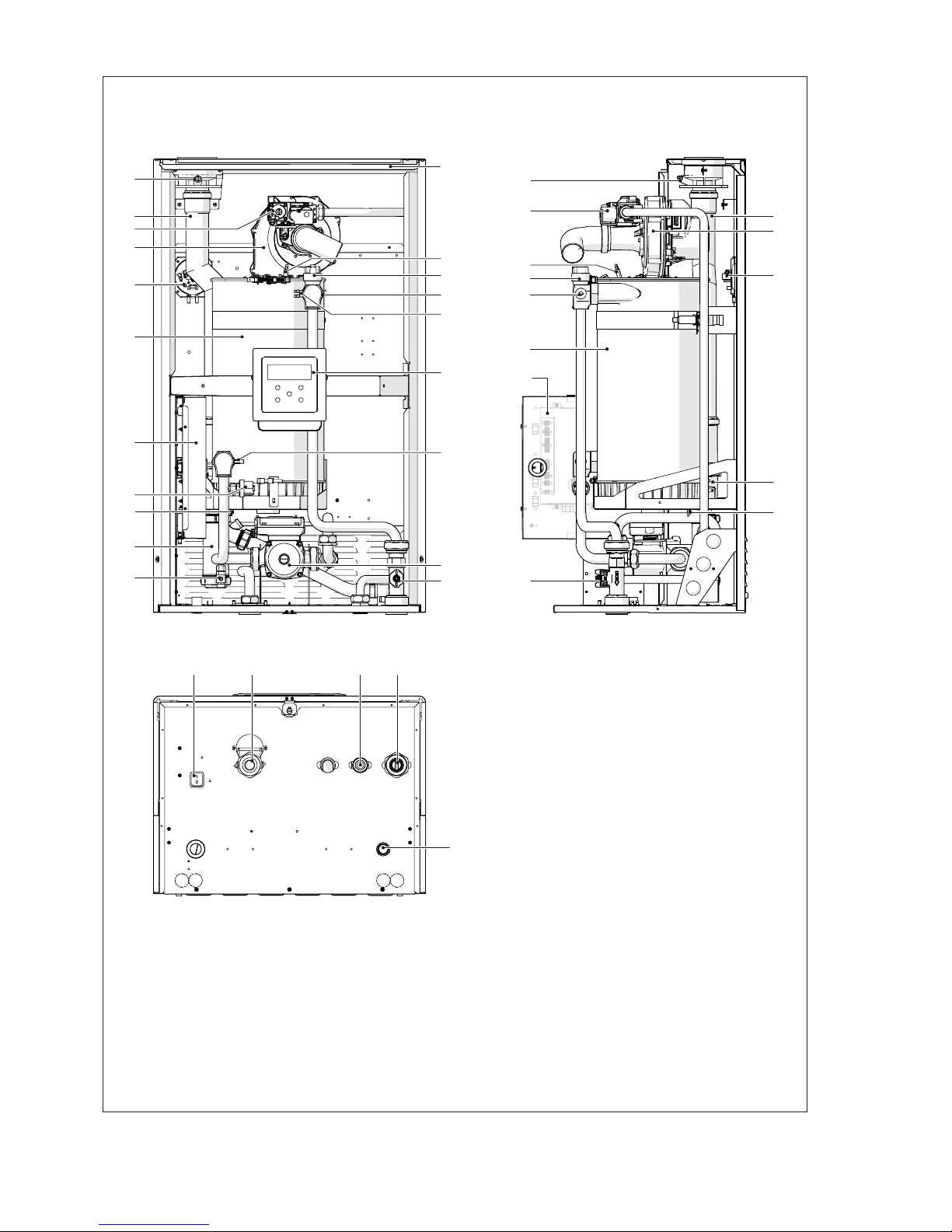

1.6 System layout

POWER MAX

50 P DEP - 50 P

1

3

6

7

17

9

2

5

4

16

13 14 15

1

2

3

4

6

5

7

8

10

9

11

17

18

19

20

12

23

22

24

26

24

21

22

23

25

1

Flue gas analysis outlet

2

Flue gas exhaust connection

3

Gas valve

4

Fan

5

Flue gases pressure switch

6

Combustion chamber

7

Electrical panel

8

Minimum Pressure Switch set at 0,7 bar

9

Exhaust ue probe

10

Condensate drain siphon

11

Drain cock

12

Main switch

13

Central heating return

14

Gas supply

15

Central heating ow

16

Condensate drain connection

17

Flow-meter

18

Pump

19

Return probe

20

Control panel

21

Safety Thermostat with manual reset by PCB

22

Flow probe

23

Automatic bleed valve

24

Ignition/detection electrode

25

Casing

26

Smoke-exhaust ue non-return valve

Page 8

8

POWER MAX

65 P - 80 P

1

2

3

4

5

1

4

5

6

10

16

6

7

8

9

10

22

20

21

23

24

17

2

21

22

23

3

16

15

1211 13 14

17

19

18

1

Flue gas analysis outlet

2

Flue gas exhaust connection

3

Gas valve

4

Fan

5

Combustion chamber

6

Electrical panel

7

Smoke-exhaust ue non-return valve

8

Drain cock

9

Minimum Pressure Switch set at 0,7 bar

10

Pump

11

Main switch

12

Central heating return

13

Gas supply

14

Central heating ow

15

Condensate drain connection

16

Flow-meter

17

Exhaust ue probe

18

Return probe

19

Control panel

20

Ignition/detection electrode

21

Safety Thermostat with manual reset by PCB

22

Flow probe

23

Automatic bleed valve

24

Casing

Page 9

9

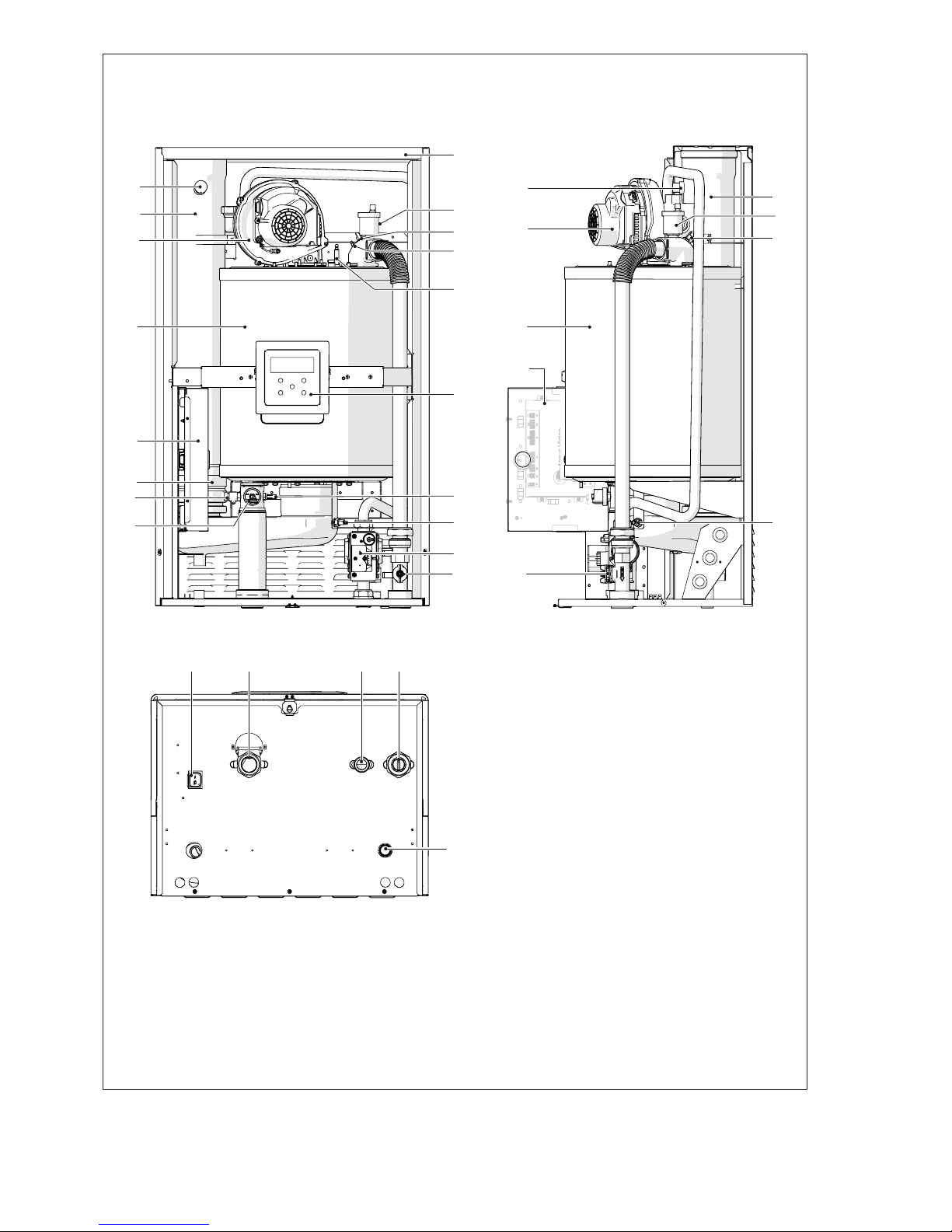

POWER MAX

100 - 110 - 130 - 150

1

3

4

5

14

16

2

21

22

13

109 11 12

1

2

3

4

5

6

7

8

19

23

14

21

20

22

16

15

18

17

1

Flue gas analysis outlet

2

Flue gas exhaust connection

3

Fan

4

Combustion chamber

5

Electrical panel

6

Smoke-exhaust ue non-return valve

7

Drain cock

8

Minimum Pressure Switch set at 0,7 bar

9

Main switch

10

Central heating return

11

Gas supply

12

Central heating ow

13

Condensate drain connection

14

Flow-meter

15

Gas valve

16

Exhaust ue probe

17

Return probe

18

Control panel

19

Ignition/detection electrode

20

Safety Thermostat with manual reset by PCB

21

Flow probe

22

Automatic bleed valve

23

Casing

Page 10

10

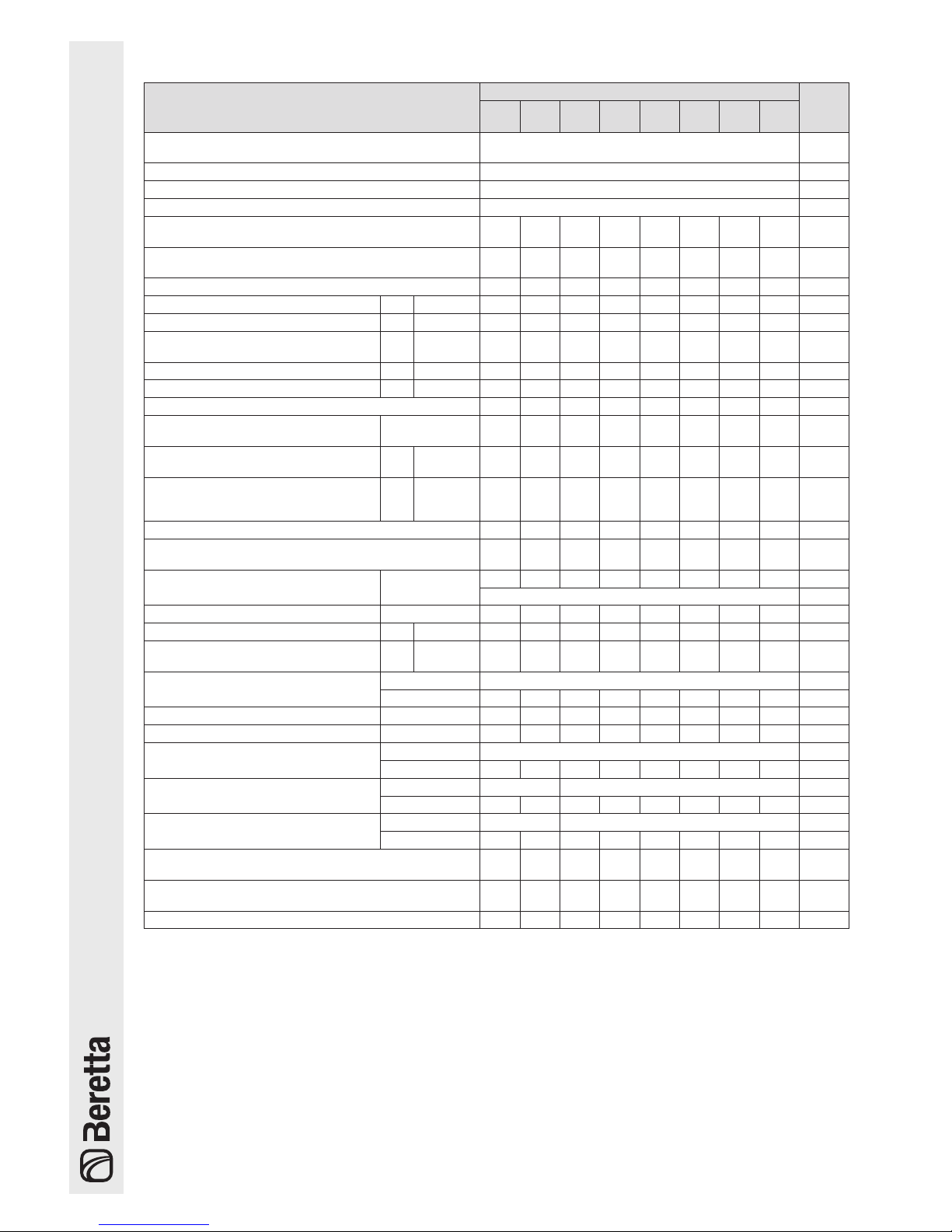

1.7 Technical specications

Description

POWER MAX

U.M.

50 P

DEP

50 P 65 P 80 P 100 110 130 150

Appliance type

Condensing boiler heating system

B23, B53; B53P

Fuel G20-G25-G30-G31

Device category II2H3P

Combustion chamber vertical

Maximum rated heat input at furnace referred to HVC

(LCV)

38,7

(34,9)50(45)63(57)76(68)

100

(90)

108

(97)

124

(112)

146

(131)

kW

Minimum rated heat input at furnace referred to HVC

(LCV)

10

(9)10(9)15(14)15(14)

21,6

(19,4)

21,6

(19,4)

24,9

(22,4)

29,2

(26,2)

kW

Useful (rated) heat output 34,4 44,2 56 68 88 95 110 129 kW

Maximum rated heat output (80-60°C) P4 G20 34,4 44,2 55,7 67,0 88,3 95,3

109,8 129,0

kW

Maximum rated heat output (50-30°C) - G20 38,0 48,8 61,9 73,9 97,4

105,1 121,1 142,1

kW

Maximum nominal heat output (6040°C)

- G20 36,6 47,0 59,6 71,4 93,8

101,1 116,2 137,3

kW

30% heat output with return at 30°C P1 G20 11,5 14,7 18,7 22,3 29,4 31,7 36,6 43,0 kW

Minimum rated heat output (80-60°C) - G20 8,9 8,9 13,5 13,5 19,2 19,2 22,1 26 kW

Efciency class in central heating mode A A A A - - - -

Seasonal energy efciency in central

heating mode

ηs

94 94 94 94 94 94 94 94 %

Efciency at rated heat input and High

temperature GCV (NCV) regime

η4

useful Pn

(60-80°C)

88,5

(98,4)

88,4

(98,3)

88,4

(98,3)

88,2

(97,9)

88,3

(98,0)

88,2

(97,9)

88,6

(98,3)

88,2

(97,9)

%

Efciency at 30% of the nominal thermal ow and on low PCS temperature

regime

η1

useful

30% of

Pn

98,4

(109,5)

98,2

(109,2)

98,2

(109,2)98(108,8)

98,1

(108,9)98(108,8)98(108,8)

98,1

(108,9)

%

Chimney losses with burner on at max. Pn (80-60°C) 2,3 2,3 2,3 2,3 2,5 2,6 2,5 2,6 %

Chimney losses with burner on at max. 30% Pn (50-

30°C)

0,5 0,5 0,5 0,5 0,6 0,6 0,5 0,6 %

Heat loss in standby mode Pstby

45 57 72 87 115 124 143 168 W

0,1 %

Annual energy consumption QHE 71 91 117 141 - - - - GJ

Noise level (sound power)

LWA

at P max 51 52 53 54 55 56 57 57 dB(A)

Emissions (*)

NOx

(referred

to HCV)

42,0 43,9 34,2 36,4 38,1 38,7 39,3 46,1

mg/

kWh

Emissions at max./min. heat input,

G20

CO

2 9 - 9 %

CO

63/2,3 73/2,3 79/6,5 90/6,5 81/7,5

91,5/7,5

89/4,6

91,5/5,6

ppm

Maximum rated heat input (LCV) G25 35 50 53 65 85 93 107 127 kW

Minimum rated heat input (LCV) G25 9 9 13 13 18,1 18,5 21,4 24,5 kW

Emissions at max./min. heat input,

G25

CO

2 9 - 9 %

CO

72/3,2 80/3,2

92/7

93,5/7

84/8 94/8 92/6 95/7 ppm

Emissions at max./min. power G30

CO

2 10,4-9,9 10,4-10,4 %

CO

132/6 137/6

138/10 142/10 148/11 159/11 172/13 180/15

ppm

Emissions at max./min. power G31

CO

2 10,4-9,9 10,4-10,4 %

CO

136/8 141/8

142/11 147/11 153/12 163/12 177/14 185/16

ppm

Flue gas temperature at max. power and min. power

80-60°C

66,5/61 67,5/61

71/61 72/61 76/62 78/62 75/61 77/61

°C

Flue gas temperature at max. power and min. power

50-30°C

44/32 45/32 45/33 46/33 47/35 49/35 45/33 48/35

°C

Flue gas mass ow rate (**)

0,015

0,02

0,025

0,03 0,04

0,046

0,05 0,06 Kg/s

(*)

Weights calculated according to EN 15502.

(**)

Values referred to atmospheric pressure at sea level.

Page 11

11

Description

POWER MAX

U.M.

50 P

DEP

50 P 65 P 80 P 100 110 130 150

Water-side resistance (∆T 20°C)

- - - - 160 210 350 510 mbar

Available useful discharge head (∆T 20°C)

420 250 490 390 - - - - mbar

Maximum working pressure 6 bar

Minimum supply pressure 0,7 bar

Maximum permitted temperature 100 °C

Lockout thermostat activation temperature 95 °C

Adjustment temperature (min / max) 30 / 80 (***) °C

Thermal module water content 5 5 15 15 17 17 23 25 l

Maximum condensation at 100% rated heat output

(50-30°C)

5,4 7,0 8,9 10,1 13,6 15,0 17,5 19,8 l/h

Power supply 230-50 V-Hz

Index of protection IPX4D IP

Consumption at full load Elmax 75 105 63 77 150 203 205 302 W

Consumption at part load Elmin 31 34 30 30 36 31 44 45 W

Electrical consumption in standby

mode

Psb 9 9 13 13 6 6 6 8 W

(***)

Up to 85°C if combined with the plate heat exchanger accessory.

1.8 Pumps

The thermal modulesPOWER MAX 50 P DEP, POWER MAX

50 P, POWER MAX 65 P and POWER MAX 80 P are tted

with a circulator.

Residual head (mbar)

0

100

200

300

400

500

600

700

800

900

0 1,5 2 2,5 3 3,510,5 4

POWER MAX 65 P

POWER MAX 80 P

POWER MAX 50 P DEP

POWER MAX 50 P

Flow-rate (m3/h)

b

At the rst start-up, and at least once a year, the rotation of the circulator shaft should be checked as, especially after long periods of not being operated, deposits and/or residuals could impede its free rotation.

b

Before loosening or removing the circulator cap, protect the electric devices located underneath from any

water that exits.

a

It is prohibited to operate the circulators without water.

Thermal modules POWER MAX 100, POWER MAX 110,

POWER MAX 130 and POWER MAX 150 are not equipped

with a circulator, which must be inside or outside the appliance (see accessories).

For its sizing, consider the thermal module's water-side

pressure drops, which are shown in the chart below.

Water-side pressure drop

Pressure drop (mbar)

0

100

200

300

400

500

600

700

800

900

1000

0 3 4 5 6 7 8 921

POWER MAX 110

POWER MAX 100

POWER MAX 130

POWER MAX 150

Flow-rate (m3/h)

Page 12

12

1.9 Water circuit

2

9

MIRI

1 6 7 8

3

4

5

1

Heat exchanger

2

Circulator (only for models POWER MAX 50 P

DEP - POWER MAX 80 P)

3

Drain cock

4

Minimum pressure switch

5

NTC return probe

6

NTC delivery probe

7

Safety thermostat temperature sensor

8

Automatic bleed valve

9

Flow-meter

MI

Central heating ow

RI

Central heating return

Values of NTC probes' resistors with changing temperatures.

Temperature

°C

Tolerance test

±10%

Resistor

Ω

Temperature

°C

Tolerance test

±10%

Resistor

Ω

-40 191908 45 4904

-35 146593 50 4151

-30 112877 55 3529

-25 87588 60 3012

-20 68471 65 2582

-15 53910 70 2221

-10 42739 75 1918

-5 34109 80 1663

0 27396 85 1446

5 22140 90 1262

10 17999 95 1105

15 14716 100 970

20 12099 105 855

25 10000 110 755

30 8308 115 669

35 6936 120 594

40 5819 125 529

1.10 Positioning the temperature

sensors

Probes placed on the related sockets of the thermal

module (POWER MAX 50 P DEP - POWER MAX 50 P):

1

Exhaust ue probe

2

Safety thermostat temperature sensor

3

CH ow temperature sensor

4

Return probe

1

4

1

3

2

Front view Side view

Probes placed on the related sockets of the thermal

module (POWER MAX 65 P ÷ POWER MAX 150):

1

Exhaust ue probe

2

Safety thermostat temperature sensor

3

CH ow temperature sensor

4

Return probe

3

2

2

3

1

1

4

Front view Side view

Page 13

13

1.11 Control panel

CONTROL PANEL AND SYMBOLS

PROG

RESET

MENU

1

2

4

3

3

1

Rear light display

2

MENU/Reset key: access to the main menu and restore functioning further to a failure lock-out

3

Navigation keys

4

Main switch (located on the lower part of the appliance)

SECONDARY INFORMATION/DISPLAY VISUALISATION

8.8:8.8

8.8:8.8

OUTSIDE

°C

°F

BAR

PSI

1 2 3 4 5 6

89

7

10

1

Icon displayed when heating mode is enabled. Blinking when there is a heat demand

2

Icon displayed when DHW mode is enabled. Blinking when there is an DHW Demand

3

Icon displayed when entering the "Installer" or "Manufacturer" menu

4

Icon displayed when the appliance burner is on

5

Icon displayed when a Permanent or Temporary error occurs

6

Icon displayed when the climatic mode is on (Par. 2001= 1 o 2)

7

Celsius/Fahrenheit temperature

8

Large numeric display: current value

9

Small numeric display: system pressure display or parameter number

10

Icon displayed when the outdoor probe is connected

Page 14

14

2 INSTALLATION

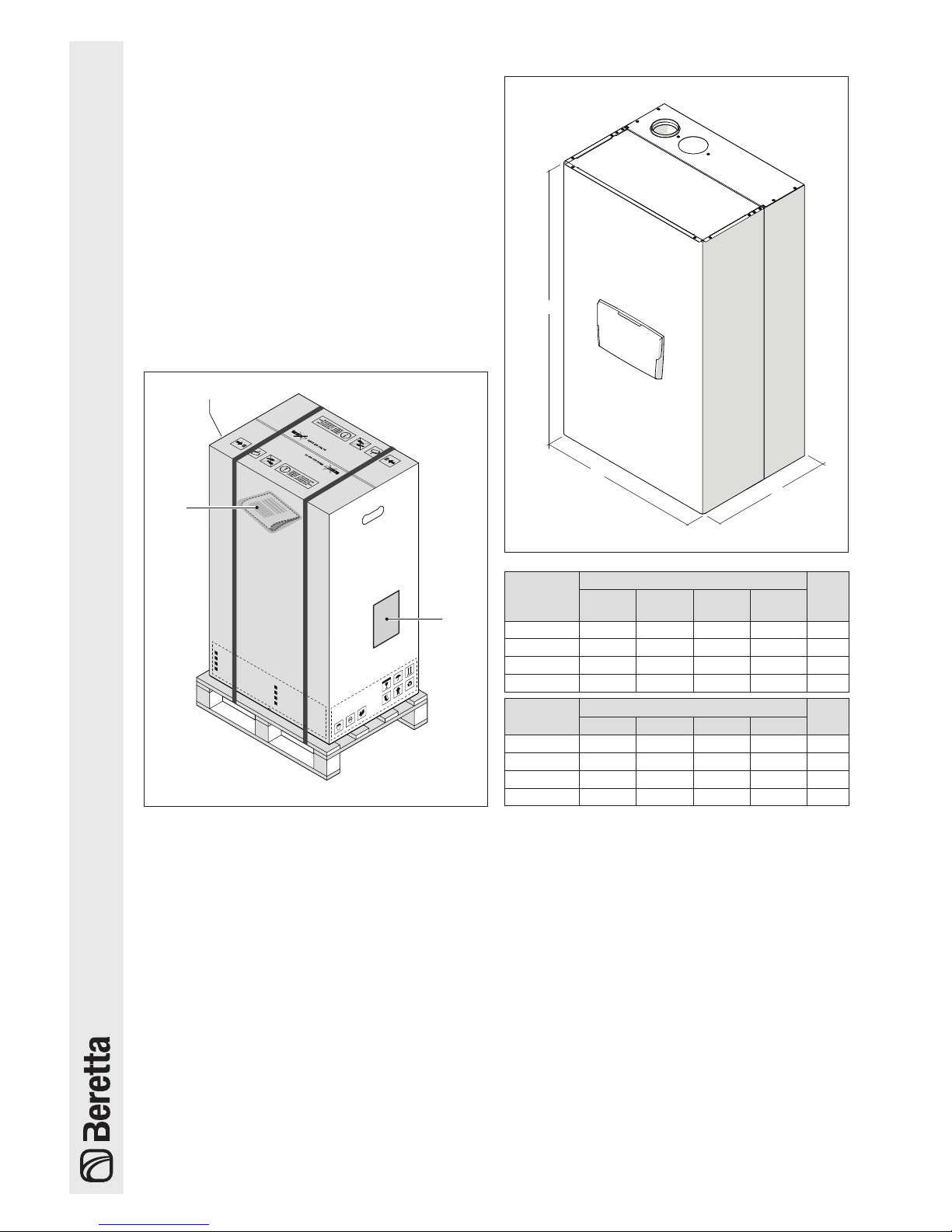

2.1 Unpacking the product

The thermal module

POWER MAX

is shipped palletised,

packaged and with cardboard protections.

The following material is supplied in a plastic envelope inside the package (1):

- Instruction manual

- Warranty information leaet B

- LPG conversion kit

- Wall-mounting bracket with plugs (no.4 plugs s=10

mm suitable for concrete, brick, compact stone and

concrete hollow brick walls)

- Hydraulic test certicate

- Energy Efciency Label (for models <70kW)

2.1.1 Positioning of labels

A

A

CALDAIA MURALE A GAS

WALL HUNG GAS BOILER

CHAUDIERE MURALE A GAZ

GAS - WANDHEIZKESSEL

IT

GB

FR

D

CALDAIA MURALE A GAS

WALL HUNG GAS BOILER

CHAUDIERE MURALE A GAZ

GAS - WANDHEIZKESSEL

IT

GB

FR

D

1

A

Packing label

b

The instruction manual is an integral part of the appliance; therefore, it should be read and stored carefully.

b

Keep the documentation envelope in a safe place.

Any replacement documents must be ordered from

Beretta who reserve the right to charge for the cost of

the replacement.

2.2 Overall dimensions and weights

P

H

L

Description

POWER MAX

50 P

DEP

50 P 65 P 80 P

L 600 600 600 600 mm

P 435 435 435 435 mm

H 1000 1000 1000 1000 mm

Net weight 65 65 70 64 kg

Description

POWER MAX

100 110 130 150

L 600 600 600 600 mm

P 435 435 435 435 mm

H 1000 1000 1165 1165 mm

Net weight 78 78 90 95 kg

Page 15

15

2.3 Installation premises

The thermal module

POWER MAX

can be installed in rooms

that are permanently ventilated and equipped with suitably

sized ventilation openings in line with Technical Standards

and Regulations applicable to the installation site.

b

When installing the boiler, allow sufcient space

around it to access all safety and control devices and

to permit easy maintenance.

b

Check that the electric protection level of the appliance is suitable for features of the room where it is

installed.

b

Make sure that comburent air is not contaminated by

substances containing chlorine or uorine (elements

found in sprays, paints, detergents etc.).

a

Do not obstruct or restrict the air vents in the room

where the boiler is installed. A free air supply is essential for correct combustion.

a

It is forbidden to leave ammable containers and

substances in the room where the thermal module is

installed.

2.3.1 Recommended minimum distances

Clearances for the assembly and the maintenance of the

appliance are shown in the gure.

≥ 1 m

≥ 0,85 m

≥ 0,4 m

≥ 0,5 m

≥ 0,5 m

The minimum surface of ventilation openings is 3,000 cm2

for gas fuel heating systems.

2.4 Installation in older systems and

systems requiring modernisation

When installing these boilers in older systems or systems

requiring modernisation, always perform the following

checks:

- Make sure that the ue is able to withstand the temperature of the combustion gases and that it has been

designed and made in compliance with applicable

standards. The ue must also be as straight as possible, sealed, insulated and not blocked or choked.

See Paragraph "Discharge of combustion products"

for any additional information.

- Make sure that the electrical supply system has been

installed by a qualied electrician in compliance with

applicable standards

- Make sure that the fuel feed line and any storage tank

are made and installed in compliance with applicable

standards

- Make sure that expansion vessels are big enough to

contain the additional volume generated by thermal

expansion

- Make sure that the ow rate, head and direction of

ow of the pumps are suitable and correct

- The system has been washed, cleaned of mud and

grime and water seals have been checked

- A treatment system is tted when the supply/rell

water has values other than those indicated in Paragraph "Water quality requirements"

b

The manufacturer declines all responsibility for dam-

age caused by incorrectly constructed ue systems.

Page 16

16

2.5 Moving and removing the

packing

b

Do not remove the cardboard packaging until your

reach the installation location.

b

Before handling the appliance and removing the

packaging, wear PPE and use tools suitable for the

appliance's size and weight.

b

This step must be carried out by several individuals

equipped with suitable means with respect to the appliance's size. Make sure that the load is not unbalanced during handling.

Proceed as follows to remove the packing:

- Remove the strapping that secures the cardboard

packaging to the pallet

- Remove the cardboard

- Remove edge protectors (1)

- Remove the Styrofoam protection (2)

- Remove the protective bag (3)

3

1

2

1

1

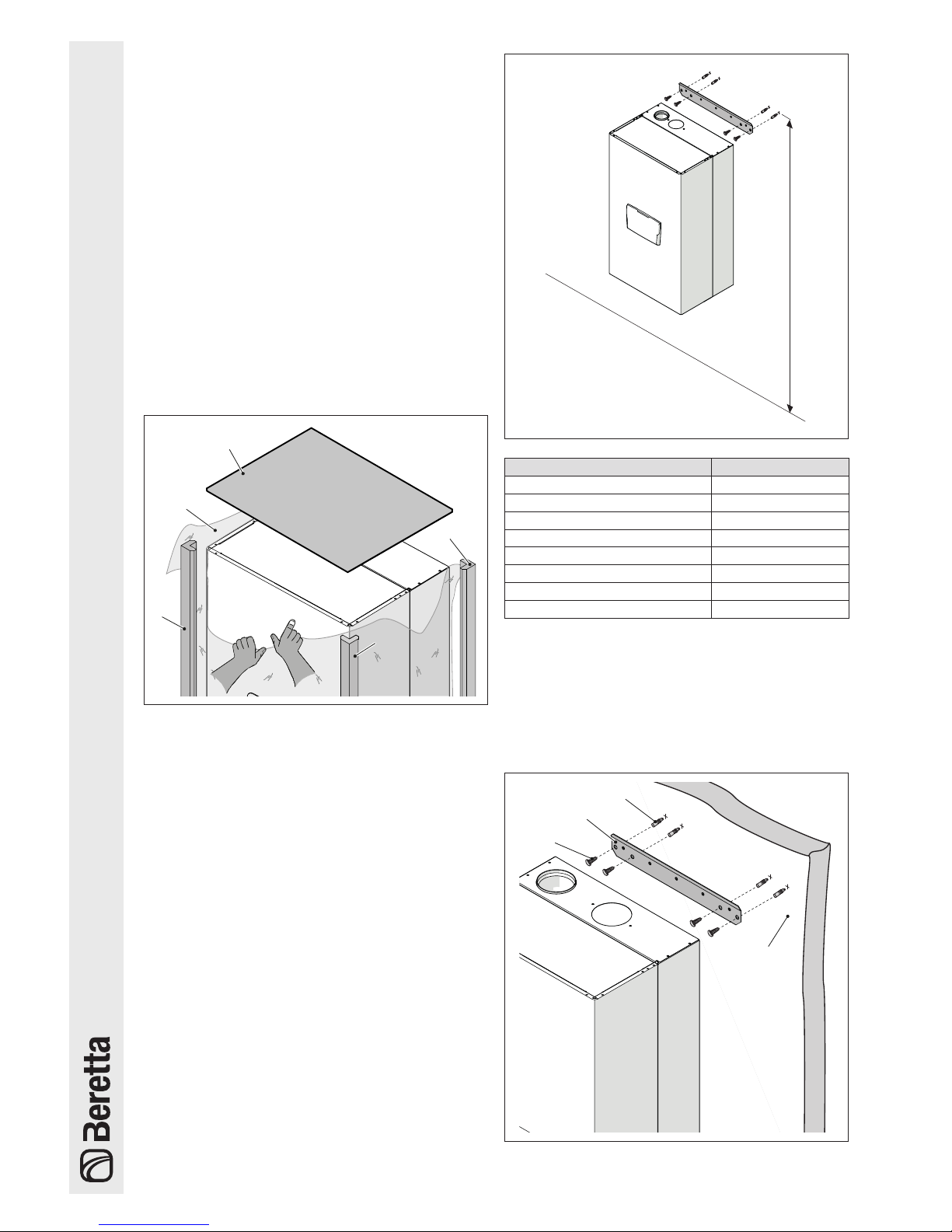

2.6 Thermal module assembly

Thermal modules

POWER MAX

are supplied complete with

a wall-mounting bracket.

b

Check that the wall on which the appliance is to be

tted is sufciently solid and supports safe screw xing points.

b

The appliance's height must be selected so as to facilitate dismantling it and maintaining it.

H

Model Height (H) mm

POWER MAX 50 P DEP 1850<H<2000

POWER MAX 50 P 1850<H<2000

POWER MAX 65 P 1850<H<2000

POWER MAX 80 P 1850<H<2000

POWER MAX 100 1850<H<2000

POWER MAX 110 1850<H<2000

POWER MAX 130 2000<H<2150

POWER MAX 150 2000<H<2150

For installation:

- Position the bracket (1) onto the wall (2), at the point

where you wish to install the appliance

- Ensure that the bracket is horizontal and mark the

points where the holes for xing plugs must be drilled

- Drill the holes and insert expansion plugs (3)

- Fix the bracket to the wall using the screws (4)

- Secure the appliance onto the bracket

1

2

3

4

Page 17

17

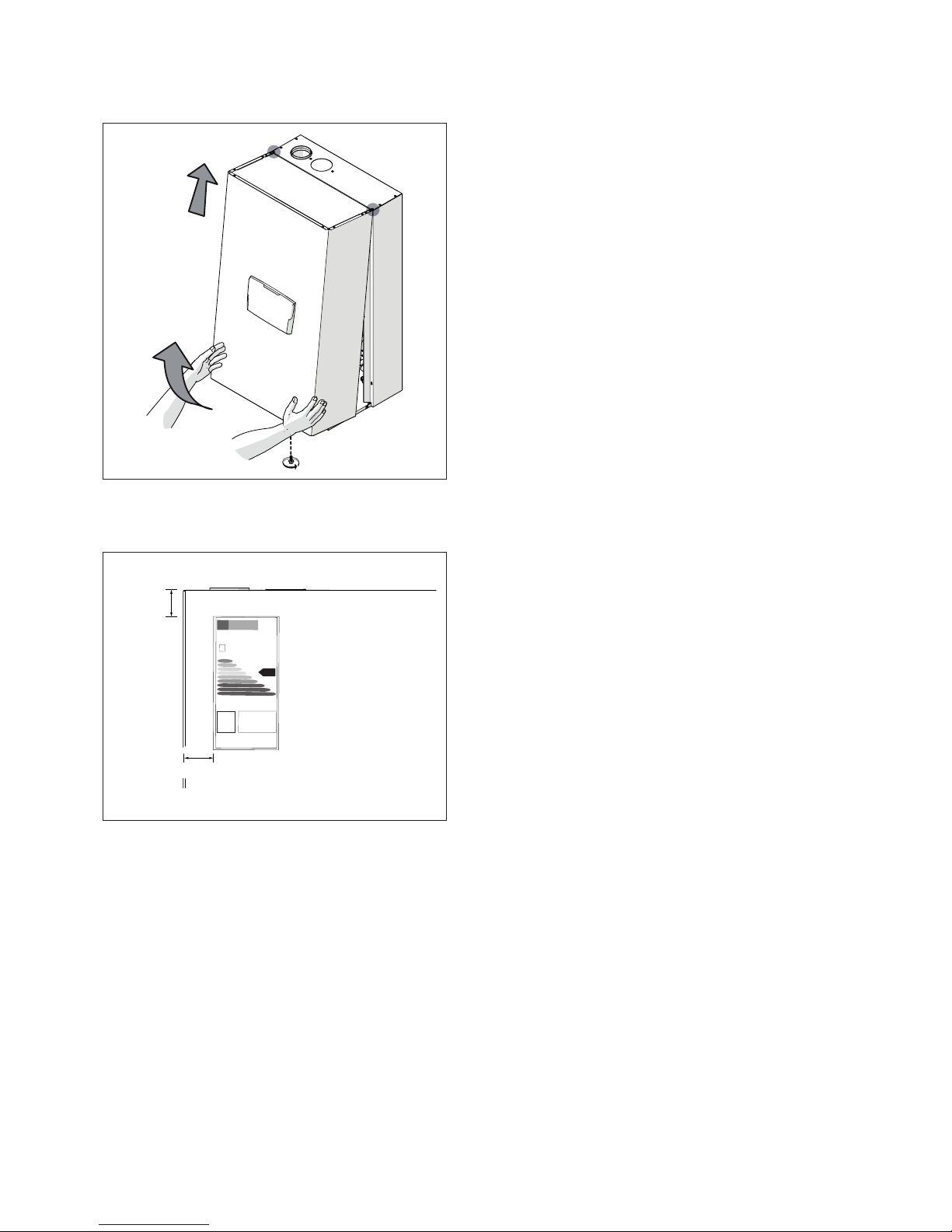

After installing the thermal module:

- remove the locking screw

- pull the front panel outwards and then to the top to

decouple it from points A.

A

A

Locate the envelope containing the product documentation

and stick the Energy Efciency Label (if any) contained in

the envelope onto the panel.

25 kW

30 mm

25 mm

Close the panelling in reverse order to the one described

above.

b

Before proceeding with the hydraulic connections the

protection plugs must be removed from the delivery,

return and condensate drain piping.

Page 18

18

2.7 Water connections

The dimensions and position of thermal module's hydraulic connections are shown in the table below.

Front view Bottom view

RI MI

B

A

F

H

C

D

E

RI G MI

SC

DESCRIPTION

POWER MAX

50 P

DEP

50 P 65 P 80 P 100 110 130 150

A 387 387 387 387 387 387 387 387 mm

B 143,5 143,5 143,5 143,5 143,5 143,5 143,5 143,5 mm

C 63,5 63,5 63,5 63,5 63,5 63,5 63,5 63,5 mm

D 283,5 283,5 283,5 283,5 283,5 283,5 283,5 283,5 mm

E 98,5 98,5 98,5 98,5 98,5 98,5 98,5 98,5 mm

F 92,5 92,5 92,5 92,5 92,5 92,5 92,5 92,5 mm

H (optional 3-way valve

attachment)

202,5 202,5 - - - - - - mm

MI (system ow)

G 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2

M

Ø

RI (system return)

G 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2 MG 1" 1/2

M

Ø

SC (condensate drain) 25 25 25 25 25 25 25 25 Ø mm

G (gas inlet) G 1" M G 1" M G 1" M G 1" M G 1" M G 1" M G 1" M G 1" M Ø

b

Before connecting the thermal module the protection

plugs must be removed from the delivery, return and

condensate drain pipes.

b

Before connecting the thermal module, it is necessary to clean the system. This step is absolutely required when the appliance replaces another one on

pre-existing systems.

In order to carry out this cleaning activity, if the old generator is still installed on the system, it is advisable to:

- add a de-scaling additive.

- Operate the system with the generator on for around

7 days.

- Discharge dirty system water and ush the system

one or more times with clean water.

If the system is very dirty, repeat the last procedure one

more time.

If the old generator is not present or available, use a pump

to circulate the water + additive through the system for

about 10 days and perform a nal washing as described in

the previous paragraph.

Once the cleaning has been completed, it is recommend-

ed to add a suitable protective uid to the system's water

before installing the thermal module.

In order to clean the heat exchanger's built-in water system, please contact Technical Assistance Centre

B.

a

Do not use incompatible liquid detergents, including

acids (for instance, chloridric acid and similar) in any

concentration.

a

Do not subject the heat exchanger to cyclical pressure changes because fatigue stress is very dangerous for the integrity of system components.

Page 19

19

2.8 Typical water system schematics

Layout 1: circuit with thermal module directly linked to heating system (check that the pump's discharge head

is sufcient to ensure adequate circulation)

10 9

EAF

MI

2

1

RI

1

11

14

4

5

6

7

8

SE

Layout 2: circuit with thermal module directly linked to heating system and DHW tank. (check that the pump's

discharge head is sufcient to ensure adequate circulation)

5

UAC

1

9

10

1

EAF

6

13

12

1

1

2

3

4

11

10 9

EAF

MI

2

1

RI

1

11

5

6

7

8

SE

6

14

4

1

Isolating valve

2

Non-return valve

3

DHW circulation pump

4

Expansion tank

5

Safety valve

6

Drain

7

Pressure gauge

8

Pressure switch

9

Water softener lter

10

Pressure reducer

11

Storage cylinder

12

Automatic bleed valve

13

Diverter valve

14

Pump (tted as standard for models POWER MAX 50 P DEP and

POWER MAX 80 P)

15

High-temperature system circulator

16

Storage cylinder circulator

SE

Outdoor sensor

MI

High temperature

system ow

RI

High temperature

system return

EAF

Domestic cold wa-

ter inlet

UAC

Domestic hot water

outlet

b

Domestic hot water and central heating circuits must be completed with expansion vessels of adequate capacity

and suitable, correctly-sized safety valves. The discharge of safety valves and appliances must be connected to a

suitable collection and disposal system (see Catalogue for compatible accessories).

b

The choice of system components and the method of their installation are left up to the heating engineer installing

the system. Installers must use their expertise to ensure proper installation and functioning in conformity to all applicable legislation.

b

Special supply/rell water must be conditioned using suitable treatment systems.

a

It is prohibited to operate the thermal module without water.

Page 20

20

Layout 3: circuit with thermal module connected to a heating system via a separator

10 9

EAF

MI

2

11

RI

1

11

15

5

6

7

8

SE

14

4

Layout 4: circuit with thermal module linked to DHW tank and heating system via a separator

15

5

UAC

1

9

10

1

EAF

6

12

1

1

2

3

4

11

10 9

EAF

MI

2

11

RI

1

11

5

6

7

8

SE

6

16

14

4

1

Isolating valve

2

Non-return valve

3

DHW circulation pump

4

Expansion tank

5

Safety valve

6

Drain

7

Pressure gauge

8

Pressure switch

9

Water softener lter

10

Pressure reducer

11

Storage cylinder

12

Automatic bleed valve

13

Diverter valve

14

Pump (tted as standard for models POWER MAX 50 P DEP and

POWER MAX 80 P)

15

High-temperature system circulator

16

Storage cylinder circulator

SE

Outdoor sensor

MI

High temperature

system ow

RI

High temperature

system return

EAF

Domestic cold wa-

ter inlet

UAC

Domestic hot water

outlet

b

Domestic hot water and central heating circuits must be completed with expansion vessels of adequate capacity

and suitable, correctly-sized safety valves. The discharge of safety valves and appliances must be connected to a

suitable collection and disposal system (see Catalogue for compatible accessories).

b

The choice of system components and the method of their installation are left up to the heating engineer installing

the system. Installers must use their expertise to ensure proper installation and functioning in conformity to all applicable legislation.

b

Special supply/rell water must be conditioned using suitable treatment systems.

a

It is prohibited to operate the thermal module without water.

Page 21

21

Layout 5: circuit with thermal module linked to heating system and DHW. tank via a separator

15

5

UAC

1

9

10

1

EAF

6

12

1

1

2

3

4

11

10 9

EAF

MI

2

11

RI

1

11

5

6

7

8

SE

6

13

14

4

1

Isolating valve

2

Non-return valve

3

DHW circulation pump

4

Expansion tank

5

Safety valve

6

Drain

7

Pressure gauge

8

Pressure switch

9

Water softener lter

10

Pressure reducer

11

Storage cylinder

12

Automatic bleed valve

13

Diverter valve

14

Pump (tted as standard for models POWER MAX 50 P DEP and

POWER MAX 80 P)

15

High-temperature system circulator

16

Storage cylinder circulator

SE

Outdoor sensor

MI

High temperature

system ow

RI

High temperature

system return

EAF

Domestic cold wa-

ter inlet

UAC

Domestic hot water

outlet

b

Domestic hot water and central heating circuits must be completed with expansion vessels of adequate capacity

and suitable, correctly-sized safety valves. The discharge of safety valves and appliances must be connected to a

suitable collection and disposal system (see Catalogue for compatible accessories).

b

The choice of system components and the method of their installation are left up to the heating engineer installing

the system. Installers must use their expertise to ensure proper installation and functioning in conformity to all applicable legislation.

b

Special supply/rell water must be conditioned using suitable treatment systems.

a

It is prohibited to operate the thermal module without water.

Page 22

22

2.9 Gas connections

The gas connection must be made respecting the installation regulations in force, and sized to ensure the correct

gas delivery to the burner.

Before making the connection, check that:

b

The gas type is suitable for the appliance

b

If the appliance needs to be adapted for use with

another gas fuel, contact your local Technical As-

sistance Centre to have the necessary modications

made. These operations may not be performed by

the installer under any circumstances.

b

The piping is thoroughly clean

b

The gas meter's ow rate is capable of ensuring the

simultaneous use of all the appliances connected to

it. The appliance's connection to the gas supply line

must be carried out in accordance with the current

regulations.

b

Intake pressure with the appliance in the off position

has the following reference values:

- powered by methane gas: optimal pressure 20

mbar

- powered by L.P.G.: optimal pressure 35 mbar

b

Check that the pressure never falls below 15 mbar

a

Do not use any fuels other than those provided under

any circumstances.

While it is normal for the intake pressure to decrease while

the appliance is in operation, it is advisable to verify that

no excessive pressure uctuations take place. In order to

limit the extent of these types of variations, the diameter of

the gas supply line to be used must be assessed based on

the length and the pressure drops of the line itself, from the

meter to the thermal module.

b

If uctuations in the gas distribution pressure are encountered, it is recommended to install an appropriate pressure stabiliser upstream of the appliance's

gas intake. For G30 and G31 gas supply, all the necessary precautions must be taken in order to prevent

the gas from freezing in the case of extremely low

outdoor temperatures.

If the gas distribution network contains solid particles, in-

stall a lter on the fuel supply line. When selecting it, consider that pressure drops due to the lter should be as low

as possible.

b

On completion of the installation, check that all joints

are sealed.

GAS 1" M

2.10 Discharge of combustion

products

The appliance is supplied as standard in B-type conguration (B23-B23P-B53P), i.e. pre-tted to suction air direct-

ly into the installation room and may be converted into a

C-type appliance with the use of specic accessories. In

this conguration, the appliance will suction the air directly

from outdoors, with the possibility of coaxial or dual piping.

For ue gas extraction and the intake of combustion air, it is

essential to use only specic pipes for condensing boilers

and ensure that they are correctly connected, as shown

in the instructions supplied with the ue gas accessories.

b

Do not connect this appliance's ue gas extraction pipes with those of other appliances, unless

this is specically authorised by the manufacturer.

Non-compliance with this precaution may cause a

build-up of carbon monoxide in the room where the

appliance is installed. This could jeopardise people's

health and safety.

b

For further information on ue gas extraction pipes for

thermal modules connected in a cascaded system,

see Catalogue and the instructions provided for the

relevant accessories.

b

Ensure that combustion air (suction line air) is not

contaminated by:

- waxes/chlorinated detergents

- chemical products based on swimming pool chlorine

- calcium chloride

- sodium chloride use to soften tap water

- refrigerant leaks

- paint or varnish removers

- chloridric acid/muriatic acid

- cements and glues

- anti-static softeners used in dryers

- chloride used for domestic or industrial applications

as detergent, whitener or solvent

- adhesives used to glue construction and other similar products.

b

To prevent contamination of the thermal module, do

not install suction line air intakes and gas ue extraction pipes near:

- dry-cleaners/laundry rooms and factories

- swimming pools

- metal processing plants

- beauty parlours

- fridge repair shops

- photo-processing facilities

- body-shops

- plastics manufacturing plants

- furniture workshops and manufacturing plants.

Page 23

23

UF AA

326

96

92

230

The AA outlet is supplied capped in B23 conguration.

DESCRIPTION

POWER MAX

50 P

DEP

50 P 65 P 80 P

FO (ue gas outlet) DN80 DN80 DN80 DN80 Ø

AS (air suction) DN80 DN80 DN80 DN80 Ø

DESCRIPTION

POWER MAX

100 110 130 150

FO (ue gas outlet)

DN110 DN110 DN110 DN110

Ø

AS (air suction)

DN110 DN110 DN110 DN110

Ø

b

For B-type installation, combustion air is taken from

the environment and goes through the openings

(shutters) on the rear panel of the device that must be

located in a suitable and ventilated technical room.

b

Read the requirements, instructions and prohibitions

detailed below carefully, since non-compliance with

them may be result in a safety hazard or the appliance's malfunction.

b

Condensation appliances described in this hand-

book must be installed with ue gas pipes compliant

with applicable legislation and expressly manufac-

tured for this specic use.

b

Check that pipes and joints are not damaged.

b

Joint seals must be executed with materials that withstand the condensate's acidity and the temperatures

of the appliance's ue gases.

b

When installing ue pipes, always bear in mind the

direction of the ue gases and of possible condensate ows.

b

Inadequate or incorrectly sized ue gas pipes may

increase combustion noise, create condensate extraction issues and negatively impact on combustion

parameters.

b

Check that pipes are suitably far (min. 500 mm) from

ammable or heat-sensitive construction elements.

b

Make sure that condensation is not built up along the

duct. For this purpose, provide a sloping duct of at

least 3 degrees towards the appliance in case there

is an a horizontal section. If the horizontal or vertical

section is longer than 4 meters, a condensate siphon

drainage must be provided at the base of the pipe.

The useful height of the siphon must be at least equal

to the value "H" (see gure below). The siphon discharge must then be connected to the sewerage system (see paragraph "Preparation for the condensate

drain" on page 24).

a

It is prohibited to block or section the ue gas extraction pipe or the combustion air suction pipe, if any.

a

It is prohibited to use pipes that not designed for this

application, because the condensate's action would

damage them quickly.

Maximum equivalent lengths are provided below.

Maximum equivalent length

of ue gas exhaust pipe

Pressure drop

45° bend 90° bend

30 m 1 m 3 m

The table with available residual discharge heads is shown

below.

Description

Discharge head

Max Min

POWER MAX 50 P DEP 300 45

POWER MAX 50 P 480 45

POWER MAX 65 P 510 35

POWER MAX 80 P 630 35

POWER MAX 100 560 32

POWER MAX 110 610 32

POWER MAX 130 500 30

POWER MAX 150 353 28

The residual discharge head values are shown in Pascal.

≥3°

H 350 mm

To change direction, use a T section with an inspection

cap to permit easy access for cleaning inside the pipe. After cleaning, always make sure that inspection caps are

replaced tightly and that their seals are undamaged and

efcient.

Page 24

24

2.10.1 Preparation for the condensate drain

The exhaust of the condensation produced by the appliance

POWER MAX

during its normal operation, must be carried out with an accessory (siphoned condensate collector)

that needs to be installed below the thermal module itself

as specied in its assembly instructions. The condensate

coming out of the drainer must be collected for dripping

into a taped vessel connected to the sewer system, if necessary by interposing a neutralizer (for more information

see paragraph "Neutralising the condensate"), according

to the following procedure:

- Fit a drip tray near the condensate discharge outlet,

adding a condensate neutraliser if necessary

- Connect the drip collection receptacle to the local

drain or sewer system using a siphon.

The drip tray can be created by tting a cup or simply a

polypropylene bend, suitable for collecting the condensate

that comes out of the appliance and any liquid leaking from

the safety valve.

The maximum distance between the condensate drainage

of the appliance and the socket (or socket pipe) must not

be less than 10 mm.

The connection to the local drain or sewer system must be

executed using a siphon in order to prevent unpleasant

odours from being released back into the room from the

sewer.

We advise using plastic (PP) piping for building the condensate drainage.

a

Never use copper pipes under any circumstances,

as the condensate itself will cause them to rapidly

deteriorate.

H

Drip tray

Condensate

basing

(accessory)

i >3%

residential discharge

b

Execute the condensate drain outlet so as to prevent

combustion gases leaking into the environment or the

drain or sewage system by sizing the siphon (height

H) as described in Paragraph "Discharge of combustion products".

b

Always maintain a slope angle “s” of over 3° and ensure that the diameter of any condensate drain pipe

is greater than that of the connection tted at the

drain outlet

b

Connect the condensate drain hose to a domestic

water drain in accordance with national and local

legislation and standards.

b

Fill the siphon with water before activating on the

thermal module in order not to release any combustion products into the environment when the thermal

module is rst switched on.

b

The condensate drain must be suitably siphoned. Fill

the siphon with drain in order to prevent the release

of combustion products when the appliance is rst

switched on.

b

It is recommended that condensate from the thermal

module and from the ue should be channelled to the

same drain pipe.

b

The connection pipes used must be as short and as

straight as possible. Any curves or sharp bends can

lead to hoses becoming clogged and, therefore, can

prevent proper condensate discharge

b

Size the condensate drain outlet so as to ensure the

proper drainage of waste liquids without leaks

b

The condensate drain must be connected to the

drain and sewage network in such a ways so that the

condensate may not freeze under any circumstances

2.11 Neutralising the condensate

The UNI 11528 Standard provides for mandatory neutralisation of condensate for systems with total power of over

200 kW. For systems with total power from 35 to 200 kW,

neutralisation may or may not be mandatory depending on

the number of ats (for residential applications) or the number of occupants (for non-residential applications) served

by the aforementioned system.

2.11.1 Water quality requirements

It is ABSOLUTELY NECESSARY to treat the water system in

order for the heat generator to work properly and to guarantee its service life, as well as that of all its components.

This not only applies to jobs carried out on existing installations but also on new installations.

Sludge, lime-scale and pollutants contained in the water

can cause permanent damage to the heat generator, also

within a short time and notwithstanding the quality standards of the materials used.

Contact the Technical Assistance Centre for any further information on type and use of additives.

The heat transfer uid (water) for the central heating circuit

must conform to the quality parameters given in the following table:

Page 25

25

Parameters Value Unit

General characteristic

Colourless, without

sediment

PH value Min. 6.5; Max. 8 PH

Dissolved oxygen < 0,05 mg/l

Total iron (Fe) < 0,3 mg/l

Total copper (Cu) < 0,1 mg/l

Na2SO3 < 10 mg/l

N2H4 < 3 mg/l

PO4 < 15 mg/l

CaCO3 Min. 50 ; Max.150 ppm

Trisodium phosphate None ppm

Chlorine < 100 ppm

Electrical conductivity <200

micro-

siemens/

cm

Pressure Min. 0.6; Max. 6 bar

Glycol

Max. 40% (only pro-

pylene glycol)

%

b

All data in the table refer to water contained in the

system after 8 weeks' operation.

b

Do not use excessively softened water. Excessive

water softening (total hardness < 5° f) results in corrosion due to contact with metal elements (pipes or

thermal module components)

b

Immediately repair any leaks or drips that could result

in air entering the system

b

Excessive pressure uctuations can cause stress

and fatigue to the heat exchanger. Keep the operating pressure constant.

b

Water used to ll a system for the rst time and water

used to top it up must always be ltered (using synthetic or metal mesh lters with a ltration rating of no

less than 50 microns) to prevent sludge from forming

and triggering deposit corrosion.

b

If oxygen enters a circuit continuously or even inter-

mittently (e.g. in under-oor heating systems whose

pipes are not protected by impermeable synthetic

sheaths, in circuits with open expansion vessels, or

in circuits that require frequent top-ups) always separate the boiler’s water circuit from the central heating

circuit.

a

It is prohibited to top up the heating system constantly or frequently, since this can damage the thermal

module's heat exchanger. The use of automatic topping up systems should be avoided for this reason.

To sum up, in order to eliminate contact between air and

water (and to prevent the latter from becoming oxidized),

it is necessary:

- that the expansion system be a closed vessel, correctly sized and with the correct pre-loading pressure

(to be regularly checked);

- that the system be always at a pressure higher than

the atmospheric one at any point (including the pump

suction side) and under any operating conditions (all

seals and hydraulic couplings in a system are designed to withstand pressure towards the outside,

but not underpressure);

- the installation be not made with gas-permeable materials (e.g. plastic pipes without oxygen barrier for

underoor heating systems)

b

Damages suffered by the thermal module, caused

by encrustations and corrosion, are not covered by

warranty. In addition, the non compliance of the water

requirements listed in this chapter will void the appliance warranty itself.

2.12 System lling and emptying

The thermal module

POWER MAX

must be provided with a

charging system to be connected to the appliance's return

line.

RI

Before lling or emptying the system, switch the system's

master switch to the OFF position and the thermal module's

master switch to (

0

).

2.12.1 Filling

- Make sure that drain cocks (1) are closed before you

start loading the system

POWER MAX 50 P DEP - POWER MAX 50 P

1

Page 26

26

POWER MAX 65 P ÷ POWER MAX 150

1

- Unscrew the vent valve's release cap

- Open the shut-off cocks in order to slowly ll the system

- Use the pressure gauge to check that the pressure is

rising and the water is exiting through the vent valves

- Close the shut-off cocks after the pressure reaches

1.5 bar

- Start the system pumps and the thermal module's

pump as shown in Paragraph "Commissioning and

maintenance"

- During this stage, check that the air is correctly eliminated

- Restore the pressure if necessary

- Switch the pumps off and on again

- Repeat the last three steps until the pressure is stabilised

b

The system must be lled up slowly the rst time;

once it is lled and the air expelled it should never

need to be topped up again.

b

Systems should also be operated at maximum work-

ing temperature the rst time they are started up, in

order to facilitate de-aeration. (Gas is not released

from the water at low temperatures).

b

An automatic spurge can be performed during the

rst ignition. The parameter that set the cycle is Par.

2139. See parameter table for more information.

2.12.2 Emptying

Before starting to empty the appliance and the storage cylinder:

- Switch the system's master switch to the OFF position

and the thermal module's master switch to (0).

- Close the water supply shut-off cocks;

- In order to empty the appliance, t a rubber hose (2)

(inner diameter int. Ø = 12 mm) to the thermal module's discharge valve (1).

POWER MAX 50 P DEP - POWER MAX 50 P

1

2

POWER MAX 65 P ÷ POWER MAX 150

1

2

Page 27

27

2.13 Wiring diagram

BUS 2

BOTTOM VIEW

BUS 1 PWMSESB SS24V

MO1

0-10V TA

EA

SF

SR

SM

TS

FL

Pm

SCH

PWM

0V (GND)

PF

J9-1

J9-3

J9-2

J9-4

J6-2

J6-1

J6-8

J6-4

J6-11

J6-6

J6-13

J6-7

J6-14

J7-5

J7-10

J8 J11 J12 J7 J10 J9

J6

J8-1

J8-2

J12-5

J12-2

J7-8

J7-7

J7-6

J12-1

J12-4

J7-4

J7-2

J6-5

J6-12

J6-10

J6-3

b h

h

h

h

h

h

b

b

bl

b

w

r

b

b

b h bl b h b h b h b h b h

b

h

1 2 3 4 9 10 11 12 13 14 15 16 17 185 6 7 8

J7-2 h

J7-3 b

PROG

RESET

MENU

J25-1 g

J25-2 b

J25-3 y

J25-4 w

J25

Key

EA

Ignition/detection electrode

SF

Exhaust ue probe

SM

Flow probe

SR

Return probe

TS

Safety thermostat

PF

Flue gases pressure switch (**)

Pm

Minimum pressure switch

FL

Flow-meter

SCH

Display and control card

MO1

Low-voltage terminal board

0-10V

0-10V input

TA

Room/heat demand thermostat

24 V

24V exit

SB

Boiler sensor (accessory)

SS

System probe (accessory)

SE

Outdoor sensor (accessory)

PWM

PWM connection (*)

Cable colour

b

brown

h

blue

r

red

w

white

bl

black

g

yellow/green

y

yellow

gr

green

(*)

Factory connections for models POWER MAX 50 P DEP ÷ POWER MAX 80 P

(**)

Only for models POWER MAX 50 P DEP ÷ POWER MAX 50 P

Page 28

28

PC (*)

VG1

VE1

IG

MO2

AE (230V ~ 50Hz)PI PC (PS)(ACS) ALPB

PWM

0V (GND)

L

N

L N

L N

L LN

L N

J2J1J3

J4J5

F1

J17

J2-1

J2-4

J1-4

J1-5

J1-1

J4-2

J4-3

J4-6

J4-5

J5-2

J5-1

J3-1

J3-7

J3-2

J3-3

J3-8

J3-5

J3-10

J3-4

J2-3

J3-9

J4-4

J4-1

g

g

g

g

b

h

g

b

h

b

h

gr

w

y

b

b

h

b

b

b

b

g

h

h

h

h

J3-6

b

bl

101 102 103 104 105 106 107 108 109 110 111 11 2 113 114 11 5

L NL N

Key

IG

Main switch

VG1

Gas valve

VE1

Variable speed fan

MO2

High-voltage terminal board

PB

Storage cylinder circu-

lator/ 3-way valve/2-way

valve (**)

PI

Central heating system pump

(ACS)

DHW circulator (**)

PC

Thermal module circulator (*)

PS

System circulator (**)

AL

Alarm output

AE

Power supply

Cable colour

b

brown

h

blue

r

red

w

white

bl

black

g

yellow/

green

y

yellow

gr

green

(*)

For models POWER MAX 50 P DEP ÷ POWER MAX 80 P circulator tted as standard; for other models, the

circulator is provided as an accessory with connections to be executed by the installer.

(**)

Valid conguration for thermal modules without heat pump c having their own two-way valve, connected

in cascade and equipped with primary system circulator. For more information, see cascade installation

manual.

Page 29

29

2.14 Electrical connections

The thermal module

POWER MAX

is manufactured fully

wired and only needs to be connected to the mains, the

room/heat demand thermostat and any other system components.

b

The following is mandatory:

- The use of an omnipolar magnetothermic switch,

line disconnecting switch in compliance with CEI-EN

standards (contact opening of at least 3 mm)

- Respect the connection L (line) - N (neutral). Keep

the earth conductor 2 cm longer than the power supply conductors

- Use cables with a section greater than or equal to 1.5

mm2, complete with cable terminal caps

- Refer to the wiring diagrams in this manual for all

electric operations.

b

The use of adaptors, multiple sockets and extensions

to power the appliance is not allowed

b

to connect external electric components, it is necessary to use auxiliary relays and/or contactors to be

tted in a dedicated external electrical panel

b

Any work on the electrical system must be carried

out only by qualied personnel in compliance with all

legal provision and safety regulations in particular

b

Secure the cables into the dedicated cable ties in

order to always guarantee their correct positioning

within the appliance.

b

Electrical supply cables and control cables (room/

heat demand thermostat, external temperature

probes, etc.) must be strictly separate the one from

the other and tting inside independent ribbed PVC

sheaths up to the electrical panel.

b

The connection to the electrical power supply must

be performed using type 1 sheathed cables (3 x

1,5) N1VVK or equivalent, while simple N07VK type

or equivalent conductors can be used for the thermoregulation and low voltage circuits.

b

If the electrical power provided by the electrical company is of "

PHASE-PHASE

" connection type, preventively contact the nearest Technical Assistance Centre.

b

Never shut the appliance off during normal operation

(with the burner on) by shutting off the electrical power supply using the On-Off key or an external switch.

This could cause the primary heat exchanger to overheat.

b

To switch it off (during the heating stage) use a room/

heat demand thermostat. The On-Off key can only be

actioned whist the appliance is in stand-by or emergency mode.

b

Before connecting any external electrical components to the appliance (regulators, electric valves,

climate control probes, etc.), check to make sure that

their electrical characteristics are compatible with the

available inputs and outputs (voltage, absorption, acceleration current).

b

Temperature probes must be NTC like. For resistance value, refer to table pag 12

b

Always check the proper operation of the "grounding

conductor" for the electrical system to which the appliance will be connected.

b

B shall bear no responsibility for any personal

injuries or property damage caused by non-compliance with wiring diagrams or the electrical system's incorrect/lacking connection to the grounding

system, or by non-compliance with applicable CEI

Standards.

a

It is strictly forbidden to use pipes of any kind to

ground the appliance.

a

It is prohibited to lay power supply and room/heat demand thermostat cables near hot surfaces (delivery

pipes). If they may come into contact with parts that

have a temperature of over 50°C, use a suitable type

of cable.

a

It is prohibited to touch electric appliances with

damp/wet body parts or when your feet are wet.

a

It is prohibited to leave the appliance exposed to

weather elements (rain, sun, wind, etc.) unless it is

equipped with the relevant weatherproof kit.

a

It is prohibited to pull, detach, or twist any electric cables coming from the thermal module even when the

latter is disconnected from the mains power supply.

Proceed as follows to access the control panel terminals:

- Remove the locking screws and the panel's front side

- Pull and slide the electrical panel's box towards the

outside (1)

1

1

Page 30

30

Loosen the xing screws (2) and remove the protection (3)

2

3

- Identify the low-tension terminal board (MO1) and the

high-tension terminal board (MO2)

MO1

MO2

FC

MO1

Control signals terminal board

MO2

Output terminal board

FC

Cable guide

b

For the connection of the devices connected to the jig

(pumps, circulators and diverting / mixing valves) use

interposed relays unless the maximum absorption of

all components connected to the board (including

the module circulator) is less than or equal to 1.5 A.

Relays sizing lays on the installer depending on the

type of connected device.

For connection, see the following gure:

~ 230 V

1

S1

0

N

( )

RA

MO2

103104 105 106 107 108 109 110 111 11 2 11 3 11 4 11 5

S1

Circuit breaker

RA

Relay / Switch (230V AC)

(*)

Refer to the device type for the supply tension.

- Execute electrical wiring in compliance with the diagrams shown below

Power supply

230V ~ 50Hz

L N

L N

L N

104 105 106 107 108 109 11 0 111 112 113 114 115

L NL N

MO2

L

Live

N

Neutral

PE

Earth/ground

Electrical wiring referred to layout 1 at page "19".

MO1

BUS 1 SESB SS24 V0-10V TA

1 2 3 4 9 10 11 12 13

14

5 6 7 8

TATA

TA

Room/heat demand thermostat

NOTE

The room thermostat connection must be dry (no

voltage).

Page 31

31

Electrical wiring referred to layout 2 at page "19".

MO1

BUS 2BUS 1 PWMSESB SS24 V0-10V TA

3 4 9 10

11 12 13 14 15 16 17

5 6 7 8

TA SB PB

MO2

PIPB

L N

L LN

101 102 103 104 105

106

TA

Room/heat demand thermostat

SB

Connect to the storage cylinder probe (Mod.

San. 1) or to the storage cylinder thermostat

(Mod. San. 2)

PB

Connect to the deviating valve (13). Contacts 101102 control the deviation on heating, contacts 102103 control the deviation on domestic hot water

NOTE

The room thermostat connection must be dry (no voltage).

Electrical wiring referred to layout 3 at page "20".

MO1

BUS 2BUS 1 PWMSESB SS24 V0-10V TA

3 4

9 10 11 12 13 14 15 16 17

5 6 7 8

TA PI

MO2

PI PC (PS)(ACS)PB

L N

L

L LN

L N

101 102 103 104 105 106 107 108 109

TA

Room/heat demand thermostat

PI

Connect to the high temperature system pump

NOTE

The room thermostat connection must be dry (no voltage).

Electrical wiring referred to layout 4 at page "20".

MO1

BUS 2BUS 1 PWMSESB SS24 V0-10V TA

3 4 9 10

11 12 13 14 15 16 17

5 6 7 8

TA SB PB PI

MO2

PI (ACS)PB

L N

L LN